Carrier for immobilizing enzyme, use thereof, and carrier immobilized with enzyme

A technology for immobilizing enzymes and carriers, which is applied in the fields of enzyme-immobilized carriers, enzyme-immobilized carriers, and polymer microspheres, and can solve the problems of poor mass transfer performance of synthetic polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

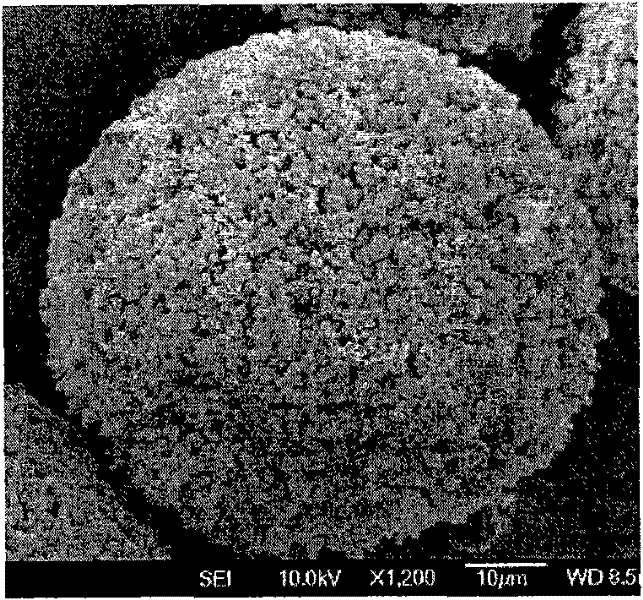

[0045] Embodiment 1 [the most probable pore diameter is the ultra-large pore PST microsphere of 313nm]

[0046] Super macroporous polystyrene (PST) microspheres ( figure 2 ), the pores of the carrier less than 90nm account for 8% of the total porosity of the microspheres, the pores of more than 90nm and less than 100nm account for 12% of the total porosity of the microspheres; the pores of more than 100nm and less than 300nm account for 39% of the total porosity of the microspheres, The pores above 300nm and less than 500nm accounted for 35% of the total porosity of the microspheres, the pores above 500nm and less than 800nm accounted for 5% of the total porosity of the microspheres, and the most probable pore diameter was 313nm. The average particle size is 100 microns, the porosity is 60%, and the specific surface area is 34m 2 / g, the degree of crosslinking is 12%.

Embodiment 2

[0047] Embodiment 2 [the most probable aperture is 104nm PST microsphere)

[0048] Super-macroporous polystyrene microspheres, the pores of the carrier less than 90nm account for 10% of the total pores of the microspheres, the pores of more than 90nm and less than 100nm account for 30% of the total pores, the pores of more than 100nm and less than 300nm account for 40% of the total pores of the microspheres, 300nm The pores above and less than 500nm account for 10% of the total porosity of the microspheres, and the most probable pore diameter is 104nm. The average particle size is 40 microns, the porosity is 60%, and the specific surface area is 86m 2 / g, the degree of crosslinking is 25%.

Embodiment 3

[0049] Embodiment 3 [most probable aperture is 400nm PGMA microsphere]

[0050] Super-macroporous polyglycidyl methacrylate (PGMA) microspheres ( image 3 ), the pores of the carrier less than 90nm account for 4% of the total porosity of the microspheres, the pores of more than 90nm and less than 100nm account for 8% of the total porosity of the microspheres; the pores of more than 100nm and less than 300nm account for 30% of the total porosity of the microspheres, The pores above 300nm and less than 500nm account for 45% of the total porosity of the microspheres, the pores above 500nm and less than 800nm account for 10% of the total porosity of the microspheres, and the pores of 800-1000nm account for 3% of the total porosity of the microspheres. The available aperture is 400nm. The average particle size is 30 microns, the porosity is 70%, and the specific surface area is 29m 2 / g, the degree of crosslinking is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com