Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342results about How to "Reduce thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

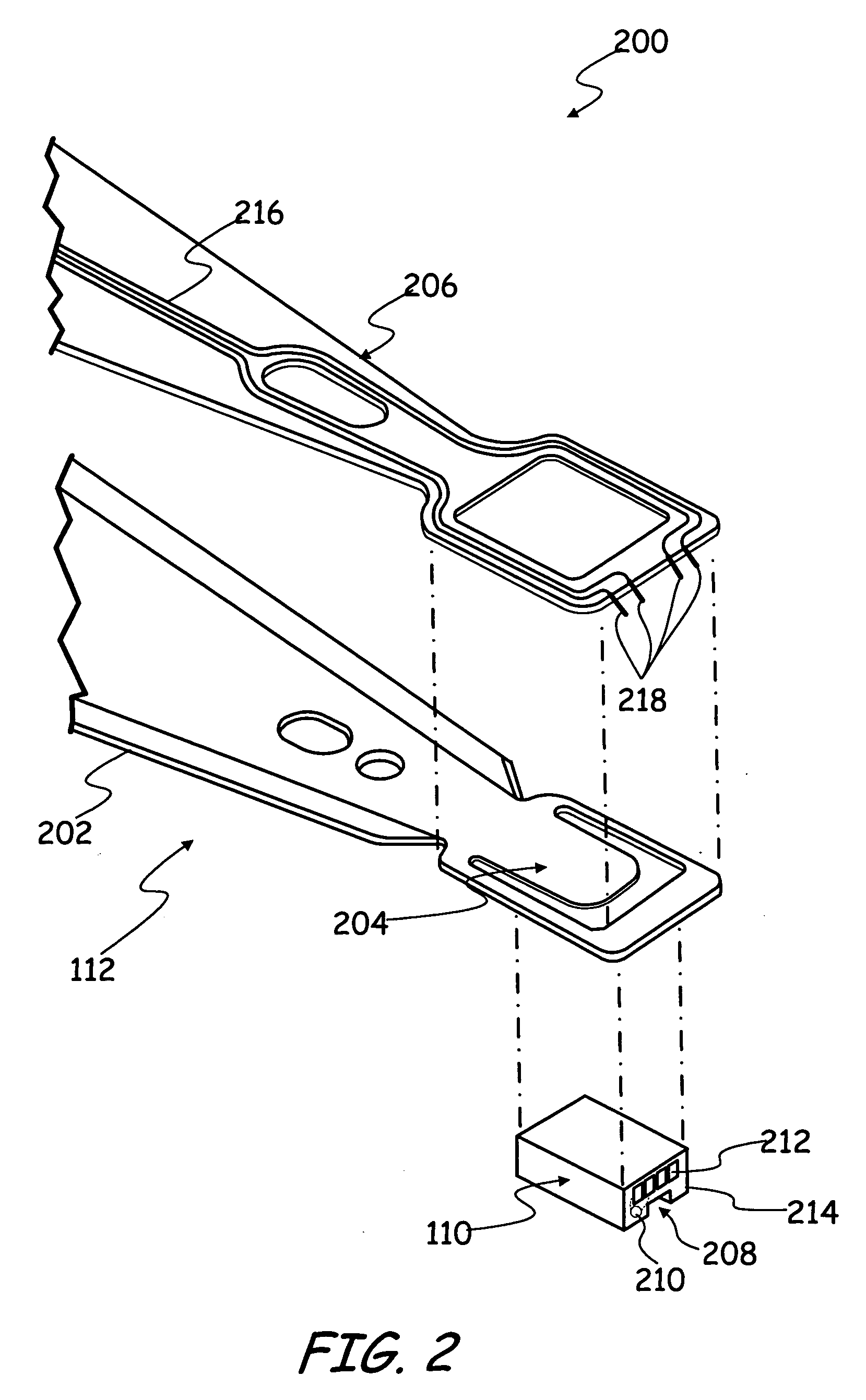

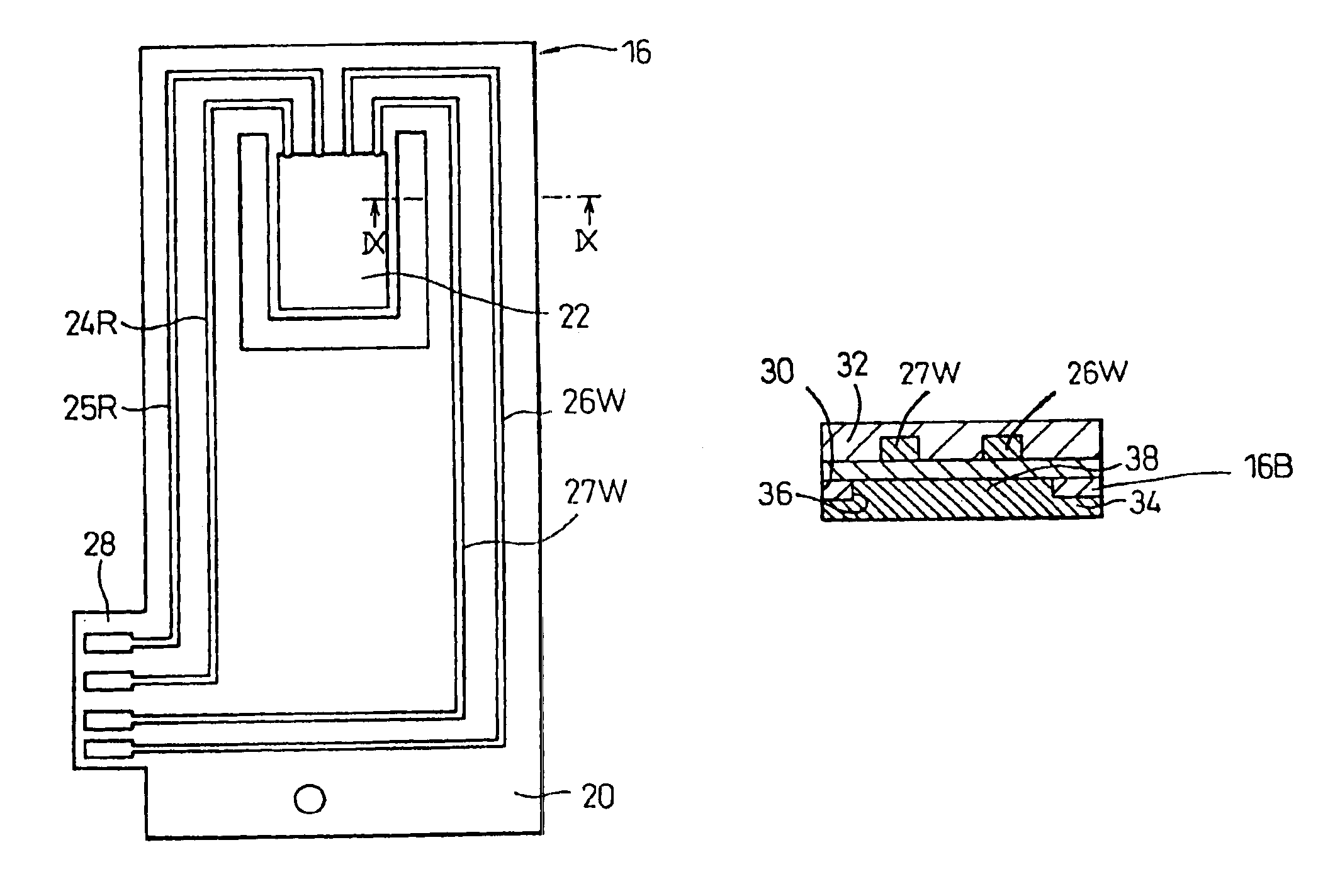

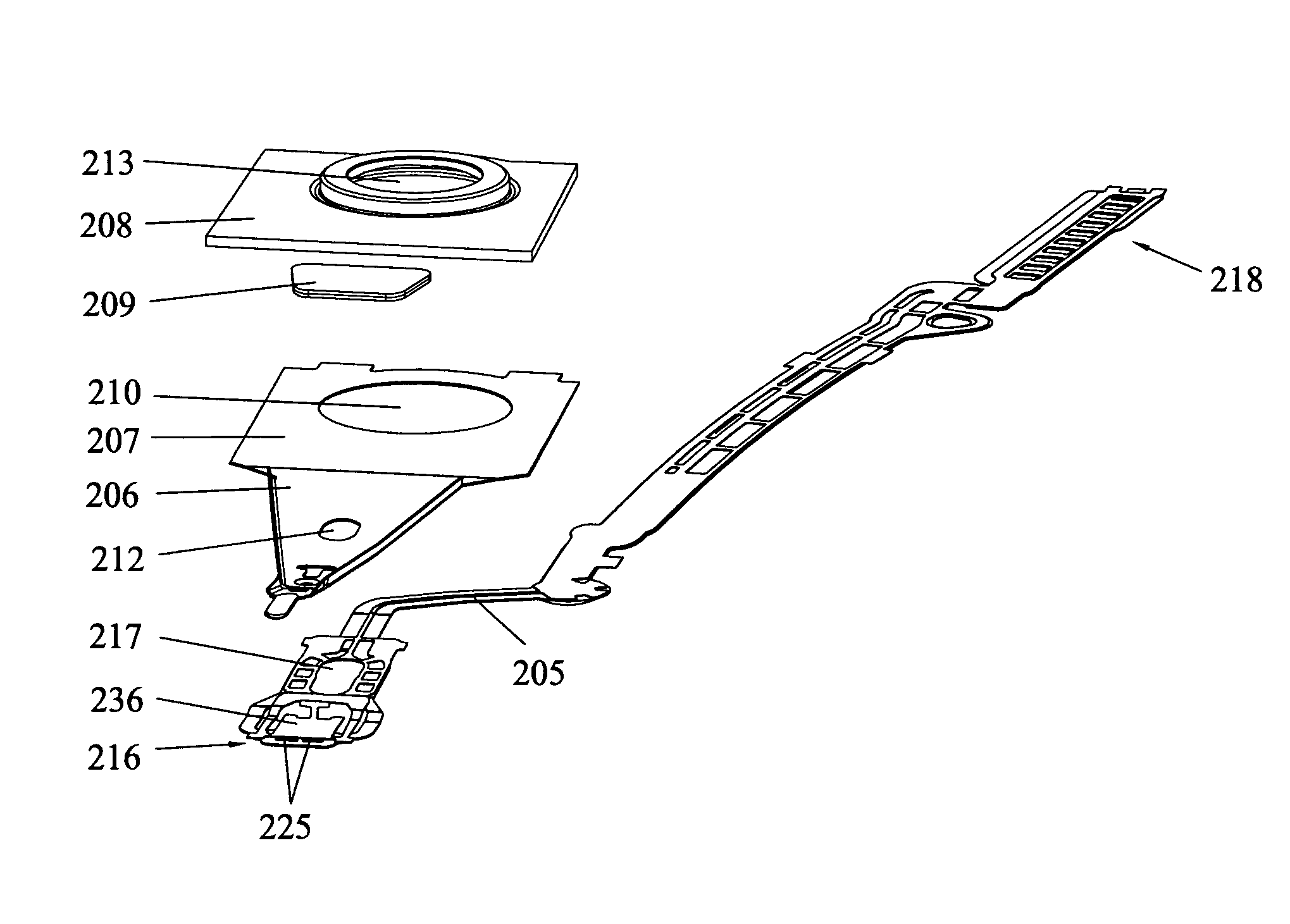

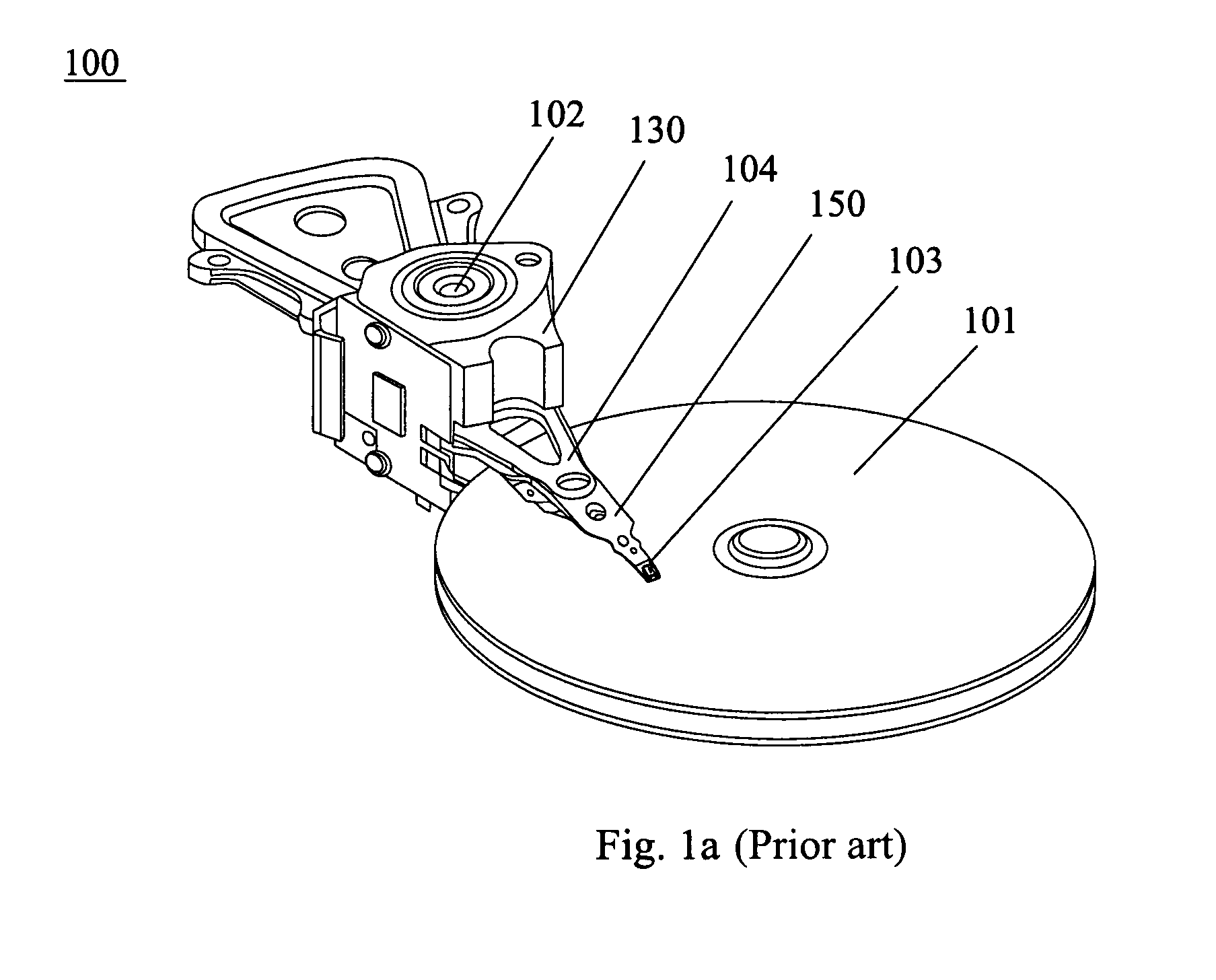

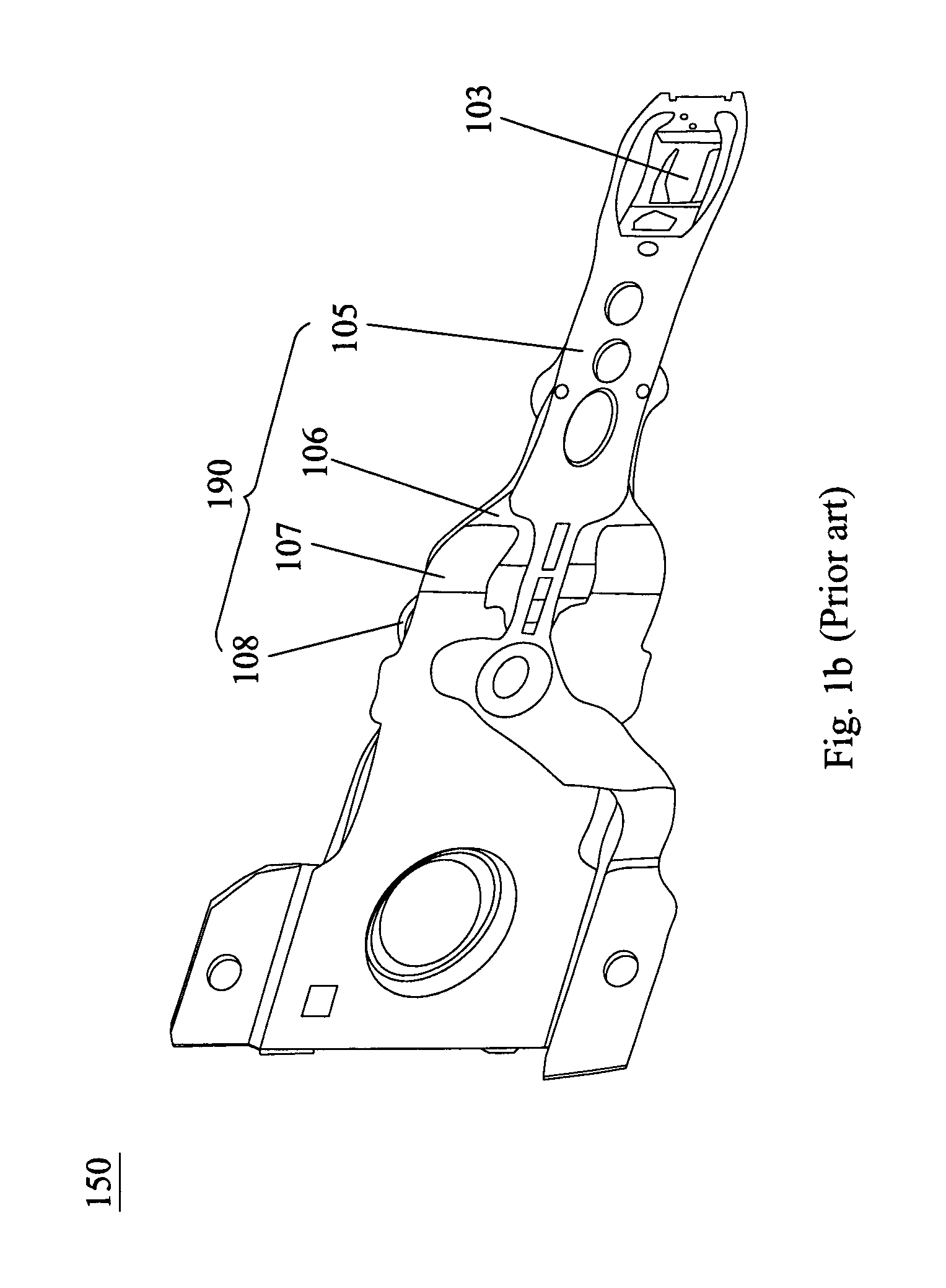

Head gimbal assembly to reduce slider distortion due to thermal stress

InactiveUS20080002299A1Reduce thermal deformationFluid-dynamic spacing of headsRecord information storageThermal expansionThermal distortion

A head gimbal assembly (HGA) is provided. The HGA includes a suspension that has a suspension coefficient of thermal expansion (CTE) and a slider that has a slider CTE. A bonding element attaches the slider to the suspension. A compensation layer, having a compensation CTE, is located on the suspension. The compensation layer serves to compensate for a thermal distortion of the slider. A method of forming a HGA is also provided. The method includes providing a suspension having a suspension CTE and forming a slider having a slider CTE. The method further includes attaching the slider to the suspension and depositing a compensation layer, having a compensation CTE, on the suspension. The compensation layer serves to compensate for a thermal distortion of the slider.

Owner:SEAGATE TECH LLC

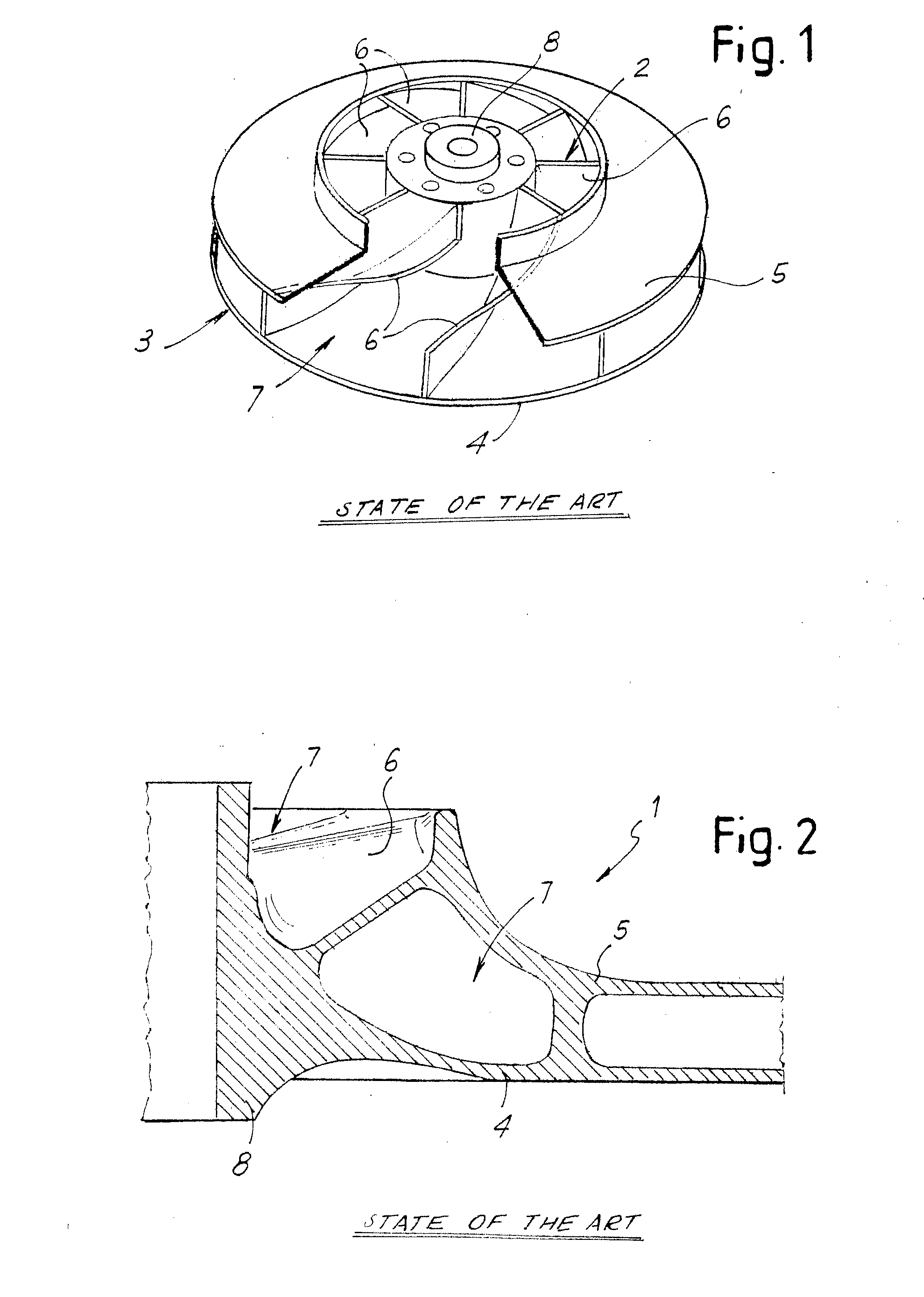

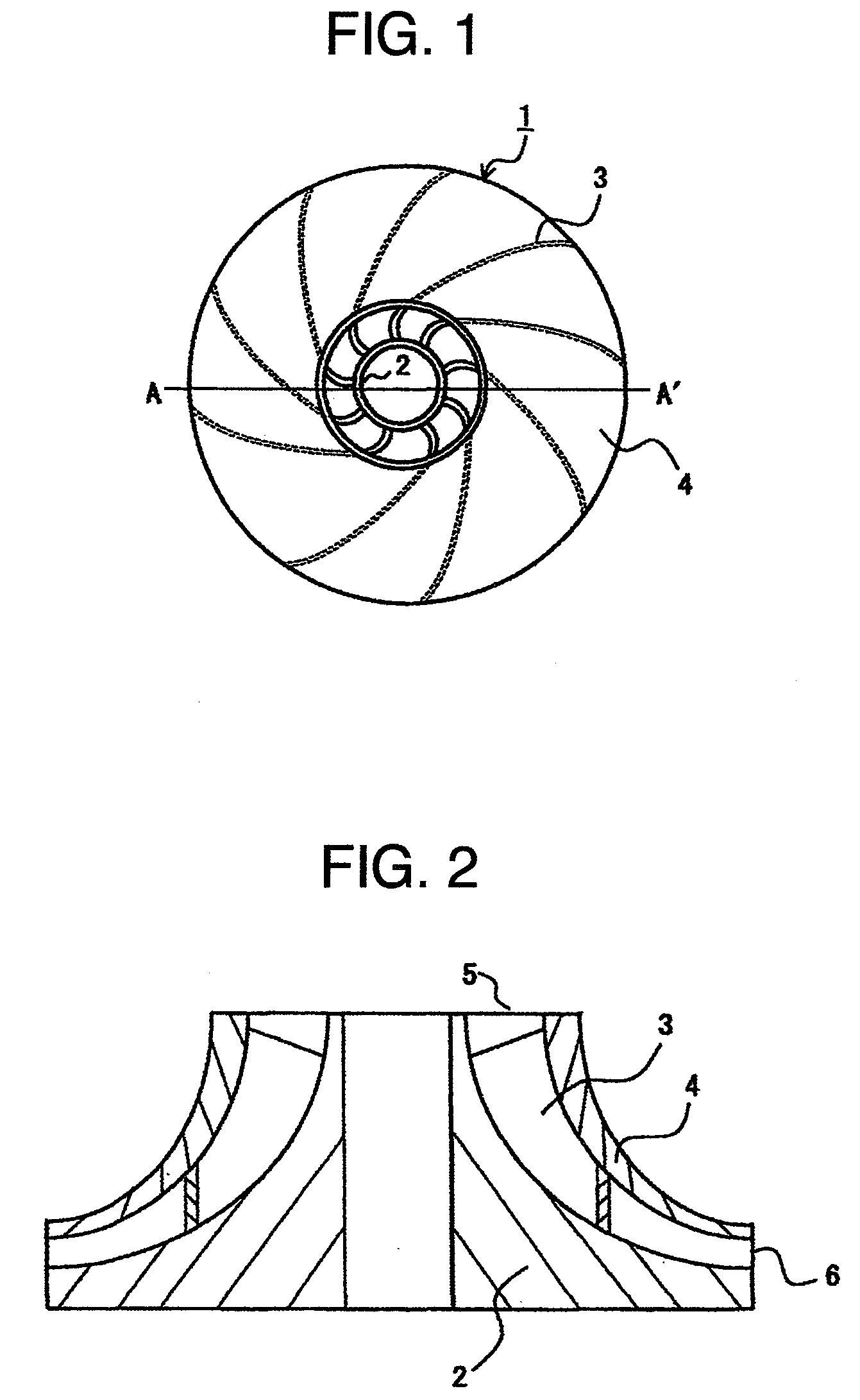

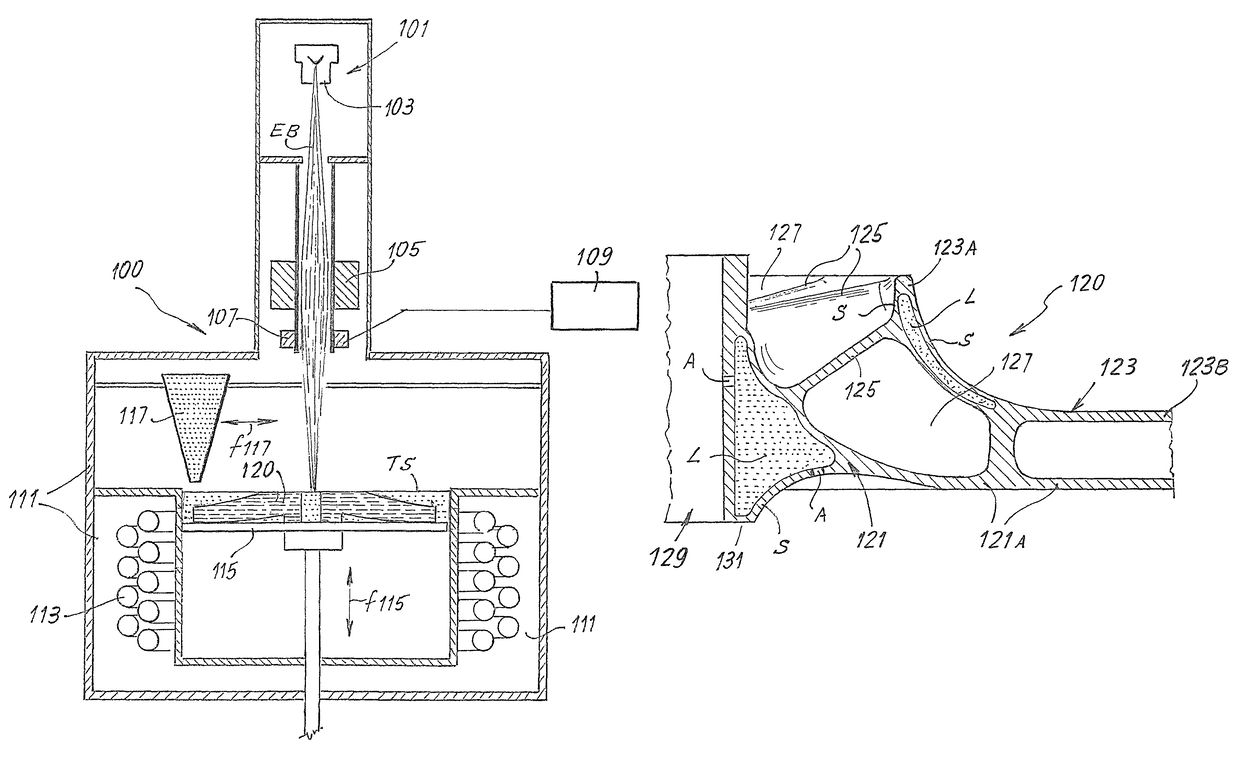

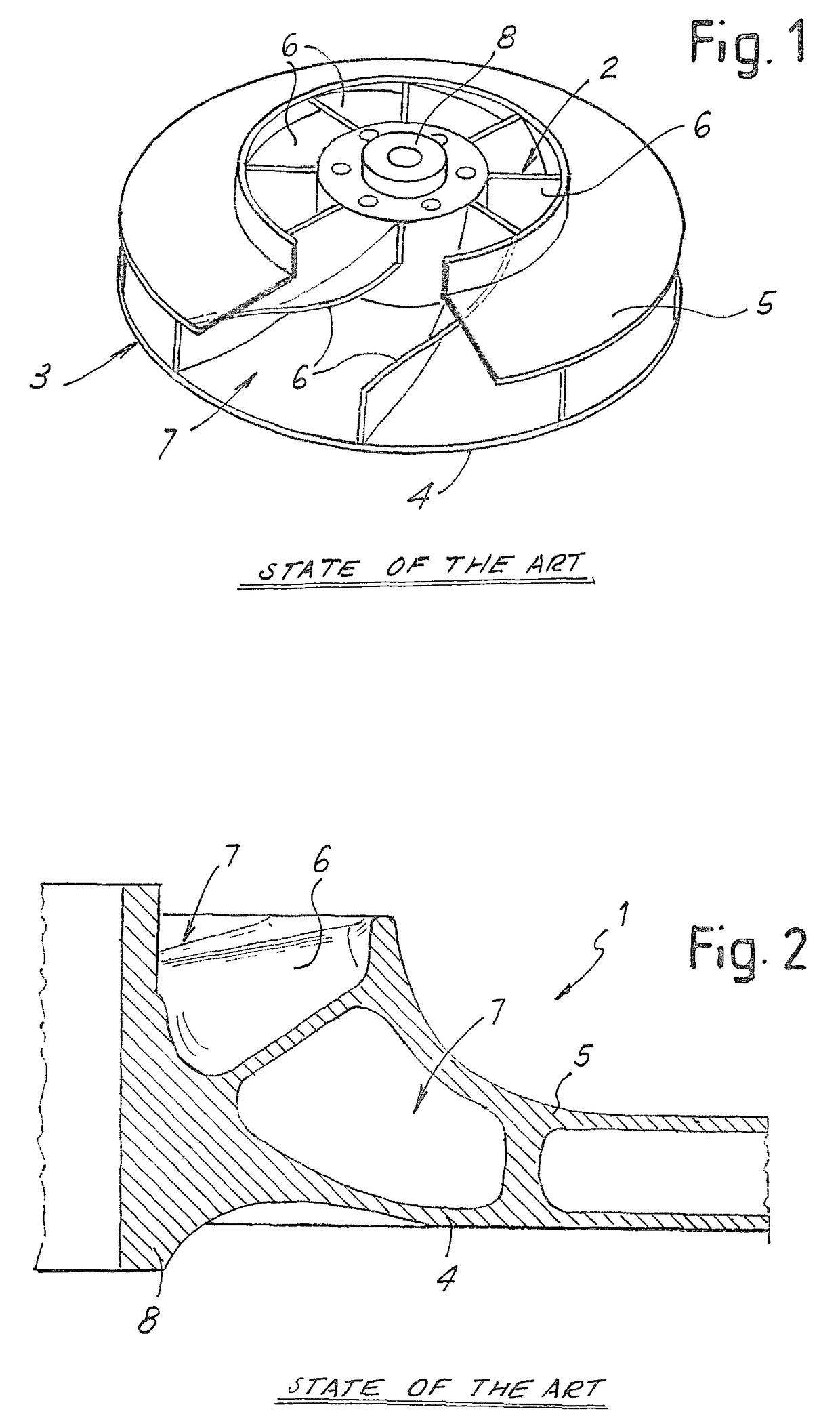

Turbo-machine impeller manufacturing

A method of manufacturing a turbo-machine impeller, which includes a hub and a plurality of blades, using powder material in an additive-manufacturing process. The method includes: applying energy to the powder material by way of a high energy source, and solidifying the powder material. At least one bulky portion of the hub is irradiated such that the powder material solidifies in a lattice structure surrounded by an outer solid skin structure enclosing the lattice structure.

Owner:NUOVO PIGNONE TECH SRL

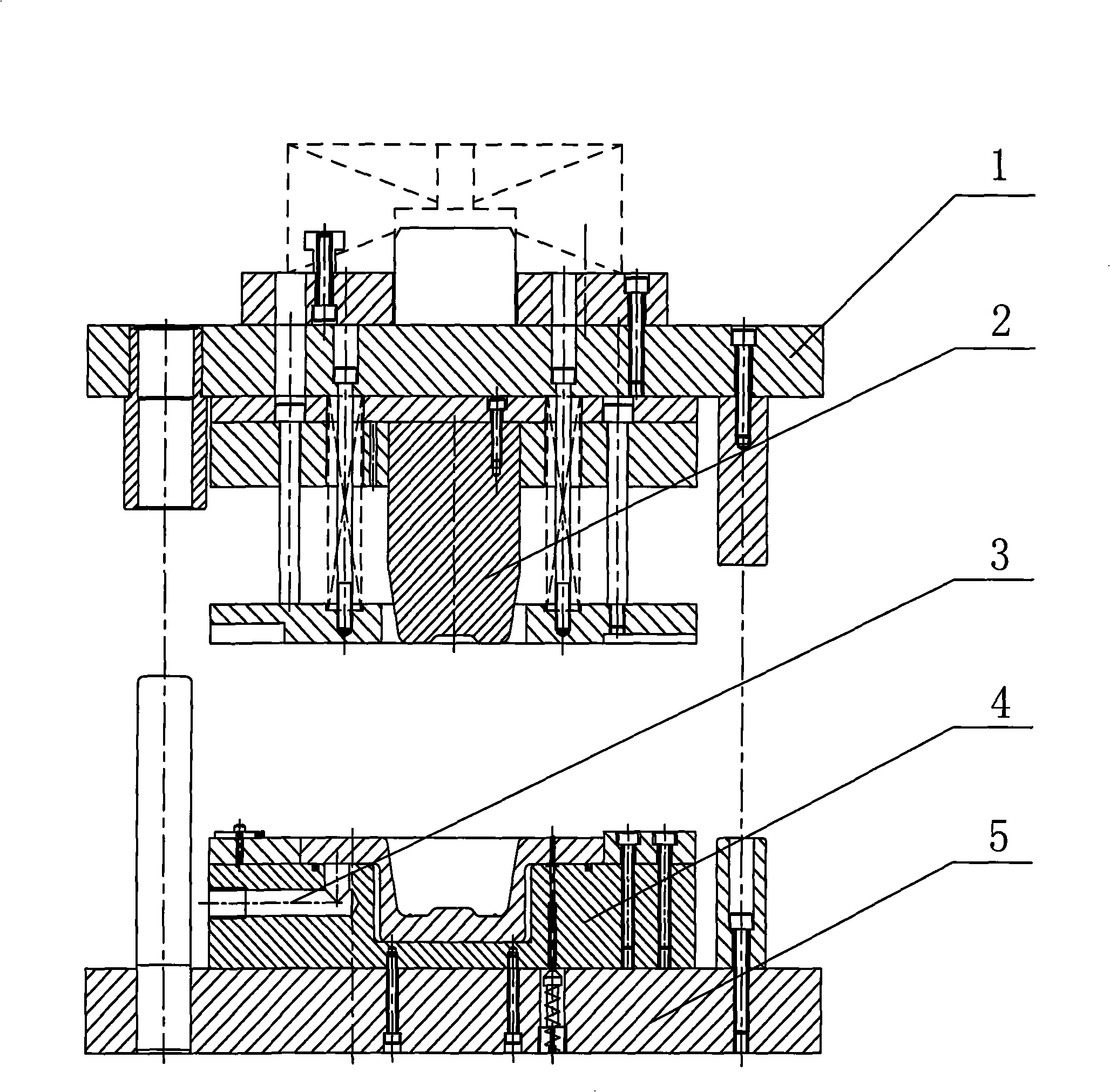

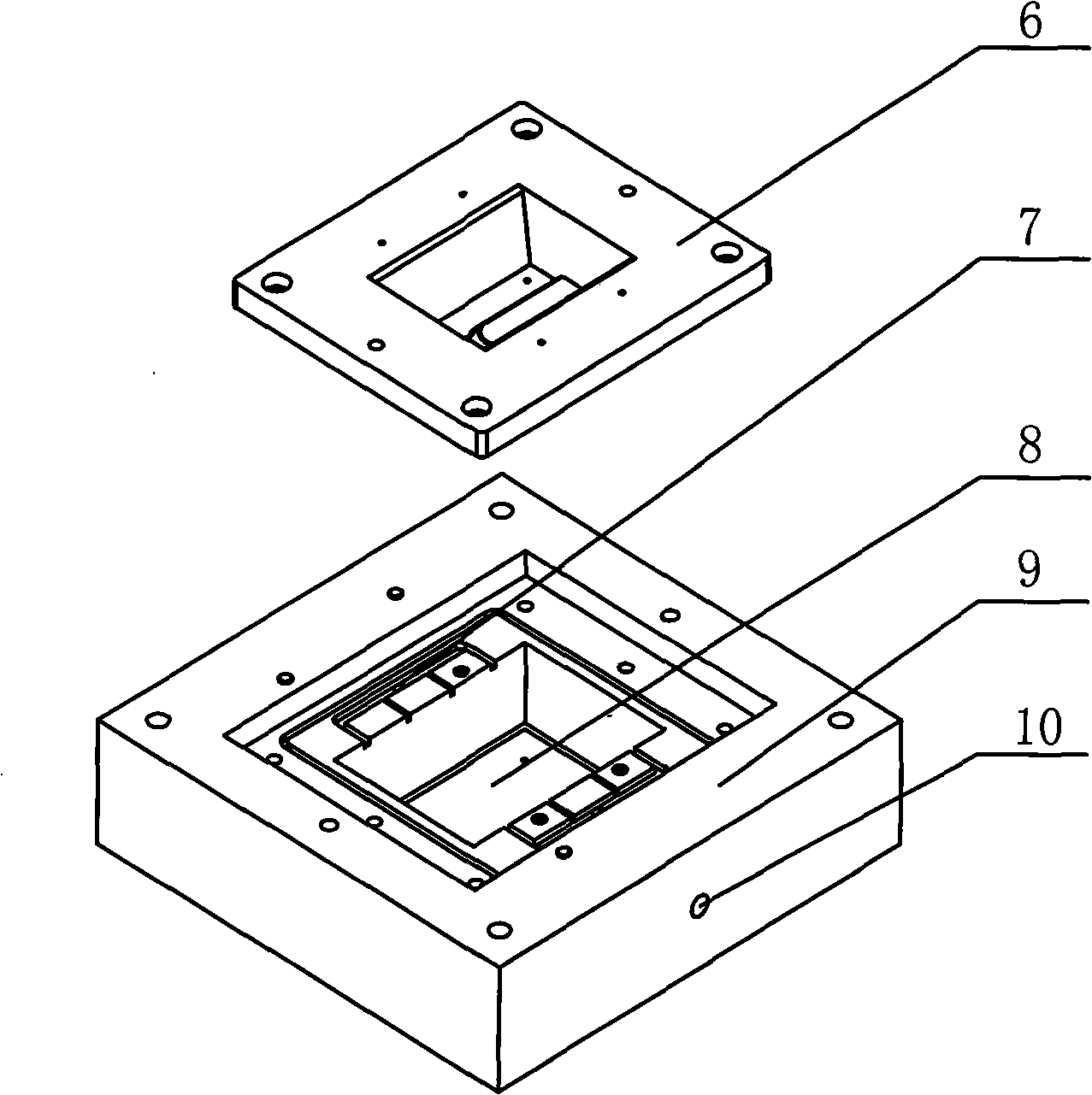

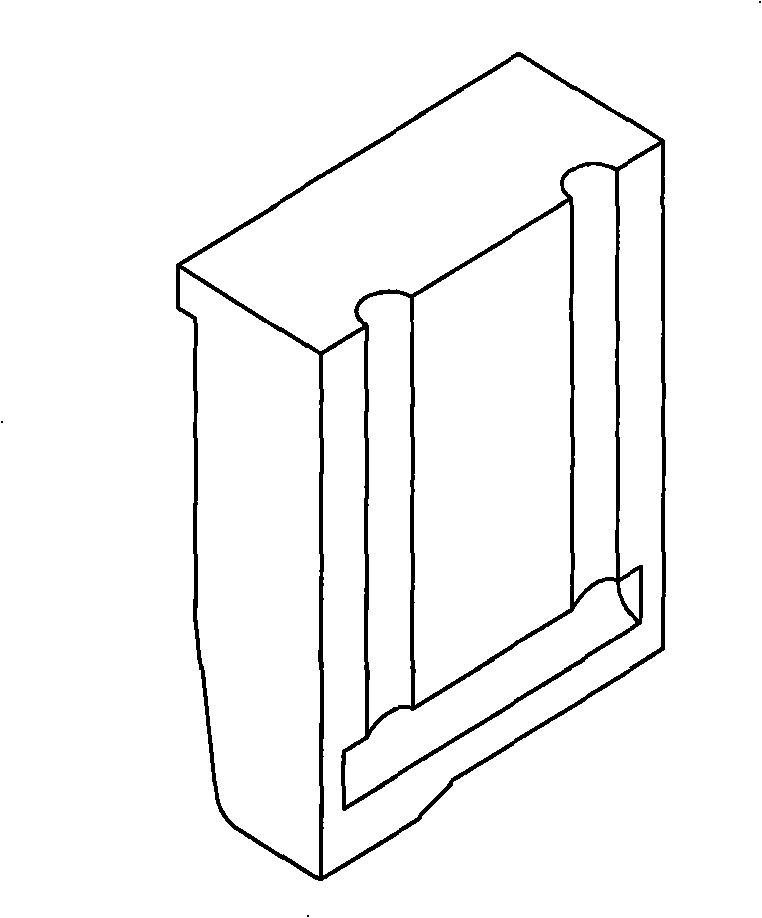

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

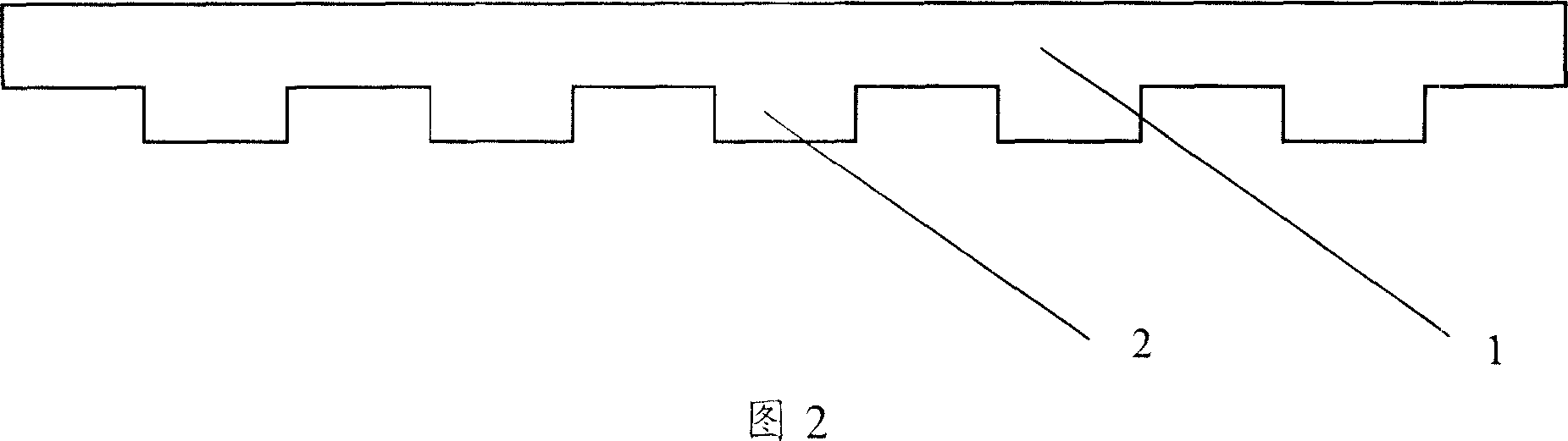

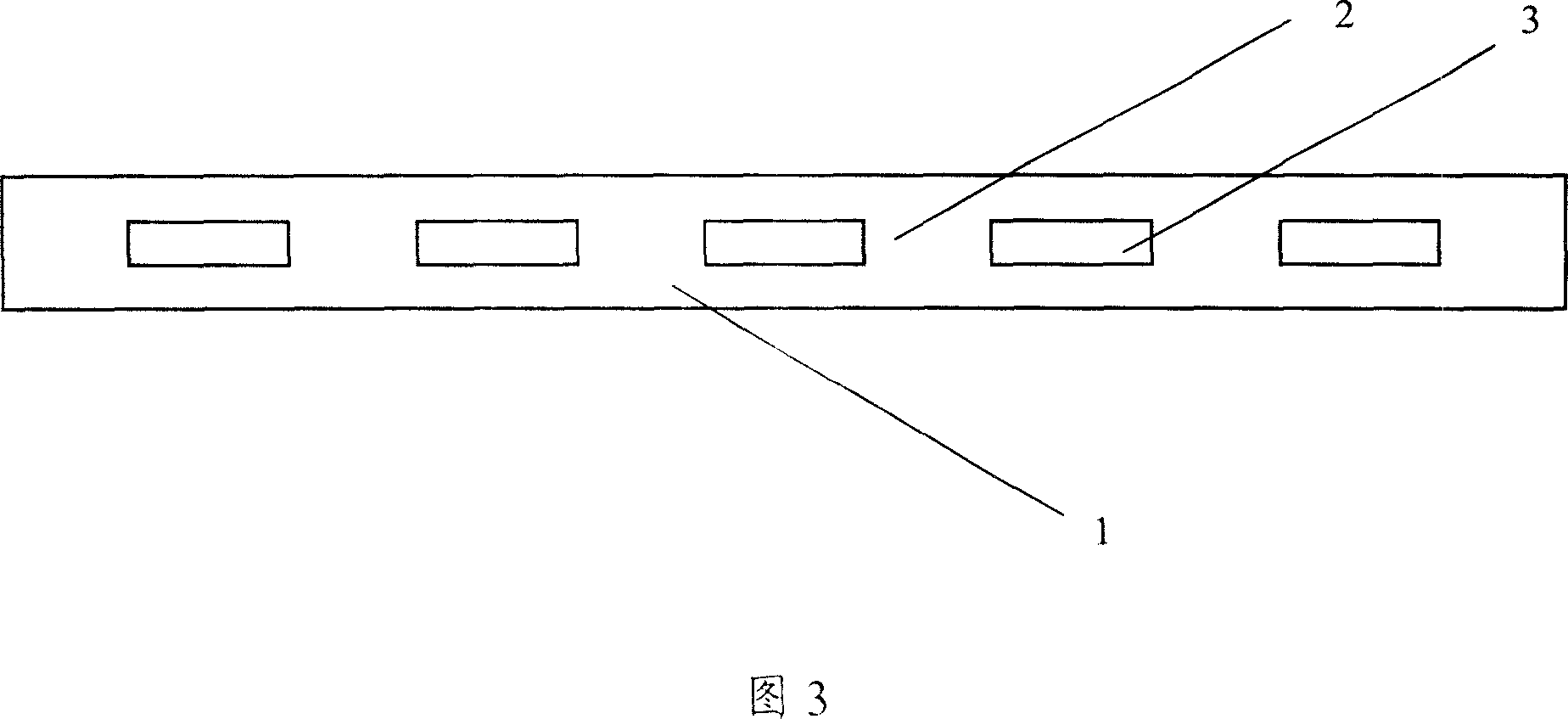

Wood plastic composite material building mould board, its preparation method and use

InactiveCN1948665AGood flexibilityGood compatibilityDomestic articlesForming/stuttering elementsWear resistantMechanical property

This invention discloses a kind of wood-plastic composite materials for construction template and its preparation methods and purposes. It belongs to building materials area. Against poor toughness, small strength and high cost defects of existing technologies, the main materials of this invention are PVC resin and / or plastic (new materials or waste materials) and wood fiber powder, the second materials are calcium power PE resins, short glass fiber, then adds the assistant, through mixing, heating, agitating, extrusion to matrix and cooling to shape, cutting steps to made into templates. It can increase the strength of plate by increasing various forms of reinforced structure in the process of preparation. It can be used for construct template of concrete processing. This invention can be recycled for several times, environmental protected, save resources and of low cost; the template are wear resistant and defend worms, non-absorbent, and hard to deform, with good mechanical properties, low coefficient of thermal conductivity, anti-acid and alkali.

Owner:四川自强科技有限公司

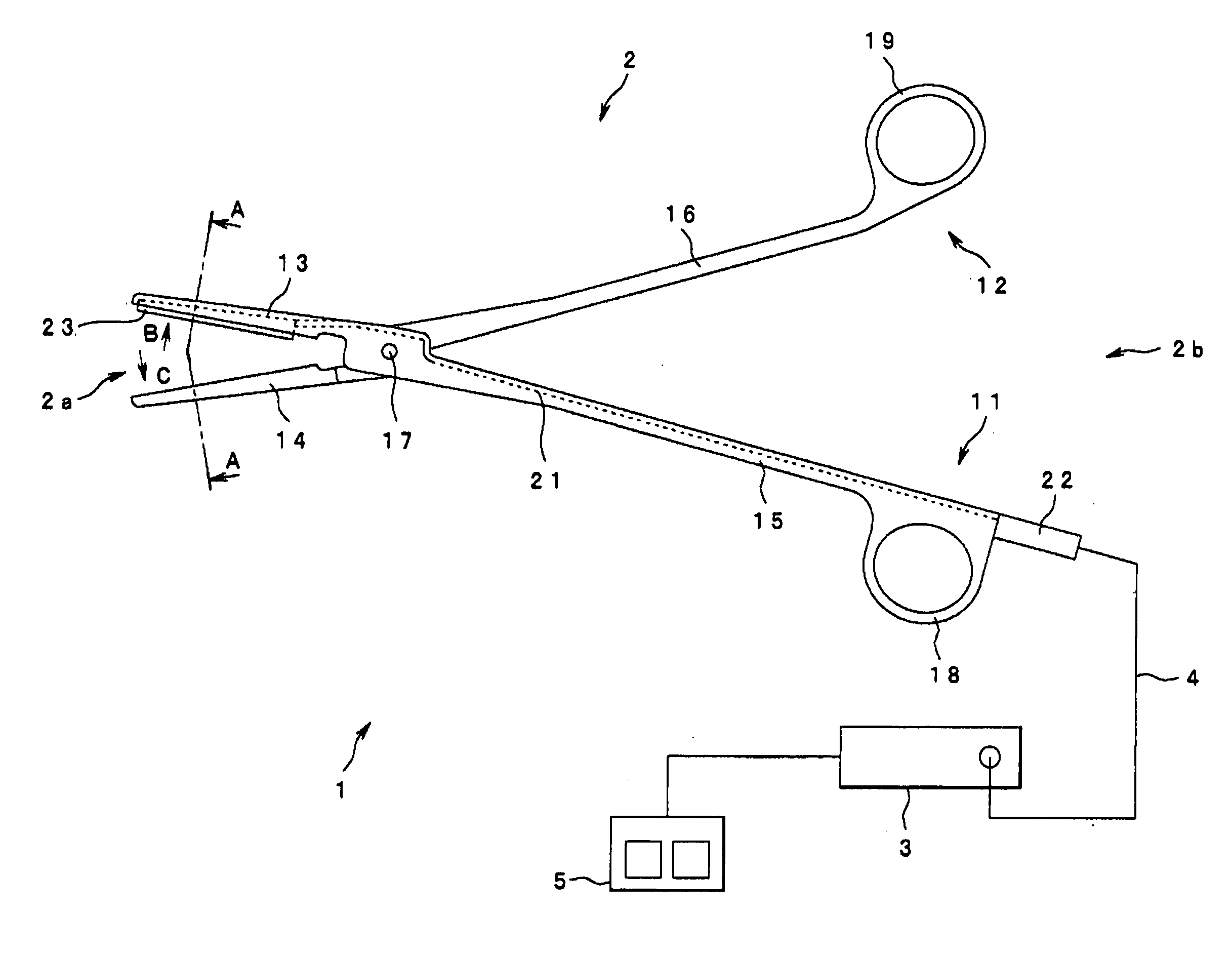

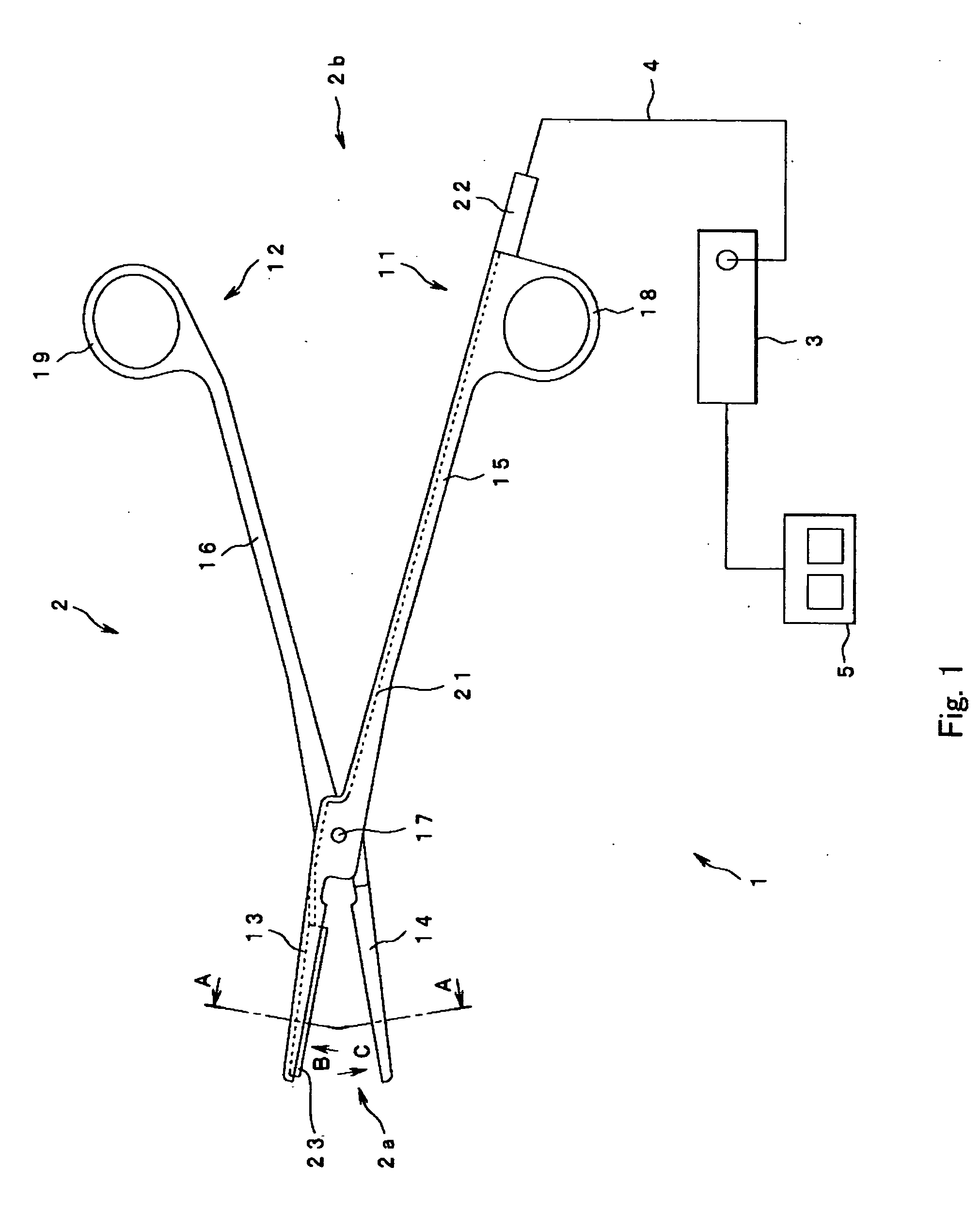

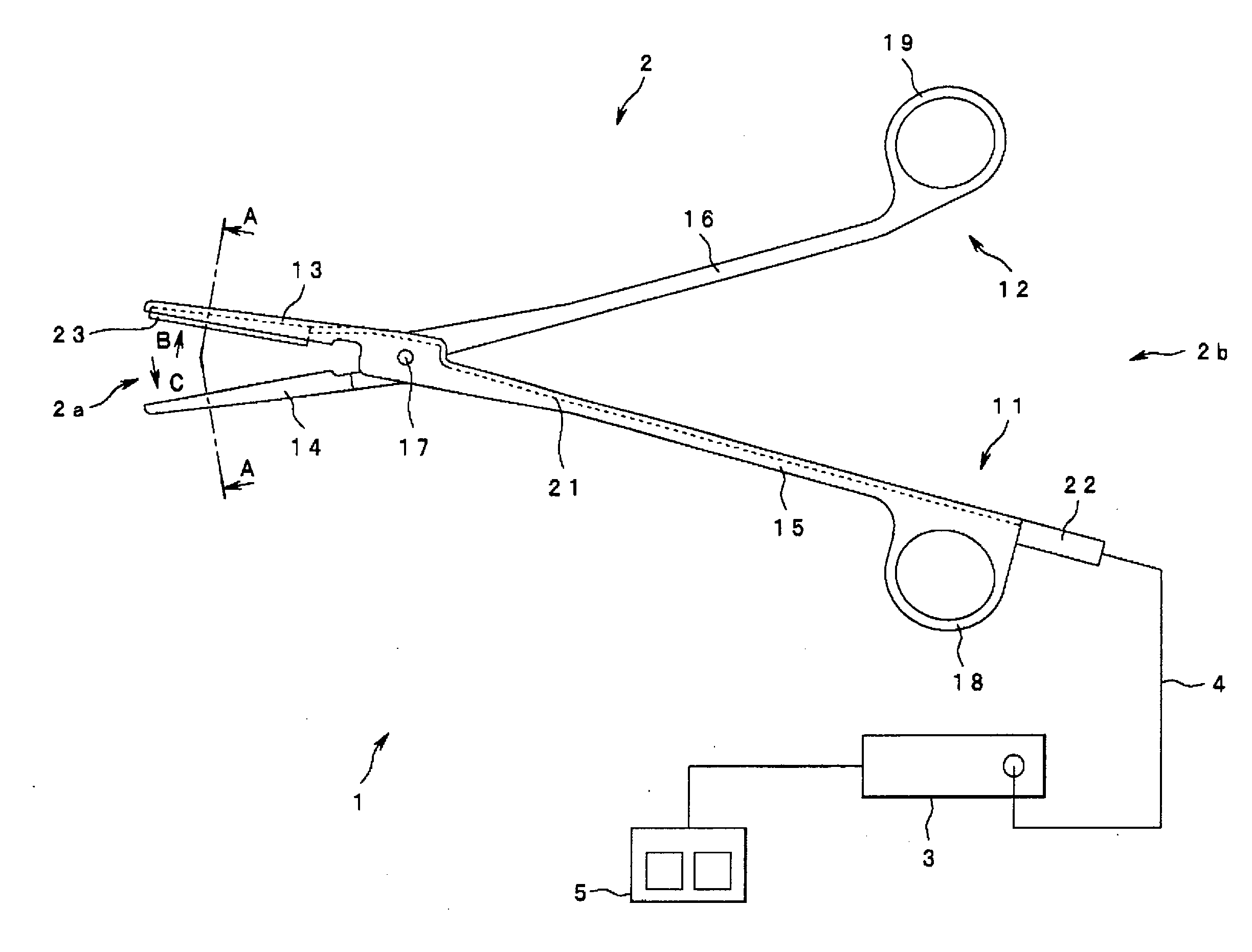

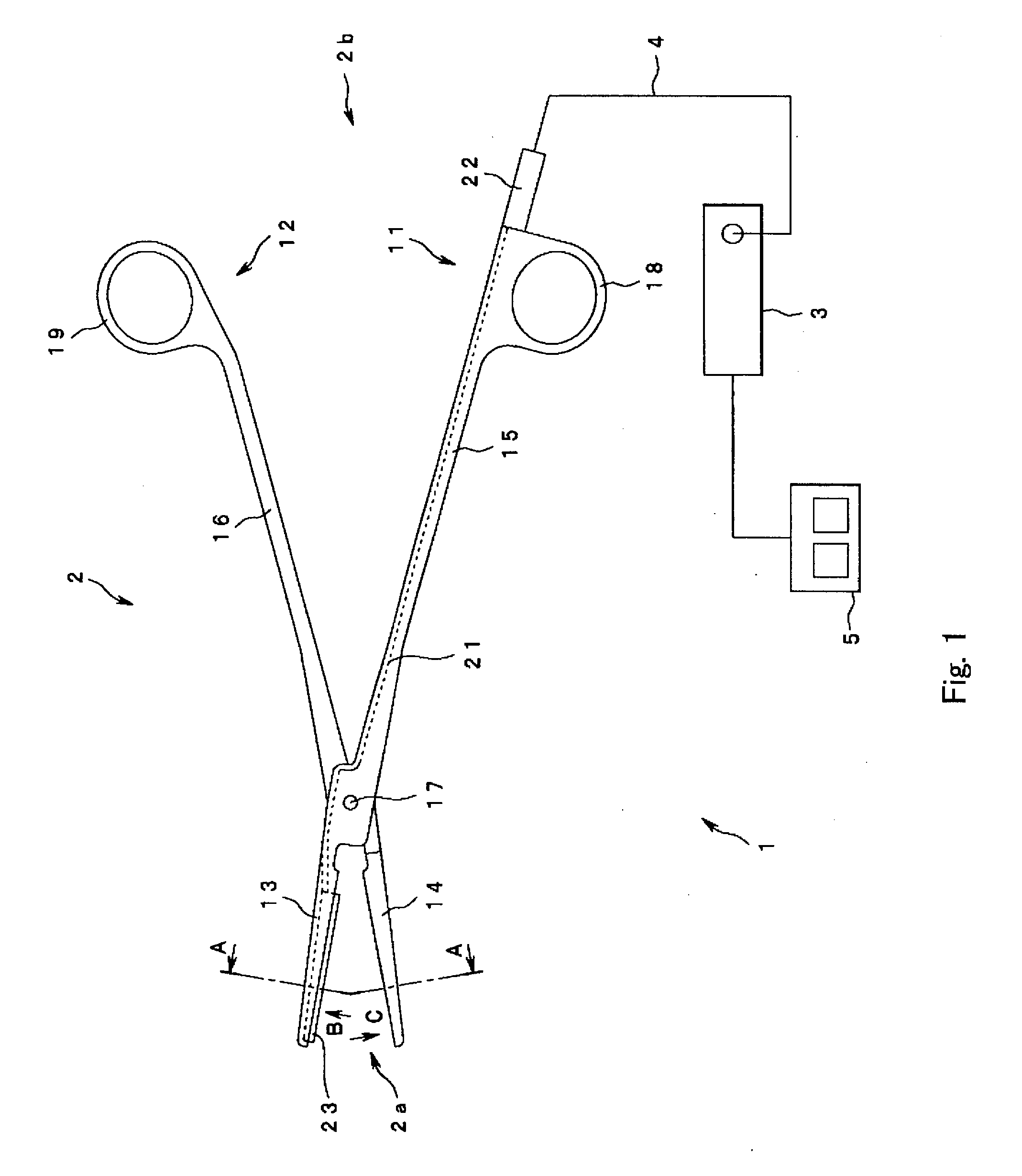

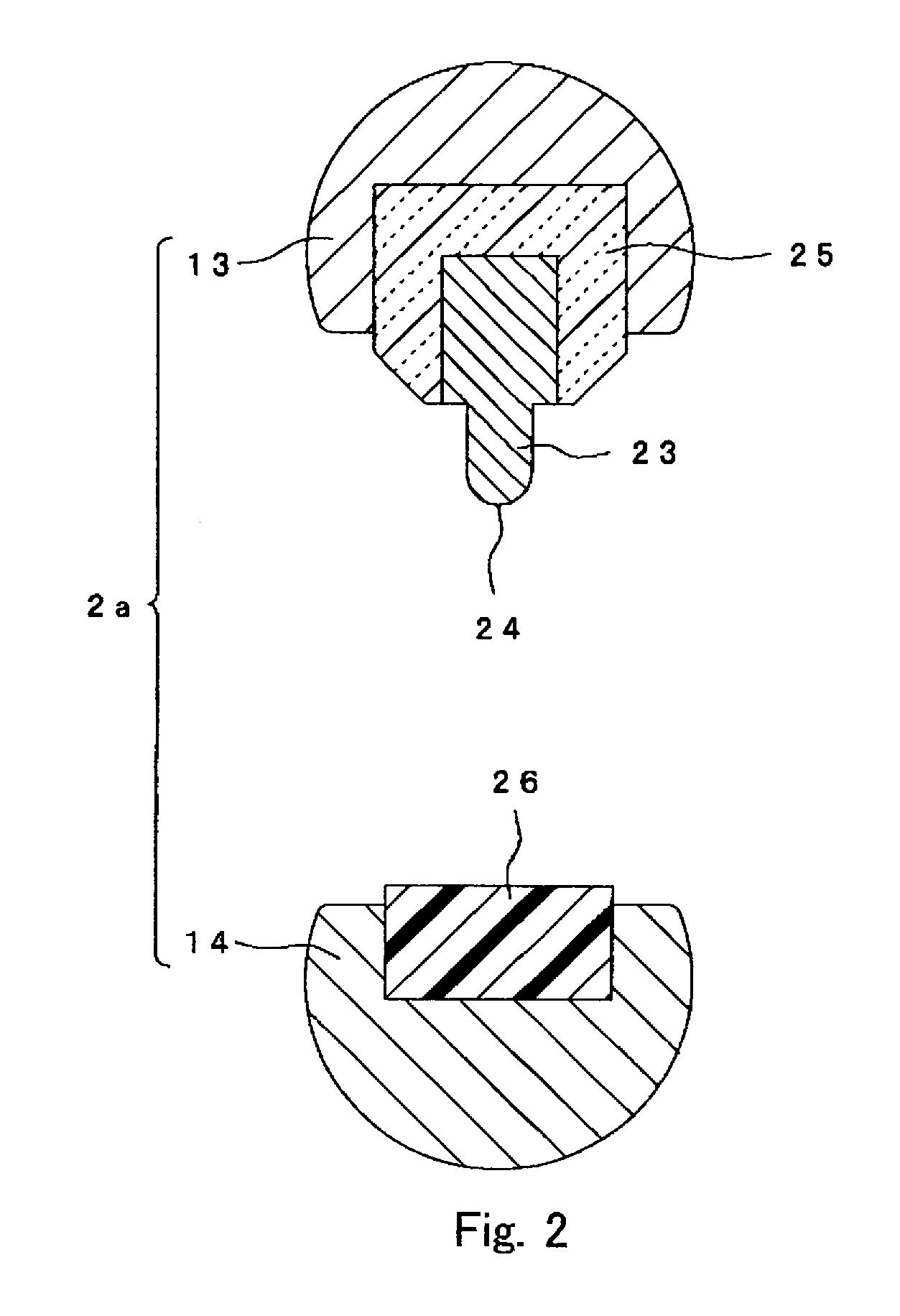

Operative instrument

InactiveUS20050222560A1Increased durabilityReduce thermal deformationSurgical instruments for heatingSurgical forcepsForcepsEngineering

An operative instrument includes forceps having a treating section for treating an anatomy at an extremity and being provided with a heat-generating body for generating heat to be provided to the anatomy and a power supply unit for supplying electric power to the heat-generating body of the forceps. The operative instrument raises the temperature of the heat-generating body by supplying substantially constant electric power to the heat-generating body. Therefore, coagulation and incision of the anatomy can be performed satisfactorily.

Owner:OLYMPUS CORP

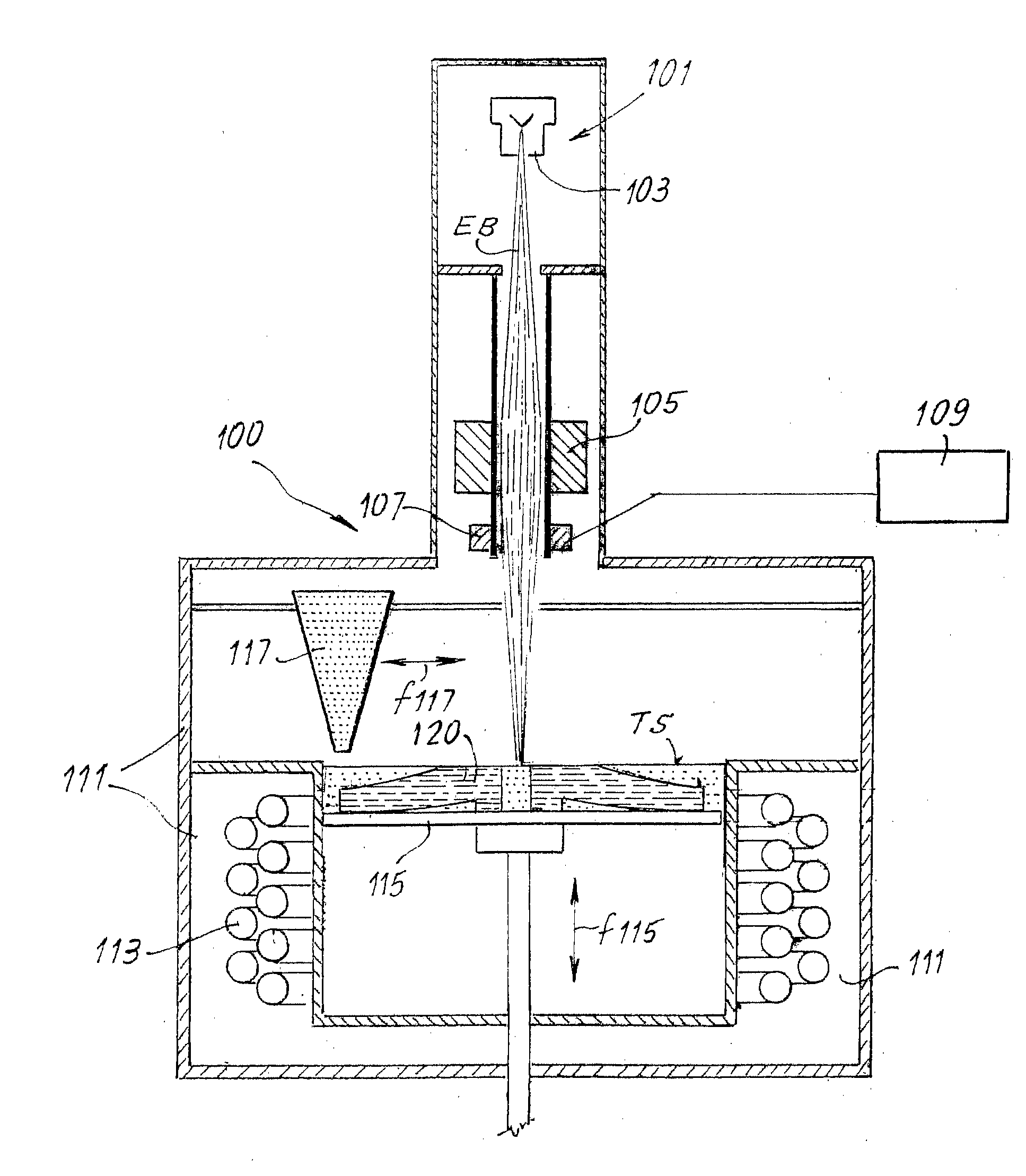

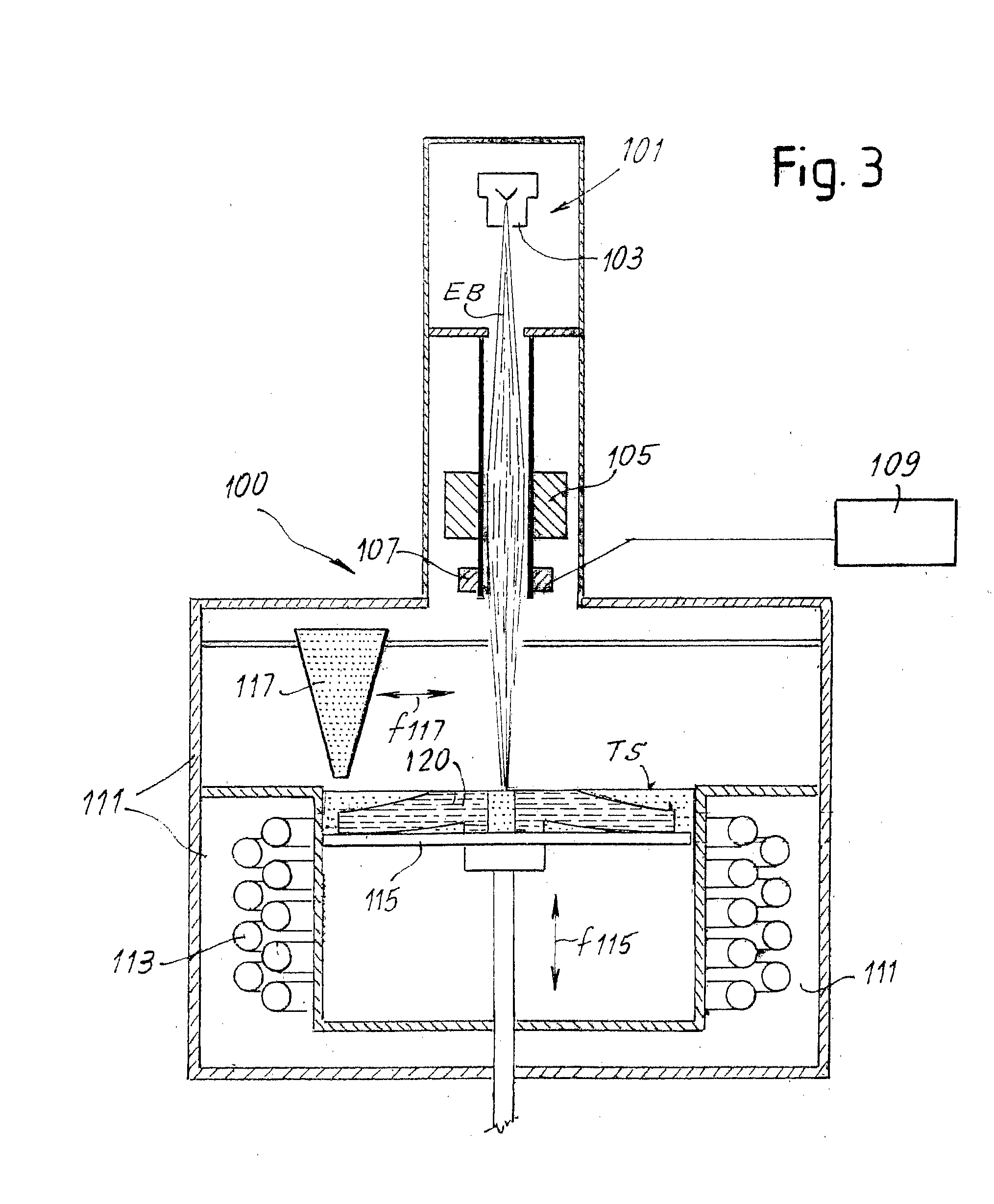

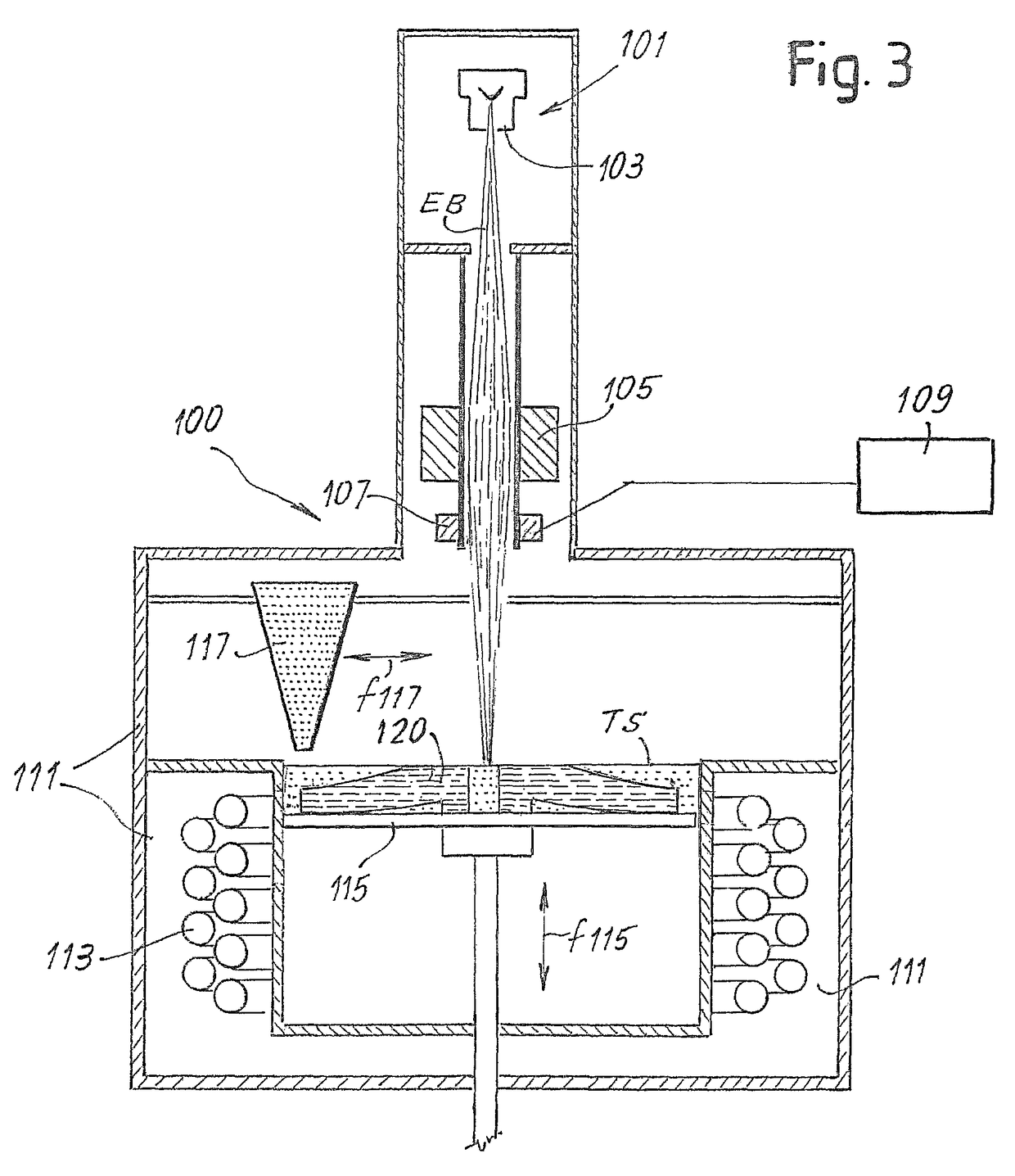

Selective laser forming metal powder preheating method and device

InactiveCN105880591AReduce thermal stressReduce thermal deformationAdditive manufacturing apparatusIncreasing energy efficiencyThermal deformationLaser scanning

The invention provides a selective laser forming metal powder preheating method and device. The device comprises a substrate heating device on a forming cylinder piston. Before machining starts, the substrate heating device preheats a substrate to preset temperature, heating is conducted by carrying out laser scanning on metal powder on the section of a workpiece after powder laying and machining, and accordingly the metal powder is preheated. Thus, thermal stress and thermal deformation of the workpiece can be greatly reduced, gas residues among powder can be greatly reduced, and accordingly the aim of improving precision, surface quality and mechanical performance of the workpiece is achieved.

Owner:北京隆源自动成型系统有限公司

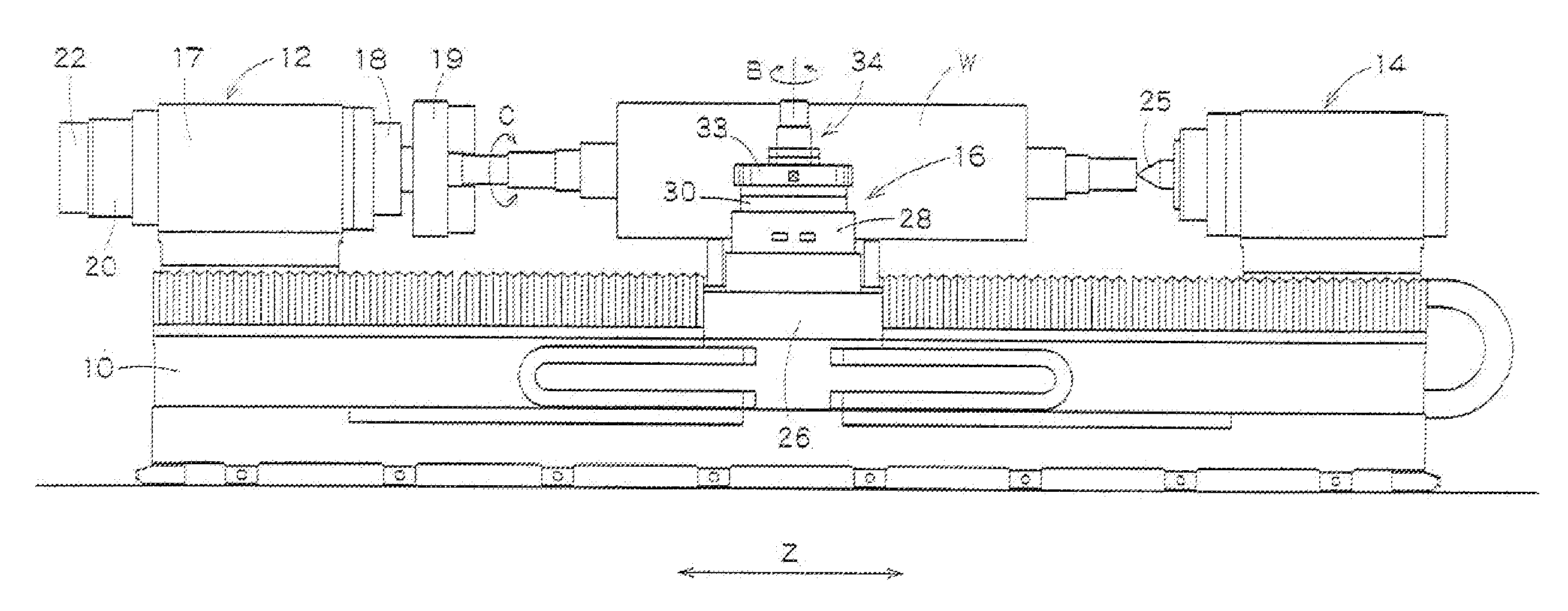

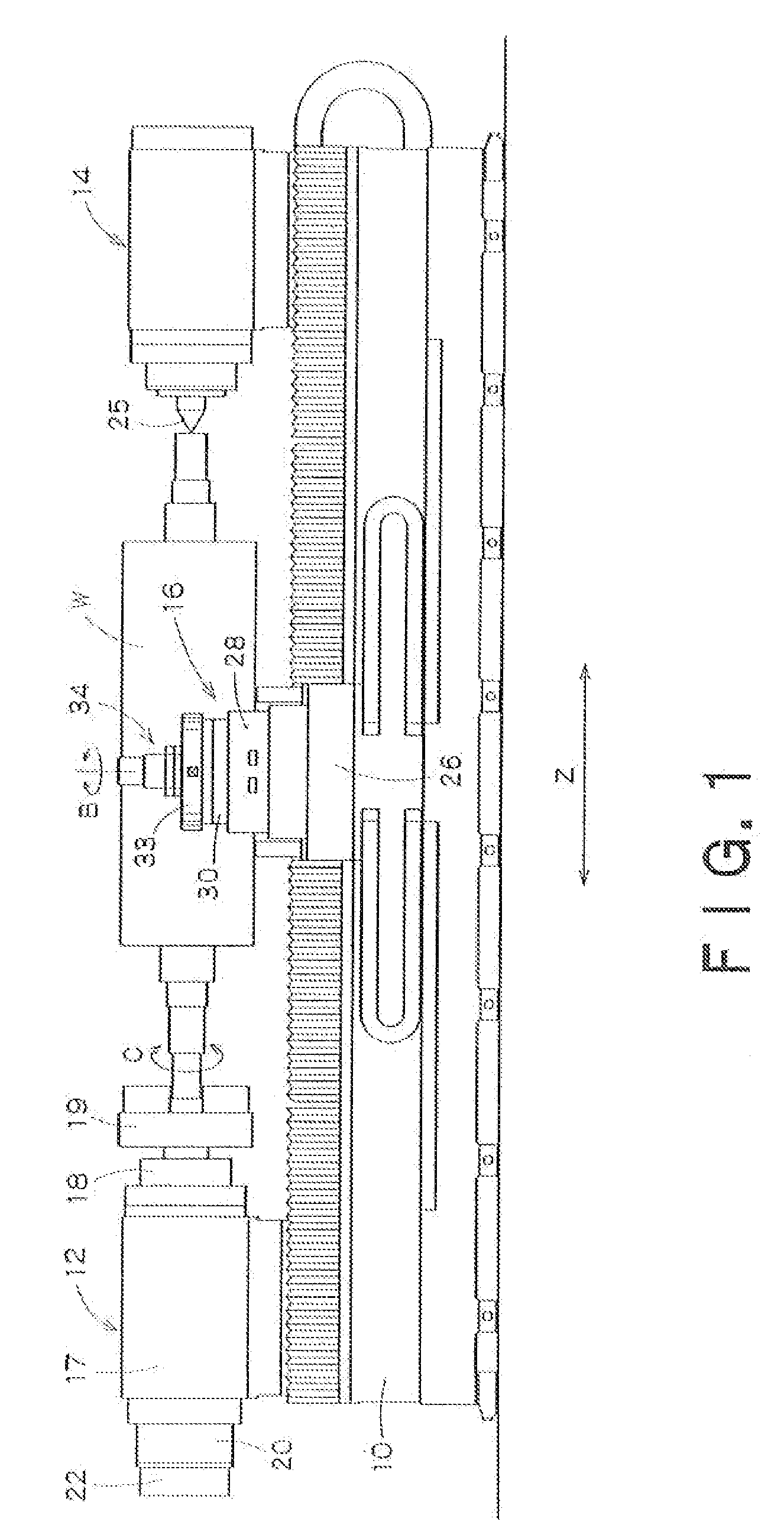

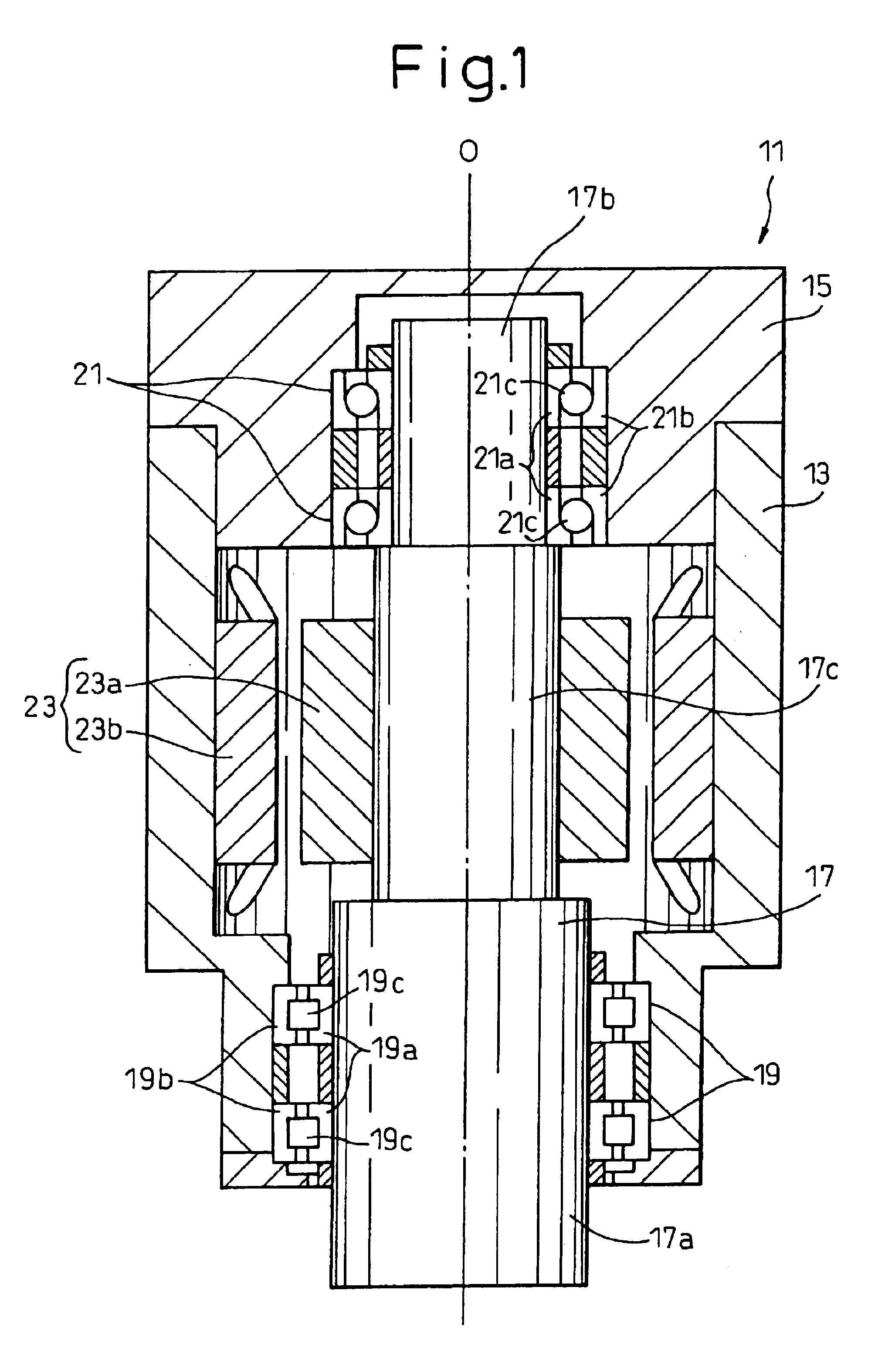

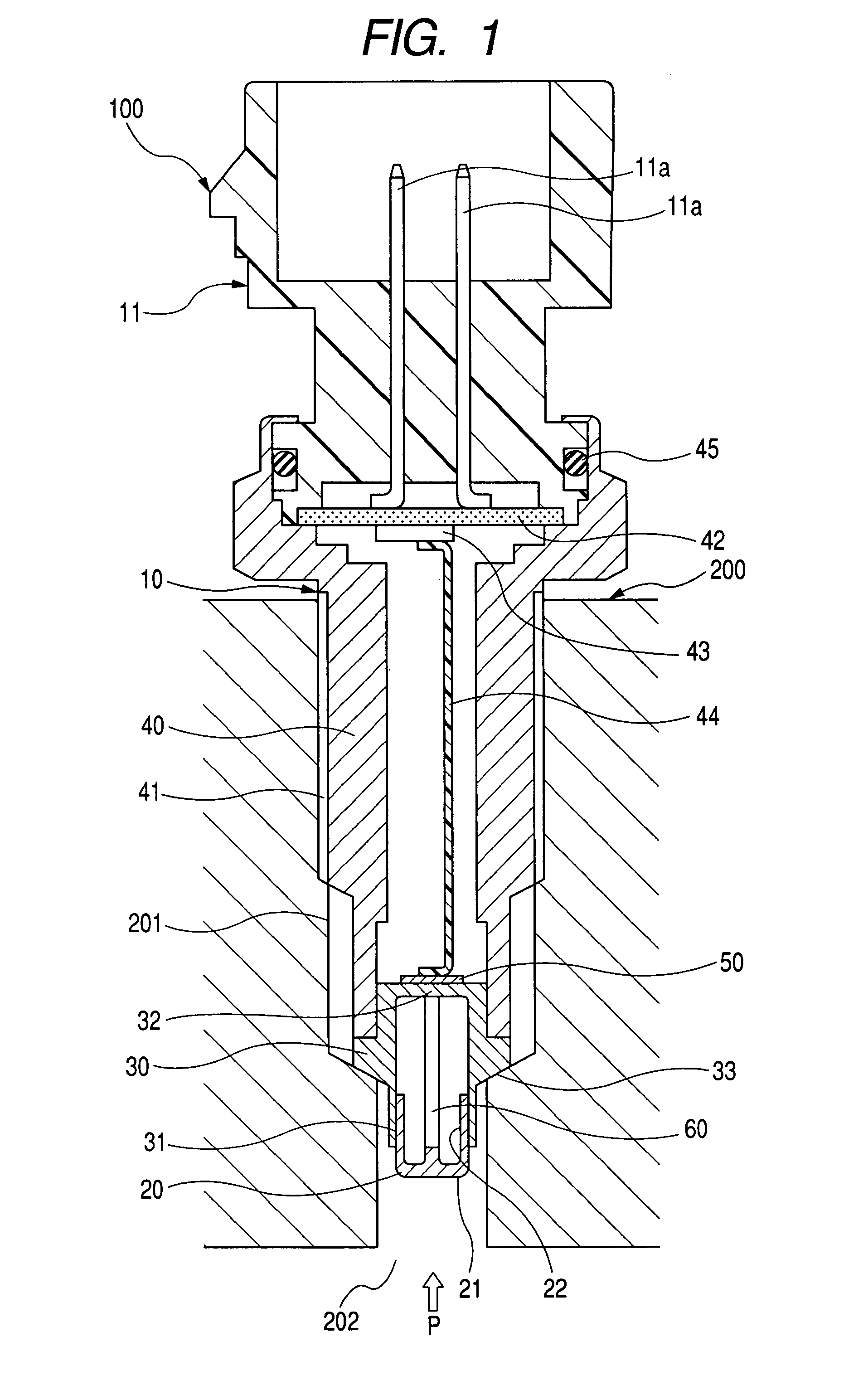

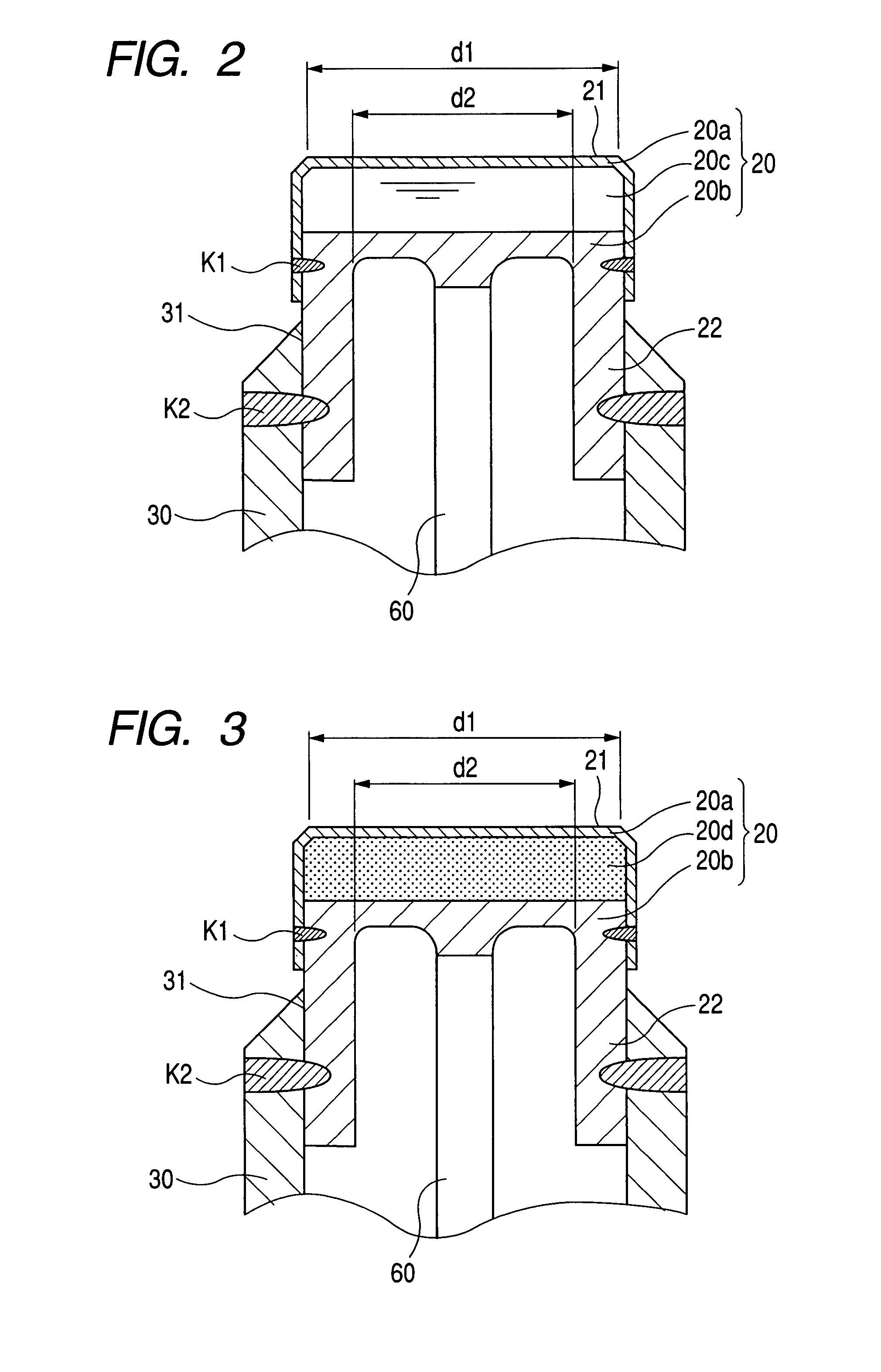

Precision roll turning lathe

ActiveUS20070251360A1High precision machiningAvoid low machining accuracyAutomatic/semiautomatic turning machinesPropelling pencilsTransverse grooveHeadstock

There is provided a precision roll turning lathe which can not only machine with high precision circumferential transverse grooves in the peripheral surface of a roll but can also machine with high precision longitudinal grooves in the peripheral surface. The precision roll turning lathe includes: a bed 10; a headstock 12, mounted on the bed 10, for rotating a roll-shaped workpiece while holding one end of the workpiece by means of a chuck, said headstock having an indexing axis (C axis) for performing circumferential indexing of the workpiece; a tail stock 14, mounted on the bed 10 and disposed opposite the headstock 12, for rotatably supporting the other end of the workpiece; a carriage 16 including a saddle 26 mounted on the bed 10 movably in the longitudinal direction (Z-axis direction) of the workpiece, and a table 28 mounted on the saddle 26 movably in a direction (X-axis direction) perpendicular to the longitudinal direction of the workpiece; a tool swivel 30 mounted on the table 28 and having an indexing axis (B axis); a tool post 33 mounted on the tool swivel 30 and having a plurality of cutting tools 36 attached thereto; and a fly cutter spindle device 34 mounted to the tool post 34 and having a cutter spindle for rotating a fly cutter 39.

Owner:TOSHIBA MASCH CO LTD

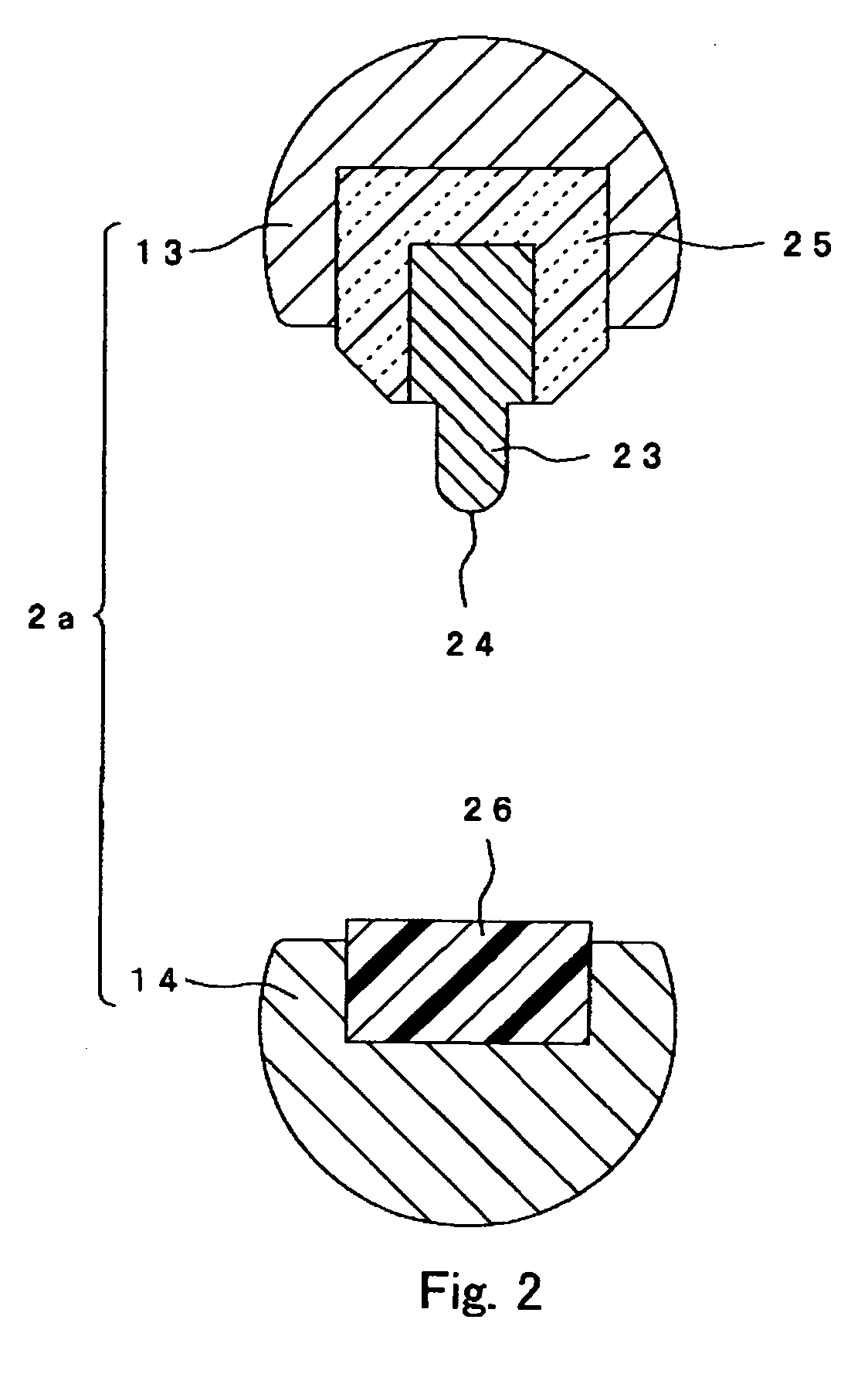

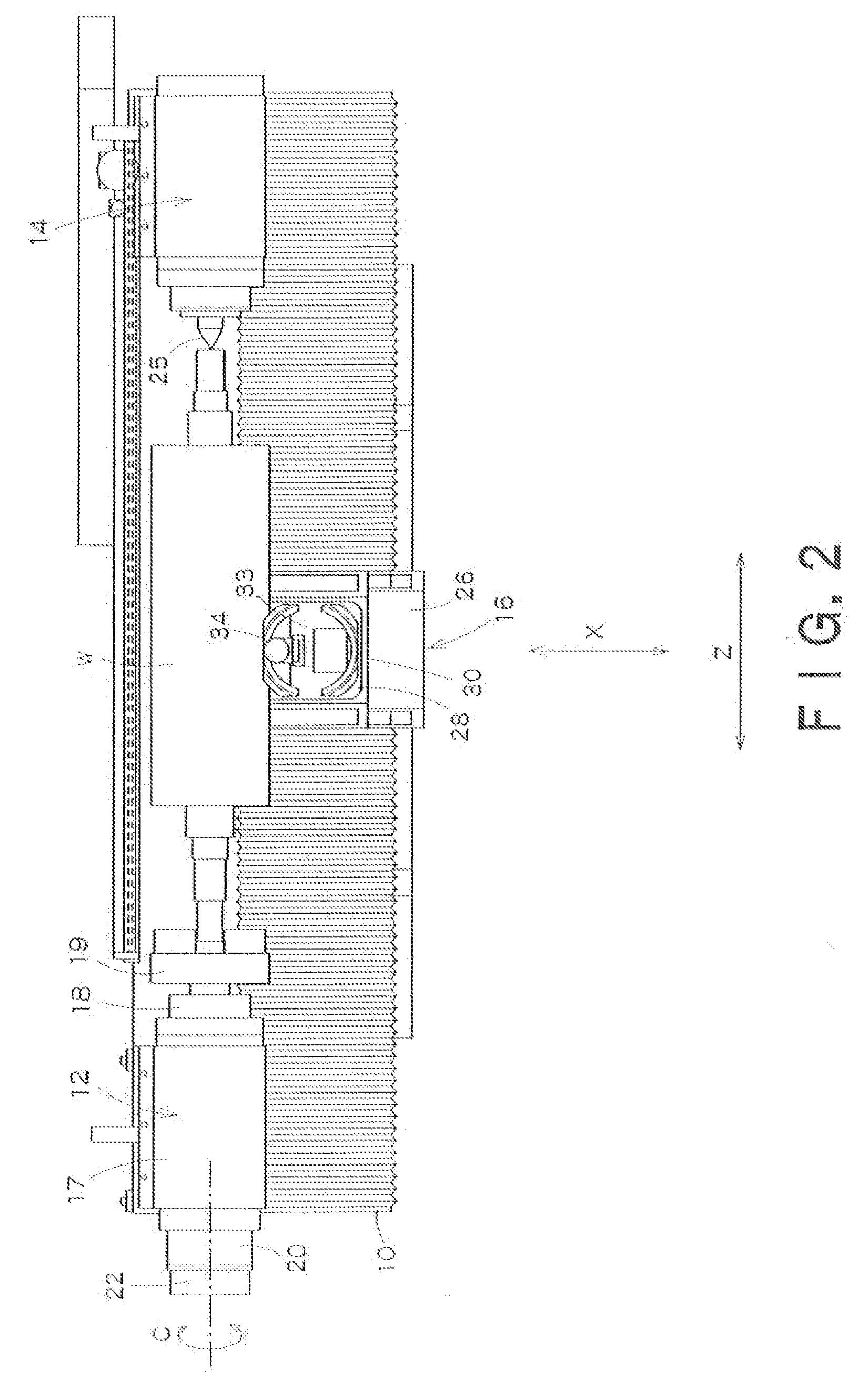

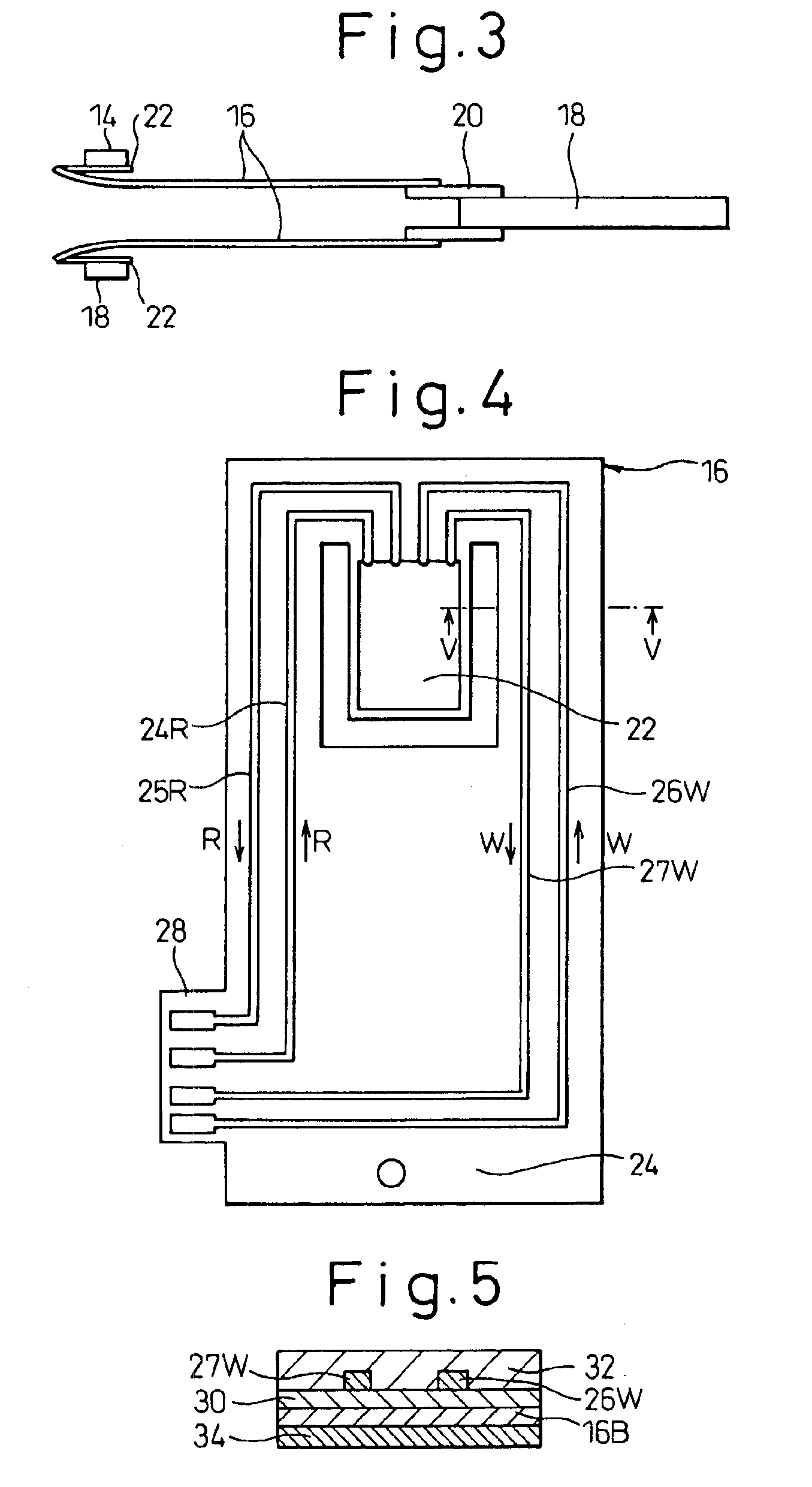

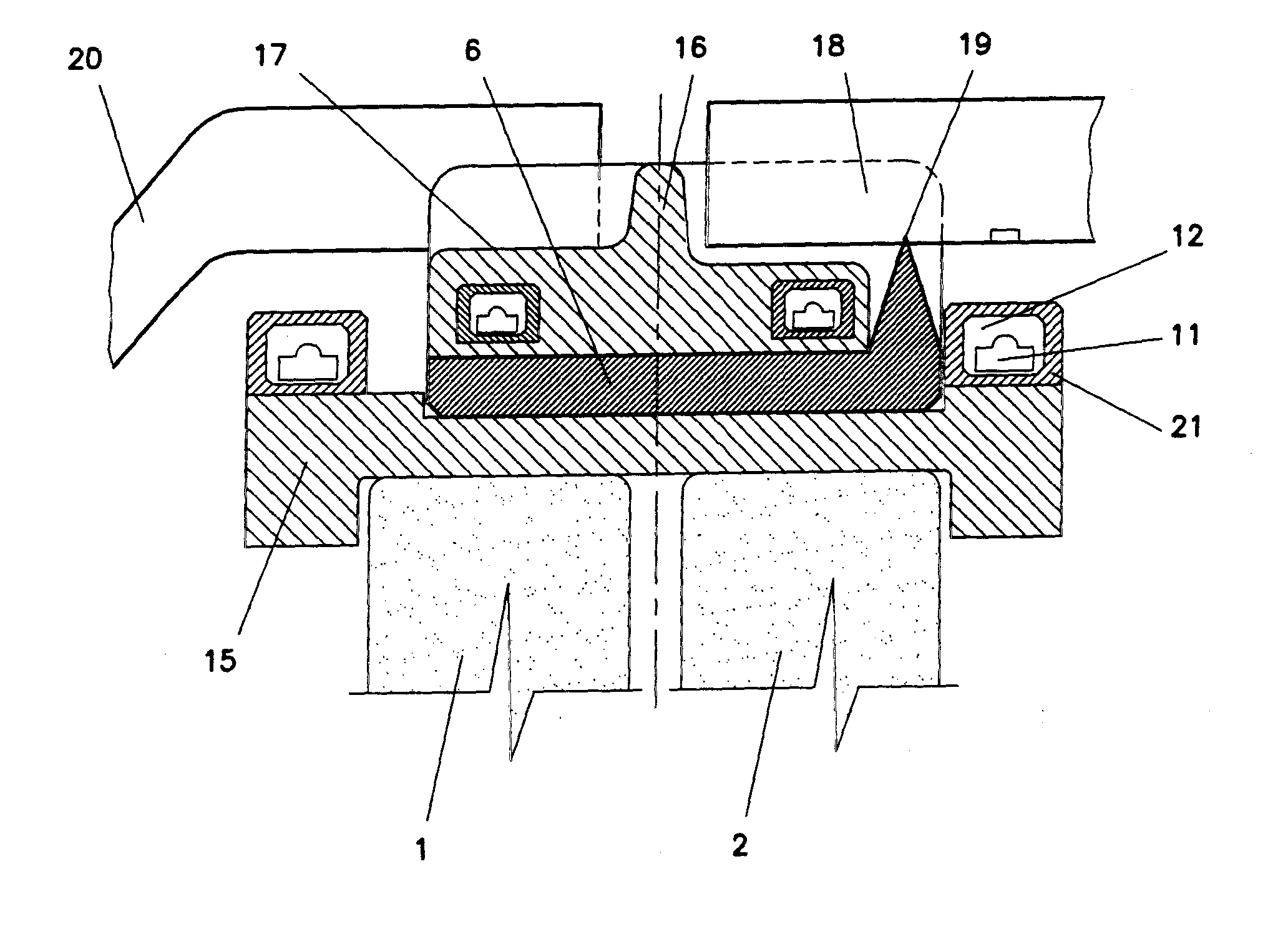

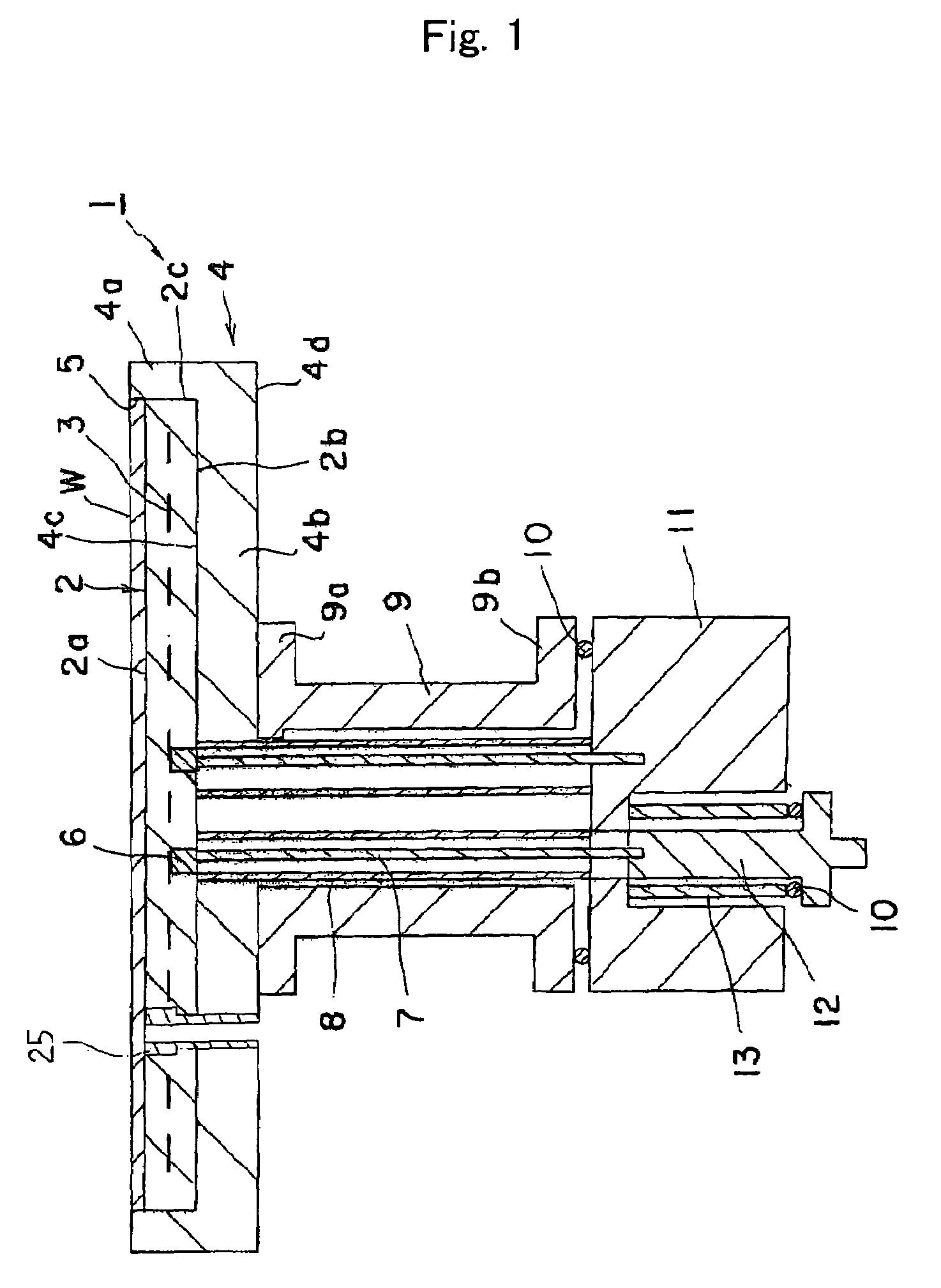

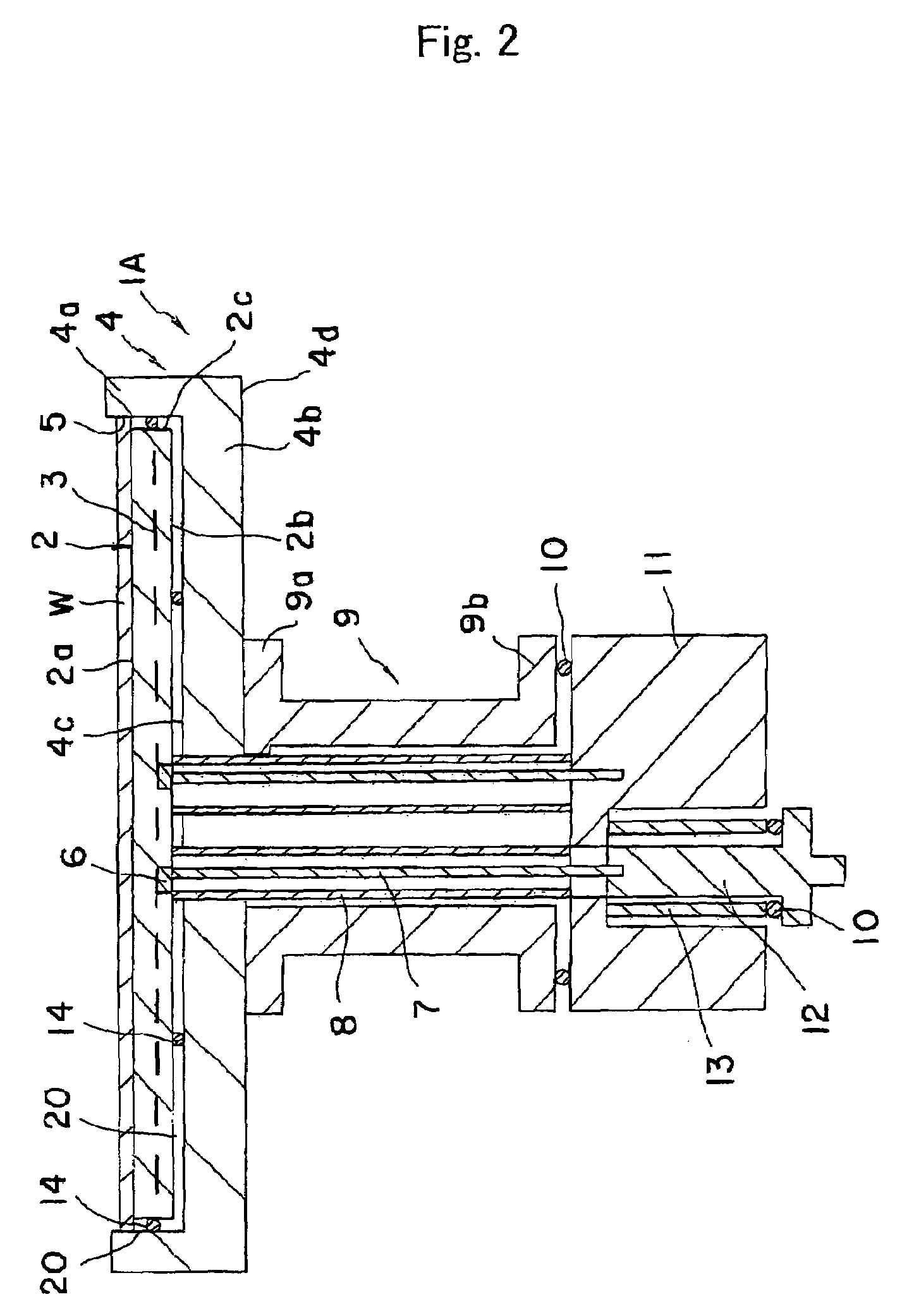

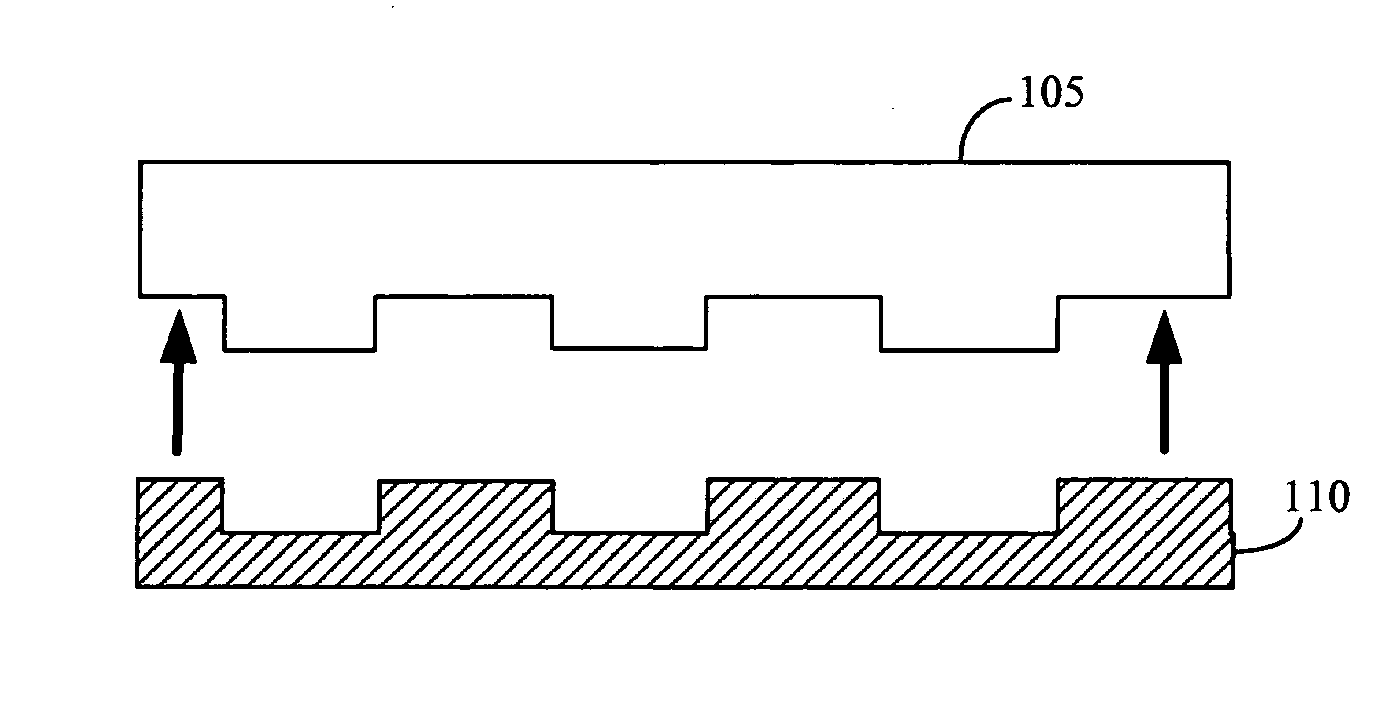

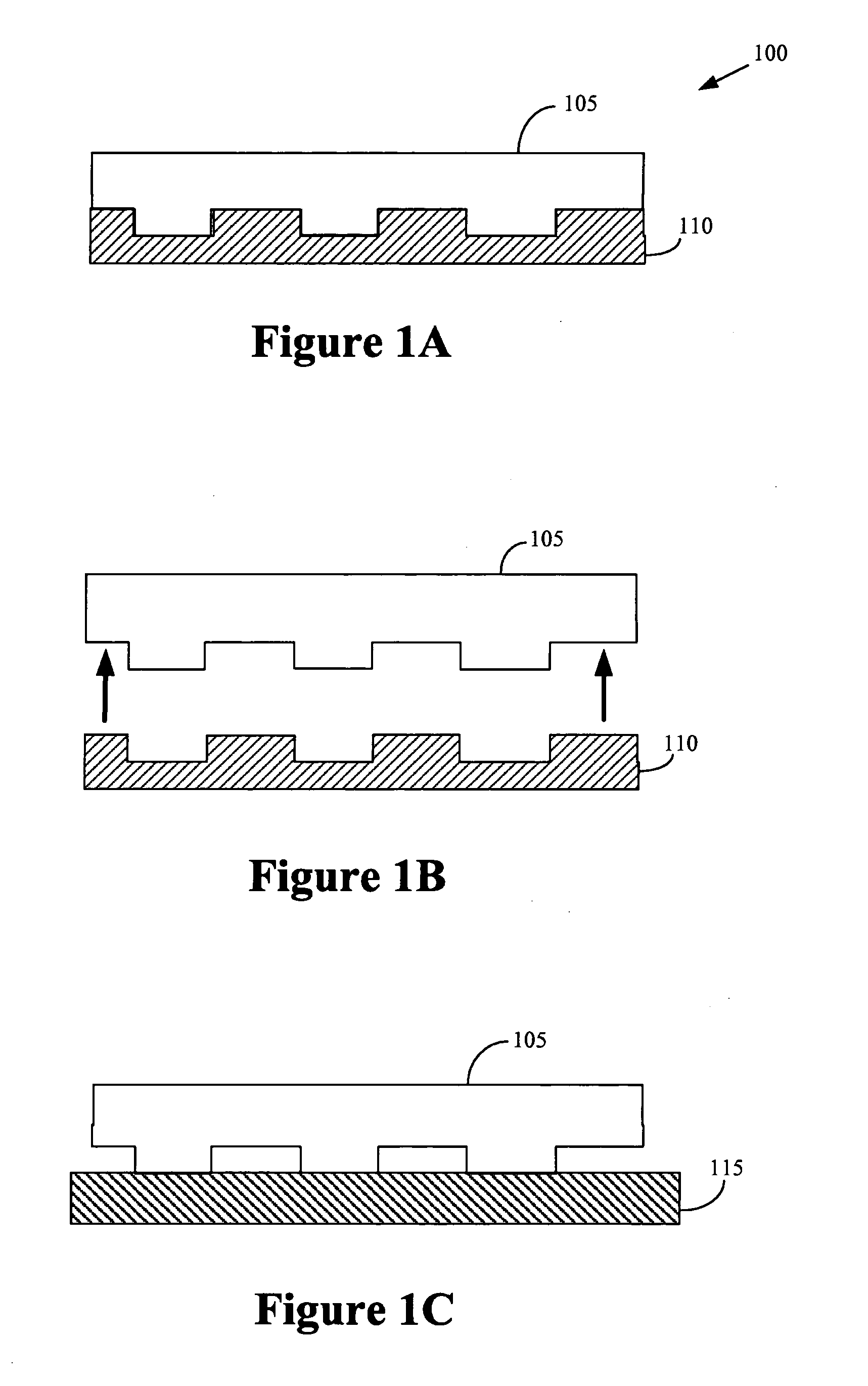

Head suspension having reduced heat deformation

InactiveUS6882506B2Reduce thermal deformationPrevent thermal deformationRecord information storageProtective measures for recording headsEngineeringProtection layer

A suspension is made of a suspension body of a stainless plate, a resin protective layer on one surface of the suspension body, a circuit pattern including read wiring and write wiring on the protective layer, and a metal layer provided on the other surface of the suspension body. In this arrangement, heat deformation of the suspension is alleviated when a write current is applied.

Owner:TOSHIBA STORAGE DEVICE CORP

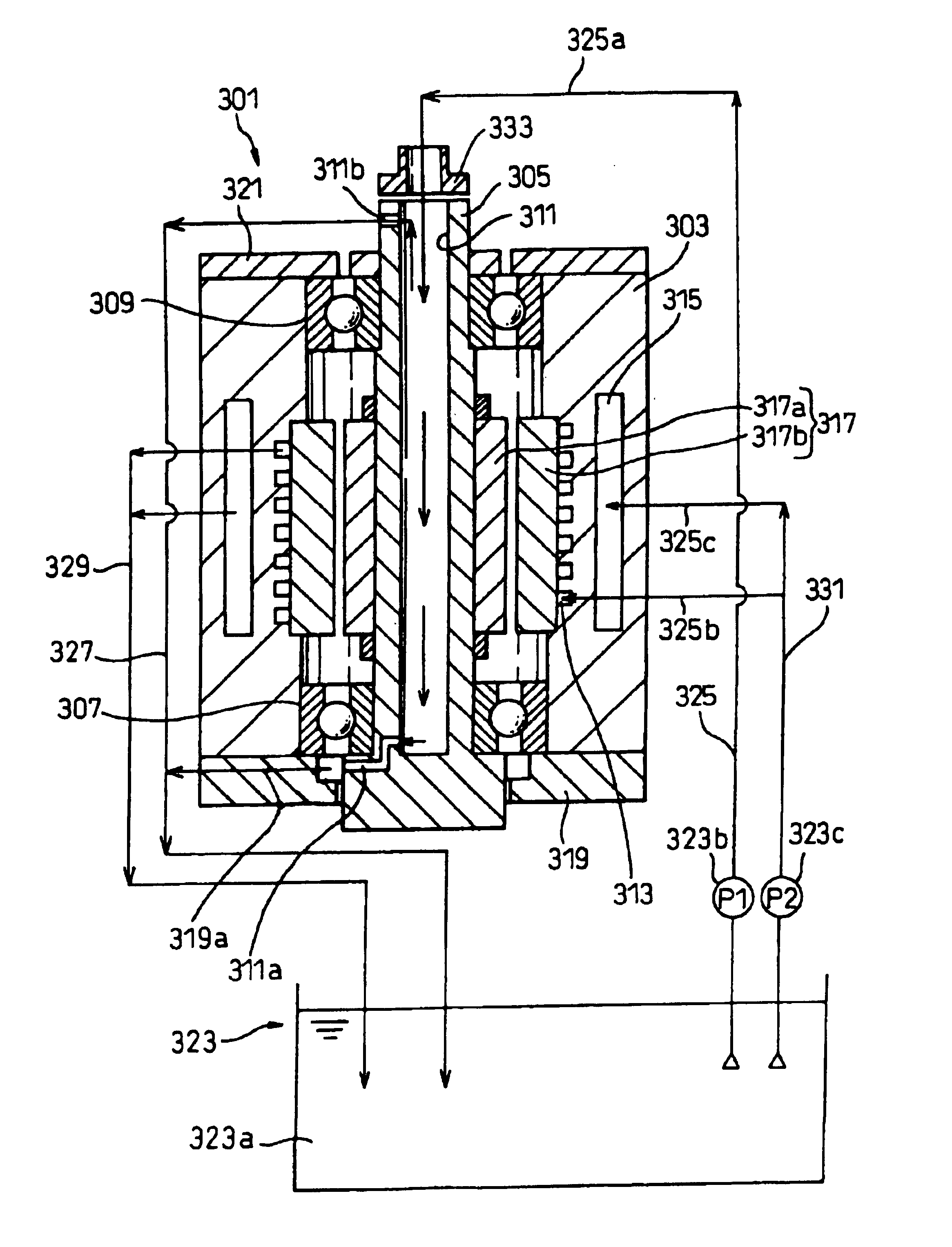

Rotating shaft apparatus

InactiveUS6913390B2Ensures rigidityLow heat generationCrankshaftsRolling contact bearingsBall bearingEngineering

A shaft 17 defines a front end portion 17a having a larger diameter and an opposite tail end portion 17b having a smaller diameter, the shaft 17 being rotatably supported by the housing 13 through a radial bearing 19 and a pair of angular ball bearings 21 at the front side large diameter portion 17a and the small diameter portion 17b, respectively.

Owner:MAKINO MILLING MASCH CO LTD

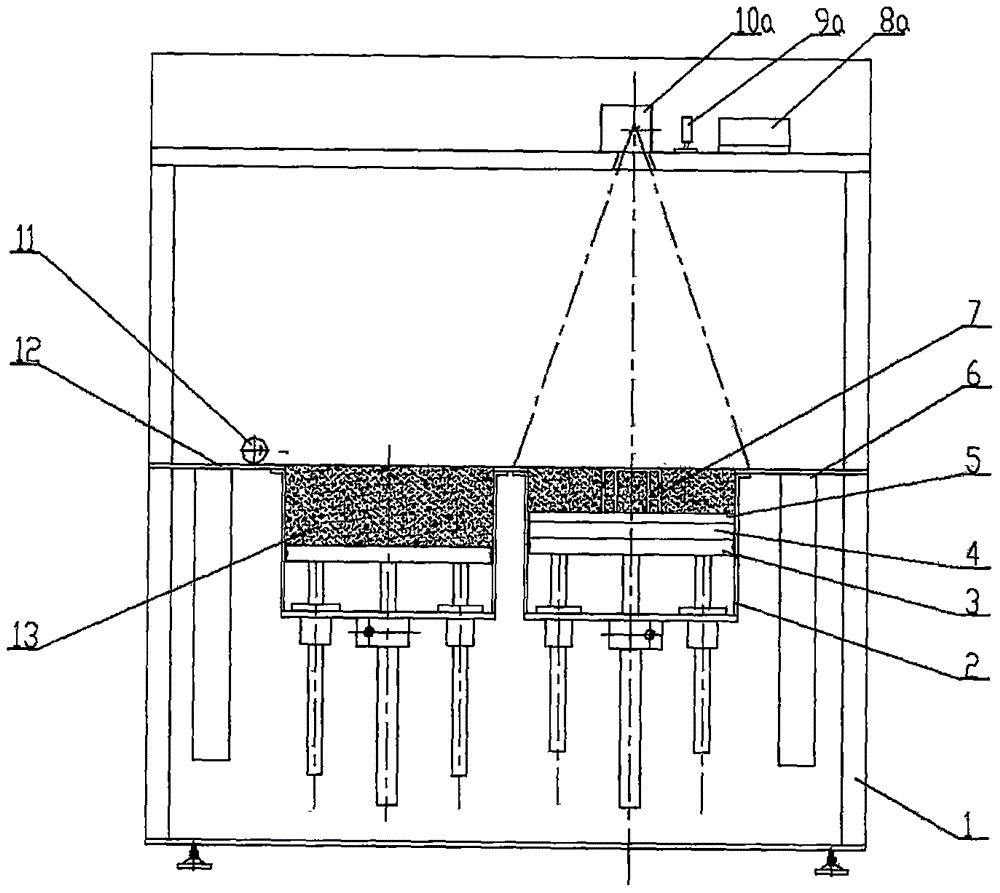

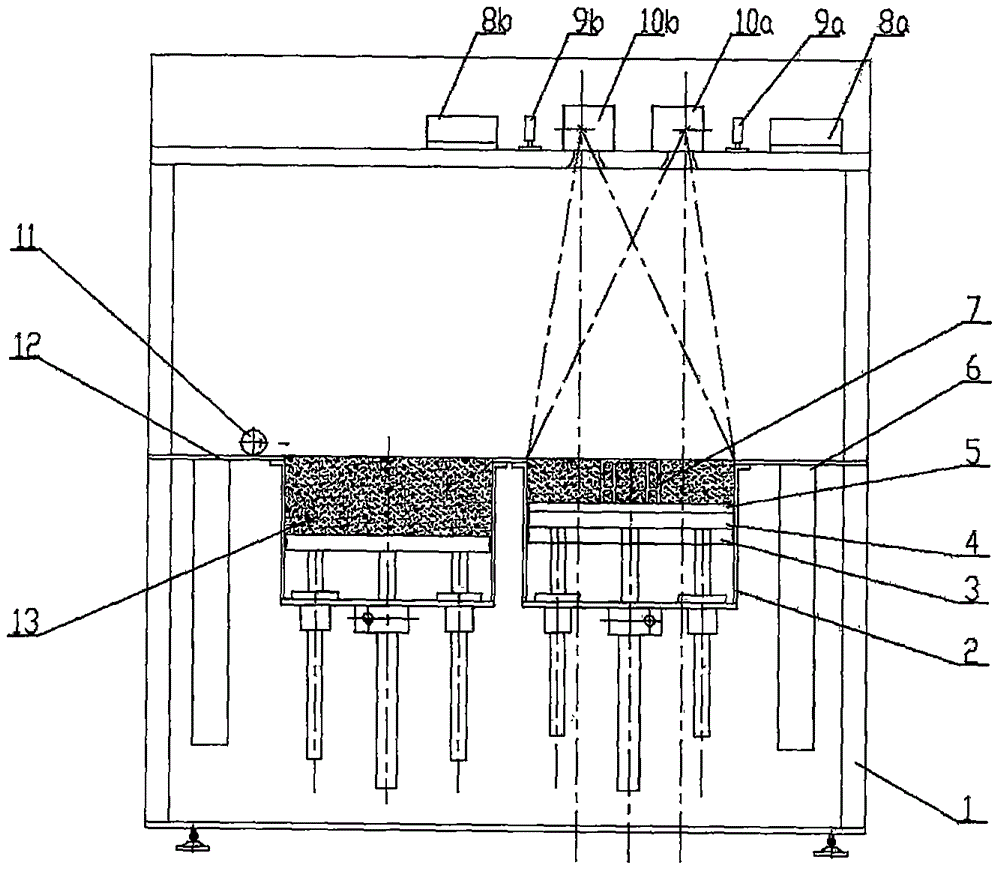

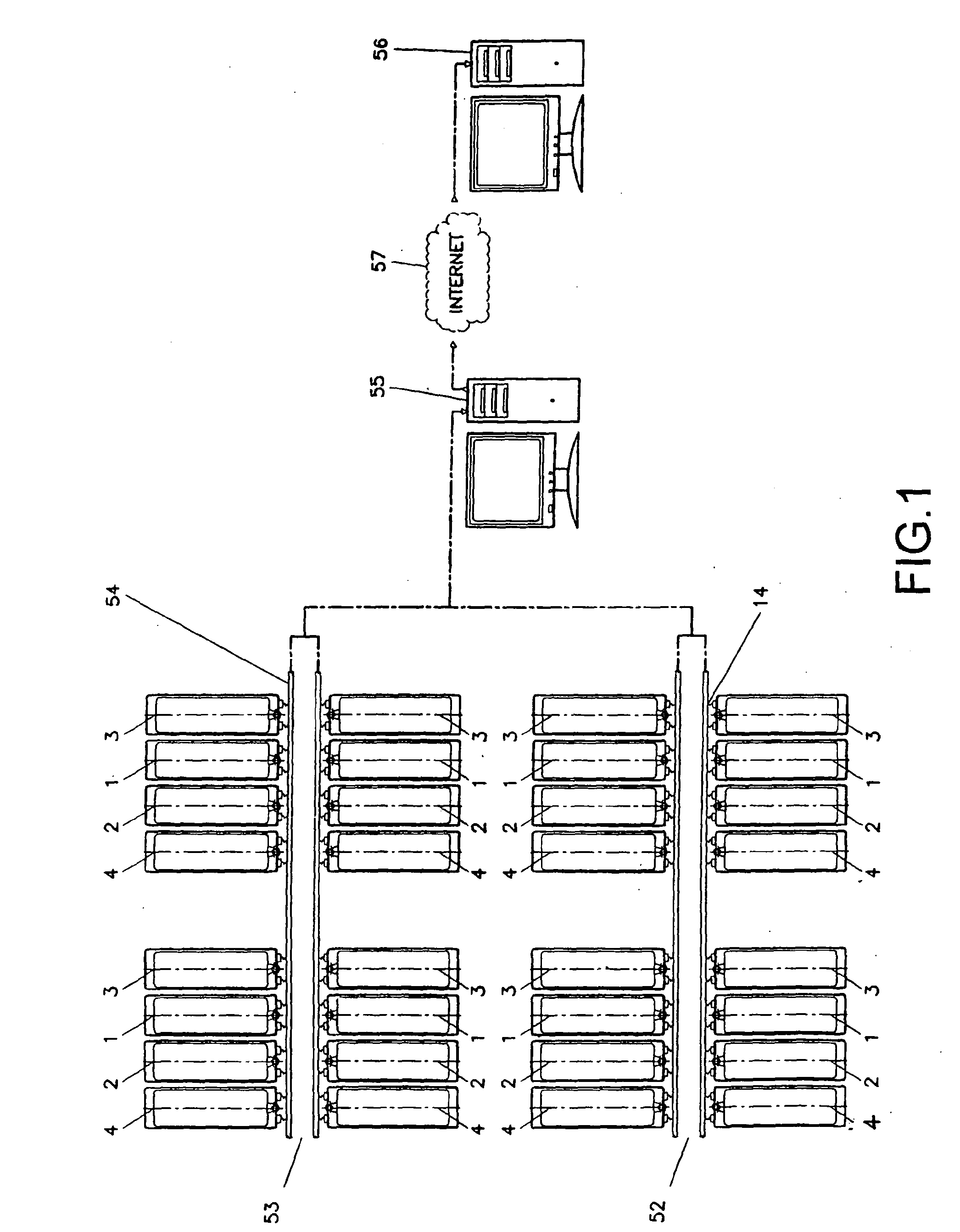

System for monitoring, control, and management of a plant where hydrometallurgical electrowinning and electrorefining processes for non ferrous metals.

InactiveUS20100258435A1Increase capacityMaximize continuityMachining electrodesCellsElectricityEngineering

A system to monitor, control and management of a plant where hydrometallurgical processes of electrowinning or electrorefining of non ferrous metals which enables measuring the process variables which comprises: at least one group of electrolytic cells, said cells having means for the collection and transmission of the variables of the process; a plurality of electrodes (5) installed in the interior of each electrolytic cell, making up, alternately, anodes and cathodes of basic cells; a plurality of electrode (5) hanger bars forming, alternately, hanger bars for electrical contact of anodes (20) and hanger bar for electrical contact of cathodes (18); a plurality of support electrical insulators (15) which are positioned in the upper portion of the lateral walls between two adjacent cells; a plurality of electrical bus bars (6) which are fitted on top of each support electrical insulator (15) and underneath the plurality of electrodes (5); a plurality of electrical spacer insulators (16) each spacer insulator (16) having monolithic non contact chairs (17) allowing installation, alternately, of hanger bar of anodes (20) and hanger bar of cathodes (18); a plurality of acid mist collection hoods (7); in which the constituting elements have at least one multifunctional chamber (12) which lodges circuits and / or electronic sensors (11) for measuring process variables which enable to monitor, control and manage the productive process.

Owner:ANCOR TECMIN

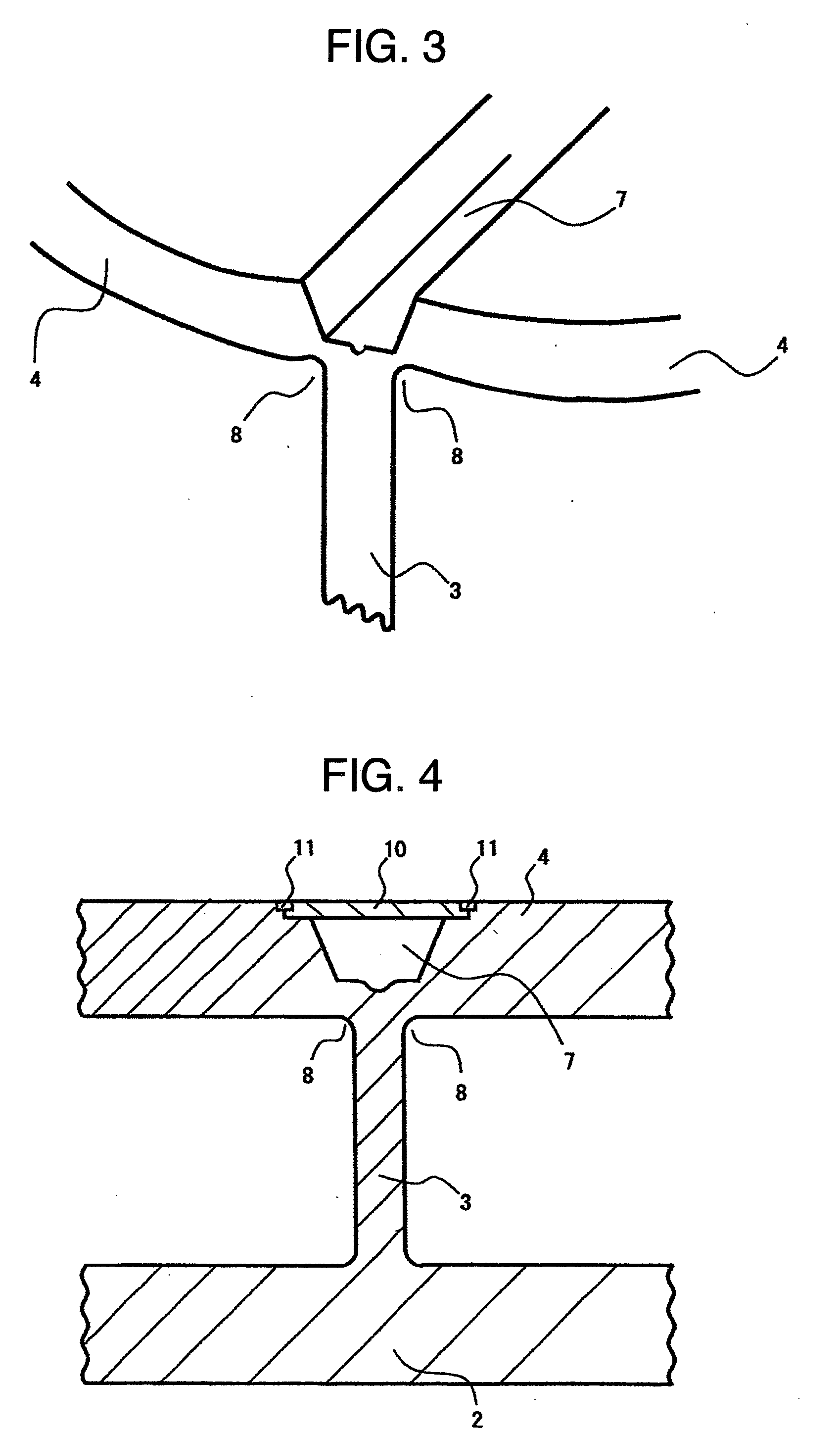

Welding slot sealing structure and welding method

InactiveUS20080237195A1Reduces thermal distortionPerformance degradationTurbinesPump componentsDistortionLaser beams

Blades are connected to the surface of a disk and slots are formed in the surface of a shroud, which is opposite from the other surface of the shroud where the blades are to be welded. The blades are arranged on the opposite surface from the slots and a laser beam is applied from the surface in which the slots are formed, to weld the shroud and the blades. If powder is melted and put in the slots formed for welding in the shroud to fill the slots, thermal distortion occurs. On the other hand, if the slots are left empty, a problem of degrading the fluid performance arises. To solve these problems, components are installed on the surfaces of the slots on the opposite side from the blades after the blades and the shroud in which the slots are formed are welded. Alternatively, the slots are filled with a material different from that of the shroud, such as a resin. With this configuration, distortion caused by welding heat can be reduced without degrading the fluid performance. This method can be applied to the case where the blades are formed on the surface of the shroud, not on the surface of the disk, and to the slots formed in the disk after the blades and the disk are laser-welded.

Owner:HITACHI LTD

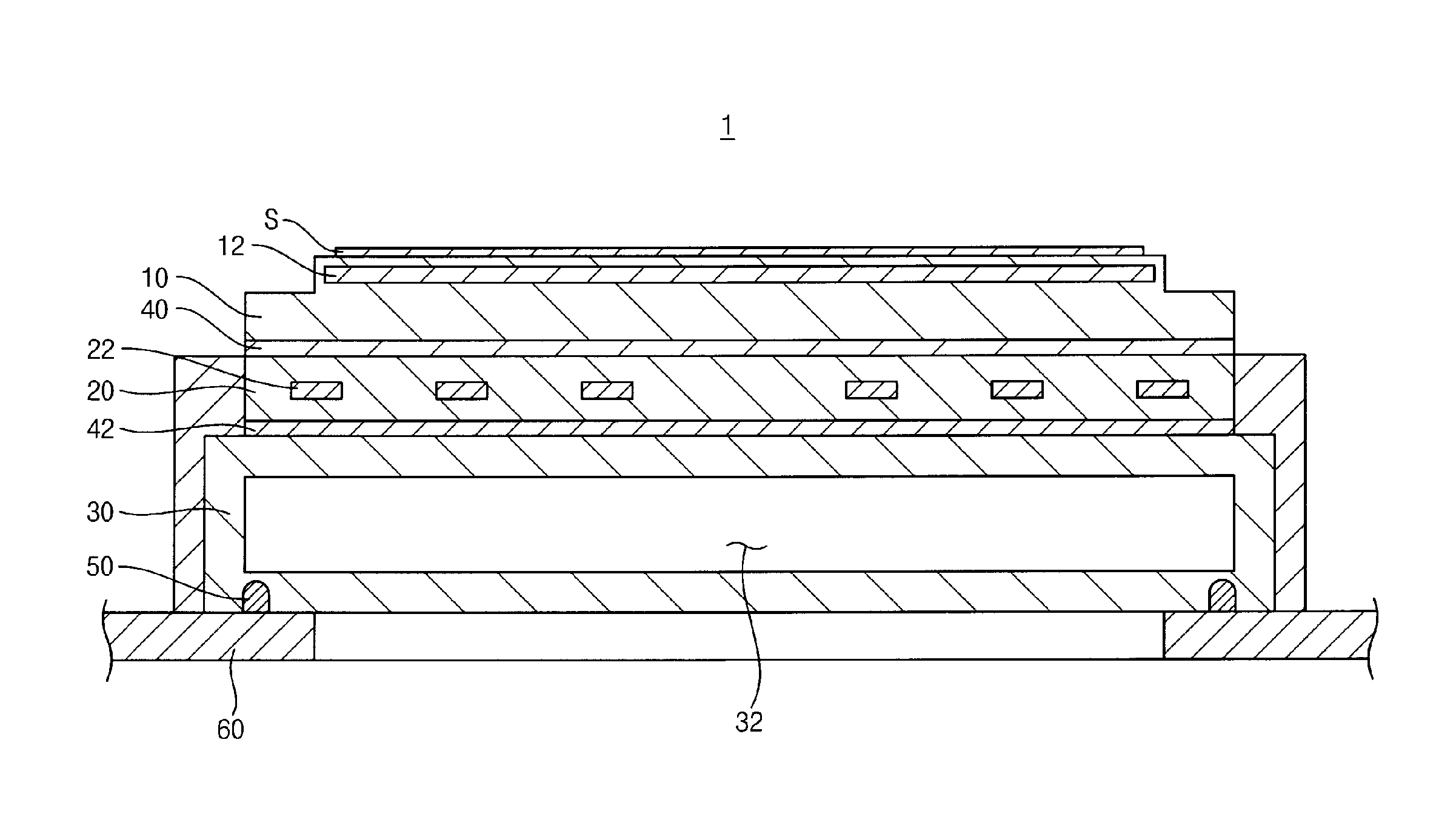

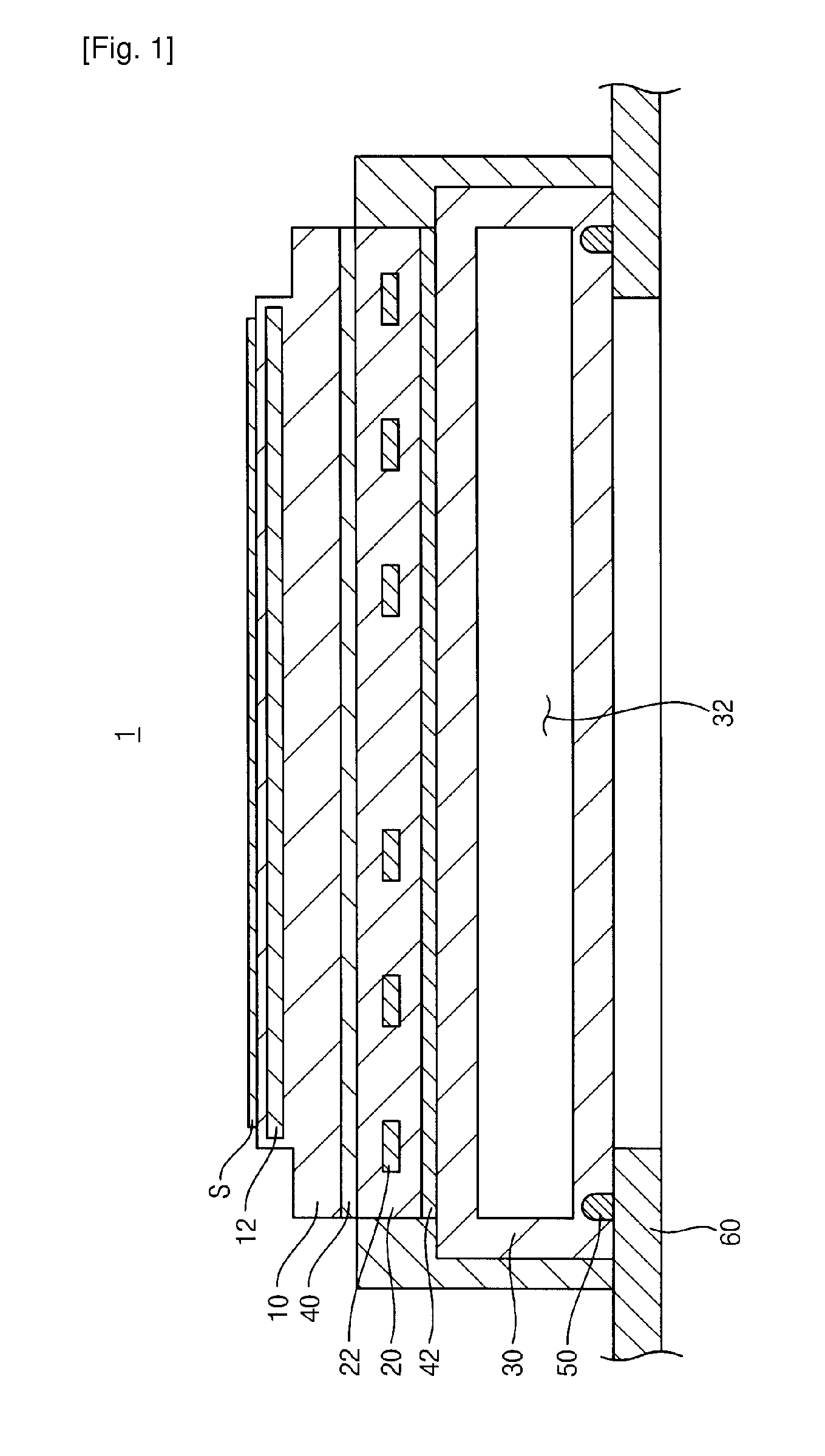

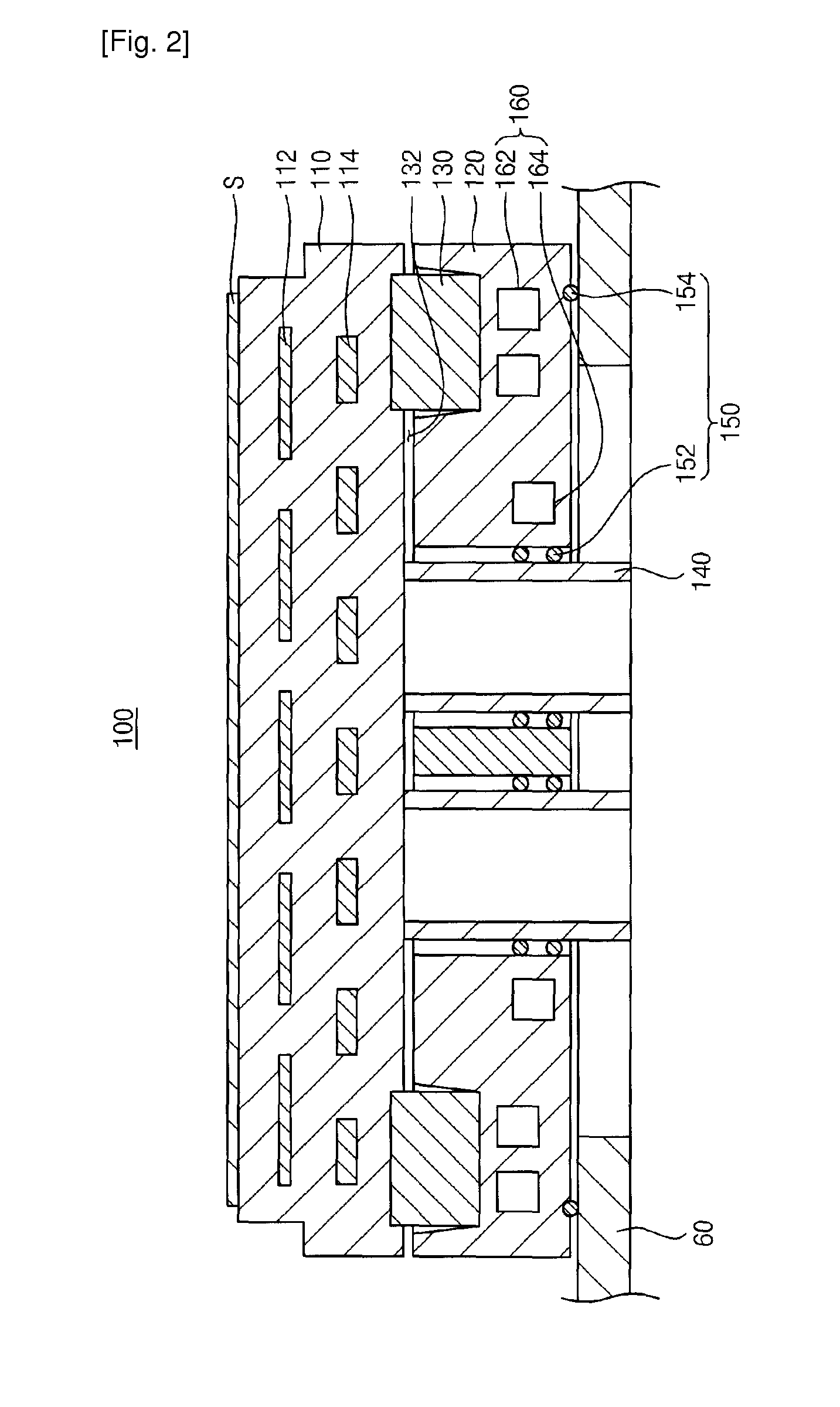

Unit for supporting a substrate and apparatus for processing a substrate having the same

InactiveUS20100193491A1Heat transferHeating effectively and uniformlyElectric heatingSemiconductor/solid-state device manufacturingBiomedical engineeringHeat transfer

A substrate support unit of a substrate processing apparatus includes a first support member, a second support member, a buffer member and a tube. The first support member has an electrode and a heater built-in and supports the substrate. The second support member is disposed beneath the first support member to support the first support member. The buffer member is disposed between the first support member and the second support member to form an air gap between the first support member and the second support member so as to reduce heat transfer between the first support member and the second support member. The tube is connected with a lower surface of the first support member. Further, the tube extends through the second support member and receives lines for applying power to the electrode and the heater.

Owner:KOMICO

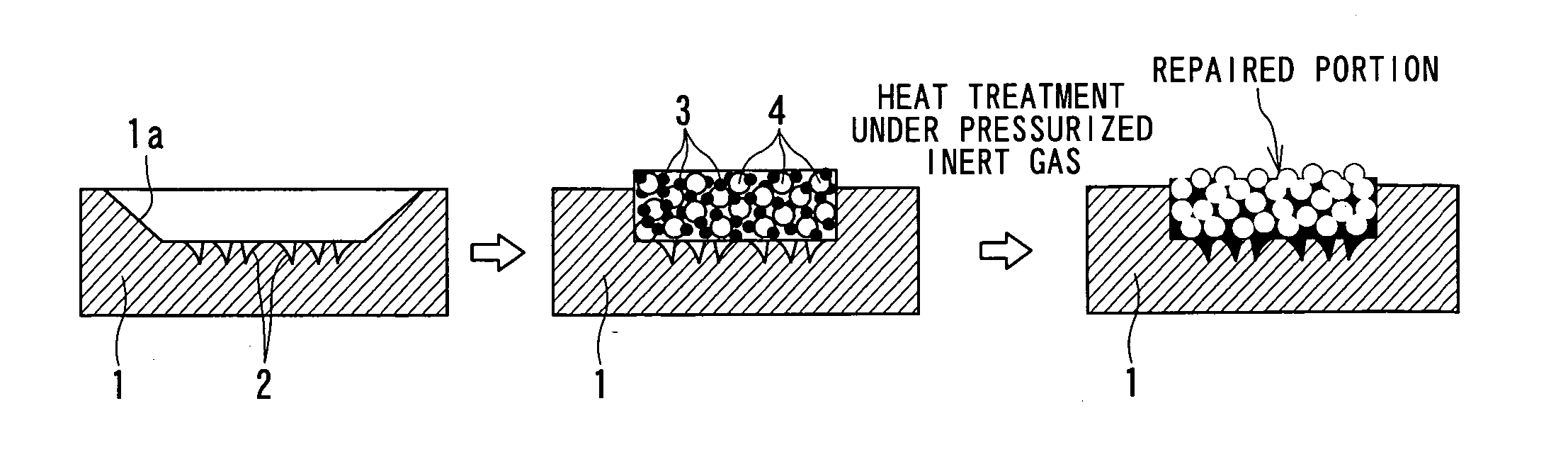

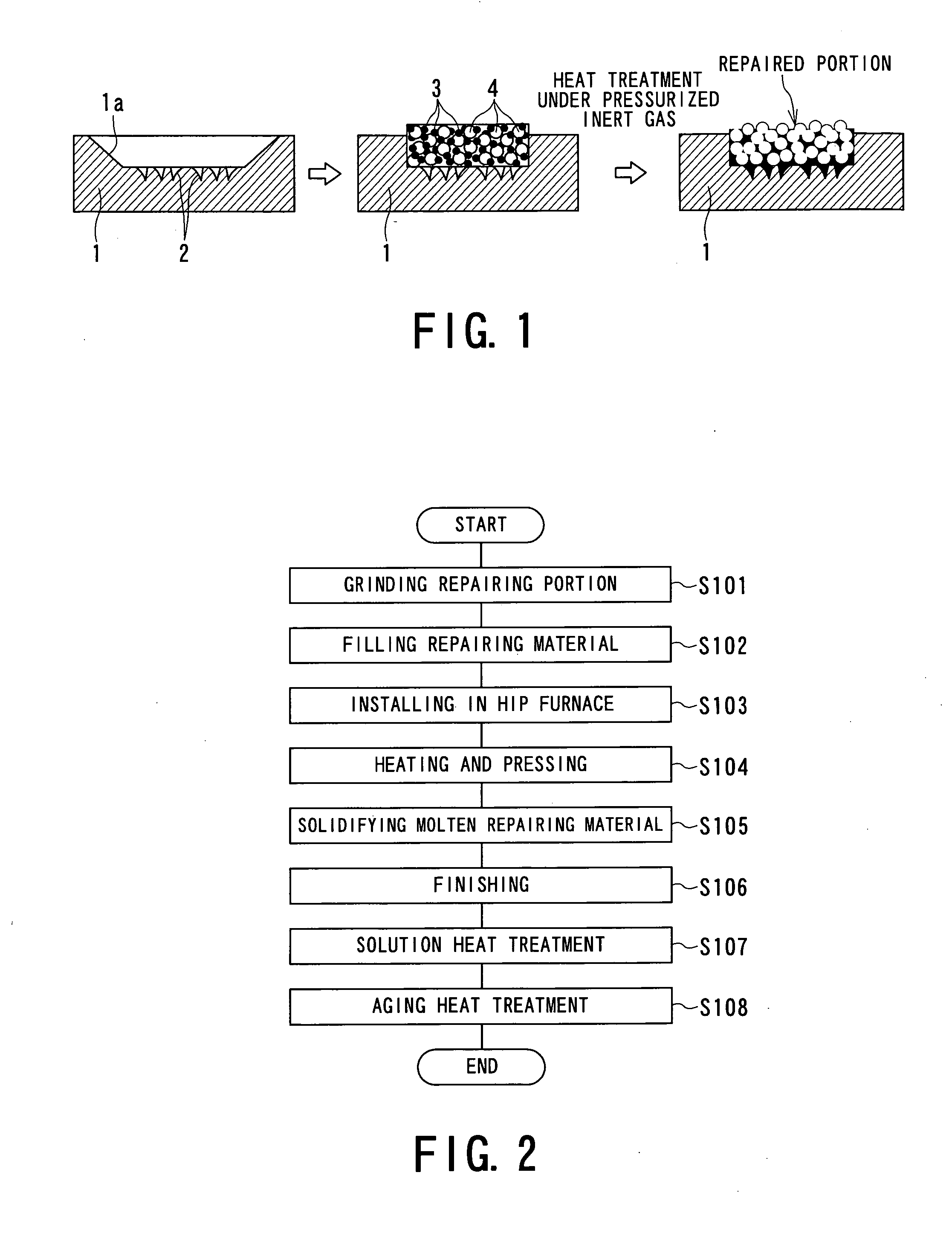

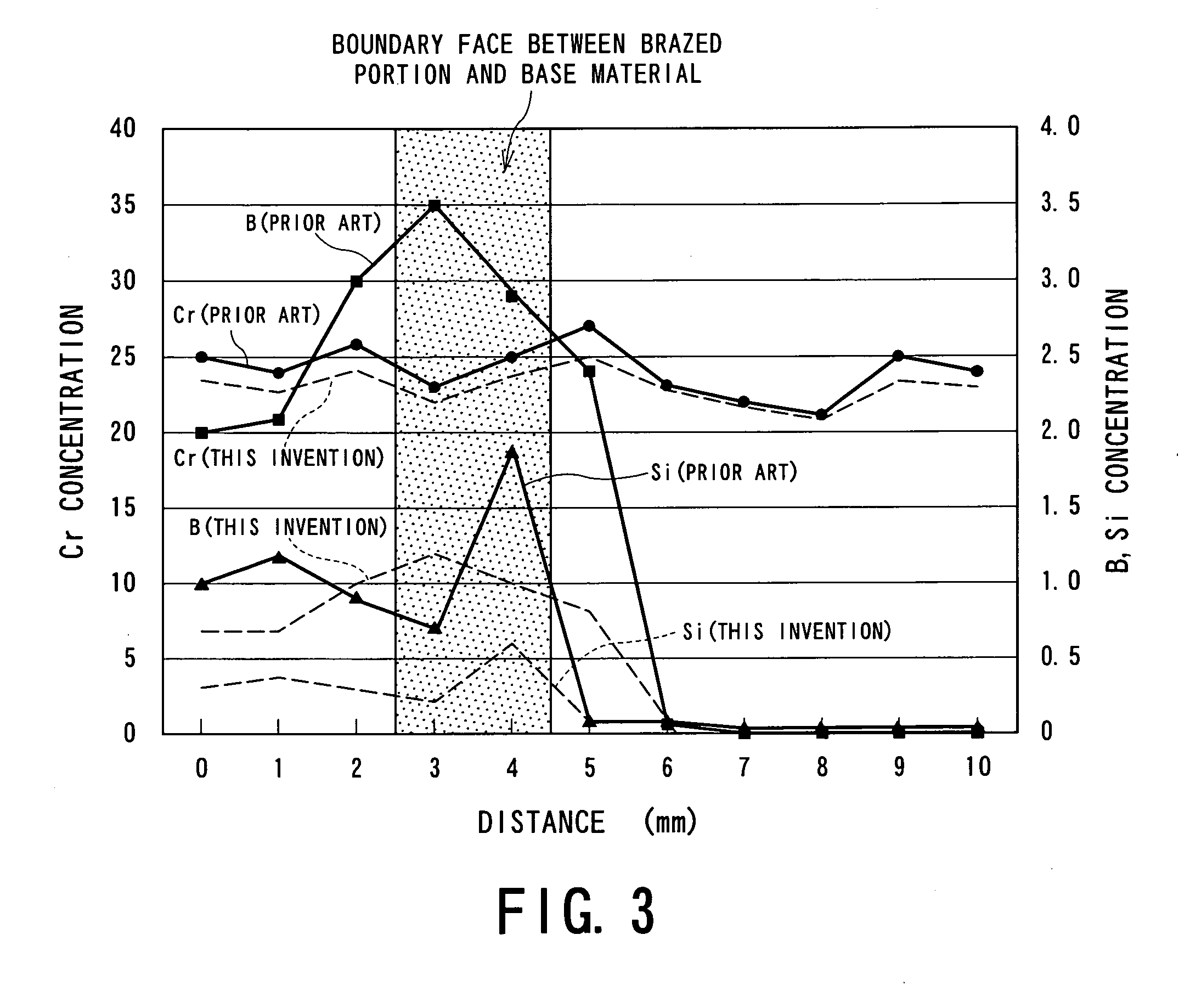

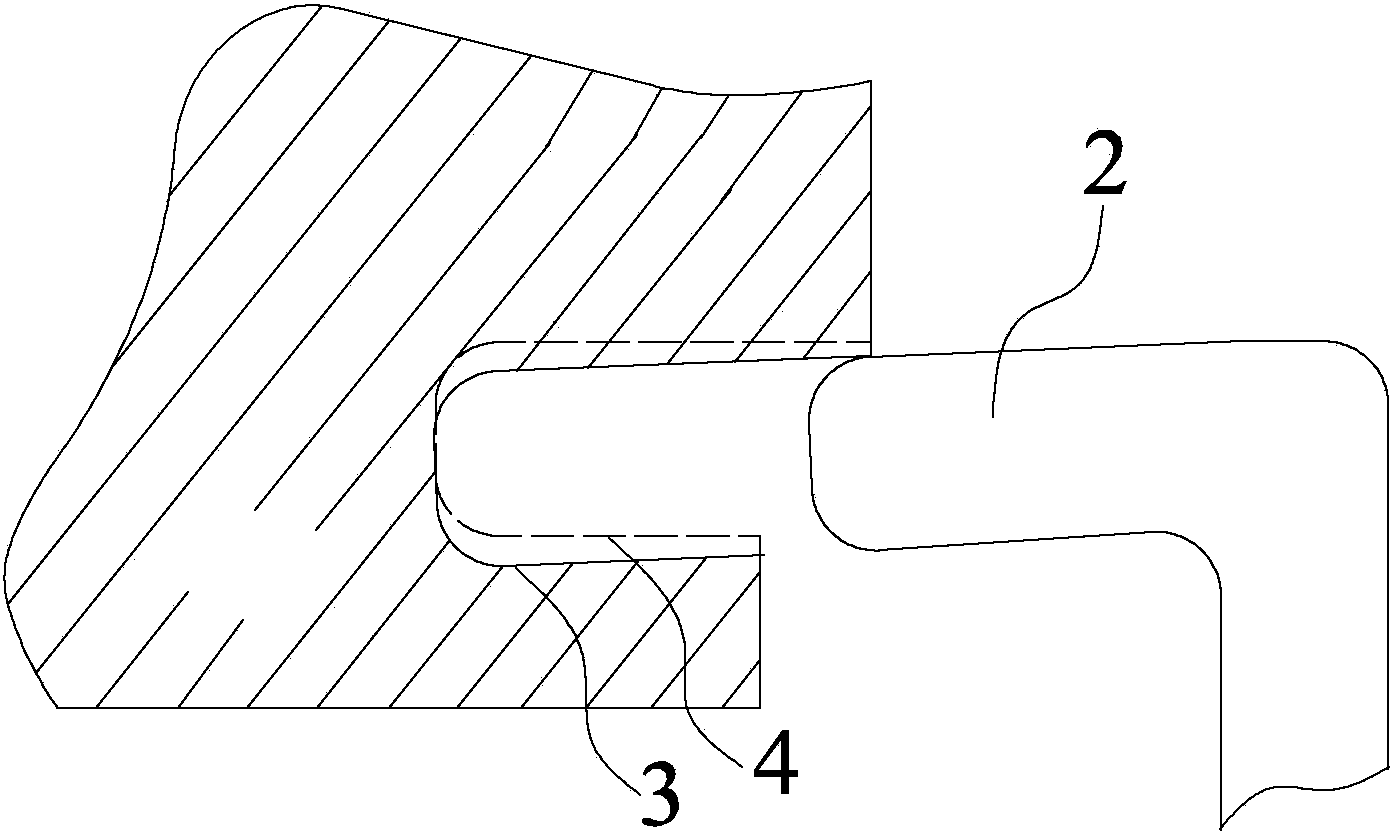

Method of regenerating stator vane of gas turbine and gas turbine

InactiveUS20070039177A1Small overall deformationEfficient regenerationTurbinesSoldering apparatusGas turbinesMaterials science

A method of regenerating gas-turbine stator vane comprising the steps of: grinding the oxidized layer and the cracks 2 formed at surface portion so that a part of the cracks 2 remains; filling an equivalent material and a brazing material 4 into the ground portion, the equivalent material 3 having an equality with the base material 1 for the stator vane, and the brazing material 4 having a melting point lower than that of the equivalent material 3; heat treating the filled portion under pressurized inert gas atmosphere so as to melt the brazing material; performing brazing treatment by diffusing the molten brazing material into the cracked portions. According to the above method, the stator vane occurred with material deterioration and damages or the like due to operation of a gas turbine can be efficiently regenerated to provide a high quality without requiring to completely grinding and removing the cracks including a closed crack formed at surface of the stator vane.

Owner:KK TOSHIBA

Operative instrument

InactiveUS20100305558A1Sufficient electricityIncreased durabilitySurgical instruments for heatingSurgical forcepsForcepsOperative instrument

An operative instrument includes forceps having a treating section for treating an anatomy at an extremity and being provided with a heat-generating body for generating heat to be provided to the anatomy and a power supply unit for supplying electric power to the heat-generating body of the forceps. The operative instrument raises the temperature of the heat-generating body by supplying substantially constant electric power to the heat-generating body. Therefore, coagulation and incision of the anatomy can be performed satisfactorily.

Owner:OLYMPUS CORP

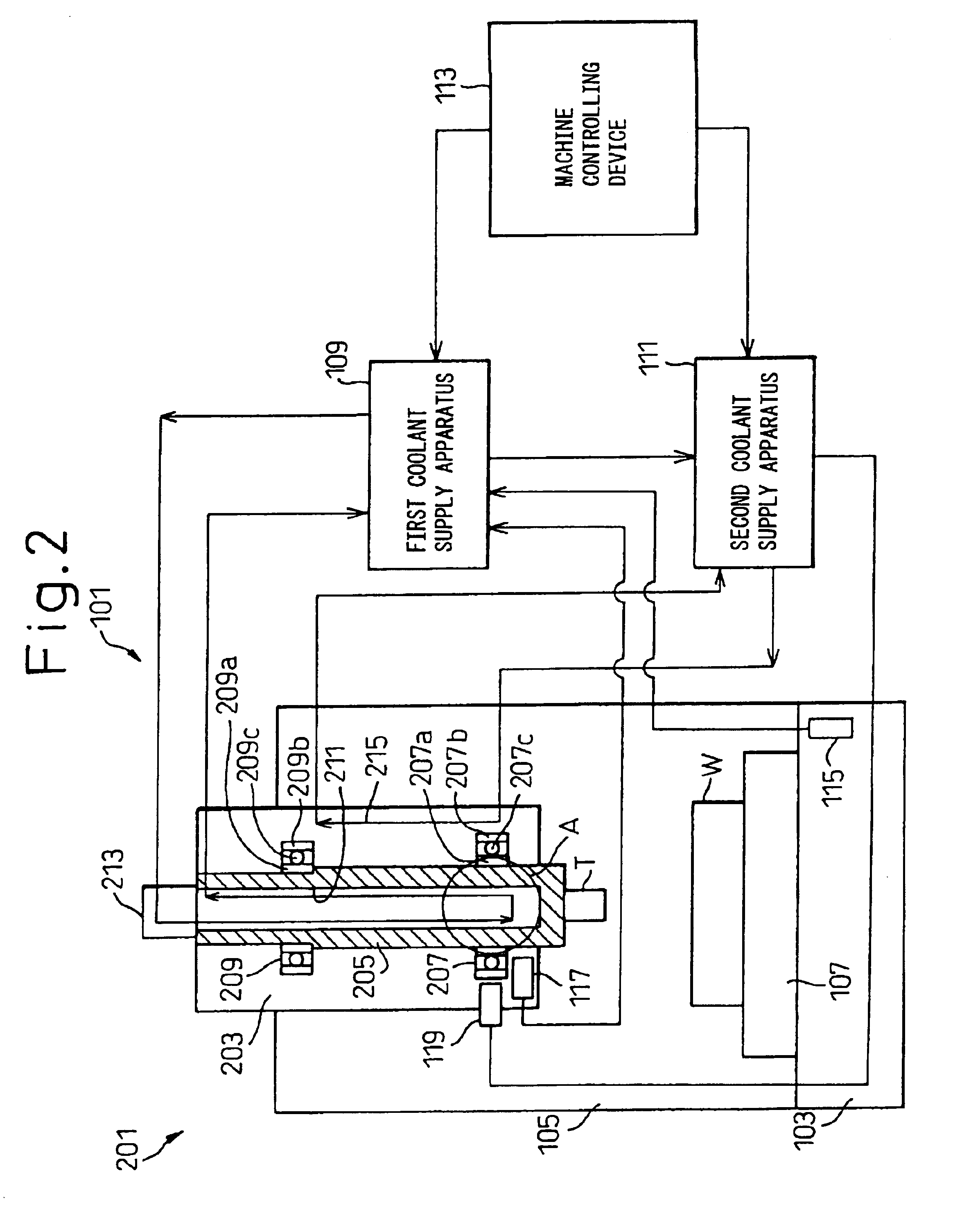

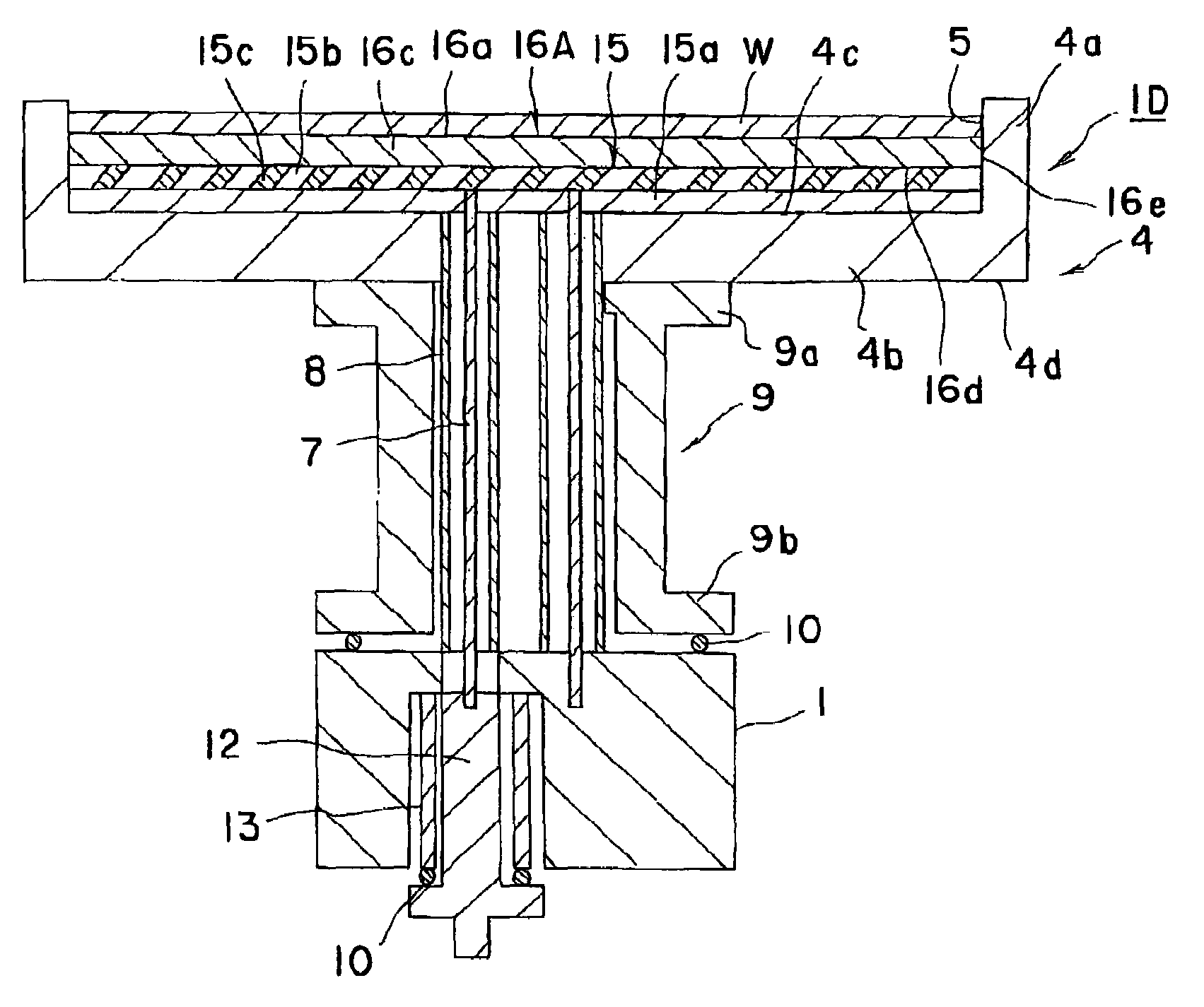

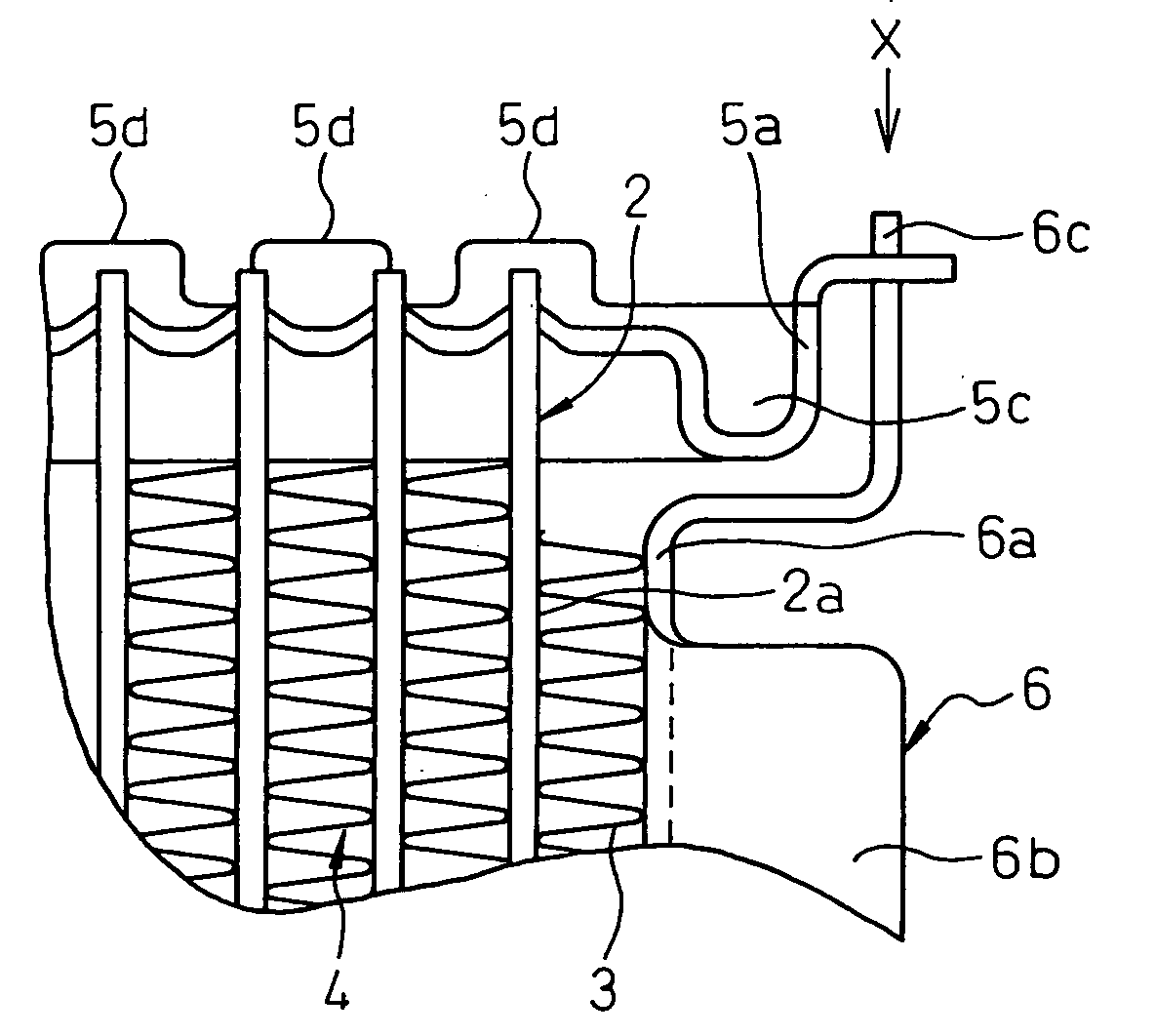

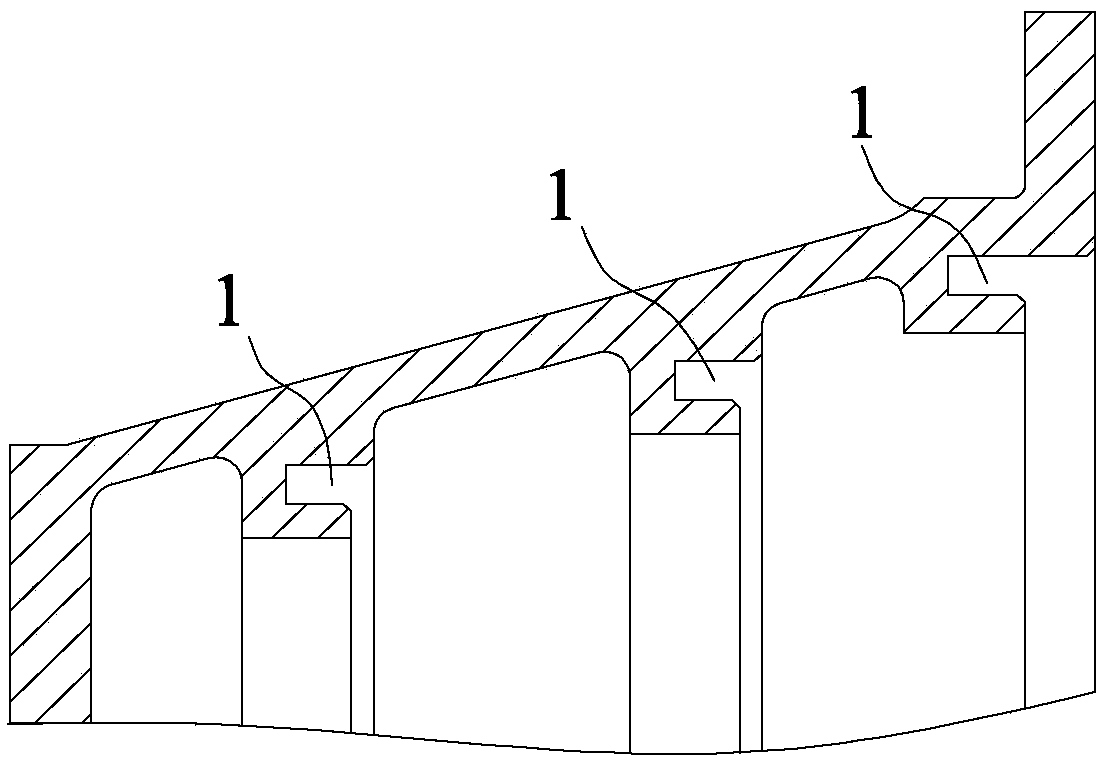

Heating systems

ActiveUS7044399B2High production costIncrease production costHeater elementsAir heatersMetallurgyThermal deformation

A heating system 1 has a ceramic substrate 2 having a mounting face 2a for mounting an object W, a back face 2b and a side face 2c; a heating means 3 for generating heat from the mounting face 2a of the ceramic substrate 2; and a plate-shaped supporting metal member 4 for supporting the back face 2b of the ceramic substrate 2. According to the system, the thermal deformation of the mounting face upon heating over time may be reduced and the flatness of the object may be maintained at a low value. It is further possible to impart a mechanical strength to the heater sufficient for its handling and to reduce the production cost.

Owner:NGK INSULATORS LTD

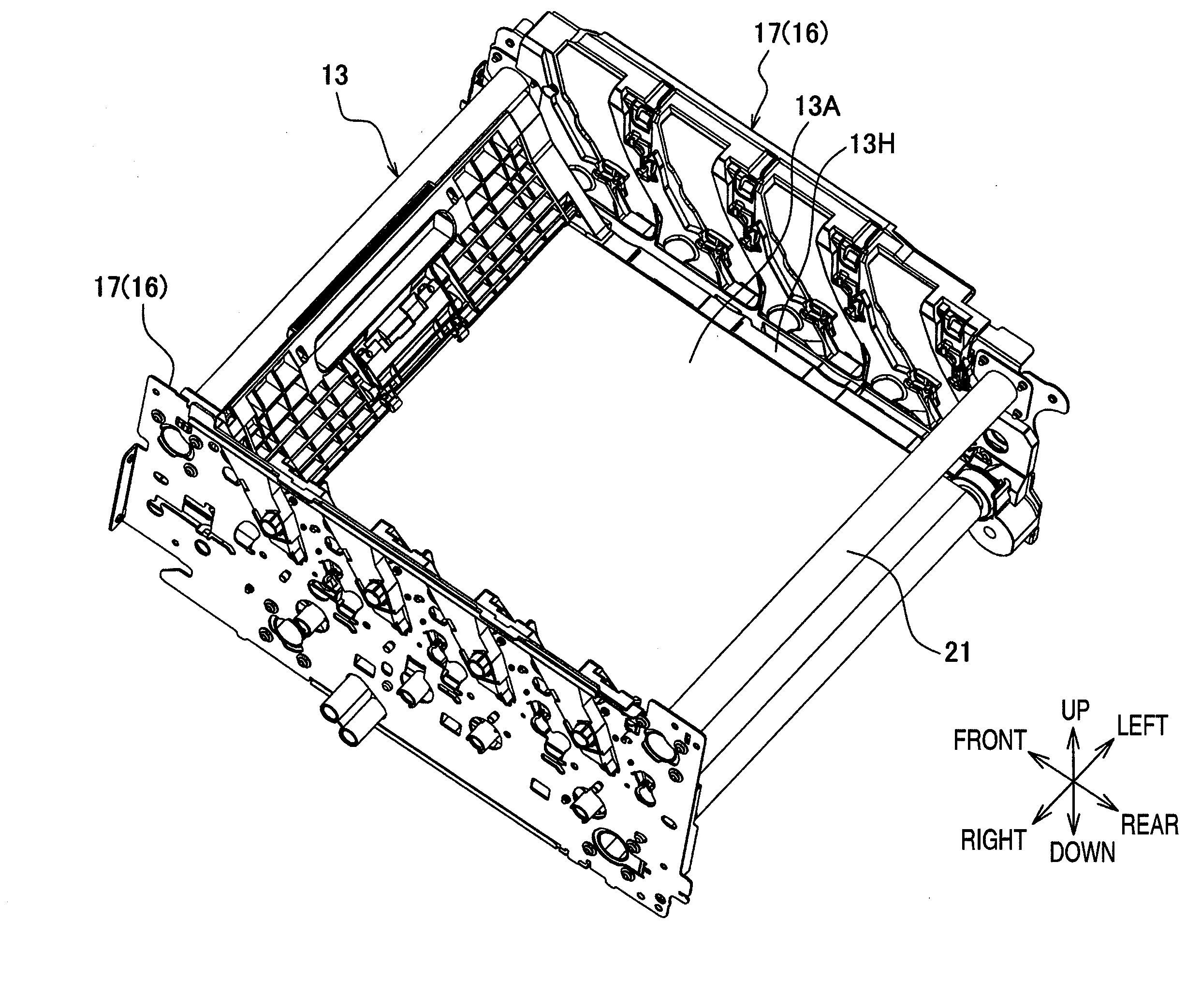

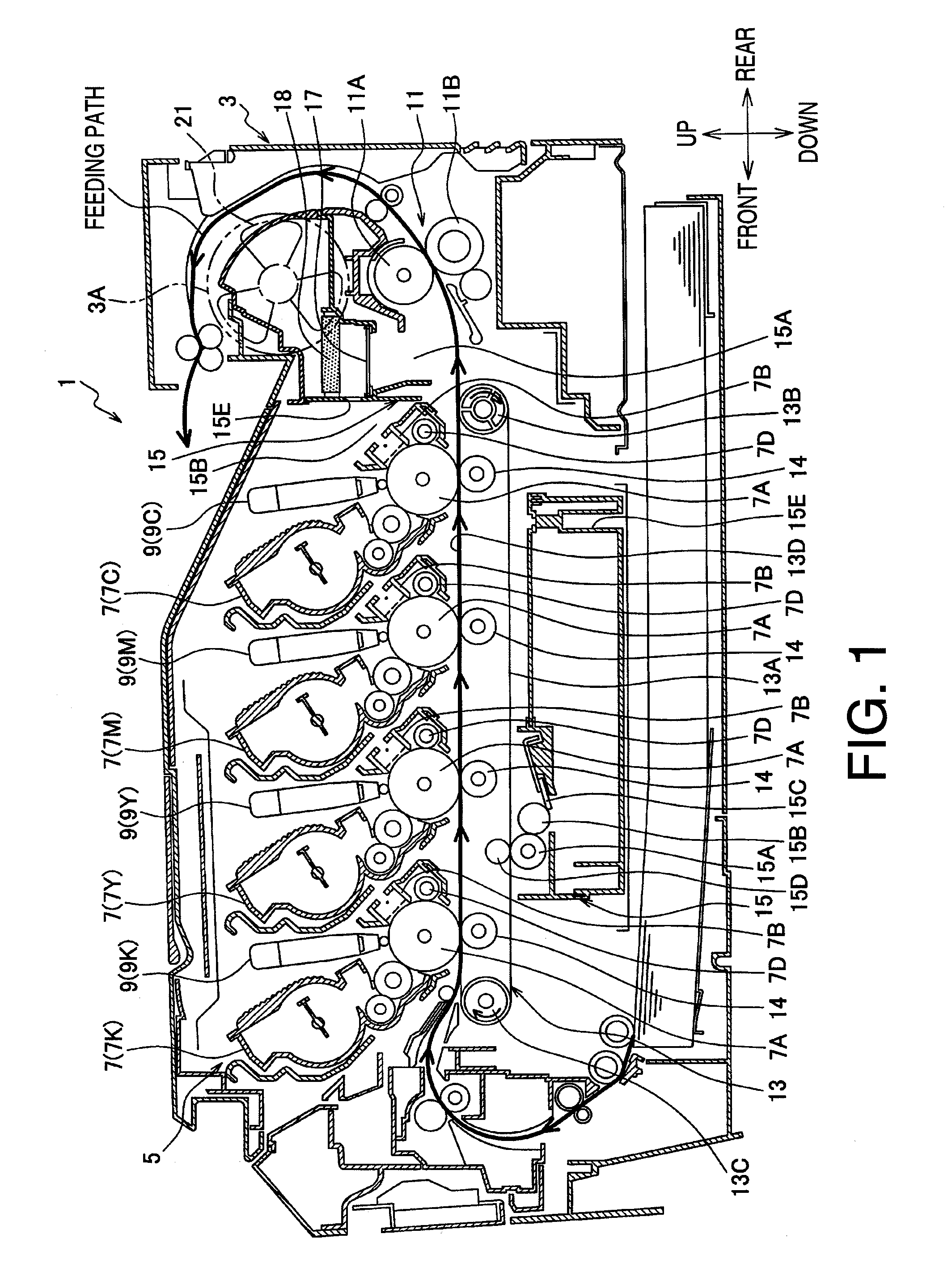

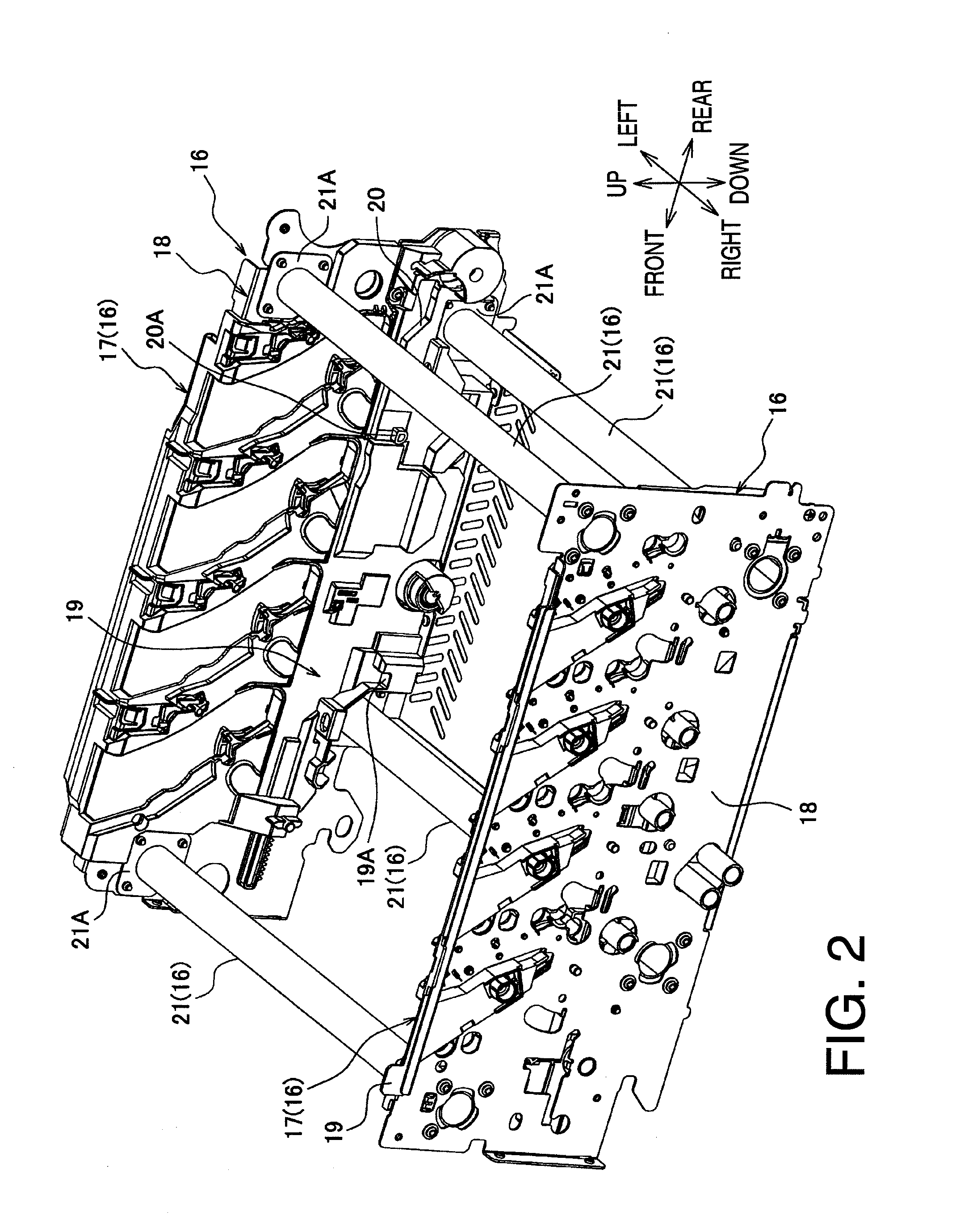

Image forming apparatus

ActiveUS20100080612A1Large clamping forceReduce the amount requiredElectrographic process apparatusImage formationEngineering

An image forming apparatus is provided. The image forming apparatus includes a plurality of detachable unit components and a frame assembly to hold the detachable unit components in predetermined positions in the image forming apparatus. The frame assembly includes a pair of metal frames and a pair of resin frames, each of which is attached to one of the metal frames. Each of the metal frames includes a first positioning structure, which corresponds to an original point of the metal frame, a first fixing structure, a second positioning structure, wherein each of the resin frames includes, a first positioning structure, which corresponds to an original point of the resin frame, a fixing structure, a second positioning structure, and a plurality of pressing pieces, by which the resin frame is pressed against one of the metal frame.

Owner:BROTHER KOGYO KK

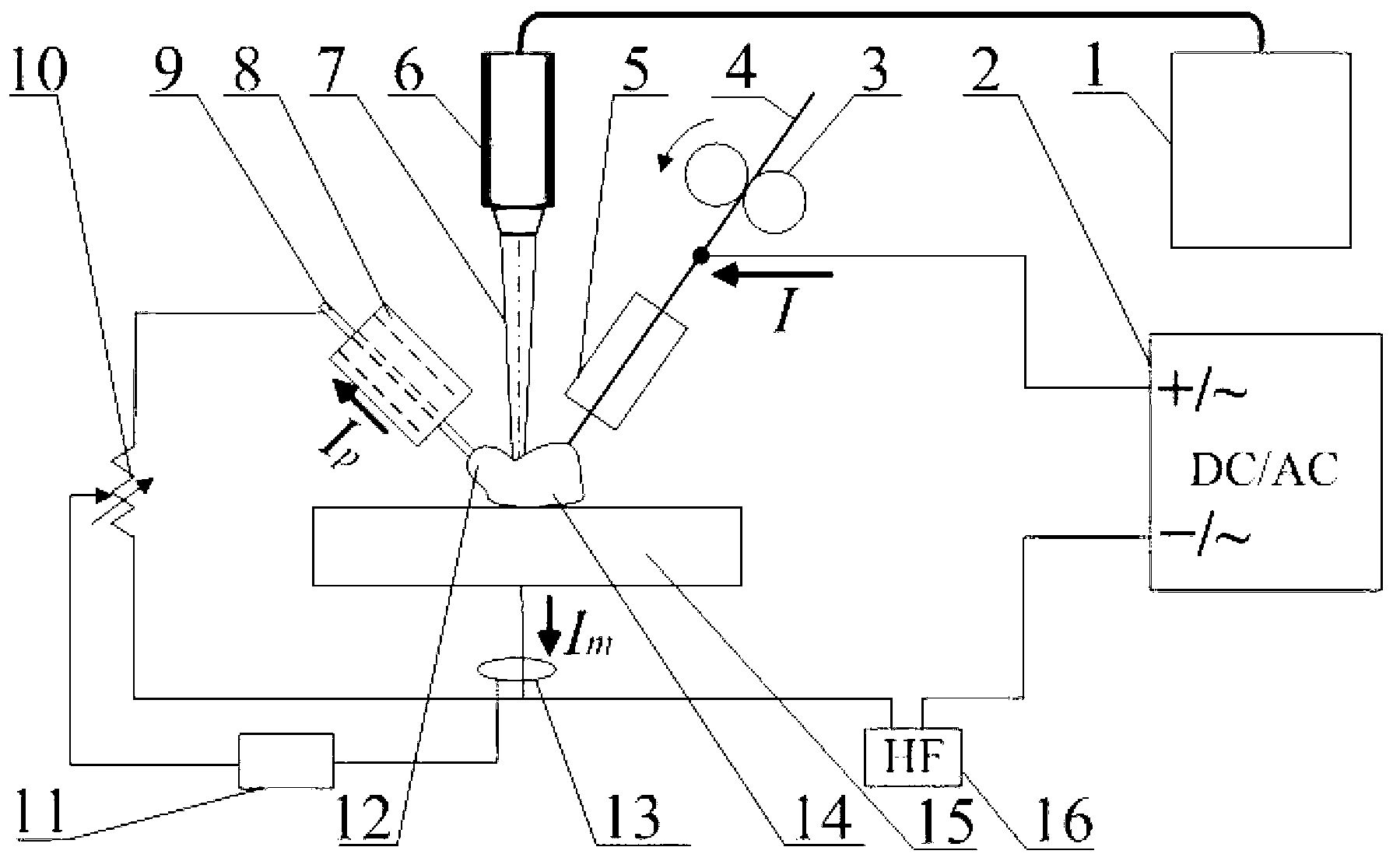

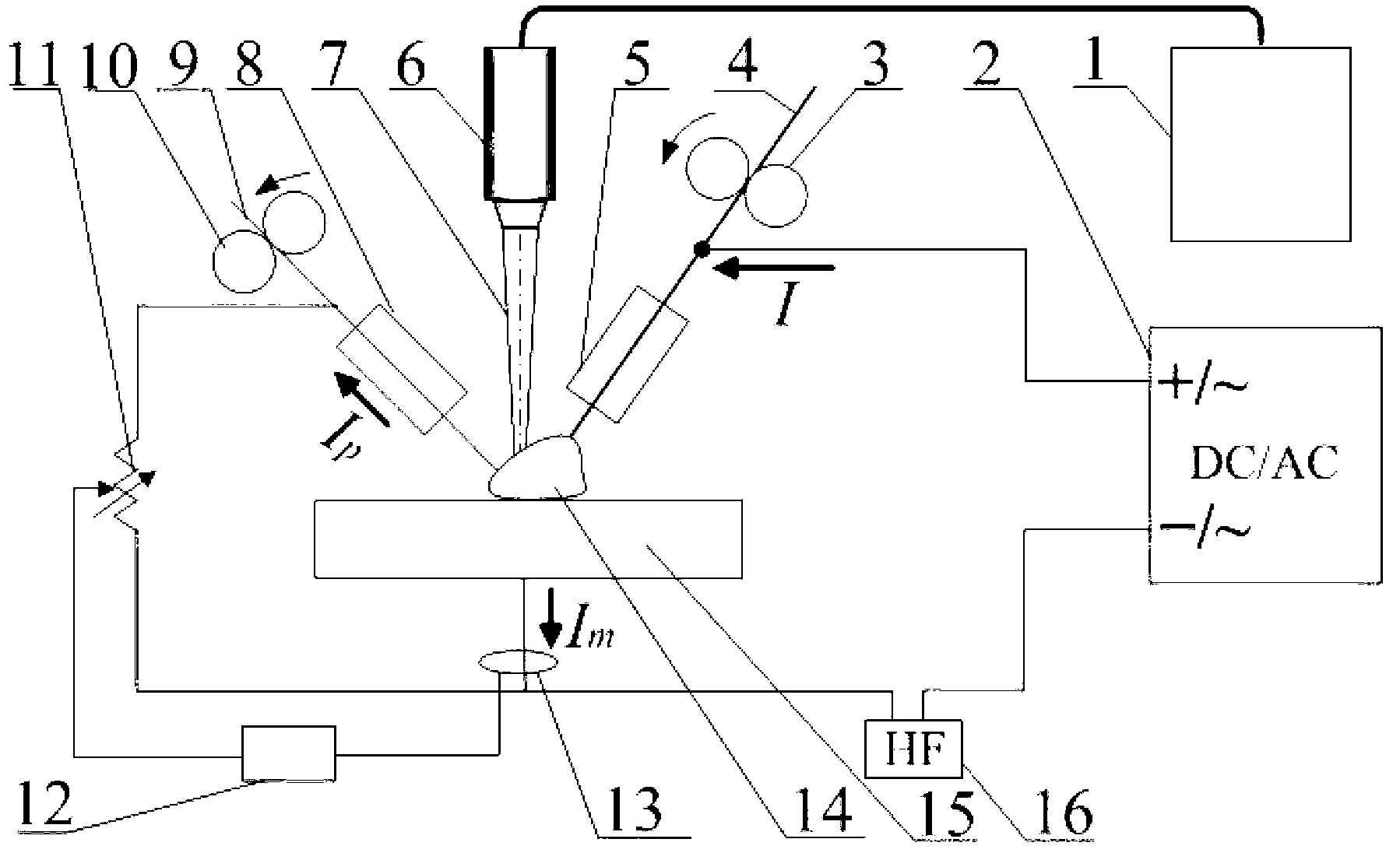

Laser-arc composite welding device based on heat input control and welding method

ActiveCN103071935ALow heat inputReduce thermal deformationLaser beam welding apparatusHeat-affected zoneInput control

The invention provides a laser-arc composite welding device based on heat input control and a welding method. The laser-arc composite welding device based on the heat input control comprises a laser device, a laser head, an arc-welding power supply, a main consumable-electrode welding gun and a wire feeding mechanism and also comprises a bypass welding gun and a rheostat, wherein the laser head is connected with the laser device, the laser head is arranged above a workpiece, the main consumable-electrode welding gun and the bypass welding gun are symmetrically placed at both sides of a laser beam formed by the laser head, the main consumable-electrode welding gun is connected with the positive pole of the arc-welding power supply, the electrifying end of the workpiece is connected with the negative pole of the arc-welding power supply, and the bypass welding gun is connected with the negative pole of the arc-welding power supply by the rheostat. According to the laser-arc composite welding device based on the heat input control and the welding method, the welding heat input of a composite laser-arc heat source can be controlled, the heat affected zone and the welding deformation are reduced, and the metallurgical performance and the microstructure of a welding seam are improved. The laser-arc composite welding device based on the heat input control and the welding method not only are suitable for the fusion welding of homogeneous metal but also are suitable for the braze (fusion) welding of dissimilar metal, such as aluminum or steel and magnesium or steel.

Owner:哈尔滨哈船特装科技发展有限公司

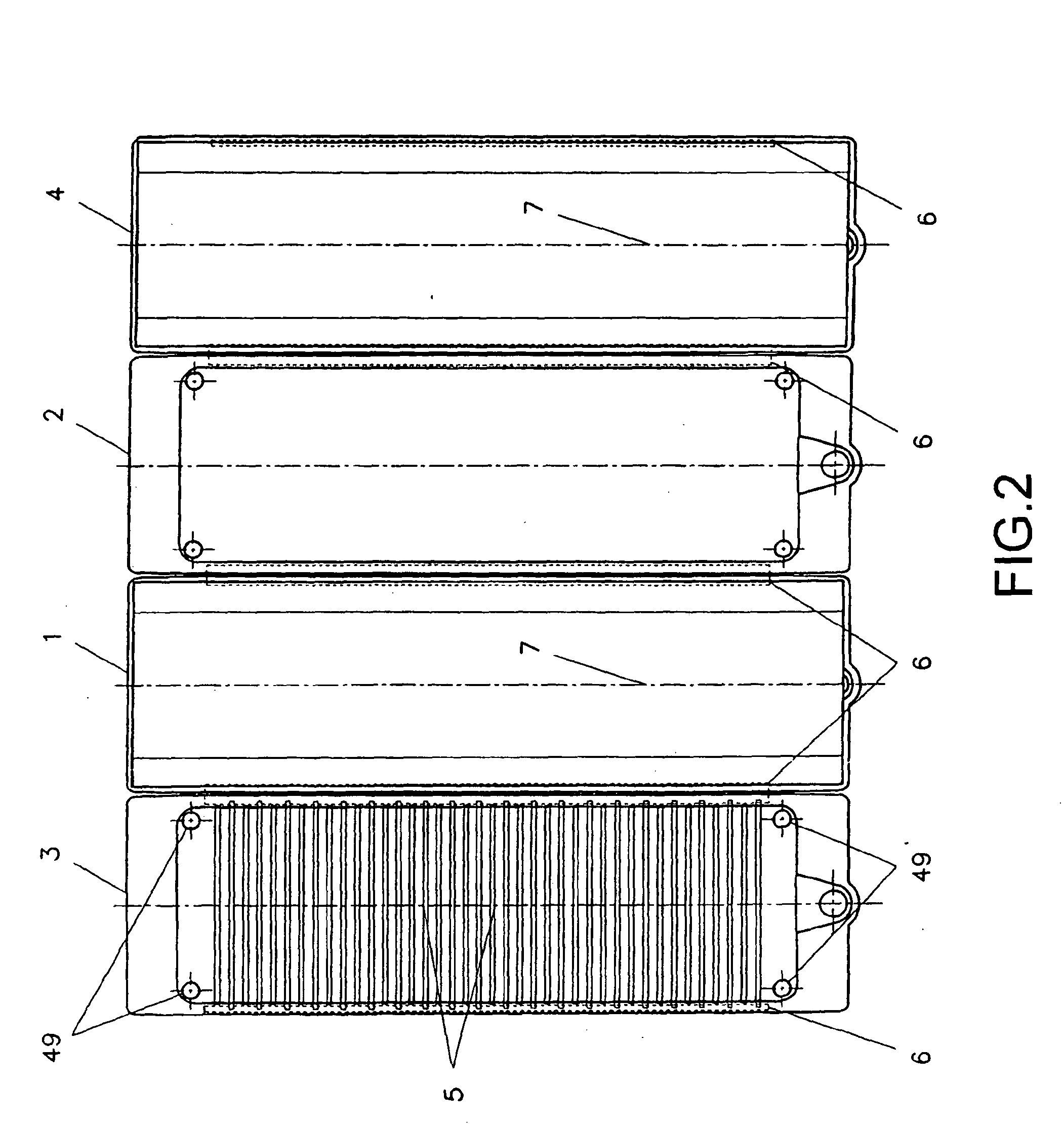

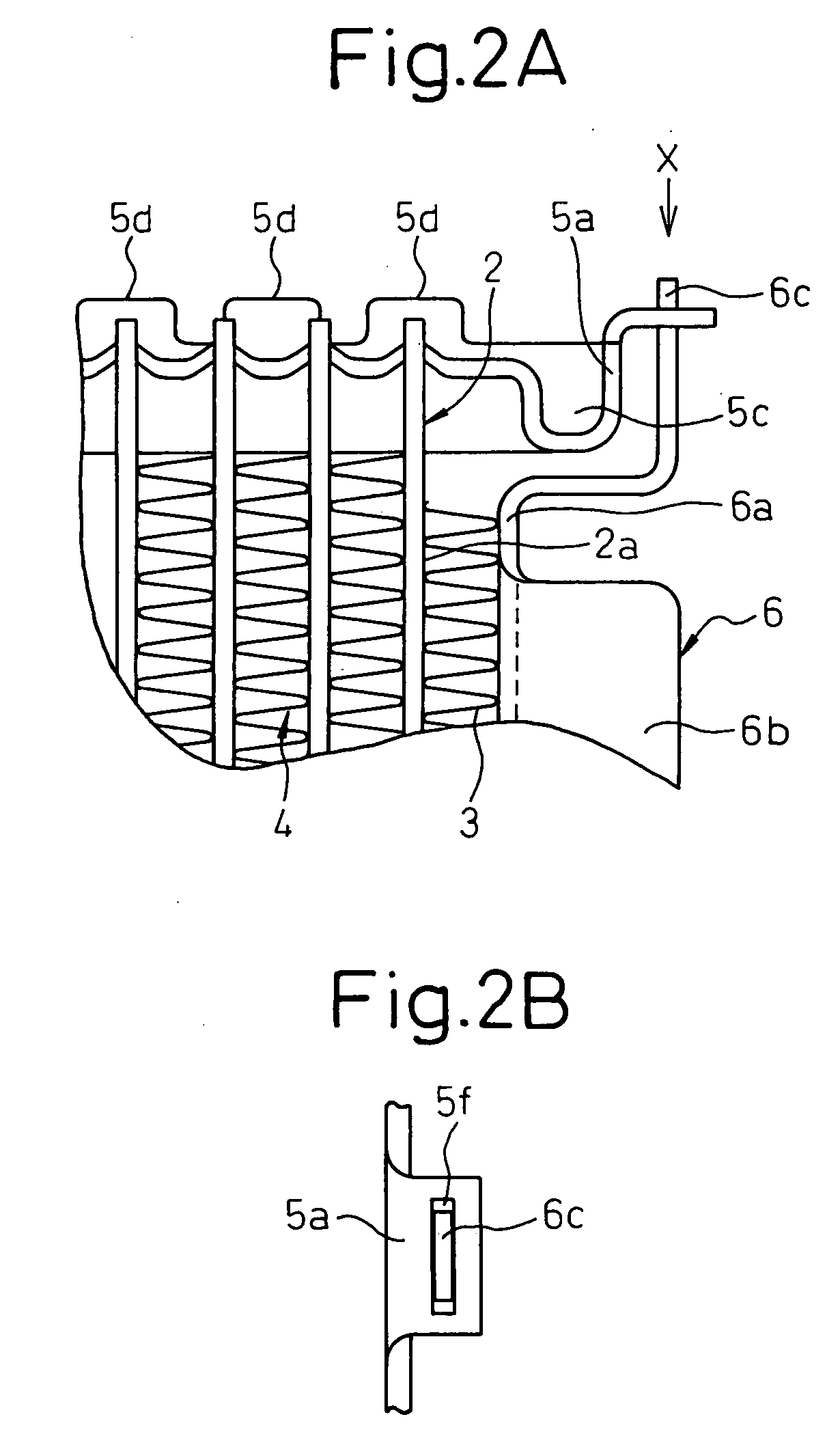

Heat exchanger

InactiveUS20070012424A1Reduce thermal deformationSecure performanceSafety devices for heat exchange apparatusStationary conduit assembliesInterior spaceNuclear engineering

A heat exchanger comprises a core portion including a plurality of tubes with a heat medium flowing therein and fins coupled to the outer surface of the tubes for promoting heat exchange with the heat medium, a pair of header tanks extending in a direction perpendicular to the length or the tubes at the longitudinal ends of the tubes and communicating with the tubes, and a pair of inserts arranged substantially parallel to the length of the tubes at the ends of the core portion to receive the heat transmitted from the core portion and having the ends thereof supported on the header tanks, each header tank includes a core plate with the tubes fixed thereon and a tank body providing the internal space of the tank with the core plate, and the ends of each insert are arranged outside the internal space of the tank and the insert is movably fitted in the header tank and along the length thereof and is immovable in a direction perpendicular to the length thereof.

Owner:DENSO CORP

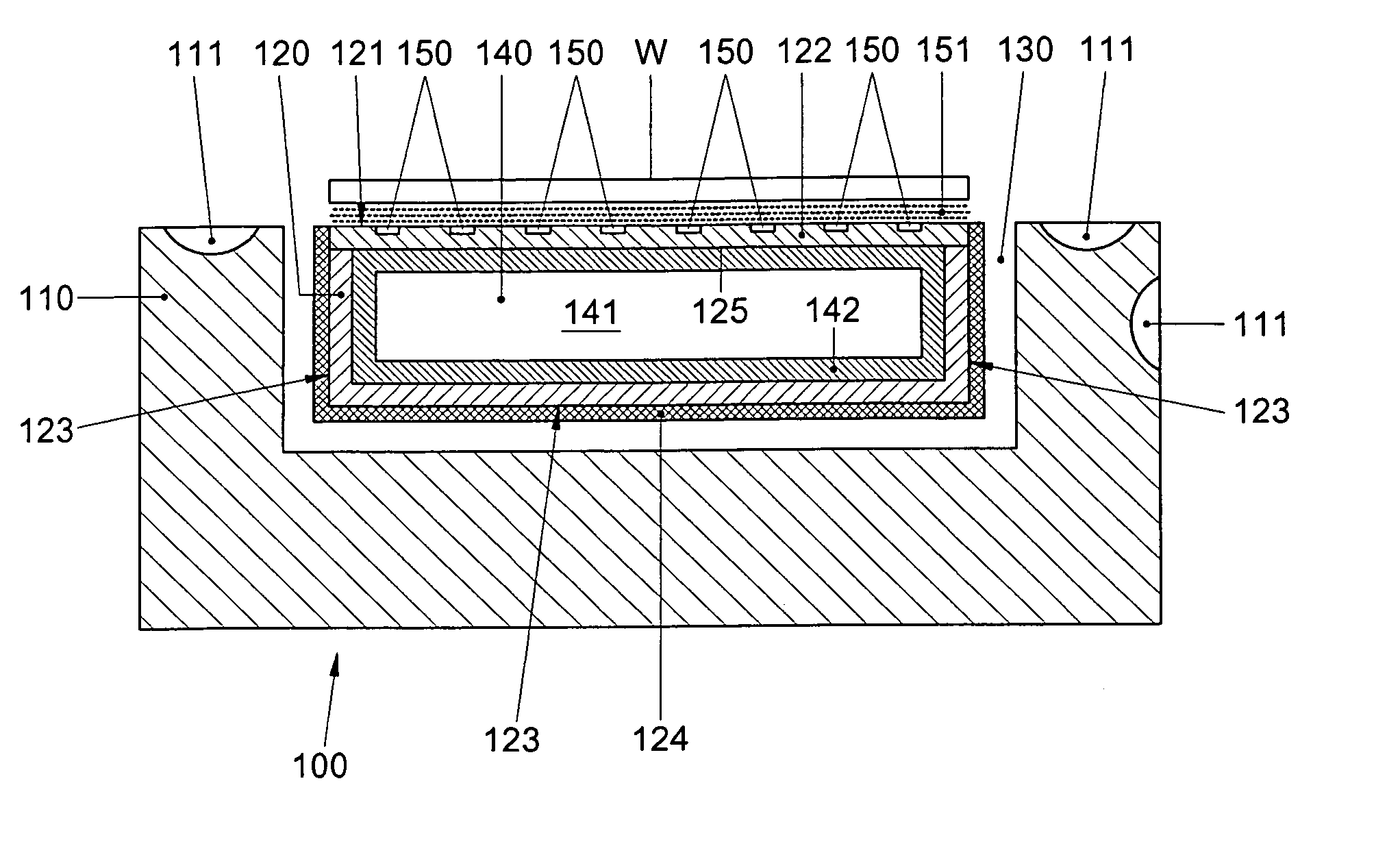

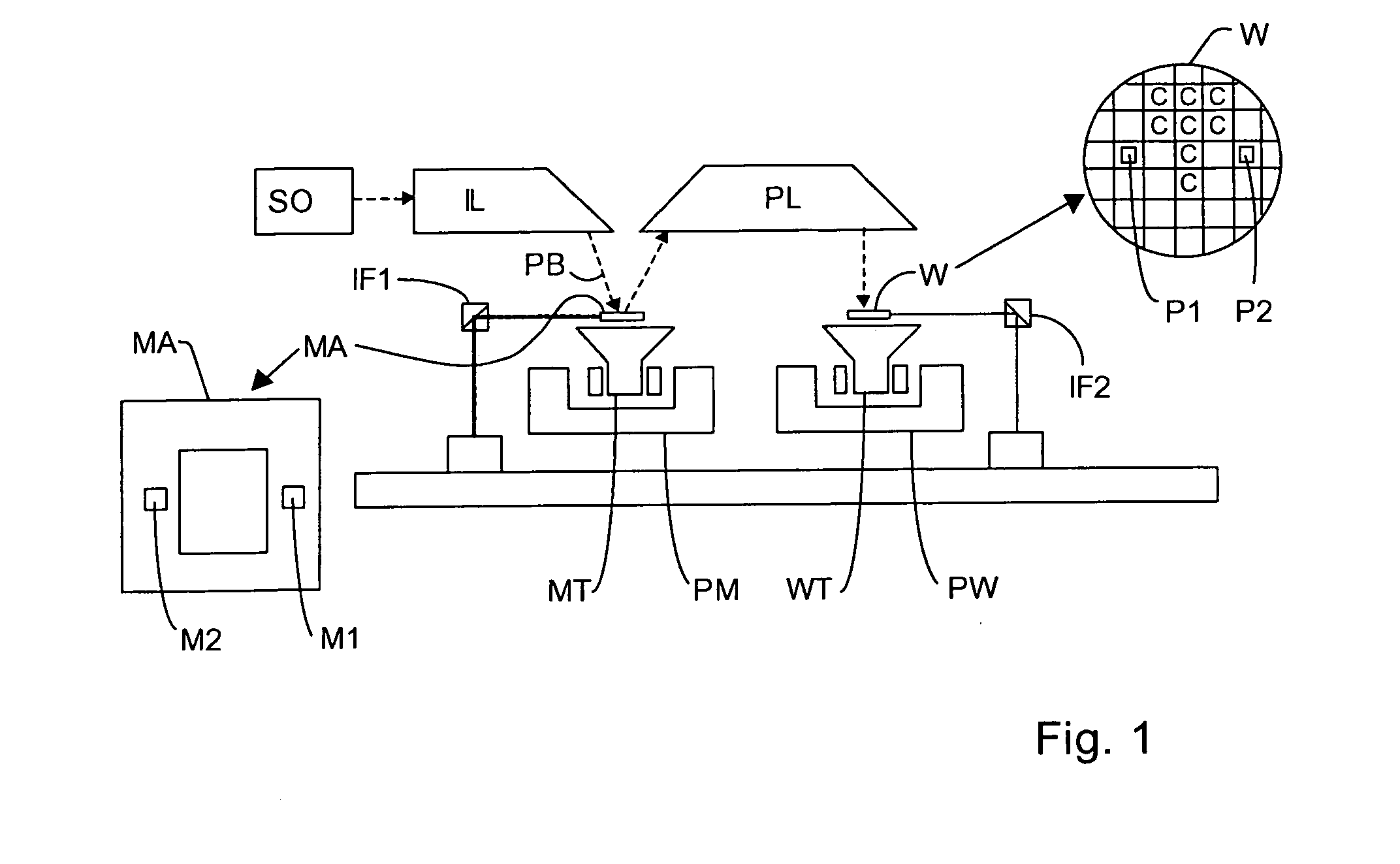

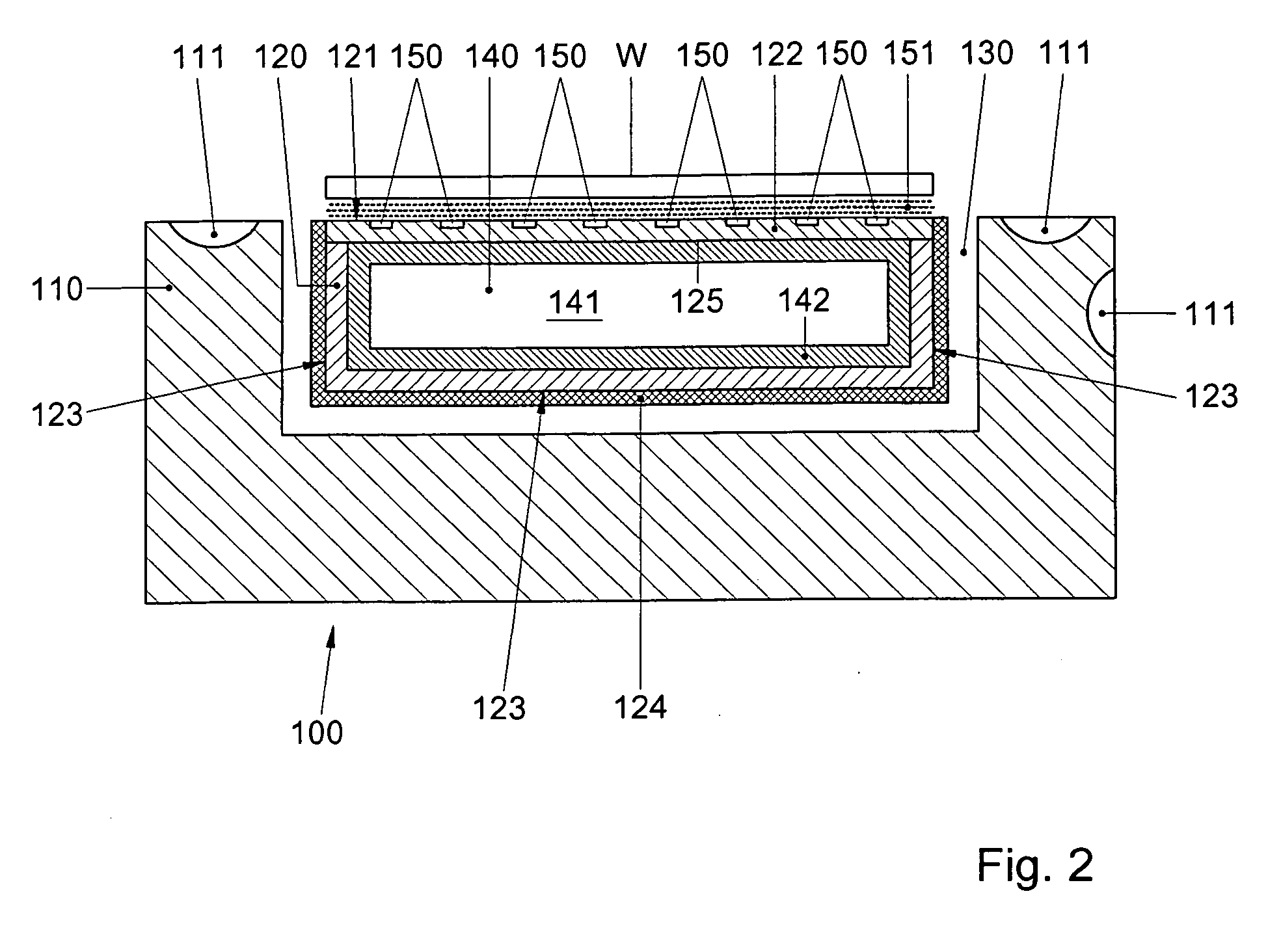

Lithographic apparatus and device manufacturing method

ActiveUS20050128448A1Improve thermal conditionsContribution to heat transferSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamEngineering

A lithographic apparatus including an illumination system for providing a beam of radiation and a support structure for supporting a patterning device. The patterning device serving to impart the beam with a pattern in its cross-section. The apparatus also having a substrate table for holding a substrate and a projection system for projecting the patterned beam onto a target portion of the substrate. The lithographic apparatus further having a chuck for supporting an object and a frame which supports the chuck with respect to other parts of the lithographic apparatus. The chuck is thermally isolated from at least the frame.

Owner:ASML NETHERLANDS BV

Honing strip and manufacturing method thereof

The invention provides a honing strip and a manufacturing method thereof. The method comprises the following steps of: mixing first metal powder prepared from components in a predetermined proportion and nonmetal powder such as graphite, Fe3O4 or MoS2 to form a bonding agent, adding a predetermined amount of abrasive such as diamond or cubic boron nitride (CBN for short) into the bonding agent, and performing granulation to obtain working layer granules; performing granulation on second metal powder to obtain transition layer granules; arranging the working layer granules in a first die to form a working layer of the honing strip, arranging the transition layer granules in the first die and on the working layer to form a transition layer, and pressing the first die to form a preformed honing strip; and charging the preformed honing strip into a second die, and performing hot pressing forming to obtain the honing strip. The honing strip has the characteristics of good exposure effect, low grinding resistance, low heating deformation of a honing head, long durability, high precision of machined workpieces, good finishment and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

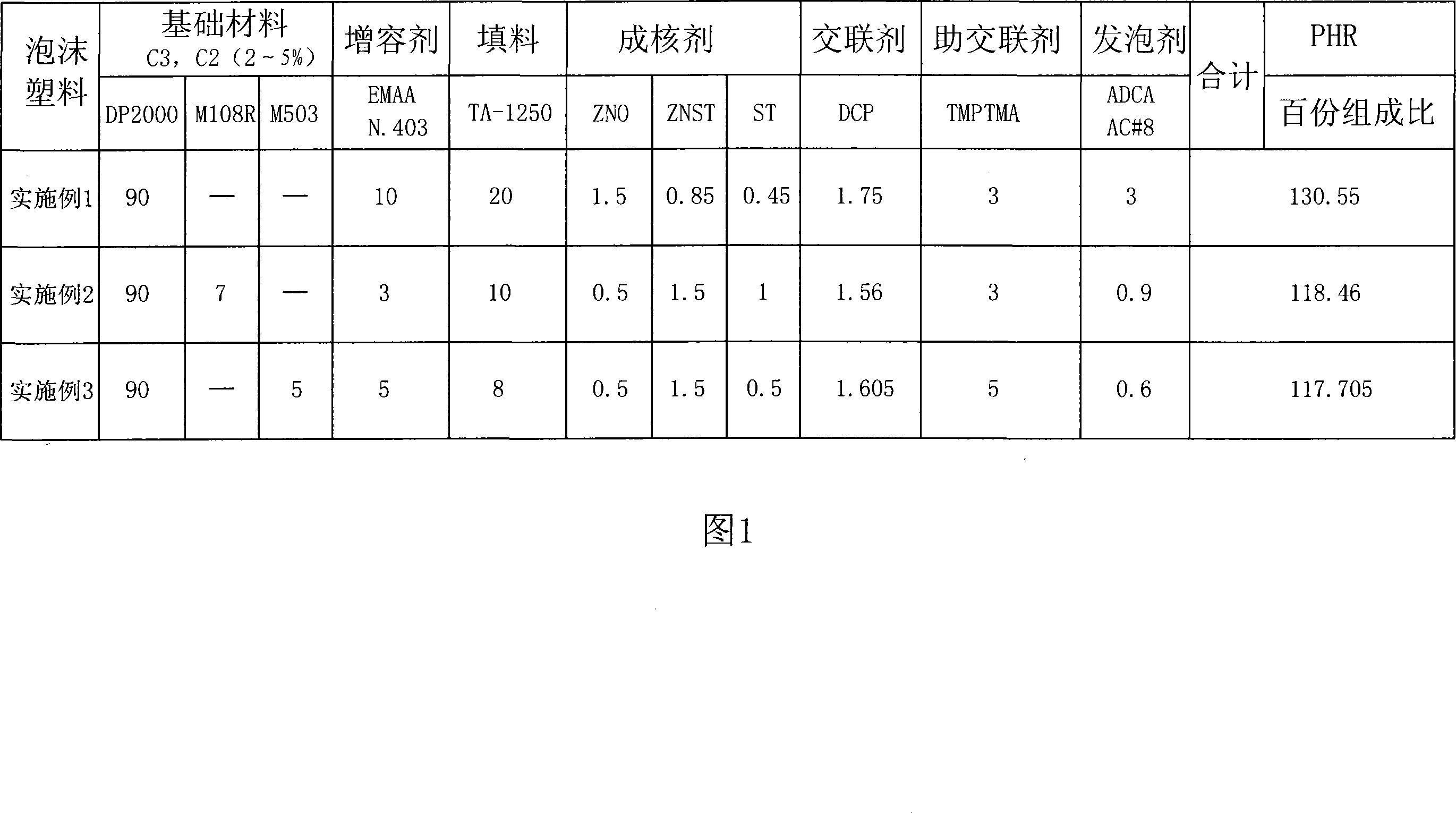

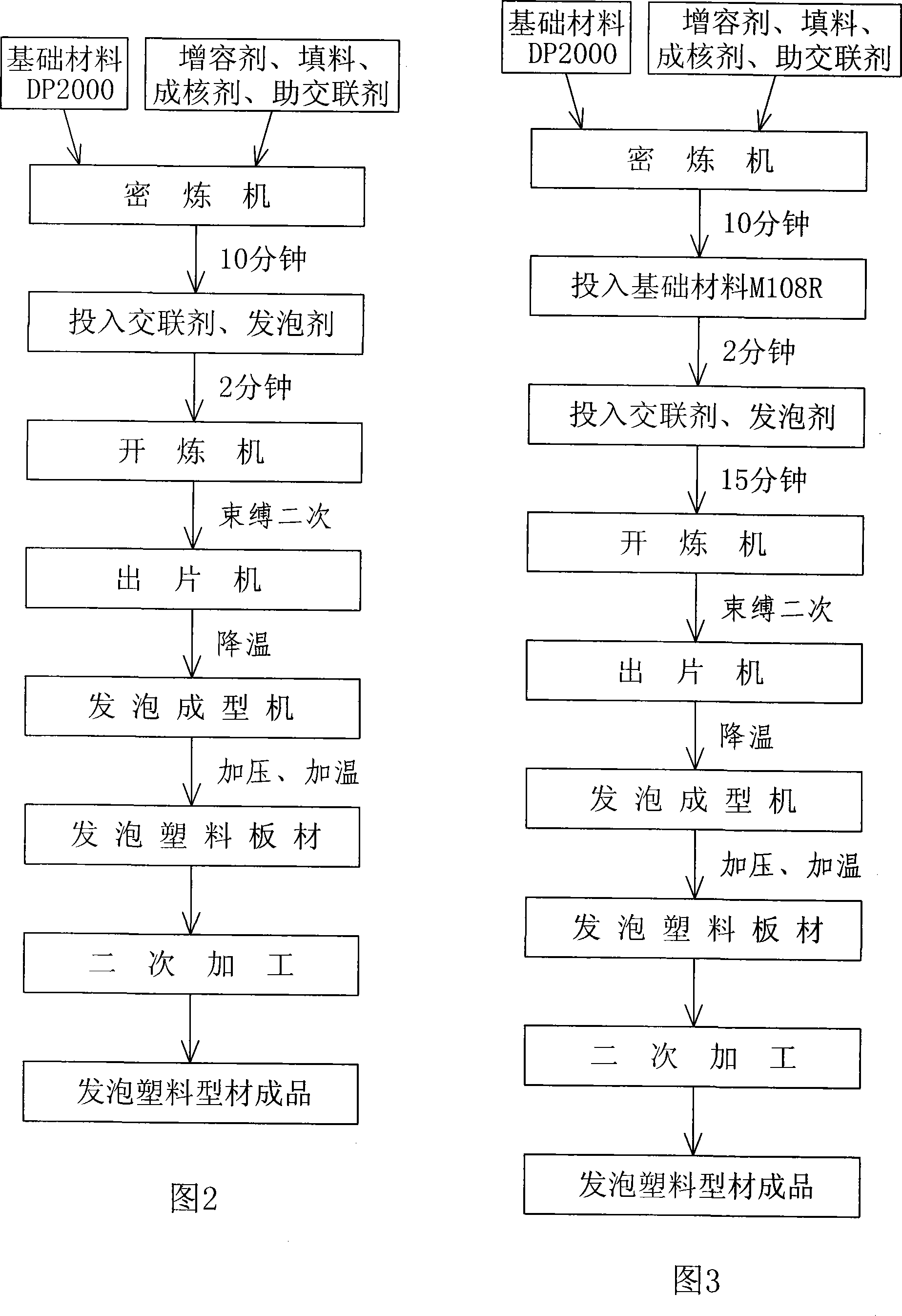

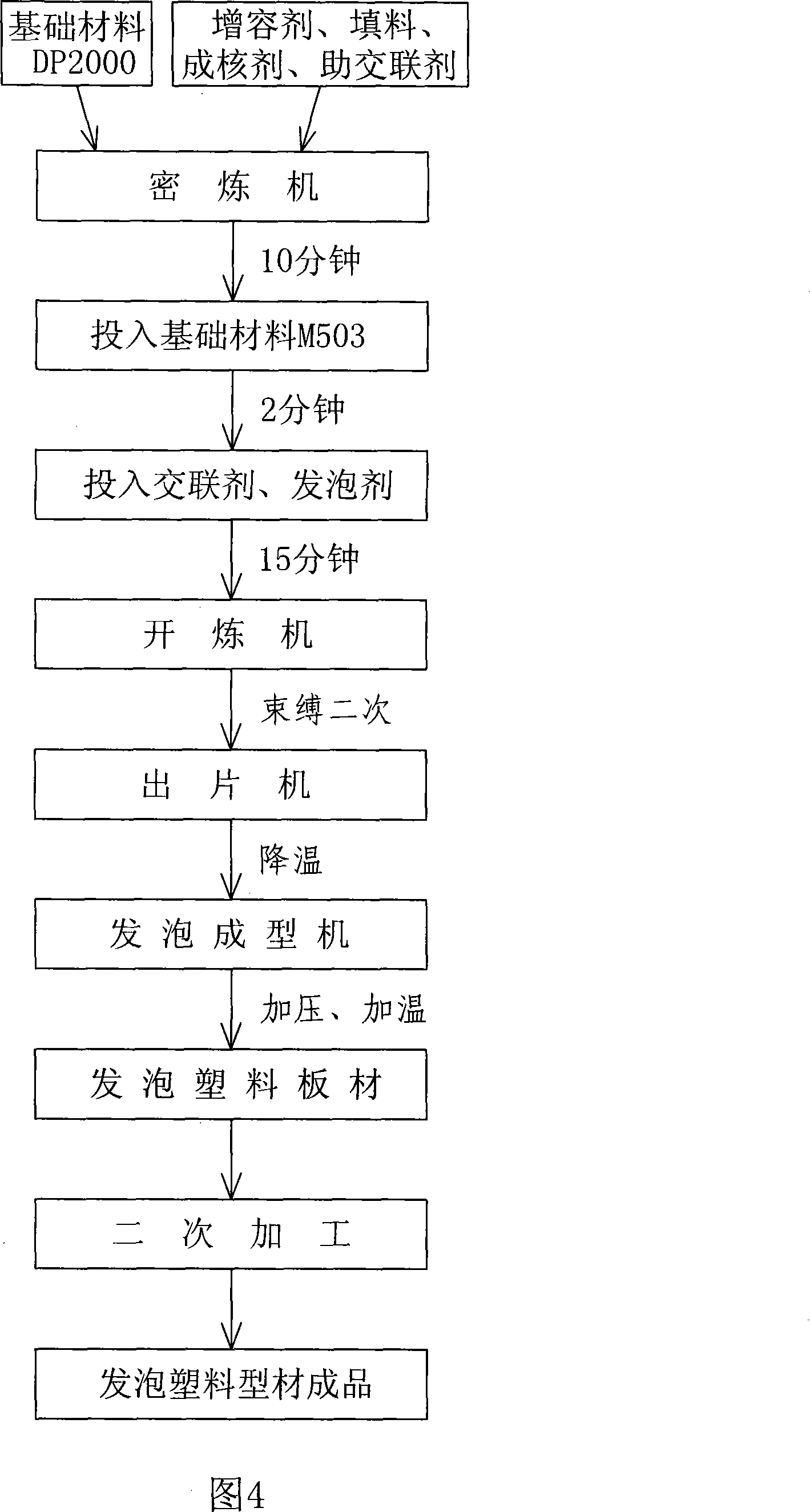

Degradable environment-friendly type polypropylene(PP) foam plastic and preparation method thereof

The invention provides an environment-friendly-type polypropylene (pp) aerated plastics and a process for preparation, and the aerated plastics utilizes plastic projectile body to be basis material, a third monomer is led in to be auxiliary crosslinking agent to crosslink and control degradation products, aerated plastics section products are made by processing graft copolymerization and cross-linking reaction to polypropylene, and closely welding, openly welding, tabletting, and foaming to shape with compatibilizer, filling material, nucleating agent, cross linking agent and inflating agent. The invention modifies the shortcomings that the traditional homopolymerized polypropylene can not get higher breakpoint extension force, high melt intensity and viscosity to foam and shape in the process of thermal foaming and shaping. The polypropylene (pp) aerated plastics products which are provided by the invention have excellent fire-resisting property and little heat distortion degree, and the softening point is between 100 DEG C and 130 DEG C. The invention can be used for long term in the temperature scope, and the application area is wide, wastes can be recycled, and can be automatically degraded, and the invention has no pollution to environment.

Owner:FUJIAN ZHENGYI IND

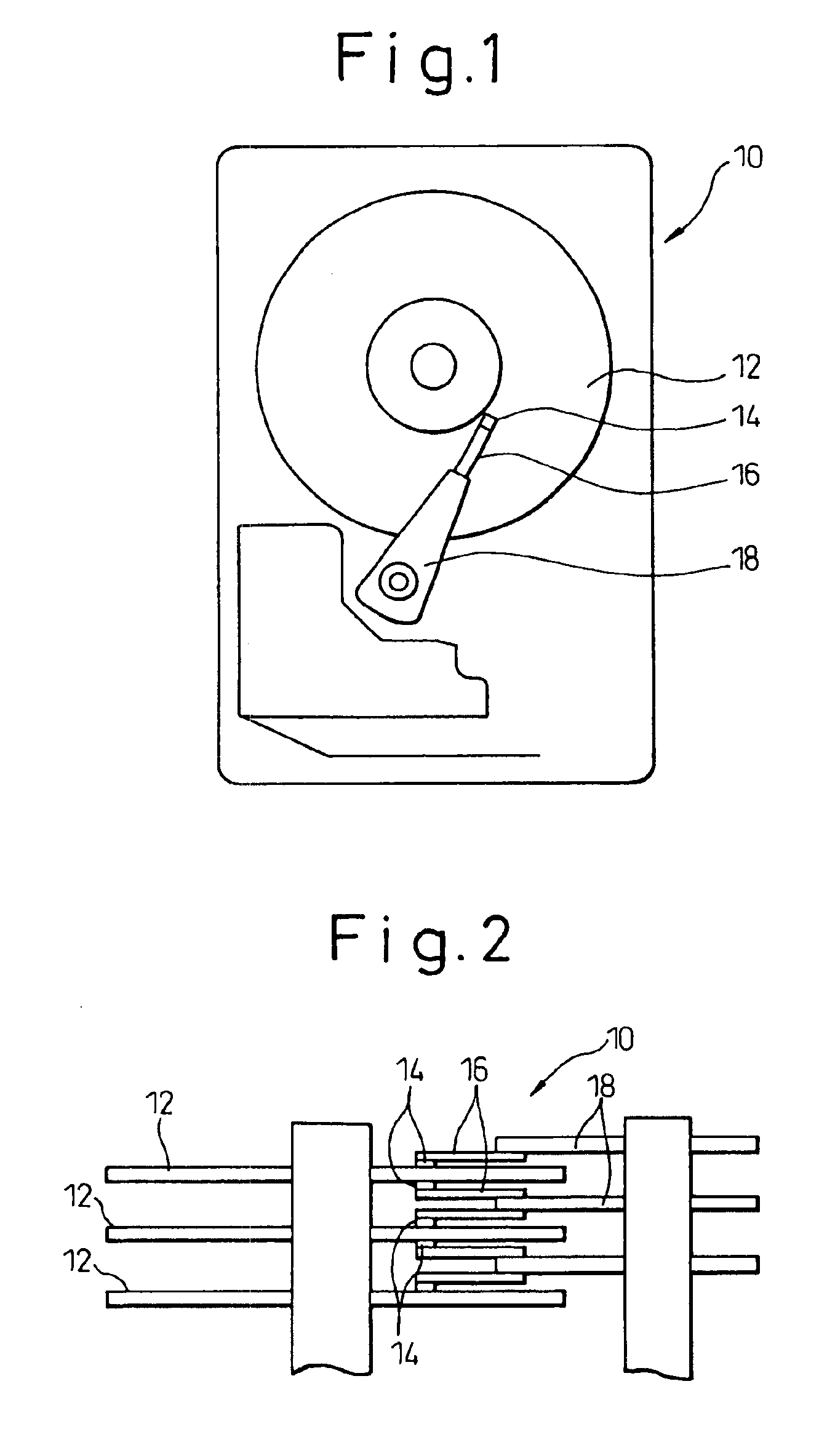

Suspension with supporting pieces, head gimbal assembly and disk drive unit with the same

ActiveUS8582243B2Reduce the temperatureReduce changesElectrical connection between head and armRecord information storageEngineeringDielectric layer

Owner:SAE MAGNETICS (HK) LTD

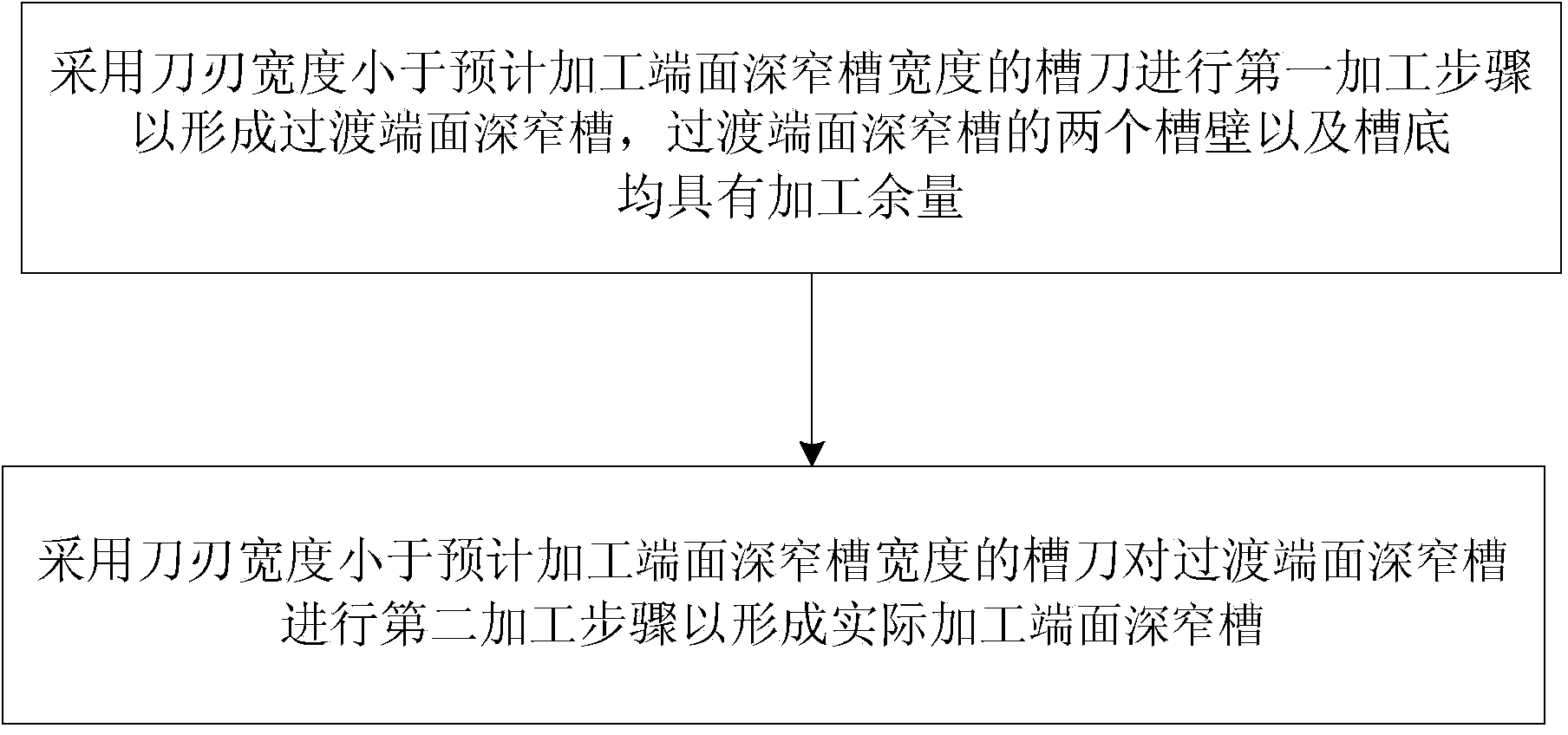

Lathe machining method for end face deep narrow groove in aerial engine crankcase

InactiveCN104028782AReduce offsetSmall thermal deformation and bending deformationEngineeringAviation

The invention provides a lathe machining method for an end face deep narrow groove in an aerial engine crankcase. The method comprises the following machining steps: 1, using a groove cutter to carry out the first machining step to form a transition end face deep narrow groove, wherein the width of a blade of the groove cutter is less than that of the end face deep narrow groove to be machined, and at least two opposite groove walls of the transition end face deep narrow groove have machining allowances; 2, removing the machining allowances of the transition end face deep narrow groove to form the actually machined end face deep narrow groove. According to the lathe machining method, the machined end face deep narrow groove is higher in machining precision.

Owner:CHINA HANGFA SOUTH IND CO LTD

Solid electrolytic capacitor

ActiveUS20090147449A1Highly accurate and reliable attachmentAvoid deformationSolid electrolytic capacitorsClosuresLead frameElectrolytic capacitor

A solid electrolytic capacitor includes a capacitor element, an anode lead frame, a cathode lead frame, and a mold resin portion. The anode lead frame includes an anode terminal portion and a rising portion, and the anode terminal portion is exposed at the bottom surface of the mold resin portion. The rising portion is formed integral with the anode terminal portion, and rises to the anode portion. In the rising portion, a through hole is formed. The cathode lead frame includes a cathode terminal portion, a pair of side surface portions and a step portion. Thus, a solid electrolytic capacitor allowing highly accurate and reliable attachment of the capacitor element to the lead frame without using any additional member is provided.

Owner:SANYO ELECTRIC CO LTD

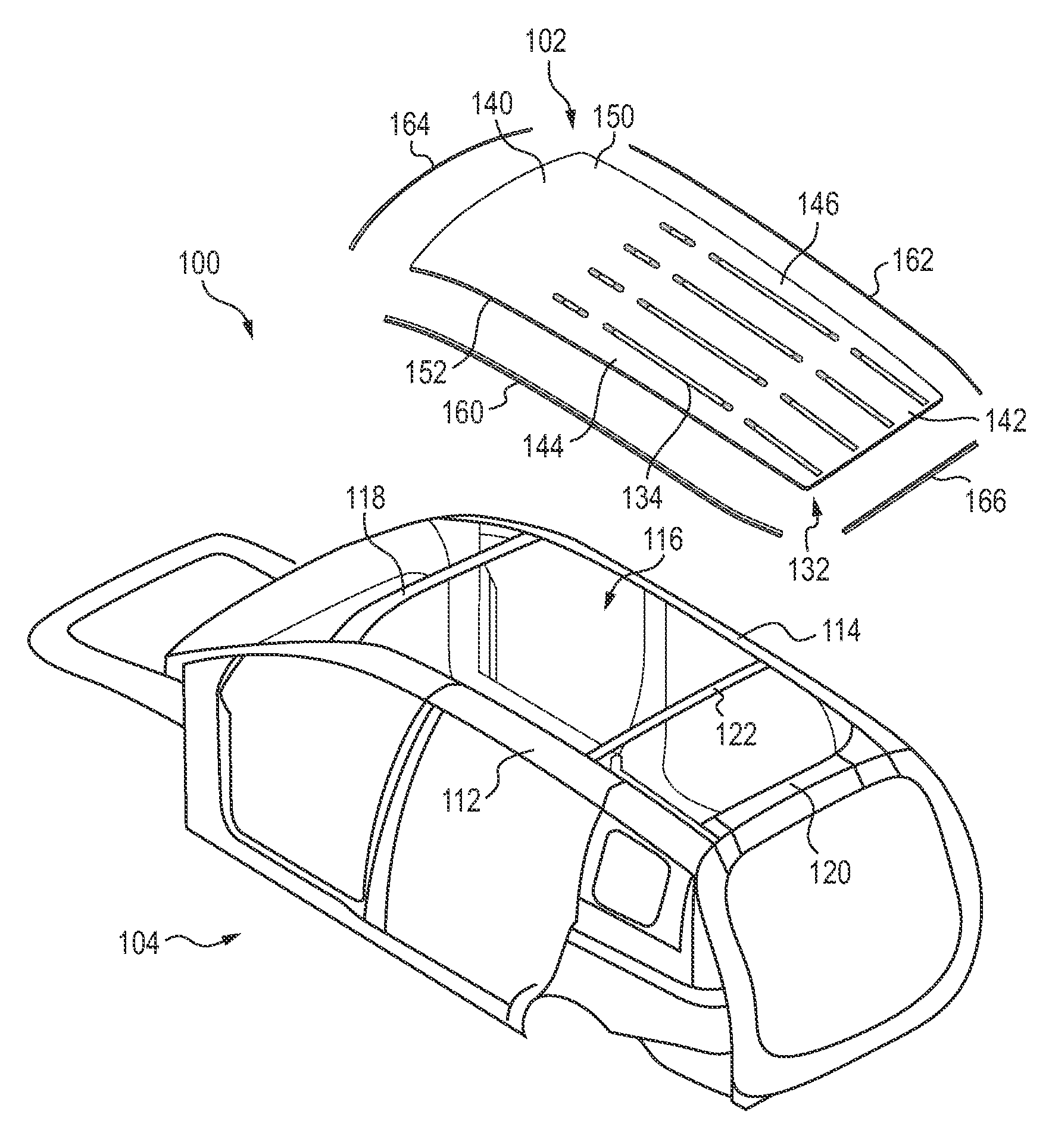

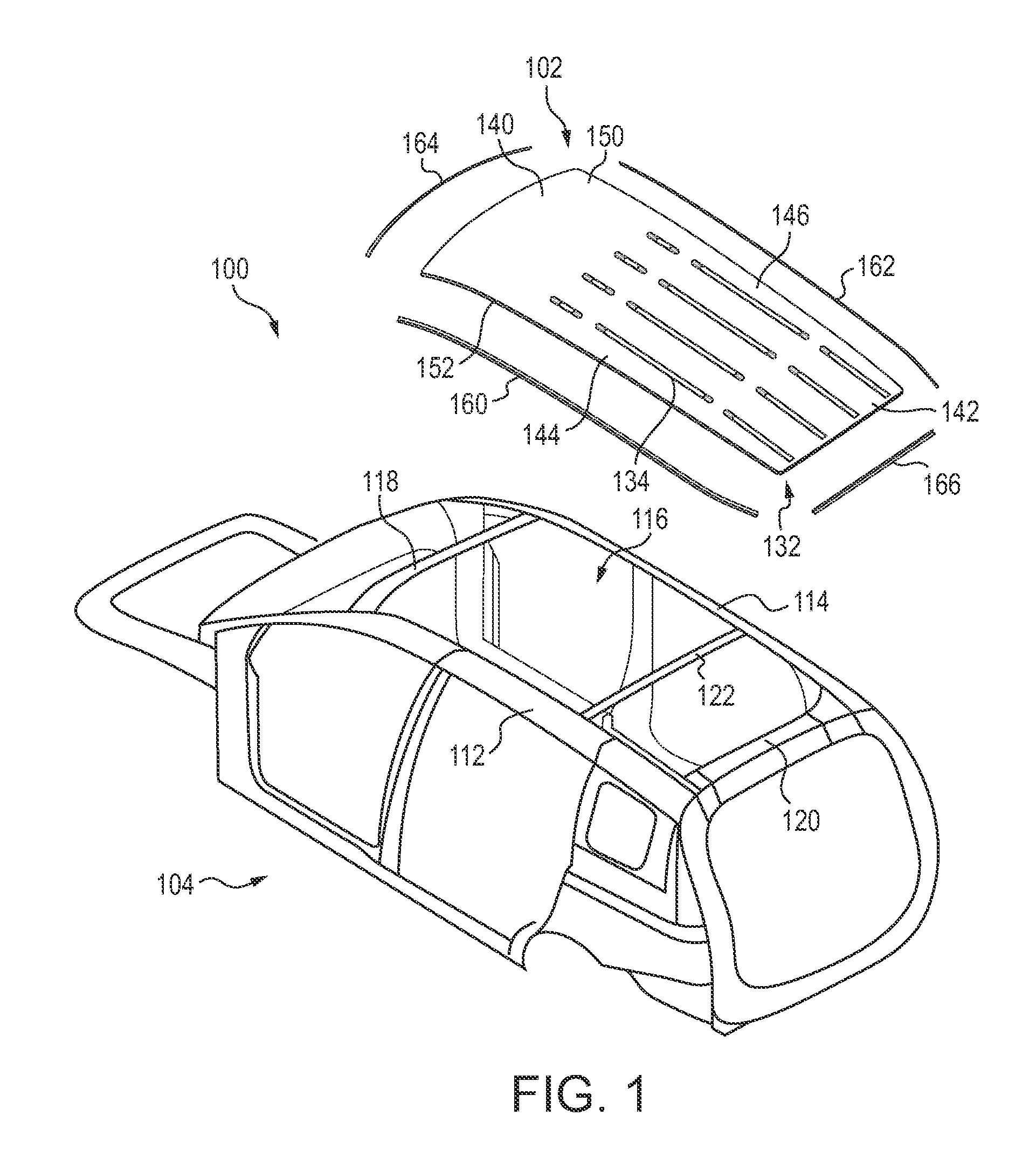

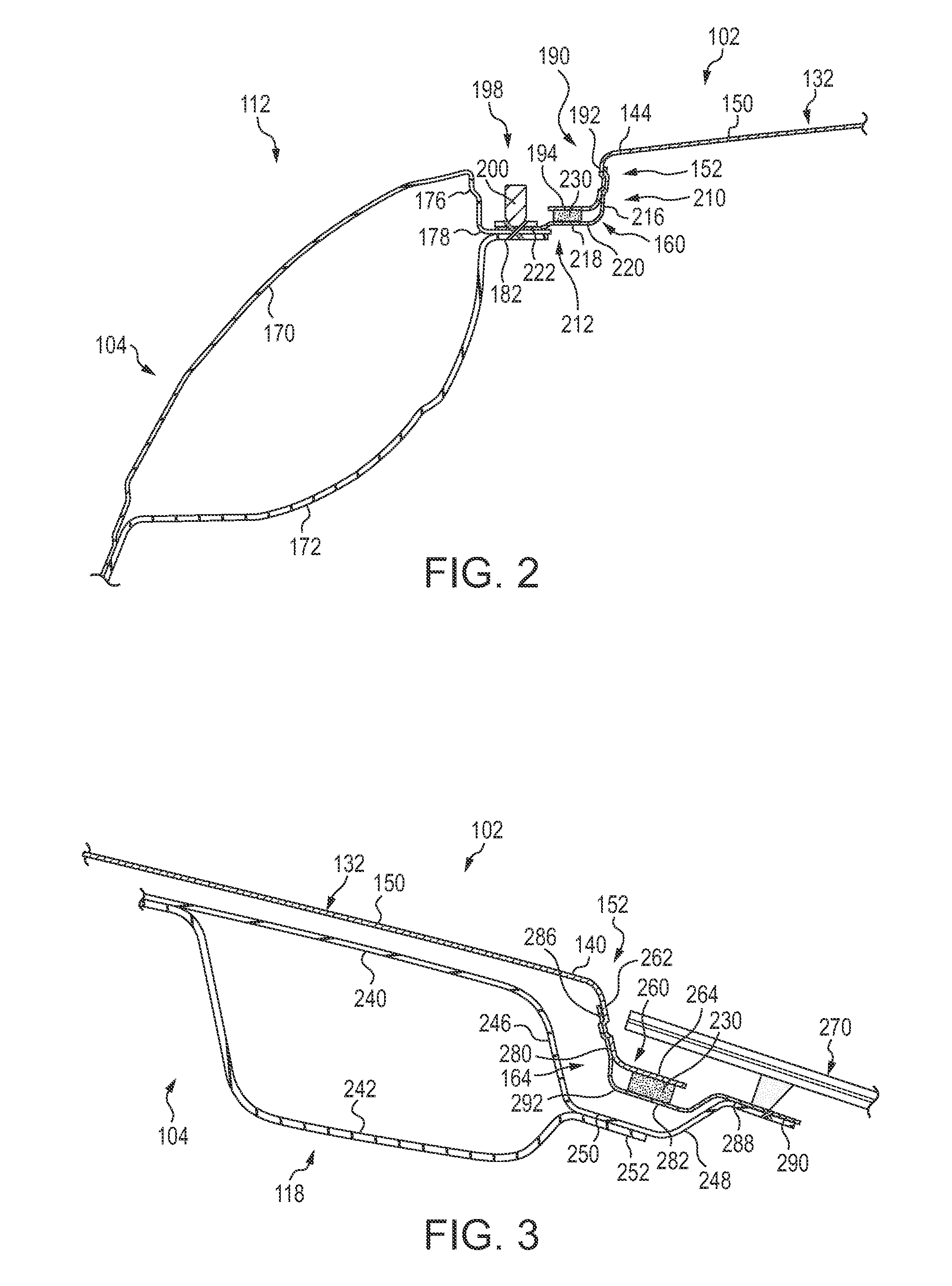

Vehicle roof structure

InactiveUS20150217812A1Prevent galvanic corrosionReduce thermal deformationSoldering apparatusSuperstructure subunitsAdhesiveAlloy

A vehicle assembly includes a roof structure having a roof panel formed of aluminum or an aluminum-based alloy and a vehicle body formed of steel or a steel alloy supporting the roof structure. The vehicle body includes a pair of laterally spaced side panels, a front roof rail and a rear roof rail. A bracket formed of steel or a steel alloy secures the roof structure to the vehicle body. The bracket has a first portion fastened to the roof panel and a second portion extending away from the roof structure and welded to the vehicle body. An adhesive located inward of the connection of the vehicle body and second portion of the bracket bonds the second portion to the vehicle body. The adhesive seals the connection of the roof panel and bracket first portion and reduces thermal distortion of the attached roof panel relative to the vehicle body.

Owner:HONDA MOTOR CO LTD

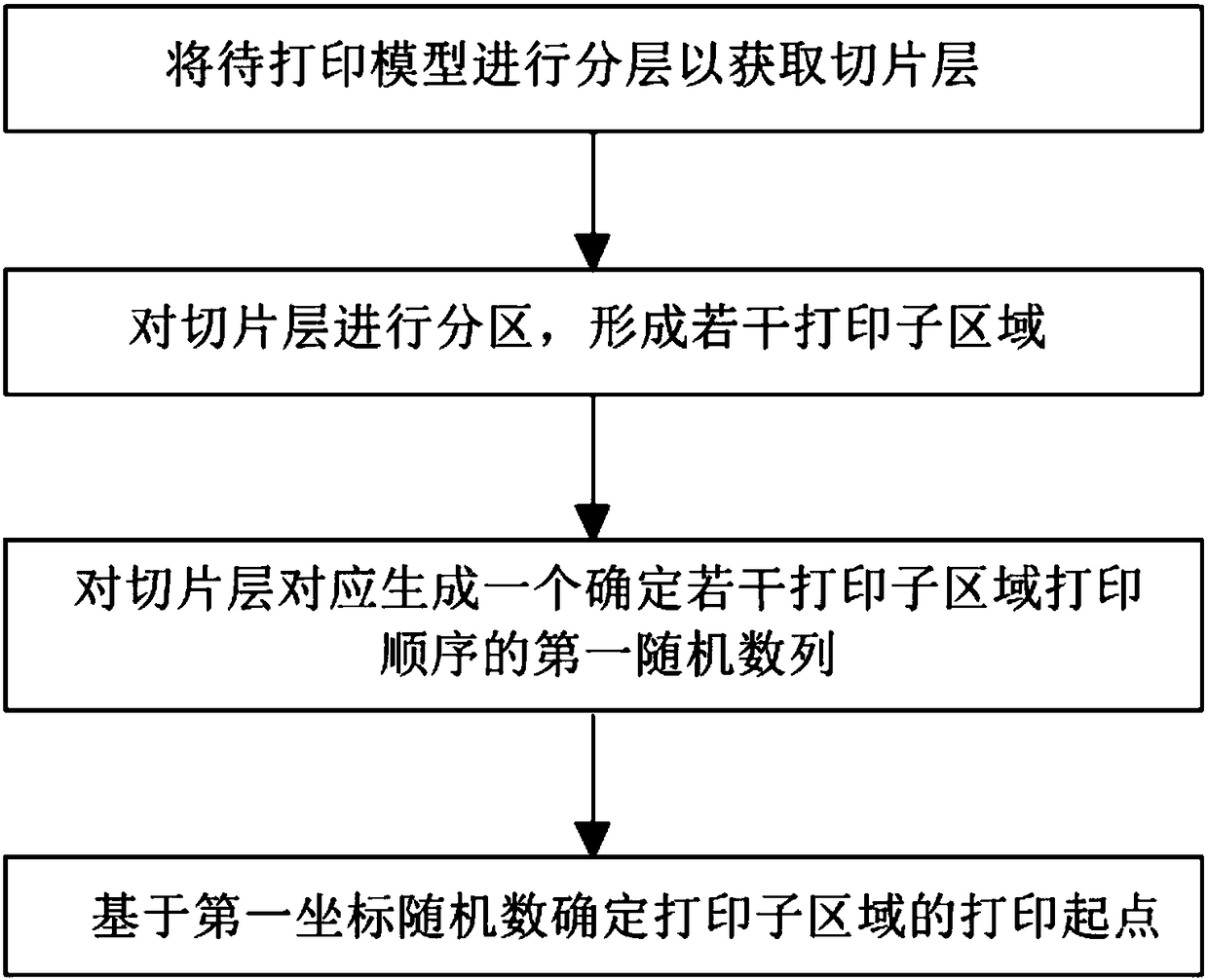

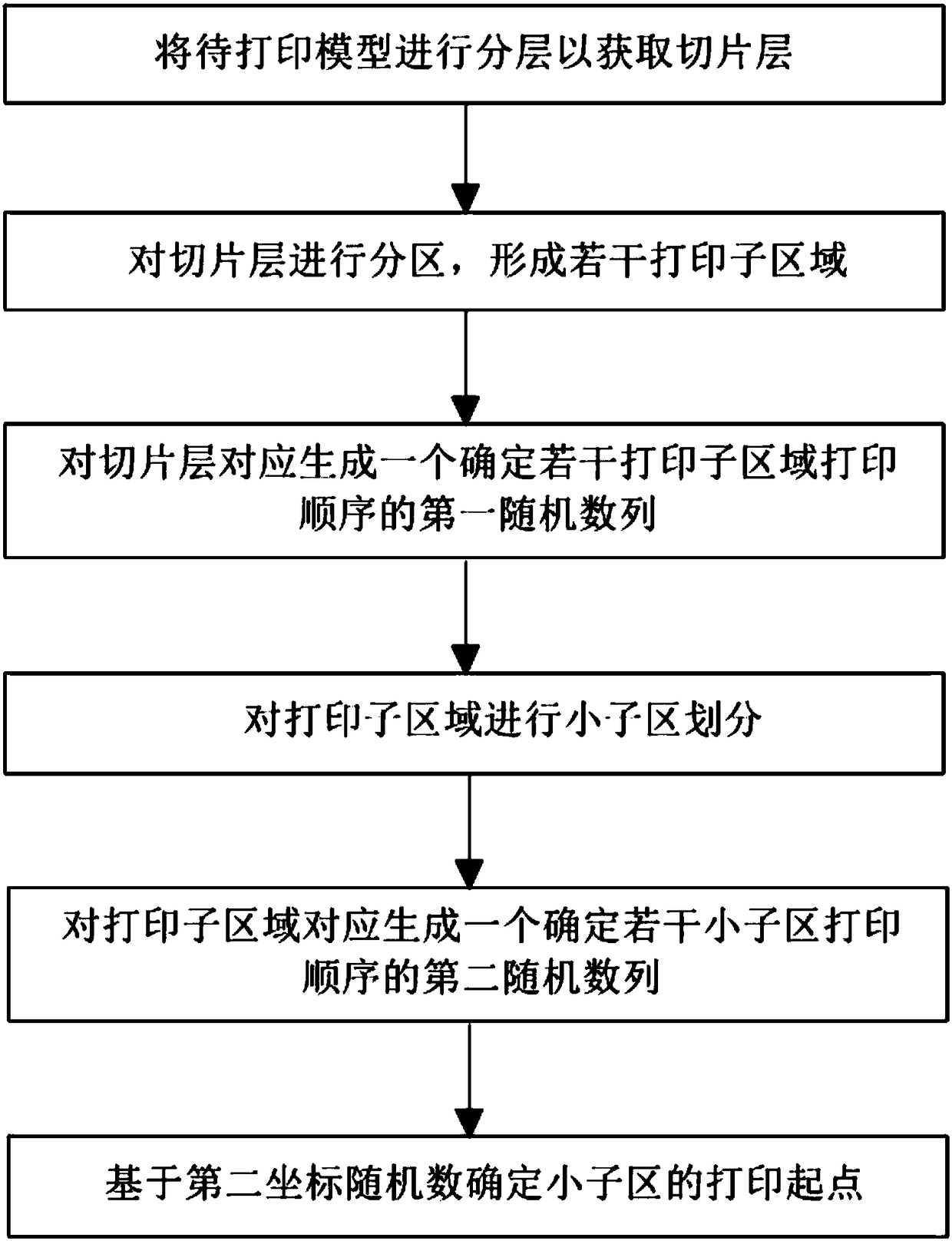

Printing path generation method of metal additive manufacturing

ActiveCN108326301AWith randomnessReduced shrinkage deformationAdditive manufacturing apparatusIncreasing energy efficiencyThermal deformationPath generation

The invention belongs to the technical field of 3D printing and particularly discloses a printing path generation method of metal additive manufacturing. The printing path generation method comprisesthe following steps that a model to be printed is layered so that section layers can be obtained; the section layers are partitioned, and a plurality of printing sub-regions are formed; a first randomnumber sequence determining the printing sequence of the multiple printing sub-regions is correspondingly generated for each section layer; and for the section layer, the printing sub-regions are sequentially printed according to the corresponding first random number sequence. According to the printing path generation method of the metal additive manufacturing, by means of the random distributionthought, the residual stress can be effectively reduced, the thermal deformation is reduced, and the surface quality and the size precision of parts are improved.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

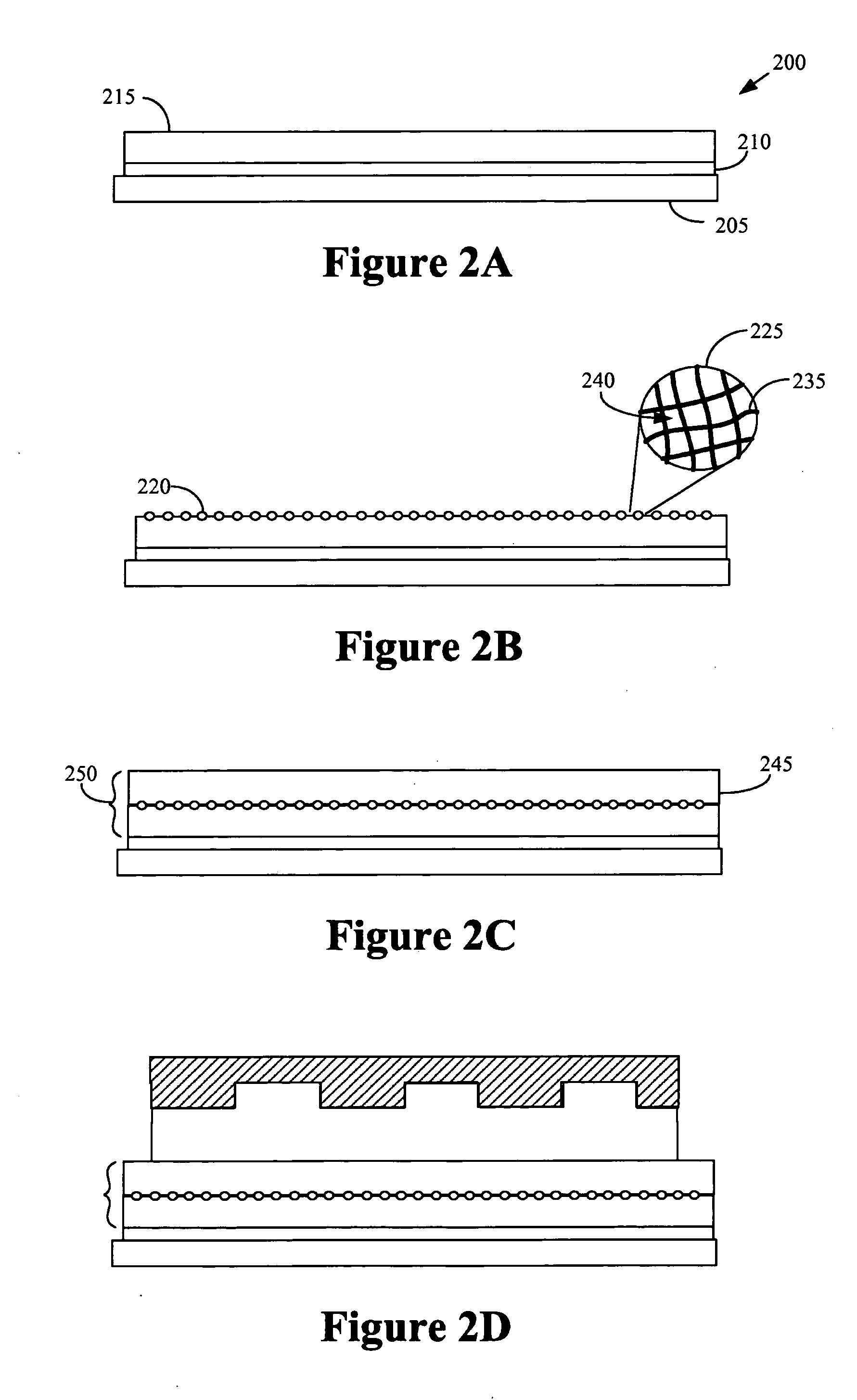

Low thermal distortion silicone composite molds

InactiveUS20100200146A1Well formedReduce thermal deformationNanoinformaticsPhotomechanical apparatusFiberElastomer

The present invention provides compositions and methods that may be used to form low thermal distortion molds. The composition may include a curable elastomeric silicone composition formed using a de-volatilized polymer and at least one de-volatilized cross-linker. One embodiment of the method may include forming a pattern on a first side of an elastomer that is impregnated with a fibrous material proximate a second side of the elastomer.

Owner:DOW CORNING CORP

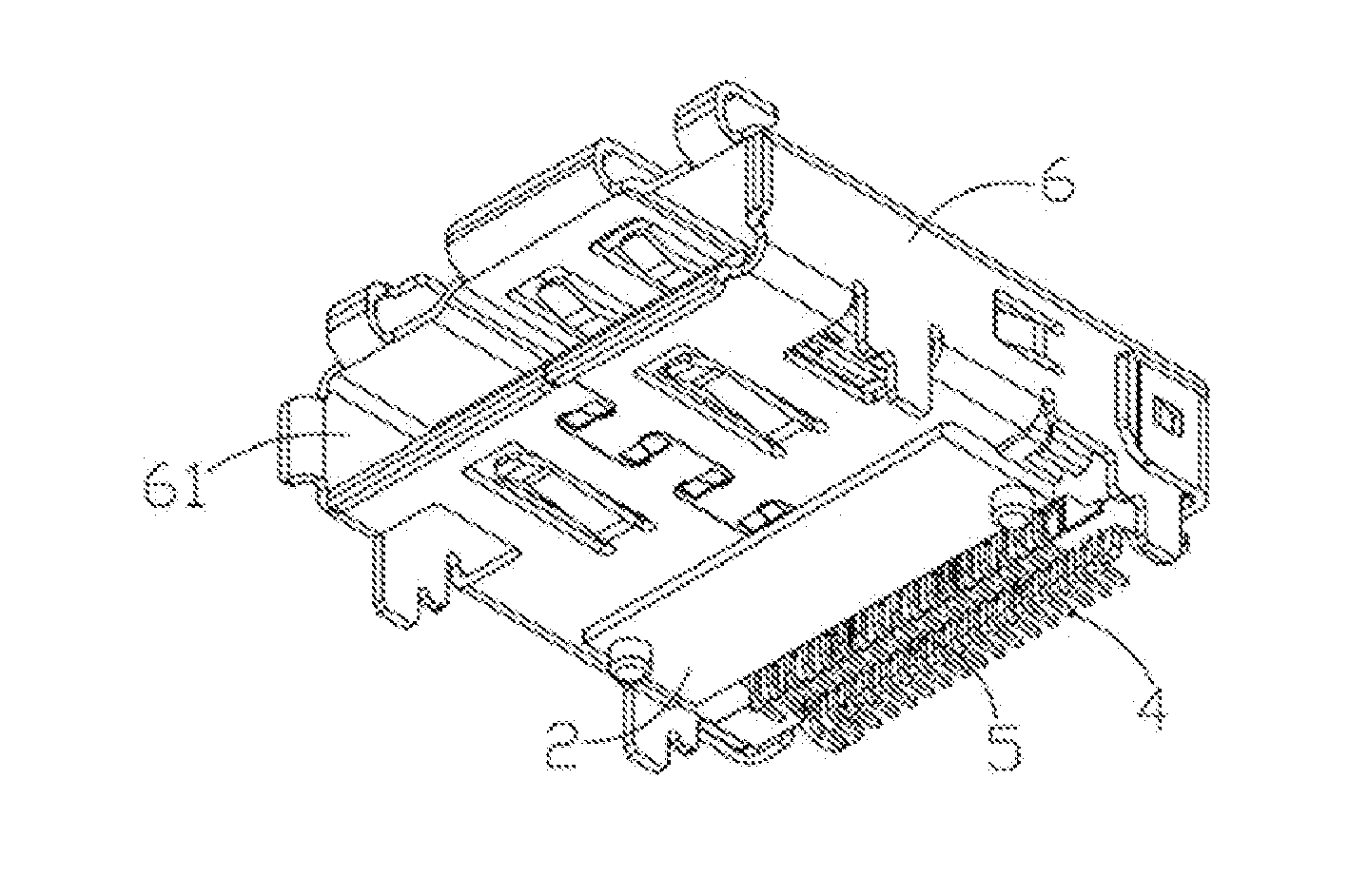

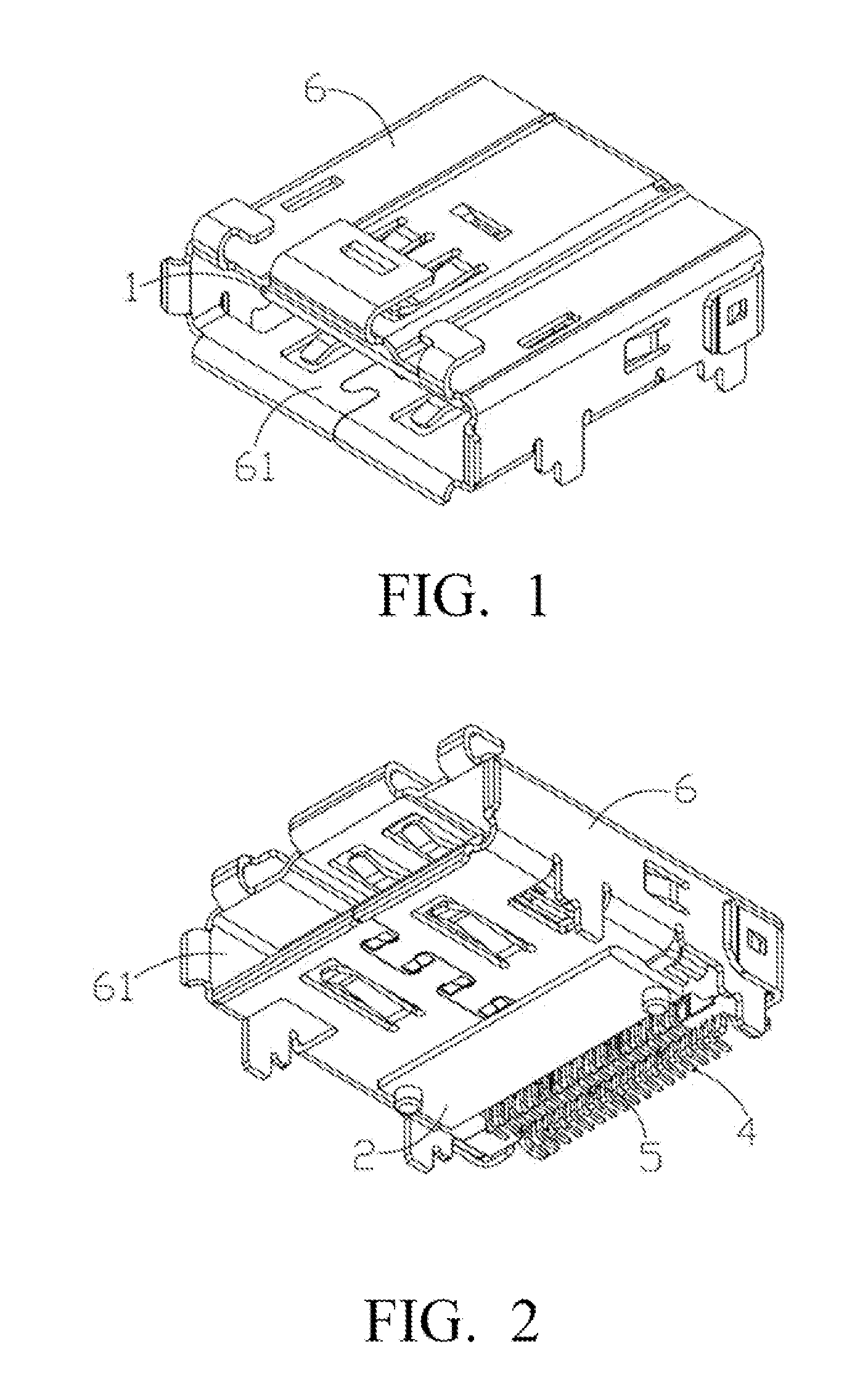

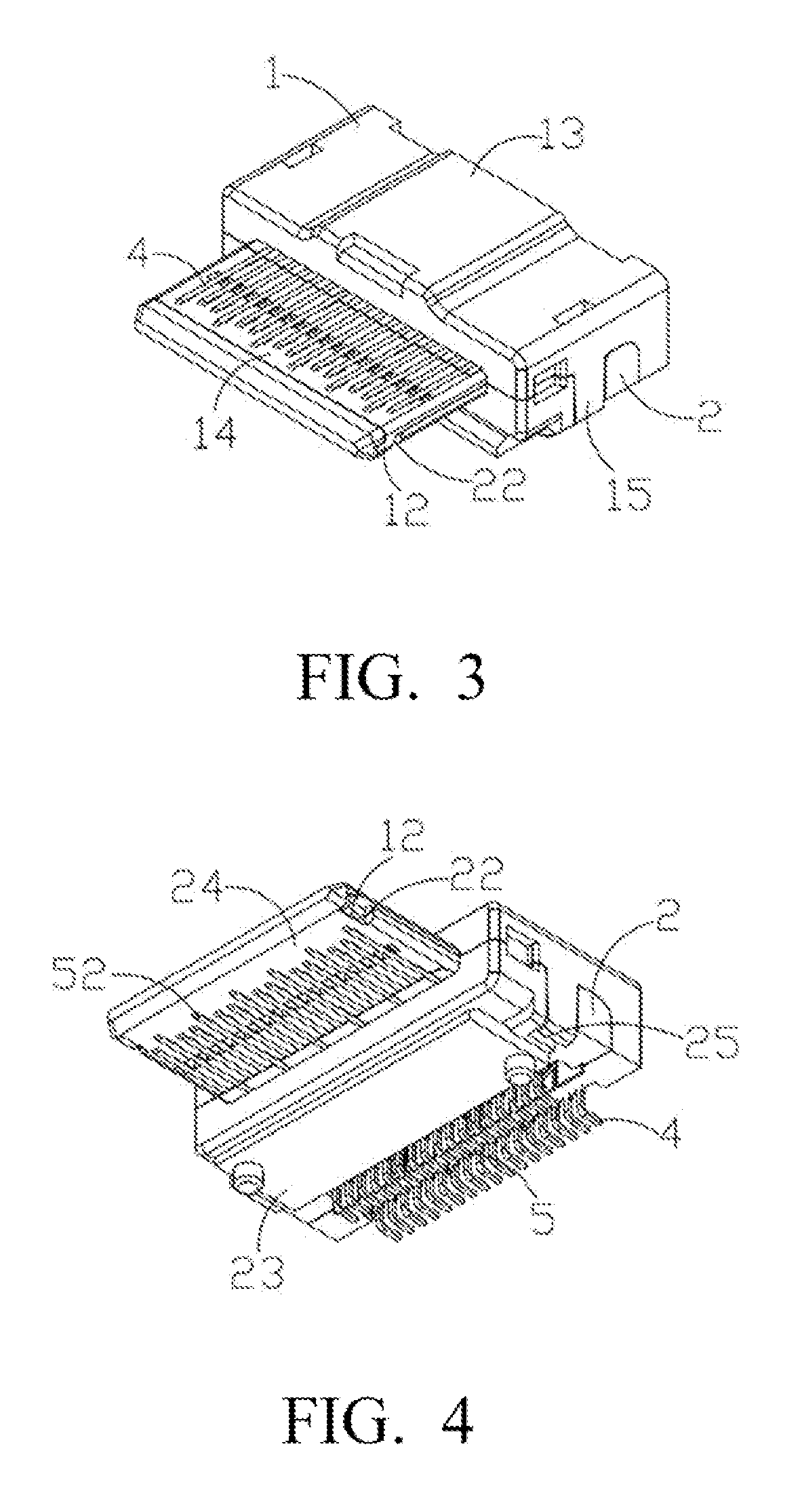

Connector assembly

InactiveUS20150380868A1Improve deformationEasy to separateCoupling protective earth/shielding arrangementsMechanical engineeringEngineering

The present invention relates to a connector assembly, which includes a first plastic body, a second plastic body, a grounding sheet, a plurality of first terminals, a plurality of second terminals and a shielding case. The first terminals are insert-molded in the first plastic body. The second terminals are insert-molded in the second plastic body. The grounding sheet is disposed between the first plastic body and the second plastic body. The first plastic body has a first fixing part. The second plastic body has a second fixing part.The first fixing part and the second fixing part are engaged with each other, thus the first fixing part and the second fixing part are assembled and fixed to each other. The shielding case covers the first plastic body and the second plastic body to form an abutting space.

Owner:SPEED TECH

Turbo-machine impeller manufacturing

ActiveUS9903207B2Reduce weightLess thermal energyTurbinesAdditive manufacturing apparatusImpellerTurbine wheel

A method of manufacturing a turbo-machine impeller, which includes a hub and a plurality of blades, using powder material in an additive-manufacturing process. The method includes: applying energy to the powder material by way of a high energy source, and solidifying the powder material. At least one bulky portion of the hub is irradiated such that the powder material solidifies in a lattice structure surrounded by an outer solid skin structure enclosing the lattice structure.

Owner:NUOVO PIGNONE TECH SRL

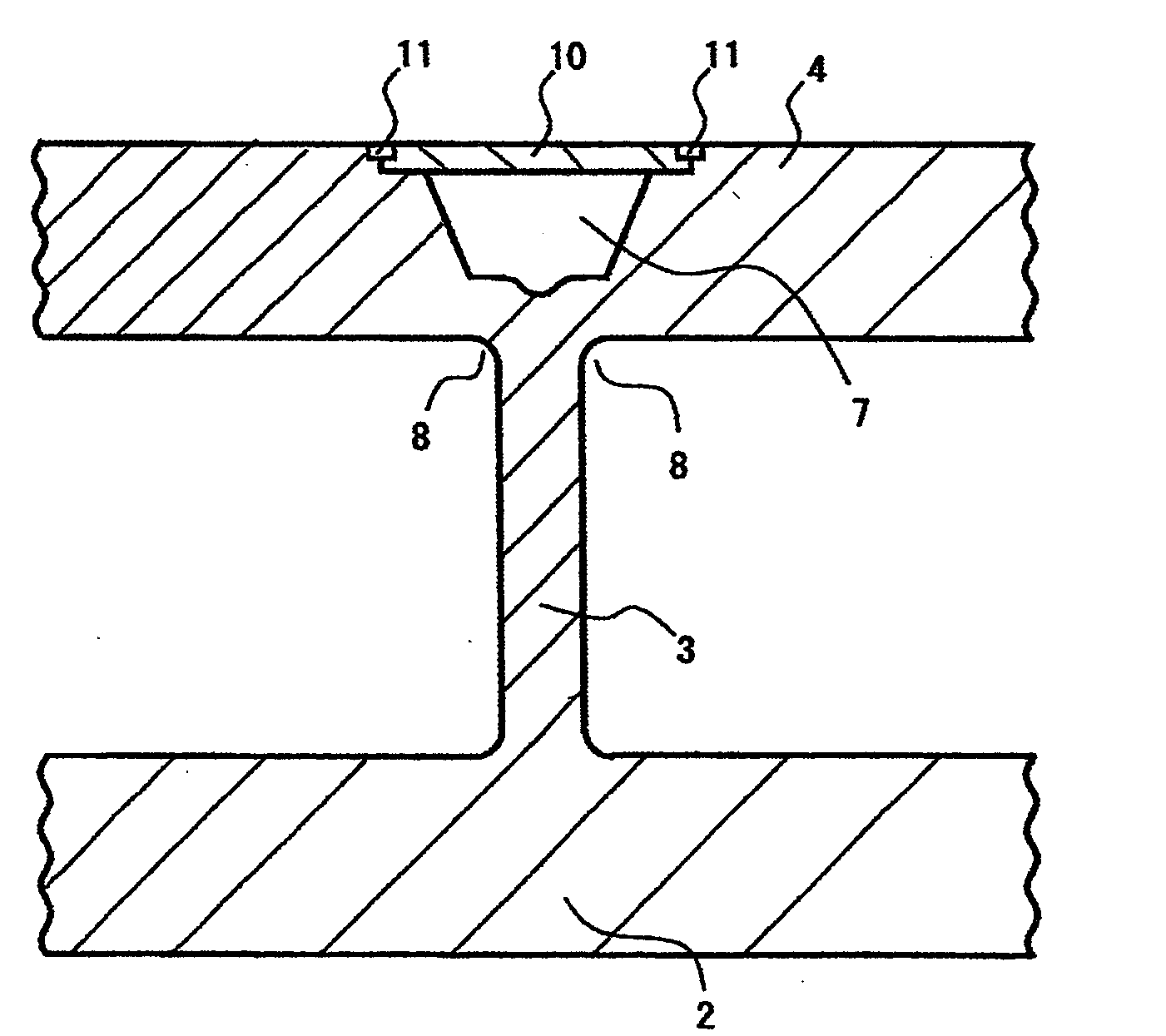

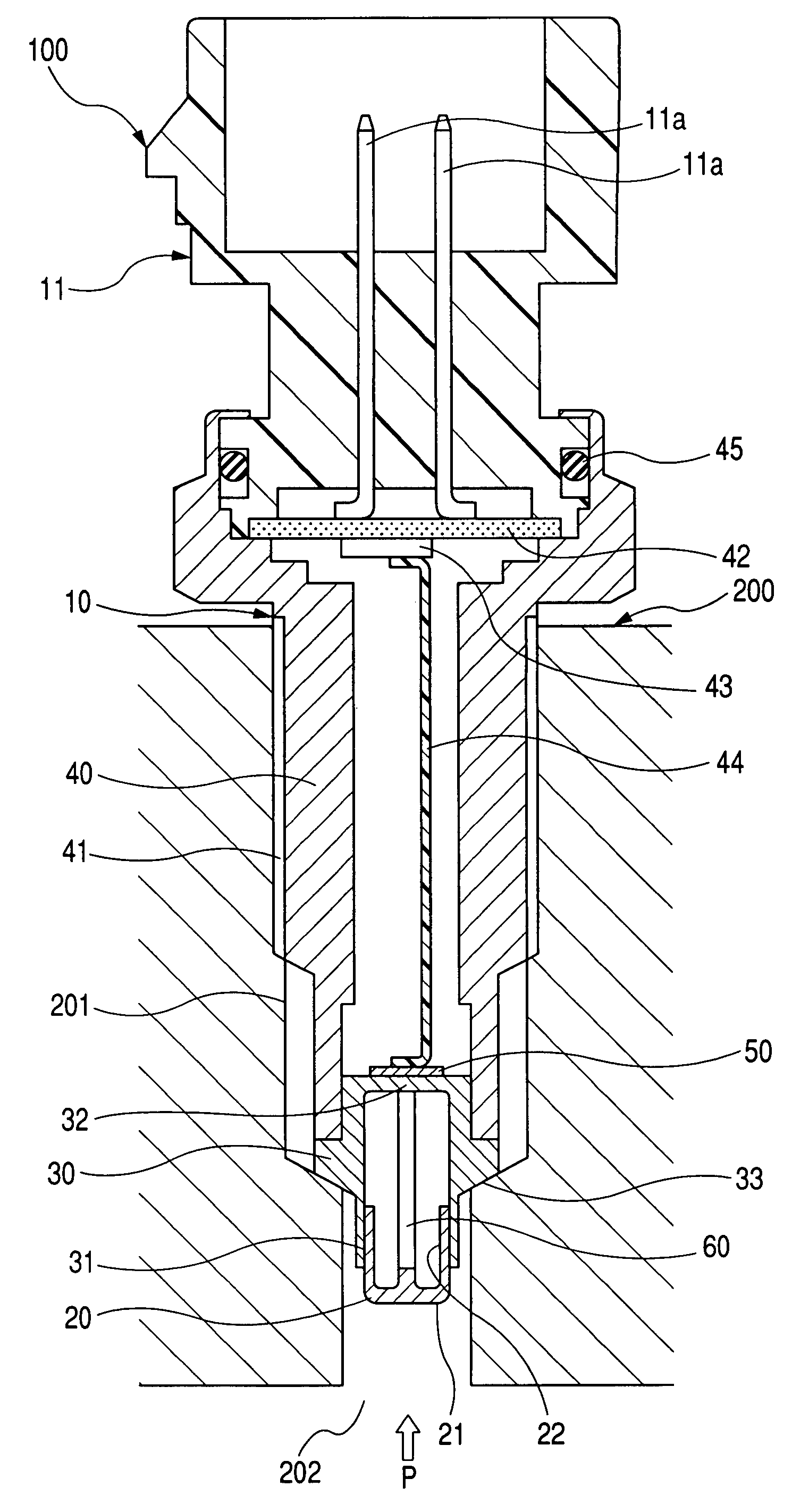

Pressure sensor equipped with pressure sensing diaphragm

InactiveUS7555957B2Minimize distortionImprove the heating effectFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsCombustionPressure transmission

A pressure sensor is provided which may be employed in measuring the combustion pressure in an internal combustion engine. The pressure sensor is equipped with a pressure sensing diaphragm assembly which includes a first diaphragm, a second diaphragm, and liquid or gel. The first diaphragm is flexible when exposed to pressure to be measured and joined to the second diaphragm to define a closed chamber filled with the liquid or gel to transmit the pressure to the second diaphragm. A pressure transmitting member is disposed in abutment with the second diaphragm to transmit the pressure, as transmitted from the first diaphragm, to a pressure sensing device. The inclusion of the liquid or gel in the closed chamber between the first and second diaphragms results in an increase in heat capacity of the diaphragm assembly to decrease the thermal distortion thereof without sacrificing the sensitivity of the pressure sensor.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com