Seawater desalination process with low cost

A low-cost, technological technology, applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve the problems of high power consumption, operating energy consumption or high production cost, and achieve burden reduction, electric power reduction, and thermal pollution reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

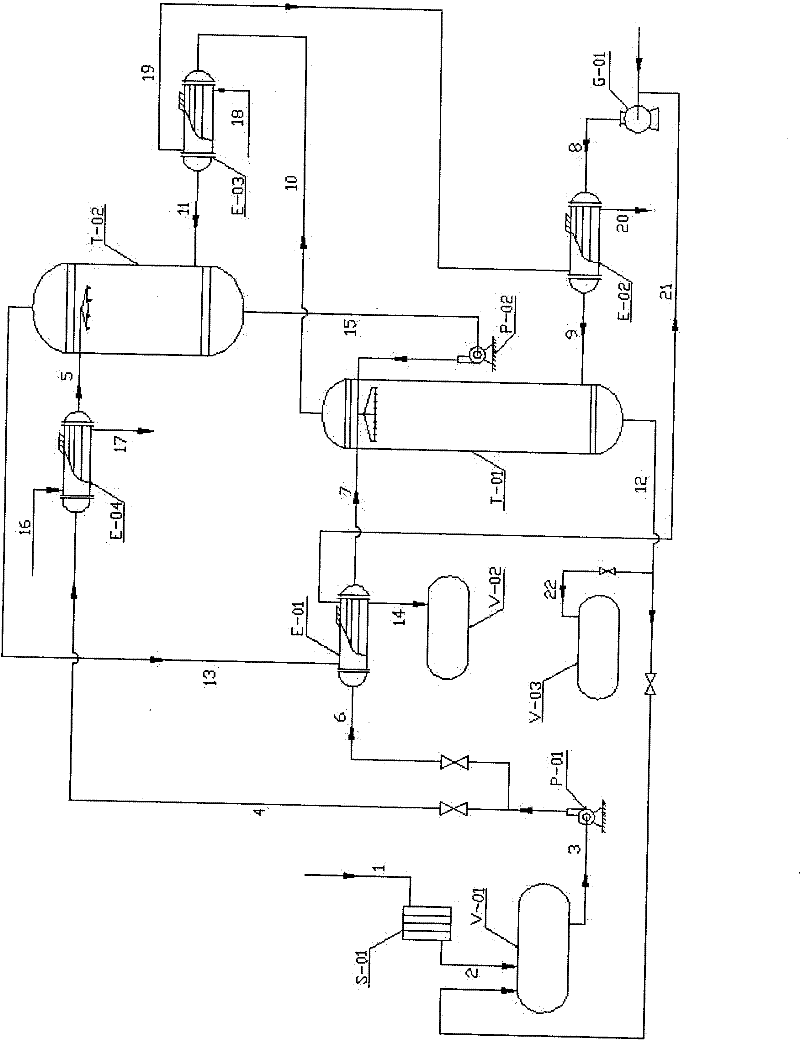

[0024] Embodiment 1: Annual production of 20,000 tons of pure water (summer)

[0025] Production facilities such as figure 1 As shown, the washing humidification tower T-01 has a diameter of 1.2 meters and a height of 10 meters, and the atomization chamber T-02 has a diameter of 1.6 meters and a height of 6 meters; the pretreated 25 ° C seawater is centrifuged at a flow rate of 38 tons / hour After the pump I P-01, it is divided into two strands. One strand is heated to 50°C by the heat exchanger I E-01 at a flow rate of 31 tons / hour, and then enters the top of the washing humidification tower T-01 for spraying. The flow rate of 7 tons / hour is heated to 75°C by heat exchanger IVE-04 and enters T-02 for atomization; 32°C natural air passes through blower G-01 to 10000m 3 The flow rate of / hr is heated to 48°C by heat exchanger II E-02 and then enters the bottom of washing and humidifying tower T-01. After heating and humidifying, it is heated again by heat exchanger III E-03 to ...

Embodiment 2

[0026] Embodiment 2: Annual production of 10,000 tons of pure water (winter)

[0027] Production facilities such as figure 1 As shown, the washing humidification tower T-01 has a diameter of 0.9 meters and a height of 8 meters, and the atomization chamber T-02 has a diameter of 1.2 meters and a height of 5 meters; the pretreated 5°C seawater is centrifuged at a flow rate of 18 tons / hour After the pump I P-01, it is divided into two streams, one stream is heated to 46°C through the heat exchanger I E-01 at a flow rate of 14 tons / hour, and then enters the top of the washing humidification tower T-01 for spraying, and the other stream is sprayed at the top of the washing humidification tower T-01. The flow rate of 4 tons / hour is heated to 70°C by heat exchanger IV E-04 and then enters the atomization chamber T-02 for atomization; the natural air at 5°C passes through the blower G-01 to 6000m 3 The flow rate of / hr is heated to 39°C by heat exchanger II E-02 and then enters the b...

Embodiment 3

[0028] Embodiment 3: Annual production of 20,000 tons of pure water (winter)

[0029] Production facilities such as figure 1 As shown, the washing humidification tower T-01 has a diameter of 1.2 meters and a height of 10 meters, and the atomization chamber T-02 has a diameter of 1.6 meters and a height of 6 meters; the pretreated 5°C seawater is centrifuged at a flow rate of 38 tons / hour After the pump I P-01, it is divided into two streams. One stream passes through the heat exchanger I E-01 to 46°C at a flow rate of 31 tons / hour, and then enters the top of the washing and humidifying tower T-01 for spraying. The flow rate of 7 tons / hour is heated to 70°C by heat exchanger IV E-04 and then enters the atomization chamber T-02 for atomization; the natural air at 5°C passes through the blower G-01 to 12000m 3 The flow rate of / hr is heated to 39°C by heat exchanger II E-02 and then enters the bottom of washing and humidifying tower T-01. After heating and humidifying, it is heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com