Coffee-flavored thin-layer coating chocolate composition and preparation method thereof

A chocolate and composition technology, which is applied in the fields of food science, cocoa, and food ingredients as taste improvers, etc., can solve the problems of long refining time and high heat of chocolate coating, and achieve a wide range of applications, rich chocolate flavor, reduced heat and The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

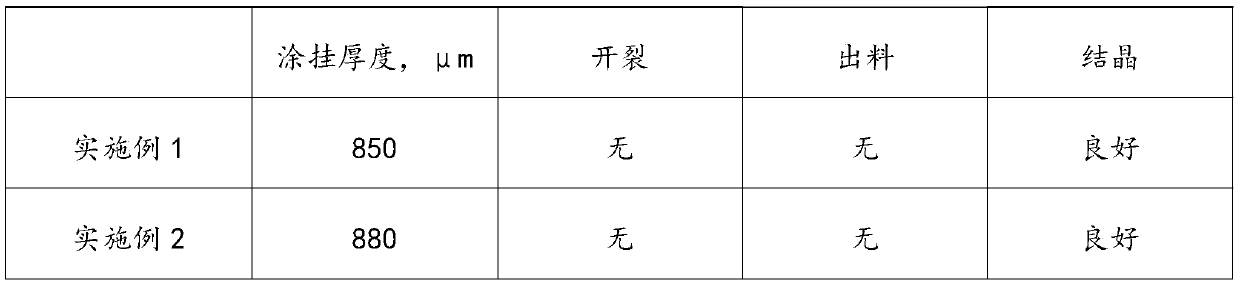

Embodiment 1

[0041] This embodiment provides a coffee-flavored thin-layer coating chocolate composition, and its product formula consists of: 33kg of white granulated sugar, 3.2kg of whole milk powder, 35.6kg of coconut oil, 14.1kg of palm oil, and 13.3kg of natural low-fat cocoa powder , Blue Mountain granule coffee 0.11kg, lecithin 0.4kg, polyglycerol ricinoleate 0.27kg.

[0042] The preparation method of the coffee-flavored thin-layer coated chocolate composition is as follows:

[0043] (1) Grinding and shearing the white granulated sugar into a powder form with a particle diameter of 50-60 microns; crushing and shearing the granulated coffee into a powder form with a particle diameter of 30-40 microns;

[0044] (2) Solid fat melts at 48°C.

[0045] (3) Add natural low-fat cocoa powder, powdered sugar, and milk powder successively to the melted fat to obtain a mixture;

[0046] (4) Lecithin (30% of the input amount) and all polyglycerol castoryl esters are joined in the above-mentioned ...

Embodiment 2

[0050] The present embodiment provides a kind of coffee-flavored thin-layer coating chocolate composition, and its product formula consists of: 35kg of white granulated sugar, 3.0kg of whole milk powder, 34.3kg of coconut oil, 12kg of palm oil, 15kg of natural low-fat cocoa powder, blue Mountain granule coffee 0.13kg, lecithin 0.3kg, polyglycerol ricinoleate 0.4kg.

[0051] The preparation method of the coffee-flavored thin-layer coated chocolate composition is as follows:

[0052] (1) Grinding and shearing the white granulated sugar into a powder form with a particle diameter of 50-60 microns; crushing and shearing the granulated coffee into a powder form with a particle diameter of 30-40 microns;

[0053] (2) Solid fat melts at 40°C.

[0054] (3) Add natural low-fat cocoa powder, powdered sugar and milk powder successively to the melted fat;

[0055] (4) Lecithin (30% of the input amount) and all polyglycerol castoryl esters are added to the above-mentioned mixed material,...

Embodiment 3

[0060] The present embodiment provides a kind of coffee-flavored thin-layer coating chocolate composition, and its product formula consists of: white granulated sugar 3kg, whole milk powder 3.4kg, coconut oil 34kg, palm oil 16kg, natural low-fat cocoa powder 12kg, coffee 0.1kg kg, lecithin 0.6kg, polyglycerol ricinoleate 0.2kg.

[0061] The preparation method of the coffee-flavored thin-layer coated chocolate composition is as follows:

[0062] (1) Grinding and shearing the white granulated sugar into a powder form with a particle diameter of 50-60 microns; crushing and shearing the granulated coffee into a powder form with a particle diameter of 30-40 microns;

[0063] (2) Solid fat melts at 50°C.

[0064] (3) Add natural low-fat cocoa powder, powdered sugar and milk powder successively to the melted fat;

[0065] (4) Lecithin (30% of the input amount) and all polyglycerol castoryl esters are joined in the above-mentioned mixed material, after half an hour, the material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com