Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Coir fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coir is a natural fiber extract from coconut husk. The Coir fibers are extracted from between the outer shell and hard internal shell of the coconut. The fibers are then screened, graded, washed and compressed into bricks. Coir has many applications but is especially useful for gardening as an alternative to peat moss.

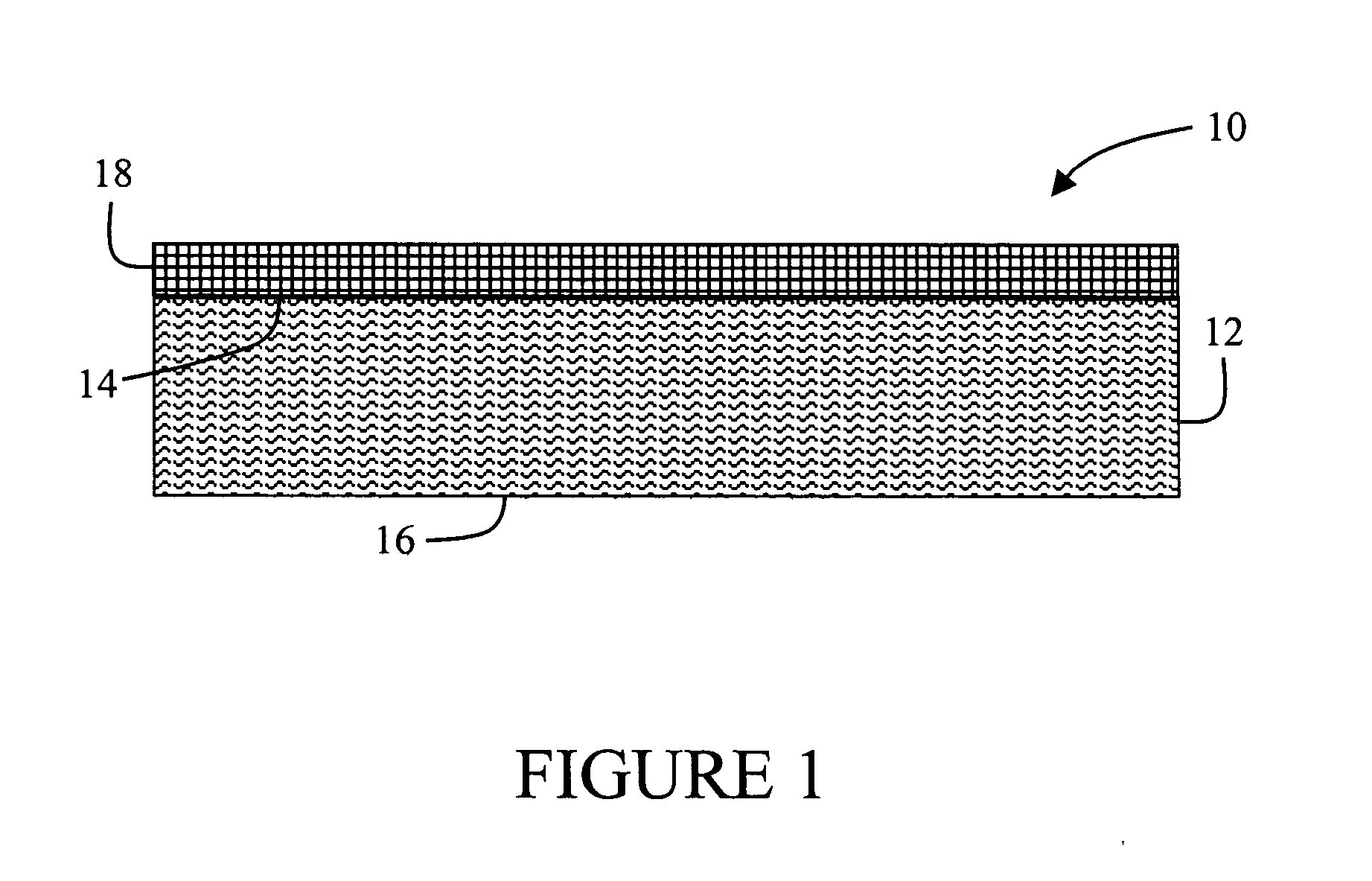

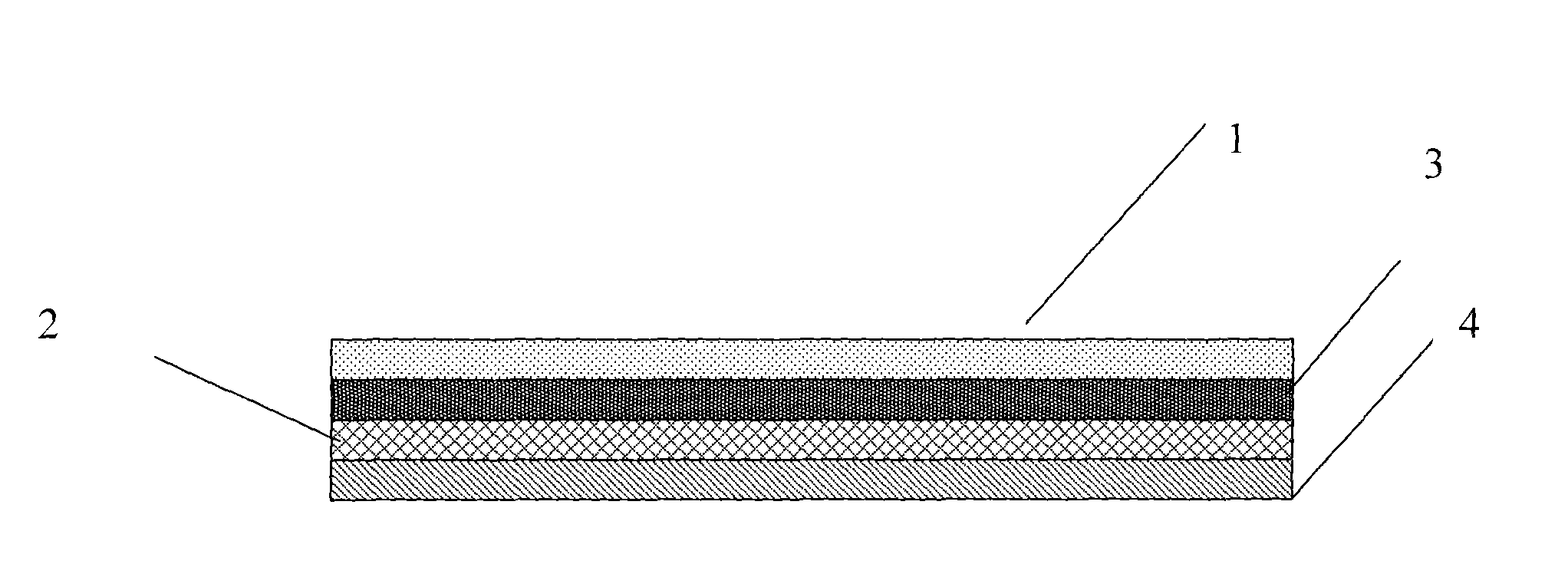

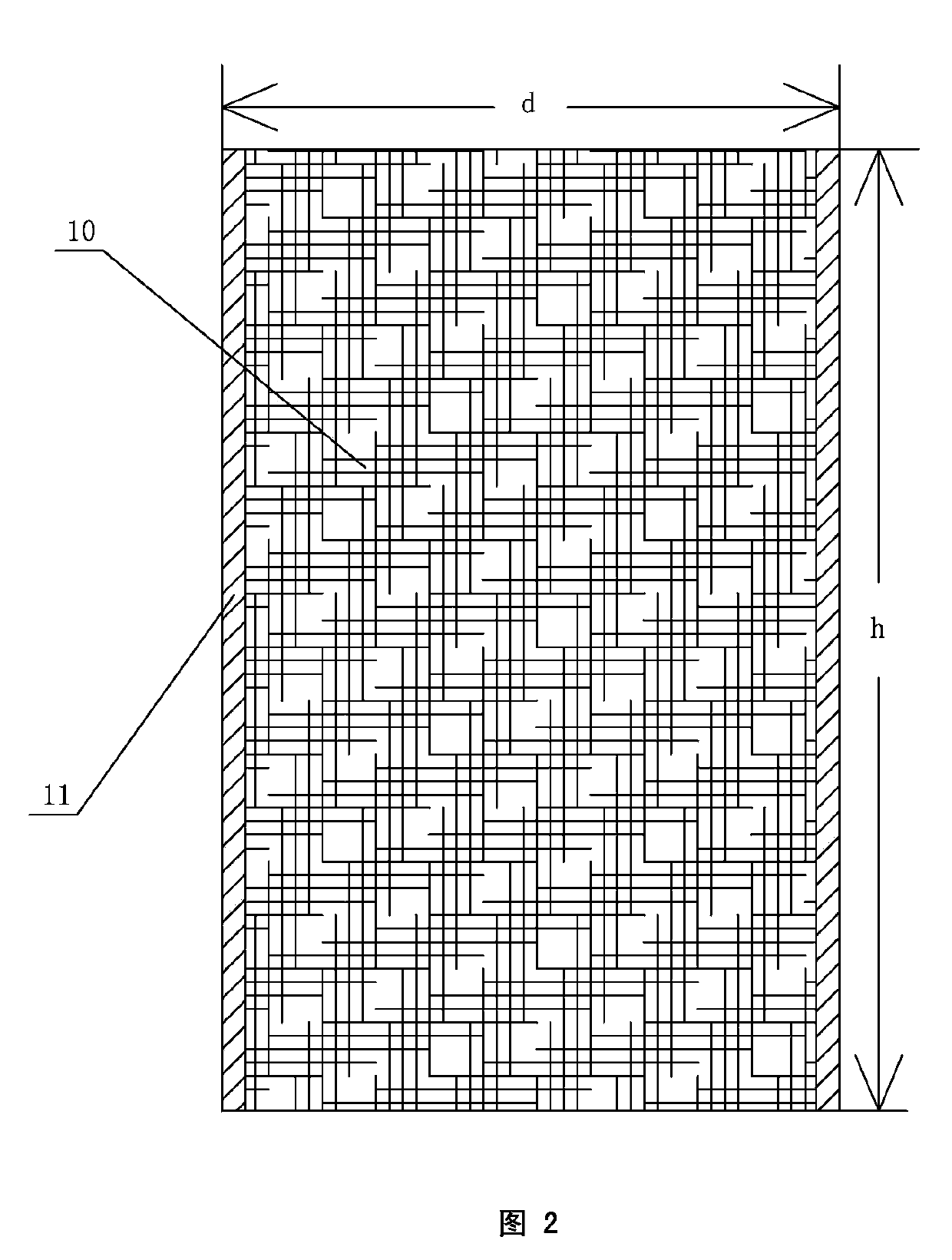

Composite thermoplastic sheets including natural fibers

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

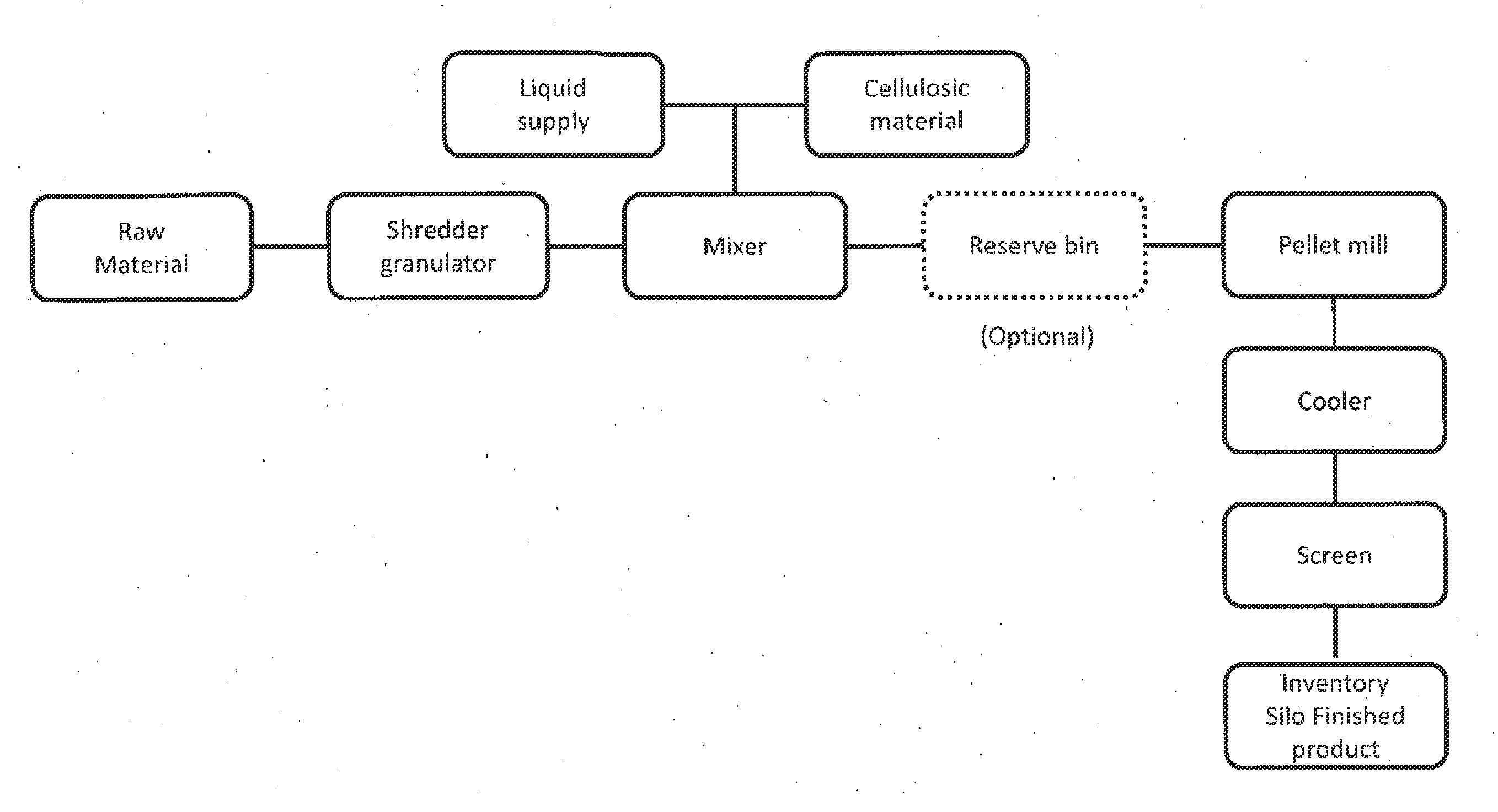

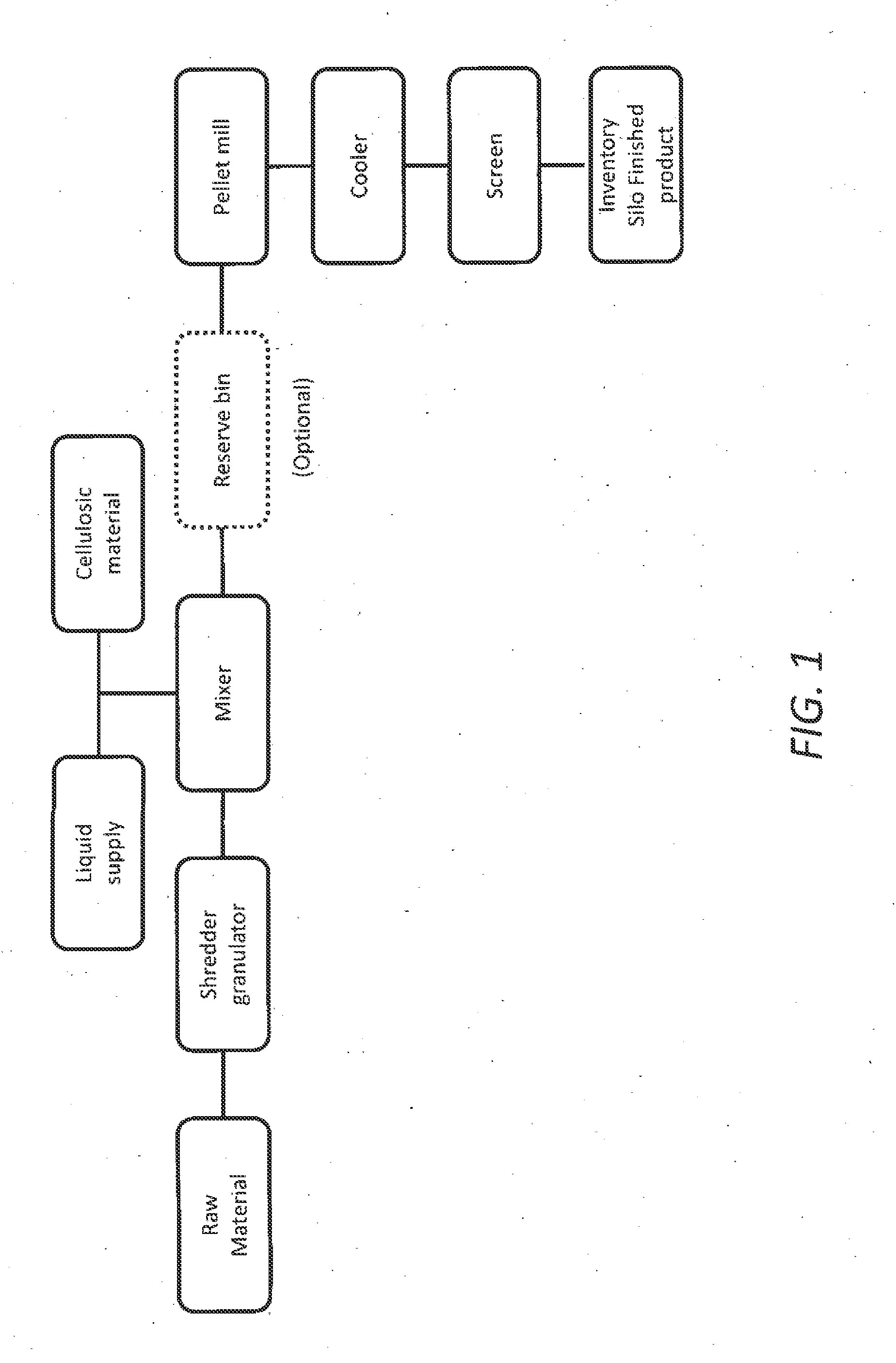

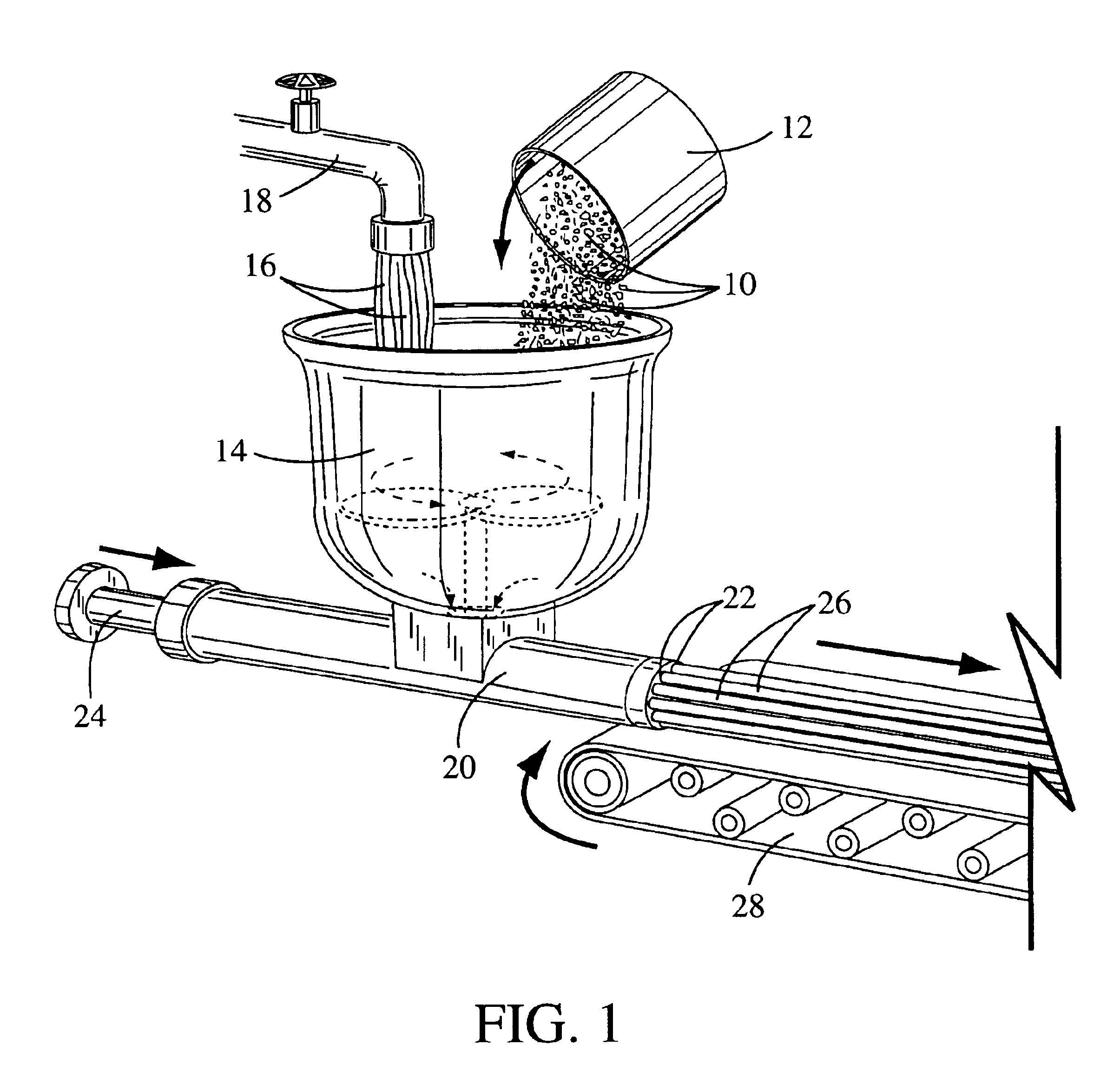

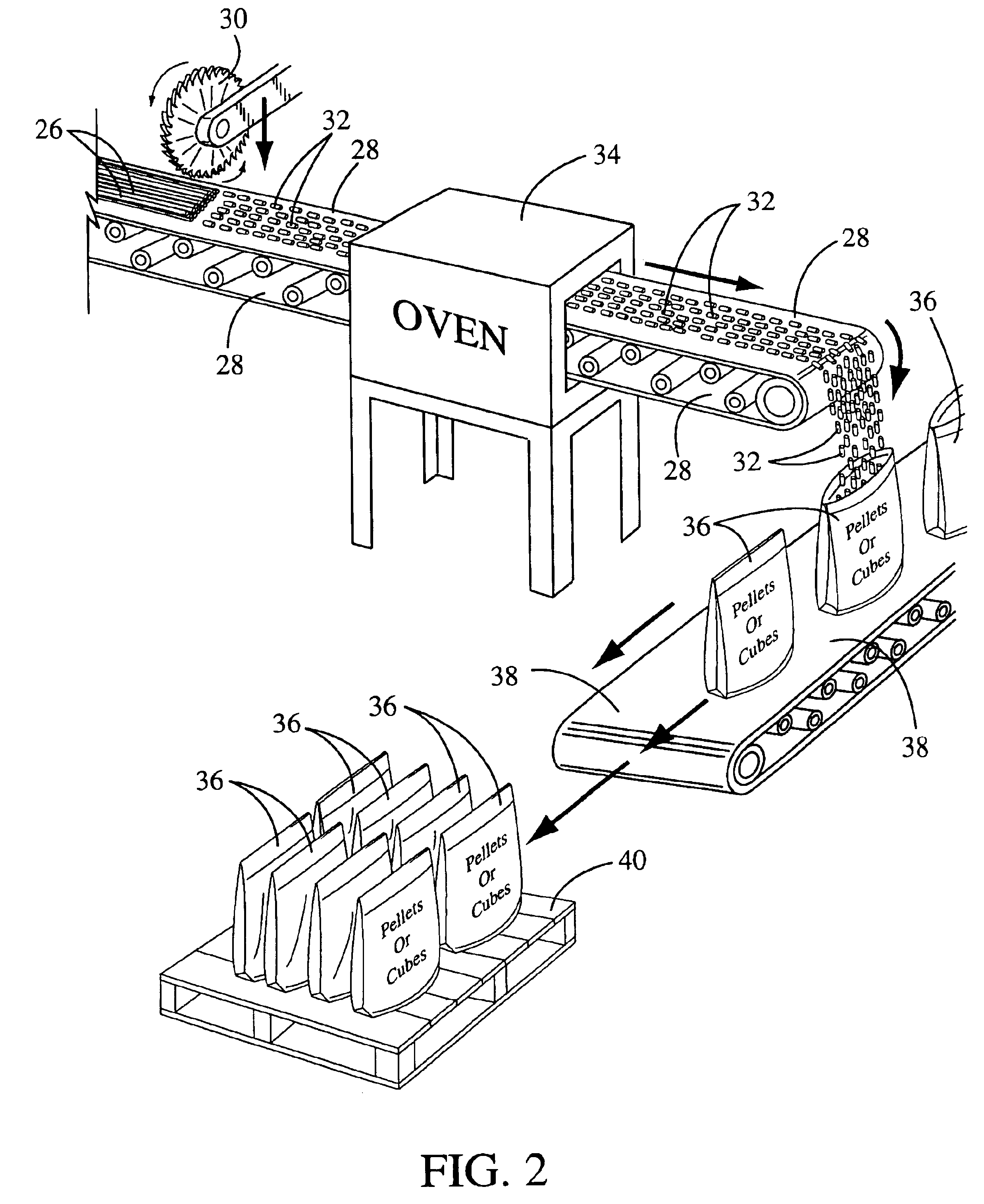

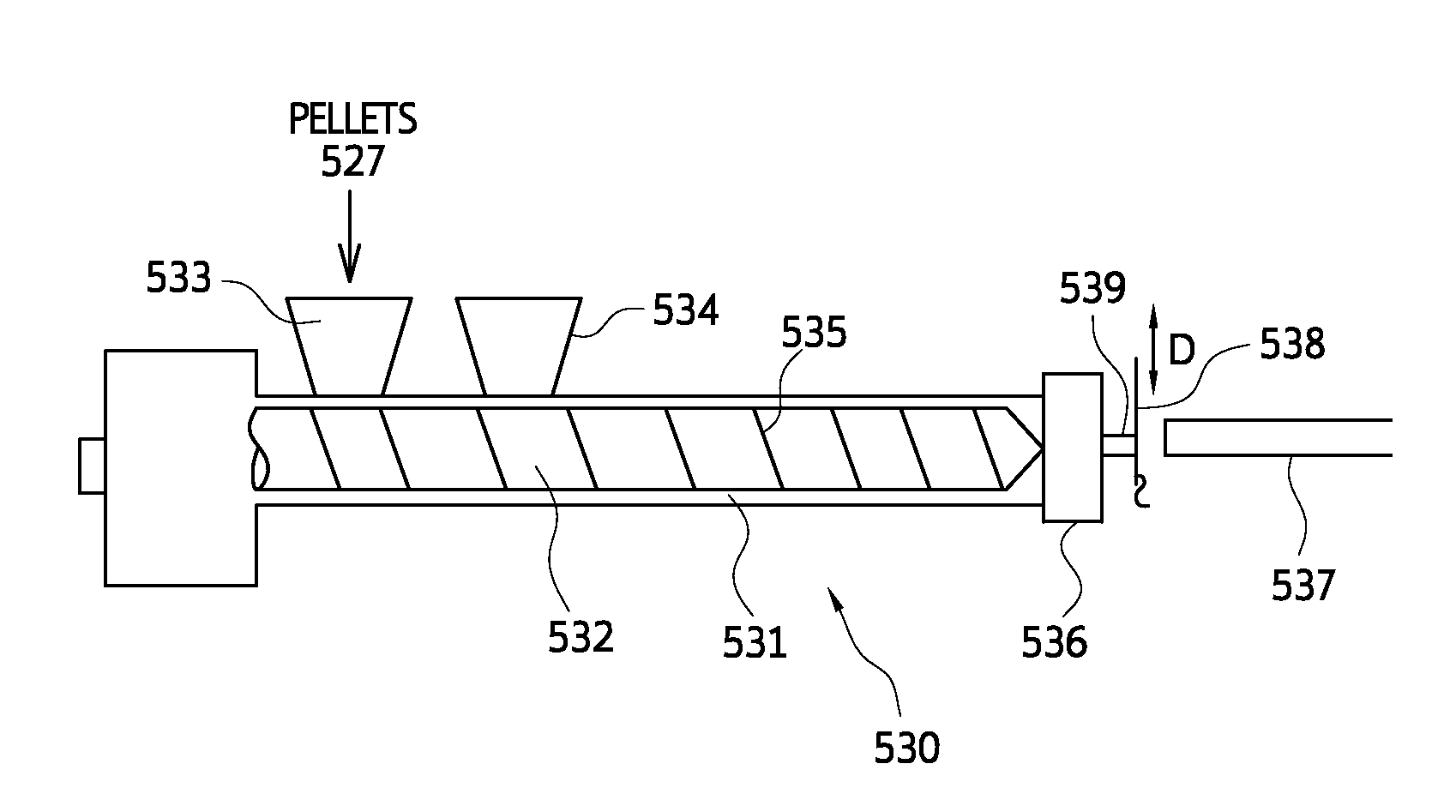

Multipurpose pellets and method of making same

A multipurpose pellet is provided comprising: from about 0.1% to about 100% by weight of a vegetable fiber chosen from cotton, bamboo fiber, rice fiber, esparto, papaya, coir, sisal, kapok, jute, ramie, flax, roselle hemp, hemp, kenaf, abaca, soybean fiber, okra fiber, vine fiber, banana fiber, rattan and nettlesjute; and from about 99.9% to about 0% by weight of cellulosic material.

Owner:LEFEBVRE ROBERT

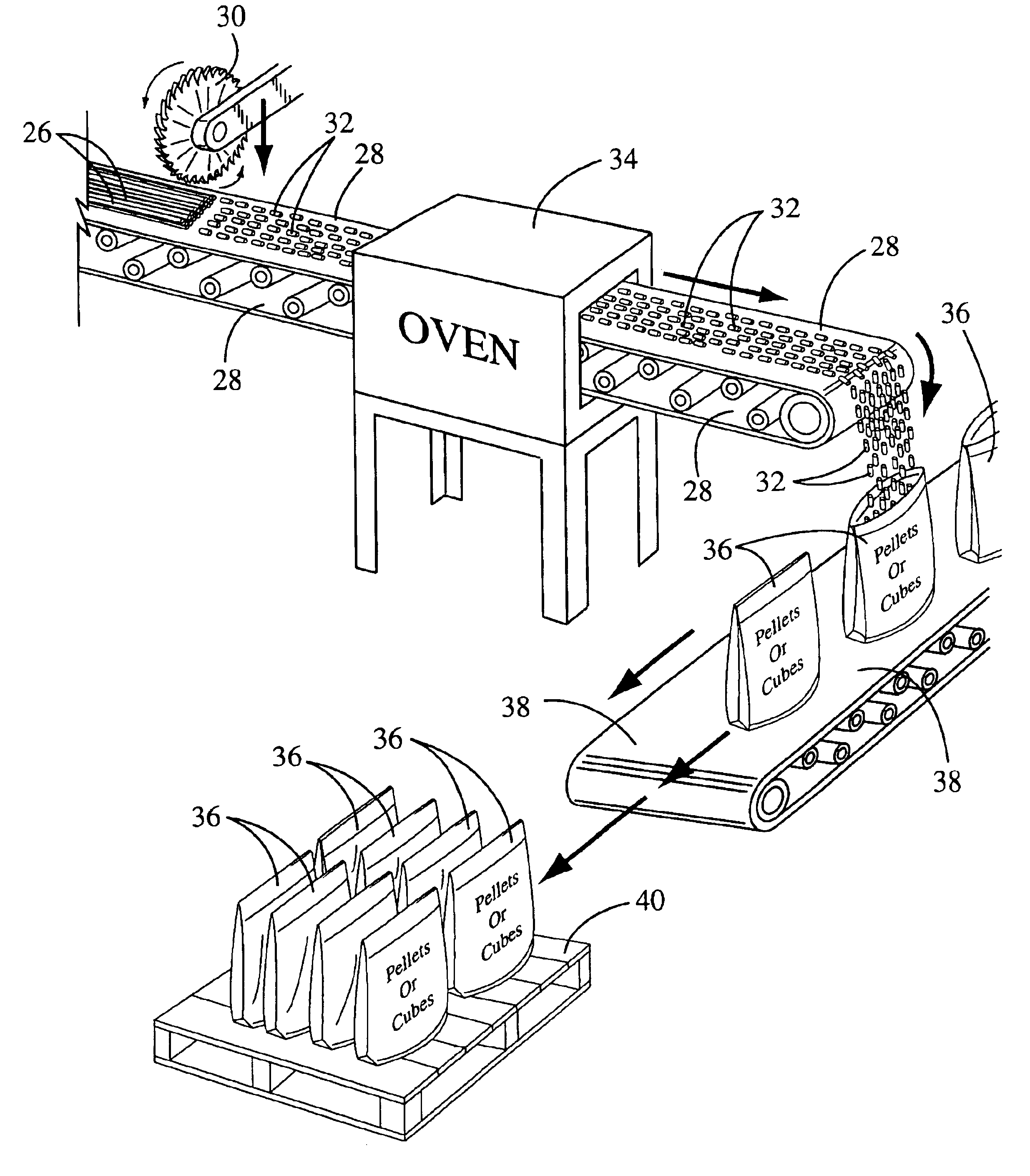

Method of making coconut coir pitch cat litter from powder created from crushed coconut husks

A method of making pellets of coconut coir pith used as cat litter. The coconut coir pith is nontoxic, lightweight and creates very little dust when compared to other cat litter products. Also, the coir pith pore structure absorbs all of the cat urine and doesn't release any of the typical cat urine smell to the atmosphere. In the method of making cat litter pellets from powdered coir pith, the first step includes crushing coconut husks and mixing the residual powdered coconut coir pith with water. The coir pith and water mixture is then compressed through a die having a plurality of ⅛th inch diameter holes therein for creating spaghetti like strings of coir pith. The strings of coir pith are then cut to a length of ½ inches or less. The pellets are heated in an oven for removing moisture and hardening them. The harden pellets are then packaged for shipment to customers.

Owner:SILVA TILAK

Production technology of spinnability soft coconut shell fine fibers and application of fiber product

InactiveCN104195650AGood flexibilityImproved elongation at breakVegetable fibres from other vegetable matterVegetable materialYarnCarding

The invention discloses a production technology of spinnability soft coconut shell fine fibers. The production technology is characterized by comprising the following steps of performing opening and cleaning, carding and impurity and block removing on original fibers of coconut shells serving as a raw material; and preparing a soaking solution, soaking the coconut shells with the solution, dewatering, steaming, drying and performing fine fiber carding, thus producing the soft and puffy ultrafine fibers. By virtue of soaking, most impurities are removed from the coconut fibers, so that the softness is improved, and the fine crushability and the fracture elongation property are improved; the fibers are complete in spinnability; due to chemical soaking, the internal structure is changed; furthermore, lignin is removed from the fibers, so that the water content is increased, and the aim of softening is fulfilled; the softened coconut fibers can be used for spinning various types of yarns which are then woven into textiles.

Owner:ZHEJIANG YIWU HENDRY WOOLEN

Composite thermoplastic sheets including natural fibers

ActiveUS7431980B2Non-fibrous pulp additionSynthetic resin layered productsSisal fiberCellulose fiber

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

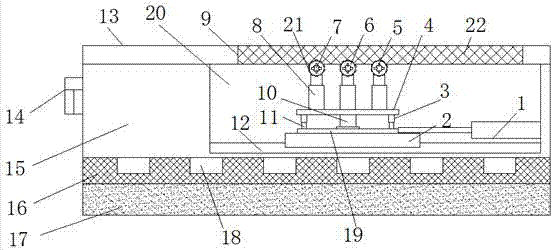

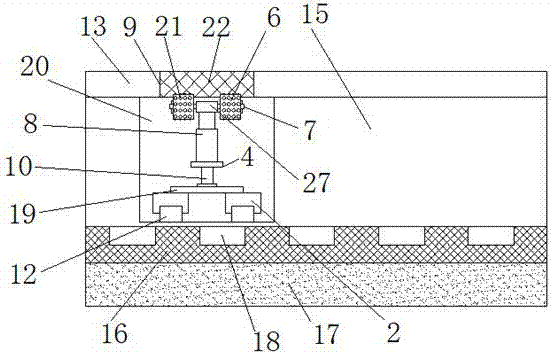

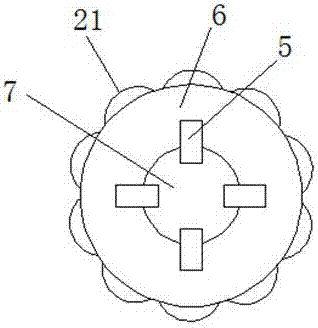

Intelligent mattress with massage and physiotherapy function

InactiveCN107157190APlay a relaxing roleImprove comfortElectrotherapyStuffed mattressesMassageEngineering

The invention relates to the technical field of intelligent mattresses, in particular to an intelligent mattress with massage and physiotherapy functions, comprising a bed board and a mattress substrate, the bottom surface of the bed board is provided with a coconut palm fiber cushion, and the coconut palm fiber cushion The bottom surface is provided with a hard cotton layer, the mattress substrate is installed on the bottom surface of the hard cotton layer, the upper surface of the hard cotton layer is embedded with a plurality of magnet blocks, and the upper surface of the coconut palm fiber cushion layer is opened There is a mounting groove, the inner bottom surface of the mounting groove is provided with two slide rails, the slide rails are provided with sliders, and the sliders slide along the surface of the slide rails, and a fixing plate is arranged between the two sliders. The interior of the installation groove is provided with an electric telescopic rod connected with the fixing plate. The invention is simple in structure and easy to use. It not only facilitates the reciprocating massage for the user, thereby improving the comfort of the massage, but also facilitates the user's adjustment and improves the simplicity of operation.

Owner:河南加特安物联网有限公司

Method for preparing coconut shell and thermoplastic plastic composite material

The invention discloses a process for preparing composite materials of coir and thermo-plastical plastic. The process enables coir to be crushed into 30-120-item coir powder of which the moisture content is equal to or less than 3% by drying. Coupling agent solution is sprayed to the coir powder at the temperature of 80 DEG C to 110 DEG C, then modified coir powder is produced and is homogenously mixed with thermo-plastical plastic resin, compatilizer, lubricant, stabilizer, stuffing material, flame retardant and the like, and then coir-plastic mixture is achieved and added to an extrusion machine to be squeezed out, consequently the composite materials of coir and plastic are achieved. The invention resolves the problems of the compatibility of the coir fiber and the thermo-plastical plastic and the treatment technology of the surface of the raw materials, thereby realizing the synthetic utilization of the coconut fruit and substitution for lumber which is lack in resource, increasing the added value of the coconut fruit, and solving the problem of the utilization of the coir waste. The composite materials prepared by the invention have the advantages of the combination of lumber and plastic, and the composite materials not only have graceful appearance, but also are capable of being antiseptic, moisture proof, borer proof and fire resistant.

Owner:GUANGZHOU SCUT BESTRY TECHNOLOGY CO LTD

Coconut palm fiber elastic cushion

InactiveCN1579927AModerate elasticityUniform densityUpholstery manufactureNatural rubber adhesivesEngineeringPalm fiber

A stretch cushion is made of coir fiber. After steamed under a high pressure, carded by mechanism, sprayed glue (which is mixed by natural lactoprenes), dried, sulfuration and other processing technics, the cushion has a good air permeability, hydraulic permeability, and hygroscopicity. Also its processing technic is simple. It is warm in winter while cold in summer. With this character, it fits to make bed-cushion and seating cushion, and also it can be used as sound-proof, non-hygroscopic and packaging materials.

Owner:黄志平

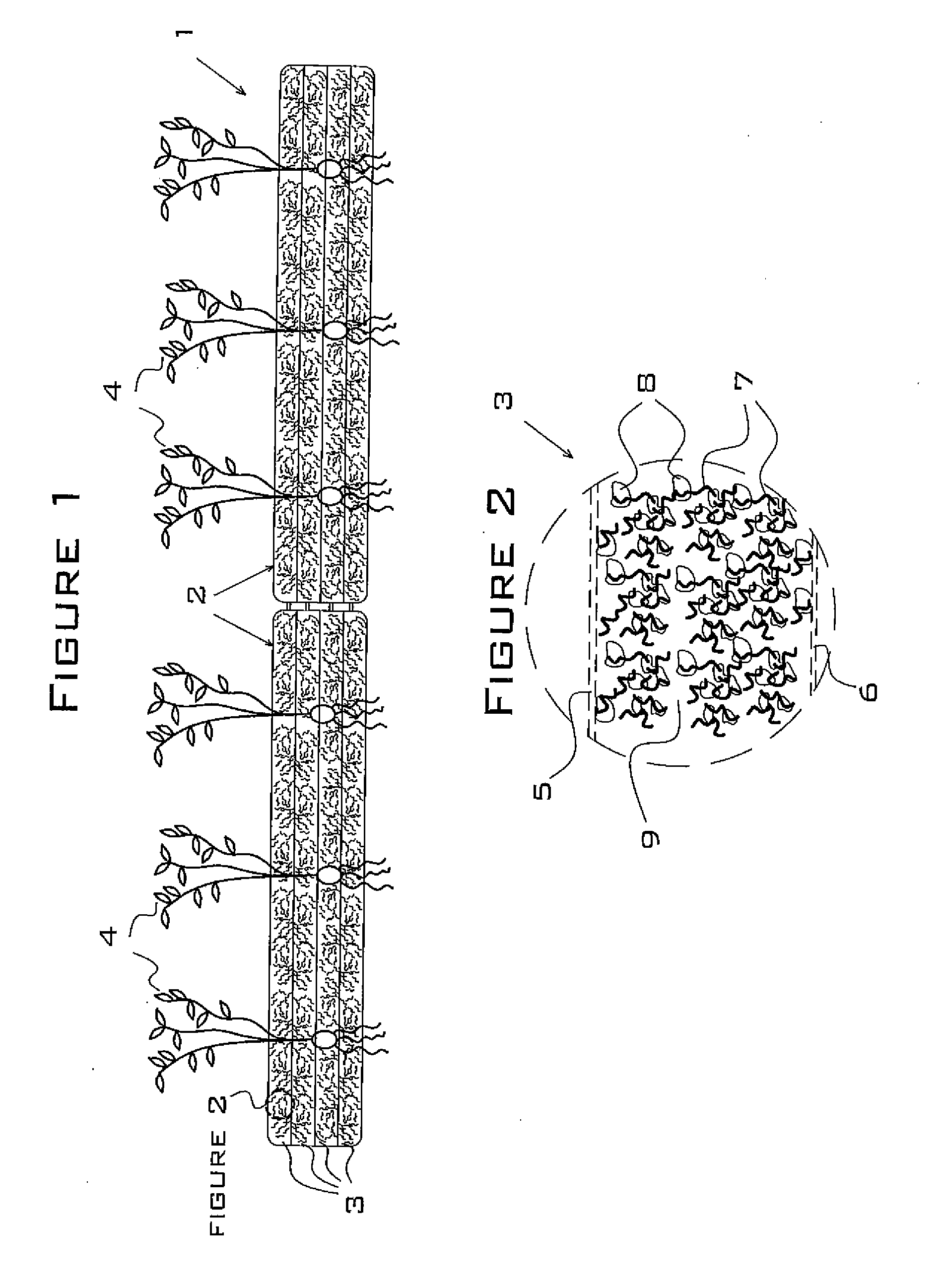

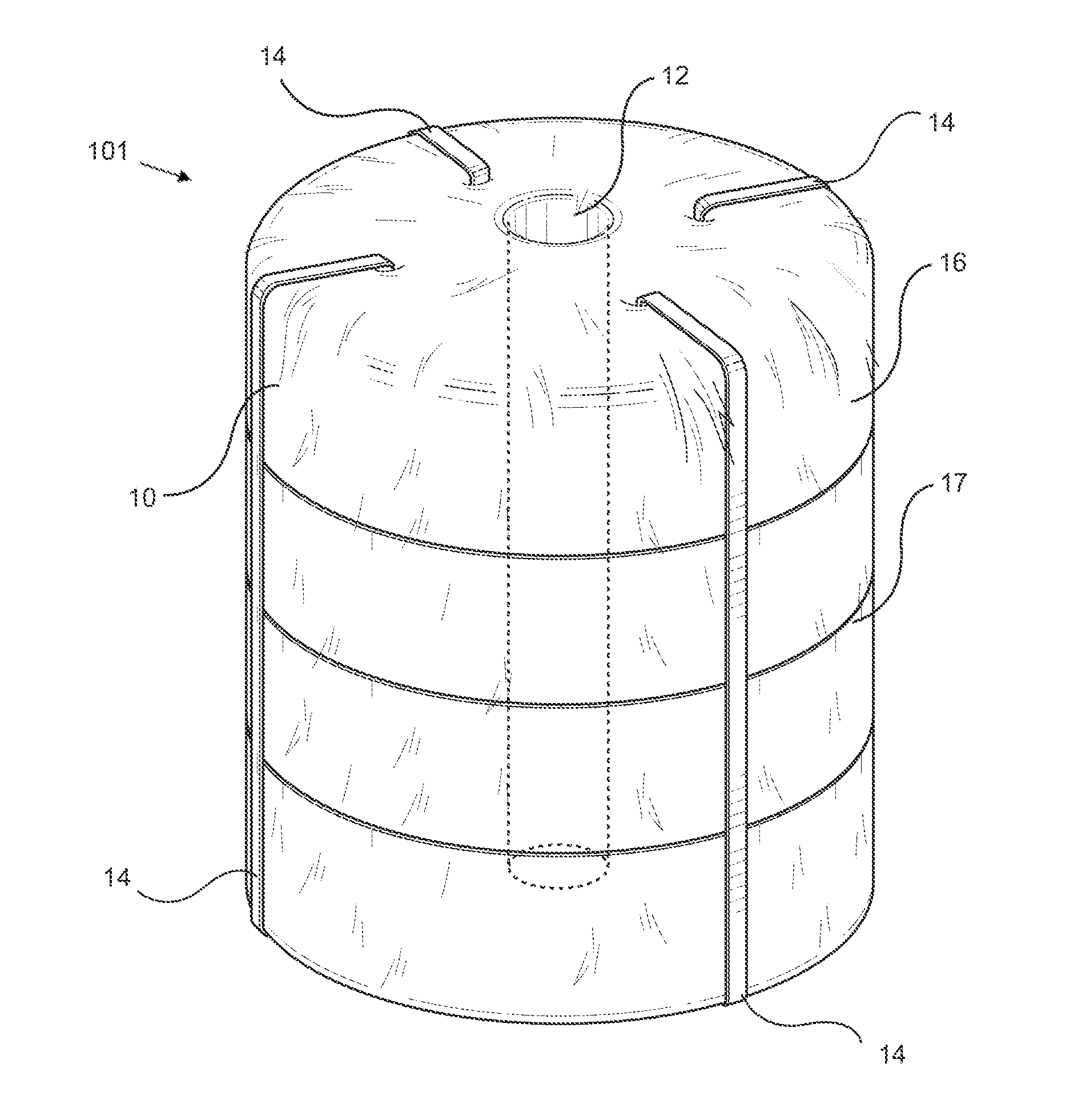

Floating island module comprised of post-consumer carpet fiber matrix and method of manufacturing same

A floating island comprising one or more modules each comprised of one or more layers of permeable and porous matrix comprised of post-consumer carpet fibers and a top covering and a bottom covering around each layer. Alternate embodiments include layers comprised of polyethylene terephthalate bottle-fiber matrix and / or jute or coir fibers. A method of manufacturing the floating island module described above.

Owner:FOUNTAINHEAD

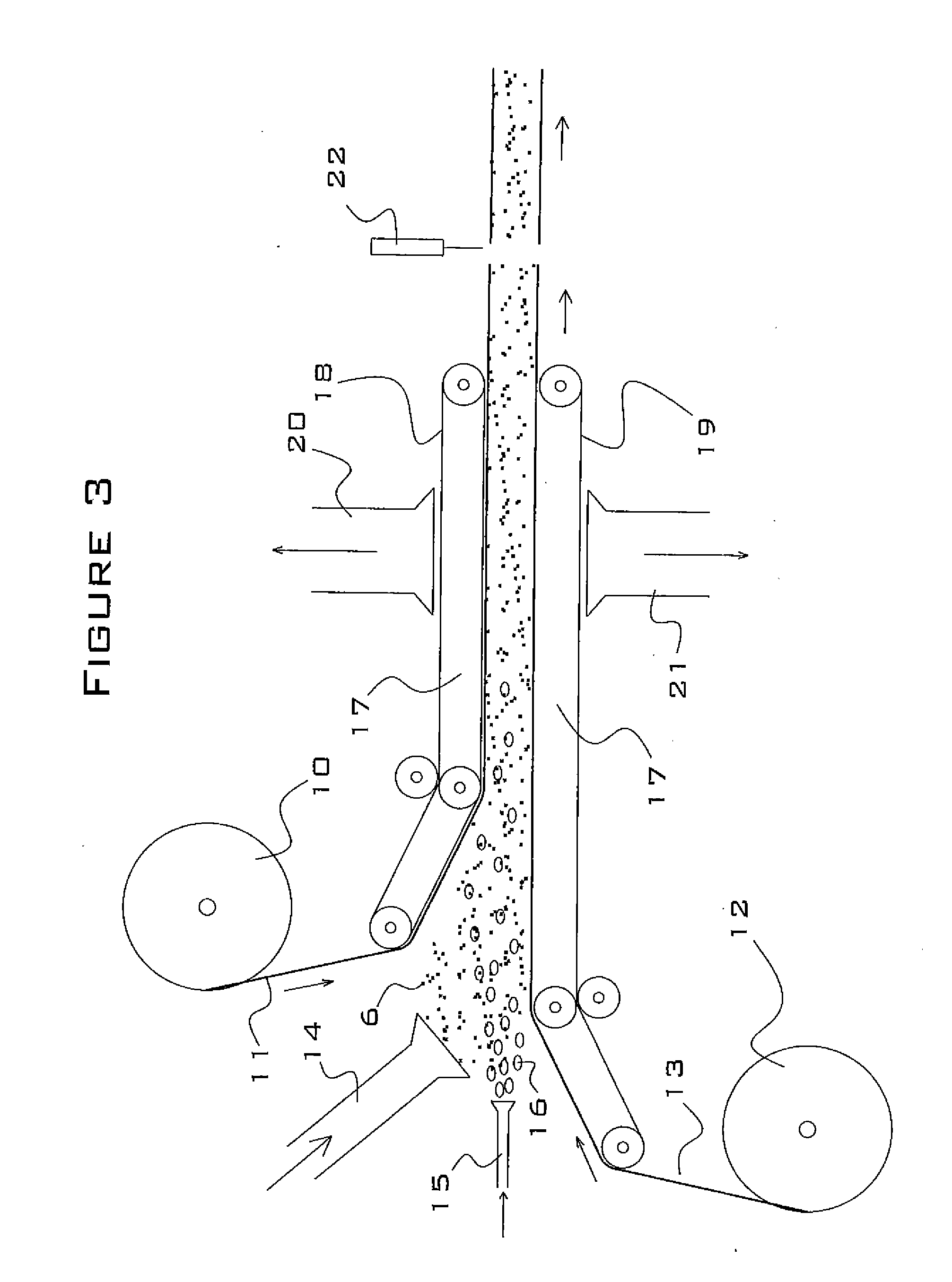

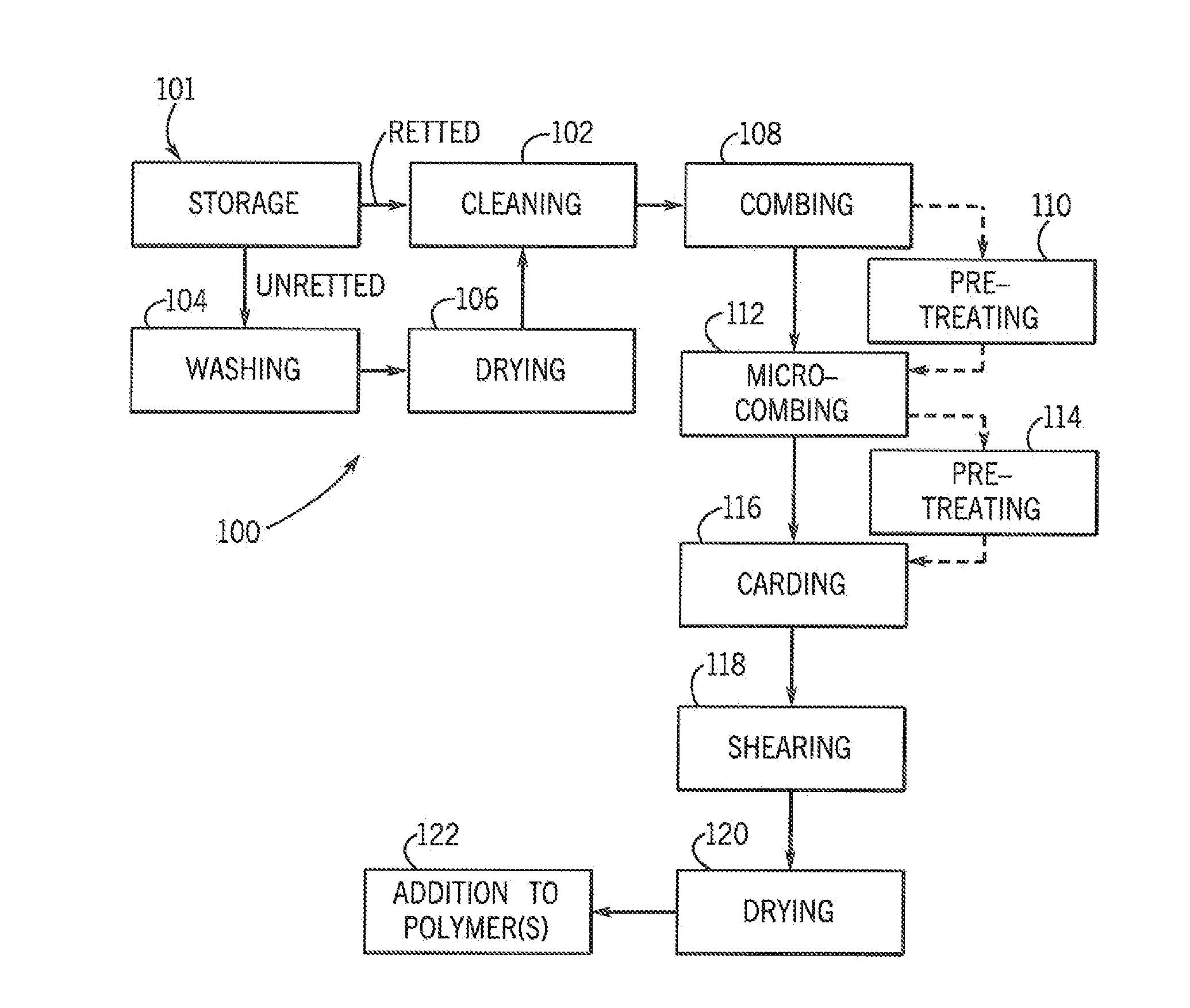

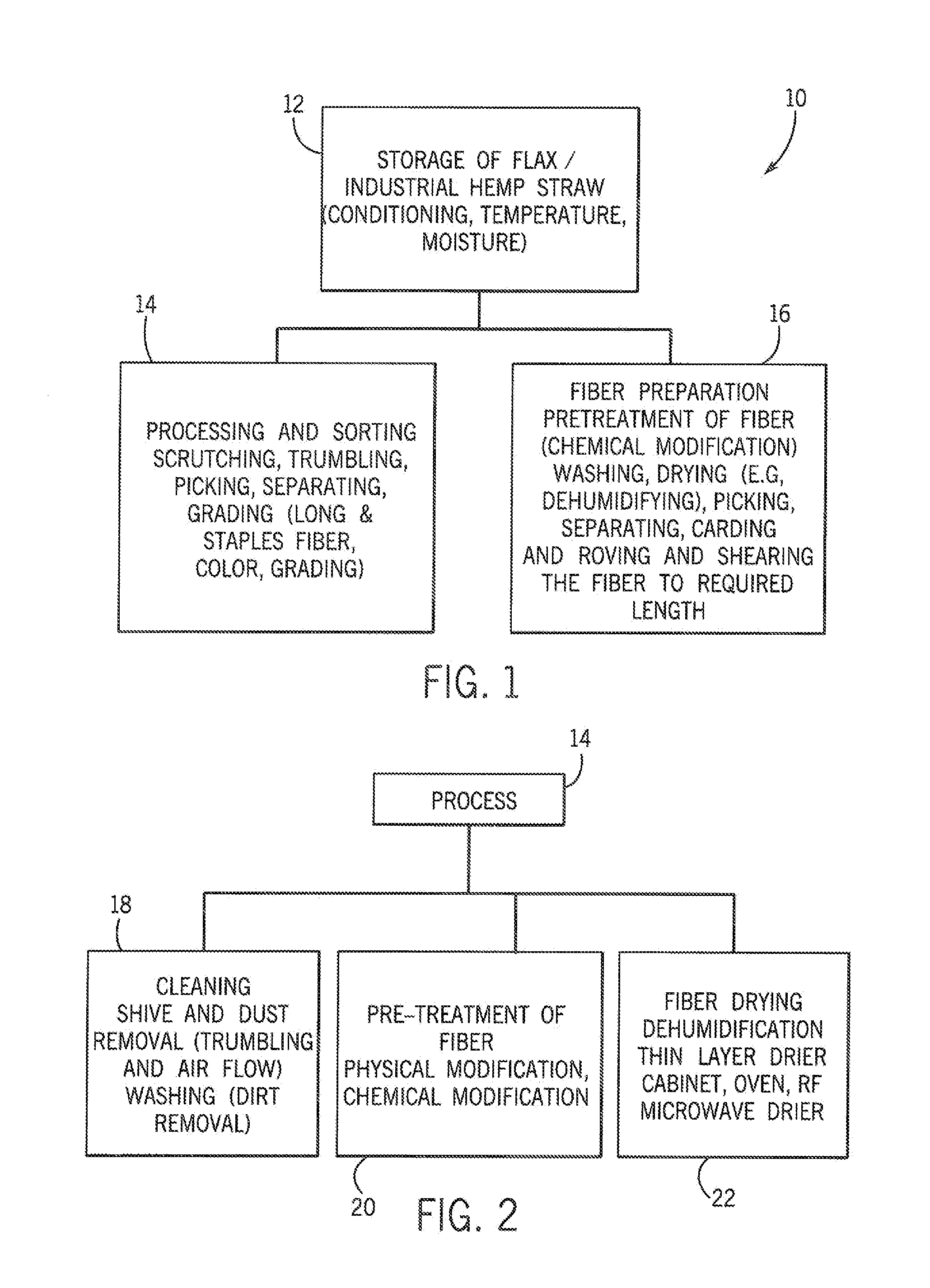

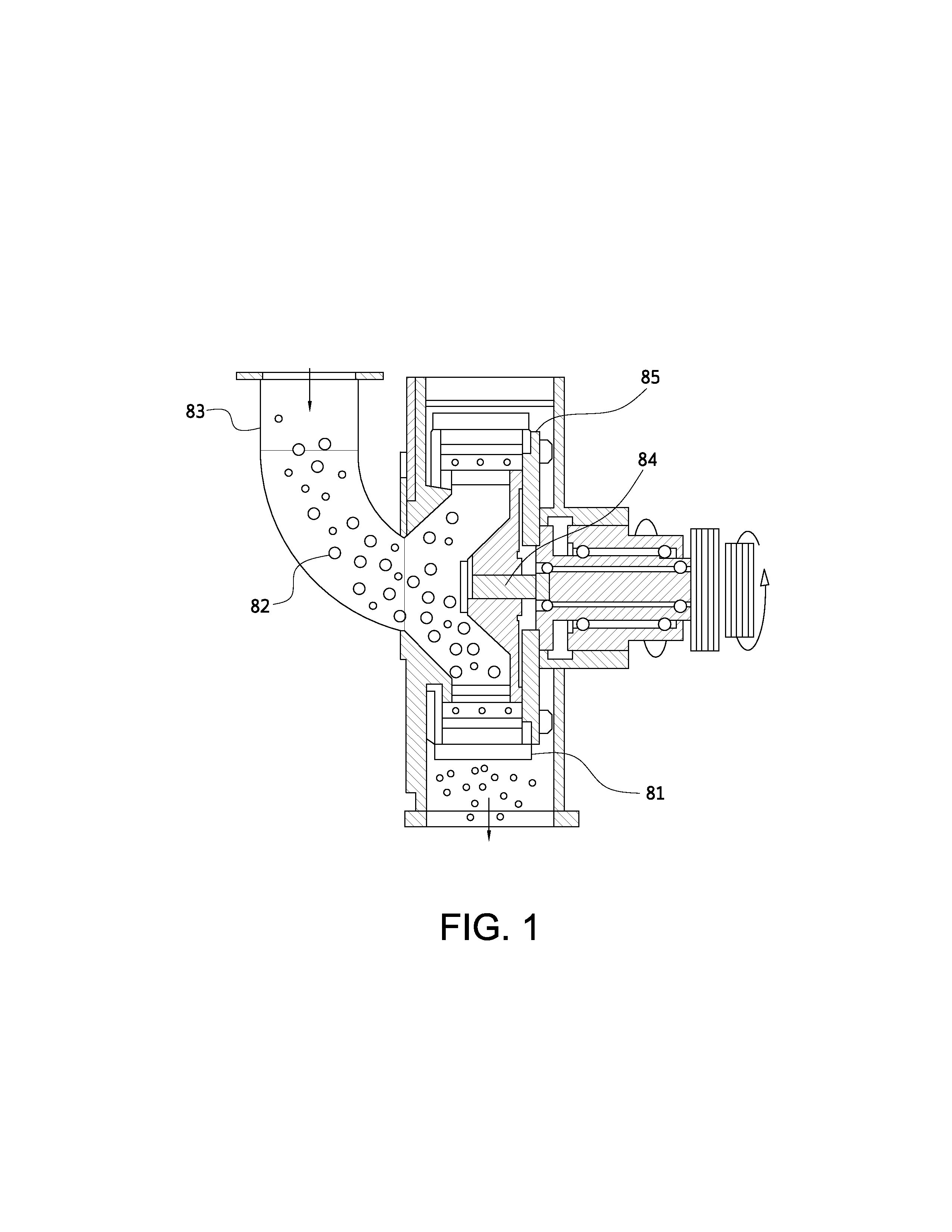

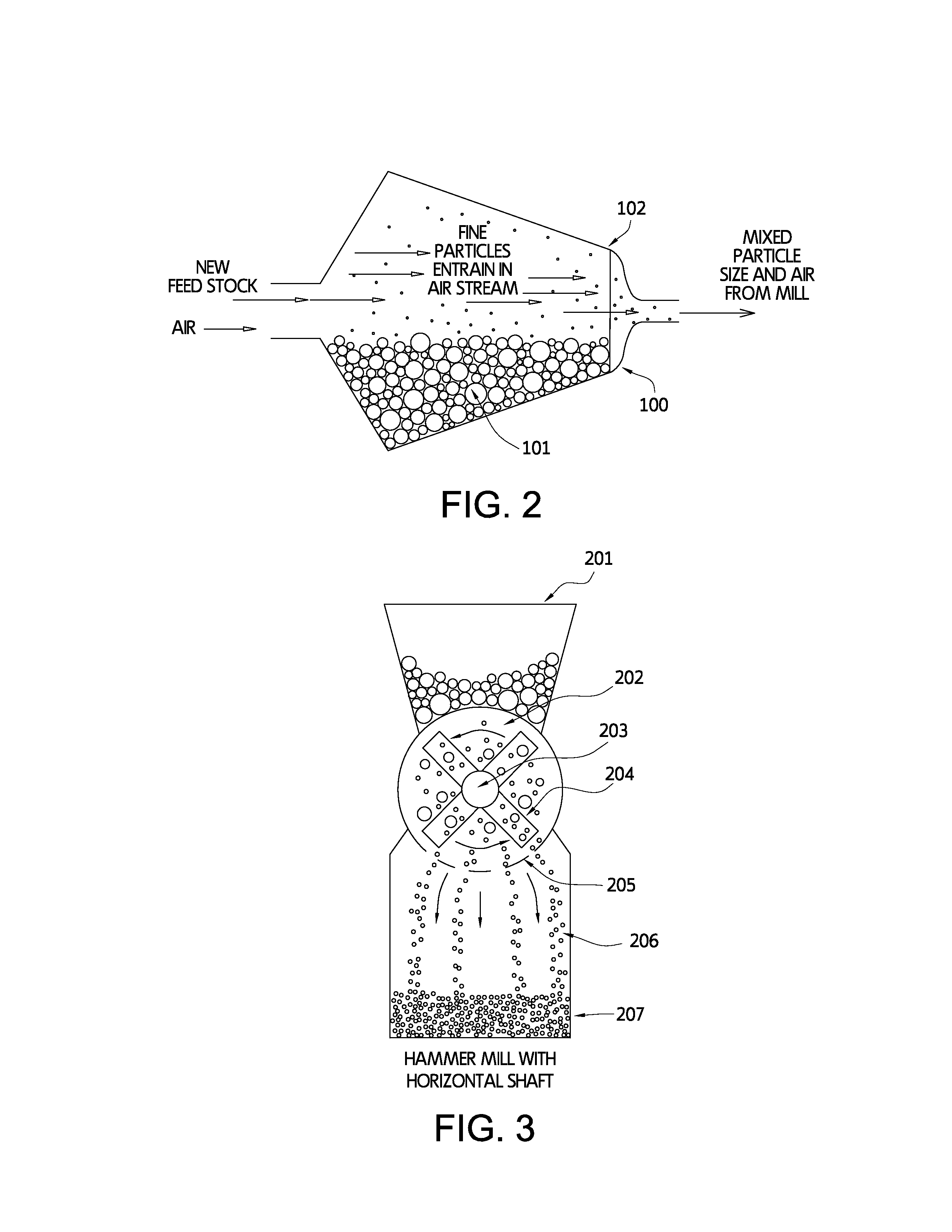

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

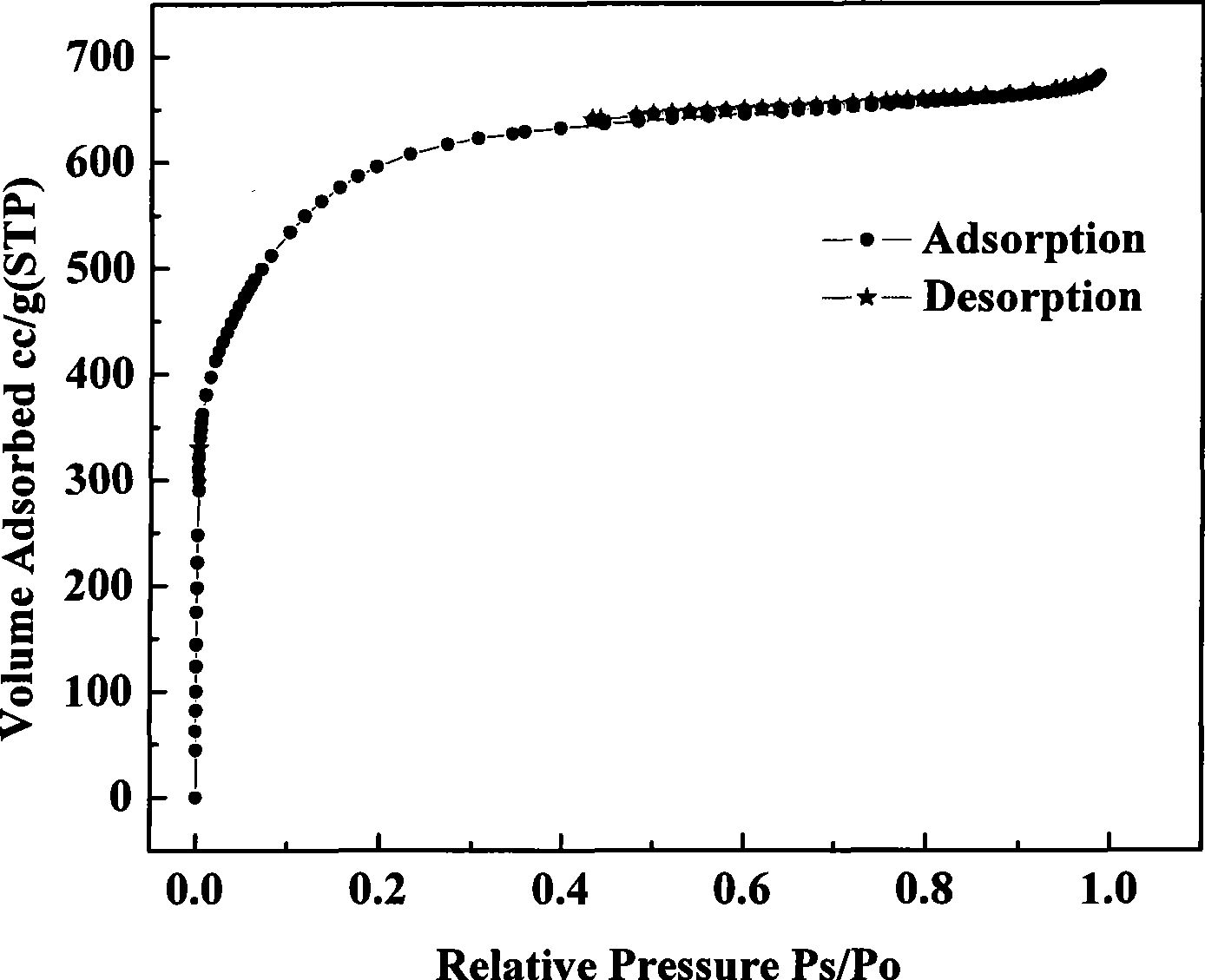

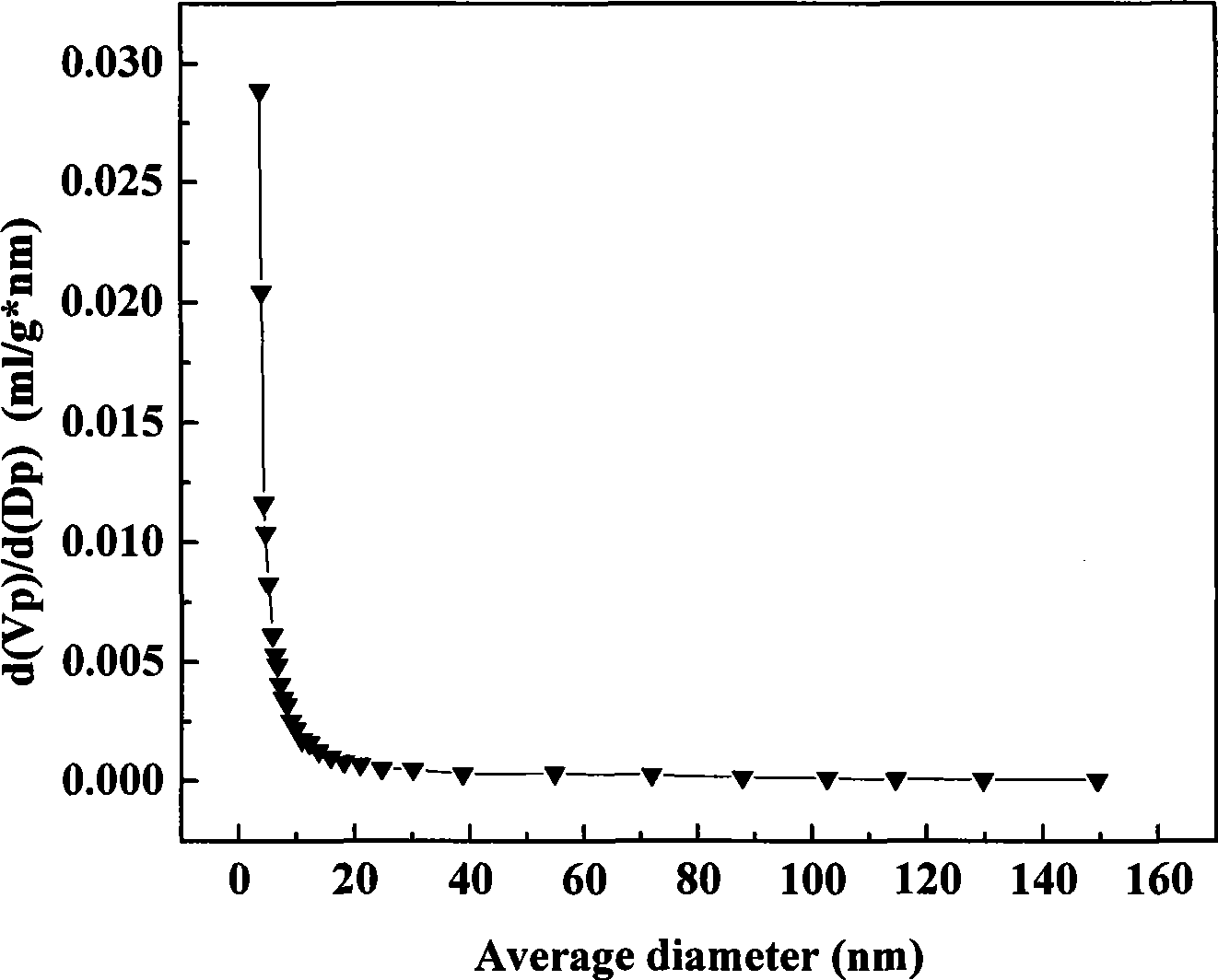

Preparation of coir fiber based activated carbon with high specific surface area

The invention discloses a preparation method of coir base high specific surface area active carbon, which comprises the following steps: taking coir as raw material to be carbonized and obtaining carbonization material; activating the carbonization material and an alkalescent active agent after being mixed; washing or pickling a product; and then filtering and drying the product. The invention has simple technical process and low cost through taking the coir as the raw material, can effectively enhance the activation of the active agent, and is the preparation method of the active carbon which has the advantages of low cost, high efficiency, environmental protection and the like; and the prepared active carbon has the advantages of high specific surface area, narrow aperture distribution and high middle aperture ratio. The invention can be applied to energy storage materials, capacitors, efficient adsorbent, separating agent and gas adsorbent, hydrogen storage materials, and the like. Furthermore, the invention has wide application prospect.

Owner:HAINAN UNIVERSITY

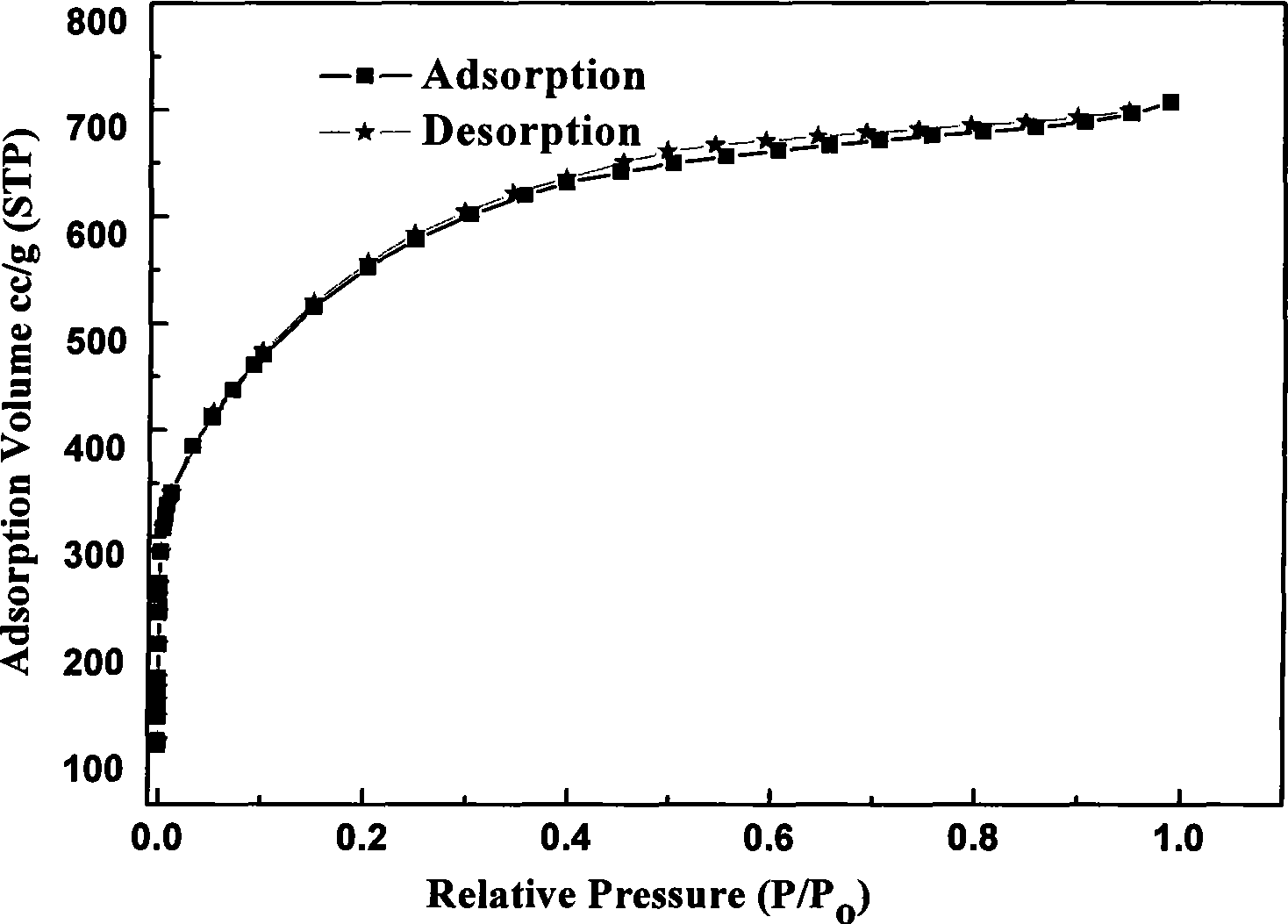

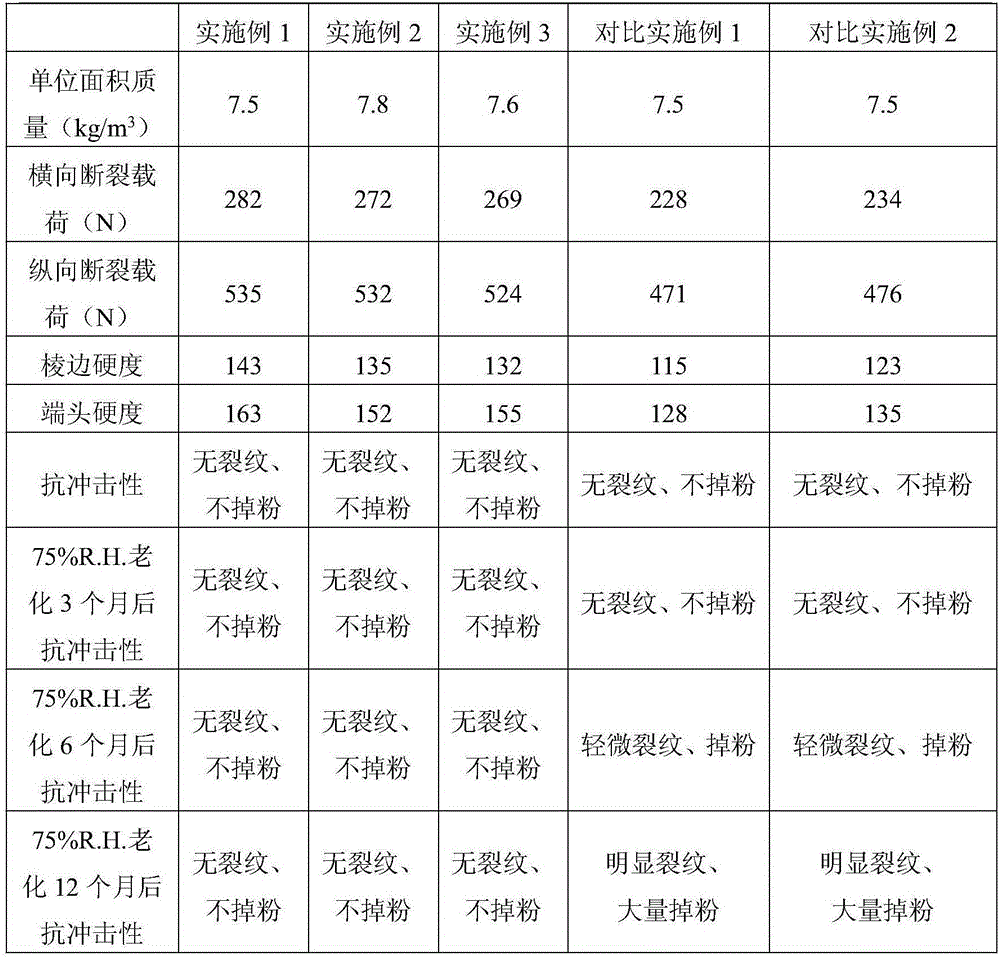

Antimagnetic plasterboard applicable to high-humidity environments and preparation method thereof

InactiveCN106478145AHigh strengthImprove electromagnetic shielding performanceConstruction materialSolid waste managementWet bondingScreening effect

The invention provides antimagnetic plasterboard applicable to high-humidity environments. The antimagnetic plasterboard is mainly prepared from the raw materials, i.e., coir fibers, a foamer, plaster clinker, graphene oxide, a humectant and causticized white clay. According to the antimagnetic plasterboard applicable to the high-humidity environments, the coir fibers and the causticized white clay are added on the basis of the conventional plaster clinker and foamer, so that the waterproof performance of the plasterboard is improved, and a very good wetted bonding effect can be achieved without adding additives such as CMC powder; by adding the graphene oxide, the strength of the plasterboard can be further improved; in order to improve the dispersion effect in the entire system, the humectant is required to be added, and proven by a large number of experiments, a very good dispersion effect can be achieved through adding a small amount of humectant Hyonic PE-100; after basalt fibers are added, the plasterboard has a very good screening effect on electromagnetic waves with the frequency band of 8GHz to 16GHz. The antimagnetic plasterboard applicable to the high-humidity environments, provided by the invention, is low in cost and high in strength, particularly, has very good bonding strength in the high-humidity environments and is free of powder falling in long-term use, and the electromagnetic screening effect is good.

Owner:长兴钦禾建材科技有限公司

Special matrix for breeding of Chinese fir and production technology thereof

ActiveCN103348903ASingle sourceEasy to obtainCultivating equipmentsSoilless cultivationGrowth plantMolding machine

The invention discloses special matrix for breeding of Chinese fir. The special matrix comprises the following components in parts by weight: 70-80 parts of coir fiber, 10-15 parts of multiple-granular agent, 10-15 parts of plant growth promoting rhinoacteria (PGPR) compound bacterial fertilizer, and 0.1-0.2 parts of humic acid, wherein the matrix forms a block shape; and the production technology of the special matrix comprises the following steps: firstly, carrying out roughening treatment on a coir fiber, adding a little of zymophyte to carry out full fermentation treatment; evenly mixing and stirring 70-80 parts of fermented coir fiber, 10-15% of multiple-granular agent, 10-15% of PGPR compound bacterial fertilizer and 0.1-0.2 parts of humic acid to prepare mixture; pressing the mixture through a molding machine to prepare a fluffy cylindrical block; and taking non-woven fabrics to enclose the peripheral surface of the cylindrical block, so as to form culture medium with upper and lower ports. The proportion of components of the special matrix is fully considered to be suitable for growth of breeding of the Chinese fir; the seedling substrate has an excellent three-phase structure for conserving manure, holding moisture and ventilating.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

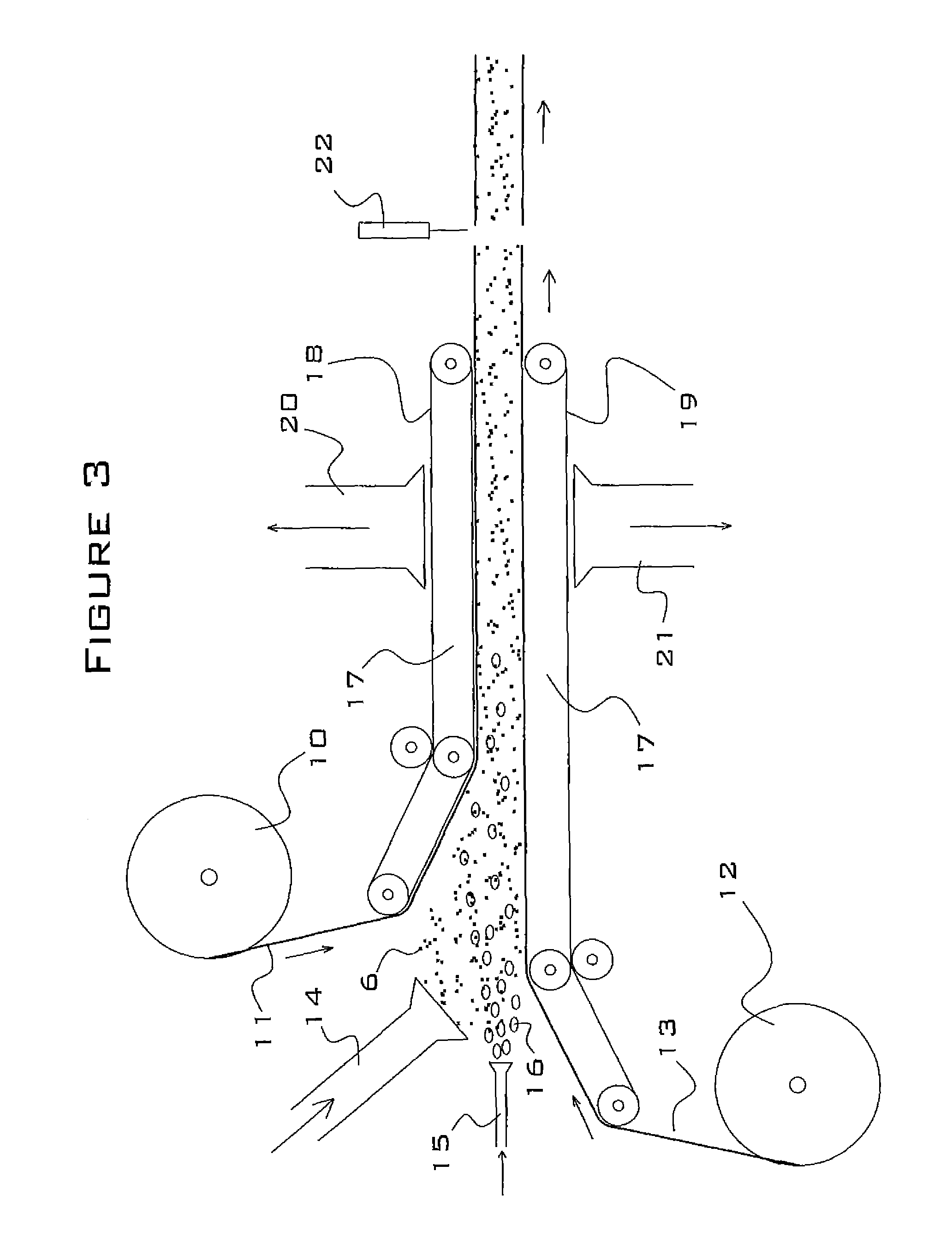

Method for producing bioactive vegetation blanket

InactiveCN101663985AOvercome the disadvantages of soil transplantationThe effect is positive and obviousAgriculture gas emission reductionCultivating equipmentsVegetationLand resources

The invention relates to a method for producing a bioactive vegetation blanket, which comprises the following steps: feeding materials, blocking and stirring the materials, laying a bottom network, delivering auxiliary materials, laying an upper network, quilting, reeling and cutting. The method uses waste plants, such as straws (rice straws, wheat straws and corn straws), coir fibers and the like, to replace the land transplant, and uses a factory production mode to change the prior artificial lawn transplant method; and the produced soil-less lawn vegetation blanket can be transported to a construction site in a reeling mode, and is directly laid into a lawn so as to completely overcome the defects in conventional soil lawn transplant cultivation and protect the limited land resources.

Owner:黄天文

Fireproof plant fiber furniture board

ActiveCN102689345AReduce thermal deformationHas added amountDomestic articlesFlat articlesAdhesivePlant fibre

The invention discloses a fireproof plant fiber furniture board, which is manufactured by the following steps of: (A), manufacturing a board blank through a paving process by taking coconut palm cellosilk as a raw material, wherein the density of the board blank is 0.16 to 0.18 g / cm<3>; (B), immersing the board blank into an inorganic gelatinized slurry for 5 to 10 minutes, wherein the inorganic gelatinized slurry consists of magnesium chloride, magnesium oxide and water; and the mass percent concentration is 50 to 70 percent; (C), conveying the immersed board blank into a roller machine for rolling, wherein the density of the rolled board is 0.8 to 0.9 g / cm<3>; and (D), maintaining, drying and solidifying the rolled board and cutting finishes to manufacture the plant fiber furniture board. By adoption of the production process, the board has the characteristics of light weight, corrosion resistance and low cost and is easily machined, and the fireproof performance is realized; and particularly, the addition quantity of water in adhesives is reduced, so that a basis for machining the high-quality and high-strength fireproof plant fiber furniture board is laid.

Owner:GUANGDONG YIXIN HOUSEHOLD MATERIALS GROUP CO LTD

Nutrient soil special for snake gourd seedling culture and preparation method thereof

InactiveCN106116926AUniform growthPromote rapid growthSuperphosphatesBioloigcal waste fertilisersPaulowniaPhosphoric acid

The invention discloses a nutrient soil special for snake gourd seedling culture. The nutrient soil is prepared from, by weight, 50-70 parts of peat soil, 8-10 parts of Luzhao soil, 20-25 parts of sea mud, 10-15 parts of plant straw powder, 5-7 parts of paulownia sawdust, 5-10 parts of edible fungus waste residue, 20-30 parts of coir fiber, 8-15 parts of modified plant ash, 3-6 pats of vermiculite powder, 3-6 parts of garlic powder, 1-3 parts of milkvetch root powder, 2-3 parts of urea and 1.5-2.5 parts of superphosphate. The nutrient soil special for snake gourd seedling culture is balanced in nutrient, suitable for snake gourd culture, long in fertilizer acting time, capable of providing nutrient needed by growth of snake gourds and effectively promoting rapid growth of snake gourds and also capable of reducing pest and disease damage and enhancing disease resistance and anti-adversity ability, meanwhile has high water-retaining property, water permeability and air permeability, and prevents new root systems of plants from being rotten.

Owner:QIANSHAN YOUYU TRICHOSANTHES KIRILOWII MAXIM DEV CO LTD

Composite boards and a method of making the same

InactiveUS20130178561A1Provide scratch resistanceProvide strength resistanceConfectioneryWood treatment detailsPolymer sciencePolyolefin

A composite board is manufactured from hydrophobic coconut coir fibers which have been treated to remove at least a portion of coconut pith therefrom; and a hydrophobic vinyl polymer, such as a polyolefin. The composite board is manufactured without any step of chemically modifying coconut coir fibers. The composite board is manufactured by removing at least a portion of coconut pith from coconut coir fibers using a cyclonic separator; combining coconut coir fibers with a hydrophobic polymer to form a mixture; and extruding the mixture to form a composite board.

Owner:ADMIRAL COMPOSITE TECH

Matrix specially used for phoebe bournei seedling raising and production technology thereof

ActiveCN103355149ASingle sourceEasy to obtainCultivating equipmentsOrganic fertilisersGrowth plantCylindrus

The invention discloses a matrix specially used for phoebe bournei seedling raising. The matrix comprises the following components in percentage by weight: 65-75 of coir fibers, 10-15 of multi-time aggregation agent, 15-20 of plant growth promoting rhinoacteria (PGPR) composite bacterial fertilizer and 0.1-0.2 of humic acid and is block type. A production technology comprises the following steps of roughening the coir fibers, then adding a small amount of zymophyte for full fermentation treatment, uniformly mixing and stirring 80-85 of fermented coir fibers, 10-15 of multi-time aggregation agent, 15-20 of plant growth promoting rhinoacteria (PGPR) composite bacterial fertilizer and 0.1-0.2 of humic acid to obtain a mixture, and pressing the mixture into a fluffy cylindrical block through a shaping machine, and encircling the circumferential surface of the cylindrical block with non-woven cloth to form a culture matrix with a longitudinal through opening. The proportions of the constituent components of the special matrix considers the growth of the phoebe bournei raising seedlings, and the seedling raising matrix has a three-phase structure with high fertilizer preservation property, water retaining performance and ventilating property.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

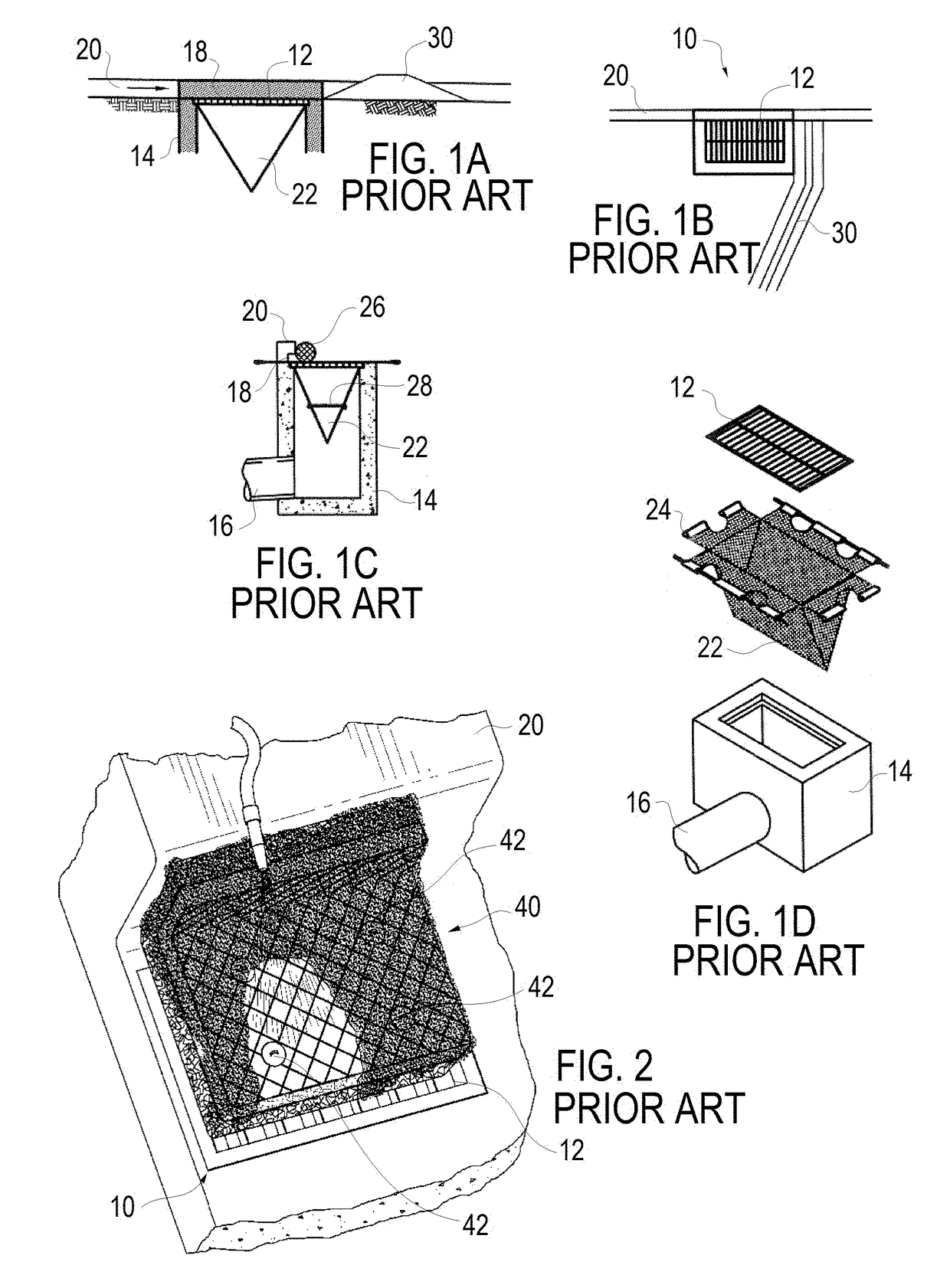

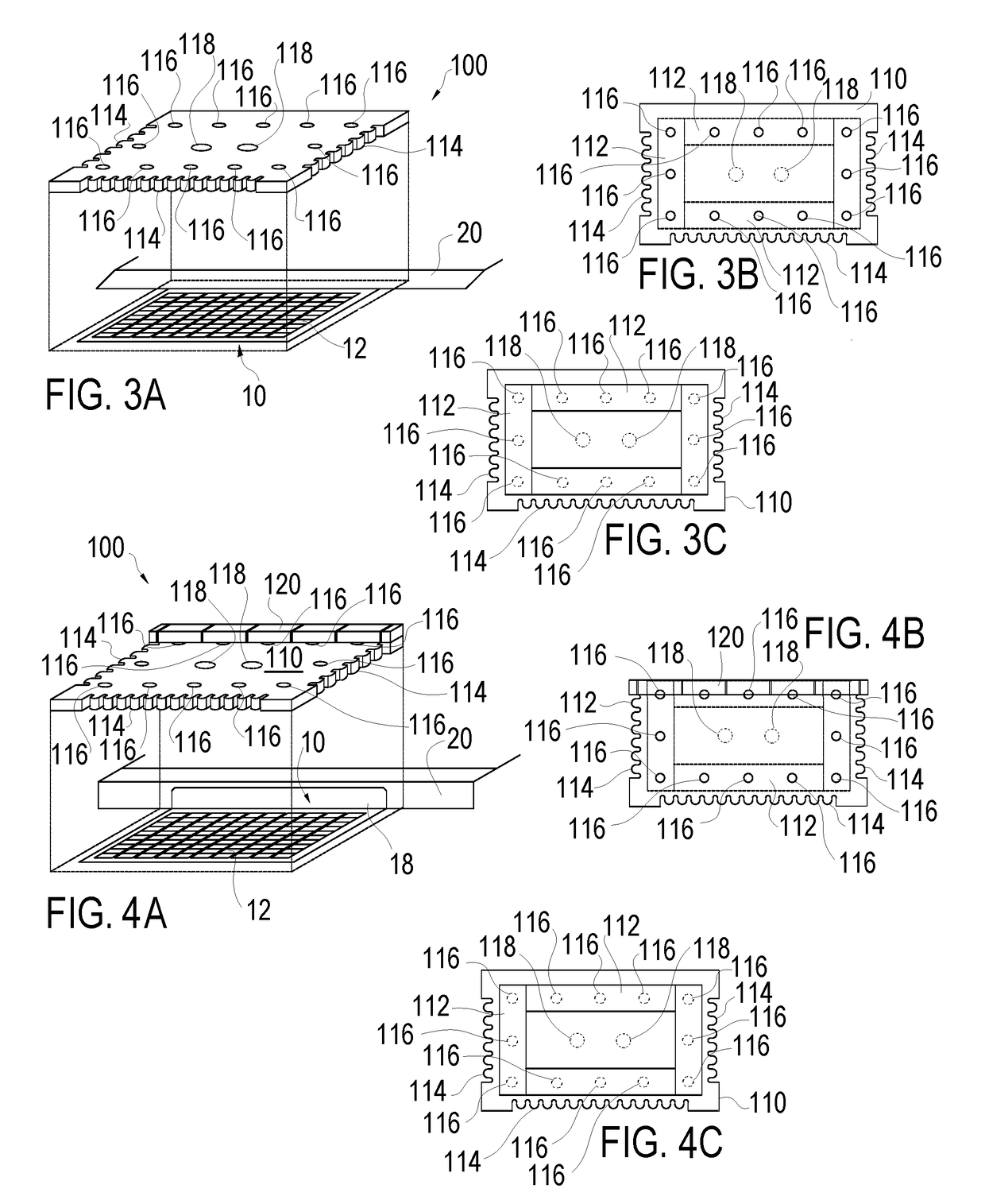

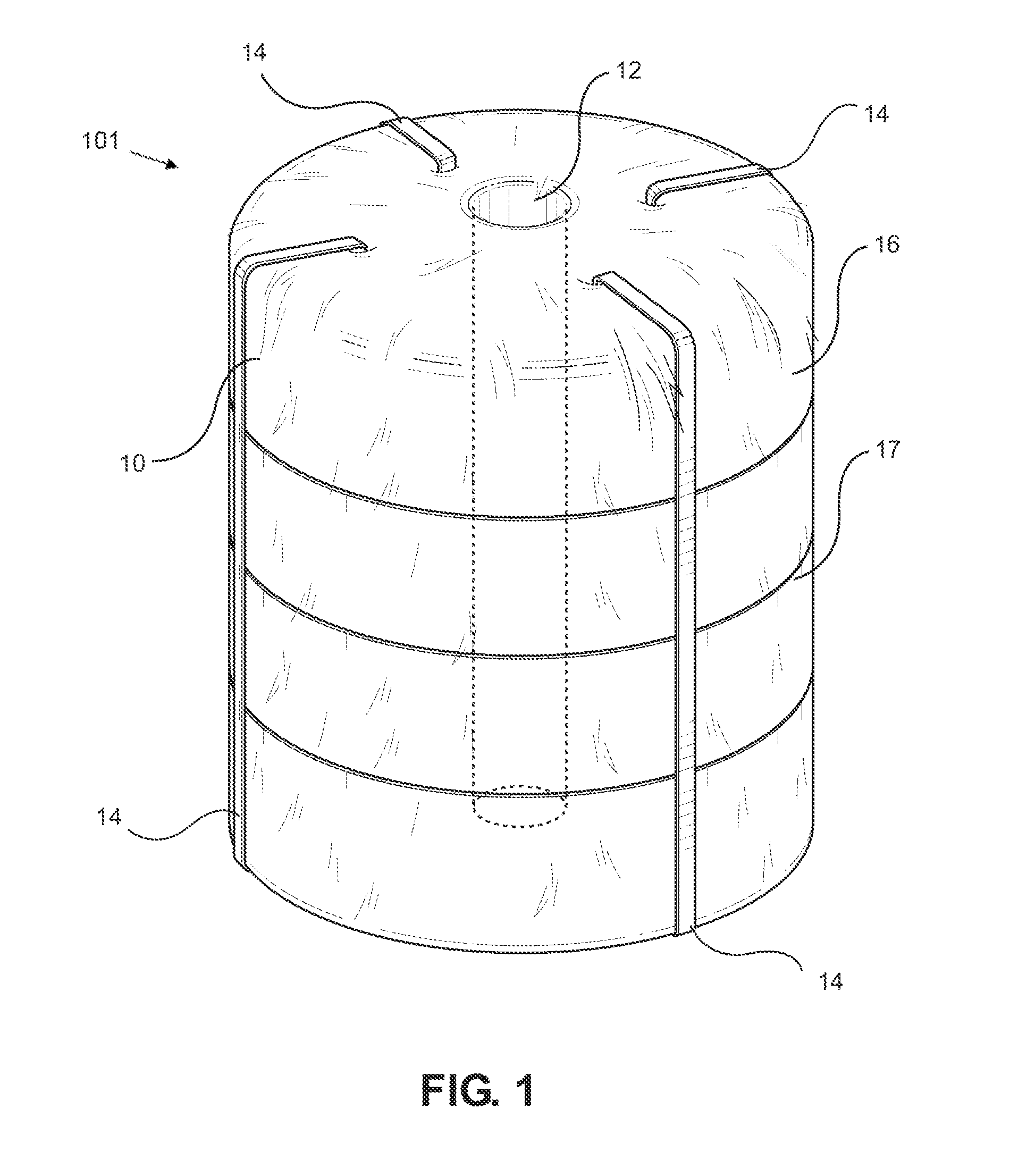

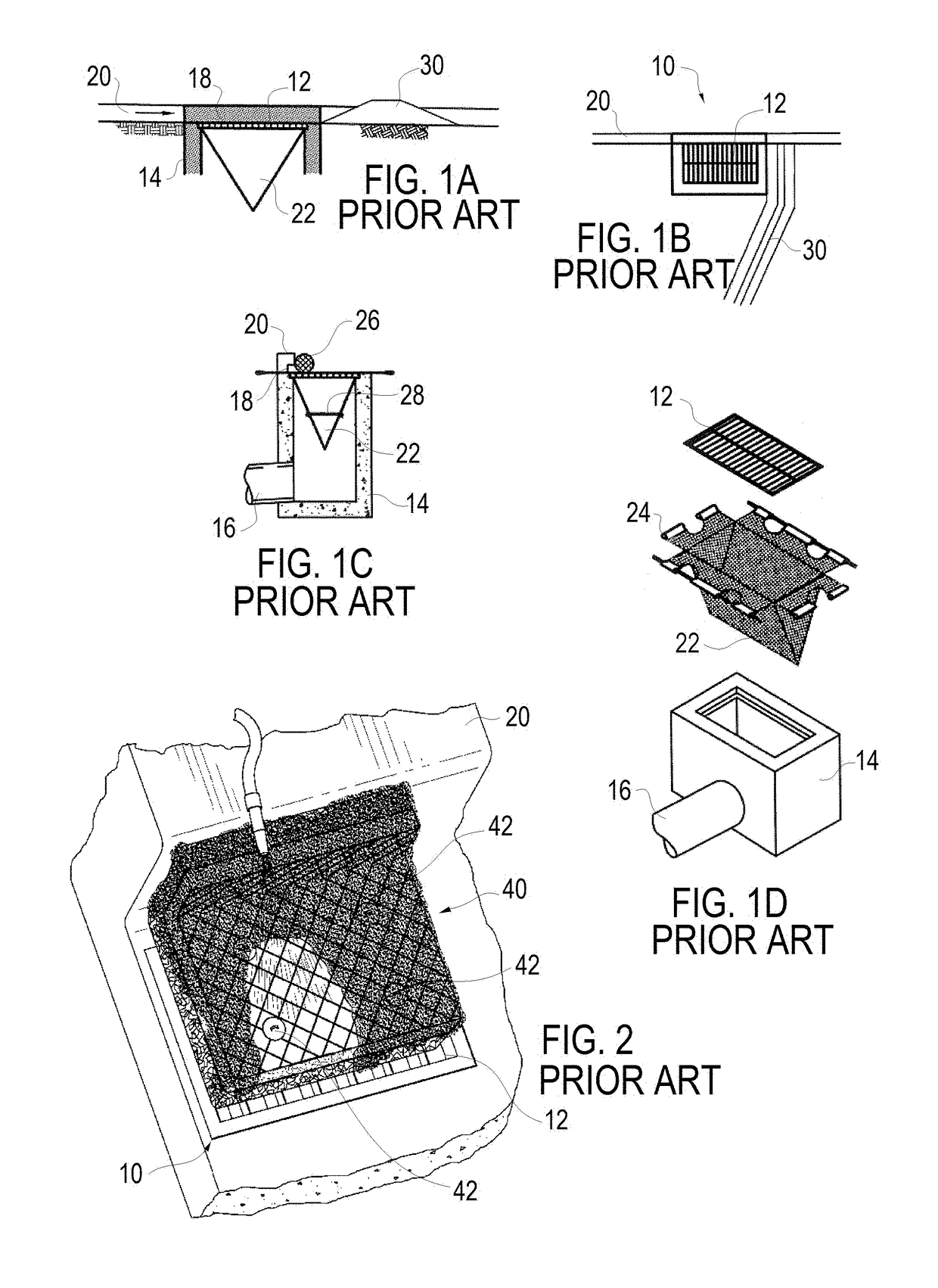

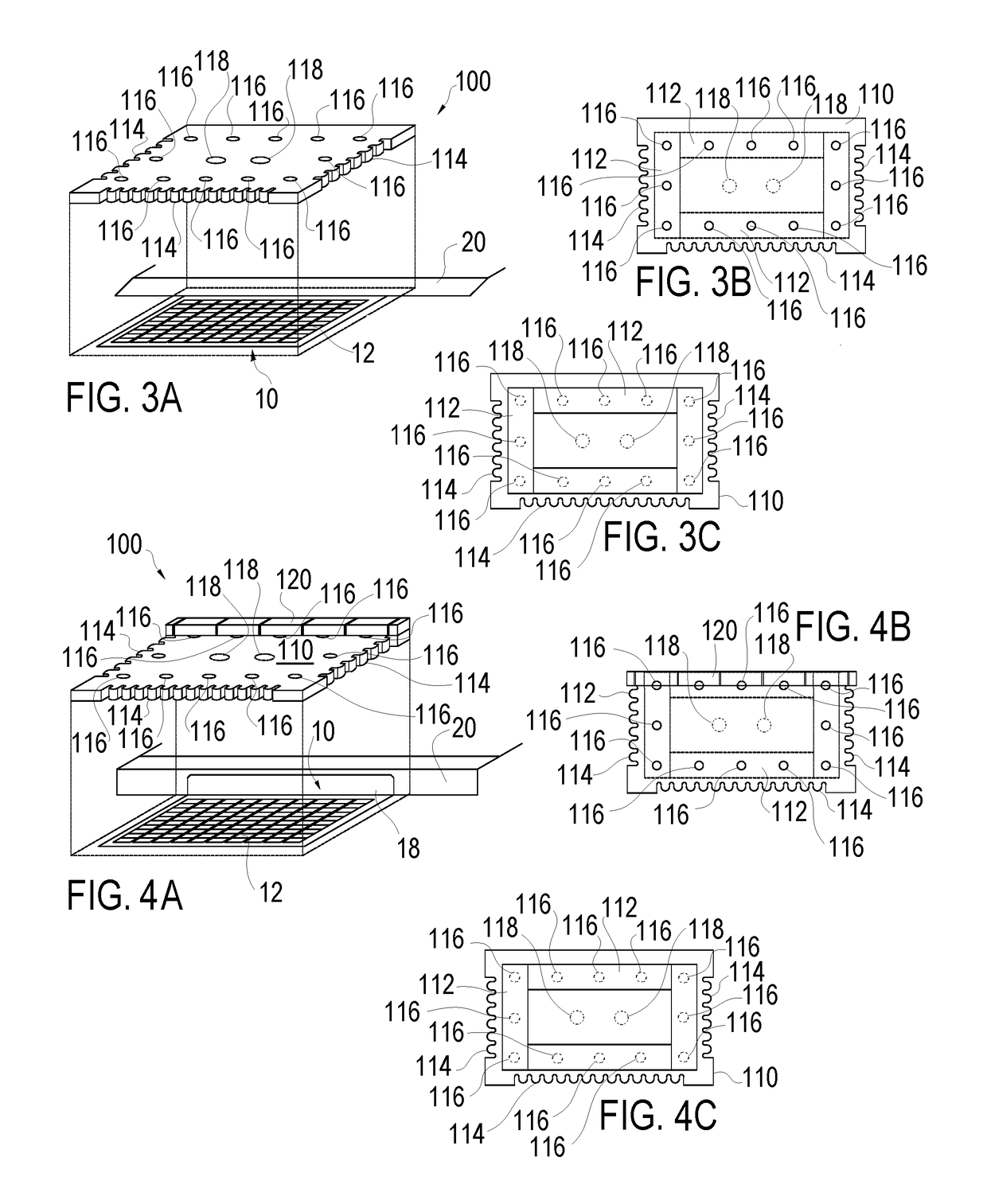

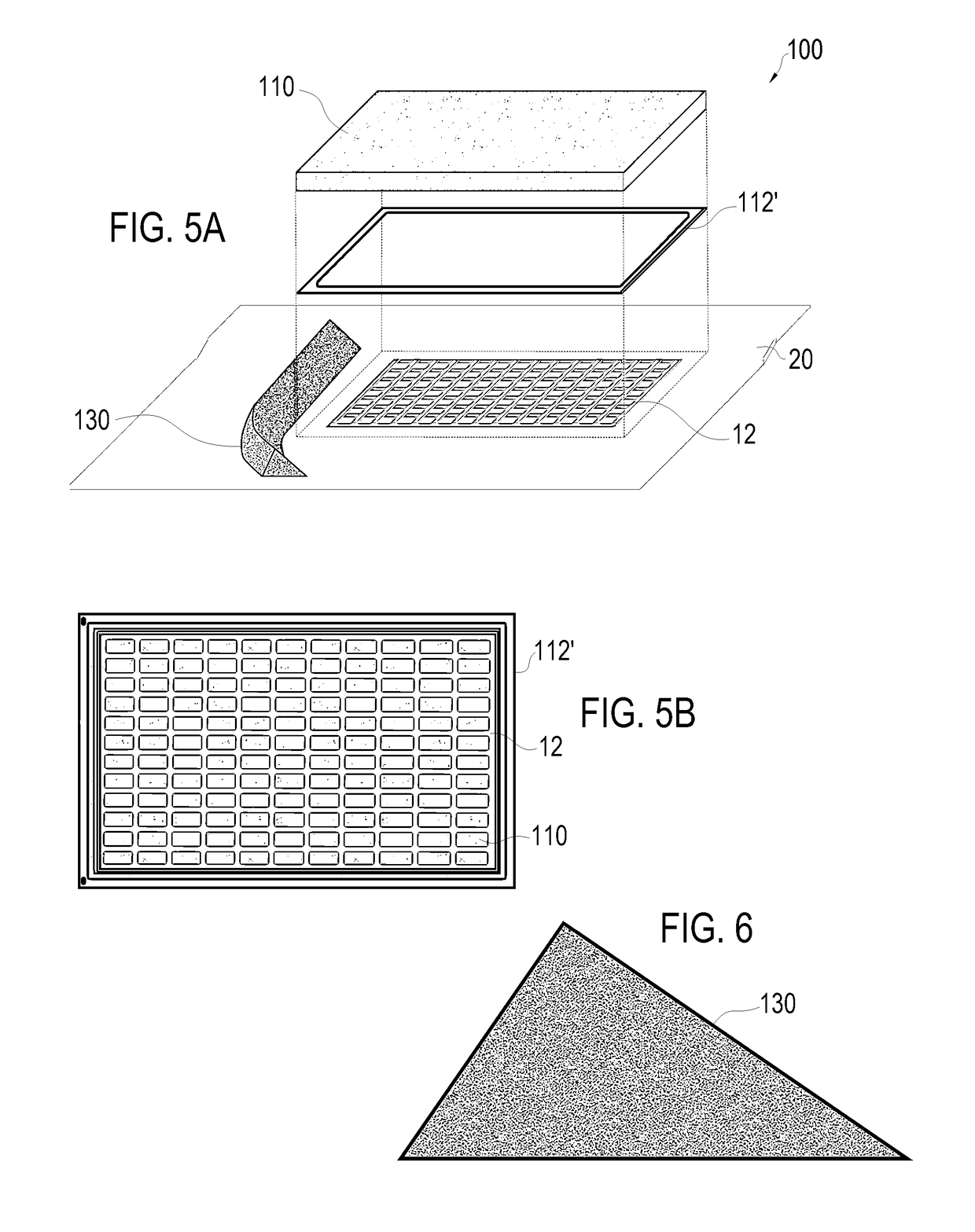

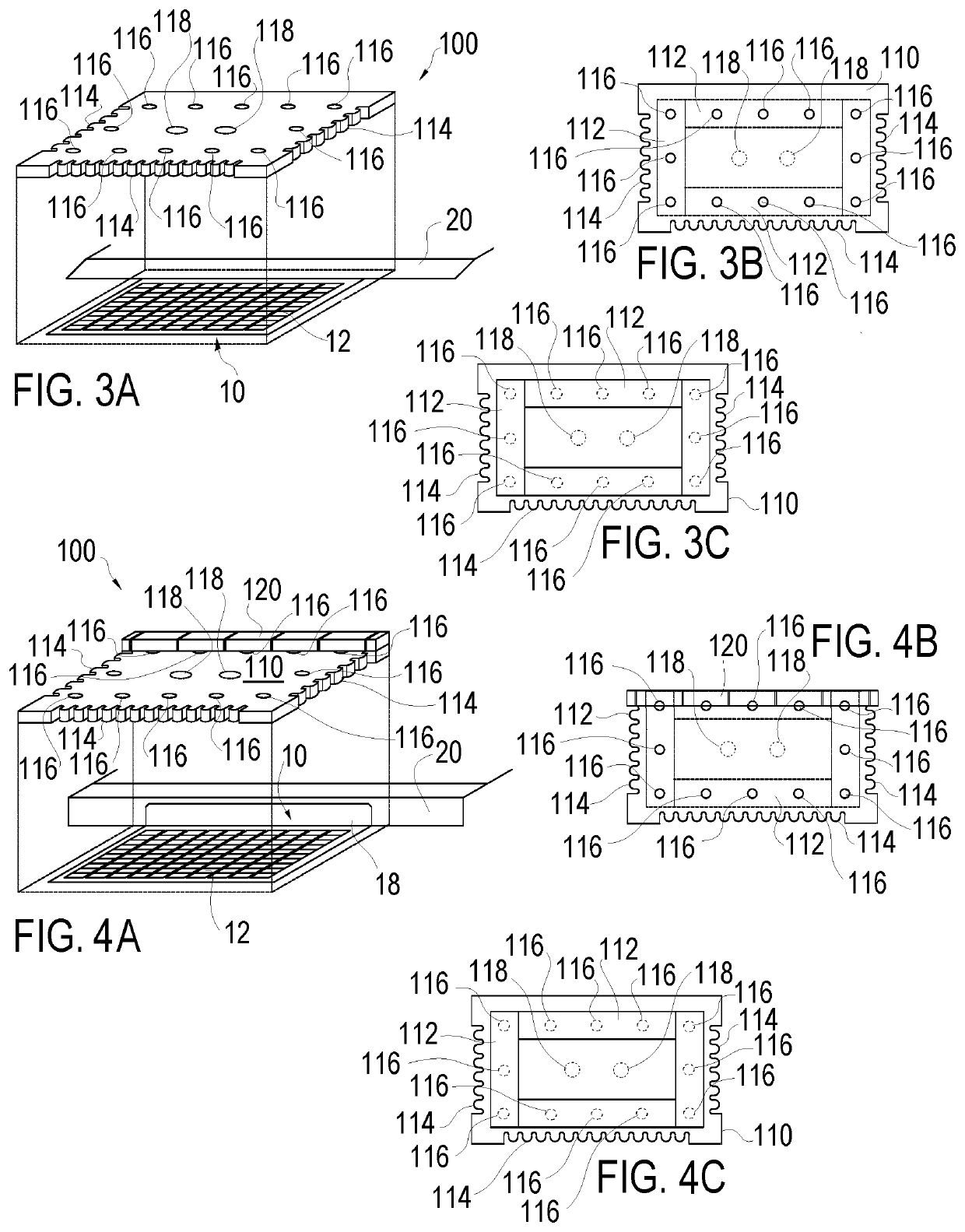

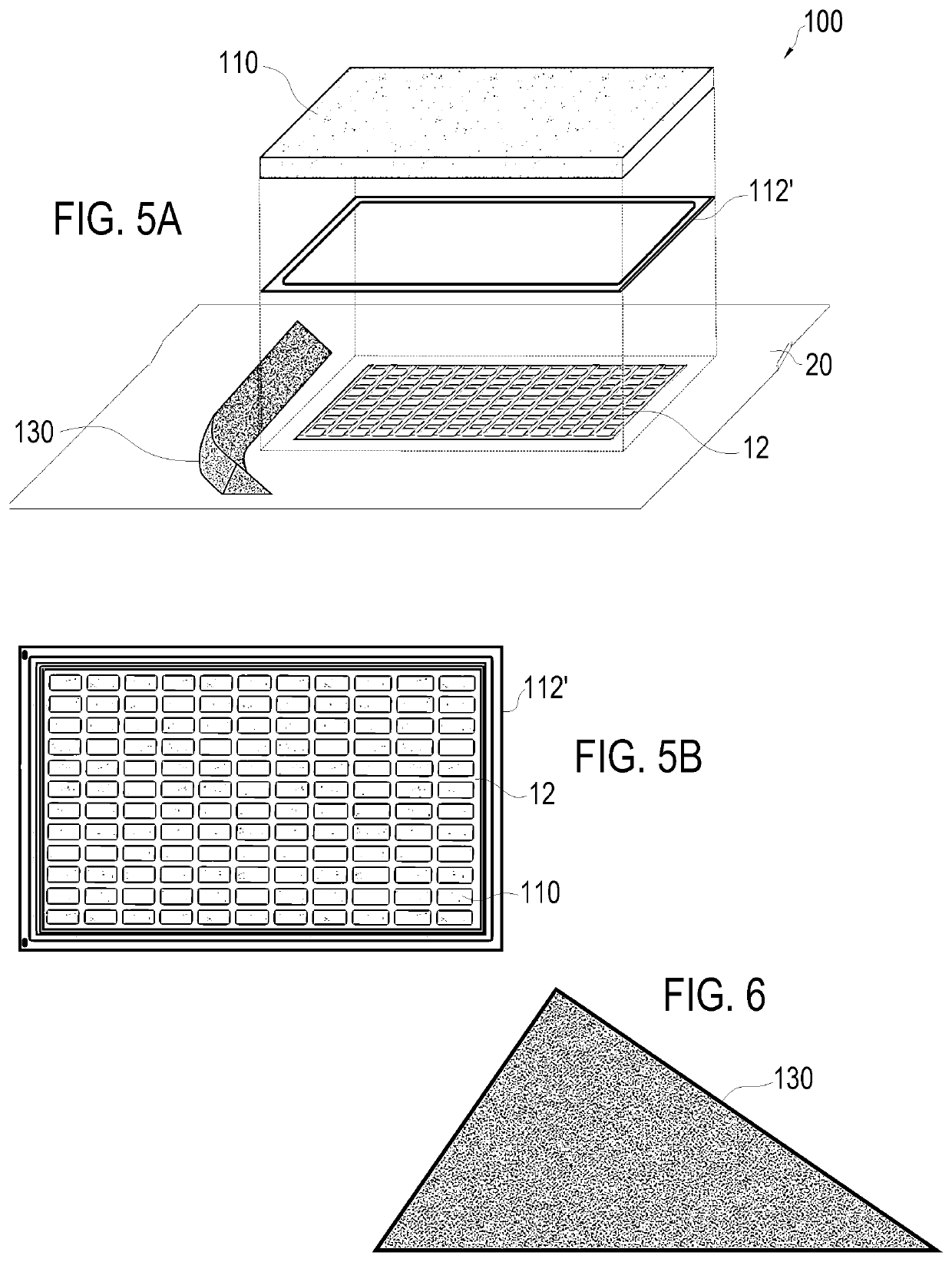

Erosion and sediment control above grate based inlet filter system

An above grate based inlet filter system for erosion and sediment control comprises a natural fiber filter mat configured to extend beyond the perimeter of the grate and a securing mechanism, such as magnets, configured to securing the filter mat around the perimeter of the grate. The system may include a filter berm secured in vicinity to the mat, and a rectangular array of magnets coupling the filter mat to the grate. The natural fiber filter mat may effectively be a coir fiber filter mat extending beyond the perimeter of the grate, wherein the coir fiber filter mat is formed of vertically aligned coir fibers. The optional filter berm may be effectively formed as triangular in cross section and formed of 100% reticulated polyether foam and formed to be at least 3″ in height.

Owner:MKB CO LLC

Coconut palm fiber cushion

InactiveCN1579928AUniform densitySimple processing methodUpholstery manufactureStuffed mattressesPalm fiberHardness

A kind of stretch cushion is made of coir fiber. After carded by mechanism, mesh placement, needled, sprayed glue, dried, hot forming and other processing technics, the cushion has a good air permeability, hydraulic permeability, and hygroscopicity. Also it has some hardness and intensity. It is warm in winter while cold in summer. With this character, it fits to make bed-cushion and seating cushion, and also it can be used as sound-proof and non-hygroscopic materials.

Owner:黄志平

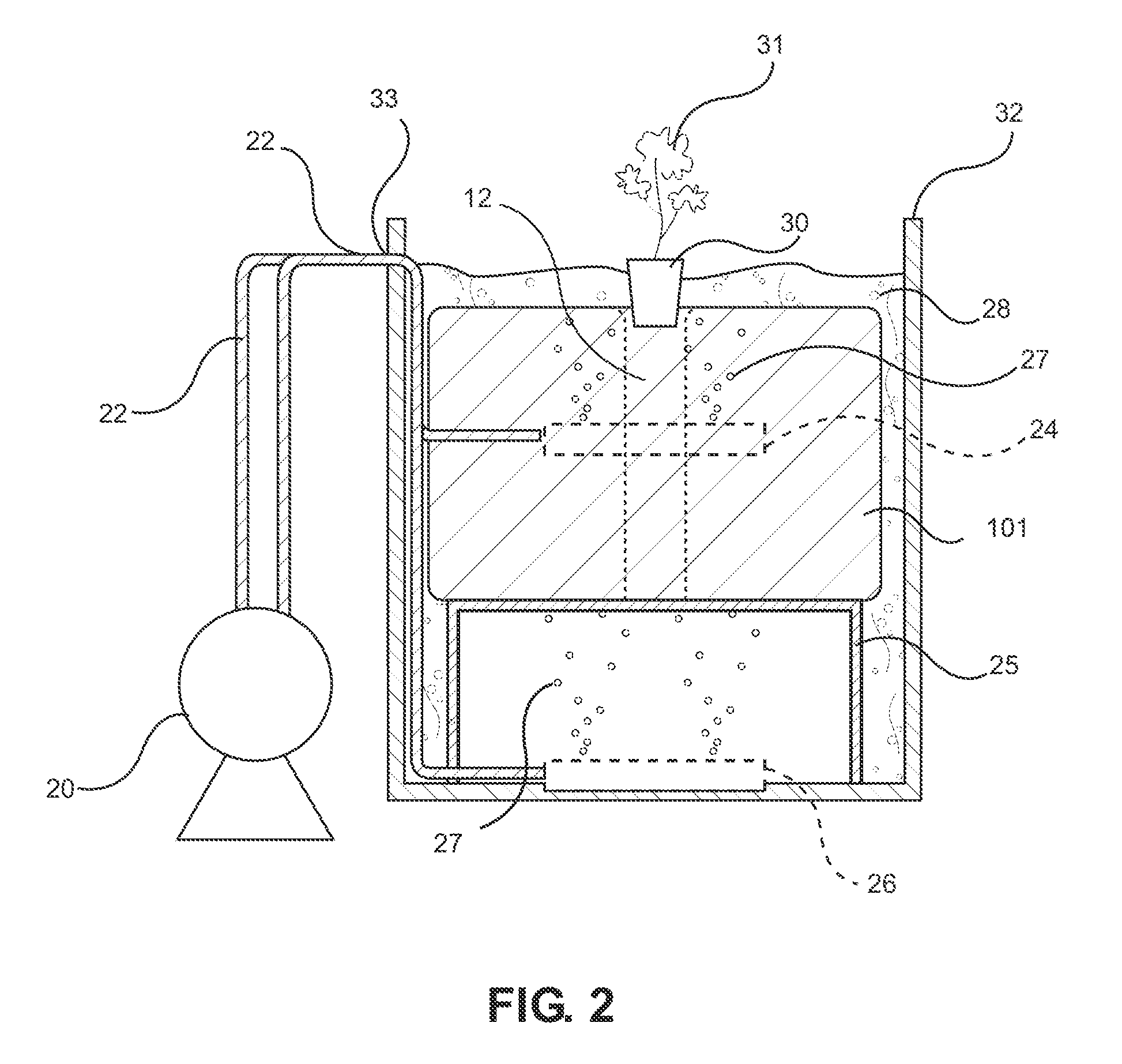

Plant growing apparatus, systems and methods

InactiveUS20170020095A1Avoid infectionProvide supportSelf-acting watering devicesCultivating equipmentsNutrient solutionPlant growth

A system of growing plants having a coco pod having at least one layer of coconut coir fiber and at least a hole for receiving a plant's roots, a nutrient solution, and a container for holding the coco pod and the nutrient solution, such that the coco pod is at least partially immersed in the nutrient solution and the plant's roots are continuously exposed to the nutrient solution and substantially protected from sunlight.

Owner:KAMHOLZ STEPHEN DONALD +1

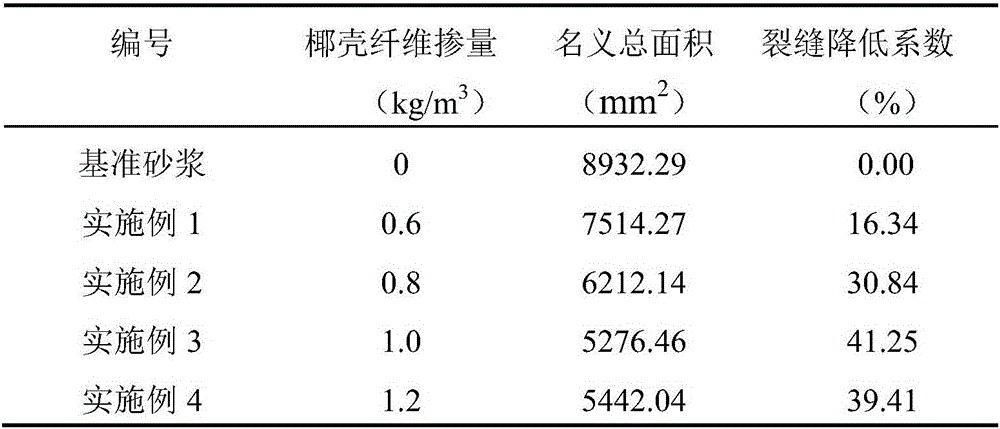

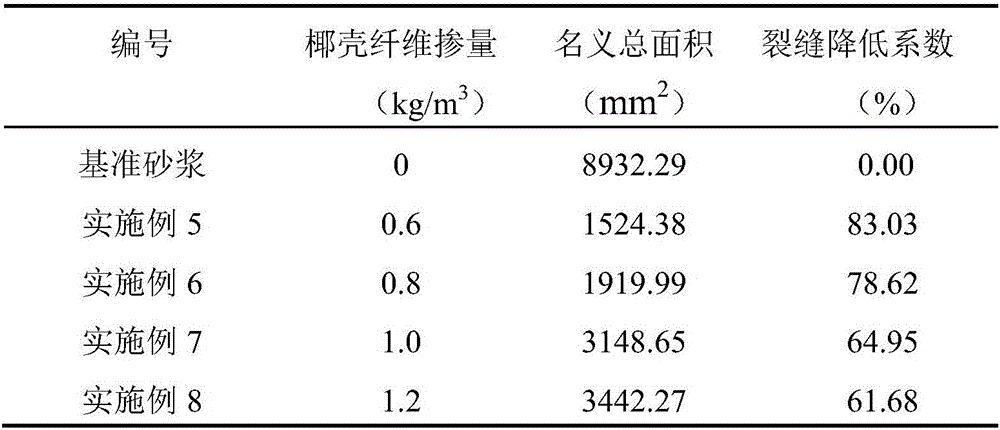

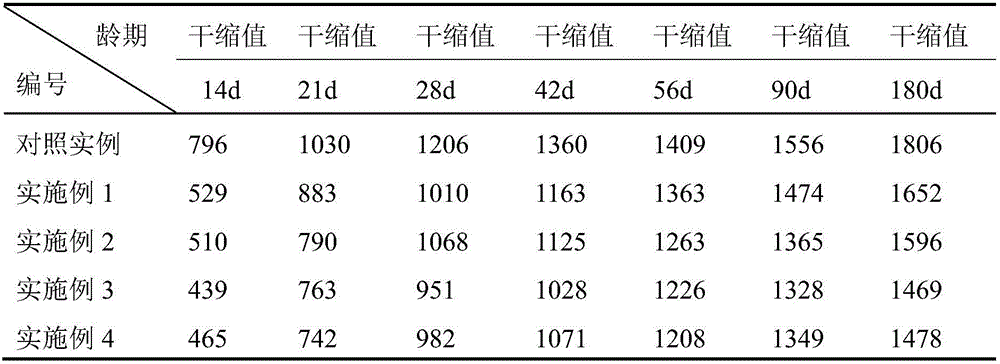

Method for preparing cracking-resistant low-shrinking cement mortar with modified coconut fibers

InactiveCN106045398AIncrease productionLow costSolid waste managementCrack resistancePolymer science

The invention discloses a method for preparing cracking-resistant low-shrinking cement mortar with modified coconut fibers. The method includes the steps that coconut fibers are washed to be clean, added into a mixed solution of a NaOH solution and H2O2, soaked and subjected to heat treatment, heat treatment is carried out, then washing, drying and shearing are sequentially carried out, and the modified coconut fibers are obtained; cement mortar is prepared, and the added modified coconut fibers are weighed; the modified coconut fibers are fully subjected to water absorption, and water-saturated modified coconut fibers are obtained; the parts of weighed cement and sand are mixed to be even, then the water-saturated modified coconut fibers are added, residual cement and sand are added in batches in the fiber adding process, water is finally added, and the mixture is fully stirred; the modified coconut fibers are evenly dispersed in the cement mortar, and the cracking-resistant low-shrinking cement mortar is obtained. According to the method, the coconut fibers are modified to be added into the cement mortar, the cracking resistance of the cement mortar can be improved, and meanwhile the air shrinkage value of the cement mortar can be further reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Erosion and sediment control above grate based inlet filter system

An above grate based inlet filter system for erosion and sediment control comprises a natural fiber filter mat configured to extend beyond the perimeter of the grate and a securing mechanism, such as magnets, configured to securing the filter mat around the perimeter of the grate. The system may include a filter berm secured in vicinity to the mat, and a rectangular array of magnets coupling the filter mat to the grate. The natural fiber filter mat may effectively be a coir fiber filter mat extending beyond the perimeter of the grate, wherein the coir fiber filter mat is formed of vertically aligned coir fibers. The optional filter berm may be effectively formed as triangular in cross section and formed of 100% reticulated polyether foam and formed to be at least 3″ in height.

Owner:MKB CO LLC

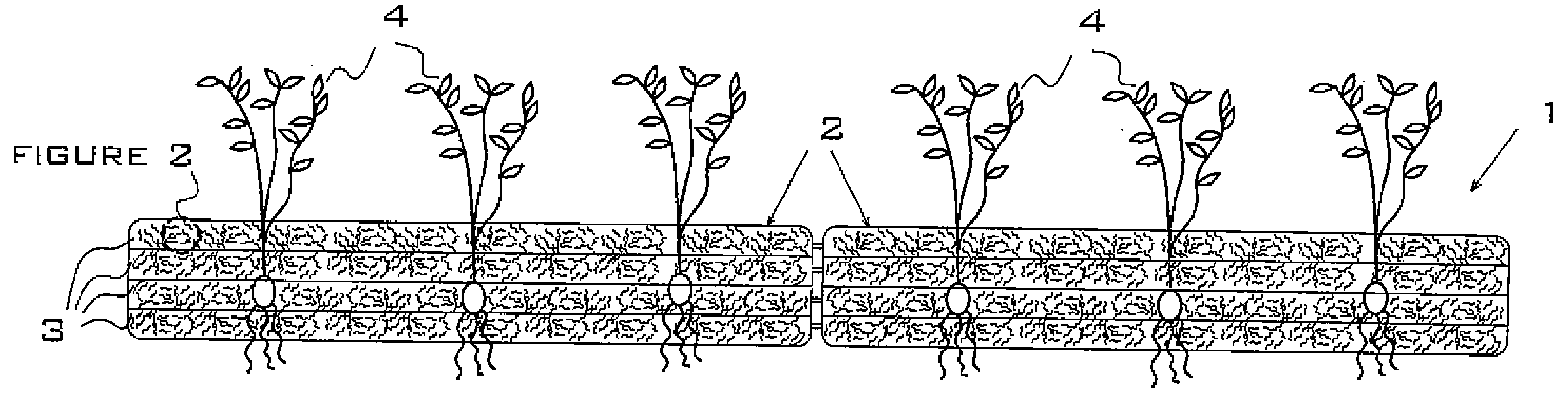

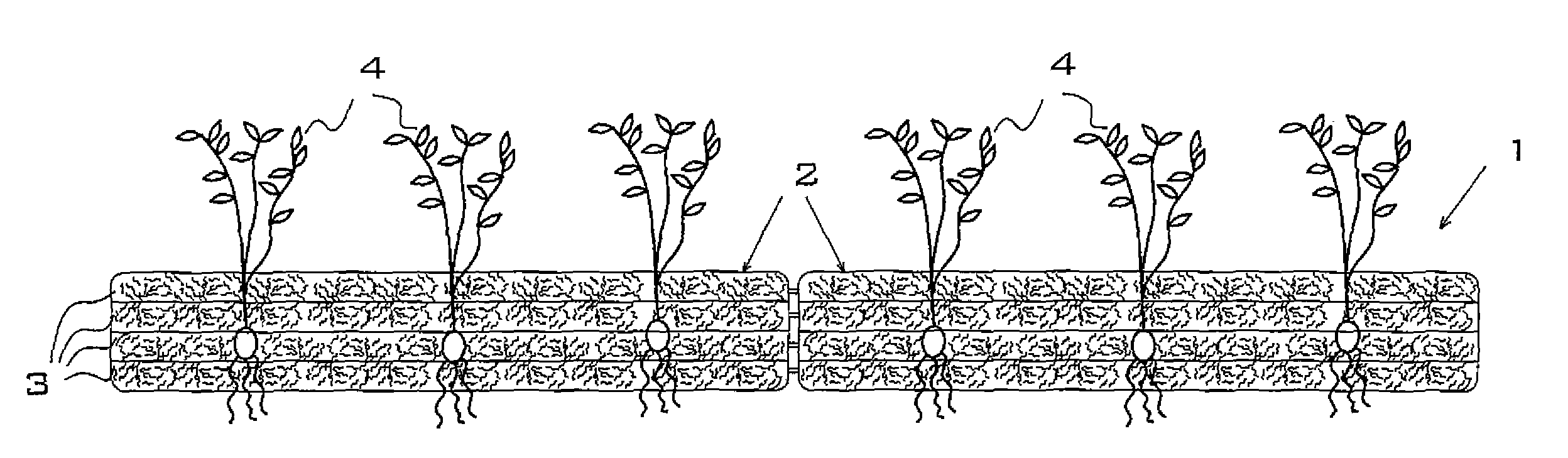

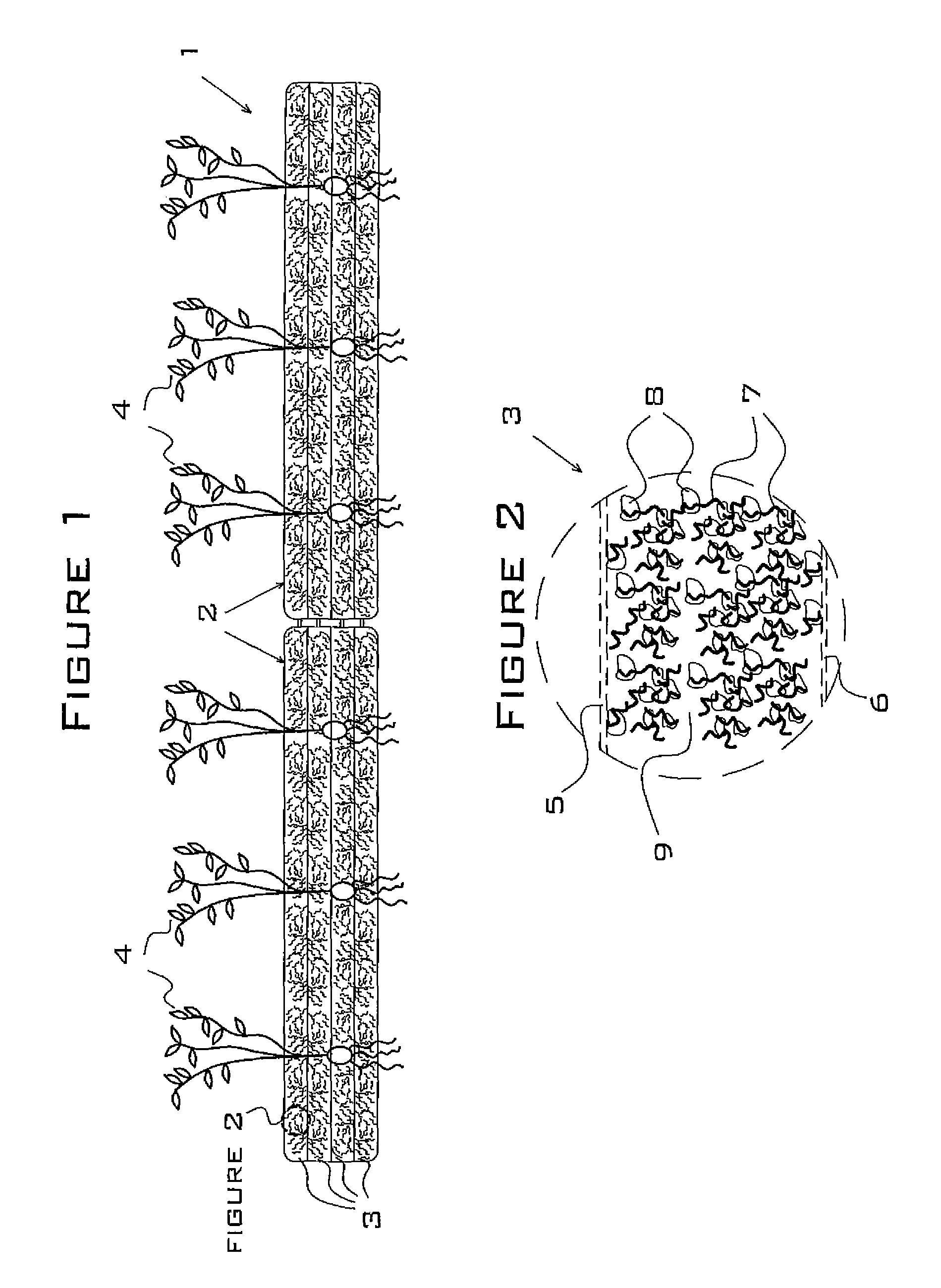

Soilless sod, its preparation method and application

ActiveCN102334399ANo lossSimple structureSynthetic resin layered productsAgriculture gas emission reductionSeederPolyolefin

The invention relates to a soilless sod and its preparation method and an application thereof. The soilless sod is prepared by the recombination of polyolefin fibrous reticulums and mixed fiber cloth, wherein the mixed fiber cloth is positioned between two layers of polyolefin fibrous reticulums. The mixed fiber cloth is made from raw materials of bamboo fiber, crop straw, coir fiber and nylon wire. Plant seeds are uniformly distributed on the mixed fiber cloth by the use of a seeder so as to form the mixed fiber cloth containing plant seeds. The preparation method provided by the invention comprises the following steps of: respectively compacting the polyolefin fibrous reticulum and the mixed fiber cloth through a briquetting machine, placing the compacted mixed fiber cloth between the two layers of polyolefin fibrous reticulums, braiding them together by the use of a braiding machine to form net cloth, and compacting by the briquetting machine to obtain the soilless sod. The invention has the following advantages: the polyolefin fibrous reticulum has strong permeability, corrosion resistance and strong tension; the raw material straw source is abundant; waste is changed into values; production processing is simple; cost is low; construction is fast; the soilless sod is widely applied with no environmental pollution, has an obvious effect of protecting water and soil and is easily popularized.

Owner:上海园林绿化建设有限公司

Erosion and sediment control above grate based inlet filter system

An above grate based inlet filter system for erosion and sediment control comprises a filter mat configured to extend beyond the perimeter of the grate and a securing mechanism, such as magnets, configured to securing the filter mat around the perimeter of the grate. The system may include a filter berm secured in vicinity to the mat, and a rectangular array of magnets coupling the filter mat to the grate. The natural fiber filter mat may effectively be formed of vertically aligned coir fibers or alternatively of reticulated foam. Multiple side edges of the mat are undulating having a pattern of repeating recesses. The mat includes a plurality of high flow holes extending into the mat and which are closed at a bottom surface thereof. The mat includes at least one removable dewatering plug configured to allow for selective mat bypass.

Owner:MKB CO LLC

Floating island module comprised of post-consumer carpet fiber matrix and method of manufacturing same

A floating island comprising one or more modules each comprised of one or more layers of permeable and porous matrix comprised of post-consumer carpet fibers and a top covering and a bottom covering around each layer. Alternate embodiments include layers comprised of polyethylene terephthalate bottle-fiber matrix and / or jute or coir fibers. A method of manufacturing the floating island module described above.

Owner:FOUNTAINHEAD

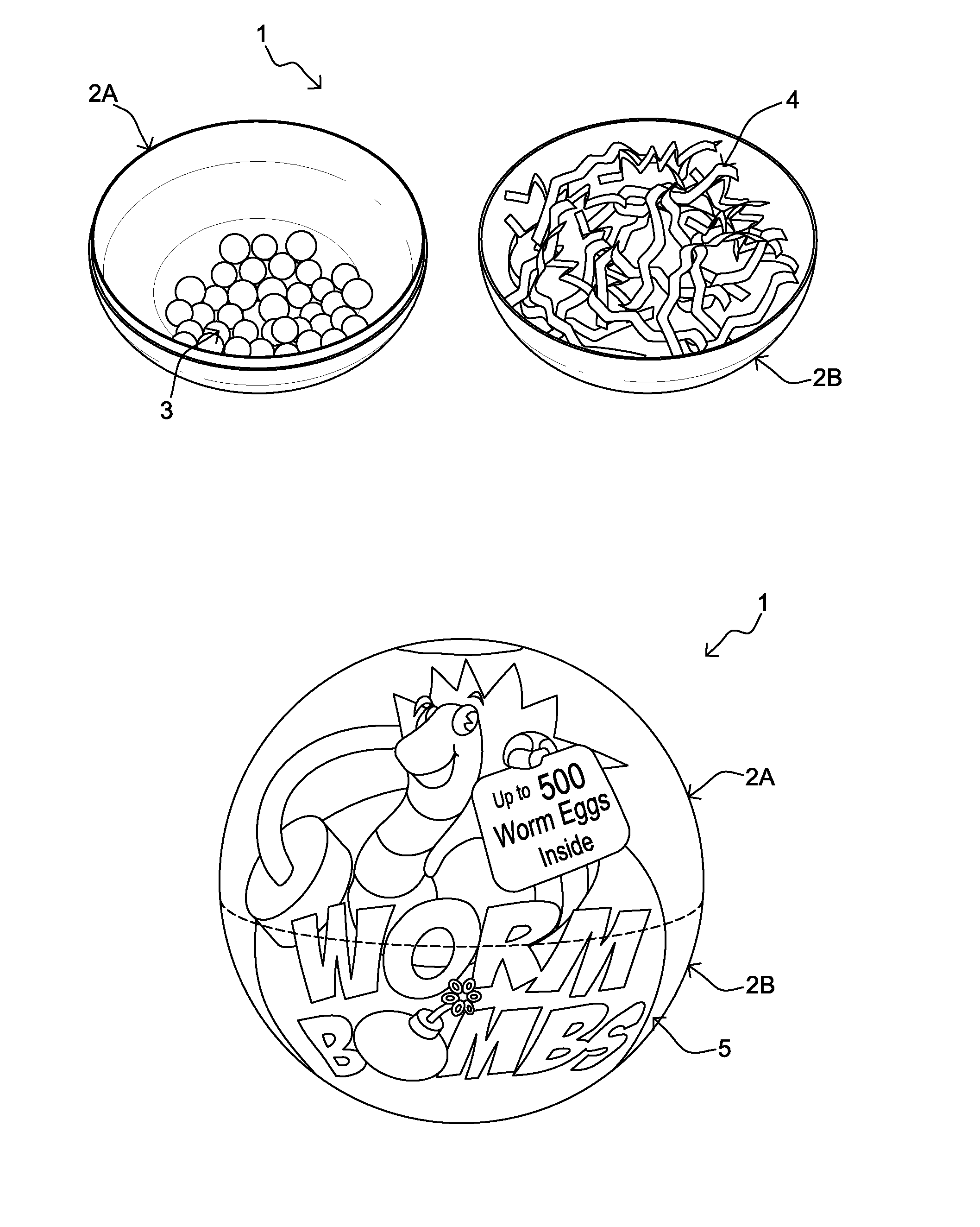

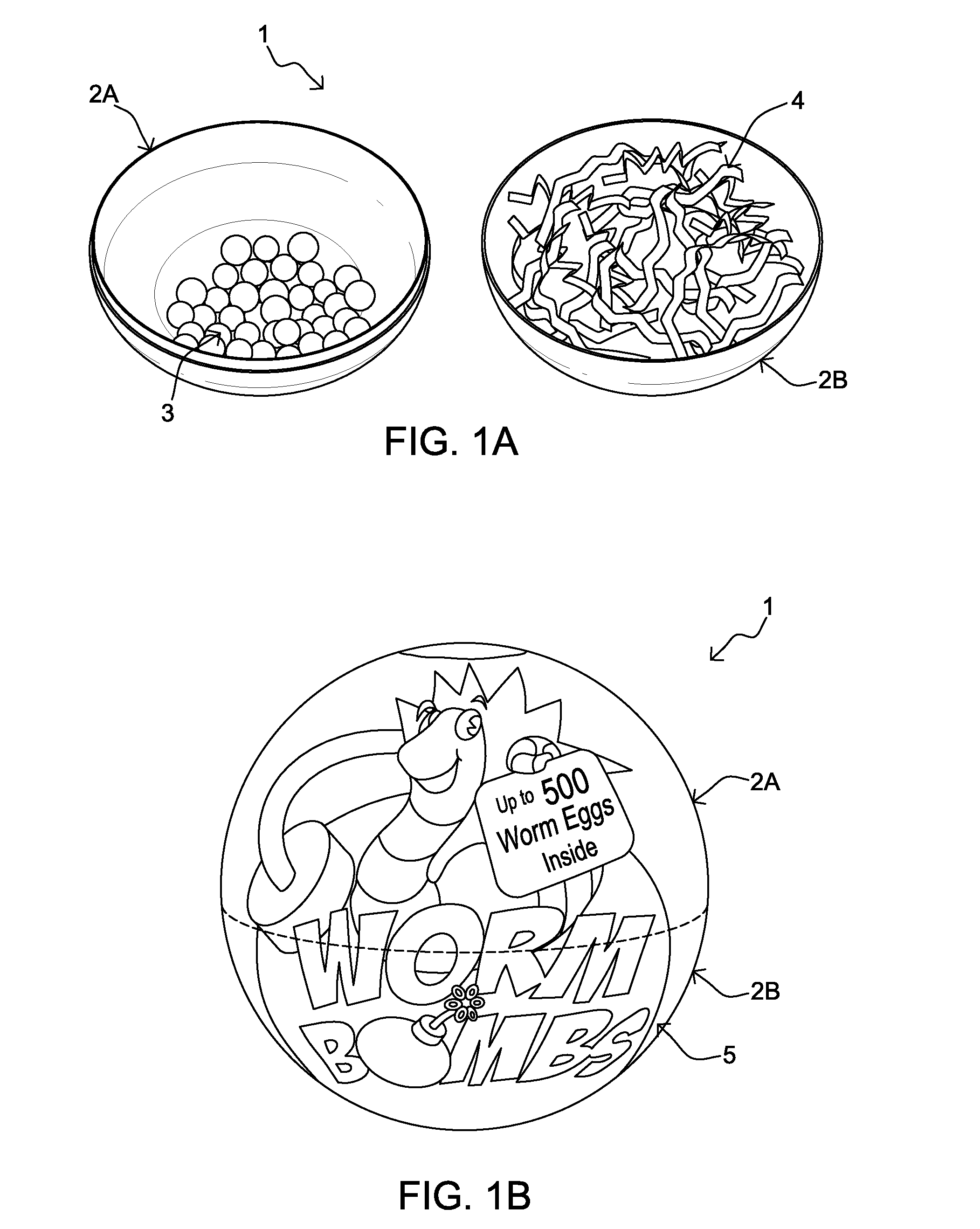

Biodegradable worm-egg-delivery system for soil enhancement and methods of use

InactiveUS20150320024A1Increased earthworm populationImprove efficiencyFlexible coversWrappersBiologyDelivery system

The present inventive disclosure is generally directed to a biodegradable device that can house multiple worm-cocoon capsules, as well as an effective amount of shredded organic fibrous materials (such as coir fiber or shredded paper) that is infused with hormones, nutrients, and / or amino acids that are beneficial to earthworms. In some embodiments, these devices are referred to as “Worm Bombs™”, which are planted at effective intervals in gardens and / or compost heaps, leading to stable and vigorous earthworm populations and softened, nutrient-rich soil that is ideal for growing. It is known in the art that earthworm biomass production can be significantly enhanced with the introduction of growth hormones, which inter alia, increases the efficiency of waste conversion of worms.

Owner:INGENIOUS MARKETING

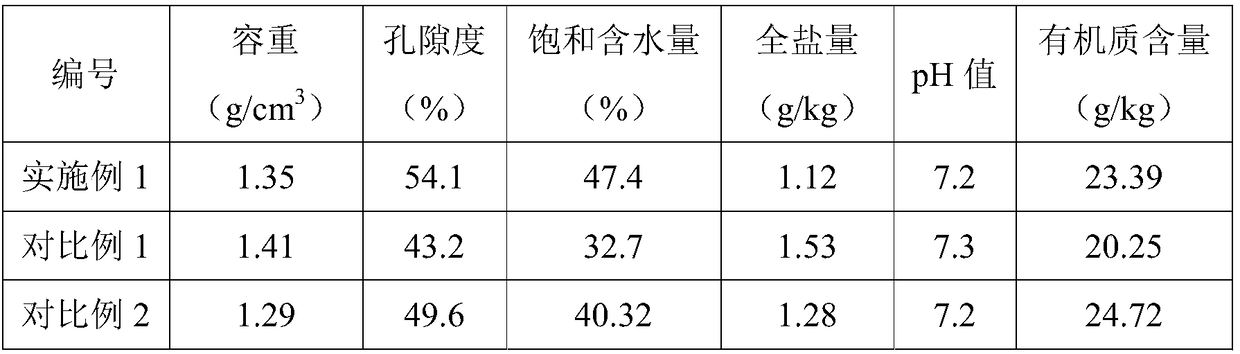

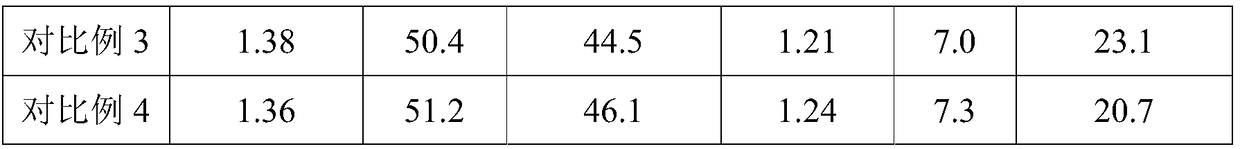

Vegetation recovery ecological matrix and preparation method thereof

ActiveCN108617465AGood interweaving performanceImprove water holding capacityExcrement fertilisersGrowth substratesMicroorganismRevegetation

The invention relates to a vegetation recovery ecological matrix and a preparation method thereof. The vegetation recovery ecological matrix is composed of, by weight percentage, 20-45% of dry sludge,20-45% of decomposed and dewatered sludge, 12-20% of coir fiber and 12-20% of straw, wherein the dry sludge is prepared by drying dewatered sludge. The vegetation recovery ecological matrix is mainlyprepared from the raw materials of the dry sludge, the decomposed and dewatered sludge, the coir fiber and the straw, and when penetrating through saline-alkali sandy soil via percolate, can providefavorable conditions for survival and accelerated reproduction of soil microorganisms, improve the granular structure of sandy soil, reduce the soil bulk density of the sandy soil, improve the physicochemical properties and the biological properties of the soil, promote soil maturation, accelerate vegetation establishment on barren soil such as the saline-alkali sandy soil and update the soil ecological system.

Owner:河南华美生态环境科技股份有限公司

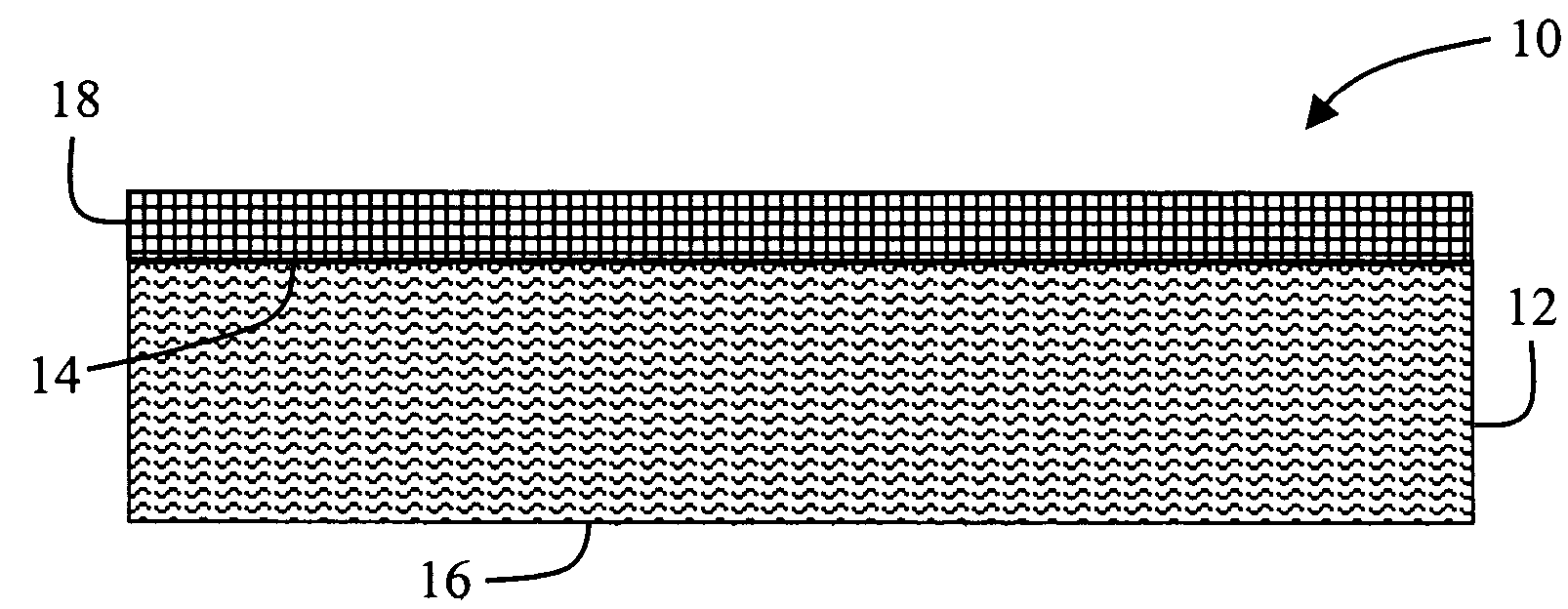

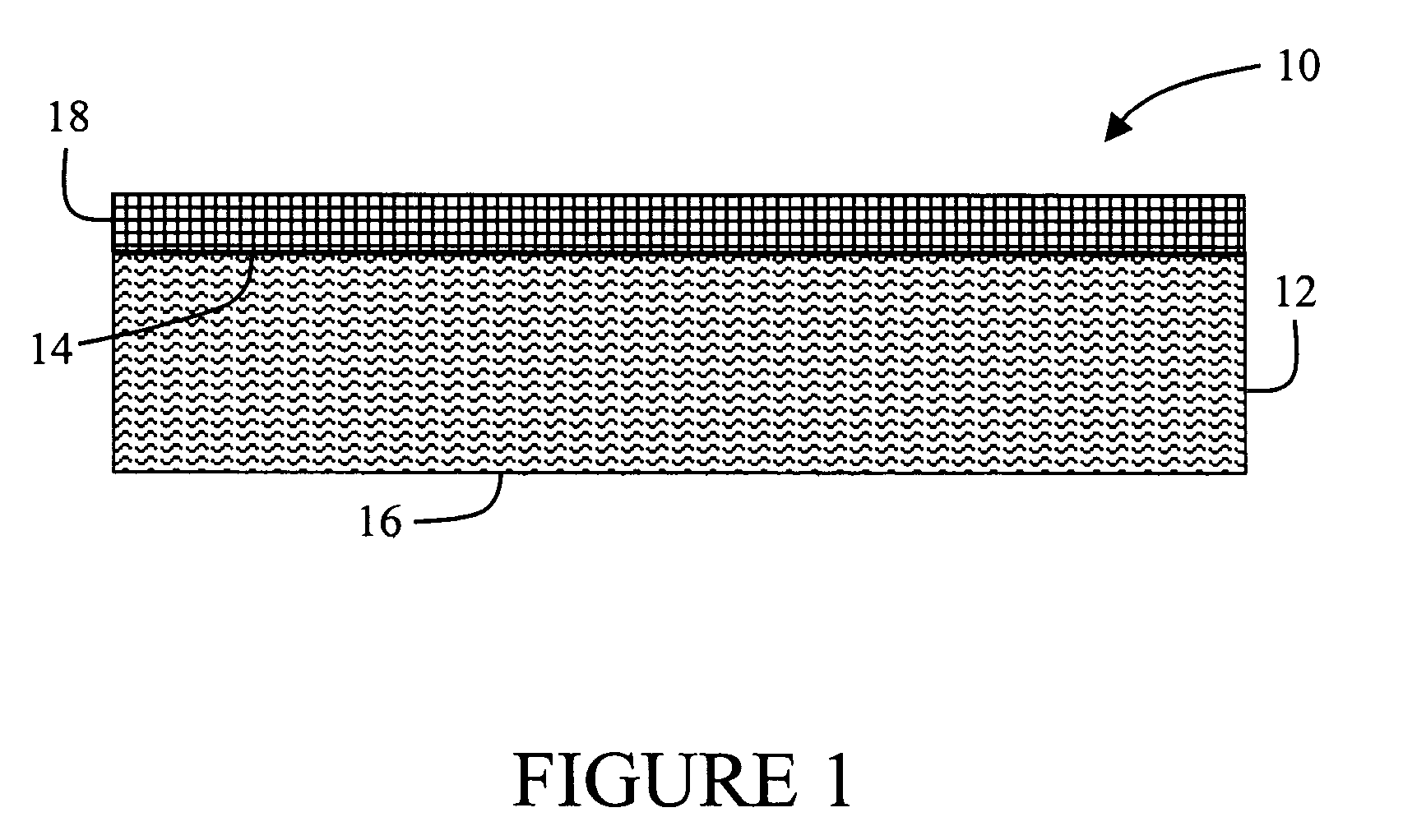

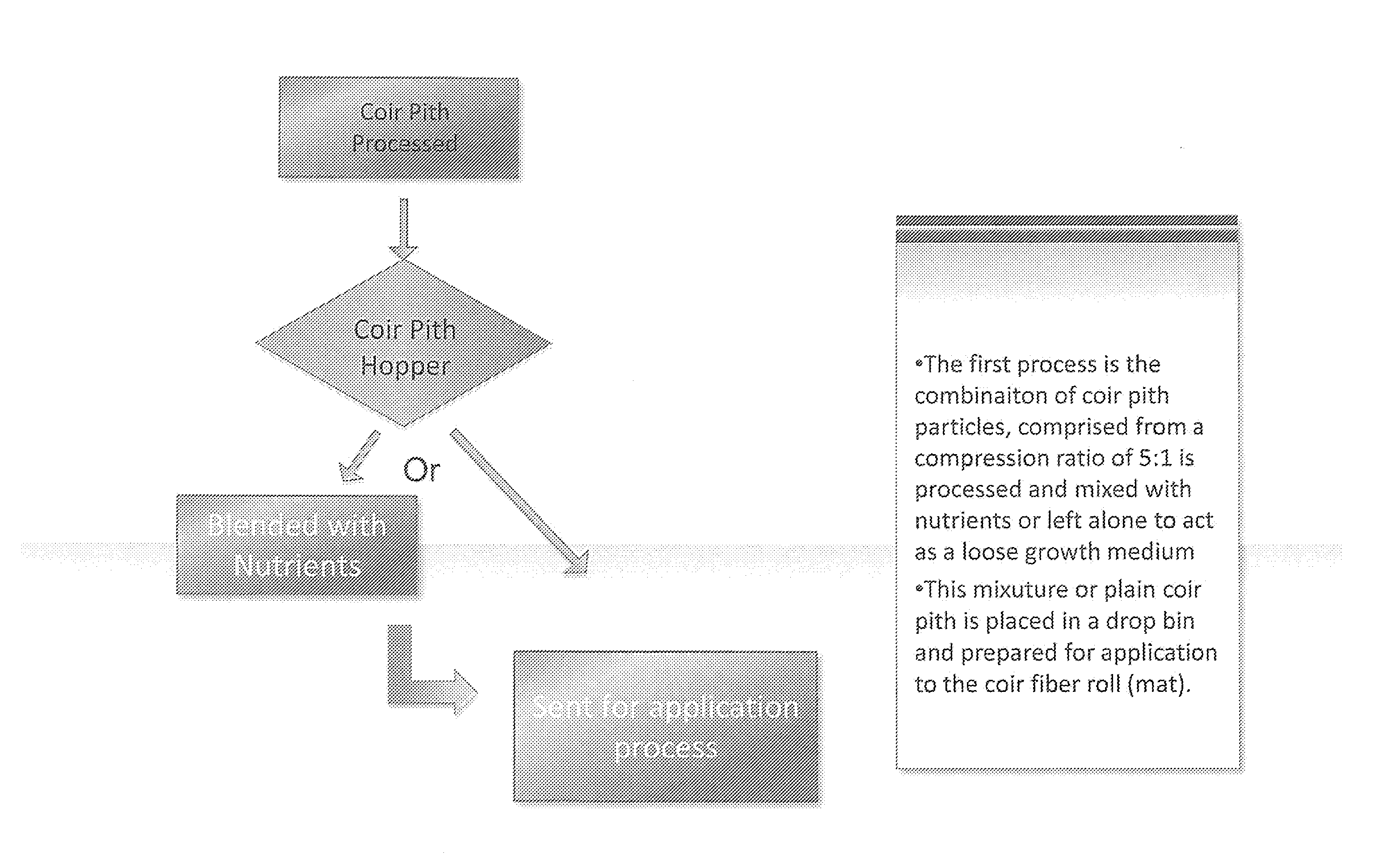

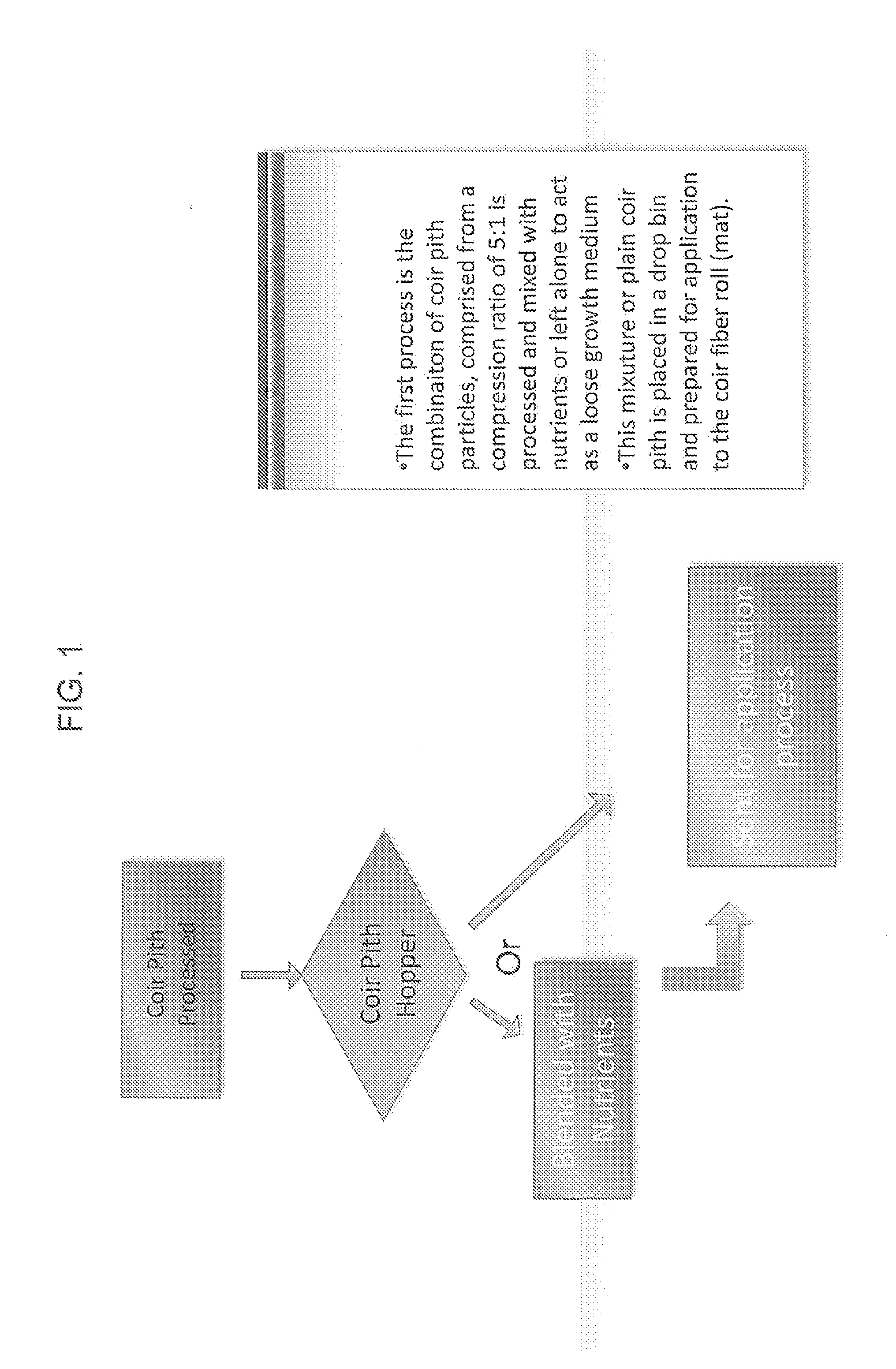

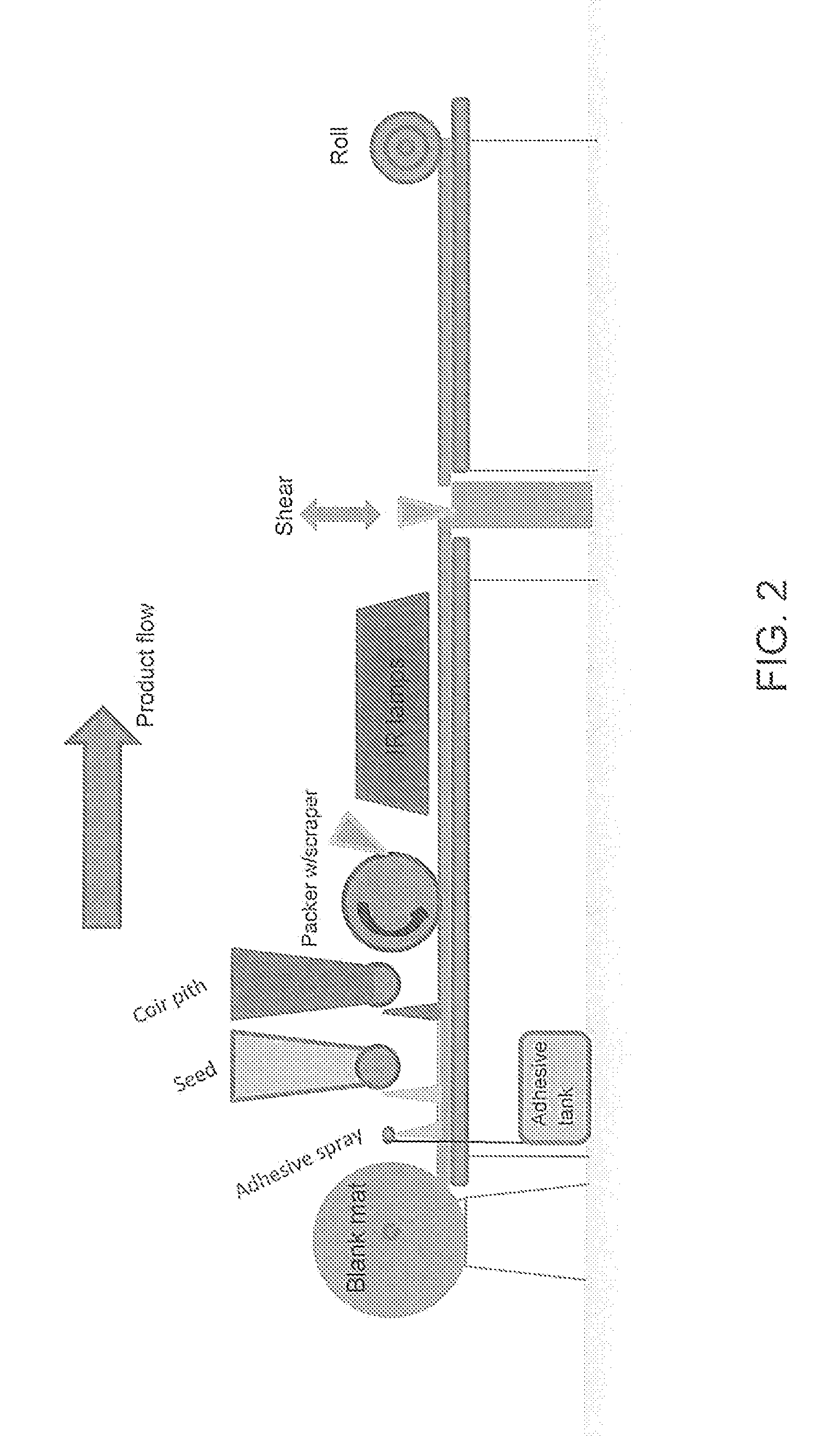

Coir fiber and coir pith seed mat

InactiveUS20140130408A1Faster and successful germinationProvide protectionClimate change adaptationPackage sterilisationAdhesiveEngineering

A seed mat utilizing coir fiber (base or bottom) with a second layer of coir pith particles adhesive, and seeds and possible nutrients (top), the coir pith has a compression of 5:1, the coir fiber layer and adhesive holds the seed and coir pith mixture in place for significant reduction of run off and also adds moisture retention allowing for faster and more successful germination and turf establishment.

Owner:X SEED +1

A preparing method of coconut charcoal fiber

InactiveCN105442095AAdd anti-static functionProtect the environmentElectroconductive/antistatic filament manufactureCelluloseAntistatic agent

A preparing method of coconut charcoal fiber is disclosed. The method includes (1) a step of preparing master batch, namely a step of recovering waste coconut shells, extracting coconut shell cellulose by dipping, beating, removing impurities and airing, heating the coconut shell cellulose to 1200 DEG C, performing high-temperature carbonization to prepare coconut charcoal, smashing the coconut charcoal into nanometer powder by utilization of a particle collision principle and through a dry grinding manner, adding anionic antistatic agent powder into the coconut charcoal powder, and fully mixing to obtain the coconut charcoal master batch, and (2) a step of spinning the coconut charcoal fiber, namely a step of preparing the hollow type coconut charcoal fiber with a three-dimensional crimp configuration by melt spinning, drawing, sizing, crimping, oiling, cutting and packaging. The prepared coconut charcoal fiber has good antibacterial, far infrared and anion-releasing performances, and the like, and accords with functional, healthy and environment friendly ideas pursued in product development. For better application in development of home textile products, the antistatic property of the fiber is improved by adding the antistatic agent, thus improving product quality.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com