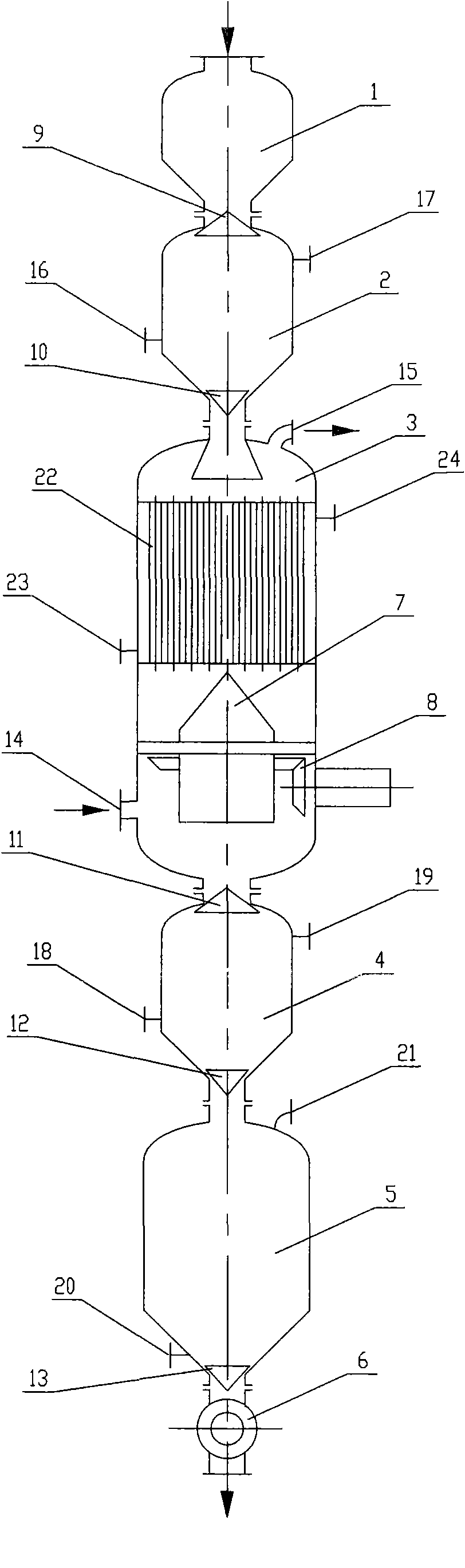

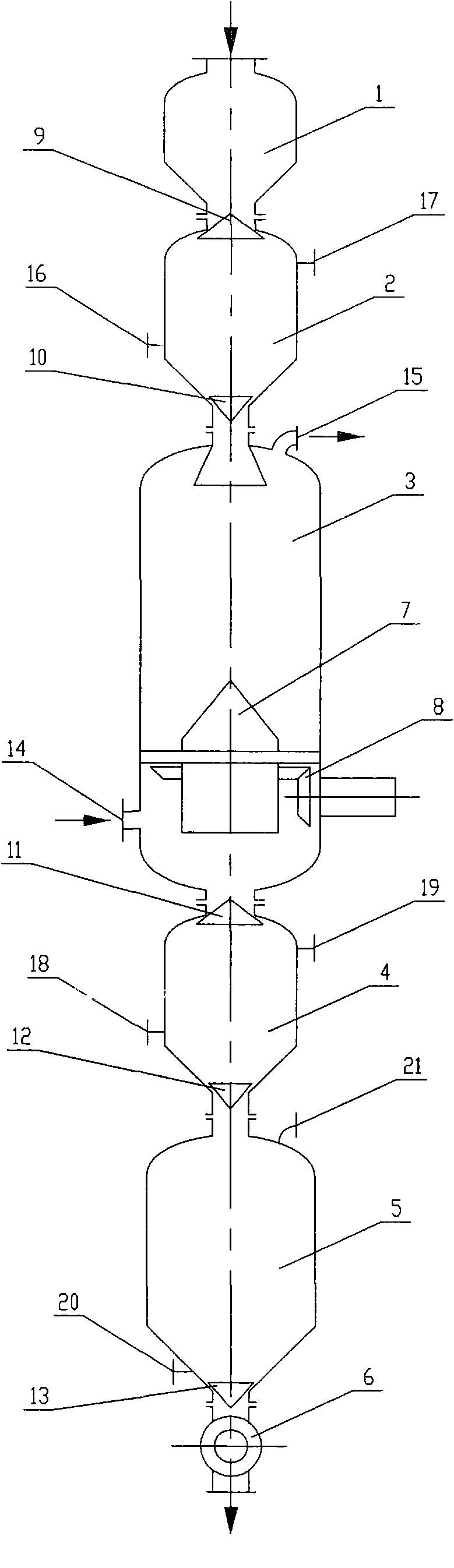

Moving bed reactor device with catalyst capable of reacting continuously and being regenerated and use method thereof

A moving bed reactor and catalyst technology, applied in chemical instruments and methods, catalytic cracking, cracking, etc., to achieve the effect of flexible adjustment and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Using catalytic cracking gasoline (FCC) modification to produce high-octane gasoline

[0040] An important problem facing FCC gasoline is the high content of olefins, reaching 40%-50%, while the national gasoline standard requires less than 35%. The IV standard and the standard trend in some developed countries are below 10%. The essence of FCC gasoline modification is to reduce the olefins in the gasoline fraction, that is, to further crack the olefins to generate ethylene, propylene, butene and other low-carbon olefins. The technical problem of the currently used molecular sieve catalyst cracking FCC gasoline process is that the catalyst surface and voids will be carbonized during the catalytic cracking reaction process, resulting in a decrease in catalyst activity, and the deactivated catalyst needs to be regenerated by burning carbon to improve the catalyst. Service life. Therefore, it is ideal to choose a moving bed reaction method and equipment that can ...

Embodiment 2

[0064] Example 2: Methanol to Aromatics (MTA)

[0065] Methanol to aromatics (MTA) is currently in a very hot period. Due to the vigorous development of coal chemical industry and coal-to-methanol in recent years, methanol-to-aromatics (MTA) is a good choice as a further expanded chemical product of methanol. The catalyst of methanol to aromatics (MTA) is currently also the choice of molecular sieve. Catalytic cracking is used. Because of the carbon formation in the reaction process, the catalyst has to be regenerated repeatedly to ensure its activity. This process naturally selects the catalyst to continuously react with The form of regenerated moving bed is ideal. This example still uses the ZSM-5 type molecular sieve catalyst made by the Shanxi Institute of Coal Chemistry, Chinese Academy of Sciences (see Patent No. 200710185473.3 for the specific preparation method).

[0066] Catalyst parameters:

[0067] Catalyst shape spherical

[0068] Catalyst size 0.2-0.5μm

[0069] A catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com