Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Increase water vapor content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

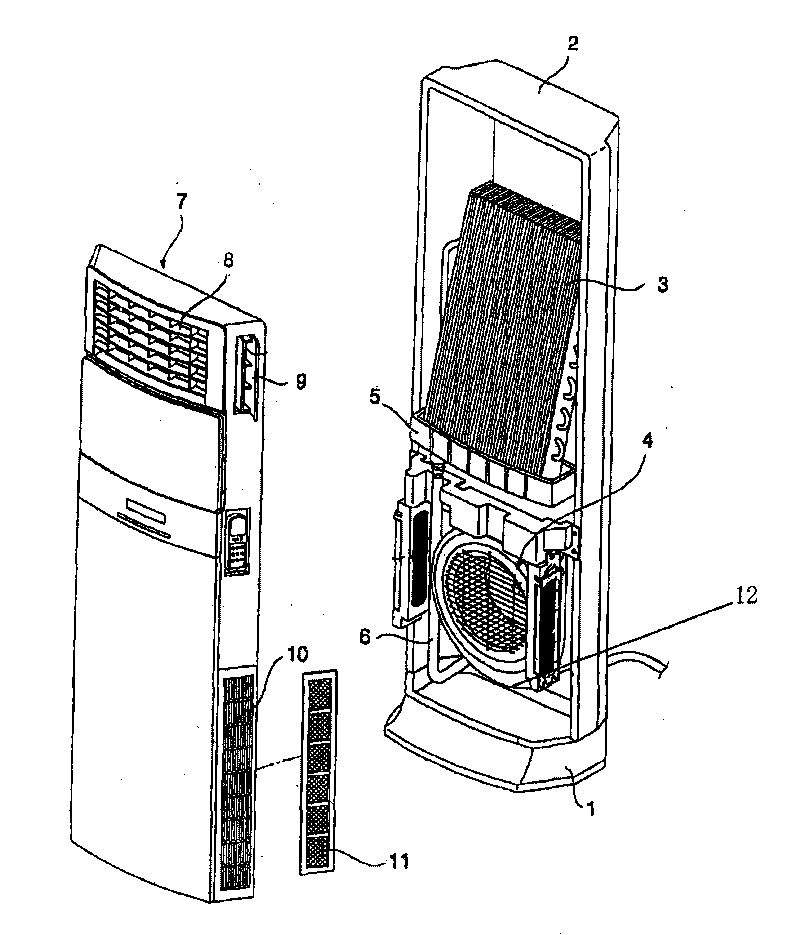

Humidification air conditioner and control method for humidification air conditioner

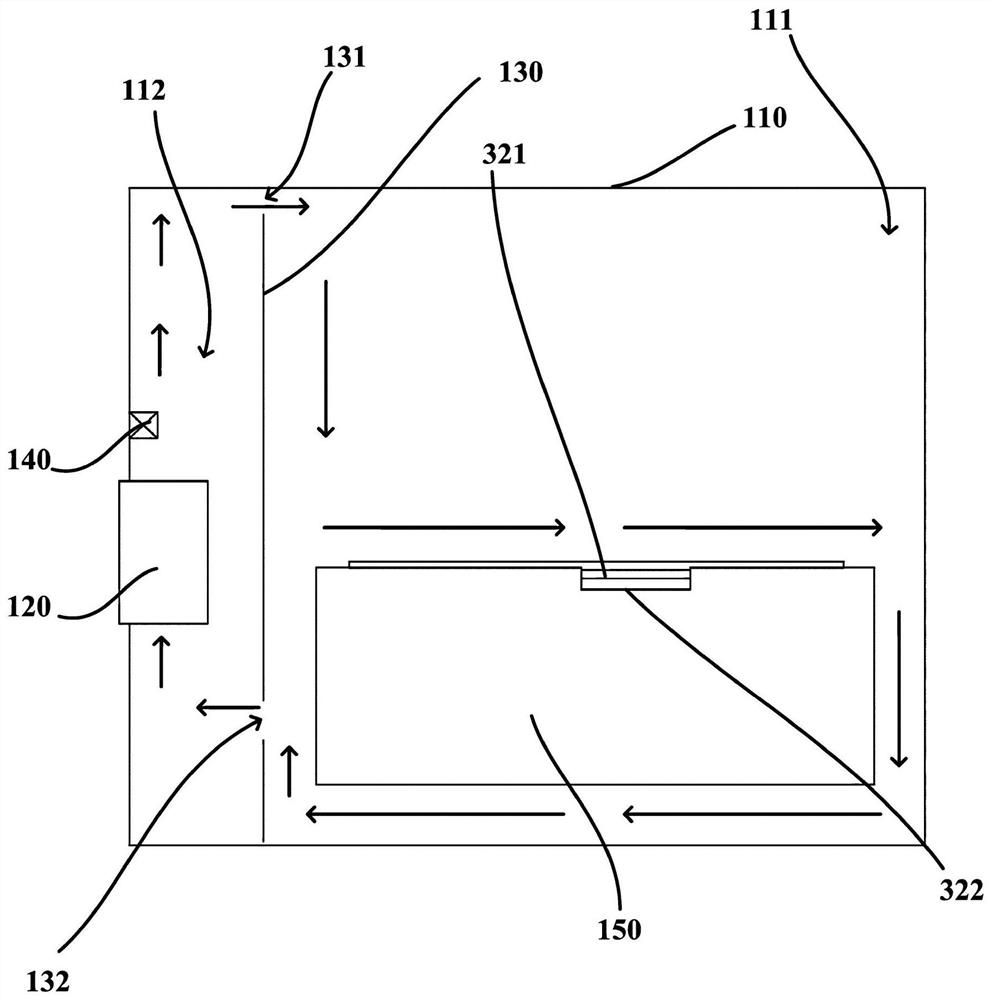

ActiveCN104764094AWater Vapor Content ControlIncrease water vapor contentMechanical apparatusSpace heating and ventilation safety systemsHigh humidityEngineering

The invention discloses a humidification air conditioner and a control method for the humidification air conditioner. The humidification air conditioner comprises a fan used for blowing surrounding moist air into a moisture absorbing device, the moisture absorbing device arranged at the air inlet side of the fan and used for absorbing the moist air and bringing the moist air into the indoor unit of the air conditioner to humidify the inside, a first condenser connected with a second condenser and forming an independent air flue system with the fan and moisture absorbing device, a switch control device arranged on the first condenser and used for controlling whether refrigerant can flow into the first condenser to heat the moist air absorbed on the moisture absorbing device, and the second condenser connected with an evaporator and used for performing normal heat exchange with the refrigerant. By means of the humidification air conditioner and the control method for the humidification air conditioner, a moisture absorbing turning wheel of the humidification air conditioner can be well protected, the moisture absorbing turning wheel is protected from a high humidity in a long time period, and accordingly the service life of the moisture absorbing turning wheel is prolonged, and the humidification requirement of a user is satisfied.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

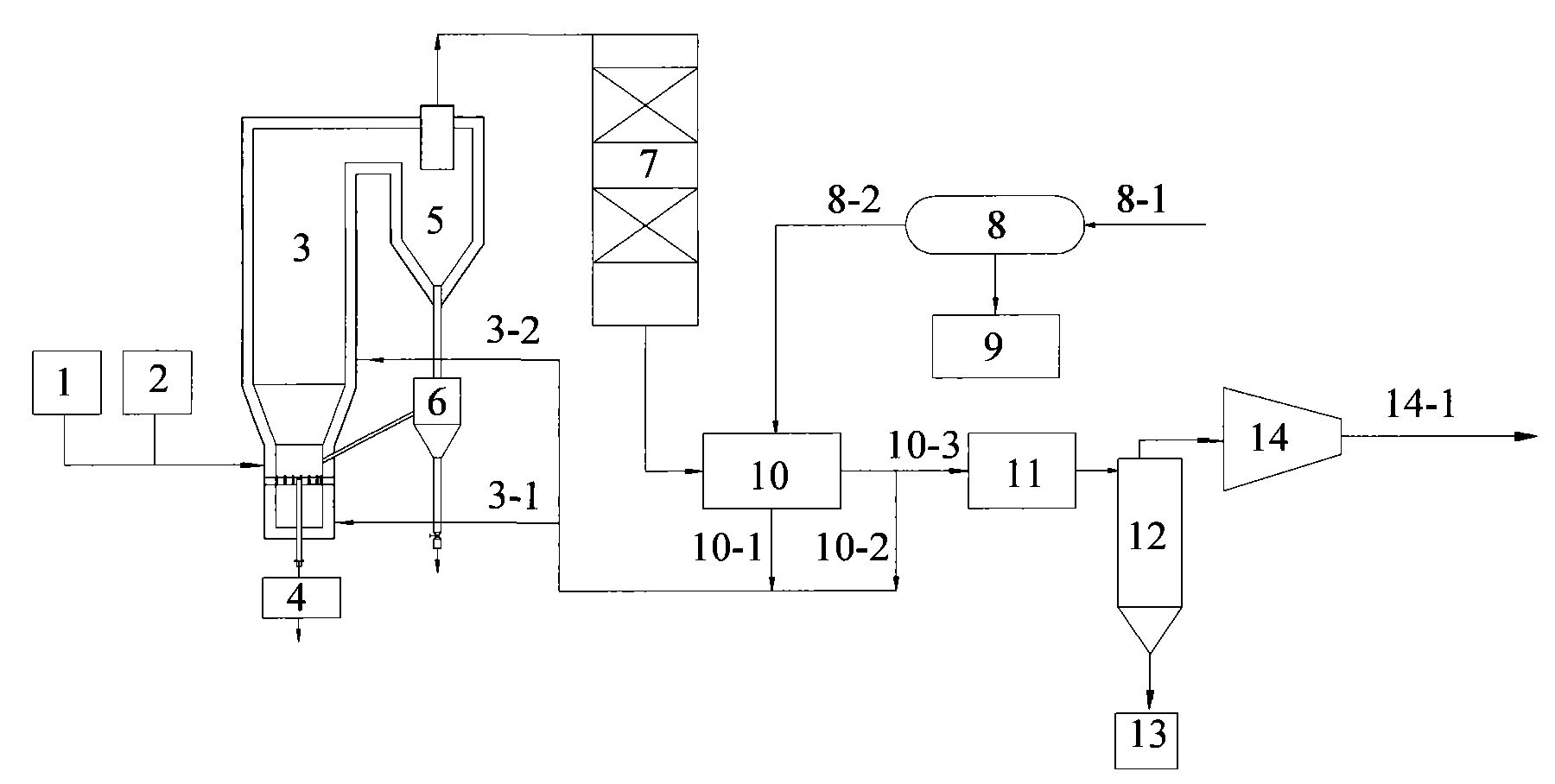

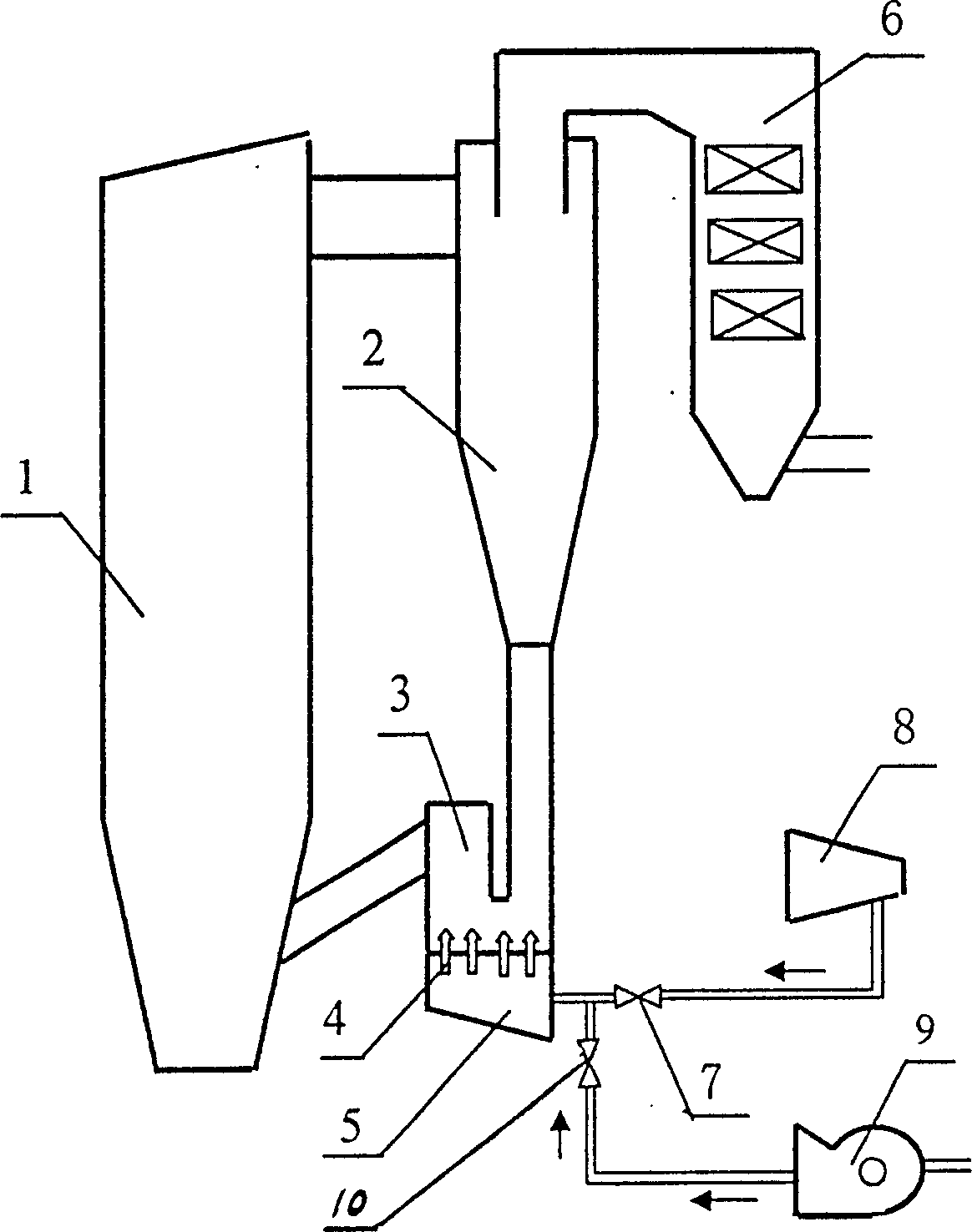

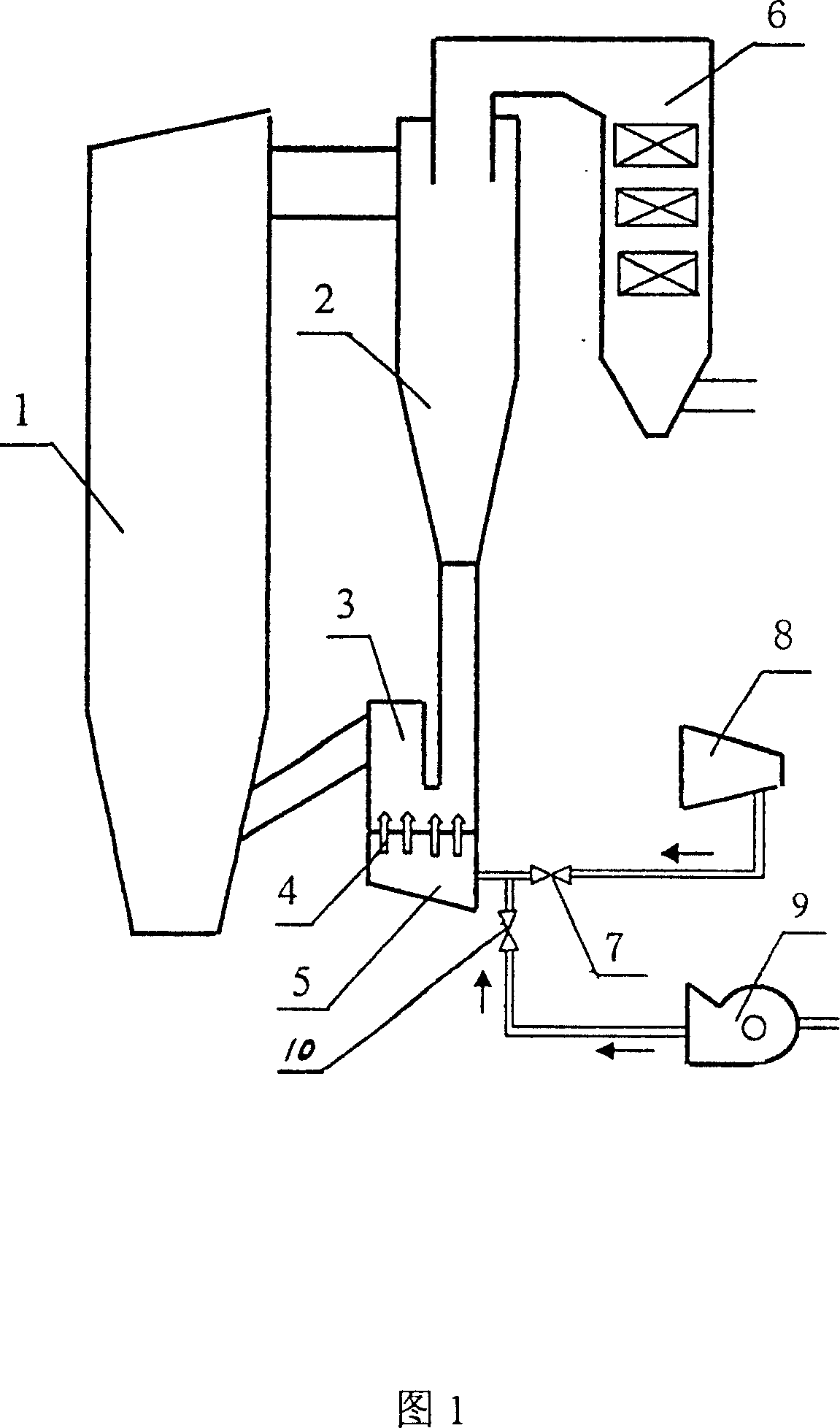

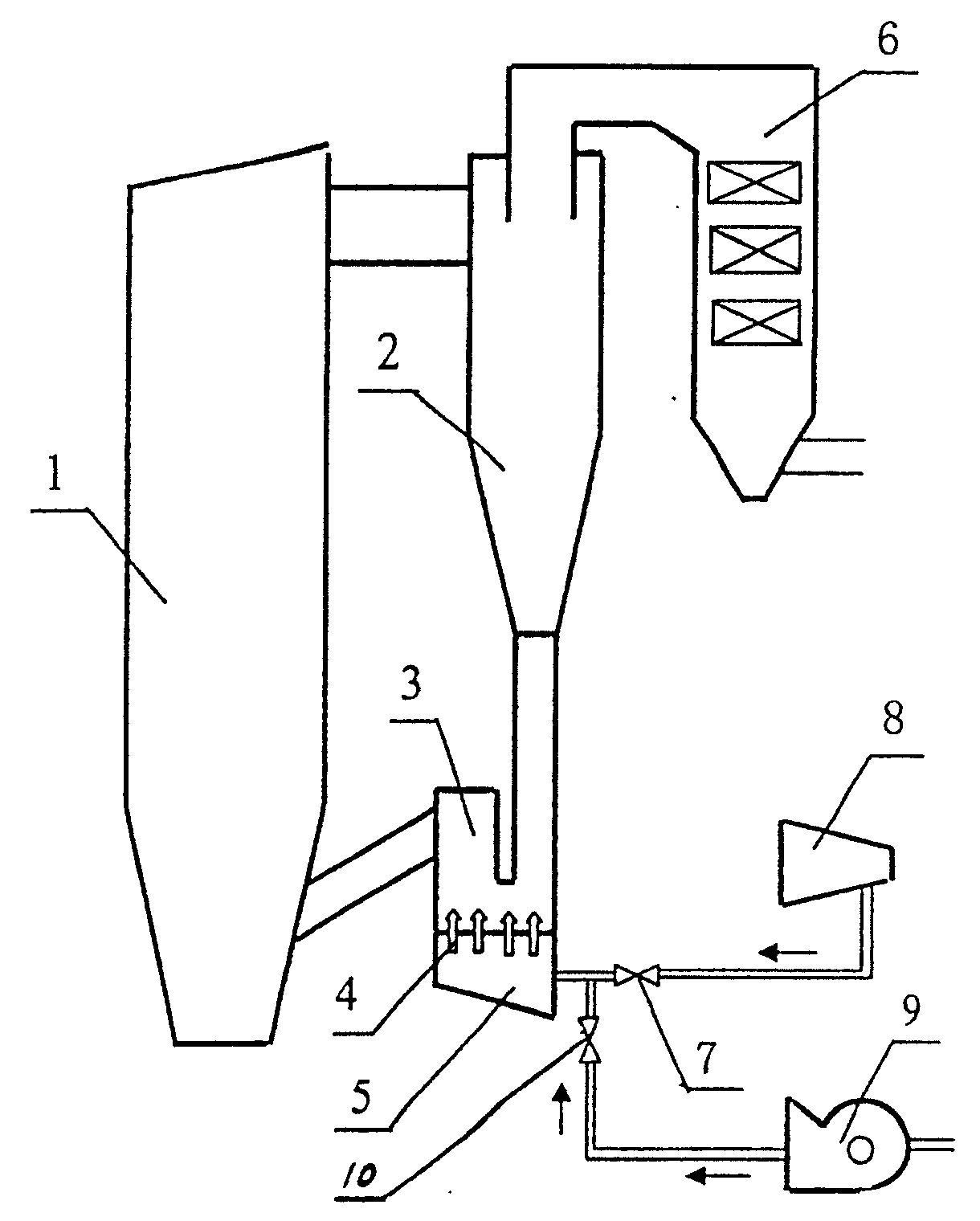

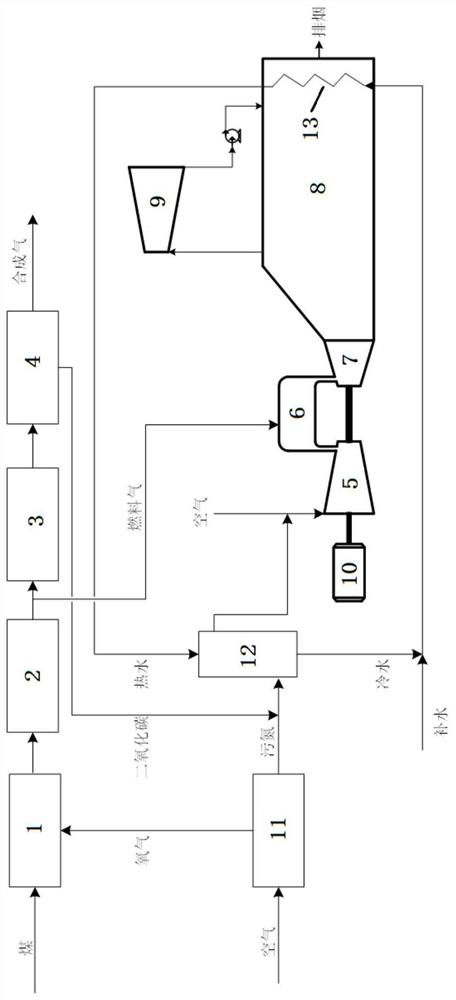

Method for reducing emission of carbon dioxide by circulating fluidized bed temperature flue gas circulation oxygen combustion

InactiveCN101634449ARealize rational utilizationHigh thermal efficiencyFluidized bed combustionDispersed particle separationResource utilizationWater vapor

The invention relates to a method for reducing emission of CO2 by circulating fluidized bed temperature flue gas circulation oxygen combustion, which is a method for realizing CO2 emission reduction applied in a circulating fluidized bed boiler based on the technology of temperature flue gas circulating oxygen combustion. The method comprises the following steps: feeding fuel and desulfurater into the circulating fluidized bed boiler, taking the gas mixture of O2 and circulating flue gas as combustion agent, passing through the heating surface at the tail by the flue gas generated by combustion, heating O2 (concentration is 96.5%-98.5%) from an air separation unit, generating temperature flue gas at the temperature of 140-150 DEG C, taking the gas mixture composed of 30%-70% of the temperature flue gas and O2 as oxidant to delivery to a furnace for combustion, carrying out dedusting by a deduster, multi-level condensation and dehydration and compression on the residual flue gas (volume concentration of CO2 is larger than 95%), and realizing resource utilization or storing in a sealing manner. The circulating glue gas is rich in vapor, entrainment unburned carbon and active desulfurater; the method enhances radiant heat exchange in the furnace, solves the problem of insufficient amount of convection heat transfer, improves combustion efficiency and desulfuration efficiency of the furnace, and can realize near-zero emission of gas pollutant; besides, the method can also lower comprehensive power consumption of space division and CO2 compression, and improve generating efficiency.

Owner:SOUTHEAST UNIV

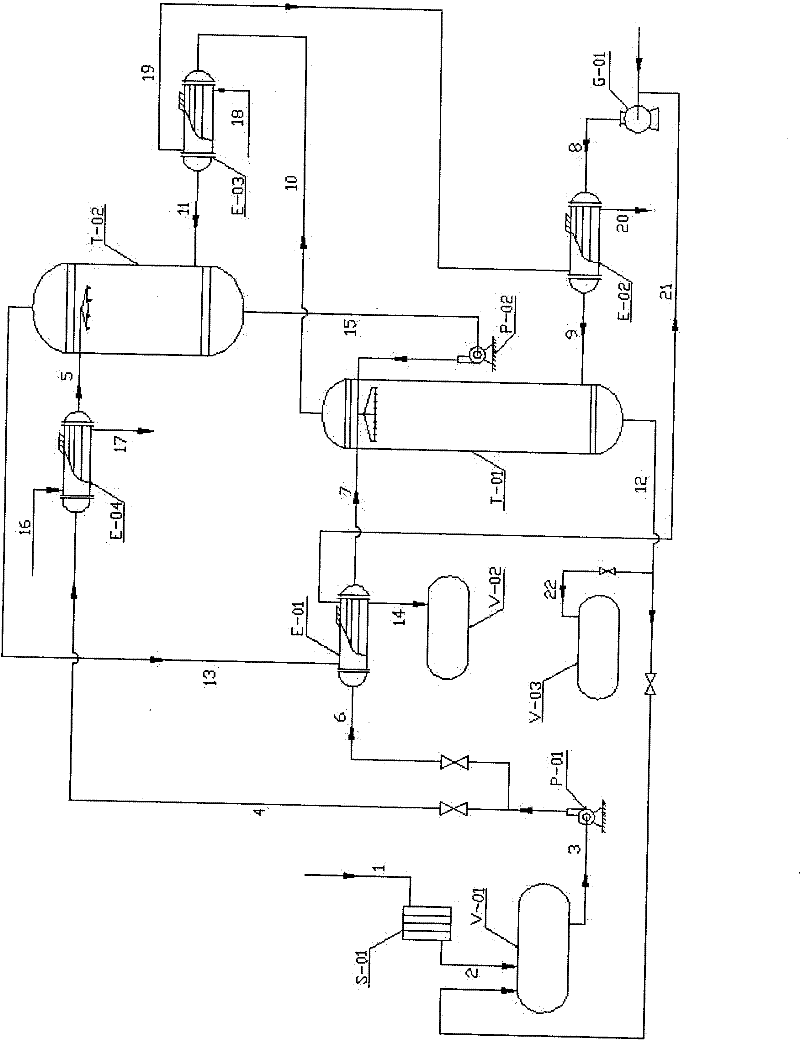

Seawater desalination process with low cost

ActiveCN101734823AReduce the burden onReduce heat pollutionGeneral water supply conservationSeawater treatmentThermal energyNuclear power

The invention relates to a seawater desalination process with low cost, which utilizes the condensate of the vapor cycle of a thermal power plant or a nuclear power station as a heat source, heats seawater to the temperature of 60-80 DEG C and atomizes the seawater in an atomizing chamber. On the other hand, natural air is heated after being washed and humidified, enters the atomizing chamber and contacts the atomized high-temperature seawater mist flow so as to enable part of the atomized high-temperature seawater mist flow to be instantaneously vaporized; fresh water mist droplets generated by the atomization of the high-temperature seawater are lifted by the kinetic energy of air to move upwards; moreover, because the density of water is different from the density of salt, the water and the salt are separated in the movement process; the two blasts of fresh water airflow are cooled by the raw material of cold seawater simultaneously and condensed into fresh water, the heated raw material of the cold seawater is used for washing and humidifying the natural air, and clean air carrying water vapor is recycled after the clean air carrying the water vapor is cooled; and the entire process flow does not consume extra heat energy and only consumes the air and less electric energy required by the transportation of the seawater. The process recovers energy in the condensate of the vapor cycle of the thermal power plant or the nuclear power station, produces the fresh water in large amounts and also produces a by-product of concentrated seawater.

Owner:NANJING UNIV

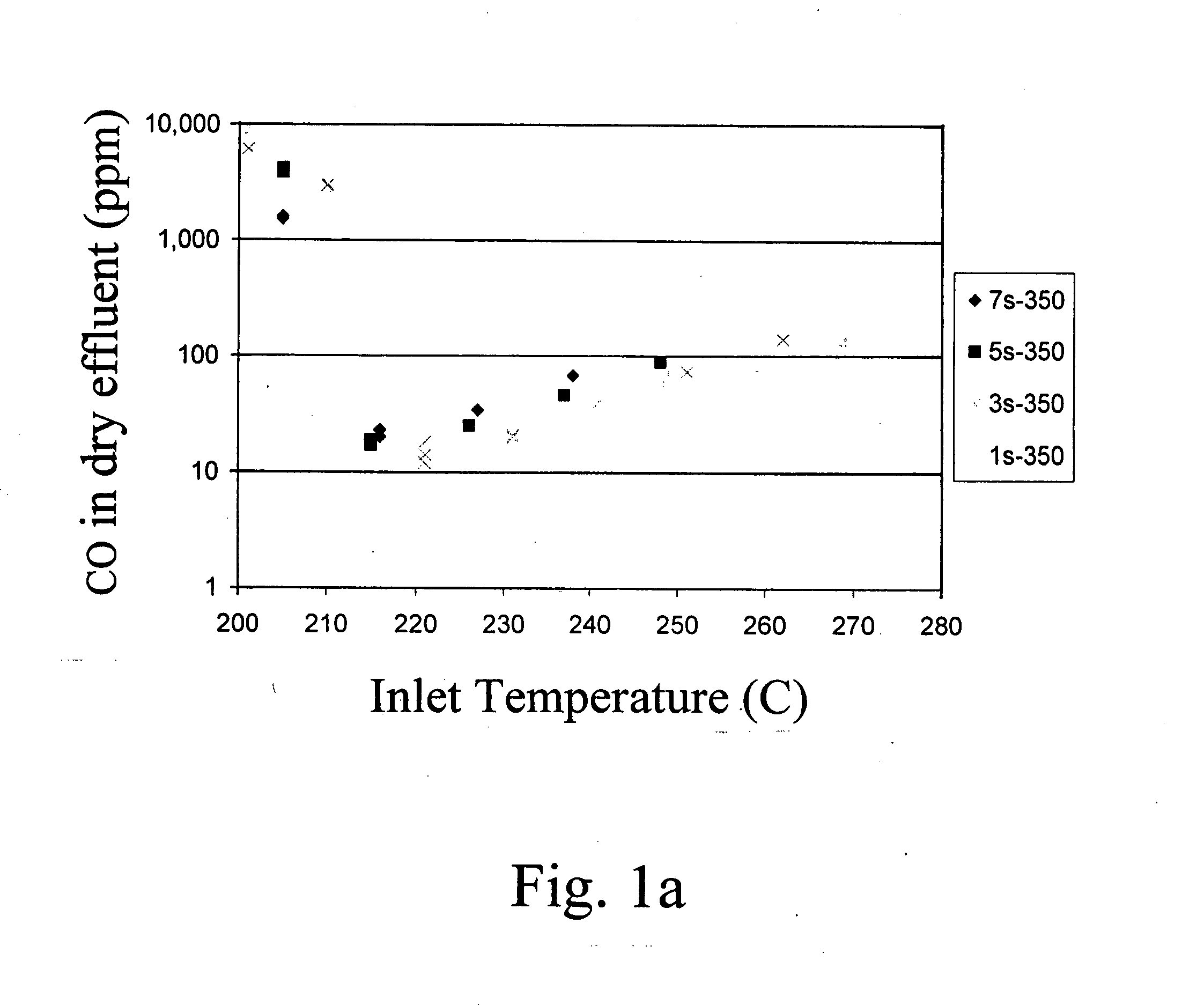

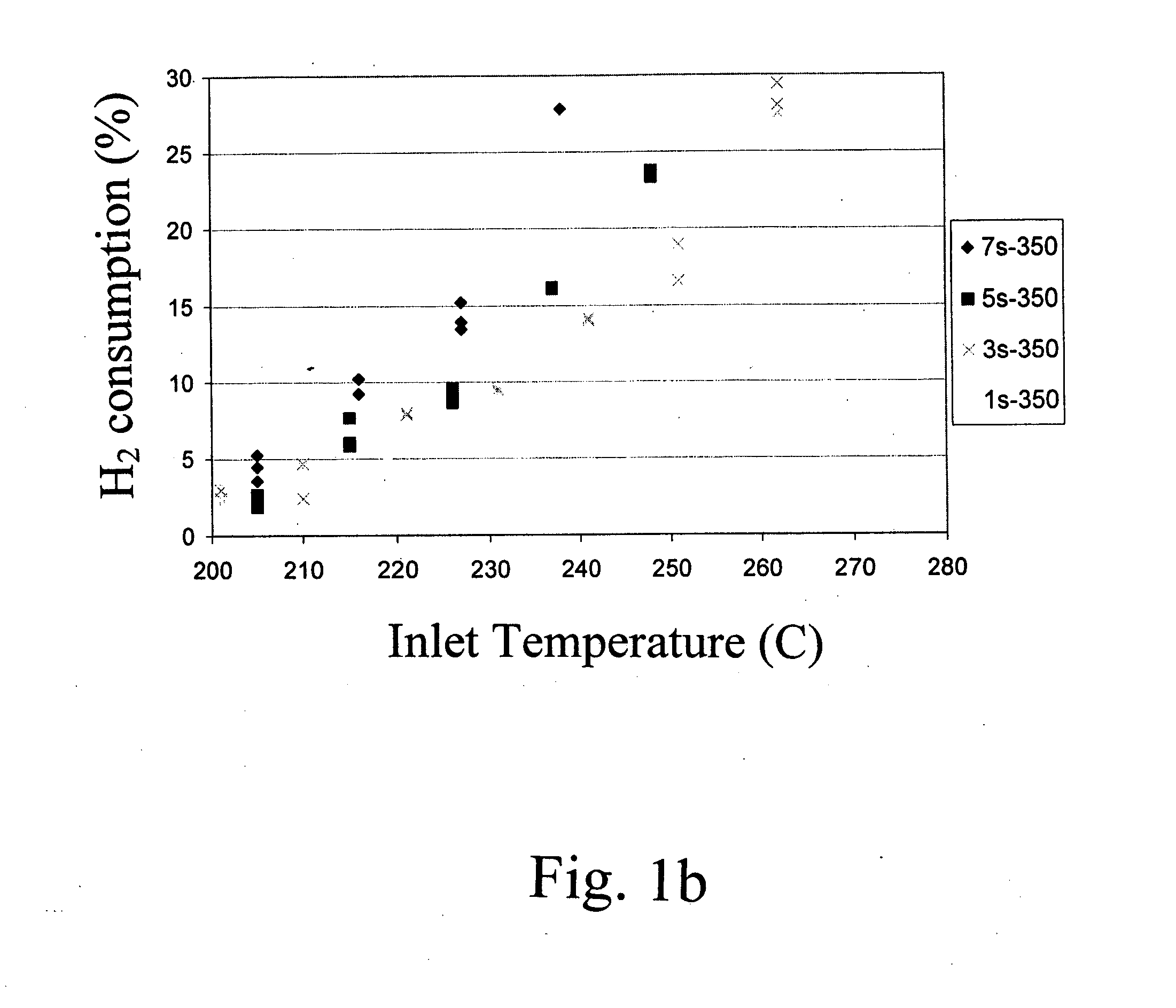

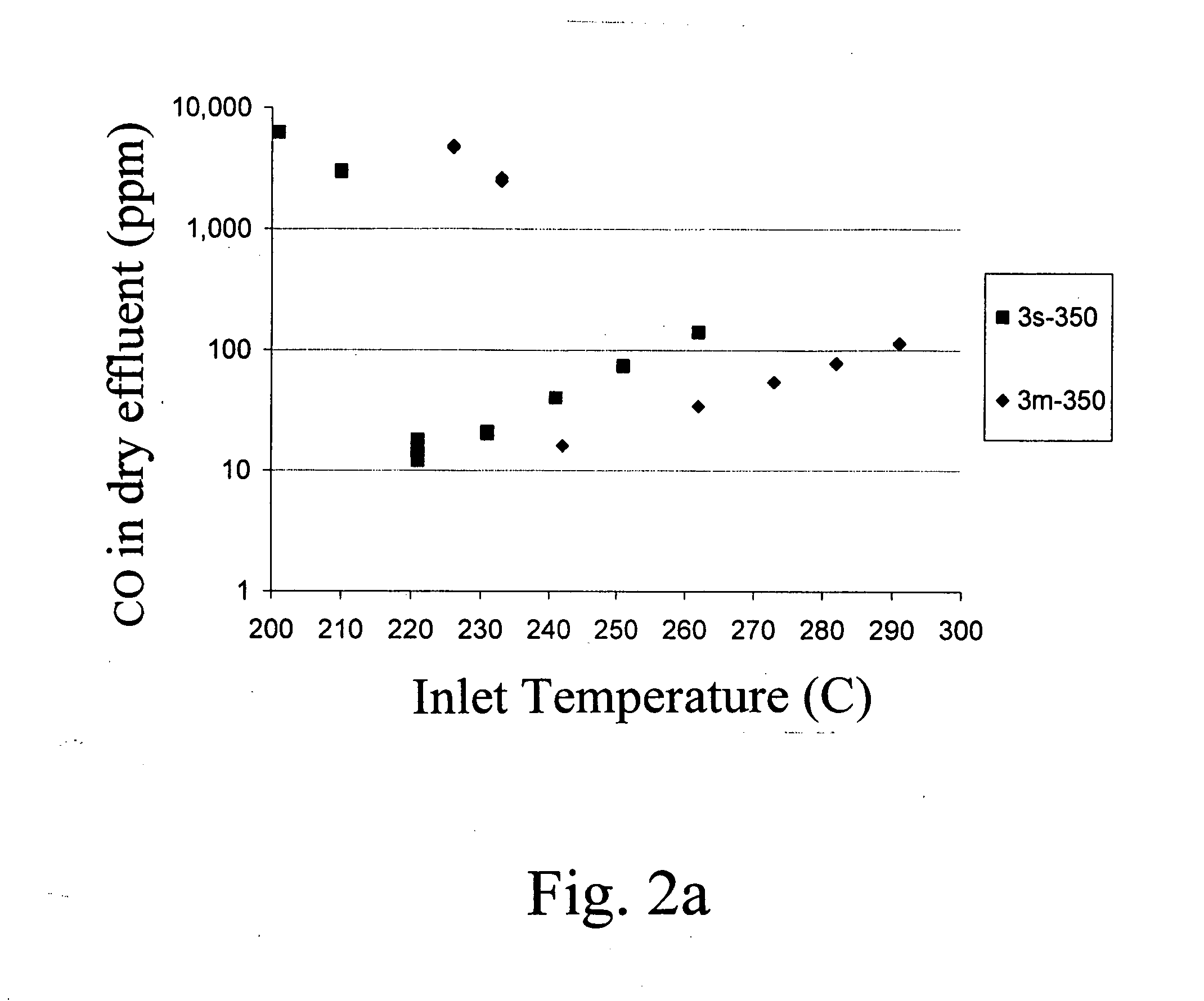

Selective CO methanation catalysis

ActiveUS20070253893A1Low feed flowratesMaximize efficiencyHydrogen productionHydrogen/synthetic gas productionChemistryMetal

Carbon monoxide (CO) is selectively reacted with hydrogen (H2) over a ruthenium (Ru) on alumina catalyst at a temperature of about 210 to about 290° C. To be a viable option for micro catalytic fuel processing devices, highly active, selective, and stable catalysts must be demonstrated with as large a temperature window for feasible operation as possible. We have studied the effects of metal loading, preparation method, pretreatment conditions, and choice of support on the performance of Ru-based catalysts for such applications. Catalyst testing results and catalyst characterization using XRD and BET are discussed. In one example, operating at a gas hourly space velocity (GHSV) of 13,500 hr−1, a 3% Ru / Al2O3 catalyst yielded CO outputs less than 100 ppm in a temperature range from 240° C. to 285° C., while not exceeding a hydrogen consumption of 10%. This catalyst was further successfully demonstrated in a microchannel device.

Owner:BATTELLE MEMORIAL INST

Method of fluidizing wind at high pressure using steam to replace air

InactiveCN1566749AAvoid cokingAvoid burnsFluidized bed combustionApparatus for fluidised bed combustionEngineeringHigh pressure

The invention relates to a method of implementing high pressure fluidization blast using steam in place of air, characterized in that: steam is used for high pressure fluidization blast in normal running of a boiler. The method includes: connecting a turbine exhaust or intermediate extraction with a stock recycler using a steam conduit; starting high pressure fluidization blower and fluidizing recycle material in the stock recycler using air when the boiler begins to start; opening stop valve of the turbine steam conduit, fluidizing recycle material in the stock recycler using steam, shutting down the high pressure fluidization blower and closing the stop valve when the temperature of recycle material in the stock recycler is above 300 Celsius degree, the fluidization steam vapor source pressure parameter is greater than 60Kpa, and the superheat degree is larger than 30 Celsius degree; starting the high pressure fluidization blower, fluidizing recycle material in the stock recycler using air, and closing the stop valve on steam turbine when the temperature of the stock recycler is under 300 Celsius degree in blow off process of the boiler. Advantages of the invention consist in that coking of the stock recycler or other high temperature zones can be prevented or abated and boiler operation reliability can be improved by using steam for replacing high pressure fluidization blast. At the same time, circulating fluid bed boiler desulfurizer utilization rate can be improved, Nox discharge concentration can be reduced, and power plant running cost can be saved by utilizing steam fluidization.

Owner:SHANGHAI BOILER WORKS

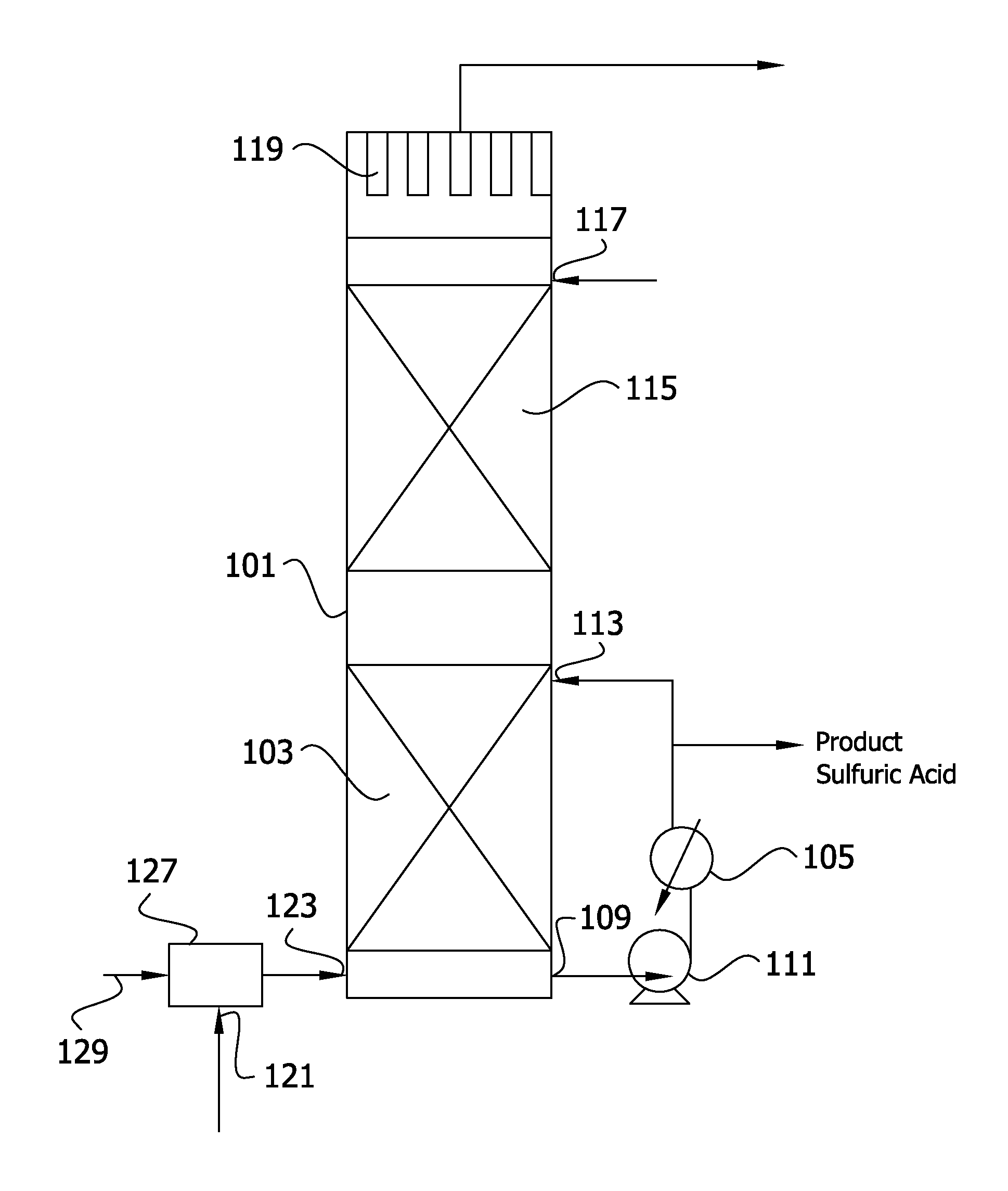

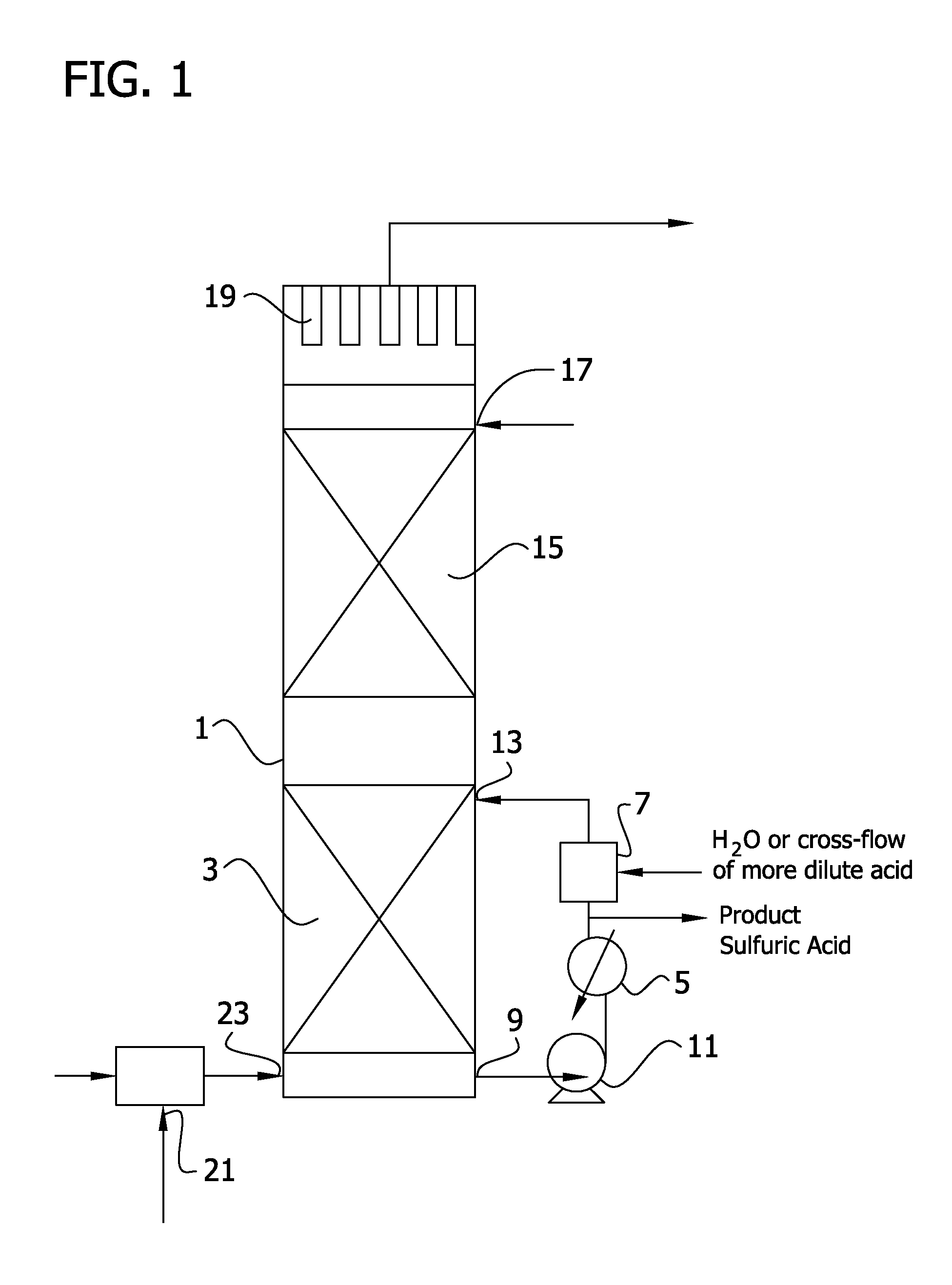

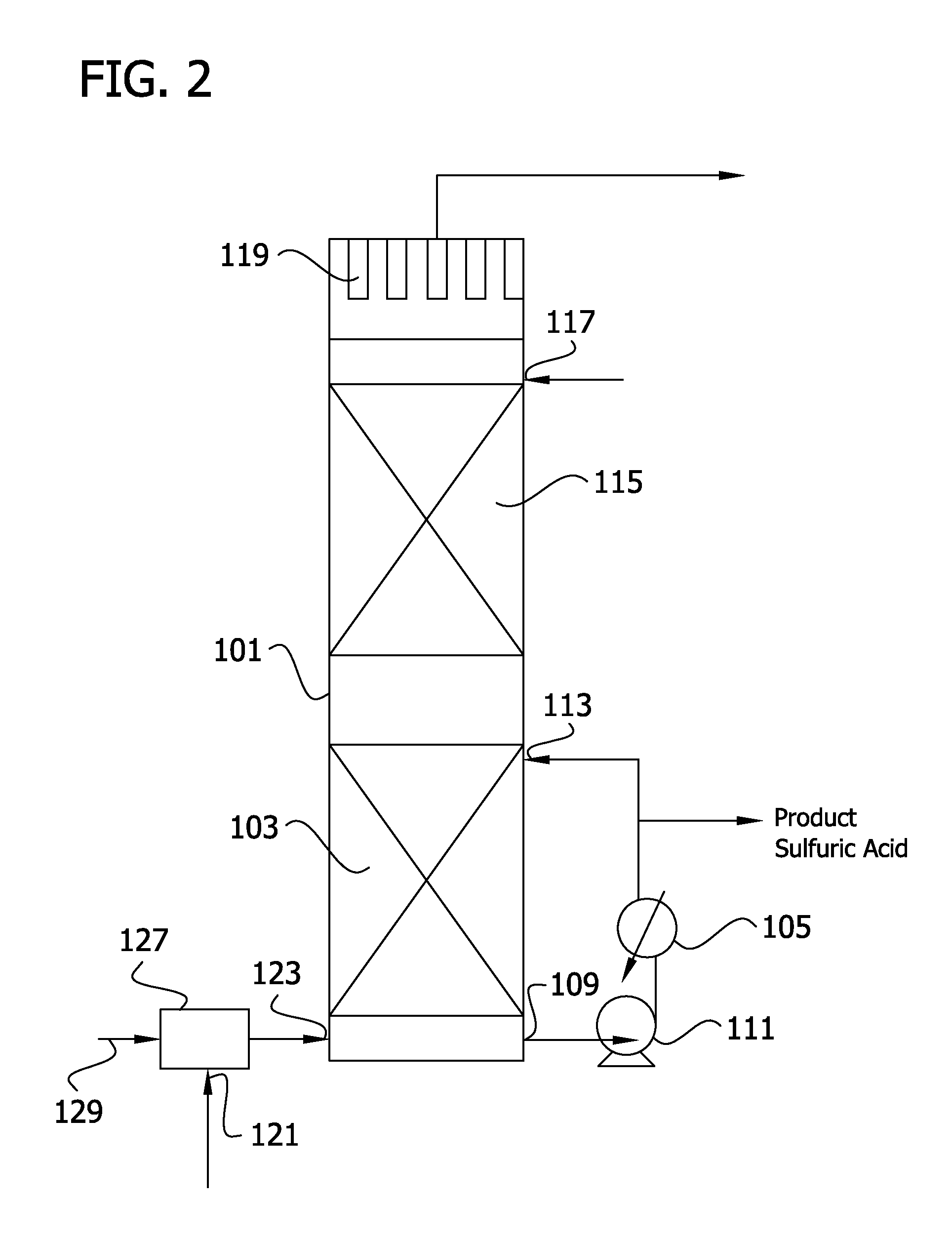

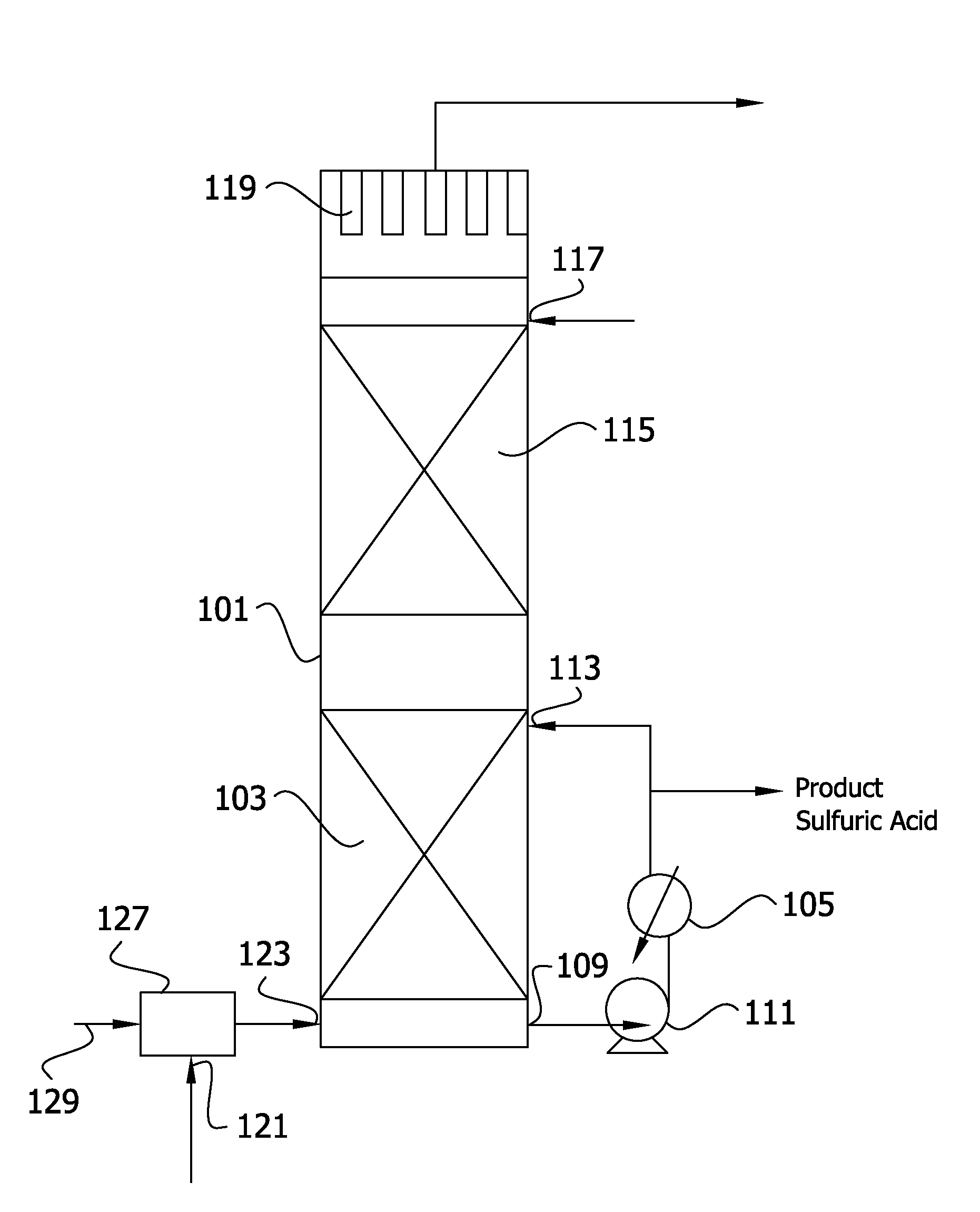

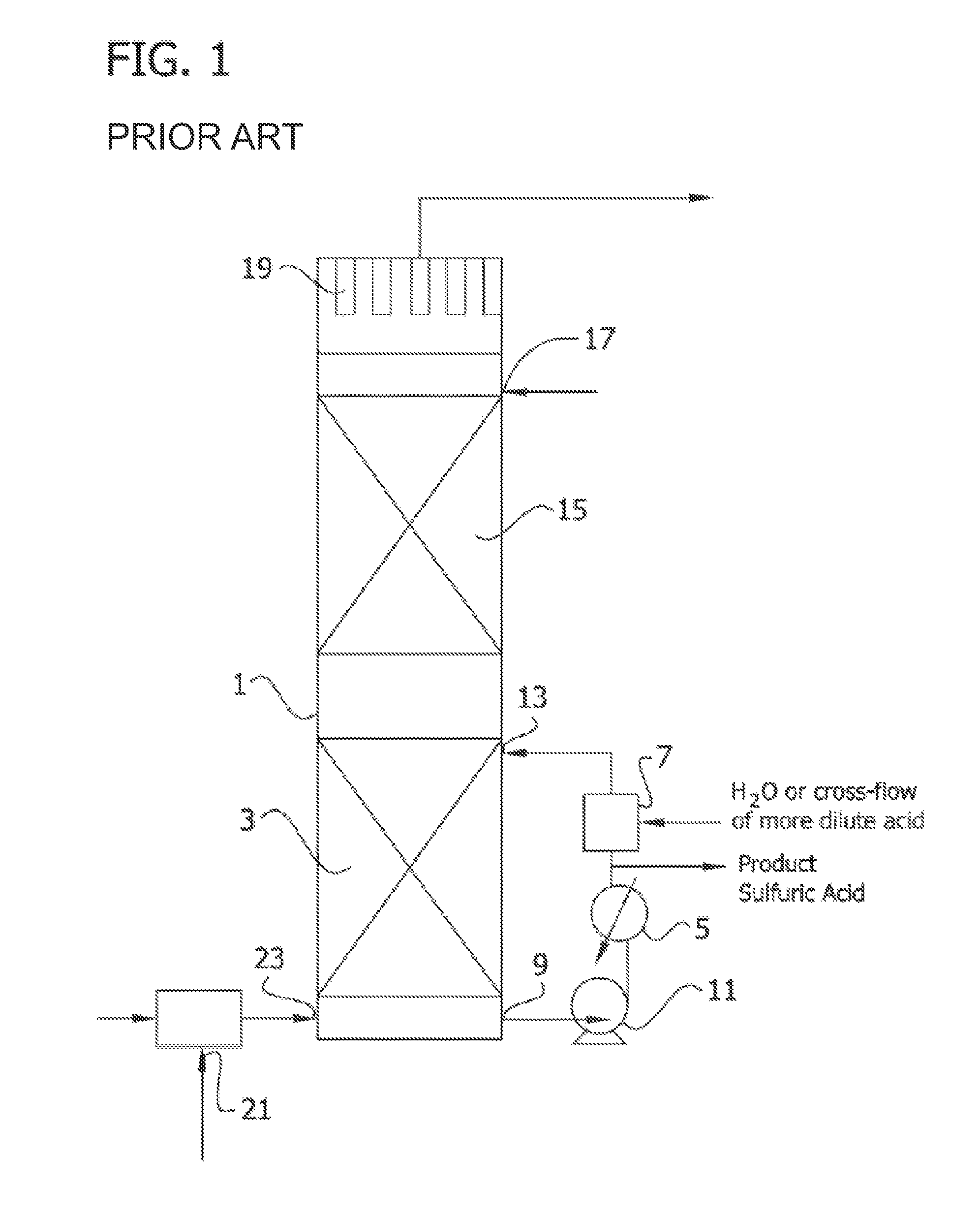

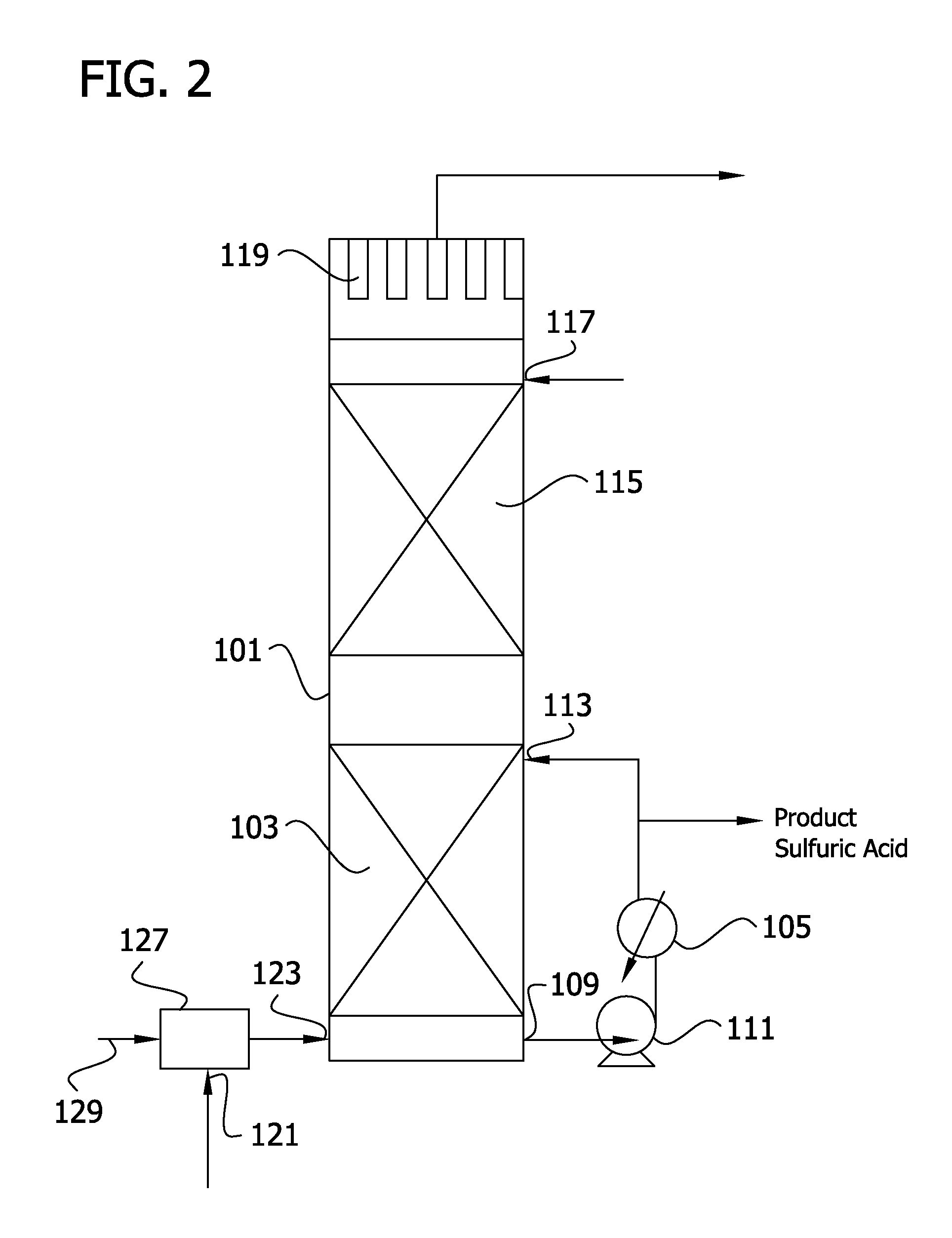

Energy recovery in manufacture of sulfuric acid

ActiveUS20130115159A1Improve energy recoveryWithout excessive and intolerable generationHollow article cleaningDispersed particle separationEnergy recoveryPhotochemistry

This invention relates to the recovery of energy in the manufacture of sulfuric acid, and more particularly to enhanced recovery of energy from the absorption of wet SO3 in sulfuric acid. The invention is further directed to control of mist formation during SO3 absorption, and of the sulfuric acid mist content of the gas stream leaving the SO3 absorption step in a process wherein SO3 absorption energy is recovered from absorption acid in useful form.

Owner:MECS

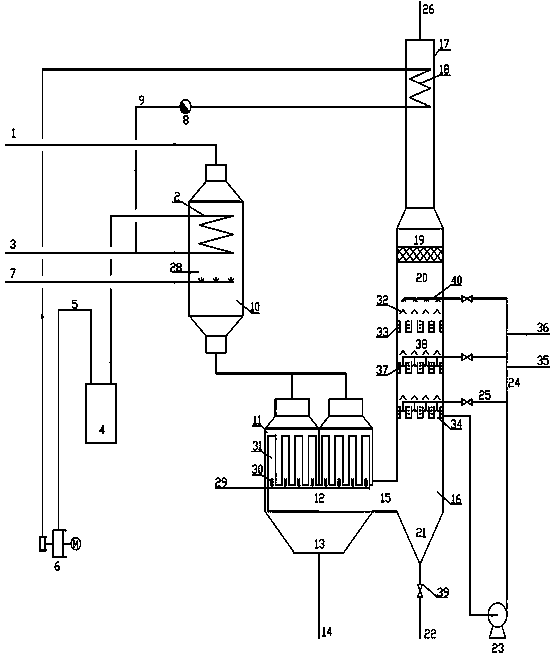

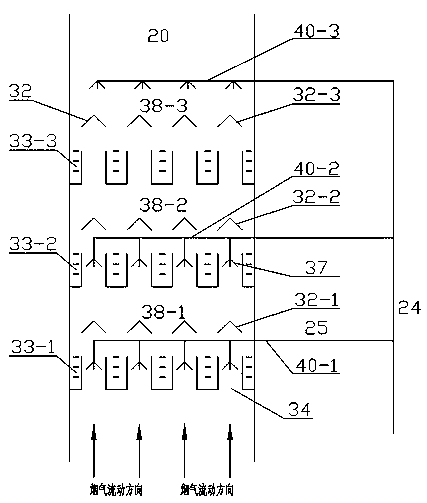

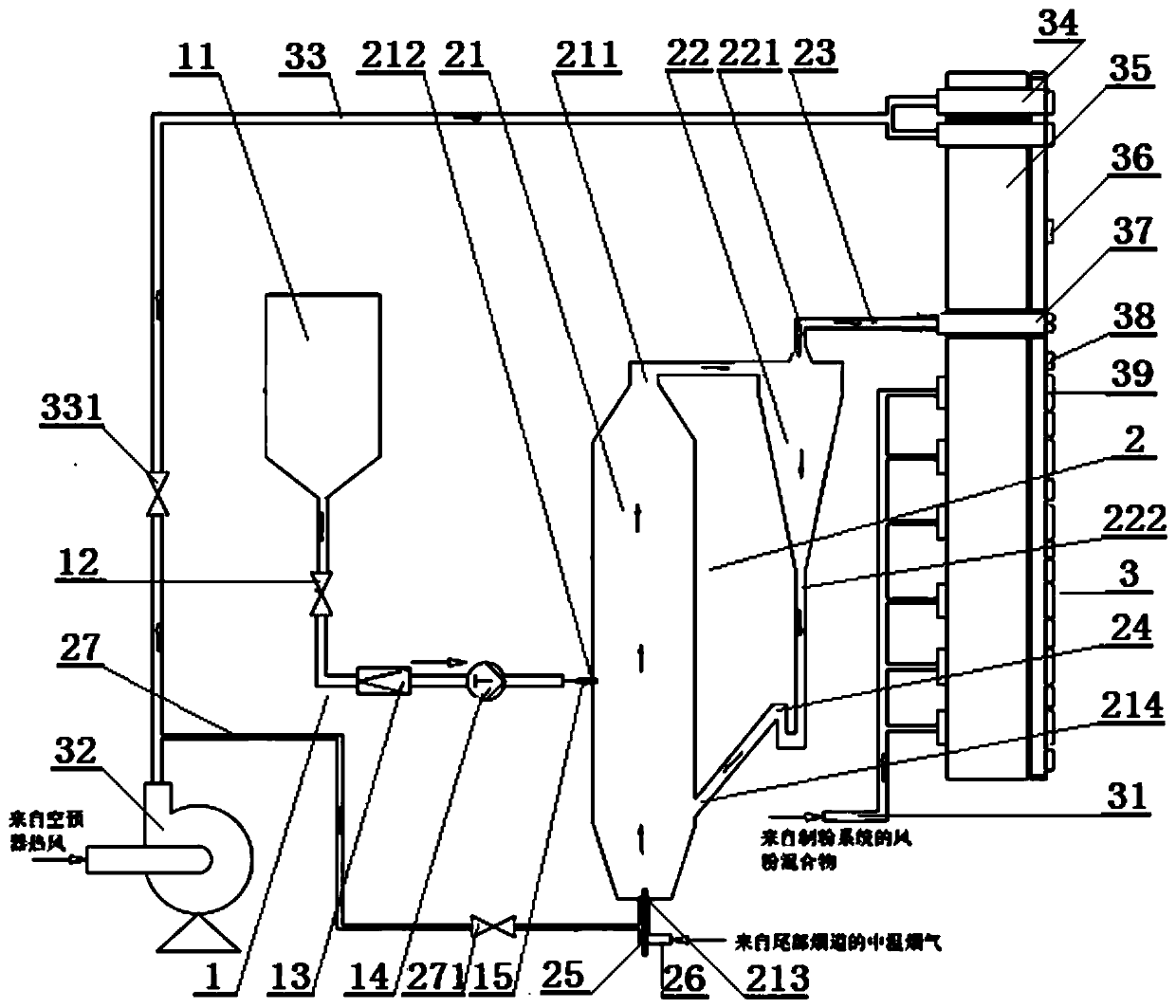

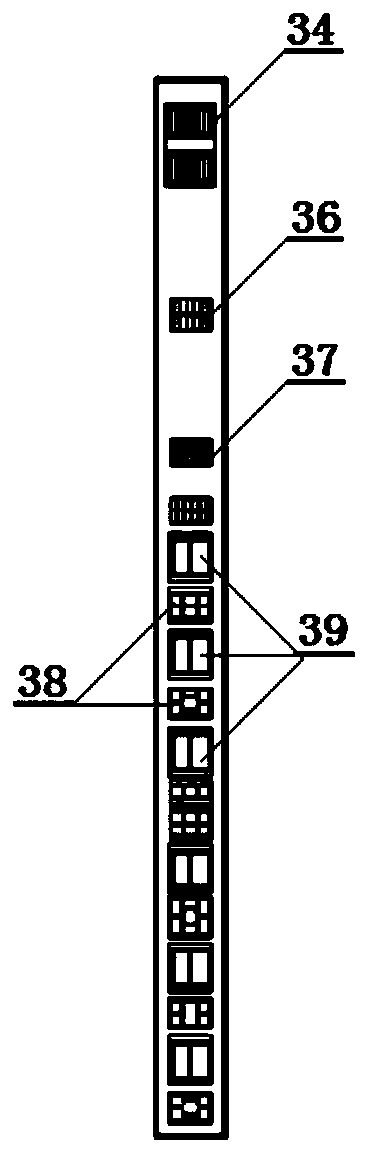

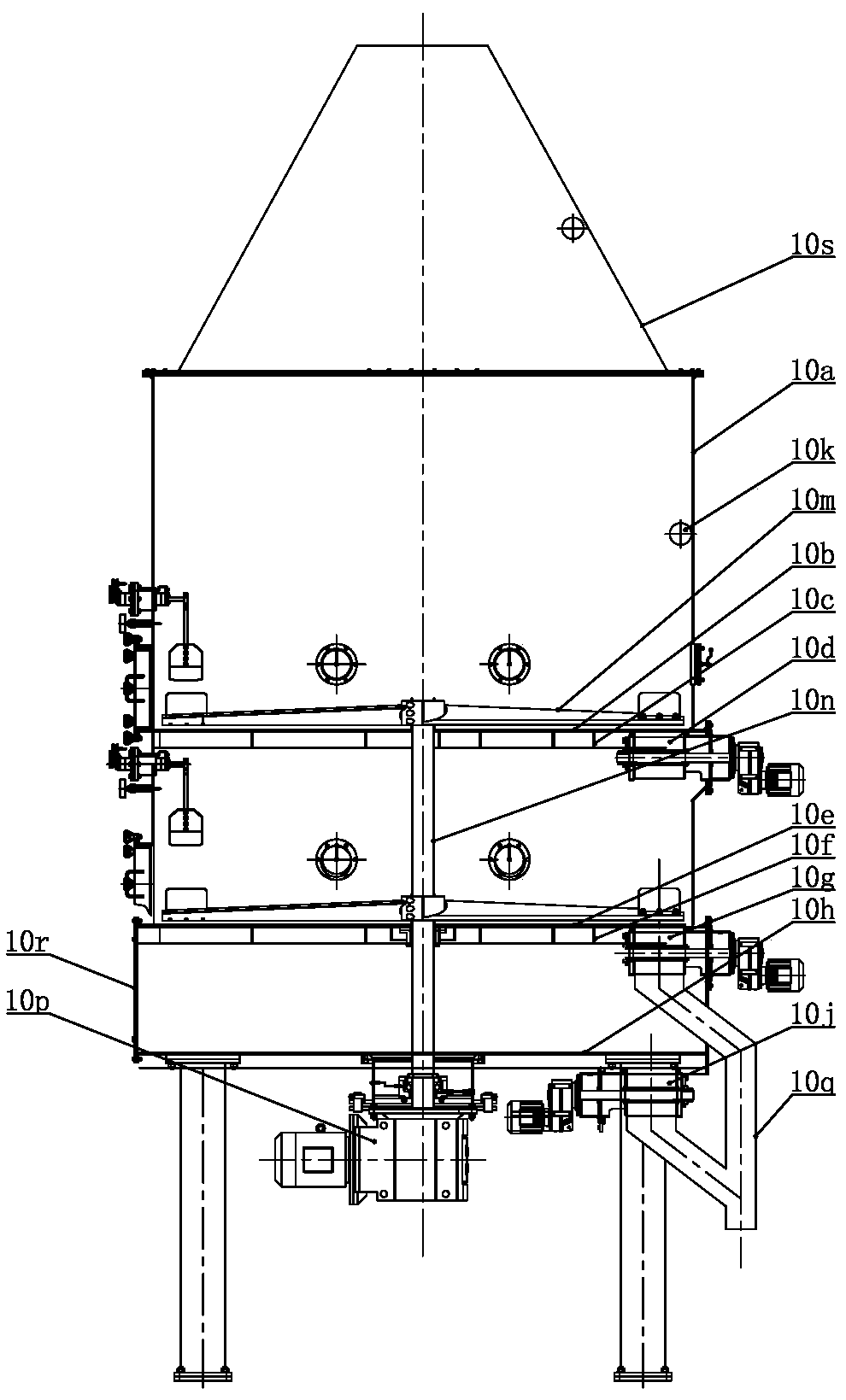

Flue gas desulfurization and desulfurization wastewater treatment method and flue gas desulfurization and desulfurization wastewater treatment apparatus

ActiveCN108686478AIncrease unsaturationDissipate in timeGas treatmentDispersed particle filtrationGas phaseTreatment costs

The invention relates to a flue gas desulfurization and desulfurization wastewater treatment method. According to the flue gas desulfurization and desulfurization wastewater treatment method, a flue gas pre-treatment tower comprises a flue gas / desalted water heat exchanger and a spraying unit; liquid-state desalted water is converted into gas-state desalted water by using flue gas in the flue gas / desalted water heat exchanger, and the gas-state desalted water enters a gas-liquid separator and is separated; the gas phase is compressed, the compressed gas phase enters the gas discharge cylinderon the top of a desulfurization tower to heat and purify the flue gas; the spraying unit is used for spraying a NaOH solution to reduce the flue gas temperature to below the dew point temperature of an acid, the cooled flue gas enters a bag type dust removing device and is treated, and the treated flue gas enters the desulfurization tower; and on the bottom of the desulfurization tower, a proper amount of desulfurization wastewater is subjected to spraying drying by using the flue gas, and the flue gas enters a desulfurization zone and is subjected to desulfurization purification. The invention further relates to a treatment apparatus of the treatment method. With the method and the apparatus of the present invention, the purified flue gas meets the discharge requirement, and the zero discharge of the flue gas desulfurization wastewater is achieved, the white smoke and the blue smoke are simultaneously eliminated, and the flue gas desulfurization and desulfurization wastewater comprehensive treatment cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

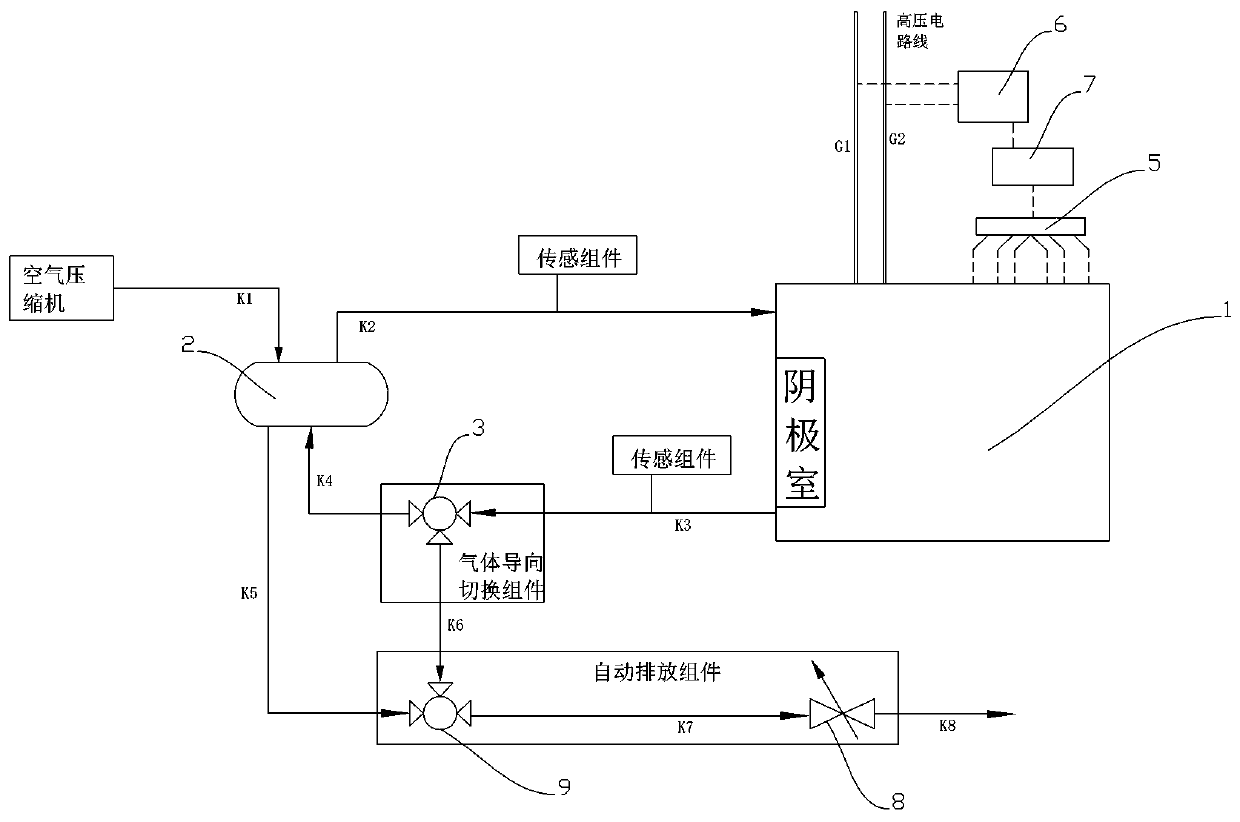

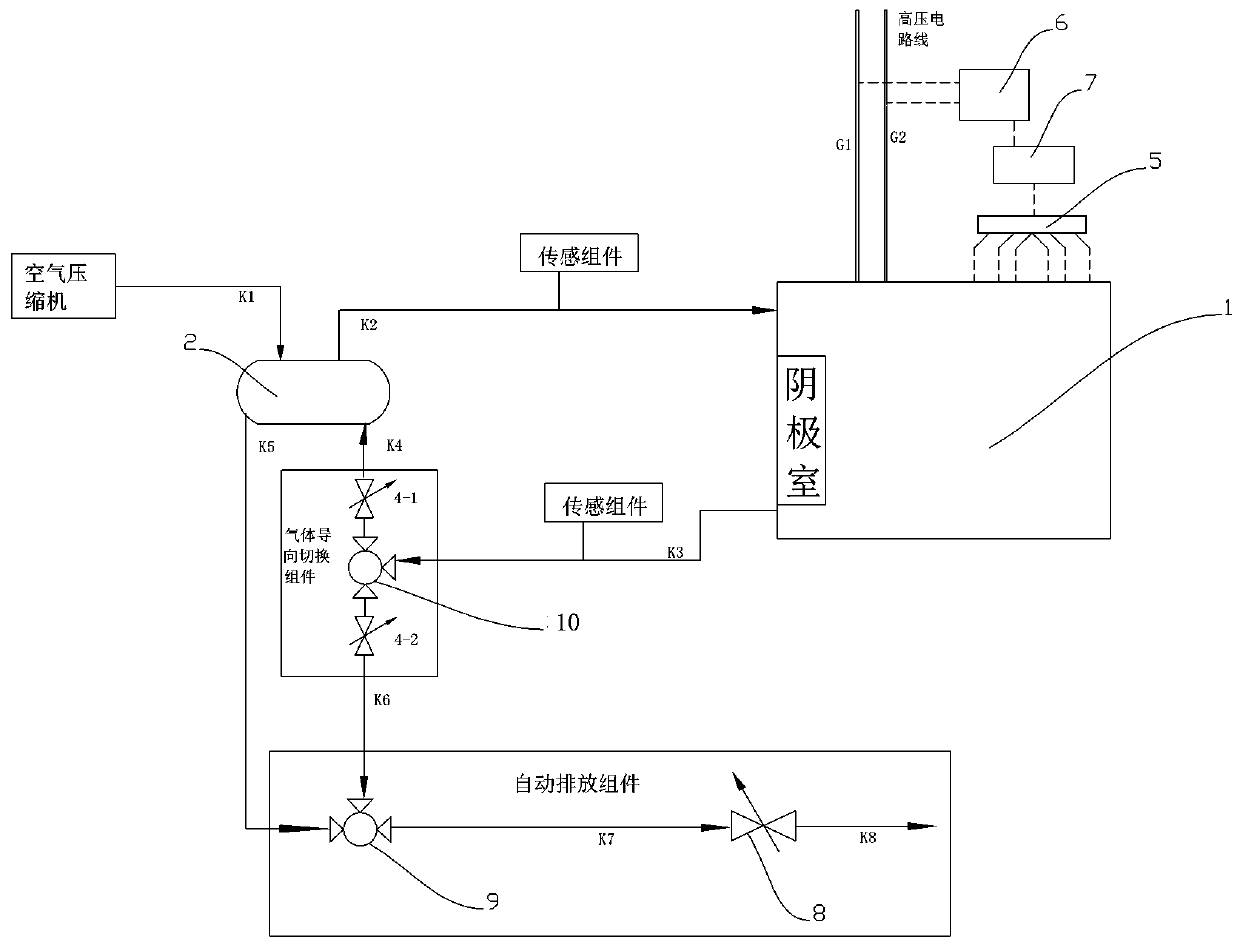

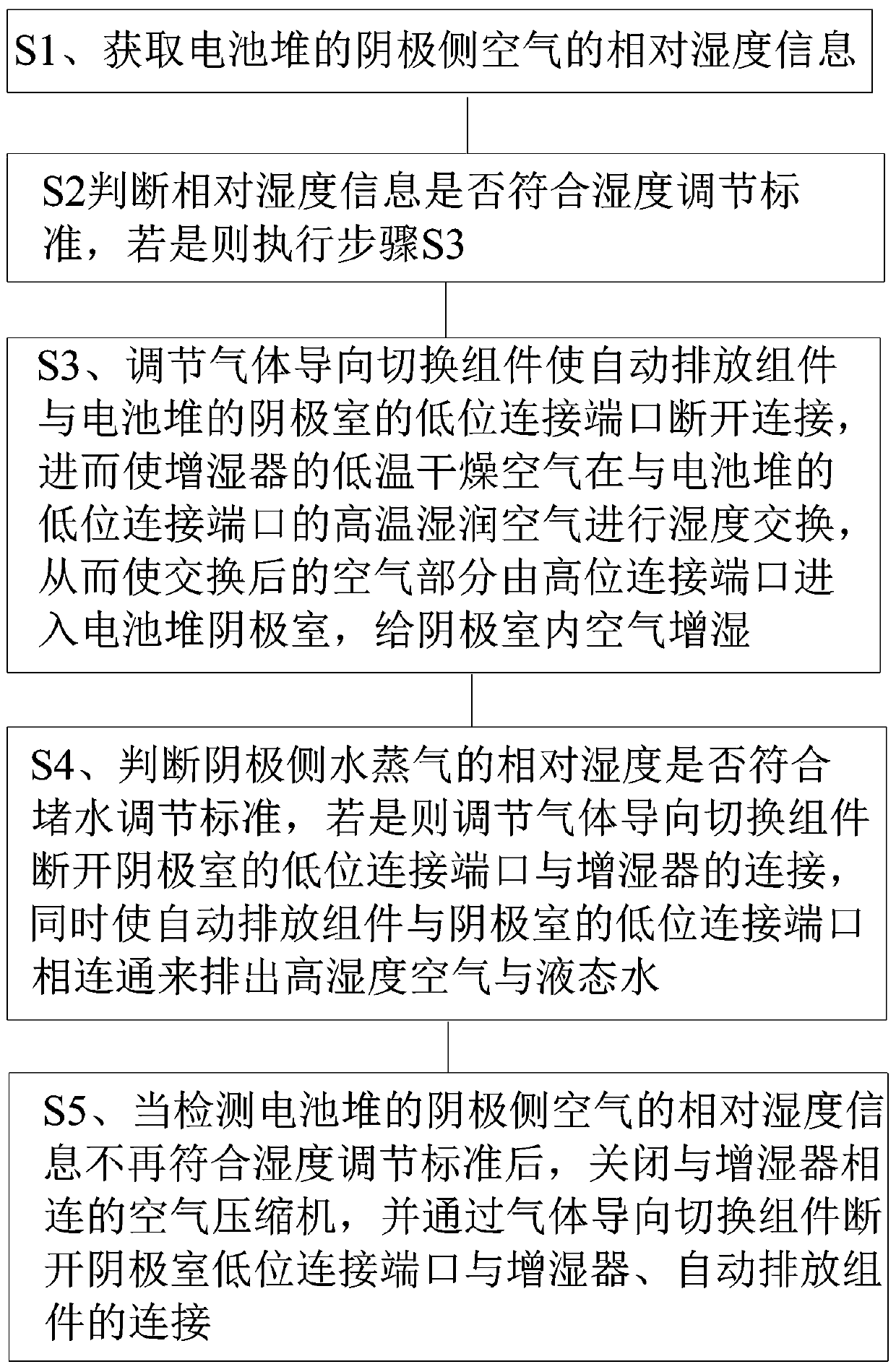

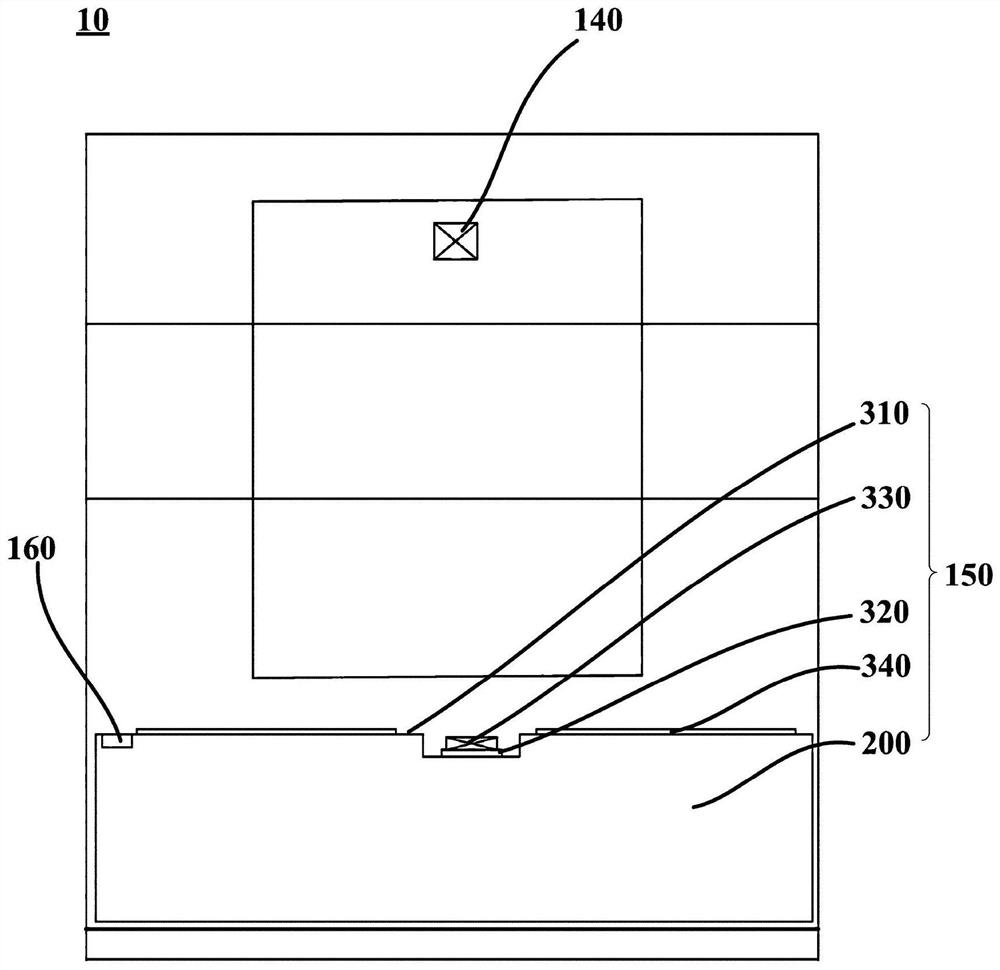

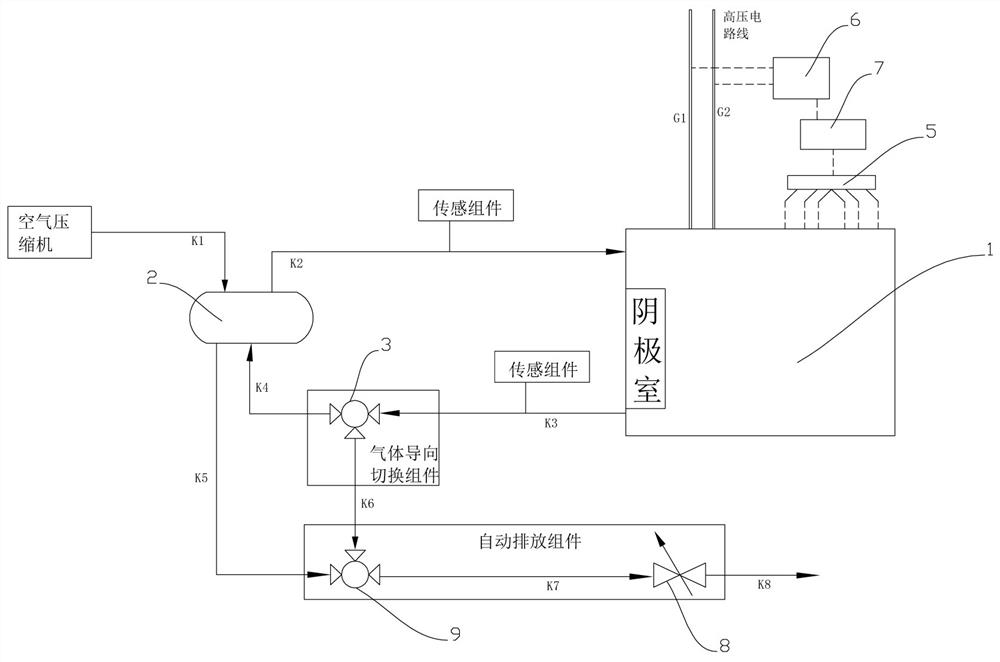

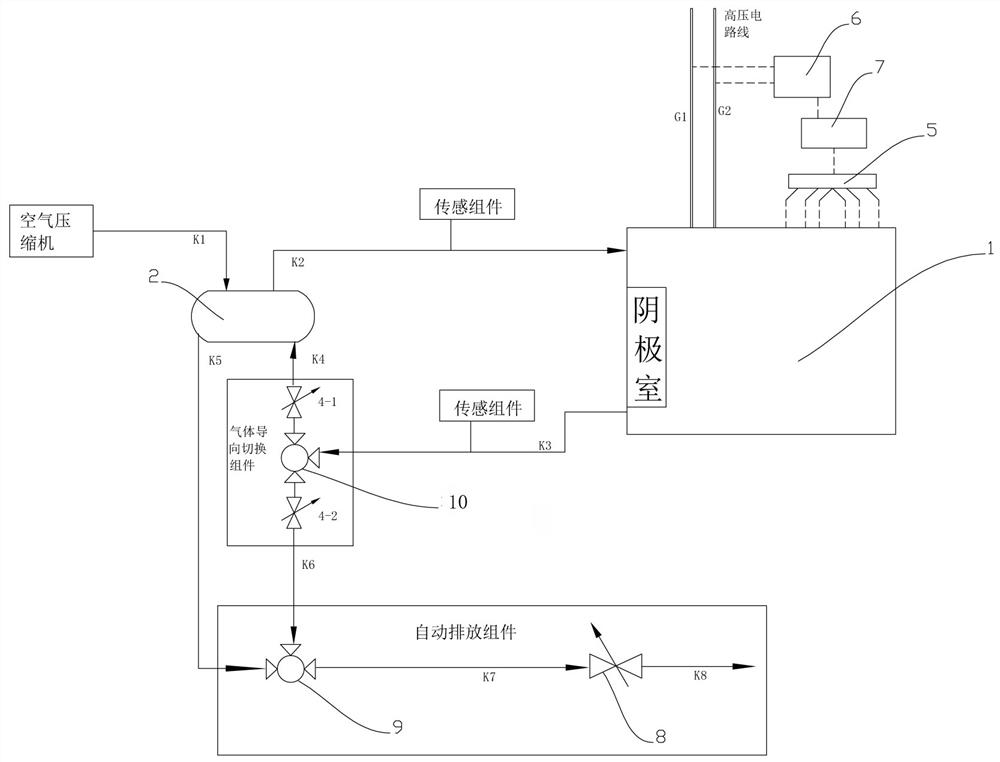

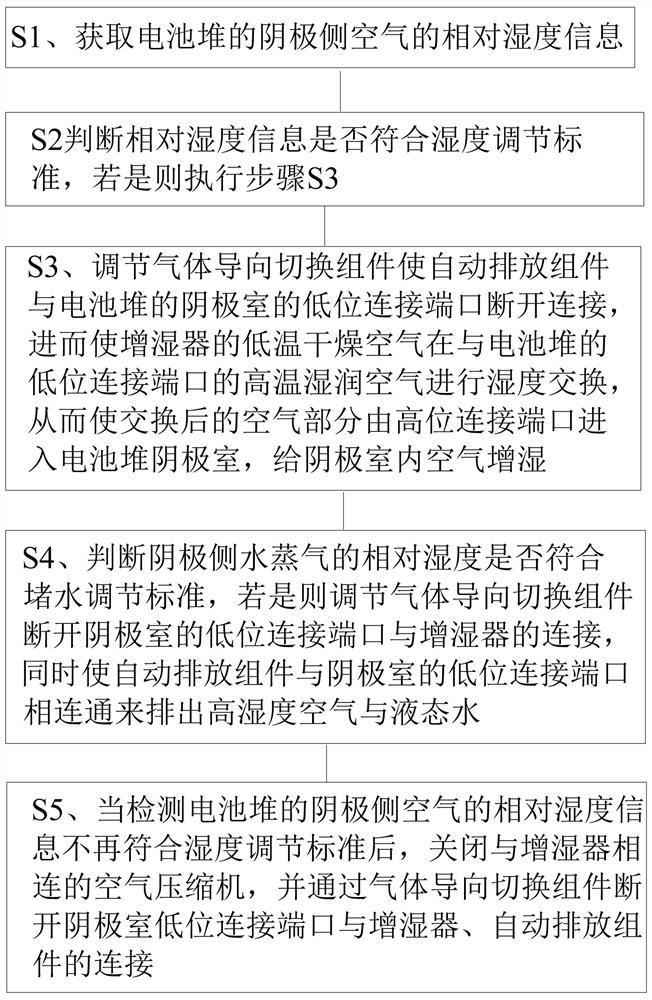

Fuel cell cathode side humidity adjustment control system and method

The invention provides a fuel cell cathode side humidity adjustment control system and method. The relative humidity condition of the cathode of the cell stack is rapidly and accurately obtained through the voltage change rule of the fuel cell, and compared with an existing humidity sensor feedback control method, the method is higher in control sensitivity and is remarkably improved in detectionaccuracy, and can reduce the loss of the fuel cell caused by dry film and water plugging phenomena. According to the invention, the water vapor content at the cathode of the fuel cell can be controlled within a certain range, so that the working efficiency of the fuel cell is improved. According to the invention, a gas guiding and switching assembly is used for intelligently adjusting the communication relationship between a low-position connection port of a cathode chamber of the cell stack and an automatic discharge assembly and a humidifier, so that air with high air relative humidity can be fed into a cathode chamber through a high-position connecting port by matching with the humidifier, and the working efficiency of the fuel cell is improved by properly improving the water vapor content of the cathode chamber.

Owner:浙江高成绿能科技有限公司

Composite reducing type low NOx emission device suitable for power station boiler

PendingCN111140865ACurb emissionsReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal waterPower station

The invention relates to a composite reducing type low NOx emission device suitable for a power station boiler. The composite reducing type low NOx emission device comprises a coal water slurry generation mechanism, a coal water slurry pyrolytic reaction mechanism and a composite reducing type combustion device, wherein the coal water slurry generation mechanism has the function of treating coal powder into coal water slurry and is internally provided with a coal water slurry tank, the coal water slurry pyrolytic reaction mechanism has the function of pyrolysis generation of pyrolysis gas withreducing active components and is internally provided with a pyrolysis reactor and a cyclone separator, and the composite reducing type combustion device has the function of deeply reducing of NOx incombustion smoke. By adoption of high-speed separation air and the proper over fire air rate, the created oxygen content in the combustion area is smaller than 1%, the NOx generated low-oxygen area in combustion can be restrained, a composite spraying port is utilized for conveying pyrolysis gas generated through the coal water slurry pyrolytic reaction and internally containing reducing active components and ammonia into the area, the reducing reaction with NOx in smoke happens in the reducing atmosphere, the limitation of usage of a temperature window during NOx reducing through a conventional reducing agent is broken through, furnace interior efficient combustion and economical reducing are ensured, the NOx concentration in smoke is totally reduced, and NOx ultra-low emission of a coalpowder combustion furnace is achieved.

Owner:SHANGHAI JIAO TONG UNIV

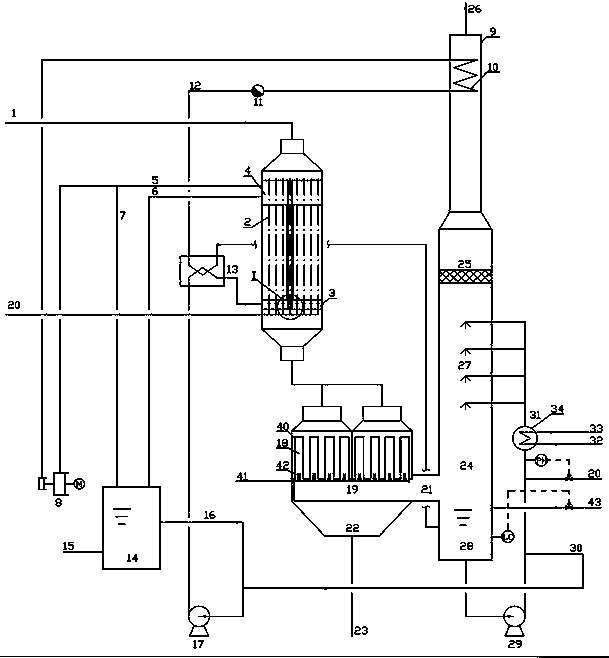

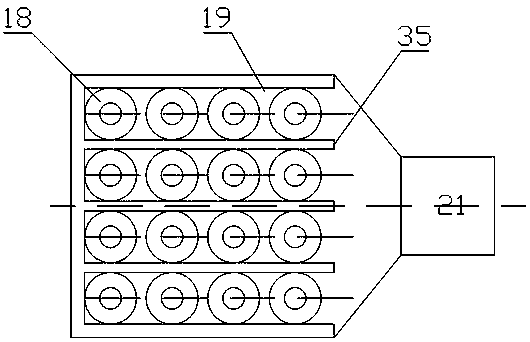

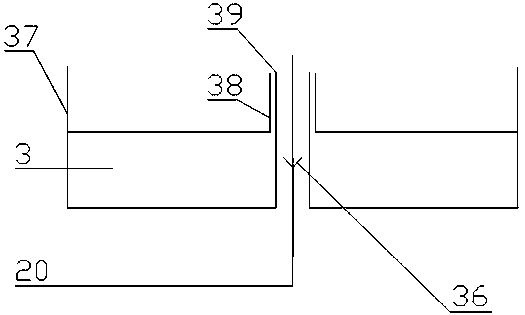

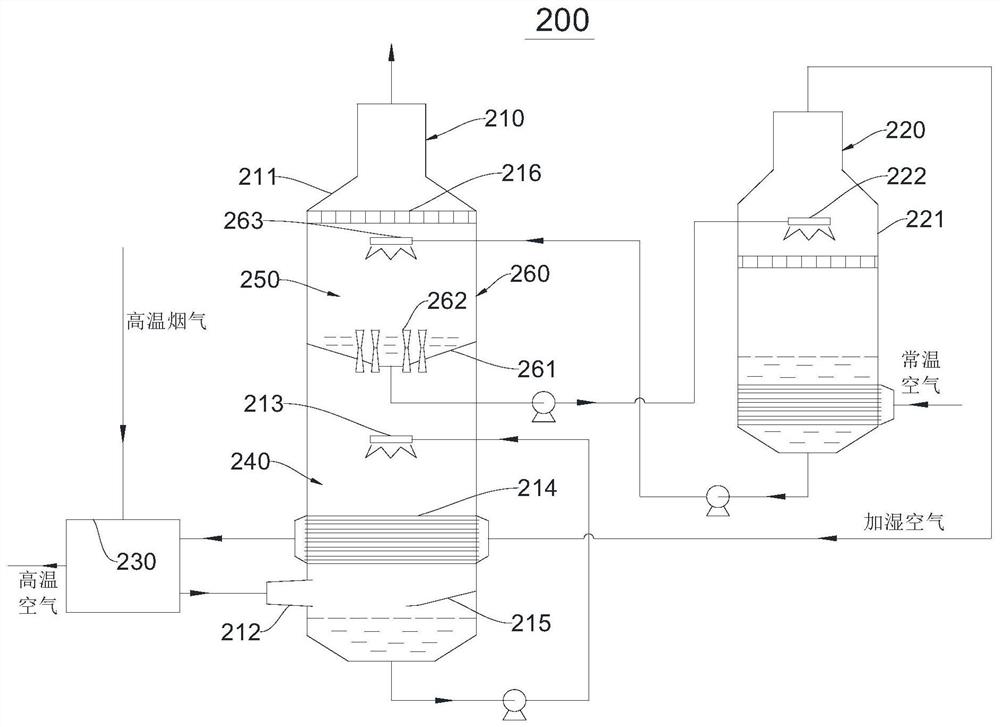

Flue gas and flue gas desulfurization wastewater treatment method and device

ActiveCN108619871AIncrease water vapor contentRaise the acid dew pointCombination devicesGas treatmentLiquid wasteSteam condensation

The invention relates to a flue gas and flue gas desulfurization wastewater treatment method and device. The flue gas is used to exchange heat and raise the temperature of desulfurization wastewater in a flue gas / desulfurization wastewater heat exchanger, a spray nozzle is arranged in a flue gas outlet to spray an NaOH solution, the temperature of the flue gas is reduced to the temperature of theacid dew point, then the flue gas enters a bag filter to remove dust and a sulfate / sulfuric acid liquid drop and then falls into a desulfurizing tower; the flue gas is desulfurized, purified and heated and the temperature is raised in the desulfurizing tower, the wastewater part at the bottom part of the desulfurizing tower serves as a circulating absorption liquid, other wastewater enters a plateheat exchanger in the form of desulfurization wastewater; and the plate heat exchanger uses steam condensation water produced in a heating coil in an exhaust funnel to preheat the desulfurization wastewater, and the preheated wastewater enters the flue gas / desulfurization wastewater heat exchanger. The double purposes of purifying the flue gas and meeting the emission requirement and achieving zero emission of the flue gas desulfurization waste liquid are achieved on the basis that the waste heat of the flue gas is fully used, meanwhile, the white smoke and the blue smoke are eliminated, andthe comprehensive treatment costs for the flue gas desulfurization and the desulfurization waste liquid are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

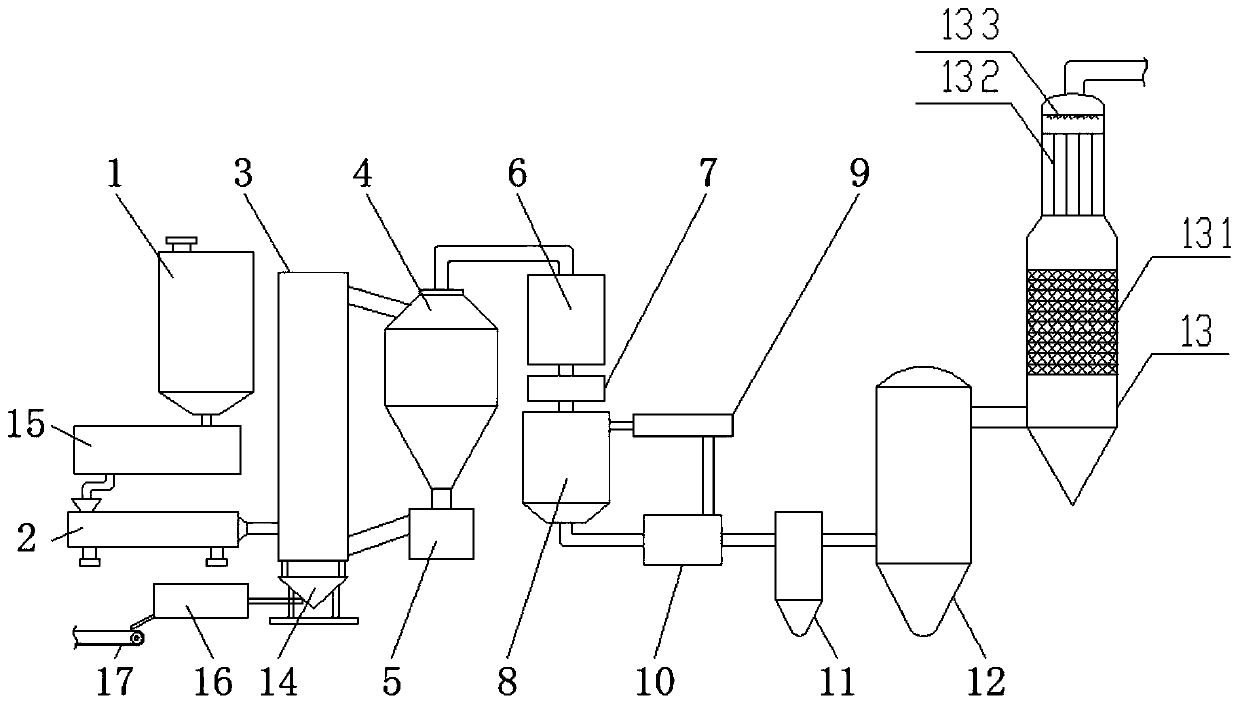

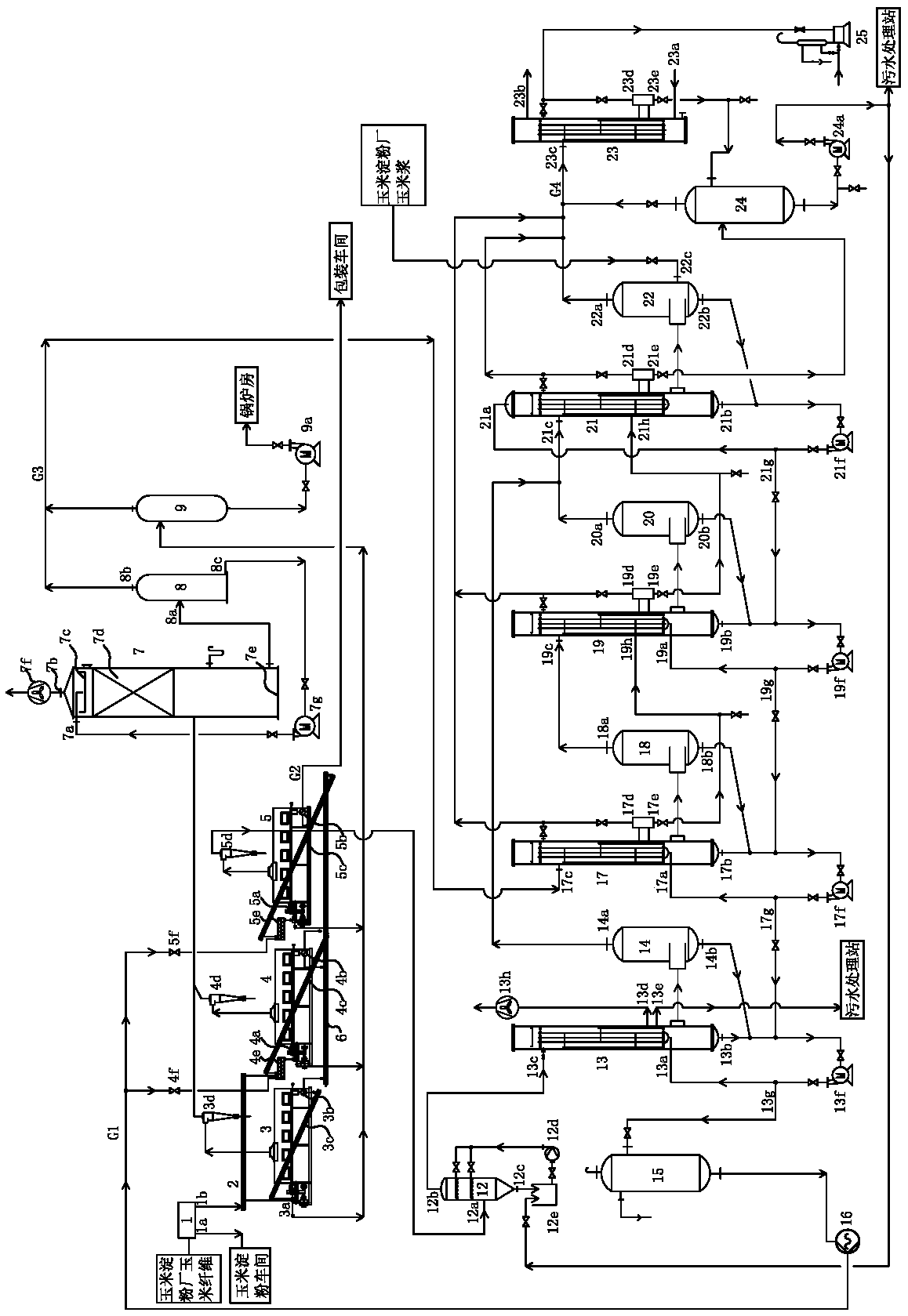

Production technology of corn pulp addition fibers

ActiveCN106387369AReduce consumptionImprove qualityFood processingAnimal feeding stuffFiberCooling tower

The invention relates to a production technology of corn pulp addition fibers. The production technology sequentially comprises the following steps of separating corn fibers in a corn starch plant into dehydrated corn fibers and dehydrated fluid, conveying the dehydrated corn fibers into a first pipe bundle drier for first-stage drying, and controlling a product return ratio; after the first-stage drying, performing primary pulp addition with thick corn pulp, performing uniform mixing to obtain a first mixture, conveying the first mixture into a second pipe bundle drier for second-stage drying, and controlling a product return ratio; after the second-stage drying, performing secondary pulp addition with thick corn pulp, performing uniform mixing to obtain a second mixture, conveying the second mixture into a third pipe bundle drier for third-stage drying, and controlling a product return ratio; enabling discharged corn fibers after the third-stage drying, namely corn pulp addition fibers to enter a multi-stage countercurrent cooling tower for cooling; and respectively performing dust removal and residual heat recover on the high-quality tail gas of the first pipe bundle drier, the high-quality tail gas of the second pipe bundle drier, and the low-quality tail gas of the third pipe bundle drier, and gradually concentrating thin corn pulp into the thick corn pulp through recovered heat. The production technology of the corn pulp addition fibers disclosed by the invention is low in steam consumption and power consumption, high in drying efficiency and good in product quality.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

Energy recovery in manufacture of sulfuric acid

ActiveUS8586001B2Improve energy recoveryRestore energyDispersed particle separationEnergy inputEnergy recoveryPhotochemistry

This invention relates to the recovery of energy in the manufacture of sulfuric acid, and more particularly to enhanced recovery of energy from the absorption of wet SO3 in sulfuric acid. The invention is further directed to control of mist formation during SO3 absorption, and of the sulfuric acid mist content of the gas stream leaving the SO3 absorption step in a process wherein SO3 absorption energy is recovered from absorption acid in useful form.

Owner:MECS

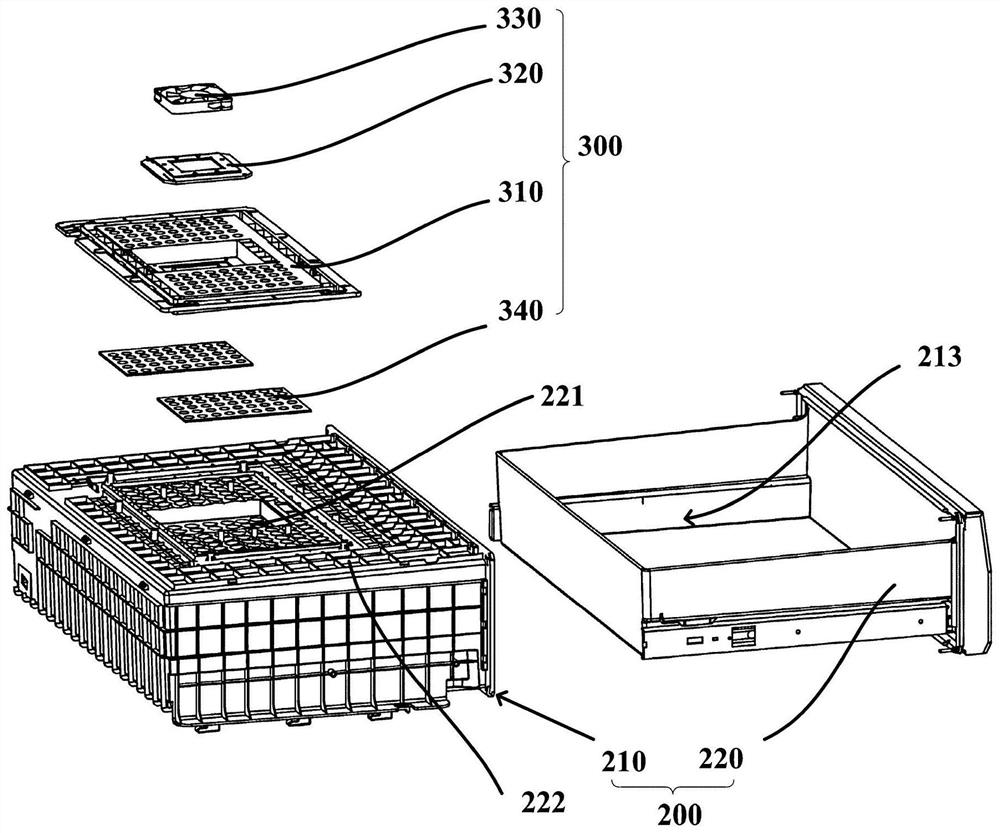

Refrigerator

PendingCN112747531AIncrease water vapor contentGood oxygen removal efficiencyLighting and heating apparatusDomestic refrigeratorsPhysicsElectrochemical response

The invention provides a refrigerator. The refrigerator comprises an inner container, an air supply fan, a storage container and an oxygen removal assembly; a storage chamber as well as an evaporator cavity and an air supply duct which are located on the back side of the storage chamber and used for containing an evaporator is formed in the inner container; the air supply fan is arranged in the air supply duct and is configured to promote formation of air flow circulating among the evaporator cavity, the air supply duct and the evaporator cavity; the storage container is arranged in the storage chamber; the oxygen removal assembly is arranged above the storage container and is provided with an electrolysis part which faces the outside of the storage container and is used for electrolyzing water vapor outside the storage container through electrochemical reaction and an oxygen consumption part which faces the inside of the storage container and is used for consuming oxygen through electrochemical reaction; and the air supply fan is further configured to continuously operate at the first preset rotating speed after a refrigeration system of the refrigerator completes refrigeration to supplement the storage chamber with the water vapor, so that enough water vapor can be provided for the oxygen removal assembly to serve as a reactant, and the electrolytic oxygen removal efficiency can be improved.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Cracking furnace tube for inhibiting catalytic coking of hydrocarbon cracking furnace tube, and manufacturing method thereof

ActiveCN102807887BLow costFast growth rateThermal non-catalytic crackingSolid state diffusion coatingCarbon numberSurface layer

The invention relates to a cracking furnace tube for inhibiting catalytic coking of a hydrocarbon cracking furnace tube, and a manufacturing method thereof. The furnace tube comprises a substrate and an oxide film combined with the substrate, wherein the oxide film is an oxide film obtained by compounding three layers of oxides, the inner layer oxide near the substrate contains at least one selected from SiO2, CeO2 and Y2O3, the middle layer oxide comprises at least one selected from Cr2O3, FeO, Fe2O3 and NiO, the surface layer oxide comprises at least one selected from MnO and MnxCr3-xO4, and x is 0.5-1.5. The cracking furnace tube is manufactured by the following steps: carrying out a step-by-step heating treatment on a nickel-chrome alloy furnace tube material in low oxygen partial pressure gas, and generating an oxide film obtained by compounding three layers of oxides on the inner surface. According to the present invention, Fe content and Ni content in the oxide film of the cracking furnace tube are low, such that catalytic coking of the radiation-section furnace tube of the cracking furnace can be significantly inhibited when the cracking furnace tube is used for production of low carbon number olefin by the hydrocarbon cracking furnace tube.

Owner:CHINA PETROLEUM & CHEM CORP +1

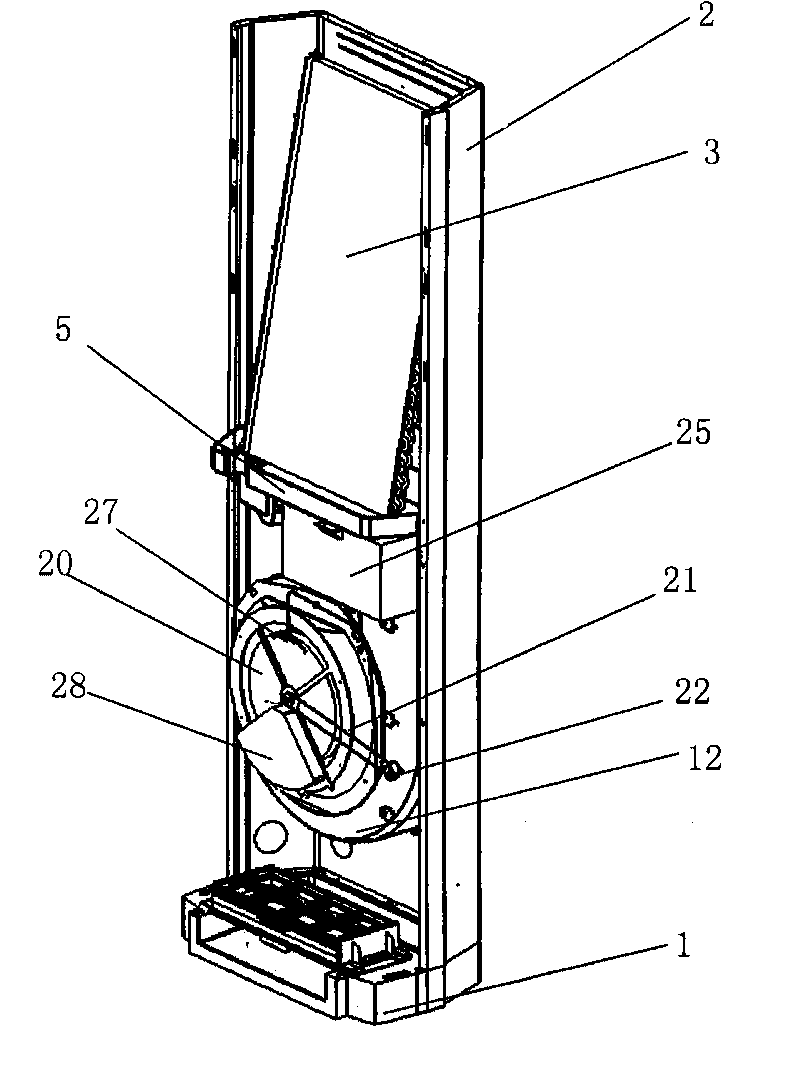

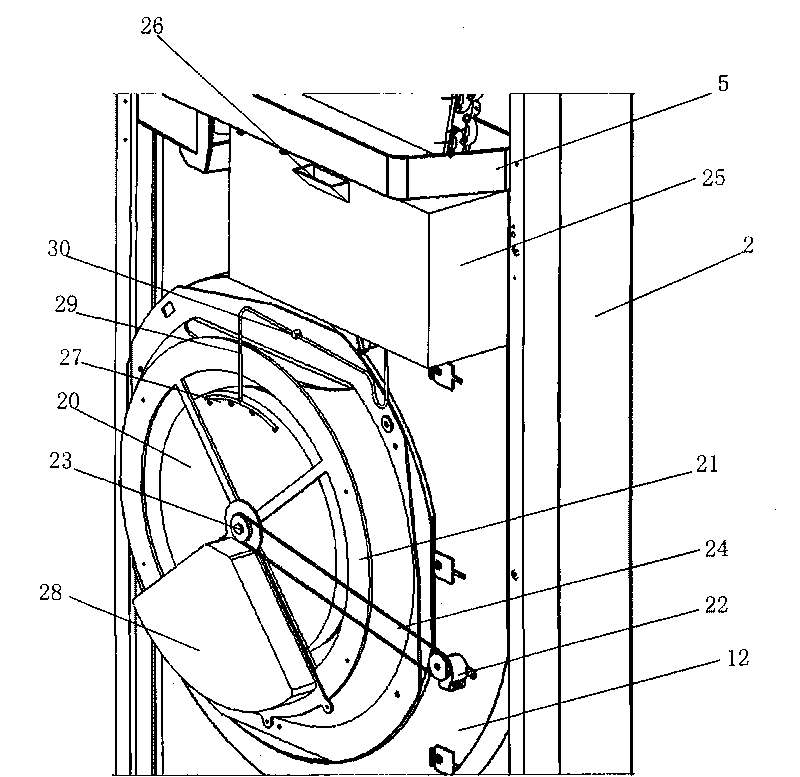

Indoor unit of cabinet air conditioner

InactiveCN101749790AIncrease humidityIncrease water vapor contentLighting and heating apparatusAir humidification systemsParticulatesThermodynamics

The invention relates to an indoor unit of a cabinet air conditioner, comprising a bottom disk, a shell, a front panel, an indoor heat exchanger, a centrifugal fan, a runner filter, a runner bracket, a motor, a water tank, a water divider and a regenerator, wherein the rotatable runner filter is arranged at a corresponding position at induced draft side of the centrifugal fan, particulate matter and impurities in air can be filtered by the runner filter, water is added to the runner filter by the water tank and the water divider, the rotating runner filter is heated by the regenerator arranged on one side of the runner bracket to evaporate the moisture of the runner filter, the steam generated in the heating process is mixed with the air collected by the centrifugal fan, and the increased steam-containing air affected by the centrifugal fan produces heat exchange with the indoor heat exchanger and is discharged indoors so as to increase stream contained in indoor air and indoor moisture and prevent persons from feeling uncomfortable due to dry indoor air.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Series quenching adiabatic fixed bed methanation reactor and process

InactiveCN104971666AReduce settingsLess investmentGaseous fuelsChemical/physical processesSyngasThermodynamics

The invention belongs to the field of chemical engineering and particularly relates to a process of a series quenching adiabatic fixed bed methanation reactor. The process comprises the following steps: (1) dividing synthesis gas passing through an ultra-fine reactor into N paths, enabling divided synthesis gas to enter the upper end of each catalyst bed layer of the reactor; (2) mixing fresh synthesis gas entering a section of catalyst bed layer with water vapor and circulating gas and then enabling the mixed gas to enter a section of bed layer; (3) mixing fresh synthesis gas entering the Mth section of catalyst bed layer with quenched gas coming from the outlet of the (M-1)th section of bed layer, and then enabling the mixed gas to enter the Mth section of catalyst bed layer; (4) pressurizing desalted water with a desalting water pump and then enabling the desalted water to enter the lower end of each bed layer of the reactor, wherein the desalted water can be used for quenching high-temperature gas at the outlet of each bed layer of the reactor.

Owner:CNOOC GAS & POWER GRP +1

Method of fluidizing wind at high pressure using steam to replace air

InactiveCN1313766CAvoid cokingAvoid burnsFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringTurbine

The invention relates to a method of implementing high pressure fluidization blast using steam in place of air, characterized in that: steam is used for high pressure fluidization blast in normal running of a boiler. The method includes: connecting a turbine exhaust or intermediate extraction with a stock recycler using a steam conduit; starting high pressure fluidization blower and fluidizing recycle material in the stock recycler using air when the boiler begins to start; opening stop valve of the turbine steam conduit, fluidizing recycle material in the stock recycler using steam, shutting down the high pressure fluidization blower and closing the stop valve when the temperature of recycle material in the stock recycler is above 300 Celsius degree, the fluidization steam vapor source pressure parameter is greater than 60Kpa, and the superheat degree is larger than 30 Celsius degree; starting the high pressure fluidization blower, fluidizing recycle material in the stock recycler using air, and closing the stop valve on steam turbine when the temperature of the stock recycler is under 300 Celsius degree in blow off process of the boiler. Advantages of the invention consist in that coking of the stock recycler or other high temperature zones can be prevented or abated and boiler operation reliability can be improved by using steam for replacing high pressure fluidization blast. At the same time, circulating fluid bed boiler desulfurizer utilization rate can be improved, Nox discharge concentration can be reduced, and power plant running cost can be saved by utilizing steam fluidization.

Owner:SHANGHAI BOILER WORKS

Under-pressure oxygen-enriched circulating fluidized bed gasification process method and system

PendingCN110643394AHigh water vapor contentSimple processGasification processes detailsGranular/pulverulent flues gasificationSlagSuperheater

The invention discloses an under-pressure oxygen-enriched circulating fluidized bed gasification process method and system. The system comprises a feed coal bunker, a screw feeder, a pressurized oxygen-enriched circulating fluidized bed gasifier and a deslagging belt, wherein the feed coal bunker is connected with a coal washer; a slag lock hopper is connected with a roller slag cooler; the deslagging belt is arranged beside the roller slag cooler; the top of a high-temperature cyclone separator is connected with the top of a gasifying agent preheater, the gasifying agent preheater is connected with a steam superheater, an economizer is connected with a cyclone dust collector, the cyclone dust collector is connected with a high-temperature filter body, and the high-temperature filter bodyis connected with a humidifying dust removal tower. According to the under-pressure oxygen-enriched circulating fluidized bed gasification process method and system, a novel structural design is adopted, so that the process flow is simple, the gasification pressure is easy to improve, the system operation cost and the investment cost are low, the dust removal efficiency is high, and the content ofwater vapor in produced coal gas is high.

Owner:济南黄台煤气炉有限公司

Cigarette suction device with water vapor generating function

PendingCN109123783AImprove suction moistnessIncrease water vapor contentTobacco pipesCombustionFlue gas

The invention belongs to the technical field of a traditional cigarette suction device, in particular, a suction device for generating water vapor to reduce irritation of smoke when conventional cigarettes are sucked. The cigarette suction device comprising a connecting section for connecting cigarettes, a steam generating section connected to one end of the connecting section and a power sectionconnected with the steam generating section for supplying power to the steam generating section. In the technical scheme of the present invention, as the cavity of the steam generating section is provided with a water-absorbing material, a microporous atomize sheet is arranged at the rear end of the water-absorbing material. As that cigarette is smoked, flue gas generated by combustion passes through the first and second air passages, and then mixing with the water vapor generated by the microporous atomizing sheet in the mixing chamber to increase the water vapor content in the flue gas, reduce the irritating effect of the flue gas and improve the suction and wetting feeling of the cigarette. The water-absorbing material of the invention can be replaced or directly added with water to thewater-absorbing material to realize the effect of reuse.

Owner:刘海伟

A kind of production technology of ddgs feed

ActiveCN106071109BImprove qualityConducive to waste heat recoveryFood processingAnimal feeding stuffAlcoholCooling tower

The invention relates to a production process of DDGS feed. The production process successively comprises the following steps: separating waste liquor of an alcohol plant into wet alcohol residues and clear liquid; concentrating the clear liquid into concentrated liquid; feeding the wet alcohol residues to a first tube bundle dryer, carrying out first-stage drying and controlling return ratio; after first-stage drying, carrying out first pulp adding by using the concentrated liquid; after mixing evenly, feeding into a second tube bundle dryer, carrying out second-stage drying and controlling return ratio; after second-stage drying, carrying out second pulp adding by using the concentrated liquid; after mixing evenly, feeding into a third tube bundle dryer, carrying out third-stage drying and controlling return ratio; defining alcohol residues discharged after third-stage drying as the DDGS feed; and cooling the DDGS feed in a multi-stage reverse flow cooling tower. High-quality tail gas of the first tube bundle dryer and the second tube bundle dryer and low-quality tail gas of the third tube bundle dryer are respectively subjected to dust removal and waste heat recycling, and the recycled heat is used for concentrating the clear liquid into the concentrated liquid step by step. The production process of the DDGS feed is low in steam and power consumption, high in drying efficiency and good in product quality.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

A kind of fuel cell cathode side humidity regulation control system and method

ActiveCN111180764BAvoid cathode water blockageEnsure safetyFuel cell controlFuel cellsElectrical battery

Owner:浙江高成绿能科技有限公司

A System for Reducing Nox Emissions from Syngas Gas Turbines

ActiveCN111441866BIncrease pressureIncrease water vapor contentGas turbine plantsSteam engine plantsSyngasThermodynamics

The invention discloses a system for reducing the NOx emission of a synthetic gas gas turbine. The air separation unit communicates with the intake pipeline of the gas turbine compressor through a pipeline through a heating humidifier, and the heated and humidified nitrogen is in a low pressure state (close to normal pressure) It is passed into the intake pipeline of the compressor and mixed with the inlet air in an appropriate proportion, and the carbon dioxide produced by the coal-to-gas decarbonization unit can be further passed through the pipeline through a heating humidifier at a low pressure state (close to normal pressure). into the air intake line of the compressor and mixed with the air therein, and the mixed gas is sent into the gas turbine compressor to reduce the oxygen concentration of the air entering the gas turbine compressor, thereby reducing the oxygen concentration of the air entering the combustion chamber of the gas turbine, realizing The purpose of reducing NOx emissions from syngas gas turbines.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

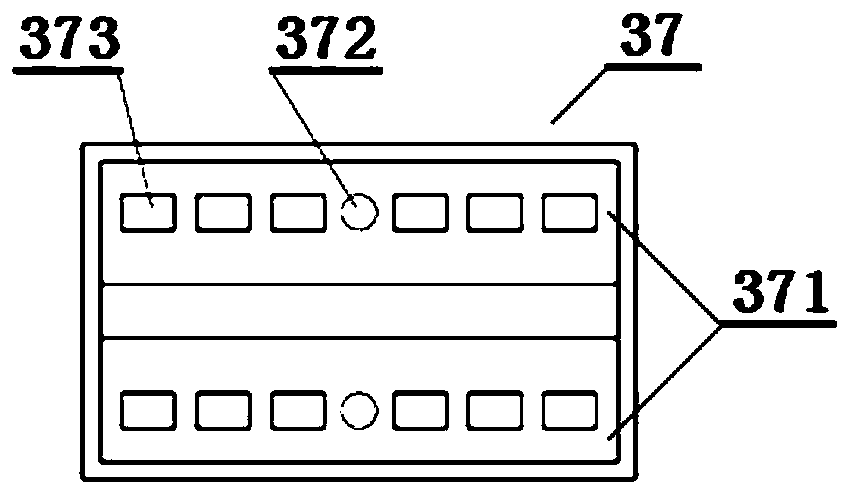

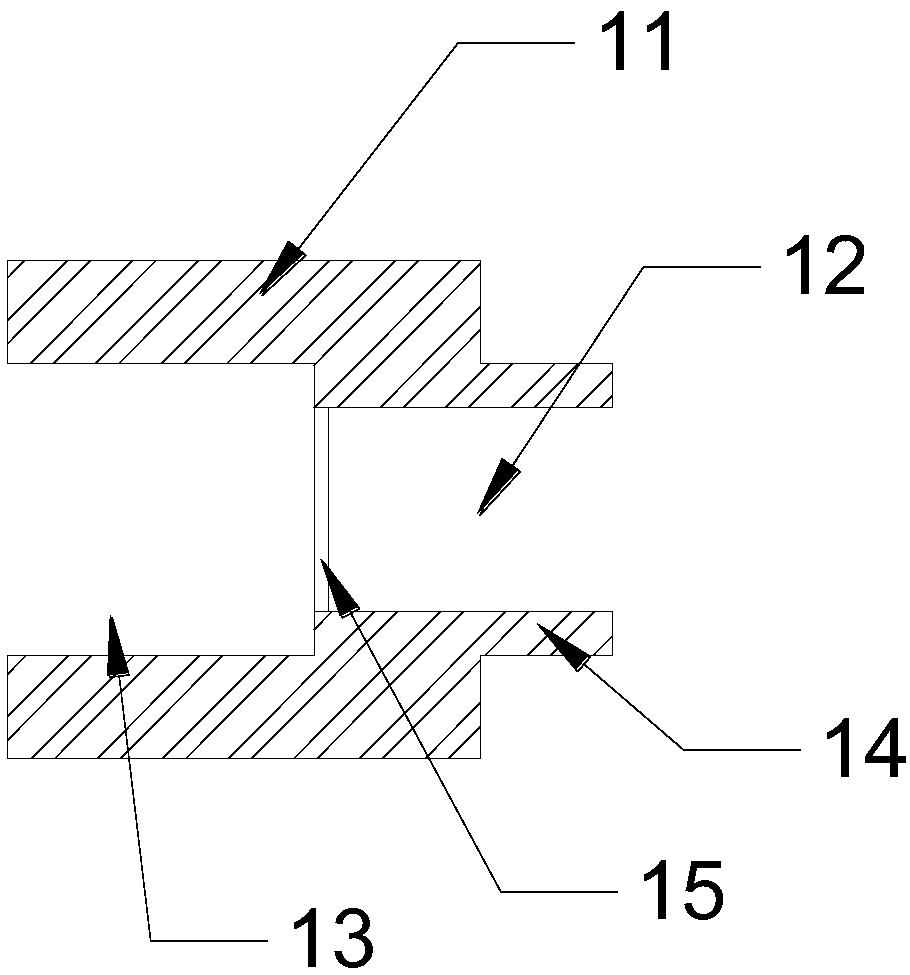

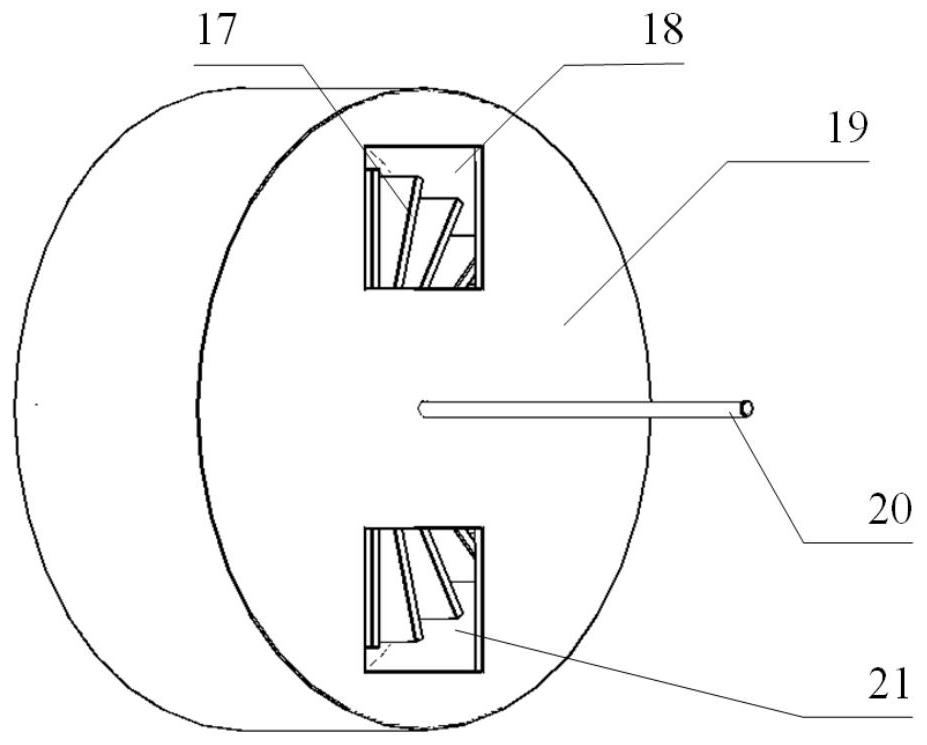

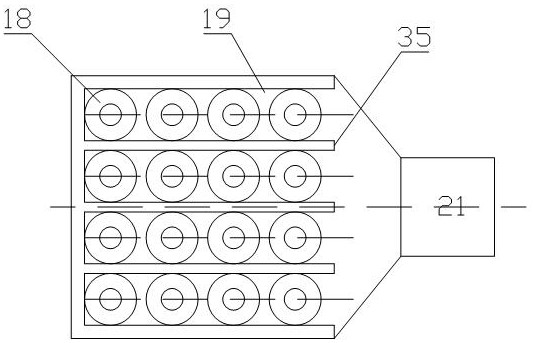

PEMFC combined supply fresh air purification, dehumidification and humidification device and control method thereof

PendingCN114135949AReduce water vapor contentIncrease water vapor contentEnergy recovery in ventilation and heatingMechanical apparatusProcess engineeringFresh air

The invention belongs to the technical field of distributed energy and air conditioning, and discloses a PEMFC combined supply fresh air purification, dehumidification and humidification device and a control method thereof.In the PEMFC combined supply fresh air purification, dehumidification and humidification device, the fresh air purification and humidification device is provided with a box body, a shaft is installed in the box body through a shaft hole, the shaft penetrates through a heat insulation and preservation material, and the heat insulation and preservation material is arranged in the box body; one end is connected with the motor; fins are arranged on the upper side of the heat insulation material and coated with an MOFs adsorption material; the upper side of the box body is provided with an upper half air inlet and outlet, and the lower side of the box body is provided with a lower half air inlet and And the fresh air purifying and humidifying device is connected with the first heat exchanger. The PEMFC provides electric quantity needed by the device and heat needed by solid adsorbent regeneration, and compared with a traditional fresh air dehumidification device, the situation that cold and heat are counteracted can be effectively avoided, the unit cost is effectively reduced, and the purposes of energy conservation and environment protection are achieved; the application requirements of the solid adsorbent can be met.

Owner:HUAZHONG UNIV OF SCI & TECH

A treatment method and device for flue gas and flue gas desulfurization wastewater

ActiveCN108619871BIncrease water vapor contentRaise the acid dew pointCombination devicesGas treatmentPlate heat exchangerBaghouse

The invention relates to a treatment method for flue gas and flue gas desulfurization wastewater. In the flue gas / desulfurization wastewater heat exchanger, the flue gas is used to exchange heat for the desulfurization wastewater, and a nozzle is set at the outlet of the flue gas to spray NaOH solution to make the flue gas At this time, the flue gas enters the bag filter to remove dust and sulfate / sulfuric acid droplets, and then enters the desulfurization tower; desulfurization purification and heating are carried out in the desulfurization tower, and the waste water at the bottom of the tower is used as The absorption liquid is circulated, and the others enter the plate heat exchanger in the form of desulfurization wastewater; the plate heat exchanger uses the steam condensed water generated by the heating coil in the exhaust cylinder to preheat the desulfurization wastewater, and after preheating, the wastewater enters the flue gas / desulfurization wastewater exchange heater. On the basis of making full use of the waste heat of the flue gas, the present invention realizes the dual purpose of purifying the flue gas to meet the emission requirements and zero discharge of flue gas desulfurization waste liquid, and simultaneously eliminates "white smoke" and "blue smoke", and reduces the cost of flue gas desulfurization. and the comprehensive treatment cost of desulfurization waste liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

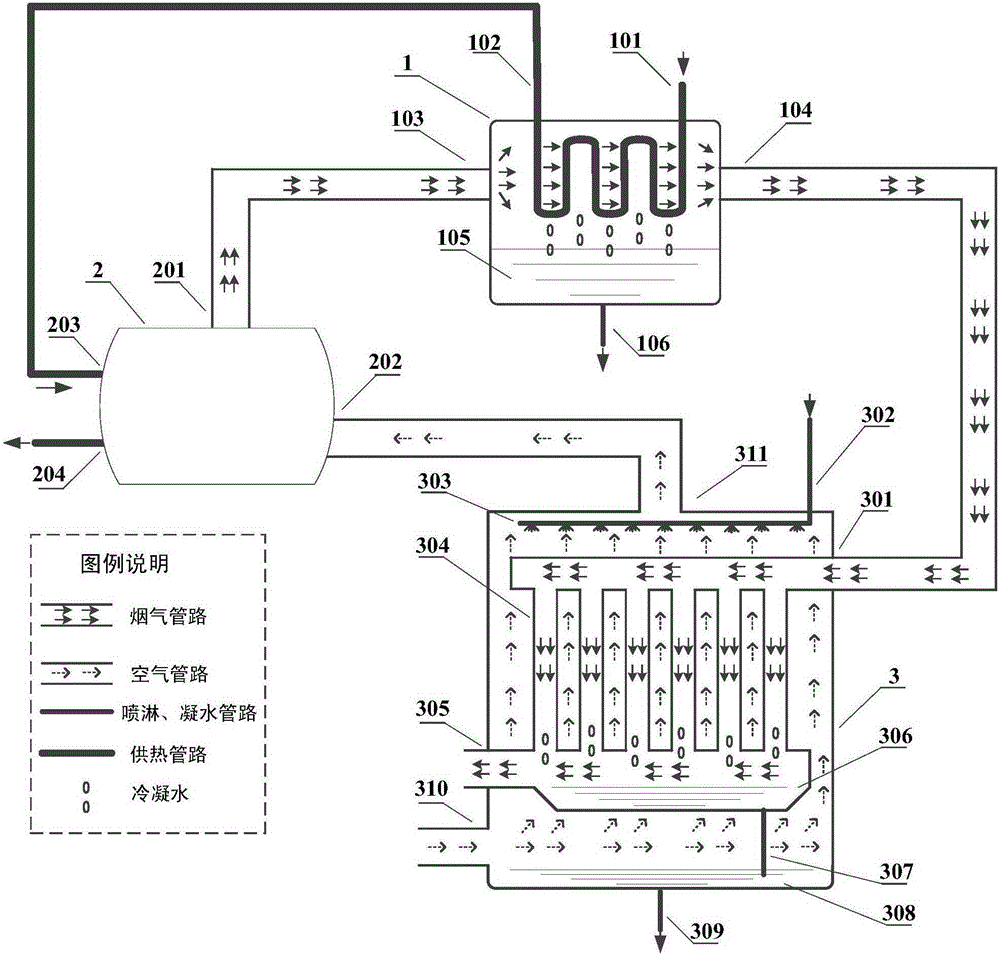

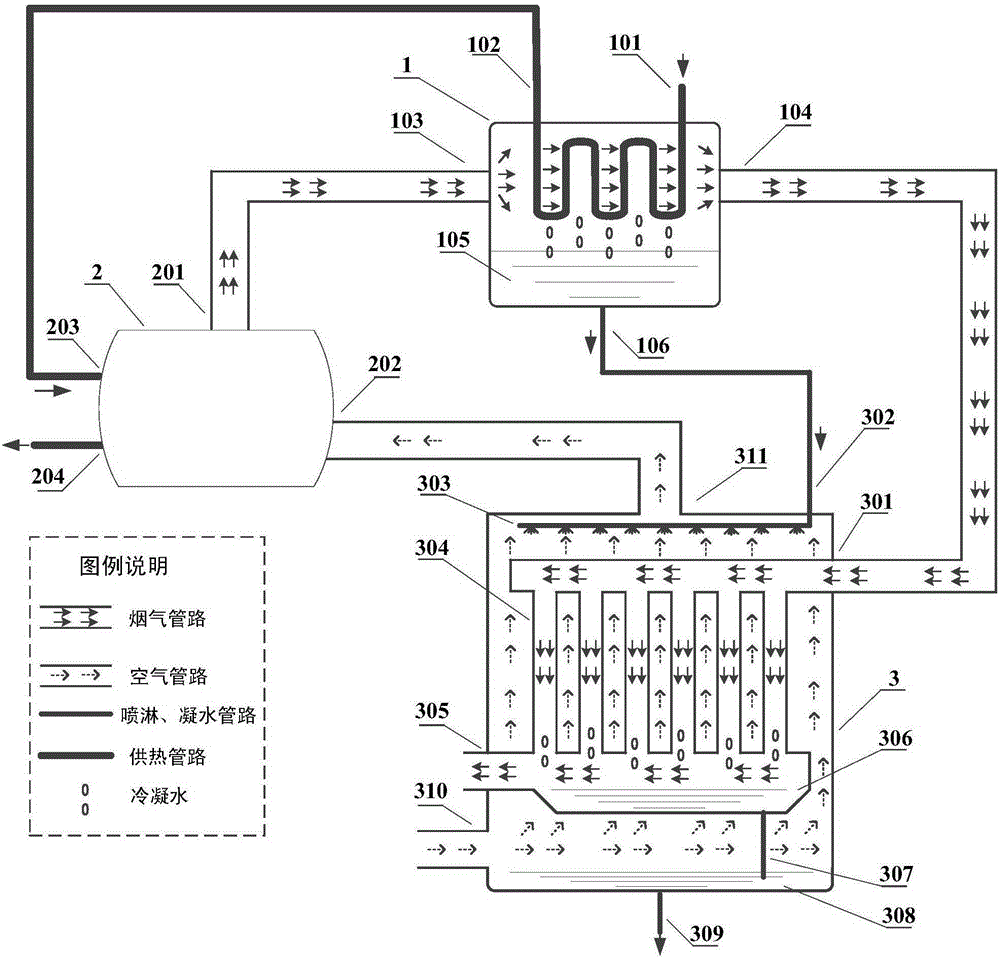

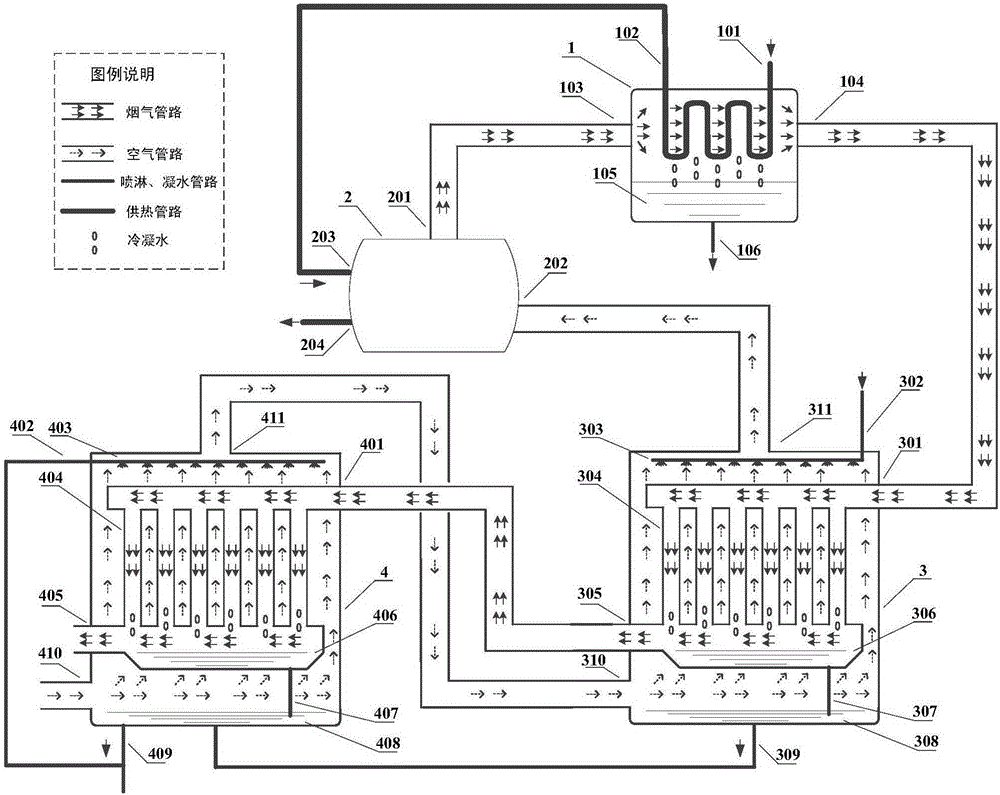

A deep heat recovery device and method for boiler flue gas

ActiveCN104110675BIncrease the equivalent heat capacityImprove heat carrying capacityFluid heatersFeed-water heatersRecovery methodEngineering

The invention discloses a deep heat recovery device and a deep heat recovery method for boiler smoke, which belong to the technical field of waste heat recovery. The deep heat recovery device disclosed by the invention comprises a boiler, a smoke-backwater heat exchanger, and N stages of heat recovery devices which are serially arranged, wherein N is not less than 1; each stage of the heat recovery device comprises a nozzle, a smoke-air heat exchanger, a smoke water-condensing groove, a smoke water-condensing tube, a heat recovery water collection groove, a heat recovery water drainage tube, and the like; each stage of the heat recovery device increases the equivalent heat capacity of air through the spray humidification for an air side, thus greatly improving the heat-carrying capacity of air, enabling the smoke discharge temperature of the boiler to be lower, and realizing deep heat recovery for the boiler smoke from the air side. According to the deep heat recovery device and the deep heat recovery method disclosed by the invention, heat exchange is carried out by virtue of the inlet air and smoke of the boiler, the water content of air is increased by means of spray humidification for the air side for air inlet, and the equivalent heat capacity of air is increased, thus realizing a higher heat exchange amount, effectively lowering the smoke discharge temperature of the boiler, and adequately recovering the waste heat of smoke; in addition, due to the increase of the humidity of a fuel, a combustion temperature can be lowered, and the formation of NOx can be reduced.

Owner:TSINGHUA UNIV

A kind of production technology of corn pulping fiber

ActiveCN106387369BReduce consumptionImprove qualityFood processingAnimal feeding stuffFiberCooling tower

The invention relates to a production technology of corn pulp addition fibers. The production technology sequentially comprises the following steps of separating corn fibers in a corn starch plant into dehydrated corn fibers and dehydrated fluid, conveying the dehydrated corn fibers into a first pipe bundle drier for first-stage drying, and controlling a product return ratio; after the first-stage drying, performing primary pulp addition with thick corn pulp, performing uniform mixing to obtain a first mixture, conveying the first mixture into a second pipe bundle drier for second-stage drying, and controlling a product return ratio; after the second-stage drying, performing secondary pulp addition with thick corn pulp, performing uniform mixing to obtain a second mixture, conveying the second mixture into a third pipe bundle drier for third-stage drying, and controlling a product return ratio; enabling discharged corn fibers after the third-stage drying, namely corn pulp addition fibers to enter a multi-stage countercurrent cooling tower for cooling; and respectively performing dust removal and residual heat recover on the high-quality tail gas of the first pipe bundle drier, the high-quality tail gas of the second pipe bundle drier, and the low-quality tail gas of the third pipe bundle drier, and gradually concentrating thin corn pulp into the thick corn pulp through recovered heat. The production technology of the corn pulp addition fibers disclosed by the invention is low in steam consumption and power consumption, high in drying efficiency and good in product quality.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

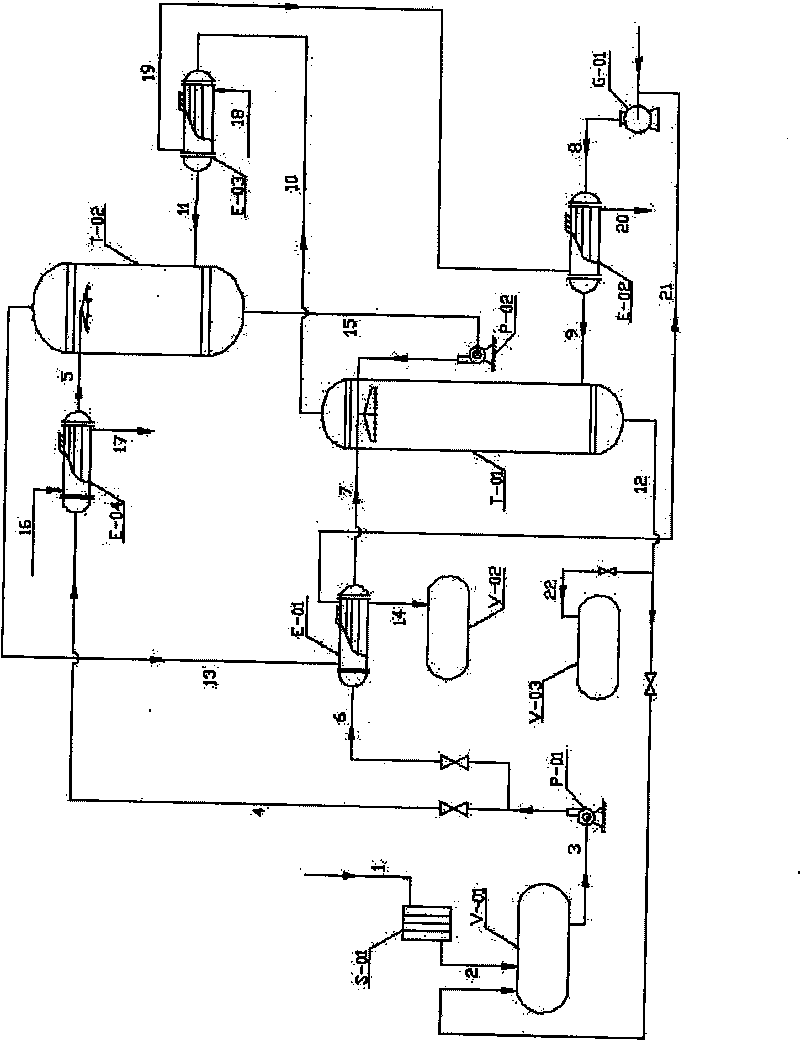

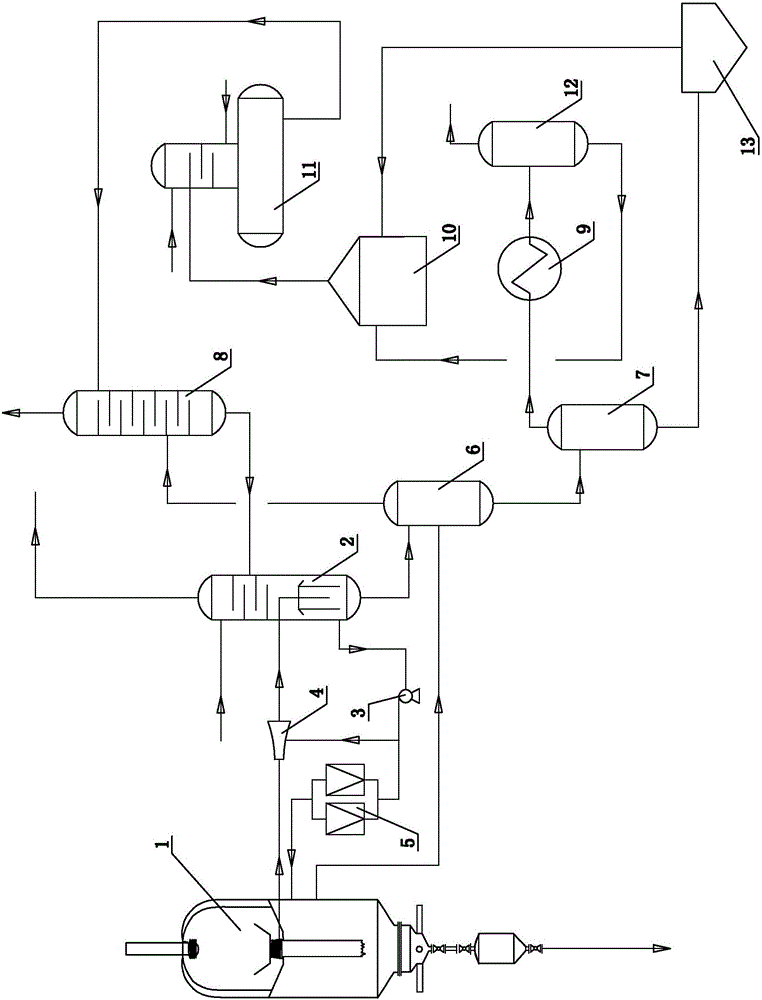

A kind of syngas scrubbing process

ActiveCN103435005BSimple processReduce pollutionHydrogen separationHydrogen productionReduction treatmentWater vapor

The invention discloses a washing treatment process for synthesis gas. The washing treatment process comprises the following steps: after black water from a shock chilling chamber of a gasification furnace is filtered and ash dreg is removed, the black water enters a buffering pot; after shock chilling water from the buffering pot passes through a circulating pump, the shock chilling water enters the shock chilling chamber of the gasification furnace; after synthesis gas is contacted with introduced washing water by a washing tower and enters a follow-up conversion working section after being contacted with converted condensing water and desalting and oxygen-removing water for dust removal; part of the washing water from the washing tower enters the shock chilling chamber of the gasification furnace; after dreg is filtered by a filter, the black water from the washing tower and the other part of the washing water are combined and then enter the buffering pot; after the washing water from the buffering pot is pressurized by a circulating pump, part of the washing water enters a venturi scrubber and the other part of the washing water enters the washing tower to be circularly used. According to the washing treatment process for the synthesis gas, the black water is not discharged out so that the pollution and the water consumption can be relieved; the wastewater discharge is reduced by 0.36 ton; the operation period of a device is prolonged and the treatment of ash water is very simple and common; the ash water does not need to be subjected to temperature reduction treatment so that the system has the relatively high water vapor content and the temperature of the synthesis gas is increased; the washing treatment process of the synthesis gas is good for the follow-up conversion working section.

Owner:刘金成

Seawater desalination process with low cost

ActiveCN101734823BReduce the burden onReduce heat pollutionGeneral water supply conservationSeawater treatmentWater vaporNuclear power

The invention relates to a seawater desalination process with low cost, which utilizes the condensate of the vapor cycle of a thermal power plant or a nuclear power station as a heat source, heats seawater to the temperature of 60-80 DEG C and atomizes the seawater in an atomizing chamber. On the other hand, natural air is heated after being washed and humidified, enters the atomizing chamber andcontacts the atomized high-temperature seawater mist flow so as to enable part of the atomized high-temperature seawater mist flow to be instantaneously vaporized; fresh water mist droplets generatedby the atomization of the high-temperature seawater are lifted by the kinetic energy of air to move upwards; moreover, because the density of water is different from the density of salt, the water and the salt are separated in the movement process; the two blasts of fresh water airflow are cooled by the raw material of cold seawater simultaneously and condensed into fresh water, the heated raw material of the cold seawater is used for washing and humidifying the natural air, and clean air carrying water vapor is recycled after the clean air carrying the water vapor is cooled; and the entire process flow does not consume extra heat energy and only consumes the air and less electric energy required by the transportation of the seawater. The process recovers energy in the condensate of the vapor cycle of the thermal power plant or the nuclear power station, produces the fresh water in large amounts and also produces a by-product of concentrated seawater.

Owner:NANJING UNIV

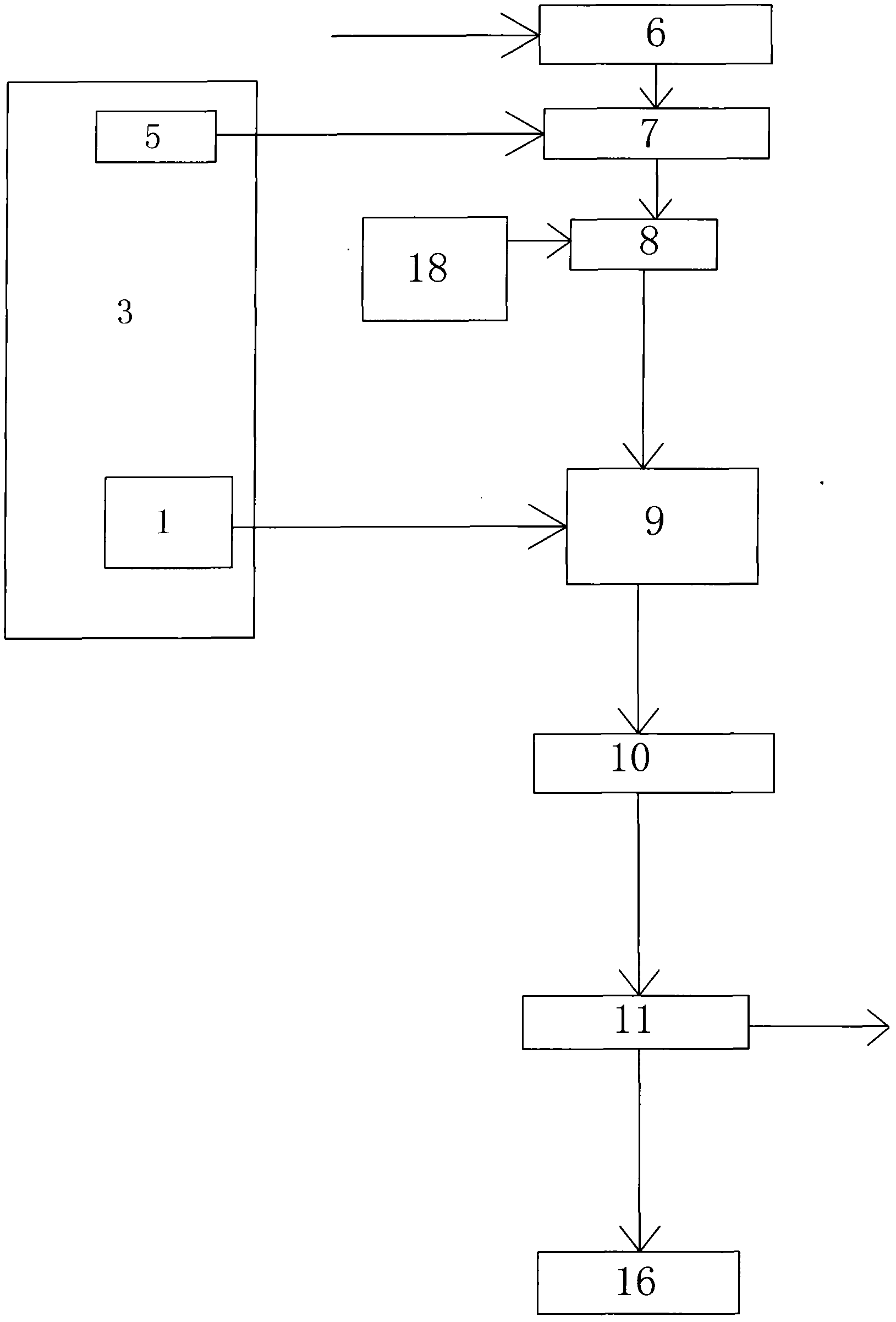

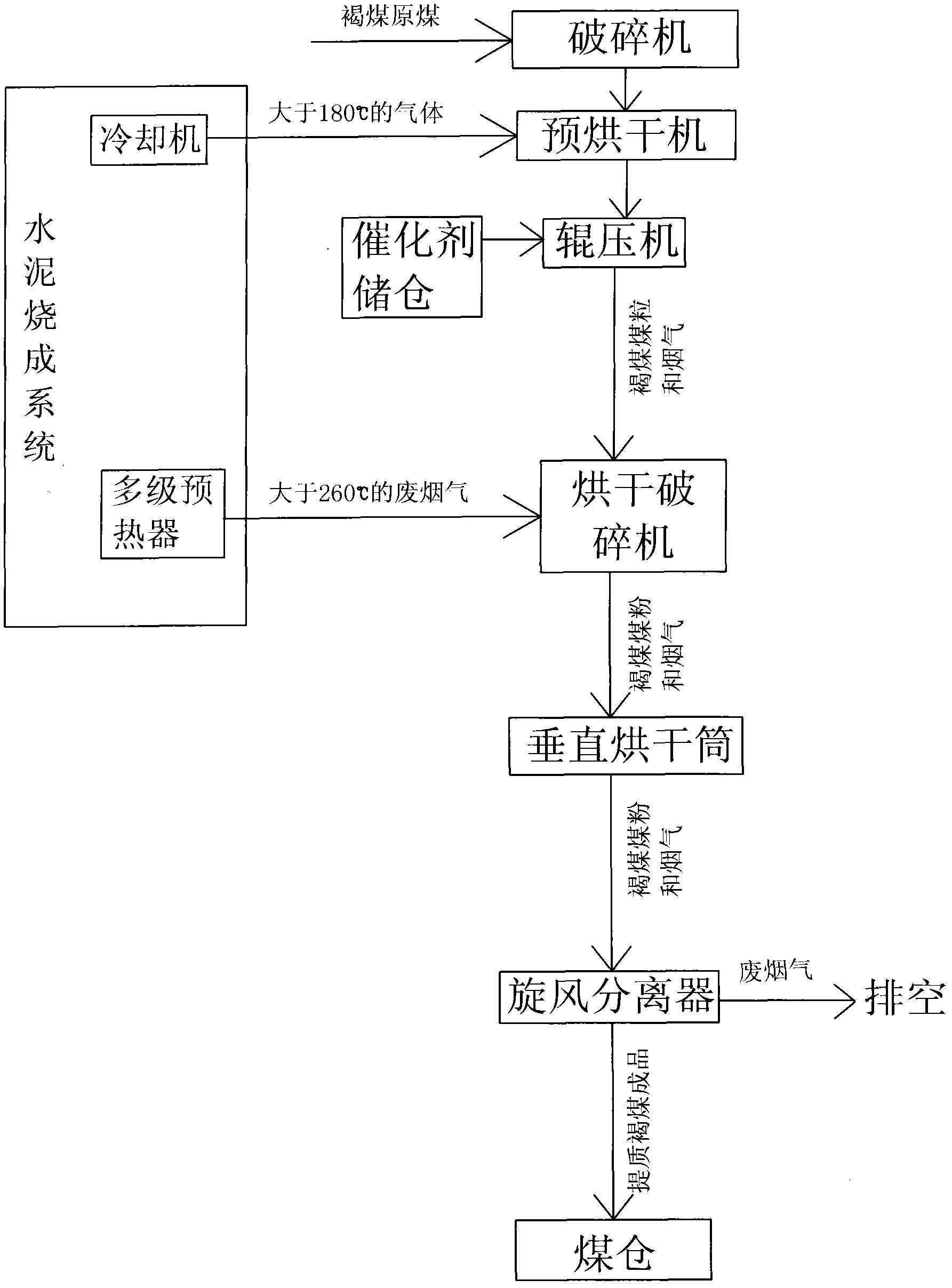

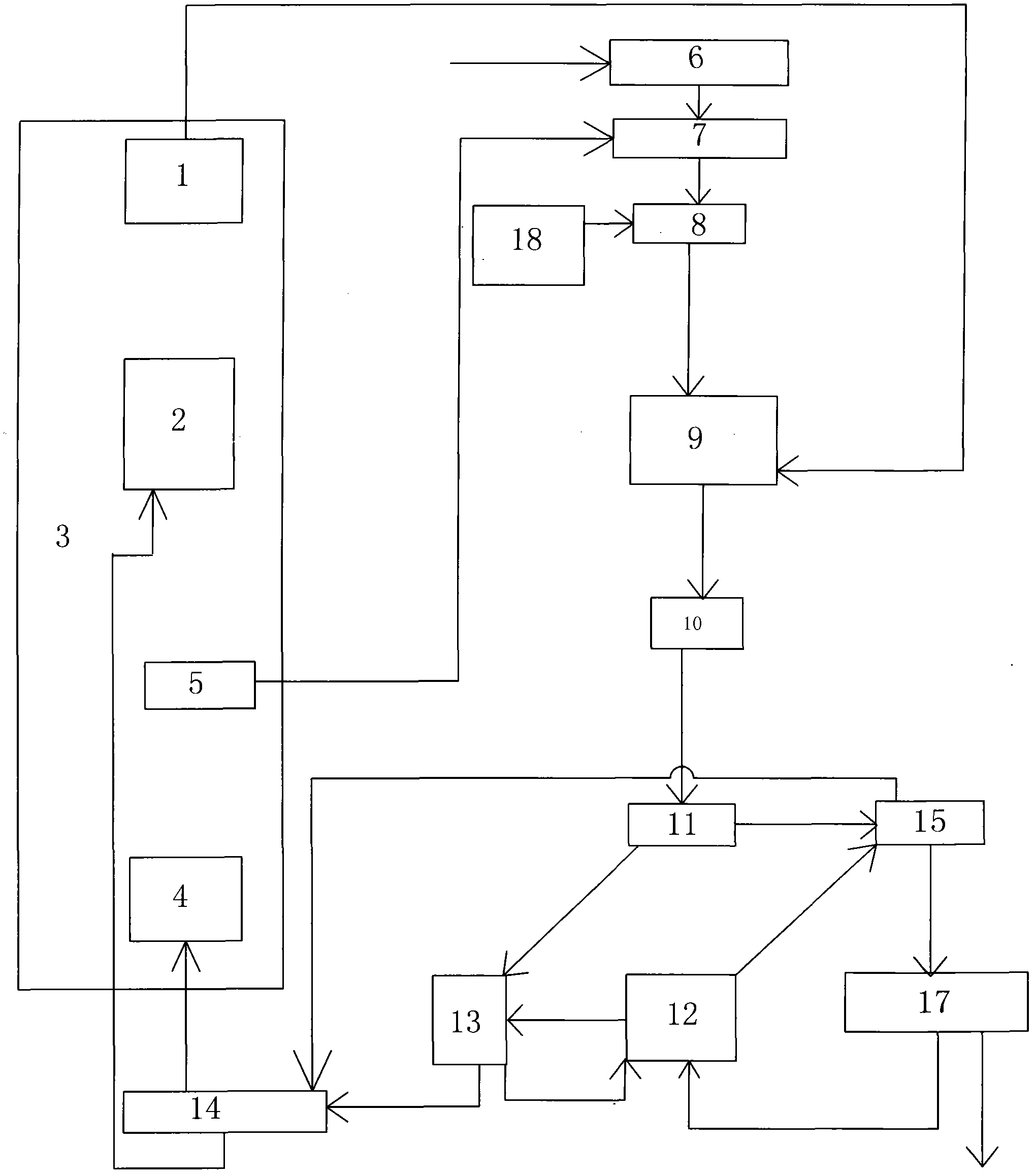

Integral purified integration system and process of lignite in cement production through catalytic mild pyrolysis

InactiveCN102061211BIncrease water vapor contentReduce dust contentSolid fuelsDrying peatCoal briquetteProduction line

Owner:INNER MONGOLIA UNIV OF TECH

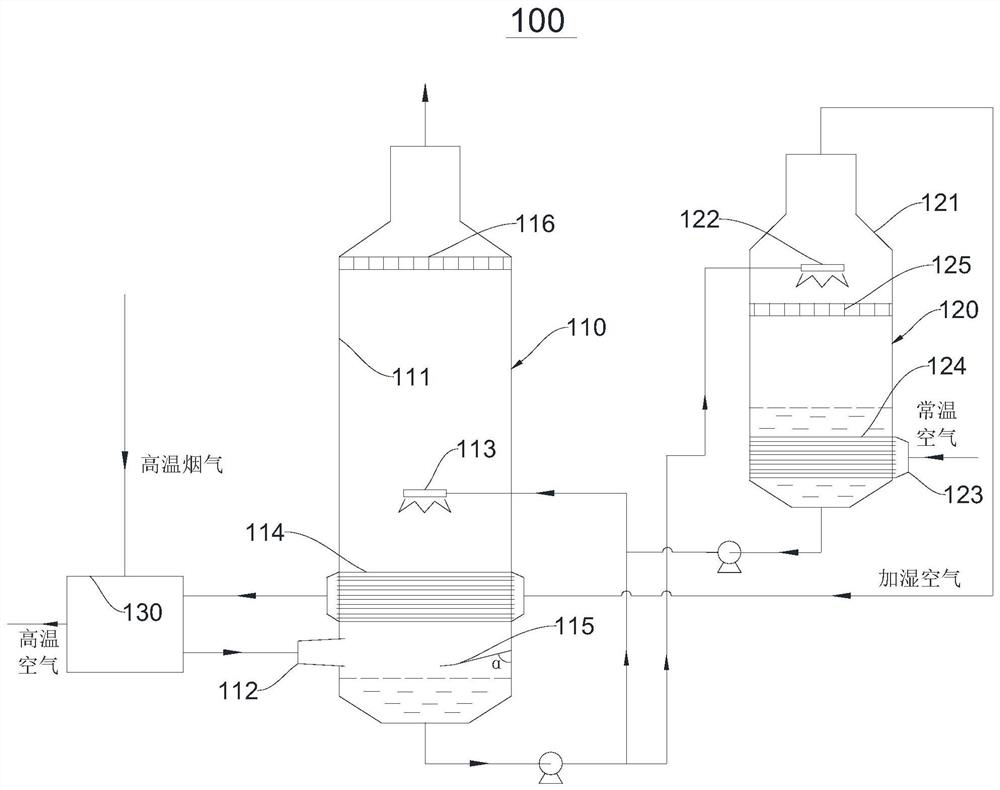

Heating furnace flue gas waste heat recovery system and combustion system

ActiveCN112229230BImprove thermal efficiencyReduce contentCombustion processIncreasing energy efficiencyCooling towerSpray cooling

The invention relates to the field of recovery and treatment of flue gas from heating furnaces, in particular to a waste heat recovery system and combustion system of flue gas from heating furnaces. It includes a spray cooling tower and an air humidification tower. The spray cooling tower includes a cooling tower body and a first spray device for spraying cooling liquid. The side of the cooling tower body relatively close to the bottom of the tower is provided with a flue gas inlet. The shower device is set in the cooling tower body and is relatively close to the top of the tower, so that the flue gas and the cooling liquid form convection; the air humidification tower includes the air humidifier body and the second spray device for spraying liquid, and the air humidifier body is relatively close to the tower There is an air inlet on one side of the bottom, and the second spraying device is arranged in the air humidifier body and is relatively close to the top of the tower. The liquid outlet of the cooling tower body is connected to the second spraying device, so that the air and the liquid form convection, The air is heated and humidified. It can effectively recover and utilize the waste heat of the flue gas of the heating furnace while reducing the content of NOx in the flue gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com