Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

619results about How to "Efficient regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of removing mercury from exhaust gases

InactiveUS6962617B2Effectively adsorbing and reacting mercurySimple methodGas treatmentUsing liquid separation agentHydrogenSorbent

Efficient removal of mercury from the exhaust gases of an industrial process or combustion process can be achieved using an adsorbent that can be regenerated by a simple and efficient method. The mercury is contacted with a sorbent material, the sorbent material being hydrogen mordenite or hydrogen clinoptilolite, for adsorbing mercury and causing the mercury to react with the sorbent material to produce mercury-laden sorbent material. The mercury-laden sorbent material can be heated to a temperature of at least about 400° C. so as to remove mercury from the mercury-laden sorbent material and to regenerate the sorbent material to allow reusing of the sorbent material for mercury removal.

Owner:LEHIGH UNIVERSITY

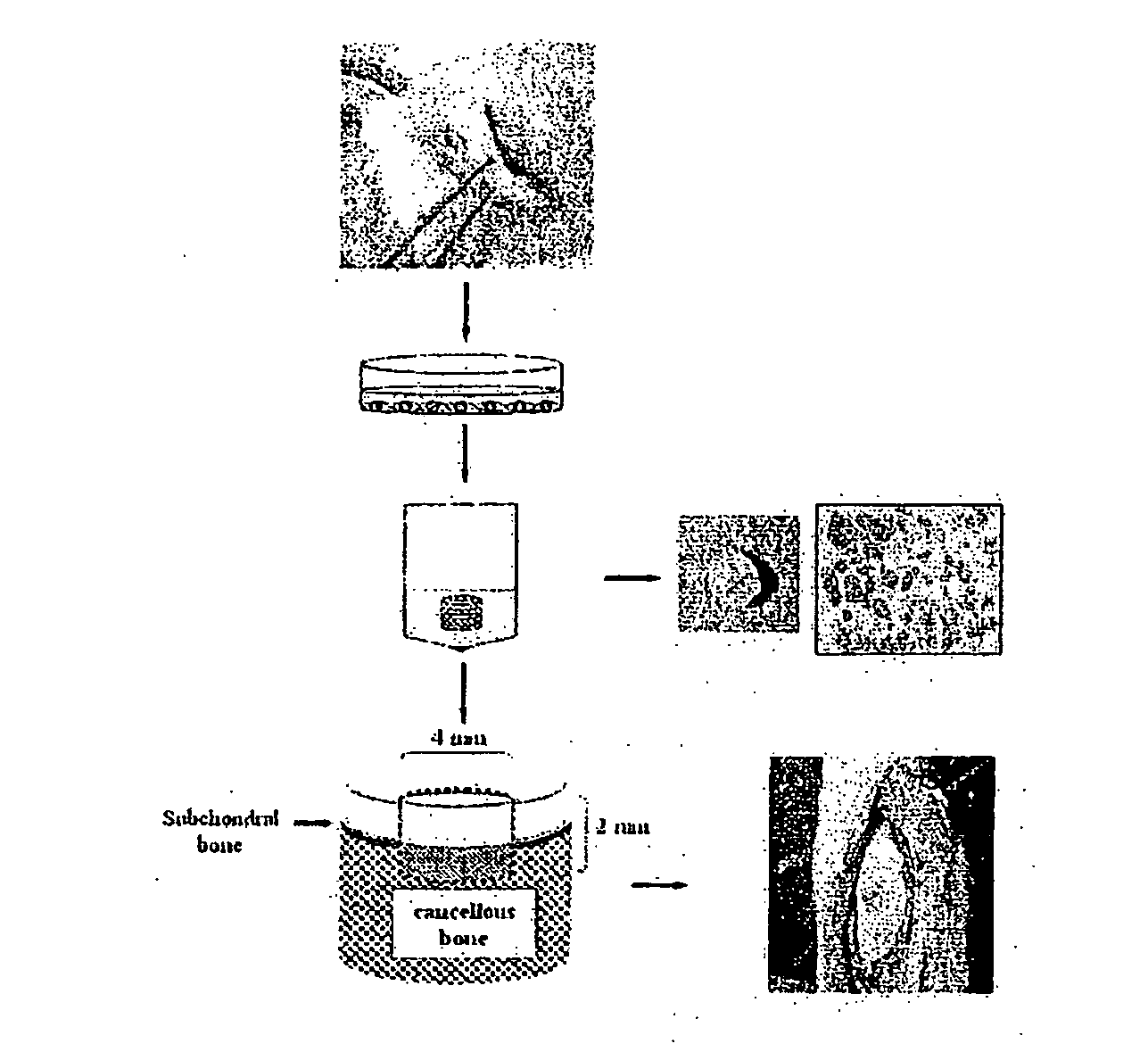

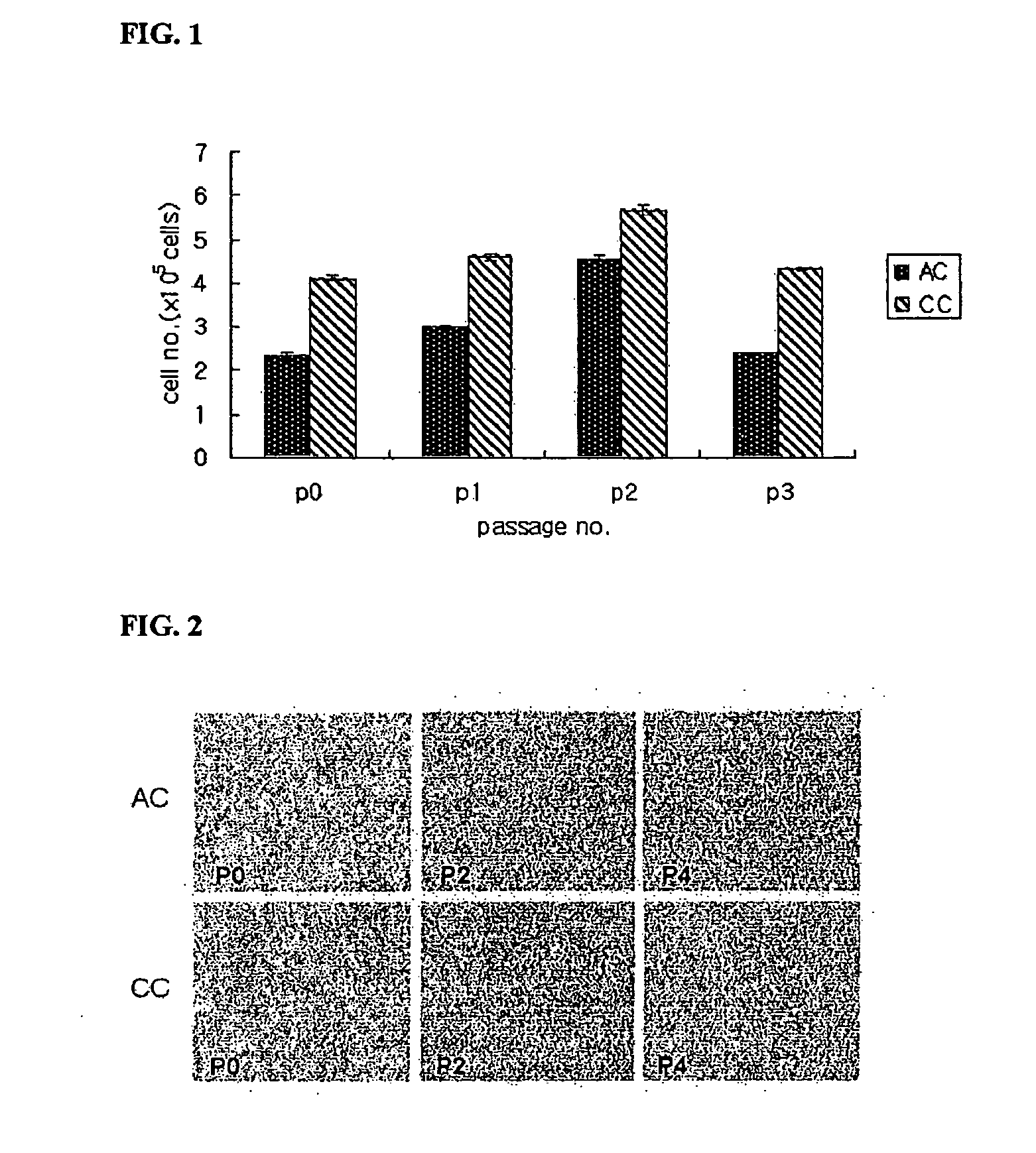

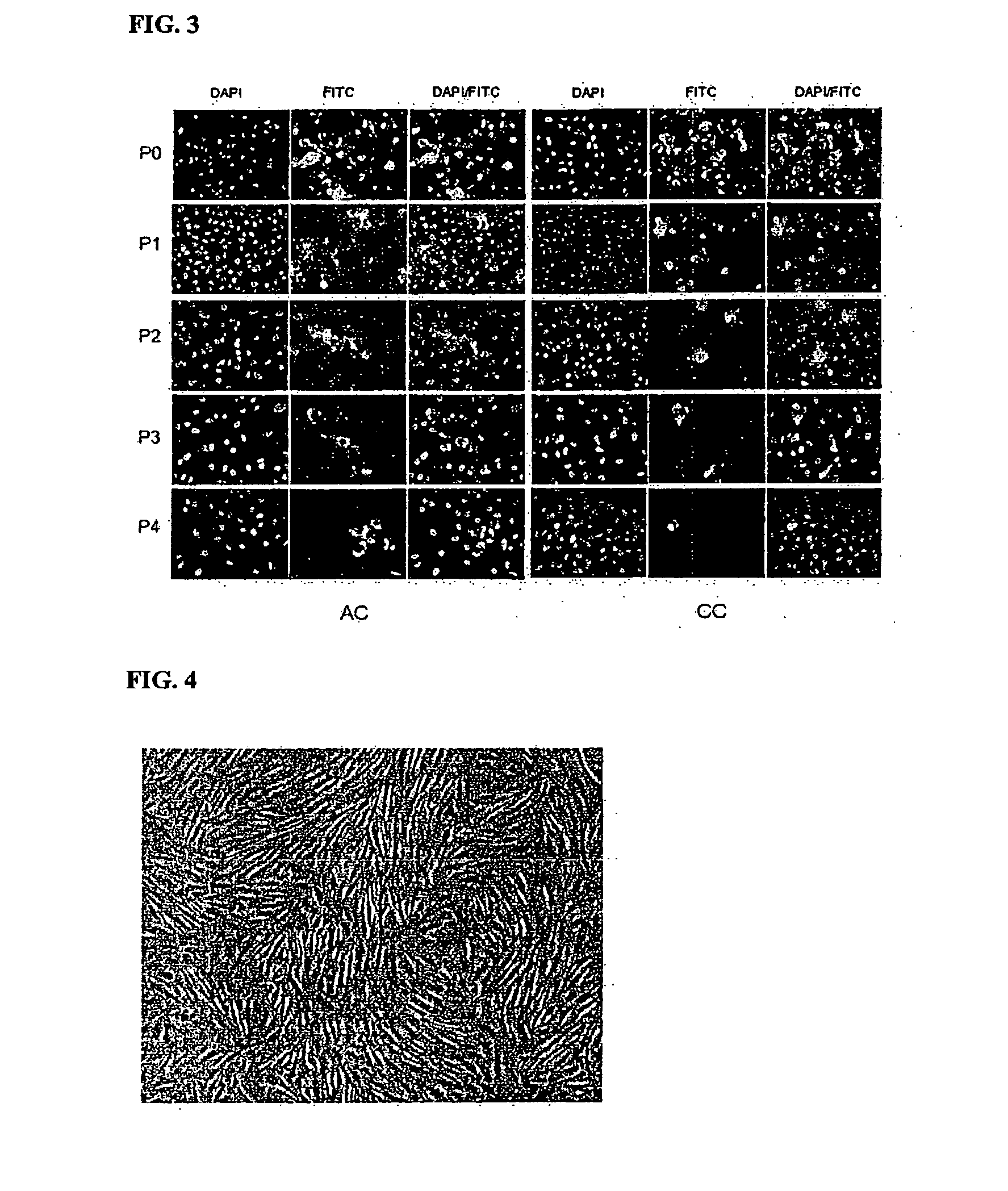

Artificial cartilage containing chondrocytes obtained from costal cartilage and preparation process thereof

ActiveUS20090228105A1Ability to useEfficient regenerationBone implantMammal material medical ingredientsMesenchymal stem cellCostal cartilage

The present invention relates to an artificial cartilage containing mesenchymal stem cell (MSC)-like dedifferentiated cells obtained by passage culturing costal chondrocytes, and a preparation process thereof.

Owner:BIO SOLUTION CO LTD +2

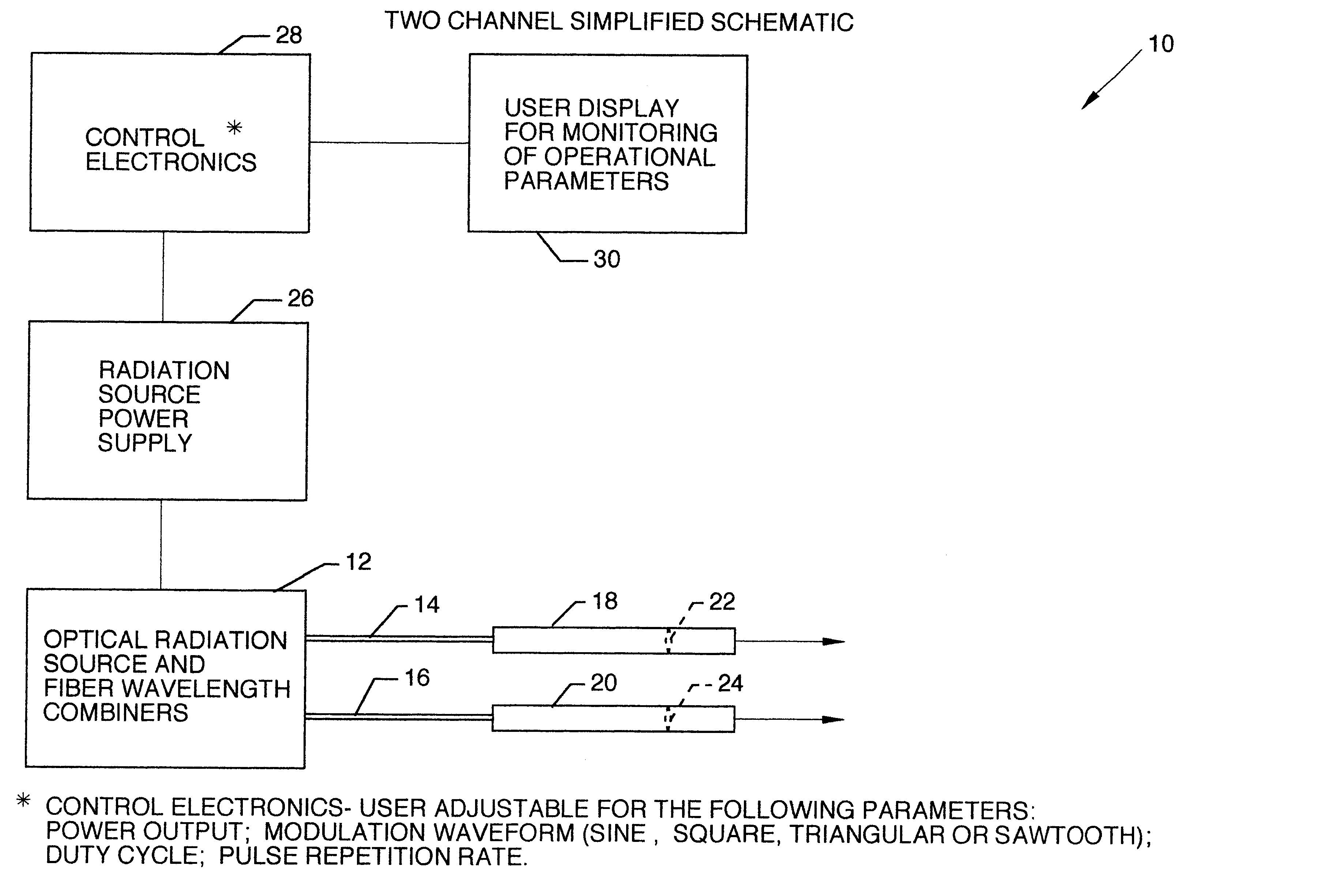

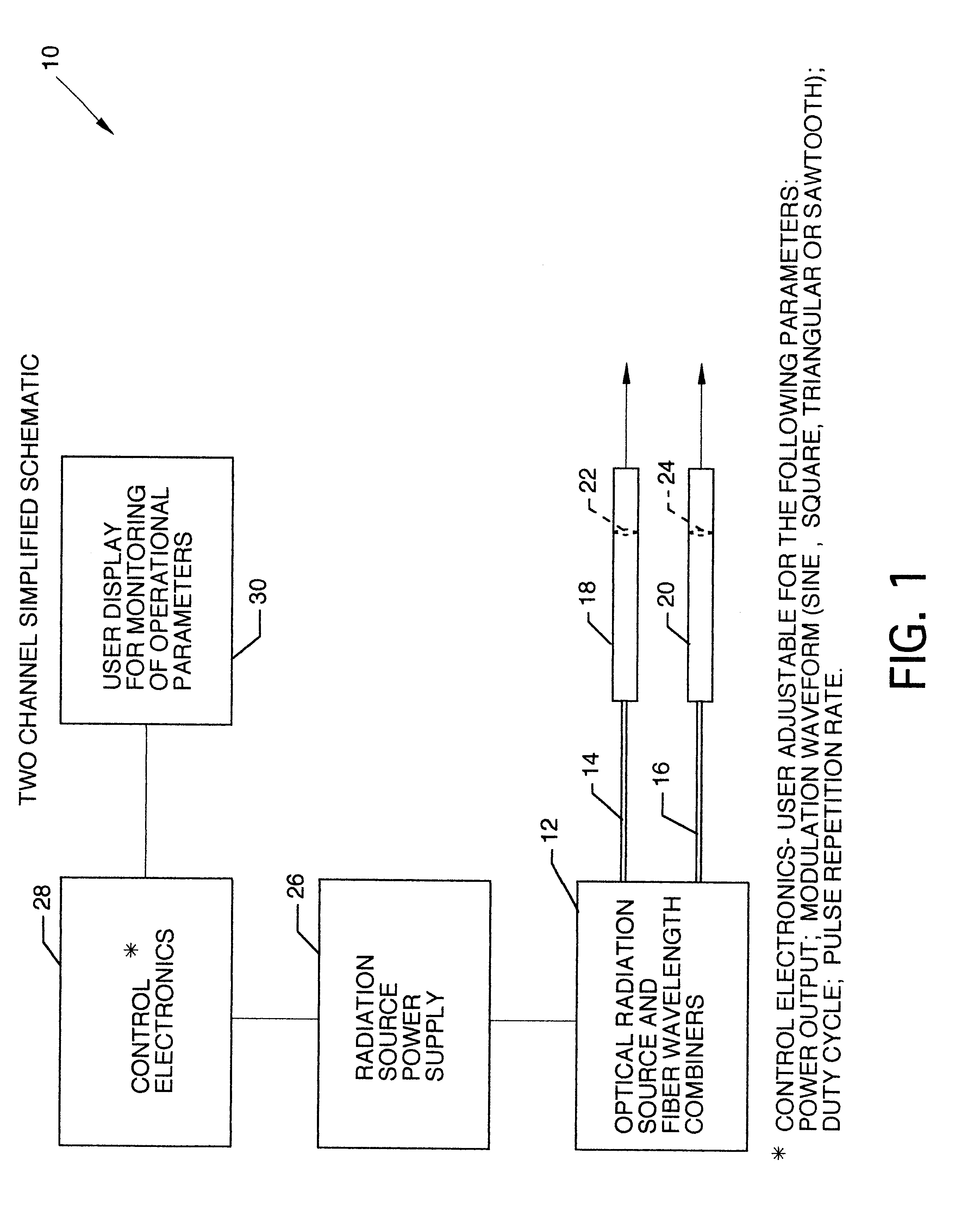

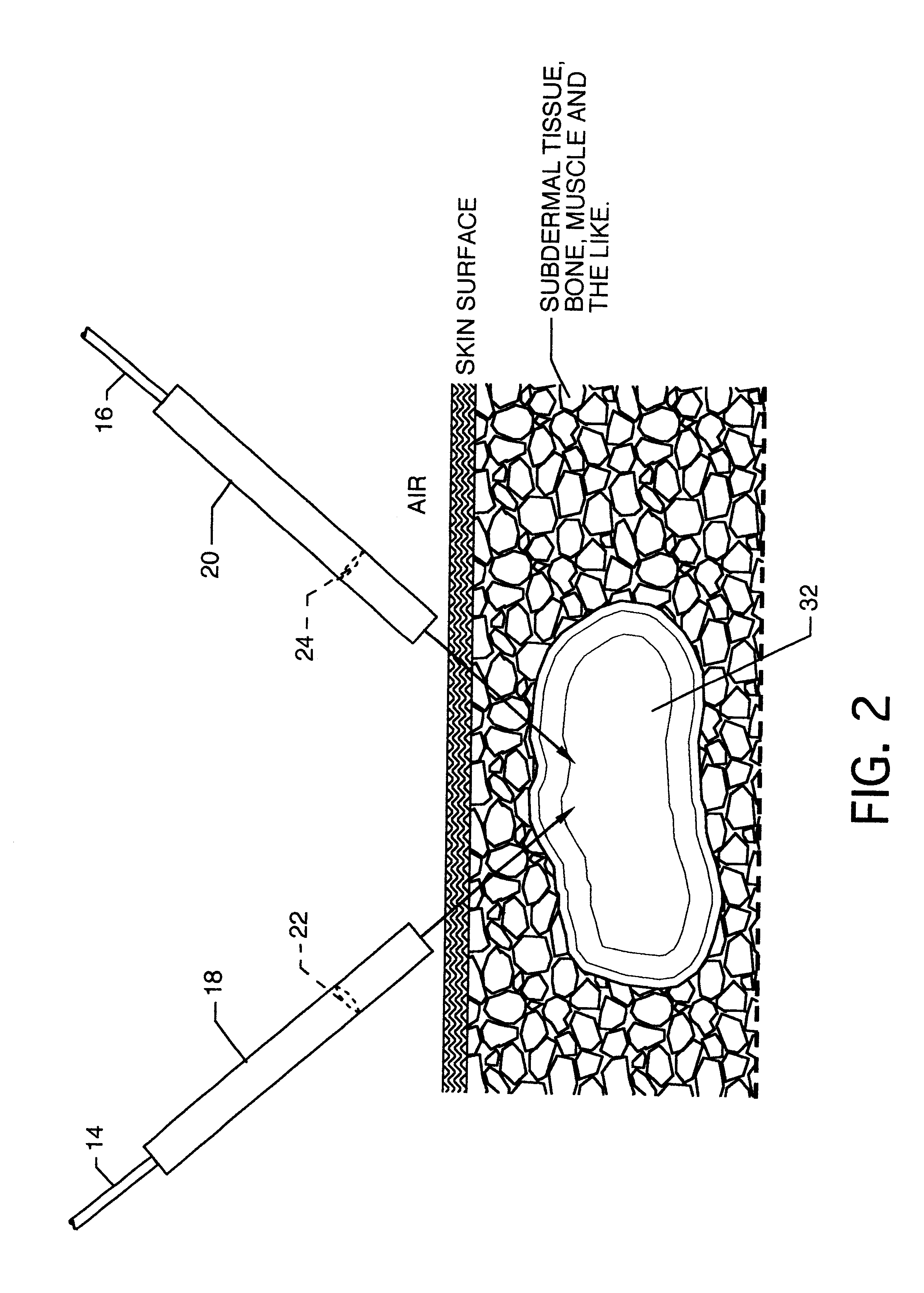

Violation of time reversal invariance in living tissue

InactiveUS6592611B1Eliminate needSynergistic effectivenessSurgical instrument detailsLight therapyDiseaseWavenumber

The present invention provides for a device, a method, and a treatment system for chronic disease conditions. The present invention was designed using the theoretical concepts of Quantum Biology. The principles of operation are based on the device's ability to stimulate a Bose-Einstein condensate and excitation of Frolich resonance in living tissue The wavenumbers necessary for this excitation are derived from the solution to the equations for optical phonon scattering in living tissue generated by optical photon excitation. The establishment of this degeneracy condition induces a super conducting state in the tissue. This super conducting state facilitates DNA replication, transcription and translation, thereby allowing the proper formation or regeneration of healthy tissue. This superconducting state provides the conditions necessary for establishing the violation of time reversal invariance in living tissue.

Owner:HOBSON MICHAEL A

SCR (selective catalytic reduction) flue gas denitration catalyst regeneration method

InactiveCN102658215AEasy to cleanEfficient regenerationDispersed particle separationCatalyst regeneration/reactivationFlue gasActive component

The invention relates to a catalyst regeneration method, and especially relates to an SCR flue gas denitration catalyst regeneration method. The method concretely comprises the following steps: purging a catalyst to be regenerated; putting the catalyst into a cleaning pool, cleaning with a cleaning solution, and drying; dipping the cleaned catalyst into an activity supplement solution to carry out activity supplement, and drying; and roasting and cooling the dried catalyst to obtain a generated denitration catalyst. The method of the invention has the following beneficial effects: catalyst carriers are not destroyed during cleaning; the catalyst can be cleaned, active substances can be supplemented, and active components of the regenerated catalyst are environmentally-friendly, so the regenerated catalyst does not generate pollution in the use process; and the denitration activity of the regenerated catalyst reaches above 90%. The method is very important for regeneration and reuse of dead toxic vanadium-titanium catalysts, and use promotion of self-developed novel environmentally-friendly and cheap titanium-based denitration catalysts.

Owner:NANJING UNIV OF TECH

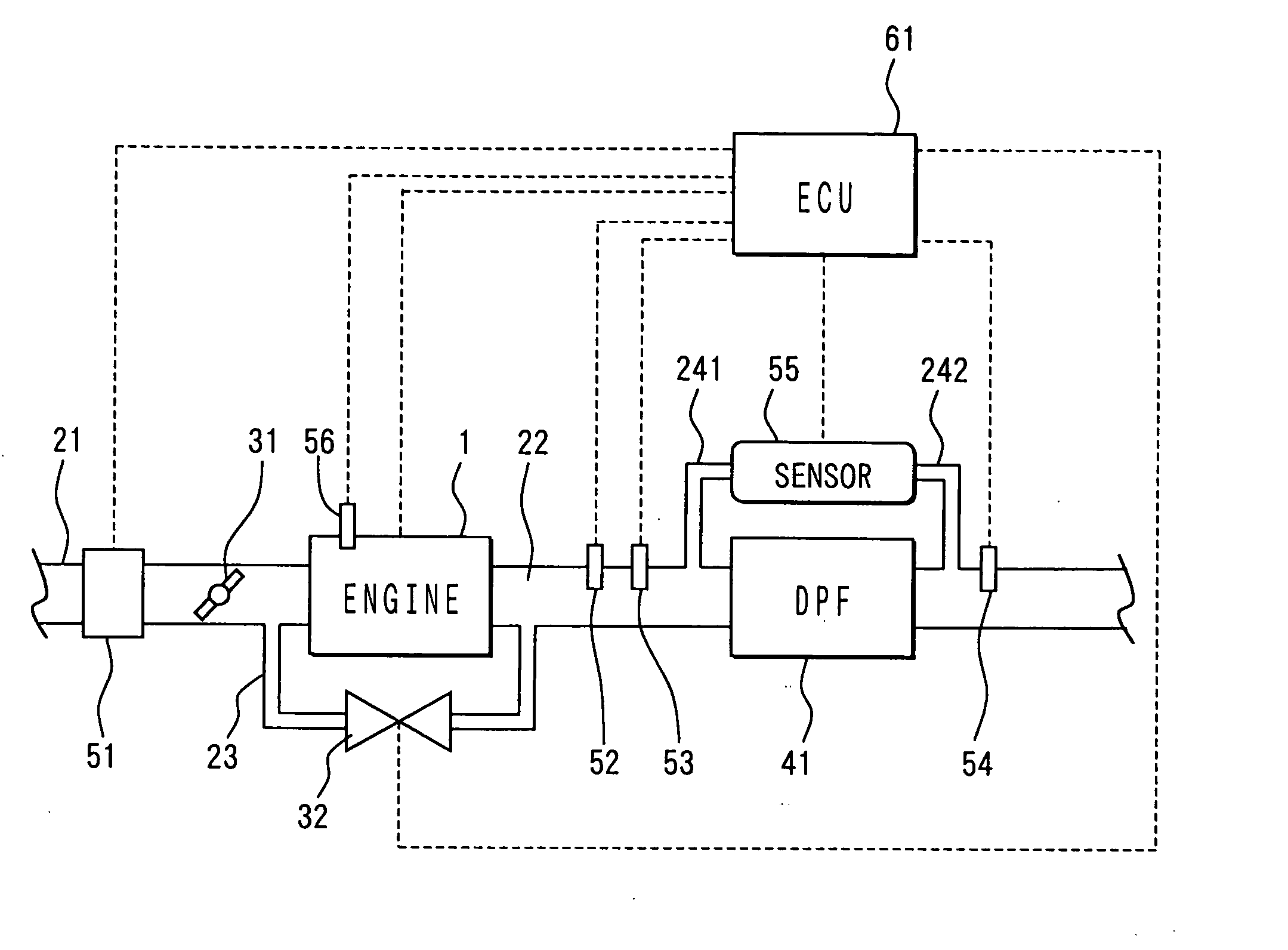

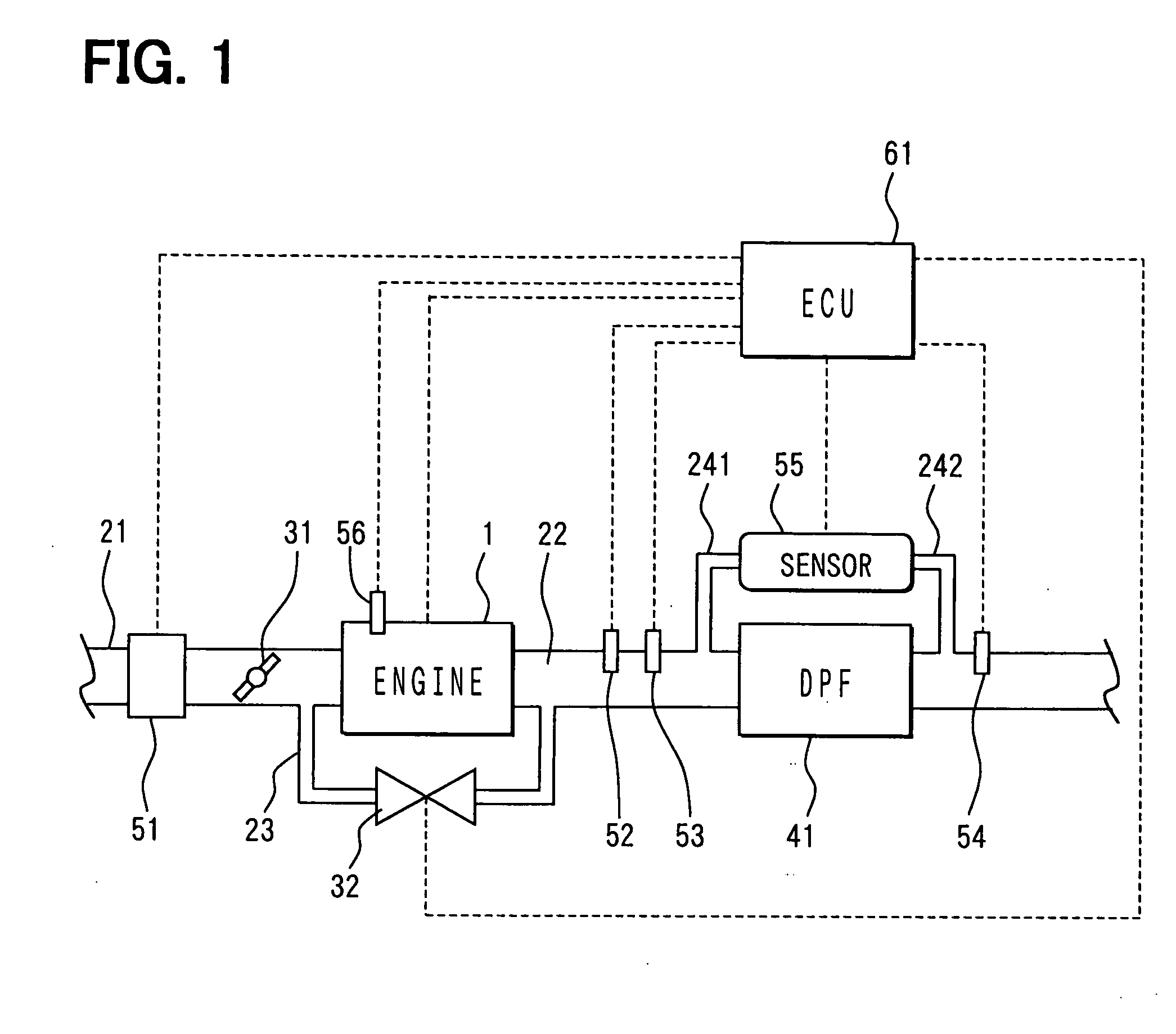

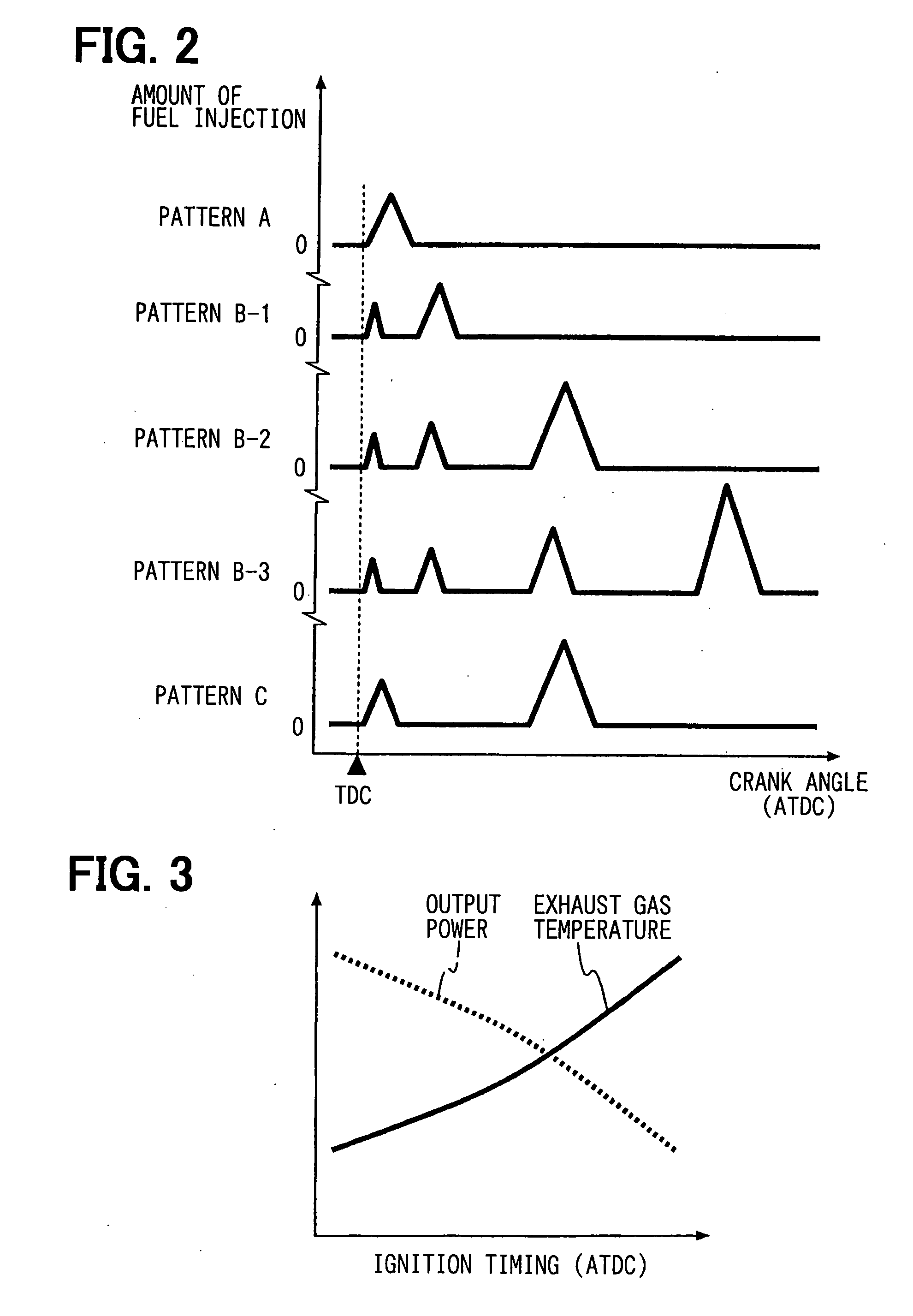

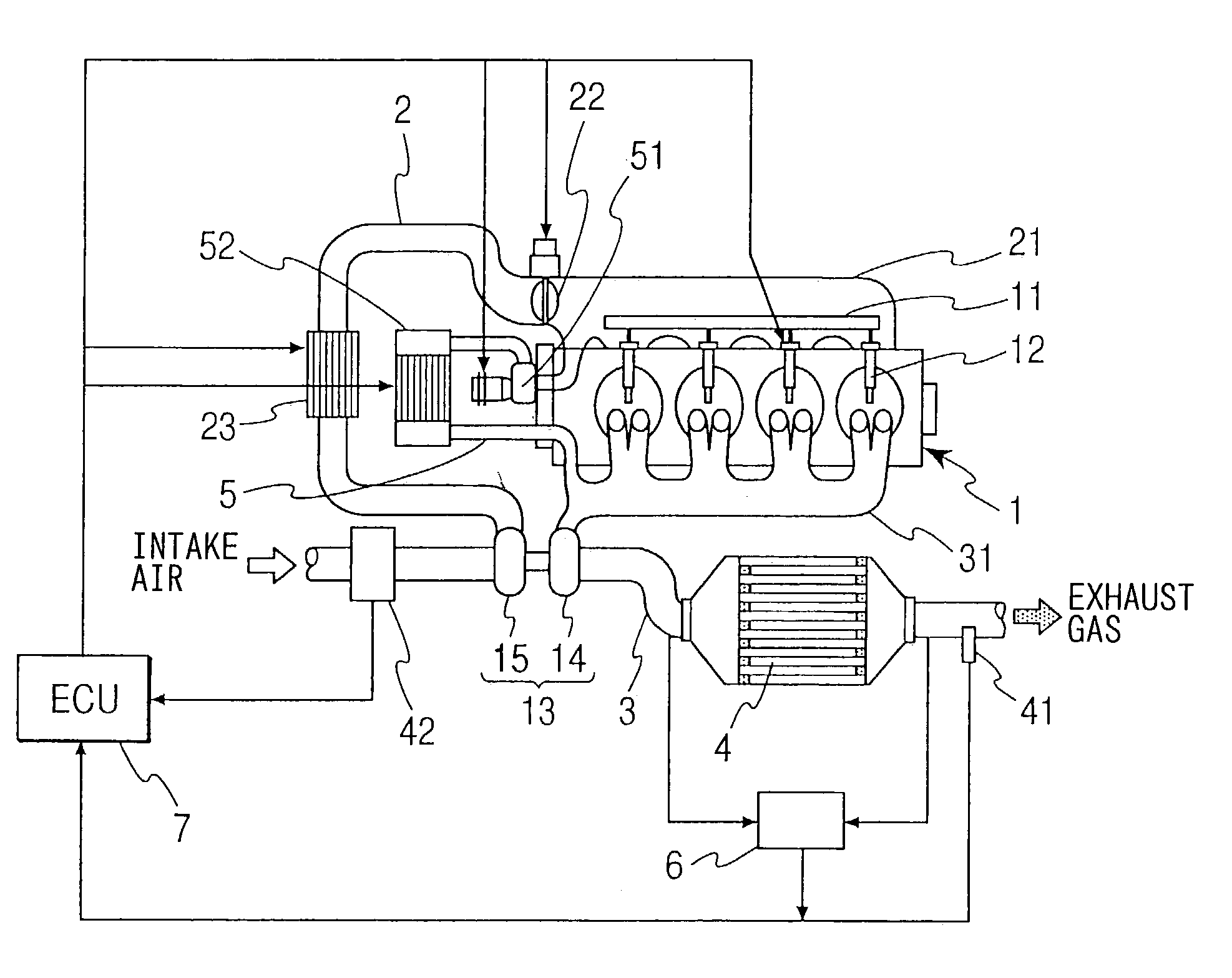

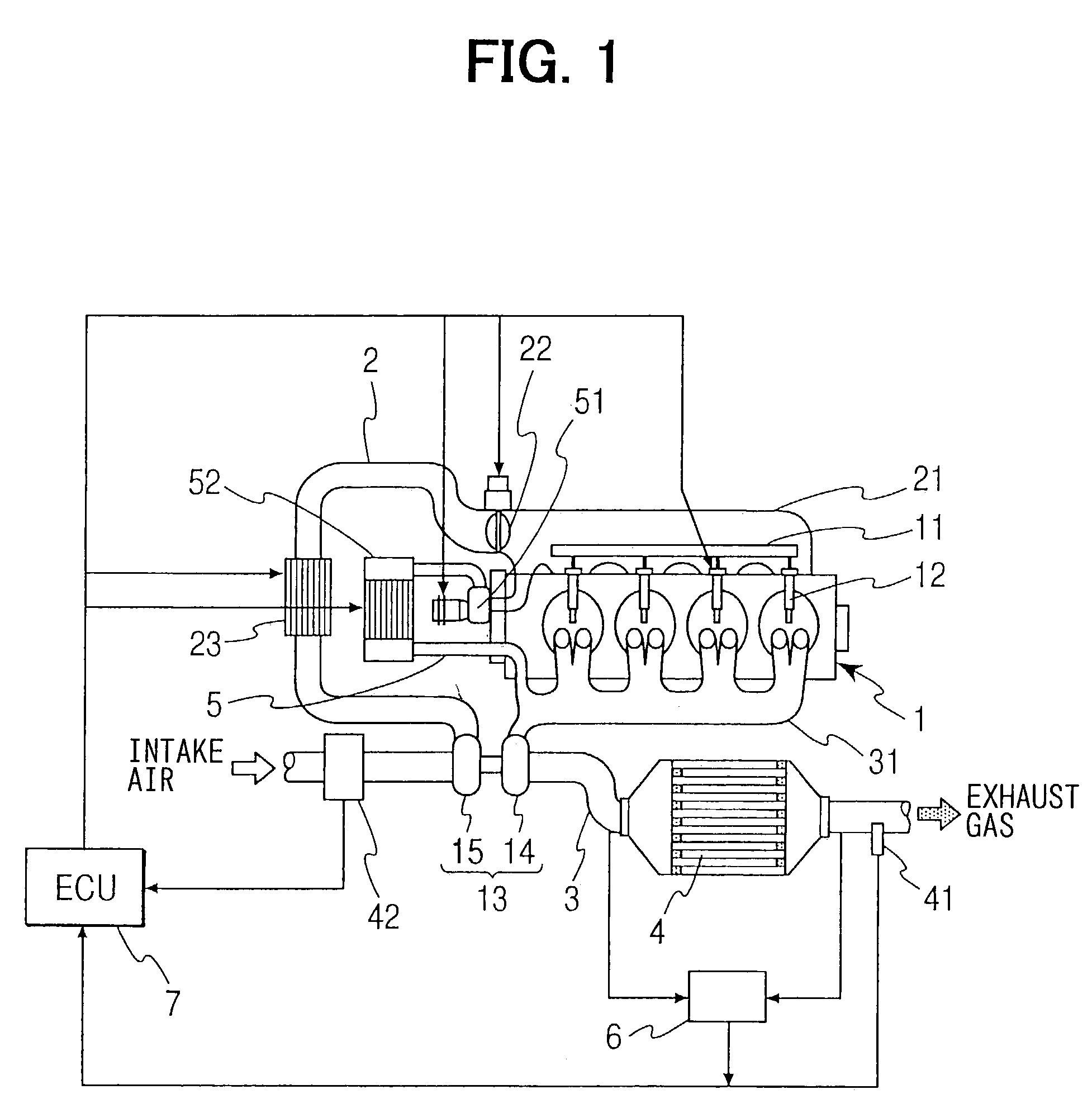

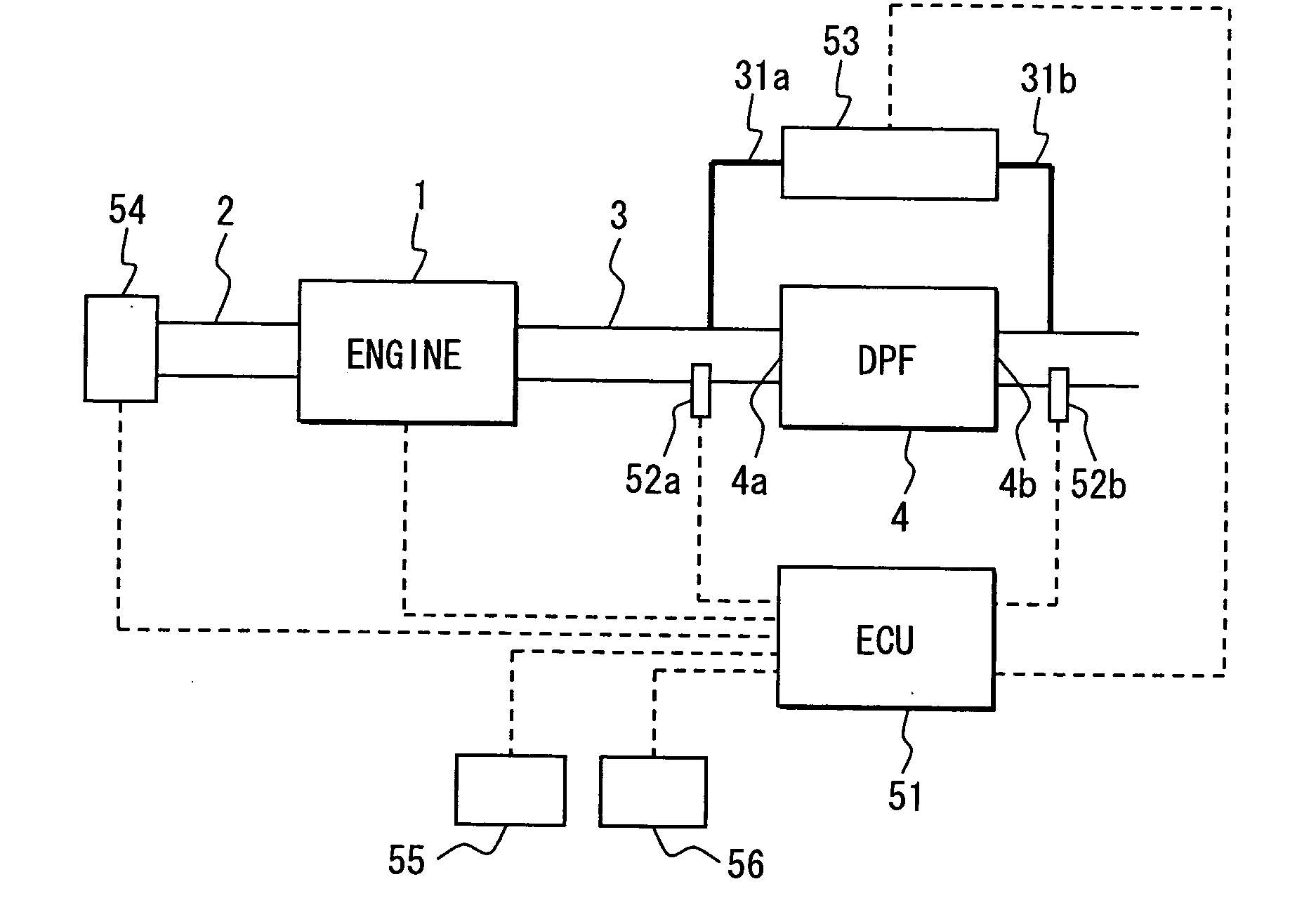

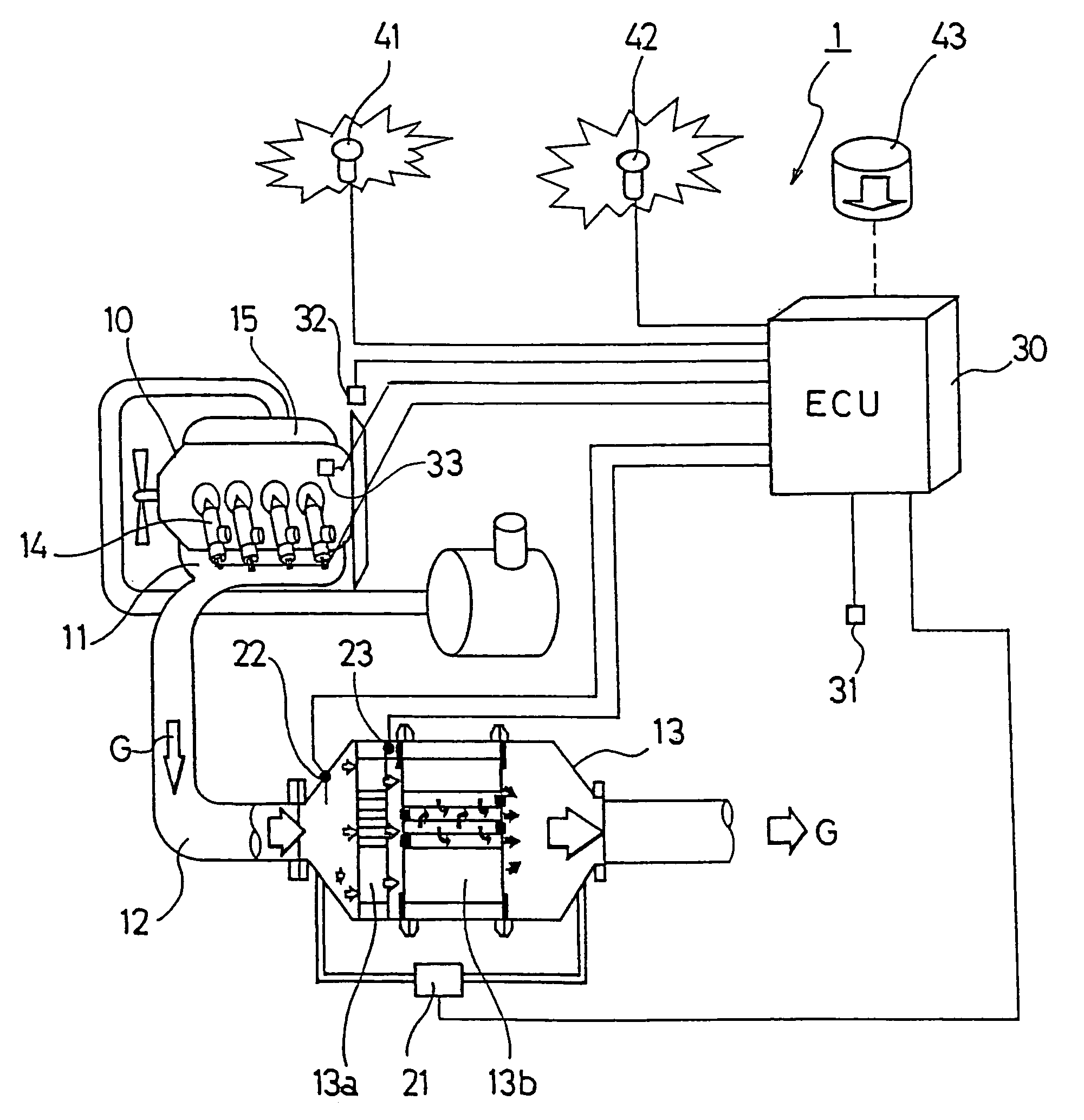

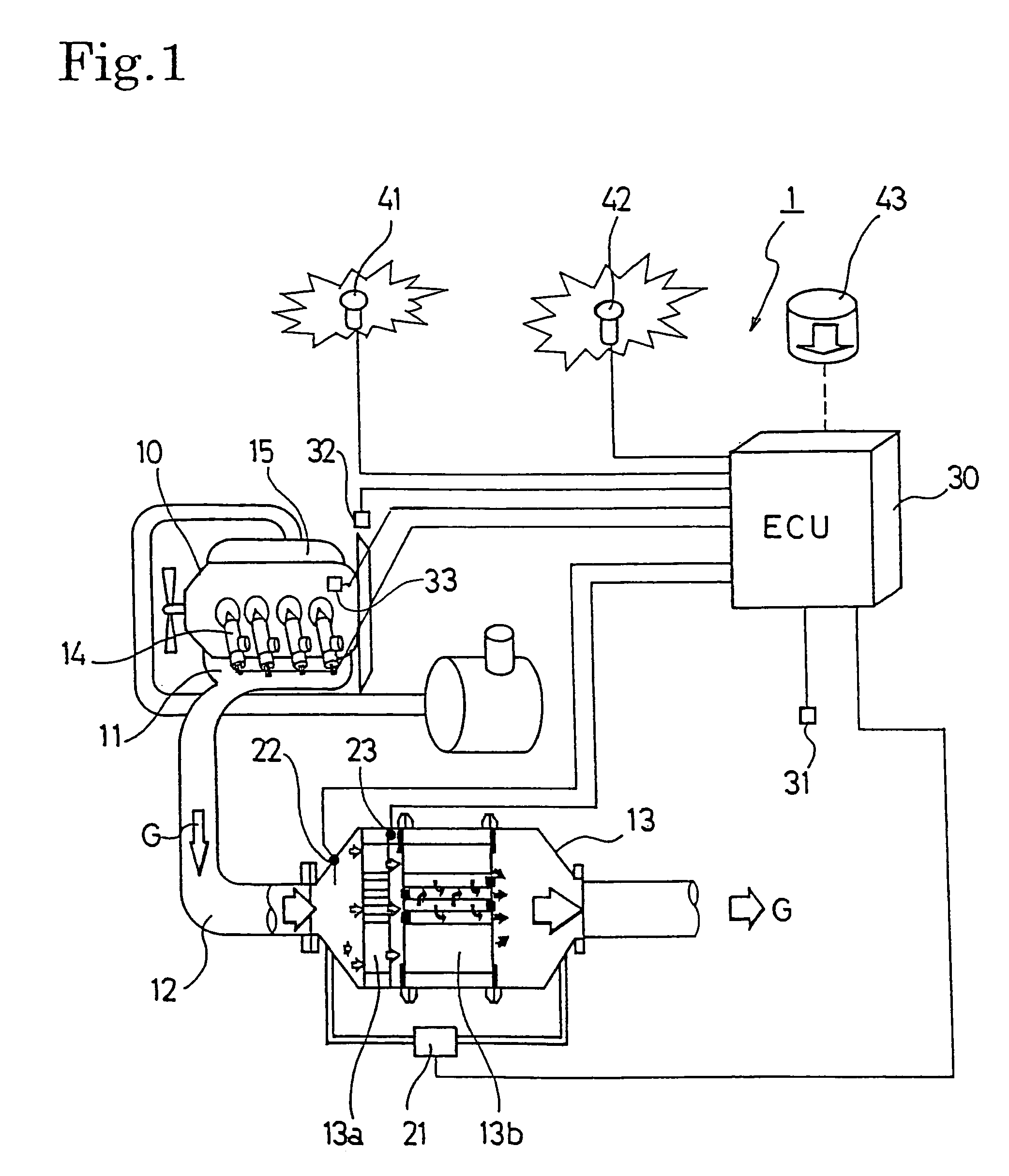

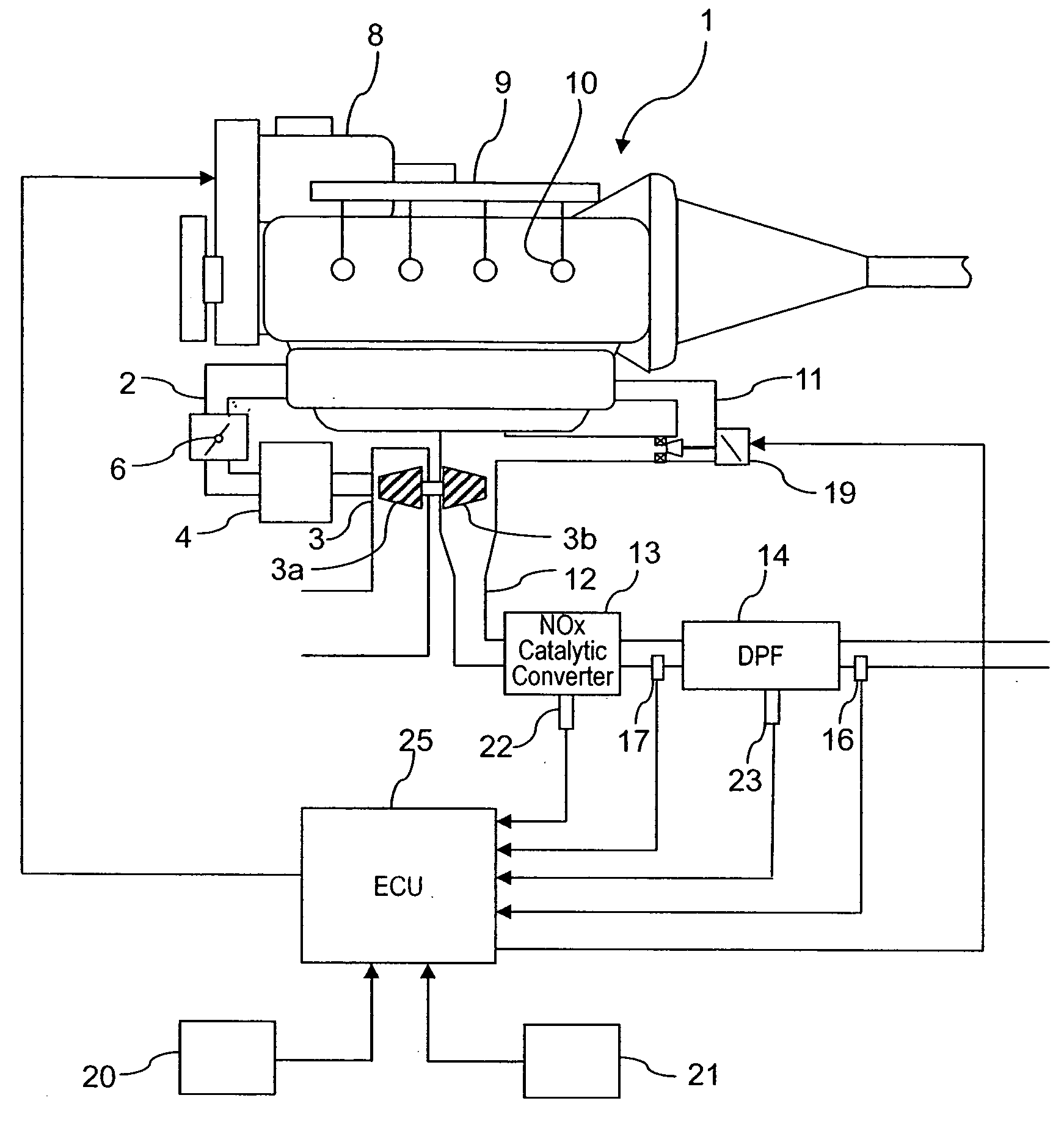

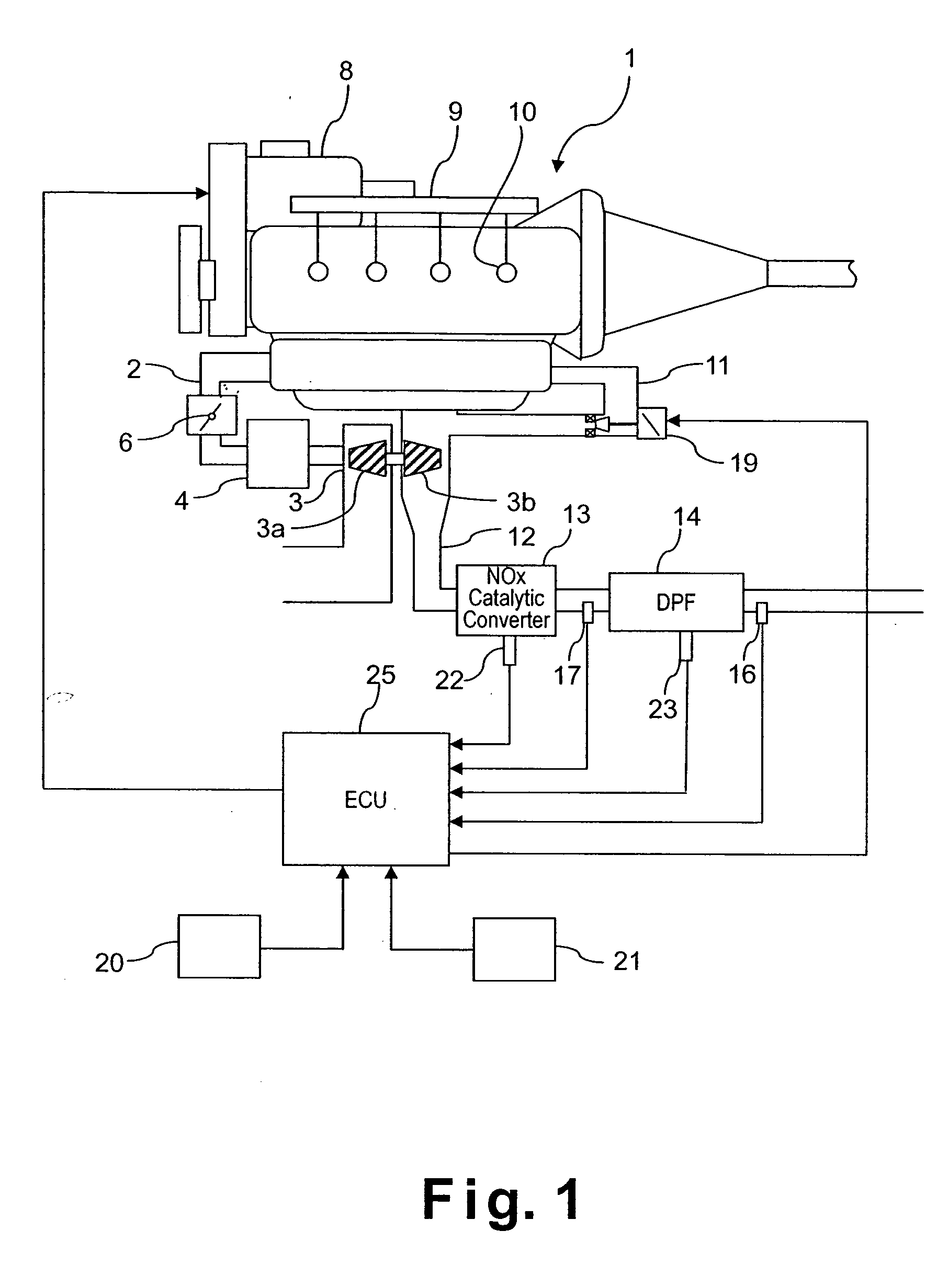

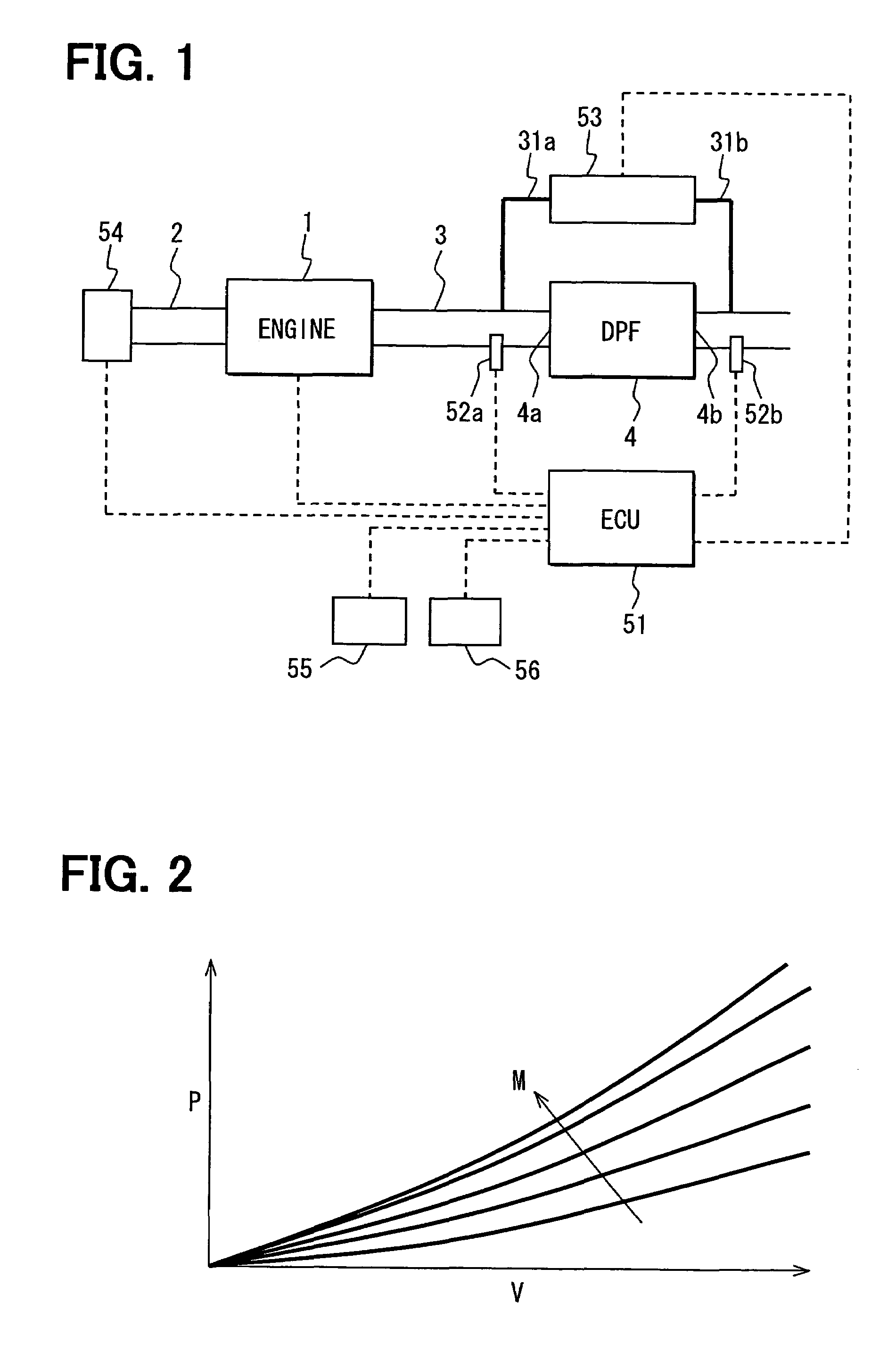

Exhaust gas cleaning device for internal combustion engine

ActiveUS20050252198A1Efficient regenerationReduce fuel consumptionElectrical controlInternal combustion piston enginesParticulatesTop dead center

In an engine, when it is determined that catalyst, which is held on a filter substrate of a particulate filter, is not in an active state, an ECU executes a fuel injection for mainly obtaining an engine power near a top dead center of a crank. Then, the ECU executes a subsequent fuel injection after lapse of a sufficient injection interval, which does not cause misfiring, to increase the temperature of exhaust gas outputted from the engine. In this way, the temperature of the filter is rapidly increased.

Owner:DENSO CORP

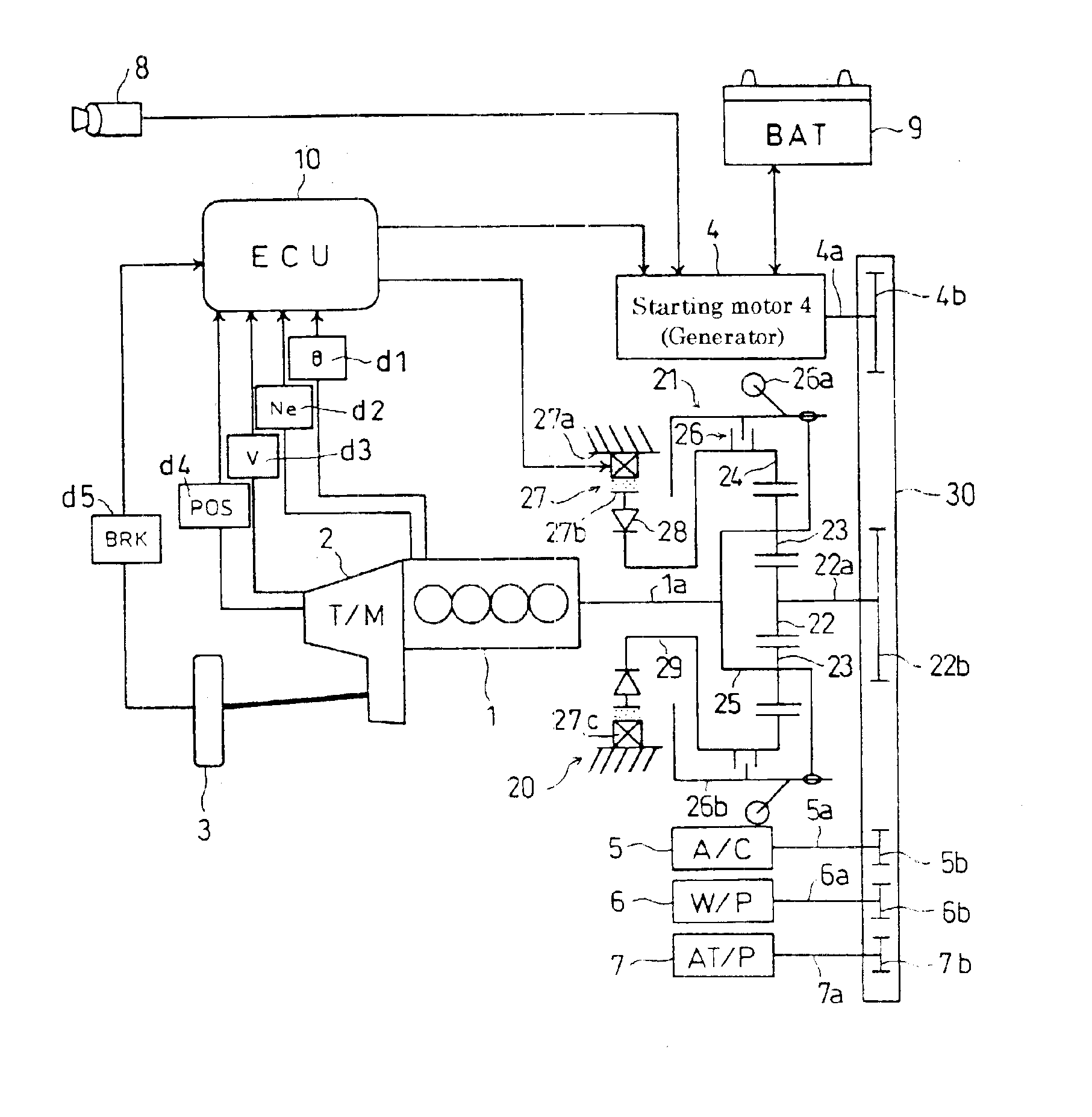

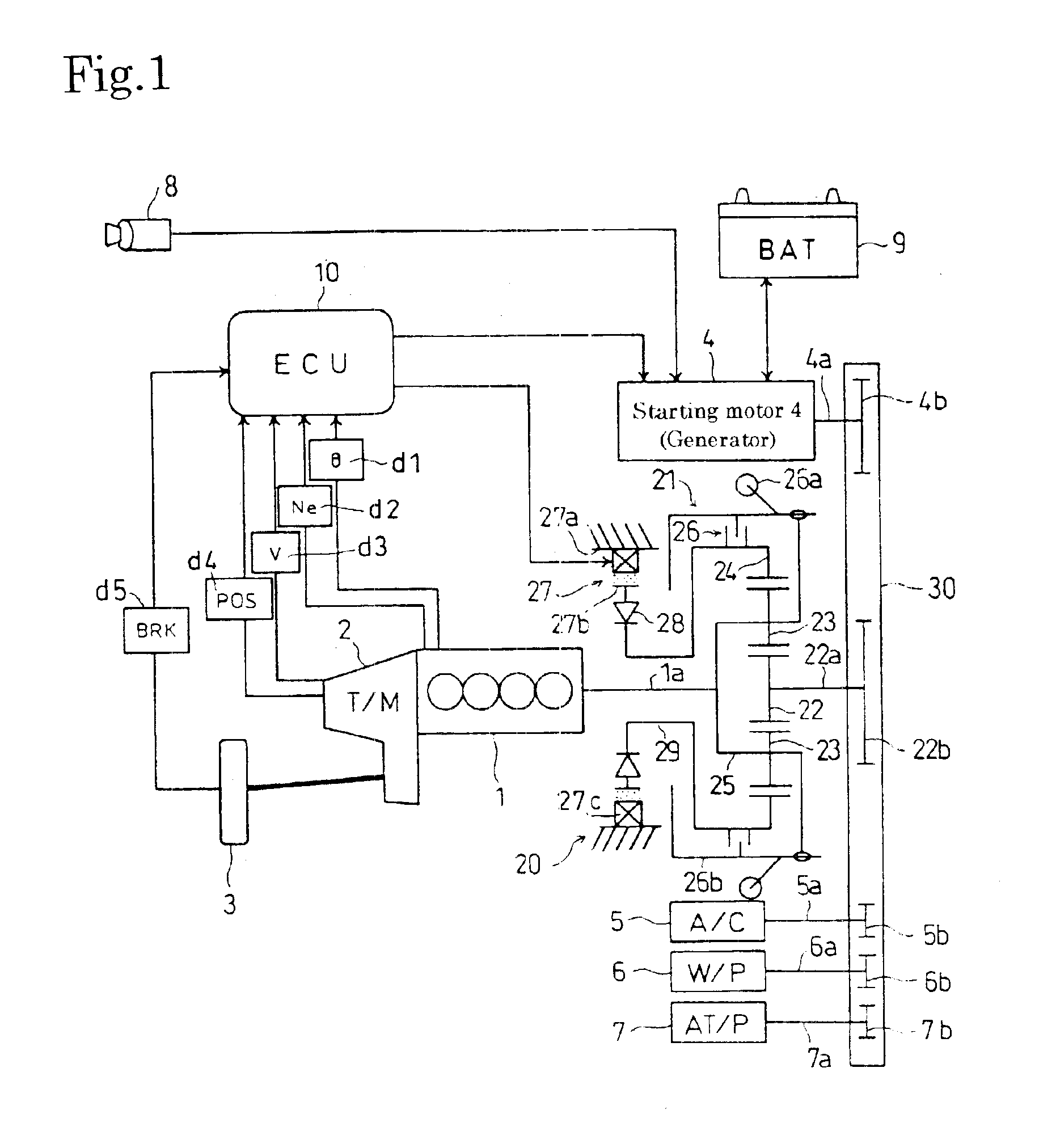

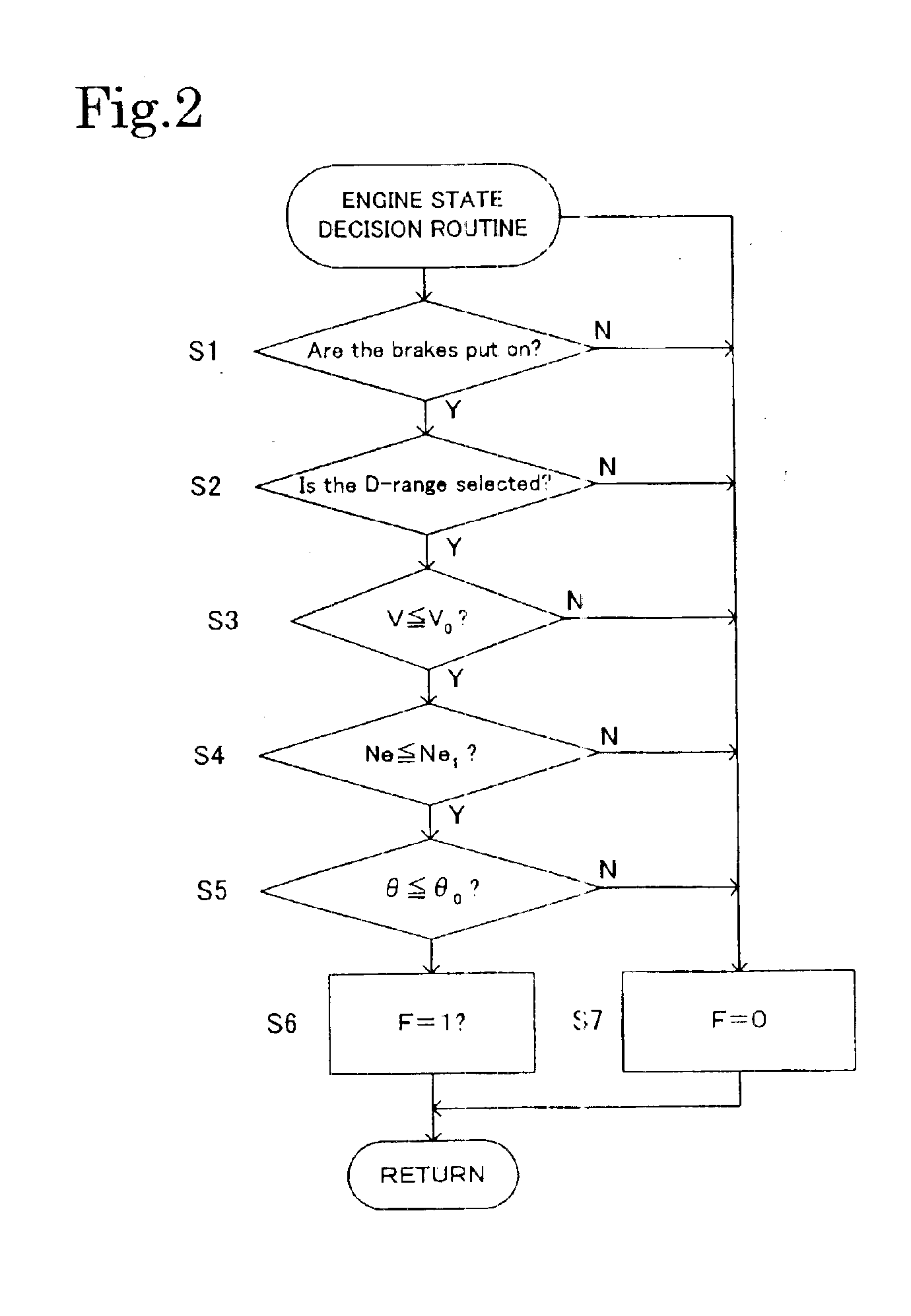

Automotive internal combustion engine control system

InactiveUS6852063B2Smooth startEfficiently regenerating energyAuxillary drivesPower operated startersControl systemExternal combustion engine

An automotive internal combustion engine control system transmits the output of a starting motor capable of operating as a generator to an internal combustion engine in starting the internal combustion engine, and transmits the output of the internal combustion engine to accessories while the internal combustion engine is in operation. The automotive internal combustion engine control system includes a transmission mechanism that transmits the output of the starting motor to the accessories while the internal combustion engine is stopped for a predetermined condition, transmits the rotation of the drive shaft of the starting motor to the crankshaft of the internal combustion engine at a high first gear ratio in starting the internal combustion engine, and transmits the rotation of the crankshaft of the internal combustion engine to the drive shaft of the starting motor at a low second gear ratio while the internal combustion engine is in operation to operate the starting motor as a generator. The transmission mechanism enables driving the accessories by the starting motor while the internal combustion engine is stopped, smoothly starting the internal combustion engine and efficient energy regeneration while the internal combustion engine is in operation.

Owner:HONDA MOTOR CO LTD

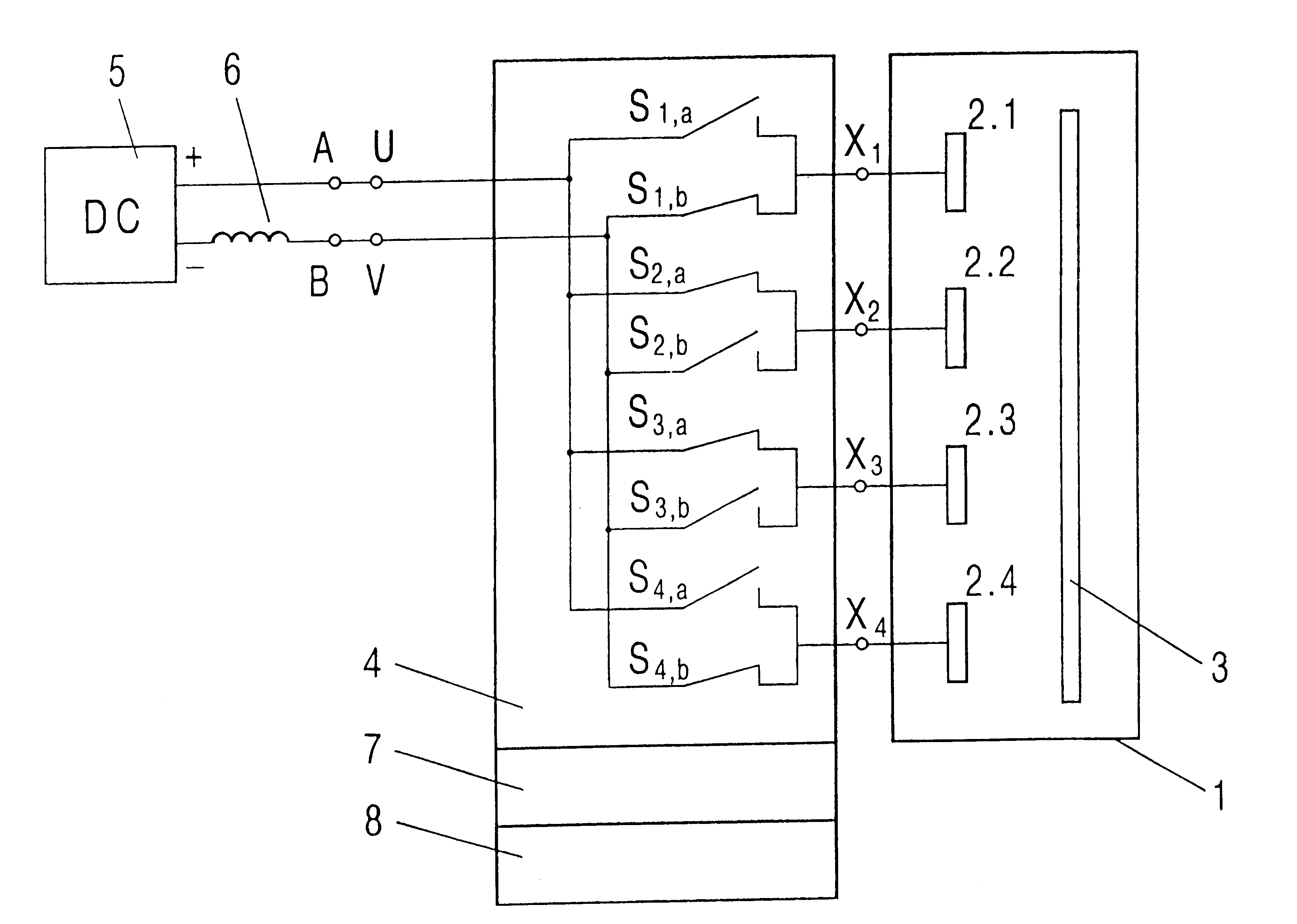

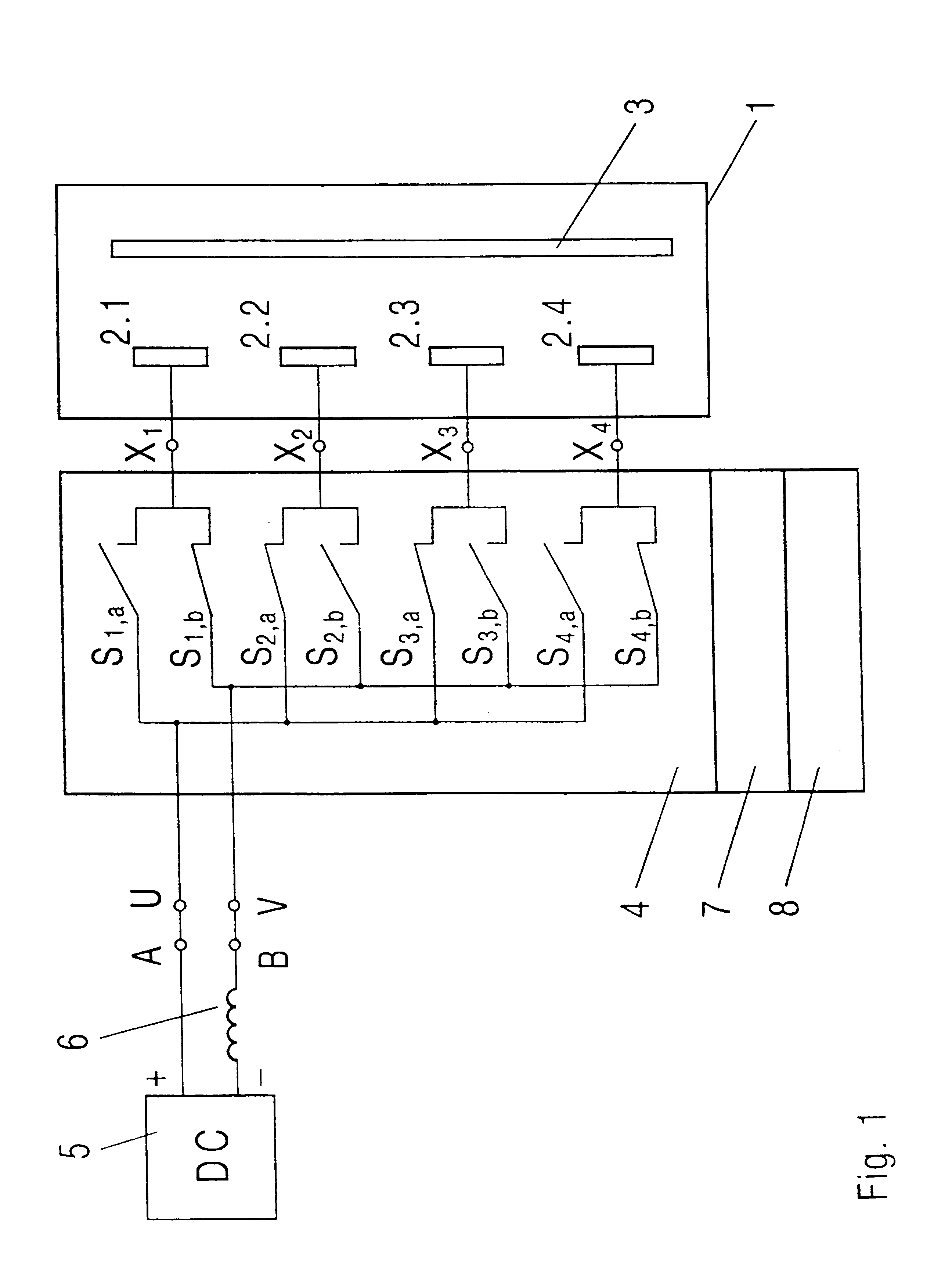

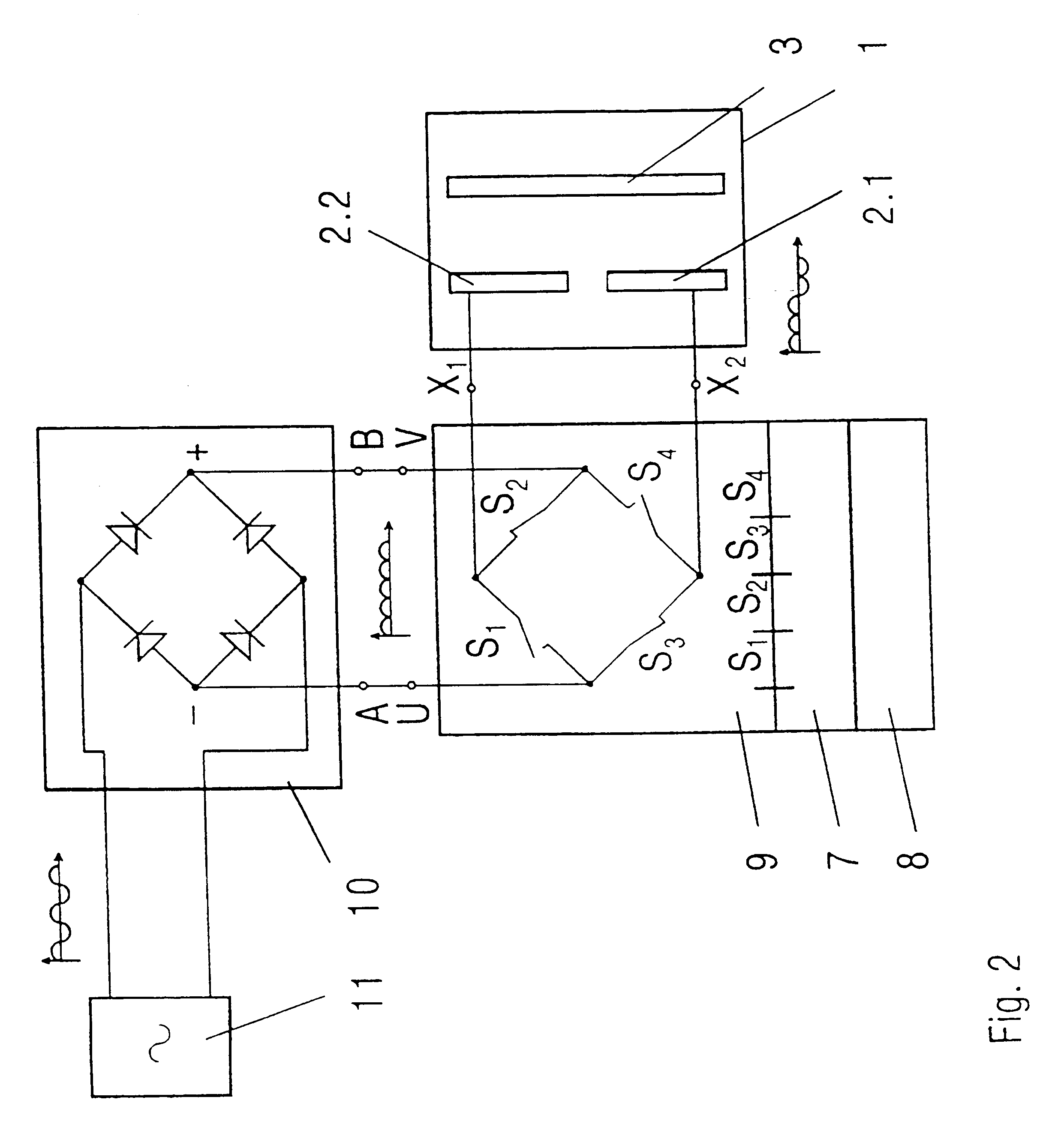

Process and system for operating magnetron discharges

InactiveUS6340416B1Improve efficiencyReduce output lossCellsElectric discharge tubesLoad carryingSupply energy

Magnetron discharges are pulse-operated to avoid the so-called "arcing". In the case of magnetron discharges from alternating current-fed magnetrons, the process is limited to the minor power of the energy supply because of the load-carrying capacity of the required electric components. When the magnetron discharges are fed by direct current, their effectiveness deteriorates because of the deposition of layers on the anode surfaces. The new process should enable a high supply power and prevent arcing. In magnetron discharges with at least two magnetron electrodes, the energy is supplied in such a way that at least one magnetron electrode is a cathode or anode and a number n1 of direct current pulses of said polarity is supplied. The poles of at least one magnetron electrode are then reversed and a number n2 of direct currents of this polarity are supplied. The process is carried on in this manner, the frequency of the direct current pulses being higher than that of the polarity reversals. The energy supply effectiveness is thus improved. This process and system enable the production of layers having the most different properties, for example for the glass, packaging, electronic, and machine construction industries.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Filter and sorbent for removal of contaminants from a fluid

InactiveUS7378372B2Lower Level RequirementsForgiving fluctuationWater contaminantsTreatment involving filtrationActivated carbonPesticide residue

Owner:SOLMETEX

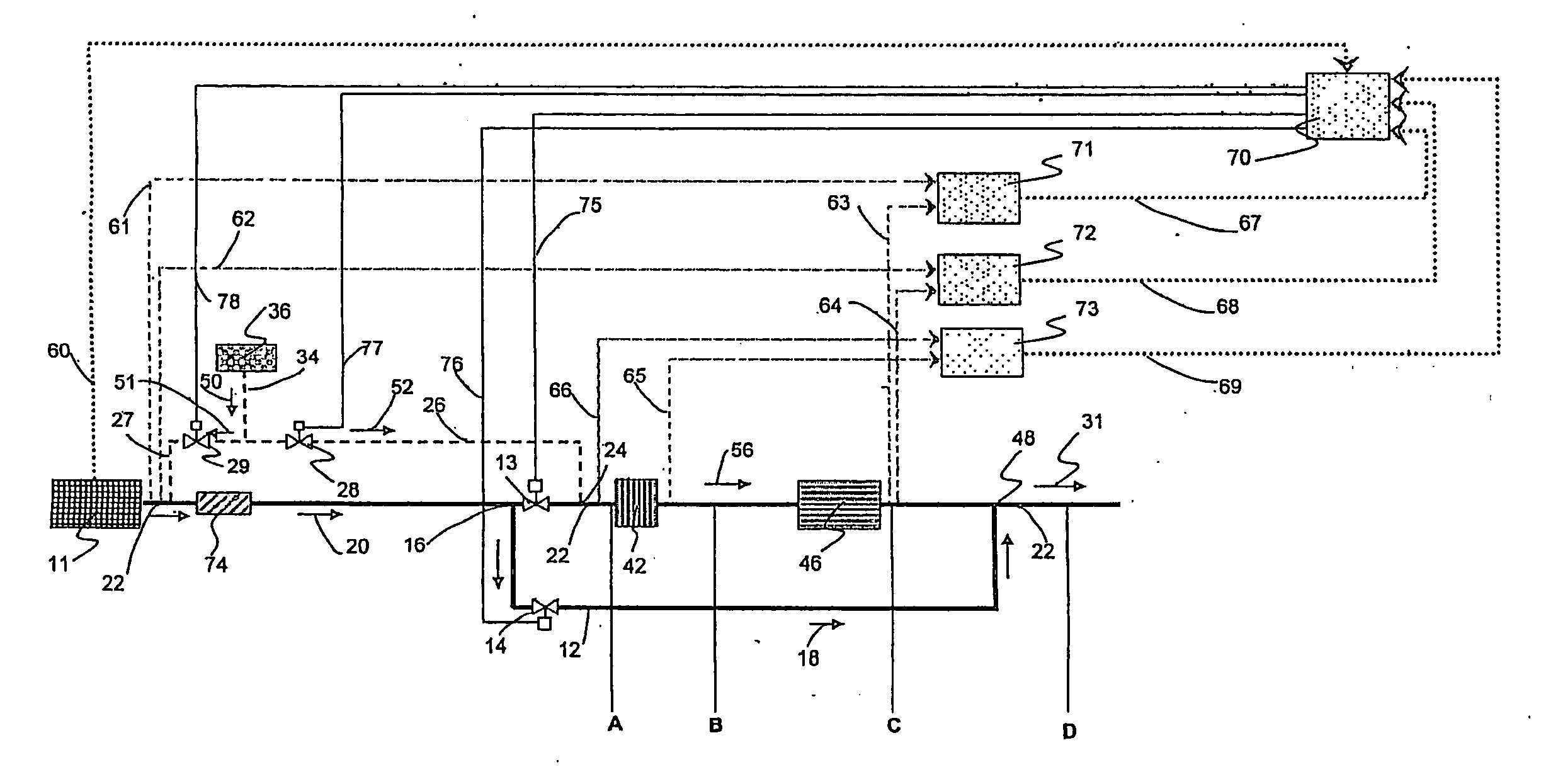

Bypass controlled regeneration of NOx adsorbers

InactiveUS20050223699A1EfficientlyRegenerating lean NOx adsorbers efficientlyNon-fuel substance addition to fuelInternal combustion piston enginesExhaust gasExhaust fumes

In a method and apparatus for regenerating a lean NOx adsorber, the NOx adsorber treats exhaust gases created during the combustion of gaseous fuels in general. A bypass line maintains a target regeneration flow of exhaust gas through the NOx adsorber during regeneration regardless of operating demands on the engine. Closed-loop and open-loop control are employed. The closed-loop control employs sensors that determine properties of the exhaust gas during regeneration, and the controller uses those properties to provide an efficient regeneration cycle. A regeneration map is also provided that uses creation of in-cylinder regeneration conditions for the exhaust gas in combination with in-line regeneration conditions for the exhaust gas.

Owner:WESTPORT POWER

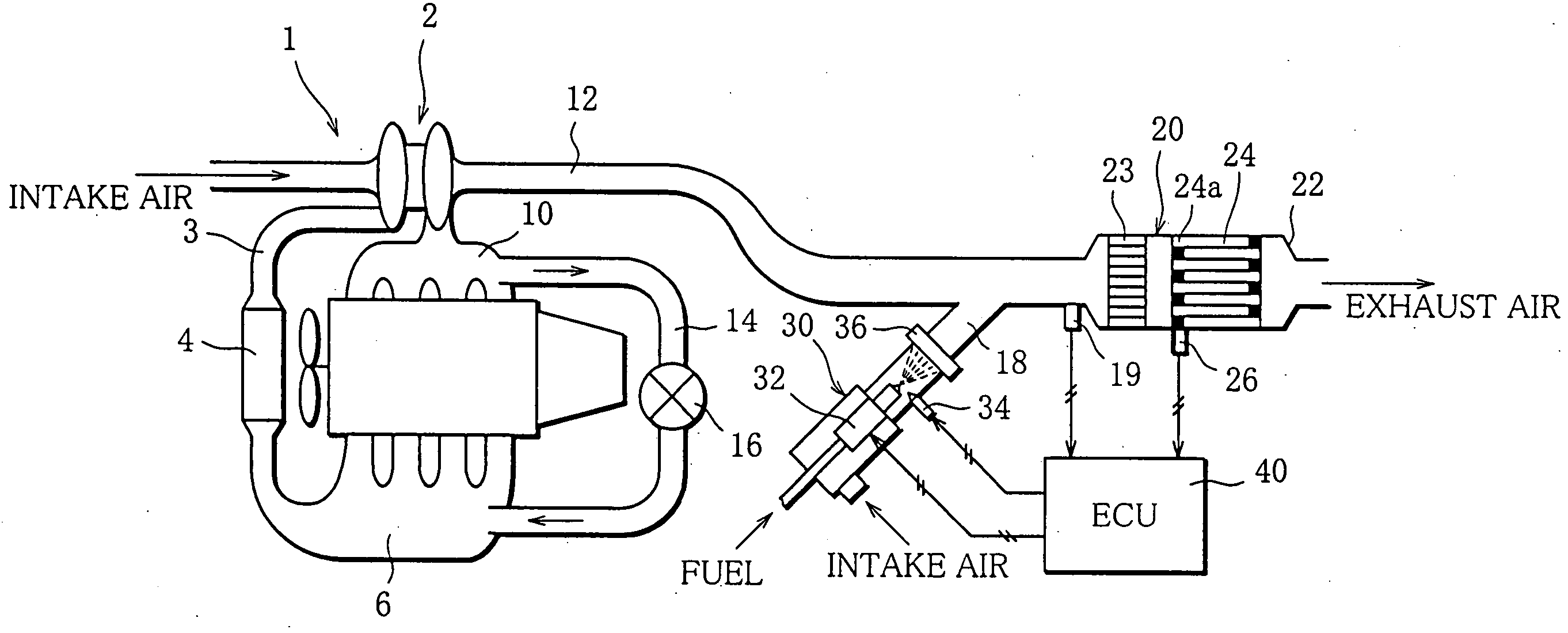

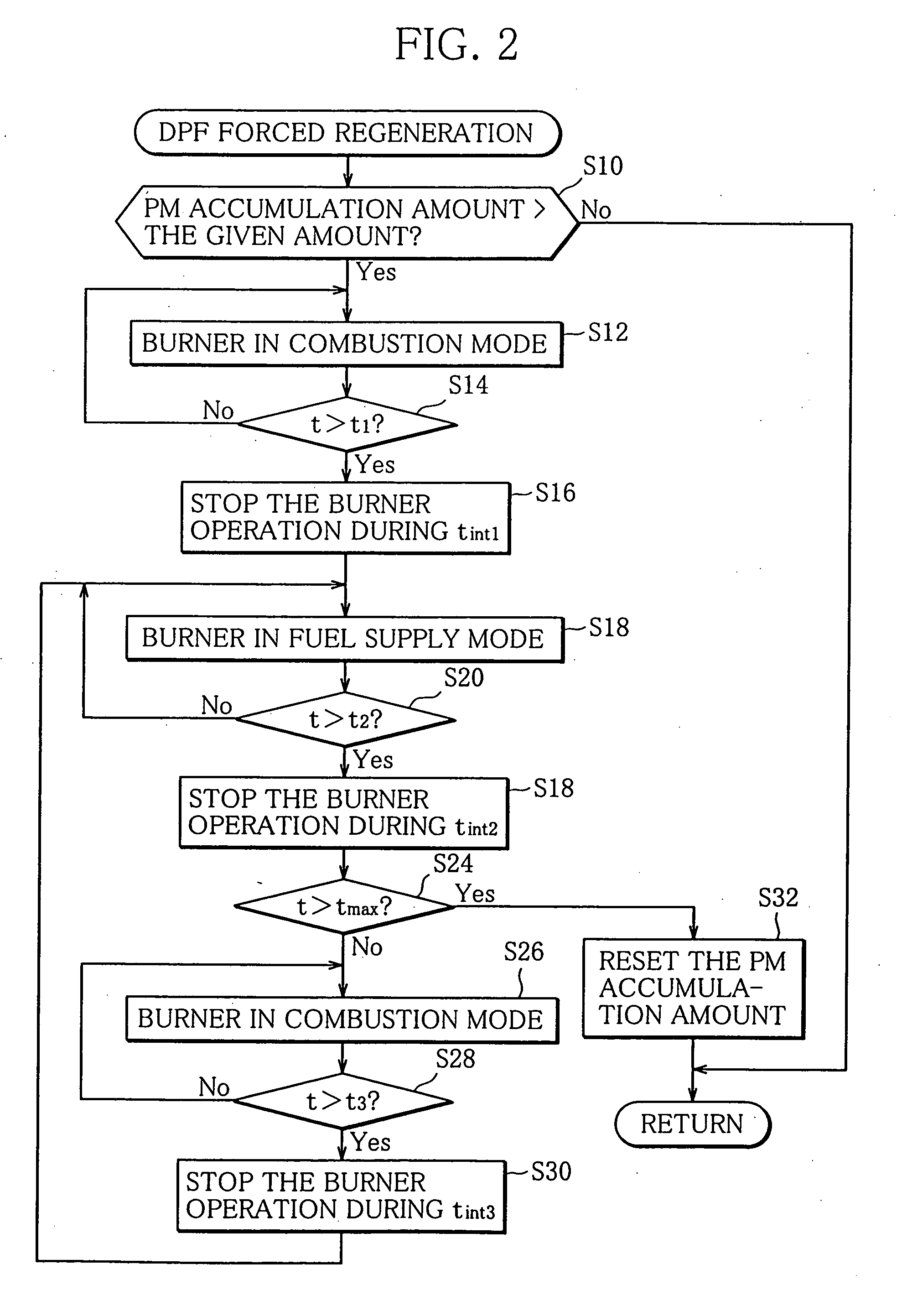

Exhaust emission control device for an internal combustion engine

InactiveUS20050000209A1Efficient regenerationSimple and inexpensive configurationCombination devicesInternal combustion piston enginesParticulatesCombustor

A forced regeneration device which performs regeneration of a particulate filter includes oxidation catalysts (23, 24a) disposed upstream from the particulate filter or in said particulate filter and a burner (30) located upstream from the oxidation catalysts and operable switching between a combustion mode for combusting a fuel spray by inflammation to raise temperature of exhaust gases in an exhaust passage and a fuel supply mode for supplying only a fuel spray to the exhaust passage without inflammation. After the burner operates in the combustion mode, the burner operation is switched to the fuel supply mode.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

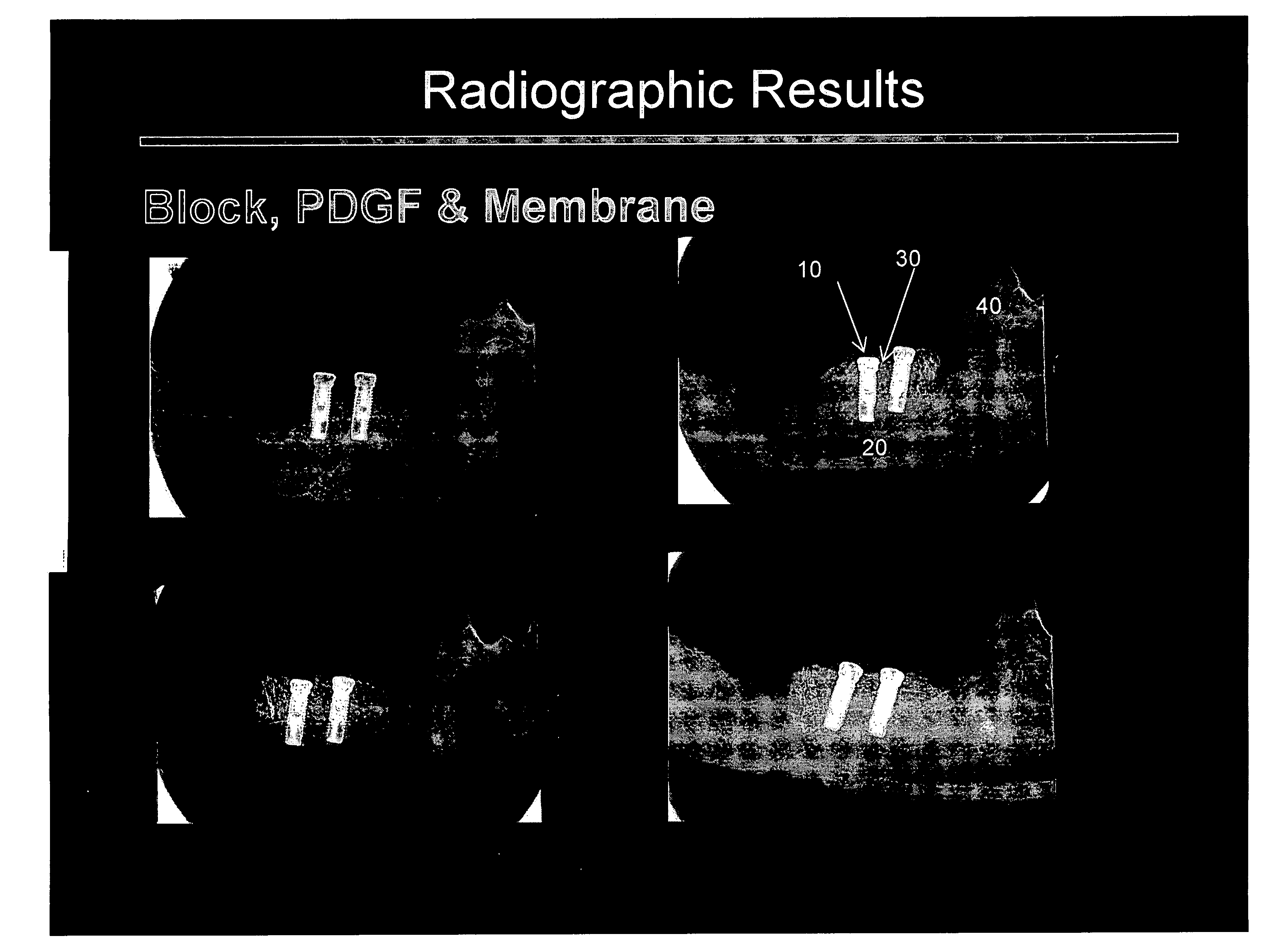

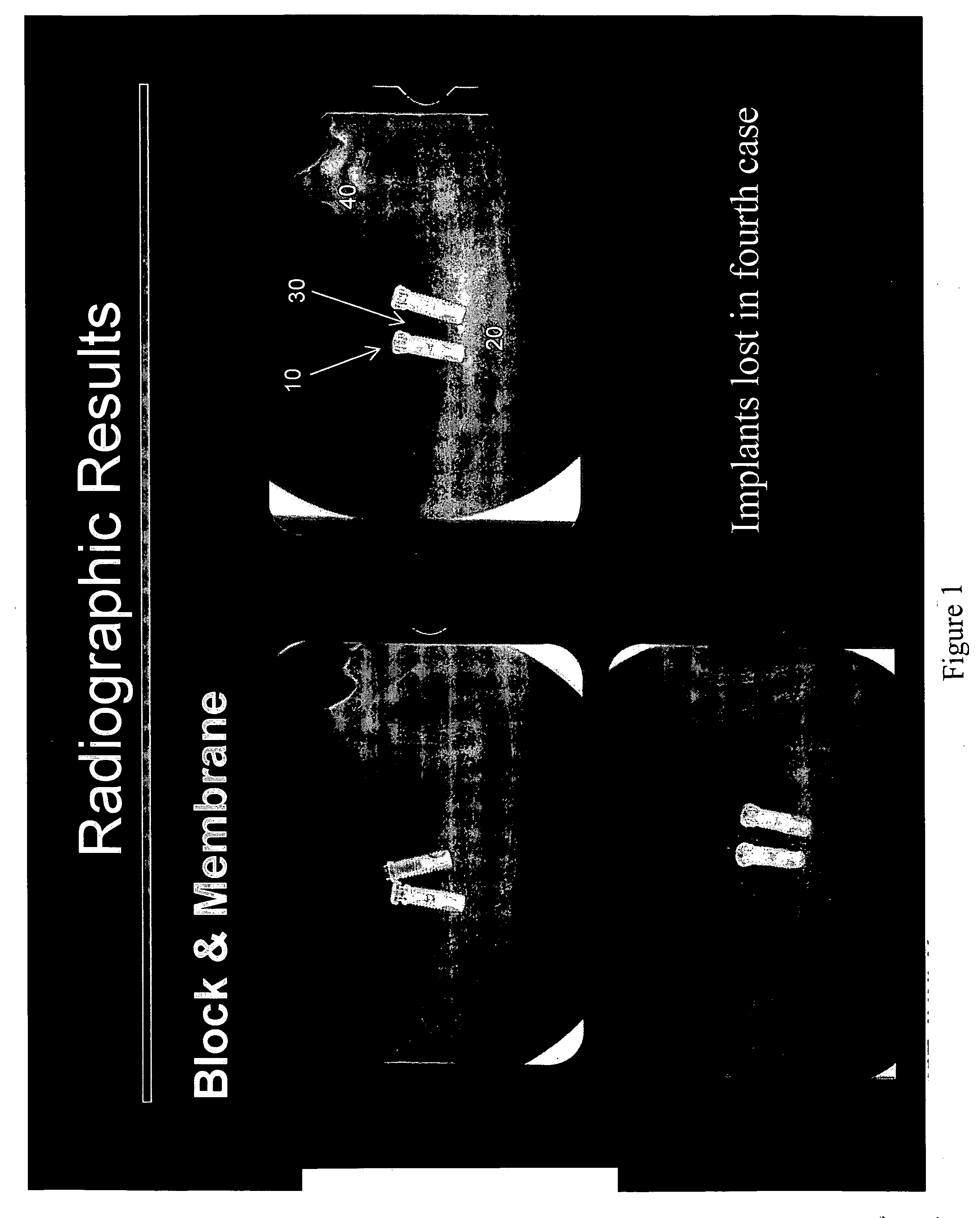

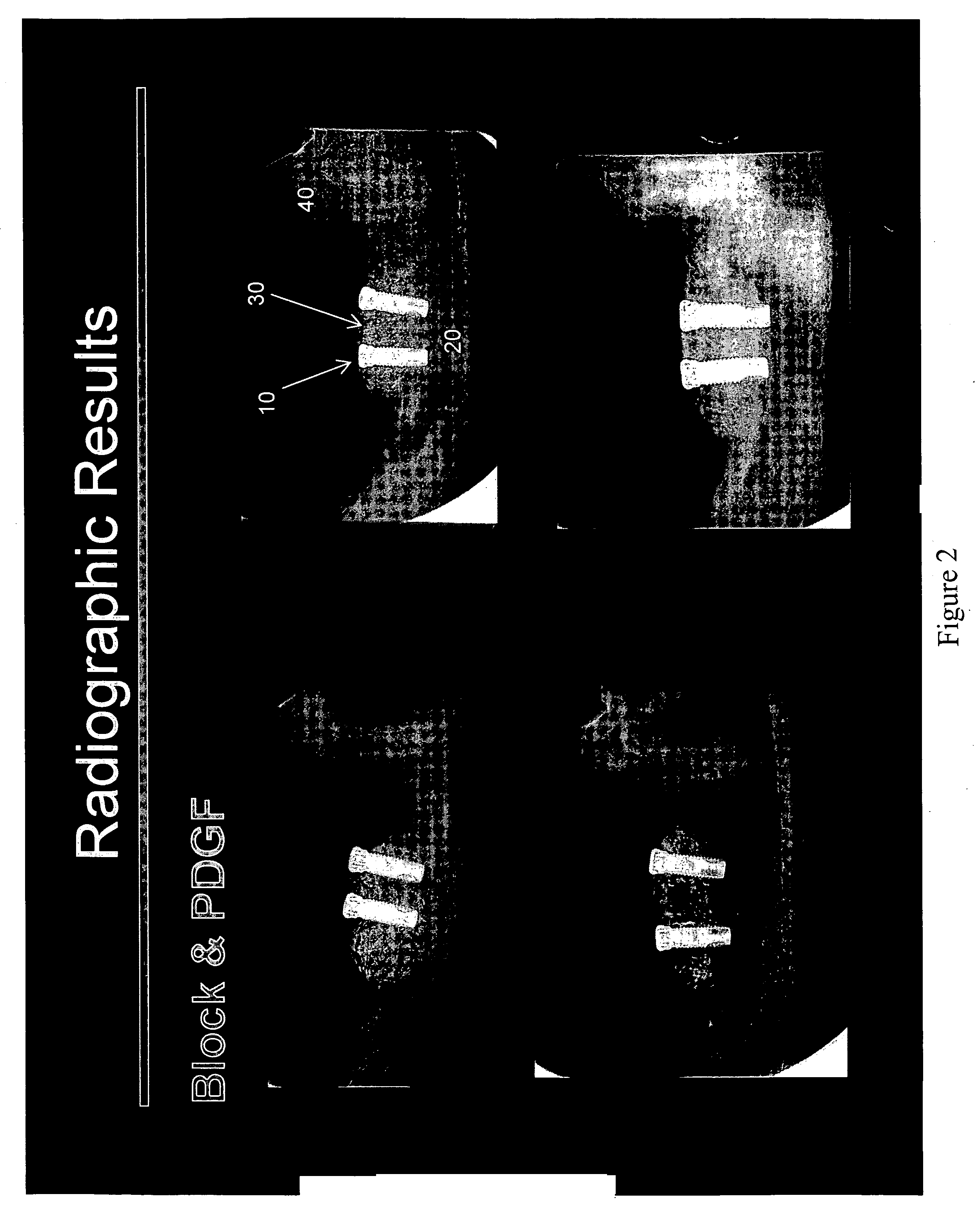

Maxillofacial bone augmentation using rhPDGF-BB and a biocompatible matrix

ActiveUS20070129807A1Facilitating bone augmentationFacilitating maxillofacial bone augmentationPowder deliveryDental implantsPresent methodBioresorbable membrane

The present invention provides effective new methods and materials for maxillofacial bone augmentation, particularly alveolar ridge augmentation, that are free of problems associated with prior art methods. In one embodiment, these materials include human recombinant platelet derived growth factor (rhPDGF-BB) and a biocompatible matrix. In another embodiment, these materials include rhPDGF-BB, a deproteinized bone block or calcium phosphate, and a bioresorbable membrane. The use of these materials in the present method is effective in regenerating maxillofacial bones and facilitating achievement of stable osseointegrated implants. The mandible and maxilla are preferred bones for augmentation, and enhancement of the alveolar ridge is a preferred embodiment of the present invention.

Owner:BIOMIMETIC THERAPEUTICS INC

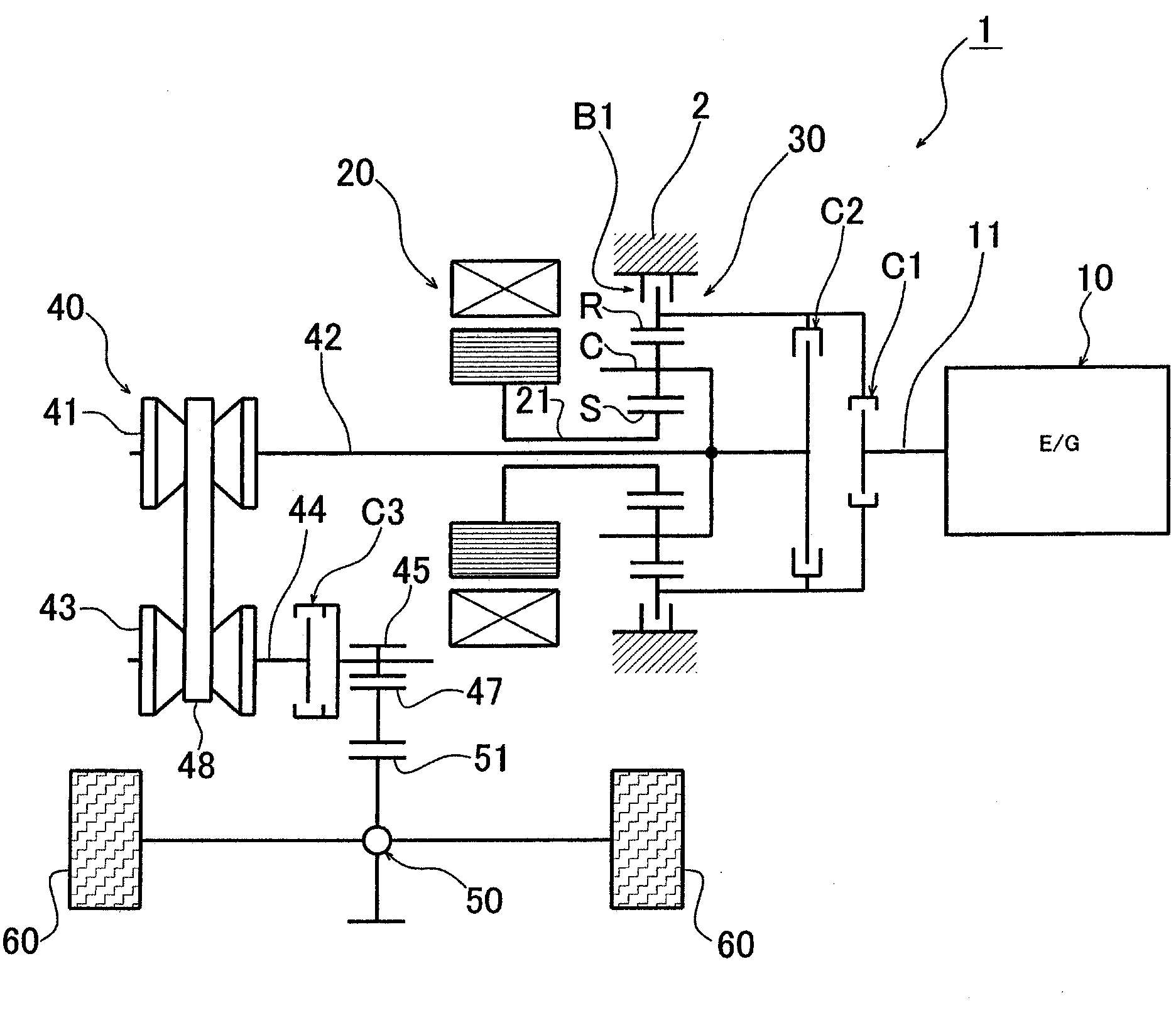

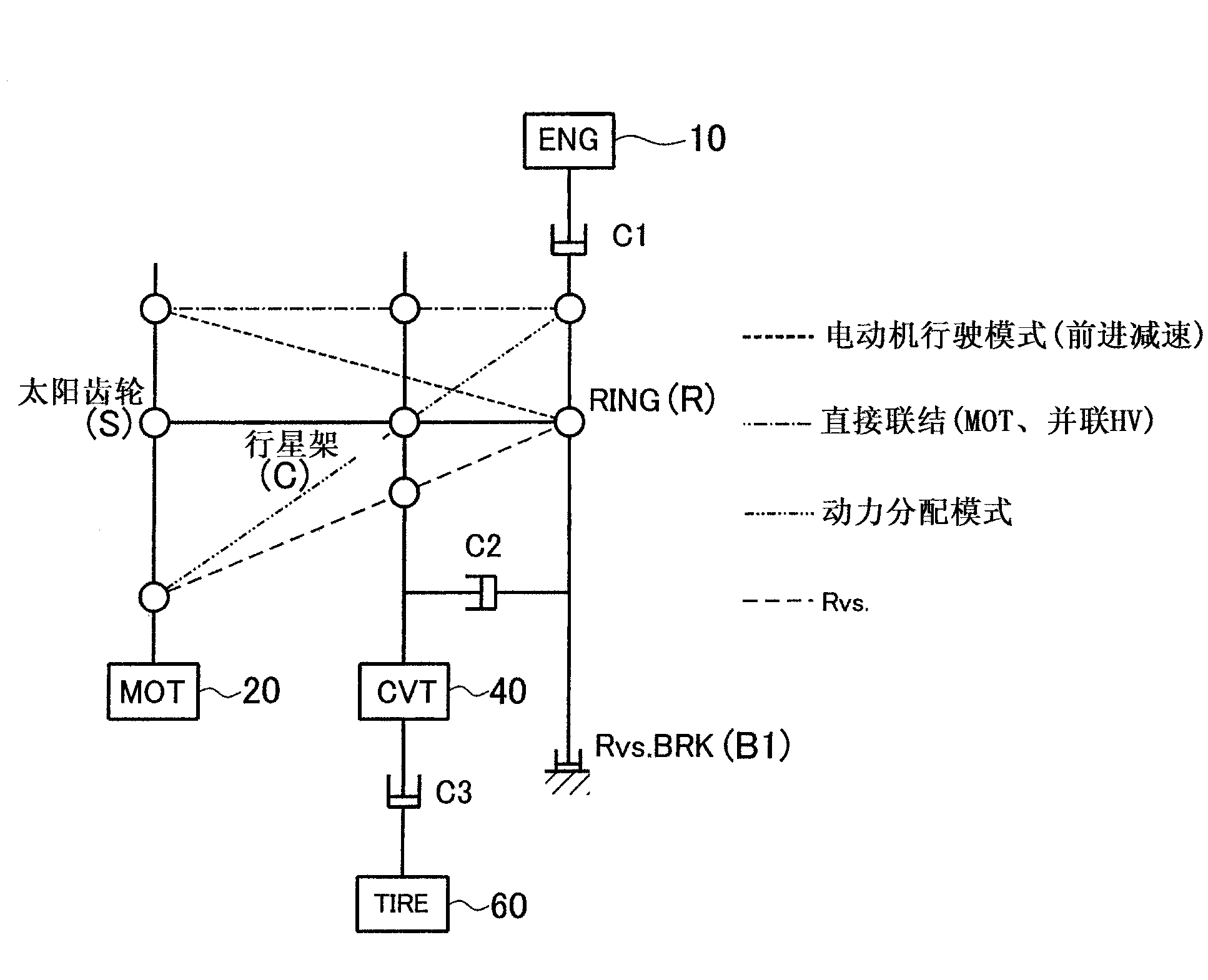

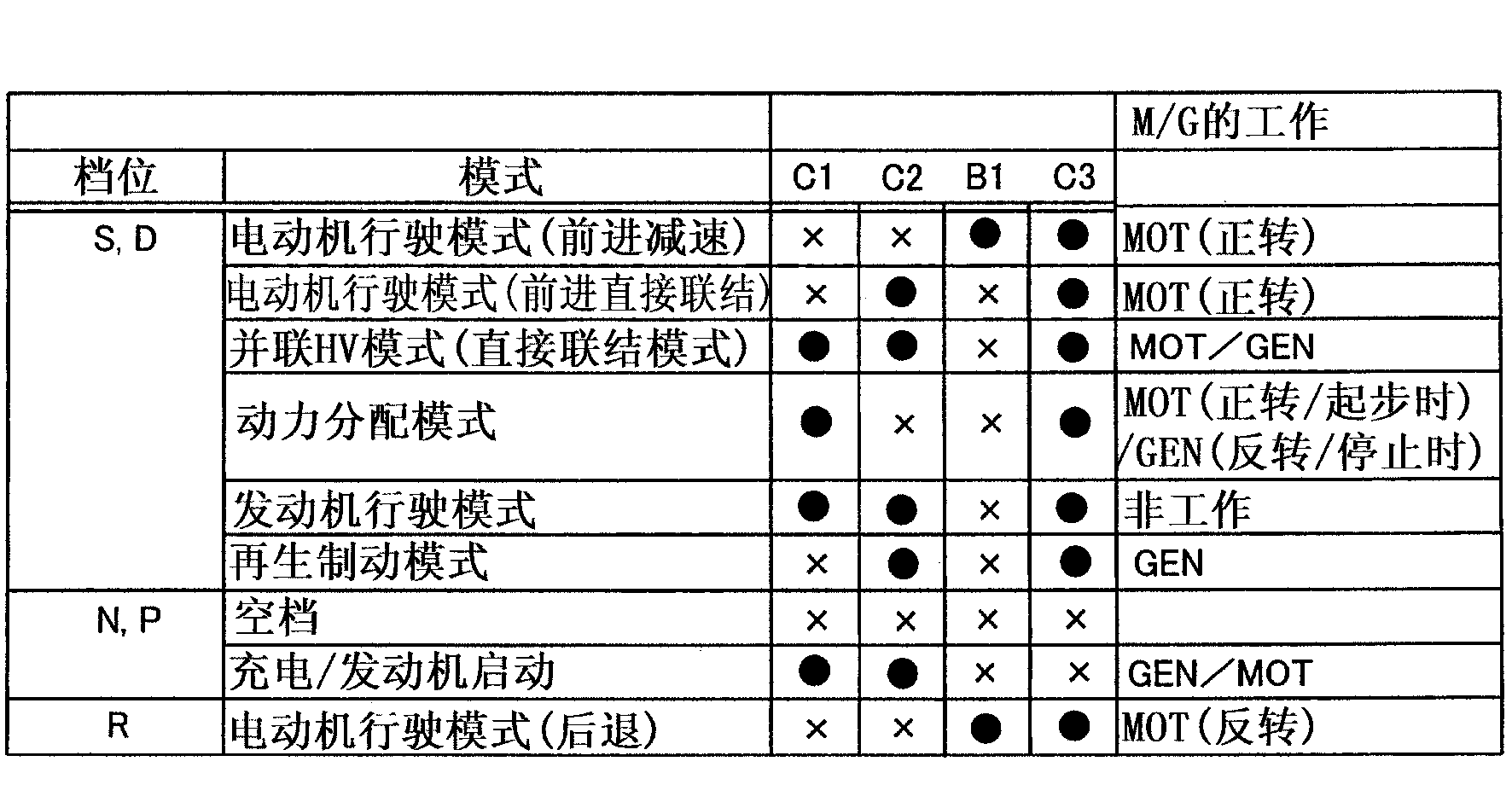

Hybrid drive apparatus

InactiveCN102910066APower transmission loss is smallEfficient regenerationGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive wheelControl theory

A hybrid drive apparatus is provided and enables efficient energy regeneration by the motor generator by separating the power transmission path through which the driving force from the engine is transmitted, from the power transmission path between the motor generator and the drive wheels, and also makes it possible to achieve a variety of driving modes while improving power transmission efficiency. In a hybrid drive apparatus (1) having an engine (10), a motor generator (20), and a planetary gear mechanism (30) in which the output shaft (21) of the motor generator (20) is coupled to a sun gear (S), the output shaft (11) of the engine (10) is coupled to a ring gear (R), and the input shaft (42) of a continuously variable transmission mechanism (40) is coupled to a carrier (C), the hybrid drive apparatus (1) includes a first clutch (C1) that can switch engagement / disengagement between the output shaft (11) of the engine 11 and the ring gear (R), a second clutch (C2) that can switch engagement / disengagement between the carrier (C) and the ring gear (R), and a third clutch (C3) that can switch engagement / disengagement on the input shaft (42) of the transmission mechanism (40).

Owner:HONDA MOTOR CO LTD

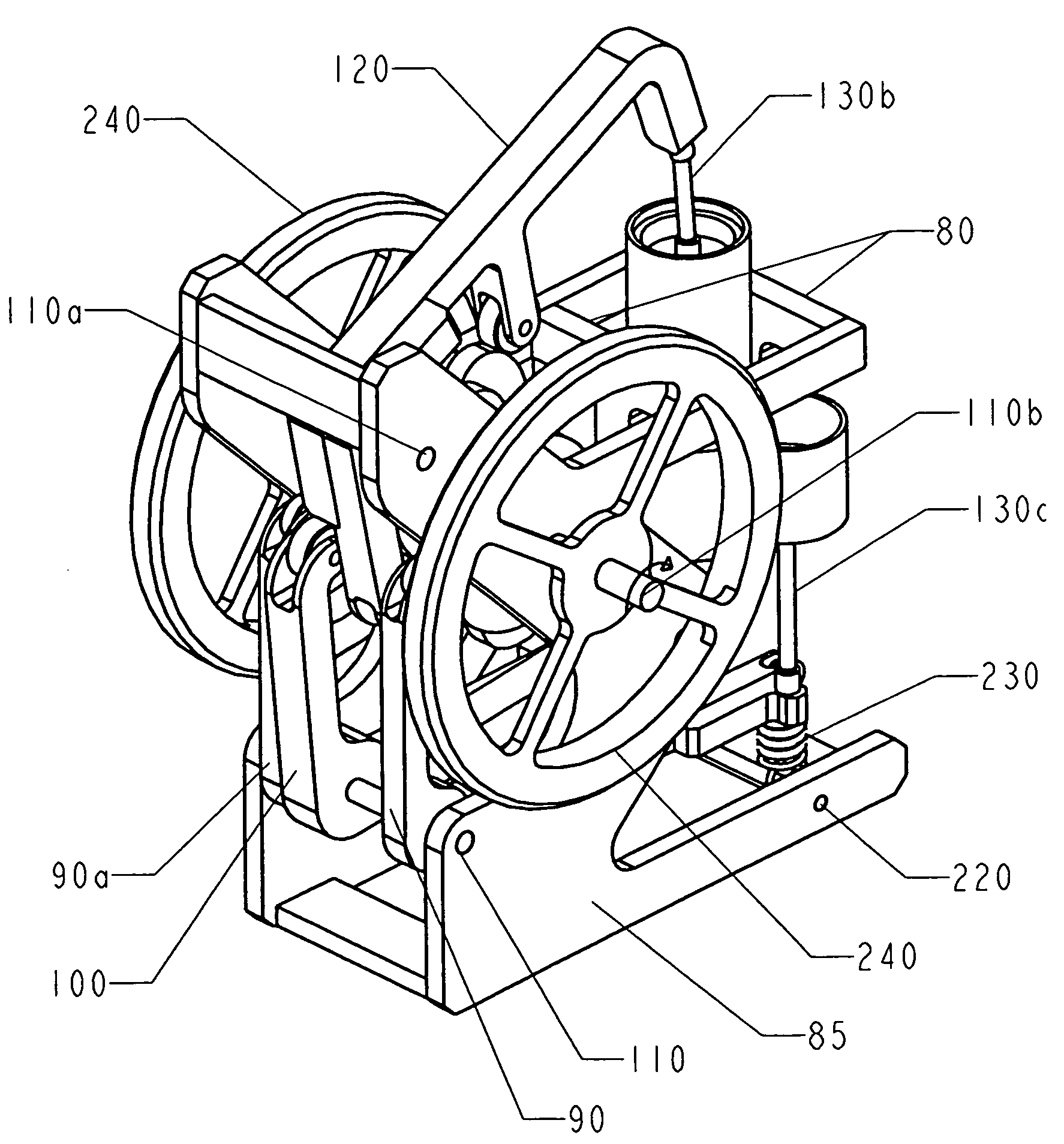

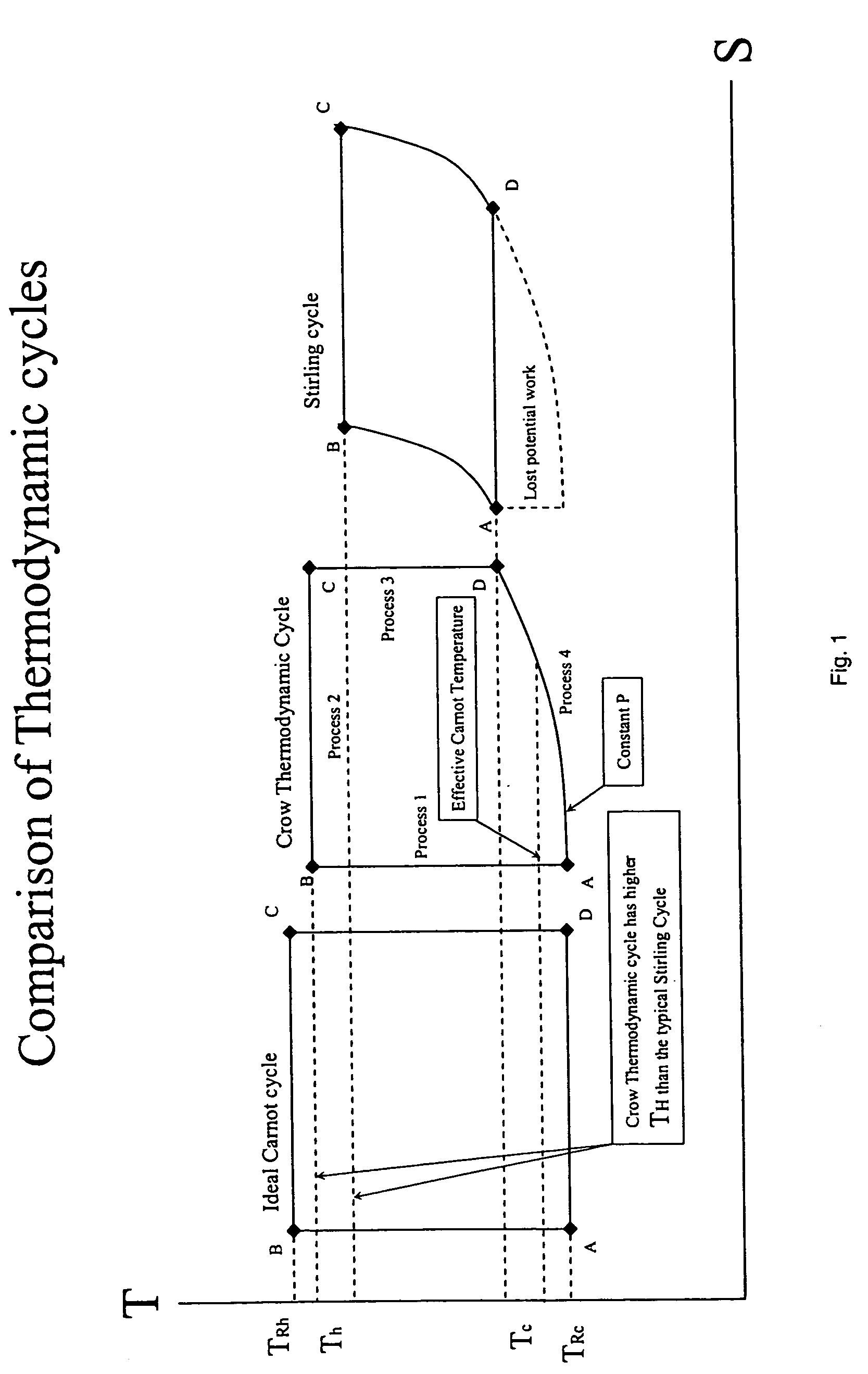

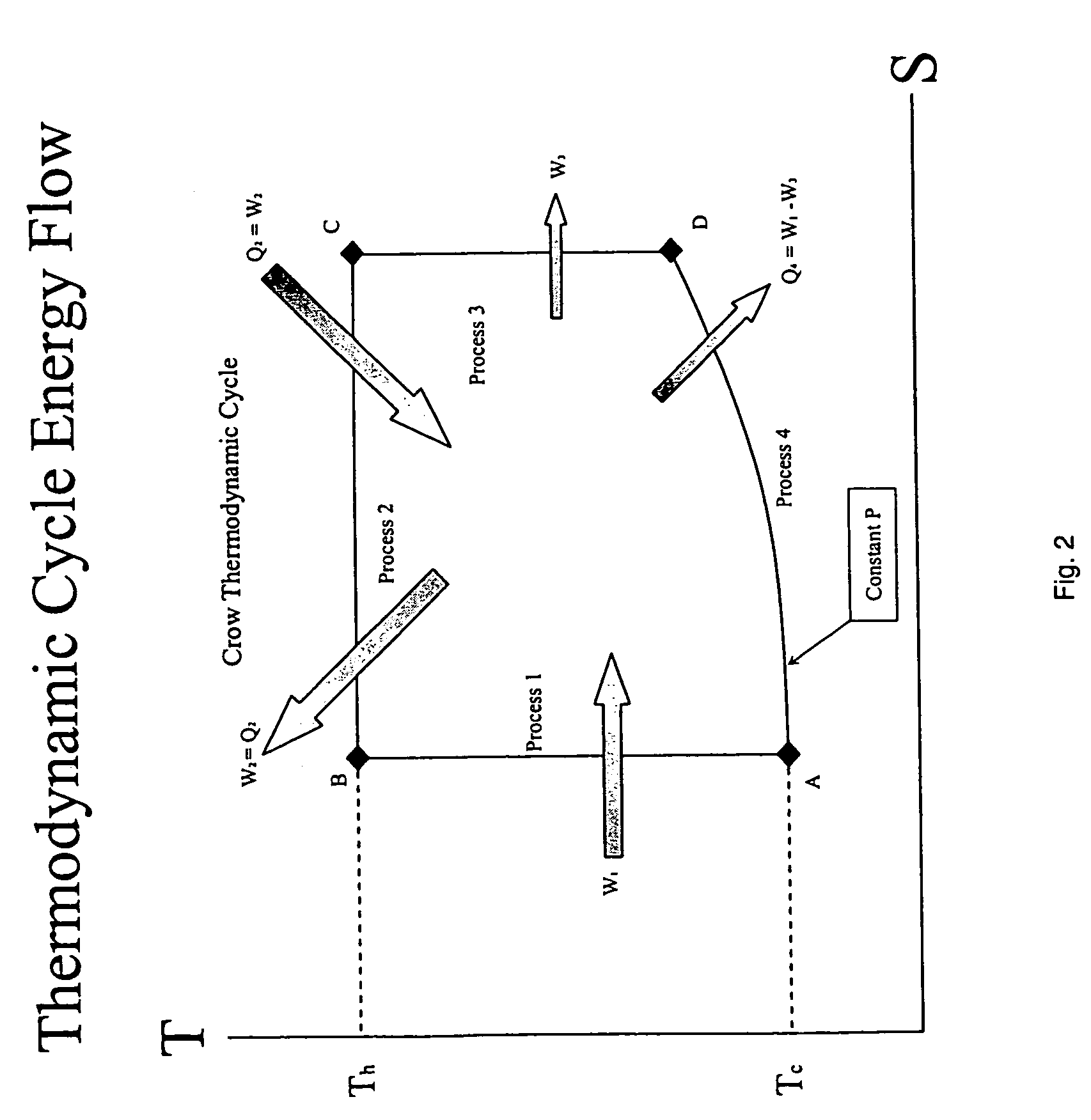

Method and apparatus for converting thermal energy to mechanical energy

InactiveUS7284372B2Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyExternal energy

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

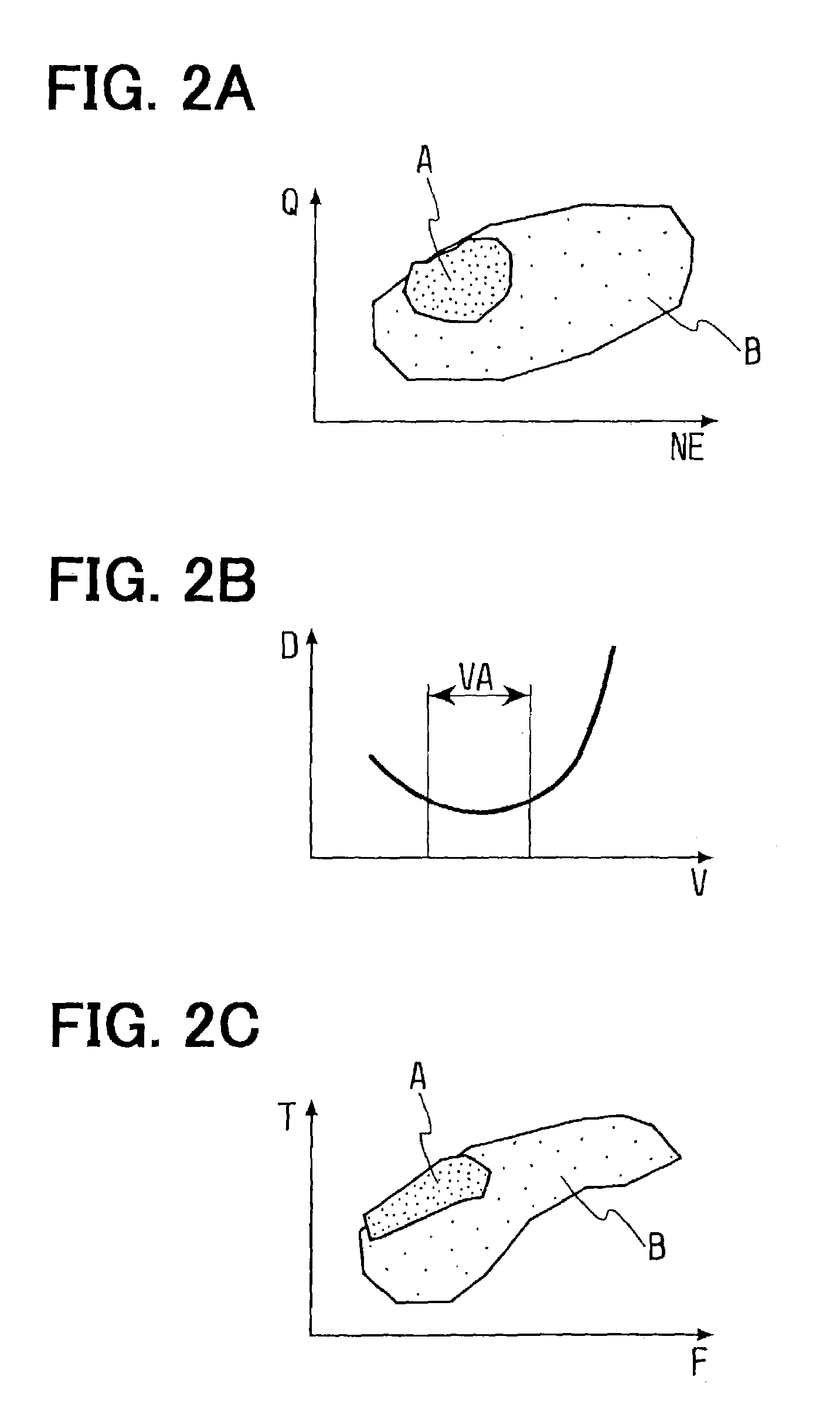

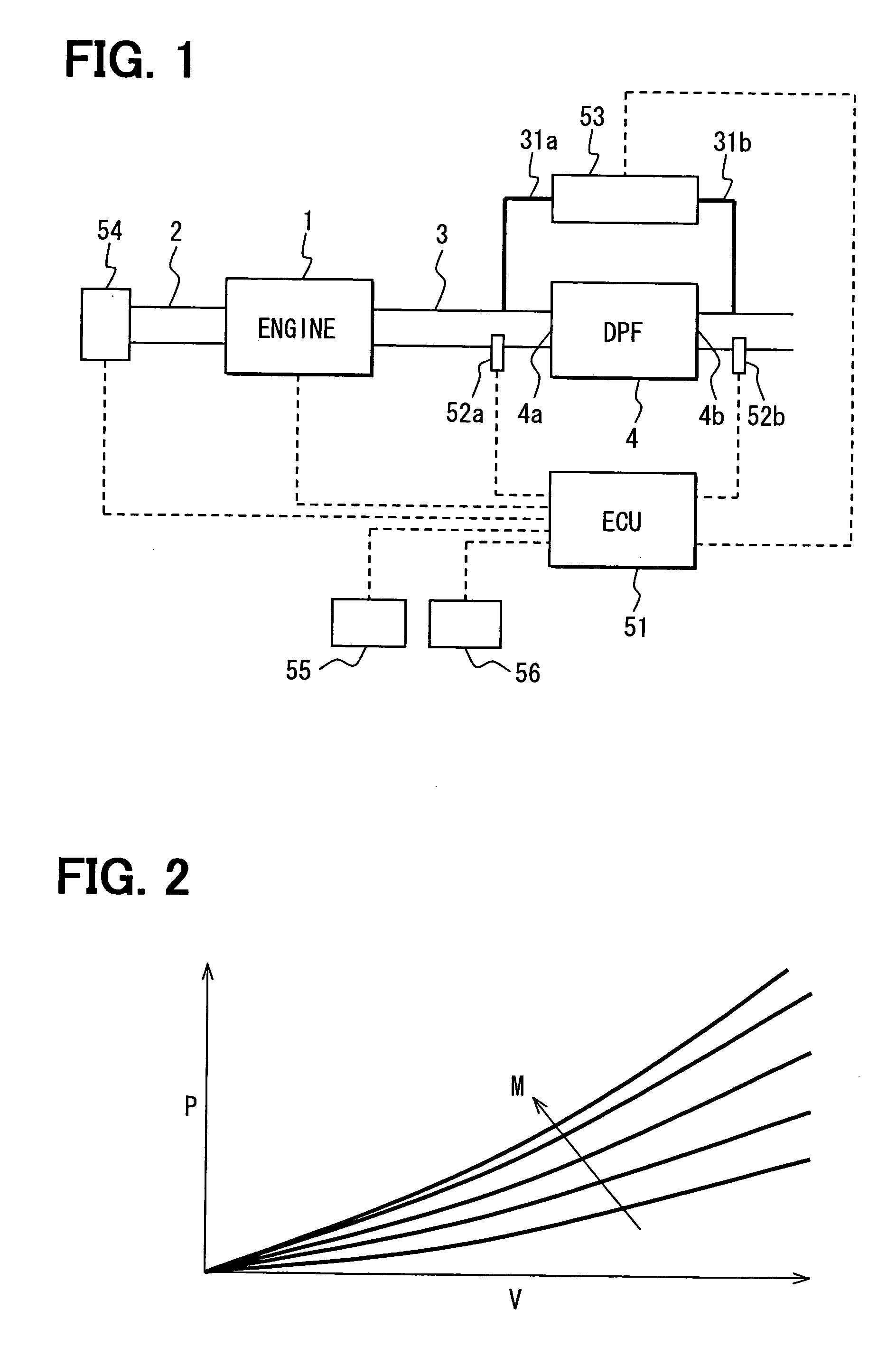

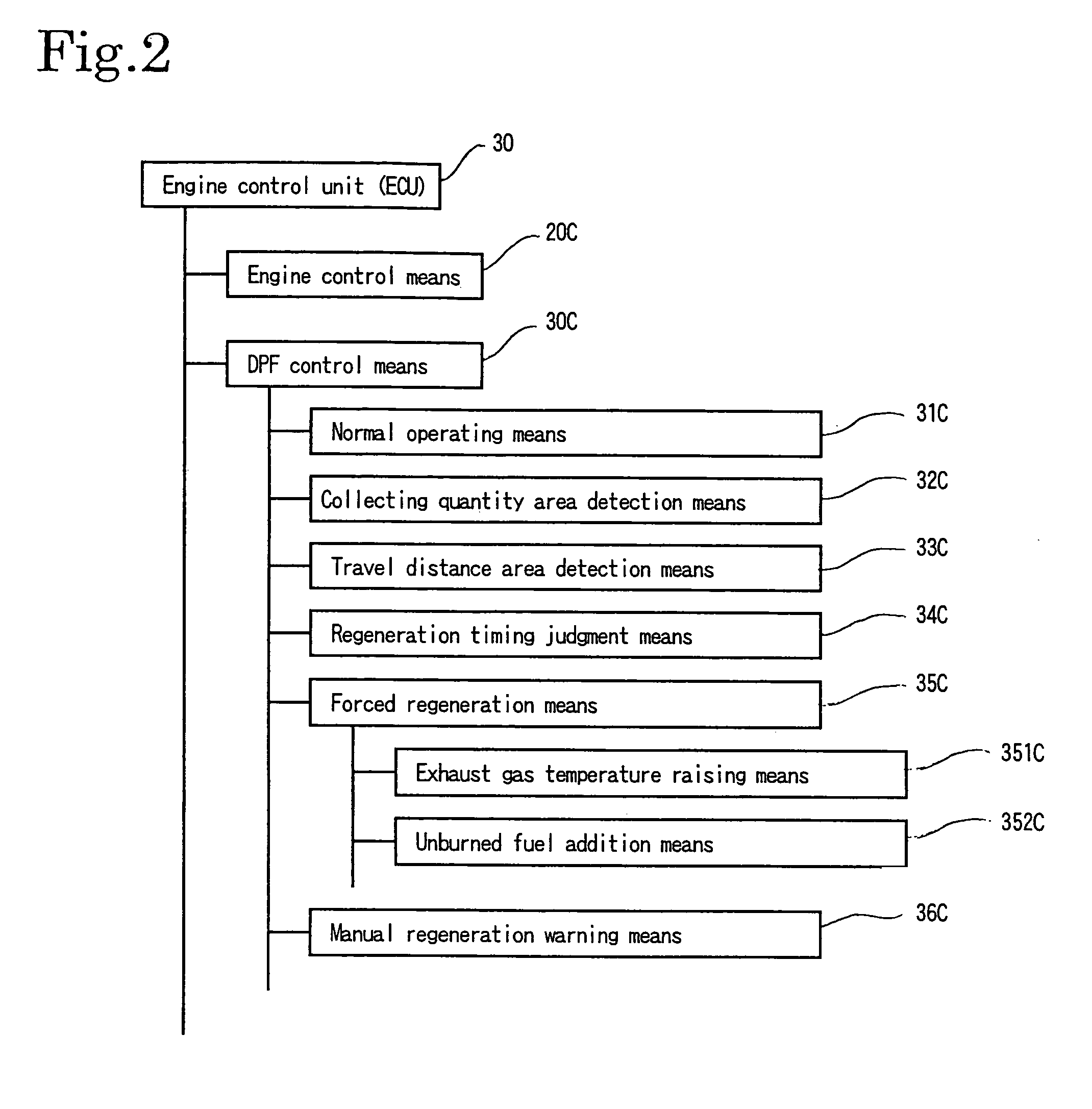

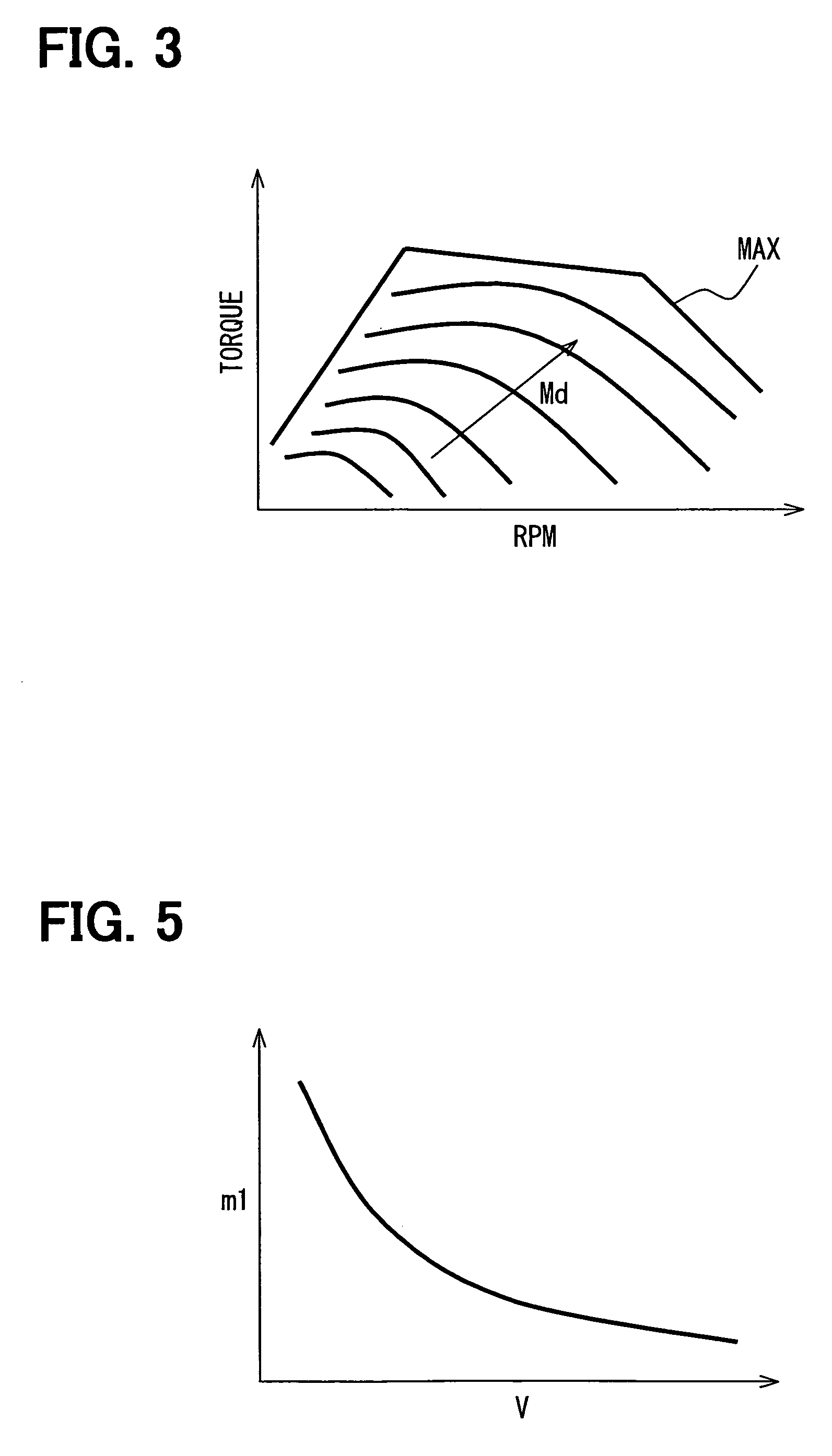

Exhaust gas cleaning system having particulate filter

InactiveUS7146804B2Efficient regenerationIncrease fuel consumptionElectrical controlNon-fuel substance addition to fuelExhaust fumesDiesel particulate filter

An exhaust gas cleaning system for a diesel engine has a diesel particulate filter (DPF) disposed in an exhaust pipe. An electronic control unit of the system controls regeneration of the DPF. The DPF is heated and regenerated only when an operating state of the engine is in an area where temperature-increasing efficiency is high, in the case where a quantity of particulate matters collected by the DPF is equal to or greater than a first threshold and is less than a second threshold. The second threshold is greater than the first threshold. If the quantity of the collected particulate matters becomes equal to or greater than the second threshold, the regeneration is performed even if the operating state is not in the area of the high temperature-increasing efficiency.

Owner:DENSO CORP

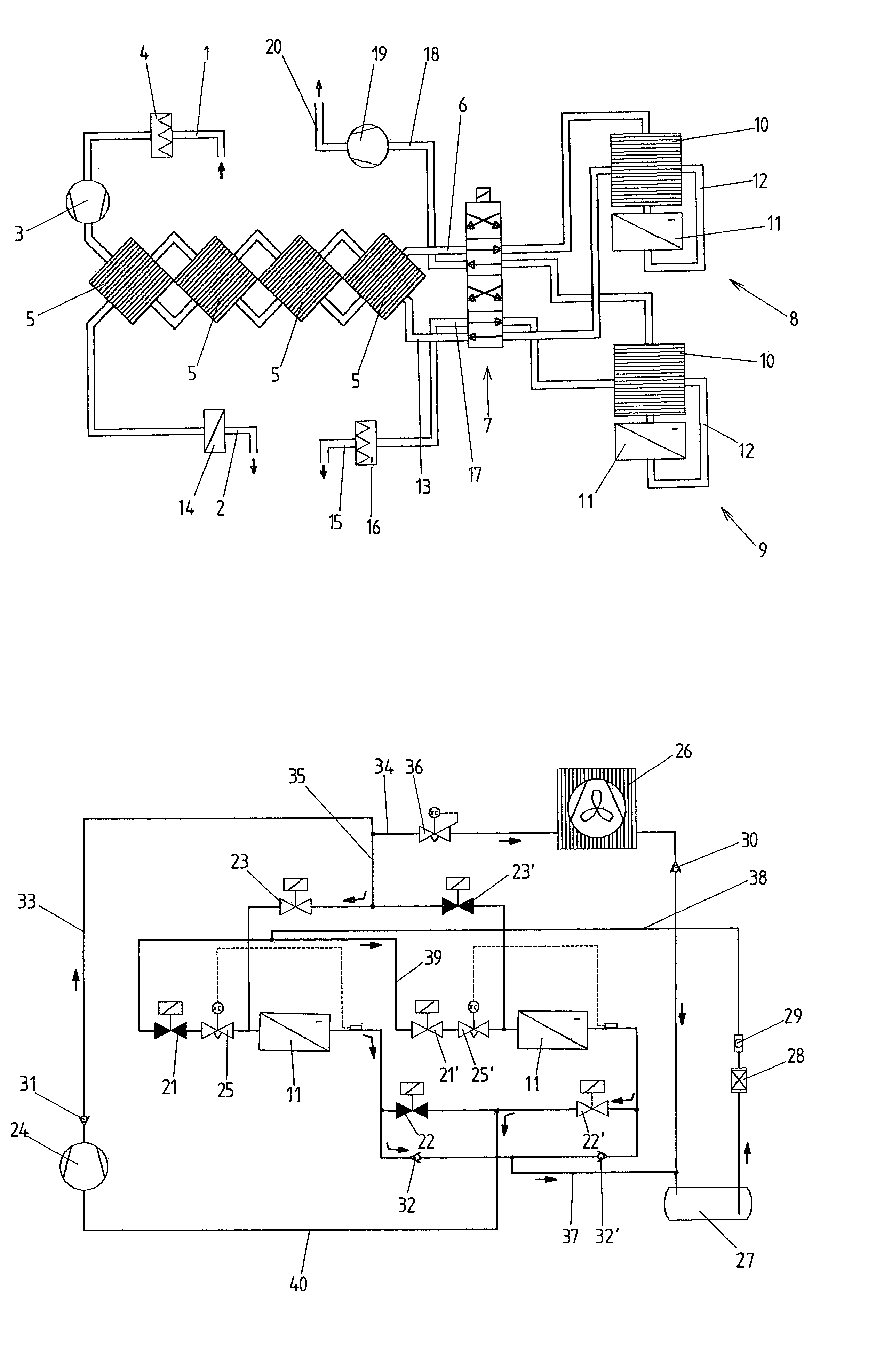

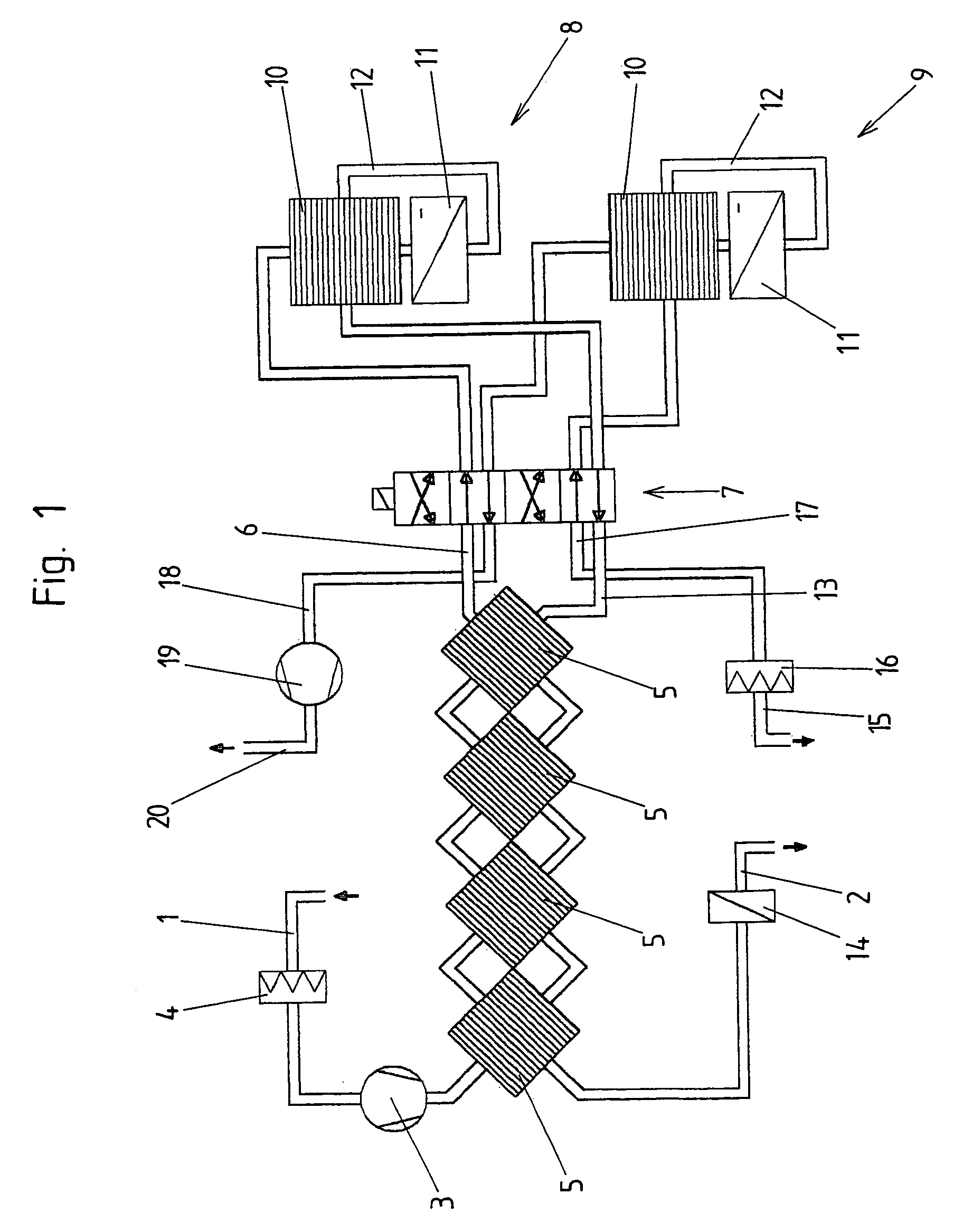

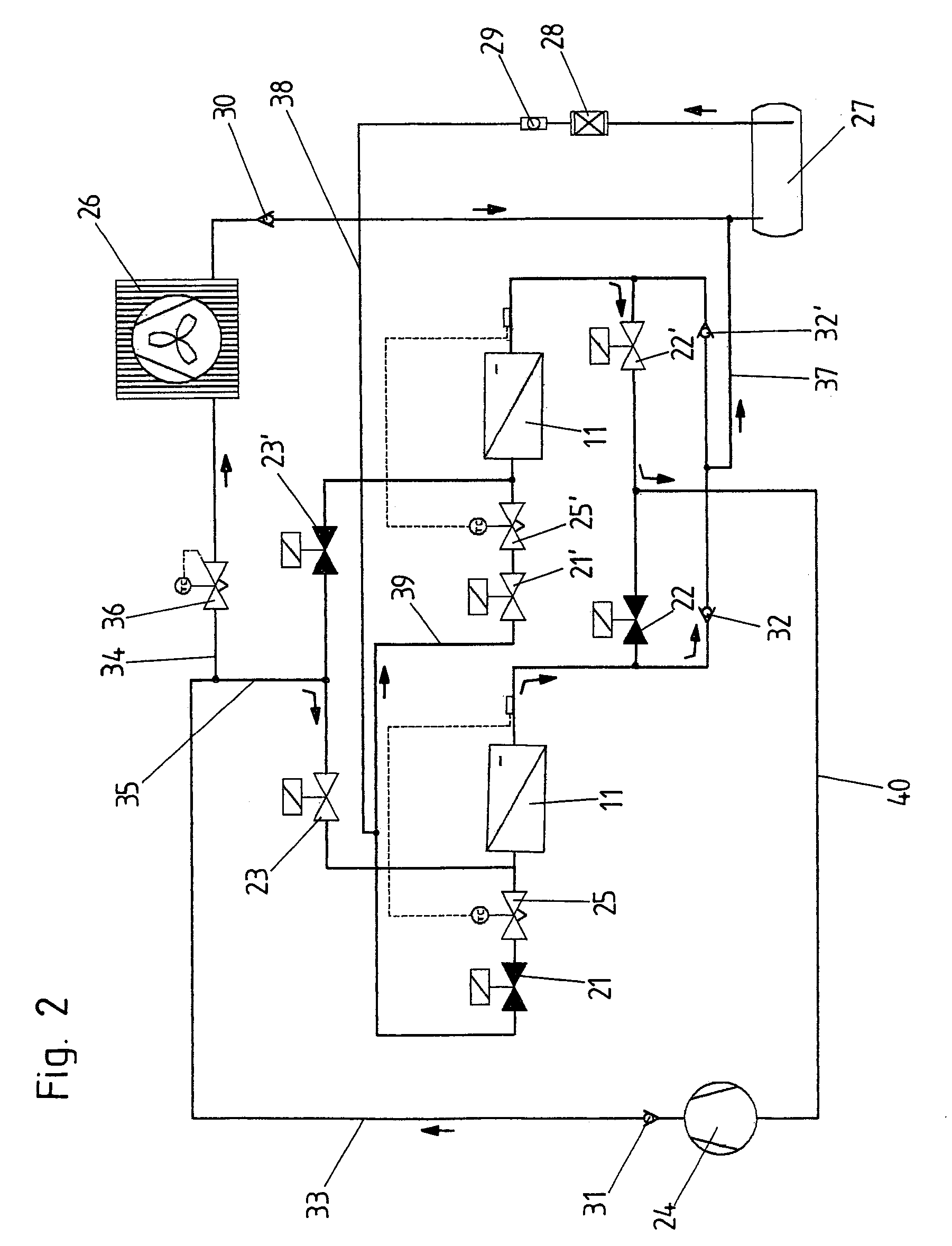

Drying device for drying a gas

InactiveUS7185447B2Lower dew point temperatureReduce energy consumptionDrying solid materials with heatDrying gas arrangementsLine tubingEngineering

A drying device for drying a gas comprises parallel cooling branches, at least one of which is in its active state at any given time. A gas-coolant heat exchanger arranged in each of the cooling branches has a first channel through which the gas to be dried flows in the active state of this cooling branch and a second channel which, in the active state of this cooling branch, forms an evaporator for a coolant circulating in at least one coolant circuit. The drying device further comprises an ambient-air input line, an ambient-air output line and an ambient-air conveyor. In the passive state of a respective cooling branch, the ambient-air input line and the ambient-air output line are connected, at least for a time, with this cooling branch by the switching device and the ambient-air conveyor conveys ambient air through the first channel of the gas-coolant heat exchanger arranged in this cooling branch.

Owner:ARBEITER PETER

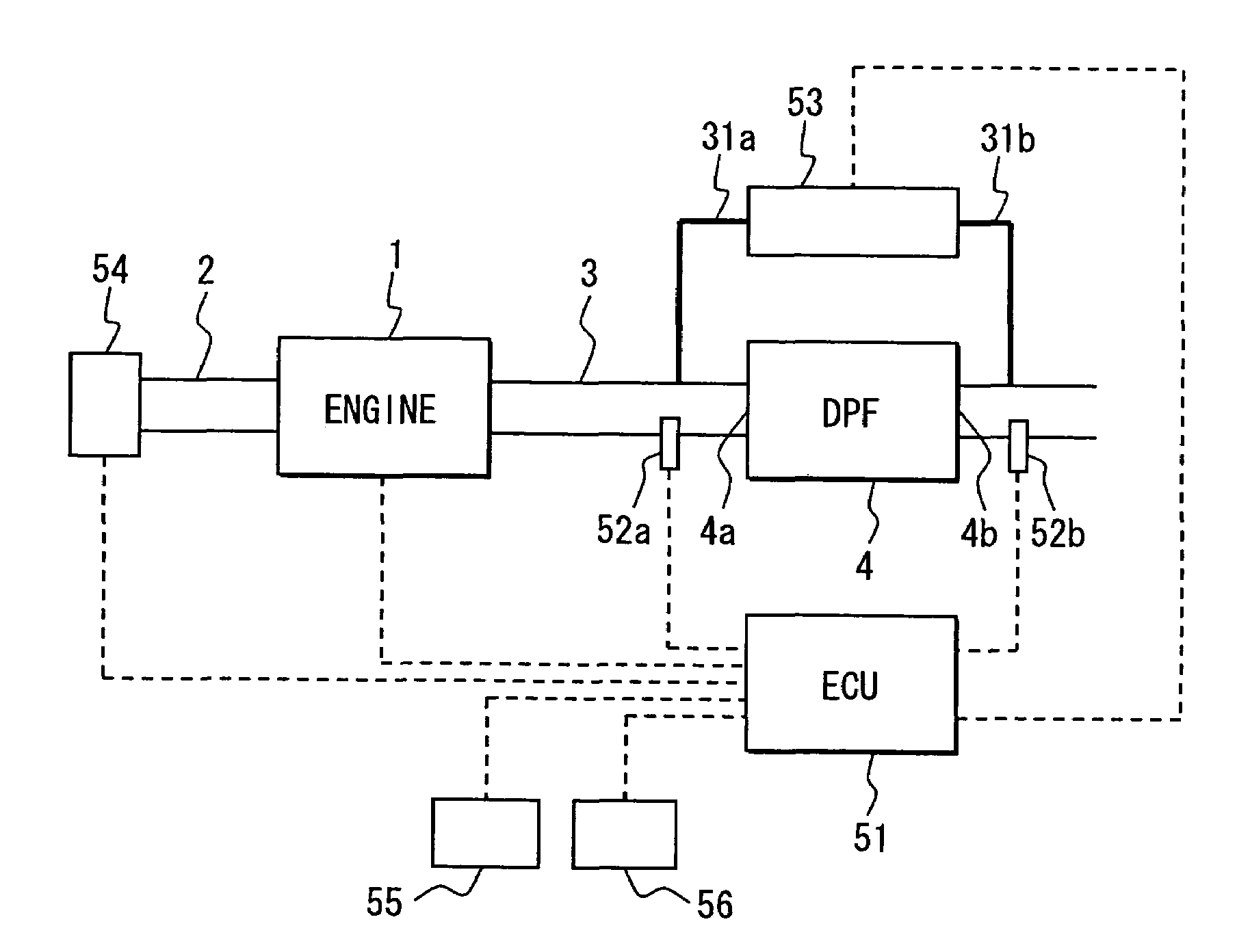

Exhaust gas purification system for internal combustion engine

ActiveUS20060179826A1Improve estimation accuracyAvoid excessive accumulationInternal combustion piston enginesExhaust apparatusExhaust fumesDiesel particulate filter

An exhaust gas purification system has a first accumulation quantity estimation device that estimates an accumulation quantity of exhaust particulate matters collected by a diesel particulate filter (DPF) based on a flowing state of exhaust gas and a second accumulation quantity estimation device that estimates the accumulation quantity based on an operating state of an engine. The first estimation device is employed only when a flow rate of the exhaust gas is equal to or greater than a predetermined value and the engine is in a steady operating state. Otherwise, the second estimation device is employed. The exhaust gas flow rate is increased if the estimation by the second estimation device continues for a long time. Thus, an opportunity to perform the accumulation quantity estimation with the first estimation device is increased, and accumulation accuracy is improved.

Owner:DENSO CORP

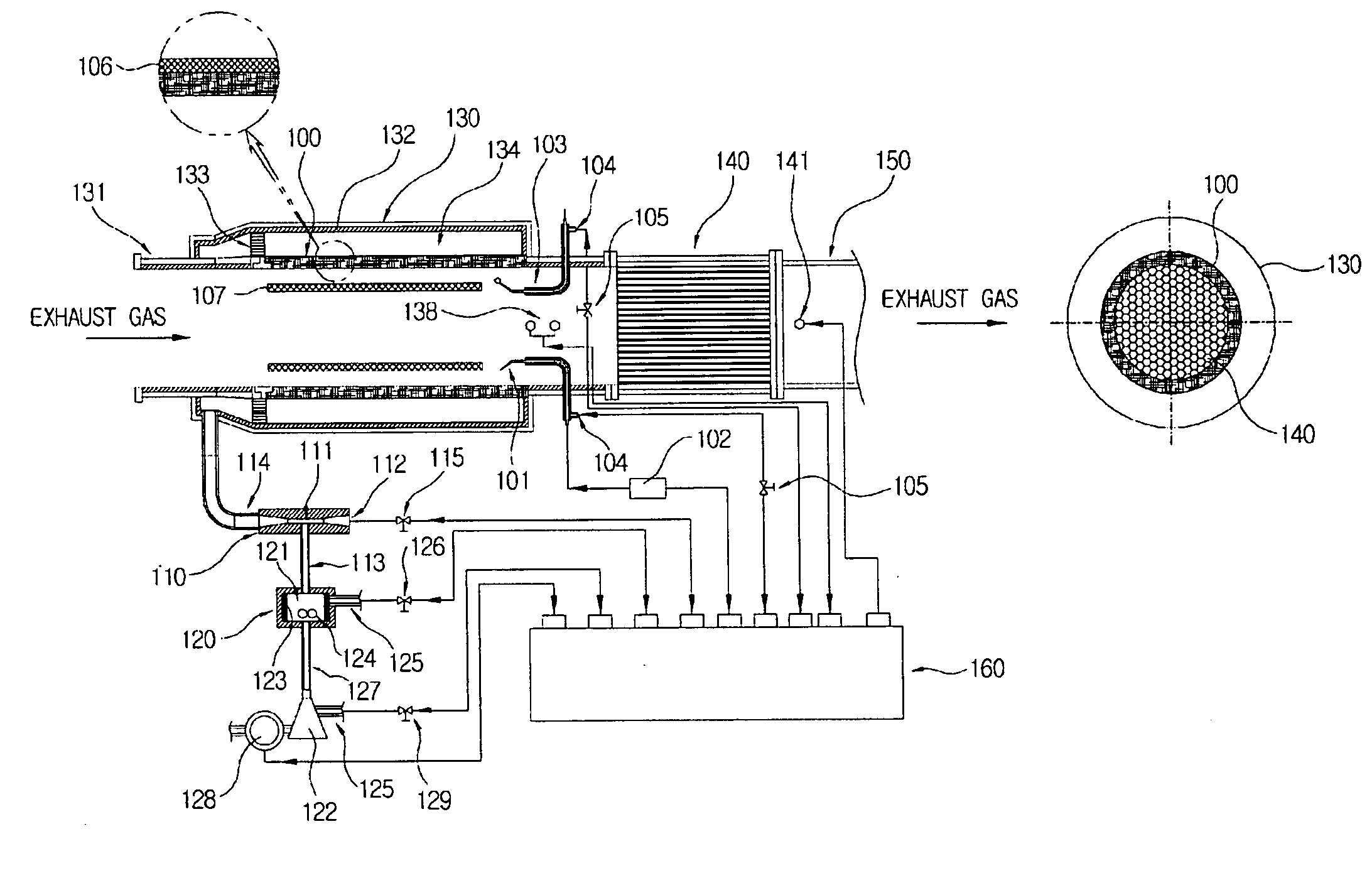

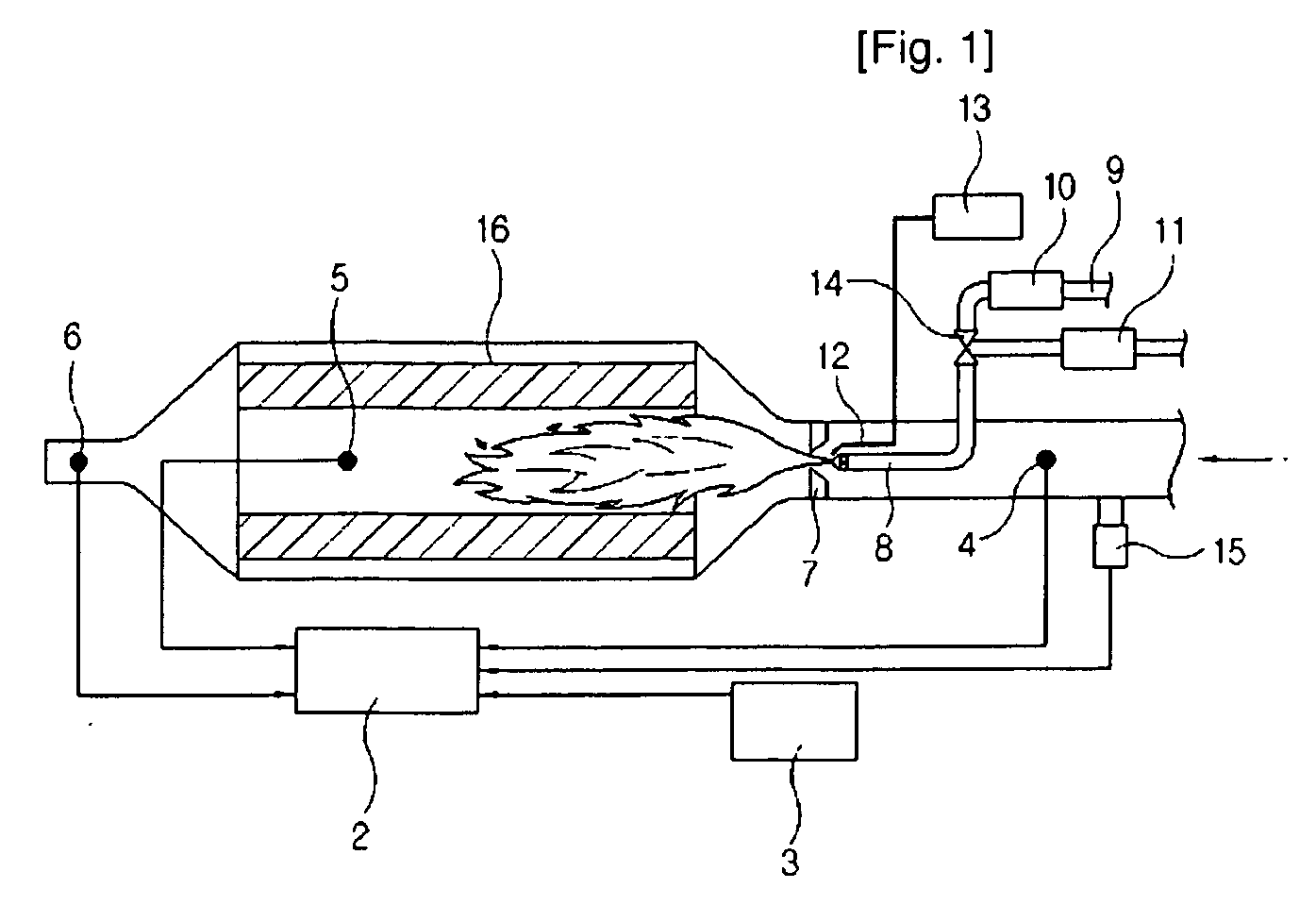

Inner flame burner for regeneration of diesel particulate filter

InactiveUS20100146939A1Quick heat transferLarge surfaceExhaust apparatusSilencing apparatusDiesel particulate filterCombustion chamber

Provided is a burner for regenerating a diesel engine particulate filter. The burner includes: a combustion chamber for receiving exhaust gas from a diesel engine; a carburetor for gasifying liquid fuel; a mixed gas supplying unit for mixing the gasified fuel with an external air, and supplying the mixed gaseous fuel to the combustion chamber; a mixed gas storing chamber disposed in the combustion chamber for receiving the mixed gaseous fuel and instantly storing the received mixed gaseous fuel; an inner flame combustor made of porous material for injecting the mixed gaseous fuel toward the inside of the inner flame combustor, and disposed in the combustion chamber to allow an exhaust gas to flow through the inner flame combustor; an igniter for igniting the mixed gaseous fuel; and a flame sensor for sensing the flame on the inner flame combustor.

Owner:KOREA INST OF MASCH & MATERIALS

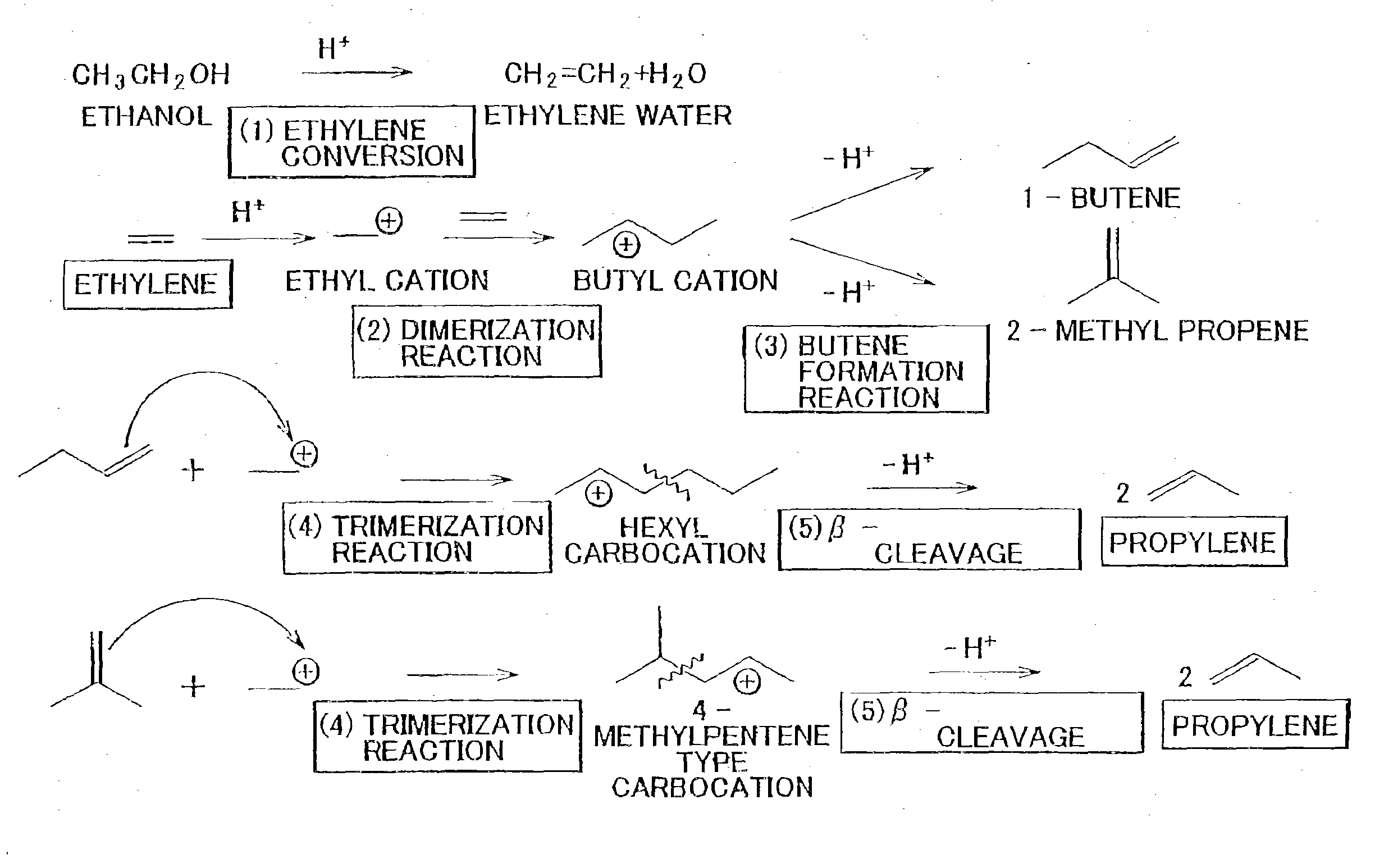

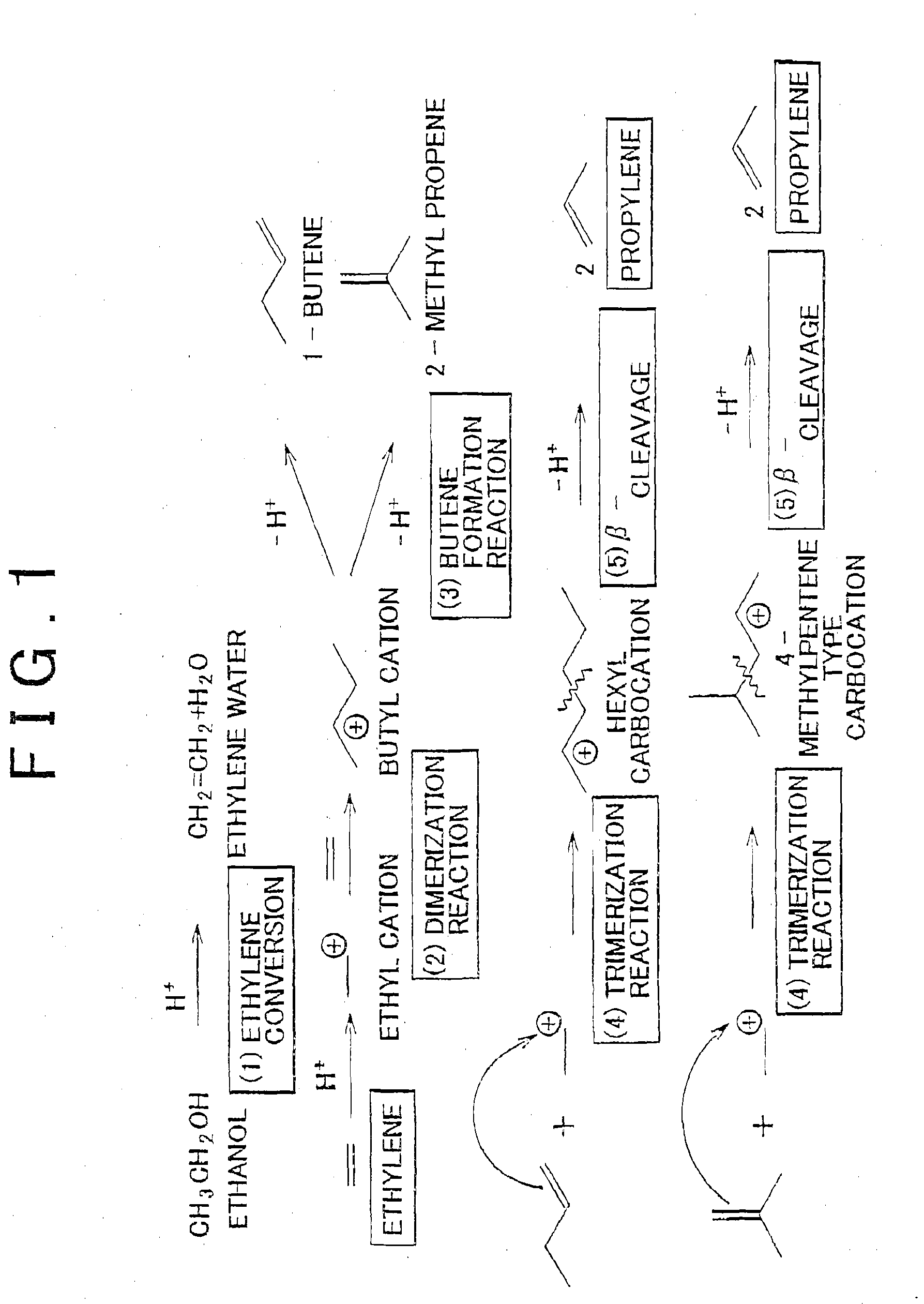

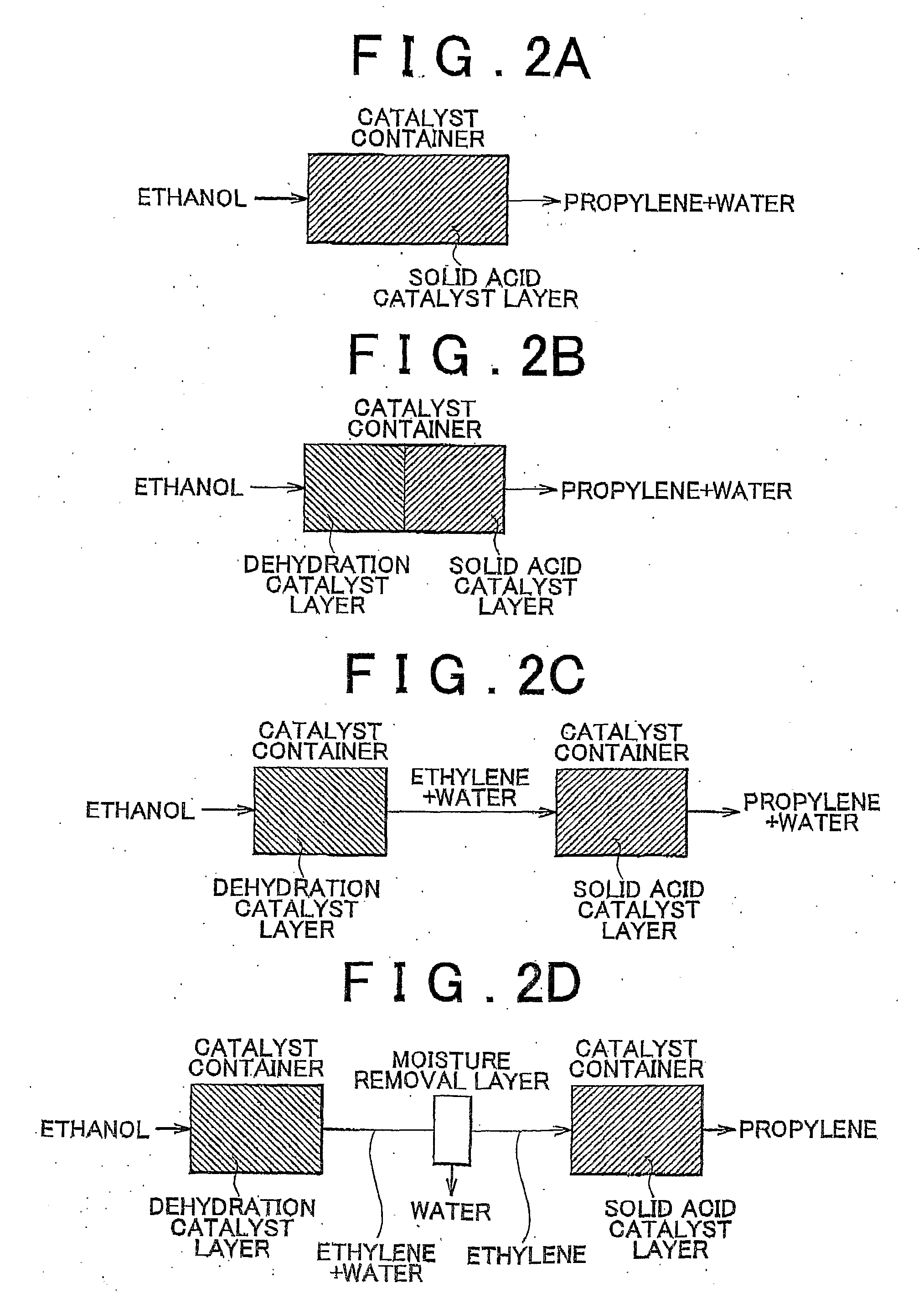

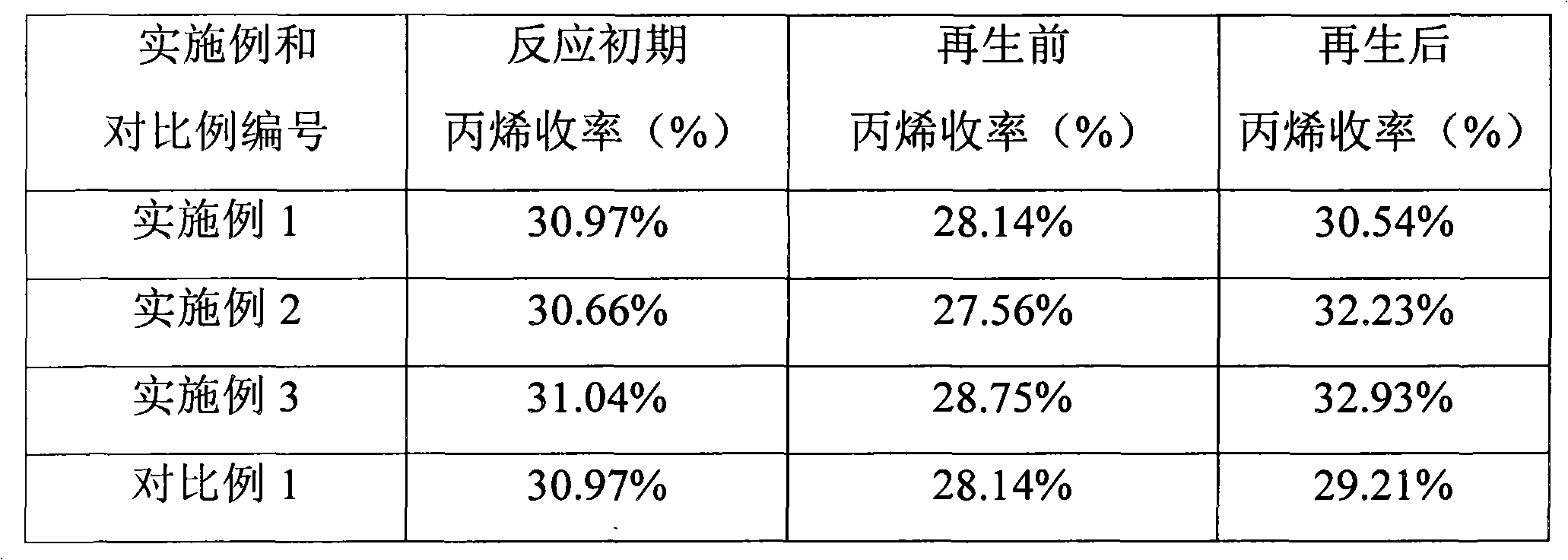

Production method for propylene, restoration method for catalyst, and solid acid catalyst

InactiveUS20100222203A1Efficiently regenerateHigh selectivity of propyleneMolecular sieve catalystsOther chemical processesConsecutive reactionPropene

A production method for propylene is characterized in that ethanol is converted into propylene by continuously reacting ethanol on a catalyst. A solid acid catalyst is characterized in that the kinetic constant k of the butane cracking reaction on the catalyst at 500° C. is 0.1 to 30 (cm3 / min·g), and the solid acid catalyst is used in the production method for propylene. A solid acid catalyst is characterized in that the aperture diameter of pores formed in surfaces of the catalyst is 0.3 to 1.0 nm, and the solid acid catalyst is used in the production method for propylene. Furthermore, a regeneration method for a catalyst is characterized in that a heating treatment in an oxygen atmosphere is perform on a catalyst that has been used to produce propylene in the production method for propylene of the invention.

Owner:TOYOTA JIDOSHA KK +1

Control method for an exhaust gas purification system and an exhaust gas purification system

InactiveUS7181909B2Burn enoughSufficiently removingElectrical controlNon-fuel substance addition to fuelExhaust fumesEngineering

Owner:ISUZU MOTORS LTD

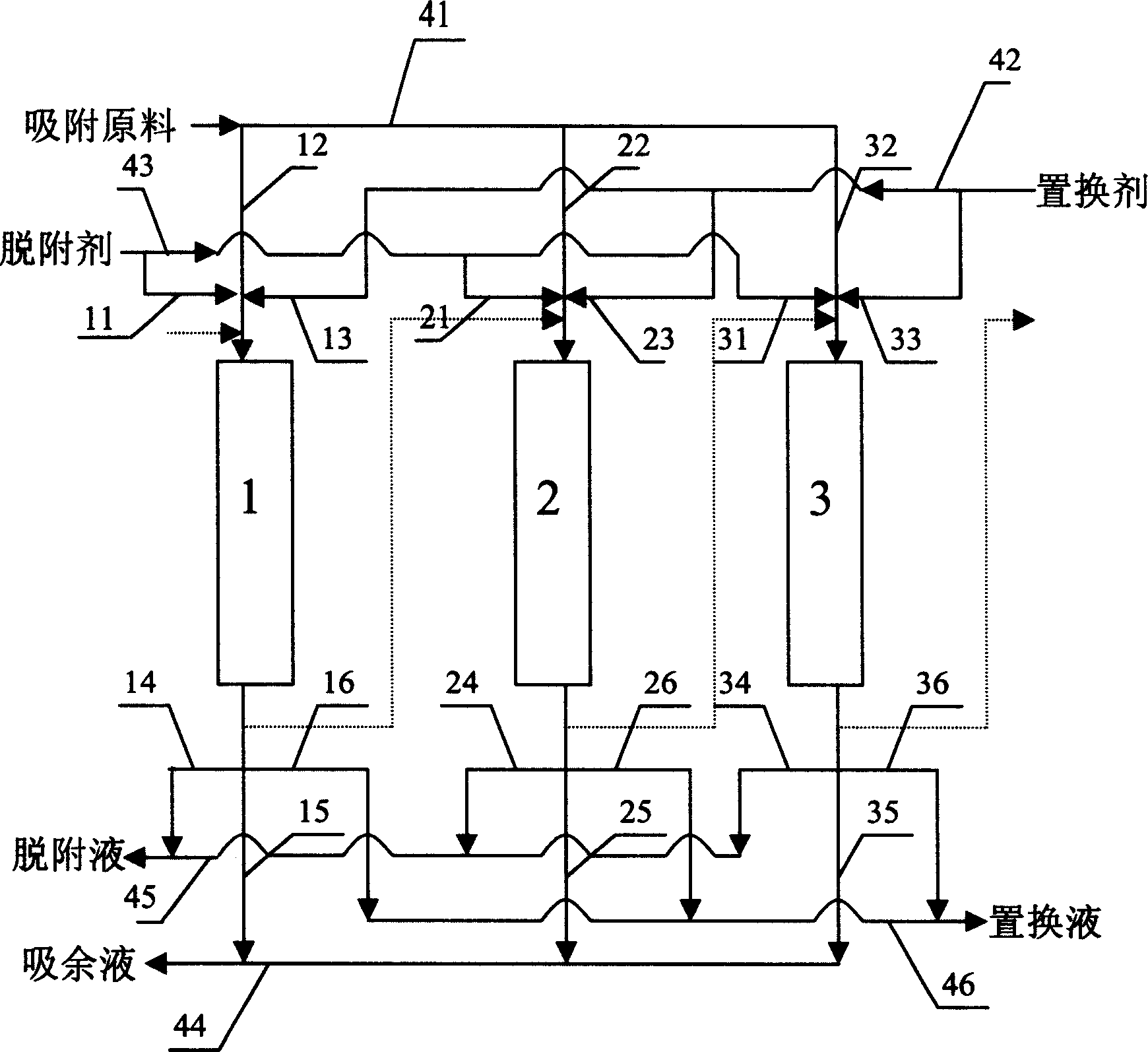

Method for separating normal alkane from full fraction naphtha

ActiveCN1715368AImprove ethylene yieldHigh yieldEthylene productionAdsorption purification/separationAlkaneNaphtha

The full fraction naphtha is first treated via one adsorption and separation process to separate out arene, and then treated via one other adsorption and separation process to separate normal alkane from non-normal alkane. The naphtha component obtained through adsorption and separation process and with rich normal alkane is used as material for steam cracking equipment to raise the ethylene yield; the component with rich non-normal alkane is used as material for catalytic re-former to increase the yield of reformed gasoline or arene; and the component with rich arene is used as material for coking or reforming apparatus. The two adsorption and separation processes have efficient desorbing agent adopted for regenerating the adsorption saturated adsorbent for reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

Exhaust emission control device for an internal combustion engine

InactiveUS7367182B2Efficient regenerationSimple and inexpensive configurationCombination devicesNon-fuel substance addition to fuelParticulatesCombustor

A forced regeneration device which performs regeneration of a particulate filter includes oxidation catalysts (23, 24a) disposed upstream from the particulate filter or in said particulate filter and a burner (30) located upstream from the oxidation catalysts and operable switching between a combustion mode for combusting a fuel spray by inflammation to raise temperature of exhaust gases in an exhaust passage and a fuel supply mode for supplying only a fuel spray to the exhaust passage without inflammation. After the burner operates in the combustion mode, the burner operation is switched to the fuel supply mode.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

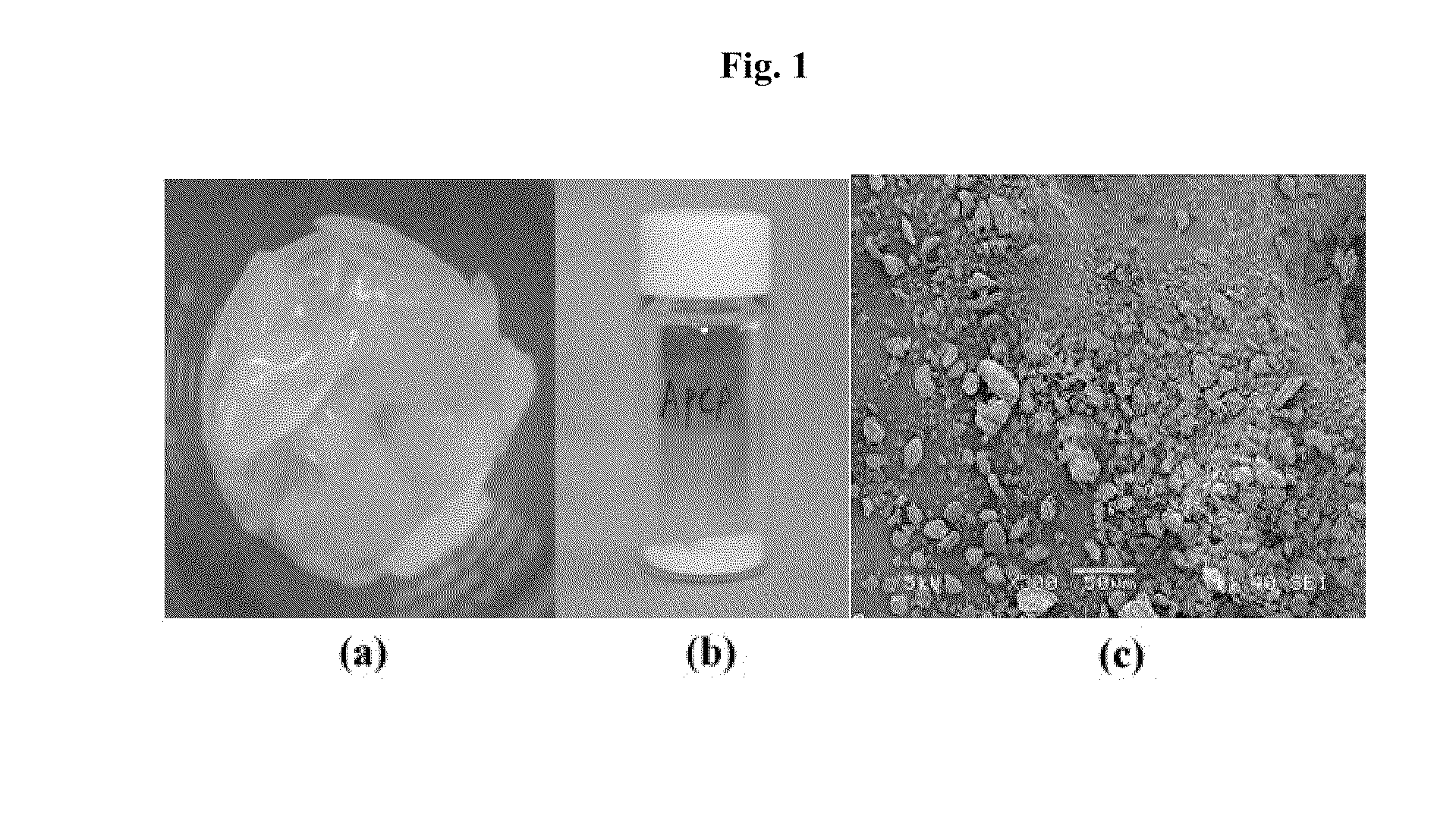

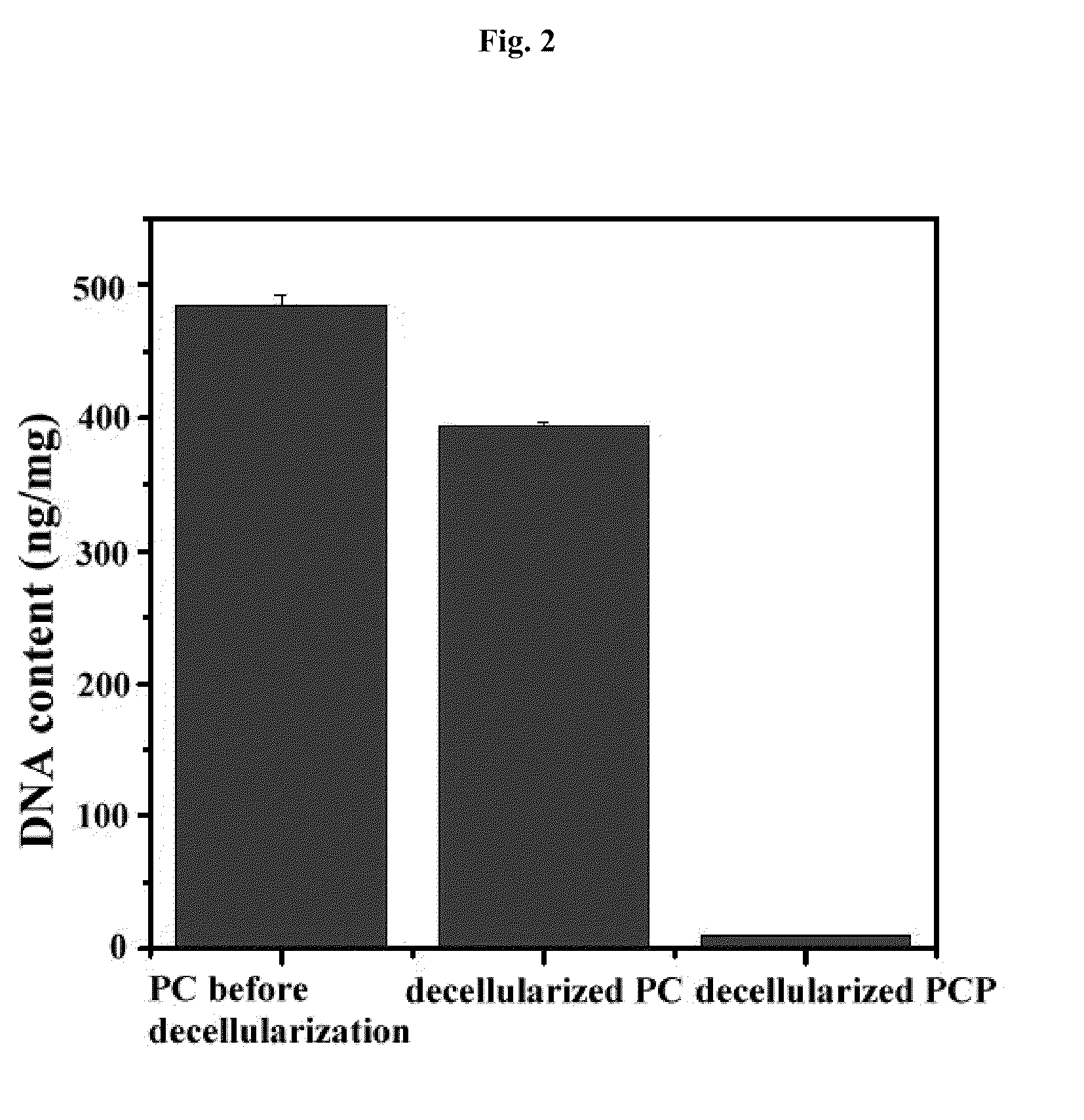

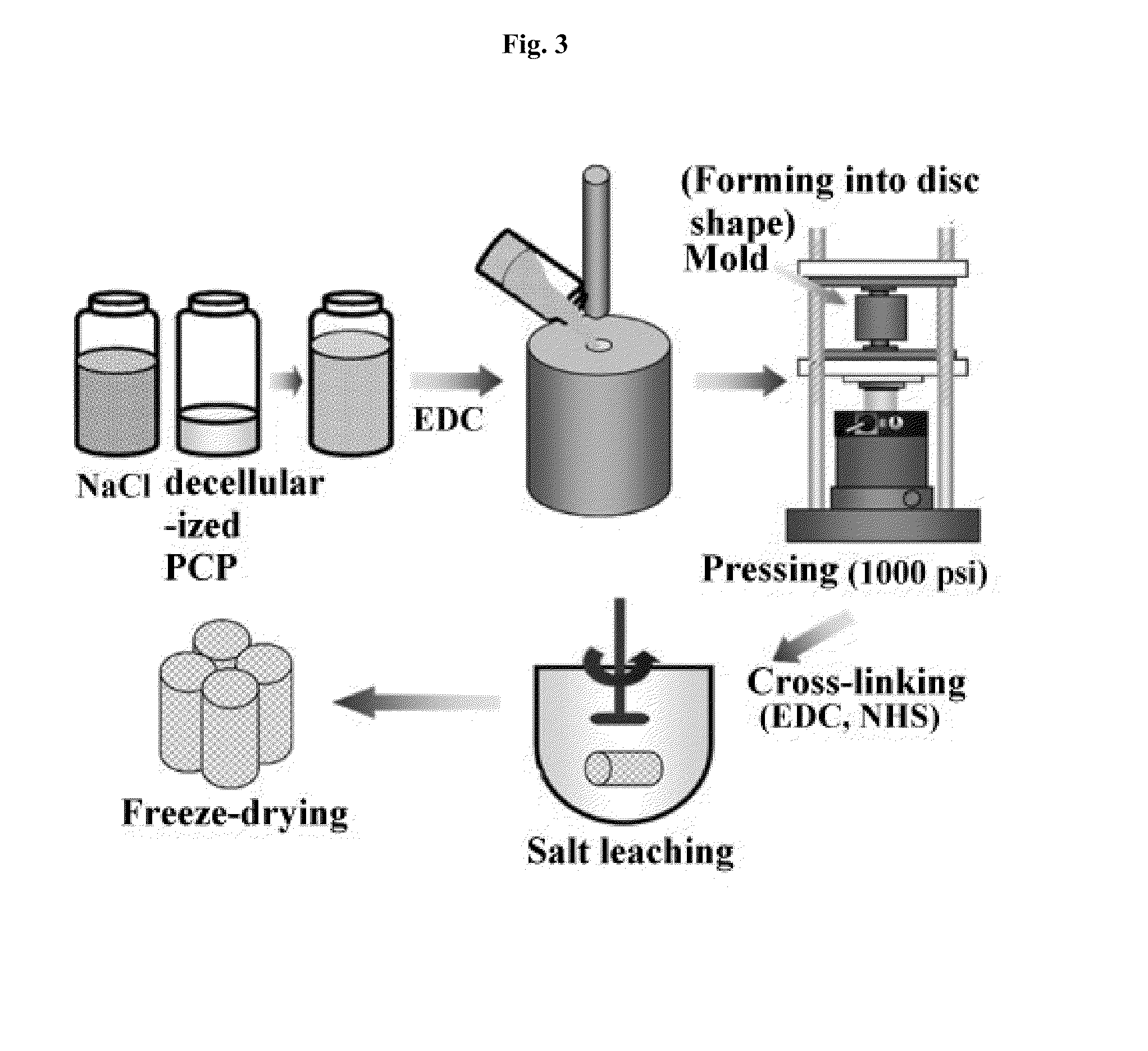

Method for manufacturing a porous three-dimensional scaffold using powder from animal tissue, and porous three-dimensional scaffold manufactured by same

InactiveUS20110195107A1Good effectEfficient regenerationBiocidePharmaceutical delivery mechanismTissue DecellularizationThree dimensional scaffolds

The present invention provides a method for manufacturing a porous three-dimensional scaffold using animal tissue powder, comprising powdering an animal-derived tissue, decellularizing the animal-derived tissue before or after powdering it, or simultaneously with powdering it, and forming the decellularized animal-derived tissue powder into a porous three-dimensional scaffold by a particle leaching method.

Owner:AJOU UNIV IND ACADEMIC COOP FOUND

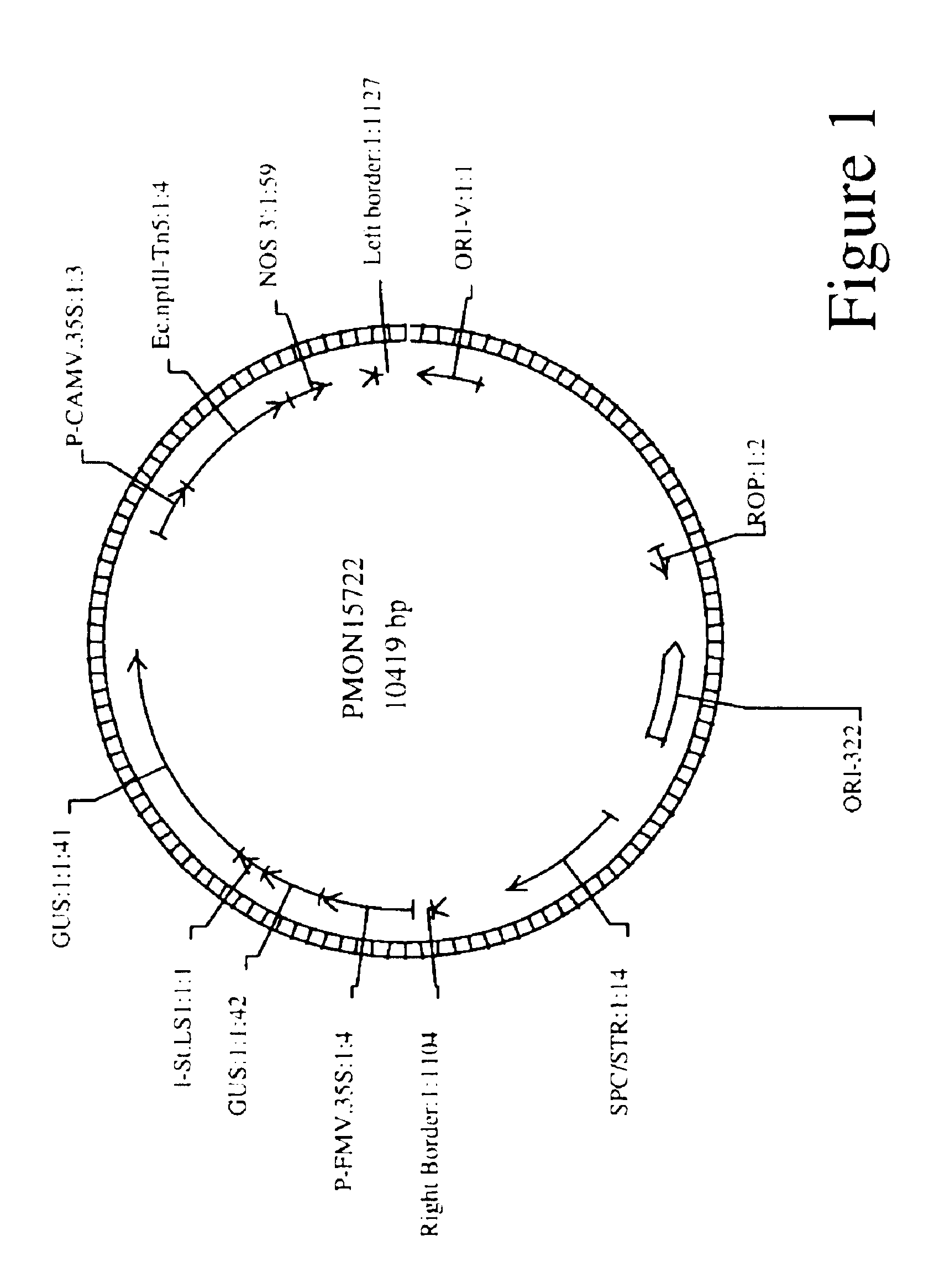

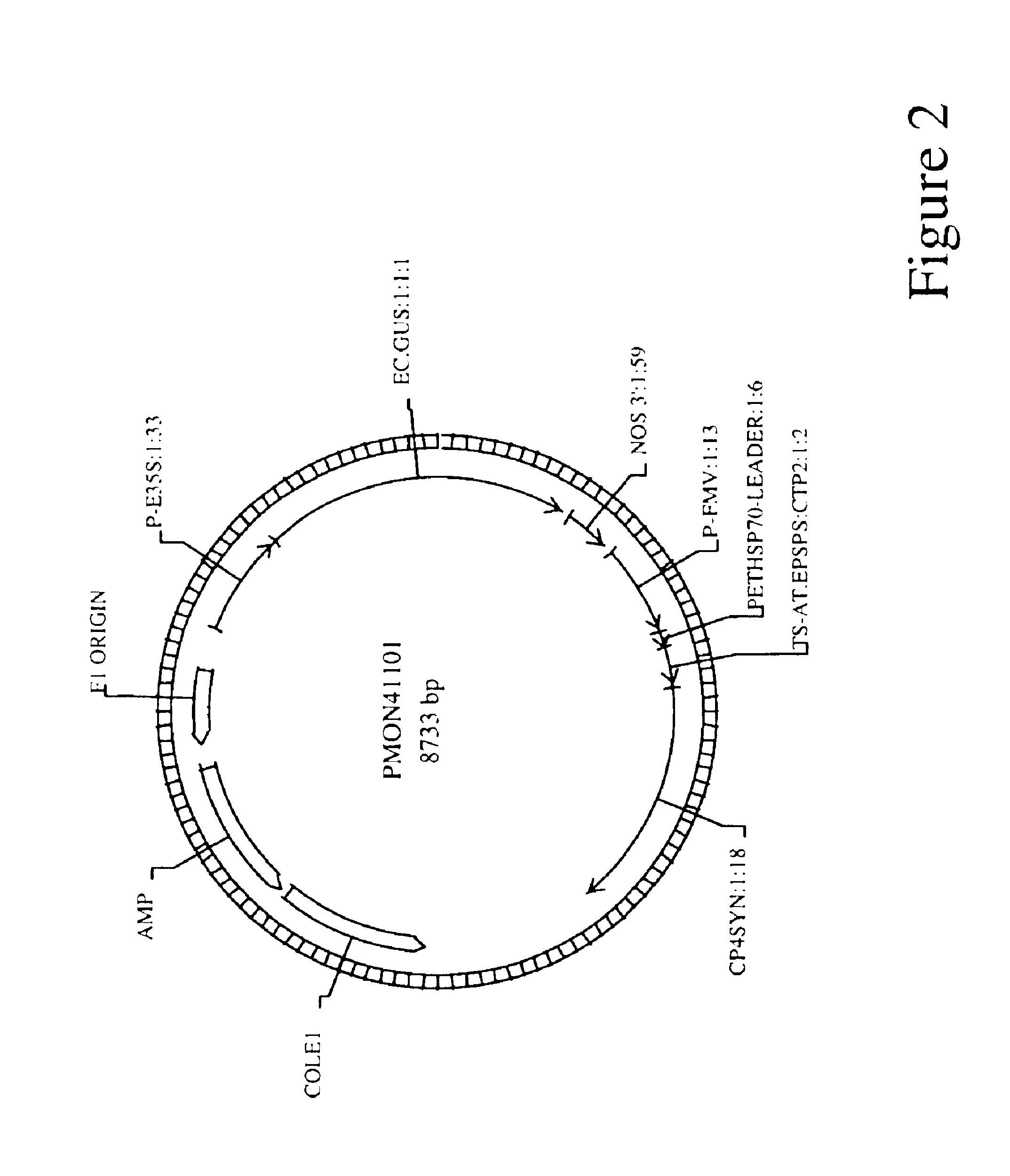

Multiple shoot proliferation and regeneration system for plants

InactiveUS6900057B2Easy to produceBig impactOther foreign material introduction processesFermentationShoot formationImproved method

Owner:MONSANTO TECH LLC

Cell or tissue-culturing carrier, and culturing method

InactiveUS6897064B2Inhibiting and suppressing excessive growthPromote regenerationBacteriaVertebrate cellsGel basedCulture cell

A cell or tissue-culturing carrier which can effectively regenerate an intended a cell or tissue, while suppressing an excessive growth of fibroblasts, and a method of culturing a cell or tissue by using the above carrier, the cell or tissue-culturing carrier wherein fibroblasts showing substantially no growing property in a gel based on the hydrogel-forming polymer, is constituted by using a hydrogel-forming polymer; an aqueous solution of which shows a thermo-reversible sol-gel transition such that it assumes a sol state at a lower temperature and assumes a gel state at a higher temperature.

Owner:MEBIOL

Regeneration method of molecular sieve catalyst

ActiveCN102836743AEfficient regenerationNo overheatingMolecular sieve catalystsMolecular sieveCarbon deposit

The invention provides a regeneration method of a molecular sieve catalyst, comprising the following steps: roasting a molecular sieve catalyst to be regenerated at 300-750 DEG C to decomposing the carbon deposit in the molecular sieve catalyst to be regenerated into CO2, wherein the roasting step is characterized in that: in the presence of oxygen-containing gas, the molecular sieve catalyst to be regenerated is subject to roasting of multiple stages at a constant temperature, the roasting of multiple stages comprises a first roasting stage and roasting stages after the first roasting stage, the roasting temperature of any one roasting stage after the first roasting stage is 5-70 DEG C higher than that of the adjacent former roasting stage, and the roasting time of each roasting stage is long enough to generate no CO2 when roasting is conducted under the roasting condition of the roasting stage. According to the invention, the performance of the regenerated molecular sieve catalyst is recovered and even better than the performance of a fresh catalyst, thus good regeneration effect can be achieved by using the method disclosed herein.

Owner:CHINA PETROLEUM & CHEM CORP +1

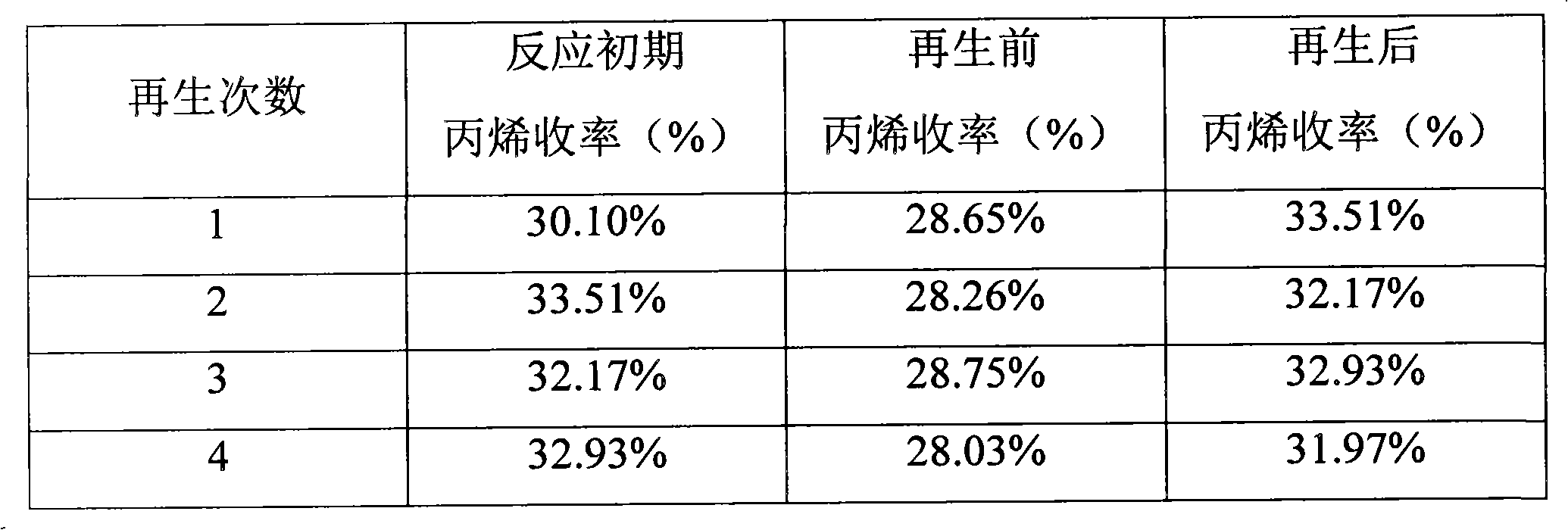

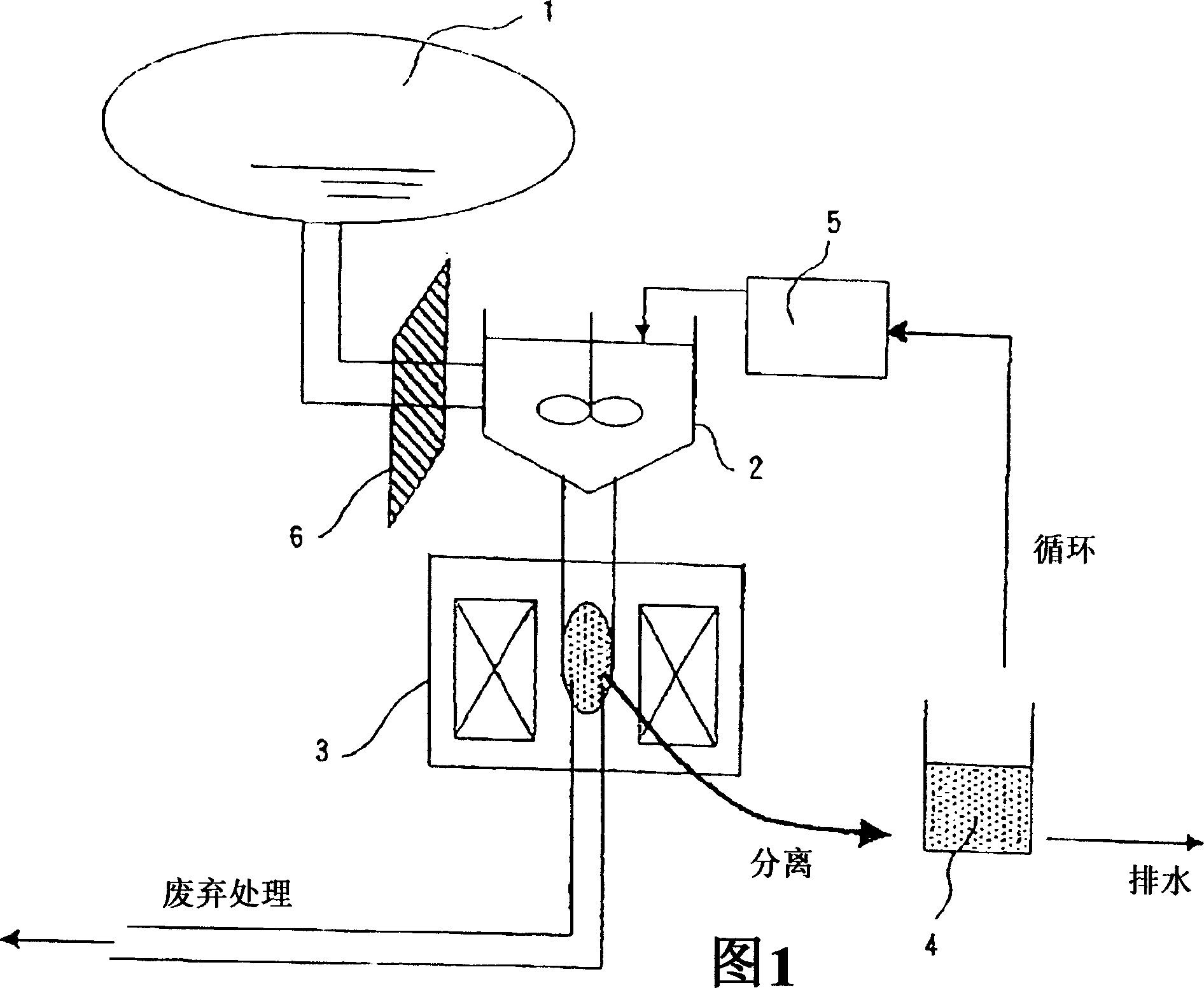

Waste water treatment system by superconductive magnetic separation

InactiveCN1697784ALow costSmall footprintTreatment using aerobic processesOpen gradient mangetic separatorsWater treatment systemMagnetic separator

An object of the invention is to provide a wastewater treatment system using a superconducting magnetic separator that can wash the magnetic filter efficiently. The system comprises in a bore of a superconducting magnet a removably built-up multiunit magnetic filter consisting of a plurality of single-unit magnetic filters. The multiunit magnetic filter has a total longitudinal length at least equal or greater than that of the superconducting magnet. During excitation of the superconducting magnet, a single-unit magnetic filter is removed from the upstream side (sewage side) of the multiunit magnetic filter by pushing in another single-unit magnetic filter from the downstream side (clean water side), and washed and returned to the downstream side again.

Owner:NIKI GLASS +2

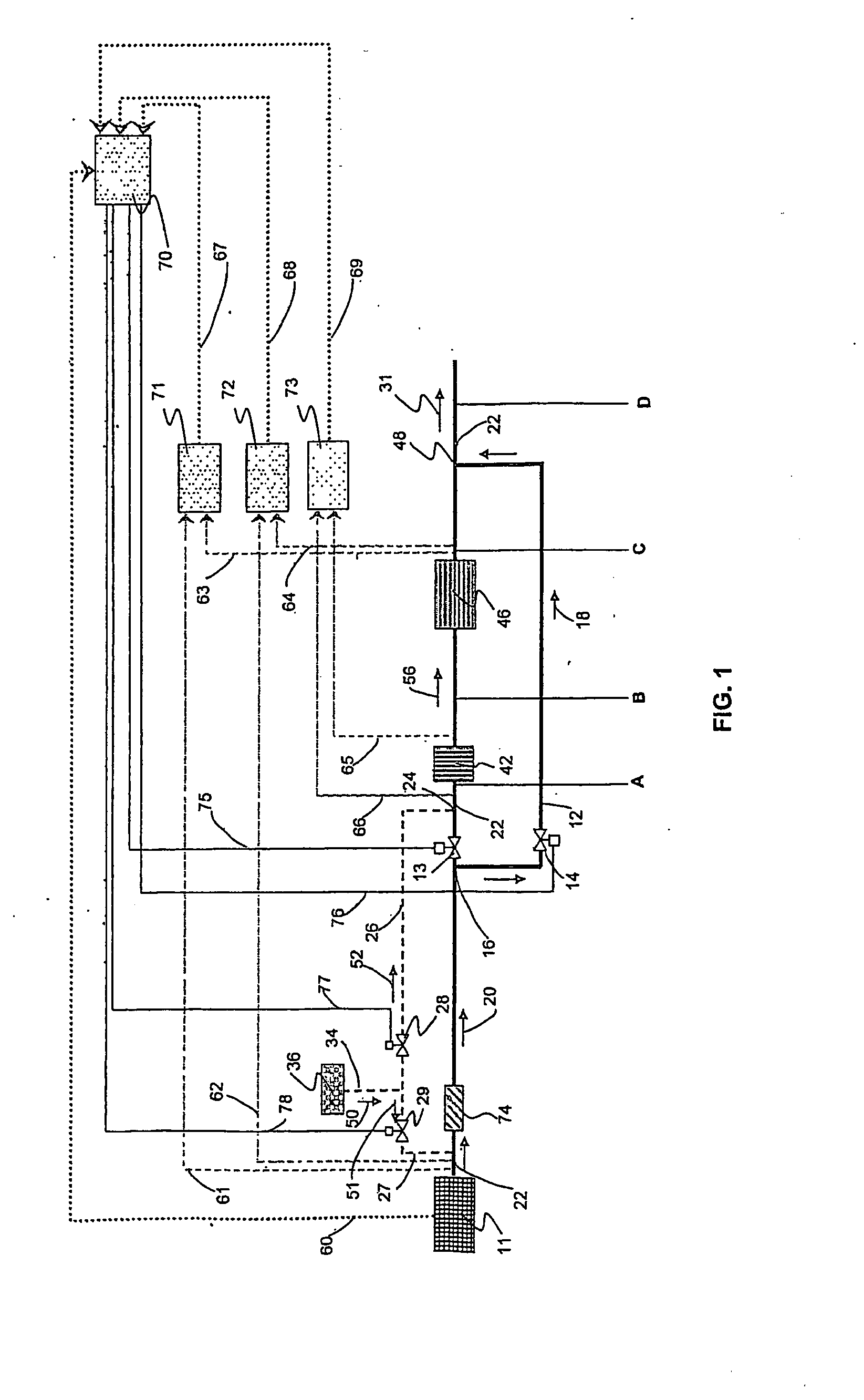

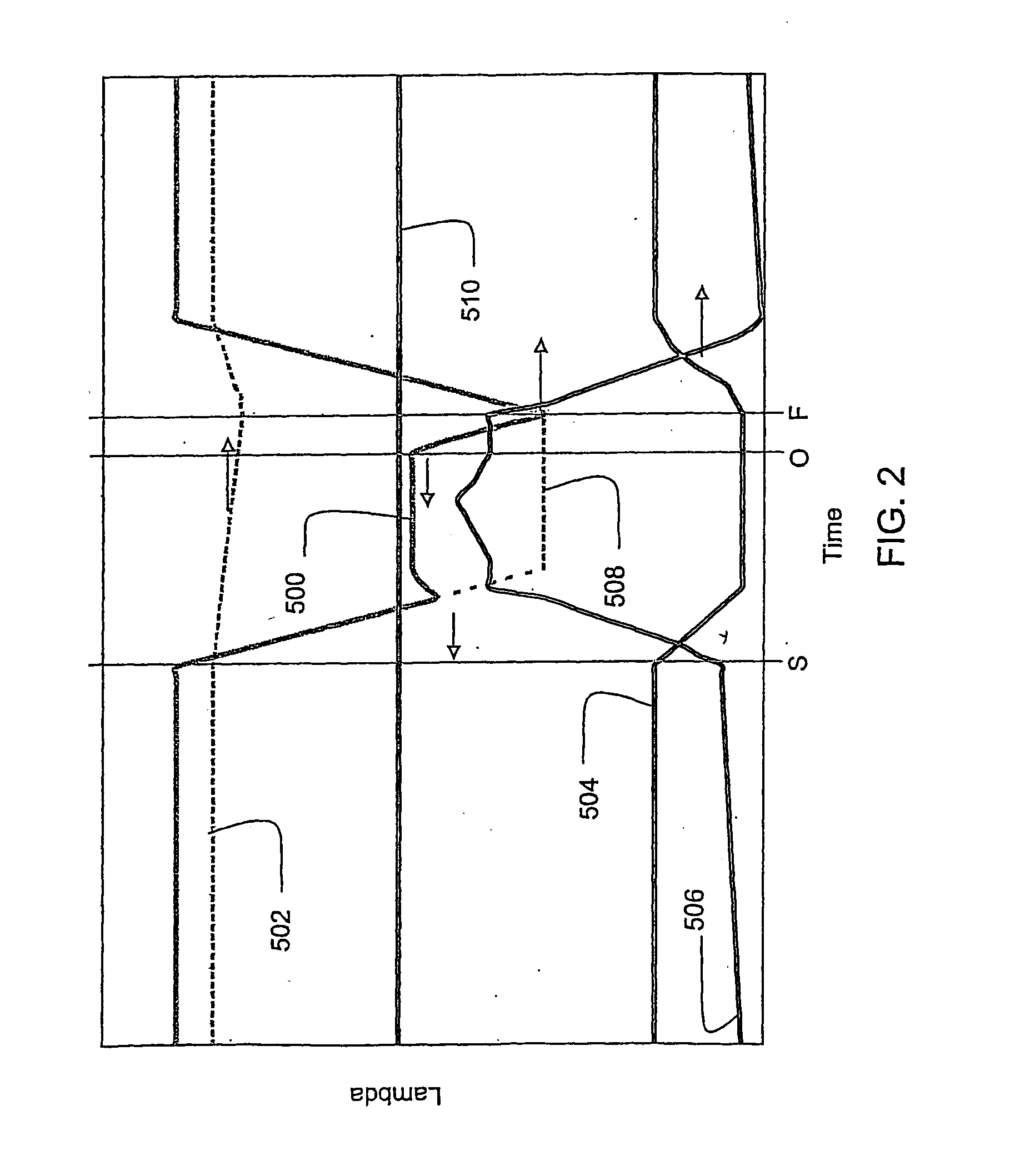

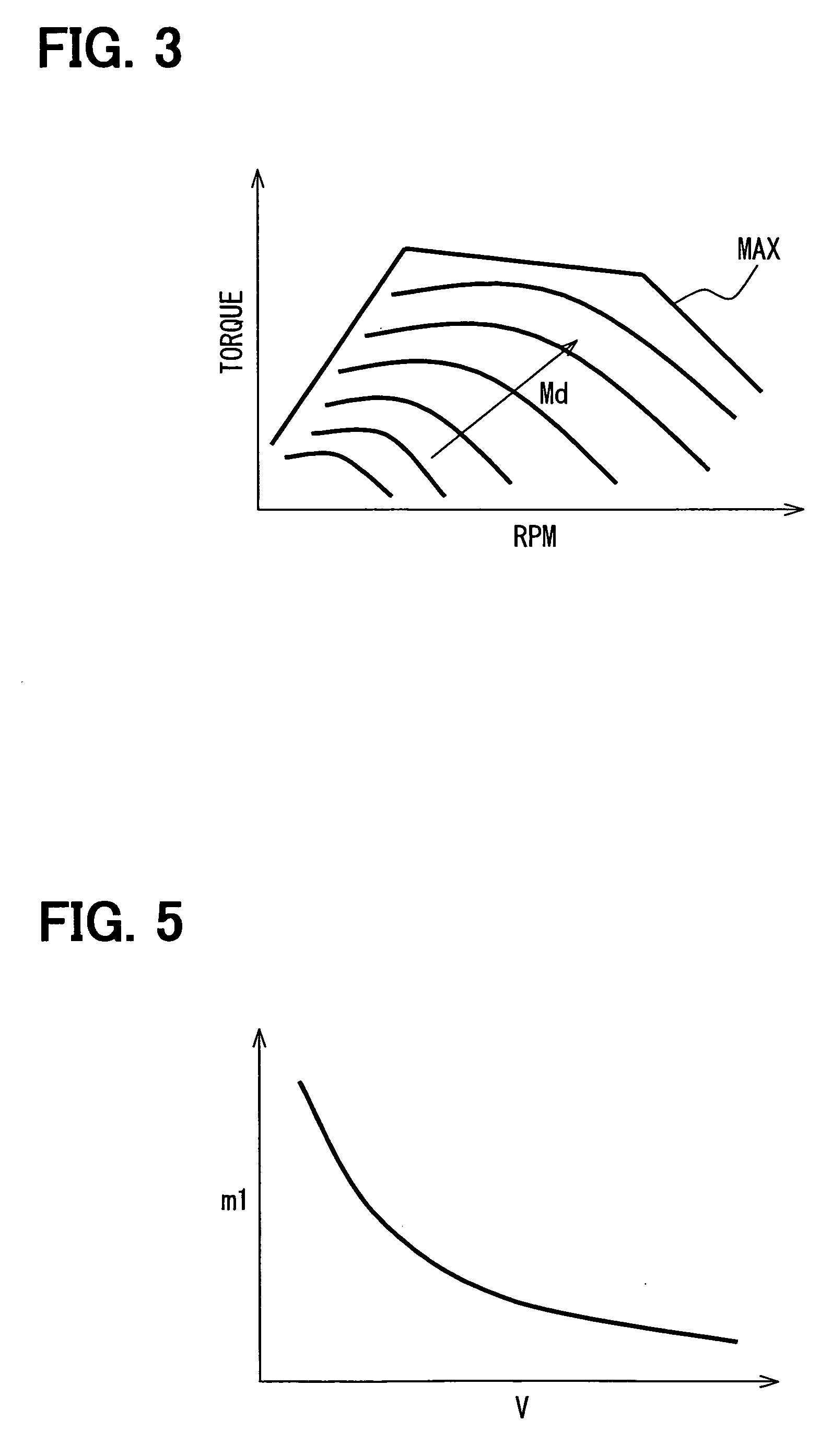

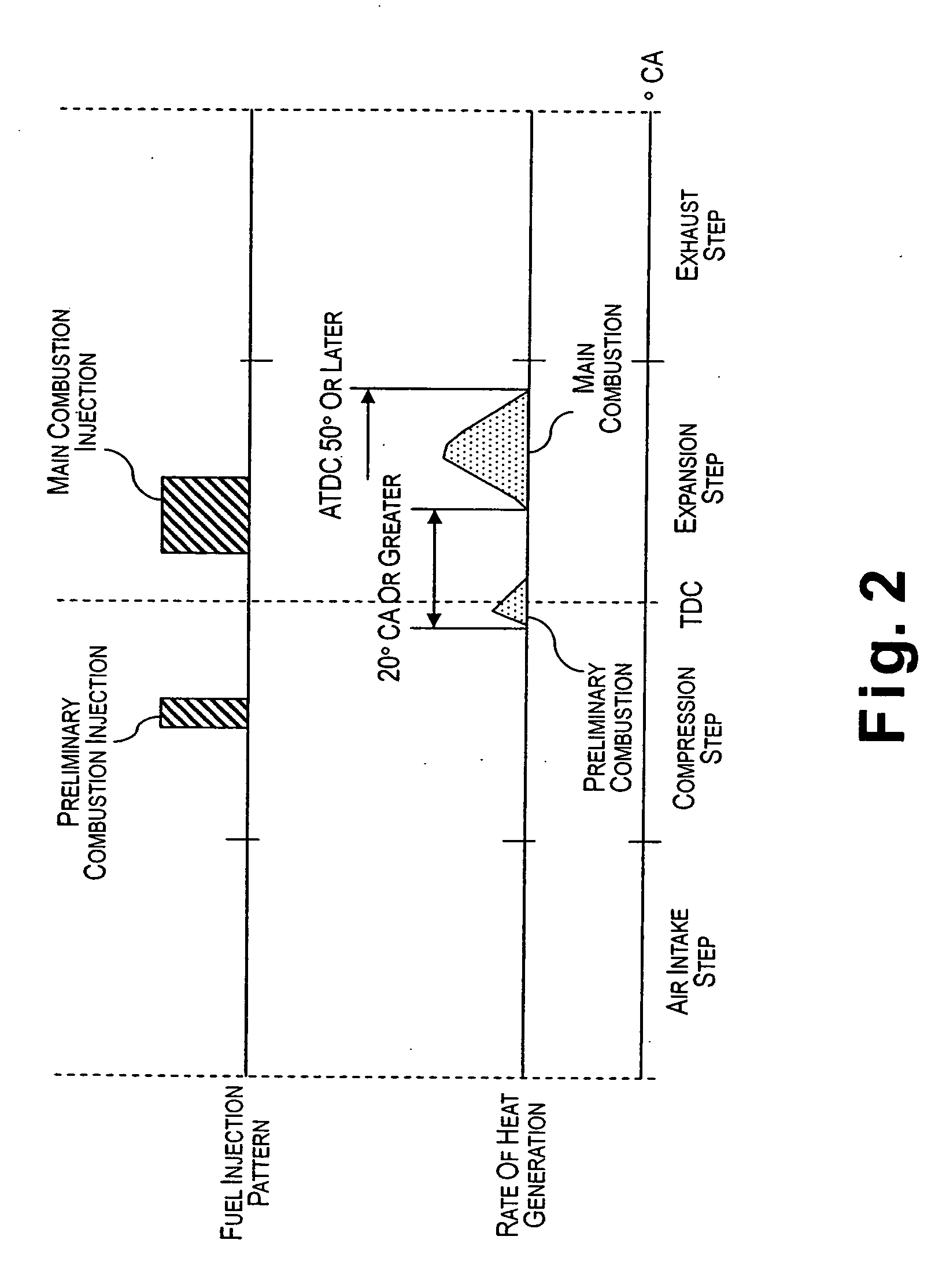

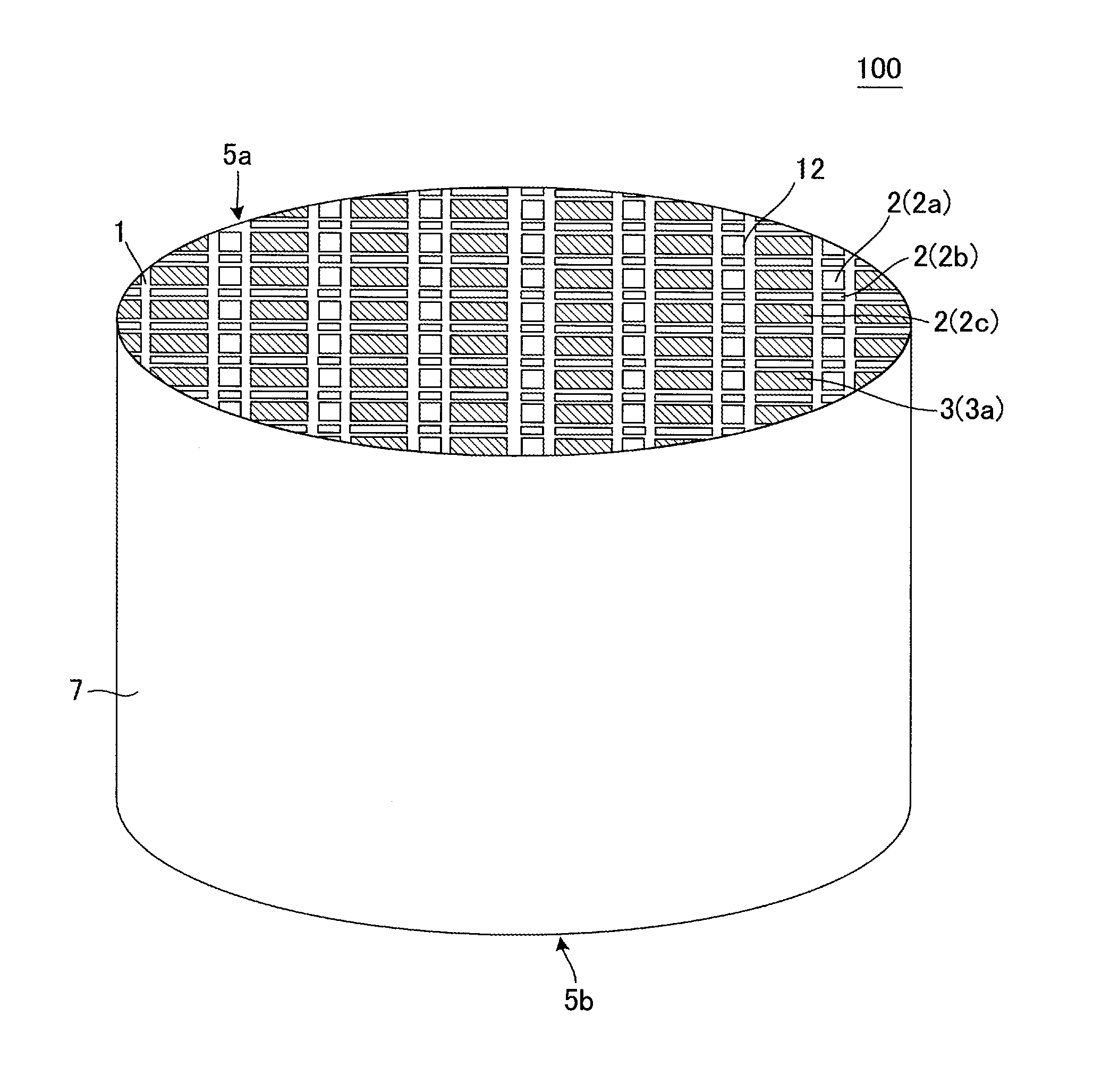

Regeneration control system

ActiveUS20050022505A1Easy to burnEfficient regenerationElectrical controlNon-fuel substance addition to fuelTop dead centerControl system

The regeneration control system is provided that conducts a regeneration processing for oxidizing particulate matter collected in the diesel particulate filter (DPF) whereby the regeneration processing can be performed efficiently while avoiding the melting of the diesel particulate filter. The regeneration control system is provided for an exhaust filter wherein at least one parameter selected from among the target filter temperature, target exhaust air-fuel ratio, and target regeneration control time in the DPF regeneration is varied in accordance with the amount of particulate matter when the exhaust air-fuel ratio and exhaust temperature are controlled to perform the DPF regeneration by staged retarded combustion, which is composed of preliminary combustion that is performed at least once in the vicinity of the top dead center, and main combustion that causes the generation of main torque and is initiated after the preliminary combustion has been completed.

Owner:NISSAN MOTOR CO LTD

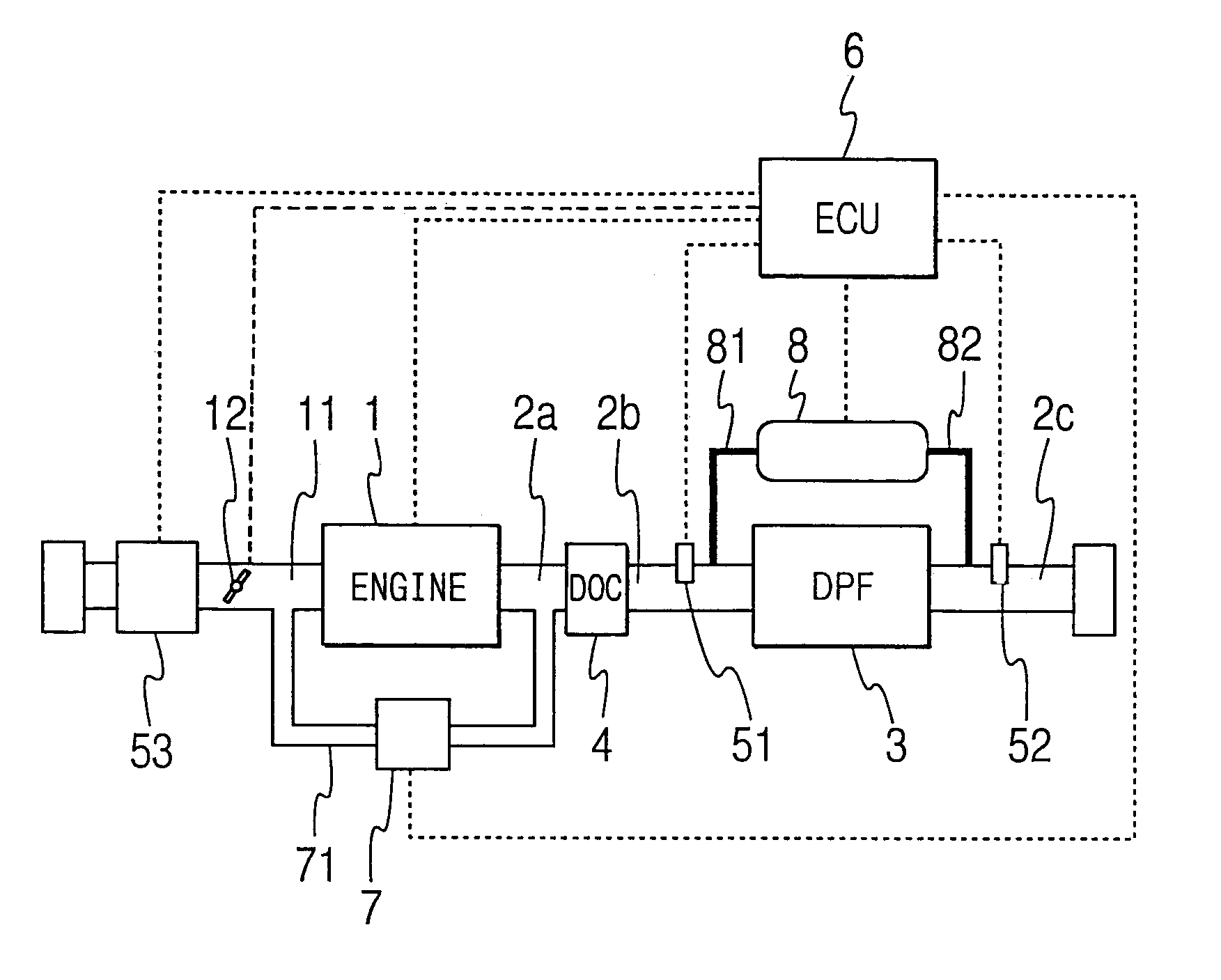

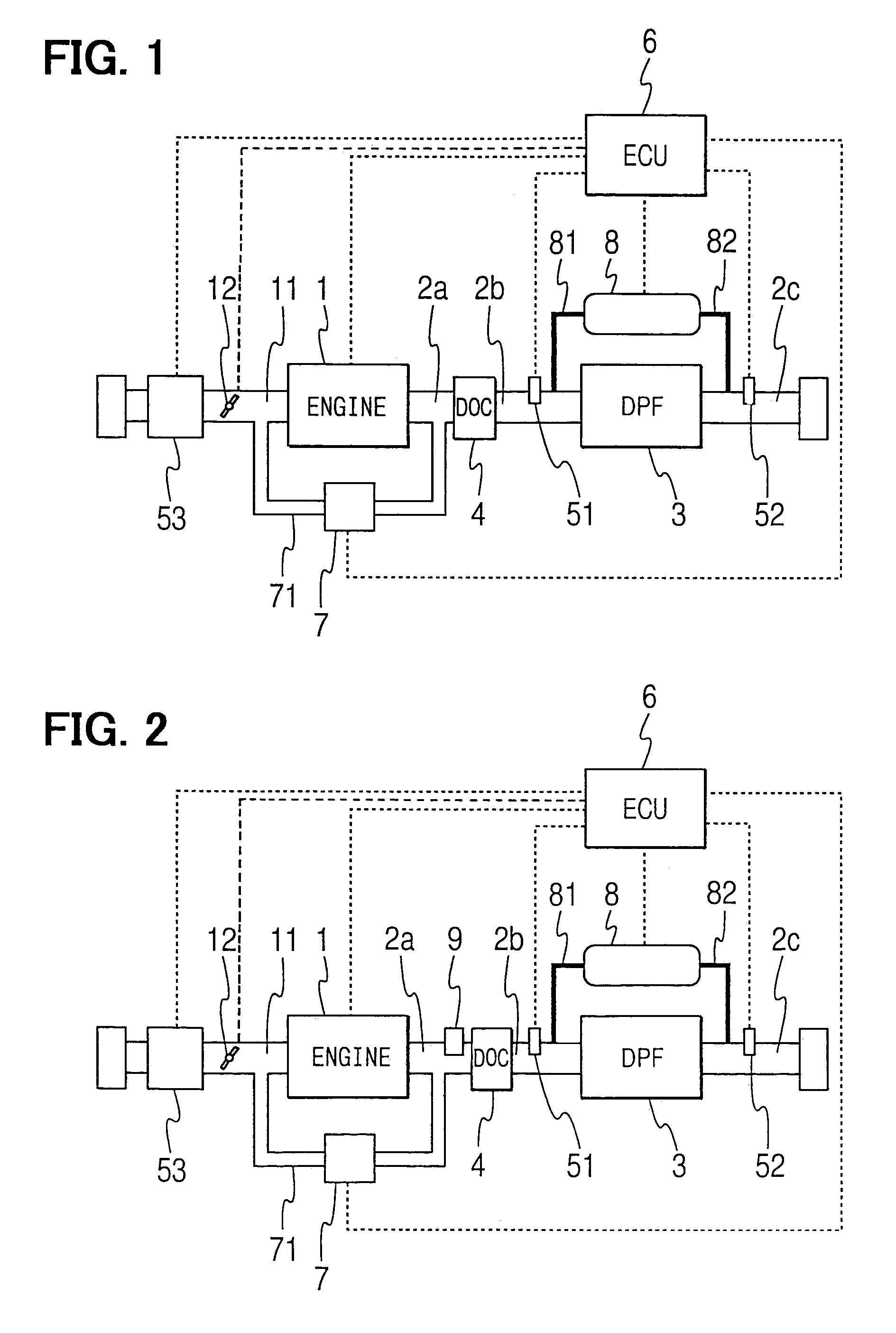

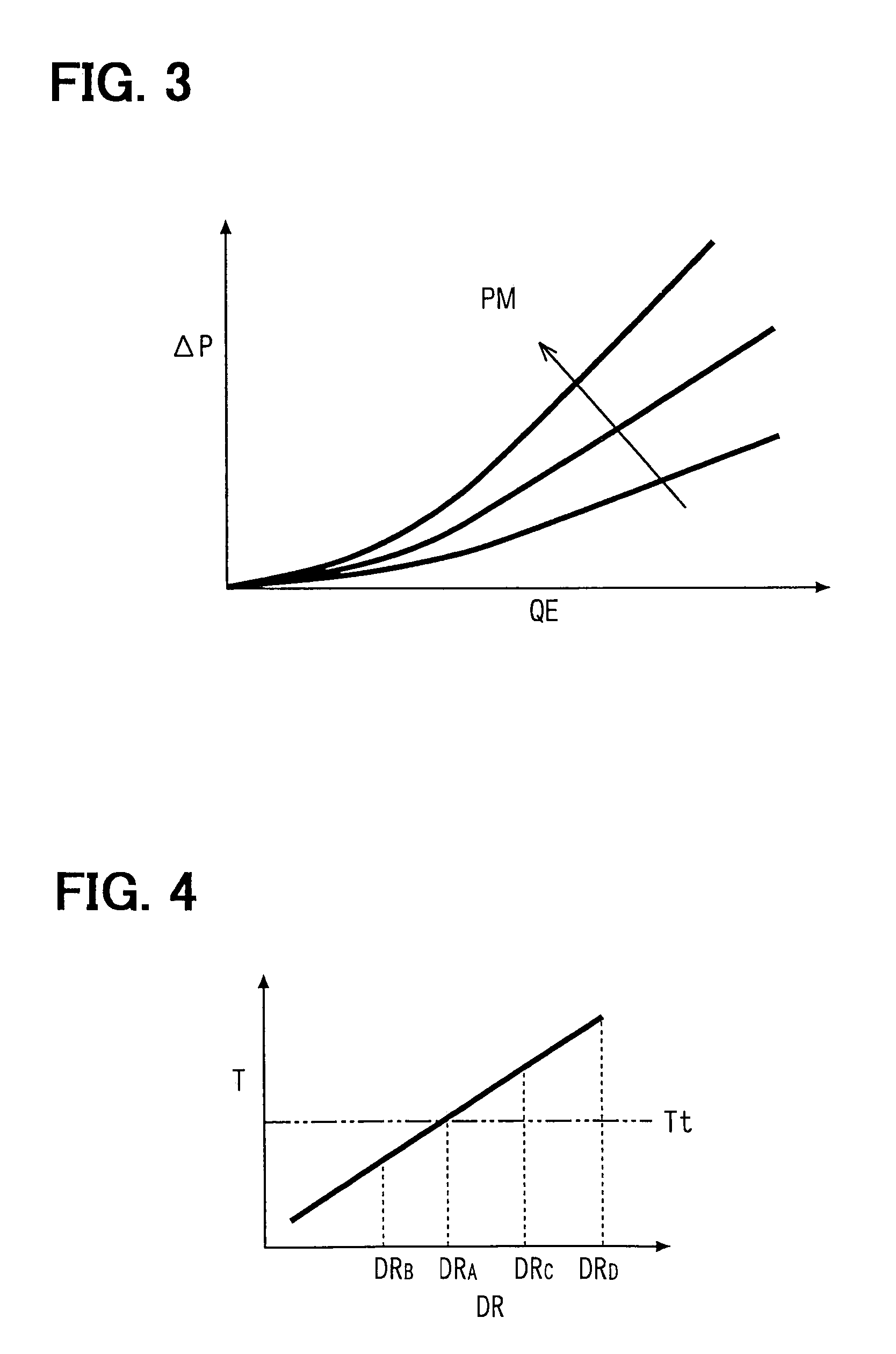

Exhaust gas cleaning system of internal combustion engine

ActiveUS7076944B2Avoid damageAvoid degradationElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

An exhaust gas cleaning system of a diesel engine includes a diesel particulate filter (a DPF) disposed in an exhaust passage, and a diesel oxidation catalyst (a DOC) disposed upstream of the DPF. When an electronic control unit (an ECU) performs a temperature increasing operation such as post-injection to eliminate particulate matters accumulated in the DPF, a ratio (a duty ratio) between a performing period and an interrupting period of the temperature increasing operation is changed in accordance with temperature of the DPF. Thus, a quantity of hydrocarbon supplied to the DOC is controlled stepwise or continuously. Thus, the temperature of the DPF can be increased to target temperature quickly and can be maintained near the target temperature when the regeneration of the DPF is performed.

Owner:DENSO CORP

Exhaust gas purification system for internal combustion engine

ActiveUS7310941B2Accurate estimateAvoid excessive accumulationInternal combustion piston enginesExhaust apparatusExhaust fumesExhaust gas recirculation

Owner:DENSO CORP

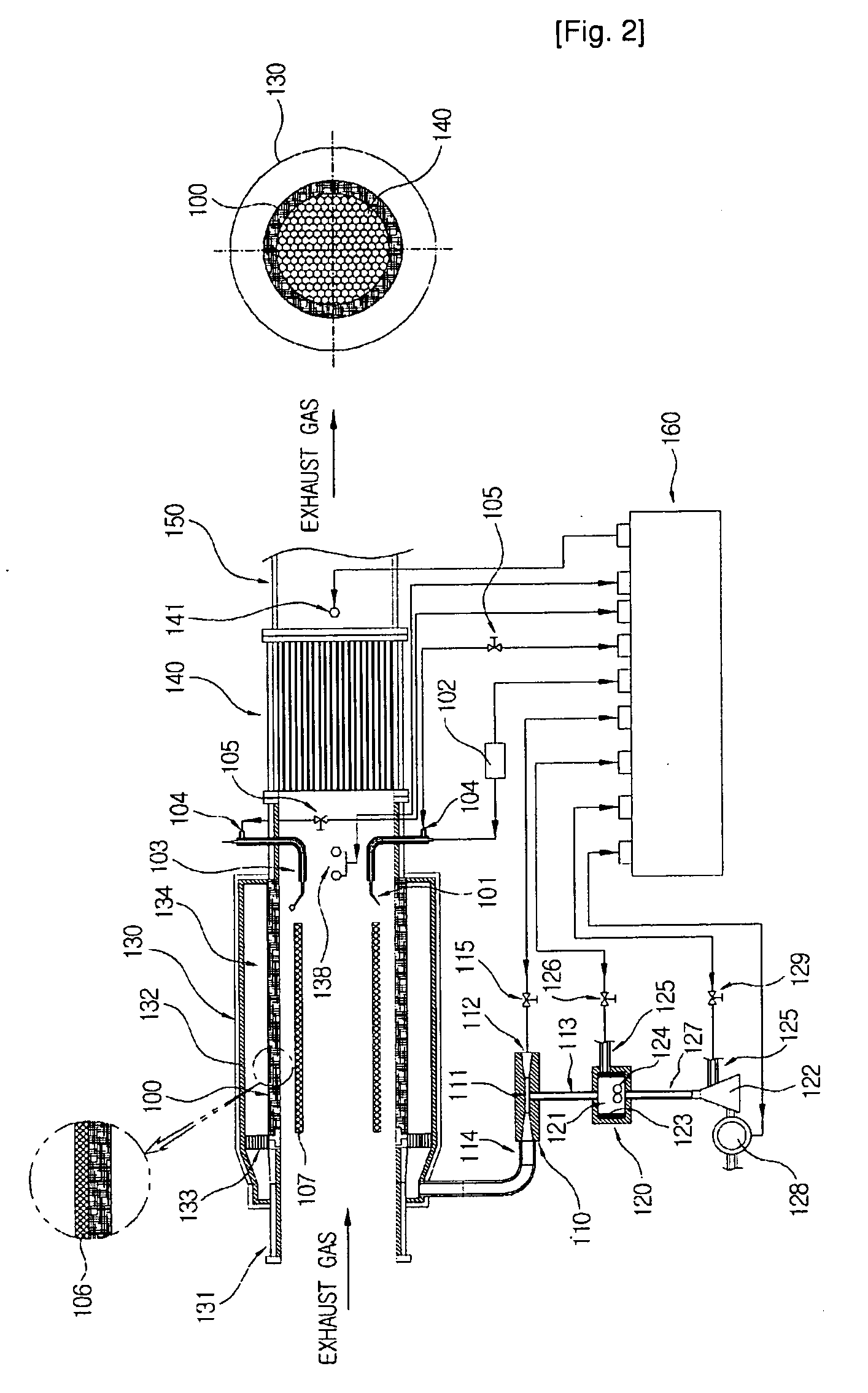

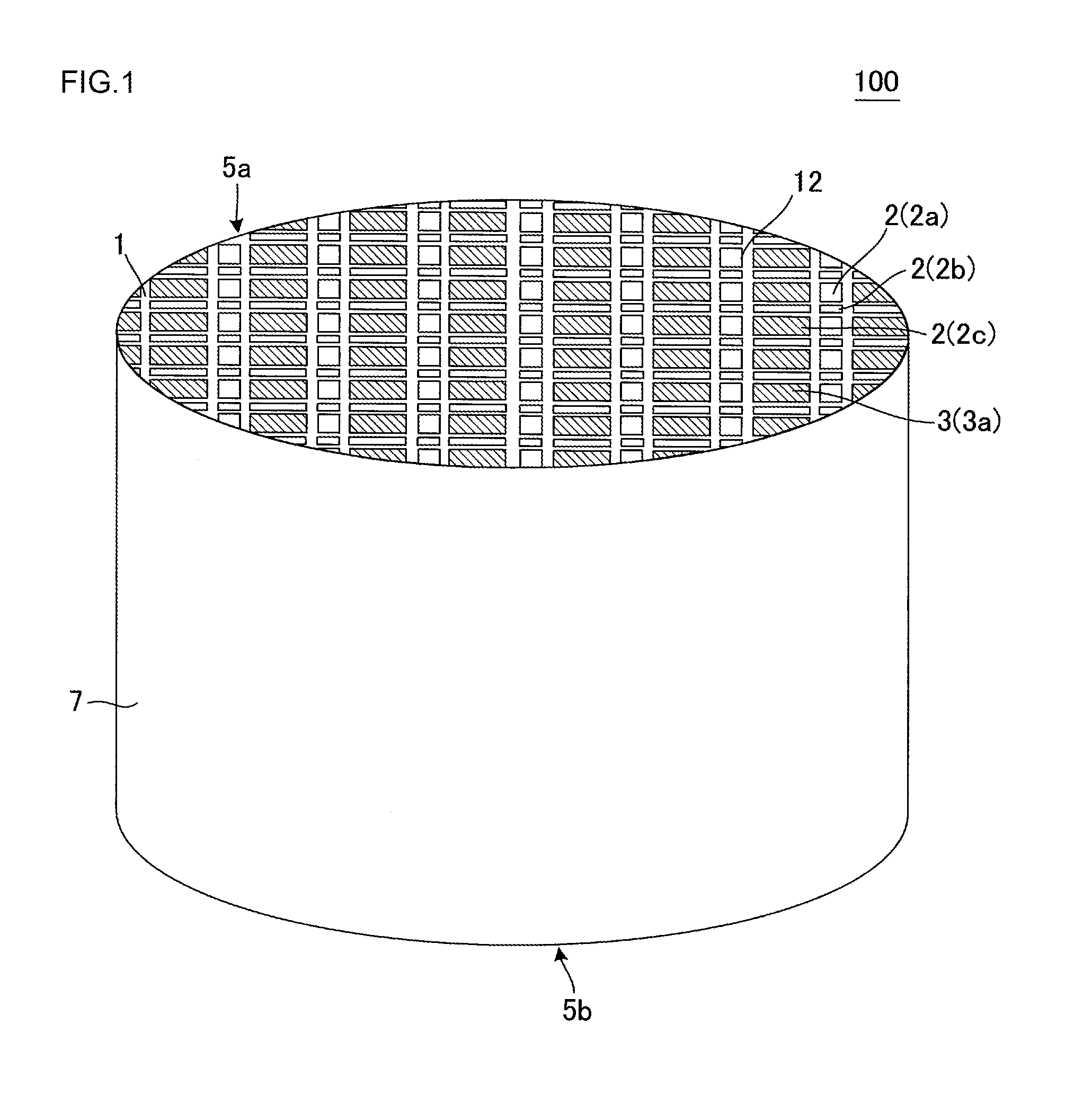

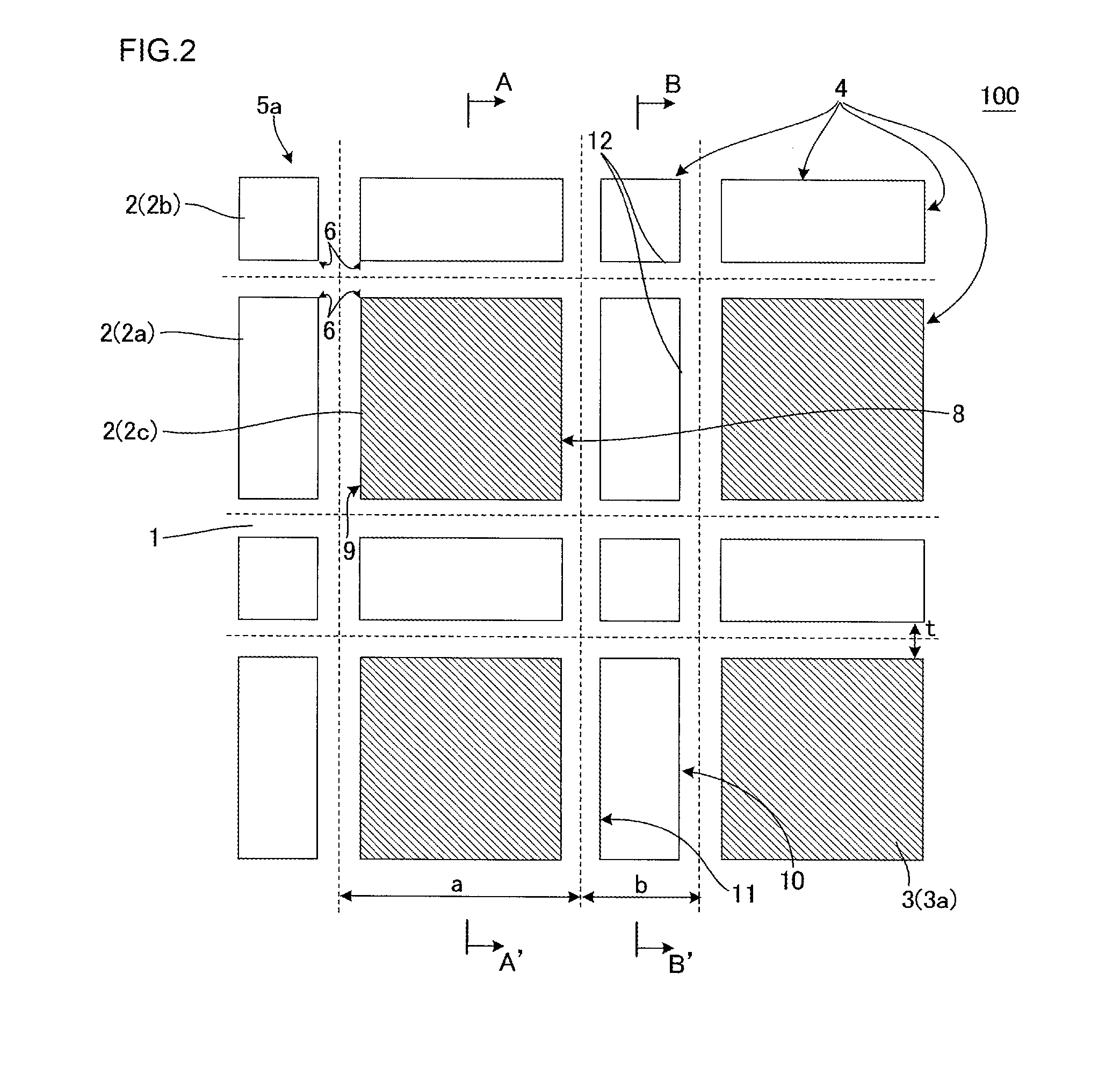

Honeycomb filter

ActiveUS20160067653A1Efficiently regenerateImprove ignitabilityCombination devicesGas treatmentHoneycombUnit volume

In a cross section perpendicular to a central axis direction of the honeycomb substrate, cells are arranged so that a periphery of an inlet plugged cell is surrounded with four rectangular outlet plugged cells and four square outlet plugged cells, and in the cross section, a partition wall center distance a, a partition wall center distance b and a partition wall thickness t satisfy the following equation (1). Additionally, an amount of a catalyst per unit volume of partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the inlet plugged cells is larger than an amount of a catalyst per unit volume of the partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the square outlet plugged cells.0.95<b / at<1.90 (1)

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com