Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

227results about "Preparation by hydrogenolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

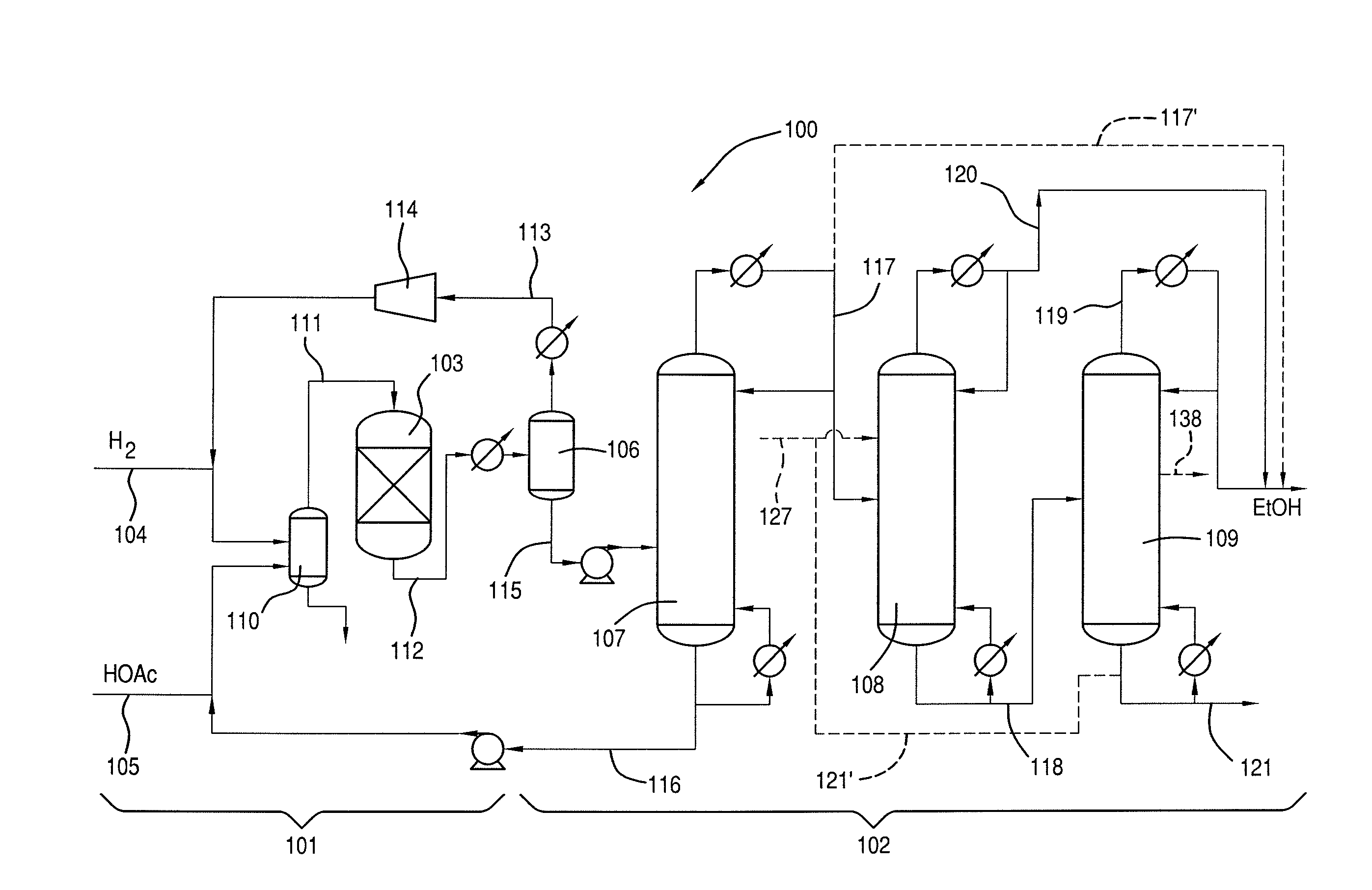

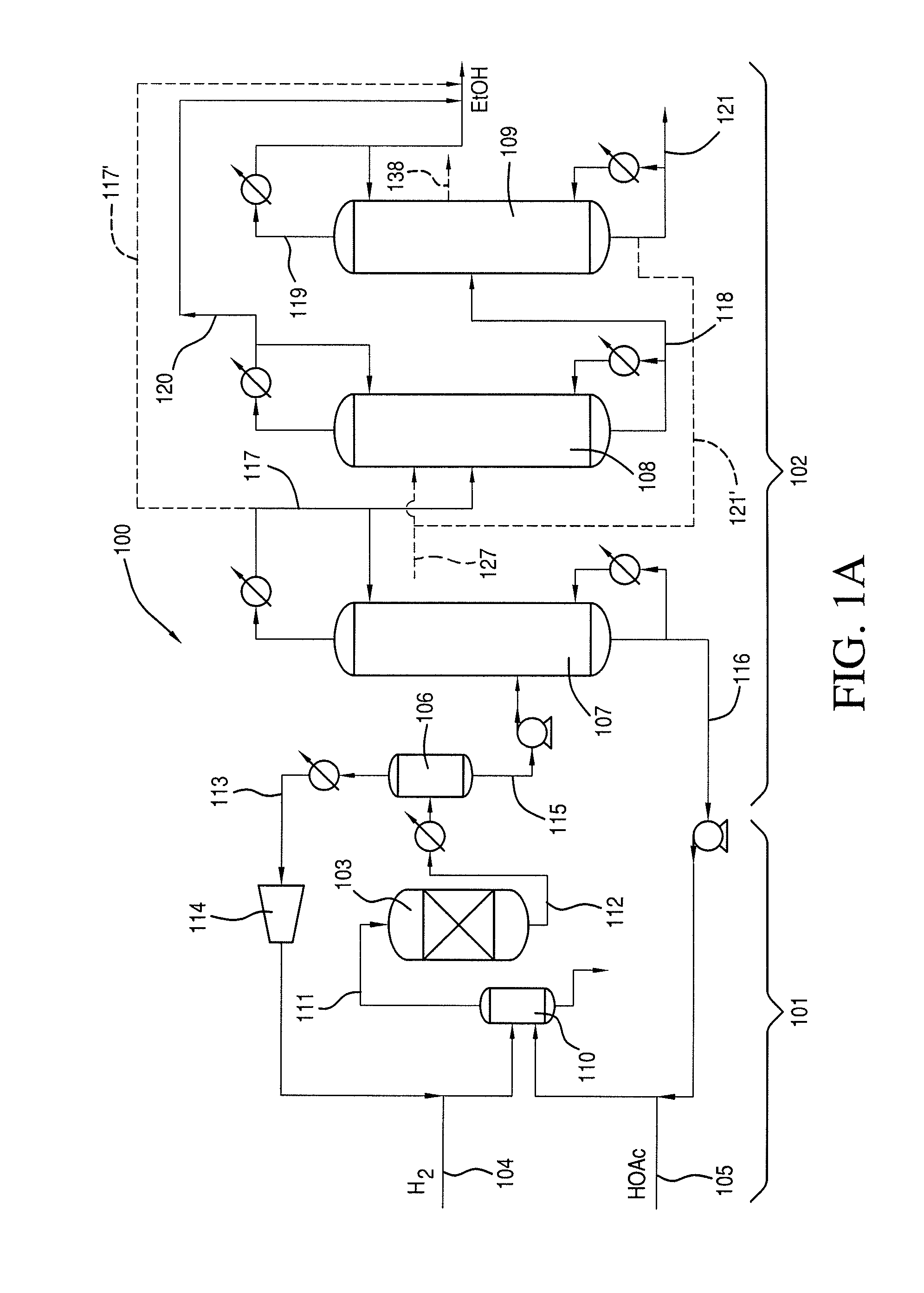

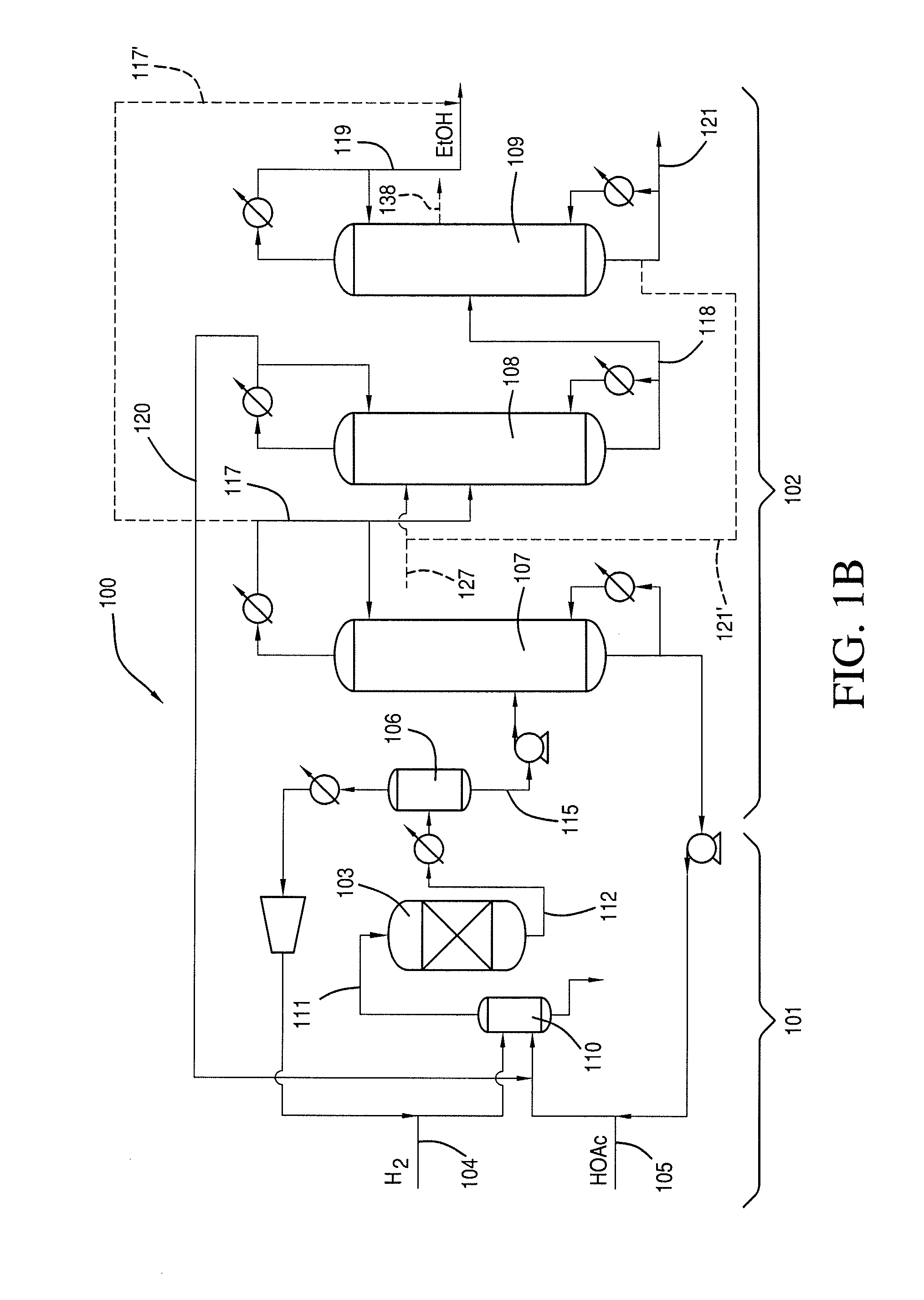

Methods and apparatus for selectively producing ethanol from synthesis gas

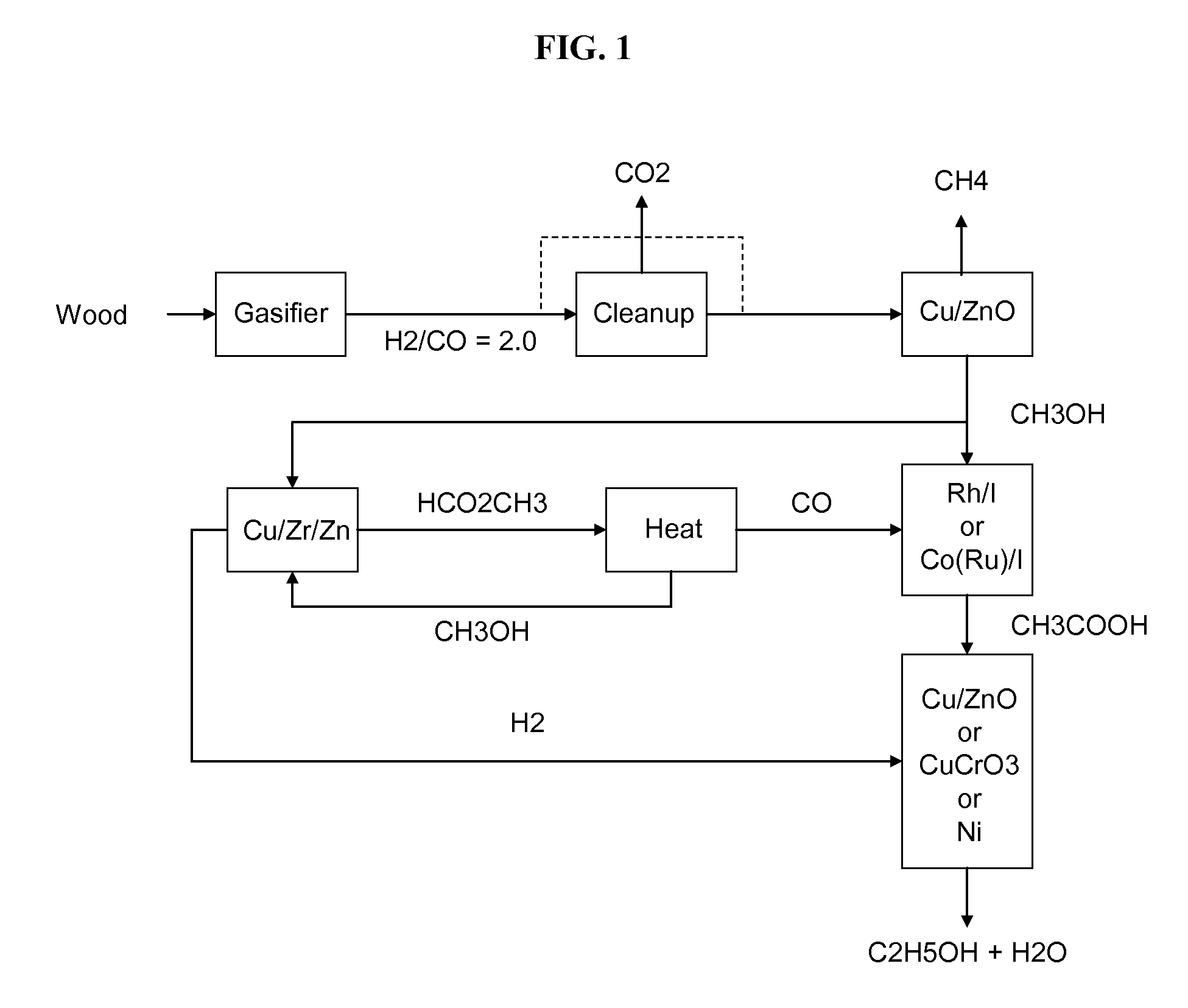

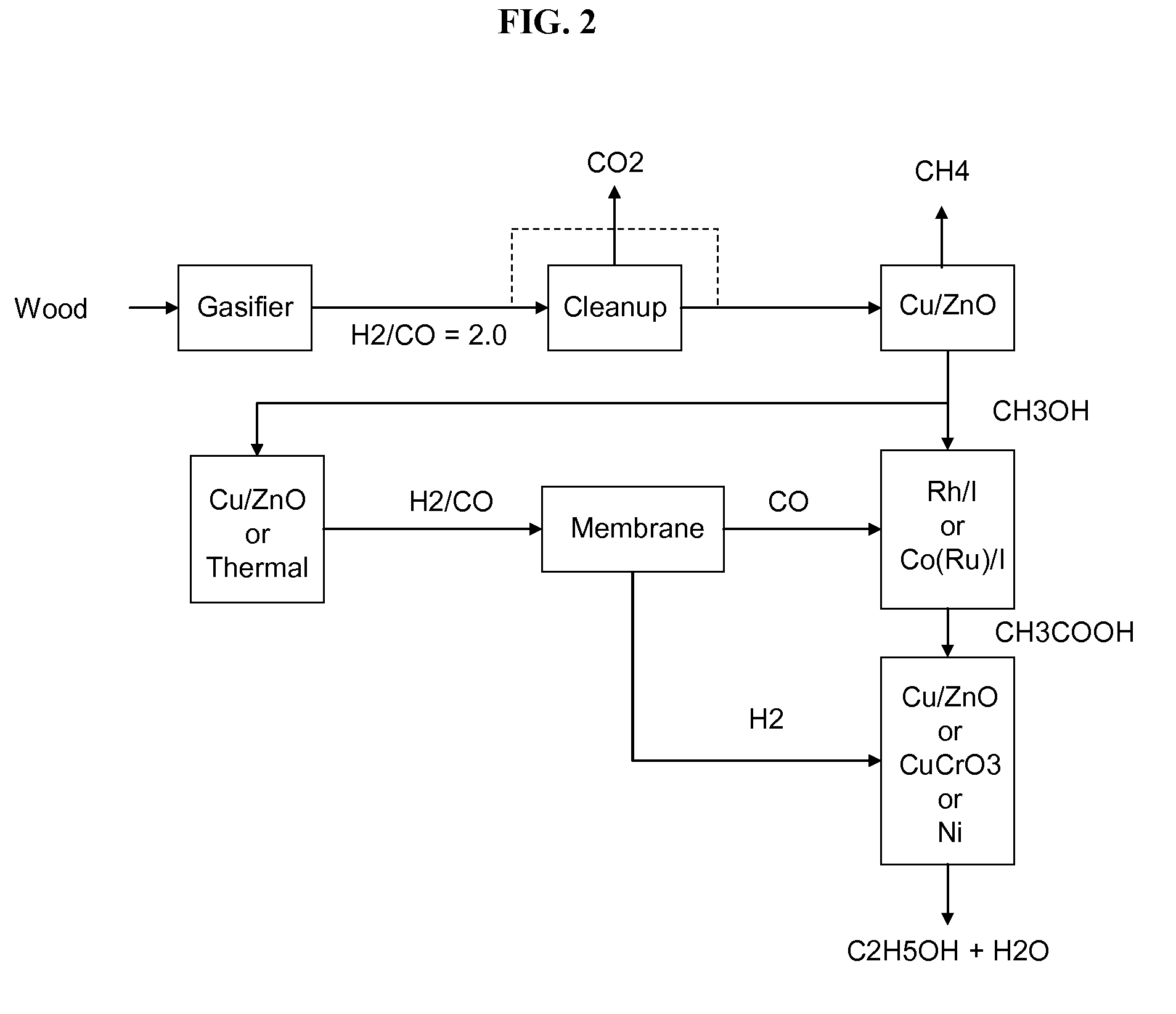

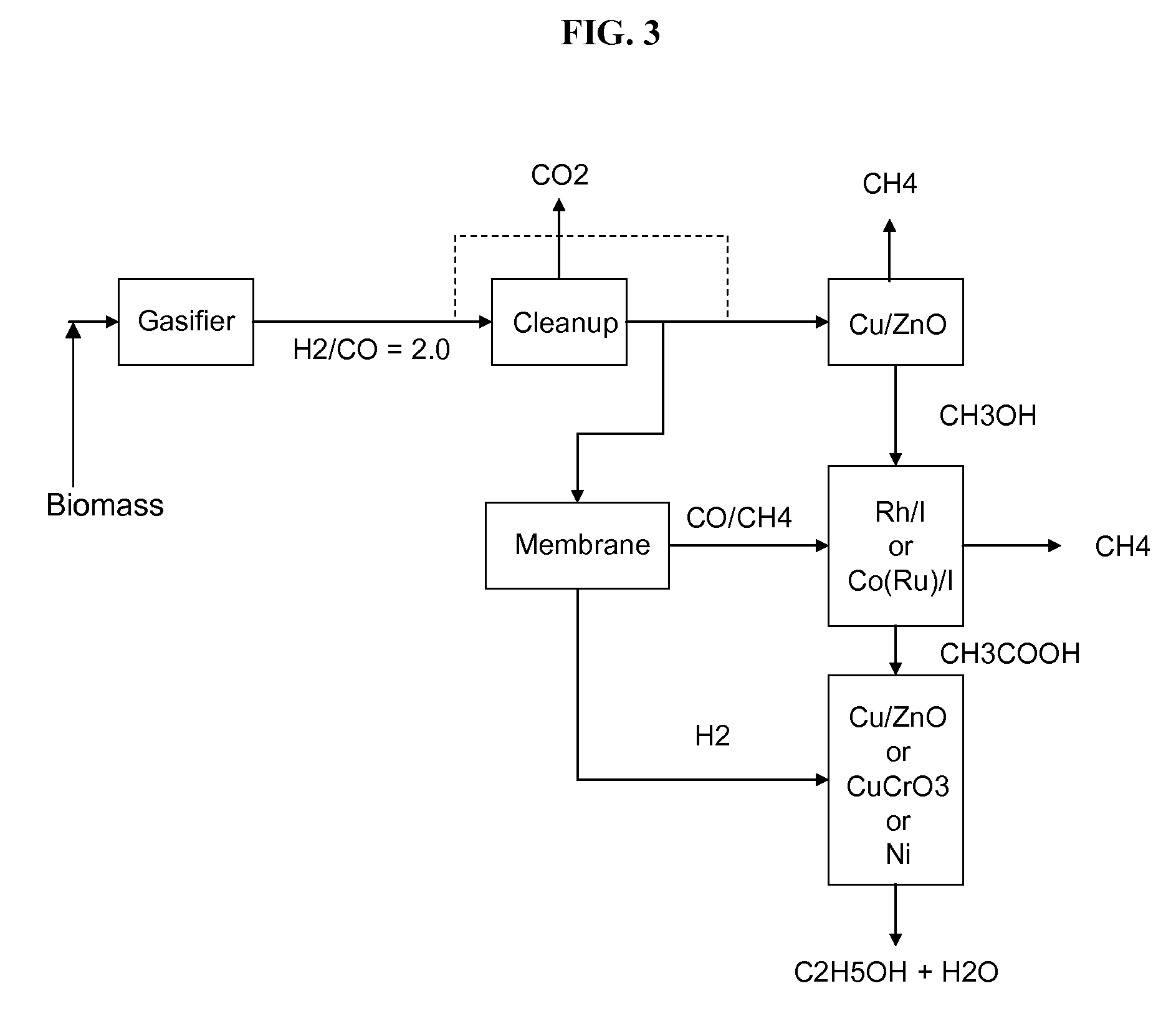

The invention provides methods and apparatus for selectively producing ethanol from syngas. As disclosed herein, syngas derived from cellulosic biomass (or other sources) can be catalytically converted into methanol, which in turn can be catalytically converted into acetic acid or acetates. Finally, the acetic acid or acetates can be reduced to ethanol according to several variations. In some embodiments, yields of ethanol from biomass can exceed 100 gallons per dry ton of biomass.

Owner:CELANESE INT CORP

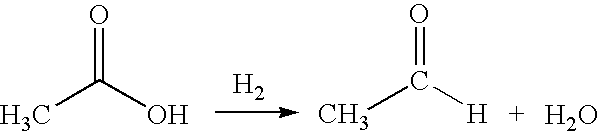

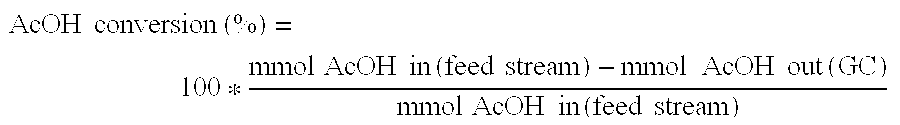

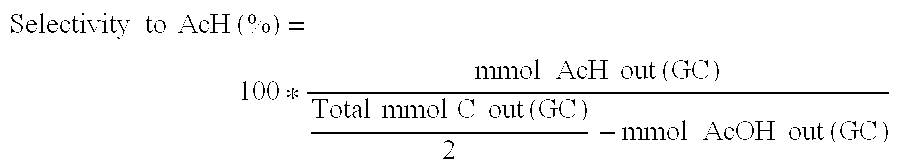

Direct and selective production of acetaldehyde from acetic acid utilizing a supported metal catalyst

InactiveUS20100029993A1High selectivityHigh yieldOrganic compound preparationPreparation by hydrogenolysisAcetic acidPlatinum

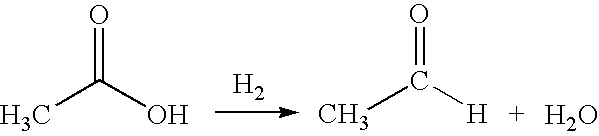

A process for the selective production of acetaldehyde by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form acetaldehyde is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C.

Owner:CELANESE INT CORP

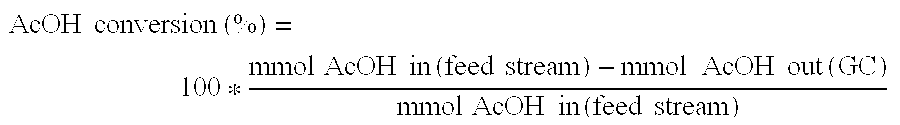

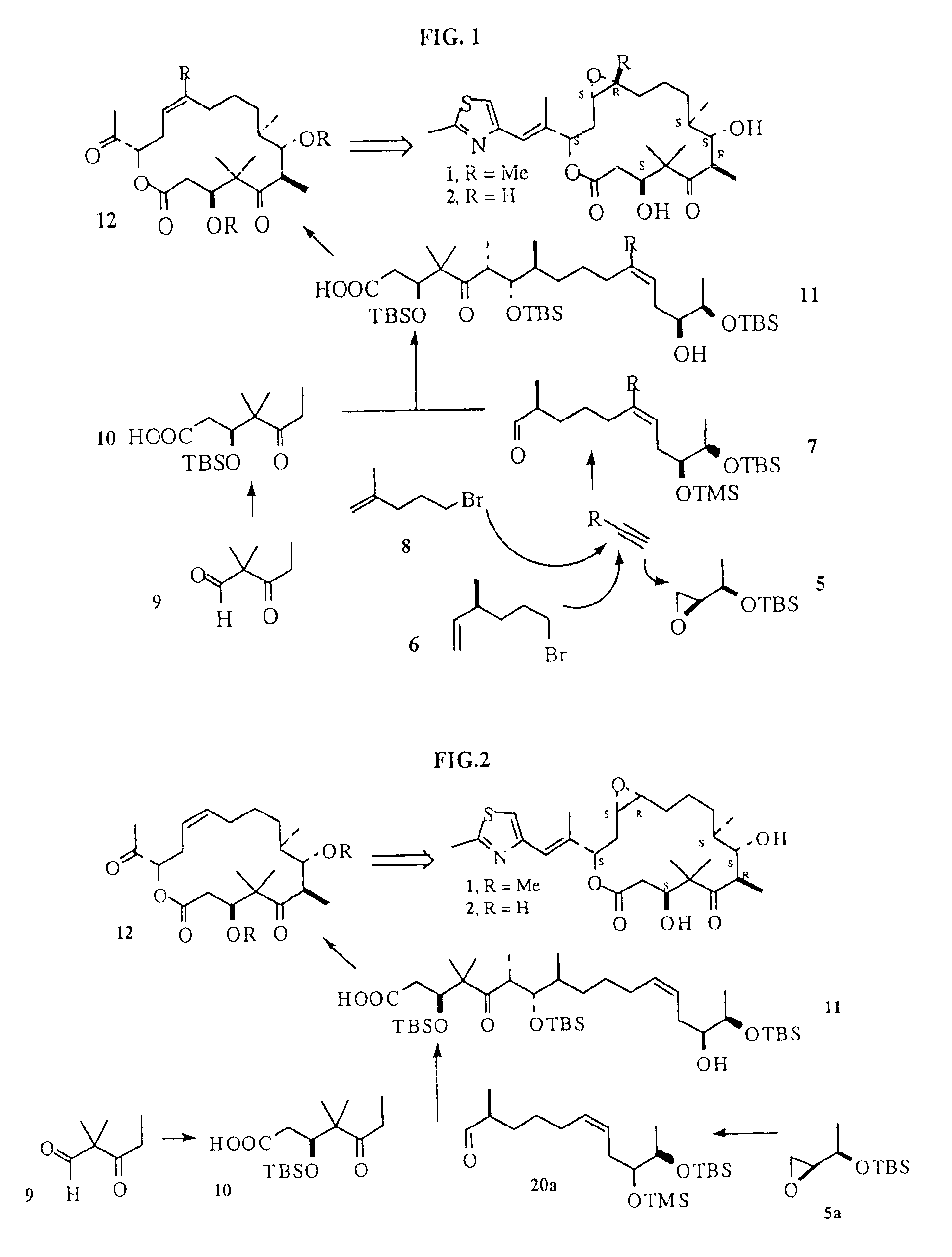

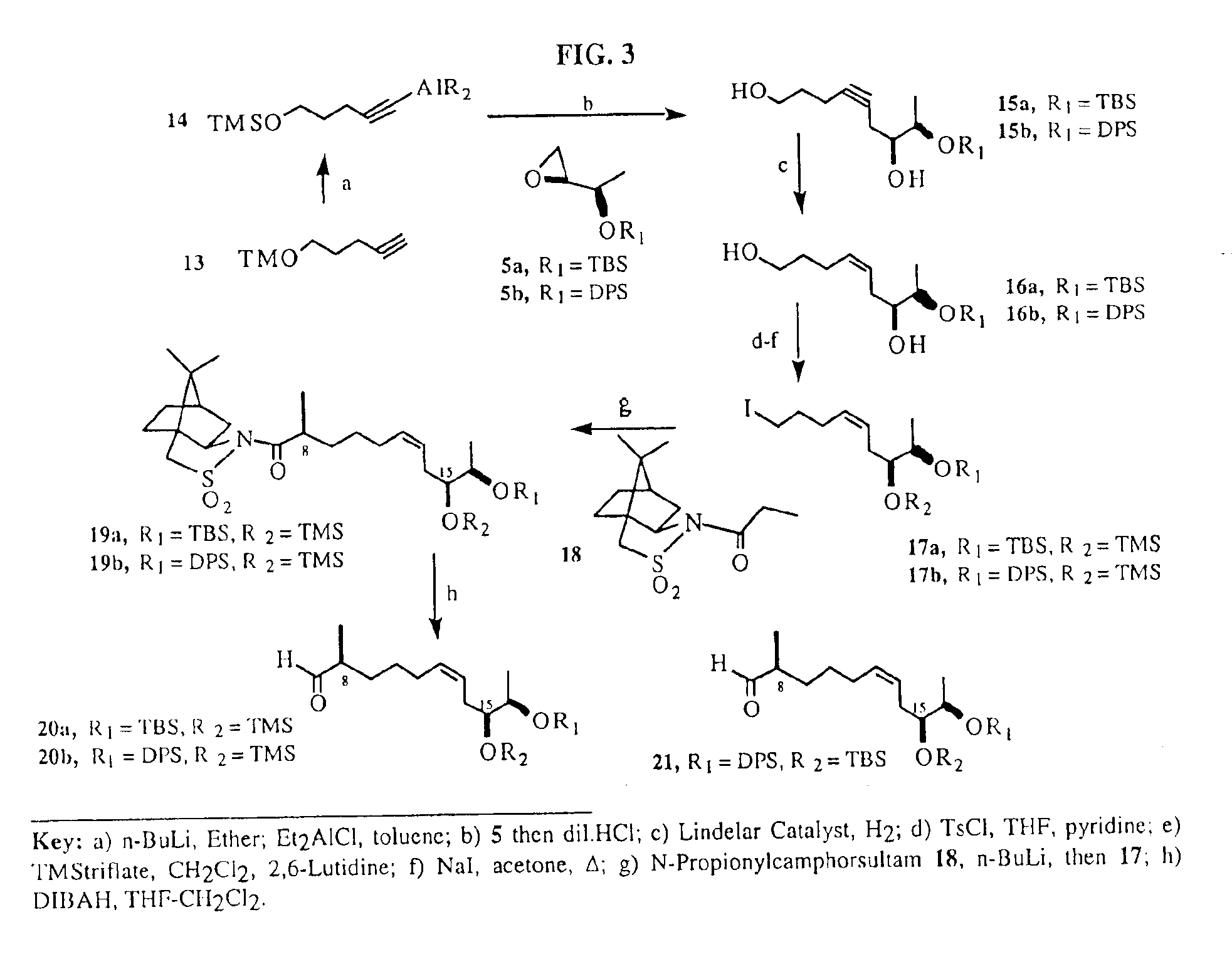

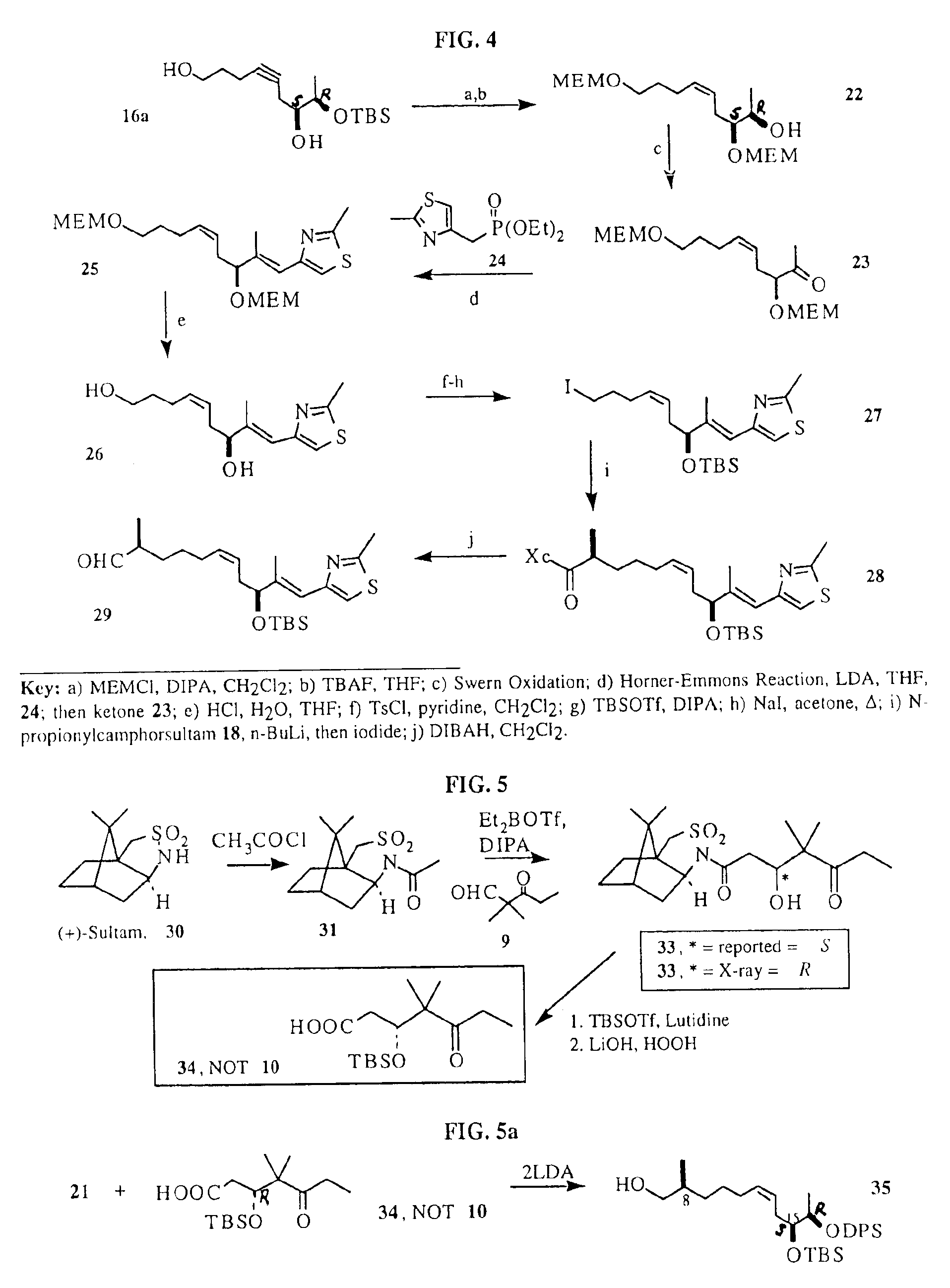

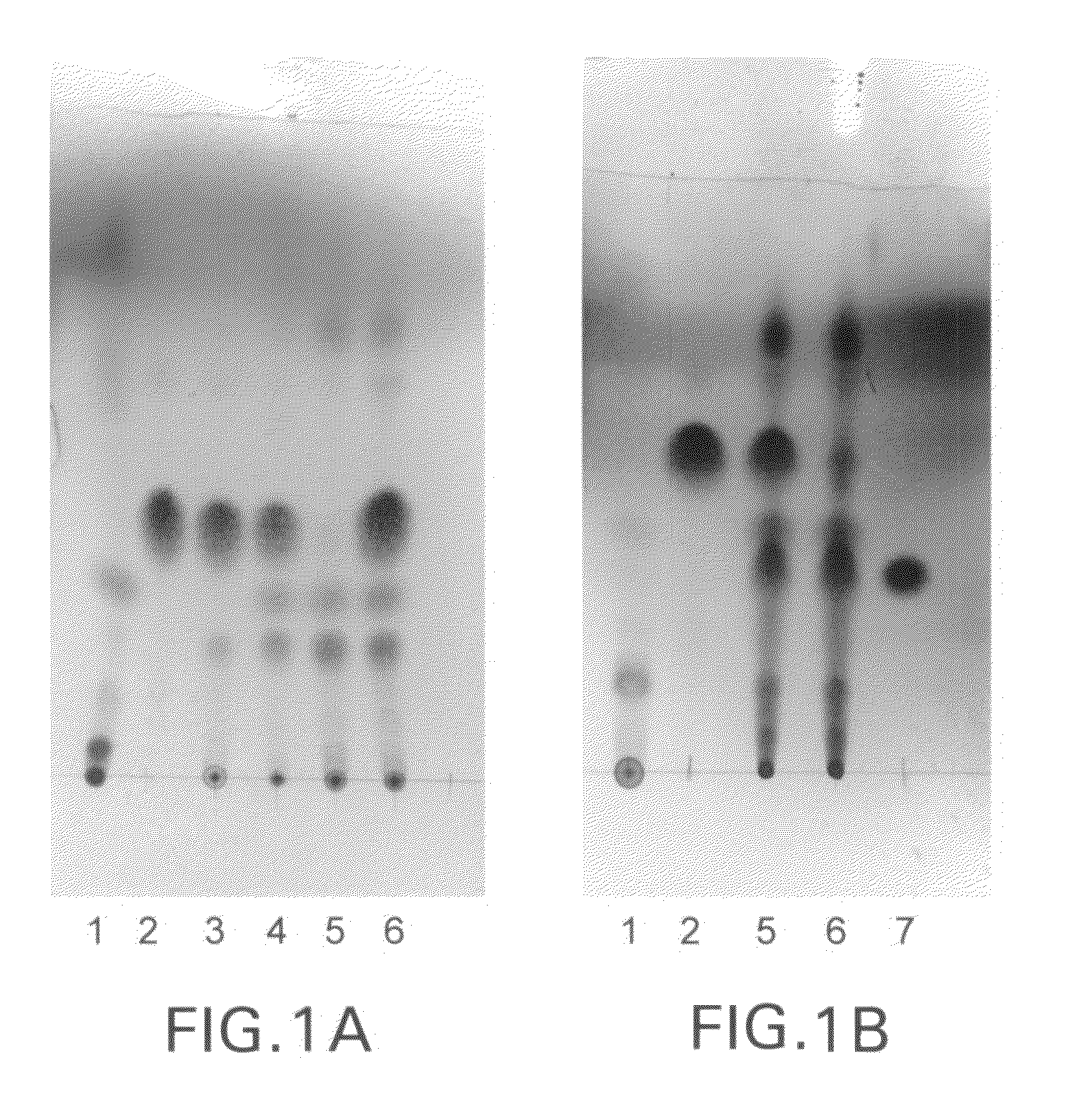

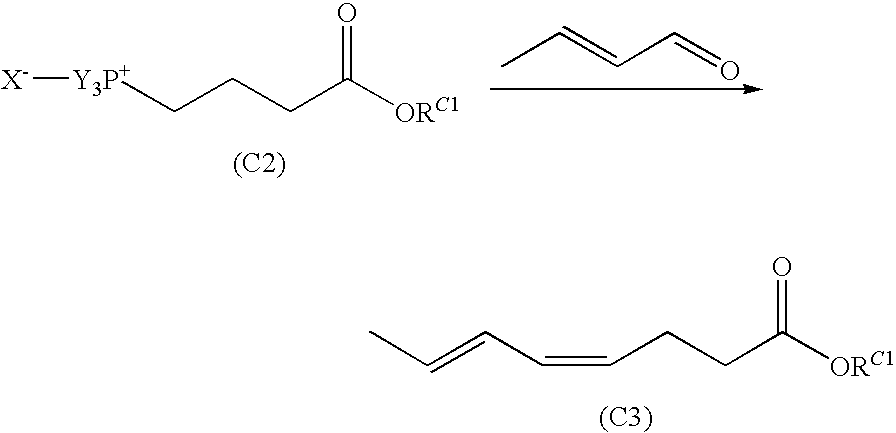

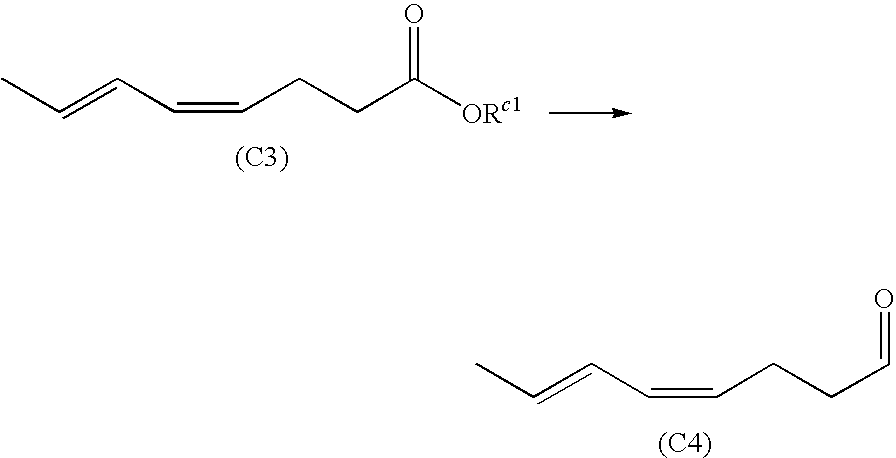

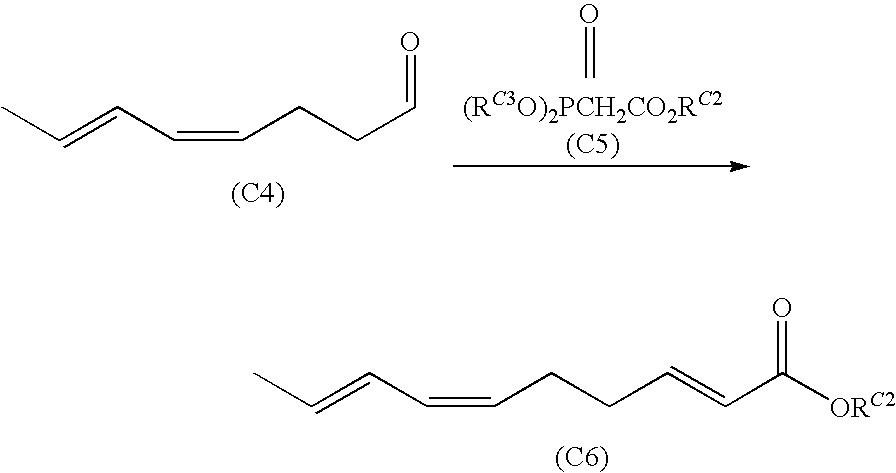

Synthesis of epothilones and related analogs

InactiveUS6989450B2Easy to understandOrganic active ingredientsGroup 4/14 element organic compoundsEpothiloneStereoisomerism

The present invention relates to methods for use in producing epothilones and analogs and derivatives thereof. A general method according to the present invention broadly comprises performing an aldol condensation of a first compound with a second compound thereby to form a third compound selected from the formulas: and stereoisomers thereof, and performing a macrolactonization of the third compound. The present invention also provides chemical compounds, and methods for producing such chemical compounds, that are useful in producing epothilones and analogs and derivatives thereof.

Owner:UNIVERSITY OF MISSISSIPPI

Direct and selective production of acetaldehyde from acetic acid utilizing a supported metal catalyst

InactiveUS7816565B2High selectivityHigh yieldOrganic compound preparationPreparation by hydrogenolysisPlatinumAcetic acid

A process for the selective production of acetaldehyde by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form acetaldehyde is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C.

Owner:CELANESE INT CORP

Enzymatic method of making aldehydes from fatty acids

ActiveUS7491854B2Organic compound preparationPreparation by hydrogenolysisCarboxylic acid reductaseFatty acid

The present invention provides methods of enzymatically preparing aldehydes from fatty acids by utilizing a carboxylic acid reductase enzyme to reduce the fatty acids to their corresponding aldehydes. The present invention also provides aldehydes prepared by the methods of the invention.

Owner:ARCHER DANIELS MIDLAND CO

Selective hydrogenation catalyst of aromatic aldehydes for refinement of terephthalic acid

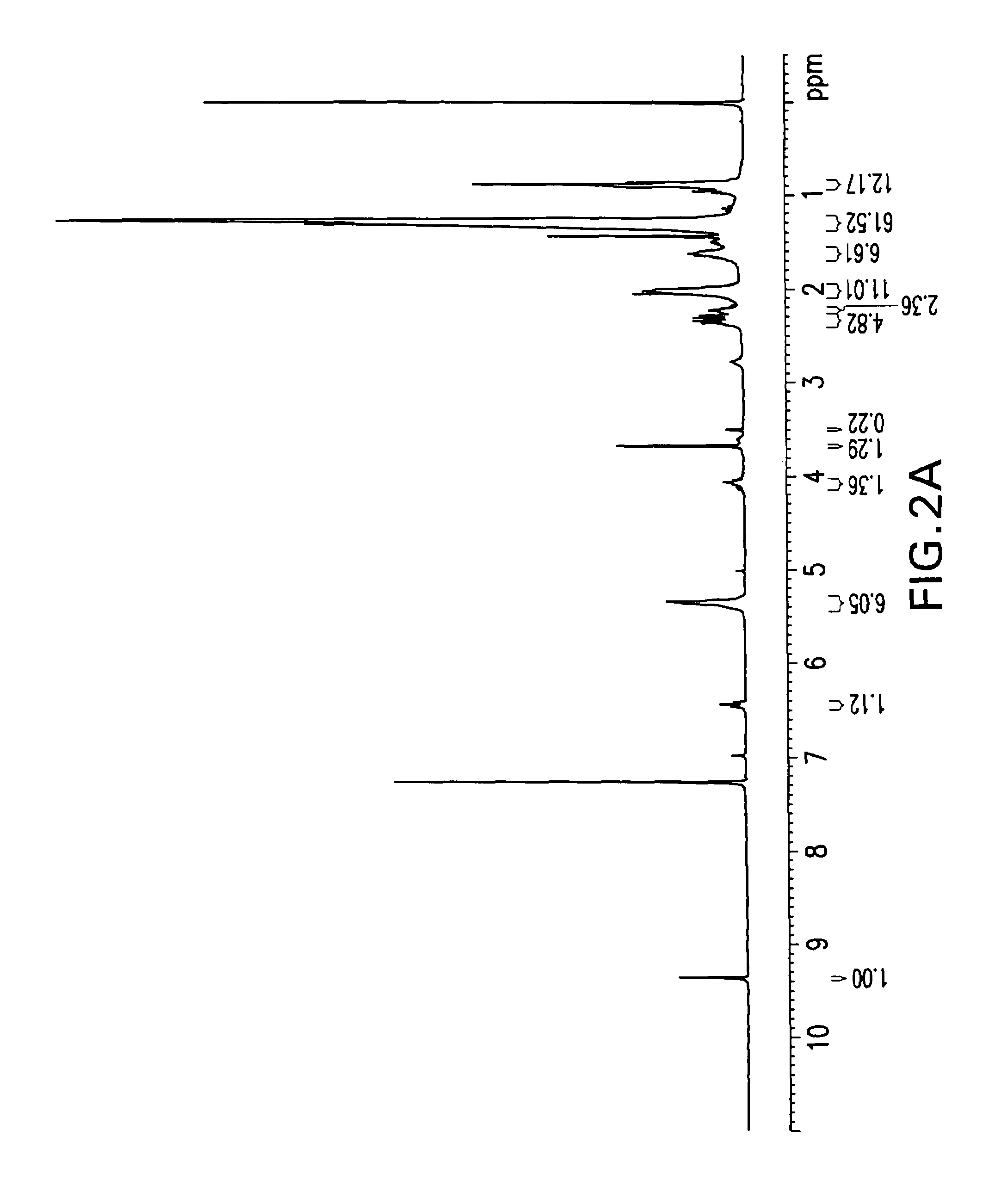

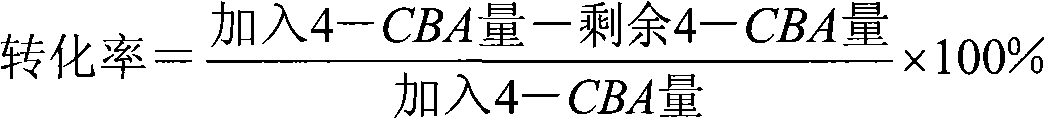

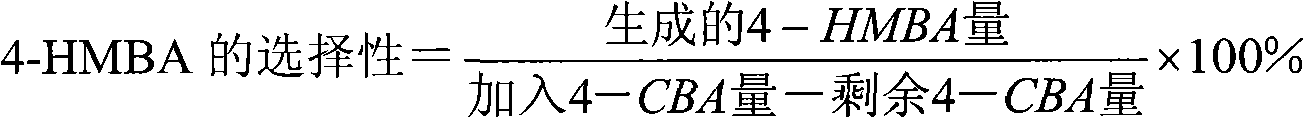

ActiveCN101347737AHigh selectivityImprove hydrogenation activityPreparation by hydrogenolysisMetal/metal-oxides/metal-hydroxide catalystsActivated carbonBenzaldehyde

The invention relates to a selective hydrogenation catalyst of aromatic aldehydes for refining of terephthalic acid. The selective hydrogenation catalyst is mainly used for solving the problems that the hydrogenation of 4-carboxy-benzaldehyde (called as 4-CBA for short) in the prior art mainly generates p-toluic acid (referred to as P-TA), the amount of hydrogen consumption is great and the operation cost is high. The selective hydrogenation catalyst adopts activated carbon as a carrier and is supported with one or more metals of palladium, ruthenium, nickel, zinc and copper, and the like; therefore, the technical proposal can better solve the problems and can be used in the industrial production for hydrogenation refining of the terephthalic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

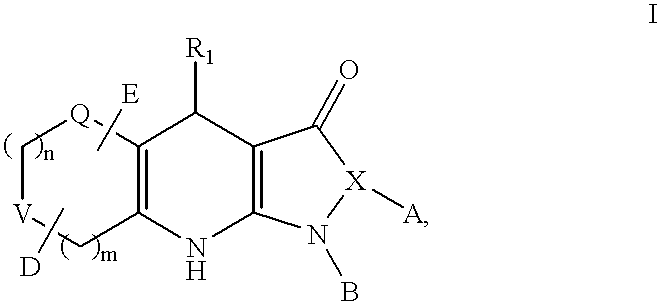

Tricyclic dihydropyrazolone and tricyclic dihydroisoxazolone potassium channel openers

Owner:ABBOTT LAB INC

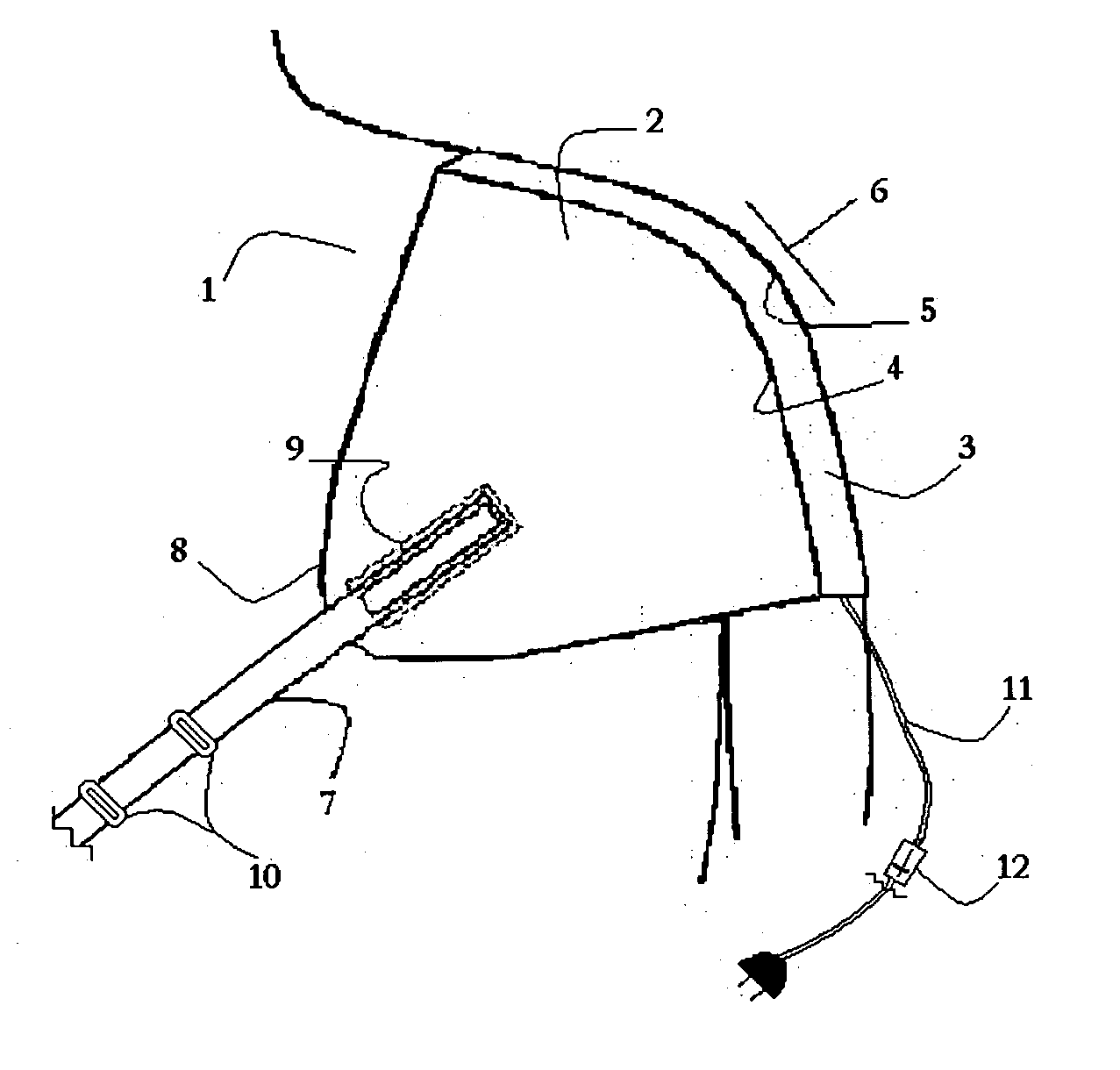

Joint heat

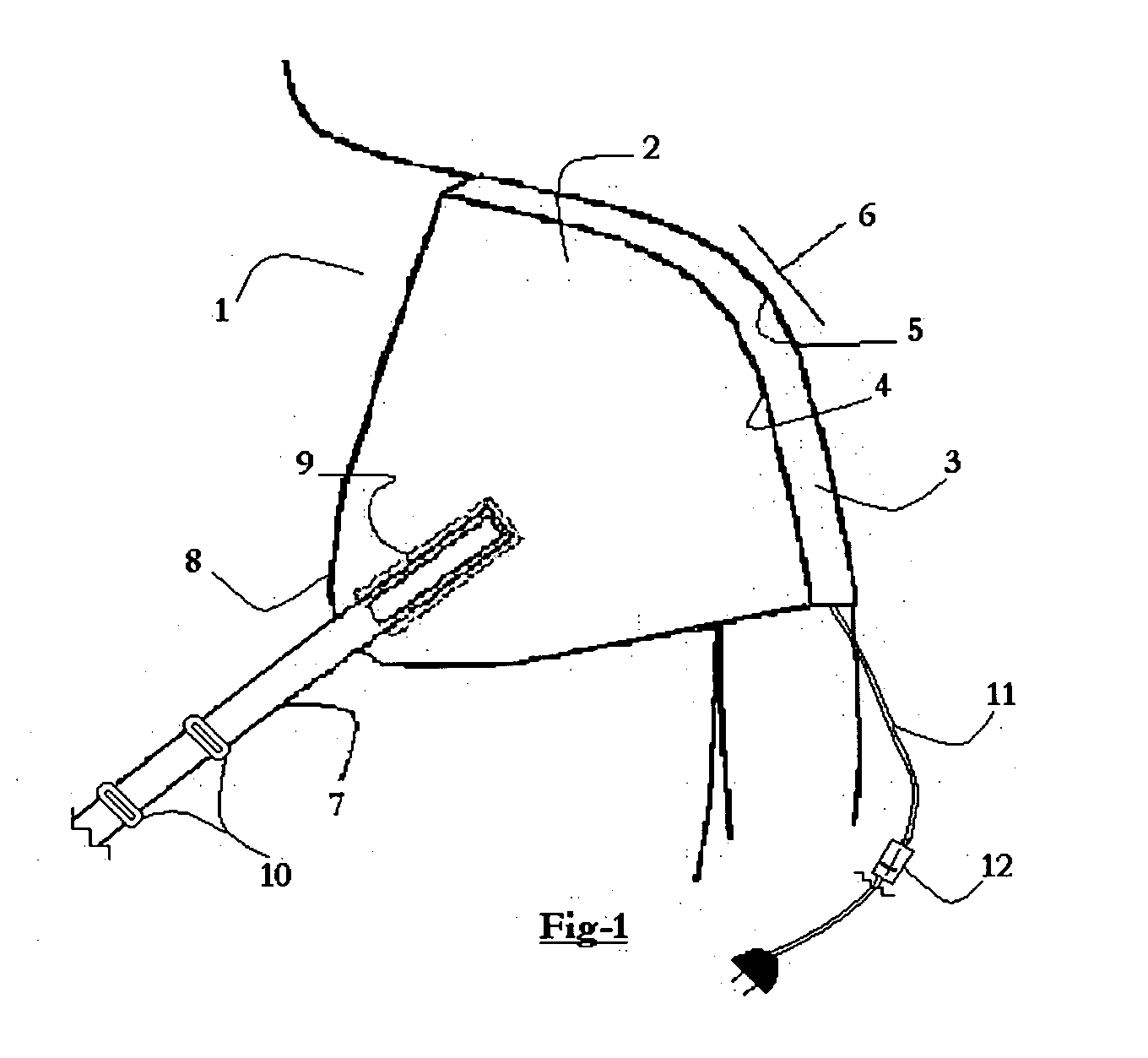

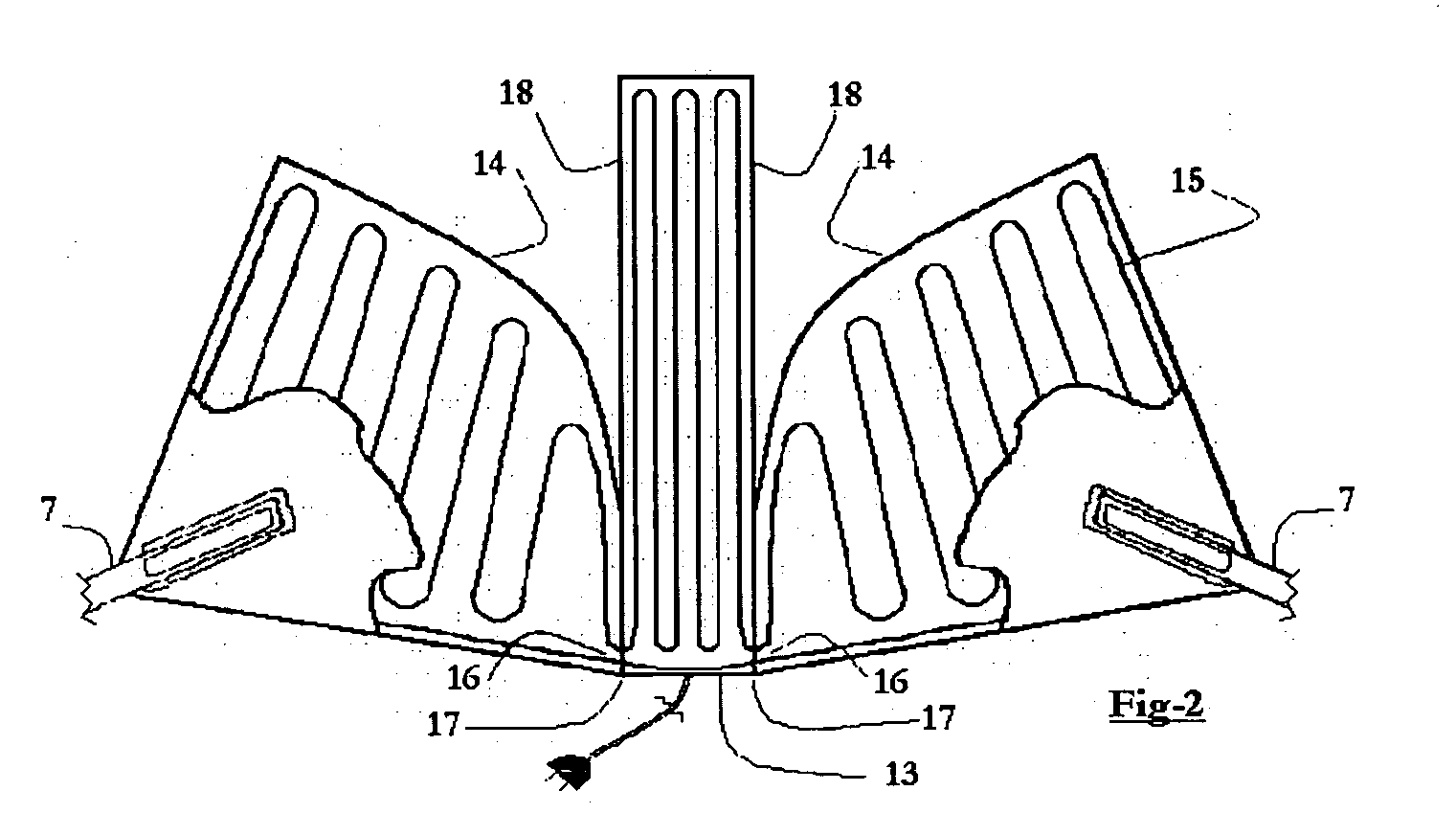

An electric heating device that is constructed in a unique fashion that allows it to be drapeable so that its three-dimensional, ‘scoop-like’ shape fits the curvature of a relaxed shoulder, a crooked knee or a crooked elbow, and is held in place by an adjustable strap whose ends are attached to the device. The heating element configuration that is contained within a singular, sealed, water-envelope tight vinyl envelope that is produced as one piece, with the three panels briefly connected at a point where the heating element wiring crosses from one panel to the other.

Owner:LEWIS DANIEL HOUSTON

Preparation of hydroresorcinol

ActiveCN1680247ALow selectivityReduce manufacturing costOrganic compound preparationPreparation by hydrogenolysisNickel catalystPalladium catalyst

Production of hydroresorcinol is carried out by taking resorcinol and inorganic alkali with amount ratio 1:1-1.5, neutralizing to be salt, hydrogenating reducing the salt under catalysis of modified skeletal nickel catalyst with molybdenum content 0.5-5%, 0.5-3Mpa and 50-150deg.C, hydrogenated and reduced product acidizing and re-arranging reacting with Bronsted acid at room-temperature, and obtaining hydroresorcinol. It achieves lower cost, higher percent conversion and selectivity.

Owner:ZHEJIANG UNIV OF TECH

Catalyst prepared by using M/Mn/Al hydrotalcite as precursor for producing benzyl formaldehyde by gaseous phase hydrogenation of benzoic acid or methoylbenzoatc

InactiveCN1473810APreparation by hydrogenolysisMetal/metal-oxides/metal-hydroxide catalystsBenzoic acidHydrogen

The present invention relates to the method of applying catalyst prepared with M / Mn / Al hydrotalcite as precursor in gaseous phase hydrogenation of benzoic acid or methyl benzoate to produce benzyl formaldehyde. The M / Mn / Al hydrotalcite precursor prepared through co-precipitation process is roasted in air or nitrogen atmosphere to obtain catalyst with high dispersivity and high specific surface area. Under the catalysis of the catalyst containing Mn, Al, M (M is Mg, Zn, Pb, Ni or Cr) and K elements, the temperature of 350-500 deg.c and pressure 0.1-1.0 MPa, proper reactant ratio and materialfeeding rate, benzoic acid or methyl benzoate is gaseous phase hydrogenated to produce benzyl formaldehyde at conversion rate and selectivity over 90 %.

Owner:FUDAN UNIV

Solid base catalyst, method for preparing the same and applications

InactiveCN101274274AHigh activitySimple washing and calcination treatmentPreparation by hydrogenolysisMetal/metal-oxides/metal-hydroxide catalystsAcetic anhydrideAdhesive

The invention provides a solid base catalyst and a preparation method thereof for preparing acetylacetone with the solid base catalyst. The solid base catalyst is prepared mainly by the components with the weight composition as follows: carrier: 100 portions of Gamma-Al2O3, load components: 0.5-8 portions of adhesive, 5-35 portions of magnesium compound, 0.5-10 portions of hydroxide and 0.5-5 portions of polyacrylamide; the invention has the beneficial effects which are mainly indicated by that: compared with the catalyst prepared by the traditional dipping method, the solid base catalyst prepared by the method of the invention directly adopts a mixed forming method, has simple preparation method and easy controlling of conditions, avoids the generation of oxide which is generated in the roasting process by adopting nitrate former body, thus generating no environmental pollution problem; when the solid base catalyst of the invention is used for catalysing the ethyl acetoacetate and acetic anhydride to synthesize acetylacetone, the yield is high, the equipment investment is little, and no three-waste exists, thus being beneficial for industrialized production.

Owner:ZHEJIANG UNIV OF TECH

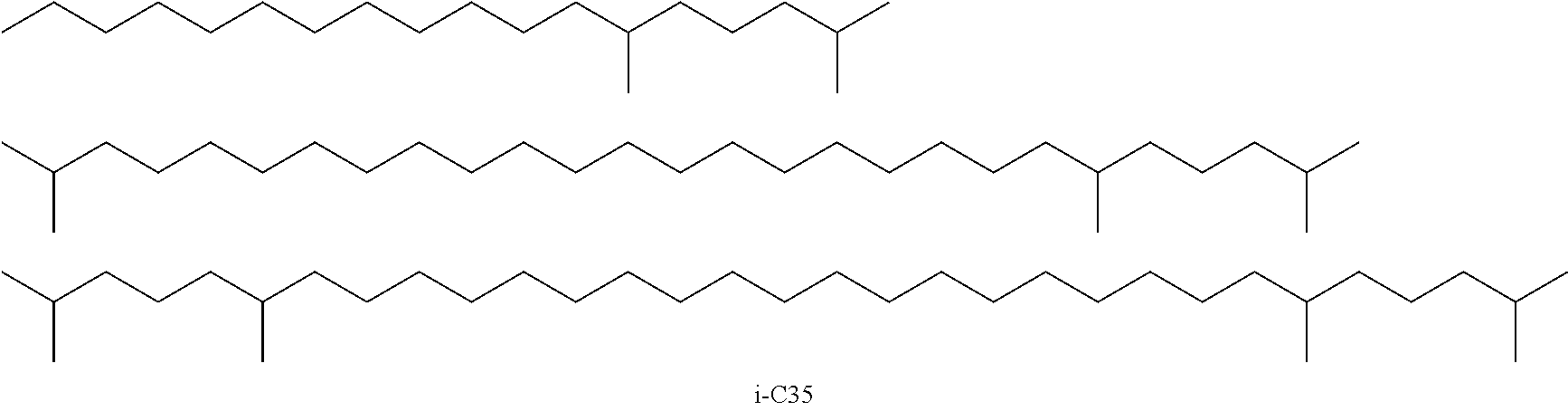

Method for Production of Hydrocarbons by Increasing Hydrocarbon Chain Length

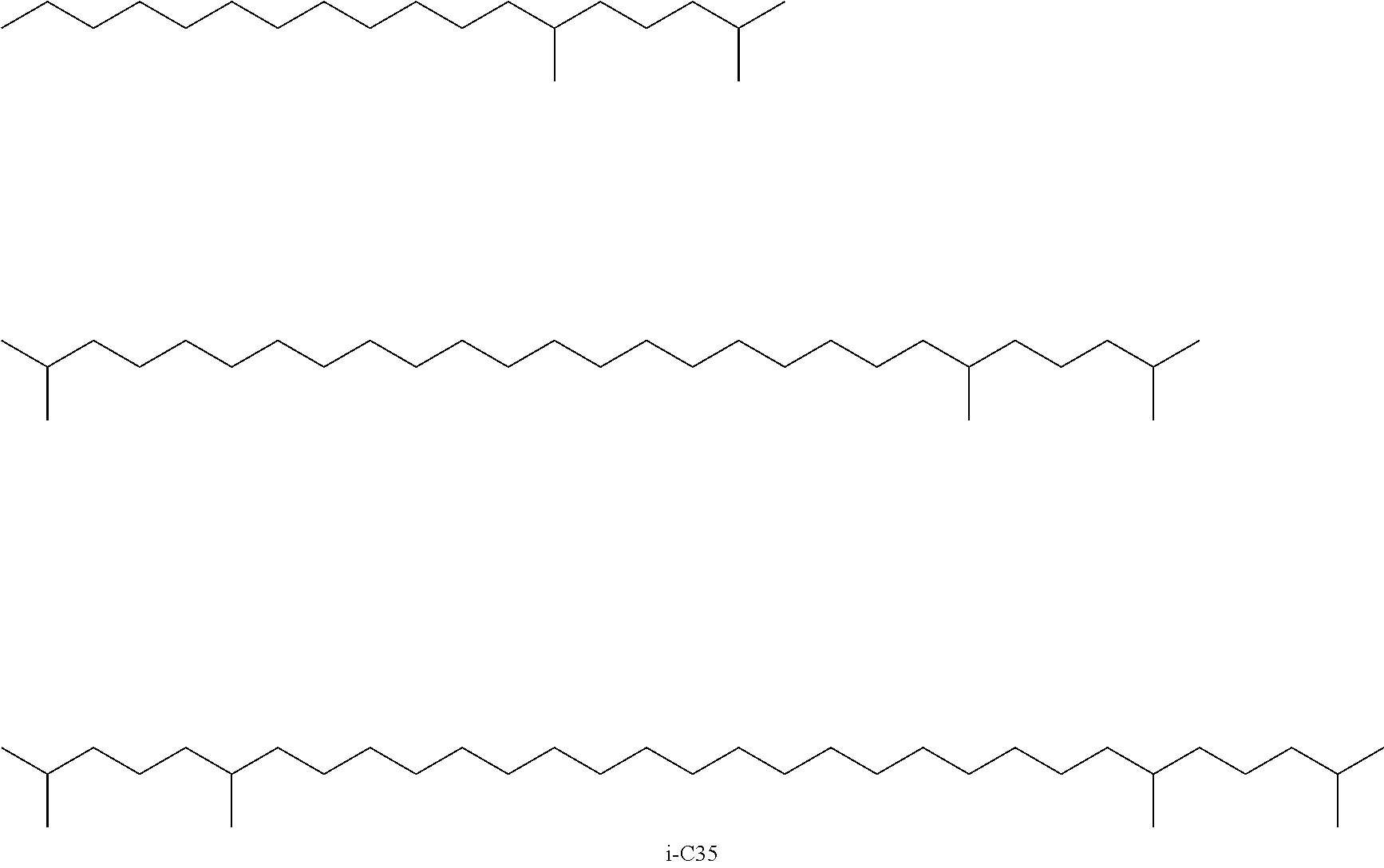

ActiveUS20150018588A1Increase chain lengthQuality improvementFatty acid chemical modificationFatty acids production/refiningHydrogen pressureChain length

The present invention provides a method for increasing hydrocarbon chain length. The method comprises providing a feedstock comprising fatty acids and / or fatty acid esters with hydrocarbon chain length below C23 into a reaction zone in which ketonisation is conducted in the presence of a hydrotreatment catalyst under hydrogen pressure. The obtained ketones have a hydrocarbon chain length of from C24 to C43. The present invention further provides a method for simultaneous production of base oil components and fuel components.

Owner:NESTE OIL OY

Processes for producing denatured ethanol

In one embodiment, the invention is to a process for producing a denatured ethanol composition comprising the steps of hydrogenating an acetic acid feed in the presence of a catalyst to form a crude ethanol product comprising ethanol, and at least one denaturant and separating the crude ethanol product in one or more separation units into a denatured ethanol composition and one or more derivative streams. The denatured ethanol composition comprises from 0.01 wt. % to 40 wt % denaturant, based on the total weight of the denatured ethanol composition.

Owner:CELANESE INT CORP

Simultaneous Production of Base Oil and Fuel Components from Renewable Feedstock

ActiveUS20150018581A1Efficient workDeactivation can be suppressedHydrocarbon by isomerisationFatty acid chemical modificationHydrogen pressureReaction zone

The present invention provides a method for simultaneous production of components suitable for production of base oil and fuel components. In the method a feedstock comprising fatty acids and / or fatty acid esters is entered into a reaction zone and subjected to a ketonisation reaction in the presence of a dual catalyst system. This system is configured to perform a ketonisation reaction and a hydrotreatment reaction, under hydrogen pressure. Subsequently ketones are obtained.

Owner:NESTE OIL OY

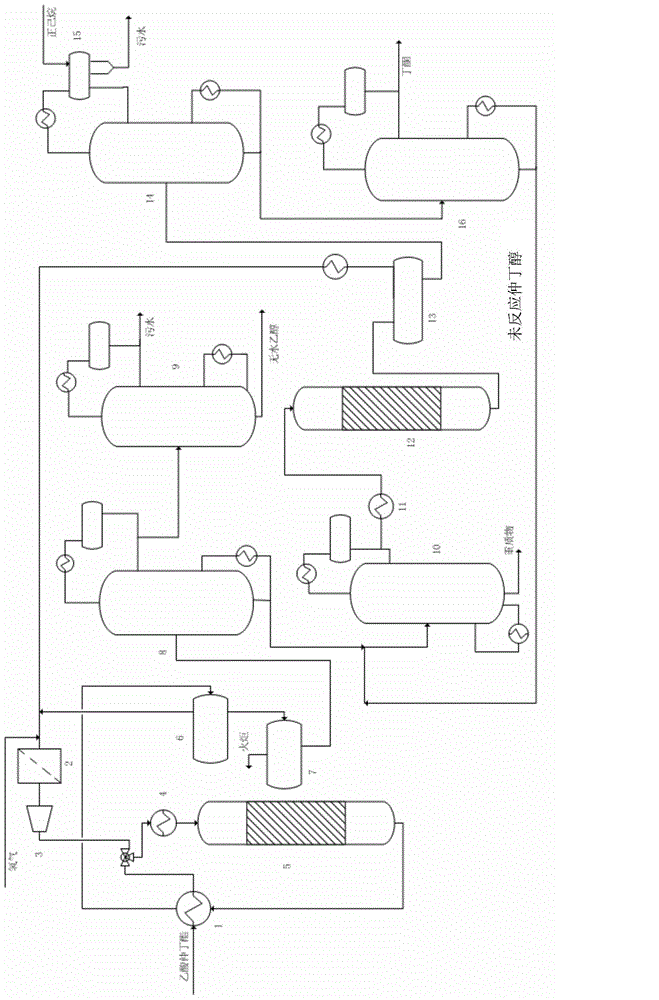

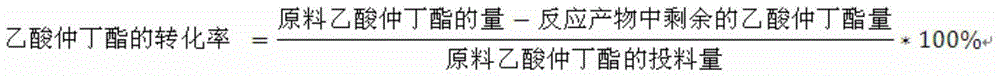

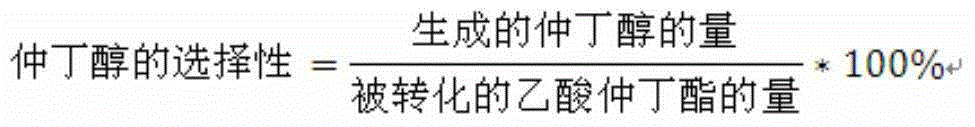

Butanone preparation and refining method

ActiveCN104370722AUniform temperature distributionHigh selectivityOrganic compound preparationPreparation by hydrogenolysisHydrogenation reactionDehydrogenation

The invention provides a butanone preparation and refining method. The method includes: (A), subjecting sec-butyl acetate and hydrogen to hydrogenation reaction in a fixed-bed reactor filled with hydrogenation catalyst; (B), feeding a hydrogenation product obtained in the step (A) into a crude alcohol separating tower for separation so as to obtain crude ethanol at the tower top, and feeding tower bottom components into a sec-butyl alcohol refining tower for refining; (C), preheating high-purity sec-butyl alcohol obtained at the tower top of the sec-butyl alcohol refining tower prior to feeding the preheated high-purity sec-butyl alcohol into a dehydrogenation reactor filled with dehydrogenation catalyst for dehydrogenation reaction; (D), feeding a dehydrogenation product obtained in the step (C) into a butanone drying tower via a buffer tank, supplementing entrainer from the top of a return tank, and removing water in crude butanone by means of azeotropic distillation; (E), feeding the dewatered crude butanone in the step (D) into a butanone refining tower for distillation so as to obtain butanone with the mass fraction above 99% from the top of the butanone refining tower.

Owner:HUNAN RUIYUAN PETROCHEM

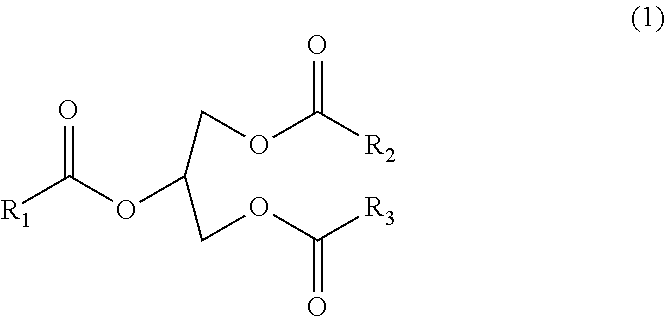

Production of fatty olefin derivatives via olefin metathesis

In one aspect, the invention provides a method for synthesizing a fatty olefin derivative. The method includes: a) contacting an olefin according to Formula Iwith a metathesis reaction partner according to Formula IIbin the presence of a metathesis catalyst under conditions sufficient to form a metathesis product according to Formula IIIb:andb) converting the metathesis product to the fatty olefin derivative. Each R1 is independently selected from H, C1-18 alkyl, and C2-18 alkenyl; R2b is C1-8 alkyl; subscript y is an integer ranging from 0 to 17; and subscript z is an integer ranging from 0 to 17. In certain embodiments, the metathesis catalyst is a tungsten catalyst or a molybdenum catalyst. In various embodiments, the fatty olefin derivative is a pheromone. Pheromone compositions and methods of using them are also described.

Owner:PROVIVI

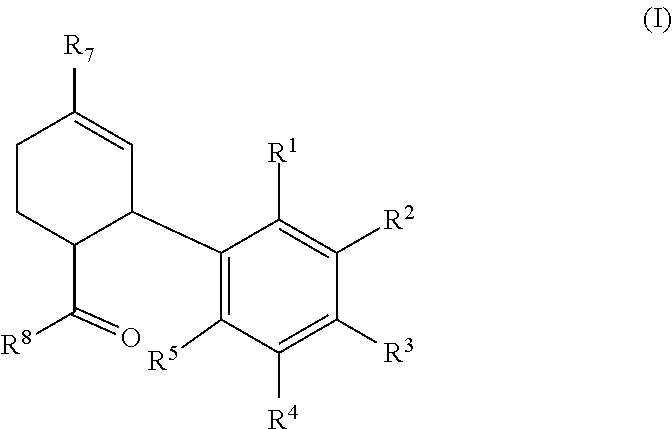

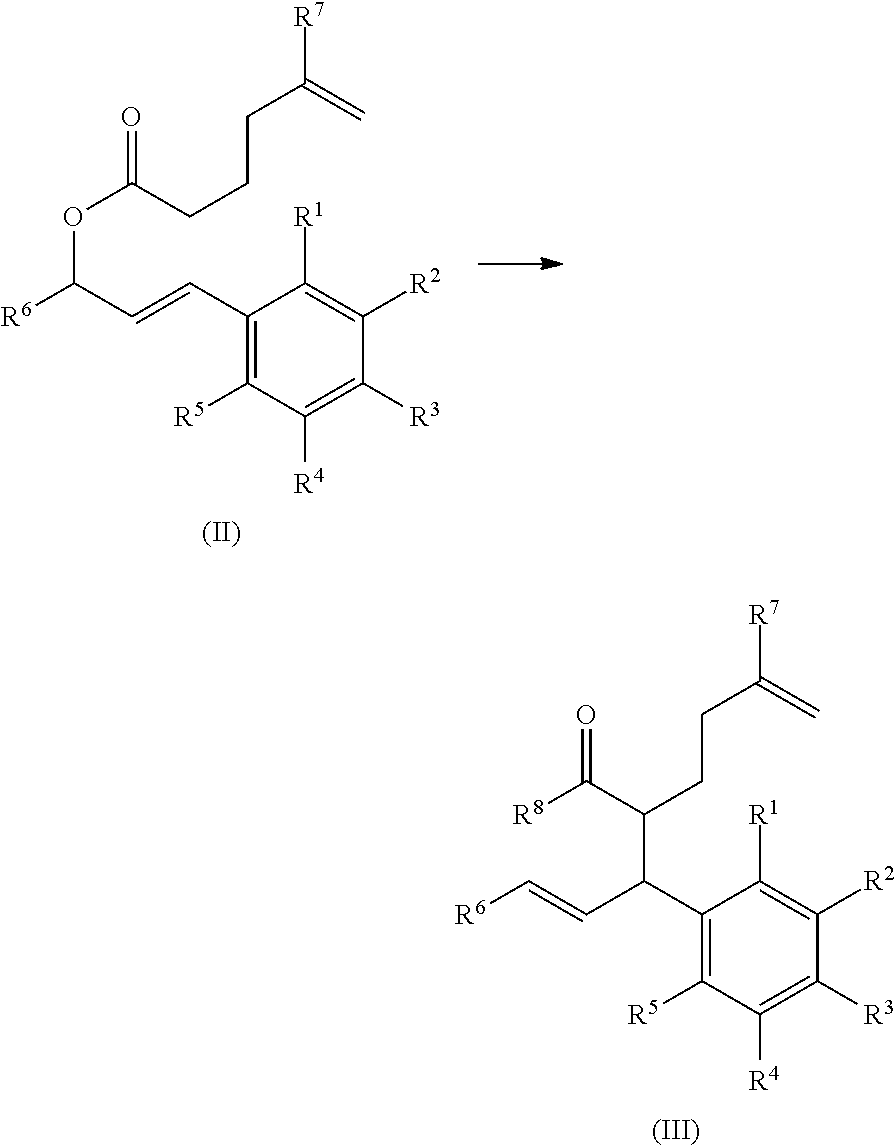

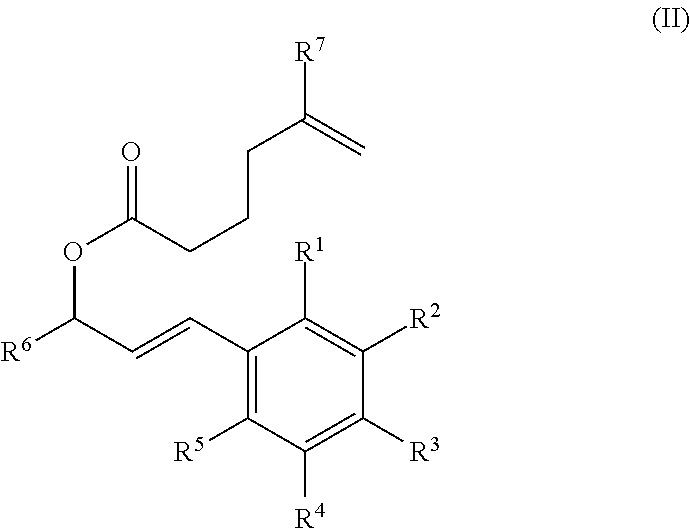

Synthesis of cannabinoids

ActiveUS20190023680A1Organic compound preparationOrganic chemistry methodsCannabinoidStereochemistry

Owner:UNIV OF SOUTH FLORIDA

Catalysts for Converting Acetic Acid to Acetone

InactiveUS20130210936A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidSilicon dioxide

The present invention relates to a process for the formation of acetone from acetic acid. The process is conducted at an elevated temperature of above 225° C. by contacting a feed stream containing acetic acid, and an optional carrier gas, with a catalyst. The catalyst comprises a support that is favorable for the production of acetone. The support may comprise titania, zirconia, ceria, silica, iron oxide, and carbon, but preferably is titania, zirconia, and ceria.

Owner:CELANESE INT CORP

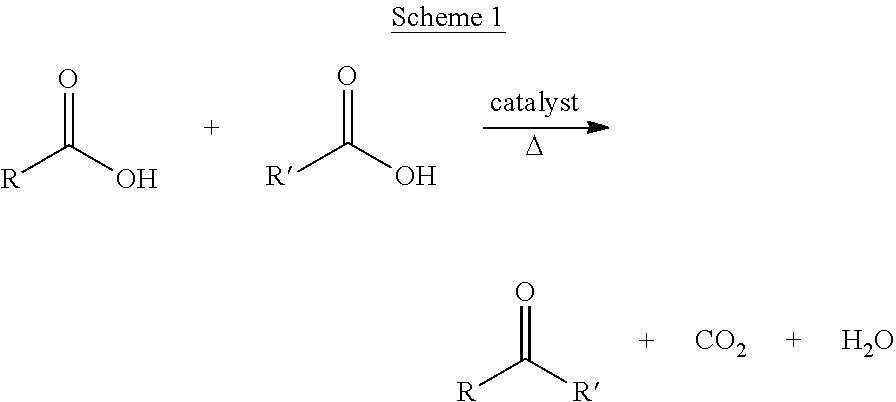

Process for producing ketones from fattyacids

ActiveUS20130324449A1Organic compound preparationPreparation by hydrogenolysisKetonic acidsGas phase

The invention relates to a process for producing ketones or hydrocarbon base oil from fatty acids preferably derived from a biological origin or other renewable source. The process is directed at making an aliphatic ketone or a mixture of aliphatic ketones having 14 to 52 carbon atoms, comprising a ketonization reaction of a fatty acid in a vapor phase with a decarboxylation-coupling catalyst to provide ketones, which can be deoxygenated to give saturated hydrocarbons, unsaturated hydrocarbons, and mixtures thereof. Base oils and transportation fuels may be produced from the process herein.

Owner:CHEVROU USA INC

Synthetic spilanthol and use thereof

ActiveUS20100184863A1Avoid volatilityFacilitate cognitionCosmetic preparationsBiocideOleoresinFood flavor

The present application provides a synthetic spilanthol flavor composition that includes (2E,6Z,8E)-N-(2-methylpropyl)-2,6,8-decatrienamide. The synthetic spilanthol composition can also contain, and at least one of (2E, 6E, 8E)-N-(2-methylpropyl)-2,6,8-decatrienamide and (2E, 6Z, 8Z)-N-(2-methylpropyl)-2,6,8-decatrienamide, the (N-(2-methylpropyl)-2,6,8-decatrienamide being present in amounts effective to impart a salivating or tingle effect while reducing the perception of off notes, as compared to the off-notes perceived upon consumption of natural spilanthol (e.g. spilanthol obtained from jambu oleoresin). Methods of increasing salivation and / or providing a tingling sensation upon consuming an orally consumable product that include adding to the product a synthetic spilanthol flavor composition are also provided. Synthetic spilanthol flavor compositions can be added to orally consumed products, such as, but not limited to, foods, beverages, pharmaceuticals, nutraceuticals, or therapeutic compositions, oral personal care products, gums (e.g. chewing gum or bubble gum), candy or lozenges.

Owner:TAKASAGO INTERNATIONAL CORPORATION

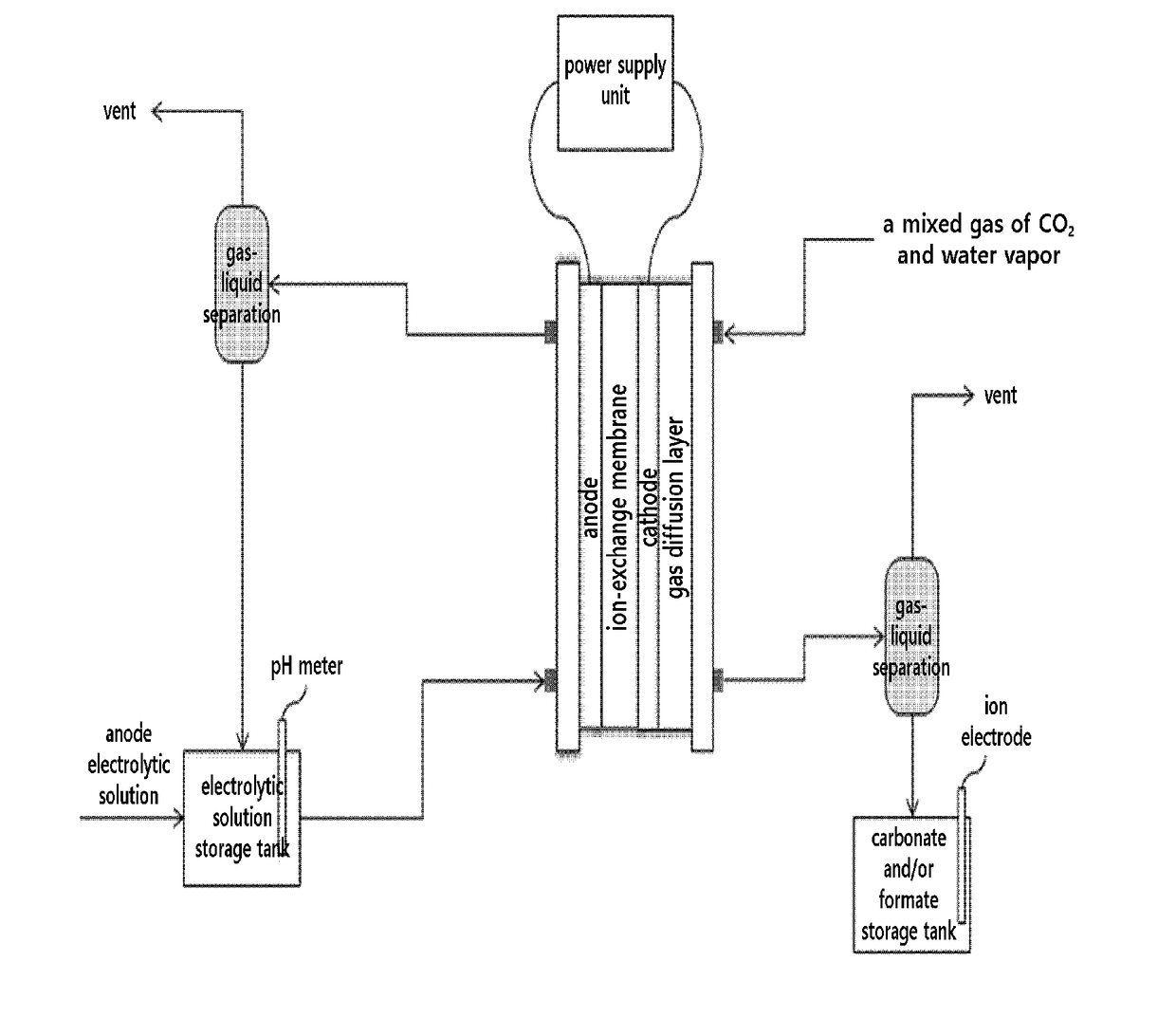

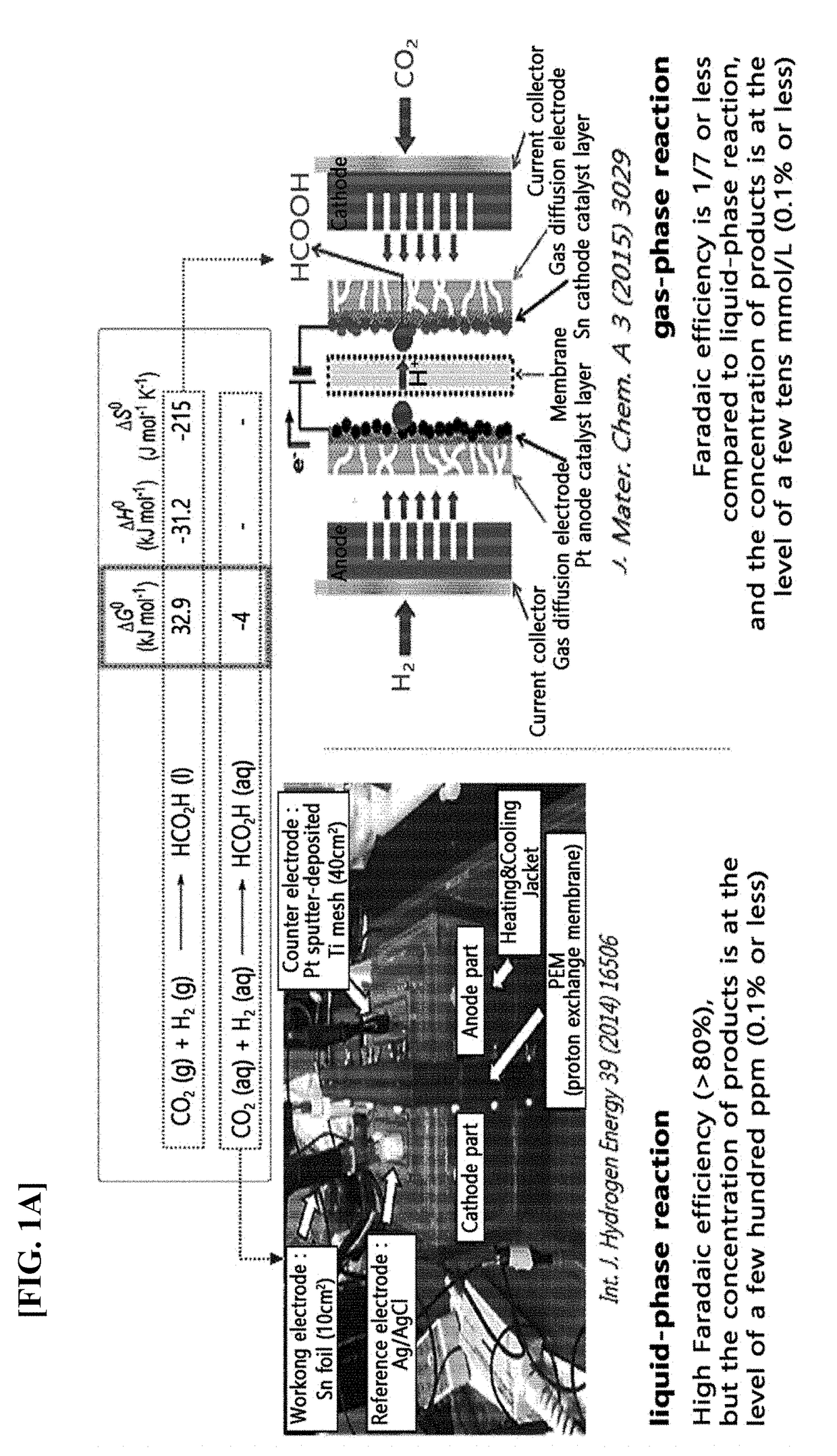

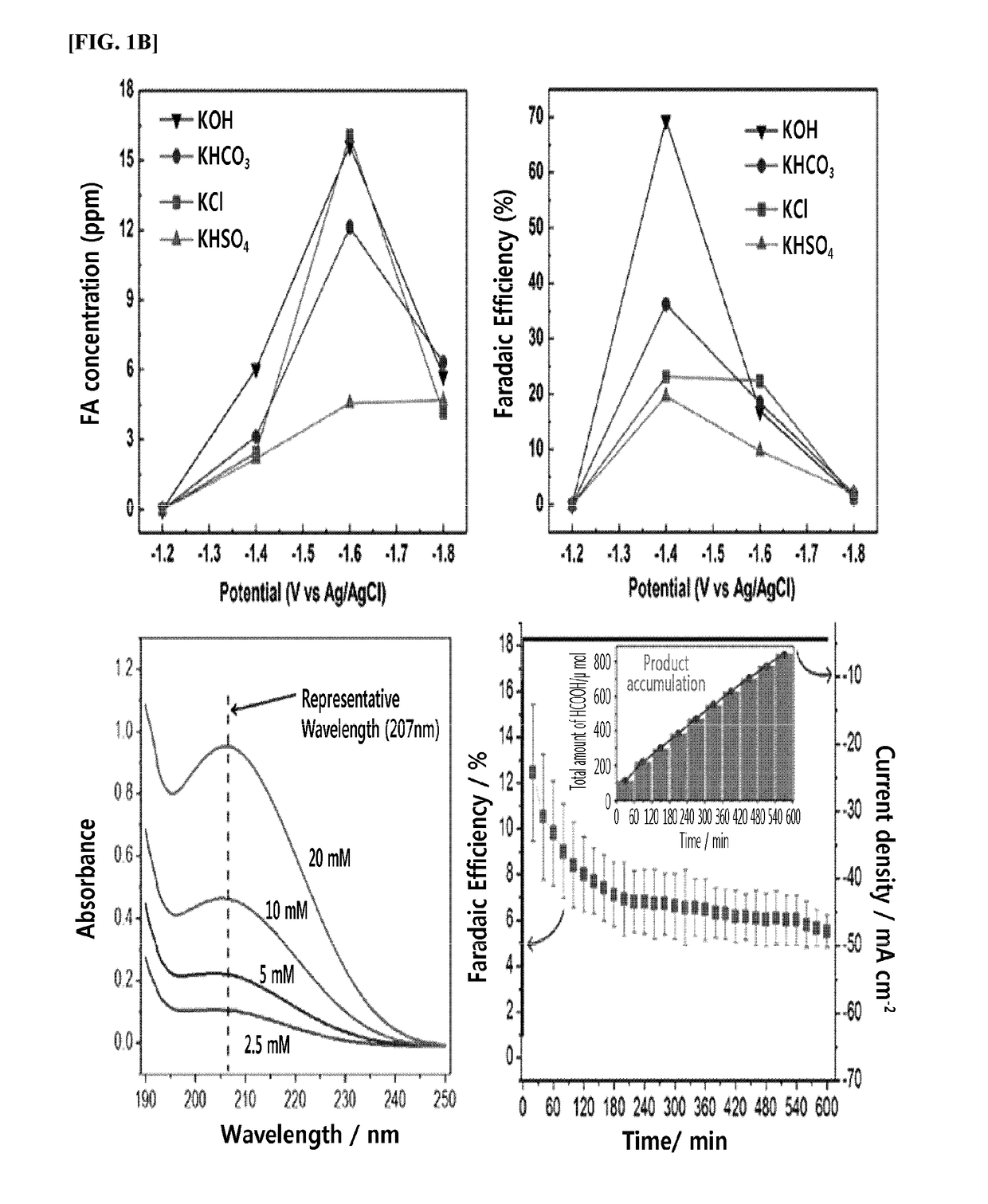

Apparatus and method of preparing carbonate and/or formate from carbon dioxide

ActiveUS20180127886A1Improve Faraday efficiencyHigh energyCellsPreparation by hydrogenolysisElectrolysisWater vapor

The present invention relates to an apparatus and method of preparing carbonate and / or formate from carbon dioxide.The apparatus of preparing carbonate and / or formate from carbon dioxide (CO2), comprising: an electrolysis reactor comprising (i) an anode which contains an aqueous solution of a Group I metal salt as an electrolytic solution, (ii) an ion-exchange membrane through which metal cations derived from the Group I metal salt and water flow from an anode to a cathode, (iii) a cathode, and (iv) a gas diffusion layer which supplies a carbon dioxide-containing gas to the cathode;a power supply unit of applying a voltage between the anode and the cathode;a first gas-liquid separator of recovering the electrolytic solution from the products formed in the anode;a second gas-liquid separator of recovering carbonate and / or formate from the products formed in the cathode;a pH meter of measuring the pH of the electrolytic solution recovered from the first gas-liquid separator;a first reactant supply unit of supplying (a) the electrolytic solution recovered from the first gas-liquid separator and (b) the aqueous solution of the Group I metal salt with which the recovered electrolytic solution is replenished according to the pH of the electrolytic solution, to the anode; anda second reactant supply unit of supplying carbon dioxide or a mixer comprising carbon dioxide and water vapor to the cathode;wherein, when a voltage is applied between the anode and the cathode,in the anode, water undergoes electrolysis to generate hydrogen ions, oxygen, and electrons, and metal cations in the Group I metal salt are substituted with the hydrogen ions, while the generated metal cations move to the cathode through the ion-exchange membrane and the electrons move to the cathode through an external electric line; andin the cathode, carbon dioxide, water, metal cations, and electrons are reacted and produce carbonate and / or formate.

Owner:KOREA INST OF ENERGY RES

Process for the preparation of acyl aromatic ethers

An improved process for the preparation of acyl aromatic ethers useful as important intermediates for drugs and pharmaceuticals by reacting an aromatic ether with an acylating agent selected from a C2-C8 acid anhydrides, employing nano- and microcrystalline zeolite beta as catalyst is disclosed.

Owner:COUNCIL OF SCI & IND RES

Method for synthesizing 2-pentanone by usig ethanol

InactiveCN1660749AHigh activityHigh selectivityPreparation by hydrogenolysisReaction temperatureKetone

A process for synthesizing pentone from ethanol features the reaction between ethanol and catalyst K-Pd / ZrO2 / MnO / ZnO in initial gas. Its advantages are high conversion rate (100%) and selectivity. Its separation method is distilling.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 5-methoxy-1-(4-trifluoromethyl phenyl)pentanone

The present invention discloses process of preparing 5-methoxyl-1-(4-trifluoromehyl phenyl) pentanone as one key intermediate for preparing depression treating medicine fluvoxamine maleate with p-trifluoromethyl benzoyl chloride and magnesium 4-methoxyl butyl halide in the presence of catalyst. The process includes following four steps: 1. preparing p-trifluoromethyl benzoyl chloride with p-trifluoromethyl benzoic acid and thionyl chloride through chlorination; 2. preparing 1-halo-4-methoxyl butane; 3. preparing Grignard reagent through reaction of 1-halo-4-methoxyl butane and metal Mg; and 4. preparing 5-methoxyl-1-(4-trifluoromehyl phenyl) pentanone through reaction of p-trifluoromethyl benzoyl chloride and the Grignard reagent. The process has the features of facile material, low cost, short reaction period, high efficiency and environment friendship.

Owner:NORTHWEST NORMAL UNIVERSITY

Catalyst for C12-C12 fat carboxylic acid ketonization and its application

ActiveCN1765490AInhibit high temperature cokingAvoid carbonizationPreparation by hydrogenolysisCatalyst activation/preparationKetonic acidsLanthanide

The invention provides a C2-C12 aliphatic carboxylic acid ketone activator. The invention uses ª†-aluminum oxide as carrier and the single, double elements, and ternary elements of lanthanum, cerium, praseodymium and neodymium of light lanthanide series rare earth as active components. While the activating carrier method comprises (1) the heat treatment process while the treatment temperature is 480-800 Deg. C; (2) azotic acid aqueous solution method while the concentration of azotic acid aqueous solution is 5-45%; (3) evacuation method. In addition, the activator is prepared via the immersion method while it can be used to C2-C12 aliphatic carboxylic acid ketone.

Owner:PETROCHINA CO LTD

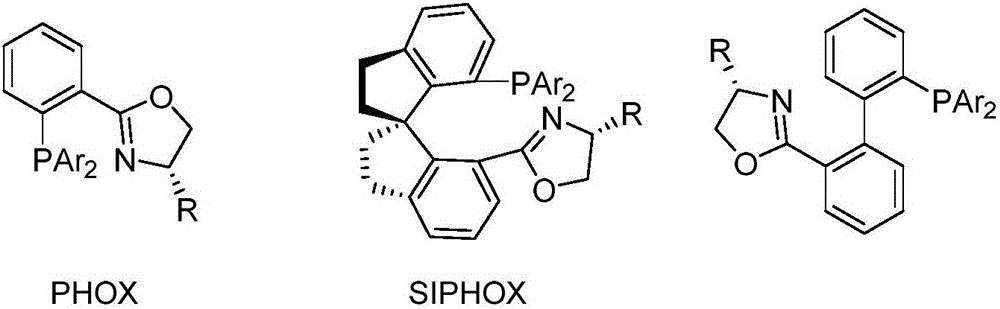

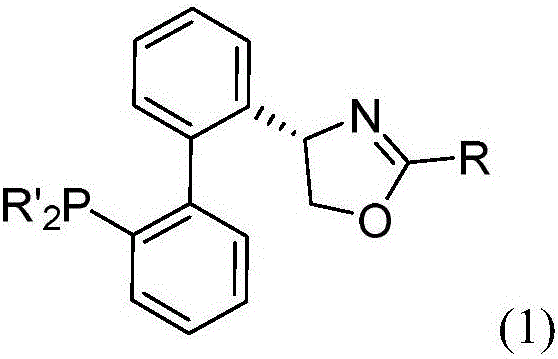

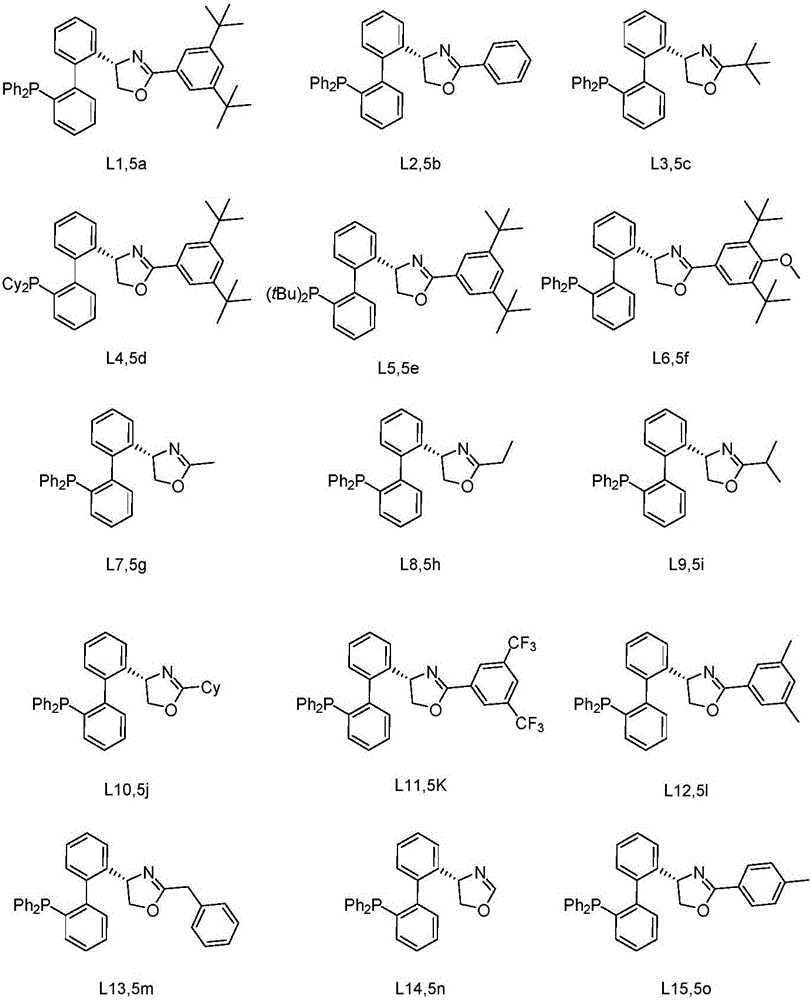

Chiral bidentate nitrogen-containing phosphine ligands and application thereof in asymmetric catalytic reaction

ActiveCN106632478AAvoid split stepsRaw materials are cheap and easy to getGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric hydrogenationNitrogen

The invention relates to bidentate nitrogen-containing phosphine ligands and an application thereof in an asymmetric catalytic reaction. The novel bidentate phosphino-oxazoline ligands are ligands with biphenyl axis instability structures, and are successfully applied to efficient high-selectivity asymmetric hydrogenation of alpha-methylcinnamic acid and derivatives of alpha-methylcinnamic acid as well as similar reactions. The ligands of the type adopt a simple synthesis route, are low in cost, realize air stability, show high activity and high selectivity to the asymmetric hydrogenation of carbon-carbon double bond and have broad industrial application prospect.

Owner:WUHAN CATALYS TECH CO LTD

Preparation method of catalyst for preparation of acetaldehyde through hydrogenation of acetic acid

InactiveCN104162446AMolecular sieve catalystsPreparation by hydrogenolysisMolecular sieveAcetic acid

The invention discloses a preparation method of a catalyst for preparation of acetaldehyde through hydrogenation of acetic acid. With silicon dioxide, a MCM-41 molecular sieve or a SBA-15 molecular sieve as a carrier, a Fe2O3 and Pt-based catalyst is prepared by adopting an isovolumetric impregnation method. The preparation method comprises the steps: (1) preparing a chloroplatinic acid solution; (2) impregnating a silicon dioxide, MCM-41 molecular sieve or SBA-15 molecular sieve carrier by using an iron nitrate solution, and mixing; (3) impregnating the silicon dioxide, MCM-41 molecular sieve or SBA-15 molecular sieve carrier impregnated by iron nitrate by using a chloroplatinic acid solution and drying; and (4) roasting the dried silicon dioxide, MCM-41 molecular sieve or SBA-15 molecular sieve carrier impregnated by using the chloroplatinic acid solution to obtain a Pt-Fe-loaded catalyst of the silicon dioxide, MCM-41 molecular sieve or SBA-15 molecular sieve carrier. The preparation method disclosed by the invention can ensure that the catalyst is prepared at more suitable temperature and pressure; and the prepared catalyst can improve the selectivity of the acetaldehyde.

Owner:EAST CHINA UNIV OF SCI & TECH

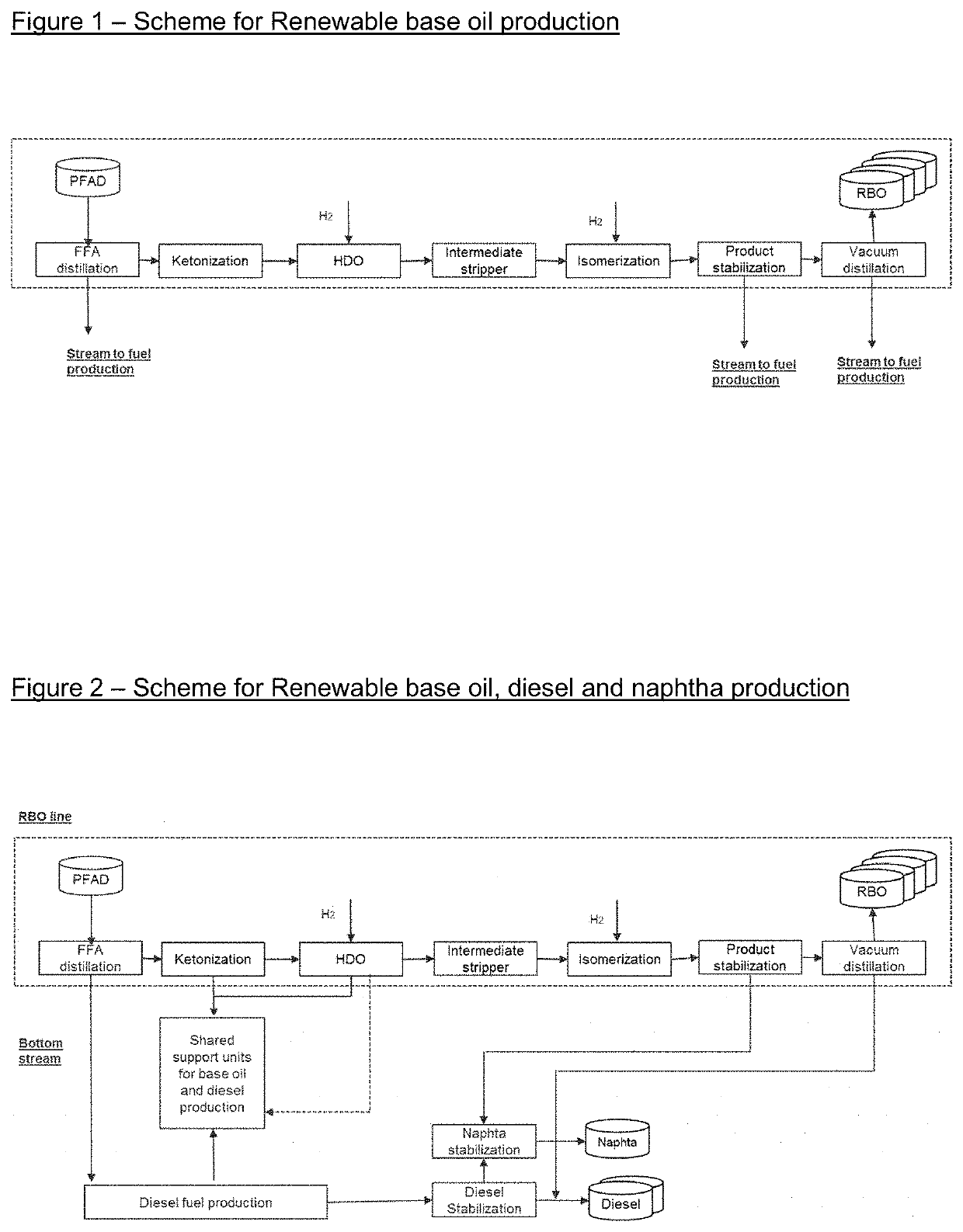

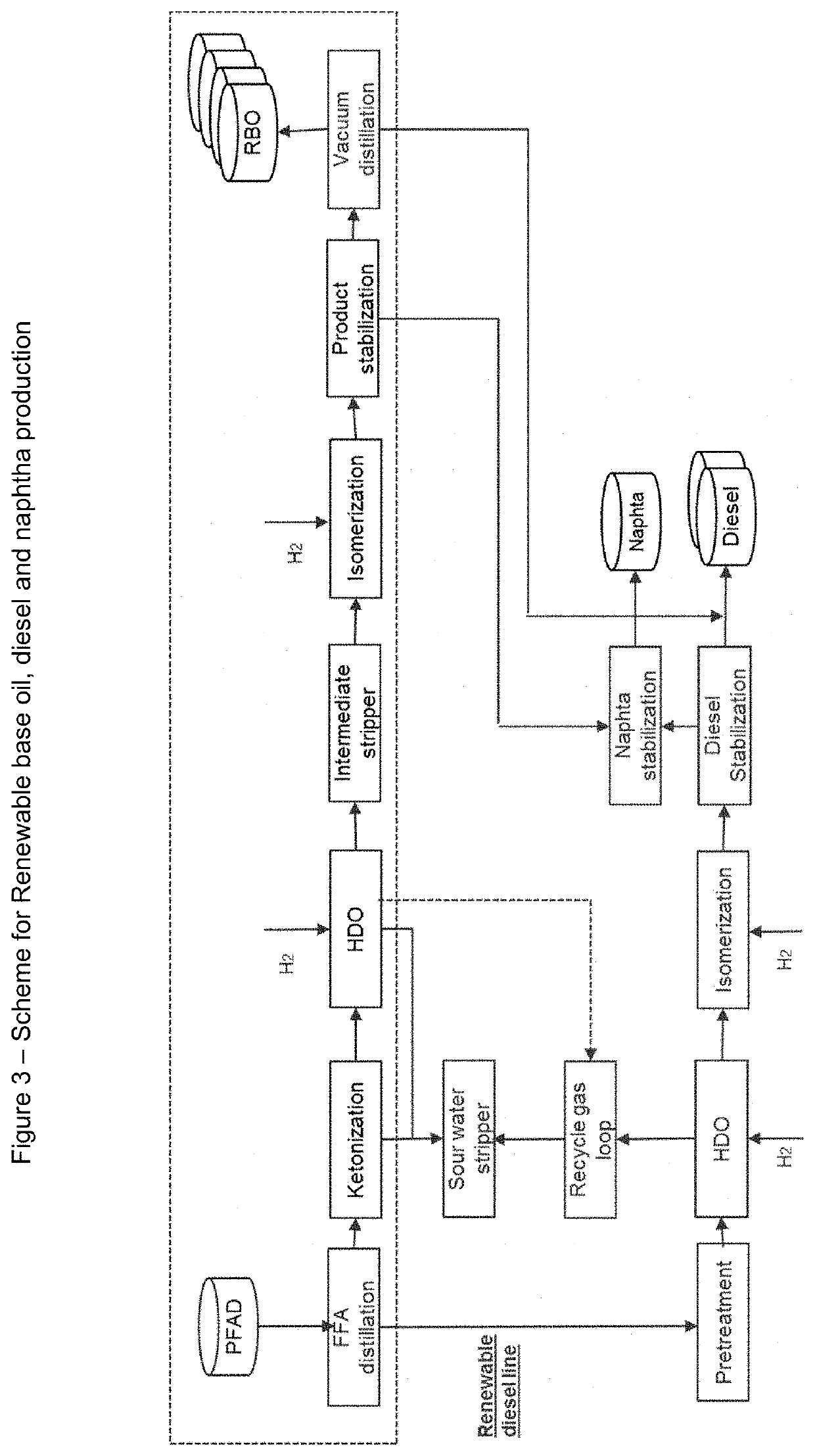

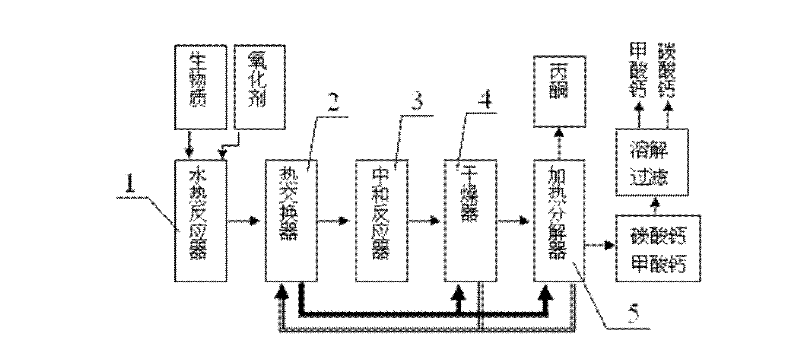

Process for the production of renewable base oil, diesel and naphtha

ActiveUS20200181504A1Reduce hydrogen consumptionLong catalyst lifeFatty acids production/refiningRefining to change hydrocarbon structural skeletonNaphthaHydrodeoxygenation

Hydrotreatment of biological oil is disclosed for producing renewable base oil and a diesel oil from low value biological oils. Low value biological oils containing free fatty acids and fatty acid esters can be processed into a renewable base oil and a renewable diesel oil in an efficient manner by first separating at least part of the free fatty acids from the feedstock and then processing separately this free acid feed in a ketonisation reaction followed by hydrodeoxygenation and hydroisomerisation reactions to yield a renewable base oil stream. The remaining free fatty acid depleted feed is processed in a separate hydrodeoxygenation and hydroisomerisation step to yield a renewable diesel stream.

Owner:NESTE OIL OY

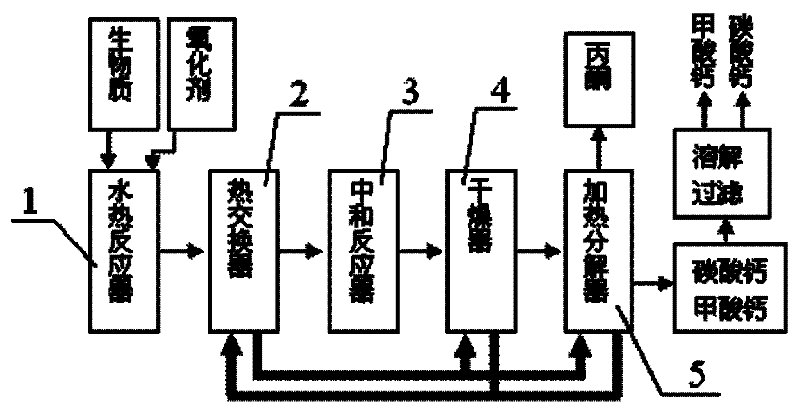

Method for preparing acetone and calcium formate by using biomass wastes

InactiveCN102219666ARealize resourcesEliminate pollutionPreparation by hydrogenolysisCarboxylic acid salt preparationCalcium formateWater insoluble

The invention relates to a method for preparing acetone and calcium formate by using biomass wastes, and belongs to the technical field of biomass waste recycling. The method comprises the following steps of: under the hydrothermal condition, performing hydrothermal oxidation of the biomass wastes to obtain acetic acid and formic acid; adding lime for neutralization to obtain a mixed solution of calcium acetate and calcium formate, drying the mixed solution to obtain a mixture of calcium acetate and calcium formate; heating the mixture so as to decompose the calcium acetate into calcium carbonate and acetone, and recovering the obtained acetone through condensation; and separating water soluble calcium formate from water insoluble calcium carbonate by using a dissolution-filtration method. Compared with the prior art, the method has the advantages of successfully recycling the biomass wastes, not causing secondary pollution and having high practical application value.

Owner:TONGJI UNIV

Hydrogenation of formic acid to formaldehyde

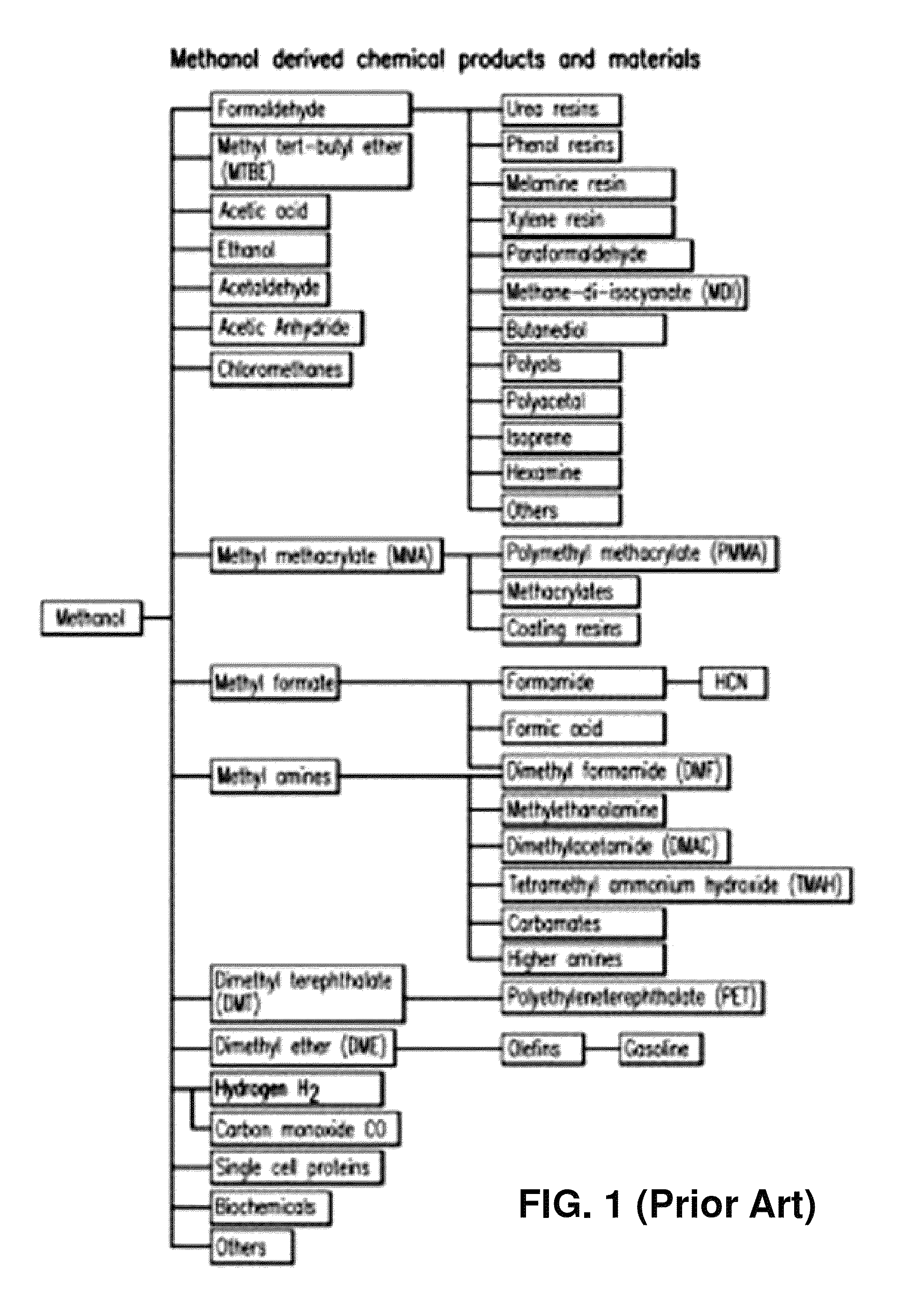

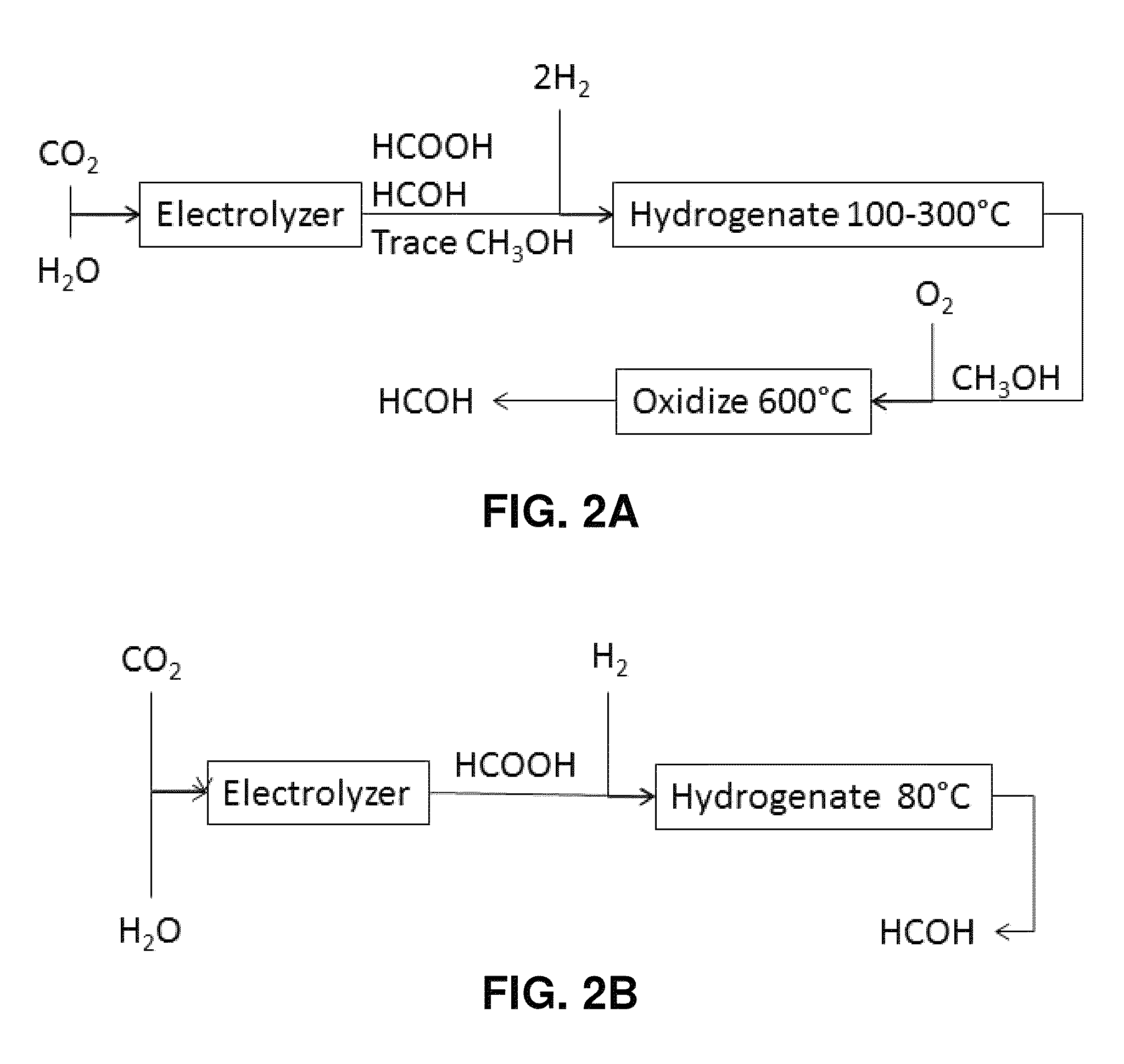

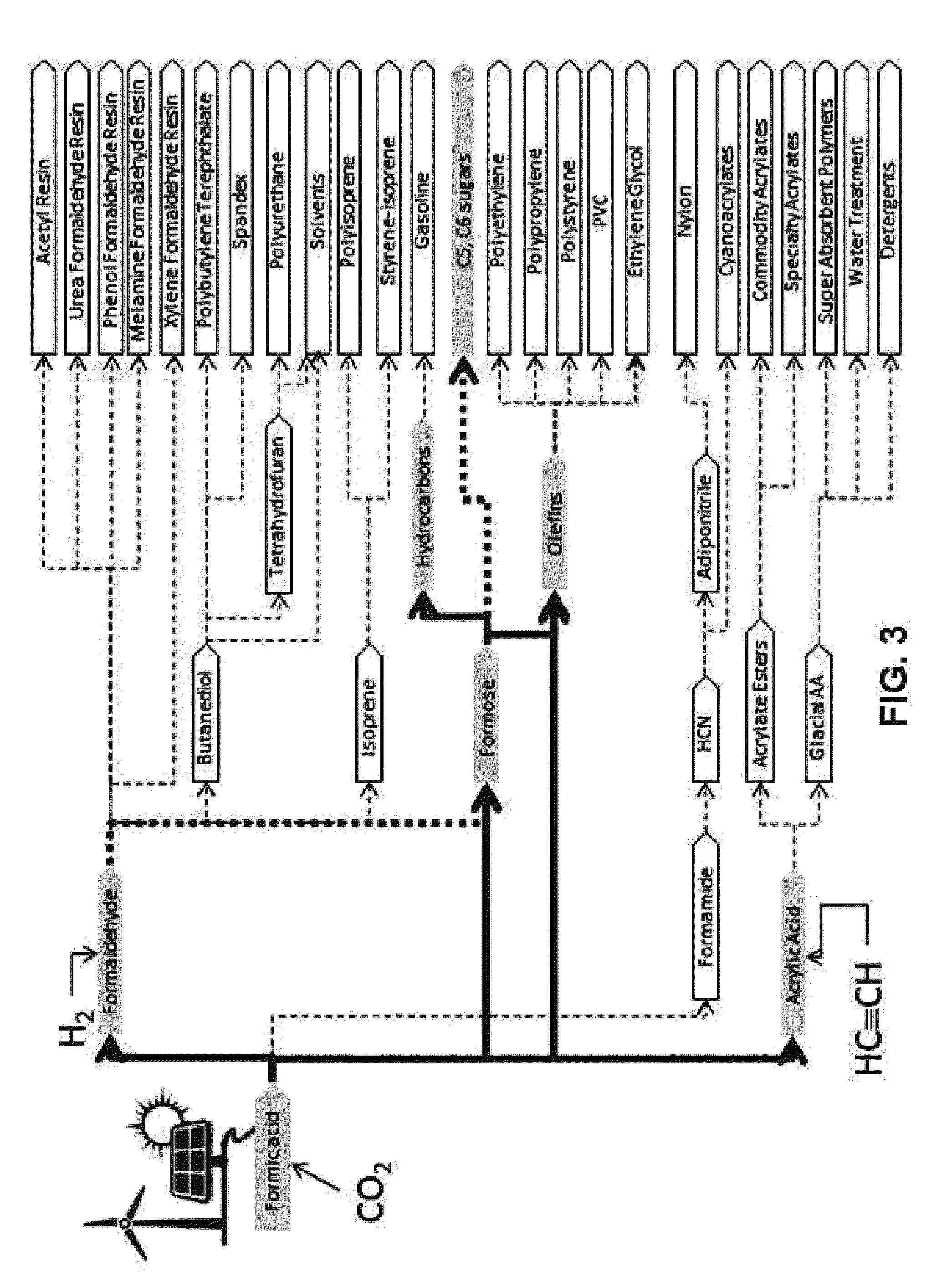

An environmentally beneficial process for the production of fuels and chemicals employs carbon dioxide from a natural source or from an artificial chemical source that would otherwise be discharged into the environment. The carbon dioxide is converted to formic acid and the formic acid is then non-biologically converted to fuels and / or chemicals without the intermediate process of hydrogenating the formic acid to methanol or reacting the formic acid with ammonia to form formamide. In the present process, formic acid is converted to one of seven primary feedstocks: formaldehyde, acrylic acid, methane, ethylene, propylene, syngas, and C5-C7 carbohydrates. The formaldehyde, acrylic acid, methane, ethylene, propylene, syngas and / or short chain carbohydrates can either be used directly, or can be converted into a wealth of other products.

Owner:DIOXIDE MATERIALS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com