Matrix specially used for phoebe bournei seedling raising and production technology thereof

A production process and substrate technology, applied in the field of seedling cultivation, can solve the problems of unsatisfactory three-phase structure of fertilizer conservation, water conservation and ventilation, untargeted seedling cultivation substrate, etc., achieving easy large-scale standardized production, and easy nutrient composition and content. Control, growth-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A special matrix for cultivating Nannan seedlings, comprising the following components by weight ratio: 70 parts of coconut fiber, 13 parts of multiple granulation agents, 17 parts of PGPR compound bacterial fertilizer, and 0.15 parts of humic acid, and the matrix is in block shape. The PGPR composite bacterial fertilizer is composed of Bacillus megaterium, nitrogen-fixing bacteria, phosphorus-solubilizing bacteria, animal manure and bagasse. The multiple granulation agent includes the following components in weight ratio: 13 parts of acrylamide-acrylic acid salt copolymerized cross-linked product, 25 parts of acrylamide-acrylic acid sodium copolymer, 57 parts of montmorillonite, and through the components combined. The acrylamide-acrylic acid salt copolymerized cross-linked product includes the following components in weight ratio: 65.5 parts of acrylamide, 23.5 parts of potassium acrylate, 9 parts of water, 0.75 parts of cross-linking agent, and through the copolyme...

Embodiment 2

[0032] The components and production process of this embodiment are basically the same as those of Example 1, the difference lies in the content of each component of the matrix. The components contained in it and the weight ratio of each component are: 65 parts of coconut fiber, 10 parts of multiple granulation agent, 15 parts of PGPR compound bacterial fertilizer, and 0.1 part of humic acid. The multiple granulation agent includes the following components in weight ratio: 10 parts of acrylamide-acrylic acid salt copolymerized cross-linked product, 20 parts of acrylamide-acrylic acid sodium copolymer, 55 parts of montmorillonite, and the chelate combined. The acrylamide-acrylate copolymerized cross-linked product comprises the following components in weight ratio: 65 parts of acrylamide, 23 parts of potassium acrylate, 8 parts of water, and 0.5 part of a cross-linking agent.

Embodiment 3

[0034] The components and production process of this embodiment are basically the same as those of Example 1, the difference lies in the content of each component of the matrix. The components contained in it and the weight ratio of each component are: 75 parts of coconut fiber, 15 parts of multiple granulation agent, 20 parts of PGPR compound bacterial fertilizer, and 0.2 part of humic acid. The multiple granulation agent includes the following components in weight ratio: 15 parts of acrylamide-acrylic acid salt copolymerized cross-linked product, 30 parts of acrylamide-acrylic acid sodium copolymer, 60 parts of montmorillonite, and the chelation of The acrylamide-acrylic acid salt copolymerized cross-linked product includes the following components in weight ratio: 66 parts of acrylamide, 24 parts of potassium acrylate, 10 parts of water, and 1.0 part of cross-linking agent.

PUM

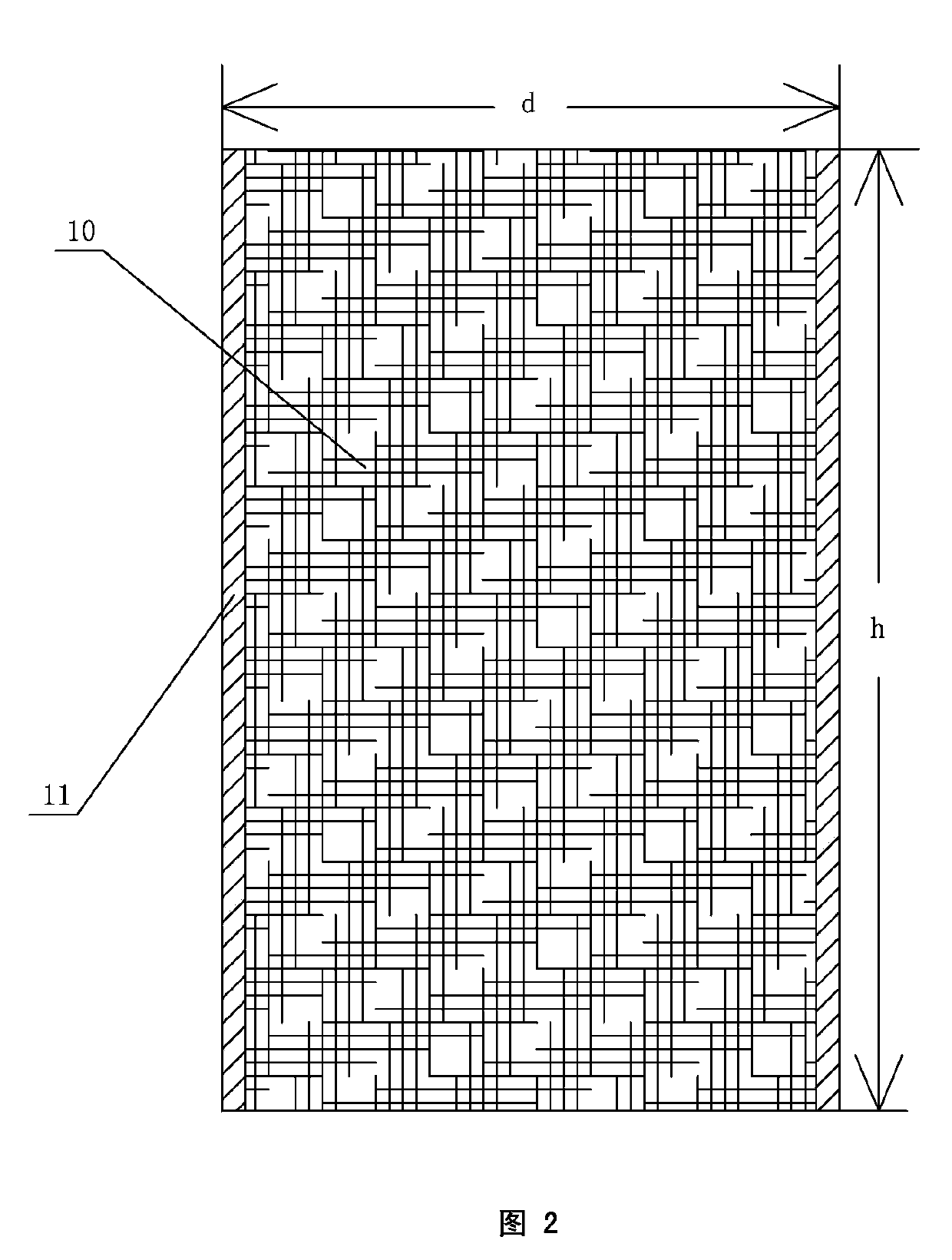

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com