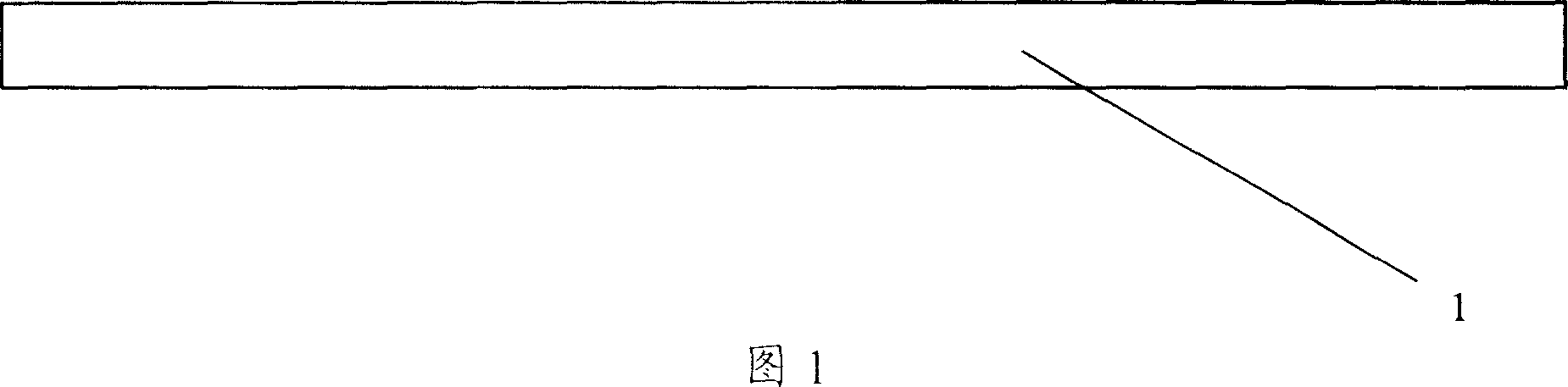

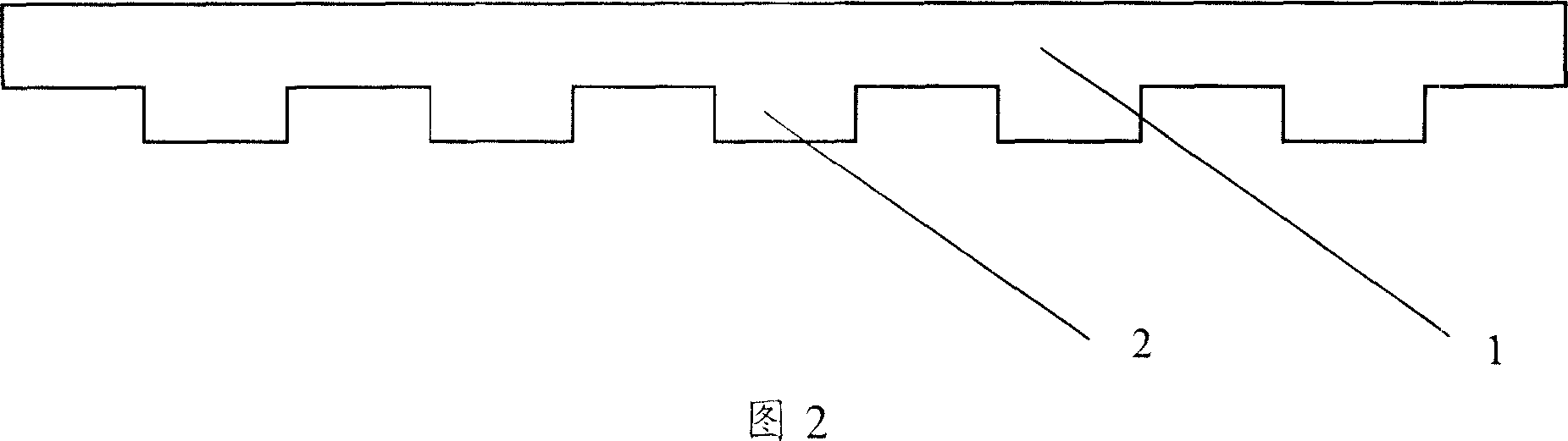

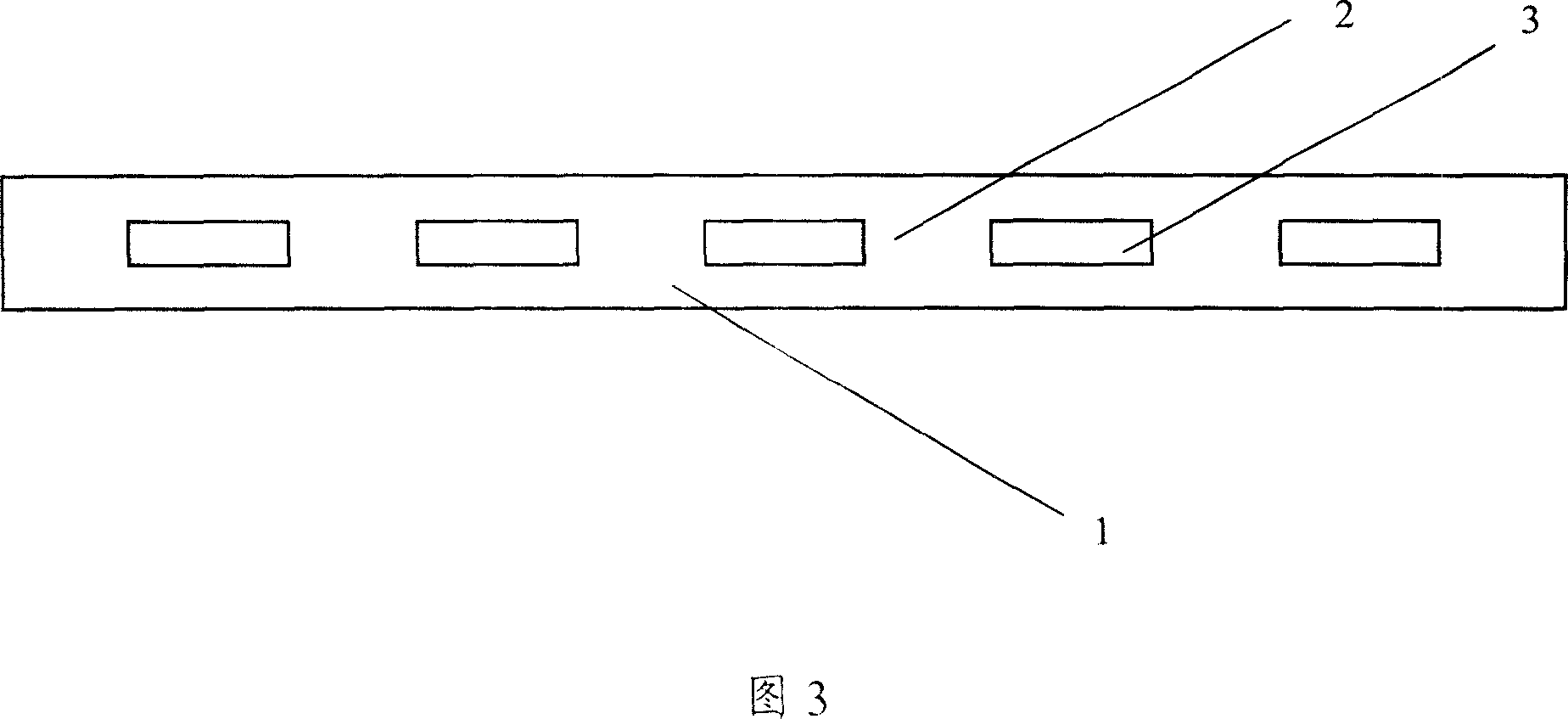

Wood plastic composite material building mould board, its preparation method and use

A wood-plastic composite material and building formwork technology, which is applied in the field preparation of building components, construction, building construction, etc., can solve the problems of large thermal deformation, less use times, low heat resistance, etc., and achieve small thermal deformation , reduce the project cost, improve the effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Collect and sort 60 parts of rice husks by weight, after crushing and grinding, the particle size is 40-80 mesh, and the moisture content after drying is less than 3%; select 40 parts of PVC new plastic powder by weight, and the selected particle size is 500-800 11 parts of calcium carbonate powder, 5 parts of PE resin, 4 parts of short glass fiber with a diameter of 5 μm and a length of 25 μm.

[0045] Auxiliaries are selected from composite lead accounting for 3% of the total weight of the main material and auxiliary materials, acrylate copolymer (ACR) accounting for 0.5% of the total weight of the main material and auxiliary materials, and chlorinated polyethylene (CPE) accounting for 1.5% of the total weight of the main material and auxiliary materials. ), stearic acid accounting for 1% of the total weight of main materials and auxiliary materials, dioctyl phthalate (DOP) accounting for 1.2% of the total weight of main materials and auxiliary materials, polyethylene ...

Embodiment 2

[0050] Collect and sort 70 parts of peanut shells by weight, crush and grind them into powder, the screening particle size is 40-80 mesh, and the moisture content after drying is less than 3%; select 30 parts of PVC resin by weight, and the selected particle size is 500-800 Purpose: 15 parts of calcium carbonate powder, 8 parts of PE resin, 5 parts of short glass fiber with a diameter of 6 μm and a length of 30 μm.

[0051] Auxiliaries are selected from composite lead accounting for 2% of the total weight of the main material and auxiliary materials, acrylate copolymer (ACR) accounting for 1% of the total weight of the main material and auxiliary materials, and chlorinated polyethylene (CPE) accounting for 1.6% of the total weight of the main material and auxiliary materials. ), stearic acid accounting for 0.8% of the total weight of main materials and auxiliary materials, dioctyl phthalate (DOP) accounting for 1.3% of the total weight of main materials and auxiliary materials,...

Embodiment 3

[0056] Collect and sort 50 parts of wheat stalks, corn stalks and corncobs by weight, pulverize and grind them into powder, the screening particle size is 40-80 mesh, and the moisture content after drying is less than 3%; select 10 parts of PVC resin by weight, 20 parts of new PVC plastic powder, 20 parts of PVC waste plastic powder, 6 parts of calcium carbonate powder with a particle size of 500-800 mesh, 4 parts of PE resin, 3 parts of short glass fiber with a diameter of 4 μm and a length of 20 μm.

[0057] Auxiliaries are selected from composite lead accounting for 2.5% of the total weight of the main material and auxiliary materials, ACR accounting for 0.7% of the total weight of the main material and auxiliary materials, CPE accounting for 1% of the total weight of the main material and auxiliary materials, and 0.7% of the total weight of the main material and auxiliary materials. Stearic acid, DOP accounting for 1.4% of the total weight of the main material and auxiliary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com