Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

479results about How to "Reduce heat pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

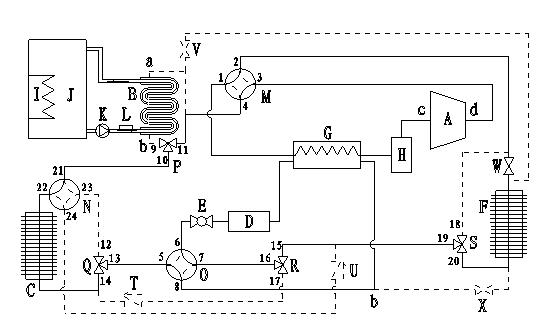

Fresh air conditioner

InactiveCN102425822AHuge latent heat ratioAvoid waterway hazardsEnergy recovery in ventilation and heatingLighting and heating apparatusIndoor air qualityFresh air

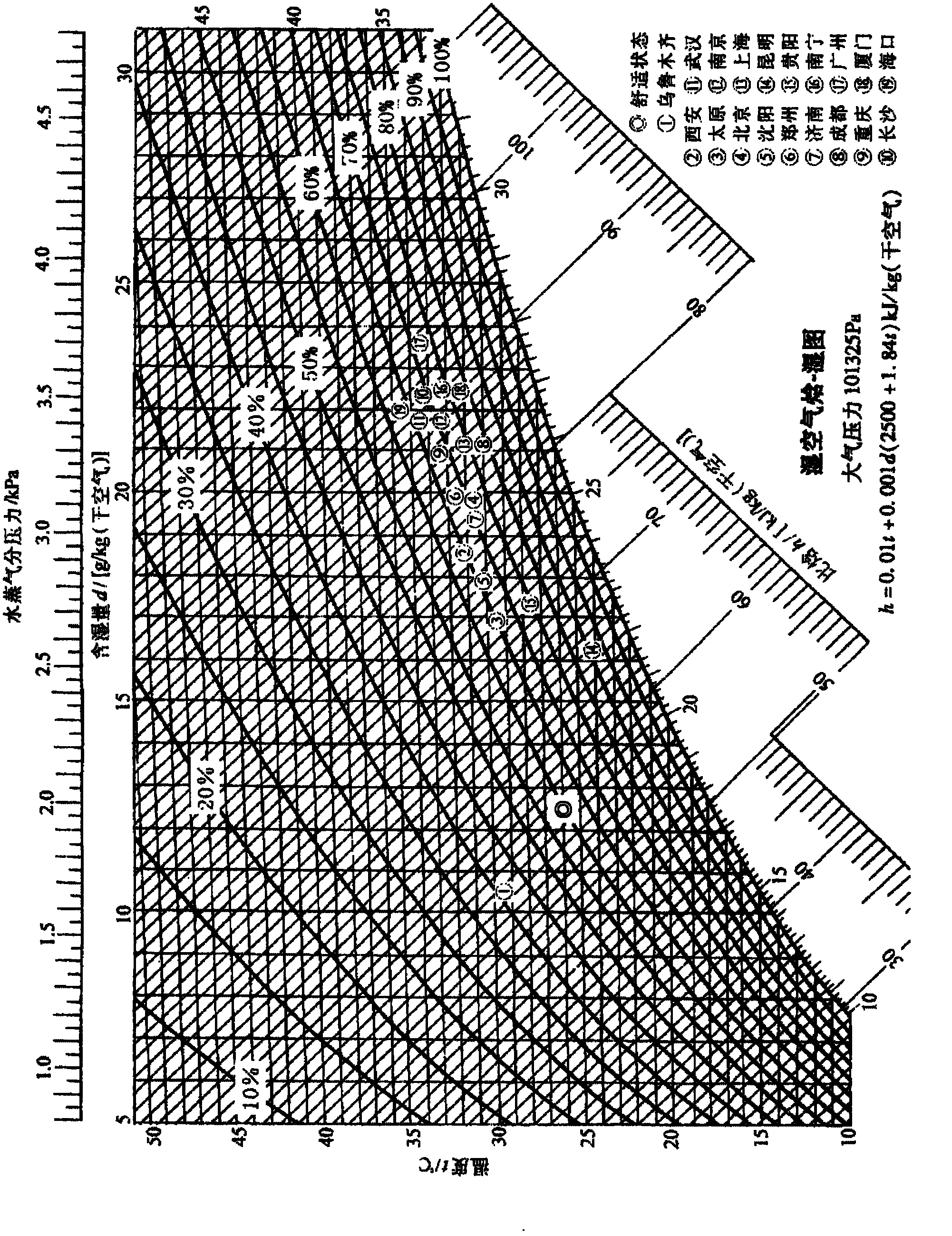

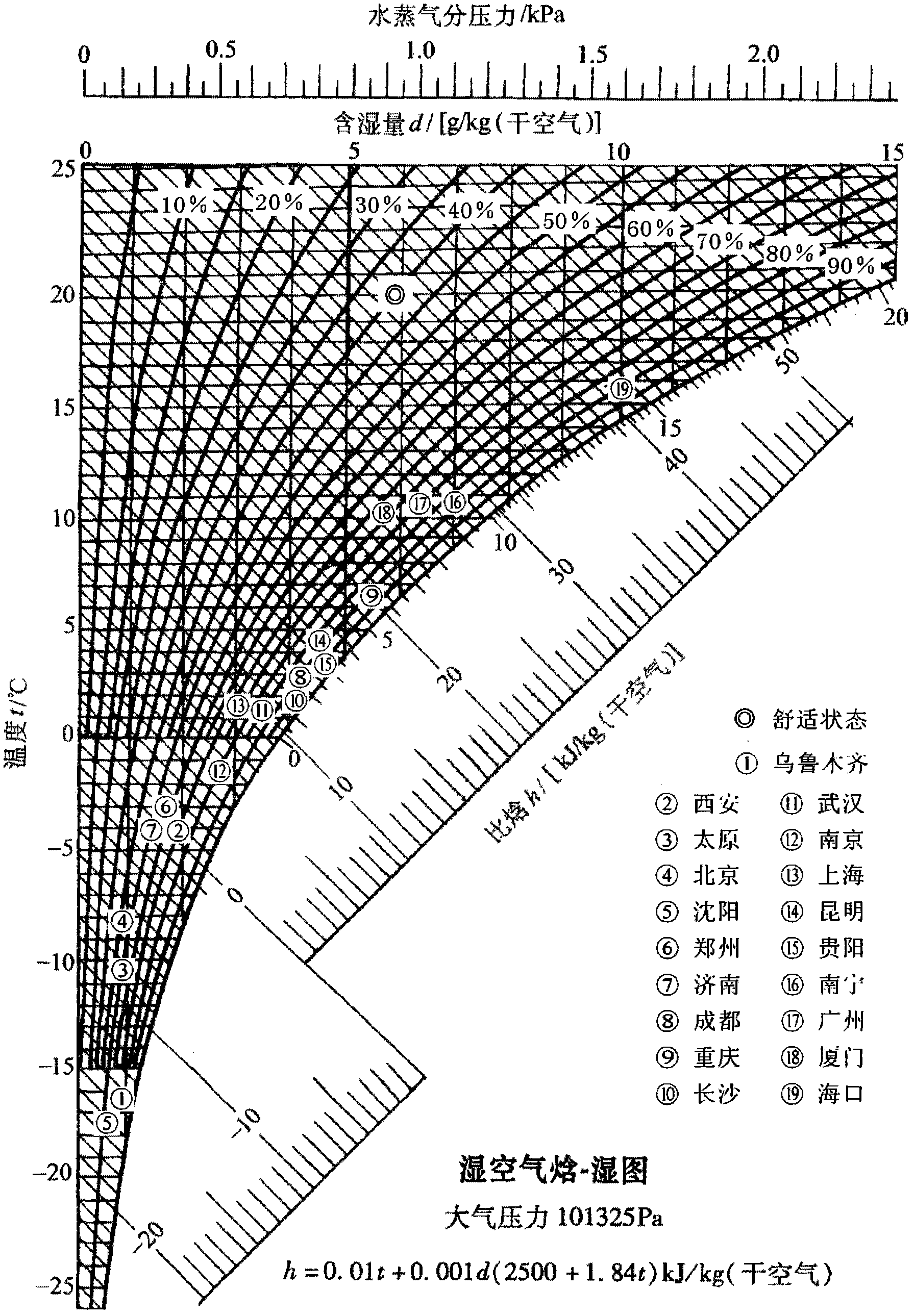

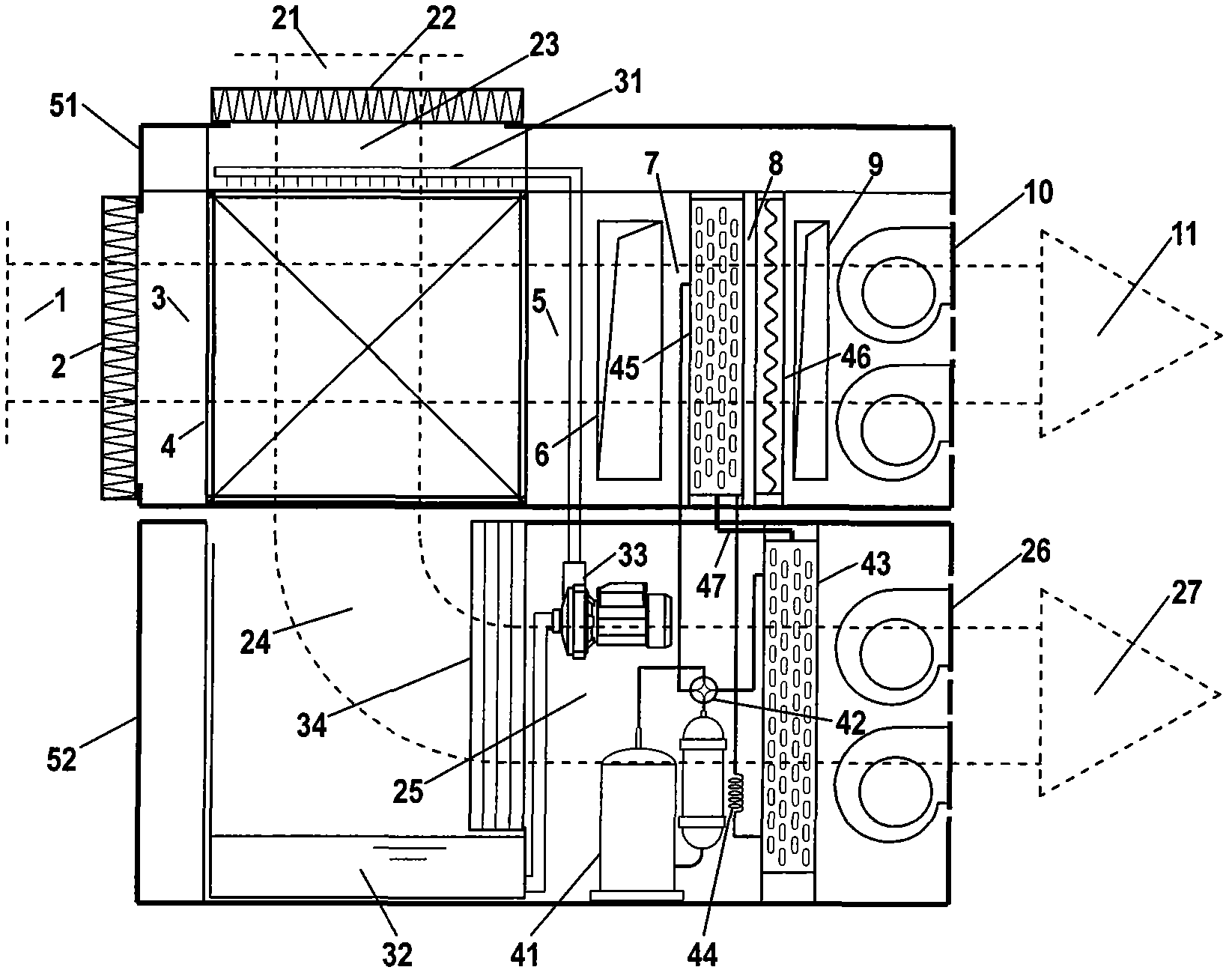

The invention relates to the field of heating ventilation air conditioners, in particular to an improved air treatment method and a fresh air conditioner device. The invention improves the problems of traditional fresh air treatment and air conditioners and particularly emphasizes that a plate-type air-air heat exchanger and indirect water evaporative cooling are used for recycling energy of sensible heat and latent heat in air exhaust in the fresh air treatment process of damp and hot regions in summer and condensed water is directly evaporated on an evaporator to improve the working condition of a compressor. Under the condition of quantificationally supplying outdoor fresh air, the energy efficiency ratio of the fresh air conditioner is increased, the thermal pollution, damp pollution and noise pollution of the fresh air conditioner to environments are reduced, the indoor air quality is improved, and meanwhile, the fresh air conditioner provides the manufacture, installation and using convenience for a local region all-air central air conditioner. The fresh air conditioner provided by the invention and a design and manufacture method of the fresh air conditioner are applicable throughout the year in various regions, particularly in the damp and hot regions; and the fresh air system provides controlled, comfortable and healthy air environments for indoor activity space of people and air conditioner environments for technology for processing, storage and the like.

Owner:张洪

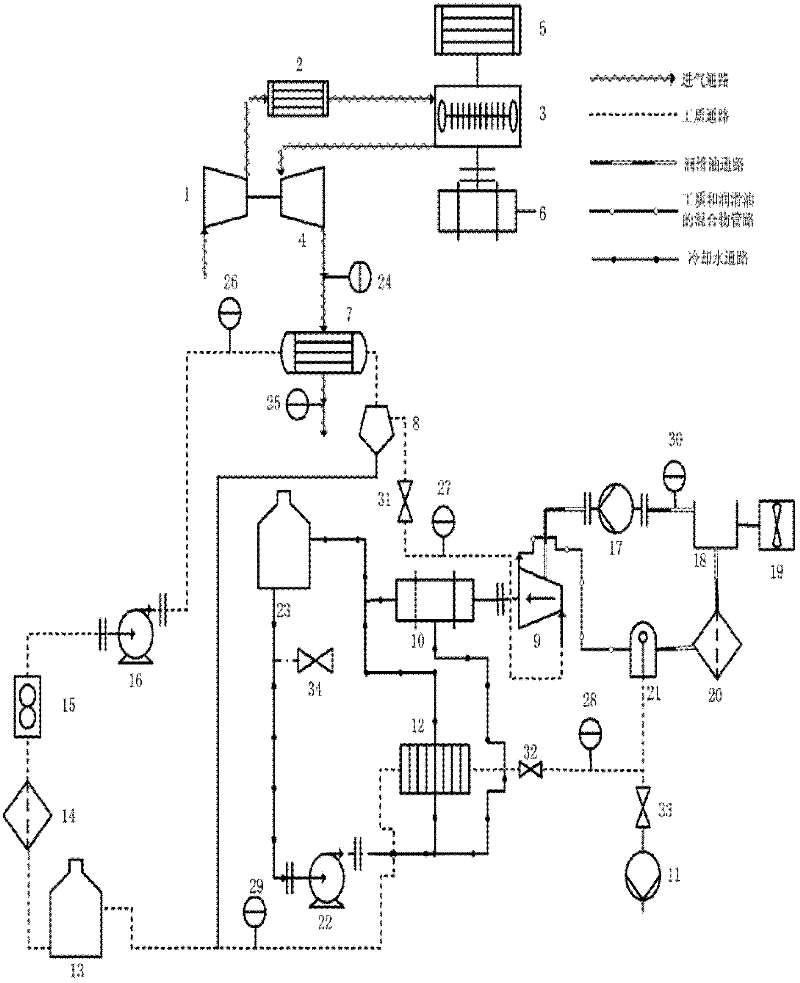

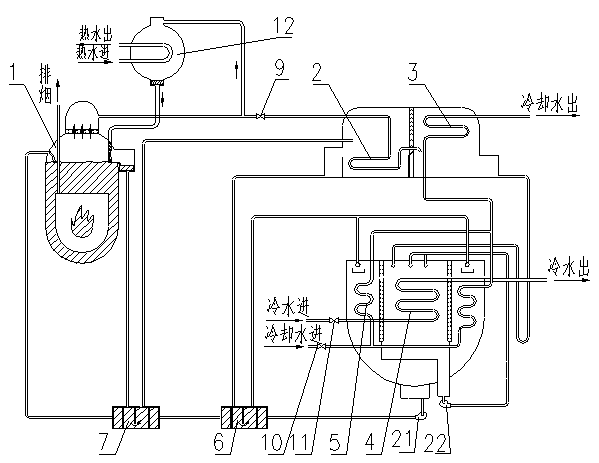

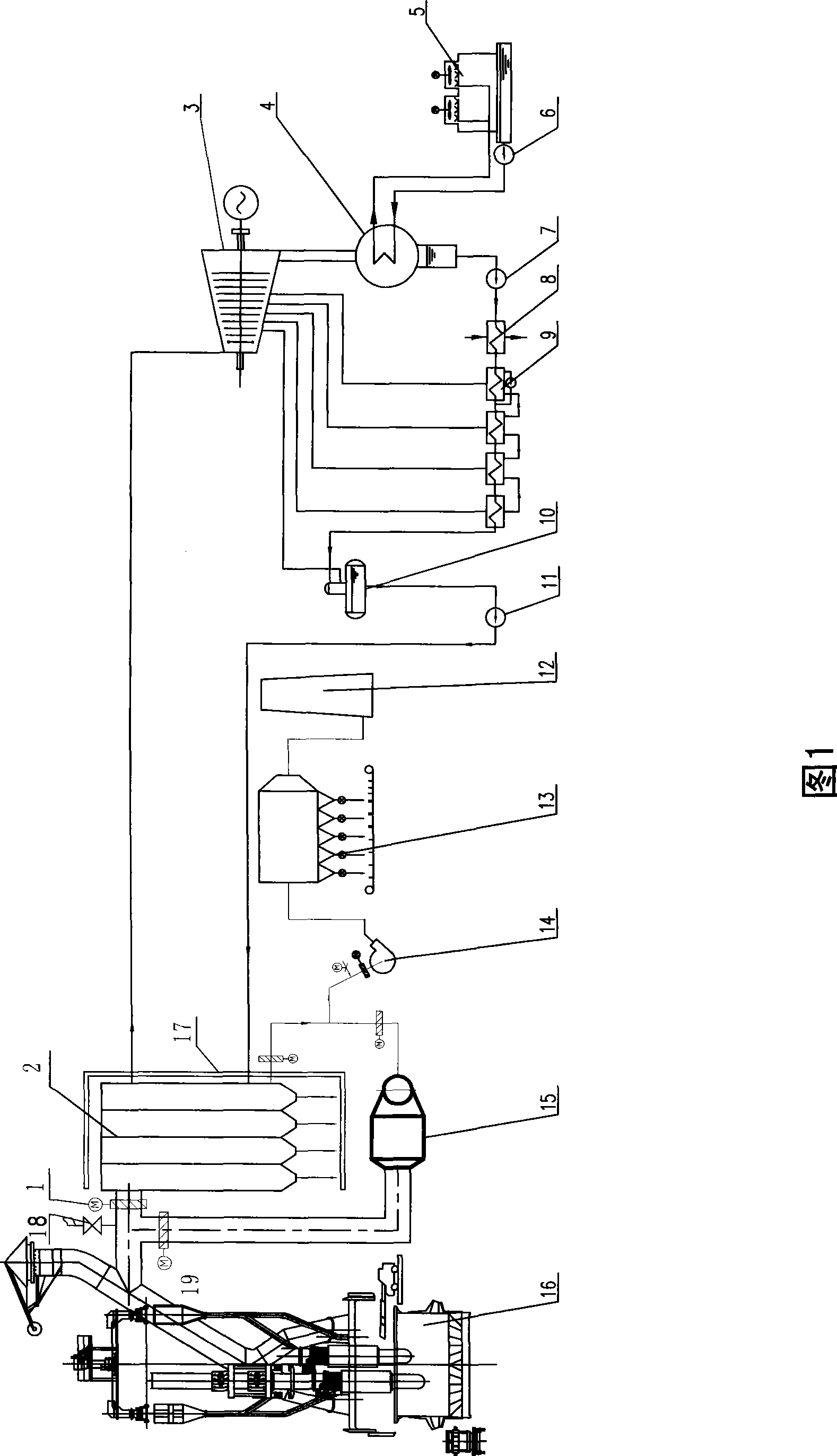

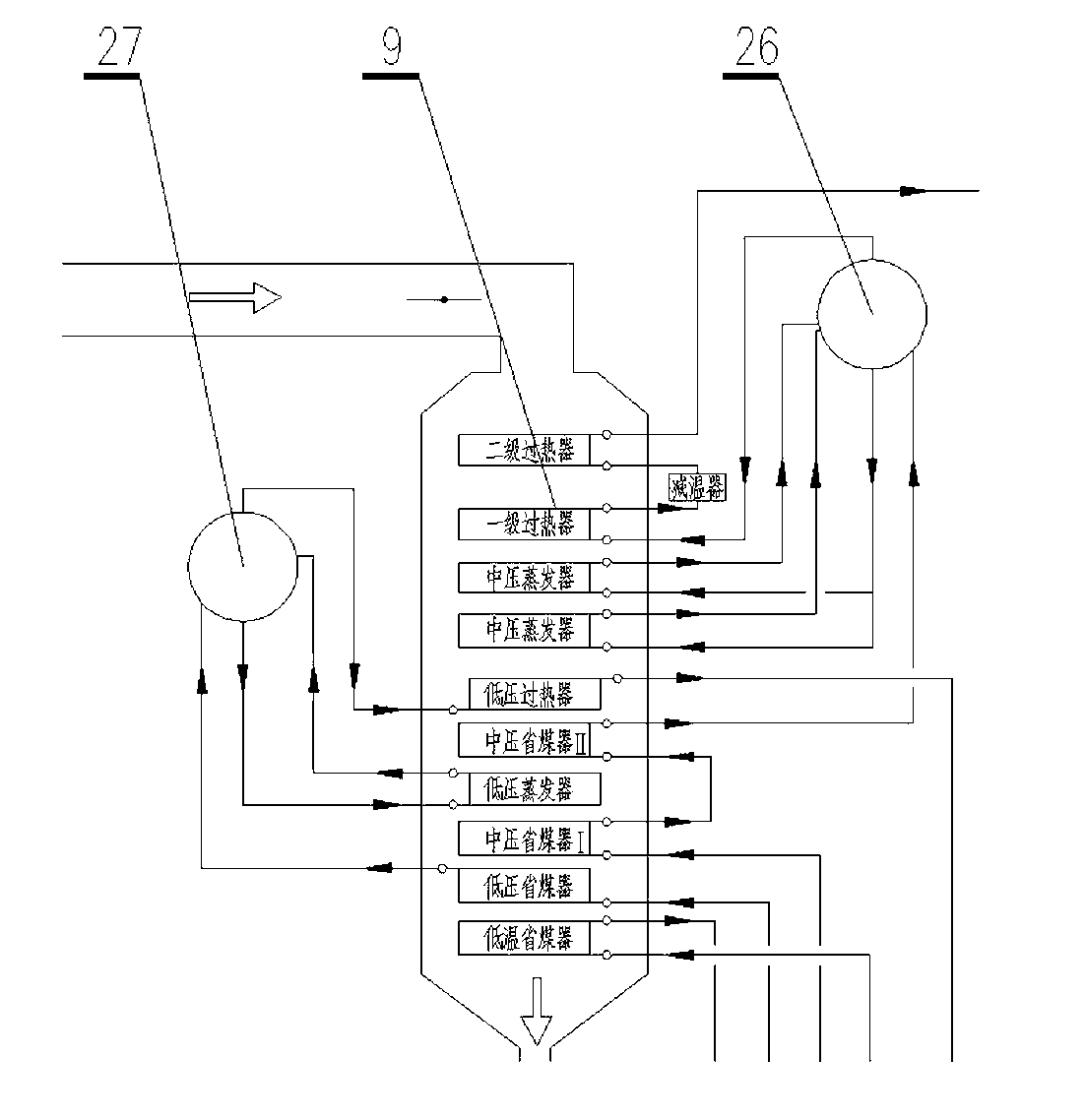

Generating set system of simple low temperature waste heat from large size cement manufacture line in dry method, and technical process

InactiveCN1601214AReduce heat pollutionConducive to environmental protectionIncreasing energy efficiencyClinker productionElectric generatorWaste heat

The invention is an electric generator system using low temperature afterheat of large-scale dry cement production line, which has two kiln head double-pressure afterheat boilers for heating, producing the whole low pressure steam and simultaneously producing partial high-pressure steam; a kiln tail afterheat boiler mainly for producing high pressure steam; the high pressure steam produced by the two afterheat boilers are mixed and then enter through pipeline into a steam -supply and -condensing steam turbine, and the low pressure steam enters in the steam turbine through steam supply pipeline; the blast steam at the tail of the turbine enters in a condenser, the condensed water enters in a vacuum deoxygenator through a condensed water pump and pipeline, the deoxygenated water in the deoxygenator is supplied through water supply pump into the boiler; the exhaust gas produced by a kiln tail preheater of cement production line is led in the kiln tail afterheat boiler through reformed pipeline.

Owner:CITIC HEAVY INDUSTRIES CO LTD

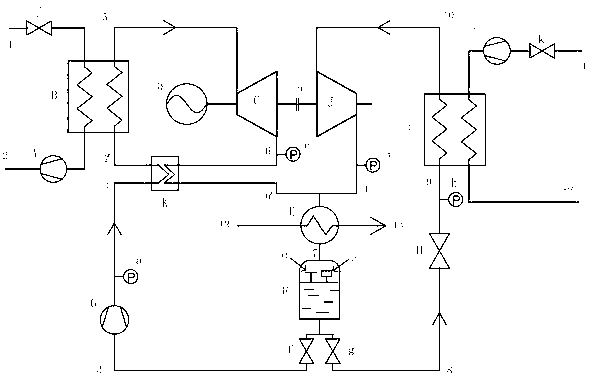

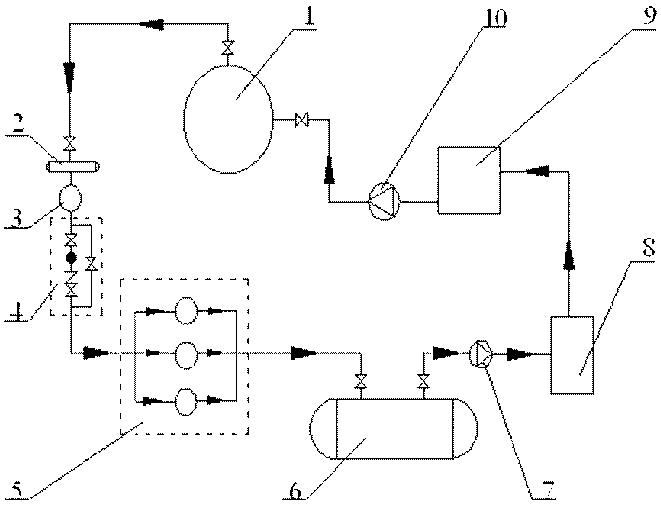

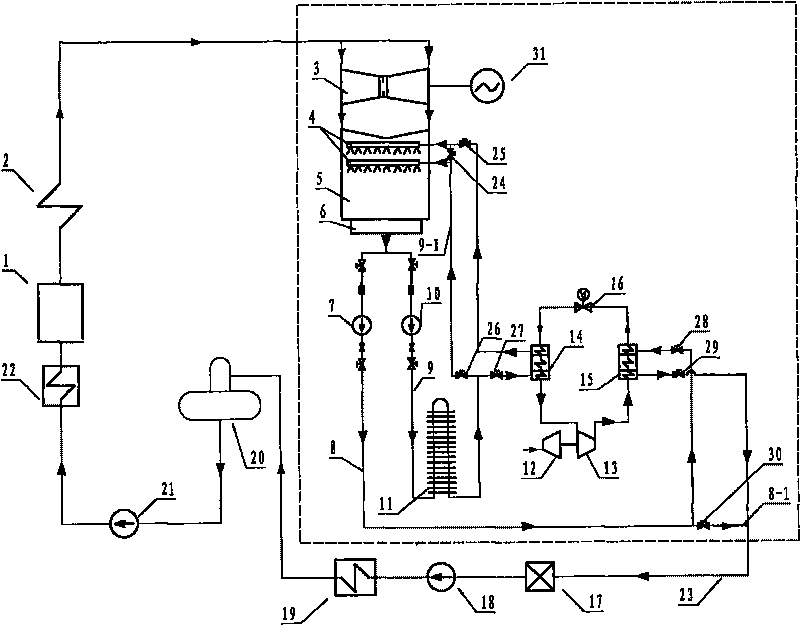

Engine exhaust gas waste heat recovery and control system and method based on organic rankine cycle

InactiveCN102410054ADoes not affect work performanceReasonable workLiquid coolingPressure lubrication with lubrication pumpOrganic Rankine cycleControl system

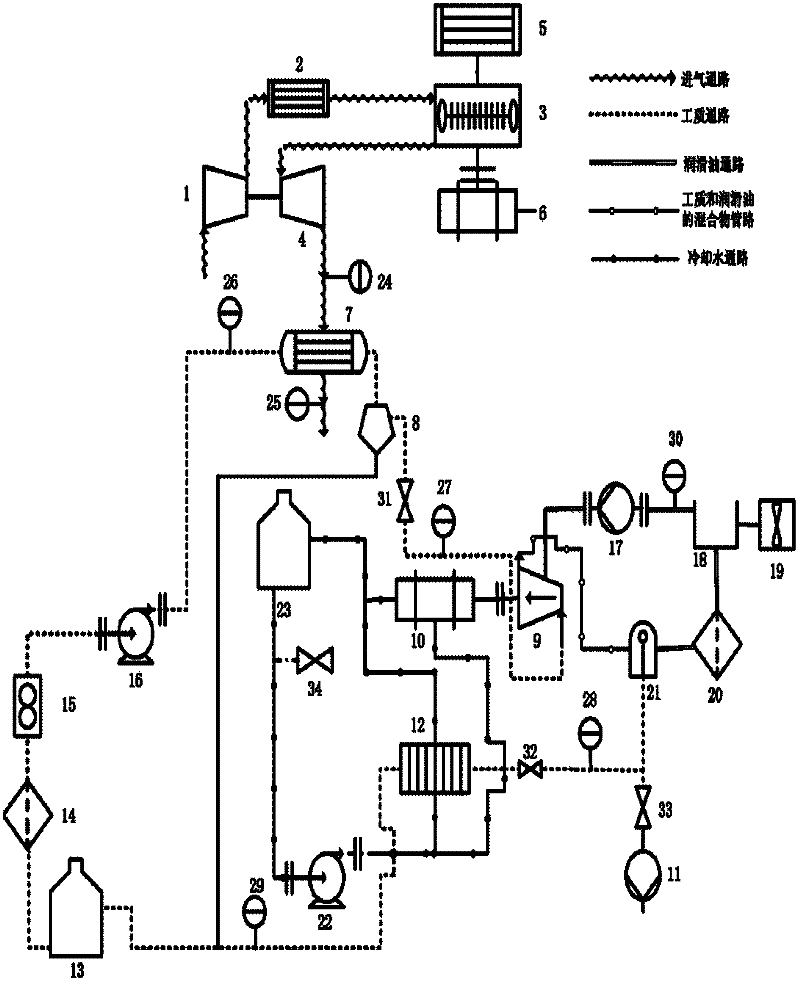

The invention discloses an engine exhaust gas waste heat recovery and control system and method based on organic rankine cycle, and belongs to the field of energy conservation and emission reduction. In the invention, a waste heat recovery system comprises engine cycle, organic rankine cycle, cooling water cycle and lubrication oil cycle which are coupled together; by means of reasonable control, the system can be convenient to start, stable to operate and rapid to stop according to the operation of the engine under different working conditions; in case of a system failure, the system can be emergently braked; and under the condition of no influence on the normal operation of the engine, the optimal performances of the system can be obtained finally, and the utilization ratio of the engine exhaust gas waste heat is improved greatly, thus thermal pollution of the engine exhaust gas to the environment is improved.

Owner:BEIJING UNIV OF TECH

Combined cooling power generation composite system based on supercritical organic Rankine cycle

InactiveCN103195526AGuaranteed uptimeGuaranteed safe operationCompression machines with non-reversible cycleSteam useElectricityOrganic Rankine cycle

The invention provides a combined cooling power generation composite system based on a supercritical organic Rankine cycle and belongs to the field of industrial energy conservation. An expansion machine, a power generator and a steam compressing cold cycling compressor of the Rankine cycle are connected coaxially, same organic working medium is used to be simultaneously cooled in a condenser, and a steam compressing refrigerating cycle is coupled effectively on the basis of basic organic Rankine cycle. In addition, supercritical pressure is used to allow heat rising of organic working medium in a heat absorber to be well matched with temperature changing curve of a heat source, system irreversible loss is further lowered, and waste heat recycling rate is improved. Industrial smoke water heat or other water heat sources are used as driving force, combined cooling power generation is performed by taking refrigerating as priority, refrigerating is not performed by using smoke waste heat for power generation and using power for refrigerating, and accordingly loss caused by energy conversion is reduced. Cooling amount and power output amount can be flexibly adjusted according to cooling amount requirements.

Owner:CHONGQING UNIV

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

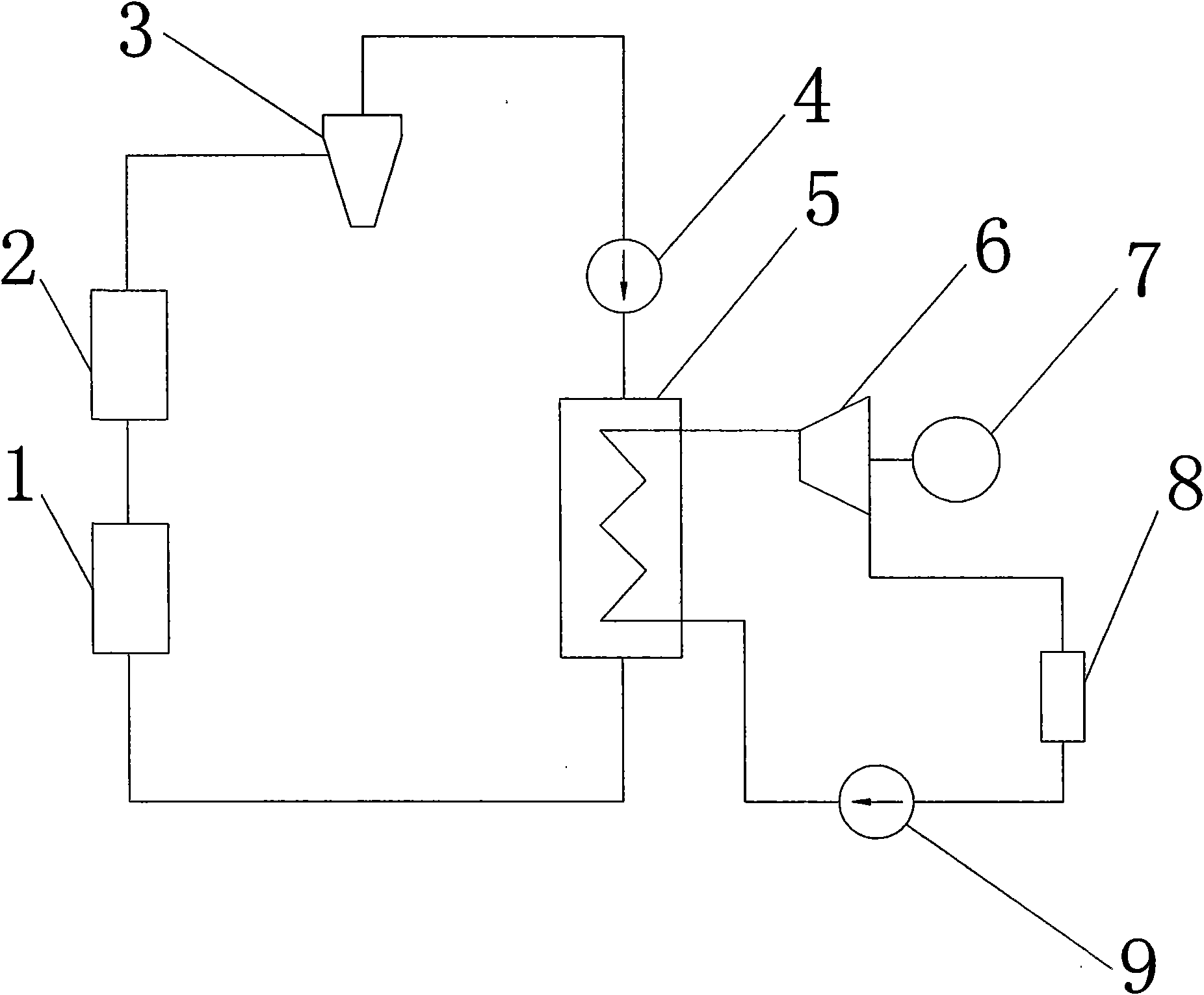

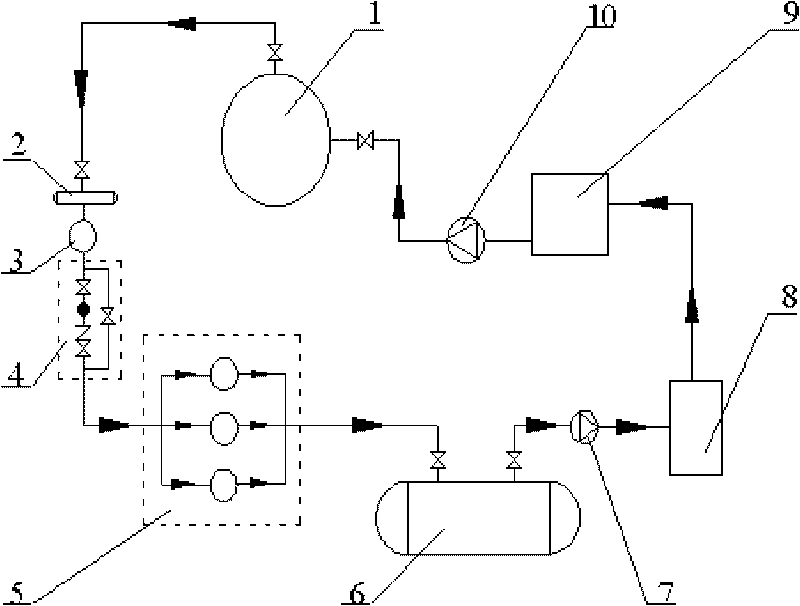

Recovery method of blast furnace slag water residual heat and method thereof

ActiveCN101550461AEnsure safetyGuaranteed lifeIncreasing energy efficiencyWaste heat treatmentRecovery methodSlag

The invention discloses a recovery method of blast furnace slag water residual heat and method thereof. The recovery system of resudual heat includes a blast furnace slag system, a sedimentation tank, a hydrocyclone separator, a water pump, a heat exchanger, a steam turbine, a refrigerant condenser, a refrigerant pump. The recovery method is that applying bicirculating low temperature hot water generation system to recovery residual heat and penerating power. The specific process is: guiding the blast furnace slag water into the heat exchanger after preprocessing of impurity precipitation and transmitting heat to low boiling refrigerant; the low boiling refrigerant absorbing heat in the heat exchanger and entering the steam turbine for expansion of doing work; the refrigerant after doing wirk changing into low-pressure superheated steam, the low-pressure superheated steam entering the concenser to releast heat and changing into liquid refrigerant of low-temperature and low-pressure, then being sent to the heat exchanger by the refrigerant pump for absorbing heat, becoming the superheated steam again to push the steam turbine to do work. The invention can recovery residual heat of the blast furnace slag water and generate power, and reduce energy consumption in steel production; and reduce temperature of blast furnace slag water which is benefit to improve quality of blast furnace water slag and reduce discharge of sulphide in slag washing process.

Owner:HANGZHOU BOILER GRP CO LTD

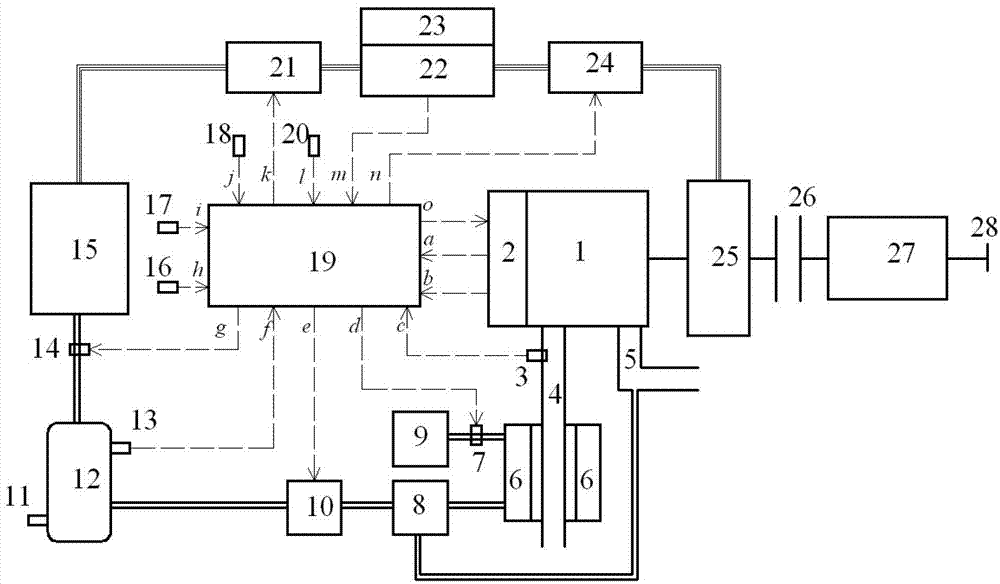

Fuel cell based hybrid power system for utilizing waste heat of internal combustion engine

InactiveCN103029559AReduce heat pollutionRealize automatic start and stopInternal combustion piston enginesExhaust apparatusHydrogenFuel cells

The invention relates to a fuel cell based hybrid power system for utilizing the waste heat of an internal combustion engine and belongs to the technical field of vehicle hybrid power. A fuel reformer is arranged on an exhaust pipe of the internal combustion engine, fuel is reformed by using the waste heat of exhaust gas, the generated reformed hydrogen rich gas is used as the fuel of a fuel cell, and electric energy which is generated by the fuel cell is stored in a storage battery, so the waste heat of the exhaust gas of the internal combustion engine can be recovered; meanwhile, a motor or a generator is arranged at an output shaft end of the internal combustion engine and used for recovering the brake energy of a vehicle in a running process, and the brake energy is also stored into the storage battery; and furthermore, by the adoption of the motor or the generator, the internal combustion engine can be automatically started or stopped, and auxiliary power is supplied under specific working conditions. The system can effectively utilize the waste heat of the exhaust gas and the brake energy of the internal combustion engine, the idling condition of the internal combustion engine can be eliminated, and the fuel consumption and harmful emission of the internal combustion engine can be reduced.

Owner:BEIJING UNIV OF TECH

Transcritical carbon dioxide heat pump type air conditioning water heater using condensation residual heat

InactiveCN102003833AIncrease profitReduce heat pollutionEnergy recovery in ventilation and heatingHeat recovery systemsRecuperatorEngineering

The invention relates to a transcritical carbon dioxide heat pump type air conditioning water heater using condensation residual heat, which comprises a compressor, a cooling-medium and water sleeve pipe type heat exchanger, a reservoir, a throttle valve, an indoor finned tube heat exchanger, a sleeve pipe type heat regenerator, a gas and liquid separator and a temperature preserving water tank, wherein a working medium inlet of a cavity between an inner pipe and an outer pipe of the cooling-medium and water sleeve pipe type heat exchanger is connected with a high pressure port of the compressor; carbon dioxide discharged from an working medium outlet enters a low pressure port of the compressor through the cavity between the inner pipe and the outer pipe of the cooling-medium and water sleeve pipe type heat regenerator, the reservoir, the throttle valve, the indoor finned tube heat exchanger, an inner pipe of the heat regenerator and the gas and liquid separator in order; both ends of the inner pipe of the cooling-medium and water sleeve pipe type heat exchanger are connected with the temperature preserving water tank by a water pipe; and the water pipe is provided with a pipeline pump. The cooling-medium and water sleeve pipe type heat exchanger is adopted for recycling the condensation residual heat of a heat pump type air conditioning system,; and the recycled heat is used for preparing domestic hot water, thus the energy utilization rate is not only enhanced, but also the heat pollution of the air conditioning system to the environment is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Direct-burning lithium bromide absorbing cold hot water unit capable of recycling smoke waste heat

ActiveCN102997483AReduce consumptionImprove cooling effectEnergy efficient heating/coolingClimate change adaptationLithium bromideInlet valve

The invention relates to a direct-burning lithium bromide absorbing cold hot water unit capable of recycling smoke waste heat. A smoke condensation heat exchanger (18) is arranged at a smoke discharging outlet pipe of a direct-burning high pressure generator, an outlet refrigerant water pipeline of a refrigerant pump (22) is divided into two branches, one branch is connected with an evaporator (4) through a refrigeration refrigerant water valve (15), and the other branch is connected with the smoke condensation heat exchanger (18) through a heating refrigerant water inlet valve (14) and then connected and joined with a pipeline at the rear side of the refrigeration refrigerant water valve (15) through a heating refrigerant water outlet valve (25) or connected with the evaporator (4) alone. A solution pump outlet dilute solution pipeline is divided into two branches, one branch of dilute solution is heated through a low-temperature solution heat exchanger and a high-temperature solution heat exchanger to be connected with the direct-burning high pressure generator, and the other branch of dilute solution is connected with a smoke condensation heat exchanger through a dilute solution inlet valve to be connected and joined with a pipeline at the rear side of the high-temperature solution heat exchanger through a dilute solution outlet valve or connected with the direct-burning high pressure generator alone. The direct-burning lithium bromide absorbing cold hot water unit can fully use the smoke heat and improves efficiency.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Phase-change heat-exchange type secondary steam heat recovery utilization method, apparatus and use thereof

ActiveCN101476825ASave heatReduce heat pollutionDrying gas arrangementsEvaporationBoiling pointThermal energy

The invention discloses a method and a device for phase-change heat exchange type secondary steam heat energy recovery utilization and application thereof, which aim to solve the technical problems that the prior secondary steam heat energy can or cannot be utilized, or the utilization rate of the heat energy is low, or the secondary steam heat energy can be efficiently utilized, but has low application range. A adopted technical proposal comprises: water for evaporation is injected into a water supply tank of a phase-change heat exchanger; a starting heat pump pumps a steam-water separator, the phase-change heat exchanger, and various evaporation connection pipes and tanks into negative pressure; secondary steam is continuously aerated into a heat exchange tube box of the phase-change heat exchanger; the water for evaporation is heated through heat conduction of a heat exchange tube to ensure that the water for evaporation is increased to a boiling point and absorbs a large amount of vaporization heat to be evaporated into clean steam; and the steam is pumped by a heat pump and is compressed to steam with heat supply network quality for supply or heat consumption equipment to use. The method and the device have the advantages of high utilization rate of the heat energy, and wide application range.

Owner:DONGFANG ELECTRIC MACHINERY

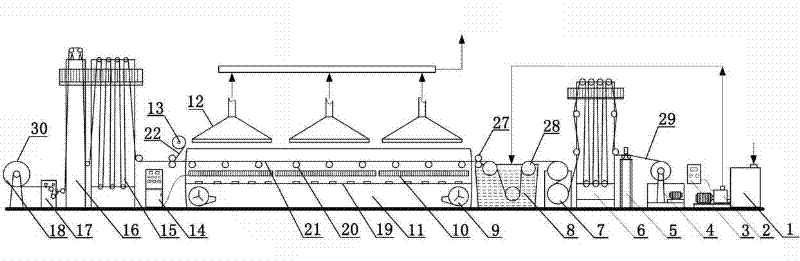

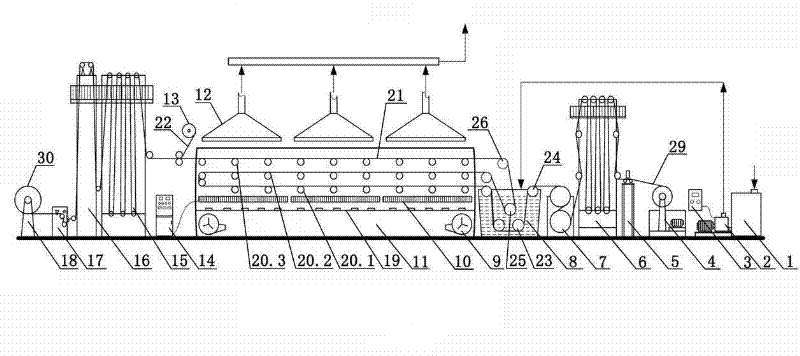

Production equipment and method of self-adhesive layer band

InactiveCN102350852AGuaranteed bondingControl UniformityLamination ancillary operationsFilm/foil adhesivesEngineeringError correcting

Production equipment and a method of a self-adhesive layer band. A base material is treated by a base material unfolding machine, a head-tail-overlapping machine, a base material buffering adjusting bracket and a base material dryer successively, enters into a gluing pool for gluing, then enters a dryer for drying; the dried base material is rolled with an isolated film on a surface thereof by a mulch applicator, cooled by a self-adhesive layer buffering adjusting bracket and adjusted by an automatic error correcting controller; then the base material can be packaged by a product winder and finally cut into dimensions required by production specifications by a cutting machine. After gluing, the base material is dried and returns to the gluing pool for a second gluing; and base material enters into the dryer again for drying after the second gluing, so as to increase peeling intensity of a self-adhesive waterproof coiled material and bonding strength of the material with a base, accelerate drying speed and increase product quality. According to the invention, base material treatment, gluing, drying, coating, cooling, rolling and packaging can be finished in a line, so as to realizeflexible operation, high degree of automation and good product quality.

Method for recovering condensation water in production process of gas concrete and recovery system thereof

InactiveCN101700675AScientific and reasonable way of using energyMake full use of waste heatCeramic shaping apparatusRecovery methodUser device

The invention discloses a method for recovering condensation water in the production process of gas concrete. The method comprises the following steps of: firstly, sending the saturated steam produced by a boiler to a still kettle in which gas concrete slabs or blocks are placed, and heating the gas concrete product, wherein the saturated steam is cooled to form the condensation water through the heat exchange; secondly, sending the condensation water drained from the still kettle to a plurality of secondary heating user devices filled with materials, and pre-heating the materials by using the afterheat of the condensation water, wherein the saturated steam is cooled to form the secondary condensation water through the heat exchange; and thirdly, after the secondary condensation water drained from the secondary heating user device satisfies the requirement of boiler water feeding through the purification treatment, sending the secondary condensation water to the boiler of the first step for recycle. By adopting the method, the afterheat resources and water resources discharged from the production process are sufficiently, reasonably and gradually utilized, and the energy and resource consumptions and the production cost of product per unit are reduced.

Owner:TIANJIN UNIV

Exhaust-free highly-effective drying system and method

InactiveCN101149213AMeet the requirements for reuseNo lossDrying gas arrangementsWater vaporProcess engineering

This invention relates to a non gas discharging high efficient drying system and its method. The discharged gas from dryer is firstly filtered and purified by filtering purification device. The generated heat energy is used to heating the dilute solution after dehumidifying in solution regenerating device. It fulfills the regeneration of concentrated solution. At the same time, part of the water vapor in the discharged gas separates out and becomes condensing water. It reduces the moisture content of discharged gas. Then, in heat regenerating device, the heat energy of the discharged gas from solution regenerator is used to heating the dry air after dehumidifying. It reduces the temperature, humidify and enthalpy of the wet air entering into dehumidifying device. In the dehumidifying device, the wet air undertakes solution dehumidifying processing. The dry air after dehumidifying enters into the heat regenerating device for initial heating. Then, the air passes through heating device in order to reach the parameter request of drying technique. At last, the dry air enters into the dryer to dry the materials. This invention saves energy and protects environment.

Owner:DONGHUA UNIV

Automobile air conditioner system using vehicle exhaust energy

InactiveCN101474954AReduce consumptionReduce pollutionAir-treating devicesVehicle heating/cooling devicesThermal energyFuel oil

The invention discloses an automobile air conditioning system utilizing automobile tail gas energy, which aims to provide the air conditioning system capable of sufficiently utilizing the heat energy and the kinetic energy of high temperature tail gas exhausted by an automobile for driving so as to reduce the consumption of fuel oil and heat pollution to the environment. The inlet of a motor tail gas pipe is connected with a tail gas outlet of an automobile motor, and the outlet of the motor tail gas pipe is connected with the inlet of a tail gas purifier. The gas outlet of the tail gas purifier is connected with the inlet of a fuel gas turbine, and the outlet of the fuel gas turbine is connected with an automobile tail gas pipe which is arranged in an air heat exchange pipe. The outlet shaft of the turbine is connected with the power input shaft of an electricity generation / electromotion combined machine through a driving mechanism, the power output shaft of the electricity generation / electromotion combined machine is connected with the master shaft of a CO2 compressor through the driving mechanism, and the wire connecting terminal of the electricity generation / electromotion combined machine is connected with the wire connecting terminal of an accumulator. The air conditioning system sufficiently utilizes the residual energy of the automobile, improves the use efficiency of energy, saves the energy and protects the environment.

Owner:TIANJIN UNIV OF COMMERCE

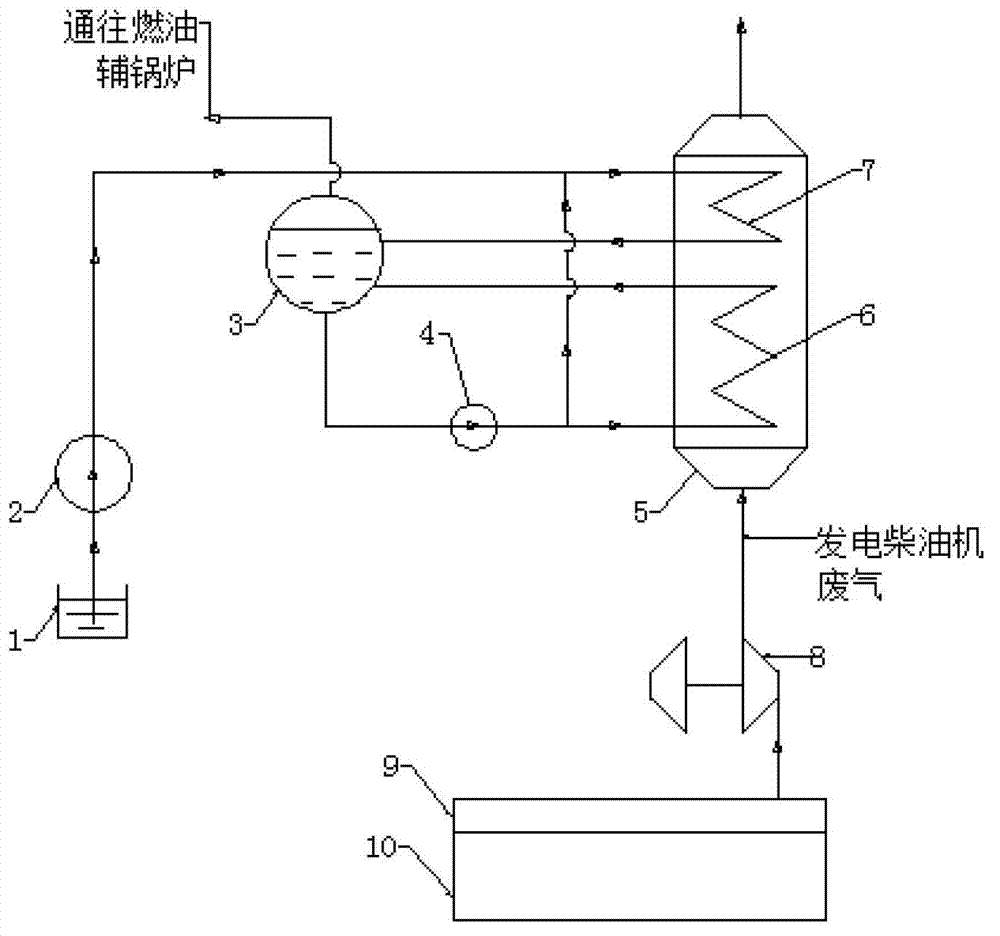

Exhaust gas waste heat steam producing system of marine diesel generating set

InactiveCN102777876AReduce fuel consumptionLower fuel costsSteam generation using hot heat carriersBoiler feedwater pumpExhaust fumes

The invention discloses an exhaust gas waste heat steam producing system of a marine diesel generating set. The exhaust gas waste heat steam producing system comprises a hot well, a boiler water-feeding pump, a steam pocket, an exhaust boiler, an evaporator and a preheater, wherein the evaporator and the preheater are installed in the exhaust boiler, and the hot well is sequentially connected with the boiler water-feeding pump, the preheater, a steam pocket first inlet, a steam pocket first outlet, the evaporator, a steam pocket second inlet, a steam pocket second outlet and a fuel auxiliary boiler. Exhaust gas produced by the marine diesel generating set is led into the exhaust boiler. The exhaust gas waste heat steam producing system can effectively recover exhaust gas waste heat of the marine diesel generating set, save fuel cost and improve ship environment friendliness.

Owner:JIANGSU UNIV OF SCI & TECH

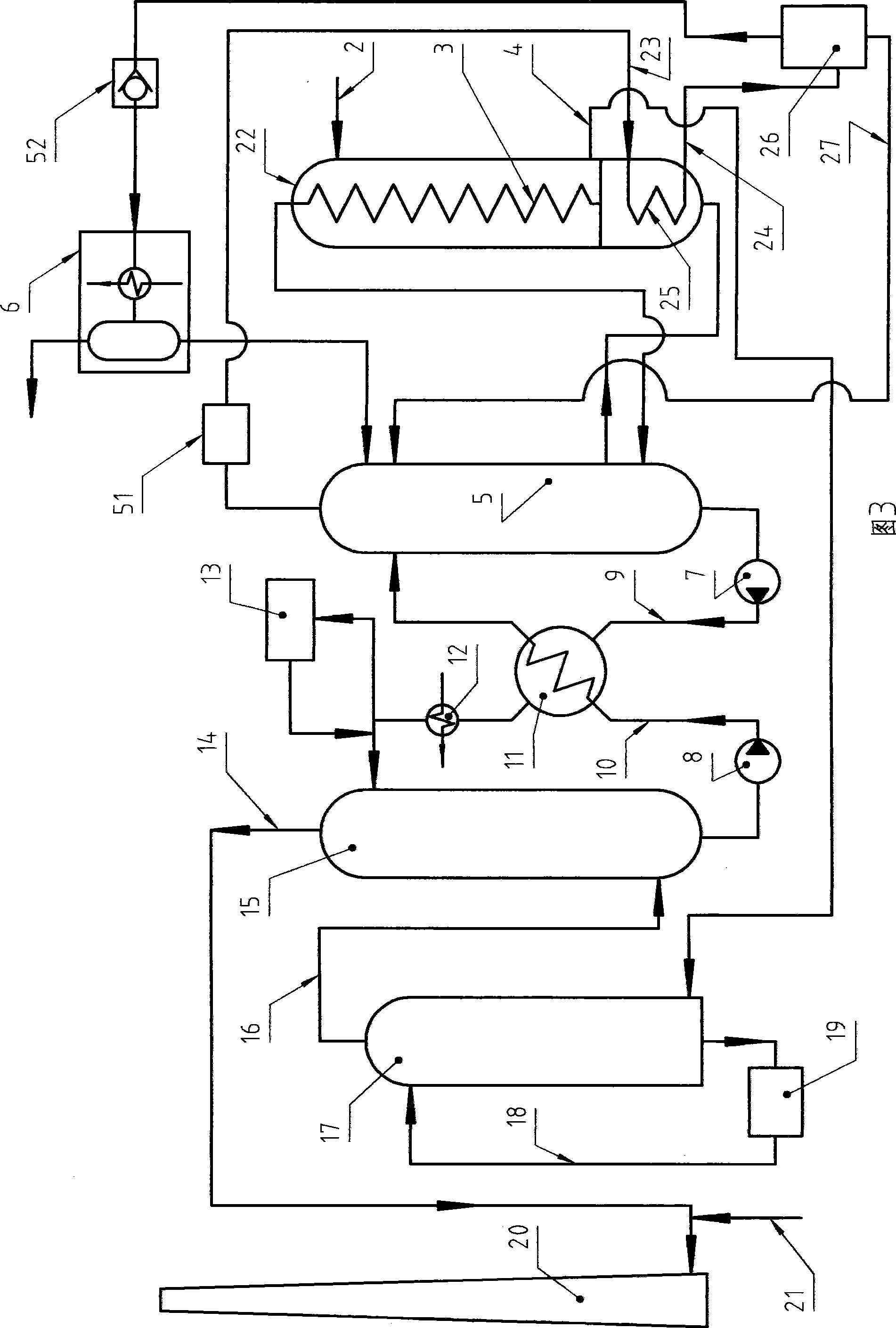

System and method for fossil fuel and solar energy-complementary distributed energy supply

ActiveCN102733956AImprove utilization efficiencyReduce heat pollutionFrom solar energySteam regenerationEngineeringHigh pressure

The invention discloses a system and a method for fossil fuel and solar energy-complementary distributed energy supply. Natural gas enters into a gas-turbine generator set to generate electricity. Discharge smoke enters into a high pressure steam generator to form high pressure steam. The discharge smoke from the high pressure steam generator enters into a flue gas waste heat exchanger to heat heating water or is directly discharged into a chimney. The high pressure steam from the high pressure steam generator and medium pressure steam from a solar driven steam generator are poured respectively into a high pressure steam inlet and a medium pressure steam inlet of a high-pressure section turbine. Exhaust steam from the high-pressure section turbine can be fed into a steam-water type heat exchanger to heat heating water or to drive an absorption refrigerator to carry out refrigeration, and also can be fed into a low-pressure section turbine to sequentially produce expansion work. The system can realize combined supply of heat and power, can realize independent power generation, can be integrated with a solar device and can only adopt natural gas as a fuel. The system and the method fully use a solar energy resource and realize integrated utilization of fossil energy and renewable energy sources.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

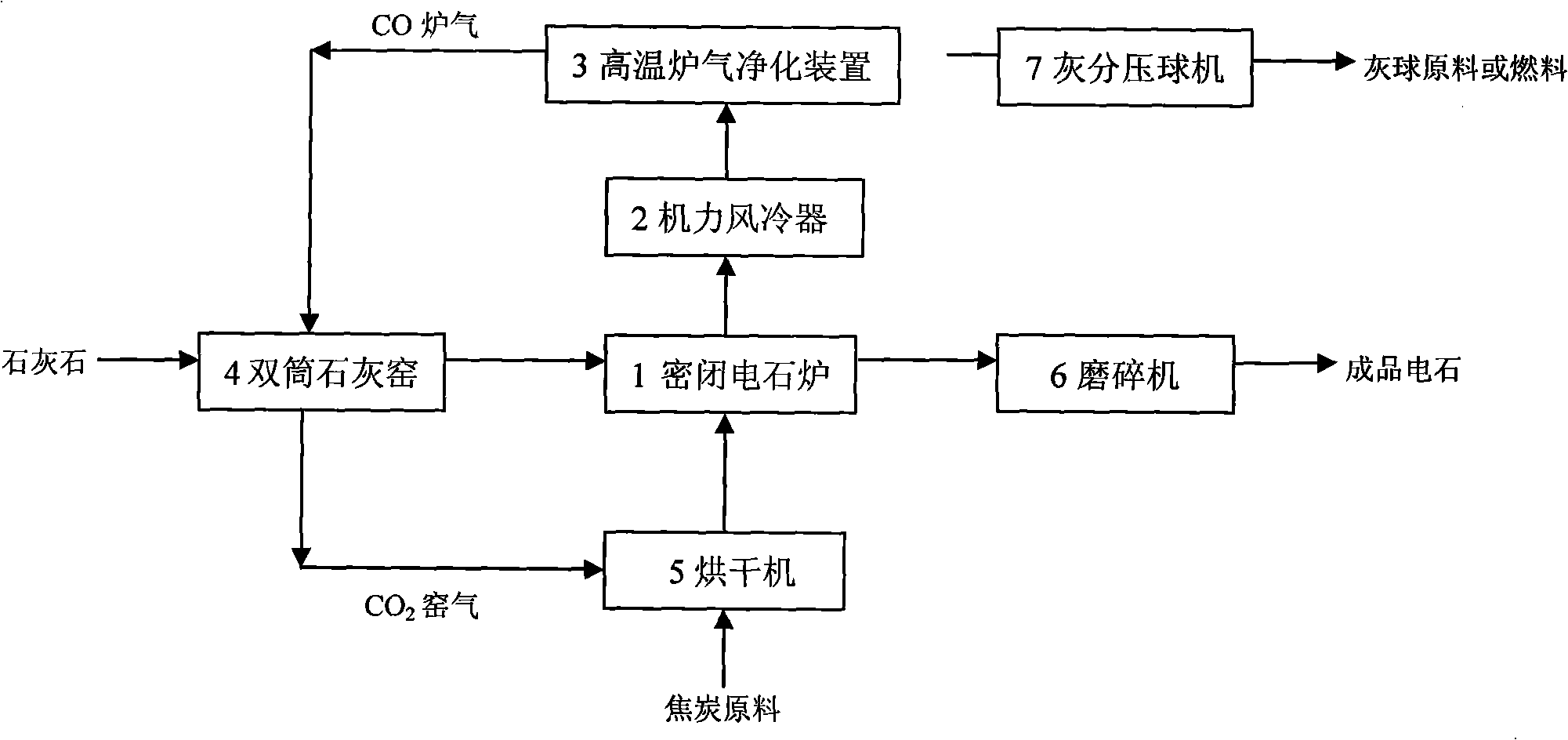

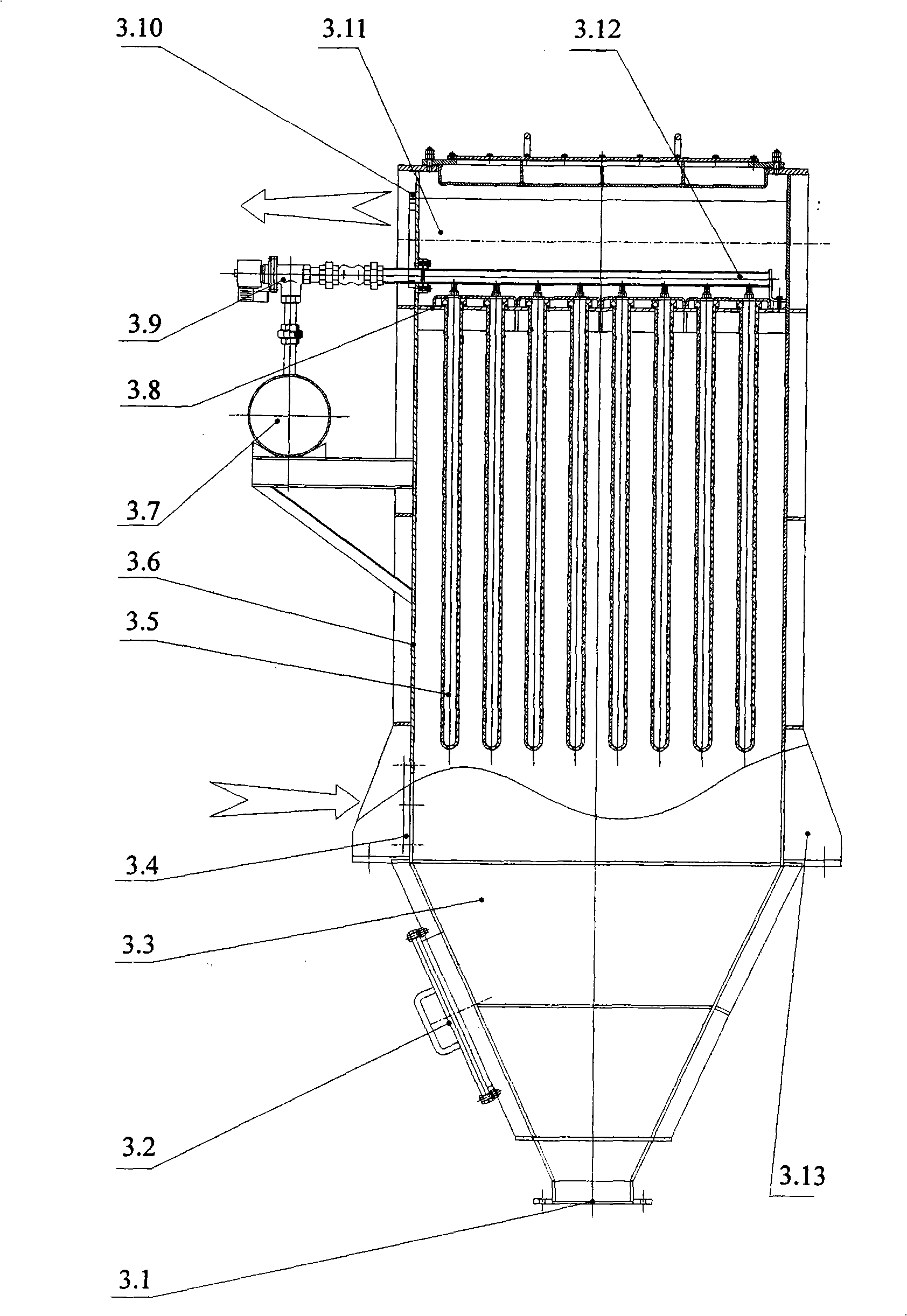

Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

InactiveCN101284666AImprove separation efficiencyImprove dust removal effectChemical industryCalcium carbideFiberFiltration

The invention discloses a system for comprehensive utilization of the high-temperature furnace gas in a hermetic calcium carbide furnace. Two inlets of the hermetic calcium carbide furnace are respectively connected with a dual-drum limekiln for supplying calcium oxide and a dryer for supplying coke. One outlet of the calcium carbide furnace is connected with a grinding machine used for grinding the calcium carbide; the inlet and the outlet of a mechanical air cooling device are respectively connected with another outlet of the calcium carbide furnace and an inlet of a high-temperature furnace gas purifying device; two outlets of the high-temperature furnace gas purifying device are respectively connected with an inlet of the dual-drum limekiln and an ash content ball press; and the dual-drum limekiln is connected with an inlet of the dryer. The high-temperature furnace gas purifying device in the system takes a foaming aluminum silicate fiber material as a filtration medium which resists high temperature and corrosion and has small resistance and high separative efficiency. The whole system has good energy-saving and environment-friendly characteristics. On the one hand, the recycle of the high-temperature CO furnace gas in the hermetic calcium carbide furnace and the kiln gas of CO2 in the limekiln can satisfy the energy need of the system; on the other hand, the coke consumption and the CO2 emission are reduced.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Steam-exhaust coagulation heat recovery system of coal-fired power plant

ActiveCN101464072AImprove economyReduce water consumptionHeat pumpsHeat recovery systemsDesorptionEngineering

The invention discloses a waste steam and condensation heat recovery system of a coal-fired power plant. The recovery system comprises a high-temperature heat pump device for absorbing heat from waste steam of the coal-fired power plant, and the temperature of a working medium of the high-temperature heat pump is improved by the circulation of the heat pump; a carbon dioxide capture device for utilizing the working medium of the high-temperature heat pump for heating an MEA absorbing agent which is used for capturing carbon dioxide in flue gas to complete the desorption process; a trans-critical carbon dioxide heat pump device for absorbing the heat from the waste steam of the coal-fired power plate, and the temperature of the working medium of the carbon dioxide heat pump is improved by the circulation of the heat pump; and a regional heating and heat using device for utilizing the working medium of the carbon dioxide heat pump for heating regional domestic water and regional heating hot water. The use of the system can improve the economics of the MEA method for capturing the carbon dioxide for the coal-fired power plate, reduce the energy consumption for regional heating and greatly reduce the water consumption of the coal-fired power plant and the thermal pollution caused by the waste steam and the condensation waste heat of the power plant.

Owner:TSINGHUA UNIV

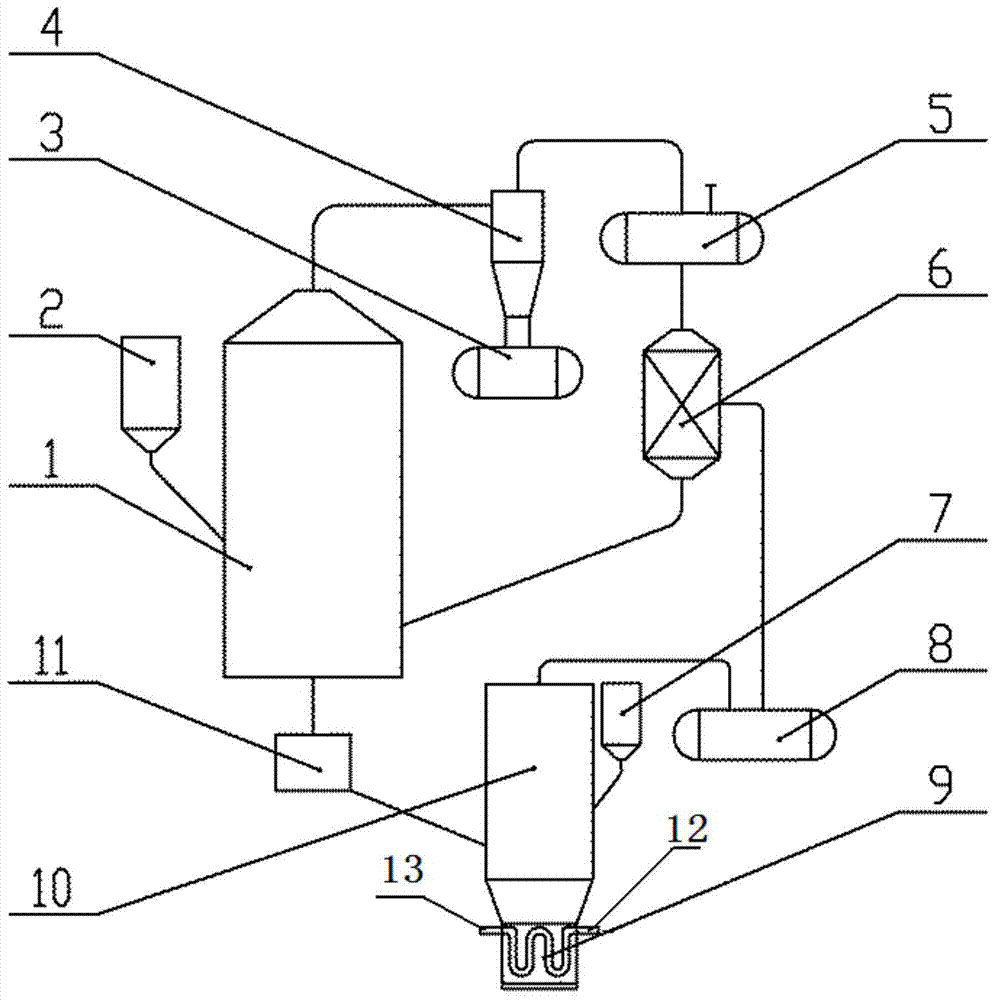

System and process for comprehensive utilization of oil shale destructive distillation and semicoke gasification

InactiveCN103923677ARealize energy utilizationReduce pollutionLiquid hydrocarbon mixture productionSpecial form destructive distillationHeat carrierWater vapor

The invention discloses a system for comprehensive utilization of oil shale destructive distillation and semicoke gasification, which comprises a destructive distillation furnace, an oil shale bin, an oil storage tank, an oil-gas separator, a gas heater, a gasification fuel bin, a combustible gas tank, a heater, a gasification furnace and a conveyer device. According to the invention, by using a process for comprehensive utilization of oil shale destructive distillation and semicoke gasification by using the system, semicoke generated by destructive distillation and powdered oil shale are subjected to gasification reaction to generate combustible gas, a part of combustible gas can be used as a fuel to be introduced into the gas heater to heat a heat carrier gas used in the destructive distillation furnace, high-temperature solid residues generated in the gasification furnace are discharged into a heat exchanger to heat cold water into hot water or vapor. According to the invention, the semicoke generated by oil shale destructive distillation is gasified to be recycled, and thus the addition benefits in an oil shale destructive distillation process is increased, heat pollution and chemical pollution of shale residues are reduced, and energy source utilization rate is improved.

Owner:SHANGHAI JIAO TONG UNIV

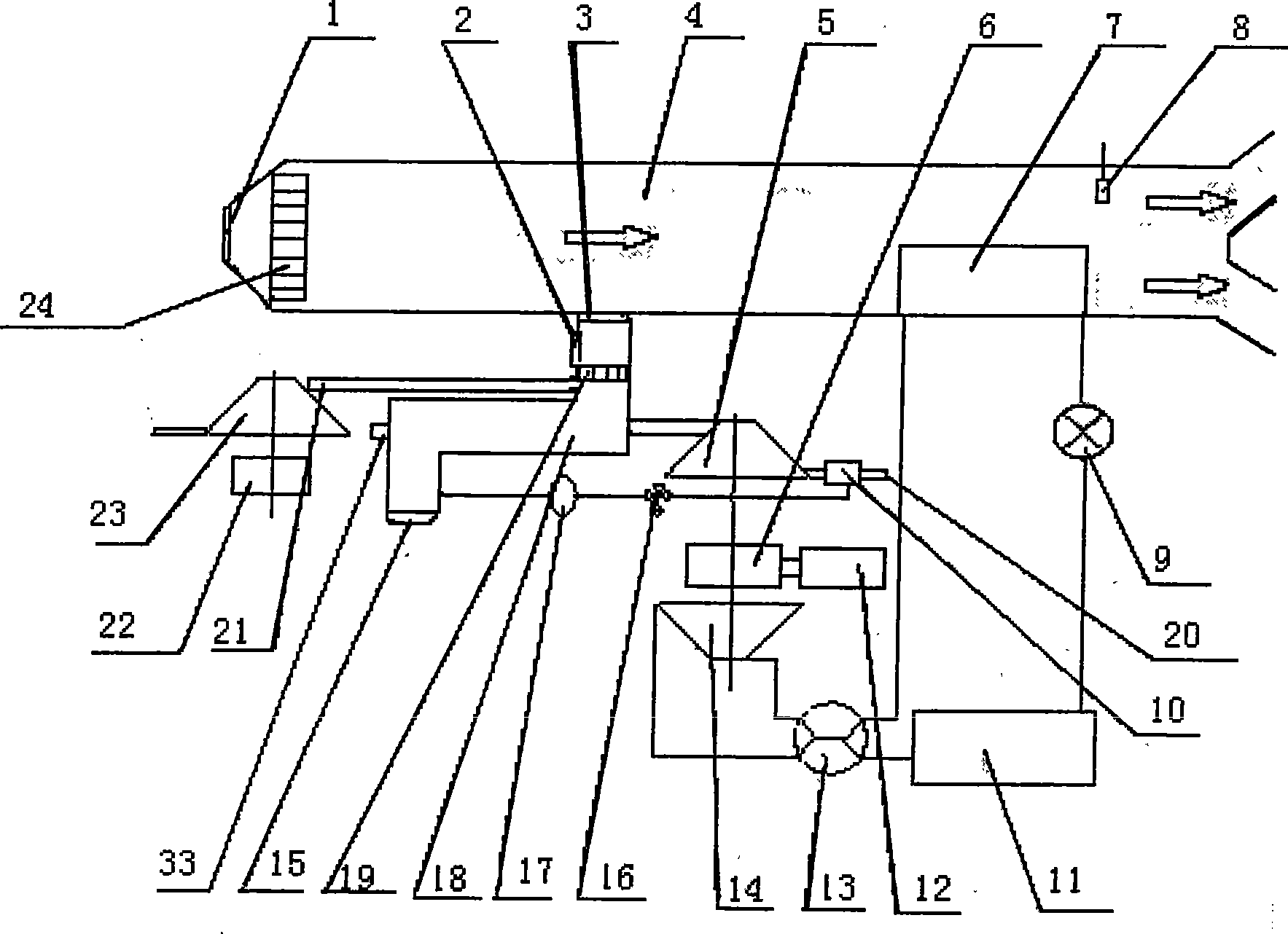

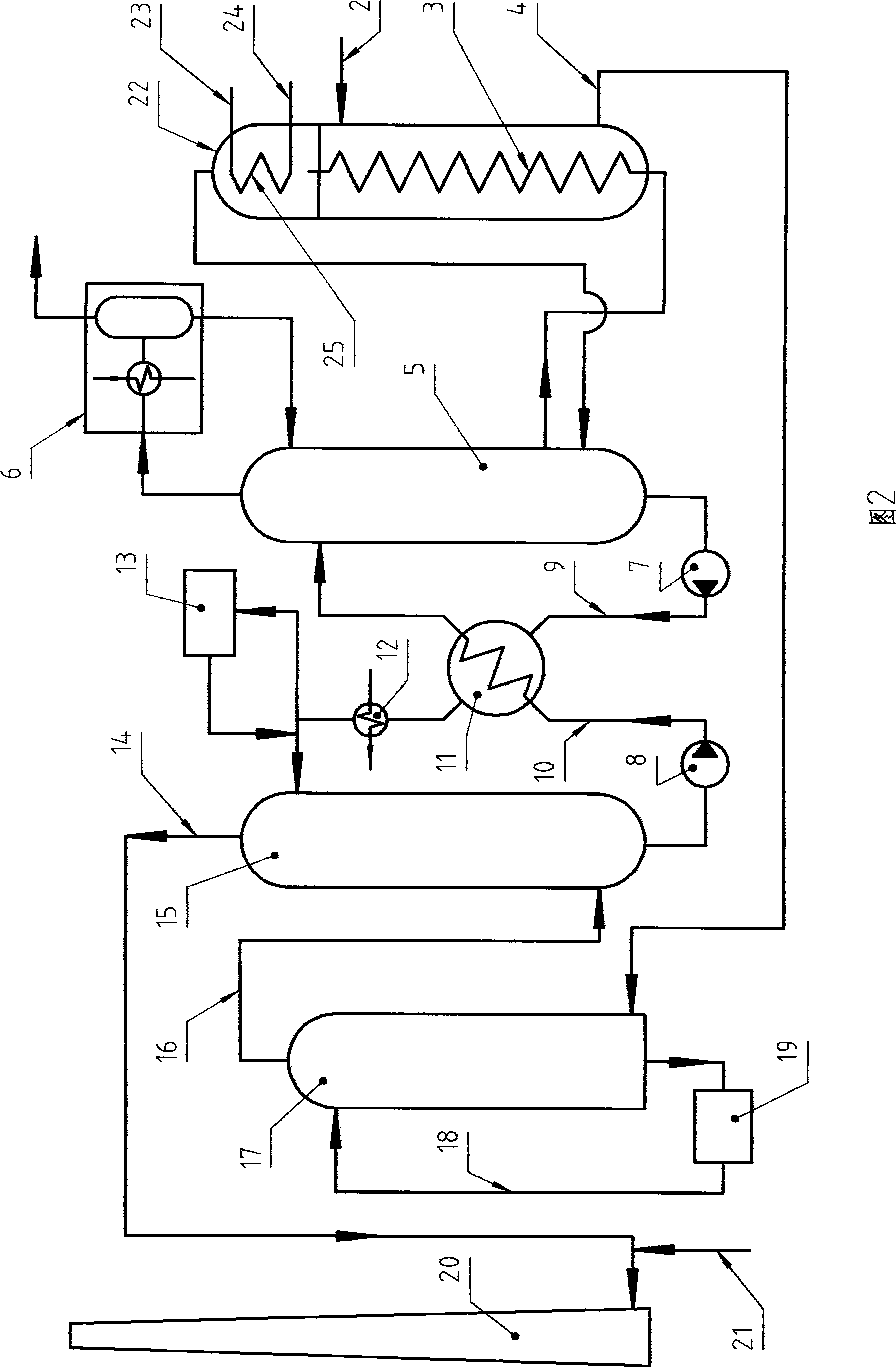

Silicon smelting electric furnace waste heat power generation process flow and configuration

ActiveCN101392992AEfficient extractionIncrease waste heatEnergy industryIncreasing energy efficiencyCooling towerAtmospheric air

The invention provides silicon smelting electric furnace waste heat power generating equipment, which consists of a valve 1, a waste heat boiler 2, a turbo generator 3, a vapor condenser 4, a cooling tower 5, a circulating water pump 6, a condensing water pump 7, a vapor seal heater 8, a low-pressure heater 9, a deaerator 10, a feed water pump 11, a chimney 12, a bag dust collector 13, an induced draft fan 14, a air cooler 15, a steel ball collection conveying distribution lifting device 17, a mixing cold air valve 18 and a by-pass valve 19, wherein waste flue gas discharged by a silicon smelting electric furnace 16 is introduced into the waste heat boiler to release partial heat; and when the temperature of the waste flue gas is reduced to nearly 180 DEG C, the waste flue gas enters the bag dust collector through the induced draft fan, and finally is discharged to atmosphere through the chimney. The desalted water enters the waste heat boiler through the feed water pump, vapor generated by the waste heat boiler enters the turbo generator; and after the vapor does work, the vapor enters the vapor condenser to be condensed into water, and the water enters the deaerator through a condensate removal pump, and the deoxidized water enters the waste heat boiler through the feed water pump. The silicon smelting electric furnace waste heat power generating equipment has the advantages of good energy saving effect, little investment and low cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method for supercritical Rankine cycle recycling low-temperature waste heat power

InactiveCN101298843AImprove overall utilizationReduce heat pollutionEnergy industrySteam engine plantsThermal energyResource utilization

The present invention relates to a method of recovering low temperature energy power, especially aiming at the low temperature waste heat discharged in metallurgical industry, generation by solar energy temperature difference and resource utilization in bi-circular terrestrial heat generation, belonging to the technical field of resource and environment. The circular working substance of the present invention adopts duality mixed working substance configured by propane and octafluoropropane, directly heats to the supercritical state from the outlet of the compressing pump under the supercritical pressure, enters into the organic turbine to apply work, expands to the steam of the condensed pressure ensured by the condensing temperature, then condenses to liquid to the inlet of the compressing pump to be circularly used. The method is able to recover the available energy in the low temperature energy at a large extent and cause the final discharging temperature of the low temperature heat stream (or remaining heat stream) to reduce in the range permitted by the environment.

Owner:KUNMING UNIV OF SCI & TECH

Renewable devulcanization technological process and use thereof

ActiveCN101362047AReduce energy consumptionLower your temperatureChemical industryDispersed particle separationThermal energyDesorption

The invention relates to a technique of renewable desulfurization, and the application thereof. The technique comprises the steps of the washing and cooling of desulfurated flue gas, the absorption and desorption of SO2 and heat energy supply during a desorption process and is characterized in that: at least part of heat energy required during the desorption process is supplied by the physical sensible heat carried by the flue gas to be desulfurated so as to solve the problems that during the desulfurization process, on the one hand, a great amount of steam is consumed for heating, and on the other hand flue gas needs to be cooled quickly at very low temperature in a pre-washing tower, thus leading to dual energy consumption. The invention also relates to the application of the technique of the renewable desulfurization, for example, flue gas desulfurization applicable to a sintering system of a steel plant, the flue gas desulfurization applicable to ironmaking blast furnace gas and the like. The technique and the application have the advantages of saving energy and water as much as possible and reducing heat pollution to the environment while saving energy.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants

InactiveCN102172461AShorten desorption timeReduce power consumptionDispersed particle filtrationIncinerator apparatusActivated carbonActive carbon

The invention relates to an automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants, which is characterized in that: (1) both opposite side walls of an active carbon bed body of an adsorption bed are set into side walls with hollow structures, an active carbon clapboard is set into an active carbon clapboard with a hollow structure, the active carbon clapboard with the hollow structure is communicated with the side walls with the hollow structures, and the two side walls with the hollow structures are respectively provided with a hot air inlet and a hot air outlet; and (2) a catalytic combustion bed is connected with a plate-type heat exchanger, and the plate-type heat exchanger is connected with the hot air inlets on the side walls withthe hollow structures of the adsorption bed through an adsorption bed heating fan. The automatic high-efficiency energy-saving purification system for the for industrial volatilizable organic pollutants has a simple and reasonable structure, can effectively reduce energy consumption, improve the purifying rate, prolong the service life of a catalyst, shorten the desorption process time, improve the purifying efficiency and reduce the operating cost, and is safe and reliable.

Owner:赛智环保科技(天津)有限公司

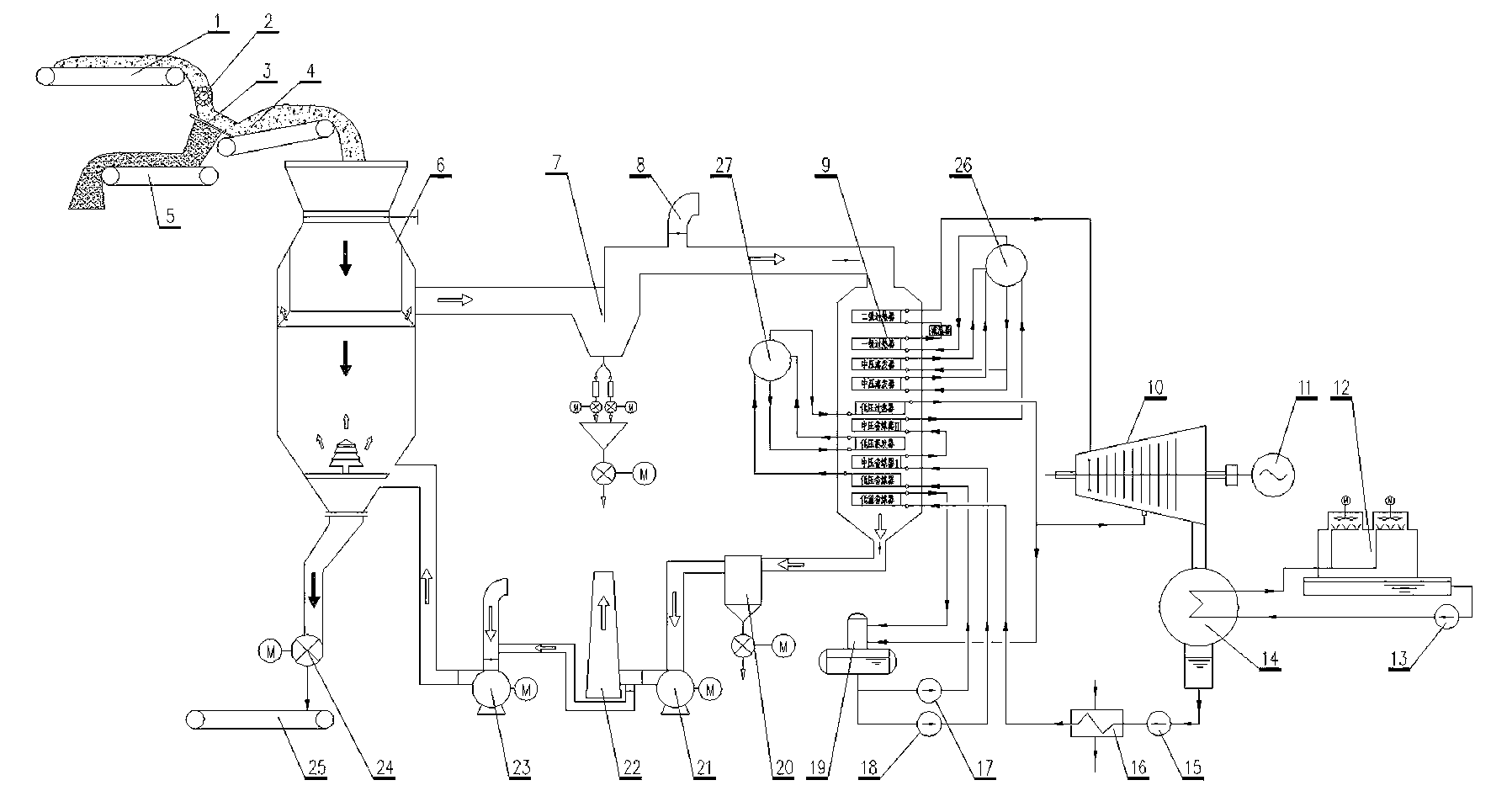

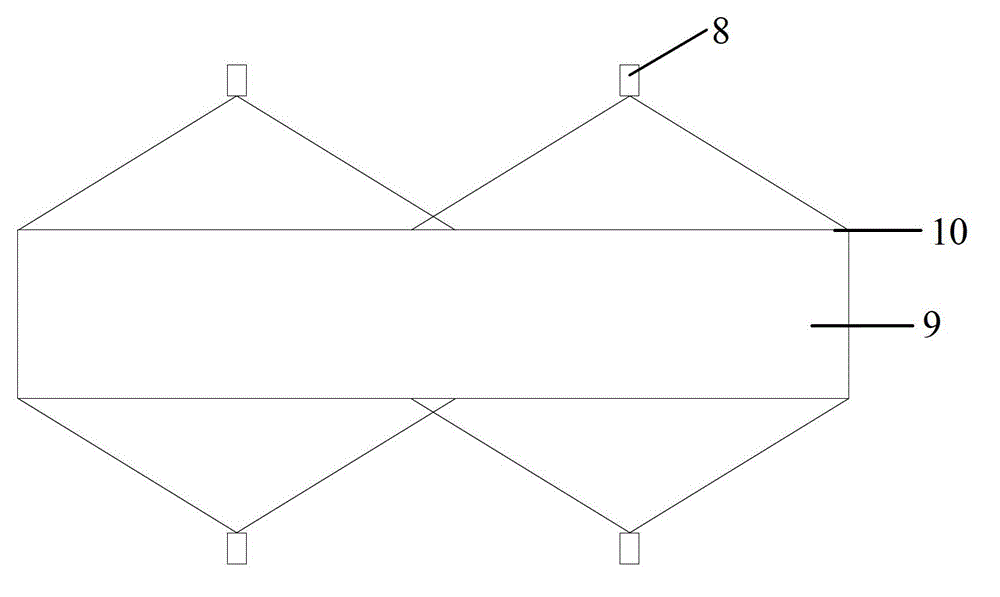

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Steam exhausting cooling method and device of condensing steam turbine of auxiliary thermal power station

InactiveCN101694167AImprove economyReduce the degree of impact on the climate environmentEngine componentsSteam engine plantsRefrigeration compressorEngineering

The invention relates to steam exhausting cooling method and device of a condensing steam turbine of an auxiliary thermal power station, belonging to the technical field of power generation and solving the defects existing in the traditional cooling system of the condensing steam equipment. The technical scheme is achieved as follows: a mixed cooling mode is adopted in a process of exhausting steam of the turbine, condensed water in a hot well of a condenser is divided into two paths, one path of the condensed water sequentially enters an air-cooled heat radiator and a refrigeration equipment evaporator for cooling, and then is sprayed into the condenser by a condenser water spraying mechanism to be mixed with exhausted steam of the turbine for heat transmission, condensation heat of the exhausted steam of the turbine is absorbed, condensation equipment is kept vacuum; and the other path of the condensed water passes through a refrigeration equipment condenser, and enters a low-pressure heater after the temperature is raised so as to realize the heat transfer. The invention can flexibly adjust the refrigerating capacity of the cooling system so as to enable the condensing steam equipment to reach an appropriate vacuum and strength the economical efficiency of thermodynamic system; can reduce the climatic environmental influence degree on machine sets and strength the output stability of the device; and also can enable partial condensation heat and the transition heat of power consumption of a refrigeration compressor and the like to be recovered by the condenser for heating and water supply, thereby reducing the loss of the low-temperature end heat.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

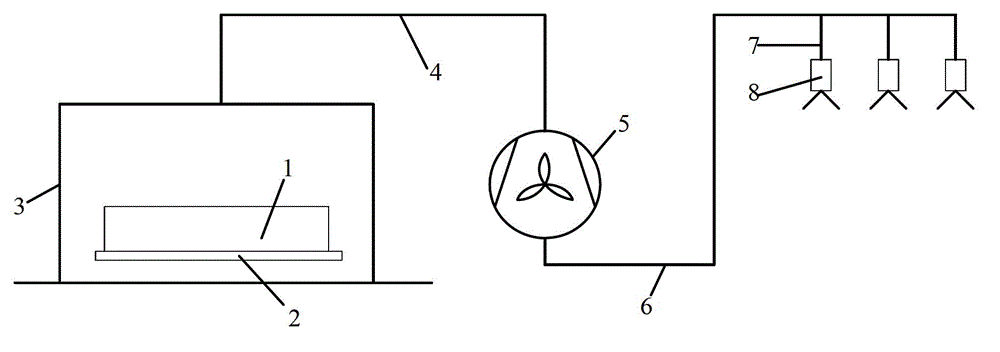

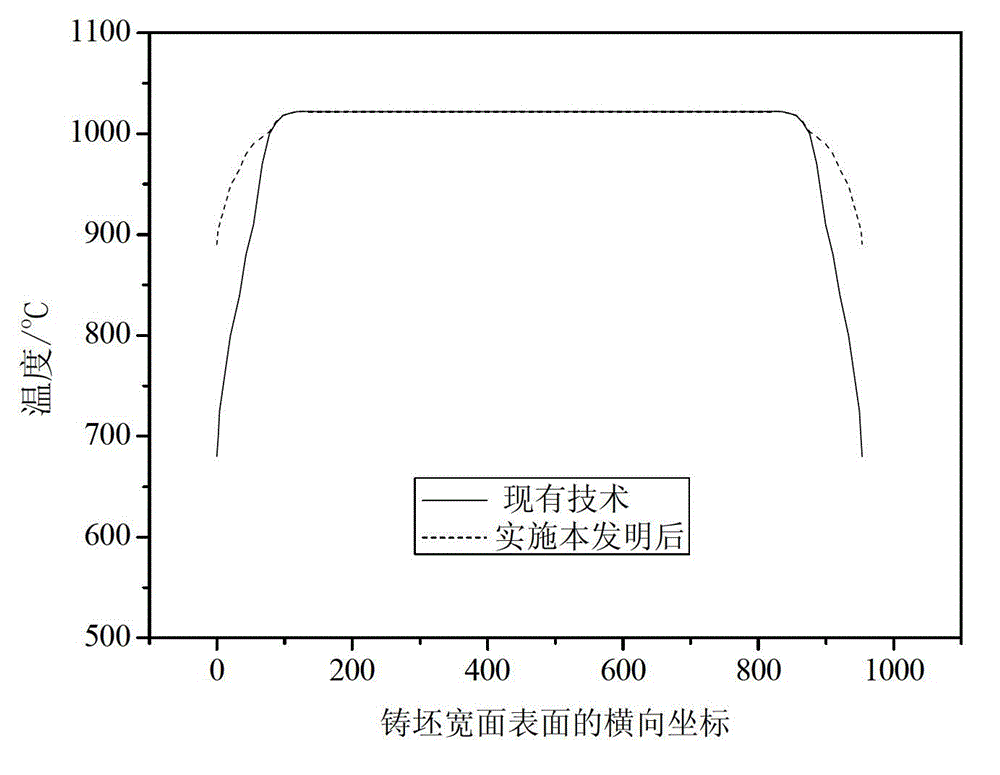

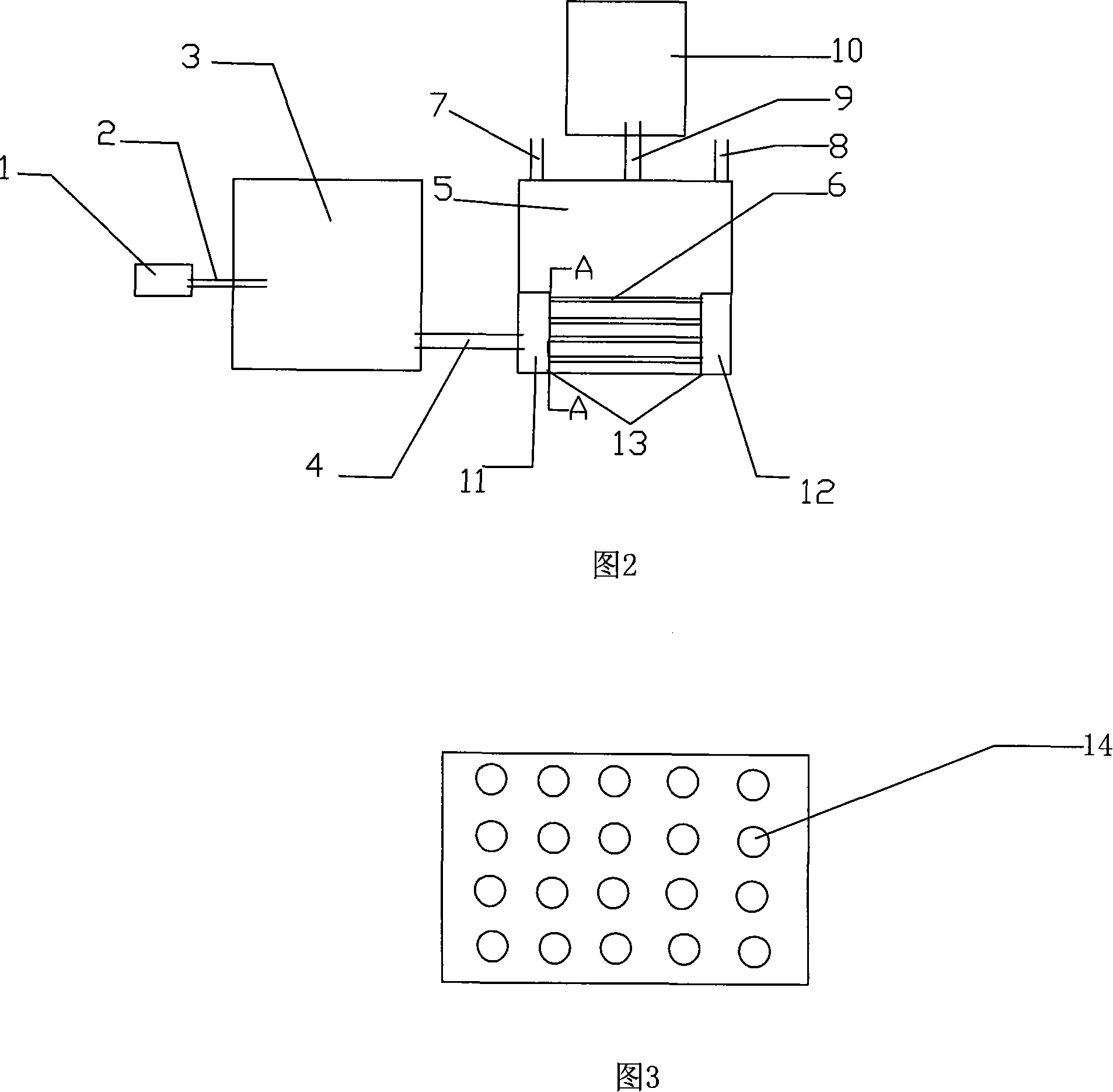

Method and device for deceasing transverse corner cracks of casting blanks

The invention relates to a method and device for decreasing transverse corner cracks of castling blanks. The method includes the steps of S1, disposing a smoke hood above a conveying roller way for cut casting blanks to collect high-temperature air; S2, delivering the collected high-temperature air under pressure; S3, delivering the high-temperature air to air nozzles disposed in a second casting blank cooling area and at corners of the casting blanks; and S4, allowing the high-temperature air to pass through the air nozzles to cover the corners of the casting blanks. The device comprises the smoke cover (3), a first heat-resistant pipe (4), a booster fan (5), a second heat-resistant pipe (6), heat-resistant branch pipes (7) and the air nozzles (8). The high-temperature compressed air can be blown to the corners of the casting blanks to prevent excessively fast cooling of the corners of the casting blanks, so that the corners of the casting blanks can be kept at the temperature higher than the upper limit of a low-temperature brittleness area before entering a straightening area, precipitation of various carbo-nitrides from the corners of the casting blanks is avoided, corner plasticity of the casting blanks is improved and transverse cracking of the corners of the casting blanks is effectively prevented during straightening.

Owner:WISDRI ENG & RES INC LTD

Method for desalinating sea water by using seawater source heat pump technology

InactiveCN101130442AImprove work efficiencyEfficient use ofGeneral water supply conservationHeat recovery systemsSystem generatorWater source

The invention discloses a desalinating technique of seawater through water source heat pump under negative pressure condition, wherein the system is composed of seawater source heat pump, jet vacuum pump, generator and pump; a lower pressure condition is formed in the generator to evaporate the seawater with temperature elevated; the steam is leaded into next generator acted by jet vacuum pump to release potential heat and evaporate seawater, which realizes the utilization effectively; the steam condensate is extracted from the generator to product fresh water. The invention improves the energy utilizing efficiency as heat supplying equipment in winter, which releases the heat pollution of circulating condensate of electric factory due to low temperature of outlet water of seawater source heat pump evaporator and system generator.

Owner:葆光(大连)节能技术研究所有限公司

One-step method and device for production of phosphonate by yellow phosphorus

InactiveCN101117215AEliminate and reduce thermal pollutionReduce heat pollutionPhosphoric acidPhosphatePhosphoric acid

The invention discloses a method and device for producing phosphate through adopting yellow phosphorus one-step method. The technical proposal of the invention are that: solid yellow phosphorus is melted into liquid elemental phosphorus inside a phosphorus melting trough and then is pumped into a phosphorus furnace for oxidizing combustion to generate high-temperature phosphorus pentaoxide gas; then, the temperature of the high-temperature phosphorus pentaoxide gas is lowered after completing heat exchange inside an exhaust heat boiler and generate high-pressure water vapor at the same time; finally, low-temperature gas enters into an alkali absorbing tower to react with alkali solution to generate phosphate. The invention can fully reclaim the chemical heat energy generated from yellow phosphorus combustion and also reduces the three major steps adopted in phosphate production to two steps, thereby omitting the intermediate process during phosphoric acid production, saving raw materials and equipment investment, avoiding discharge of acid mist and reducing environmental pollution.

Owner:罗宗恬 +1

Automatic drainage device of air conditioner

InactiveCN101608824AReduce the temperatureReduce heat pollutionCondensate preventionSiphonWater storage

The invention relates to an automatic drainage device of an air conditioner, comprising an evaporator and a condenser which are arranged inside a shell, wherein a water accumulation area is arranged below the evaporator, and a condensation fan is arranged at the side of the condenser. A water storage area communicated with the water accumulation area is arranged below the condensation fan, and the outward end of each fan leaf of the condensation fan or the outer ring of the condensation fan is immersed in the condensed water of the water storage area. The shell comprises a bottom board, wherein the water accumulation area is a water accumulation groove formed on the bottom board by stampimg, the water storage area is a water storage groove formed on the bottom board by stamping, and the water accumulation groove is communicated with the water storage groove. The water storage groove is communicated with one end of a siphon pipe, and the other end of the siphon pipe extends outside the shell. The highest water level of the water storage groove is higher than the highest water level of the siphon pipe. The invention has the advantages of small size, low manufacture cost, flexible operation and warranted energy-efficiency ratio and has the characteristic of automatic drainage without using outer input power.

Owner:GUANGDONG GALANZ GRP CO LTD

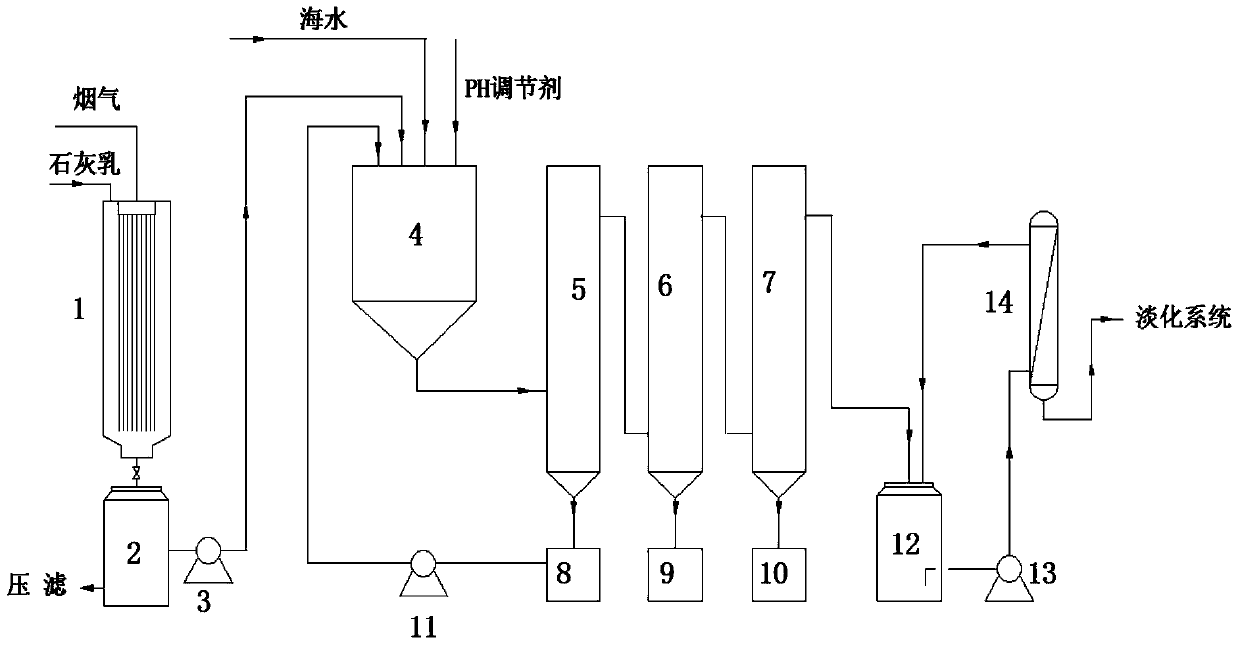

Method for reducing emission of thermal power generation smoke CO2 and subsidiarily producing superfine nanometer CaCO3 from thermal power generation smoke CO2

ActiveCN103990370ARemove calcium ionsRealize low carbon emissionsCalcium/strontium/barium carbonatesMaterial nanotechnologyWater desalinationEngineering

The invention provides a method for reducing the emission of thermal power generation smoke CO2 and subsidiarily producing superfine nanometer CaCO3 from the thermal power generation smoke CO2. A device for realizing the method comprises a decarburization tower, a settling tank, a water inlet pump I, a reaction tank, a first-level settling tank, a second-level settling tank, a third-level settling tank, an intermediate tank, a water inlet pump II and a ceramic membrane filter which are successively connected through a pipeline, wherein the settling tanks are all connected with a calcium carbonate storing groove. The method provided by the invention has the advantages that smoke discharged from thermal power generation is purified and decarburized, the low carbon emission of the smoke of a power plant is realized, the environment stress of the power plant is relieved, and the green power generation is realized; the temperature of the smoke is reduced through the contact heat transfer of seawater and the smoke, waste heat is fully utilized, and the heat pollution caused by high temperature smoke emission is reduced; the CO2 in the smoke is converted into a CaCO3 product after being absorbed, the waste is turned to wealth, the smoke decarburization and the seawater decarburization are combined, the treating cost spent on the seawater decarburization is reduced, and an equipment scaling problem in the later sea water desalination process is prevented.

Owner:天津海桓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com