Preparation of coir fiber based activated carbon with high specific surface area

A technology of high specific surface area and coir fiber, which is applied in the field of composite activators to prepare high specific surface area, high and medium porosity activated carbon, can solve the problems of few composite activators, little or no mesopore structure, and limit the application range of activated carbon, etc., to achieve High mesoporosity, low cost, enhanced activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In this embodiment, coconut fiber is used as a raw material, and KOH is used as an activator.

[0017] First, the raw material coconut fiber is carbonized at 600°C for 30min, 7g of carbonized material is ground and mixed with KOH at a ratio of 1:2, and then the mixture is subjected to a constant temperature activation reaction at 850°C for 120min, and the heating rate is 15 °C / min. After the activation reaction, the product was taken out, ground and washed with tap water to remove KOH therein, and then chloride ions were washed away with distilled water. Then put it in a drying oven and dry it at 120°C before loading. The prepared activated carbon is mainly microporous, with an iodine adsorption value of 1894mg / g and a specific surface area of 2158m 2 .g -1 , The total pore volume is 1.0466ml.g -1 .

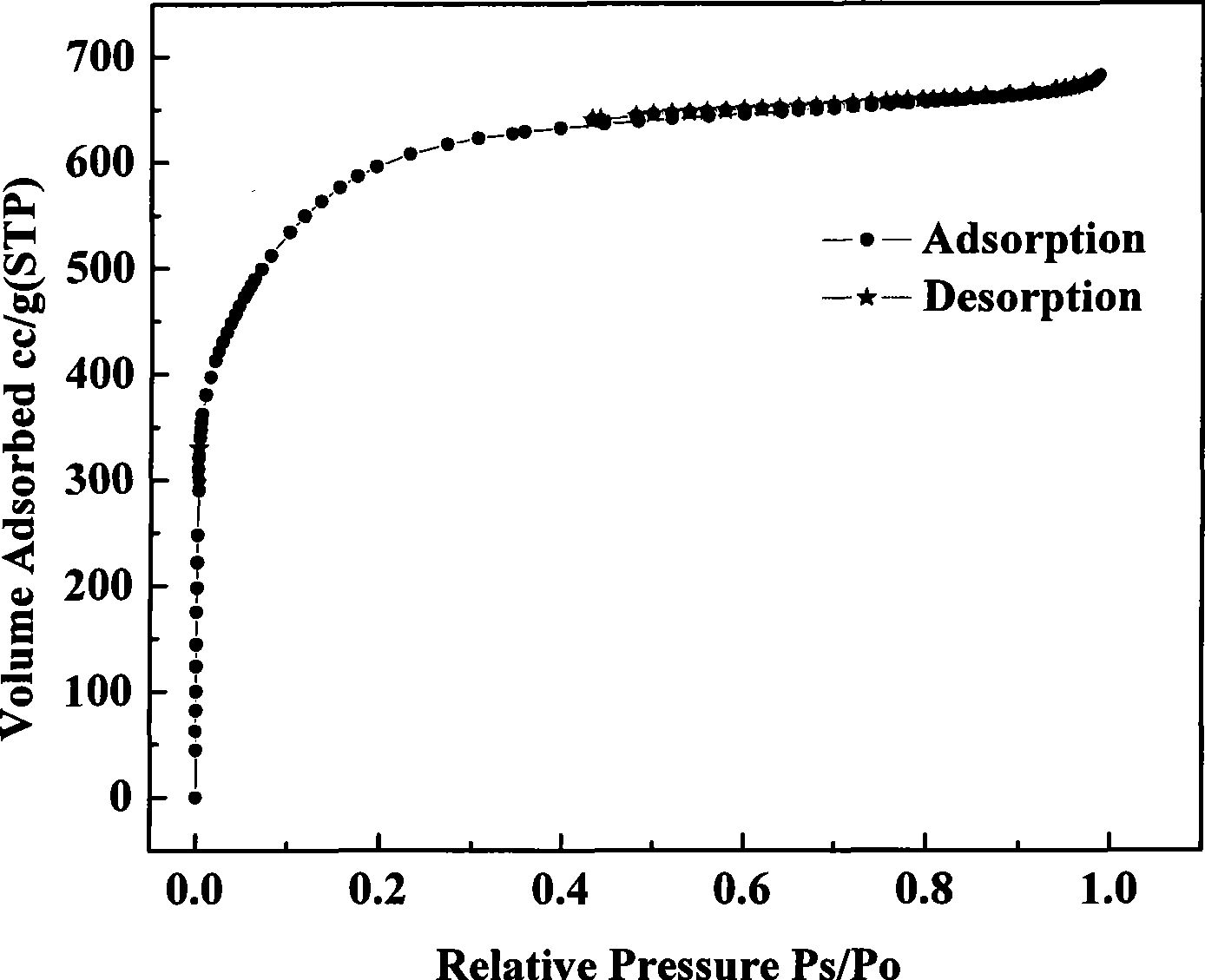

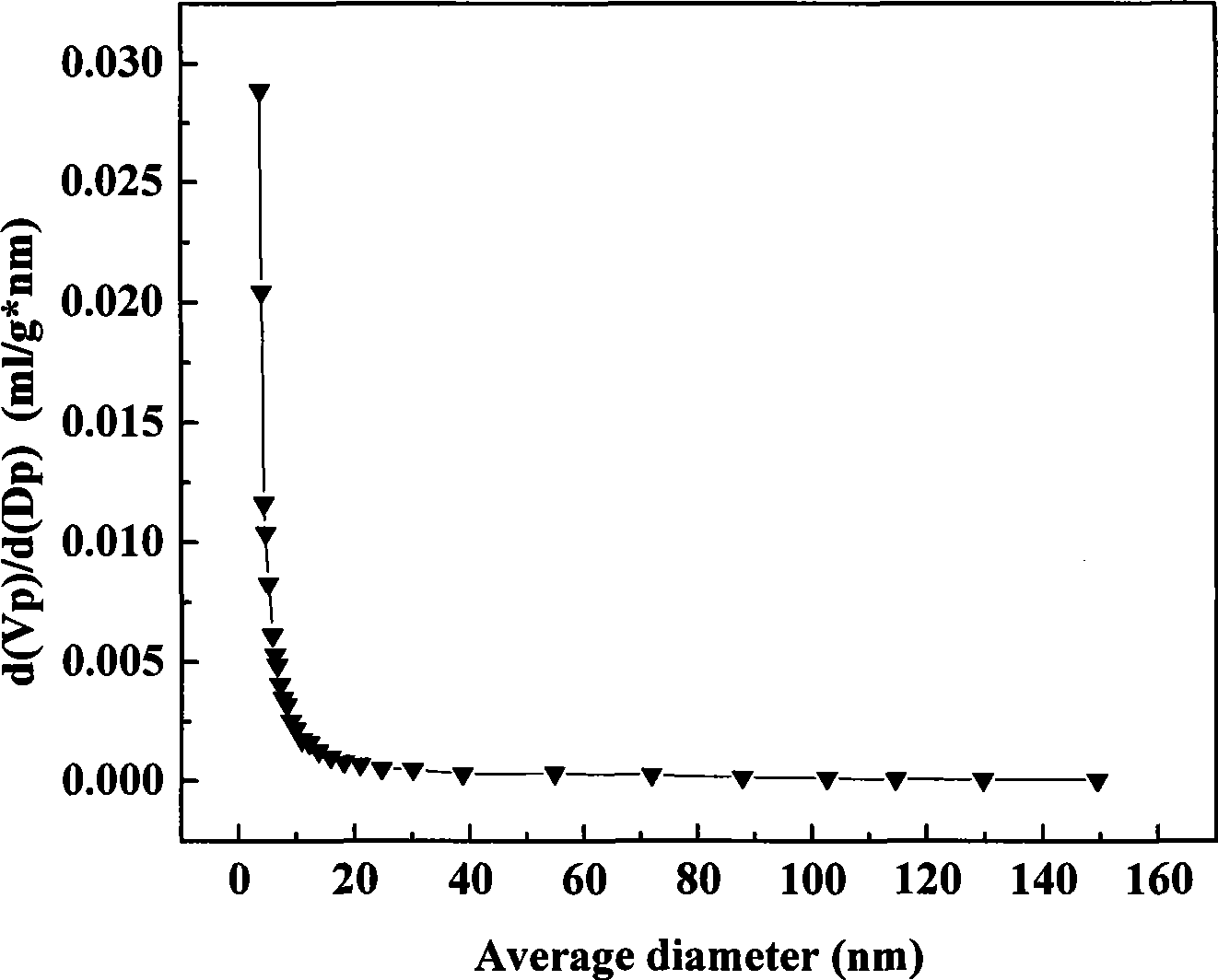

[0018] like figure 1 , figure 2 Shown are respectively the isotherm adsorption curve and the pore size distribution curve of the sample obtained in this embodime...

Embodiment 2

[0020] In this embodiment, coconut fiber is used as a raw material, and NaOH and KOH are used as composite activators.

[0021] First carbonize the raw material coconut fiber at 400°C, take 20g of carbonized material and composite activator at a ratio of 3:1:1 (NaOH:KOH:carbonized material), grind and mix evenly, put the mixture into a stainless steel tube and place it at 900 The activation reaction was carried out at ℃ for 120 minutes, and the heating rate of the activation reaction was 15 ℃ / min. After the activation reaction is completed, the product is taken out and washed with an appropriate amount of hydrochloric acid, then washed with excess deionized water, and finally dried and collected at 150°C. The prepared activated carbon has a high mesoporosity up to 24.8%, its iodine adsorption value is 1435.0mg / g, methylene blue adsorption value is 495mg / g, and its specific surface area is 2031.9m 2 / g, the yield can reach 48.76%.

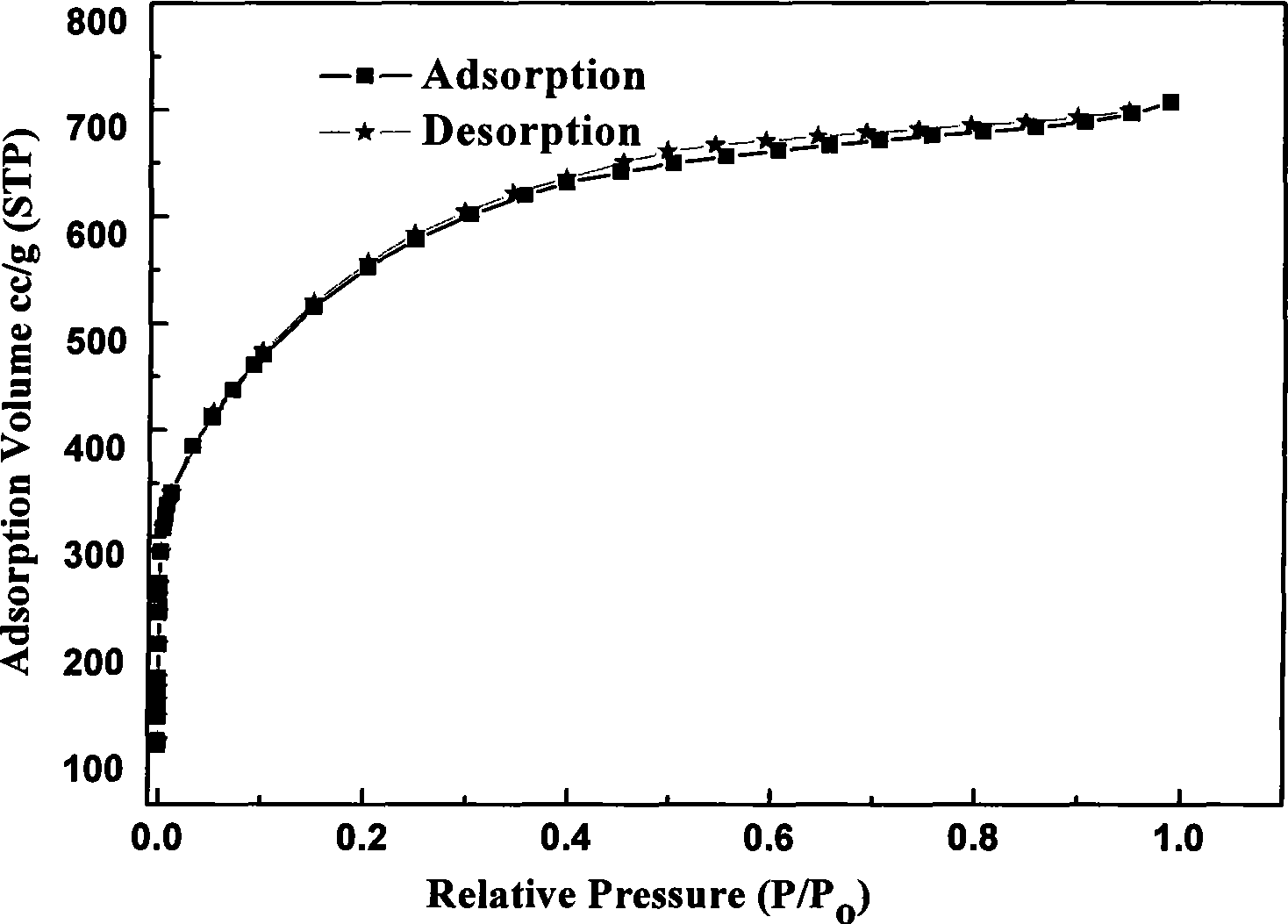

[0022] like image 3 , Figure 4 Shown ar...

Embodiment 3

[0024] In this embodiment, coconut fiber is used as a raw material, and NaOH and KOH are used as composite activators.

[0025] First carbonize the raw material coconut fiber at 500°C, take 20g of carbonized material and composite activator at a ratio of 3:1:1 (NaOH:KOH:carbonized material), grind and mix evenly, put the mixture into a stainless steel tube and place it at 900 The activation reaction was carried out at ℃ for 150 min, and the heating rate of the activation reaction was 5 °C / min. After the activation reaction is completed, the product is taken out and washed with an appropriate amount of hydrochloric acid, then washed with excess deionized water, and finally dried and collected at 150°C. The activated carbon prepared in this example has a relatively high mesoporosity up to 25.2%, its iodine adsorption value is 1402.05mg / g, methylene blue adsorption value is 457.5mg / g, and its specific surface area is 1547m 2 / g, the yield can reach 49.59%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Adsorption value of methylene blue | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com