Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

281 results about "Consecutive reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

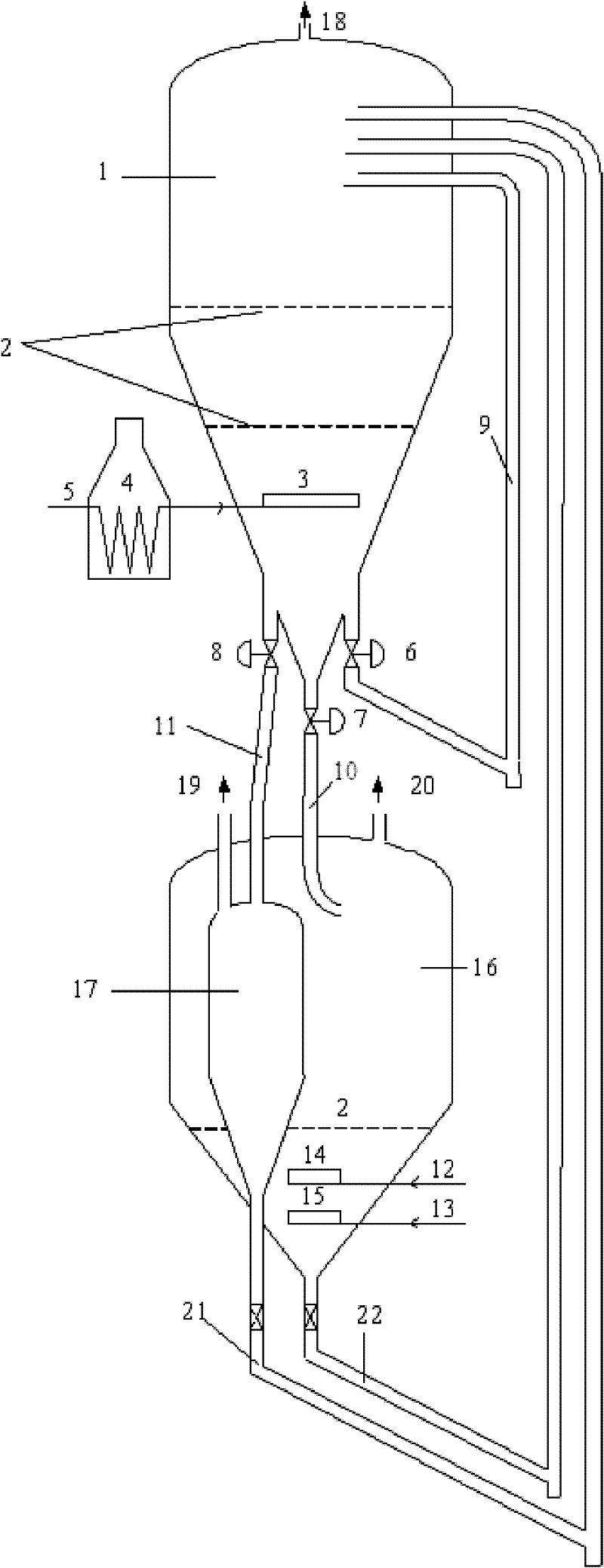

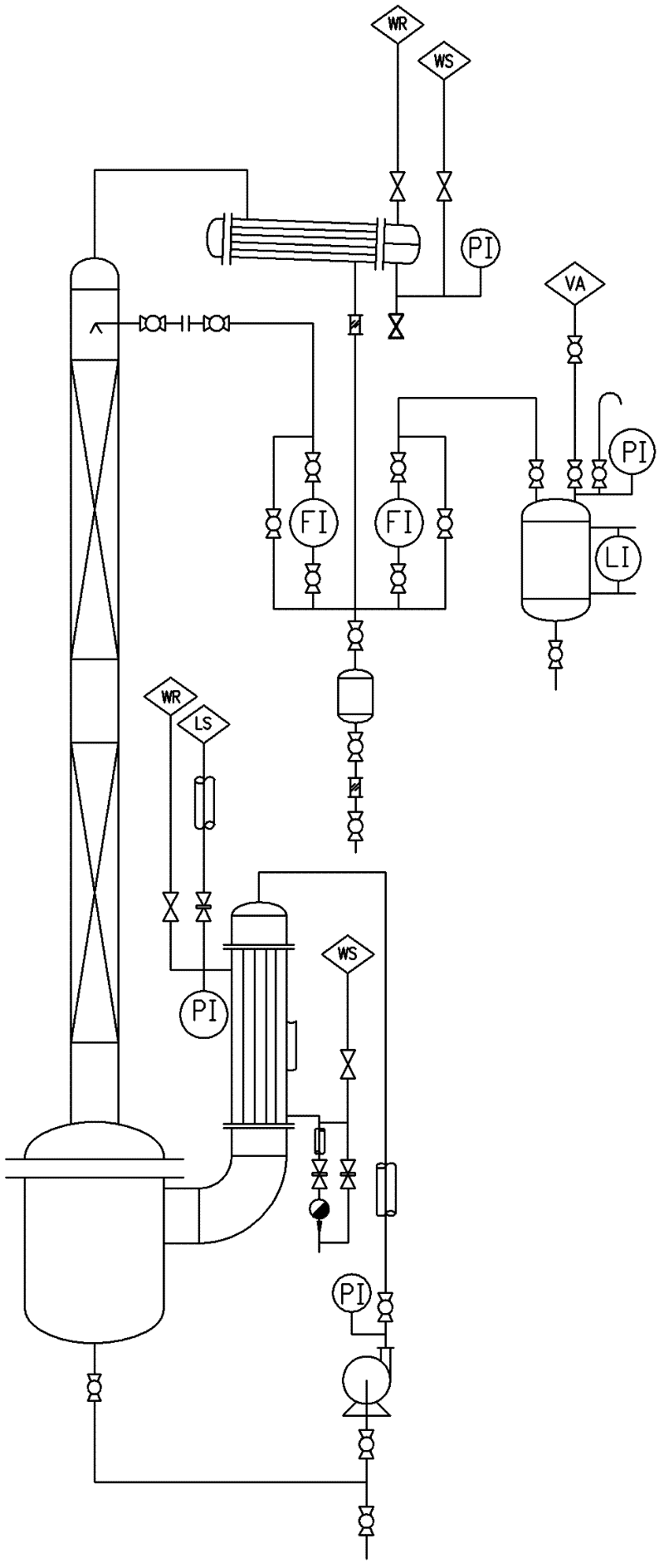

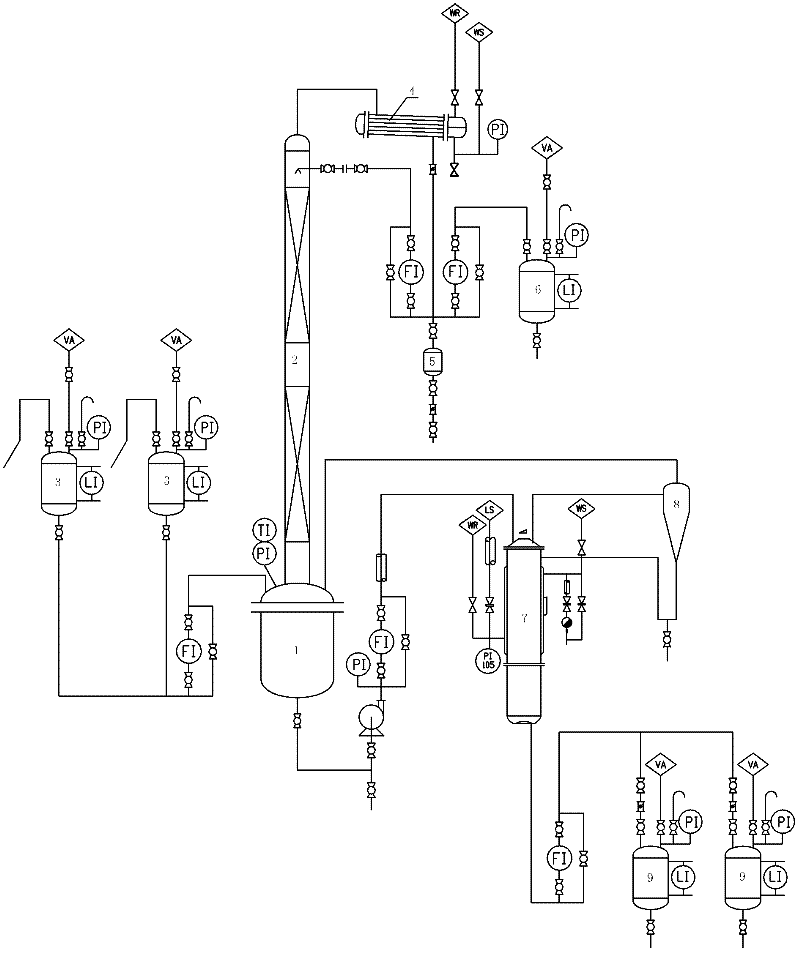

Catalyst for alkane dehydrogenation and device

ActiveCN102451677AHigh catalytic activityHigh selectivityHydrocarbonsChemical recyclingAlkaneAlkali metal oxide

The invention provides a catalyst for alkane dehydrogenation as well as a continuous reaction regeneration device and method using the catalyst for catalytic dehydrogenation. The catalyst comprises four ingredients, the ingredient A is oxides of one kind of element or several kinds of elements from Ti, Nb, Ta, Mo, W, Re, In or Ga, the ingredient B is one kind or several kinds of materials in MgO, P2O5, ZrO2, Al2O3 or SiO2, the ingredient C is oxides of one kind of material or several kinds of materials from Zn, Cd and Sn, and the ingredient D is one kind of material or a mixture of several kinds of materials from alkali oxides or alkaline earth metal oxides. The catalyst does not contain noble metal such as Pt and the like, does not contain toxic ingredients such as Cr and the like and cannot pollute the environment. The activity of the catalyst is high, the selectivity of olefin generated by alkane dehydrogenation is high, the stability of the catalyst is good, the mechanical intensity is high, the continuous reaction regeneration device is used for alkane dehydrogenation, the reaction and the catalyst regeneration are continuously carried out, the efficiency is high, and the safety is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

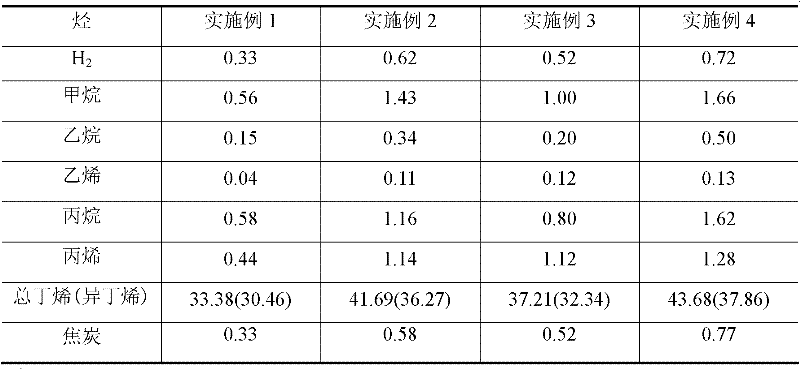

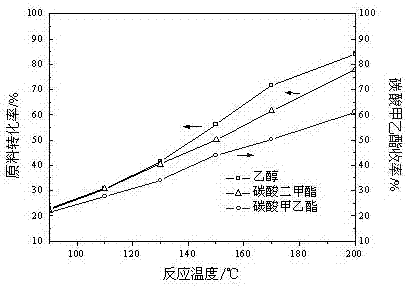

Method for preparing ethyl methyl carbonate through ester exchange method

InactiveCN107473968AGood dispersionImprove mass transfer effectPhysical/chemical process catalystsPreparation from organic carbonatesDispersityMethyl carbonate

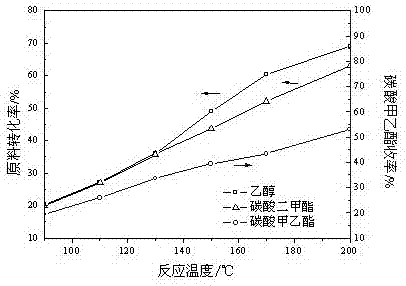

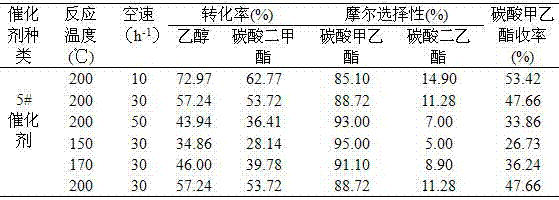

The invention provides a method for preparing ethyl methyl carbonate through an ester exchange method, and relates to a method for preparing a chemical raw material. A first catalyst prepared by the method simultaneously has macropore and micropore structures, wherein the macropores can obviously improve the mass transfer effect; and the micropores can obviously improve the specific surface area of a carrier and simultaneously improve the dispersity of active centers. Meanwhile, the prepared first catalyst simultaneously has an alkali active center and a Lewis acid catalytic active center. The prepared 15%MgO-5%MgCl2-2%La2O3 / Al2O3-SiO2 is used in a dimethyl carbonate and ethanol ester exchange fixed bed continuous reaction; when the reaction temperature is 200 DEG C and the space velocity is 30h<-1>, the catalyst is not inactivated after 5000h of continuous reaction, the dimethyl carbonate conversion rate can be kept at 70%, the ethanol conversion rate can be kept at 80%, and the yield of the product ethyl methyl carbonate is 56%; and after the reaction, the catalyst can be reused through simple filtration treatment, and the activity of the catalyst can still be kept unchanged after the catalyst is reused for multiple times.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

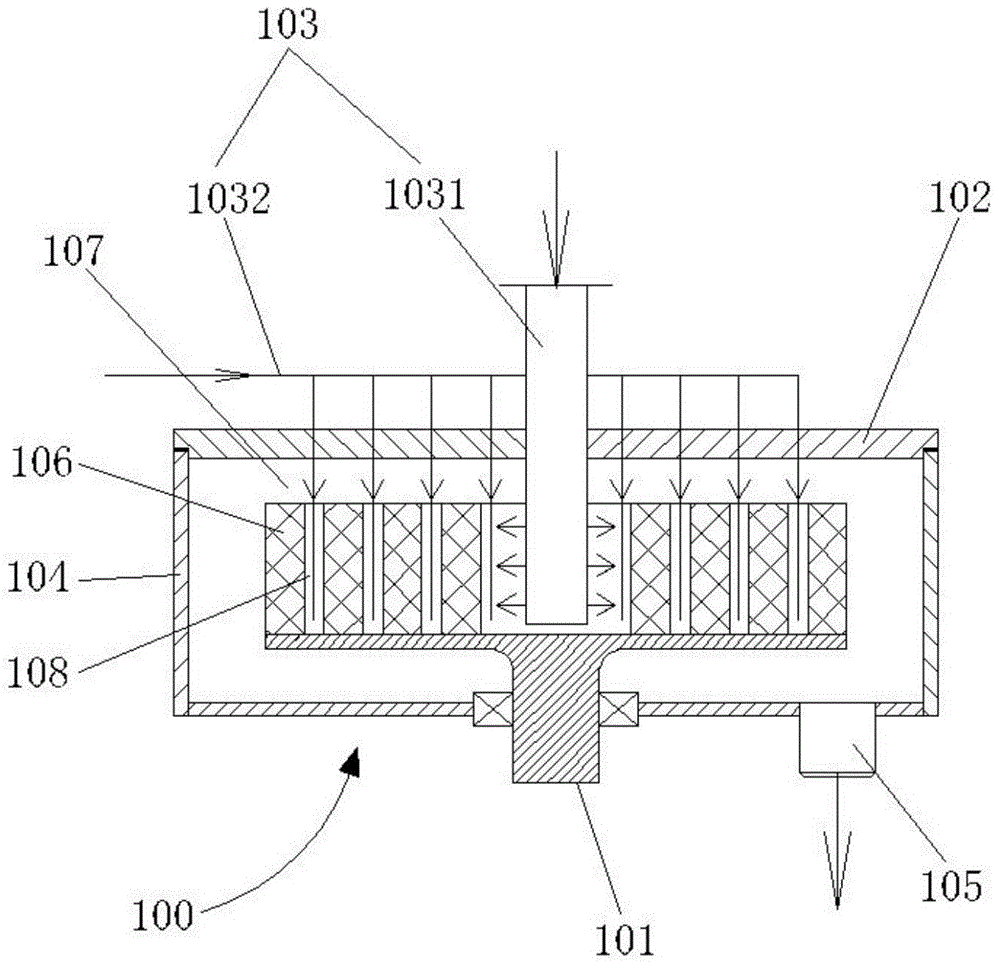

Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

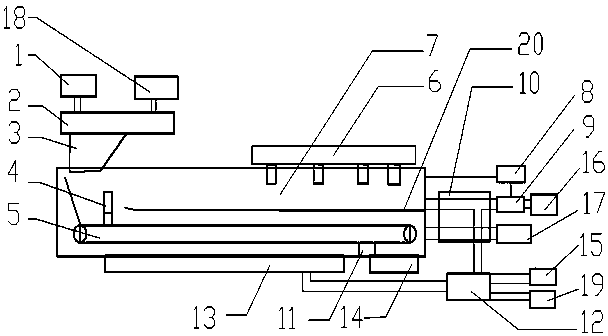

ActiveCN104163555AGood heating selectivityRapid pyrolysisSludge treatment by pyrolysisByproduct vaporizationRadiation lossNitrogen generator

The invention discloses a consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as a method thereof. The condensation comprises a sludge warehouse, a stirrer, a hopper feeder, a sludge-shaped controller, a belt sender, a power control microwave irradiation device, a microwave pyrolysis reaction chamber, a pressure sensing controller, a blower fan, a condensation heat exchanger, a scraper plate separator, an oil-water separating device, a liquid dredging groove, a coke storage tank, a product oil tank, a product gas tank, a nitrogen generator, a coke crusher, a sludge water pot and a gas shunting plate. According to the invention, microwave material internal heating characteristic can be fully used for reducing heat radiation loss, moisture sludge is directly performed with anhydration and pyrolysis to obtain the cracking oil, combustible gas and solid coke; heat recovery of the product gas and auxiliary microwave heating characteristic of the products residue are fully used for reducing the operation cost, and sludge pyrolysis efficiency and products quality can be increased. The apparatus has the advantages of simple structure, small volume, reasonable design and convenient market popularization, and is suitable for industrial application of microwave sludge continuous pyrolysis.

Owner:ZHEJIANG UNIV

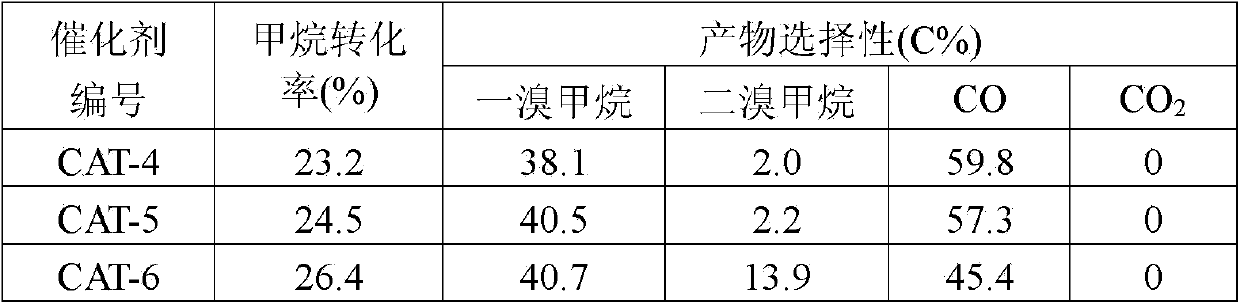

Catalyst used for preparation of bromomethane and CO through methane bromination-oxidation, and preparation method and application thereof

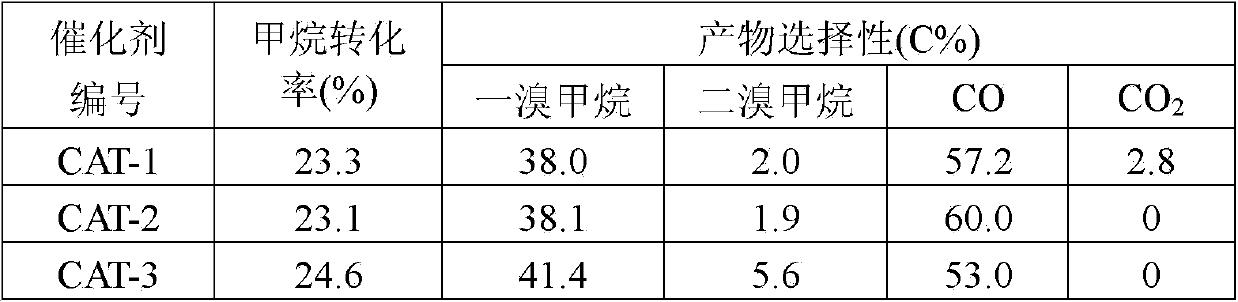

InactiveCN104209134AImprove performanceNo carbon depositCatalyst activation/preparationCarbon monoxideActive componentOxygen

The invention provides a catalyst used for the preparation of bromomethane and CO through methane bromination-oxidation. The catalyst contains a main active component and a carrier, wherein the main active component is one or more selected from FePO4, Fe3P2O7 and Fe3(P2O7)2, the carrier is one or more of TiC-SiC and TiO2-SiC, and the content of the main active component in the catalyst is 1.0-50.0wt%. The catalyst is prepared through the steps of supporting an impregnation liquid containing the main active component onto the carrier through an impregnation technology, drying and roasting, and the catalyst can catalyze a mixture comprising methane, oxygen and an aqueous solution of HBr converted into bromomethane and CO in a high activity and high selectivity manner under reaction conditions comprising normal pressure and a temperature of 400-800DEG C. The catalyst has the advantages of good performances, on obvious inactivation in a continuous reaction process carried out for above 1400h, and no carbon deposition on the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

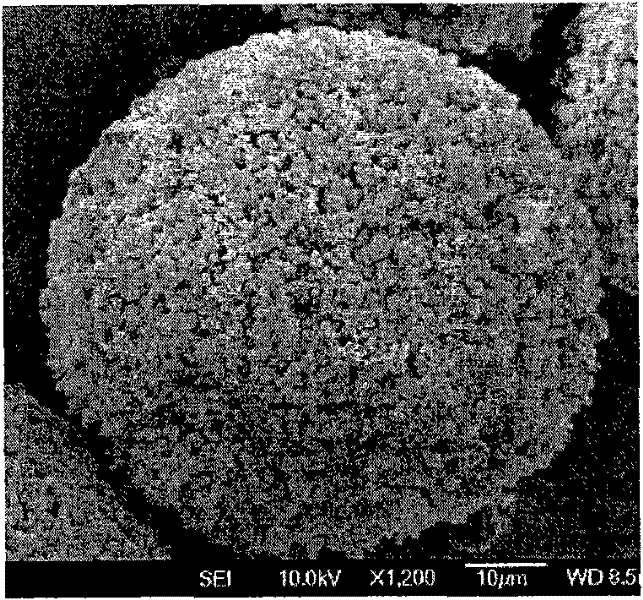

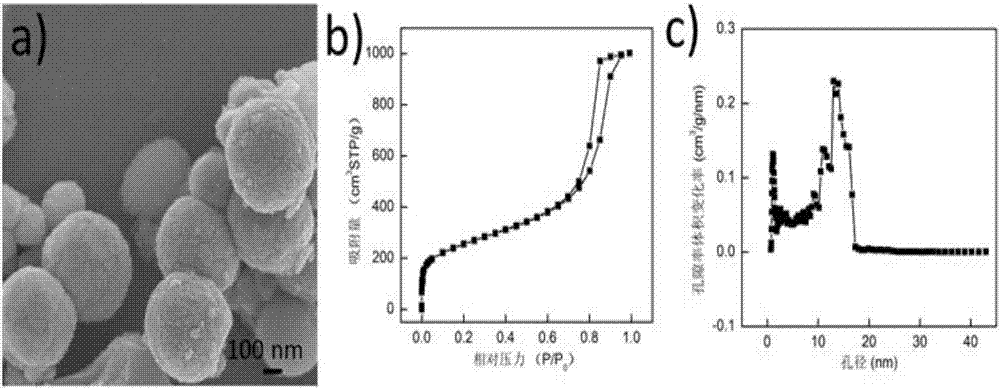

Carrier for immobilizing enzyme, use thereof, and carrier immobilized with enzyme

ActiveCN102260662AProtectImprove stabilityOn/in organic carrierContinuous reactionImmobilized enzyme

The invention relates to a novel carrier with good permeability for immobilizing enzymes. The carrier is a polymer microsphere not only with small and medium pores smaller than 90nm, but also with large pores of hundreds of nanometers. The carrier can be used for both single-enzyme immobilization and multiple-enzyme immobilization. The utilization rate of the microsphere surface can reach 70%-100%. The present invention also relates to the use of the carrier for immobilizing enzymes in immobilizing enzymes and the carrier immobilized with enzymes. Because the enzyme can be immobilized inside the carrier and can be well protected by the carrier, it has good stability, activity and reusability, and is especially suitable for column packing for continuous reactions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

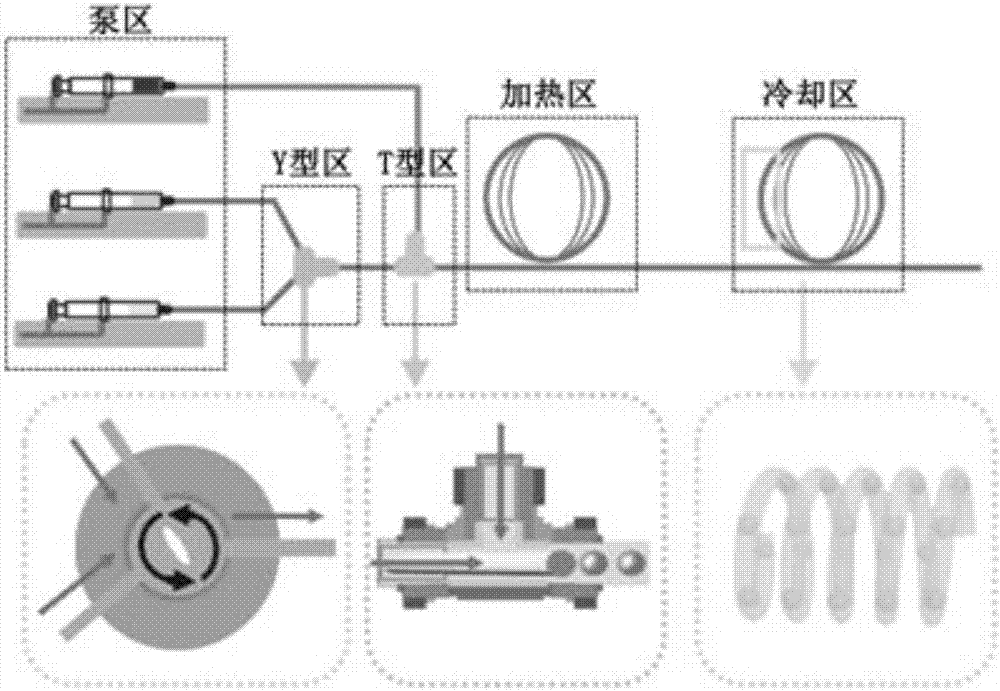

Continuous synthesis method of metalorganic frame compound with stepped hole structure

ActiveCN106893109ARealize continuous synthesisIncrease productionChemical/physical/physico-chemical microreactorsSynthesis methodsFiltration

The invention relates to a continuous synthesis method of a metalorganic frame compound with a stepped hole structure. The continuous synthesis method has the following steps that 1, a continuous reaction device is erected; 2, metal salt is dispersed in a solvent A and is added into an injector of a pump I, anorganic ligand is dispersed in a solvent B and is added into an injector of a pump II, and a continuous phase is added to an injector of a pump III; 3, a heating area is heated to reach set reaction temperature; 4, the flowing speeds of the three pumps are set, and the three pumps are started; 5, a product is collected from the output end of a pipeline, the product is separated out through centrifugation or filtration, and a stepped-hole MOF material is obtained. By adopting a continuous flow s synthesis method, continuous synthesis of the stepped-hole MOF material can be achieved. A template agent and aftertreatment process are not needed in the synthesis process, the stepped-hole MOF prepared by adopting the preparation method can be up to very high space-time yield and conversion rate, straight amplification can be performed in a simple reactor number increasing mode, and the continuous synthesis method is easy to operate and suitable for large-scale continuous production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

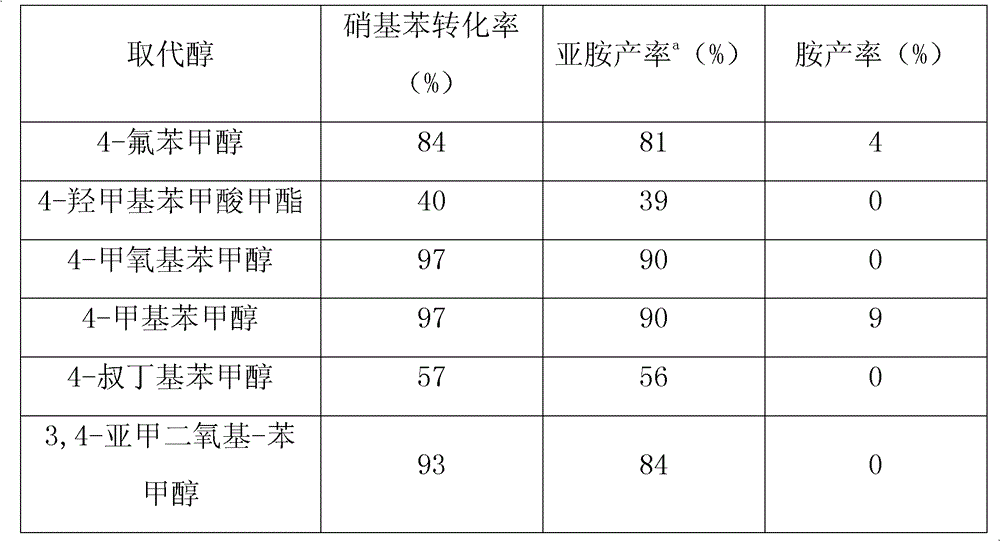

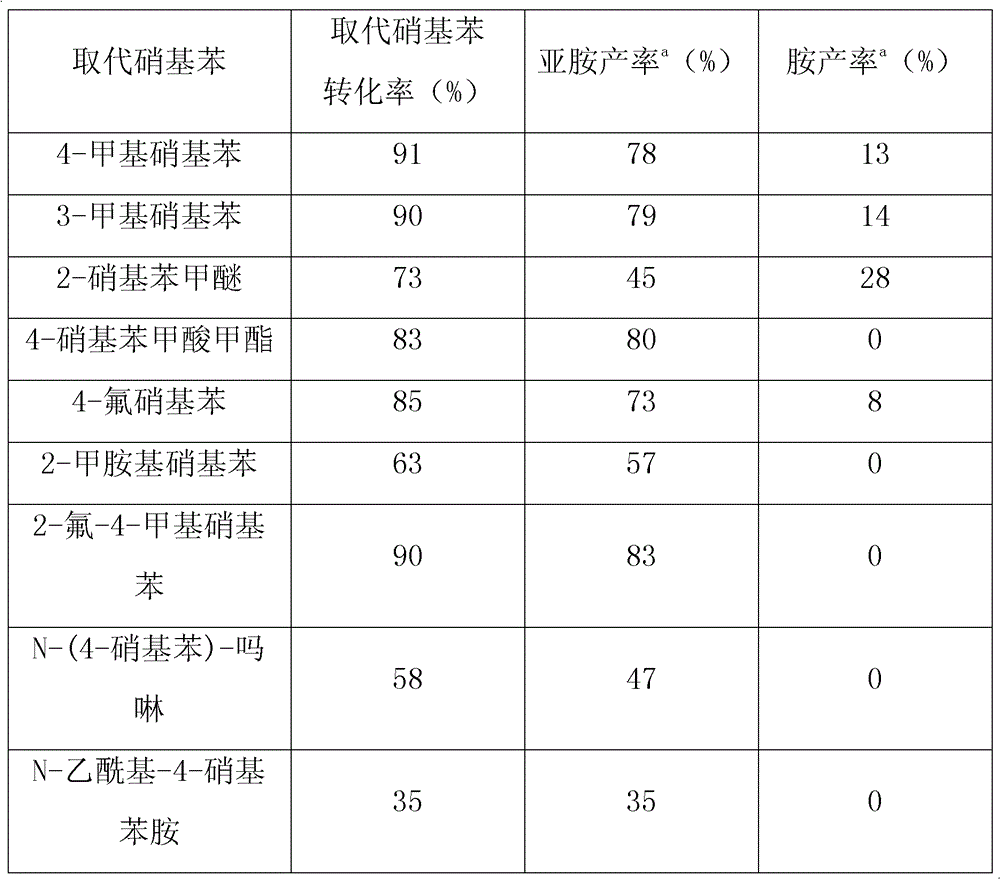

Method for synthesizing amine and imine

InactiveCN103058805AHigh yieldOrganic compound preparationCarboxylic acid amides preparationPtru catalystNitrobenzene

The invention provides a method for synthesizing N-benzalaniline and N-benzyl aniline, and relates to an efficient method for synthesizing N-benzalaniline and N-benzyl aniline through a continuous reaction on raw materials of aromatic alcohol and nitryl aromatic compound in the presence of a transition metal supported solid catalyst. The catalyst is loaded on hydrotalcite, hydroxyapatite and oxides by using palladium, gold or rhodium through an impregnation method or a precipitation method. The catalytic reaction is carried out in an inert atmosphere; conversion rate of nitrobenzene and total yield of N-benzalaniline and N-benzyl aniline can reach higher than 99% (imine yield of 93%, and amine yield of 7%). The catalyst can be used repeatedly. The method is applicable to a variety of substituted aromatic alcohols and substituted aromatic compounds, and can realize high conversion rate and high selectivity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide

ActiveCN103980310AHigh reaction yieldLow costGroup 5/15 element organic compoundsPtru catalystPhenacyl

The invention discloses a preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide as an efficient free radical photoinitiator. The preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide comprises the concrete steps of with 2,4,6-trimethylbenzaldehyde as a raw material, enabling 2,4,6-trimethylbenzaldehyde and phenylphosphine oxide to be subjected to condensation reaction in the existence of a catalyst, and then, carrying out oxidation reaction. Extraction and solvent replacement are not needed and continuous reaction can be realized in the reaction process. The preparation method of phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide, disclosed by the invention, is low in price, environment-friendly, easy to operate and suitable for realizing industrialization.

Owner:湖南久日新材料有限公司

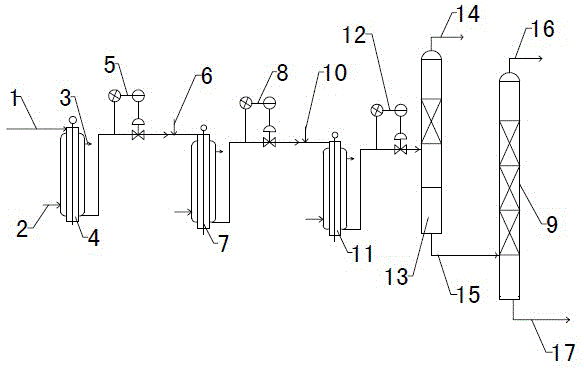

Method for preparing tert-butyl ether

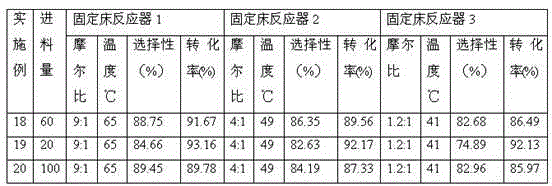

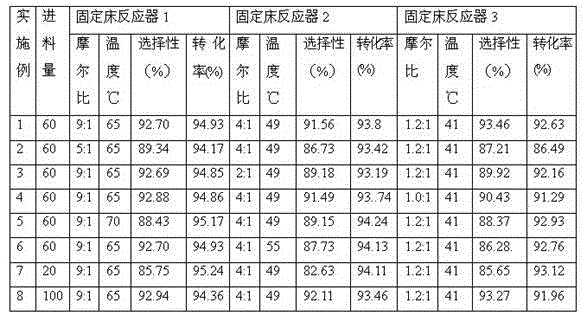

InactiveCN104557478AImprove conversion rateHigh selectivityEther preparation by compound additionPtru catalystFixed bed

The invention discloses a method for preparing tert-butyl ether, belongs to the field of organic chemical industry, and particularly relates to a method for preparing ethylene glycol tert-butyl ether in the presence of a catalyst. The method is characterized by comprising the following specific steps: mixing isobutylene containing 30-90% by mass of inert gas with ethylene glycol, introducing a mixture into a continuous distributed control reaction assembly for reaction, performing flash evaporation on a light component after the continuous reaction, and performing refinement and separation on a reaction product, wherein the continuous distributed control reaction assembly consists of three fixed bed reactors continuously connected in series, the fixed bed reactors are a reactor I (4), a reactor II (7) and a reactor III (11) respectively, different reaction conditions are required in the fixed bed reactors, and same or different solid catalysts are arranged in the fixed bed reactors. According to the method, ethylene glycol tert-butyl ether generated by mixing ethylene glycol with isobutylene according to a relatively low molar ratio is relatively high in selectivity which reaches more than 90%, and isobutylene is relatively high in conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP

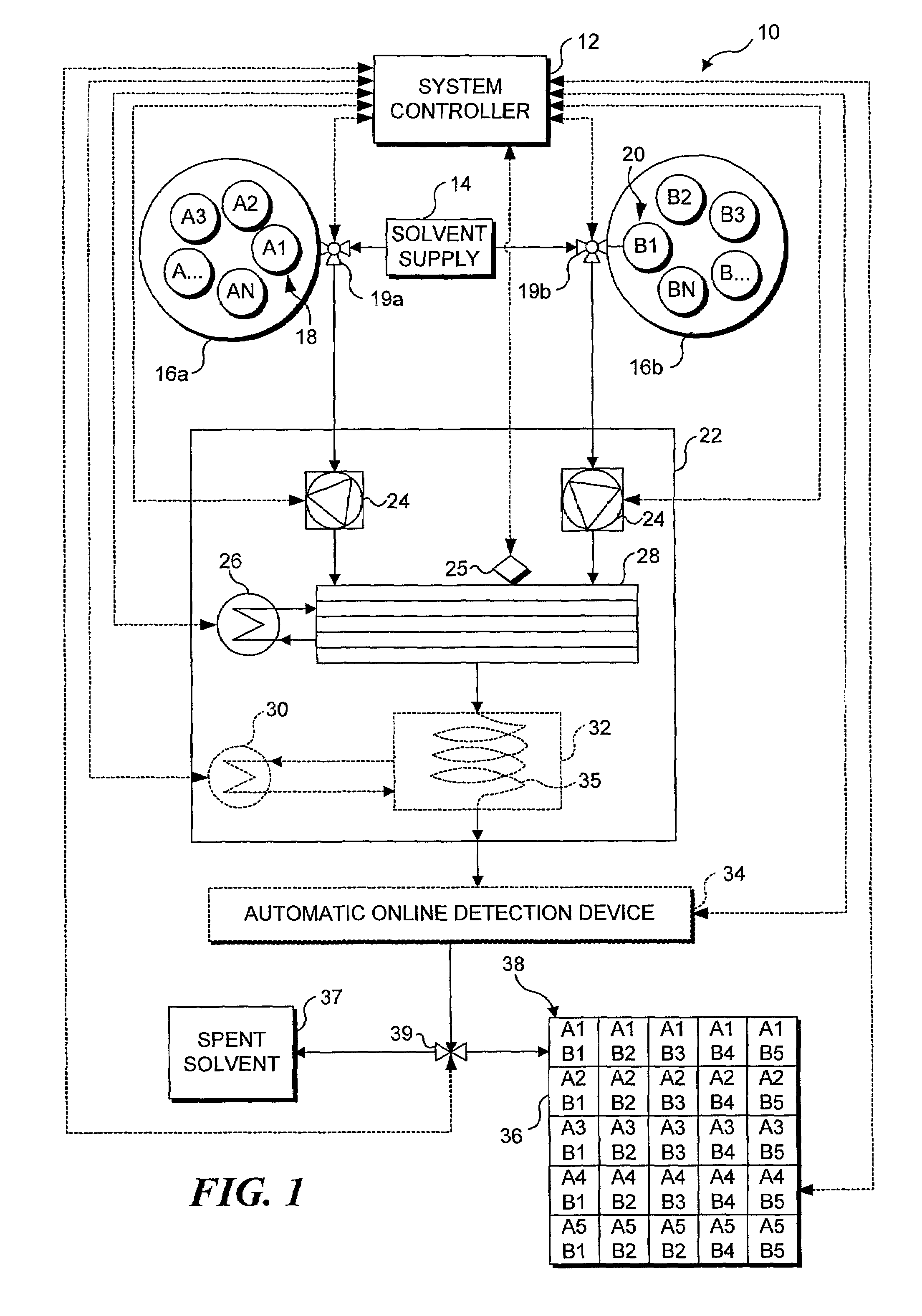

Sequential reaction system

InactiveUS7413714B1Production Process AutomationSampled-variable control systemsSequential/parallel process reactionsChemical reactorSolvent

An automated sequential reaction system that can be used to either sequentially produce a plurality of different products each requiring a single reaction, or to produce a desired product that requires a series of sequential reactions. A system controller controls an automated reactant supply, a solvent supply, a reaction module, a detector, and a product collector. Prior to initiating any reaction, the system is flushed with solvent and a heat exchanger supplies the reaction module with a temperature-conditioned fluid to maintain the reaction module at a desired temperature. For single reactions, a plurality of reactants are injected into a chemical reactor included in the reaction module. As fluid exits the chemical reactor, the detector determines if the fluid is a desired chemical product or solvent, and routes the fluid to the appropriate receptacle. Once a predetermined volume of a desired product is obtained, the system is flushed with solvent, and a different set of reactants are injected into the chemical reactor to produce the next desired product. The process is repeated until a substance library of the desired products is obtained. For products requiring sequential reaction steps, either a plurality of reactors are employed, or an intermediate product produced by a previous reaction is reintroduced into the reaction module with an appropriate reactant to complete the next sequential reaction.

Owner:YMC

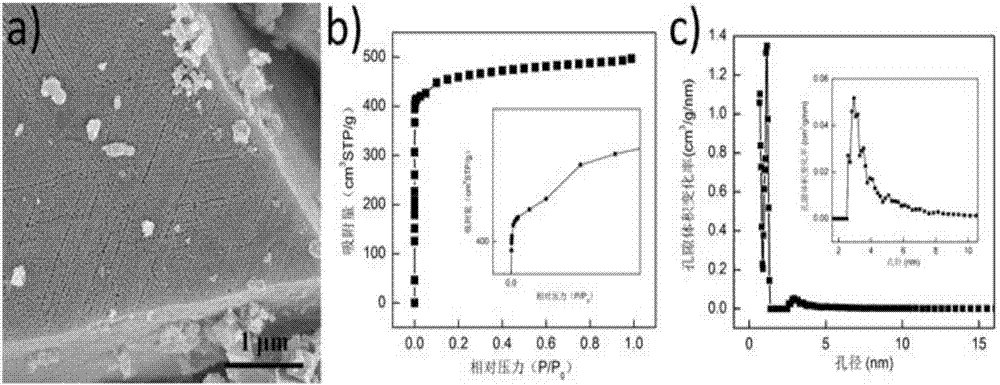

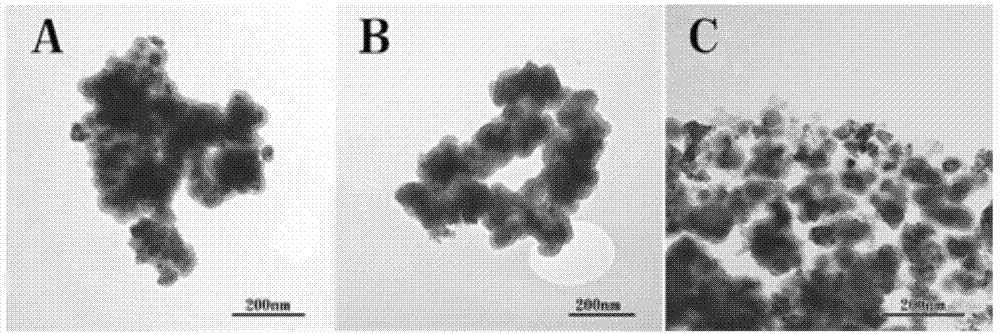

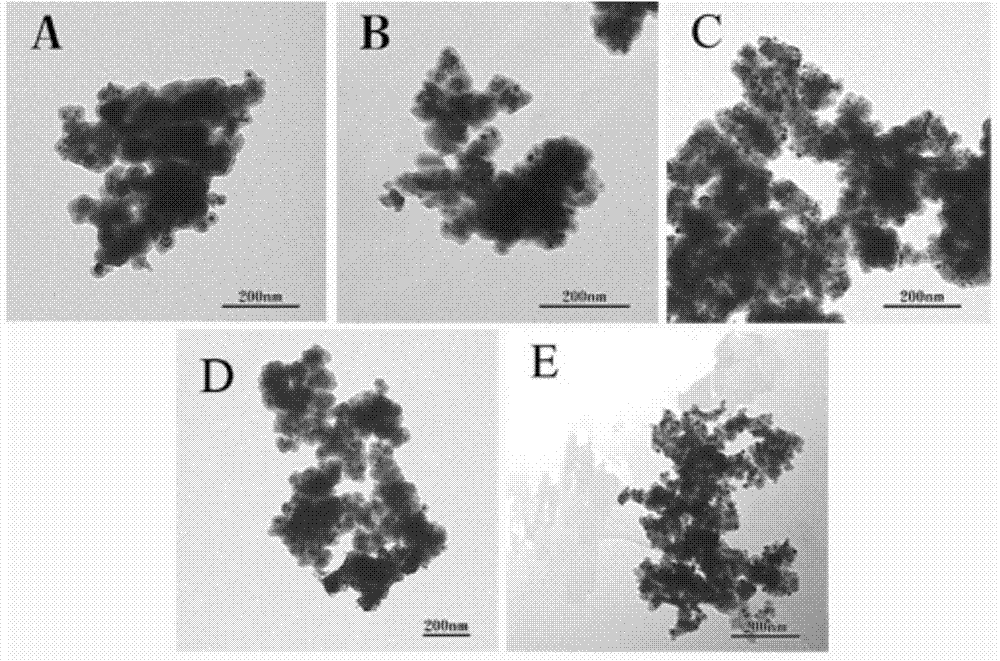

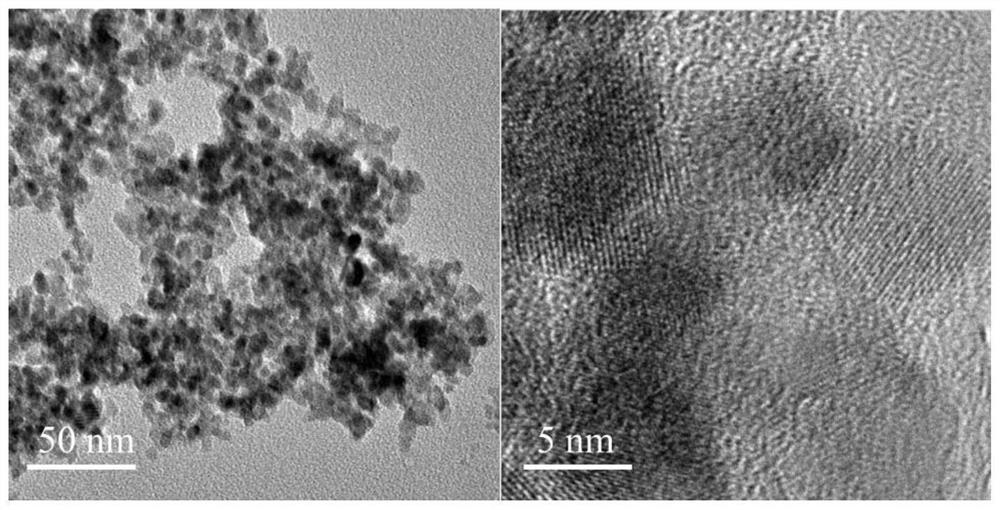

Ru-based core-shell catalyst and its preparation method and use in methane oxidation reforming preparation of synthetic gas

The invention discloses a catalyst for methane partial-oxidation preparation of synthetic gas. Ruthenium oxide or nickel-ruthenium oxide nanoparticles are synthesized and then are coated with SiO2 so that a core-shell structure is formed, and the core-shell structure undergoes in-situ reduction so that ruthenium oxide or nickel-ruthenium oxide core particles are reduced into metal ruthenium or nickel-ruthenium dimetal and a core-shell metal catalyst with a microcapsule structure is obtained. The microcapsule structure is conducive to reactant molecule enrichment, adsorption on the catalyst surface and activation. The catalyst is used for methane partial-oxidation preparation of synthetic gas, has high catalyst activity, a methane conversion rate greater than 95%, CO / H2 selectivity greater than 90% or a methane conversion rate greater than 90%, and CO / H2 selectivity greater than 95%. After consecutive reaction for 10 days, a conversion rate and selectivity are not reduced and thus the catalyst for the object reaction has high efficiency and good stability. The invention discloses a preparation method of the Ru-based core-shell catalyst.

Owner:南京大学扬州化学化工研究院 +1

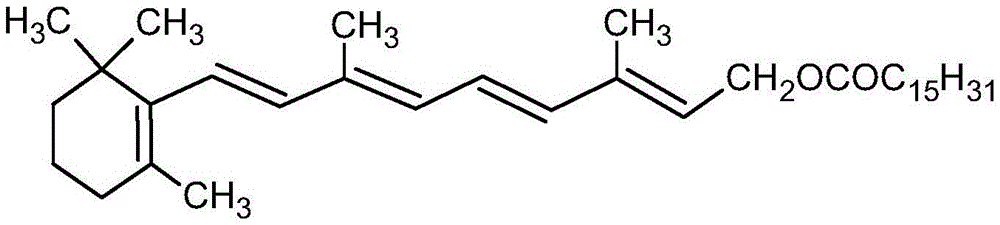

Synthesis method of vitamin A palmitate

ActiveCN105969833AAvoid influenceReduce the difficulty of separation and purificationFermentationEnzyme methodConsecutive reaction

The invention discloses a synthesis method of vitamin A palmitate. The method is characterized in that vitamin A palmitate is prepared by vitamin A acetate and palmitic acid through an enzyme method reaction. The method comprises the following steps: vitamin A acetate and palmitic acid are dissolved in an organic solvent to prepare a reaction material, the reaction material is pre-heated and is sent to a reaction column for consecutive reaction according to a certain flow; the reaction column is filled with immobilization lipase and ion exchange resin, the reaction material is proportional lipase and ion exchange resin; and after the reaction is completed, a reaction solution is post-treated to obtain the vitamin A palmitate. The vitamin A palmitate has the advantages of high yield and good quality. The appearance of the vitamin A palmitate is a light yellow grease substrate. By analyzing with United States Pharmacopeia USP28, the content is greater than 95%.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

Continuous reaction method

ActiveCN102557849AIncrease production capacityEliminate time spent on non-productive operationsOrganic compound preparationCarboxylic acid esters preparationPhysical chemistryProcess engineering

The invention discloses a continuous reaction method. The conventional intermittent reaction is almost balanced reaction, conversation rate is low, the proportion of nonproductive time in the total production time is small, and unit capacity of equipment is low. The continuous reaction method comprises the following steps of: feeding raw materials for reaction into a reaction kettle, feeding the raw materials flowing out of the bottom of the reaction kettle into reaction heating equipment, starting the reaction heating equipment and heating, feeding vapor and liquid mixture flowing out of the top of the reaction heating equipment into vapor-liquid separation equipment, feeding raw material vapor obtained from the top of the vapor-liquid separation equipment into a reaction kettle, wherein a rectifying column arranged on the reaction kettle is stably in a refluxing state, and feeding light components flowing out of the top of the rectifying column into a light component collection tank; and feeding liquid flowing out of the bottom of the vapor-liquid separation equipment into the reaction heating equipment again, and feeding liquid flowing out of the bottom of the reaction heating equipment into a product tank. Common intermittent reaction is improved to continuous reaction, and unit capacity of equipment is improved.

Owner:ZHEJIANG NHU CO LTD

Method for producing gasoline and diesel oil by mixing and refining plastic oil, coal tar, ethylene tar or tire oil

InactiveCN102839020AImprove conversion rateHigh selectivityHydrocarbon distillationTreatment with hydrotreatment processesFractionationCatalytic distillation

The invention discloses a method for producing gasoline and diesel oil by mixing and refining plastic oil, coal tar, ethylene tar or tire oil, and belongs to the field fields of environmental protection and energy. The method is characterized in that the waste plastic oil and the coal tar, the ethylene tar or the tire oil are mixed in a ratio of 1:(0.1-1.1) to form a raw material, and the raw material is catalytically distilled and hydrofined into the high-quality gasoline and diesel oil; and the method comprises the following steps of: fractionating the raw oil into light components and heavy components at the temperature of 300 DEG C through a pre-fractionation tower, directly performing hydrofining reaction on the light components, performing catalytic distillation cracking on the heavy components, regulating the fraction proportion of the gasoline and the diesel oil to reduce the colloid content of the fraction, performing hydrofining reaction, reducing the sulfur and nitrogen content of the oil, regulating the octane value and the acid value, distilling the obtained distillate oil, and thus obtaining high-quality gasoline, diesel oil and the like. By the method, the conversion rate of balanced reaction and the selectivity of consecutive reaction are improved, the coking quantity is greatly reduced, the consumption is reduced, energy is saved, the service life of a catalyst is prolonged, the flow is simple and the investment is saved.

Owner:DALIAN UNIV OF TECH

Process for extracting theaflavin product

The invention discloses a process for extracting a theaflavin product, and relates to the technical field of the deep processing of tea products. In order to solve the problems of excessive oxidization and low yield caused by the uncontrolled consecutive reaction in traditional in-vitro enzymatic oxidization process for the preparation of theaflavin, the invention provides the process for extracting the theaflavin product, which comprises the following steps of: (a) the preparation of a substrate solution; (b) the preparation of an enzymatic catalyst; (c) the preparation of fermentation; (d) the separation of an ester phase; (e) the concentration and phase inversion; and (f) drying. When the process is adopted, the process control of the fermentation process is realized, the conversion rate and specification of the theaflavin product are improved, and the process cost for the follow-up refining and purification is reduced.

Owner:HANGZHOU TEA RES INST CHINA COOP

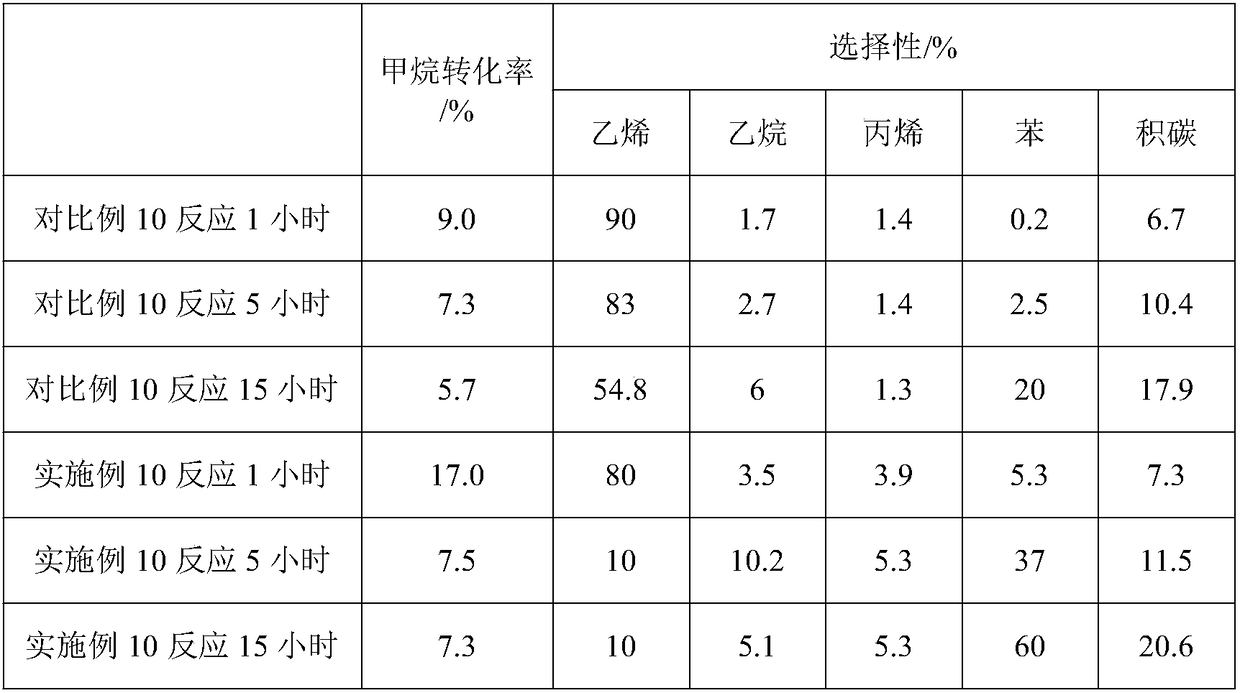

Method for preparing higher hydrocarbons by low-temperature conversion of methane

ActiveCN109420517AIncrease added valueGood choiceMolecular sieve catalystsLiquid hydrocarbon mixtures productionAlkaneAromatic hydrocarbon

The invention discloses a method for preparing higher hydrocarbons by low-temperature conversion of methane. The method comprises the steps of: placing a catalyst in a fixed bed reactor, introducing methane, and conducting reaction at 400 to 600 DEG C to obtain alkanes, olefins and aromatic hydrocarbons. The method of the invention can complete the conversion of methane at 400-600 DEG C to form achemical raw material with high added value (for example: ethylene, BTX, etc.); the product has good selectivity, for example, BTX has selectivity of 60% or above; and a catalyst with a long service life can continuously reacts for 60 hours without inactivation.

Owner:BEIJING UNIV OF CHEM TECH

Continuous hydrosilylation process

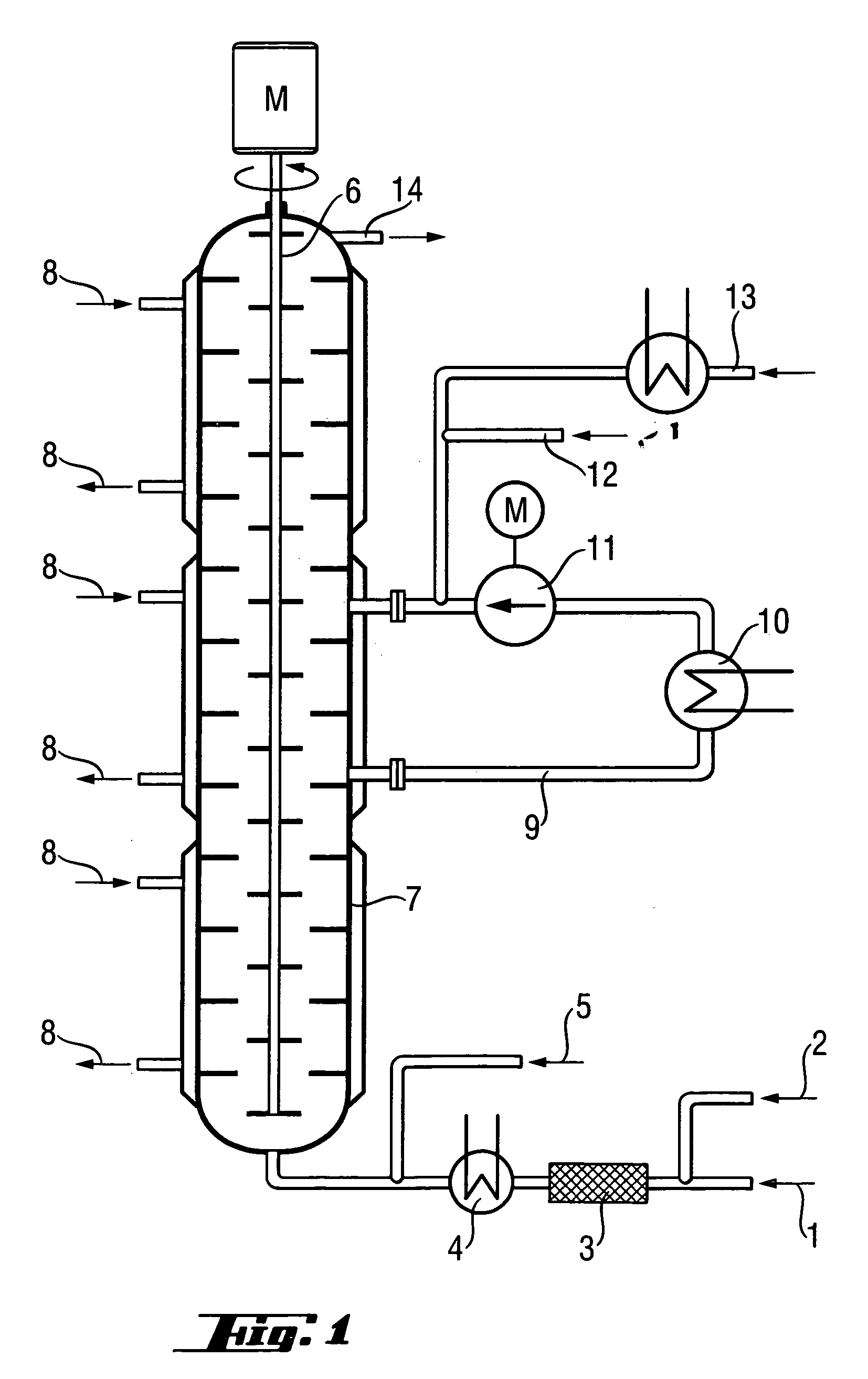

Continuous hydrosilylation of compounds (A) bearing C—C multiple bonds by means of silicon compounds (B) having Si—H groups, in which the reaction components (A) and (B) are reacted continuously in an integrated loop-tube reactor, with reaction mixture being conveyed from the tube into the loop and back again so that a section of the tube is part of the loop circuit, provides a highly controllable reaction process with high product yields.

Owner:WACKER CHEM GMBH

Multi-stage material feeding supergravity liquid-liquid reactor apparatus and applications thereof

InactiveCN105080446AFlexible adjustment of molar ratioReduce generationChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringDistributor

The present invention discloses a multi-stage material feeding supergravity liquid-liquid reactor apparatus, which comprises a rotor, a housing upper cover, a liquid distributor and a housing, wherein the lower end of the housing is provided with a liquid outlet. The multi-stage material feeding supergravity liquid-liquid reactor apparatus is characterized in that the liquid distributor comprises an inner liquid distributor and an outer liquid distributor, the rotor is provided with concentric filler rings with different diameters and is arranged inside the housing, gaps are arranged between the filler rings and the housing upper cover, the gaps between the concentric filler rings with different diameters and the housing upper cover are communicated, the inner liquid distributor extends into the middle portion of the rotor, and the outer liquid distributor respectively extends into the space between the concentric filler rings. According to the present invention, the sealed device is not required to be arranged between the top end of the filling ring and the housing upper cover, the liquid distributor of the apparatus is arranged inside the rotor to achieve the multi-stage material feeding, and the rapid and uniform molecular scale mixing required by the parallel reactions and the consecutive reactions can be achieved, such that the reaction selectivity can be significantly improved, and the advantages of less fewer byproduct, high product yield and the like are provided.

Owner:浙江中巨海锐科技有限公司

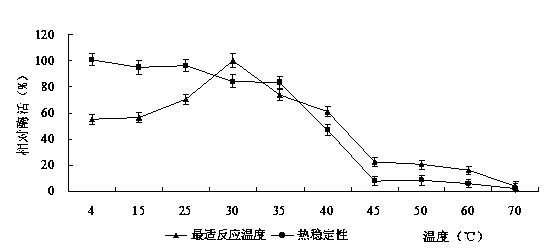

Immobilized 3-phenoxy benzoic acid degrading enzyme and its preparation method

InactiveCN103642785ANo need for separation and purificationEasy to makeMicroorganism based processesOn/in organic carrierBenzoic acidIce water

Belonging to the immobilized enzyme field, the invention discloses a preparation method for an immobilized 3-phenoxy benzoic acid degrading enzyme. The method includes the steps of: (1) centrifuging a Sphingomonas sp. SC-1 fermentation liquid, collecting thalli, mixing the thalli with a Tris-HCl buffer solution evenly, then conducting ultrasonic crushing under ice water bath, performing centrifugation to remove intracellular enzyme, adding the Tris-HCl buffer solution to cell debris deposits to a volume before crushing to make an enzyme solution; and (2) mixing the enzyme solution with a sodium alginate solution in certain proportion, dripping the mixed solution in a calcium chloride solution uniformly to perform embedding immobilization. The immobilized 3-phenoxy benzoic acid degrading enzyme prepared by the invention has high enzyme activity under a wide temperature range (4DEG C-40DEG C) and a wide pH range (5.0-9.0), and has strong continuous reaction performance. The preparation method is simple, and the production cost is low.

Owner:SICHUAN AGRI UNIV

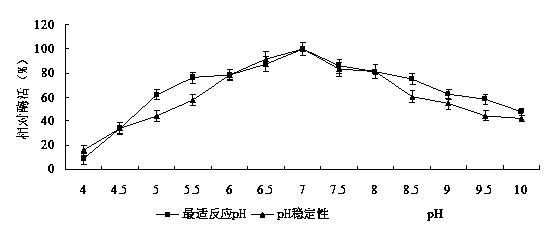

Catalyst for hydrogen production by methanol steam reforming, preparation method and application thereof, and reaction for hydrogen production by methanol steam reforming

ActiveCN113209976ALow selectivityStable structureHydrogenHeterogenous catalyst chemical elementsSteam reformingChemical industry

The invention belongs to the technical field of energy and chemical industry, and provides a catalyst for hydrogen production by methanol steam reforming, a preparation method and application thereof, and a reaction for hydrogen production by methanol steam reforming. The catalyst provided by the invention comprises an oxide carrier, and a copper oxide and fullerene C60 which are loaded on the oxide carrier. The fullerene C60 has excellent electron acceptor properties, can reversibly capture and release electrons, can effectively adjust the electrons on the copper surface, and controls the equilibrium distribution and stability of the copper valence state, thereby ensuring the stability of the catalyst. According to the catalyst provided by the invention, under the conditions that the temperature is 240 DEG C, the pressure is 0.1 MPa, the molar ratio of water to methanol is 1.2: 1, and the mass space velocity of methanol is 4.5 h <-1 >, the hydrogen production rate is 0.4 mol / g / h, the CO selectivity is lower than 0.3%, the structure and performance are kept stable after continuous reaction for 200 h, and the inactivation phenomenon does not occur.

Owner:XIAMEN UNIV

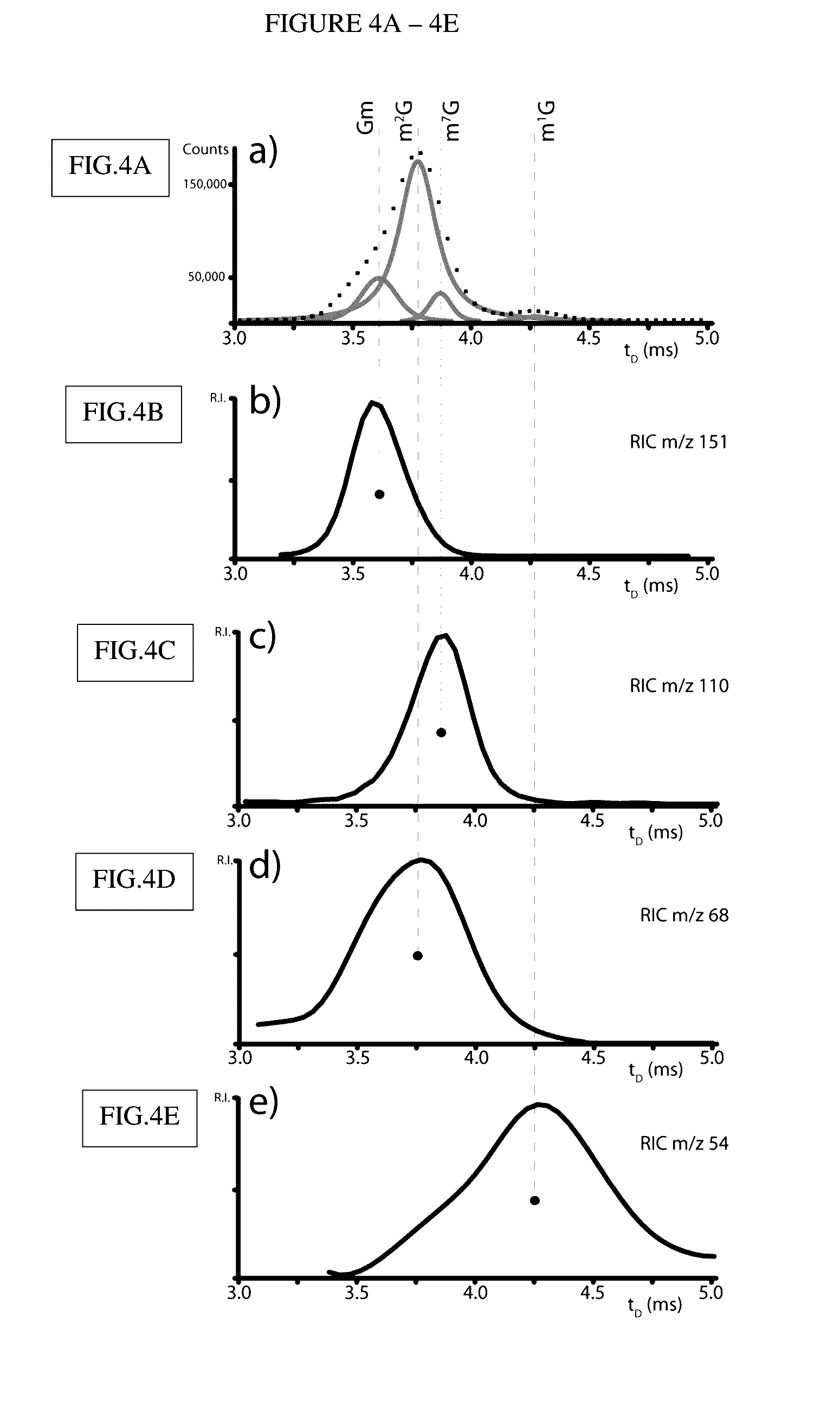

Profiling chemically modified dna/rna units for disease and cancer diagnosis

ActiveUS20170044619A1Easy to analyzeParticle separator tubesMicrobiological testing/measurementCancers diagnosisProstate cancer

The present invention relates to high-throughput methods comprising direct infusion electrospray ionization mass spectrometry (ESI-MS), multistep tandem mass spectrometry (MSn), consecutive reaction monitoring (CRM), ion mobility spectrometry mass spectrometry (IMS-MS), high-resolution MS, and IMS-MS, for genome-wide (whole cell or tissue) profiling of DNA and RNA nucleotides / nucleosides having a wide variety of variant structural modifications. In particular, these methods are contemplated for providing a specific profile of variant DNA and / or RNA chemically modified nucleic acids (i.e. structures) associated with specific medical conditions. Medical conditions may include, but are not limited to: cancer; including prostate, lung, uterus, larynx, ovary, breast, kidney, and many other types of cancers; specific stages of cancer; bacterial infections; viral infections; genetic and metabolic disorders; and any condition involving changes in DNA and / or RNA structural modifications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

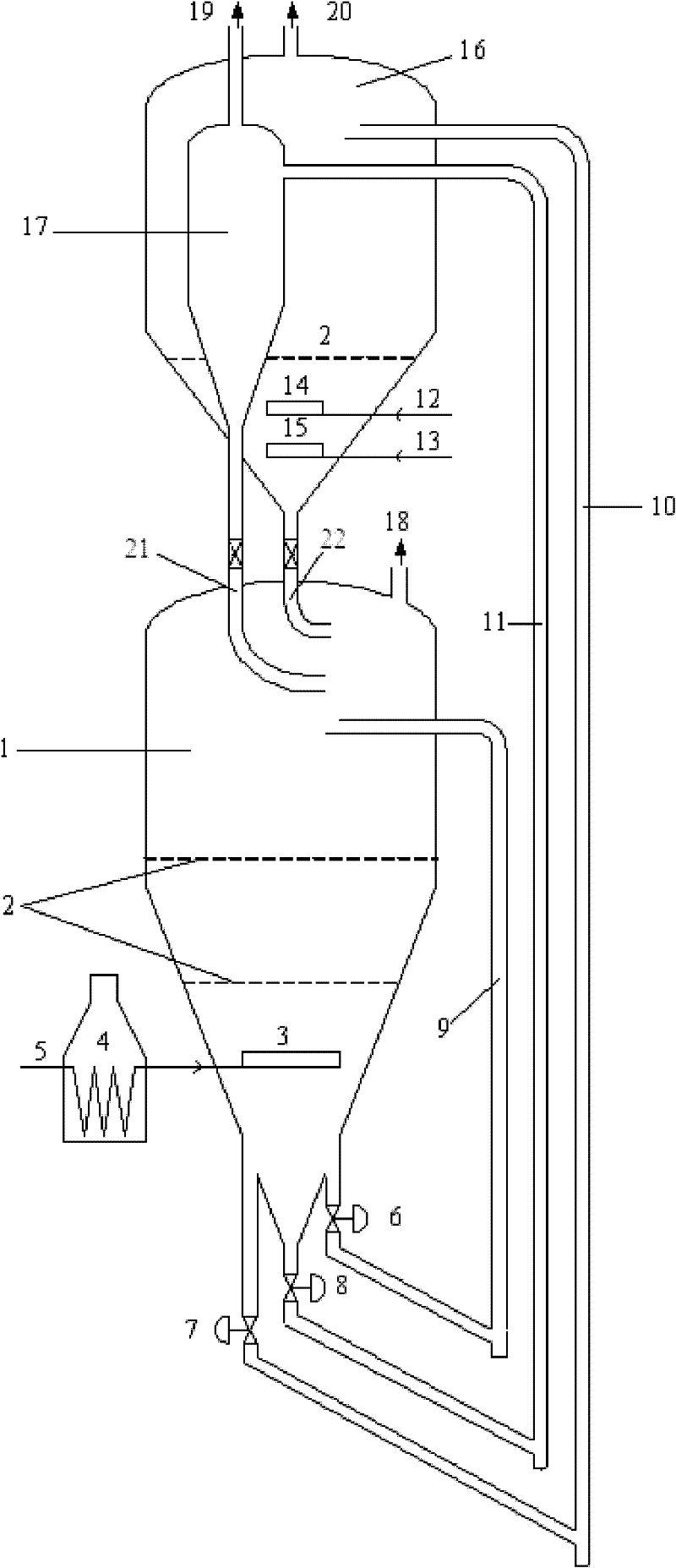

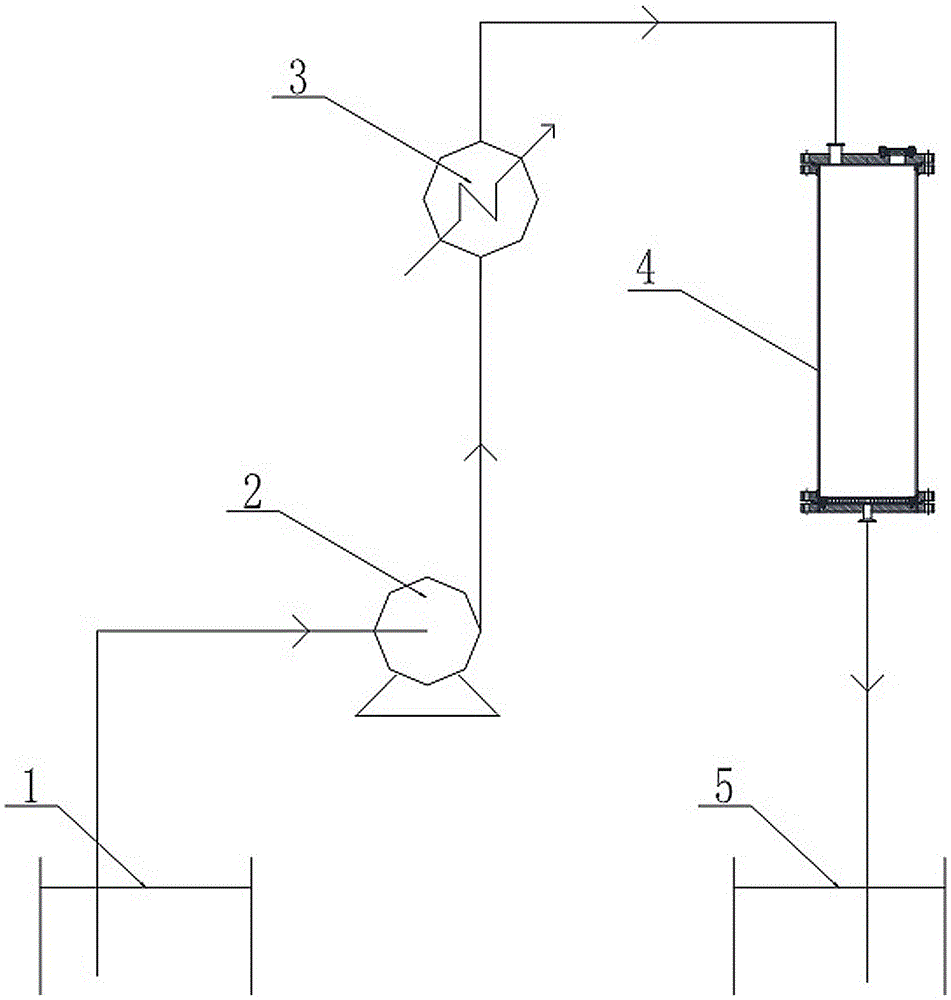

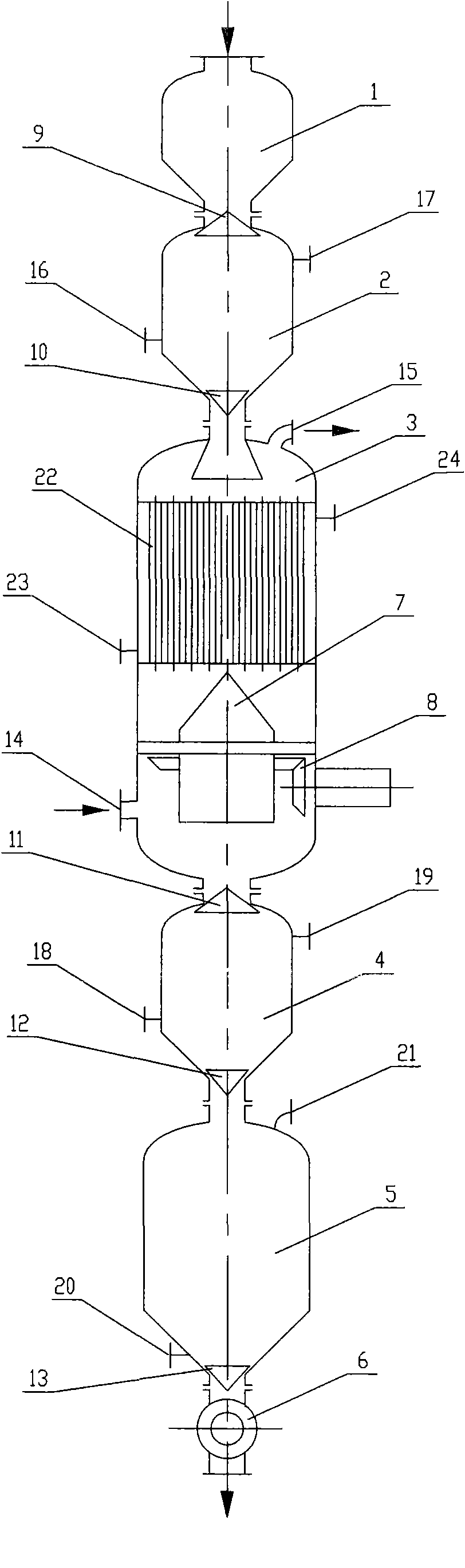

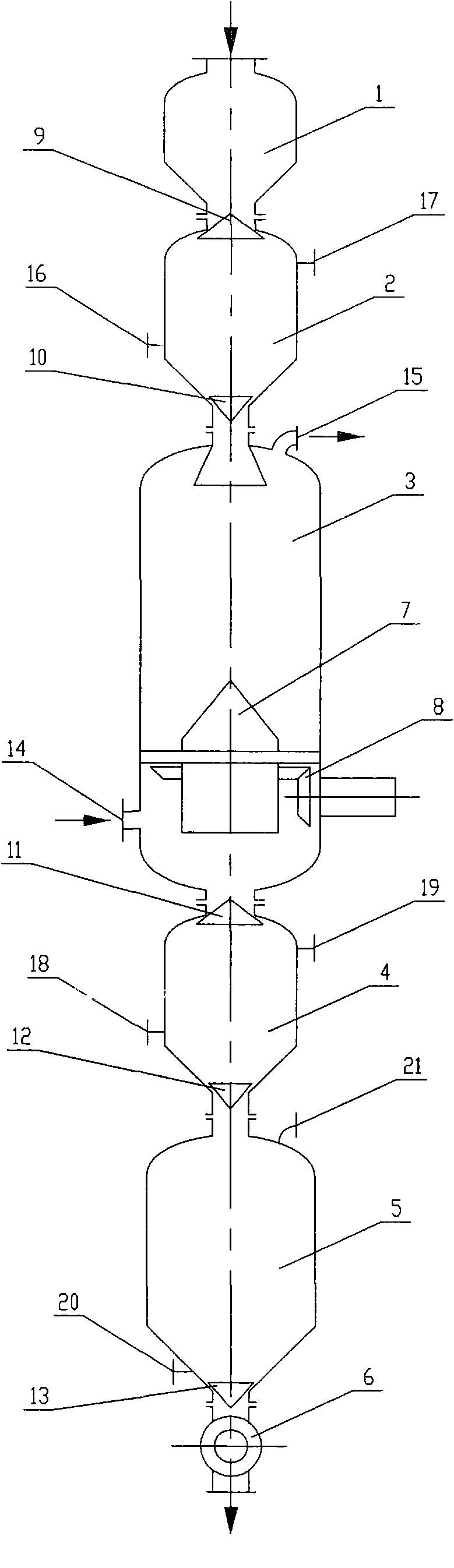

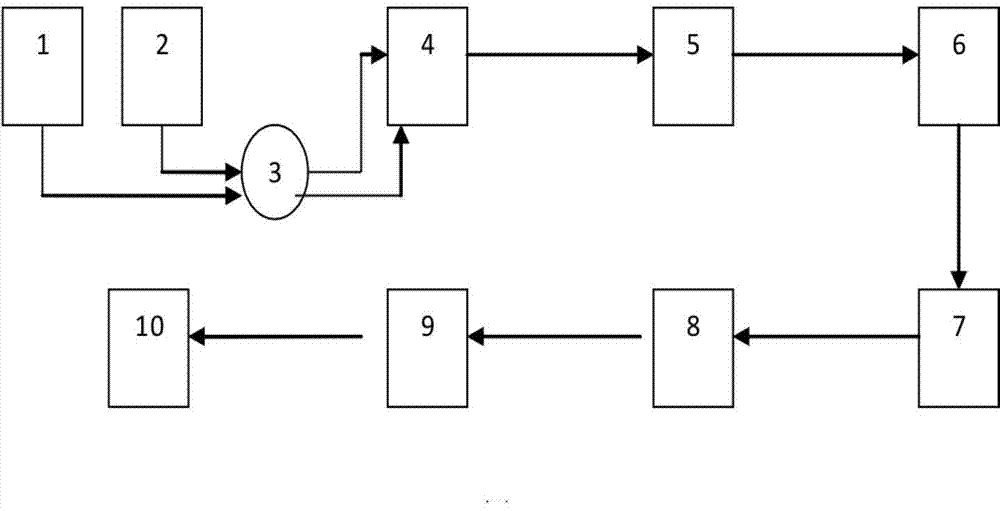

Moving bed reactor device with catalyst capable of reacting continuously and being regenerated and use method thereof

InactiveCN101683602AFlexible adjustmentCatalytic crackingChemical/physical processesProduct gasProcess engineering

The invention relates to a moving bed reactor device with a catalyst capable of reacting continuously and being regenerated. The top end of a moving bed reactor (3) of the moving bed reactor device iscommunicated with an upper lock hopper (2) through a lower cone valve (10) of the upper lock hopper (2); the upper lock hopper (2) is communicated with a measuring hopper (1) through an upper cone valve (9) of the upper lock hopper (2); the lower part of the upper lock hopper (2) is provided with an upper lock hopper replacement gas inlet (16); the upper part of the upper lock hopper (2) is provided with an upper lock hopper replacement gas outlet (17); the lower part of the moving bed reactor (3) is provided with a rotary feed plate (8), a gas distribution cone (7) and a feed gas inlet (14);the upper part of the moving bed reactor (3) is provided with a reaction gas outlet (15); the bottom end of the moving bed reactor (3) is communicated with a lower lock hopper (4) through an upper cone valve (11) of the lower lock hopper (4); the lower lock hopper (4) is communicated with a catalyst regeneration reactor (5) through a lower cone valve (12) of the lower lock hopper (4); the lower part of the lower lock hopper (4) is provided with a lower lock hopper replacement gas inlet (20); the upper part of the lower lock hopper (4) is provided with a lower lock hopper replacement gas outlet (19); the bottom end of the catalyst regeneration reactor (5) is provided with a rotary discharge valve (6); the lower part of the catalyst regeneration reactor (5) is provided with a regeneration gas inlet (20); and the upper part of the catalyst regeneration reactor (5) is provided with a regeneration gas outlet (21). The moving bed reactor device can be adjusted flexibly and has a wide application range, and a solid catalyst can be used in reactions continuously and regenerated.

Owner:SEDIN ENG +1

Homogeneous catalysis low boiling point olefin hydrogen peroxide continuous reaction method and system

The oxidizing continuous reaction method by homogeneous catalysing lower-boiling olefin hydrogen peroxide uses the azeotropy of water and constituents in reaction liquid to remove most water and increase epoxide yield and realize continuity; the catalyst needs not to separate and can recycle. The reaction system comprises mainly: a reactor, a condenser, a rectification tower, an oil-water separator, and a gasifier. Wherein, it uses thermal energy of reaction self and benzene solution to distill off the residual material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Continuous preparation method of herbicide intermediate 2, 4-dichlorphenoxyacetic acid

ActiveCN102659571AReduce labor intensityEmission reductionOrganic compound preparationCarboxylic acid salt preparationFiltrationInterval method

The invention provides a continuous preparation method of herbicide intermediate 2, 4-dichlorphenoxyacetic acid, which comprises the steps of subjecting 2, 4-dichlorphenoxyacetic acid with a mole ratio of 1: (1.2-1.5) and chloroacetic acid to consecutive reaction through a multistage condensation reaction tower at a temperature of 80-110 DEG C, controlling the PH value of the reaction to be 8-12 through addition of alkali liquor, and finally cooling the liquid material after reaction, subjecting the liquid material to suction filtration and obtaining the 2, 4- dichlorphenoxyacetic acid. Existing interval methods are replaced with the continuous preparation method for preparing the herbicide 2, 4-D acid intermediate 2, 4-dichlorphenoxyacetic acid, the preparation method is easy to operate, the production is safe and can be controlled, the labor intensity of workers is reduced greatly, the production field environment is improved, the safety of the reaction is improved, the discharge of the three wastes is reduced and the production during unit time is increased.

Owner:先正达集团股份有限公司

Modified boron nitride supported metal catalyst and preparation method and application thereof

InactiveCN112264078ALow costImprove thermal stabilityPhysical/chemical process catalystsOrganic compound preparationPtru catalystMetal catalyst

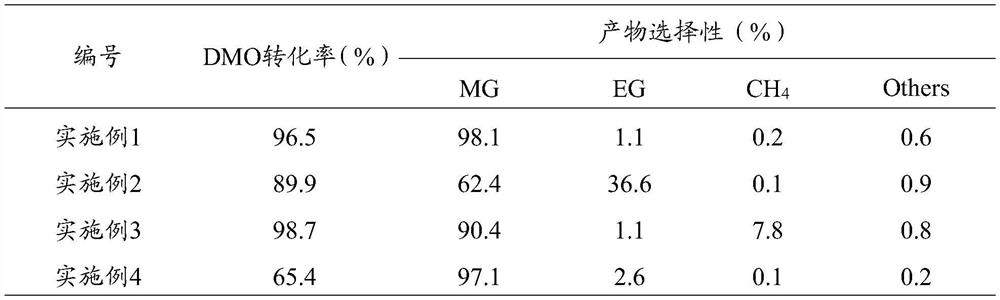

The invention provides a modified boron nitride supported metal catalyst and a preparation method and application thereof, and belongs to the technical field of catalytic materials. The modified boronnitride supported metal catalyst provided by the invention comprises a modified boron nitride carrier and an active component loaded on the modified boron nitride carrier, wherein the active component comprises one of metal ruthenium, nickel, silver and copper; the mass fraction of the active component in the modified boron nitride loaded metal catalyst is 0.1-5%; defect sites and functional groups exist on the surface of the modified boron nitride carrier; the defect sites comprise a nitrogen defect site and a boron defect site; the functional group is a hydroxyl functional group and / or an amino functional group. Results of the embodiment show that when the catalyst provided by the invention is used for catalyzing hydrogenation of dimethyl oxalate, the conversion rate of dimethyl oxalateis 95.4-99.9%; the selectivity of methyl glycolate is 95.0-98.9%, no obvious inactivation phenomenon exists after continuous reaction is conducted for 100 h, and the structure and the performance arekept stable.

Owner:XIAMEN UNIV

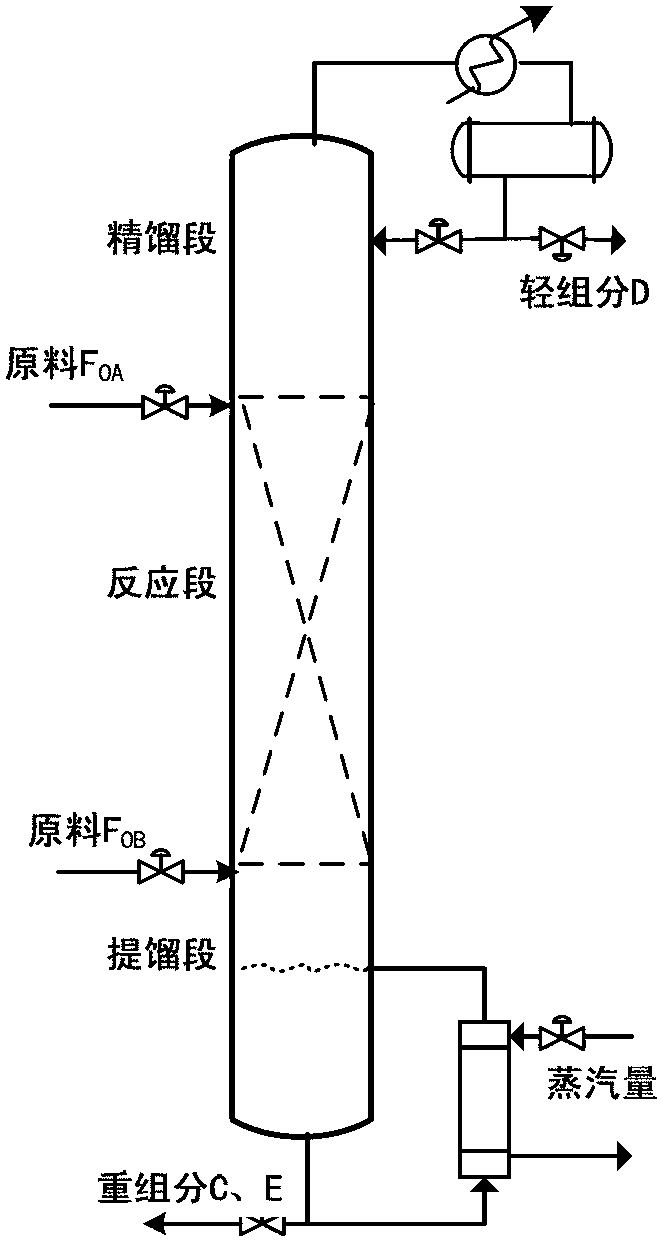

Design method of automatic control system for vapour-liquid consecutive reaction rectifying process

InactiveCN103157427AGuaranteed uptimeStrongly nonlinearChemical/physical/physico-chemical stationary reactorsFractional distillationAutomatic controlControl system design

The invention discloses a design method of an automatic control system for the vapour-liquid consecutive reaction rectifying process. The design method comprises the following steps of: (1) determining an optimal steady-state technological parameter of a vapour-liquid consecutive reaction rectifying tower; (2) determining a control target designed by the control system; (3) reasonably selecting a manipulated variable and an operating variable; (4), determining the position of the temperature of a sensitive plate; (5) designing a multi-loop automatic control system for the reaction rectifying process; and (6) adjusting and setting a controller structure parameter of the multi-loop automatic control system. The design method of the automatic control system for the vapour-liquid consecutive reaction rectifying process, provided by the invention, can effectively avoid the problems that the dynamic maladjustment of reaction and separating capacity in the tower can be easily caused by reaction mass properties and external disturbance, so that the product quality is reduced and the energy consumption is increased, and by using the method, a long-term stability operation of a closed-loop system of a vapour-liquid consecutive reaction rectification integration device is realized.

Owner:NANJING UNIV OF TECH

Catalyst for preparing propylene by directly converting ethylene, and application method thereof

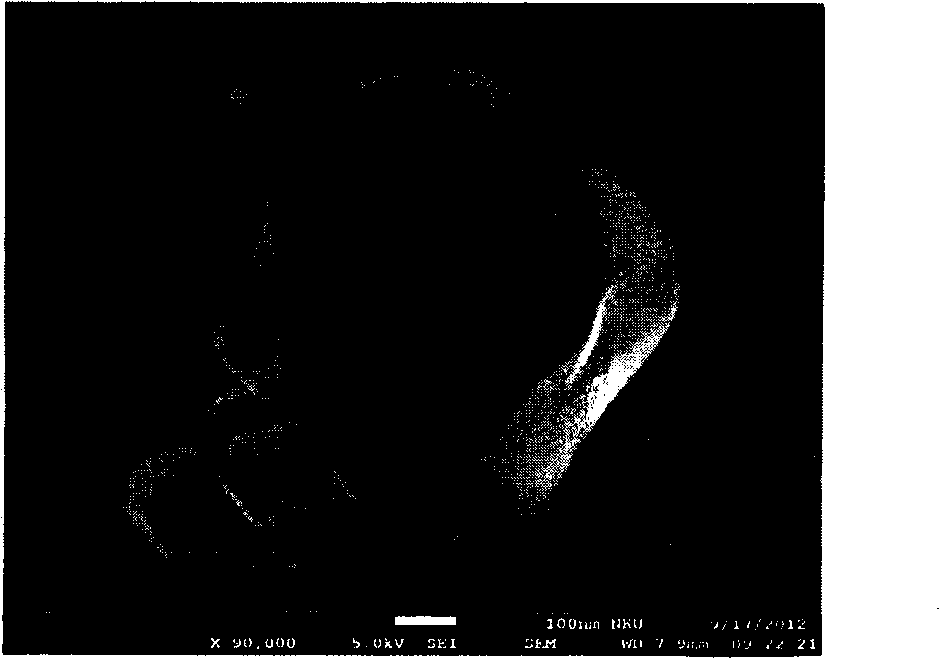

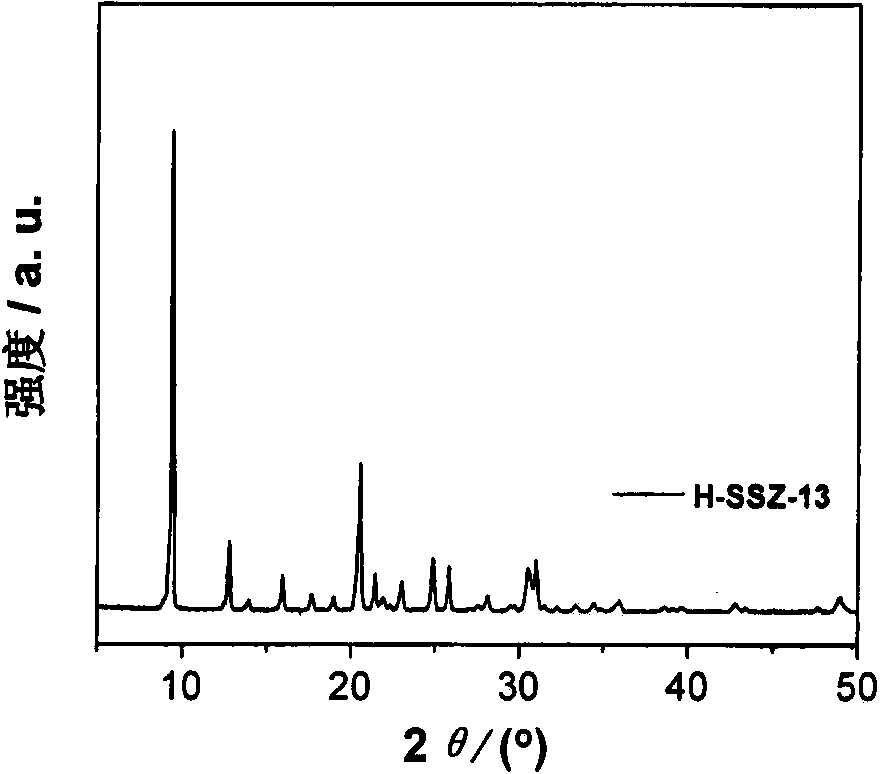

ActiveCN103846102ASuitable channelStrong acidMolecular sieve catalystsHydrocarbonsMolecular sieveEthylene

The invention discloses a catalyst for preparing propylene by directly converting ethylene, and an application method of the catalyst. An H-SSZ-13 zeolite molecular sieve is taken as an original catalyst and can be directly used for the reaction for preparing the propylene by modulating the ethylene by an acid treatment method, so that the problems of low ethylene conversion rate and poor propylene selectivity can be solved. The original catalyst is easy to obtain, and the catalyst is good in stability and simple in post-processing method; the obtained catalyst can continuously react on a fixed bed, is high in activity and long in service life and can be used for the industrial production of preparing propylene by directly converting ethylene.

Owner:NANKAI UNIV

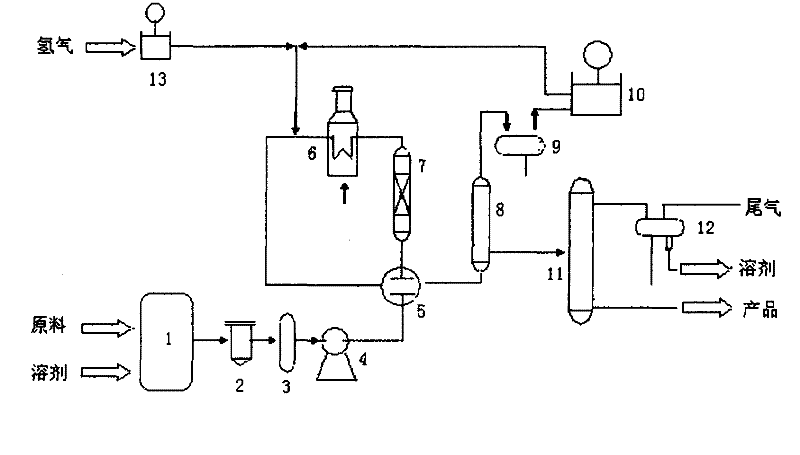

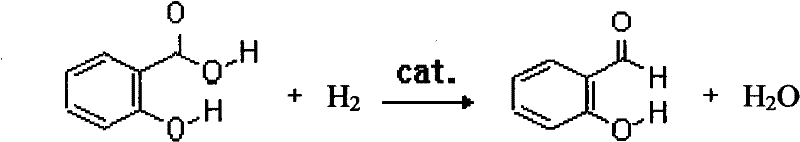

Preparation method and application of hydrogenation deoxygenation catalyst for oxygen-containing organic compound

InactiveCN102188988ASimple preparation processGood repeatabilityPhysical/chemical process catalystsPreparation by hydrogenolysisSimple Organic CompoundsPtru catalyst

The invention relates to a hydrogenation deoxygenation catalyst for the deoxygenation reduction of an oxygen-containing organic compound. The catalyst is spherical, comprises elements such as P, B, F, K, Zn, Zr, Mo, Fe, Cu, Ni and the like, has the diameter of 2 to 4mm, the specific surface area of 100 to 280m<2> / g, the pore volume of 0.45 to 0.85ml / g, the pore size distribution of 12 to 30nm, and the crushing strength of 180 to 320N / cm, and can be used for the common dynamic continuous hydrogenation reaction process and intermittent hydrogenation reaction; reaction materials can be gas-phase or liquid-phase materials; and operation process conditions are that: hydrogen partial pressure is 1.5 to 4.5MPa, the temperature is 200 to 450 DEG C, the space velocity is 0.5 to 3.5v / v, and the ratio of hydrogen to oil is 100 to 600h<-1>. Product yield is over 96 percent when the catalyst is used for hydrogenation deoxygenation reaction, and the catalyst has high reaction activity, stability and selectivity.

Owner:NANJING MAISEN SCI & TECH DEV

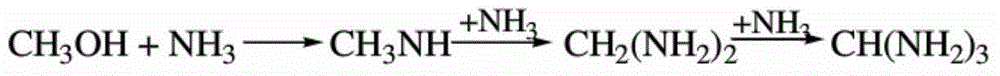

Beta-aminopropionitrile consecutive reaction process

InactiveCN102827031AImprove conversion rateHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationAcrylonitrileBeta aminopropionitrile

The invention discloses a beta-aminopropionitrile consecutive reaction process, which comprises the following steps: mixing ammonia water and a phase-transfer catalyst, reacting the ammonia water and acrylonitrile according to certain proportion under certain temperature condition, then performing ammonia removal under reduced pressure, dehydrating and removing a solvent, and then distilling to obtain the beta-aminopropionitrile. The invention employs the consecutive reaction technology, the usage of the special phase-transfer catalyst enables strong reaction selectivity, the side reaction is inhibited, and the ammonification reaction yield is substantially enhanced, simultaneously, the reaction pressure is greatly reduced, and the reaction can be completed below 1.0 MPa, thereby the safety coefficient of the reaction can be substantially increased.

Owner:江西兄弟医药有限公司

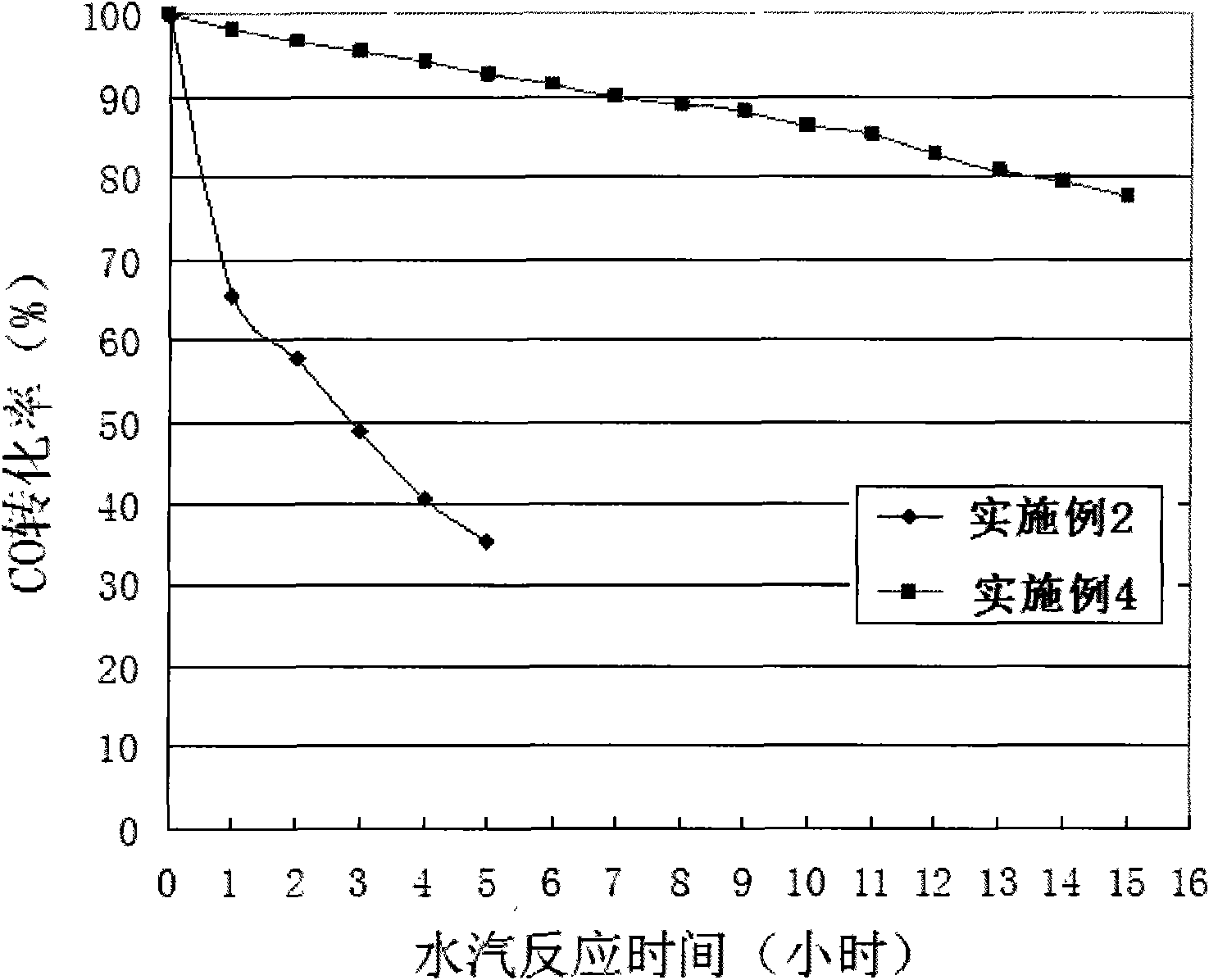

Room temperature catalytic oxidation carbon monoxide catalyst and preparation method thereof

InactiveCN101579635AImprove conversion rateSimple regeneration methodDispersed particle separationCatalyst activation/preparationCatalytic oxidationRoom temperature

The invention relates to a room temperature catalytic oxidation carbon monoxide catalyst and a preparation method thereof in the technical field of catalyst; the catalyst has the following components by mass percent: 0.5-1.0% of PdCl2 and 99.5-99.0% of gamma-AL2O3; the preparation method of the catalyst has the following steps: preparing steeping fluid, configurating mixed steeping fluid and carrying out drying. Compared with other normal temperature carbon monoxide catalysts, the activity of the catalyst prepared by the method of the invention is more than 98% and the conversion rate can reach as high as 77.7% in case of reaction for 15 hours in a row under saturated vapor pressure, meanwhile the catalyst is reproducible and the method therefor is simple and effective.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com