Method for preparing tert-butyl ether

A technology of tert-butyl ether and No. 1, applied in the field of organic chemical industry, can solve the problems of poor selectivity of mono-tert-butyl ether, harsh equipment material requirements, high pressure requirements, etc., and achieves improved conversion rate, high conversion rate, and high selection. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

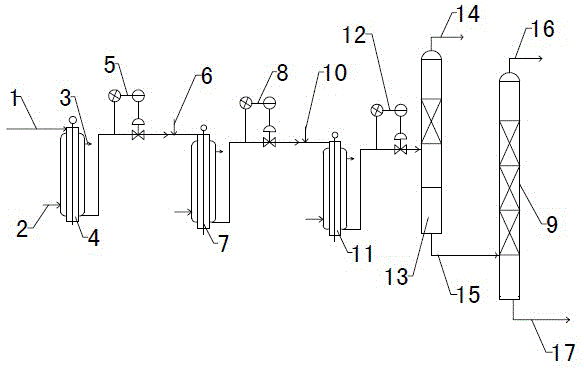

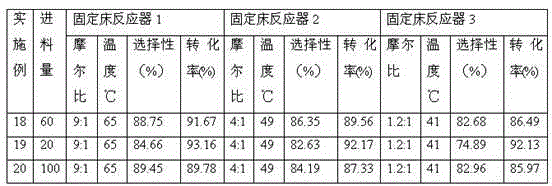

[0032] The metered 99% chemically pure ethylene glycol and mixed C4 (mass content of isobutylene 27.16%) were respectively injected into the first fixed bed pre-reactor equipped with resin catalyst and controlled at 60~65°C by plunger pump, and then Use a metering pump to inject the reaction product and additional mixed carbon dioxide into the second fixed-bed reactor equipped with a resin catalyst and whose temperature is controlled at 45~50°C, and then inject the further reaction product and additional mixed carbon dioxide into the second fixed-bed reactor with a metering pump Injected with resin catalyst, temperature control

[0033] The third fixed-bed reactor was manufactured at 38-42°C. The length of the fixed-bed reactor was 1500m, the inner diameter of the reactor was 8mm, and the loading amount of the catalyst was 100ml on a dry basis. The test results are shown in Table 1 above.

[0034] Table 1 Reaction results of resin as catalyst

[0035]

[0036] Note: The f...

Embodiment 9~12

[0038] Compared with Examples 1-8, only the content of isobutene (57.95%) in the mixed C4 was changed, and the conditions of the fixed-bed reactor and other conditions were unchanged. The test results are shown in Table 2.

[0039] Table 2, the reaction result of changing the concentration of isobutene in mixed carbon four

[0040] .

Embodiment 18~20

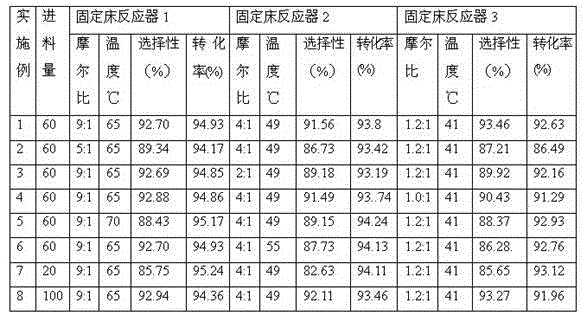

[0046] The metered 99% chemically pure ethylene glycol and mixed C4 (mass content of isobutylene: 27%) are respectively injected into the first fixed bed equipped with molecular sieve catalyst, the temperature is controlled at 60~65°C, and the reaction pressure is 1.5MPa. Pre-reactor; then the reaction product and additional mixed carbon four are injected into the second fixed-bed reactor with a molecular sieve catalyst, temperature controlled at 45~50°C, and reaction pressure 1.5MPa (alcohol isobutene molar ratio 3 : 1); and then inject the further reaction product and additional mixed carbon four into the third fixed-bed reactor equipped with molecular sieve catalyst, temperature controlled at 38~42°C, and reaction pressure 1.5MPa with a metering pump. The length of the fixed-bed reactor is 1500m, the inner diameter of the reactor is 8mm, and the loading amount of the catalyst is 100ml on a dry basis. The test results are shown in Table 4.

[0047] Table 4, the reaction re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com