Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

A technology of microwave irradiation and pyrolysis reaction, which is used in pyrolysis treatment of sludge, vaporization of by-products, etc., can solve the problems of lack of description and operability of thermal recycling method, unstable reaction process, and unsuitable for industrialization promotion. , to achieve the effect of improving heat utilization efficiency, rapid pyrolysis, and reducing operation difficulty and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

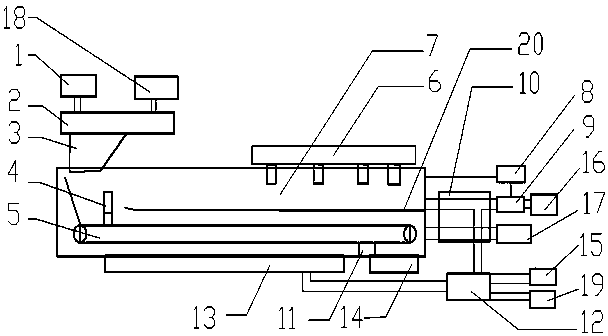

[0013] Such as figure 1 As shown, the microwave irradiated wet sludge drying pyrolysis continuous reaction device includes sludge bin 1, agitator 2, hopper feeder 3, sludge shape controller 4, belt conveyor 5, power control microwave irradiator 6. Microwave pyrolysis reaction chamber 7, pressure sensor controller 8, fan 9, condensation heat exchanger 10, scraper separator 11, oil-water separator 12, lyophobic tank 13, coke storage tank 14, product oil tank 15 , product gas tank 16, nitrogen generator 17, coke crusher 18, sludge water tank 19 and gas splitter plate 20; microwave pyrolysis reaction chamber 7 is provided with sludge shape controller 4, belt conveyor 5, scraper Separator 11, gas splitter plate 20, gas splitter plate 20 is arranged above the belt conveyor 5, a sludge shape controller 4 is arranged at the upper end of the left side of the belt conveyor, and a scraper separator 11 is arranged at the lower end of the right side of the belt conveyor, The sludge outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com