Method for preparing acetone and calcium formate by using biomass wastes

A technology of biomass waste and calcium formate, applied in the field of biomass waste resource utilization, can solve problems such as unreasonable disposal methods, environmental pollution, resource waste, etc., to achieve resource utilization, eliminate environmental pollution, and reduce production costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

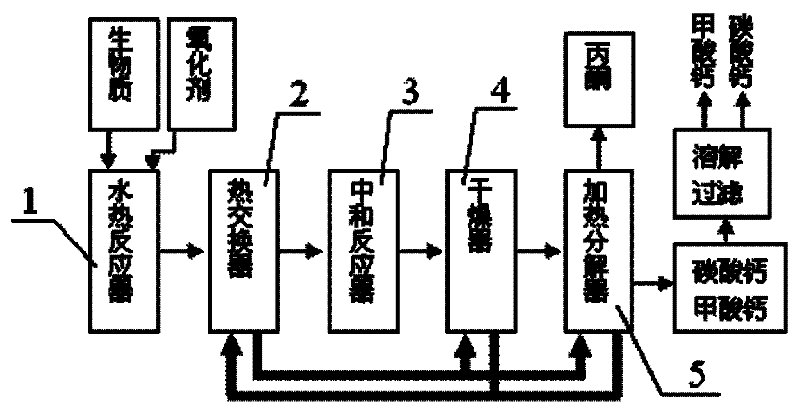

Image

Examples

Embodiment 1

[0028] Preparation of Acetone and Calcium Formate from Cellulose

[0029] With cellulose as reactant, H 2 o 2 As an oxidizing agent, Ca(OH) 2 As a catalyst, it is placed in a SUS 316 water-heated tubular reactor, and the water filling rate is controlled to be 35%. The hydrothermal oxidation reaction is carried out at a temperature of 200-450° C. and a pressure of 4-35 MPa. After reacting for 3 minutes, the reactor was quickly taken out, cooled, and the reaction was terminated. Quantitative analysis by HPLC showed that the yields of acetic acid and formic acid were 8-36.5% and 1-5.7%, respectively, and acetic acid and formic acid accounted for 96.1-98.3% of the total product.

[0030] Lime is added to the hydrothermal reaction product to obtain a mixed solution of calcium formate and calcium acetate, which is dried to obtain a mixture of calcium acetate and calcium formate. Control the temperature at 150-170°C, heat the mixture of calcium acetate and calcium formate, conde...

Embodiment 2

[0032] Production of Acetone and Calcium Formate from Vegetable Wastes

[0033] Vegetable waste is used as the reactant. Before the reaction, the vegetable waste should be pretreated by washing, crushing and sieving. After pretreatment, the particle size of the vegetable waste is 80-200 mesh. to compress O 2 or O 3 As an oxidizing agent, Ca(OH) 2 As a catalyst, it is placed in a SUS316 water heat pipe reactor, and the water filling rate is controlled to be 35%. The hydrothermal oxidation reaction is carried out at a temperature of 200-350° C. and a pressure of 4-25 MPa. After reacting for 1 min, the reactor was quickly taken out, cooled, and the reaction was terminated. Quantitative analysis by HPLC showed that the yields of acetic acid and formic acid were 6-23.6% and 0.8-4.2%, respectively, and acetic acid and formic acid accounted for 92.4-97.2% of the total product.

[0034] Subsequent steps are the same as in Example 1. The analysis results show that based on the ac...

Embodiment 3

[0036] Preparation of Acetone and Calcium Formate from Phenol Wastewater

[0037] Using phenol in phenol-containing wastewater as a reactant, the phenol-containing wastewater, oxidant H 2 o 2 and catalyst Ca(OH) 2 After mixing and preheating, it is input into a continuous flow tubular hydrothermal reactor. The hydrothermal oxidation reaction is carried out at a temperature of 200-300°C and a pressure of 5-20 MPa. The residence time of the reaction material in the tubular hydrothermal reactor is 1.5 minutes. After the reaction is completed, the product flows out through the back pressure valve. Quantitative analysis by HPLC showed that the yields of acetic acid and formic acid were 28.6% and 4.2%, respectively, and acetic acid and formic acid accounted for 95.6% of the total product.

[0038] Subsequent steps are the same as in Example 1. The analysis results show that based on the acid content in the mixed solution of acetic acid and formic acid, the yield of acetone can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com