Degradable environment-friendly type polypropylene(PP) foam plastic and preparation method thereof

A technology of foamed plastics and polypropylene, which is applied in the field of degradable and environmentally friendly polypropylene foamed plastics and its preparation, can solve the problems of not being able to form air bubbles, gas is difficult to enclose, and processing is difficult, so as to improve cold resistance and low-temperature impact performance, Excellent physical and mechanical properties, superior electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

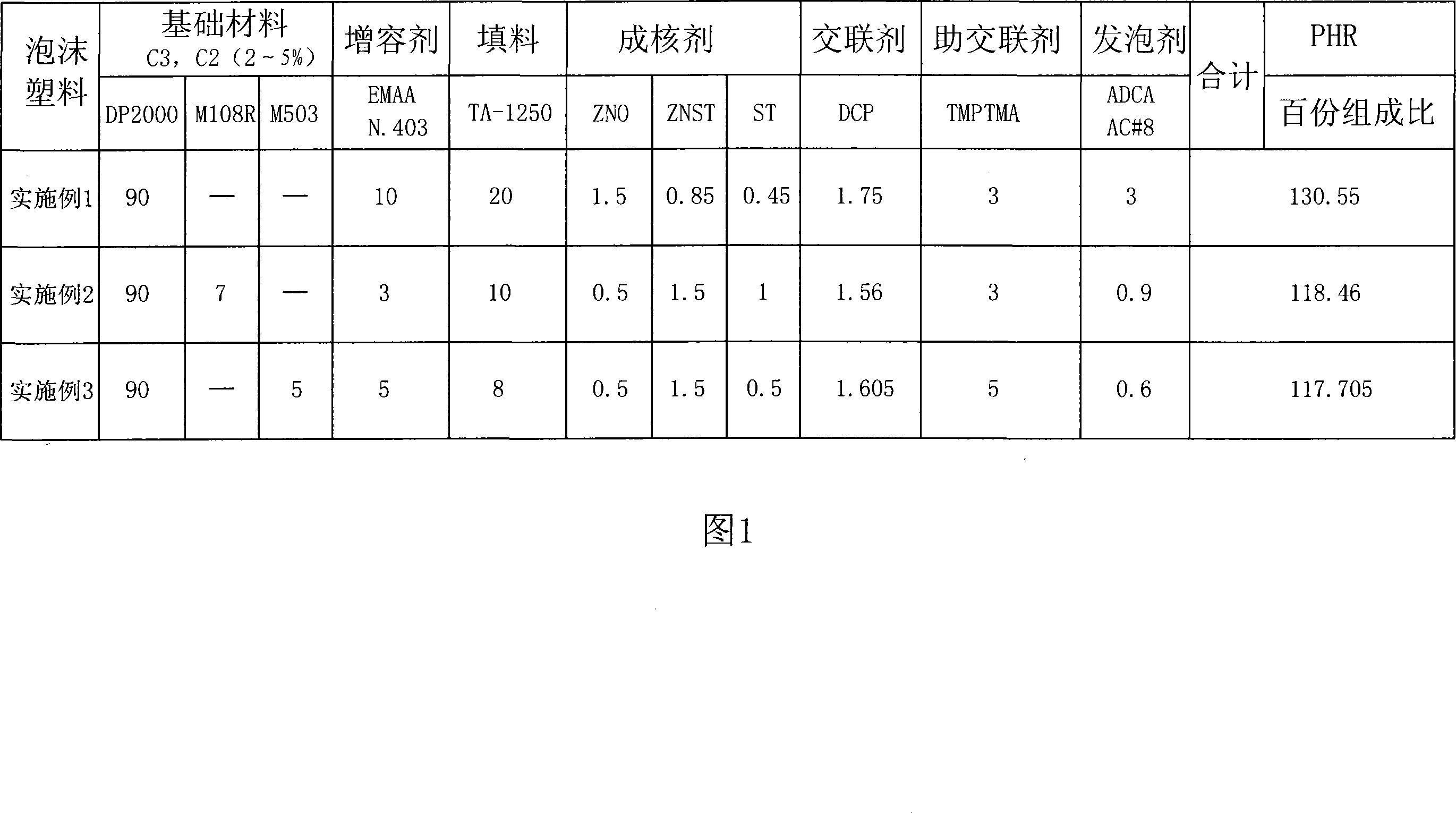

[0035] Embodiment 1: A kind of degradable and environment-friendly polypropylene (pp) foamed plastics, comprises base material, compatibilizer, filler, nucleating agent, crosslinking agent, linking aid agent, blowing agent. With reference to the foamed plastic embodiment 1 among Fig. 1:

[0036] Basic material: Copolypropylene (block copolymer type) copolymerized polypropylene polymer with an ethylene content of 2-5%, containing 90 parts by weight of DP2000; based on 90 parts by weight of DP2000;

[0037] Compatibilizer: adopt ethylene, acrylic acid copolymer (EmAA), its weight part is 10;

[0038] Filler: Talcum powder TA-1250 is used, and its weight part is 20;

[0039] Nucleating agent: contains zinc oxide powder (ZNO), zinc stearate (ZNST), stearic acid (ST), and is also used as a promotion, heat transfer, and lubricating release agent; the weight part of zinc oxide powder (ZNO) 1.5, zinc stearate (ZNST) parts by weight are 0.85, and stearic acid (ST) parts by weight are...

Embodiment 2

[0052] Embodiment 2: with reference to the foamed plastics embodiment 2 among Fig. 1, can find out:

[0053] The degradable and environment-friendly polypropylene (pp) foam plastic provided in this embodiment includes a base material, a compatibilizer, a filler, a nucleating agent, a crosslinking agent, a linking aid, and a foaming agent.

[0054] Basic material: Copolypropylene (block copolymer type) copolymerized polypropylene polymer with an ethylene content of 2-5%, containing 90 parts by weight of DP2000 and 7 parts by weight of M108R; based on 90 parts by weight of DP2000;

[0055] Compatibilizer: adopt ethylene, acrylic acid copolymer (EmAA), its weight part is 3;

[0056] Filler: use talc powder TA-1250, its weight part is 10;

[0057] Nucleating agent: contains zinc oxide powder (ZNO), zinc stearate (ZNST), stearic acid (ST), and is also used as a promotion, heat transfer, and lubricating release agent; the weight part of zinc oxide powder (ZNO) 0.5, zinc stearate (...

Embodiment 3

[0071] Embodiment 3: with reference to the foamed plastic embodiment 3 among Fig. 1, can find out:

[0072] The degradable and environment-friendly polypropylene (pp) foam plastic provided in this embodiment includes a base material, a compatibilizer, a filler, a nucleating agent, a crosslinking agent, a linking aid, and a foaming agent.

[0073] Basic material: Copolypropylene (block copolymer type) copolymerized polypropylene polymer with an ethylene content of 2-5%, containing 5 parts by weight of M503 and 90 parts by weight of DP2000; based on 90 parts by weight of DP2000;

[0074] Compatibilizer: adopt ethylene, acrylic acid copolymer (EmAA), its weight part is 5;

[0075] Filler: Talcum powder TA-1250 is used, and its weight part is 8;

[0076] Nucleating agent: contains zinc oxide powder (ZNO), zinc stearate (ZNST), stearic acid (ST), and is also used as a promotion, heat transfer, and lubricating release agent; the weight part of zinc oxide powder (ZNO) 0.5, zinc ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com