Exhaust gas waste heat steam producing system of marine diesel generating set

A diesel generator set, exhaust gas technology, applied in the steam generation method using heat carrier, etc., can solve the problems that the exhaust gas temperature cannot be reduced to a reasonable temperature, and the waste heat of the exhaust gas of the main engine cannot be fully utilized, so as to reduce fuel consumption, The effect of saving fuel costs and saving maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

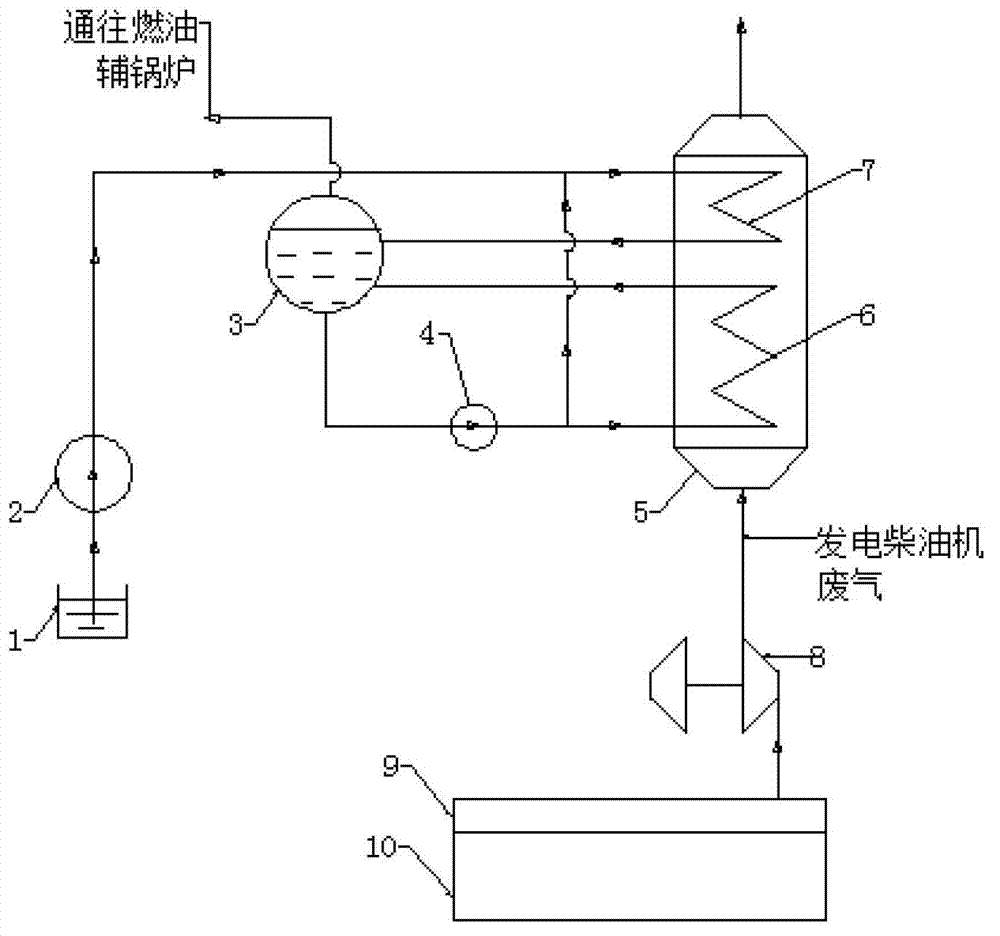

[0029] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

[0030] Since the current working pressure of the marine exhaust gas boiler and the auxiliary fuel oil boiler is usually 0.7 MPa, this embodiment takes the working pressure of the exhaust gas boiler as 0.7 MPa to illustrate the working characteristics of the system.

[0031] Such as figure 1 As shown, the exhaust gas produced by the marine diesel generator set 10 first enters the exhaust manifold 9, and then the exhaust gas enters the exhaust turbine (not shown) in the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com