Method for separating normal alkane from full fraction naphtha

A technology for n-alkane and naphtha, which is applied in the petroleum industry, adsorption purification/separation, and refined hydrocarbon oil, etc., can solve the problems of affecting the operation cycle, easy coking, affecting the adsorption capacity and adsorption rate of n-alkane, etc. The effect of improving the yield of ethylene and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

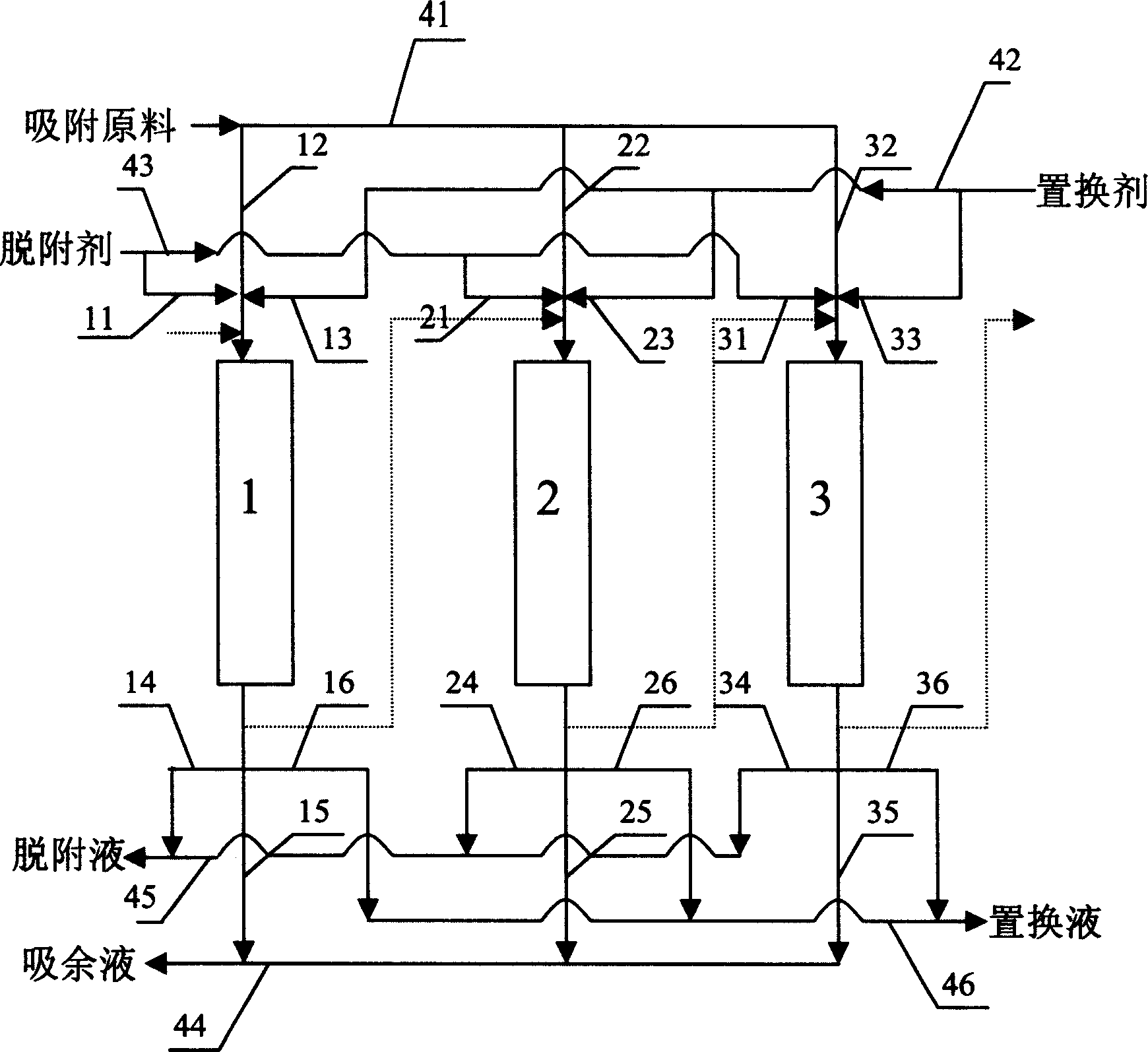

Image

Examples

example 1

[0031] Take 90 grams of NaA molecular sieve raw powder (produced by Wenzhou Catalyst Factory), 10 grams of kaolin (produced by Wenzhou Catalyst Factory), grind, mix evenly, press into tablets, and roast at 540° C. for 4 hours. With 0.1M calcium chloride solution at 80°C and volumetric space velocity for 2.0 hours -1 Carry out column ion exchange under the conditions of 2 hours, and then dry at 200 ℃ in nitrogen flow for 24 hours, break into 20-40 mesh (0.5-1.5 micron) particles, and obtain adsorbent A, its physical and chemical properties are shown in Table 1 .

example 2

[0033] Take 100 grams of NaA molecular sieve raw powder, use 0.1M calcium chloride solution as the exchange solution, and conduct kettle-type ion exchange twice under the conditions of 80°C and liquid / solid volume ratio of 5:1, each time for 1 hour, to make 5A molecular sieve raw powder, and then made into small balls with a diameter of 0.5-0.8 mm by the oil column drop ball molding method, and roasted at 540 ° C for 4 hours to make Adsorbent B. Its physical and chemical properties are shown in Table 1.

example 3

[0035] The surface area of 100 grams is 485 meters 2 Coarse pore chromatography silica gel (produced by Beijing Chemical Plant) with a pore volume of 0.284 ml / g is placed in an adsorption column of φ20×1200 mm, at 25° C., normal pressure, and volume space velocity for 1.0 hour -1 Under certain conditions, the raw naphtha raw material with a boiling range of 40-150°C is pumped into the adsorption column for adsorption operation, and aromatic hydrocarbons are collected to absorb residual oil. After the adsorption is saturated, that is, when the content of aromatics in the effluent of the adsorption column is 1.0% by mass, nitrogen is used as the displacing agent, and the time is 2.0 hours -1 The volume space velocity is passed into the adsorption column to replace the adsorption raw material in the invalid volume of the adsorption column, and the nitrogen gas is passed into the adsorption column for 2 minutes. After the displacement is over, use n-octanol as a desorbent, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com