Heteroatom-modified fluorinated carbon quantum and preparation method thereof

A technology of carbon fluoride and carbon heterofluoride, which is applied in the preparation of new carbon fluoride materials and its battery applications, can solve the problems of not being able to increase the solid phase diffusion rate of lithium ions, and achieve excellent rate performance and high discharge specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

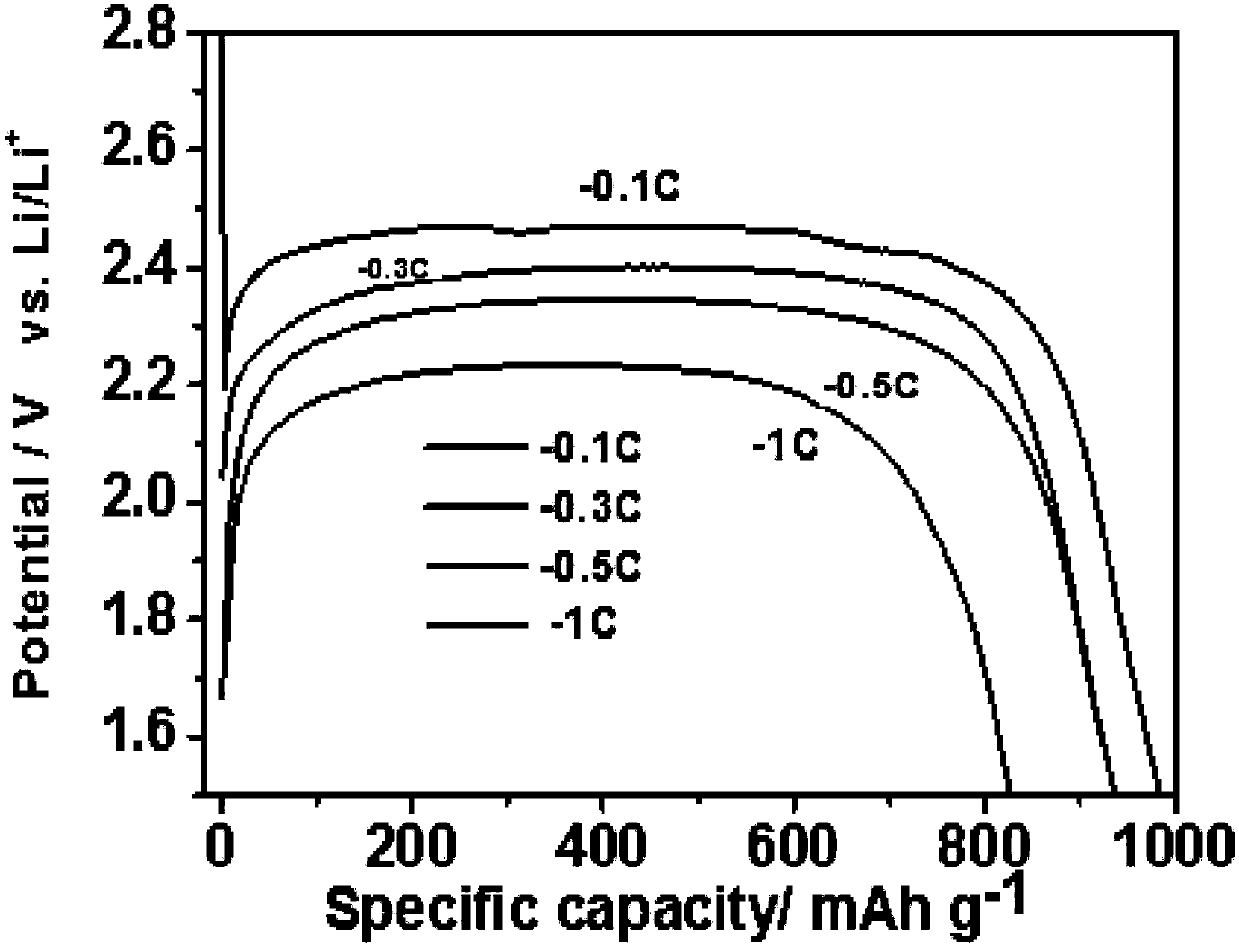

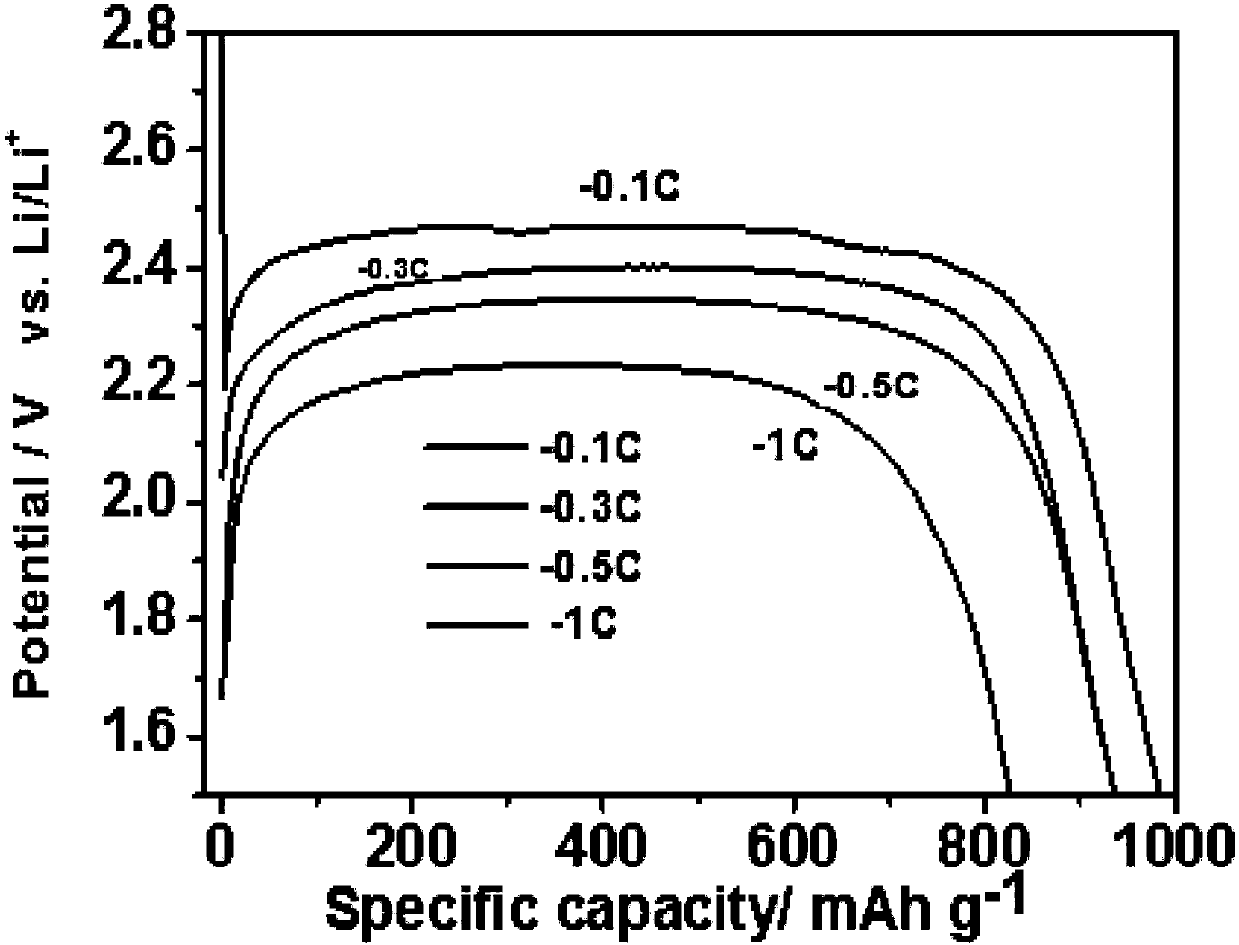

Embodiment 1

[0020] Take 1.0g of glucose, dissolve it in a mixed solution of 100ml of deionized water and 200ml of absolute ethanol, stir evenly, add 0.01g of boric acid, and stir until dissolved. The reaction system was put into a microwave-assisted synthesis reactor for microwave-assisted polymerization, the microwave power was 600W, and the total reaction time was 6h. After the reaction, the sample was filtered and dried at 60°C. Then, under the condition of nitrogen protective gas, carbonize at 600°C for 2h, and then 1200V for 1h to prepare boron-containing carbon quantum dot materials. The prepared carbon material was subjected to fluorination treatment at 200° C. for 4 hours under the flow rate of 50 ml min-1 F2 to obtain a boron-doped fluorinated carbon quantum dot material. The fluorine content of the prepared material is 58wt%, and the content of heteroatom boron is 2wt.%. The discharge specific capacity of 1.5V cut-off voltage is 810mAh g-1, and the discharge voltage is 2.15V. ...

Embodiment 2

[0022] Take 1.0g of aniline, dissolve it in a mixed solution of 100ml of deionized water and 200ml of absolute ethanol, stir well, add 0.01g of ferric chloride, add 0.005ml of phosphoric acid, and stir until dissolved. Put the reaction system into a microwave-assisted synthesis reactor for microwave-assisted polymerization, the microwave power is 500W, and the total reaction time is 5h. After the reaction, the sample was filtered and dried at 60°C. Then, under the condition of nitrogen protective gas, carbonize at 600°C for 2h, and then at 1200°C for 1h to prepare nitrogen-containing carbon quantum dot materials. The prepared carbon material was subjected to fluorination treatment at 250° C. for 4 hours at a flow rate of 10 ml min-1 F2 to obtain a nitrogen-phosphorus-doped fluorinated carbon quantum dot material. The mass percentage of fluorine in the prepared material is 55wt.%, the mass percentage of heteroatom nitrogen is 1.5wt.%, and the mass percentage of heteroatom phos...

Embodiment 3

[0024] Take 1.0g of pyrrole, dissolve it in a mixed solution of 100ml of deionized water and 200ml of absolute ethanol, stir evenly, add 0.01g of ferric chloride, add 0.005ml of boric acid, and stir until dissolved. The reaction system was put into a microwave-assisted synthesis reactor for microwave-assisted polymerization, the microwave power was 300W, and the total reaction time was 4h. After the reaction, the sample was filtered and dried at 60°C. Then, under the condition of nitrogen protective gas, carbonize at 600°C for 2h, and then at 1200°C for 1h to prepare nitrogen-containing carbon quantum dot materials. The prepared carbon material was subjected to fluorination treatment at 400° C. for 4 hours at a flow rate of 20 ml min-1 F2 to obtain a nitrogen-boron-doped fluorinated carbon quantum dot material. The mass percentage of fluorine in the prepared material is 60wt.%, the mass percentage of nitrogen is 1.5wt.%, and the mass percentage of boron is 2wt.%. The F / C mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com