Regeneration method of molecular sieve catalyst

A molecular sieve and catalyst technology, applied in the field of molecular sieve catalyst regeneration, can solve the problems of molecular sieve catalyst dealumination, permanent deactivation, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

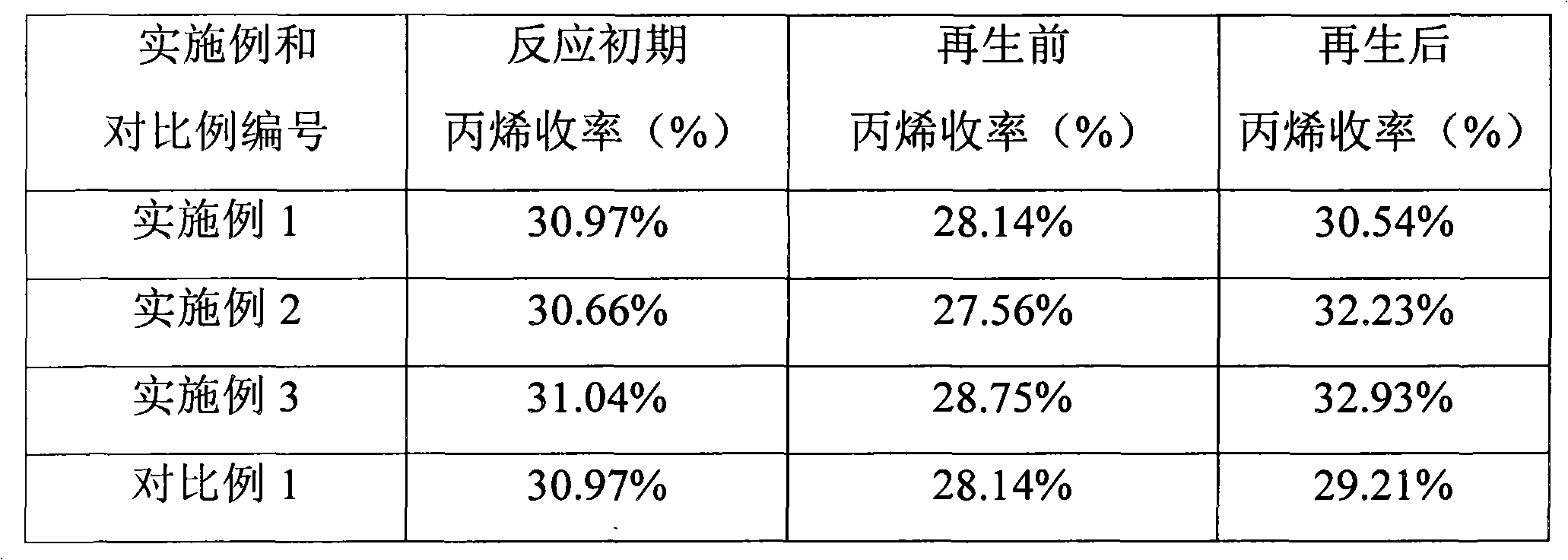

[0031] This example is used to illustrate the regeneration method of the molecular sieve catalyst provided by the present invention.

[0032] (1) The reaction process of preparing propylene from C4 hydrocarbons:

[0033] 20g of molecular sieve catalyst 1 was loaded into a fixed bed reaction tube, wherein the inner diameter of the fixed bed reaction tube was 18 mm, and the aspect ratio was 5. Control the reaction temperature to be 520°C and the reaction pressure to be 0.1MPa, and the mixture of water and C4 hydrocarbons with a weight ratio of 0.5 to be heated for 2.5h -1 The weight space velocity is passed into the reaction tube. A section of heating jacket for controlling the heating temperature is arranged outside the fixed bed reaction tube. The calculated propylene yield at the beginning of the reaction was 30.97%, and after 500 hours of operation, the calculated propylene yield was 28.14% before the catalyst was regenerated.

[0034] (2) Regeneration of molecular sieve ...

Embodiment 2

[0046] This example is used to illustrate the regeneration method of the molecular sieve catalyst provided by the present invention.

[0047] (1) The reaction process of preparing propylene from C4 hydrocarbons:

[0048] The catalytic reaction was carried out according to the method described in Example 1, except that the catalyst was molecular sieve catalyst 2. The calculated propylene yield at the beginning of the reaction was 30.66%, and after 1000 hours of operation, the calculated propylene yield was 27.56% before the catalyst was regenerated.

[0049] (2) Regeneration of molecular sieve catalyst:

[0050] Stop feeding the mixture of water and C4 hydrocarbons into the reactor, and lower the temperature in the fixed-bed reaction tube to 300°C. Feed nitrogen and air in described fixed-bed reaction tube, the flow of controlling nitrogen is 100 milliliters / minute, the flow of air is 70 milliliters / minute, promptly the oxygen content in the mixed gas of nitrogen and air is 8...

Embodiment 3

[0053]This example is used to illustrate the regeneration method of the molecular sieve catalyst provided by the present invention.

[0054] (1) The reaction process of preparing propylene from C4 hydrocarbons:

[0055] The catalytic reaction was carried out according to the method described in Example 2. The difference was that the operating reaction time was 500 h, the calculated propylene yield at the initial stage of the reaction was 31.04%, and the calculated propylene yield before the catalyst was regenerated was 28.75%.

[0056] (2) Regeneration of molecular sieve catalyst:

[0057] 1) Stop feeding the mixture of water and C4 hydrocarbons into the reactor, and lower the temperature in the fixed-bed reaction tube to 300°C. Feed nitrogen and air in described fixed-bed reaction tube, the flow of controlling nitrogen is 100 milliliters / minute, the flow of air is 70 milliliters / minute, promptly the oxygen content in the mixed gas of nitrogen and air is 8.6 volume %, at 300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com