Flue gas desulfurization and desulfurization wastewater treatment method and flue gas desulfurization and desulfurization wastewater treatment apparatus

A technology for desulfurization wastewater and treatment methods, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of unreduced flue gas temperature, high power consumption and high power consumption of electric demisters, and increase water consumption. Steam content, improvement of treatment effect, effect of increasing acid dew point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The flue gas composition of a boiler after flue gas denitration treatment is shown in Table 1.

[0040] Table 1 Composition of sulfur-containing flue gas after denitrification of a certain boiler flue gas

[0041]

[0042] Calculate the dew point temperature of flue gas acid (sulfuric acid) before and after desulfurization treatment according to the following formula:

[0043]

[0044] in,[ H 2 O ]——the content of water vapor in the flue gas, vol%.

[0045] [ SO 3 ] - sulfur trioxide content in flue gas, vol %.

[0046] Different water vapor content and different SO 3 The sulfuric acid dew point temperature under the concentration is shown in Table 2.

[0047] Table 2 Different water vapor content and different SO 3 flue gas dew point

[0048]

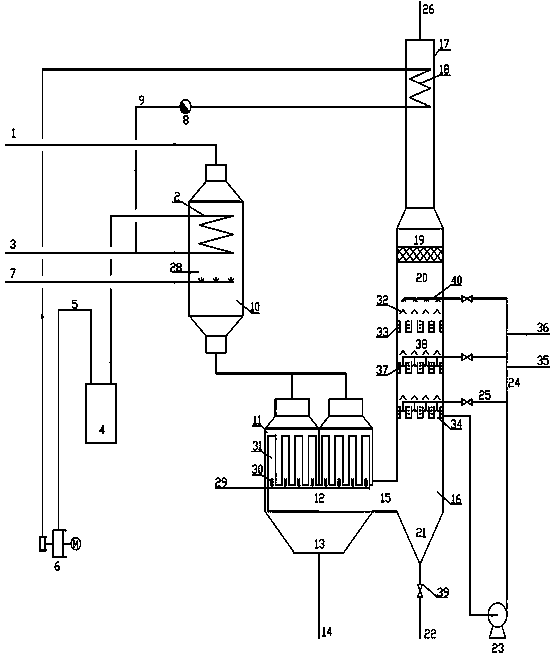

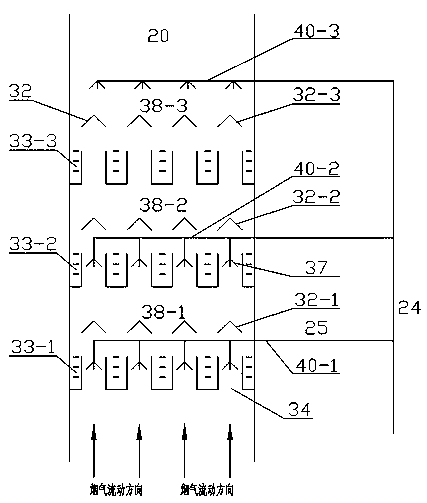

[0049] Adopt the present invention to attach figure 1 The processing device: the flue gas / demineralized water heat exchanger on the upper part of the flue gas pretreatment tower adopts a coil heat exchanger,...

Embodiment 2

[0052] flue gas SO 2 Concentration 2500mg / Nm 3 , SO 3 Concentration 200mg / Nm 3 , smoke volume and other parameters are the same as in Example 1. The same processing apparatus as in Example 1 was used. Specific operating conditions: (1) Control the flue gas temperature after heat exchange to 115°C, spray NaOH solution with a mass concentration of 1.6% at the outlet of the flue gas / demineralized water heat exchanger, and water vapor in the flue gas entering the bag filter The content is 15%, and the flue gas temperature is 107°C, which is 110°C lower than the acid dew point temperature of the flue gas. (2) Control the filtration speed of the bag filter to 1.0m / s; when the pressure drop of the bag filter reaches 1.0kPa, start the blowback cleaning system. (3) Use NaOH solution with a mass concentration of 30% as absorbent for flue gas desulfurization, control the pH value of the circulating absorption liquid to 7.5-8.0 to adjust the replenishment of fresh absorption liquid, ...

Embodiment 3

[0055] The processing flow and operating conditions are the same as in Example 1. The difference is that the spindle-shaped structured packing described in CN104607009A is filled in the dust removal and desulfurization zone of the dust removal and desulfurization tower.

[0056] Effect: Purify SO in flue gas 3 Not detected, dust concentration 3mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com