Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

777 results about "Gas heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas heater is a space heater used to heat a room or outdoor area by burning natural gas, liquefied petroleum gas, propane or butane. Indoor household gas heaters can be broadly categorized in one of two ways: flued or non-flued, or vented and unvented.

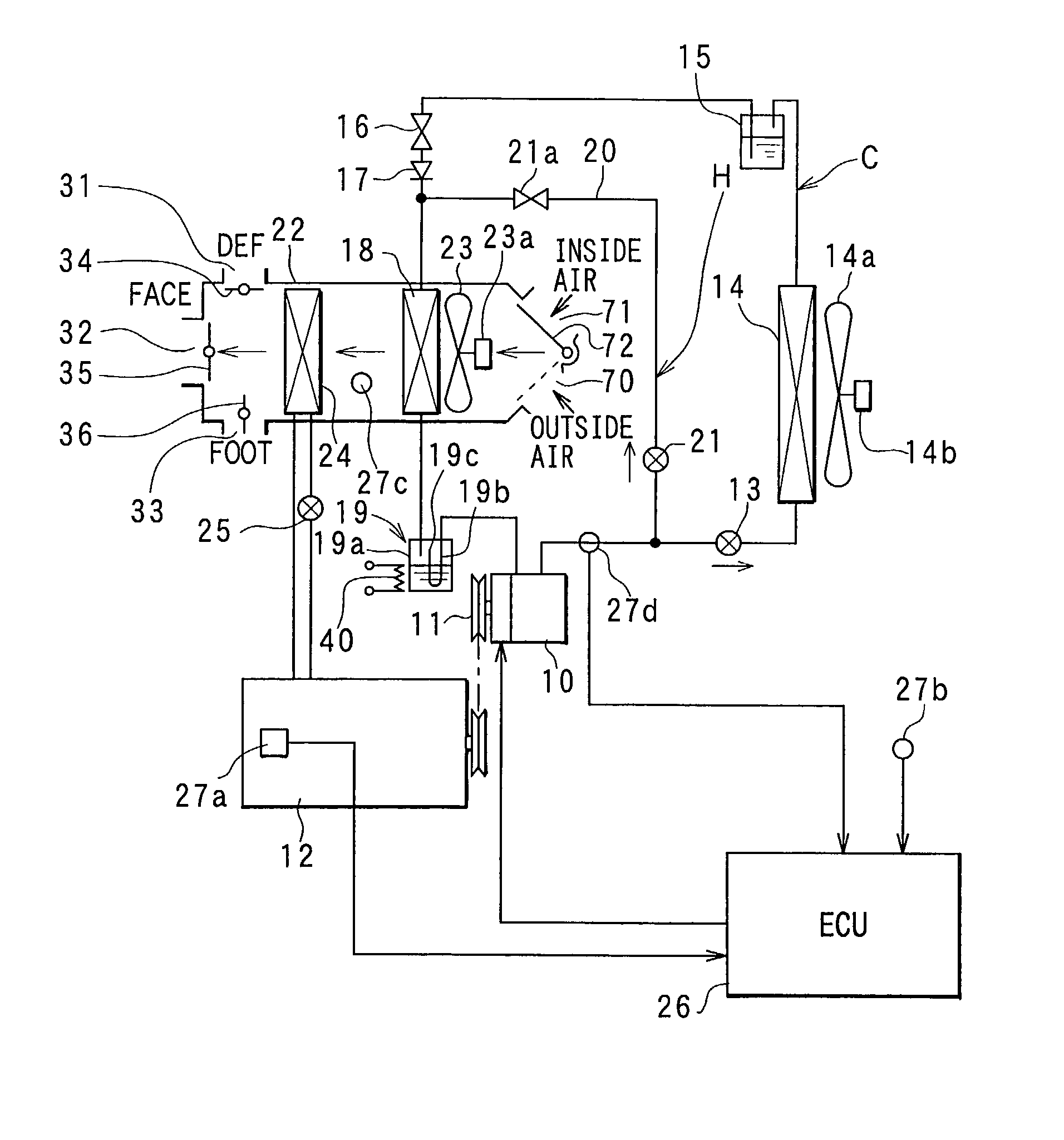

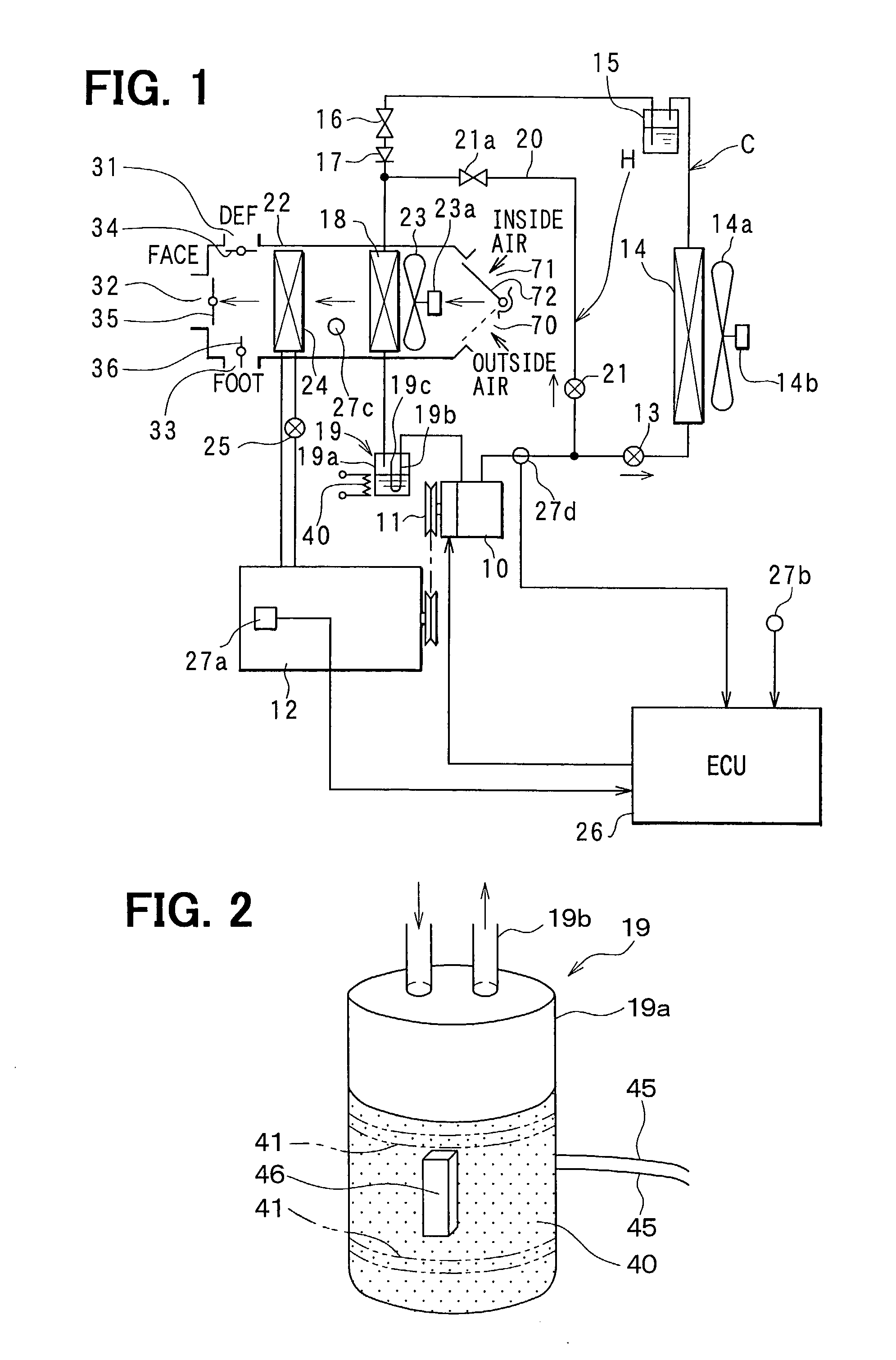

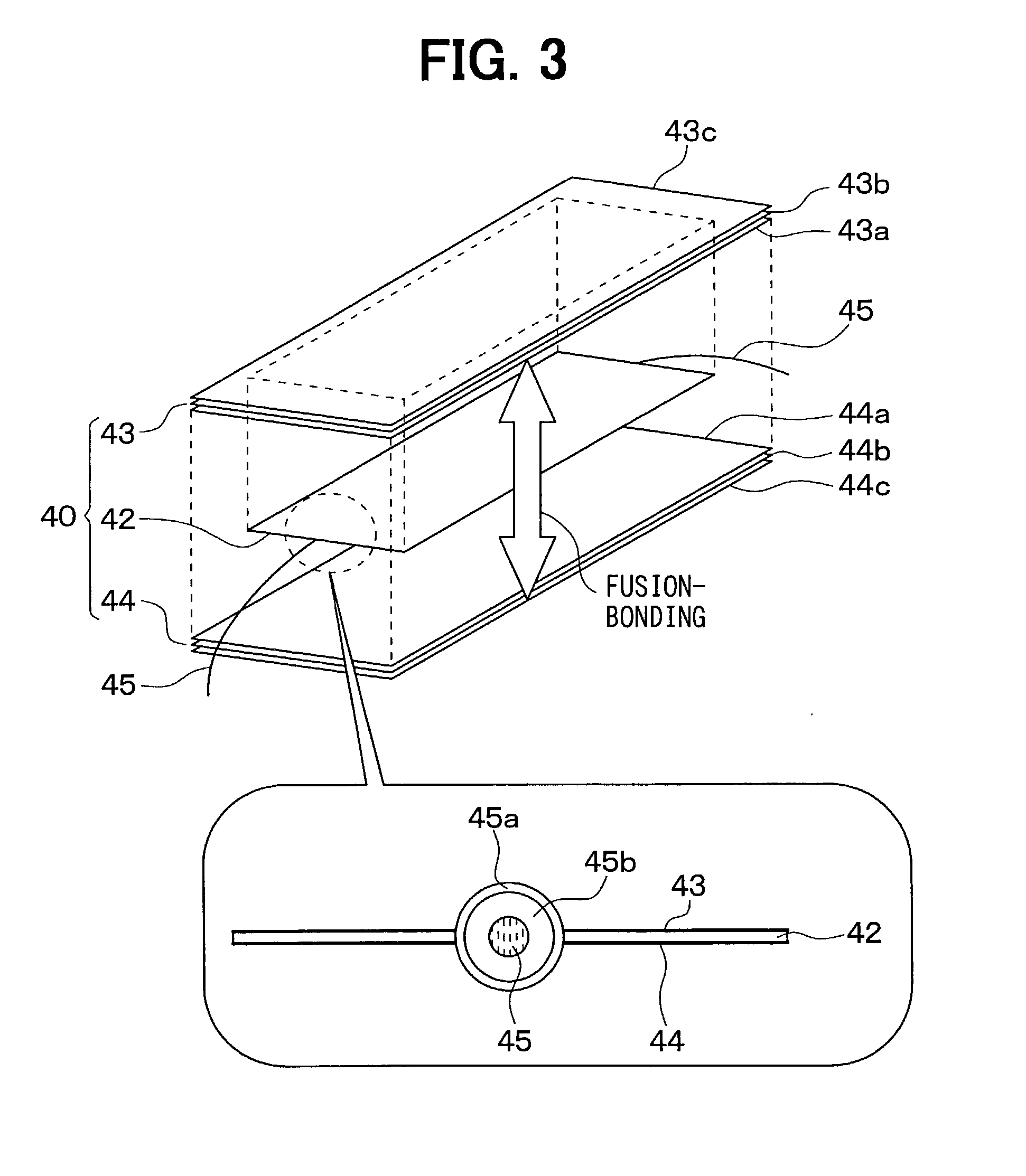

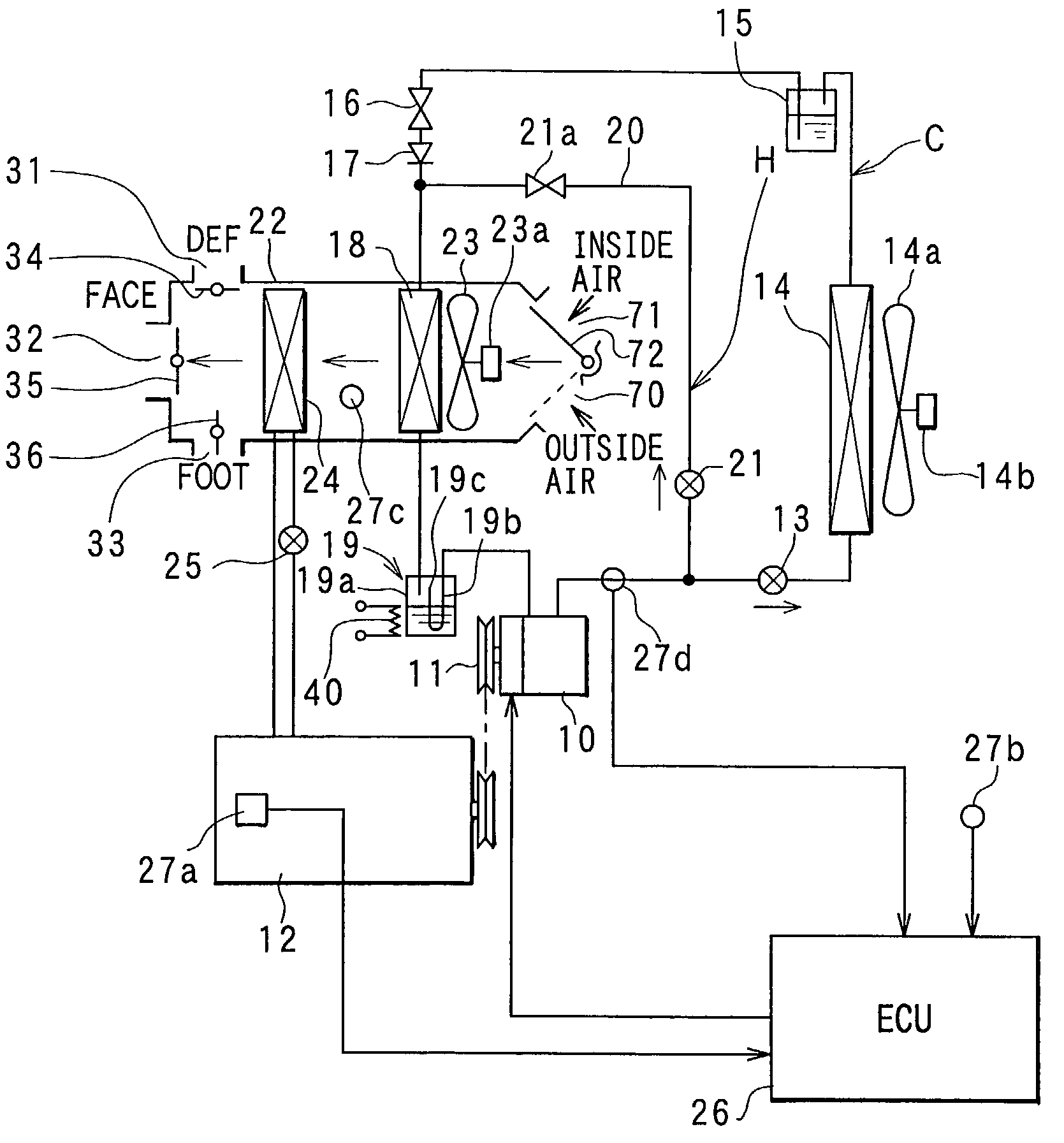

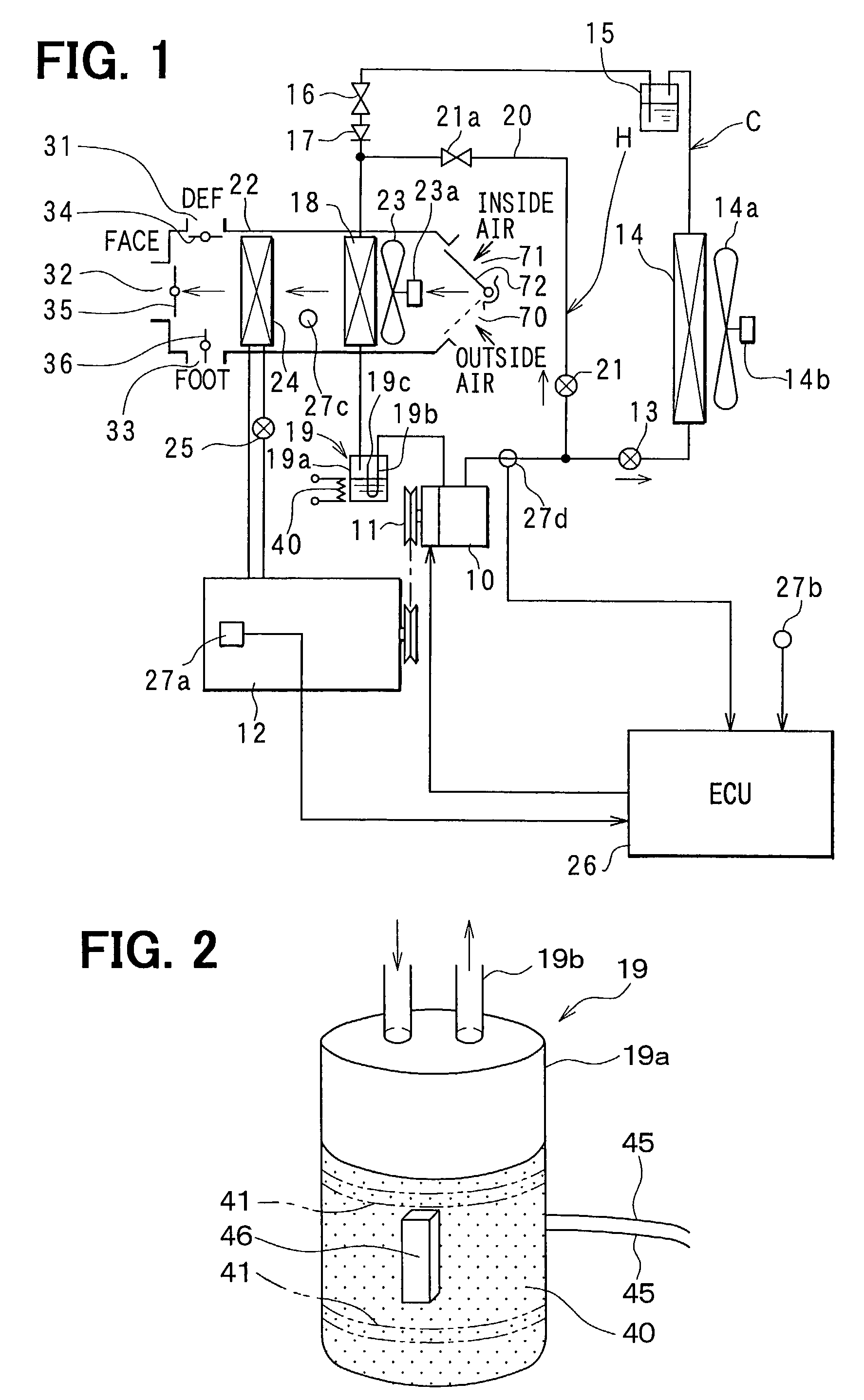

Vehicle air conditioner with hot-gas heater cycle

InactiveUS20030089493A1Improve the heating effectGuaranteed normal transmissionMechanical apparatusAir-treating devicesGas heaterEngineering

A vehicle air conditioner selectively switches one of a cooling mode in which an interior heat exchanger of a refrigerant cycle is operated as an evaporator for cooling air, and a heating mode in which the interior heat exchanger is operated as a radiator for heating air. In the vehicle air conditioner, an accumulator, for separating gas refrigerant and liquid refrigerant from each other and for storing the separated liquid refrigerant therein, is disposed between an outlet of the interior heat exchanger and a suction port of a compressor. Further, the accumulator includes a heating device for heating the liquid refrigerant stored in the accumulator in the heating mode. Therefore, heating performance for heating air in heating mode can be efficiently improved.

Owner:DENSO CORP

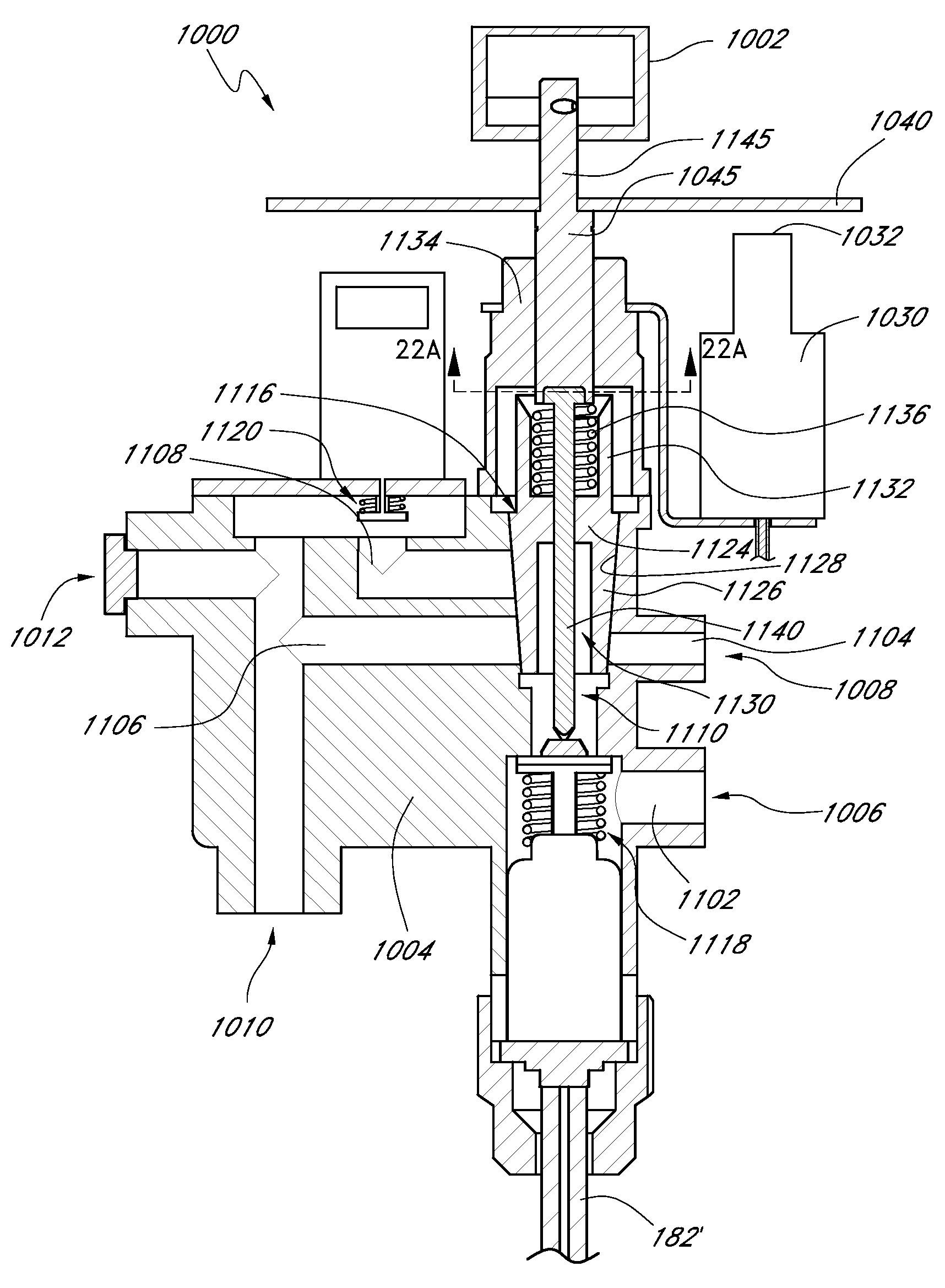

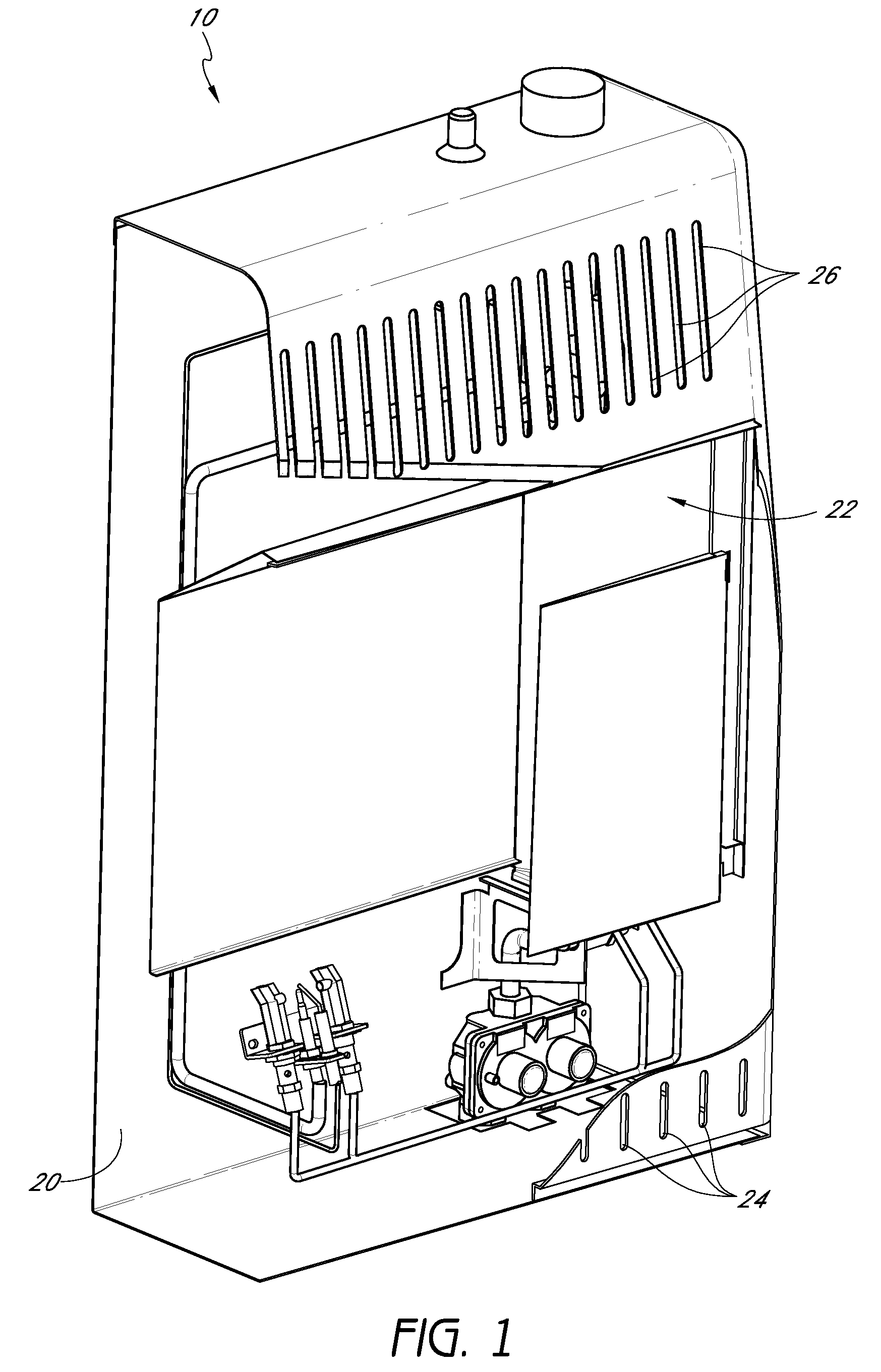

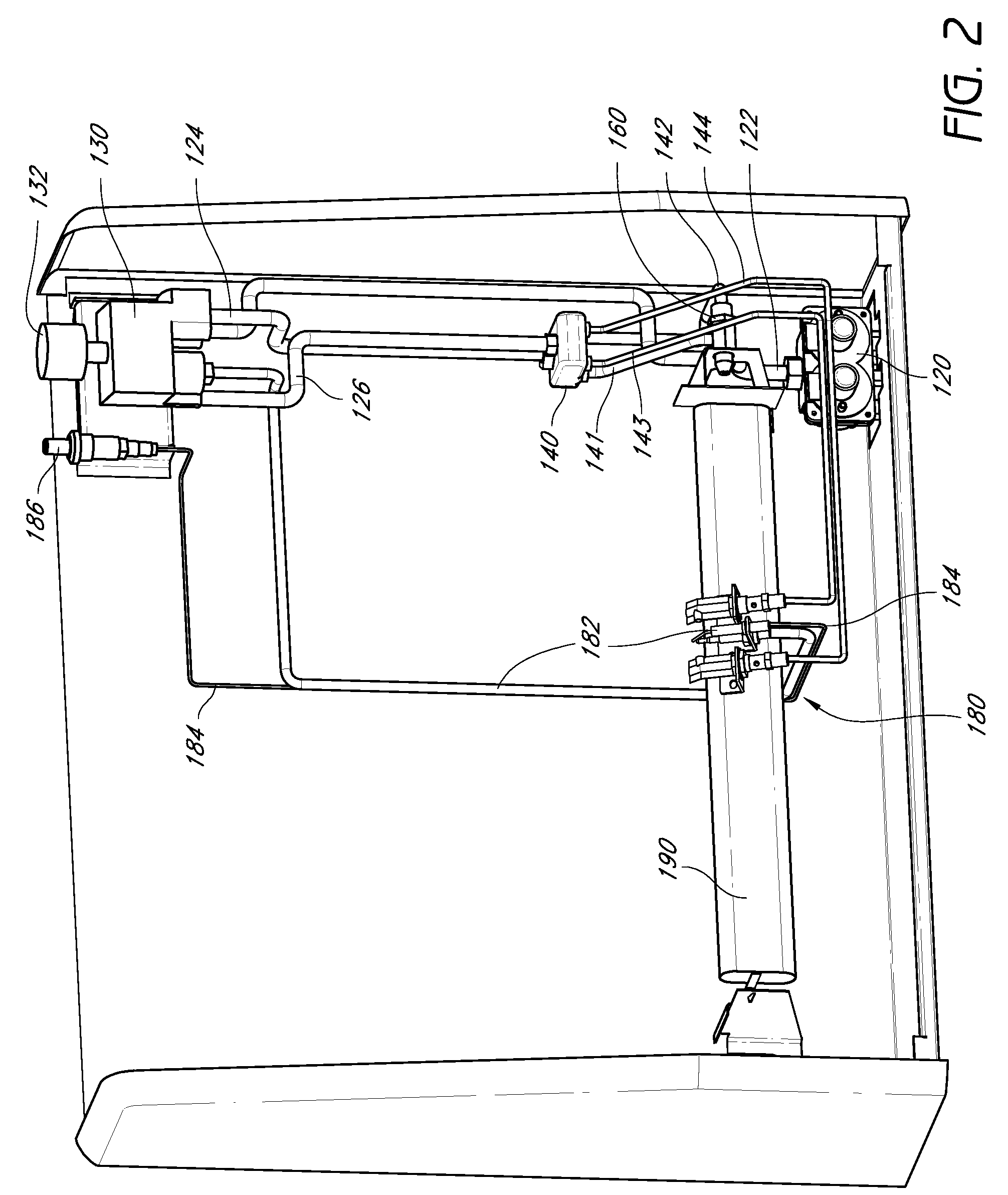

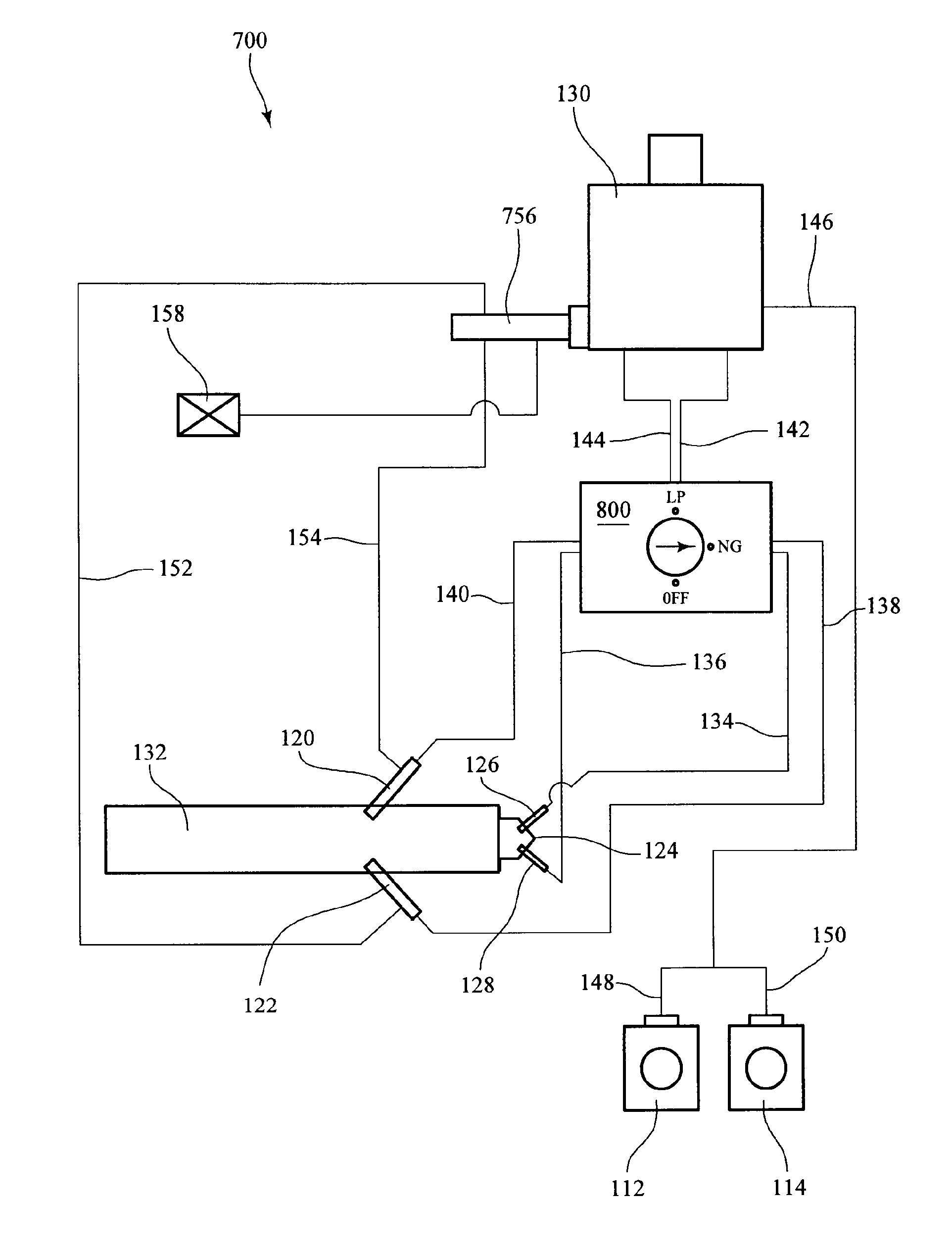

Control valves for heaters and fireplace devices

In certain embodiments, a control valve assembly for gas heaters and gas fireplace devices includes a housing. The housing can define an inlet for accepting fuel from a fuel source, a first outlet for delivering fuel to an oxygen depletion sensor, and a second outlet for delivering fuel to a burner. The assembly can include a valve body configured to selectively provide fluid communication between the inlet and one or more of the first outlet and the second outlet, and can include an actuator configured to move the valve body relative to the housing. The actuator can be configured to transition between a resting state and a displaced state. The assembly can include an igniter that includes a sensor, the igniter electrically coupled with an electrode and configured to repeatedly activate the electrode when the sensor senses that the actuator is in the displaced state. The assembly can include a shutoff valve electrically coupled with the oxygen depletion sensor and configured to operate in response to an electrical quantity communicated by the oxygen depletion sensor.

Owner:PROCOM HEATING

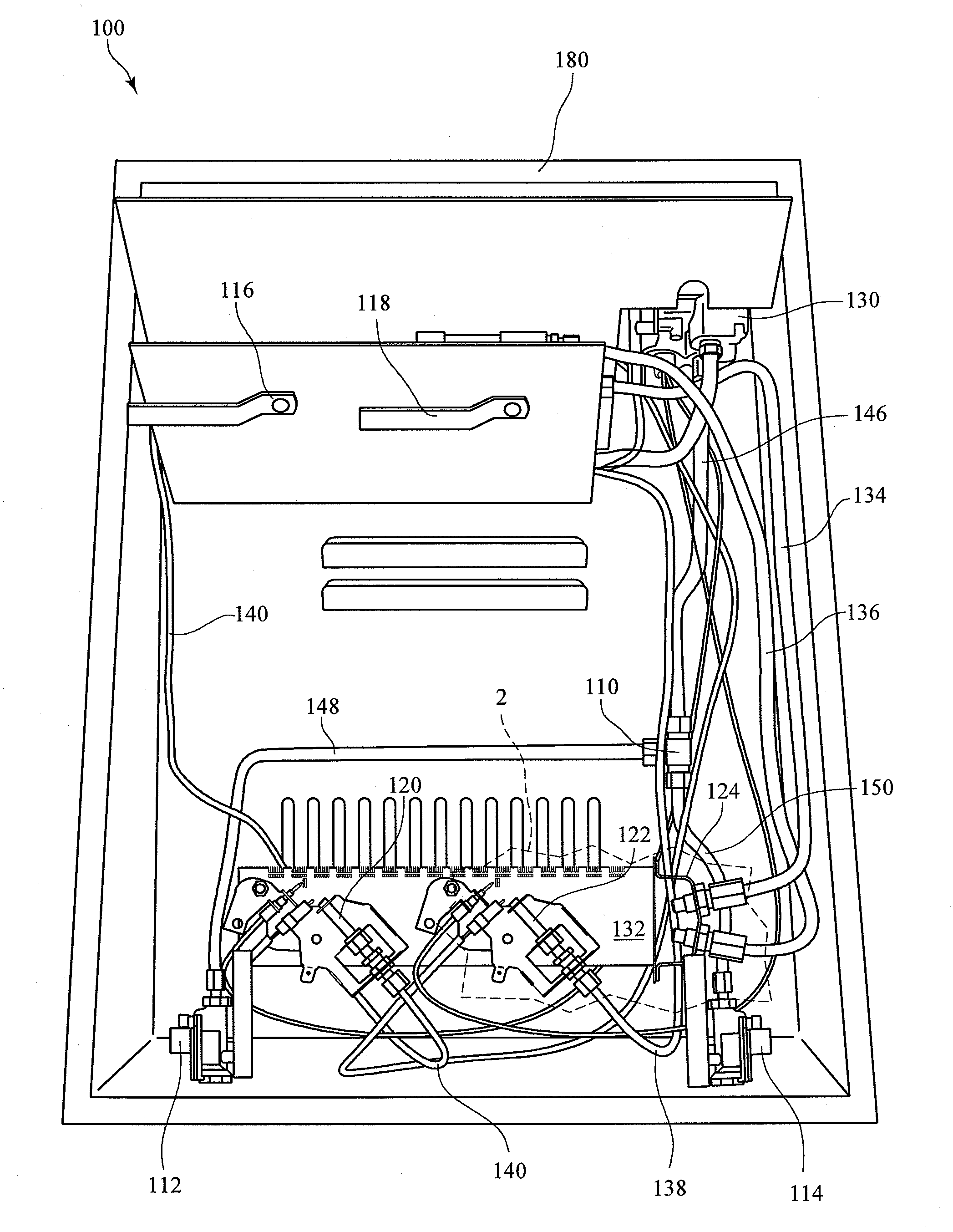

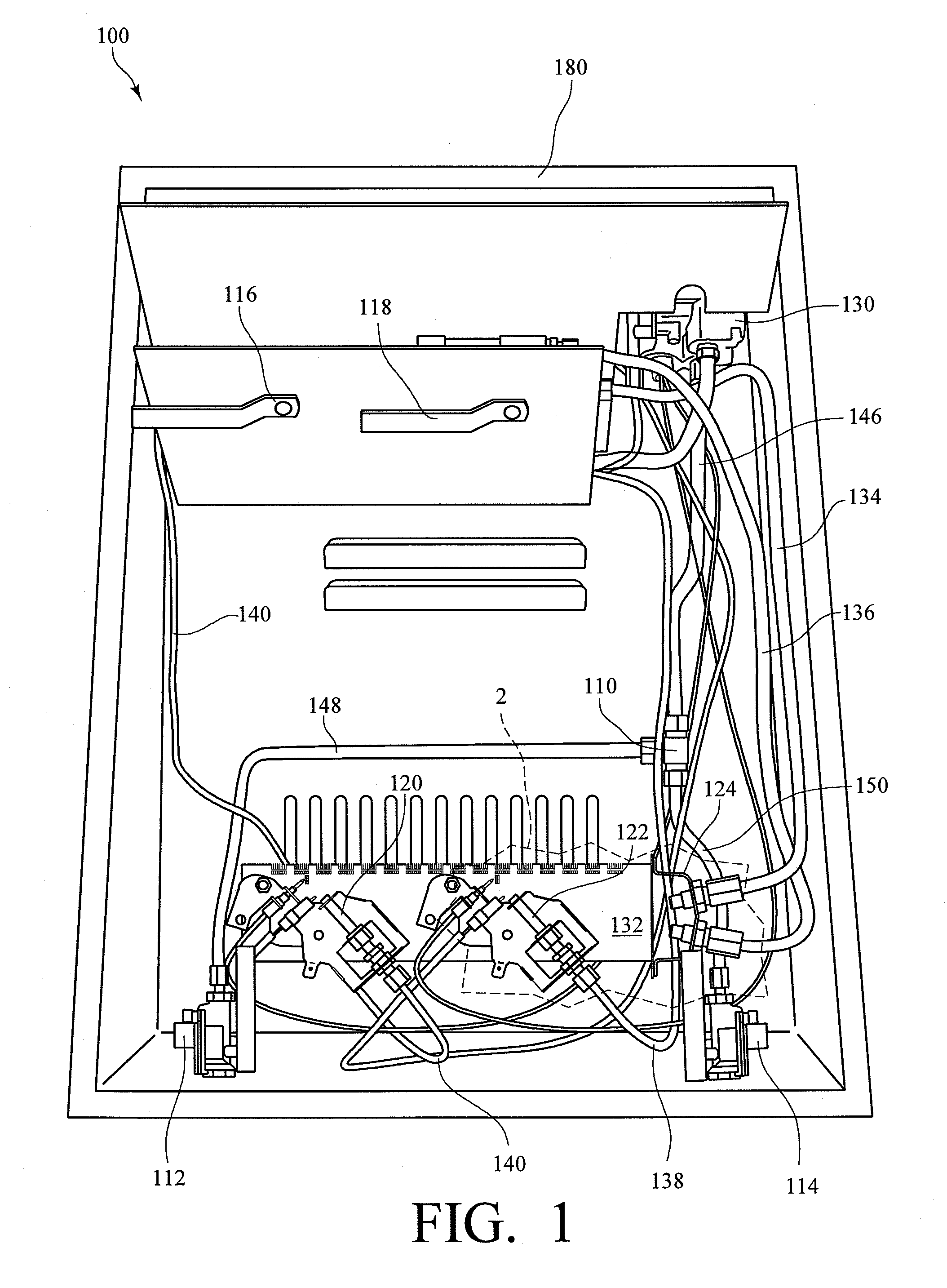

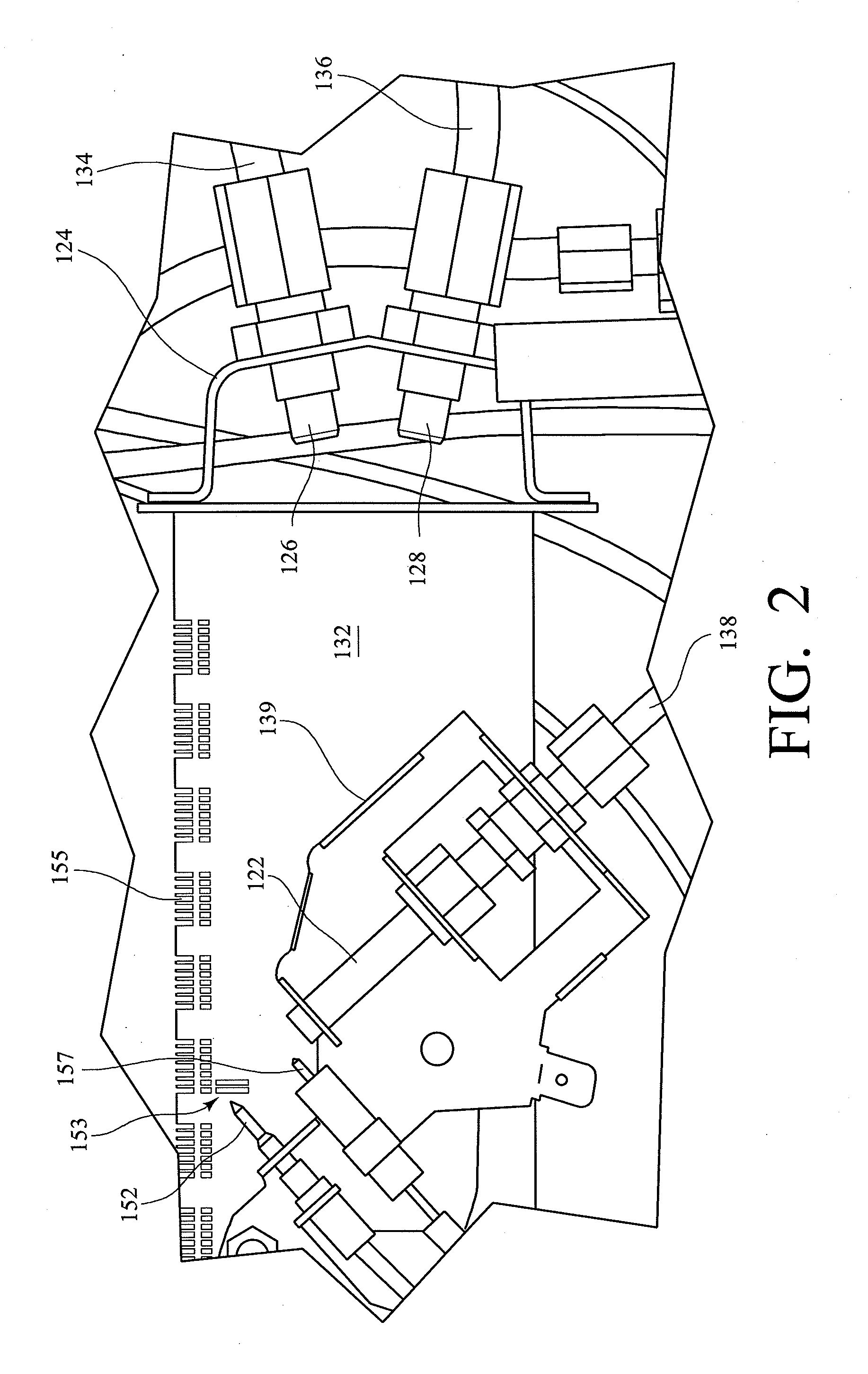

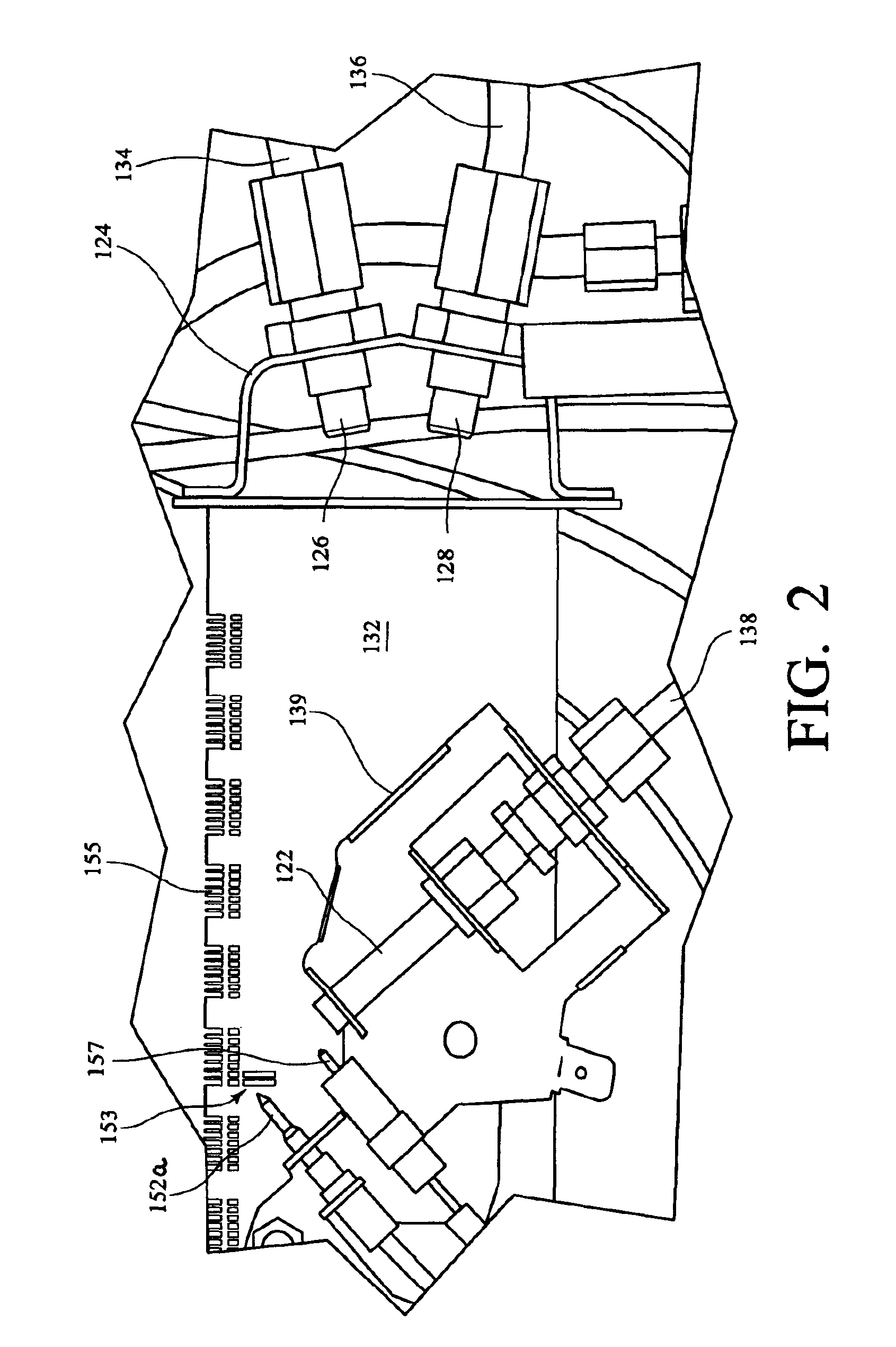

Dual fuel vent free gas heater

ActiveUS20100095945A1Enhanced natural convectionFuel supply regulationAir-treatment apparatus arrangementsControl systemNuclear engineering

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

Dual fuel vent free gas heater

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

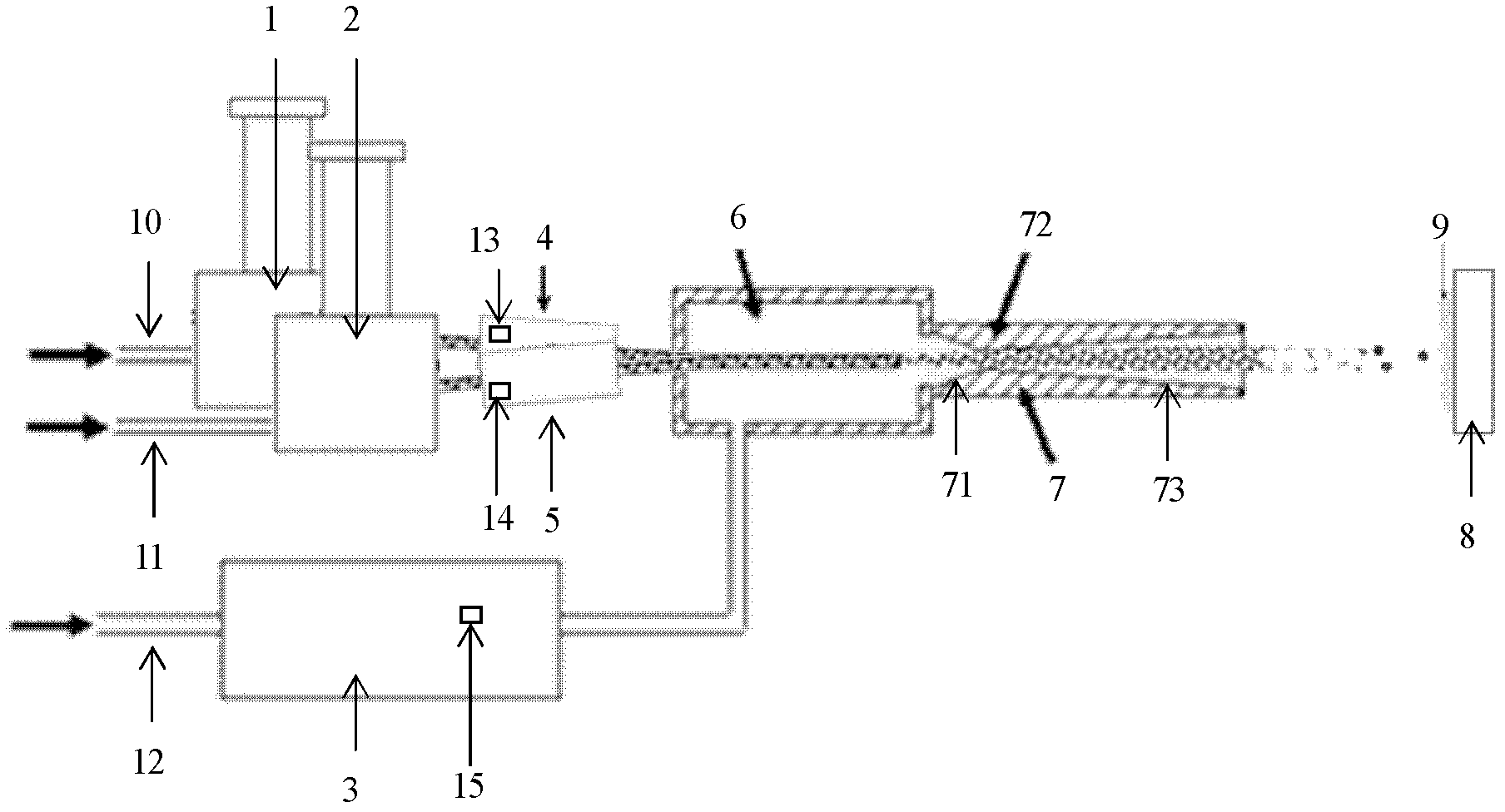

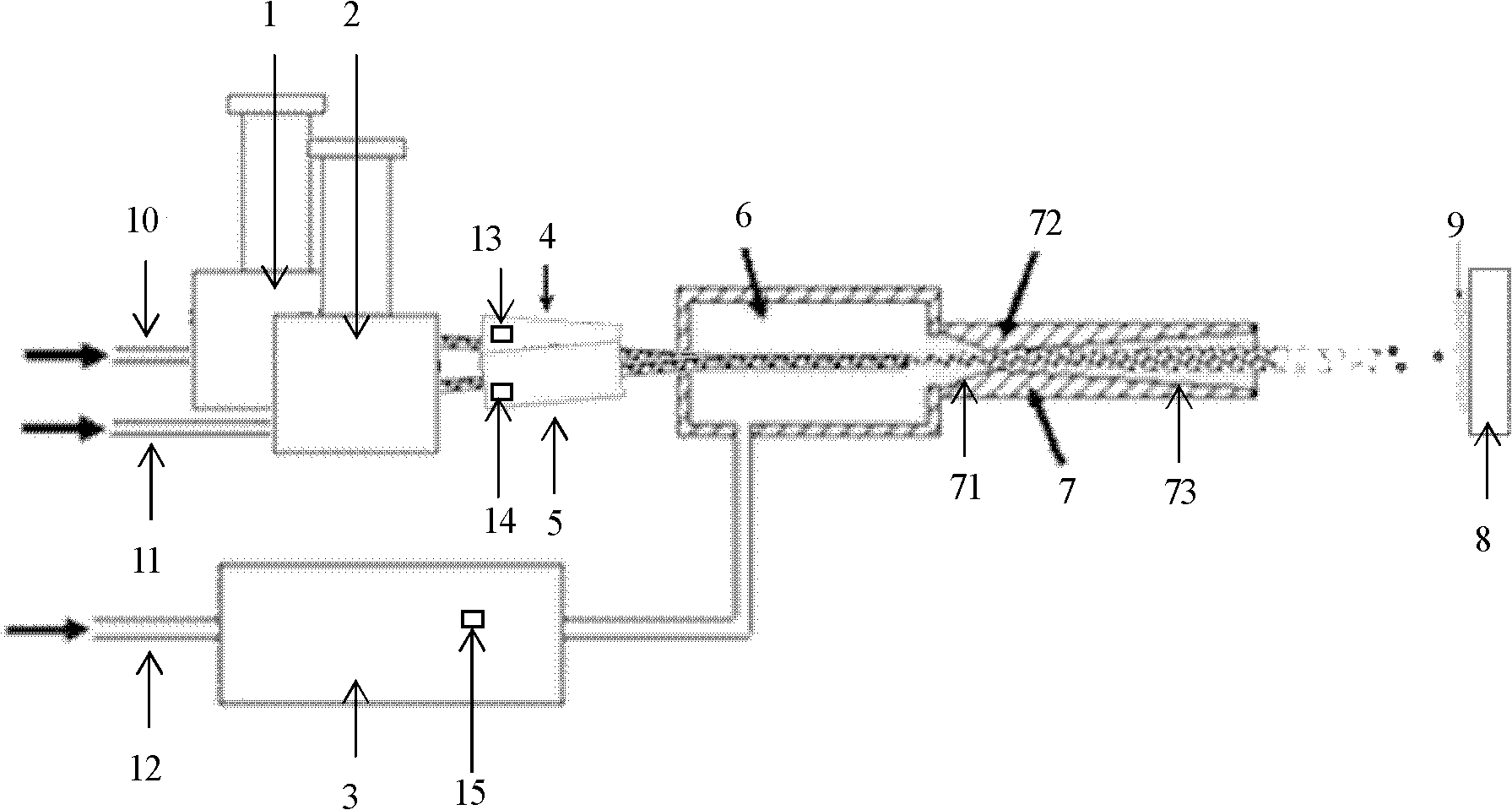

Cold spray device and method for preparing metal composite gradient quasicrystal coating

InactiveCN102527544AHigh speedLow spraying temperatureLiquid spraying apparatusSpecial surfacesForming gasGas heater

The invention relates to the field of surface coating preparation and particularly relates to a cold spray device and method for preparing a metal composite gradient quasicrystal coating. A quasicrystal powder feeder and a metal or alloy powder feeder of the device are respectively connected to a gas-solid mixing chamber through a pipeline to form a dual-channel powder feeding structure, a quasicrystal heater and a metal or alloy powder heater are respectively arranged on the pipelines, a gas heater is connected with the gas-solid mixing chamber through a pipeline and a supersonic flow nozzle is arranged at an outlet of the gas-solid mixing chamber. One path of the gas source compressed gas enters into the quasicrystal powder feeder, one path enters into the metal powder feeder, and one path enters into the heater, the gas and the powders enter into the supersonic flow nozzle via the gas-solid mixing chamber to form gas-solid dual-phase flow, solid particles in the gas-solid dual-phase flow are injected onto the surface of a workpiece and generate severe plastic deformation and finally deposit on the surface of the workpiece. The method provided by the invention can solve the problems of fragility and phase change and the like of coatings, and can be used for preparing two-component or multi-component alloy quasicrystal gradient coatings of various series.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

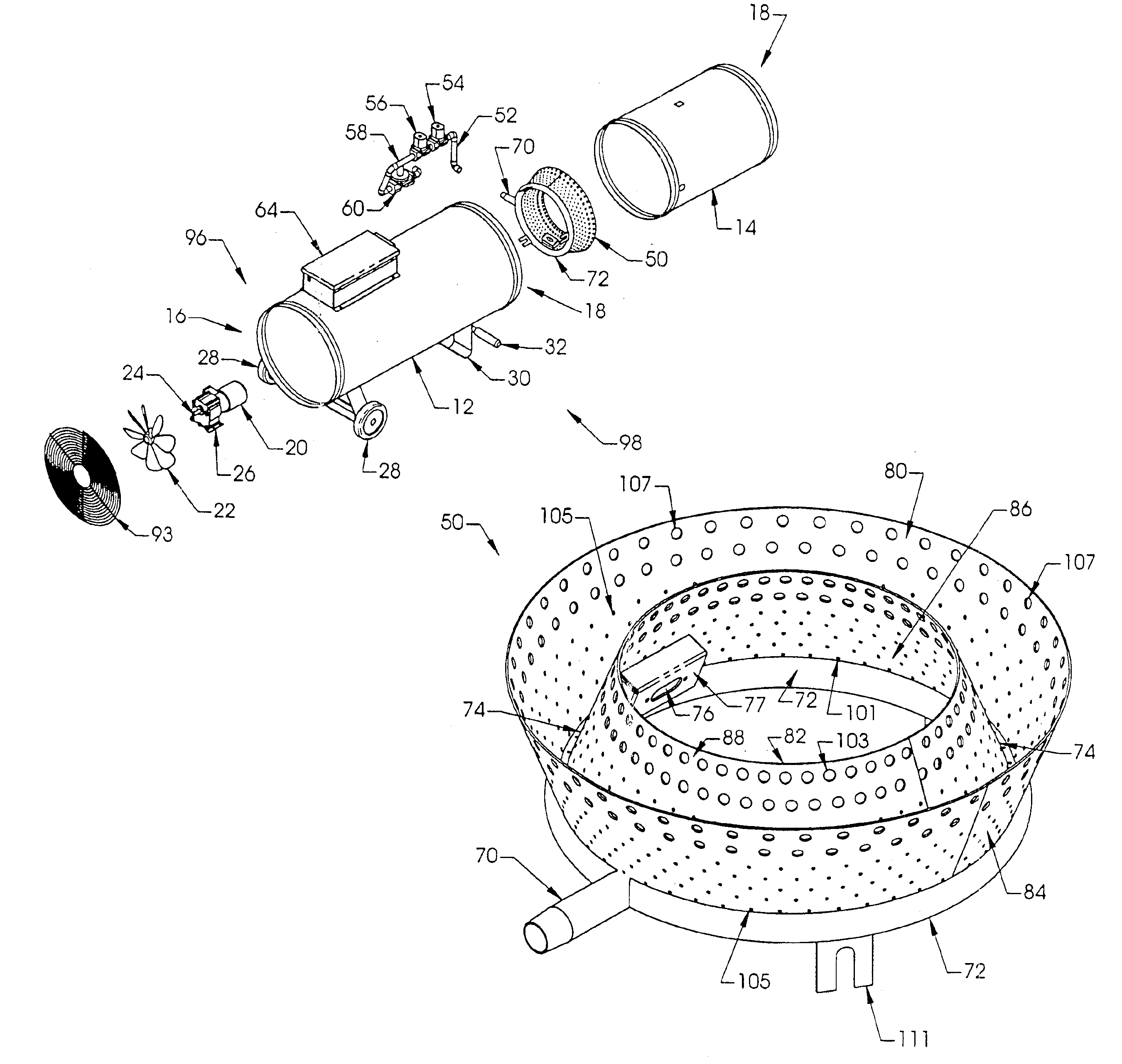

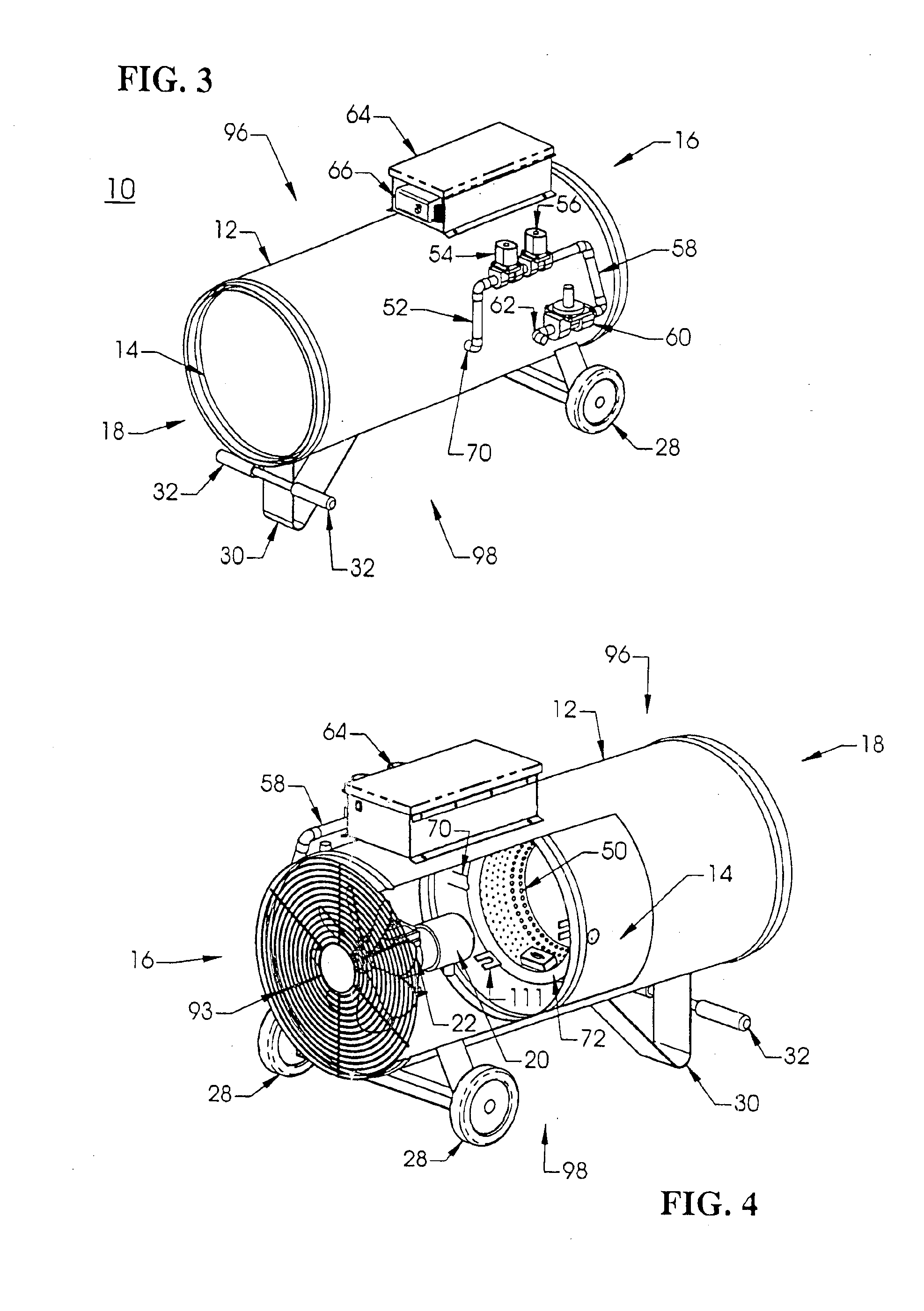

Combustion system for a heater

InactiveUS6880549B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemGas heater

A combustion system for a portable forced air heater having two frusta-conical sections attached to a circular burner tube, wherein each frusta-conical section has pre-determined vent hole patterns that allow the gas heater to have a variable burn rate.

Owner:SUNBELT RENTALS INC

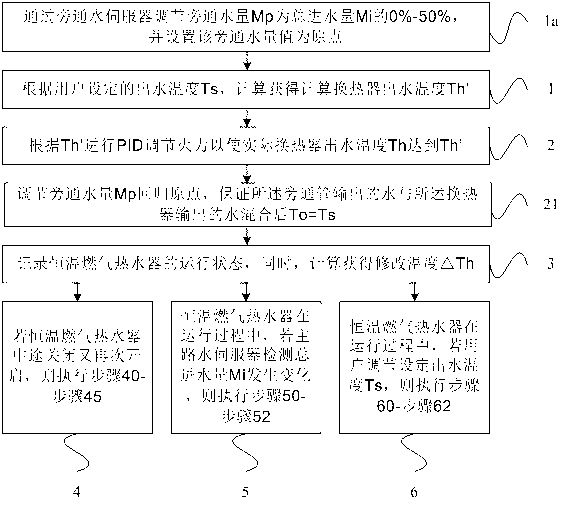

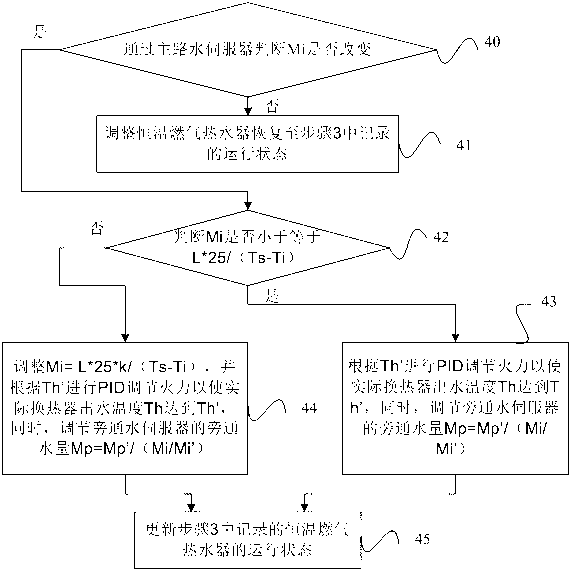

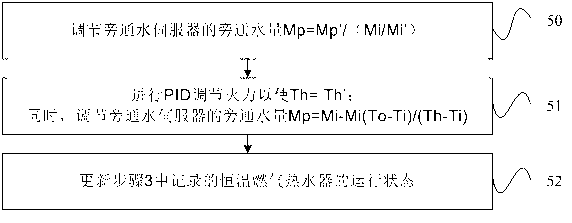

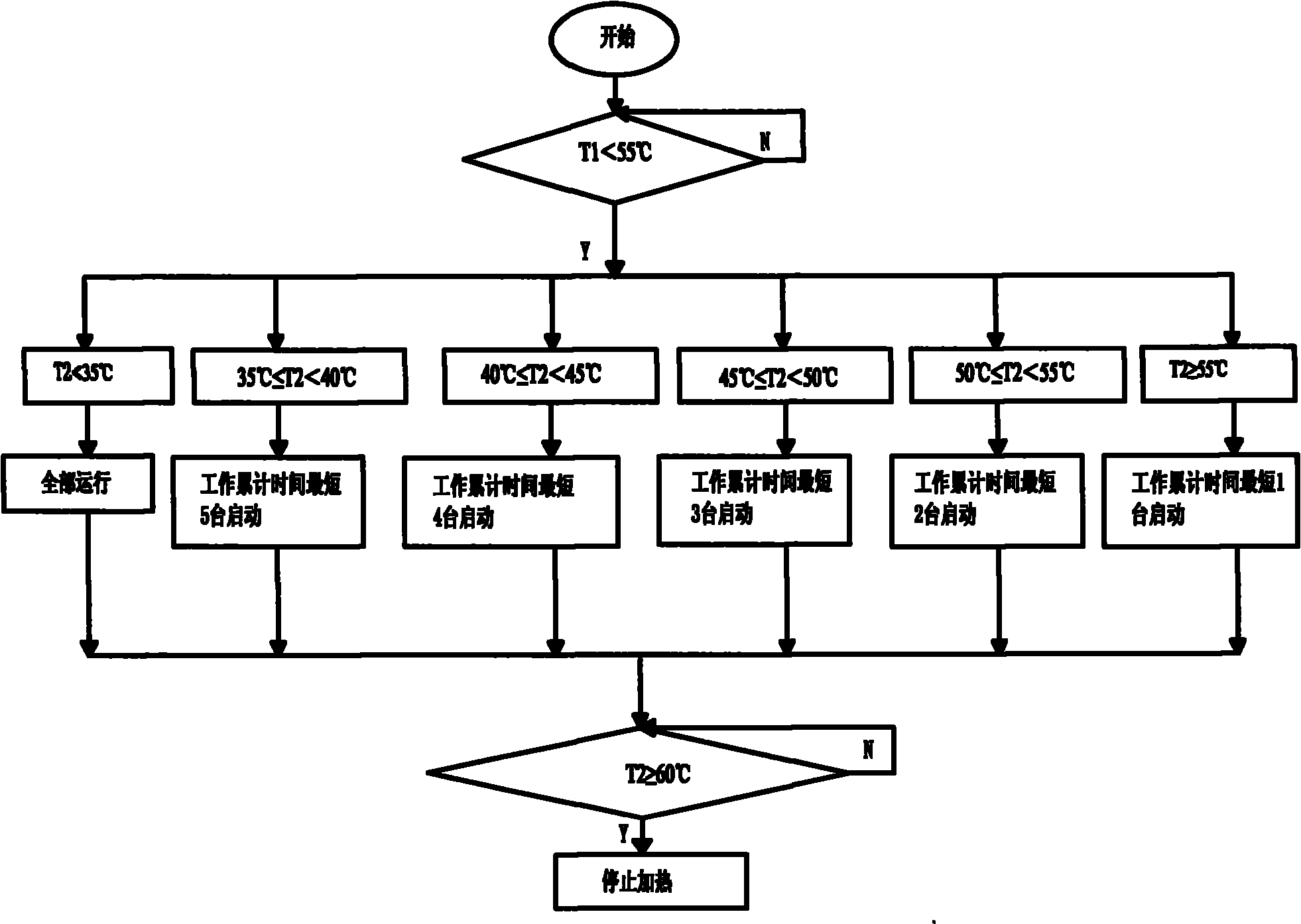

Constant-temperature gas heater control method and constant-temperature gas heater

The invention provides a constant-temperature gas heater control method and a constant-temperature gas heater. The constant-temperature gas heater comprises a main control panel, a heat exchanger, a combuster, a water inlet pipe and a water outlet pipe, and further comprises a bypass pipe. The bypass pipe is connected with the water inlet pipe and the water outlet pipe, and is provided with a bypass water server. An outlet of the heat exchanger is provided with a first temperature sensor. An outlet of the water outlet pipe is provided with a second temperature sensor. The first temperature sensor, the second temperature sensor and the bypass water server are respectively in electric connection with the main control panel. The bypass pipe is arranged between the water inlet pipe and the water outlet pipe, the bypass pipe is provided with the bypass water server, and the main control panel controls the bypass water server to operate to adjust water flow of the bypass pipe according to temperature information collected by the first temperature sensor and the second temperature sensor, so the water outflowing temperature of the water outlet pipe is constant, the situation that hot water at exceedingly high temperature is output is avoided, the water outflowing temperature of the constant-temperature gas heater is constant, and comfort and safety of the constant-temperature gas heater are improved.

Owner:HAIER GRP CORP +2

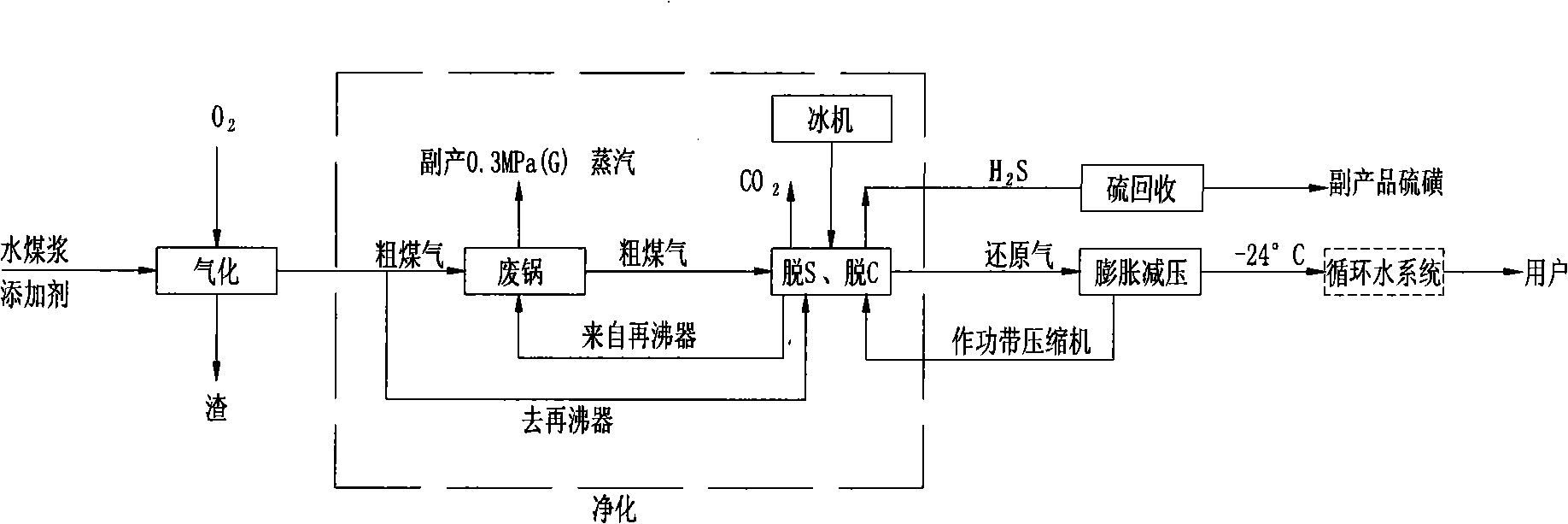

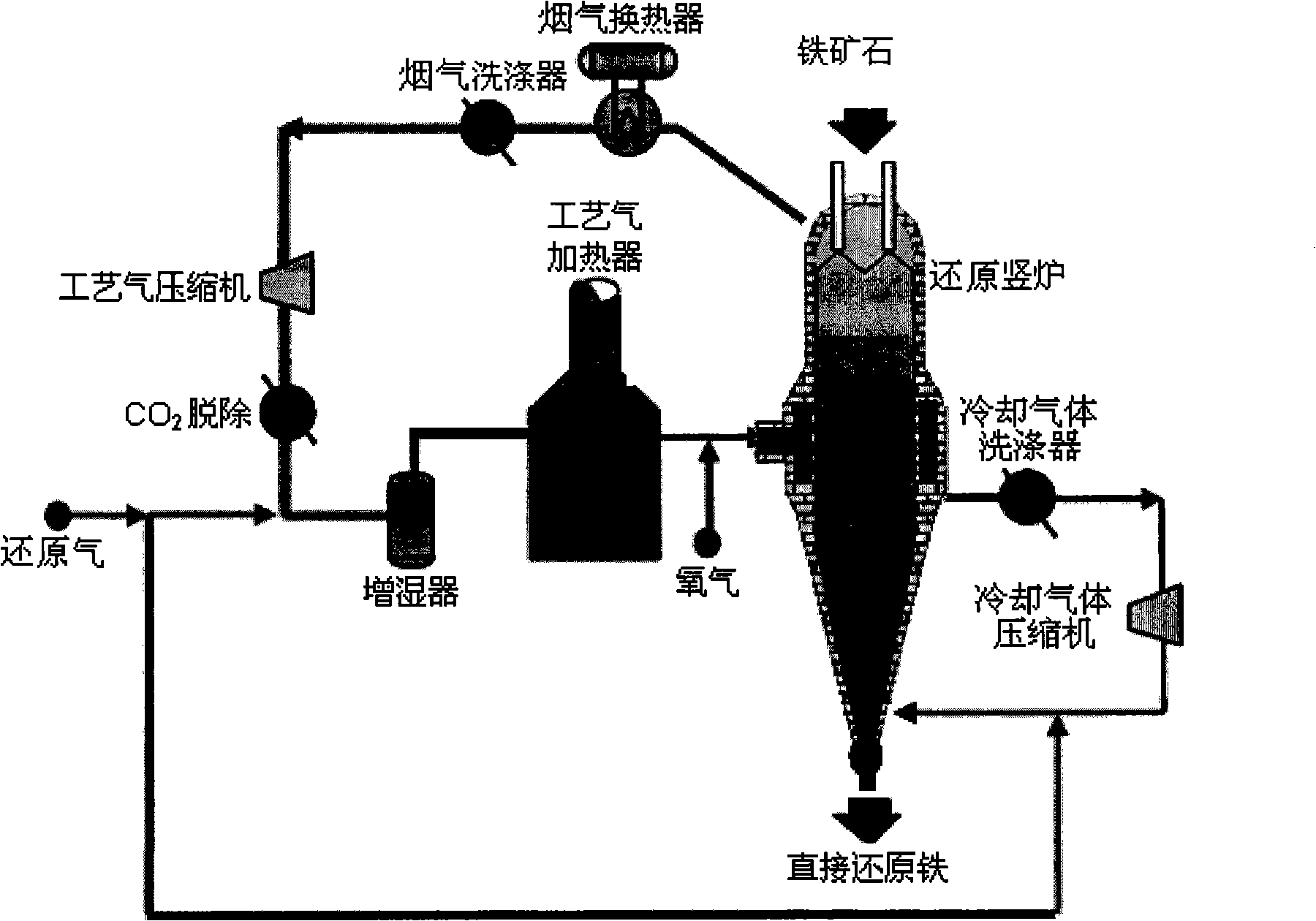

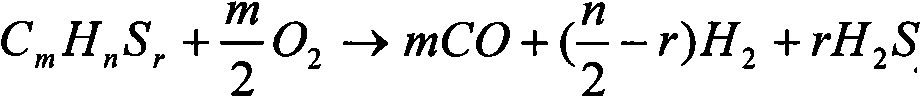

Coal reducing gas direct reduction metallurgical process in gas-based shaft kiln and system

ActiveCN101358258ASimple structureReduce processing costsExhaust gas handlingShaft furnaceGas heaterProduct gas

The invention discloses a coal-derived reducing gas base shaft furnace direct reduction metallurgical method and a system thereof. Reducing gases with CO and H2 serving as the main components are prepared from coal through a coal-derived reducing gas system, and are treated by the reducing reaction with iron ore through a direct reduction metallurgical system. The reducing gases are mainly used as the reducing agents of the reducing flow, the cooling agents of the cooling flow and the fuel of the direct reducing metallurgical system. The reducing flow is composed of a reducing shaft furnace, a furnace top gas heat exchanger, a furnace top gas shock chilling / scrubbing system, a process gas recycle compressor, a compressor secondary cooler, a CO2 absorber, a process gas humidifier, a process gas heater, etc. The conical part of the lower part of the shaft furnace is the cooling zone of the shaft furnace direct reduction metallurgical furnace. The cooling gases are sprayed in from the conical region of the lower part of the shaft furnace direct reduction metallurgical furnace, and flow upwards across the metallurgical furnace. The hot cooling gases flow away the cooling region and then are cooled, compressed and recycled. The system is simple in structure and low in process cost.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

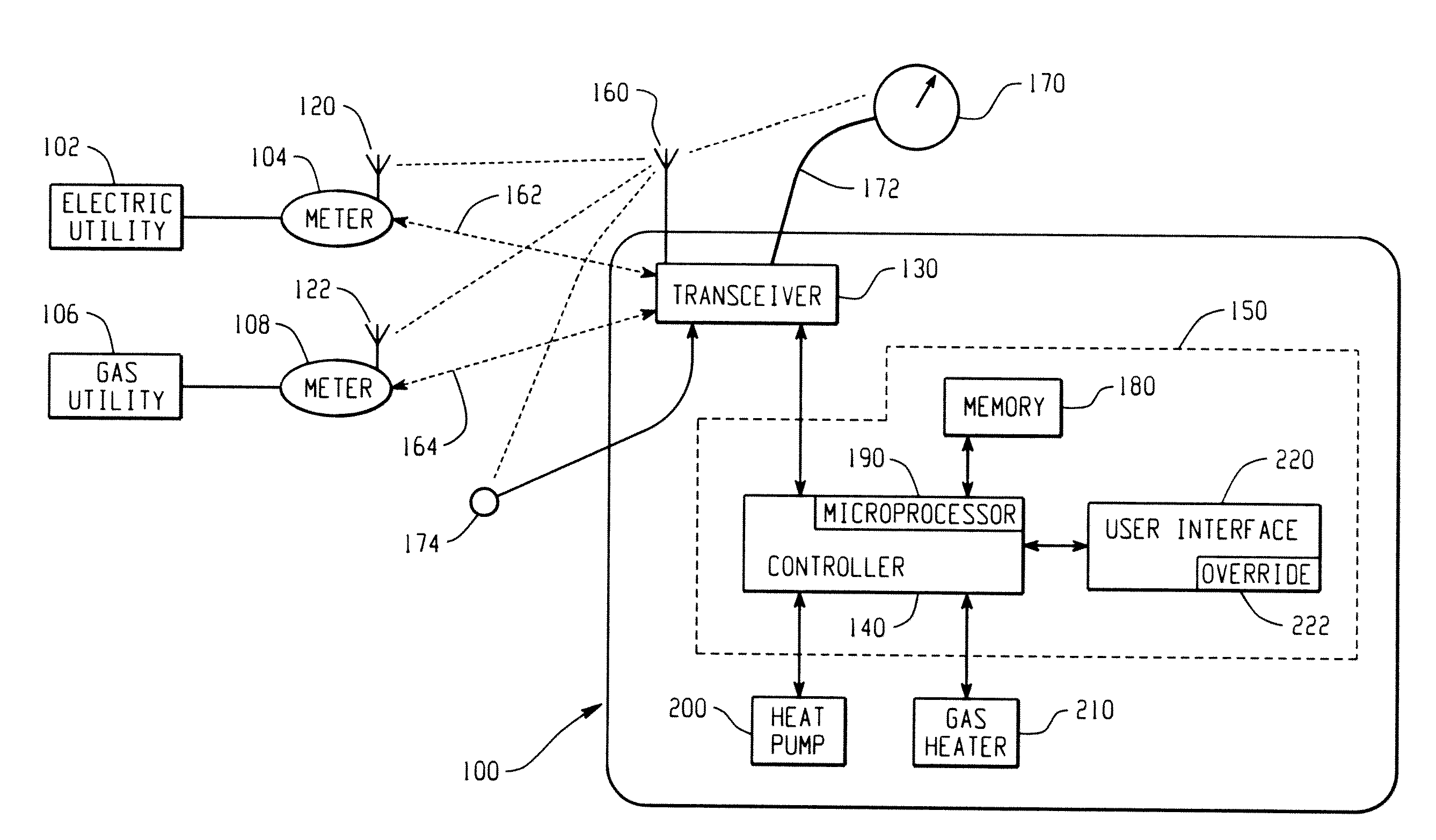

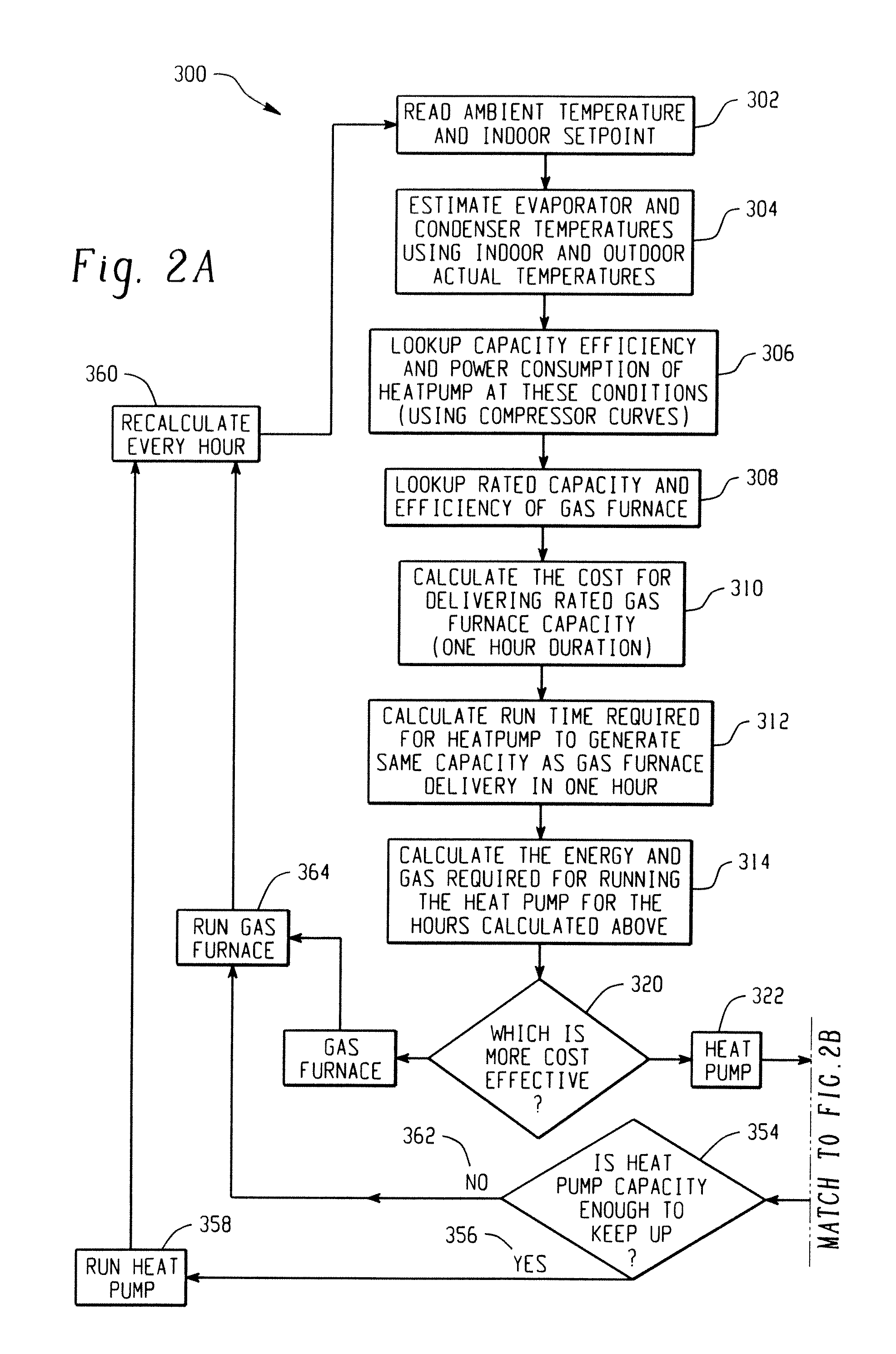

Smart hybrid thermostat

InactiveUS20120029725A1Improve efficiencyIncrease savingsHeating fuelMechanical apparatusGas heaterControl engineering

A system and method for controlling operation of a hybrid heating system that includes a heat pump and a gas heater is disclosed. Peak demand or pricing information is received from gas and electric utilities, and outdoor ambient temperature data is also fed to a smart hybrid thermostat. A controller processes this data and calculates overall efficiency of operating the heat pump versus the gas heater by accessing stored performance data relating to the heat pump in memory.

Owner:GENERAL ELECTRIC CO

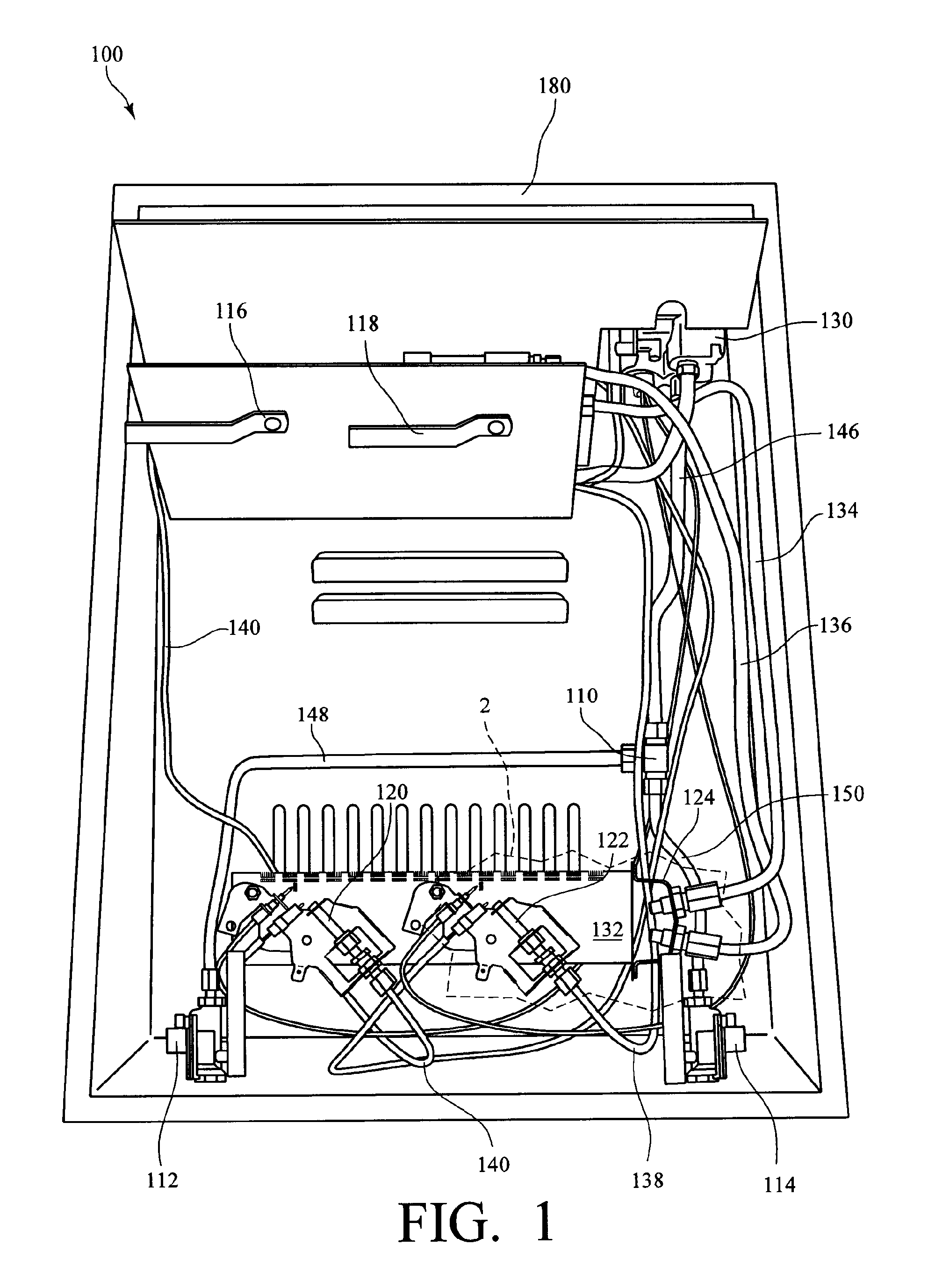

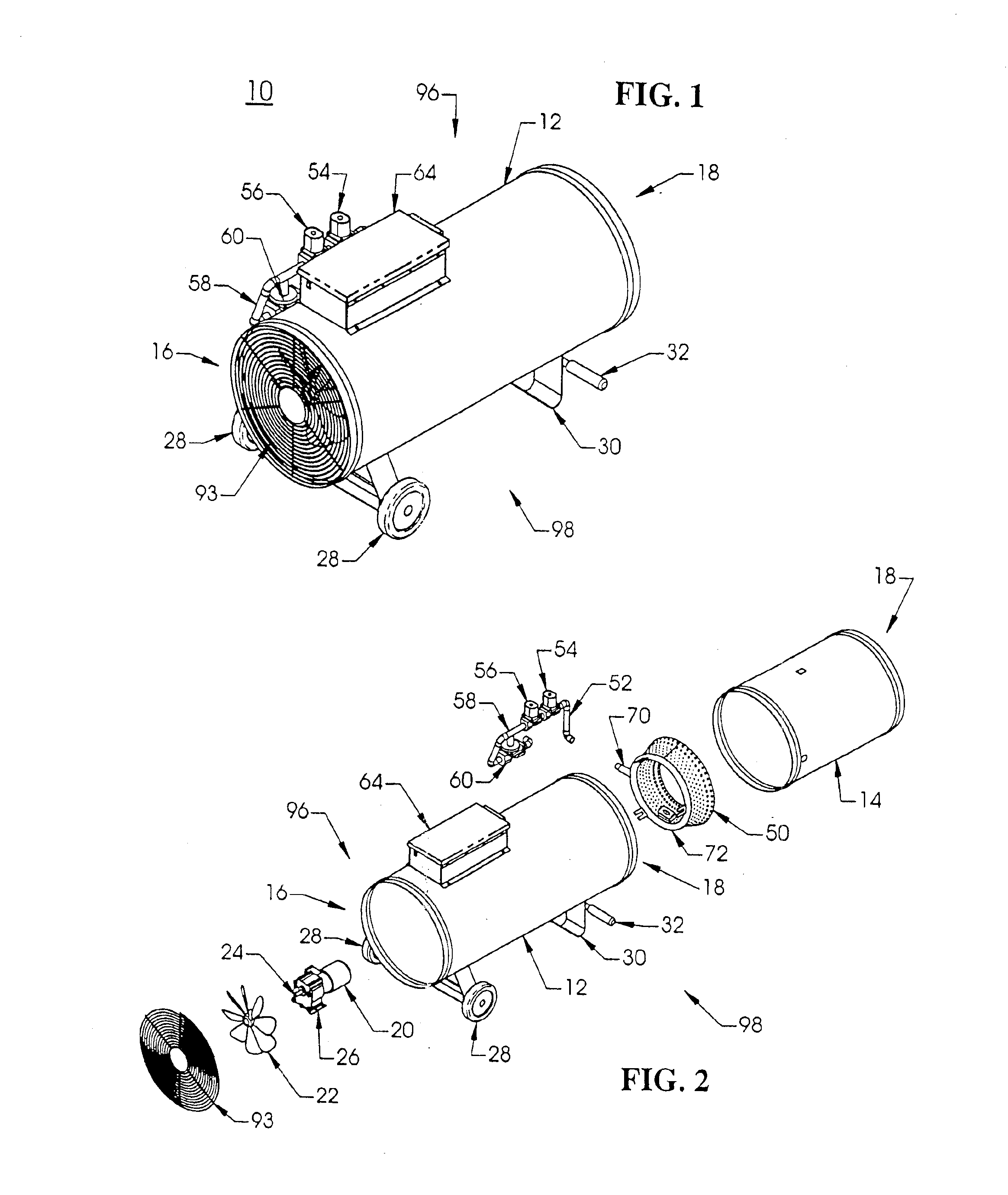

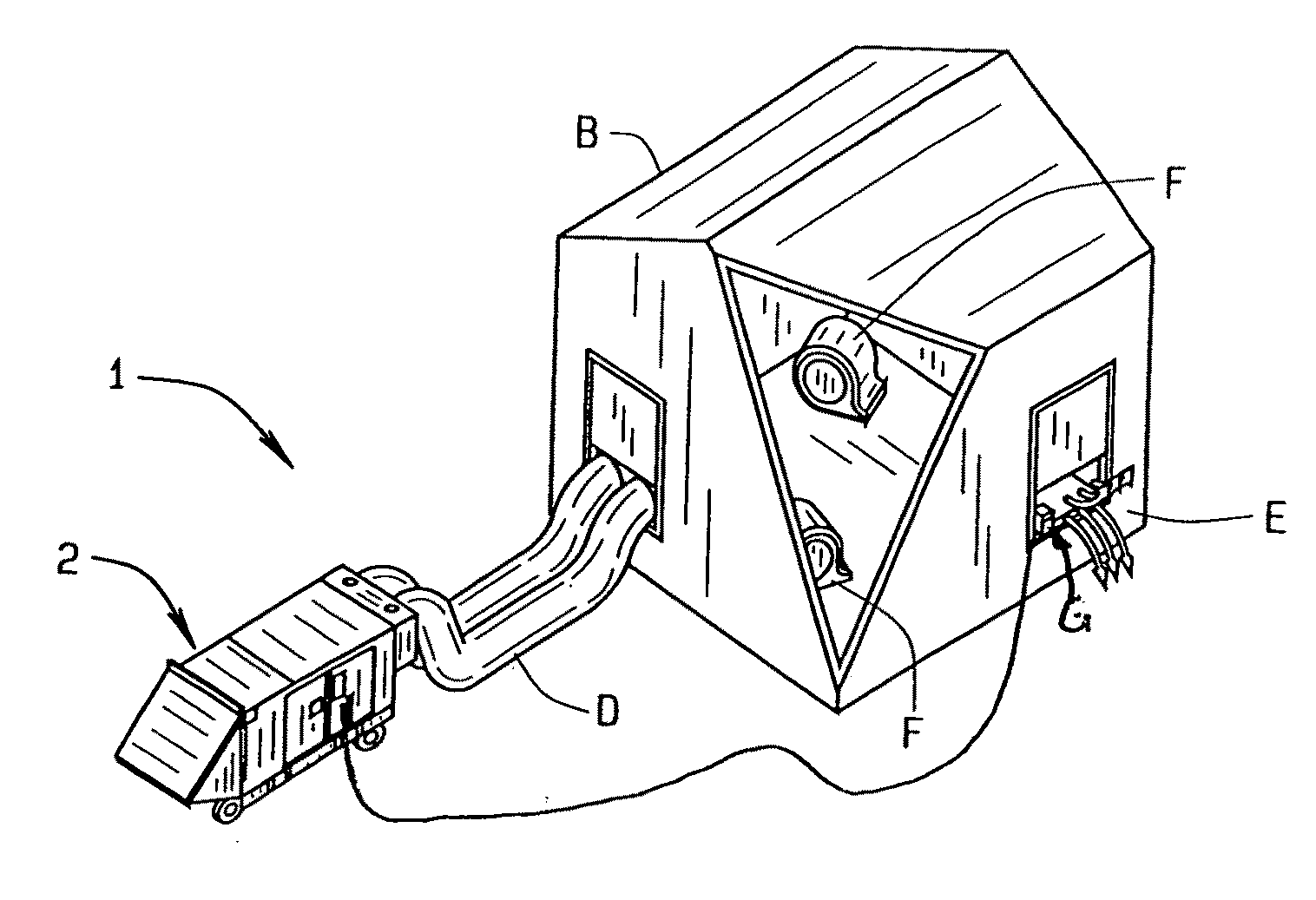

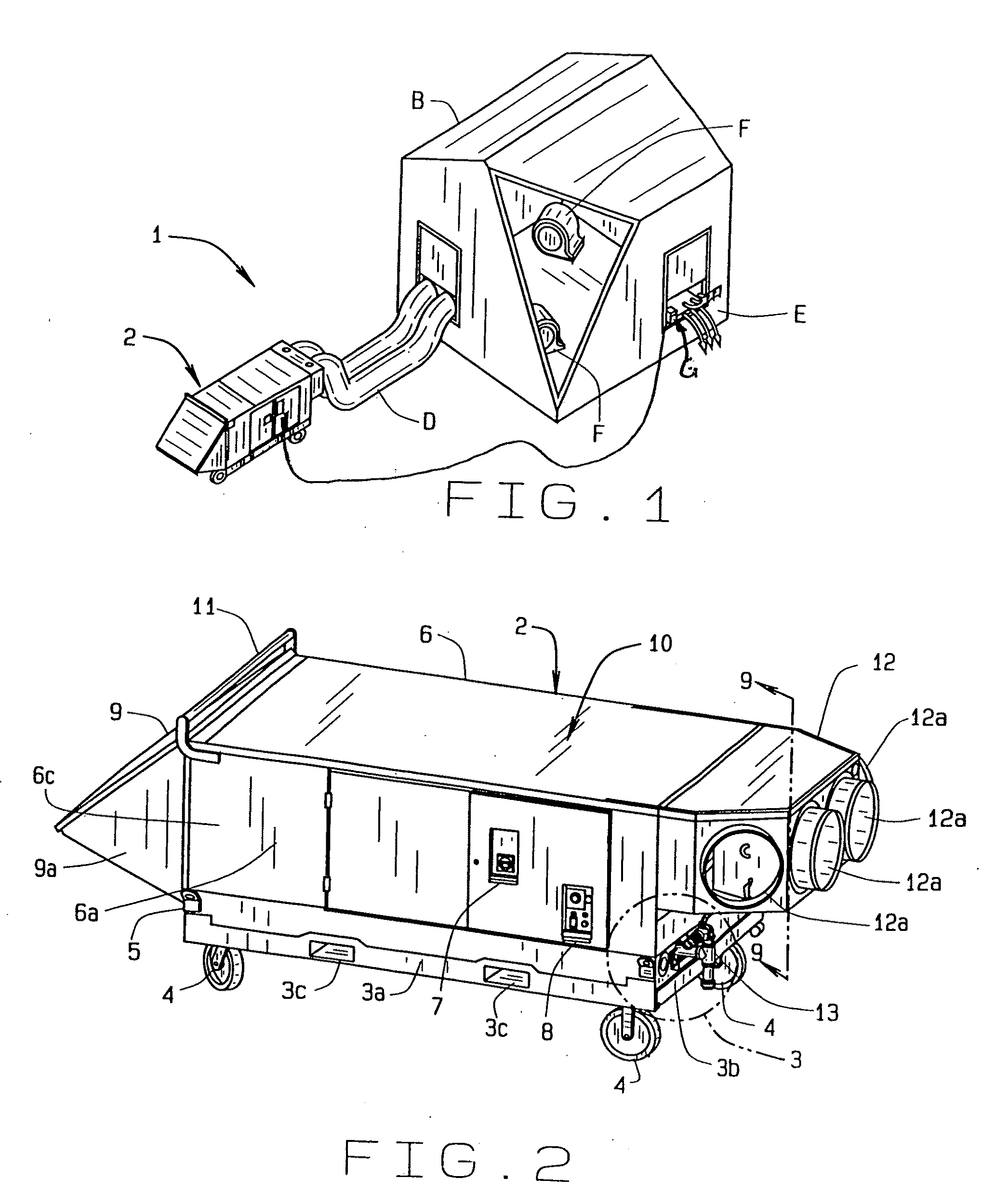

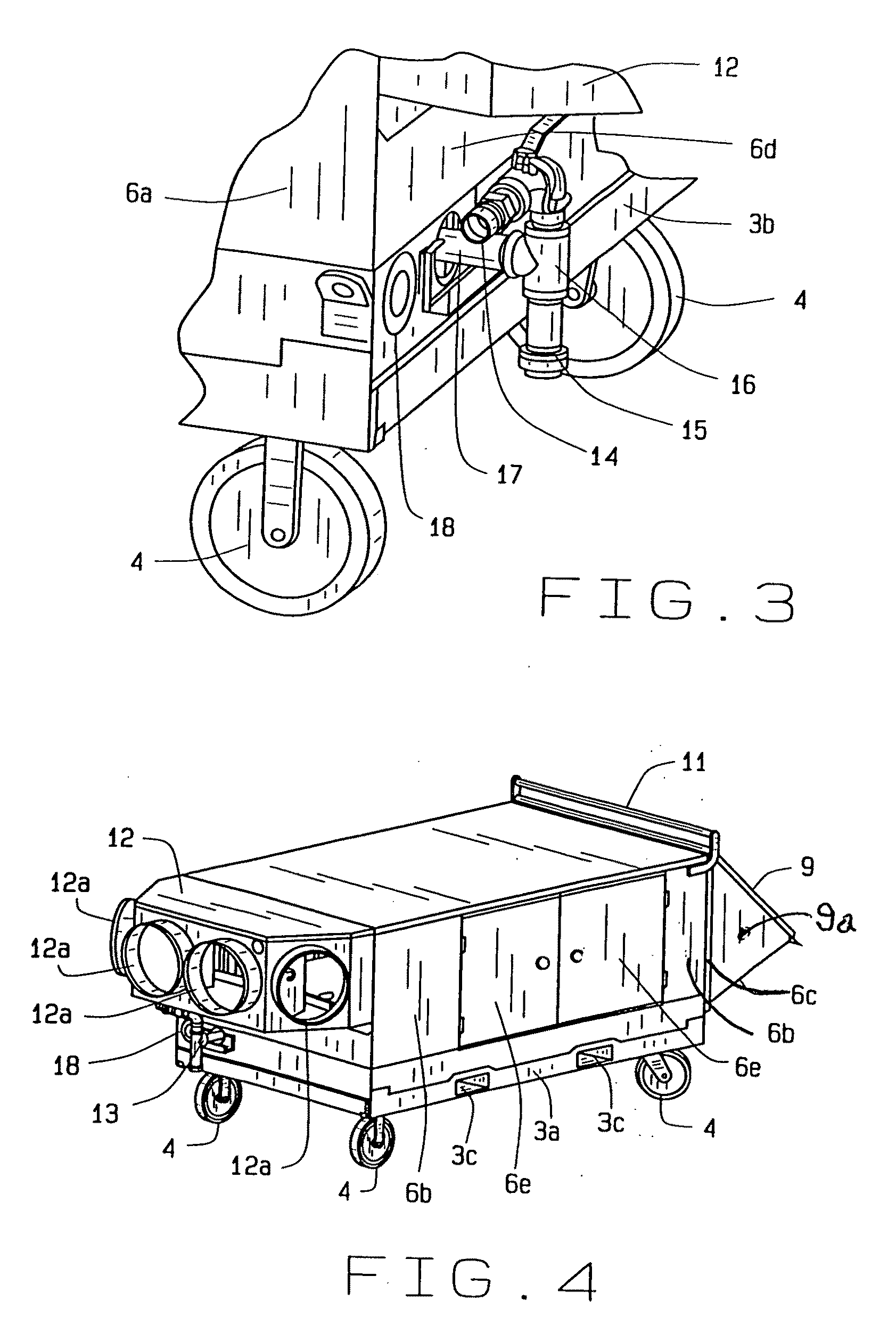

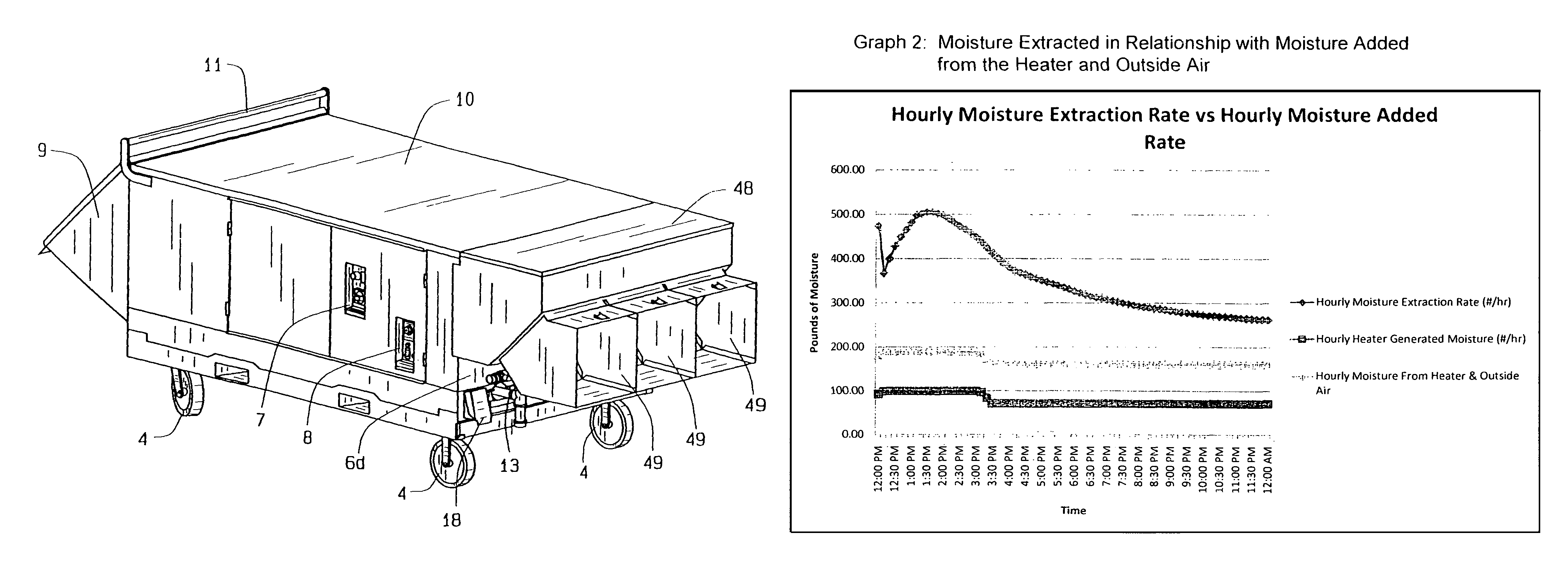

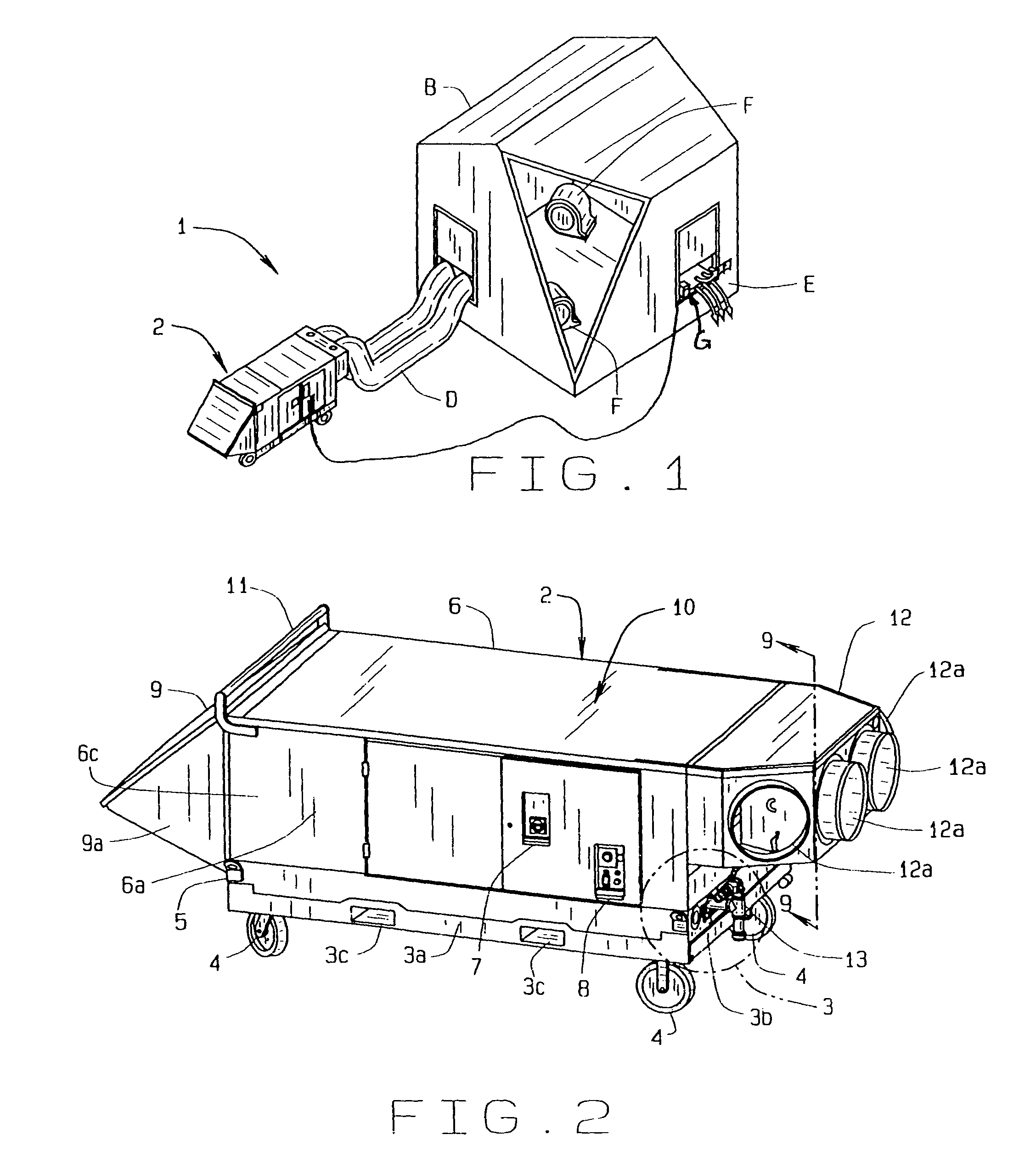

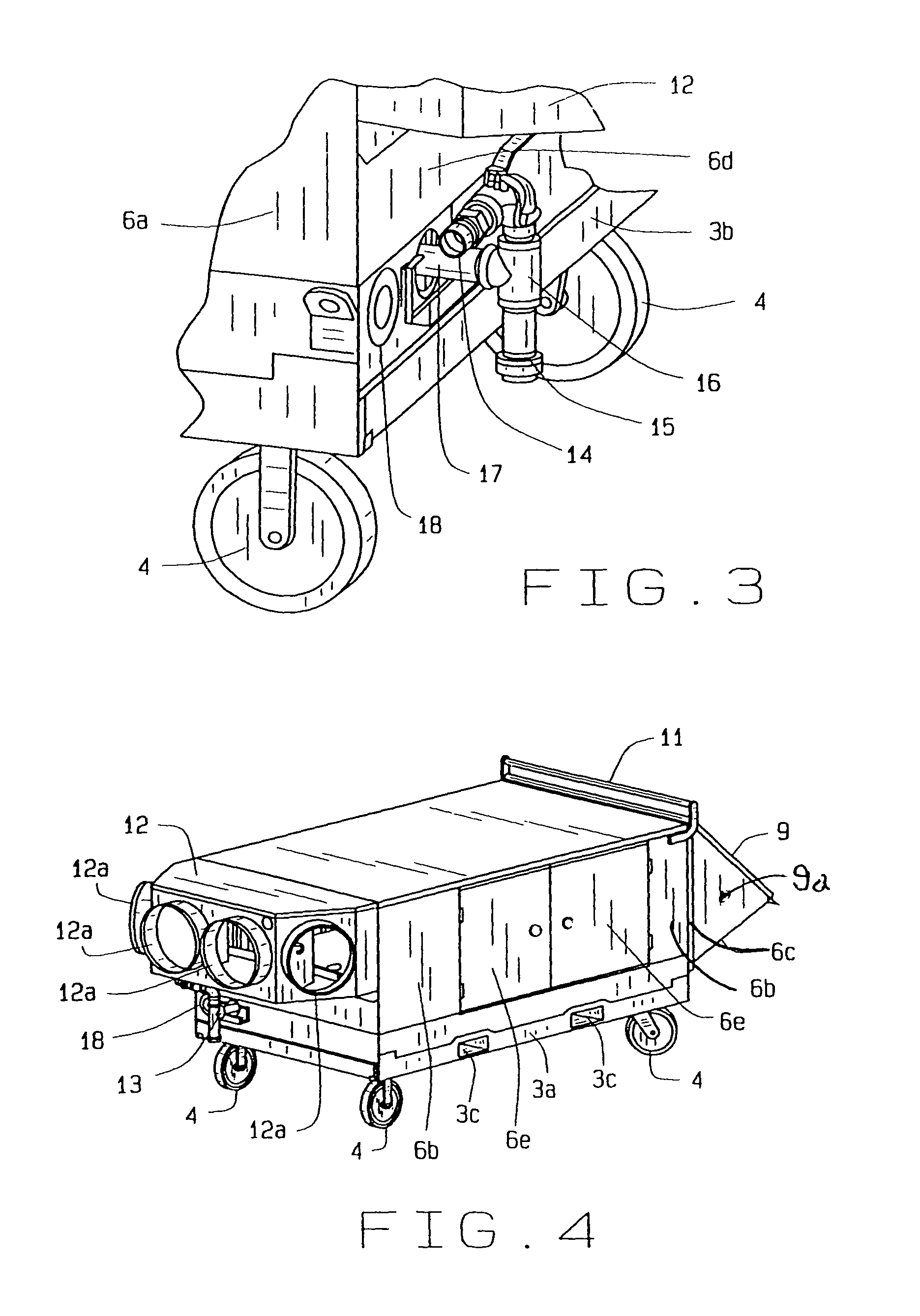

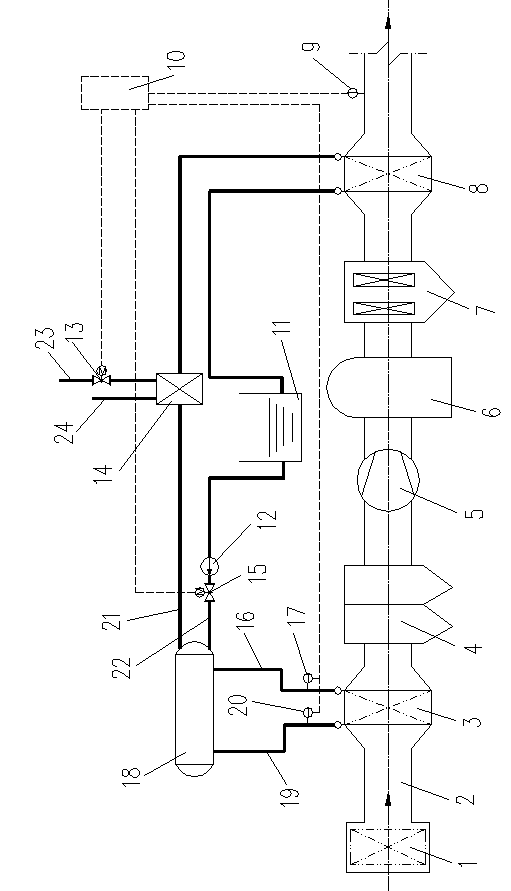

Heater and controls for extraction of moisture and biological organisms from structures

InactiveUS20100024244A1Tremendous ability to absorb water vaporFuel supply regulationDrying solid materials with heatGas heaterAtmospheric air

A gas heater with specialized controls allows an operator to deploy a single device to heat and to dry when extracting moisture from a structure. The heater has a fan in a blow thru arrangement ahead of a burner. The burner uses either natural gas or liquefied petroleum gas. The heater has air flow, fan motor, temperature, and ignition controls and sensors. The heater delivers high temperature air to the structure that hastens evaporation as the heated air absorbs great concentrations of water vapor. Then the moisture laden heated air exits the building as the heater draws in fresh air, ducts it into a structure, and pressurizes the structure. This moisture laden air then leaks from the building through select windows using the energy imparted from the fan and then exhausts the moisture to the atmosphere, drying the structure.

Owner:POTTER GARY J

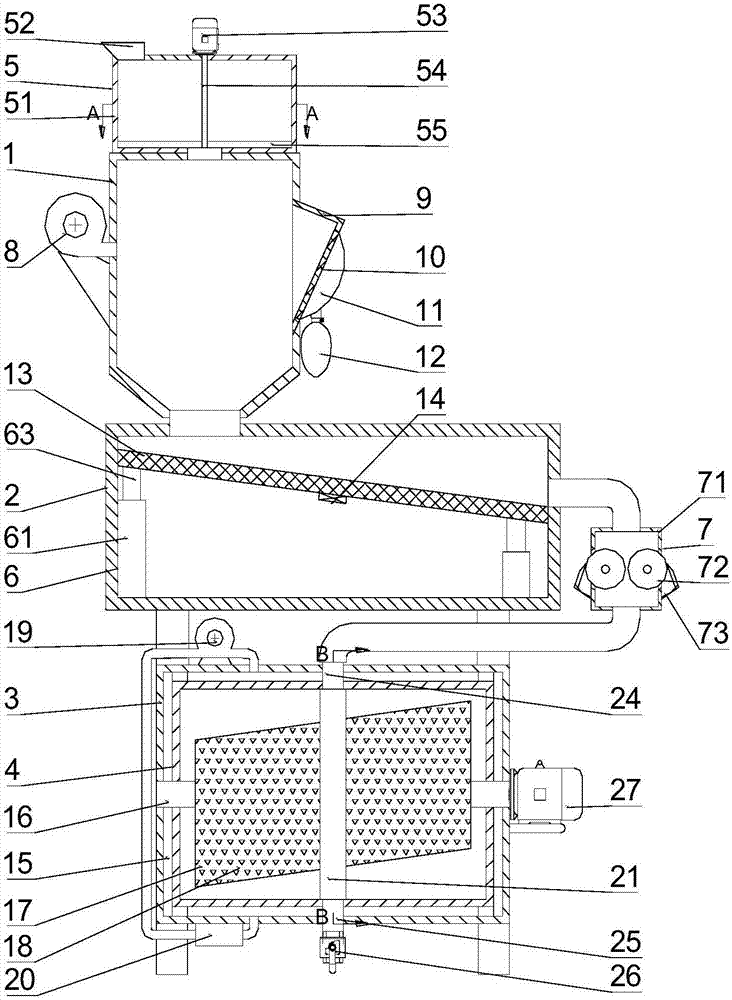

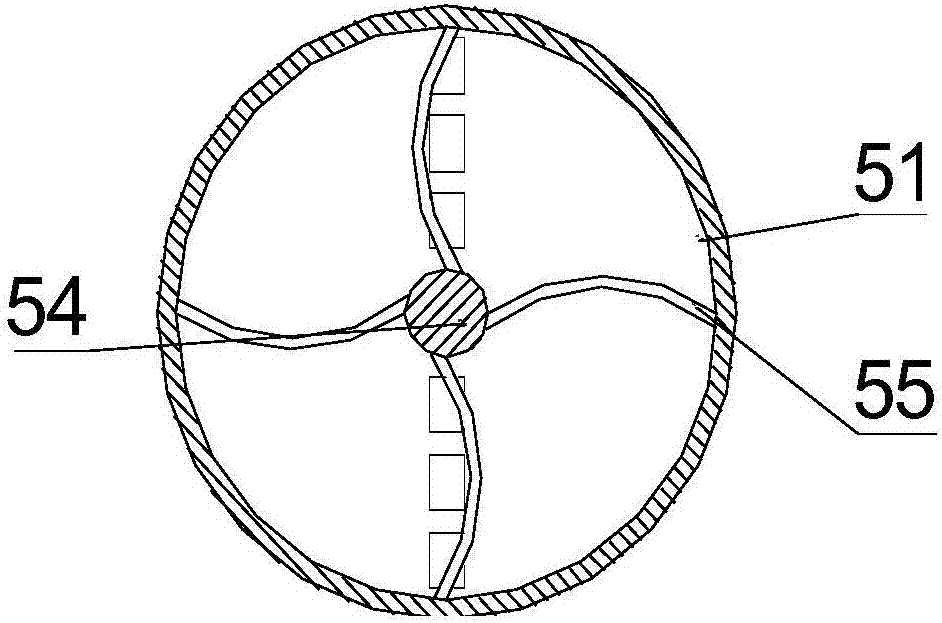

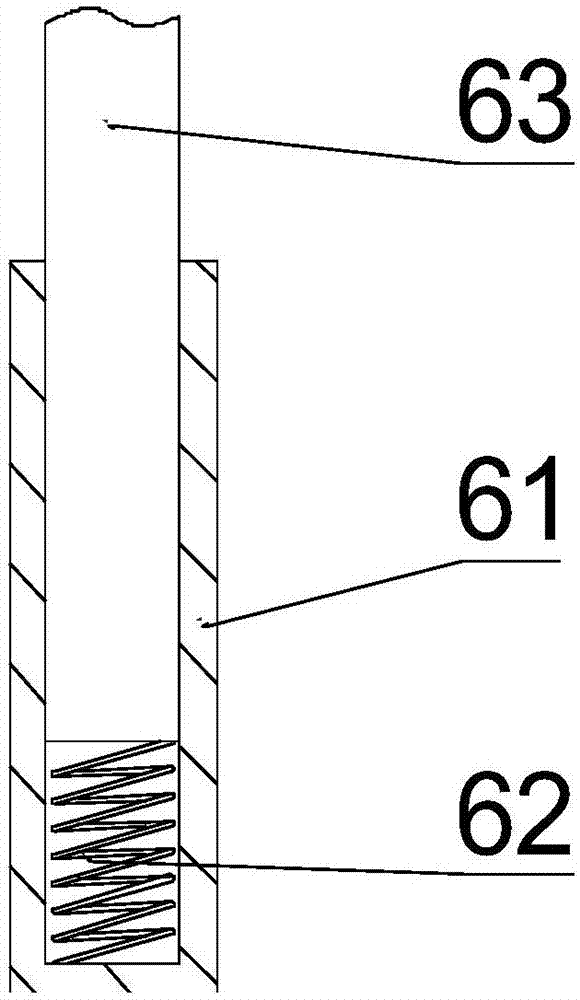

Separating drying device for fodder machining production

PendingCN107309085AEvenly and evenly heatedImprove bake qualitySievingGas current separationAgricultural scienceGas heater

The invention discloses a separating drying device for fodder machining production. The device comprises a blanking cylinder, a first screen net, a communication box, a small particle receiving bin, a high-pressure draught fan, a large particle screening box, a second screen net, an elastic telescopic device, a vibration motor, a slag removal device, an outer shell, an inner shell, a rotating column, an air blower, an air flue type gas heater, an inclined columnar rotating cylinder, a rotating ring and a fixed ring; fodder enters the slag removal device through a discharging pipe, slag is attracted by a magnet roller and scraped by a scraping knife, the air blower feeds hot air generated by the air flue type gas heater into a hot air cavity, hot air in the hot air cavity enters the air flue type gas heater again, heat recycling is formed, in the rotating process of the inclined columnar rotating cylinder, fodder in the inclined columnar rotating cylinder slides to the right side from the left side and then slides to the left side from the right side in a reciprocated manner, fodder is in the dynamic state, fodder can be evenly heated, and the baking quality of the fodder can be improved.

Owner:银川金帮手信息科技有限公司

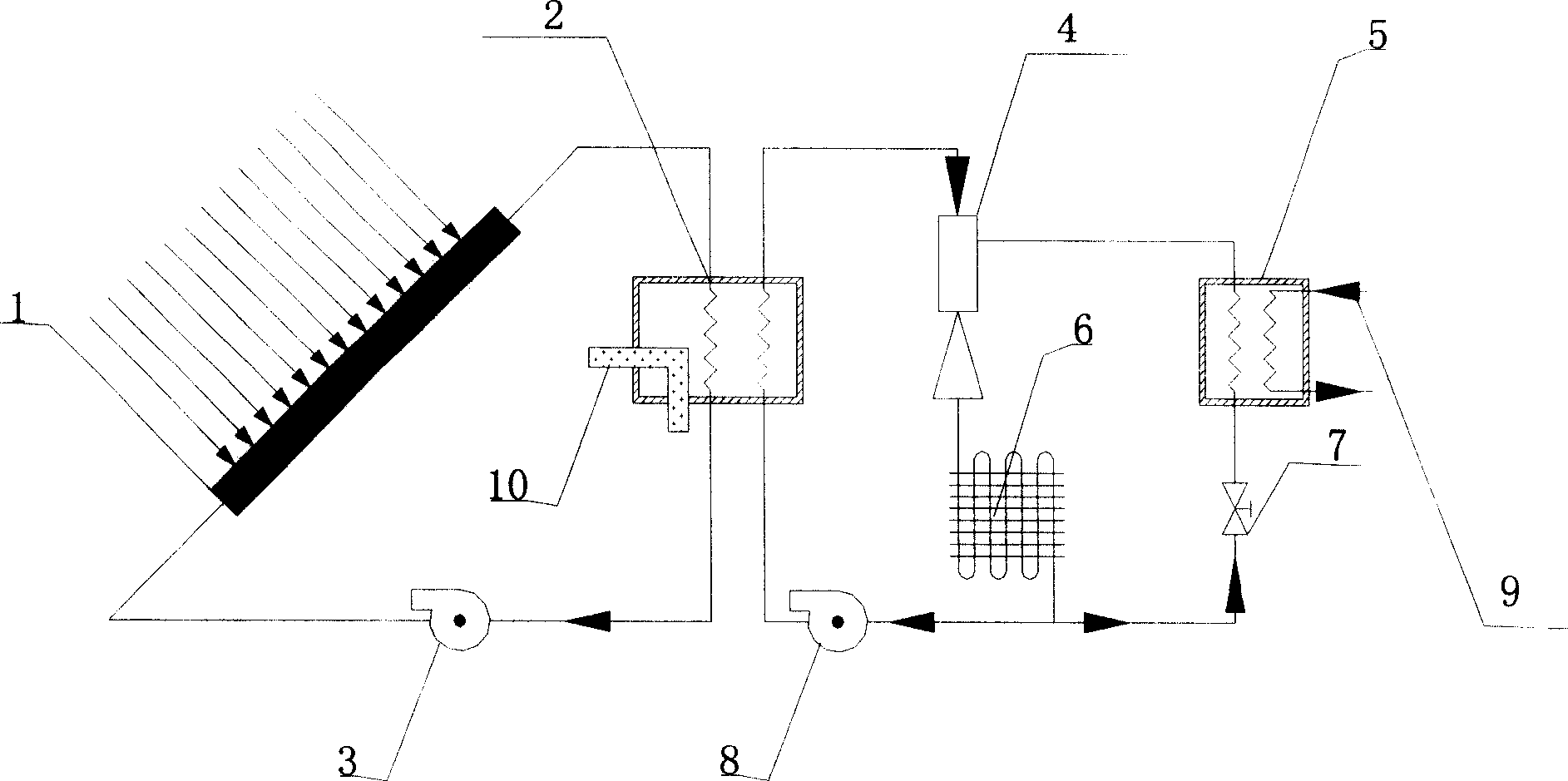

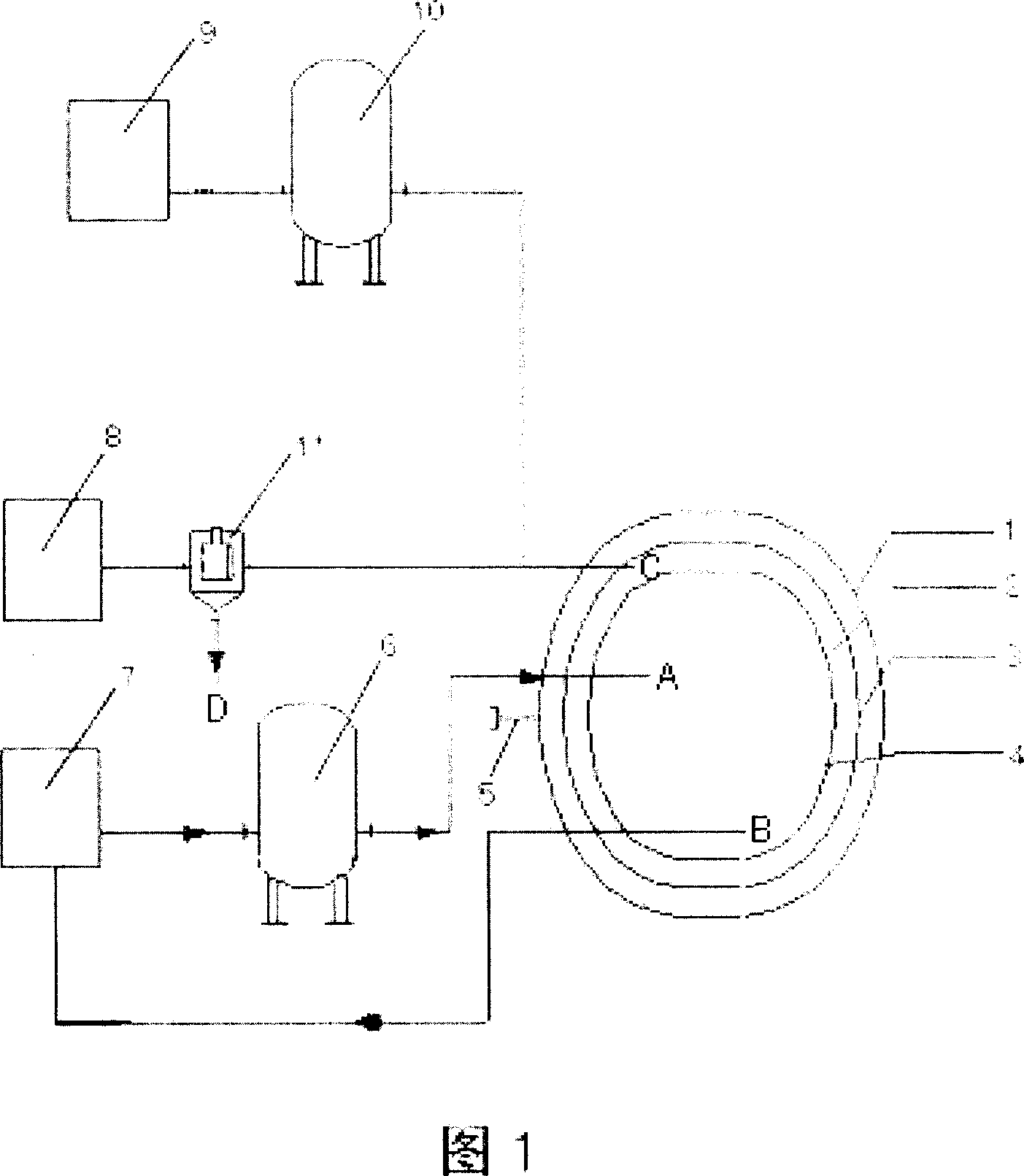

Novel solar gas-injection refrigerating system

InactiveCN101153757ASimple structureEasy to operateMachines using refrigerant evaporationTemperature controlGas heater

The invention organically combines an application of solar energy, gas and ejector refrigeration, and provides a novel solar energy ejecting refrigeration system. A steam generator, a pump, an inlet of a solar energy collector are orderly connected with an outlet of the solar energy collector through pipes to form a heating water circulating device; an outlet of the steam generator is connected with a working steam inlet of an ejector through a pipe, an evaporator is connected with a refrigerant pipe, an outlet of the evaporator is connected with an ejector steam inlet of the ejector through a pipe, and an outlet of the ejector is connected with the evaporator. The steam generator is also connected with a gas heater controlled by a temperature controller, heating water circulating device is at least provided with one set, if a plurality of heating water circulating devices are provided, the heating water circulating devices and the evaporator can either be connected in serial or connected in parallel. The invention has a wide adaptability, can save enormous energy, thereby reaching a refrigeration effect of sustainable high efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

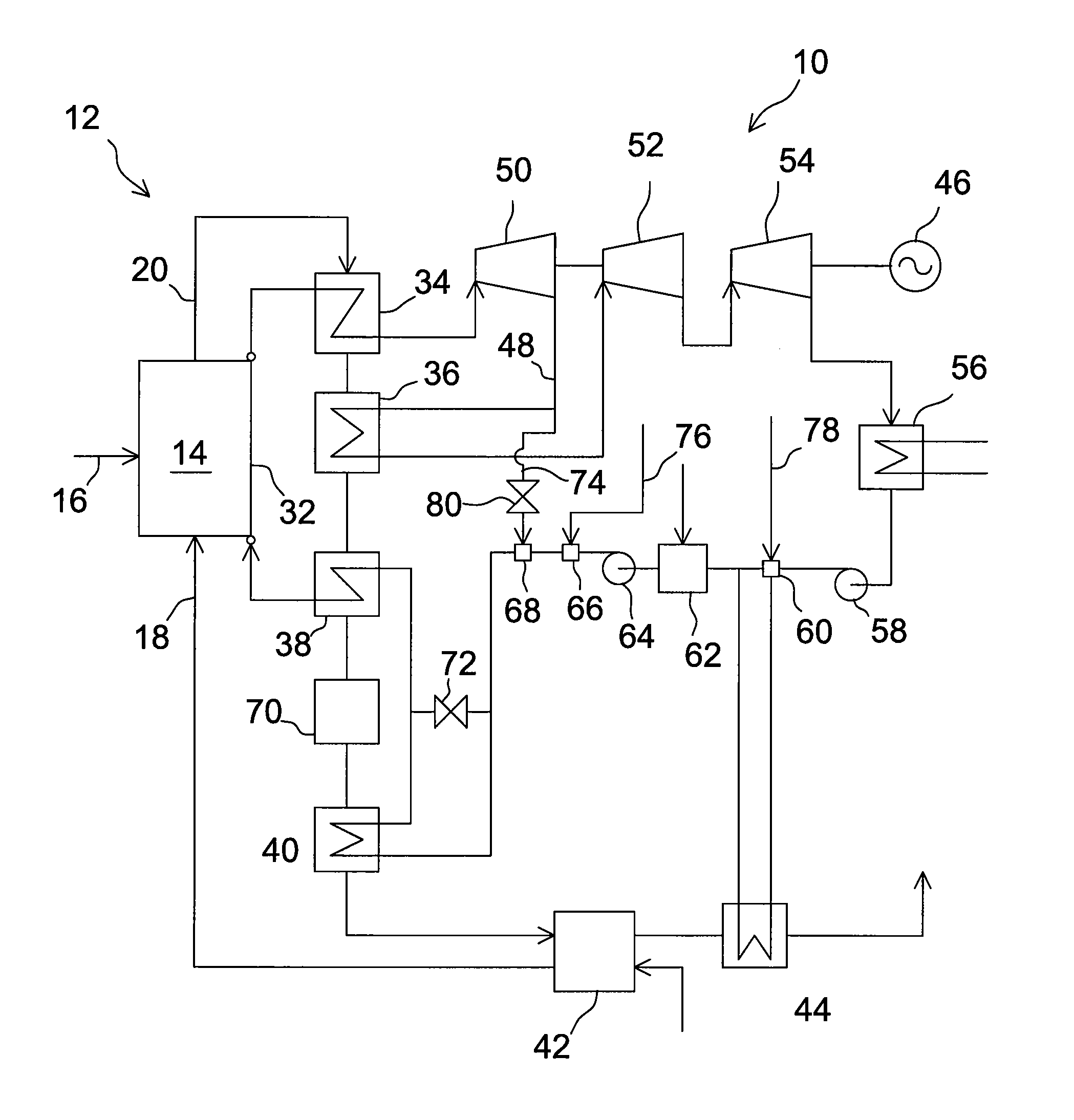

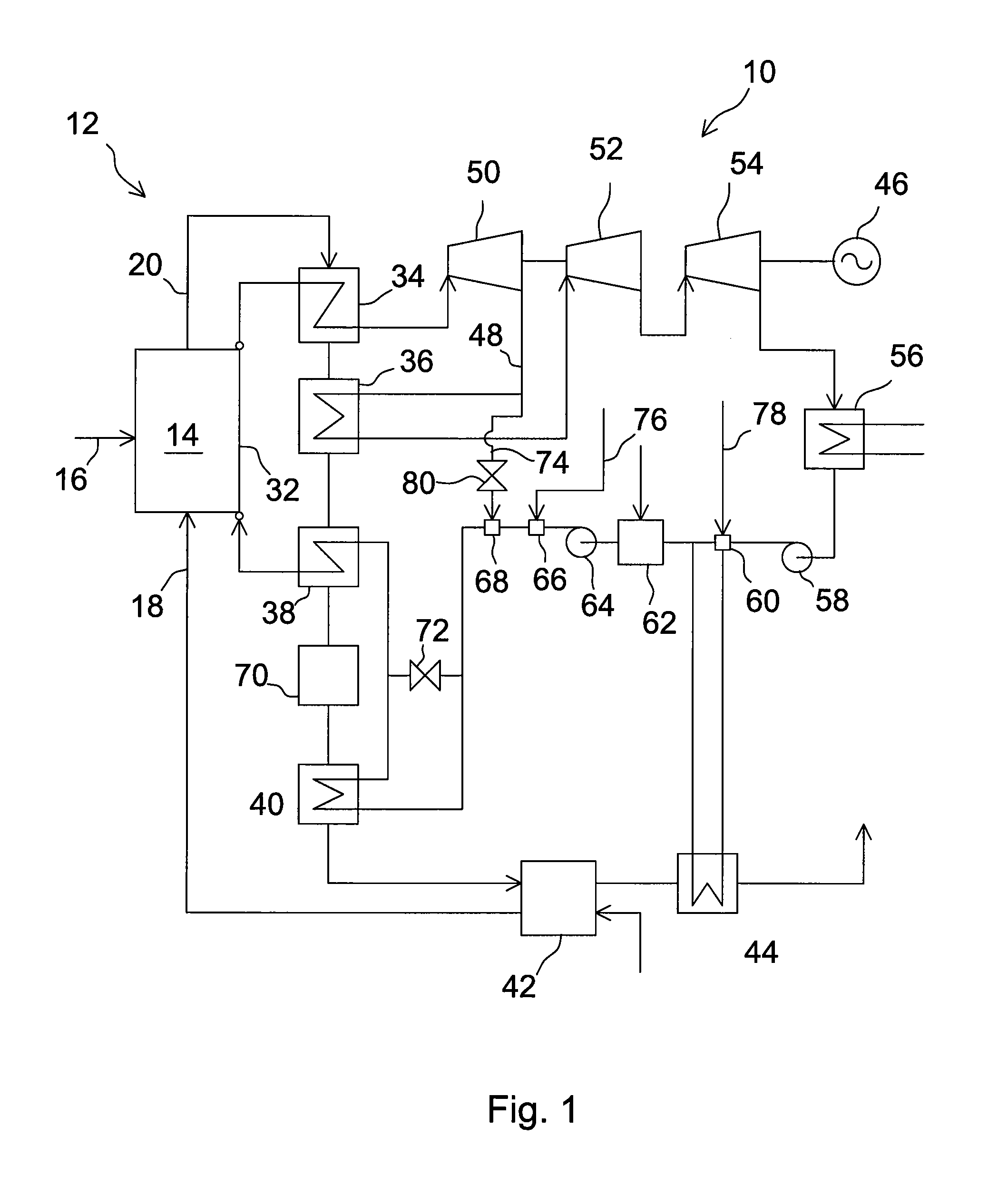

Method of Increasing the Performance of a Carbonaceous Fuel Combusting Boiler System

InactiveUS20110094228A1Increase powerImprove thermal efficiencySteam regenerationSteam useGas heaterProduct gas

A method of increasing the power of a carbonaceous fuel combusting boiler system includes the steps of (a) feeding carbonaceous fuel into a furnace of the boiler system, (b) feeding oxidant gas into the furnace for combusting fuel to produce exhaust gas, (c) discharging the exhaust gas from the furnace via an exhaust gas channel, (d) conveying a stream of feedwater from a boiler economizer arranged in the exhaust gas channel to evaporating and superheating heat exchange surfaces arranged in the furnace and in the exhaust gas channel for converting the feedwater to superheated steam, (e) expanding the superheated steam in a high-pressure steam turbine for generating power, (f) extracting steam from the high-pressure steam turbine at a decreased rate for preheating the feedwater, (g) conveying steam from the high-pressure steam turbine at an increased rate to a reheater arranged in the exhaust gas channel for generating reheated steam, (h) expanding the reheated steam in an intermediate pressure steam turbine for generating power, and (i) conveying the exhaust gas in the exhaust gas channel from the reheater through a boiler economizer to a gas heater. The heat exchange surface area of at least one of the reheater and the boiler economizer is increased and / or a high pressure economizer is added downstream of the boiler economizer and upstream of the gas heater.

Owner:FOSTER WHEELER ENERGY CORP

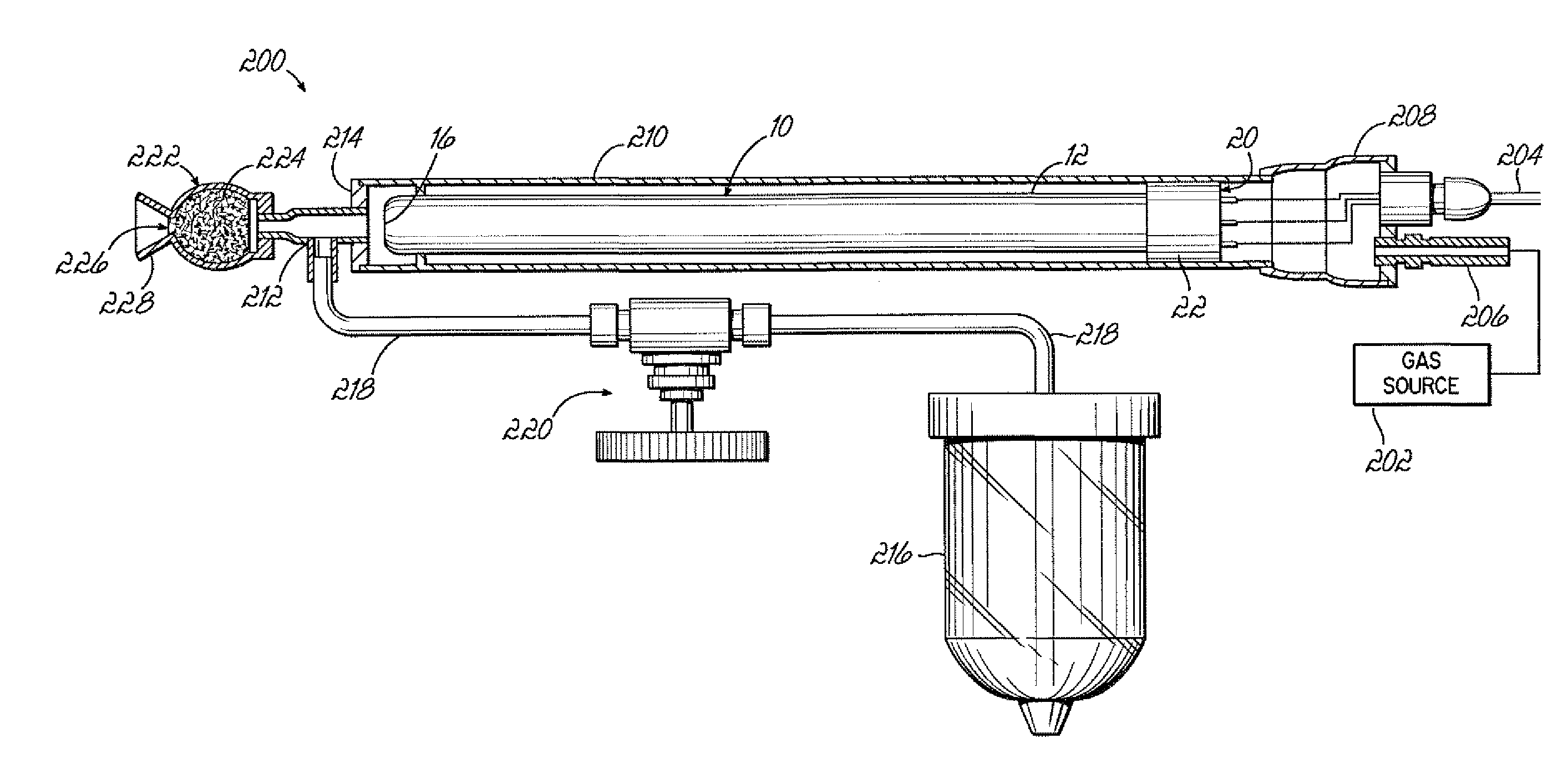

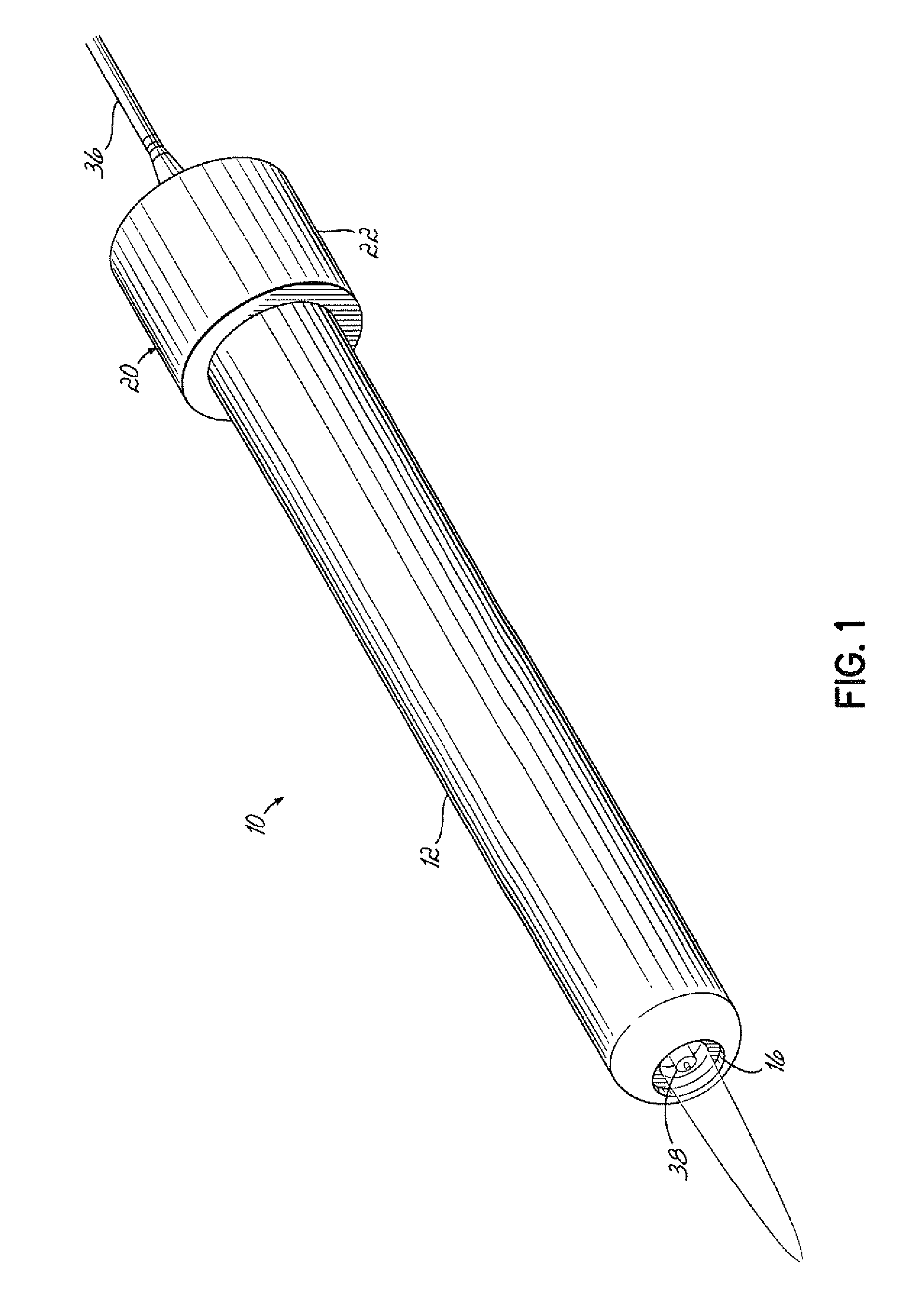

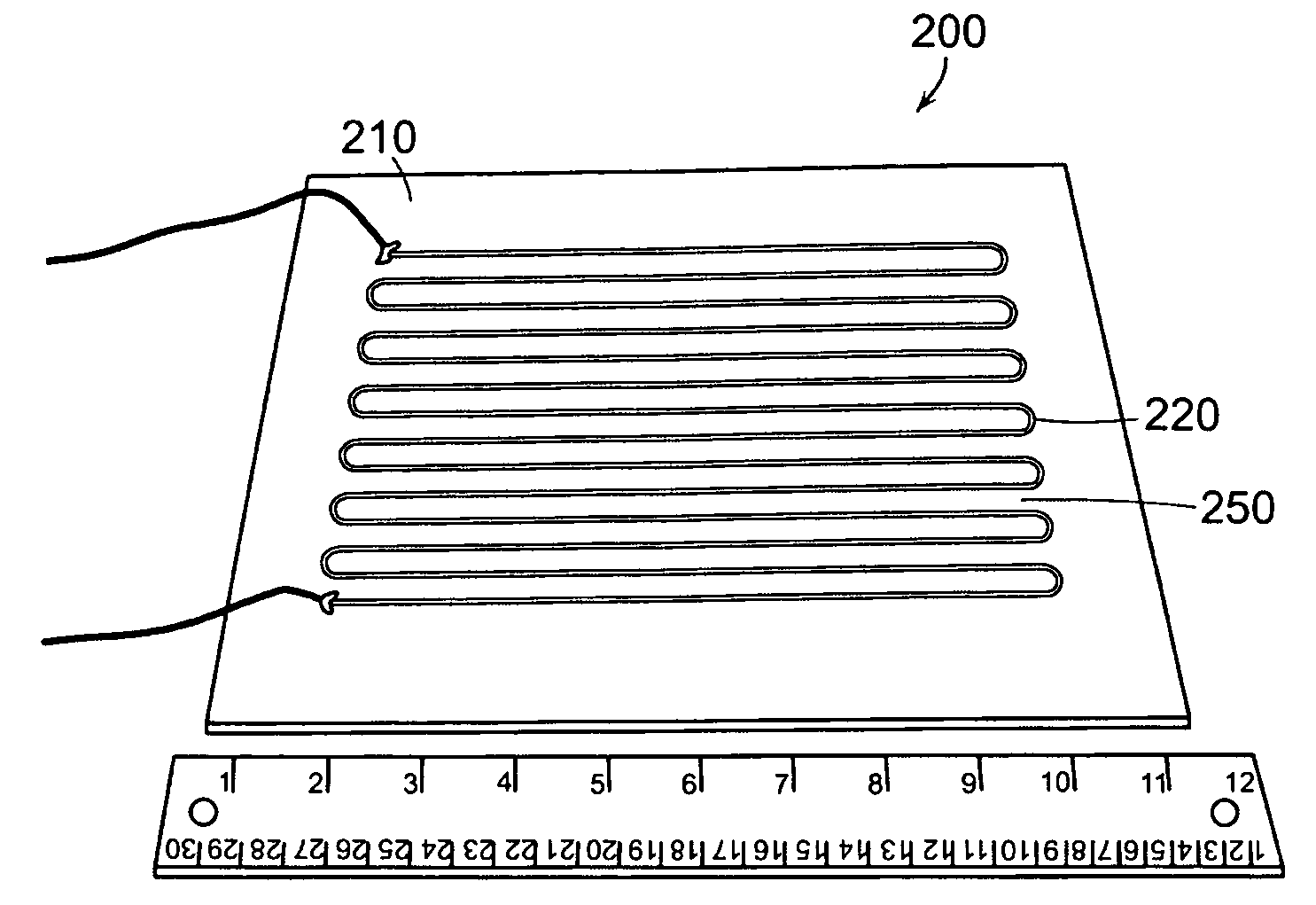

Heating and sterilizing apparatus and method of using same

ActiveUS20100129157A1Deformation MinimizationMinimize gas flowPressurized chemical processContaminated soil reclamationGas heaterHand held

An apparatus (200, 300, 400) for generating superheated steam capable of reducing or eliminating microorganisms associated with an item (230) includes a gas heater (10) for heating a gas, a steam generator coupled to the gas heater (10) and having a reservoir (216, 304) for supplying water, wherein the heater (10) heats the gas such that when water is combined therewith, a mixture of superheated steam and gas capable of reducing or eliminating microorganisms is discharged from the apparatus (200, 300, 400). The generation of the steam-gas mixture may be done at one atmosphere of pressure and the mixing may be done prior to expelling the fluid from the apparatus (200, 300, 400). The apparatus (400) may be configured as a hand-held device, A method of treating an item (230) for microorganisms includes generating a superheated steam at approximately one atmosphere of pressure, directing a flow of the steam onto the item (230), and reducing or eliminating microorganisms using the steam.

Owner:MHI HEALTH DEVICES

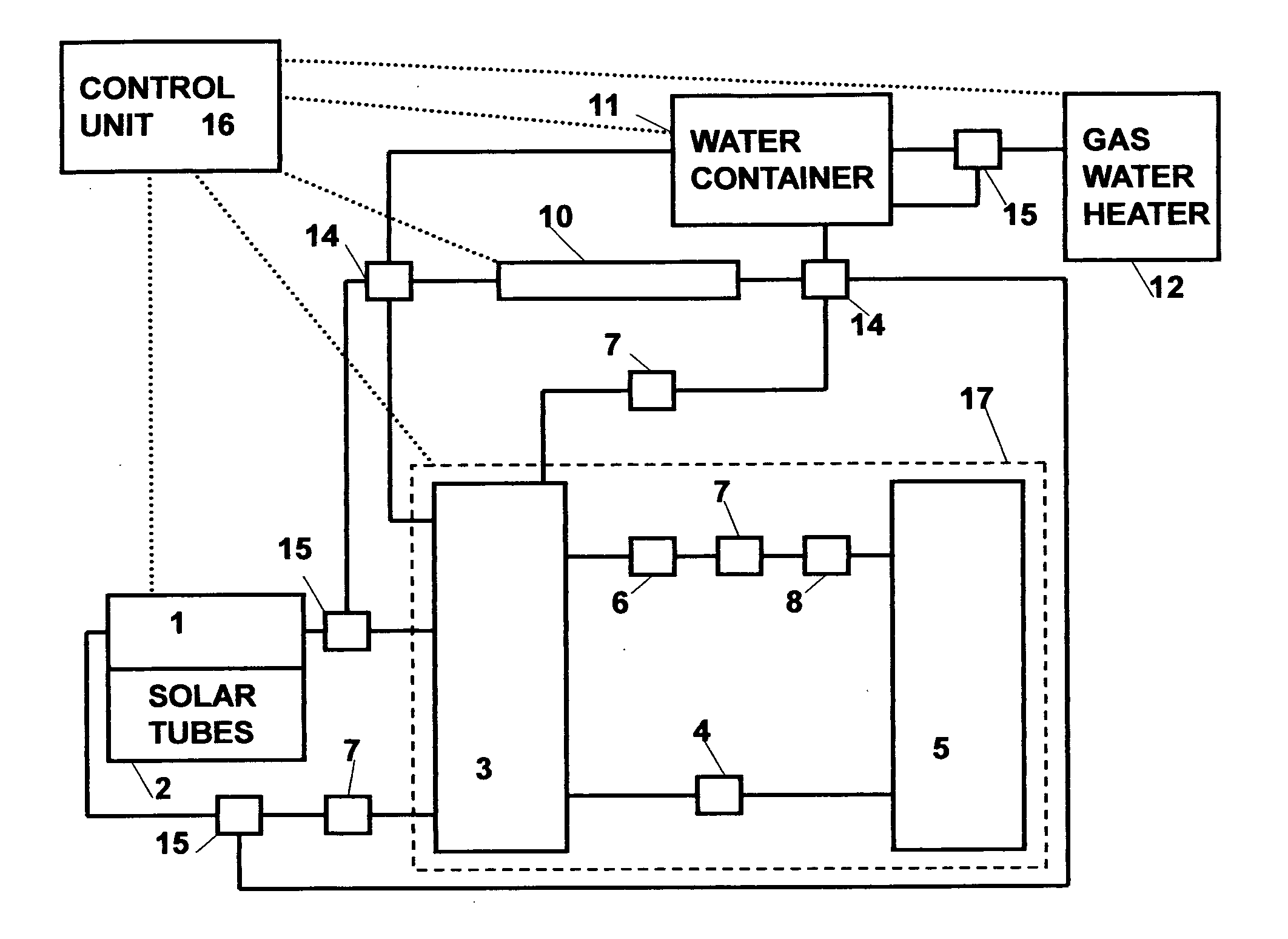

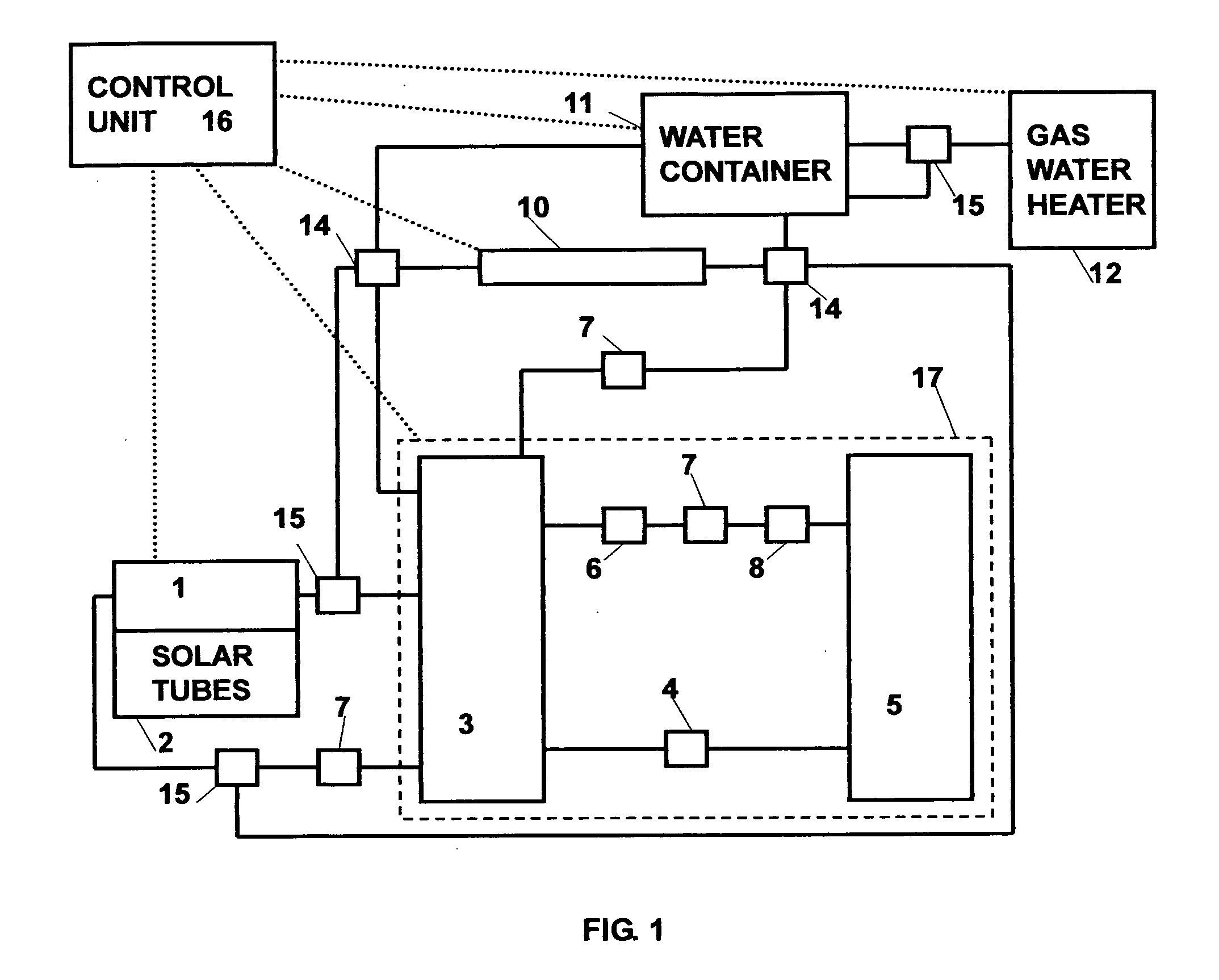

Solar energy saving system using gas and electricity as compensation

InactiveUS20090159076A1Save energyEmission reductionSolar heating energyCentral heating with accumulated heatComputer control systemElectricity

A solar energy saving system composed of solar collectors, a custom built heat pump and a conventional gas heater, a centralized computer control system, a group of sensors, pumps and valves, and the mechanical and electrical connections, is disclosed herein along with the processes and methods for applying the system.

Owner:ZHENG KE TING

Heater and controls for extraction of moisture and biological organisms from structures

ActiveUS8726539B2Tremendous ability to absorb water vaporDrying using combination processesDrying solid materials with heatAtmospheric airGas heater

A gas heater with specialized controls allows an operator to deploy a single device to heat and to dry when extracting moisture from a structure. The heater has a fan in a blow thru arrangement ahead of a burner. The burner uses either natural gas or liquefied petroleum gas. The heater has air flow, fan motor, temperature, and ignition controls and sensors. The heater delivers high temperature air to the structure that hastens evaporation as the heated air absorbs great concentrations of water vapor. Then the moisture laden heated air exits the building as the heater draws in fresh air, ducts it into a structure, and pressurizes the structure. This moisture laden air then leaks from the building through select windows using the energy imparted from the fan and then exhausts the moisture to the atmosphere, drying the structure.

Owner:CAMBRIDGE ENG

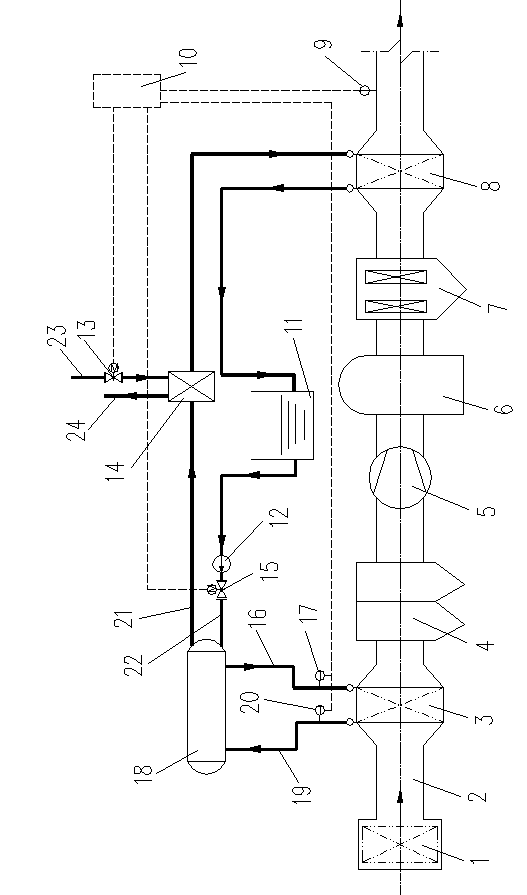

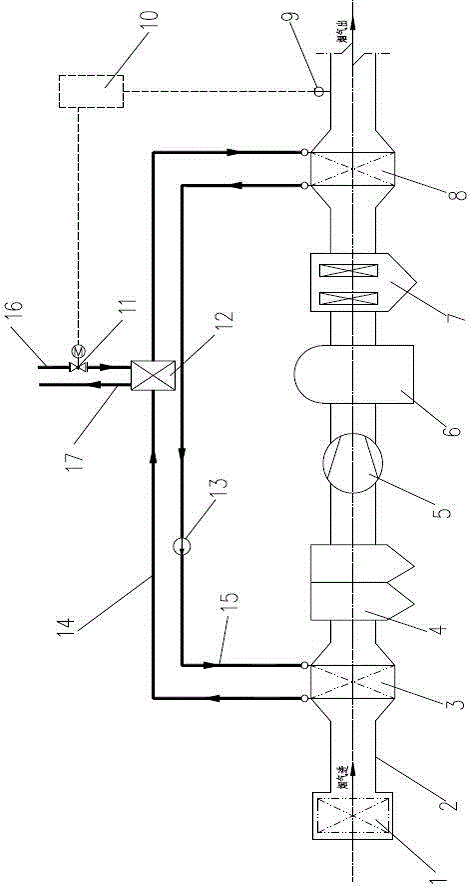

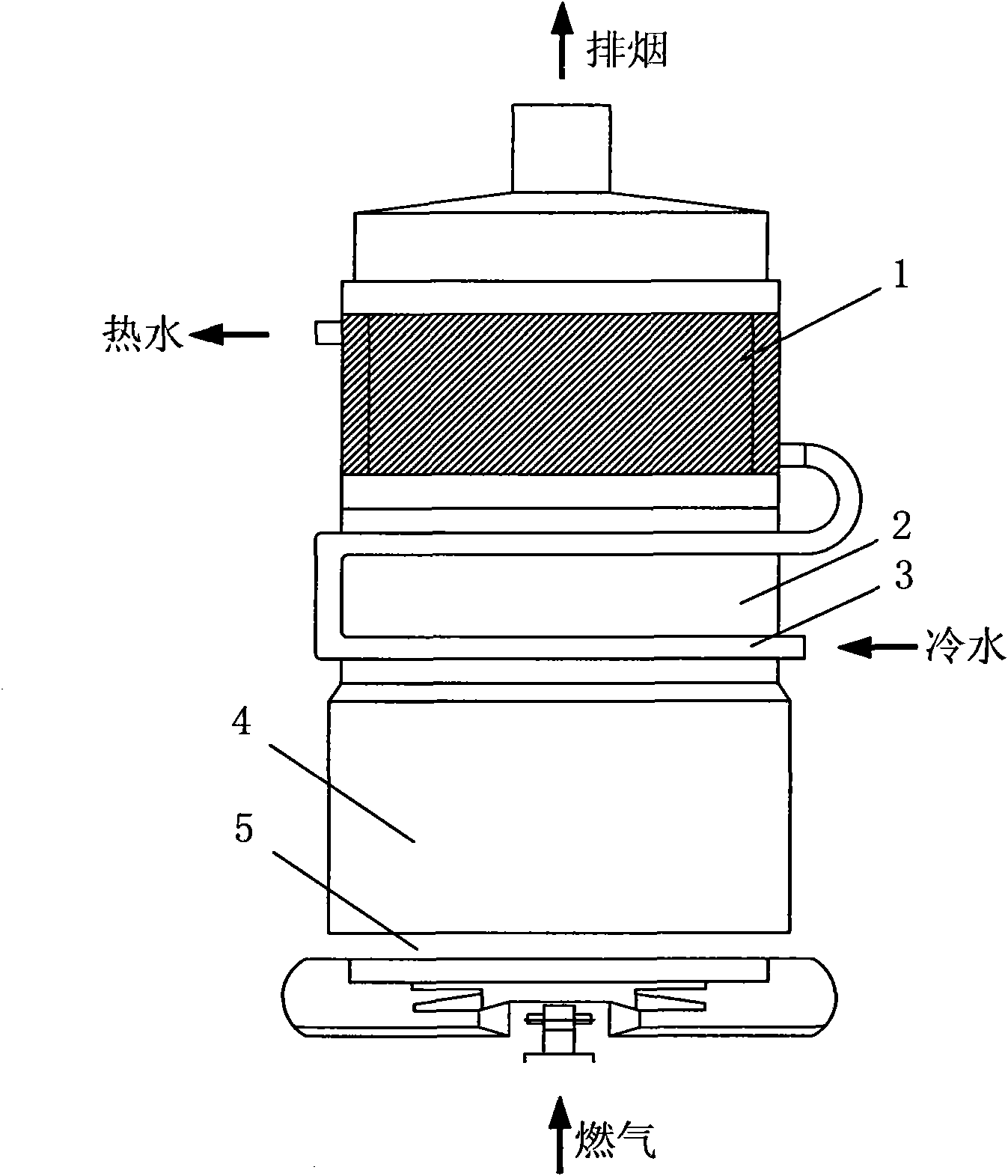

Smoke reheating device of combining phase-change heat exchanger with net gas heater

ActiveCN102997267ASolve the problem of air leakageSolve the cloggingLighting and heating apparatusAir preheaterGas heater

The invention relates to a smoke reheating device of combining a phase-change heat exchanger with a net gas heater. No smoke reheating device capable of preventing a chimney from being corroded, and emitting white smoke and misty rain, and the like exists at present. The smoke reheating device comprises a smoke flue, and a smoke thermometer, wherein the smoke reheating device is characterized by also comprising an air pre-heater, the phase-change heat exchanger, the neat gas heater, a terminal controller, a downcomer, a condensed refrigerant thermometer, a phase-change heat-exchange steam pocket, a riser pipe, a heat transfer medium thermometer, a water inlet pipe, a water return pipe, a steam inlet pipe and a steam outlet pipe; the air pre-heater, the phase-change heat exchanger and the net gas heater are arranged inside the smoke flue; one end of the water inlet pipe is fixed on the phase-change heat-exchange steam pocket; the other end is fixed on the net smoke heater; and the smoke thermometer, a steam regulating valve, a flow regulating valve, the condensed refrigerant thermometer and the heat transfer medium thermometer are electrically connected with the terminal controller. The smoke reheating device can avoid the situations that the chimney is corroded, emits white smoke and misty rain.

Owner:HANGZHOU HUADIAN ENERGY ENG

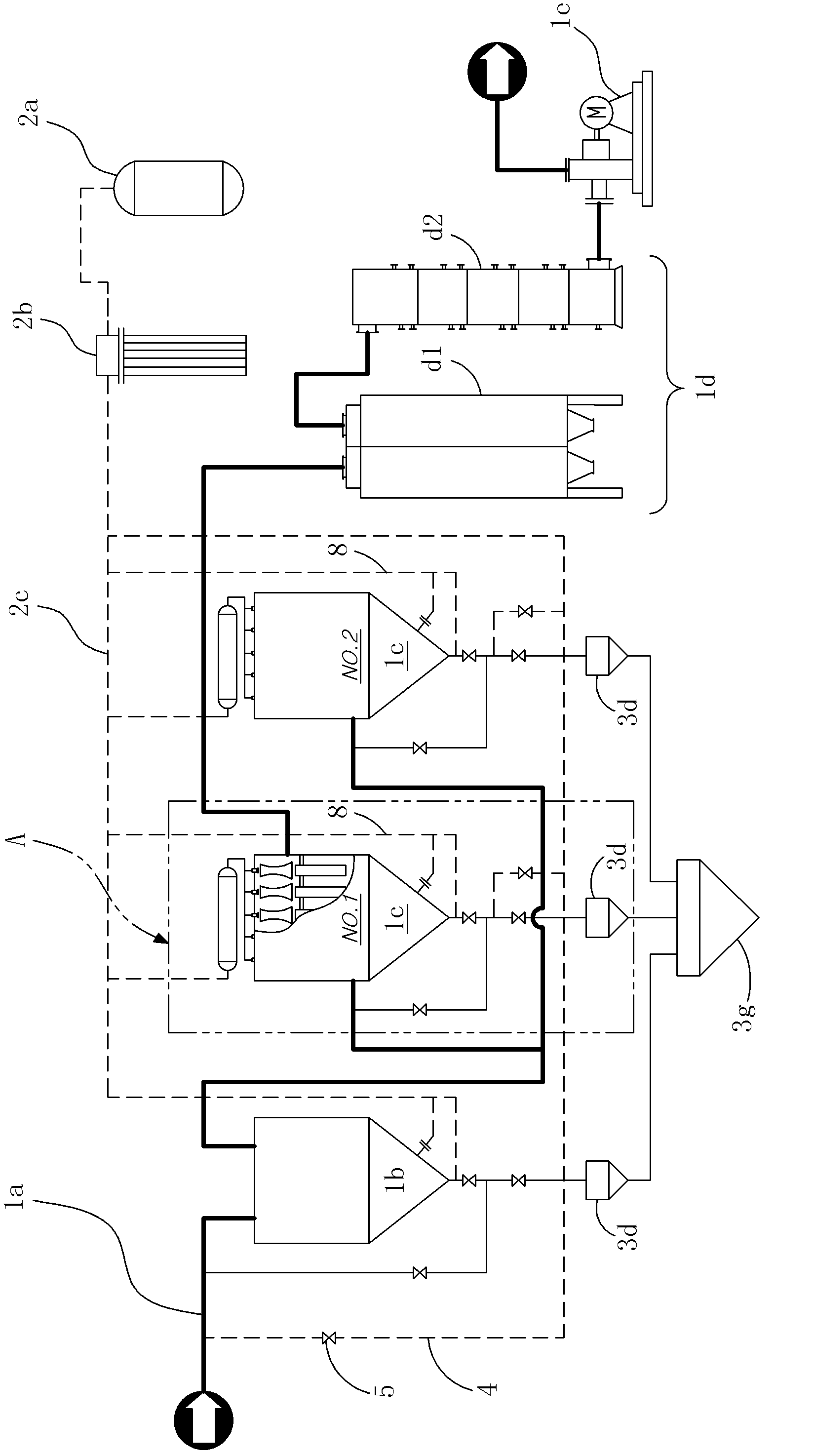

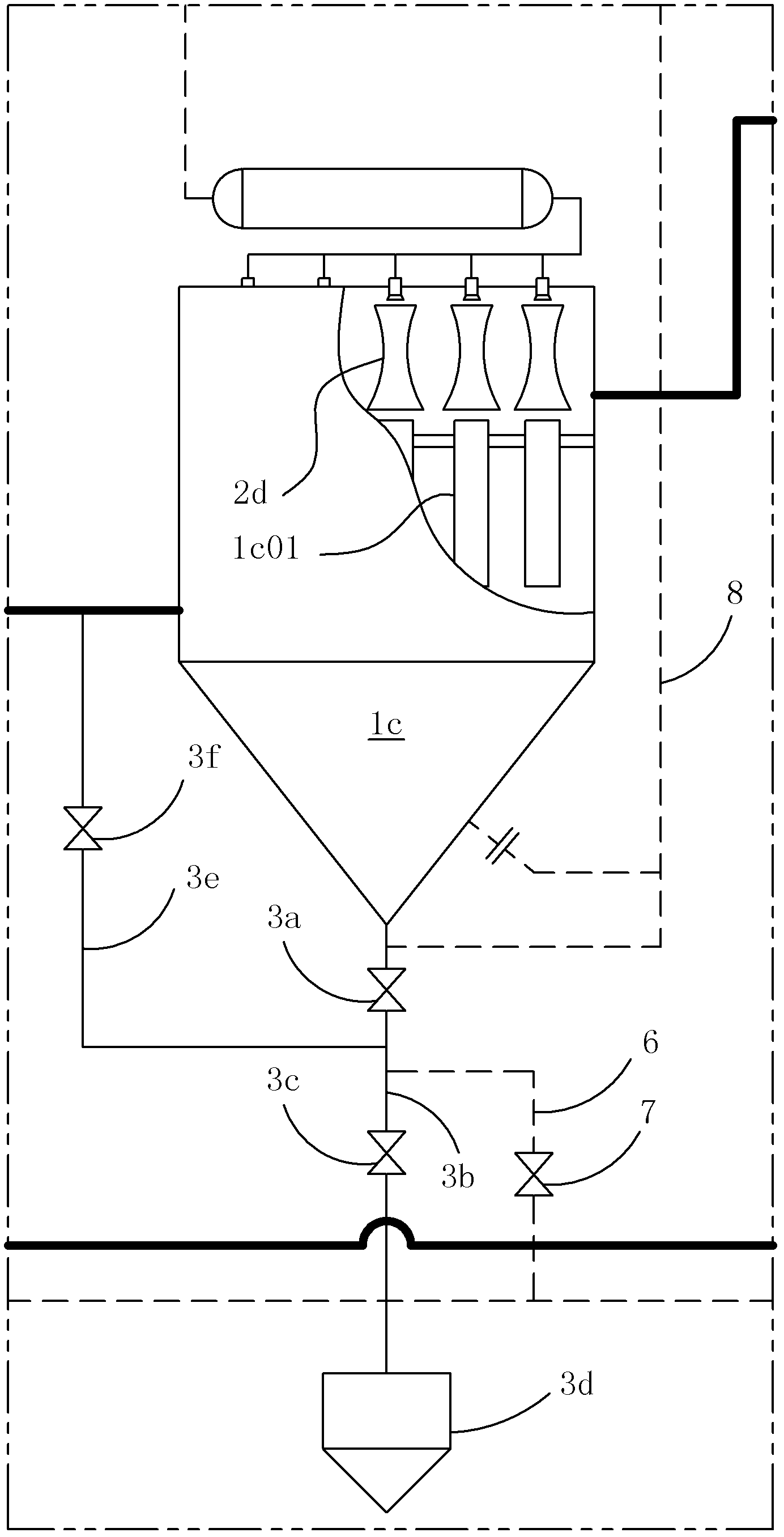

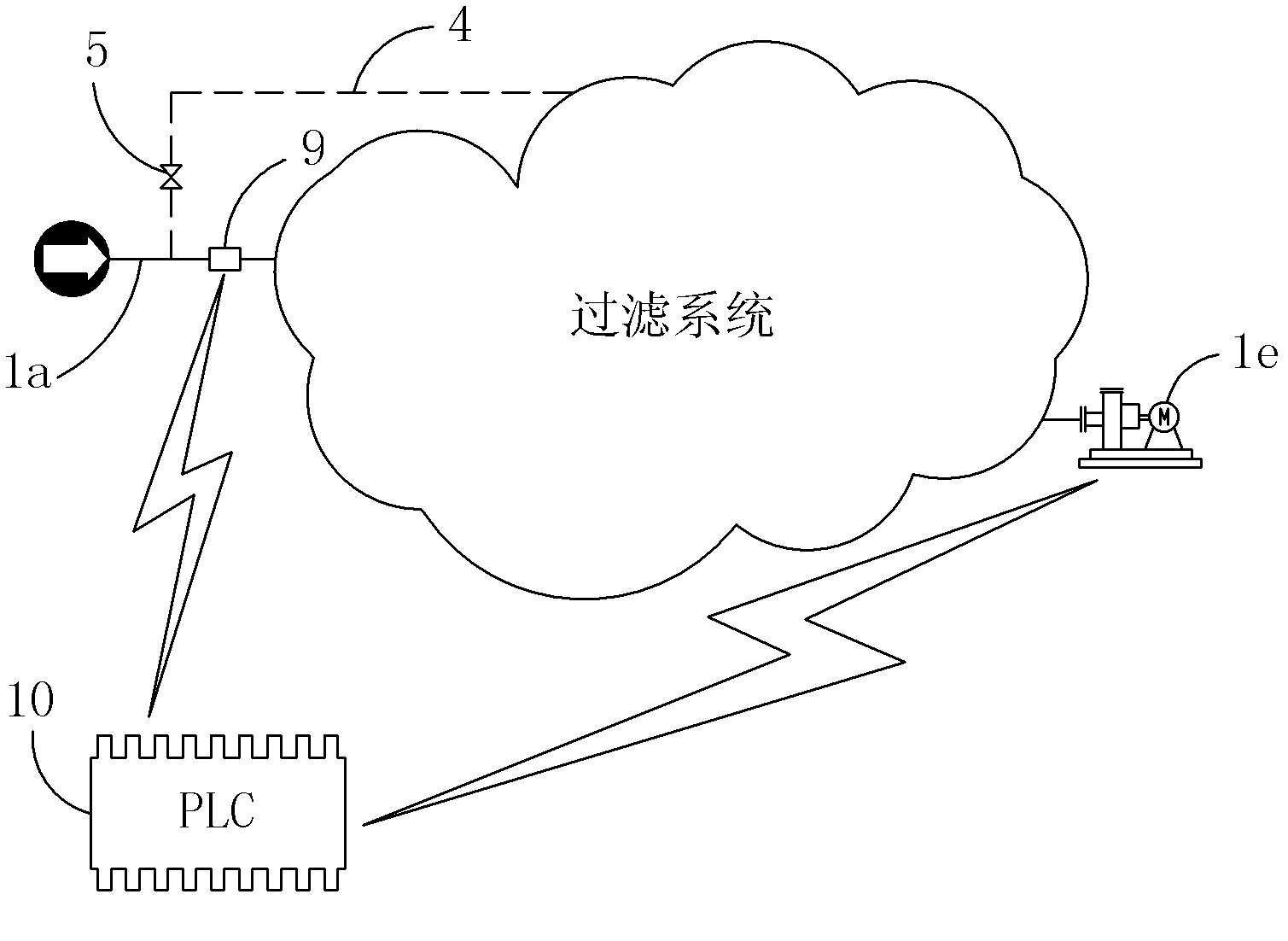

High-temperature flue gas cleaning system

InactiveCN102631820AAvoid condensationAvoid tar filmingCombination devicesDispersed particle filtrationFlue gasMoisture condensation

The invention discloses a high-temperature flue gas cleaning system which is moisture condensation resistant, and tar film pasting resistant. The system comprises a filtering system, a blowback system and an ash discharging system, wherein the filtering system comprises a high-temperature flue gas connecting pipe, at least one part of a filter connected with the high-temperature flue gas connecting pipe and a fan driving the gas to be cleaned to pass through the filter, the filter is respectively connected with the blowback system and the ash discharging system, the blowback system takes protective gas as a blowback medium, and the blowback system is internally provided with a protective gas heater; and when the high-temperature flue gas cleaning system is turned on, the blowback system is taken as a filter core moisture condensation-resistant system for preheating a filter core in the filter in a blowing way, and when the high-temperature flue gas cleaning system is turned off, the blowback system is further taken as a protective gas displacement system for displacing the original gas in the filter in a blowing way. In the stage that high-temperature flue gas cleaning system is turned on, the filter core is preheated by the protective gas, so that the phenomena of moisture condensation and tar film pasting on the surface of the filter core can be avoided.

Owner:CHENGDU INTERMENT TECH

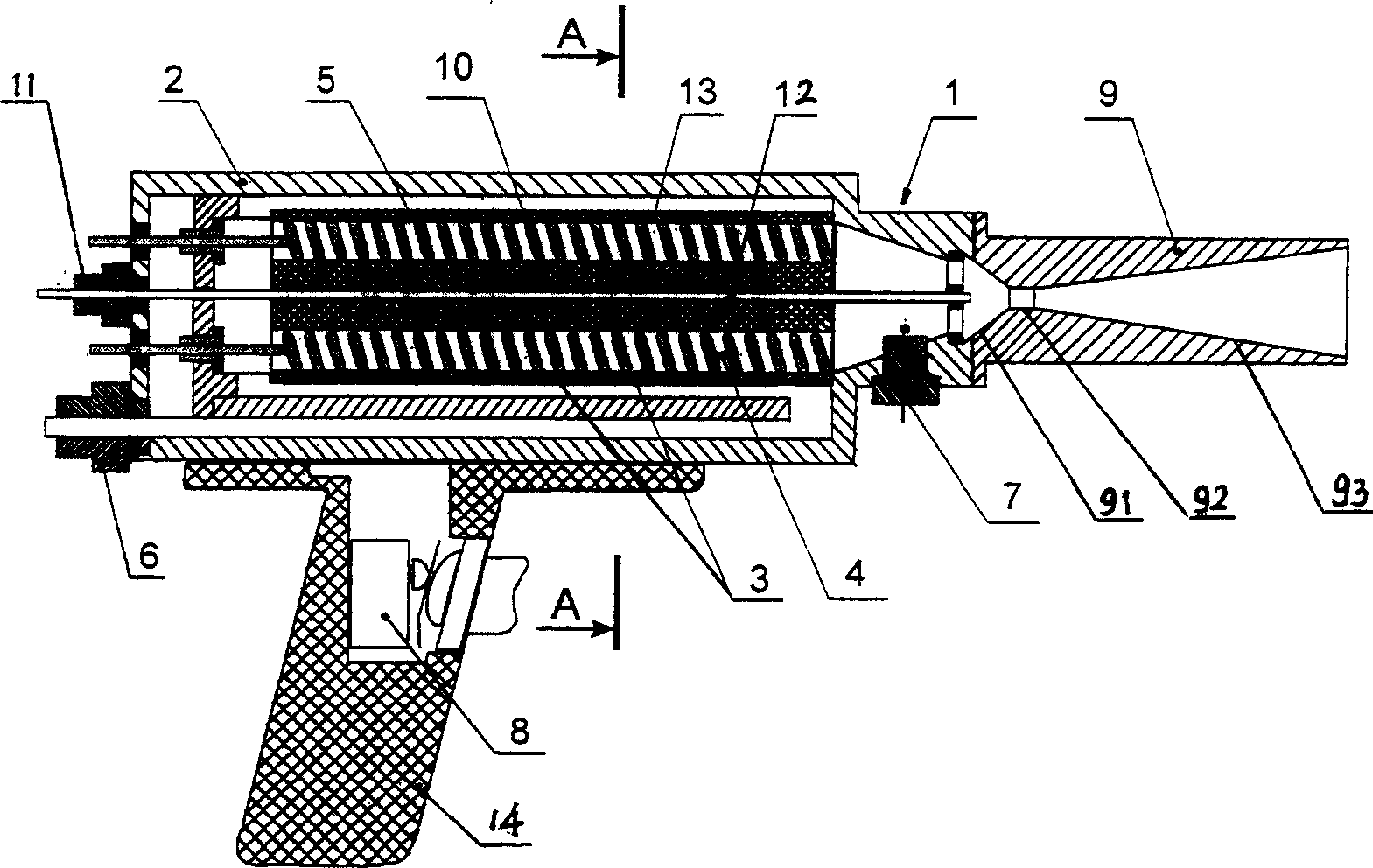

Pneumatic powder spraying apparatus

InactiveCN1603008ABroaden the scope of industrial applicationsEasy to carryLiquid spraying apparatusPressure inorganic powder coatingGas heaterMechanical energy

This invention opens one kind of gas dynamic powder spraying device which is composed with compression gas source,powder feed unit and spray mechanism.The spray mechanism includes gas heater and supersonic nozzle that is rigid linkage structure of coaxial setting.Gas heater includes metal shell,heat element and electrothermal insulator.One end of metal shell is fixed coaxial with the supersonic nozzle,the other end of metal shell is equipped with carrier gas joint and feed powder joint.The electrothermal insulator which is installed in the metal shell is composed with two coaxial emboitement internal and external tube,the center of the internal tube has a channel which two ends respectively connect powder feed unit and supersonic nozzle.In the exine of the internal tube,there are agroove gas direct channels which connect to the compress gas source,the heat element lies in the agroove gas direct channals.This invention which can be used to prepared monolayer and multi-layer coating widens industry application,reduces equipment weight,simplifies design structure and equipment maintanance and improves the spraying efficiency,being suitable for mechanical energy and metallurgy etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

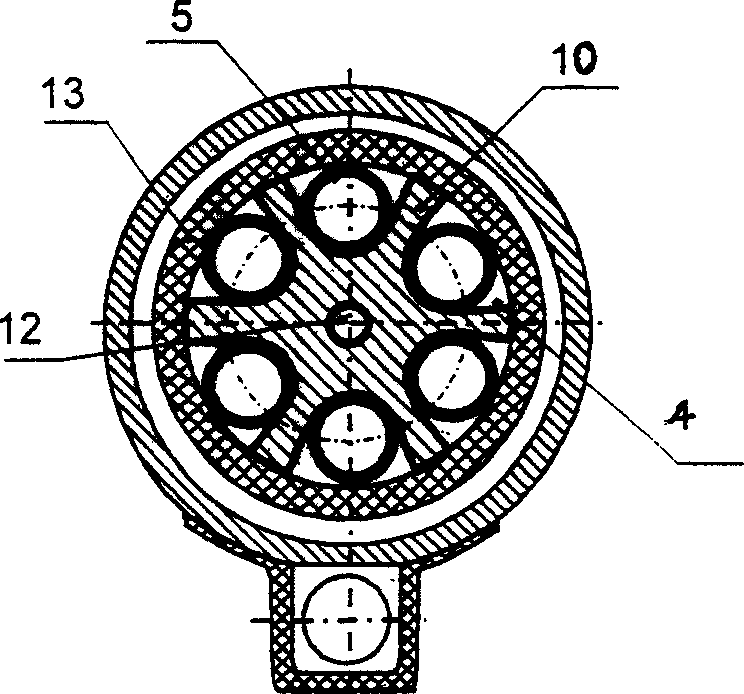

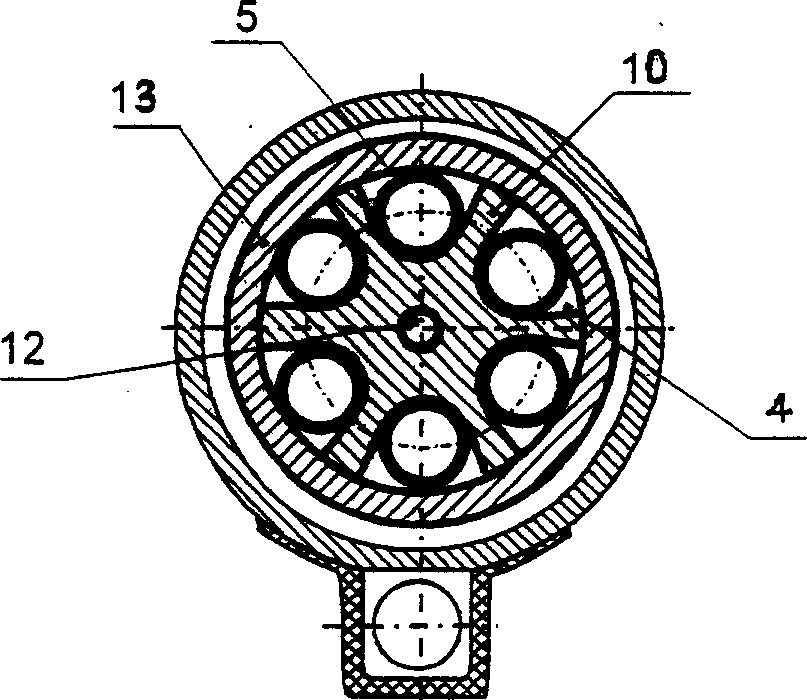

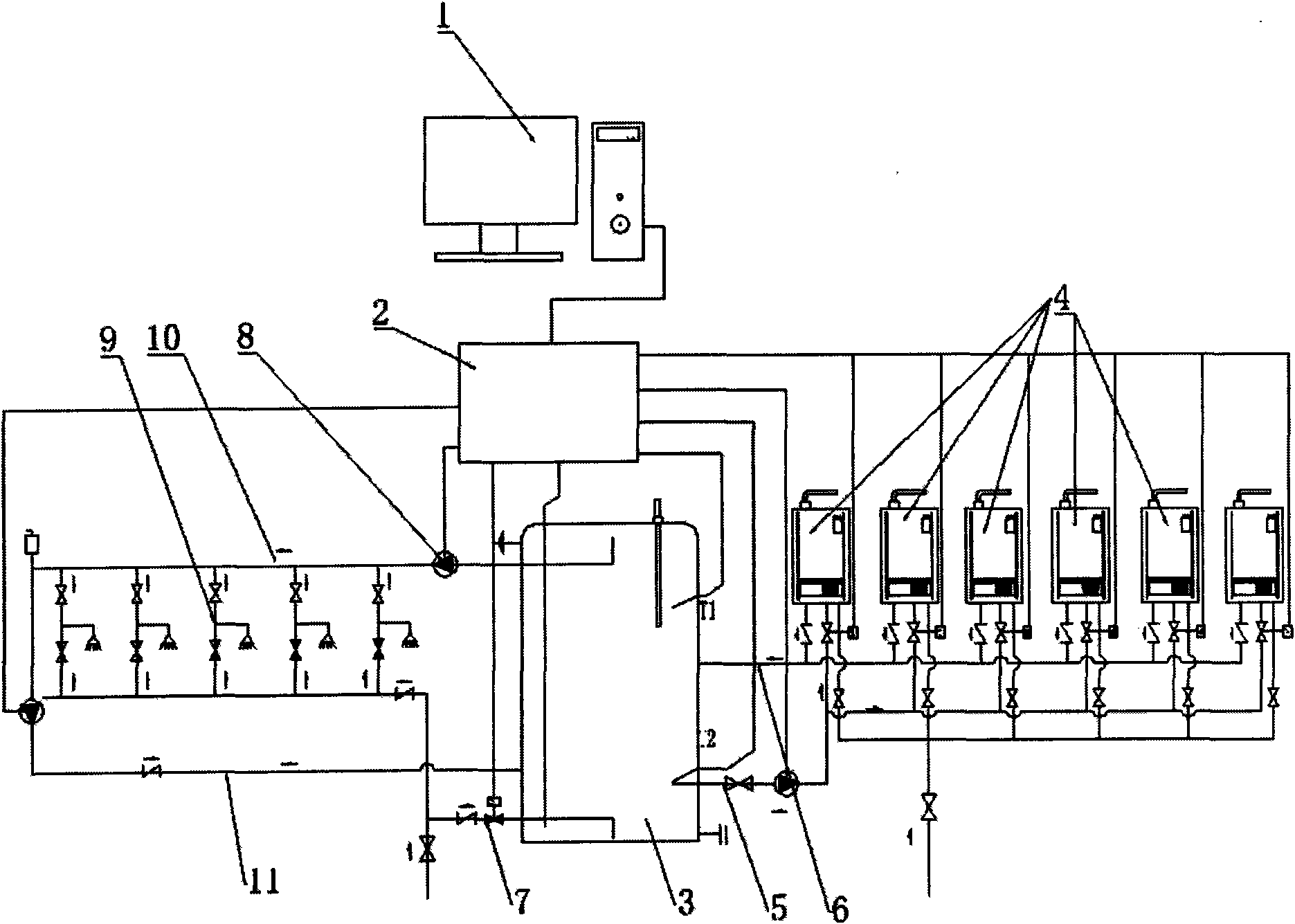

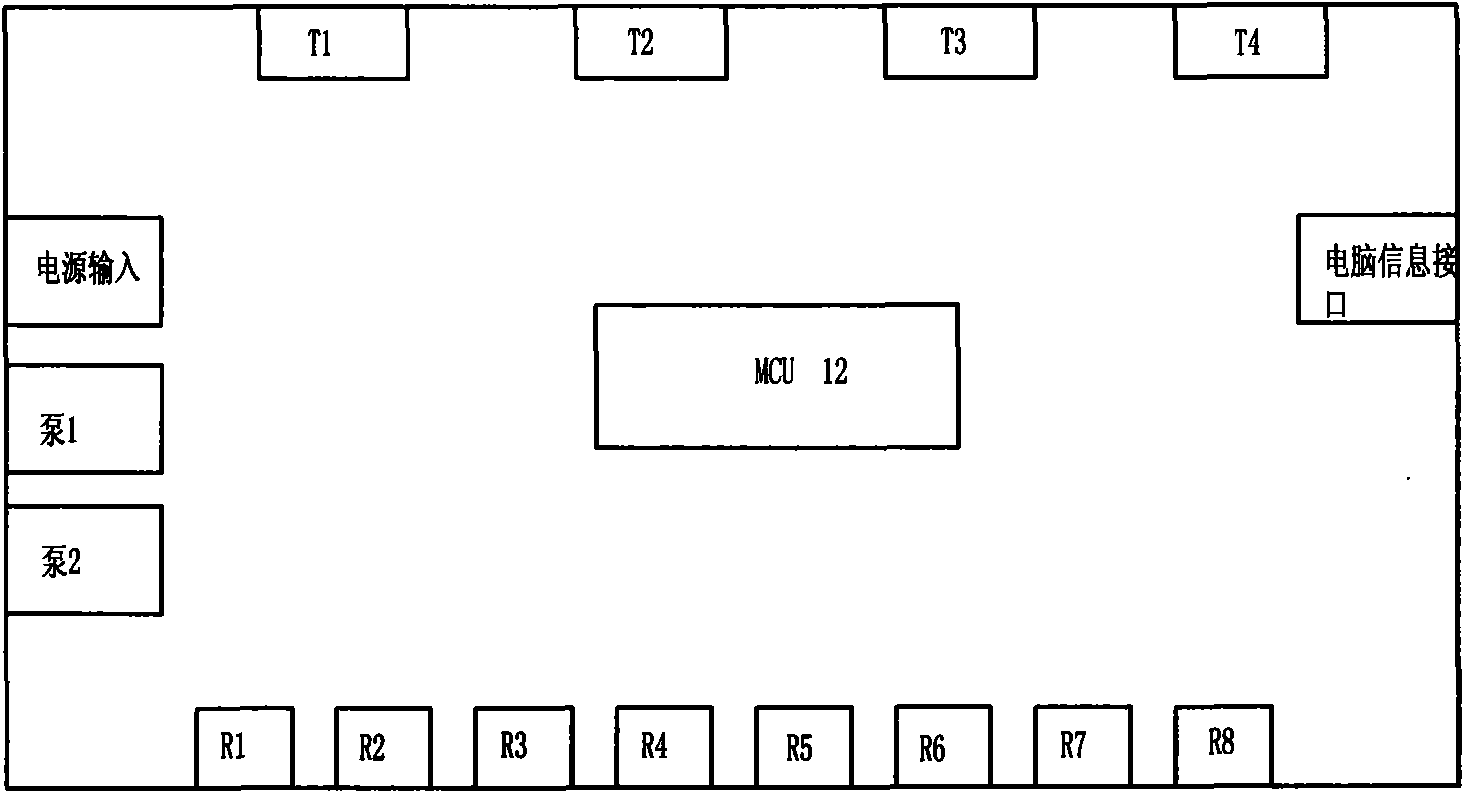

Method and system for parallel connection of multiple gas heaters

The invention discloses a method and a system for the parallel connection of multiple gas heaters. The system is characterized in that a temperature sensor signal is received through an MCU (micro control unit), and a corresponding gas heater heating system, which is mainly composed of a plurality of hot water heaters connected in parallel, is initiated according to demanded hot water quantity and temperature. The system comprises a central controller, a constant temperature water tank and a gas heater generating unit the working state of which is controlled by the central controller. Water inlet and outlet pipes are connected between the gas heater generating unit and the constant temperature water tank, the constant temperature water tank is externally connected with a water point by a water booster pump and a circulation water pipeline. The system of the invention employs a PC as an operating unit to work out special software system, has the advantages of strong expansibility, convenience in installation and maintenance, simplicity in operation and energy conservation, and can be installed both indoors and outdoors.

Owner:GUANGDONG MACRO GAS APPLIANCE

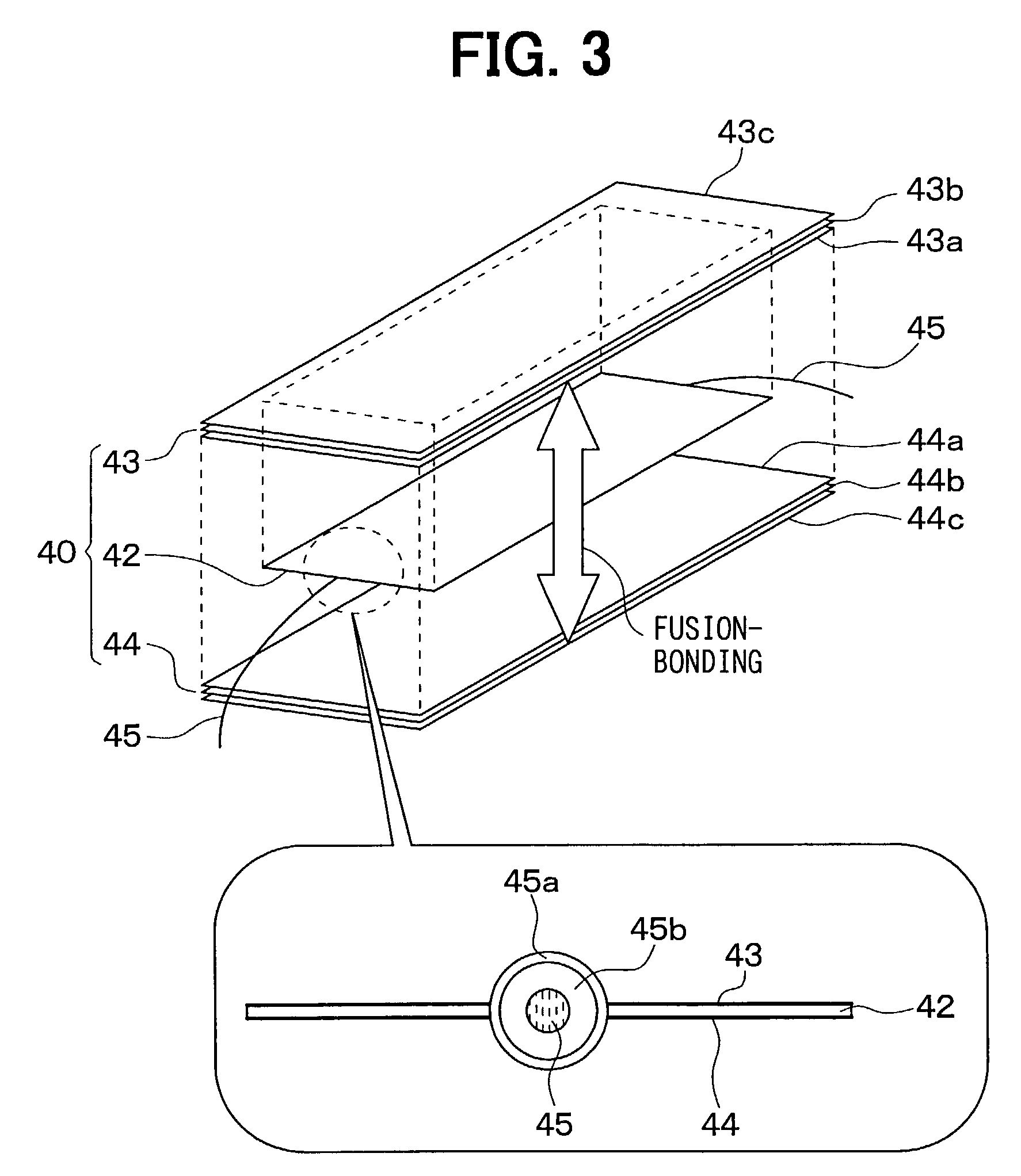

Vacuum-pumping method and apparatus thereof

ActiveCN101021209AReduce leakageGood for vacuumPumpsPositive-displacement liquid enginesVacuum pumpingGas heater

The present invention discloses an evacuation method and its equipment for evacuating sandwich between external barrel and internal barrel of multi-layer heat-insulating container. Said evacuation equipment includes first gas-conveying device, it has a gas outlet; first gas heater, its inlet is communicated with gas outlet of first gas-conveying device, its outlet is communicated with gas inlet of said internal barrel; evacuation machine unit, it is communicated with said sandwich; second gas-conveying device, it has a gas outlet; and second gas heater, its inlet is communicated with gas outlet of said second gas-conveying device, and its outlet is communicated with said sandwich.

Owner:CIMC VEHICLES (GROUP) CO LTD

Flue gas processing system and flue gas processing method capable of enabling low-low temperature electrostatic precipitation to be combined with water pollination type GGH (Gas Gas Heater)

InactiveCN104676620AEmission reductionEffective control of emission concentrationLighting and heating apparatusDispersed particle separationGas heaterEmission standard

The invention relates to a flue gas processing system and a flue gas processing method capable of enabling low-low temperature electrostatic precipitation to be combined with a water pollination type GGH (Gas Gas Heater). At present, a flue gas processing system and a flue gas processing method which are capable of meeting a new emission standard and preventing the corrosion of a chimney are not provided. The flue gas processing system disclosed by the invention is characterized by comprising a terminal controller, a steam regulating valve, a steam auxiliary heater, a water inlet pipe, a water return pipe, a steam inlet pipe and a steam outlet pipe, wherein the steam auxiliary heater is arranged on the water inlet pipe, the steam inlet pipe and the steam outlet pipe are both connected to the steam auxiliary heater, and a flue gas temperature detector and the steam regulating valve are electrically connected with the terminal controller. The flue gas processing method disclosed by the invention is characterized by comprising the following steps of carrying out heat exchange between high-temperature flue gas in a flue gas duct and a low-temperature working medium in a flue gas heat recycling device when the high-temperature flue gas in the flue gas duct flows through the flue gas recycling device, and carrying out heat exchange between a high-temperature working medium and low-temperature purified flue gas which is output through a desulfurizing tower and a demister in the flue gas duct after the low-temperature working medium is heated into the high-temperature working medium. According to the flue gas processing system and the flue gas processing method, disclosed by the invention, the new emission standard is met, and the corrosion of the chimney is prevented.

Owner:HANGZHOU HUADIAN ENERGY ENG

Gas heating apparatus and methods

InactiveUS20080217324A1High resistivityLess-expensive to manufactureDomestic stoves or rangesMolten spray coatingThermal sprayingGas heater

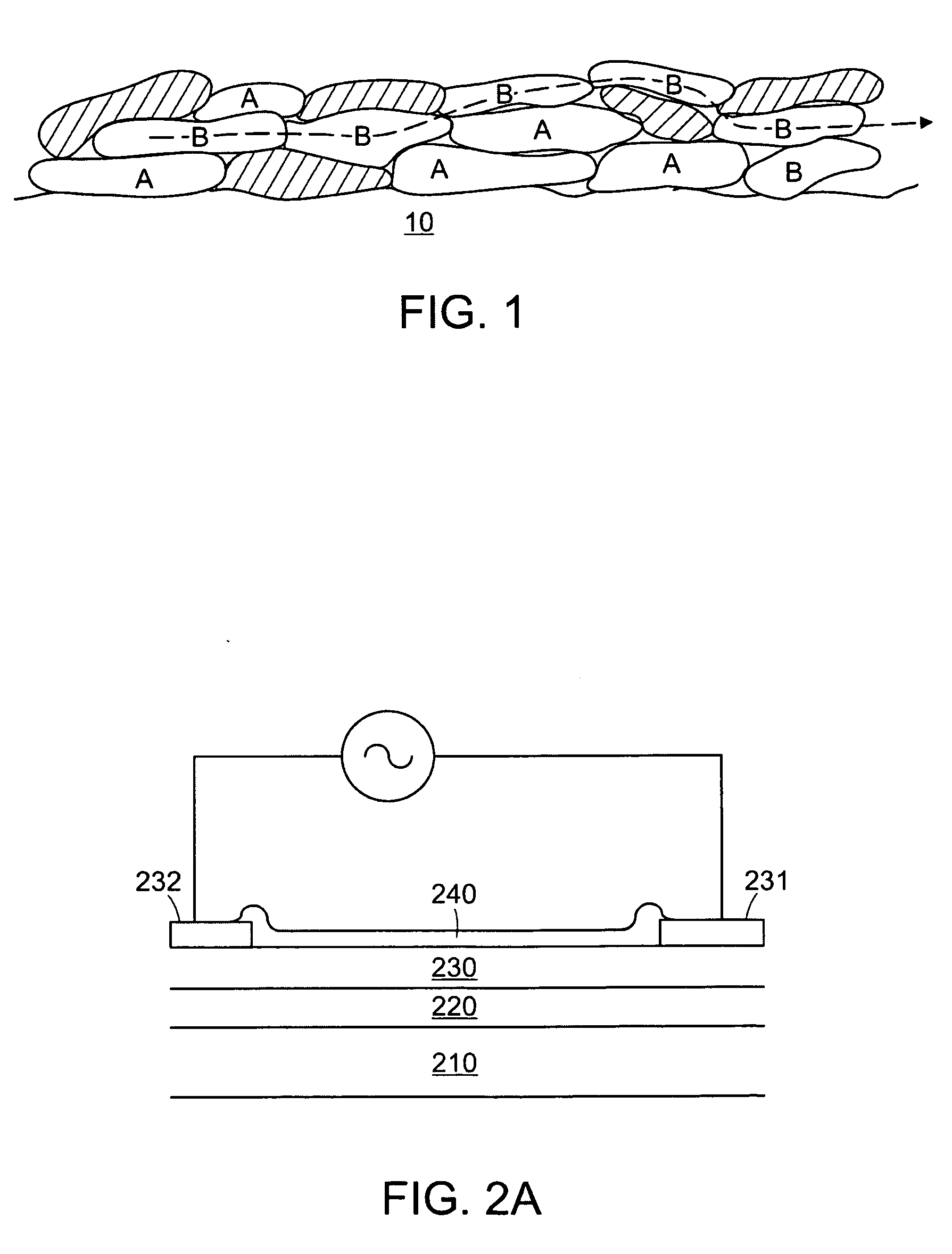

A thermally sprayed gas heater comprises a gas flow apparatus that propels a gas through a housing; and a thermally sprayed heater bonded to a surface of the apparatus, the heater positioned to heat the gas flow in the housing. In other aspects, a heater system for a turbulent flow gas duct comprises a duct having a gas flow channel, the channel having a shaped surface providing turbulent gas flow in the channel, and a thermally sprayed heater positioned to heat the gas flow in the channel.

Owner:REGAL WARE

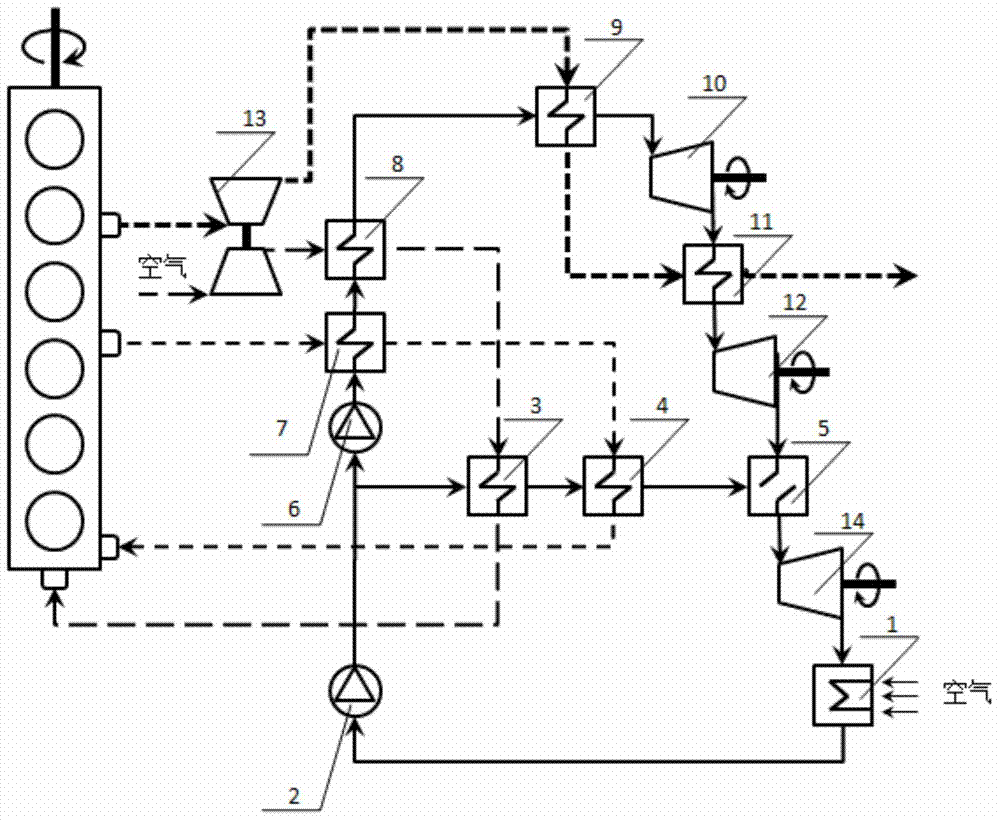

Internal combustion engine waste heat recovery system adopting double-pressure multistage expansion reheating

ActiveCN103670558AImprove fuel economyIncrease output powerInternal combustion piston enginesExhaust apparatusGas heaterTurbocharger

The invention discloses an internal combustion engine waste heat recovery system adopting double-pressure multistage expansion reheating. The internal combustion engine waste heat recovery system is composed in a manner that an ORC main circulation system is formed by sequential serial connection of a condenser, a low-pressure working medium pump, a high-pressure working medium pump, a preheater, a high-temperature intercooler, a gas-gas heater, a first expansion machine, a reheater, a second expansion machine, a mixed heat exchanger and a third expansion machine. Working media output from the low-pressure working medium pump are divided into two groups and flow to a high-pressure branch and a low-pressure branch, and the working media of the two branches are converged in the mixed heat exchange. Cooling water circulation is formed by serial connection of a cylinder sleeve cooling water outlet, the preheater, a low-pressure evaporator and a cylinder sleeve cooling water inlet. A pressurization air loop is formed by serial connection of an air inlet, a turbocharger compressor inlet, the high-temperature intercooler and a low-temperature intercooler. An exhaust heat utilization system is formed by connection of an exhaust port, a turbine in a turbocharger, the gas-gas heater and the reheater. According to the internal combustion engine waste heat recovery system, loops are formed according to quality grading of internal combustion engine waste heat, so that waste heat of each part is utilized fully and heat recovered from waste heat sources can be increased.

Owner:TIANJIN UNIV

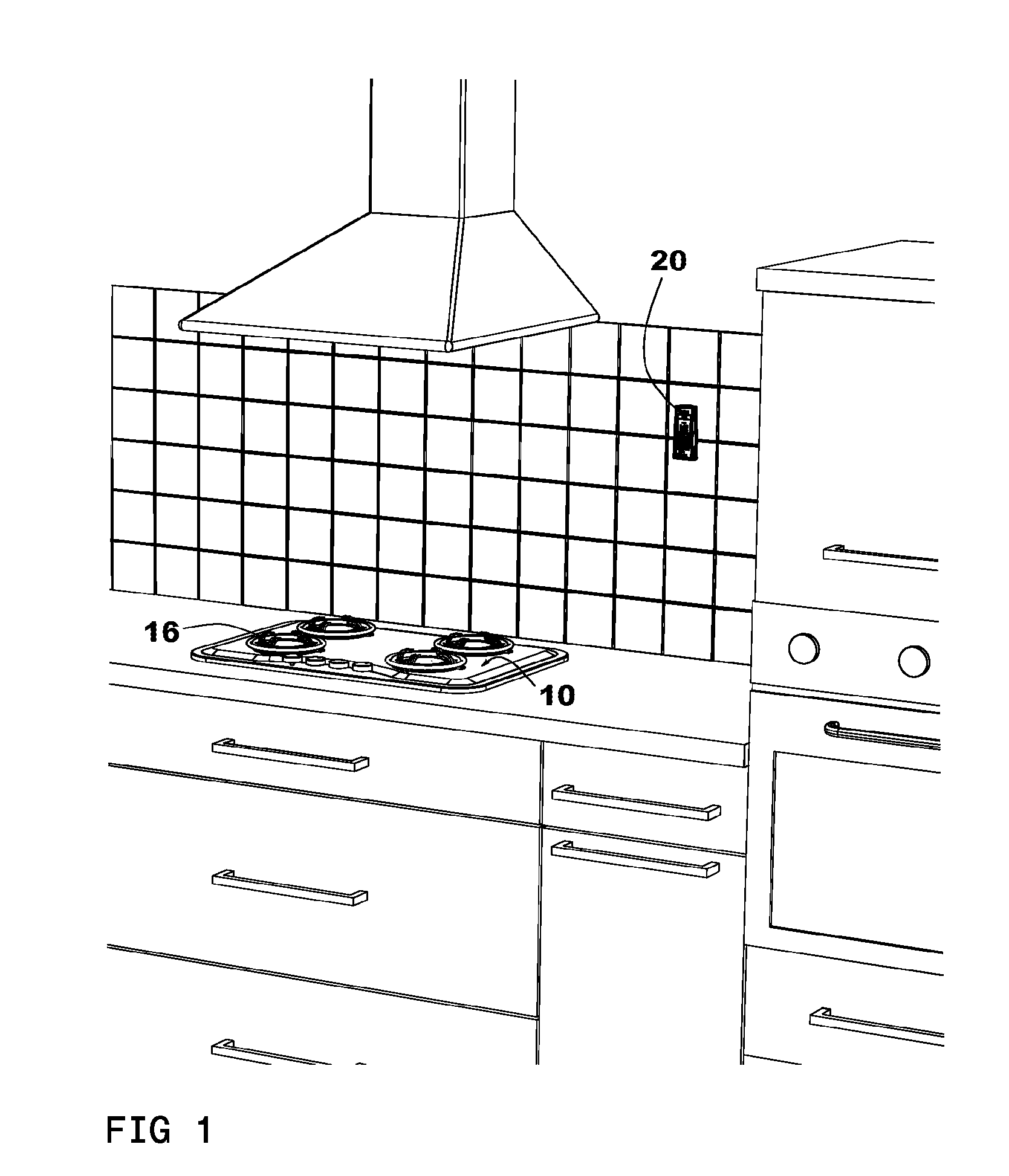

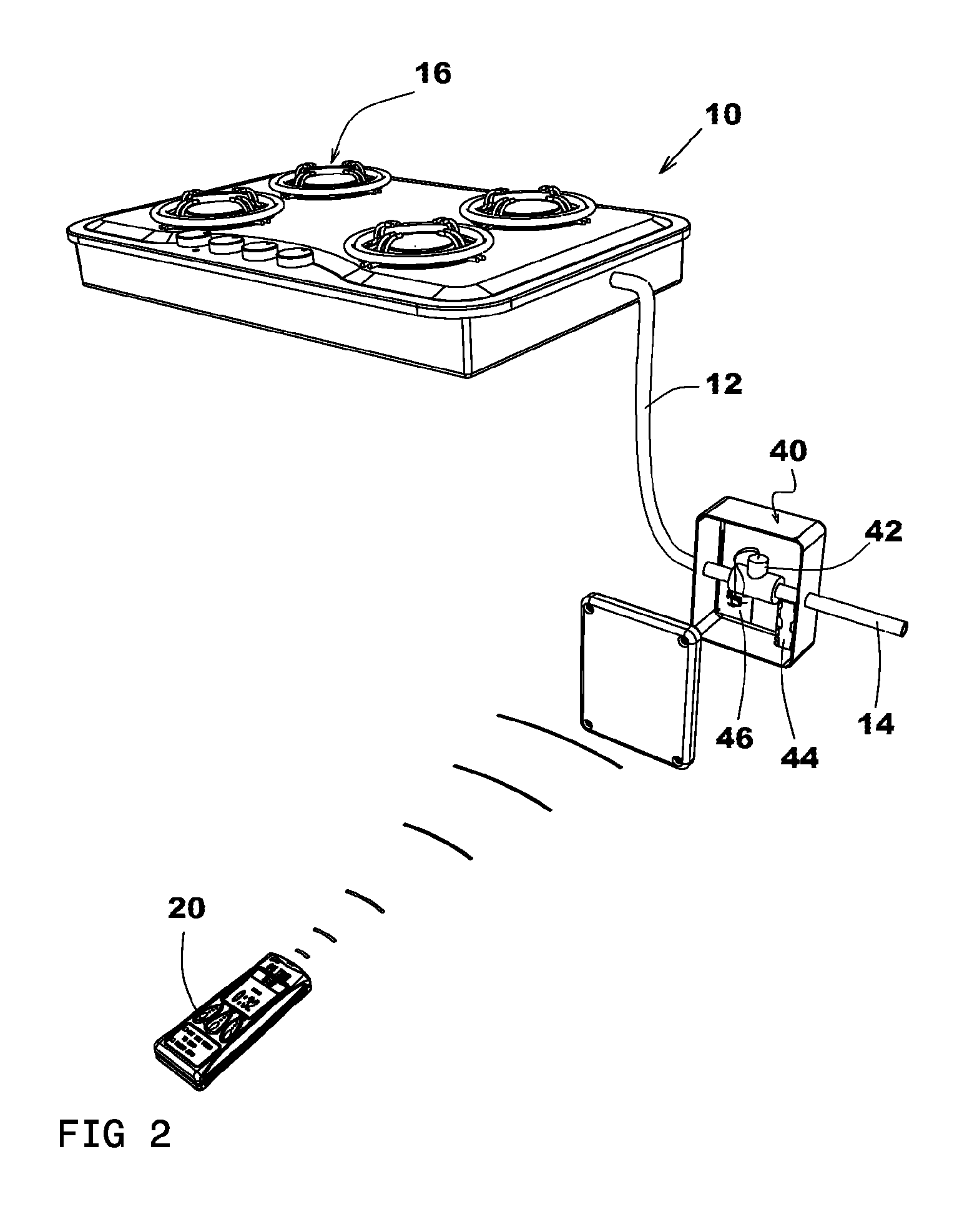

System for controlling gas supply to a gas heater

In one aspect, the present invention is directed to a system for controlling the gas supply to a gas heater (such as a gas stove, a heating stove, and so on), the system comprising: an electric valve, for blocking and unblocking a gas supplying pipe to said gas heater; a control unit, for controlling the operation of said electric valve; a timer, for determining a delay in activation of said electric valve to block said gas supply; and a remote-control unit, for providing, in a mobile manner, user interface for setting said timer; and a processing unit, for concentrating information from said timer, and activating the operation of blocking gas supply passage whenever the time of said timer runs out.

Owner:BRENNER DANI

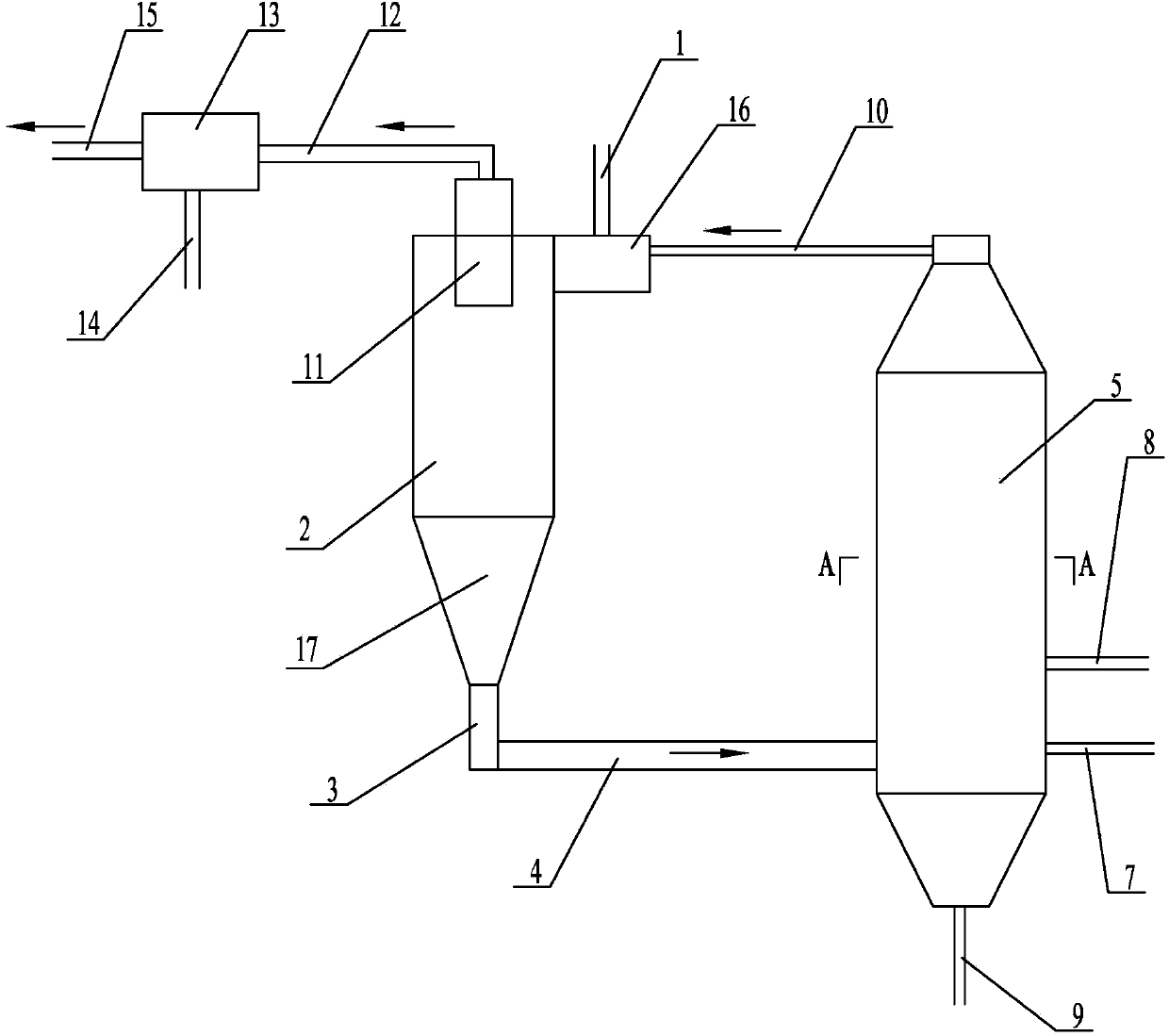

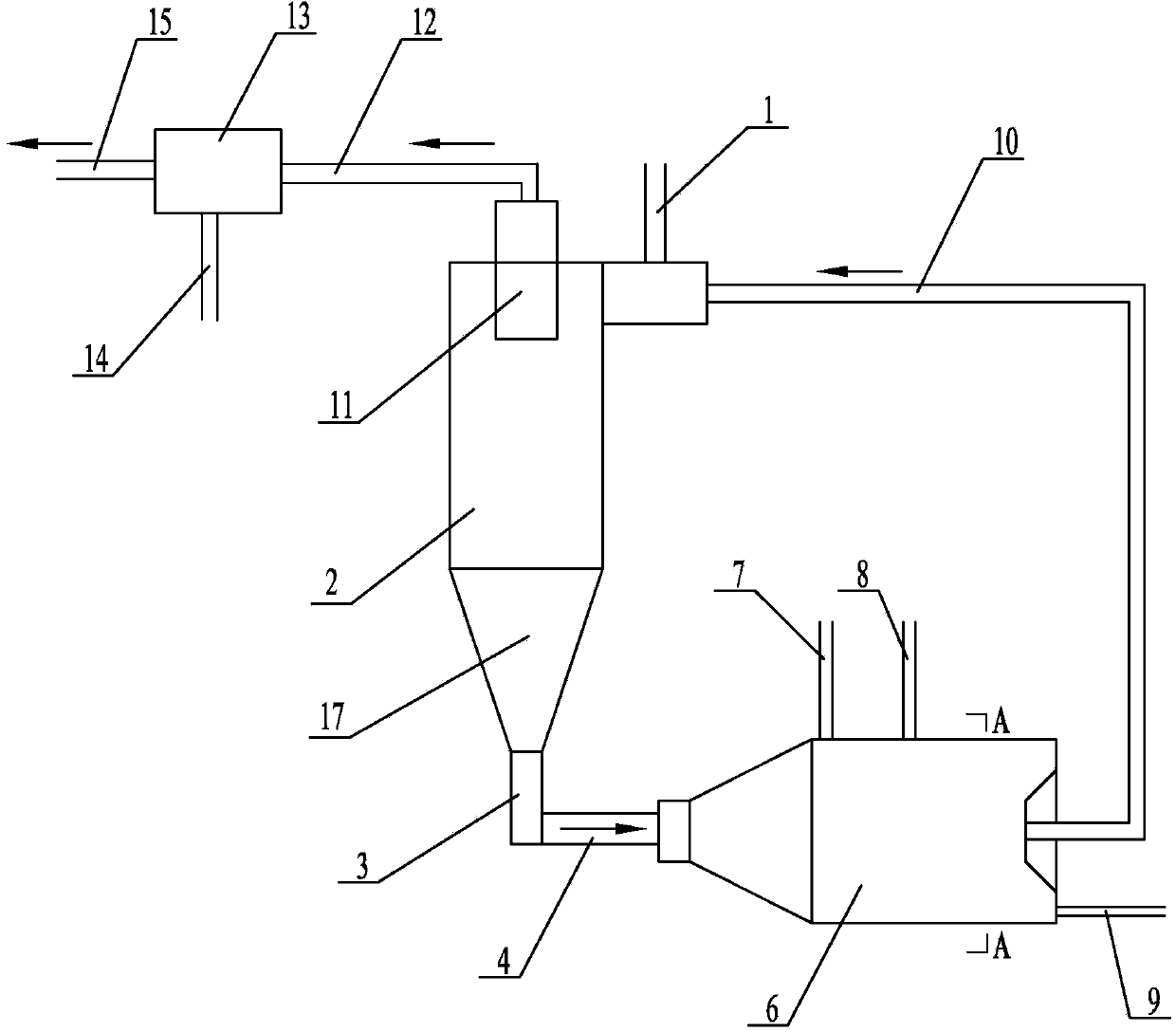

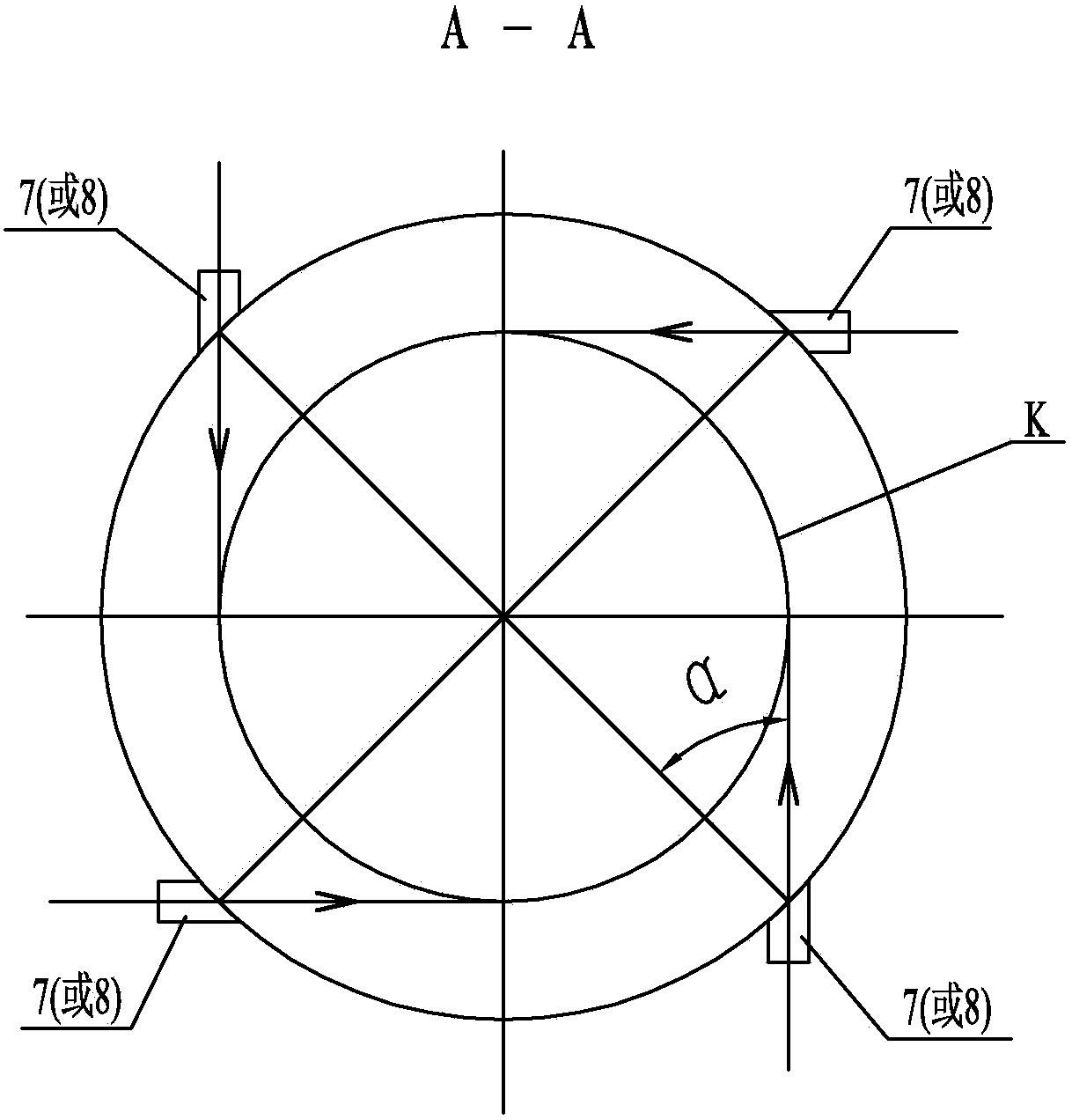

Double-cyclone coal pyrolysis gasification step converting device and double-cyclone coal pyrolysis gasification step converting method

ActiveCN103992824AIncrease profitFully pyrolyzedGranular/pulverulent flues gasificationCycloneWater vapor

The invention discloses a double-cyclone coal pyrolysis gasification step converting device and a double-cyclone coal pyrolysis gasification step converting method, and relates to a combusting device and a combusting method. The device is characterized in that a cyclone pyrolyzing furnace is communicated with a cyclone gasifying furnace by a material backing device and a pyrolyzing semi-coke channel; the cyclone gasifying furnace is communicated with the cyclone pyrolyzing furnace by a high-temperature raw coal gas channel; the cyclone pyrolyzing furnace is communicated with a cooling device by a pyrolyzing gas-mixing channel; an oxidant spray nozzle and a vapor spray nozzle are arranged on the outer wall of the cyclone gasifying furnace. The method is as follows: firstly, feeding coal dust into the cyclone pyrolyzing furnace under blocking and feeding of the high-temperature raw coal gas; secondly, pyrolyzing the coal dust in the cyclone pyrolyzing furnace, exhausting the pyrolyzed gas mixture into the cooling device, cooling, and conveying back the pyrolyzed semi-coke to the cyclone gasifying furnace; thirdly, spraying the oxidant and the vapor into the cyclone pyrolyzing furnace by the oxidant spray nozzle and the vapor spray nozzle at the same time, wherein the produced high-temperature raw coal gas is re-fed into the cyclone pyrolyzing furnace as a coal pyrolyzing gas heater carrier; coal residue in the cyclone gasifying furnace is exhausted through an ash residue discharge hole in the form of solid or liquid. The double-cyclone coal pyrolysis gasification step converting device and the double-cyclone coal pyrolysis gasification step converting method are used for gasifying clean coal gas.

Owner:HARBIN INST OF TECH

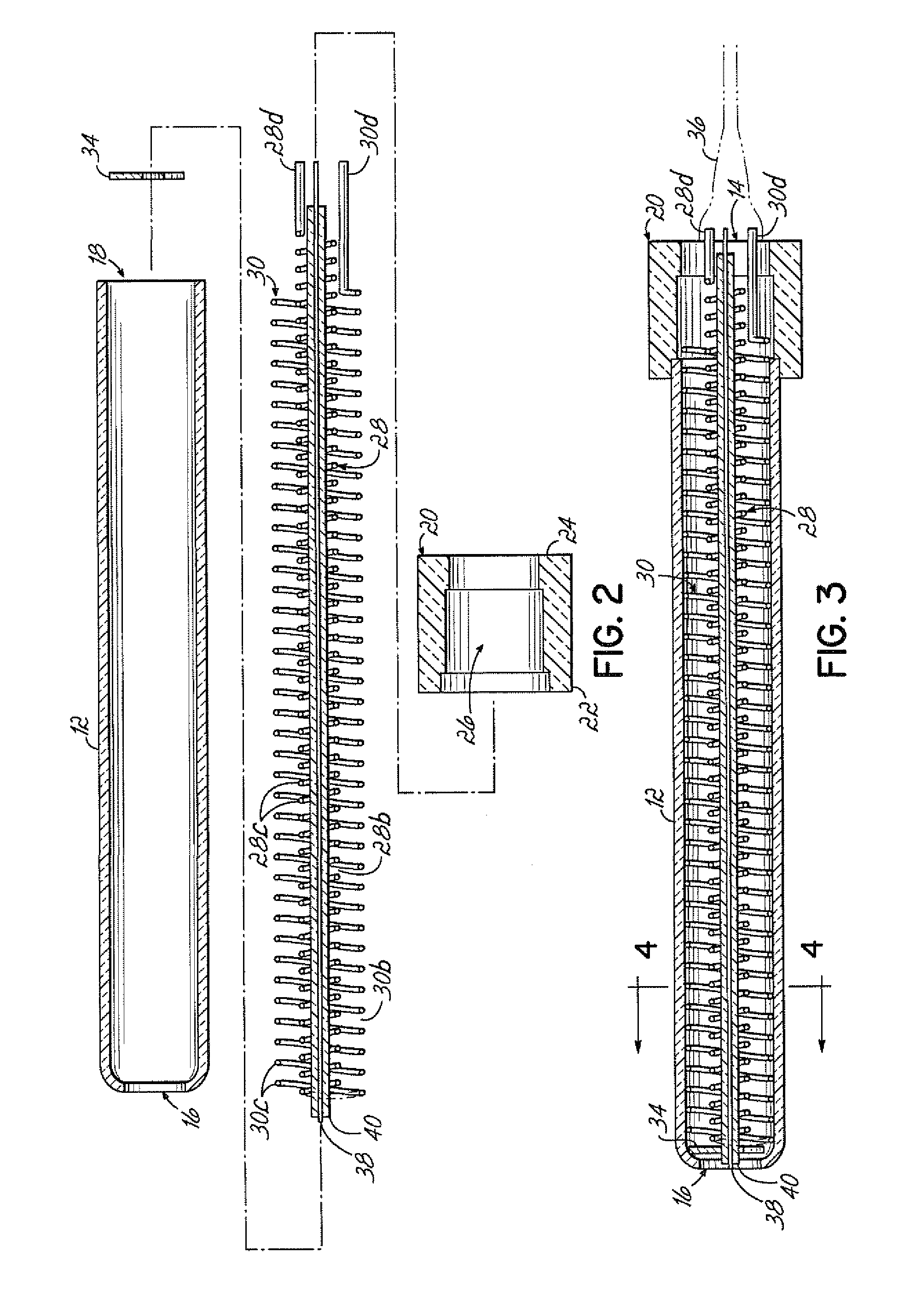

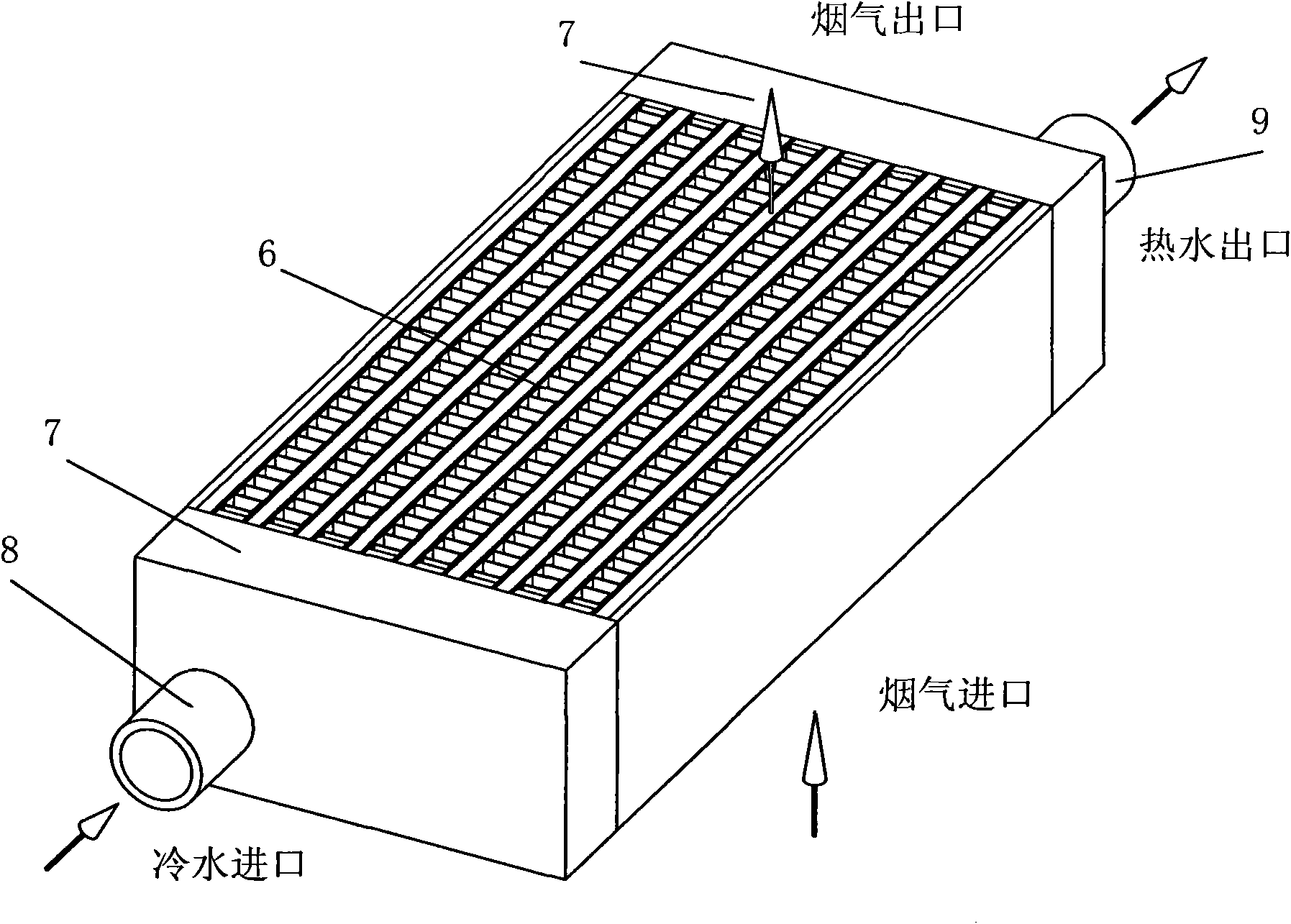

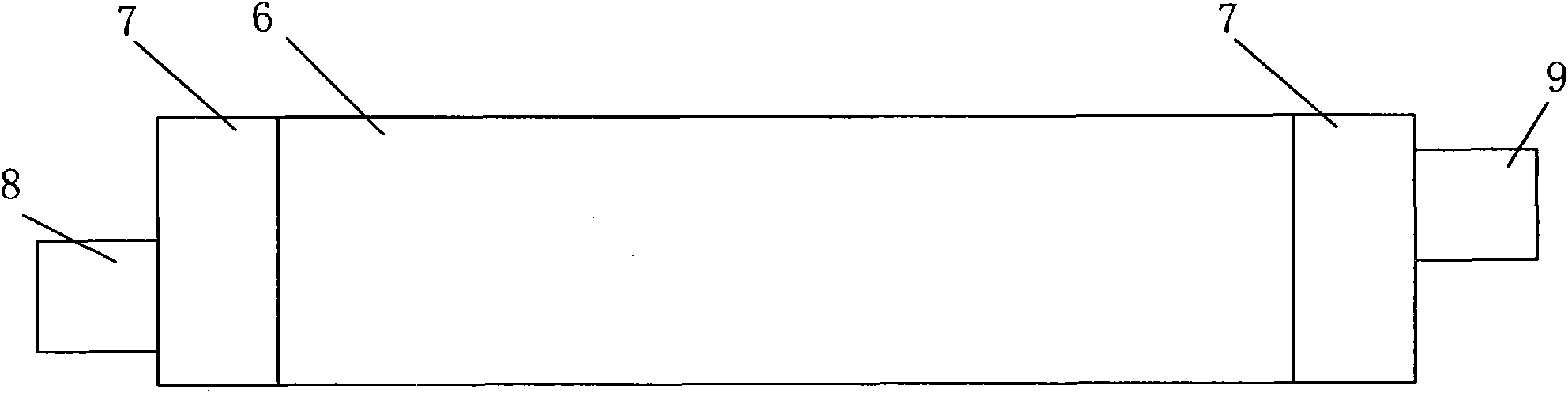

Plate-fin heat exchanger for gas heater

InactiveCN101832723ASave materialHighly compact structureHeat exchange apparatusStationary plate conduit assembliesFlue gasGas heater

The invention discloses a plate-fin heat exchanger for a gas heater, comprising a core body, seal heads, an inlet connection pipe and an outlet connection pipe, wherein the core body comprises a plurality of flue gas channels and sanitary water channels which are divided by partition plates in a rectangular cavity and are alternately connected; in the flue gas channel, flue gas side fins are arranged between two metal partition plates and are longitudinally arrayed, and the left and the right sides of each flue gas side fin are sealed by sealing tapes; in the sanitary water channel, water side fins are arranged between two metal partition plates and are transversely arrayed, the upper and the lower sides of each water side fin are sealed by sealing tapes, the left and the right ends of each water side fin are respectively communicated with the two seal heads, the seal heads at both sides are respectively connected with the inlet connection pipe and the outlet connection pipe of sanitary water, and the flue gas side fins and the water side fins are in continuous groove structures. The gas-water exchanger of the gas heater has high heat exchange efficiency, reduces the consumption of gas and achieves the purposes of saving energy, reducing device size and reducing production cost.

Owner:SOUTH CHINA UNIV OF TECH

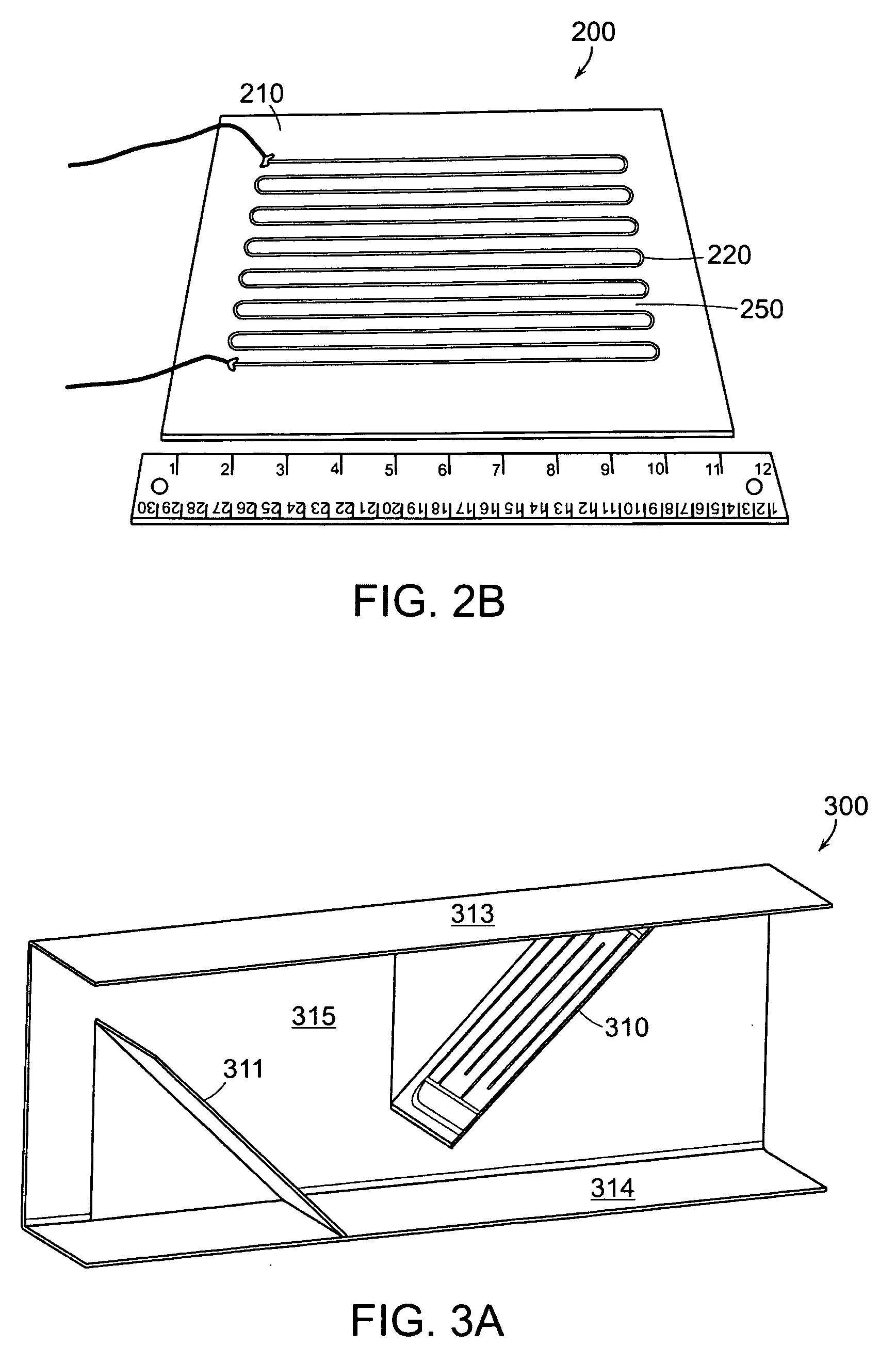

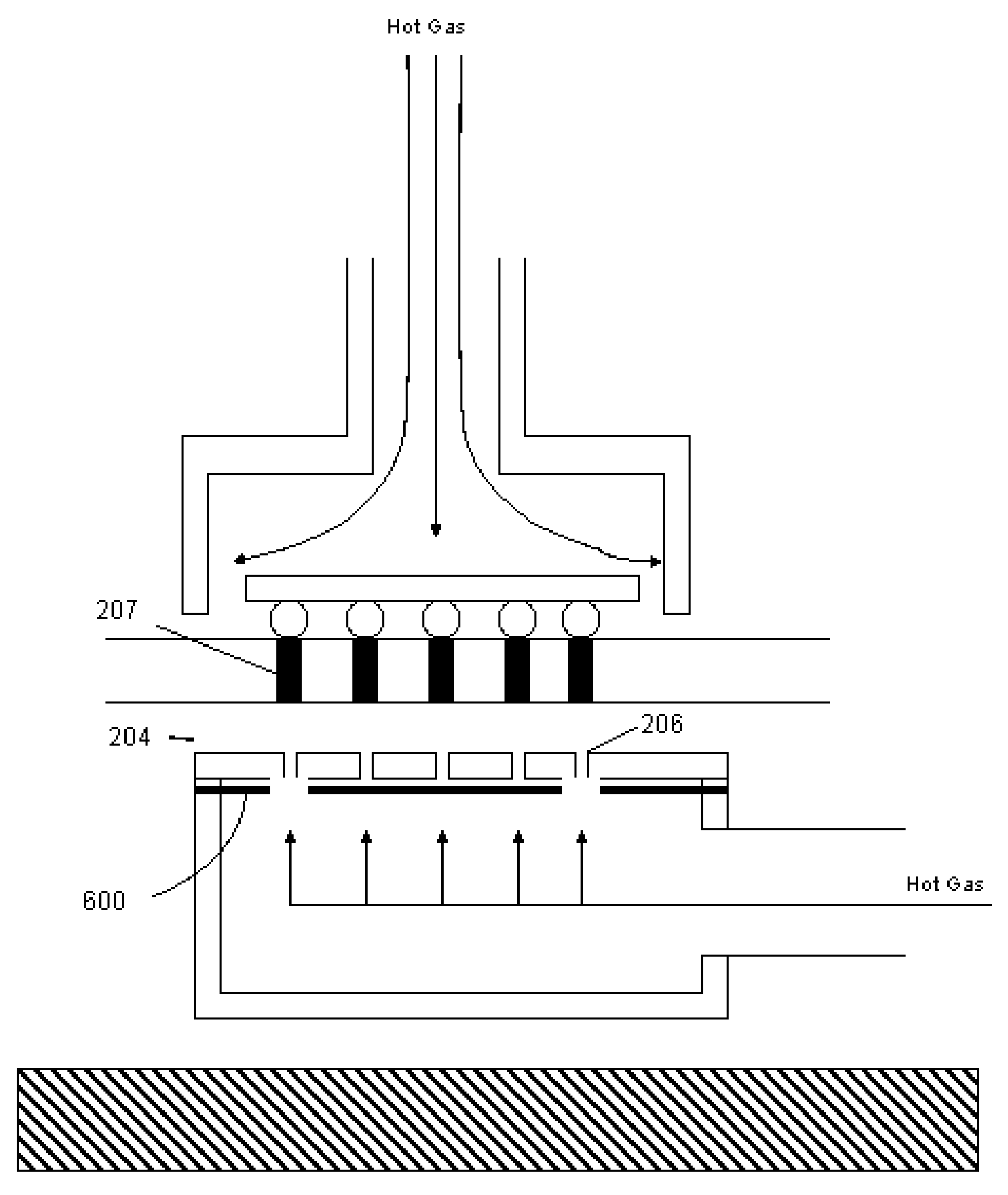

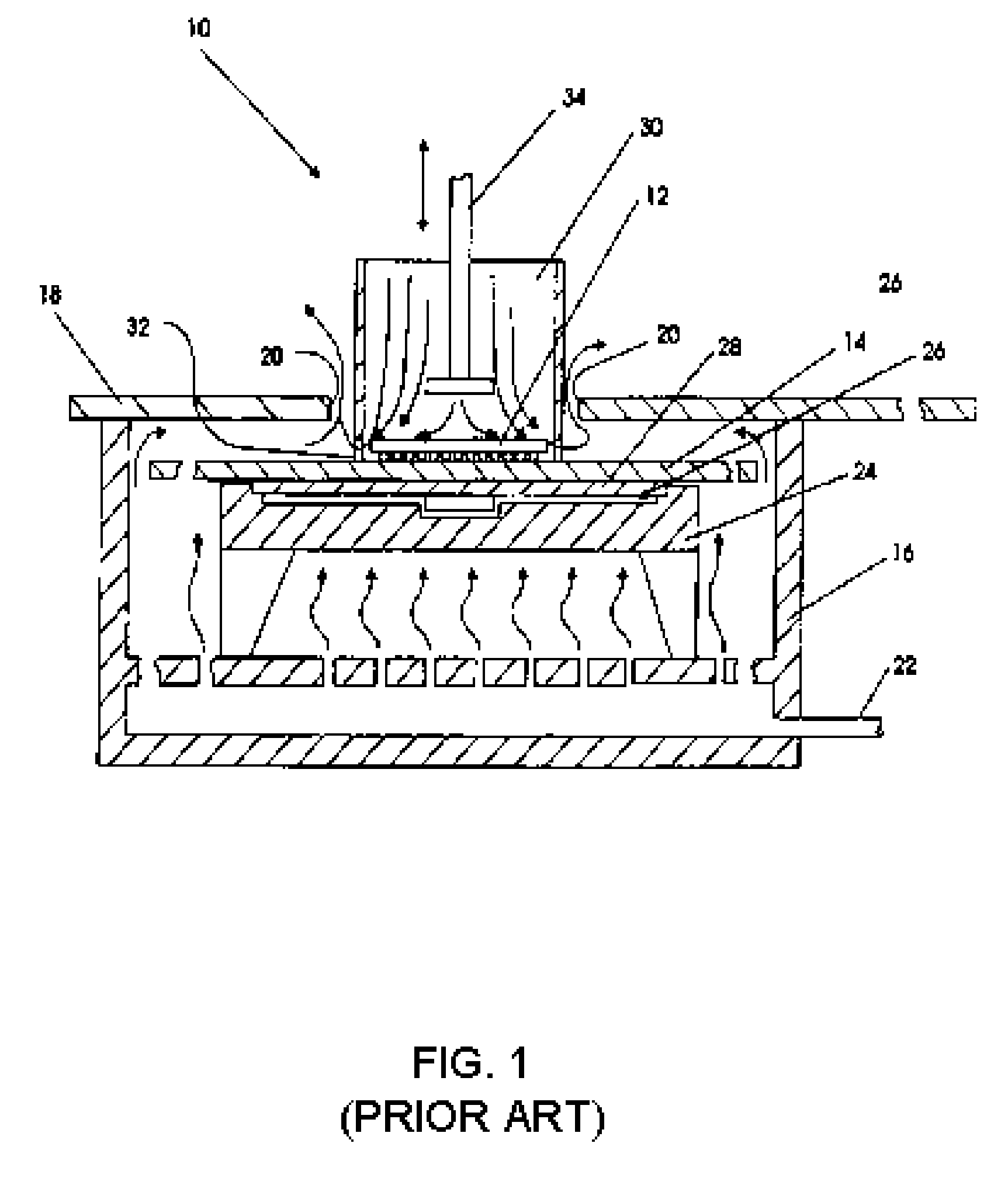

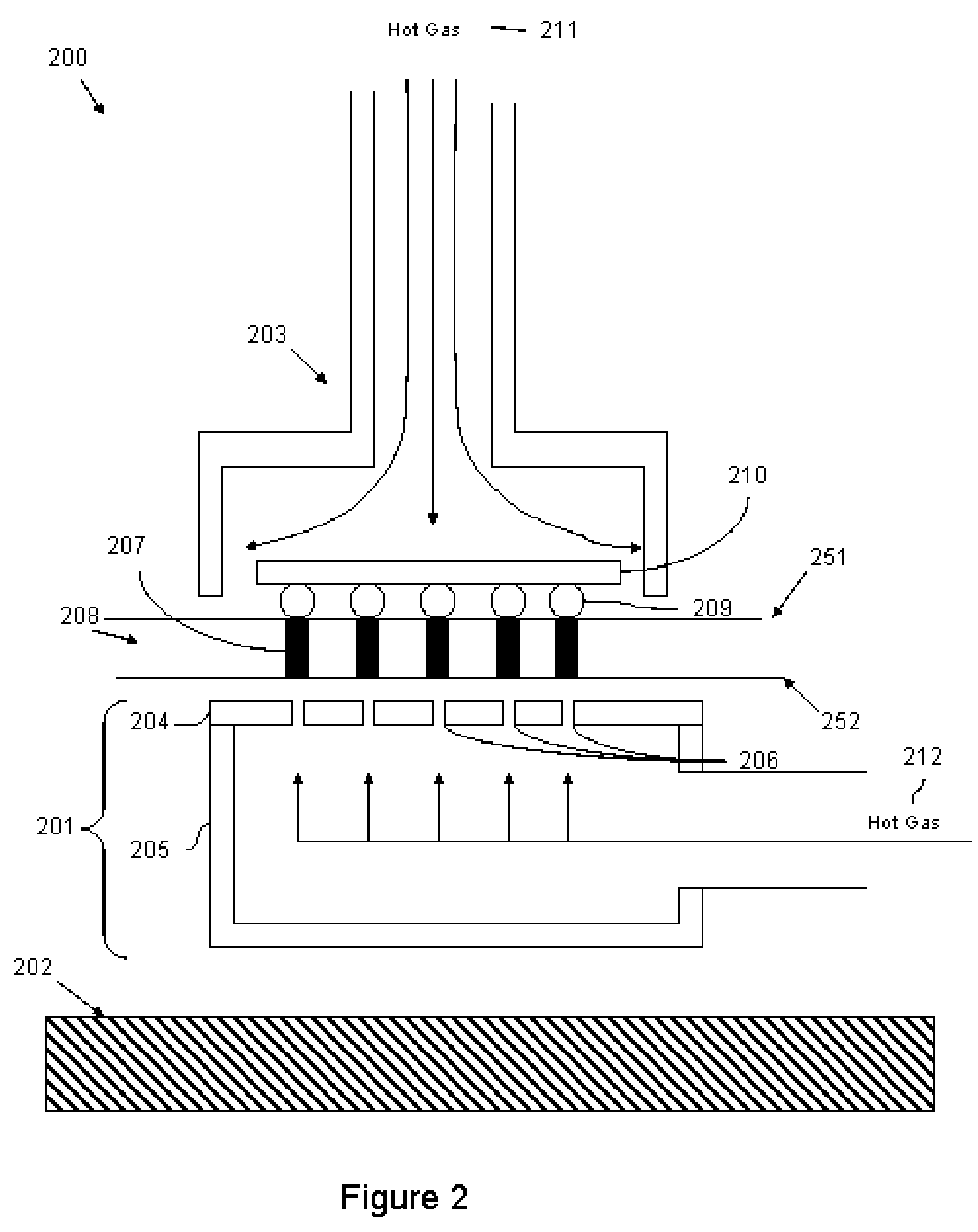

Enhanced heat system for bga/cga rework

A method and system for heating a circuit board component to an approximately uniform temperature sufficient to reflow the connections between the circuit board component and the circuit board. The method and system include a supplemental gas heater having a diffuser plate. The circuit board is placed against the diffuser plate and heated gas is channeled through openings in the diffuser plate into vias in the circuit board to heat a circuit board component connected on the opposite side of the circuit board. Heated gas can be channeled through selected vias towards predetermined areas and / or specified connections such as towards those areas or connections where there is a temperature differential greater than approximately 10 degrees Celsius compared to other areas or connections across the circuit board component. Hot gas can be channeled through selected vias by baffling or patterning the diffuser plate, accordingly.

Owner:IBM CORP

Vehicle air conditioner with hot-gas heater cycle

InactiveUS7028767B2Improve the heating effectSimple structureMechanical apparatusStationary conduit assembliesGas heaterEngineering

A vehicle air conditioner selectively switches one of a cooling mode in which an interior heat exchanger of a refrigerant cycle is operated as an evaporator for cooling air, and a heating mode in which the interior heat exchanger is operated as a radiator for heating air. In the vehicle air conditioner, an accumulator, for separating gas refrigerant and liquid refrigerant from each other and for storing the separated liquid refrigerant therein, is disposed between an outlet of the interior heat exchanger and a suction port of a compressor. Further, the accumulator includes a heating device for heating the liquid refrigerant stored in the accumulator in the heating mode. Therefore, heating performance for heating air in heating mode can be efficiently improved.

Owner:DENSO CORP

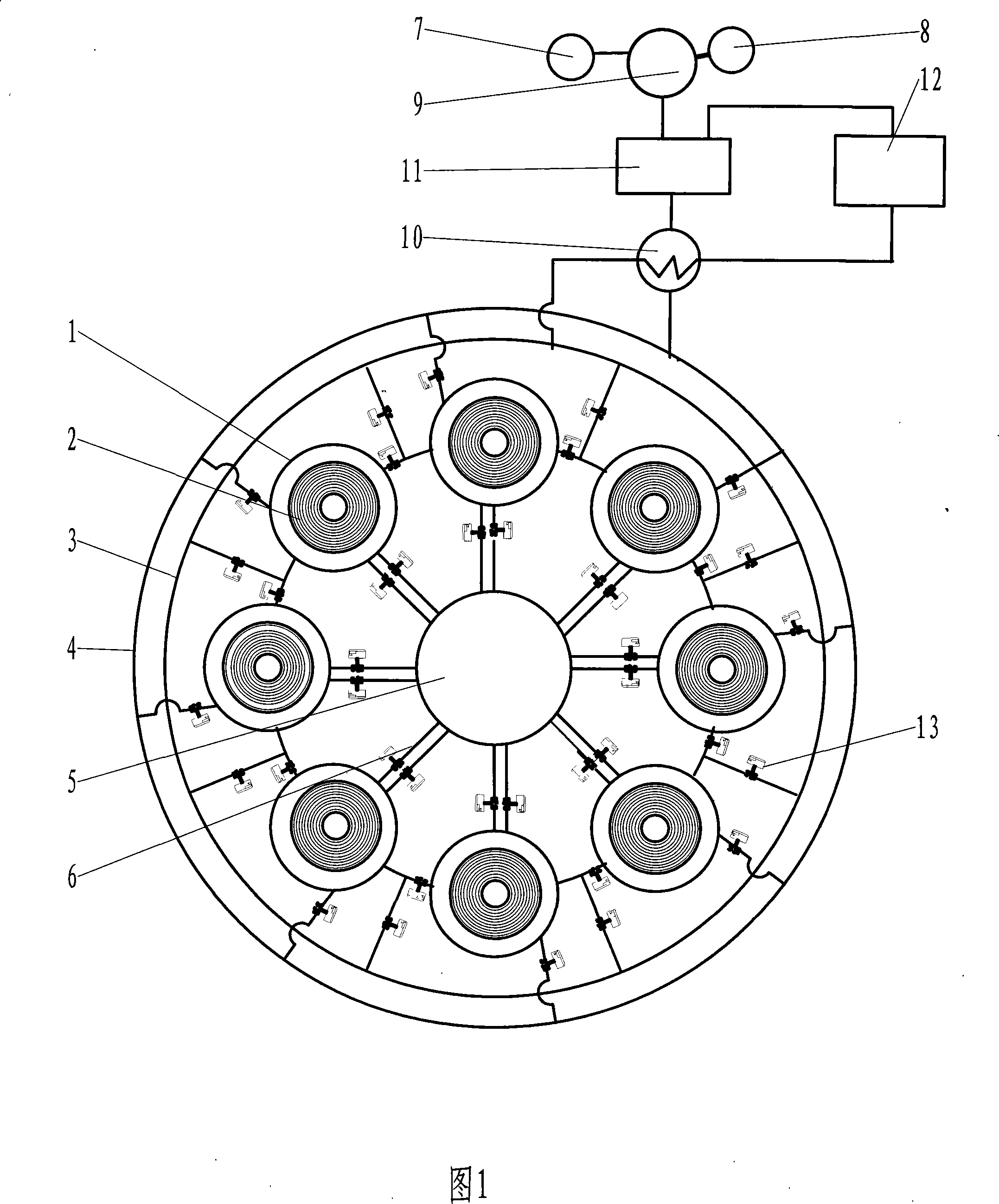

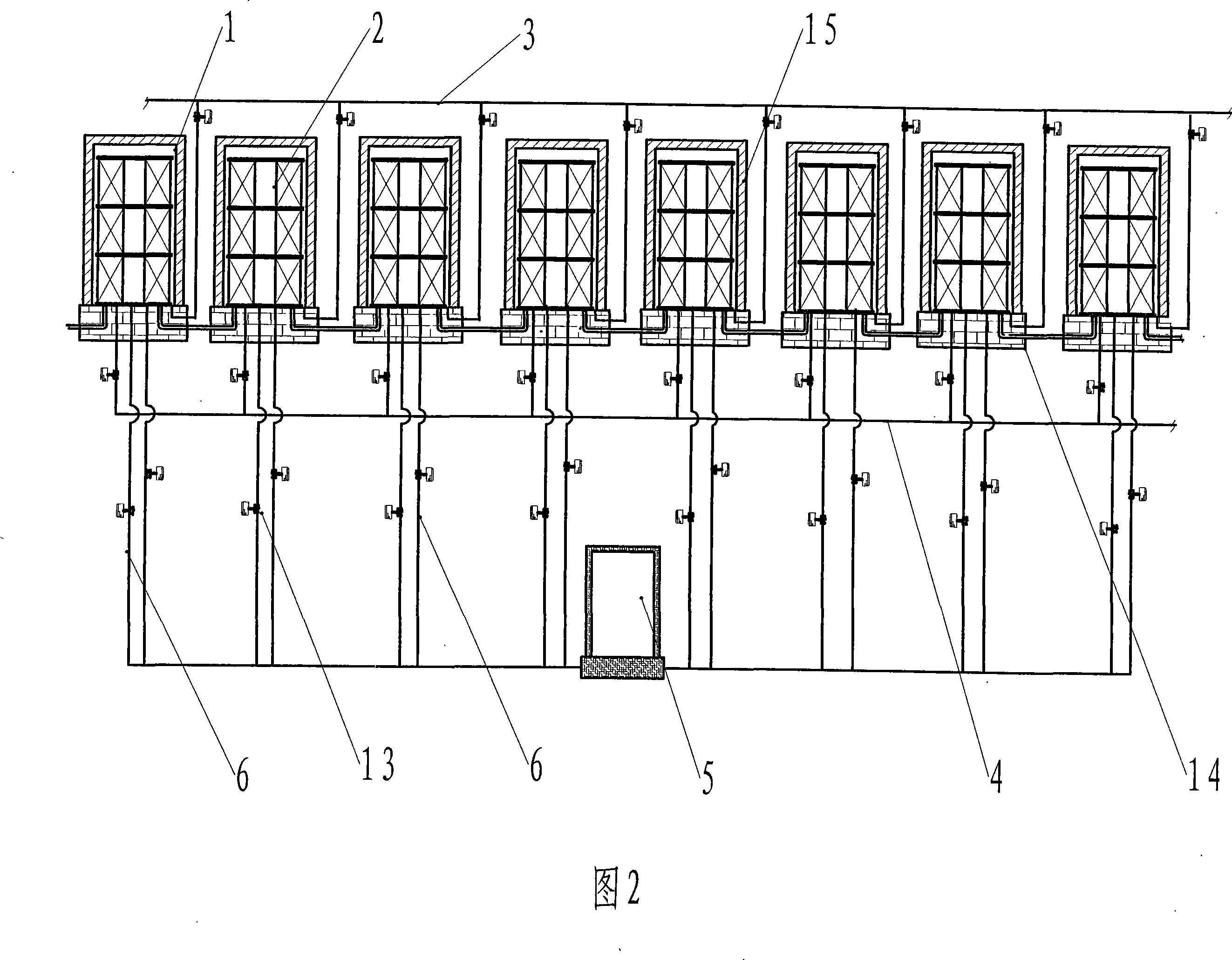

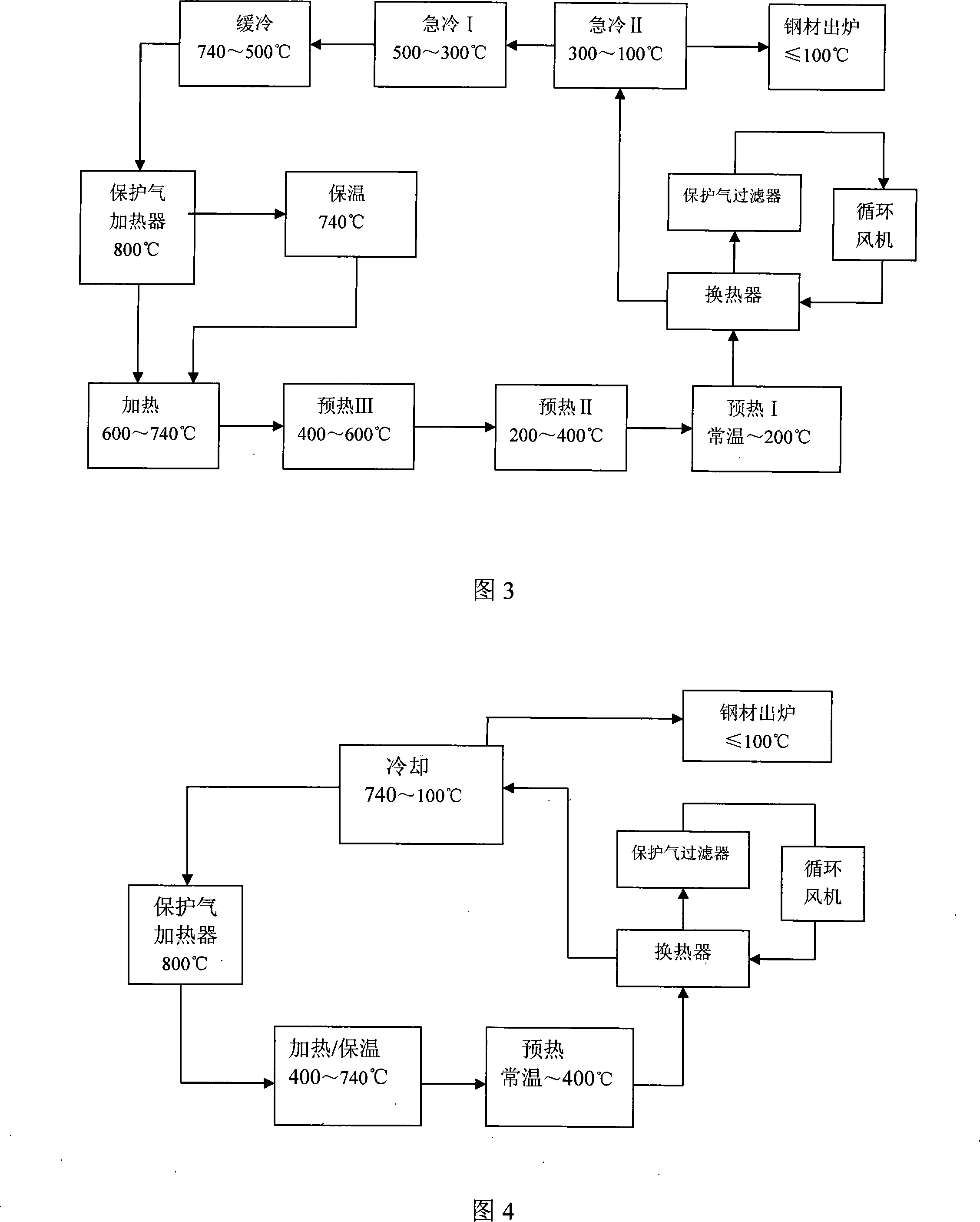

Combined hood-type furnace annealing method and annealing furnace device thereof

The invention relates to a combined cover annealing method and annealing furnace device thereof. At least two cover furnaces are installed in series, protecting gas central heater and matched feeding device are provided, using the heated protecting gas, preheat, heat, heat-insulate and cool the annealing material inside of the protective cover, the protecting gas circularly flows in the cover furnace during the annealing process, the excessive heat at high temperature stage is transferred to the next low temperature stage, the low temperature protecting gas returns to the protecting gas heater after the cooling stage, the turbid gas returns to the protecting gas system for used after filtering. Compared with current technology, the advantages of the invention reside in: the heat during the annealing process is recycling, which saves 30% to 40% of energy; no heating cover or cooling cover is used during the annealing process, heat or cool material inside the protective cover by protecting gas, which simplifies the operation process, saves equipment cost and operation expense, and the annealed material has good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com