Method for recovering byproducts generated in processing process of medicinal chrysanthemum flowers

A technology of chrysanthemum processing and recovery method, which is applied in the direction of drug combination, pharmaceutical formula, perfume formulation, etc. It can solve the problems of not considering the recovery and utilization of volatile oil, ignoring the development and utilization of volatile oil, and the loss of volatile oil, so as to achieve good economic and social benefits , High degree of unsaturation, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

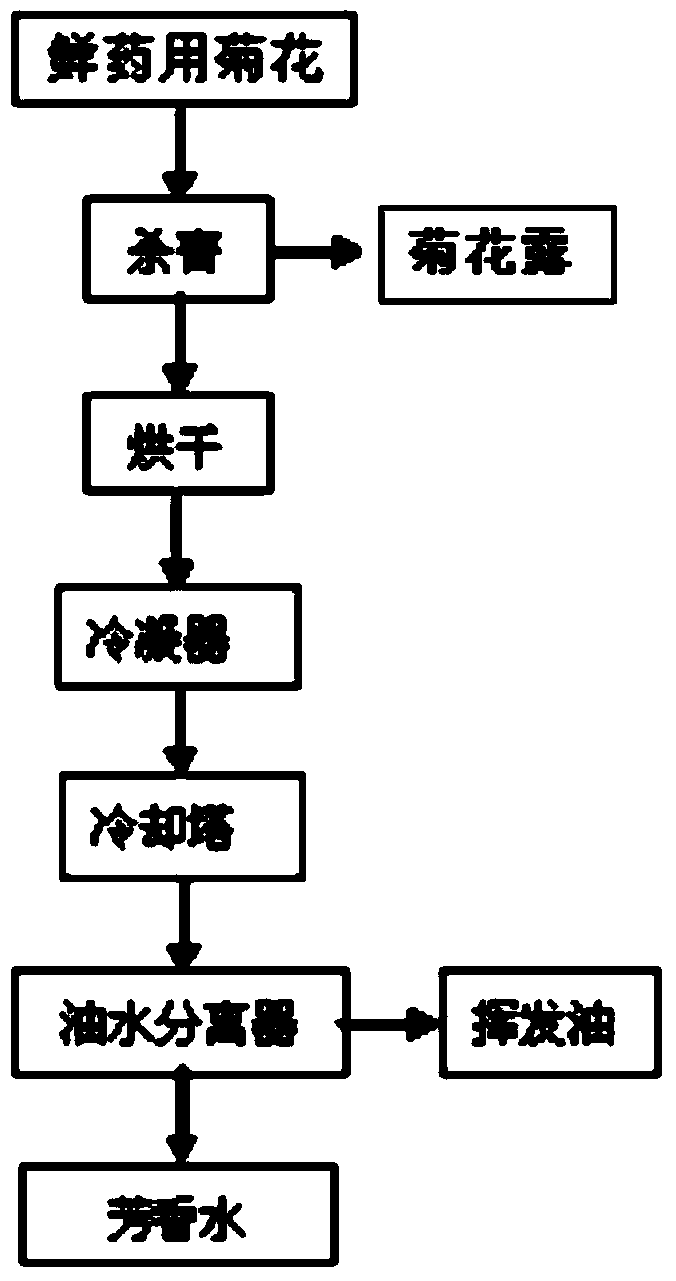

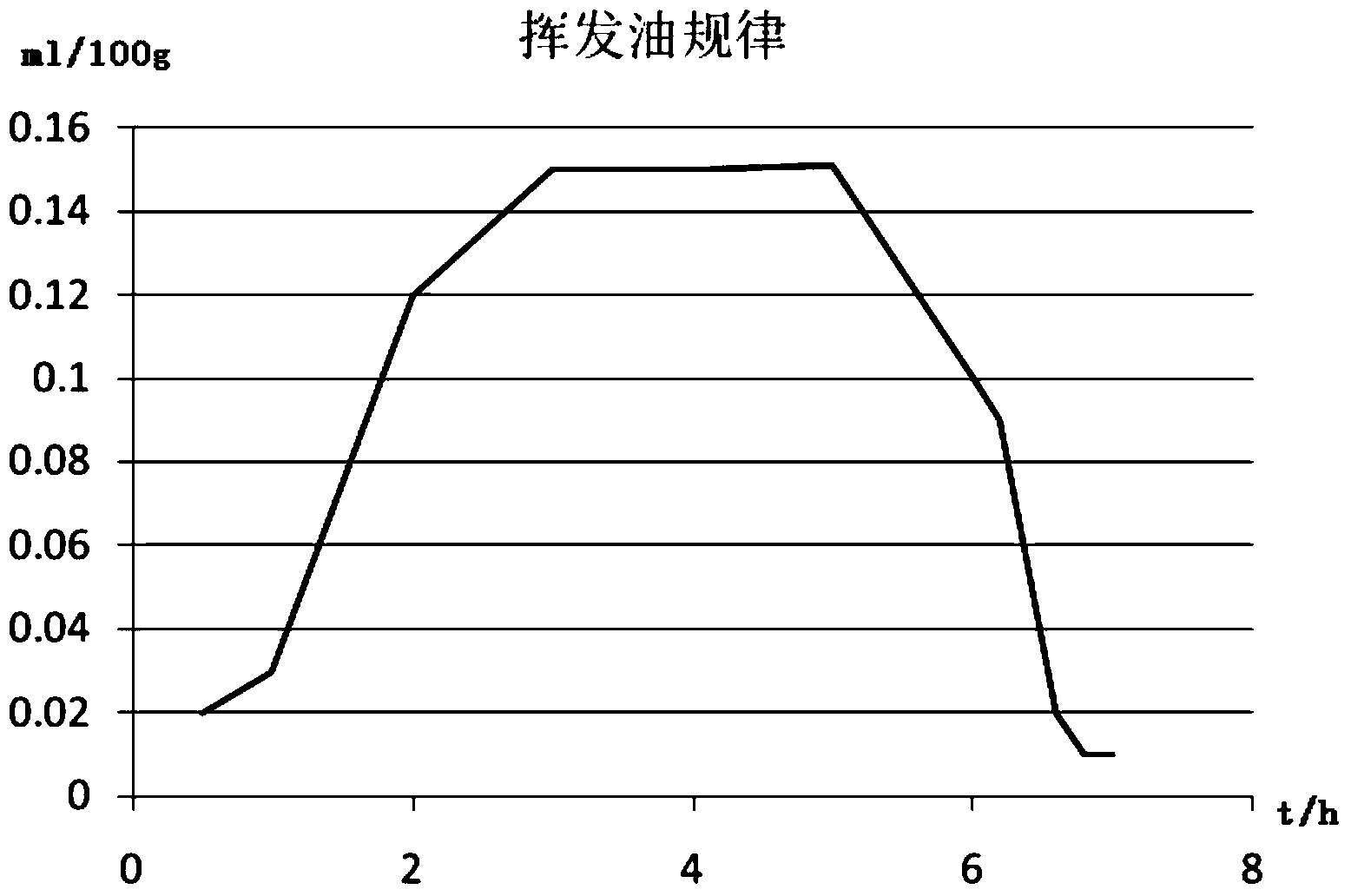

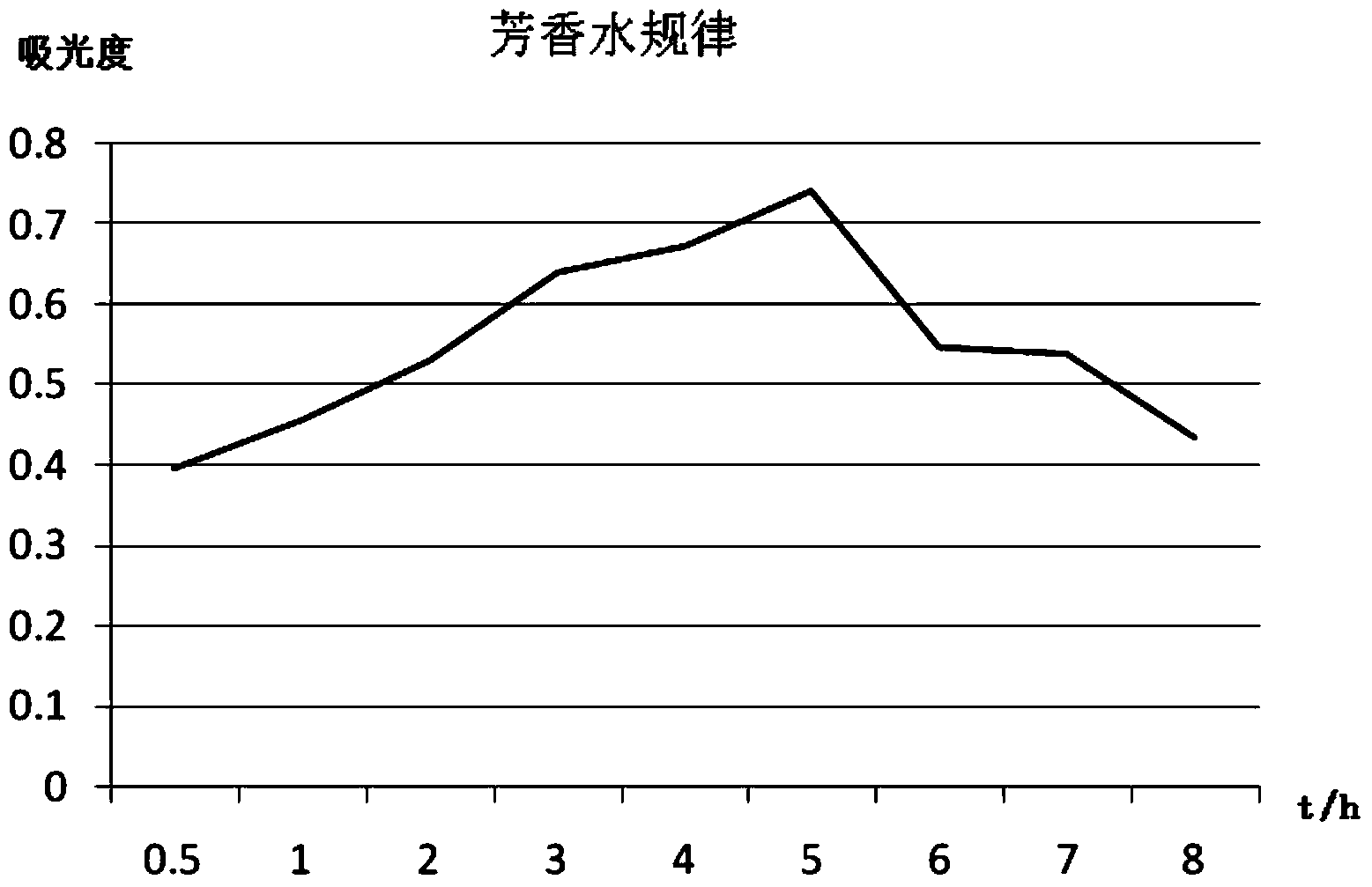

[0025] Example 1: After the fresh medicinal chrysanthemum enters the automatic de-enzyme drying machine, it is first de-enzymed at a high temperature of 100°C for 50s; , within 2 to 6 hours of drying time, collect the generated water-oil mixed steam and enter the condenser, cooling tower cooling and oil-water separator in turn for oil-water separation. After the oil-water is fully separated, open the oil-water separator to collect the upper oil layer. Volatile oil, collect the lower water layer to obtain aromatic water, and the recovery of aromatic water should not exceed 1.5 to 2 times the fresh weight of medicinal chrysanthemums.

Embodiment 2

[0026] Example 2: After the fresh medicinal chrysanthemum enters the automatic de-enzyme drying machine, it is first de-enzymed at a high temperature of 110°C for 45 seconds. At this time, part of the volatile oil with a high boiling point will be lost with water vapor, because the water content of this part of water-oil mixed steam is relatively high. Large, the overall volatile oil content is low, and it is not suitable for recovery as volatile oil due to economic considerations. Therefore, it can be developed into primary products such as chrysanthemum dew after passing through a circulating condensing device, cooling and recycling, and simple processing. In order to ensure quality, chrysanthemum The recovered amount of dew should not exceed the fresh weight of chrysanthemums. Next, the chrysanthemum is automatically transferred to a dryer for drying, the drying temperature is controlled at 70° C., and the drying time is 6.5 hours. According to the experience in the process...

Embodiment 3

[0028] Example 3: The basic steps are the same as those in Example 2, the difference is: the temperature for killing greens is controlled at 105° C., and the time for killing greens is 55 seconds; the drying temperature is 72° C., and the drying time is 7.5 hours. The water-oil mixed steam generated within 3-5 hours of drying time is collected and subjected to subsequent treatment to separate and obtain volatile oil, which has high unsaturation and excellent quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com