Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3249results about "Apparatus for fluidised bed combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

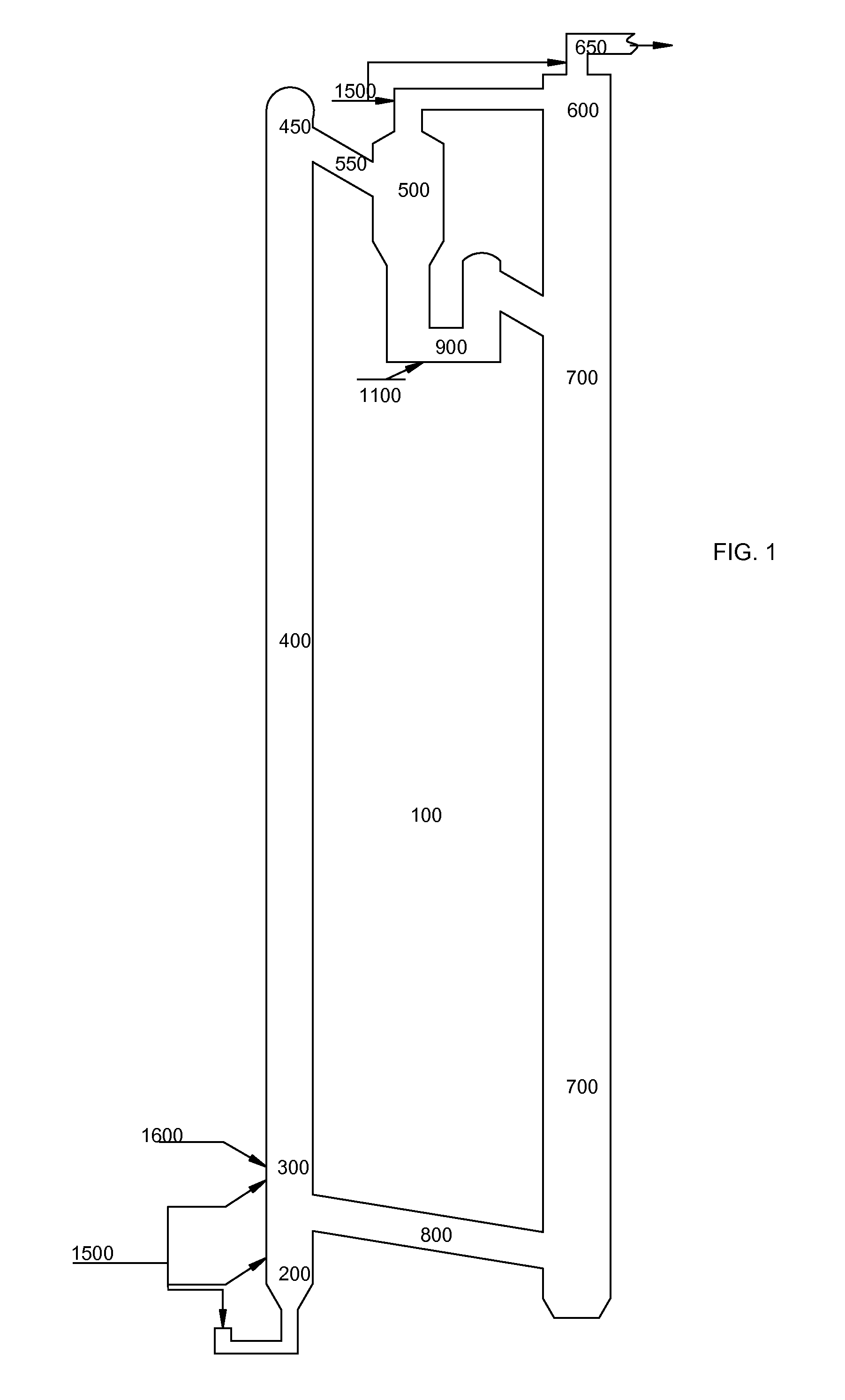

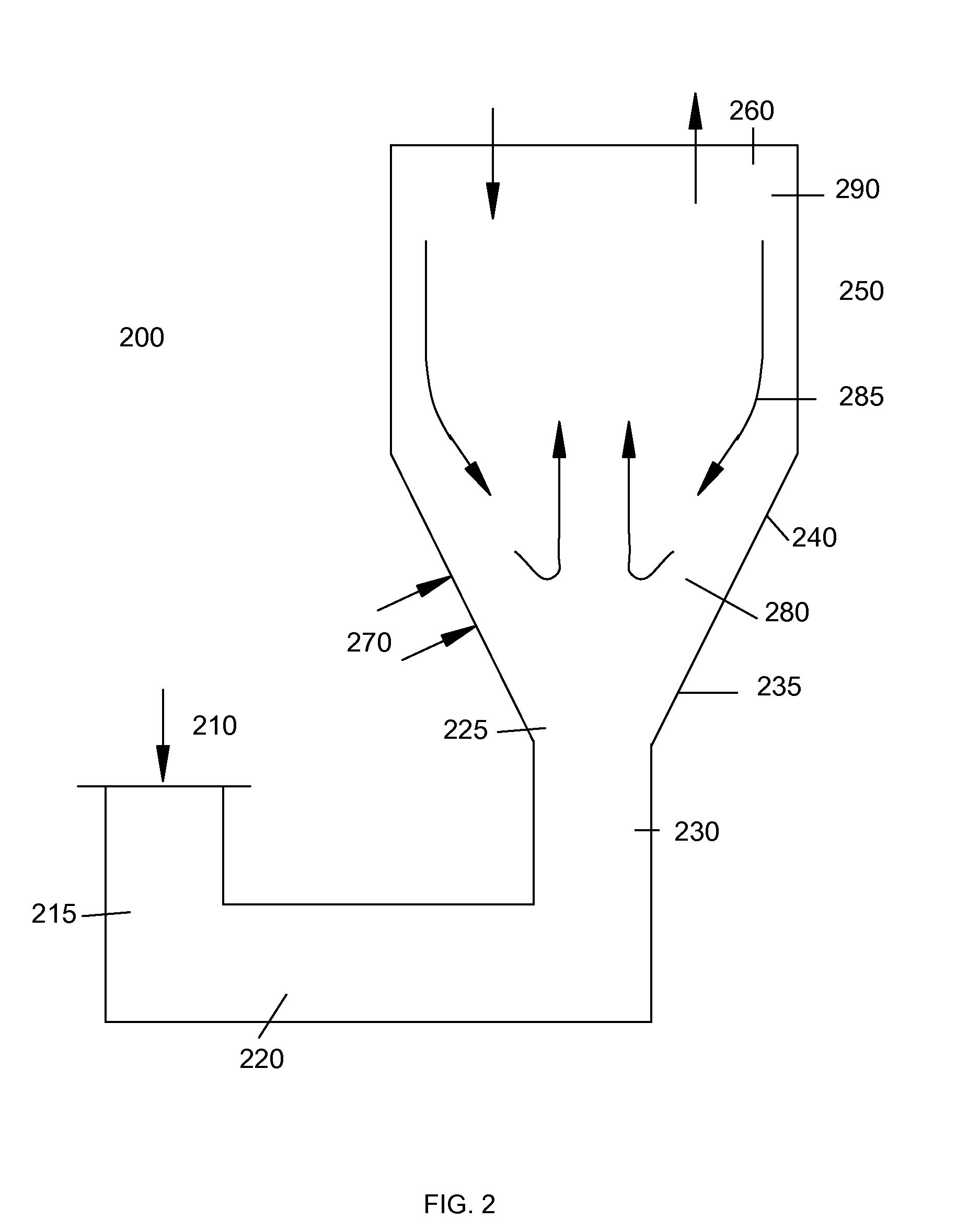

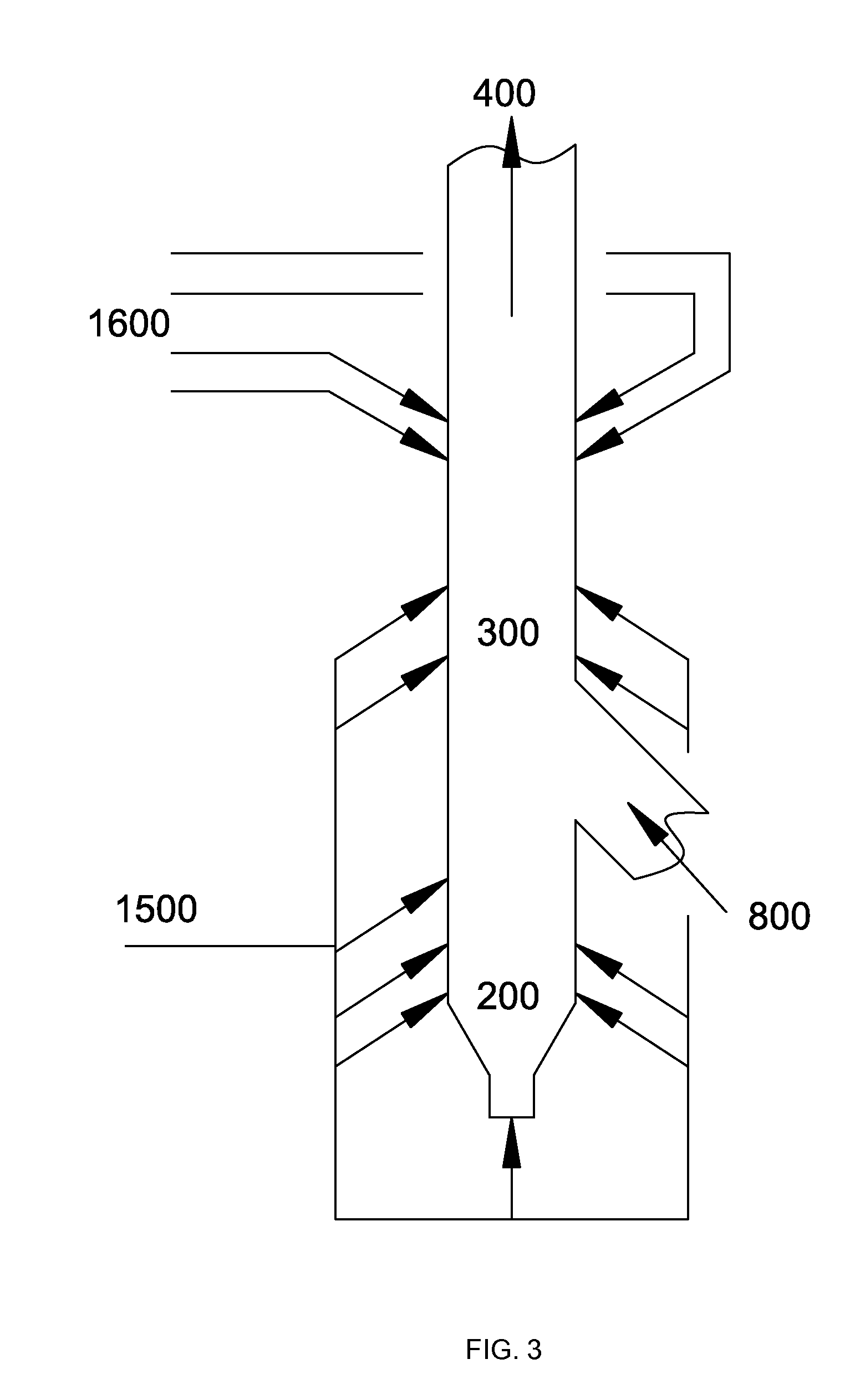

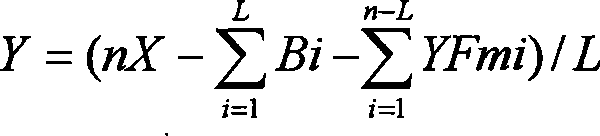

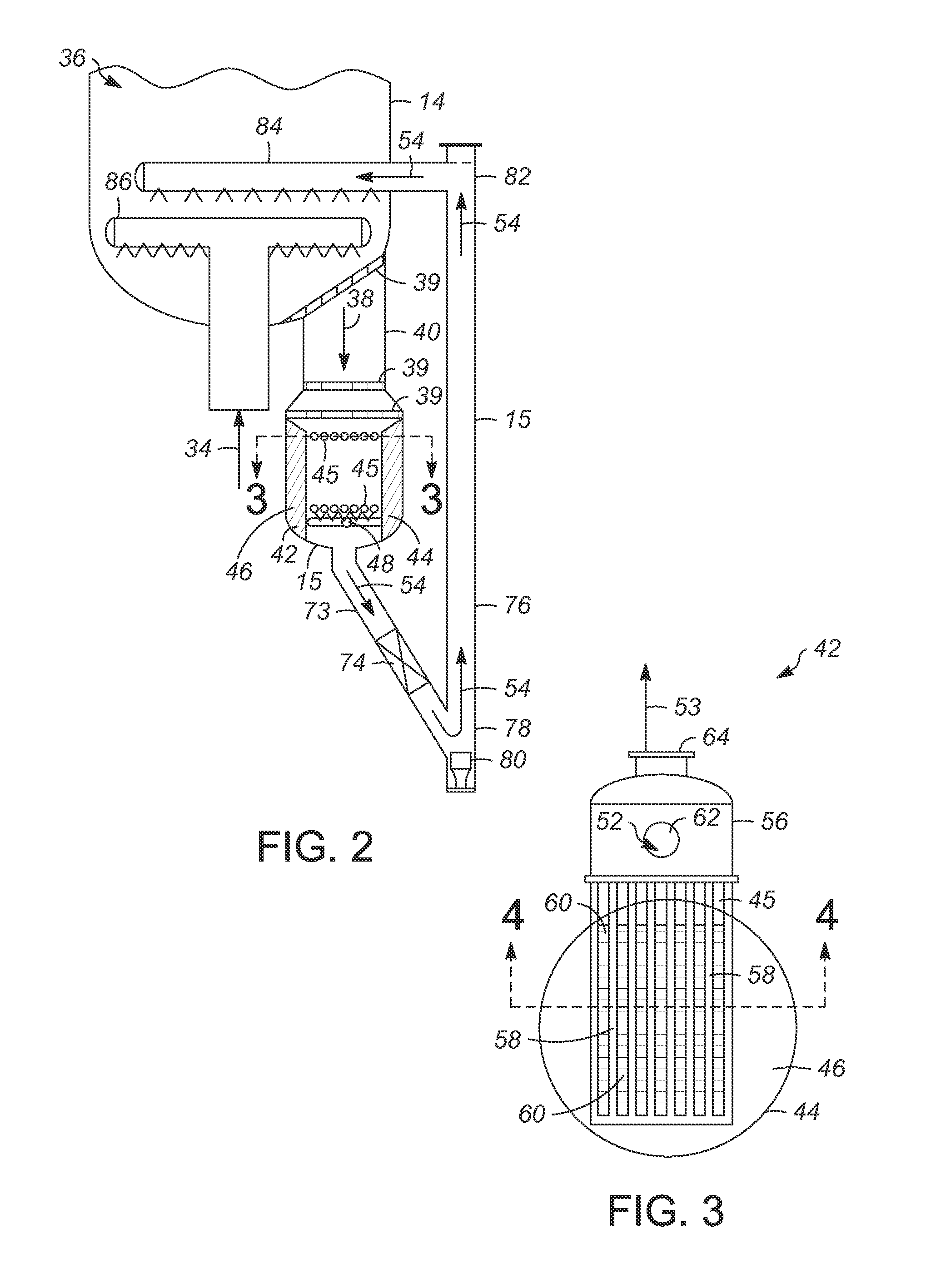

Apparatus, Components and Operating Methods for Circulating Fluidized Bed Transport Gasifiers and Reactors

ActiveUS20110146152A1Reduce and prevent reverse flow of gasOvercome problemsHydrogenFluidized bed combustionCycloneFluidized bed

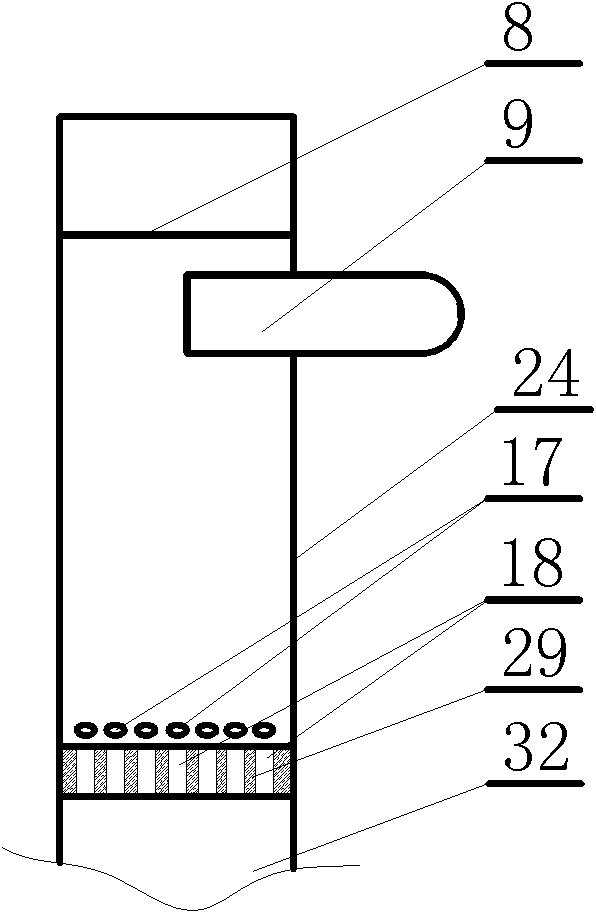

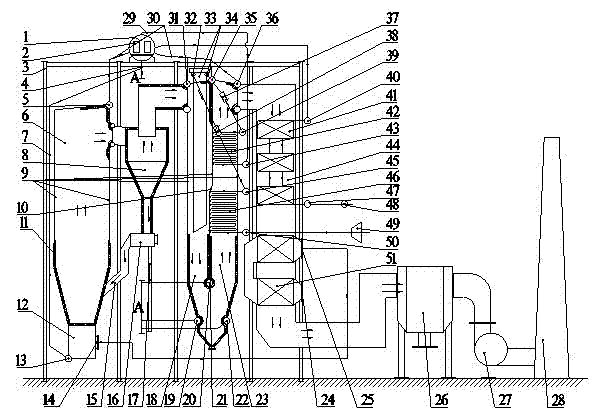

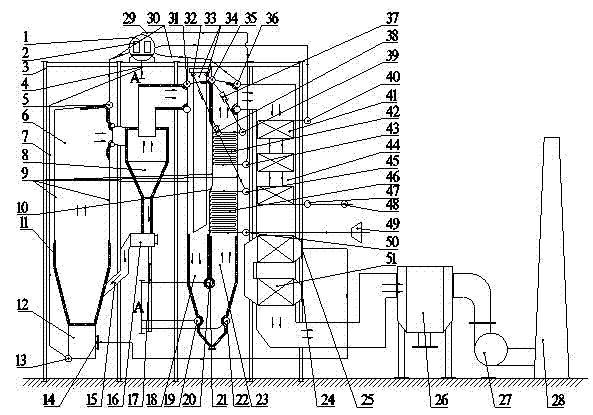

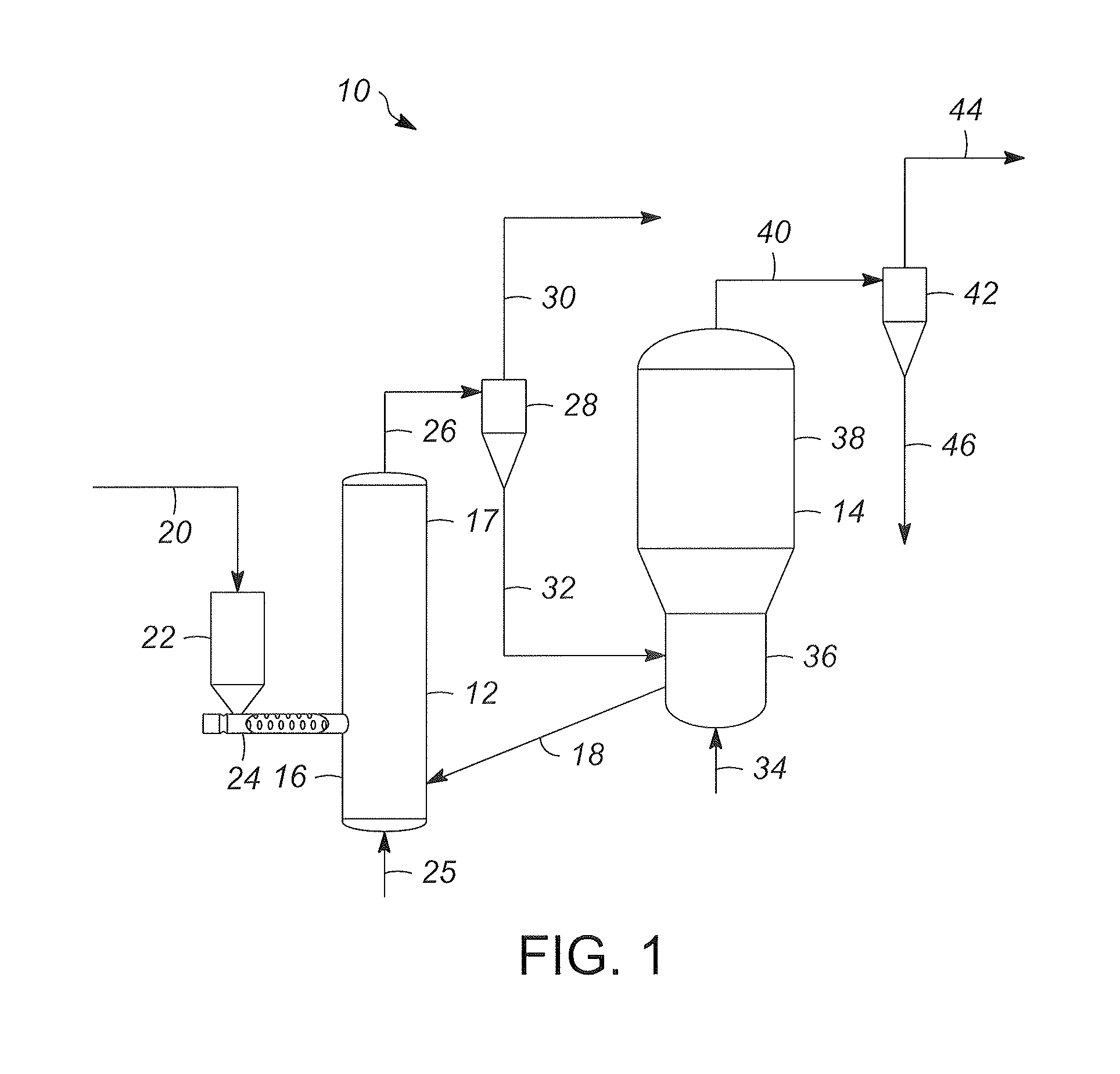

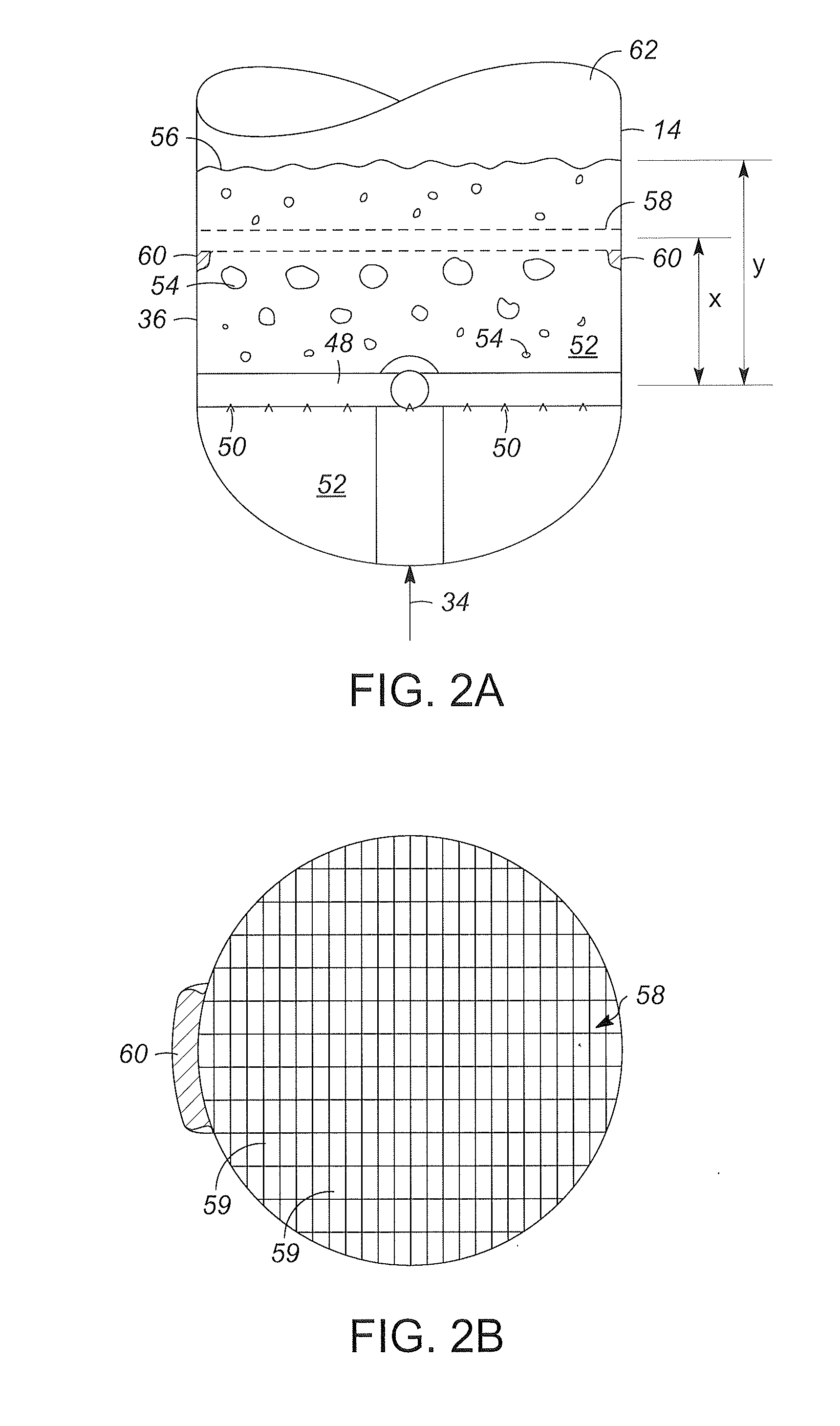

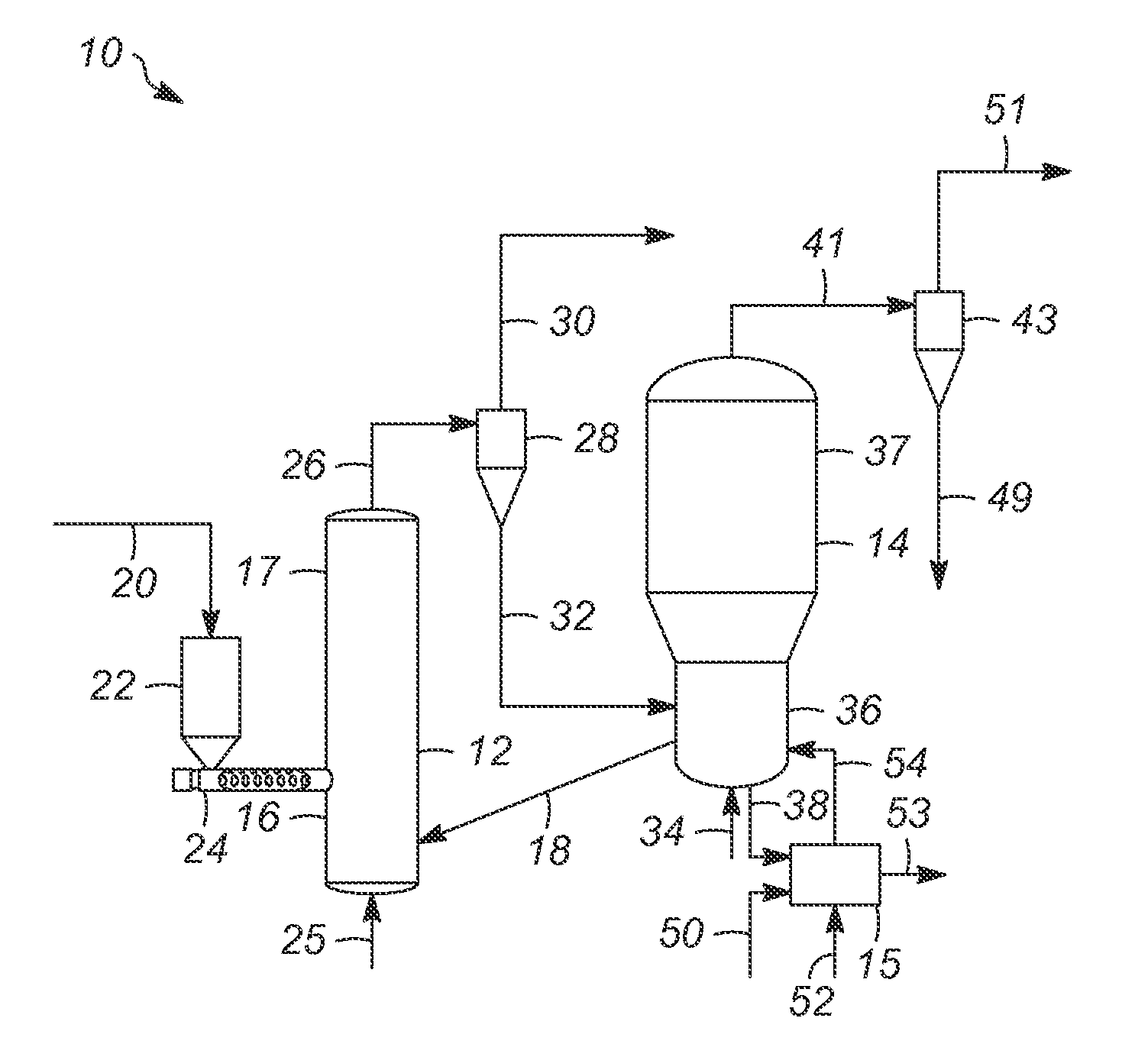

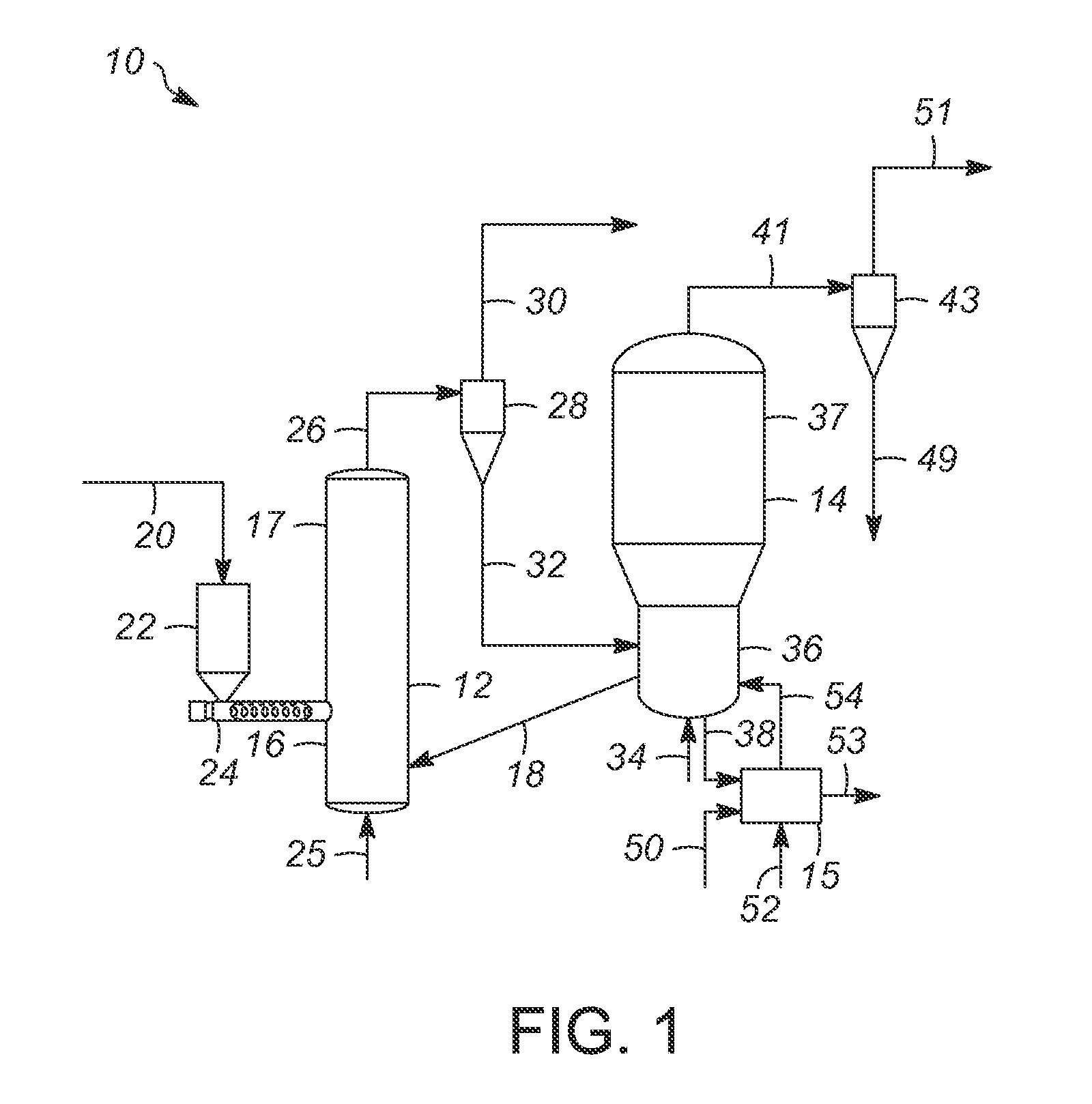

The improvements proposed in this invention provide a reliable apparatus and method to gasify low rank coals in a class of pressurized circulating fluidized bed reactors termed “transport gasifier.” The embodiments overcome a number of operability and reliability problems with existing gasifiers. The systems and methods address issues related to distribution of gasification agent without the use of internals, management of heat release to avoid any agglomeration and clinker formation, specific design of bends to withstand the highly erosive environment due to high solid particles circulation rates, design of a standpipe cyclone to withstand high temperature gasification environment, compact design of seal-leg that can handle high mass solids flux, design of nozzles that eliminate plugging, uniform aeration of large diameter Standpipe, oxidant injection at the cyclone exits to effectively modulate gasifier exit temperature and reduction in overall height of the gasifier with a modified non-mechanical valve.

Owner:SOUTHERN COMPANY SERVICES

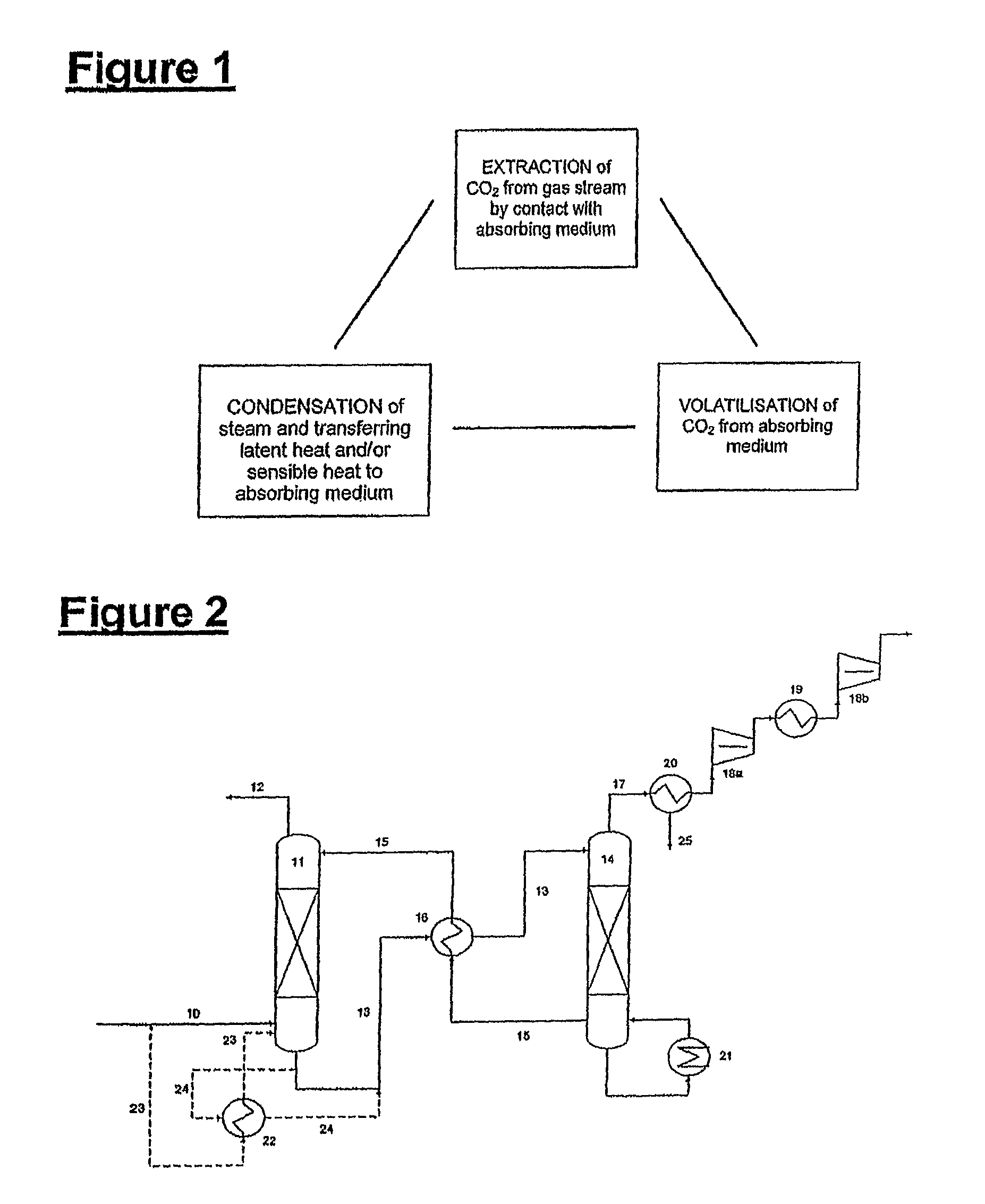

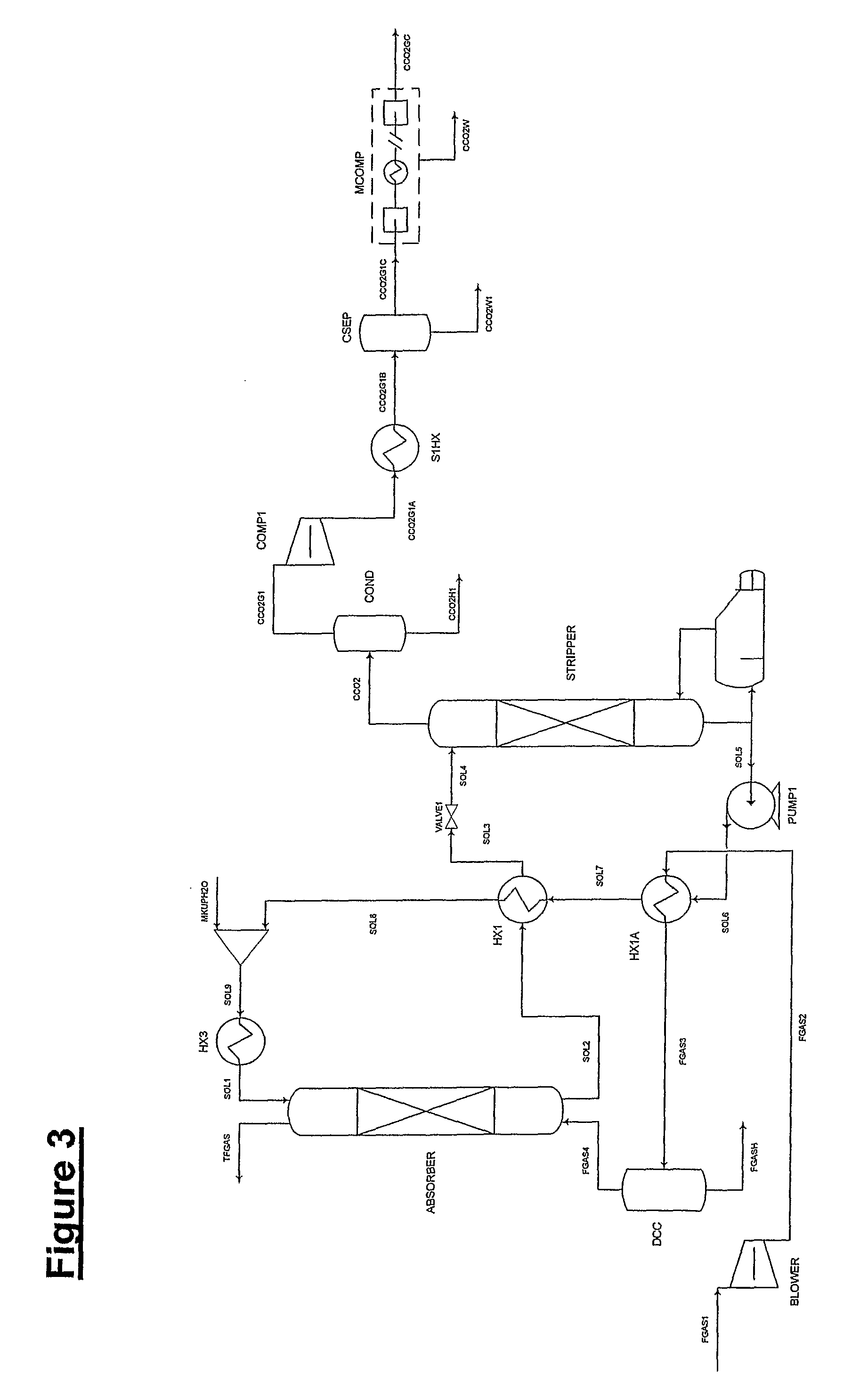

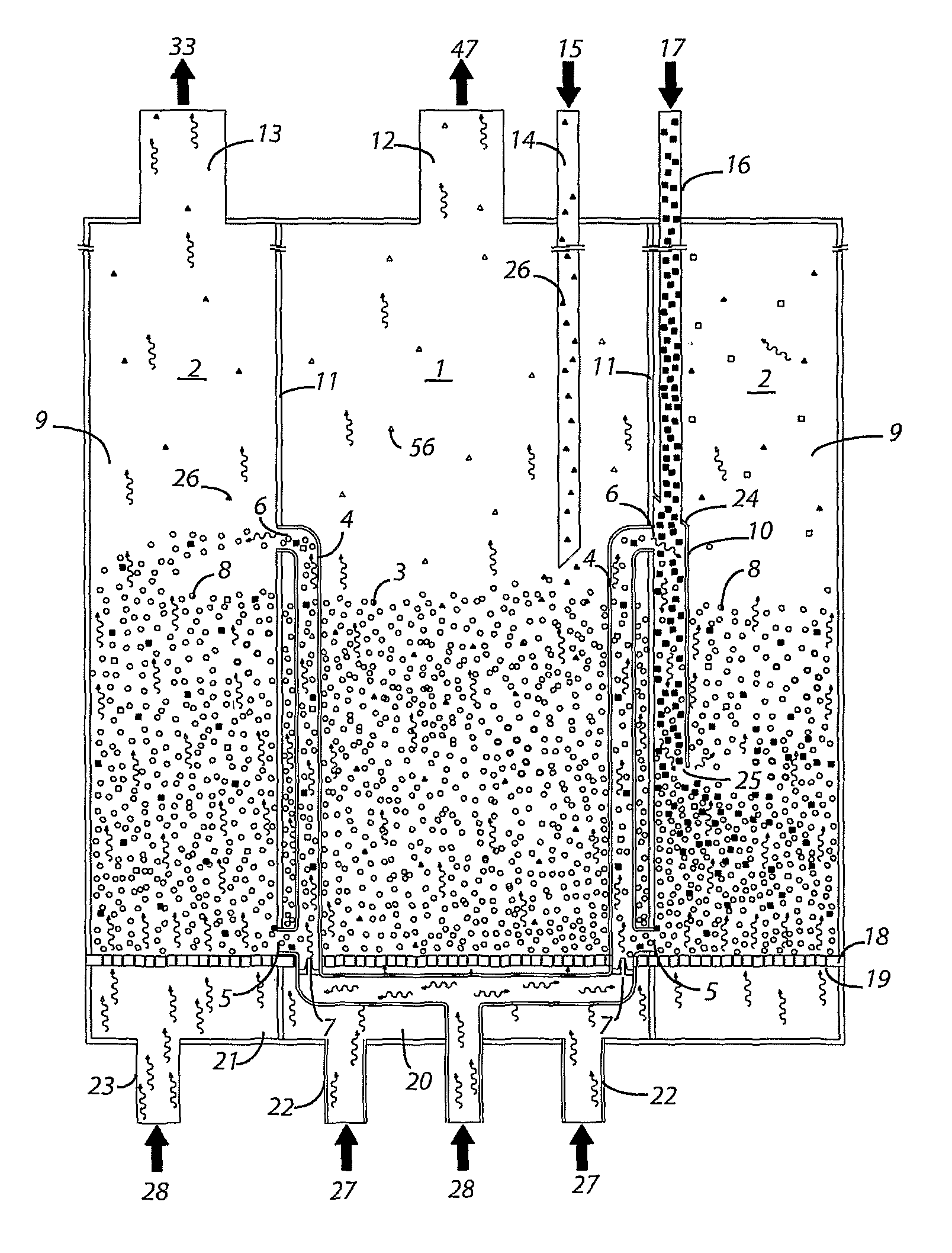

Plant and process for removing carbon dioxide from gas streams

ActiveUS7976803B2Minimizing overall energy requiredAssist in volatilizationFluidized bed combustionIndirect heat exchangersComponents of crude oilCoal

Owner:KC8 CAPTURE TECH LTD

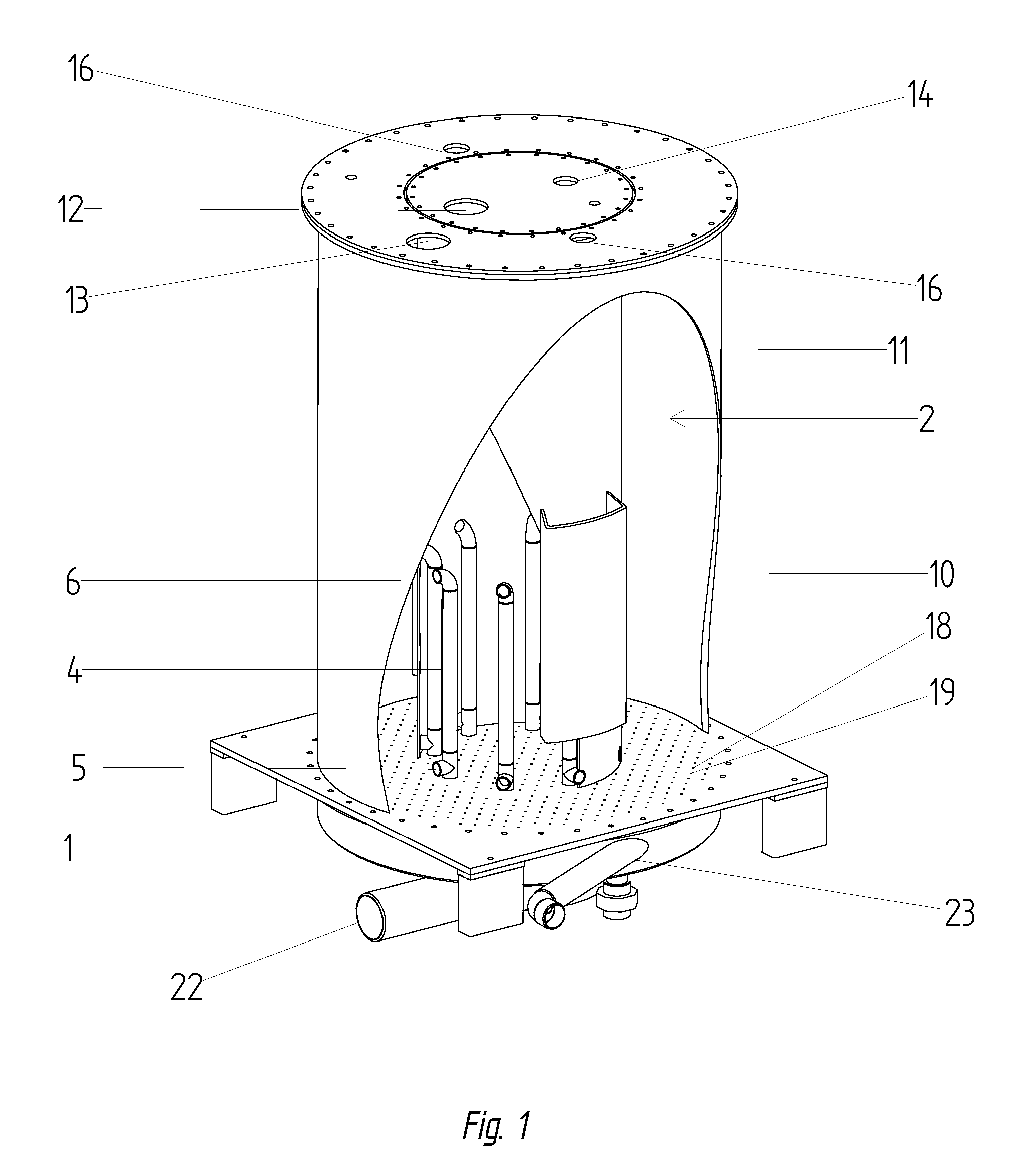

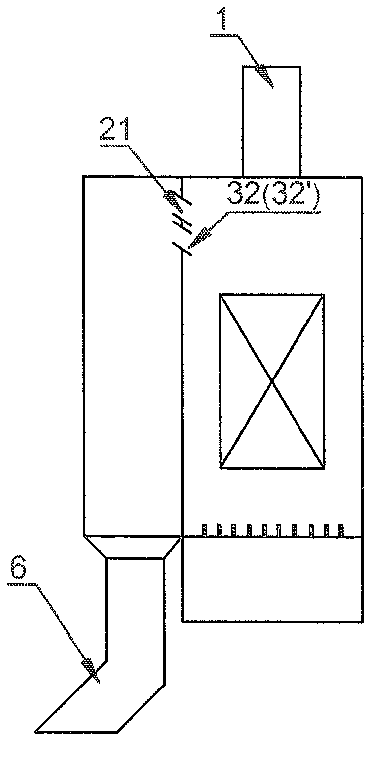

Apparatus and process for the pyrolysis of agricultural biomass

InactiveUS7943014B2Avoid cloggingPrevent escapeFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

Method and device for pyrolyzing and gasifying organic substances or substance mixtures

InactiveUS7214252B1Small particle sizeAllow useFluidized bed combustionSolid waste disposalReaction zoneAmount of substance

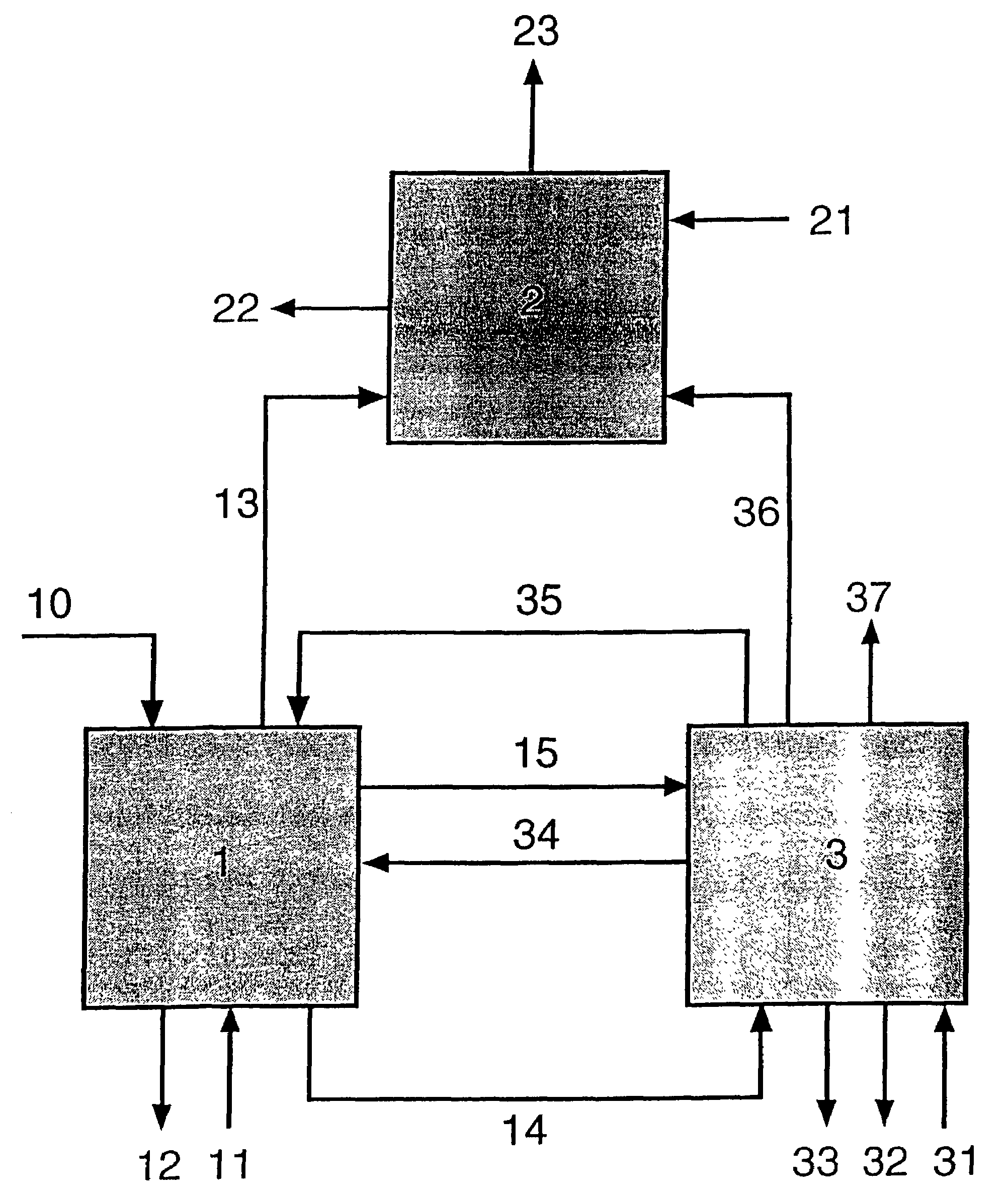

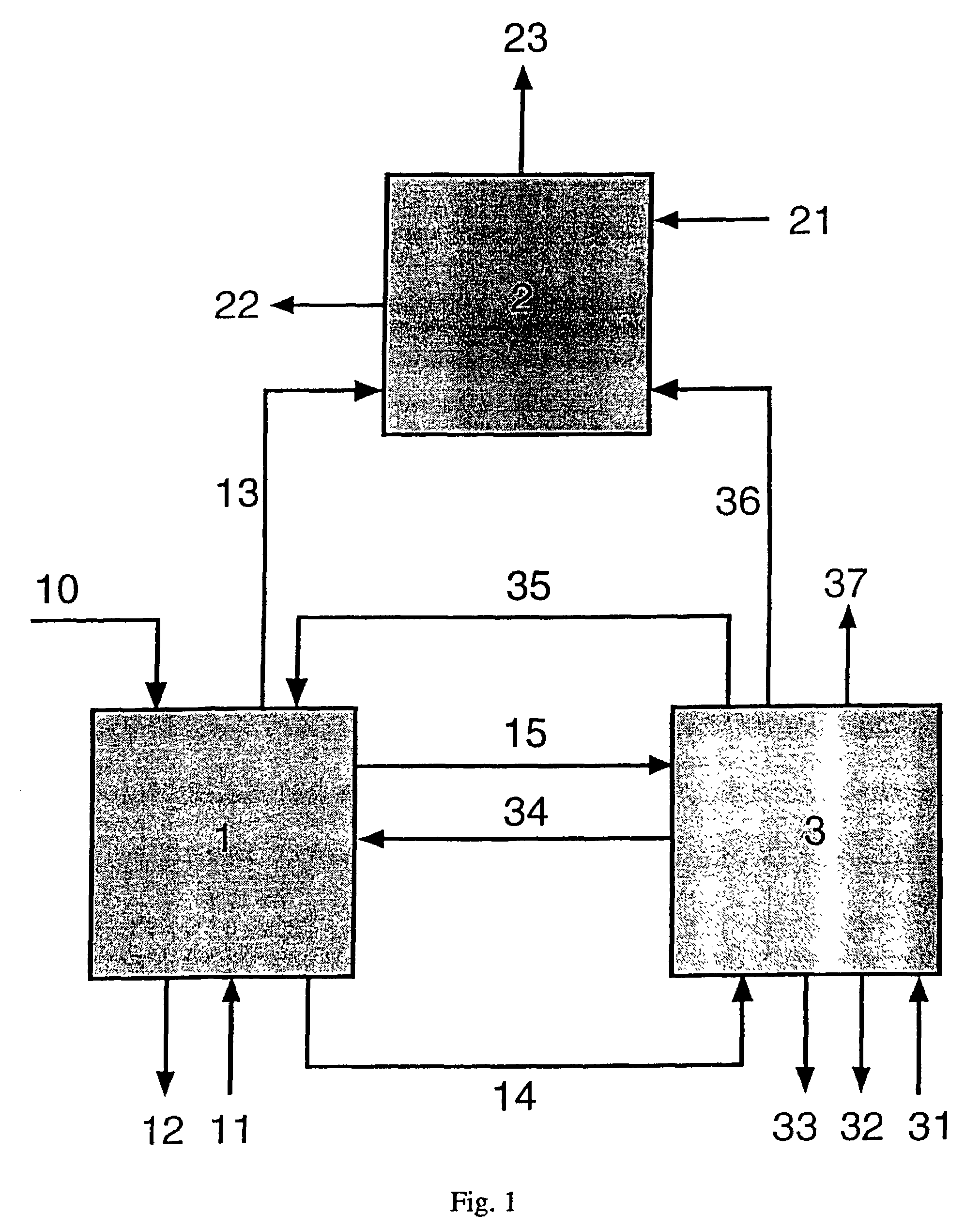

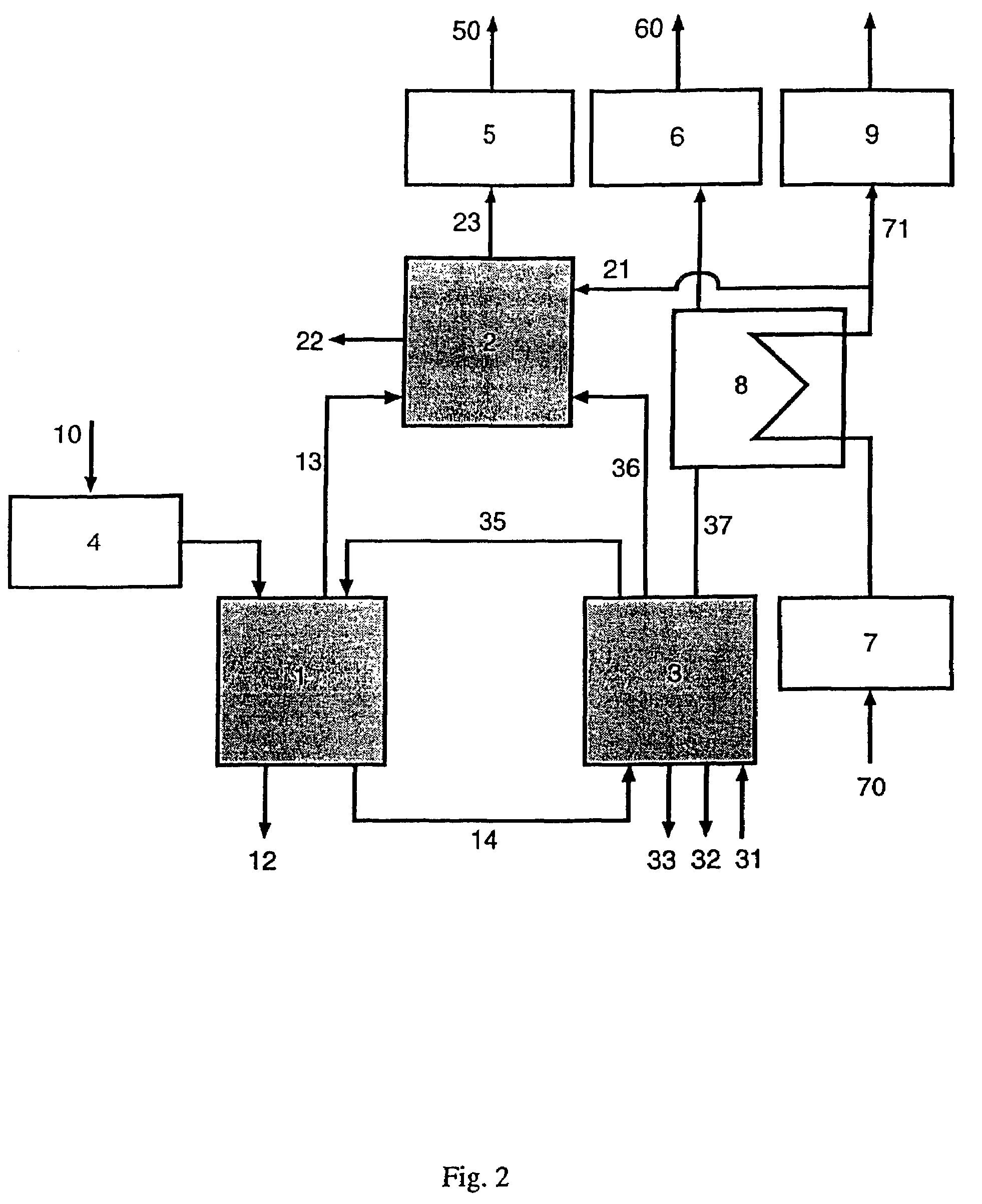

An apparatus for pyrolysis and gasification of organic substances and mixtures thereof is provided with a pyrolysis reactor (1), a fluidized-bed firing (3) for pyrolysis residue, a reaction zone (2) for the pyrolysis gases (13) and circulating fluidized-bed material (35). The pyrolysis reactor (1) has a sluice for introducing application material (10) thereinto. An inlet for the fluidized-bed material (35) is disposed next to the combustion fluidized bed (3). Transport apparatus (14) for mixture of solid pyrolysis residue and circulating fluidized bed material (35) is disposed at or near a bottom of the fluidized bed (3) and lower end of the pyrolysis reactor (1). An overflow is situated at or near the top of the fluidized bed (3) while a heat transfer member is positioned within the reaction zone (2).

Owner:HERHOF UMWELTTECHN

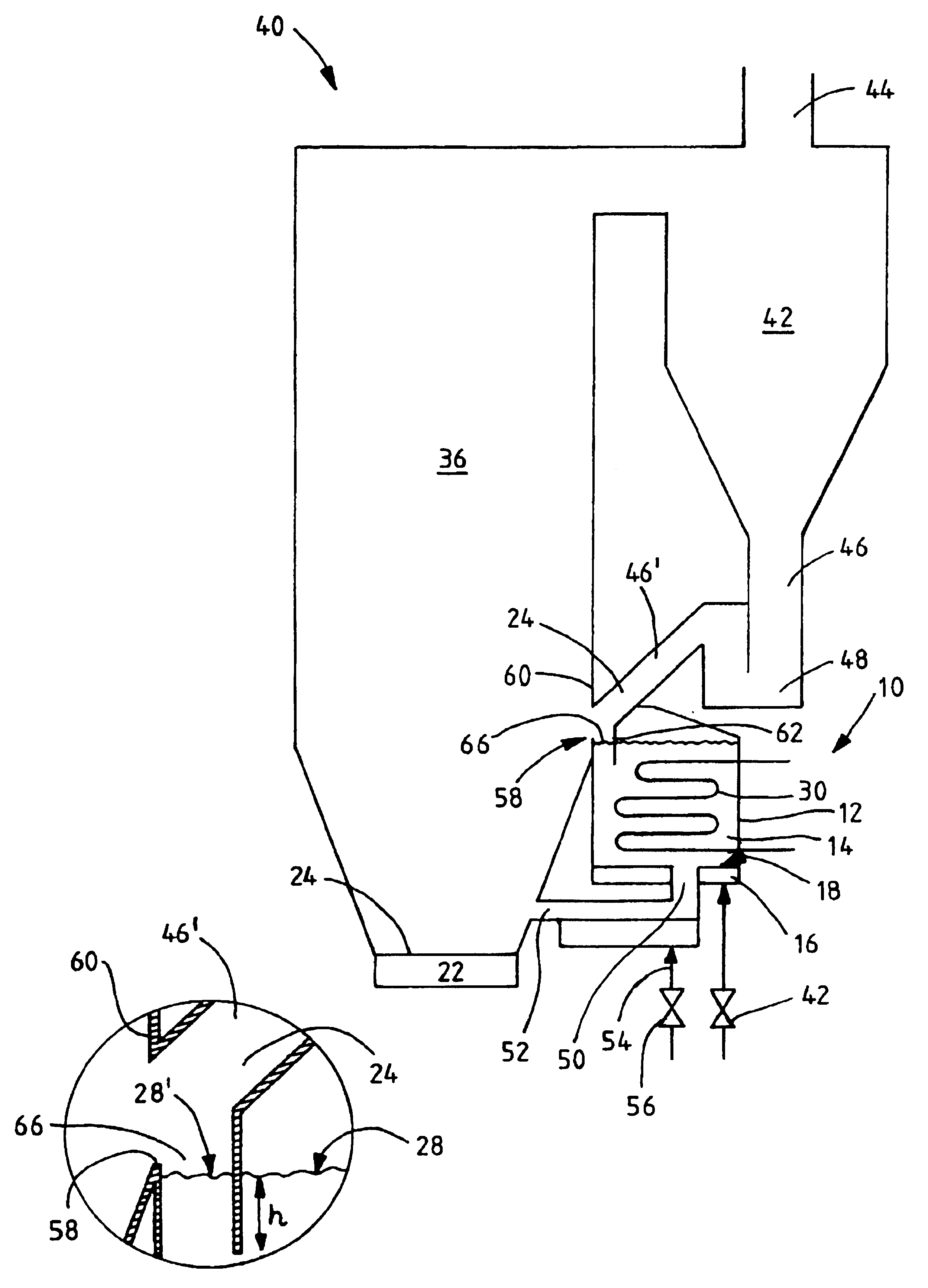

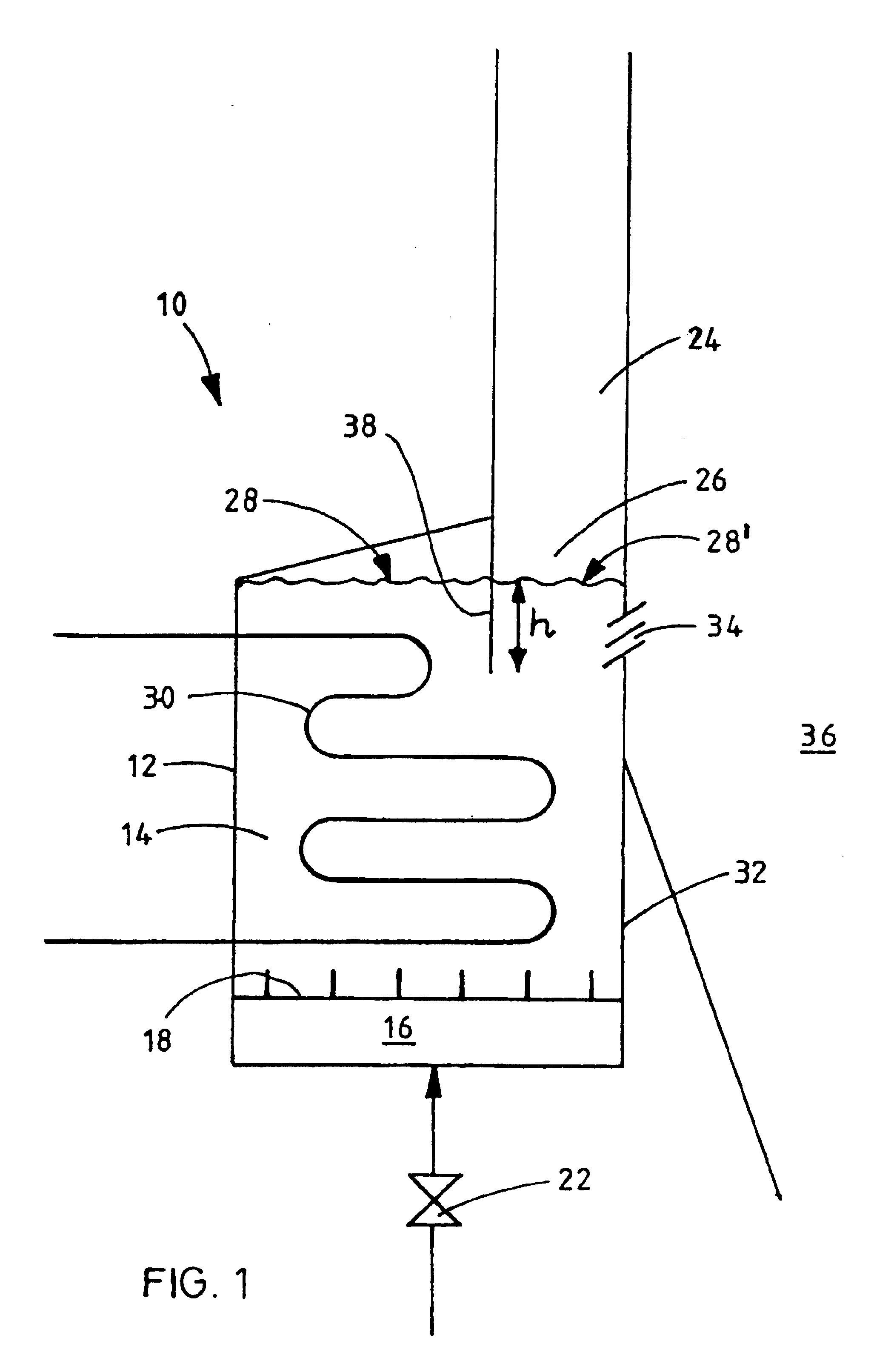

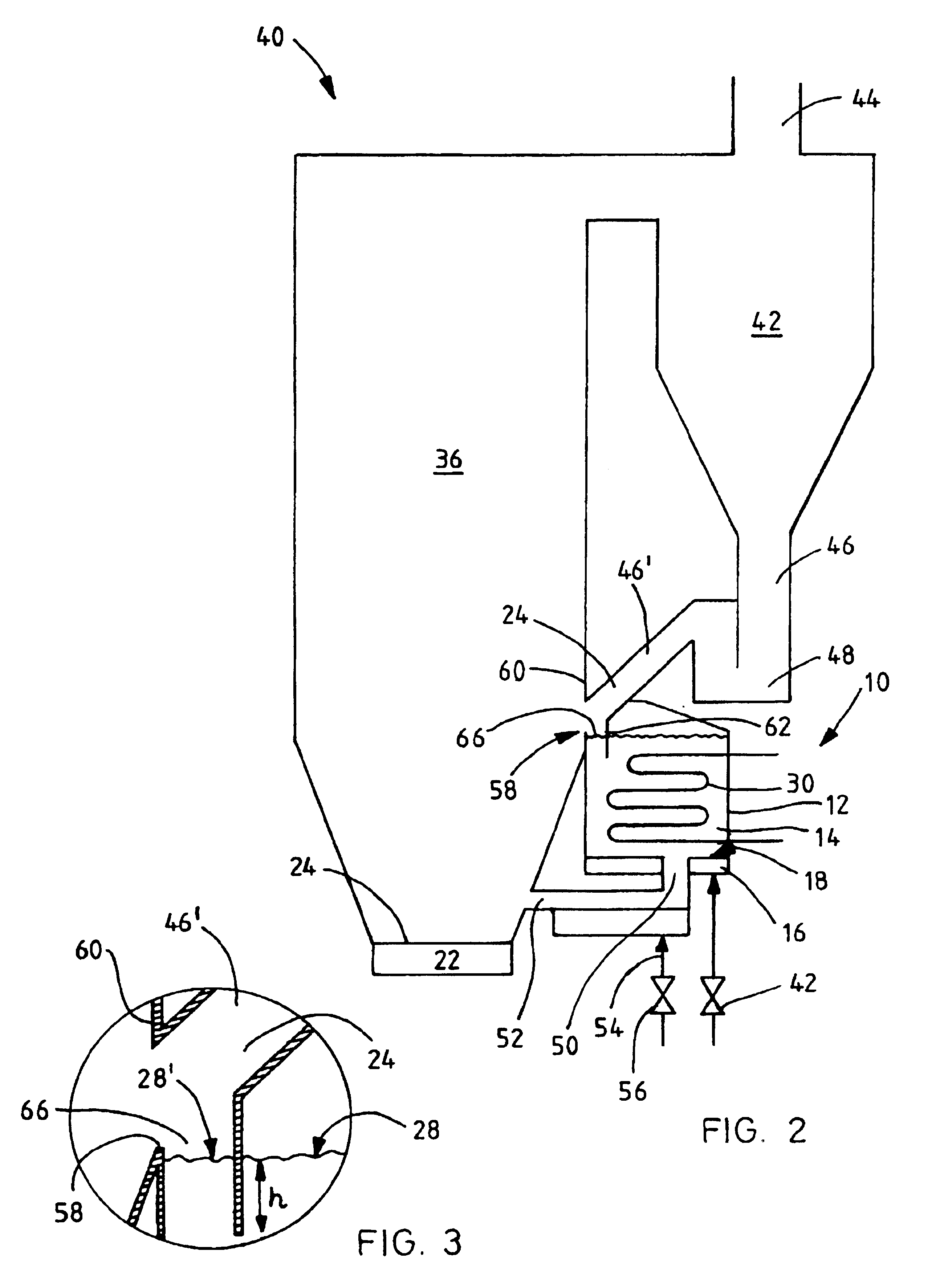

Method and apparatus in a fluidized bed heat exchanger

InactiveUS6962676B1Easy to adjustEfficient and wide-ranging adjustment of heat transferFluidized bed combustionFluidised-bed furnacesFluidized bedEngineering

A method and an apparatus in a fluidized bed heat exchanger including a heat exchange chamber having a fluidized bed of solid particles, heat transfer surfaces, an inlet, and an outlet. Particles are fed through the inlet onto the upper surface of the bed of solid particles by a guiding channel. The guiding channel, which extends from above the upper surface of the bed of solid particles to the surface thereof, or to below the surface, passes the solid particles to the restricted area of the surface. The outlet is formed in the area of the guiding channel to remove particles from the area delimited by the guiding channel. Uncooled particles can thus be removed from the heat exchange chamber.

Owner:FOSTER WHEELER ENERGIA OY

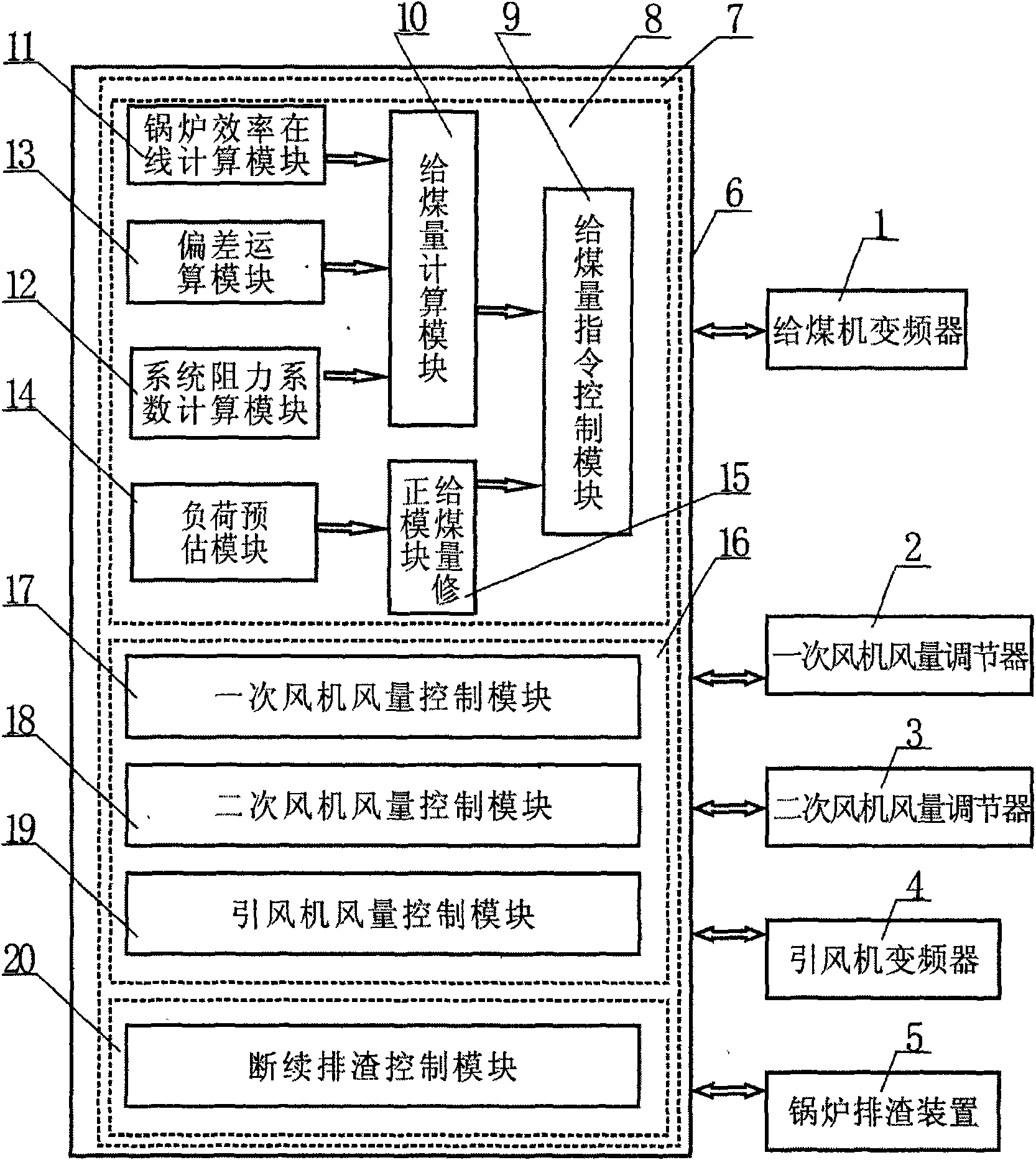

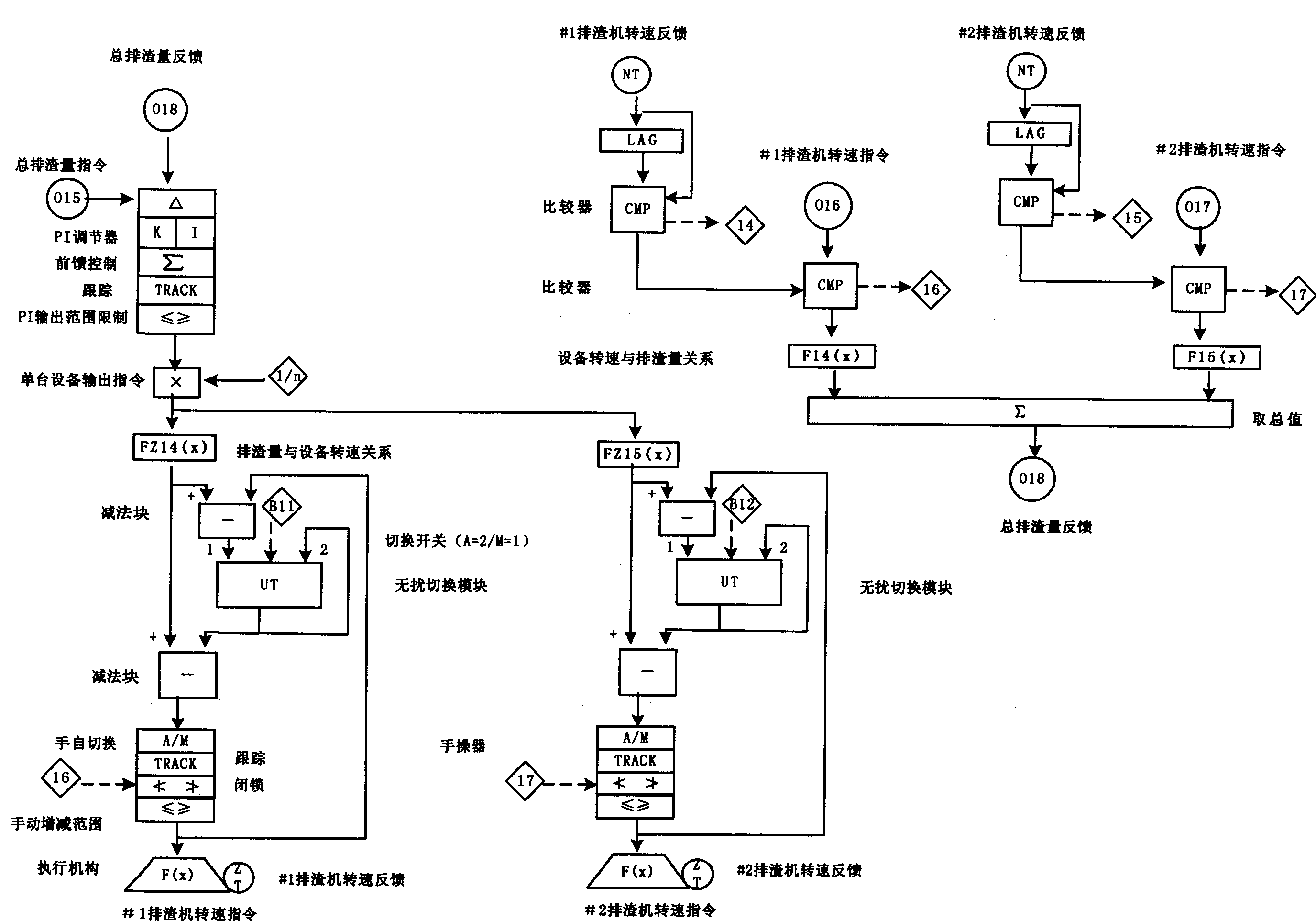

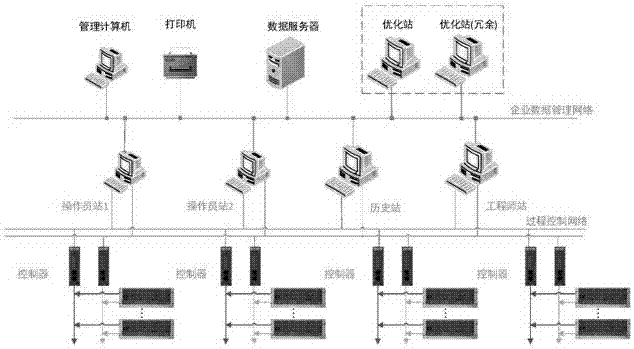

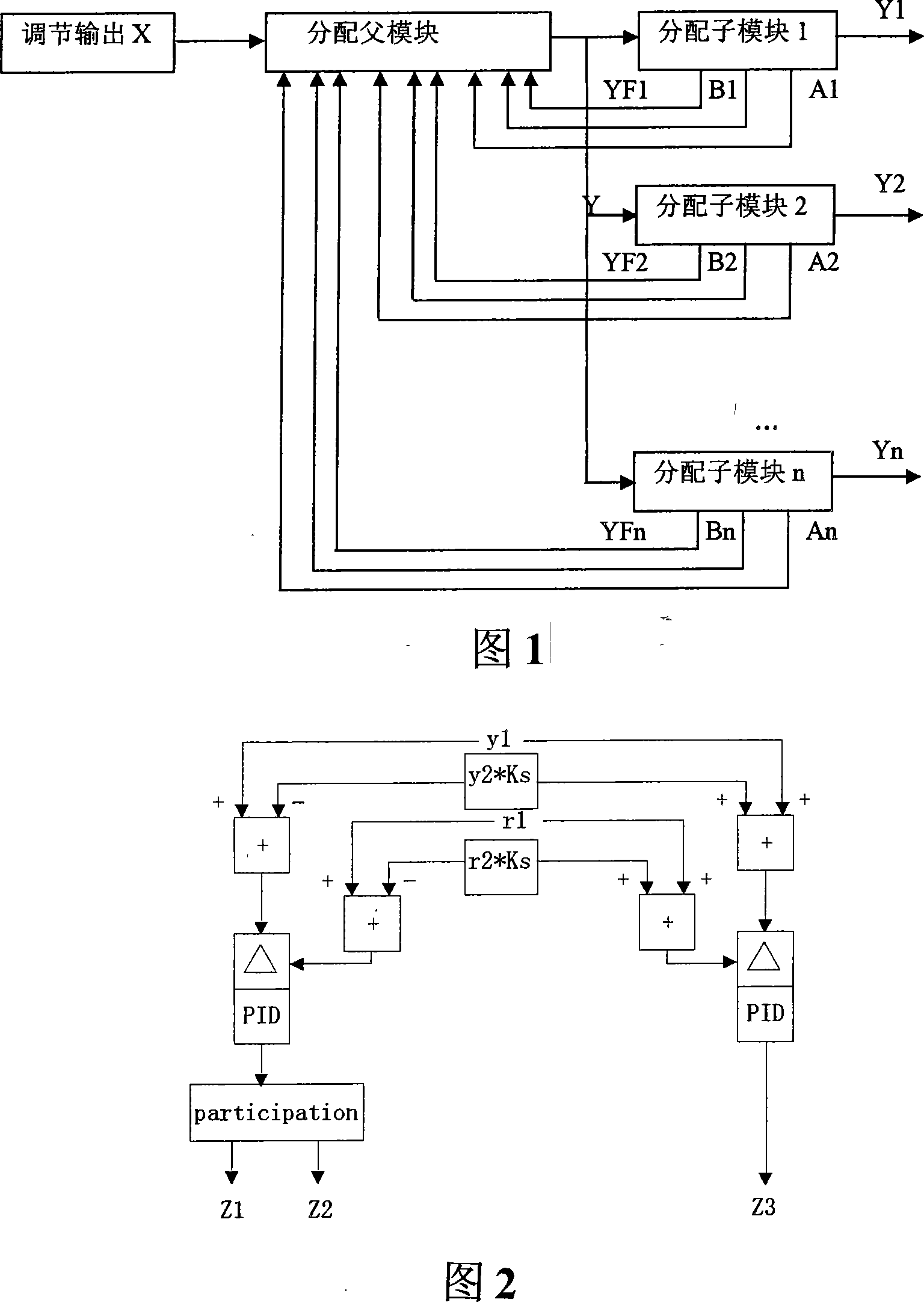

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

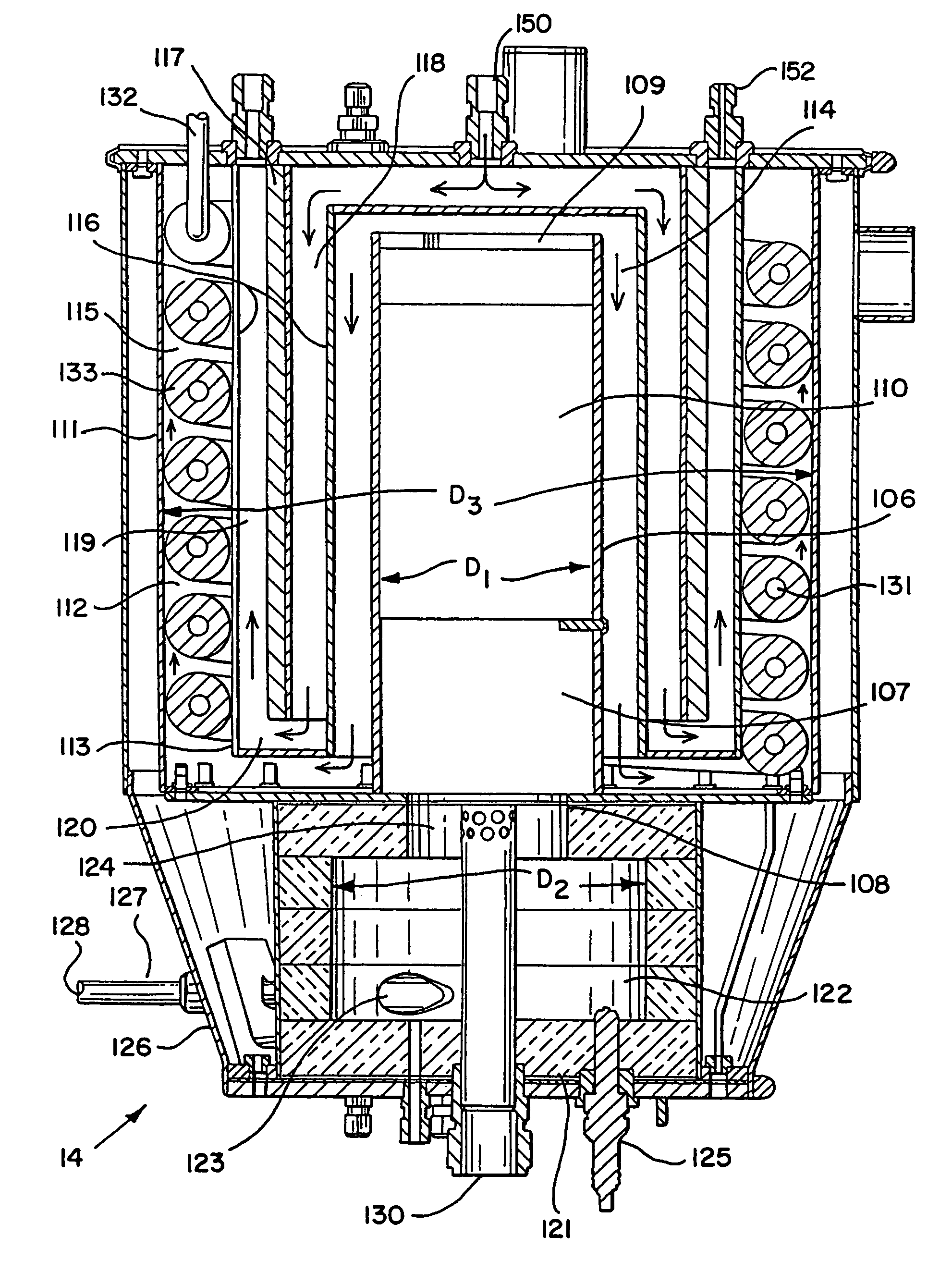

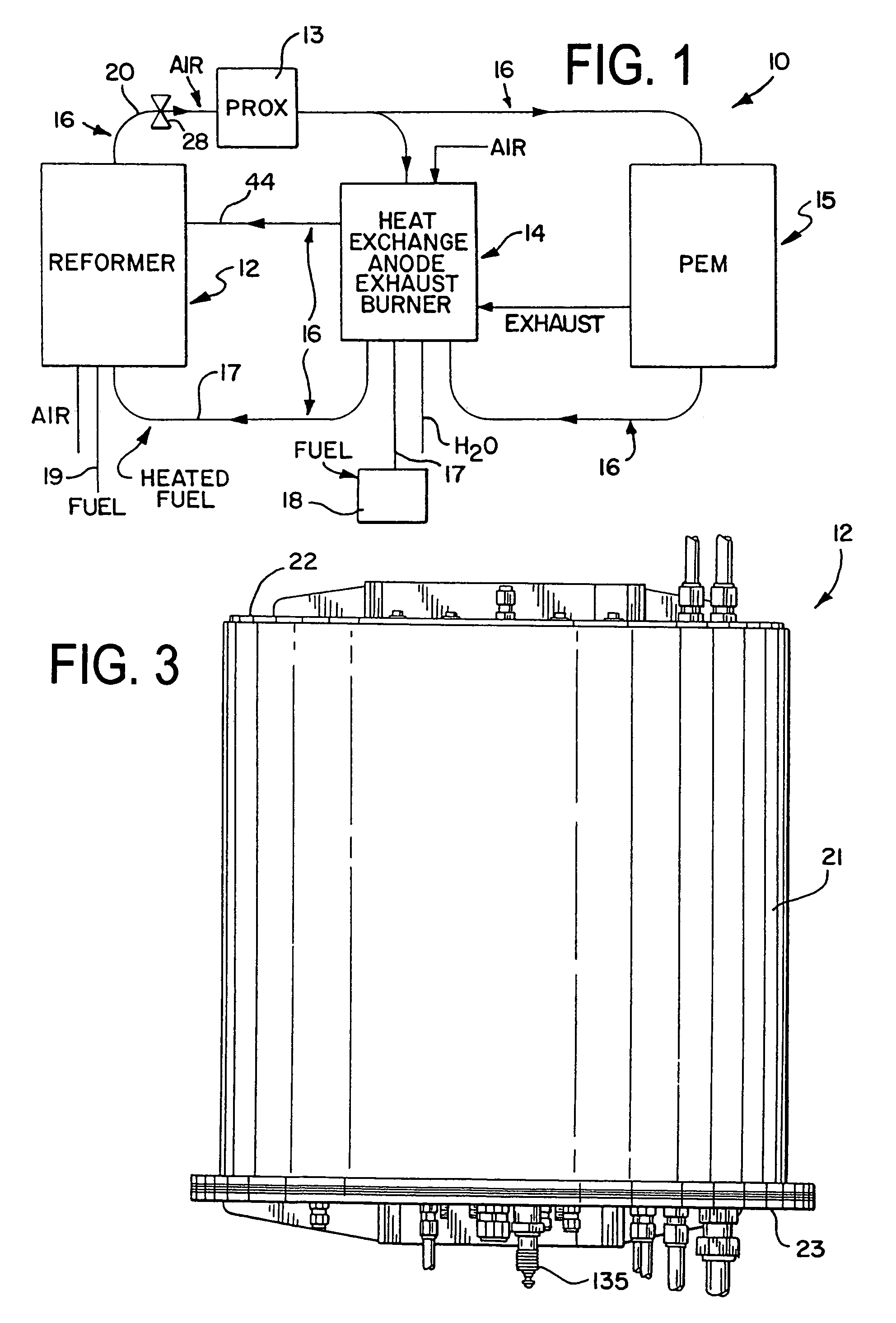

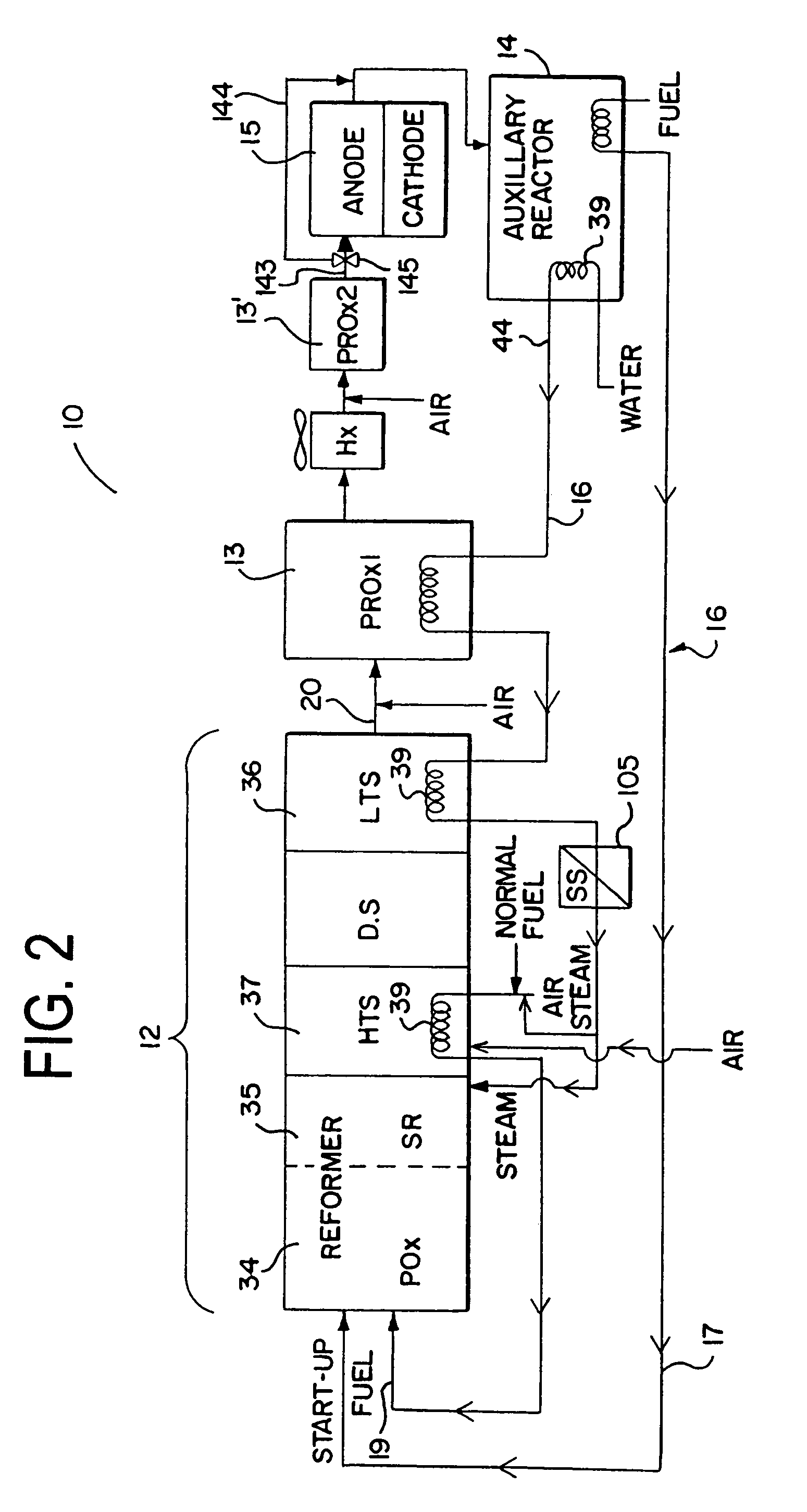

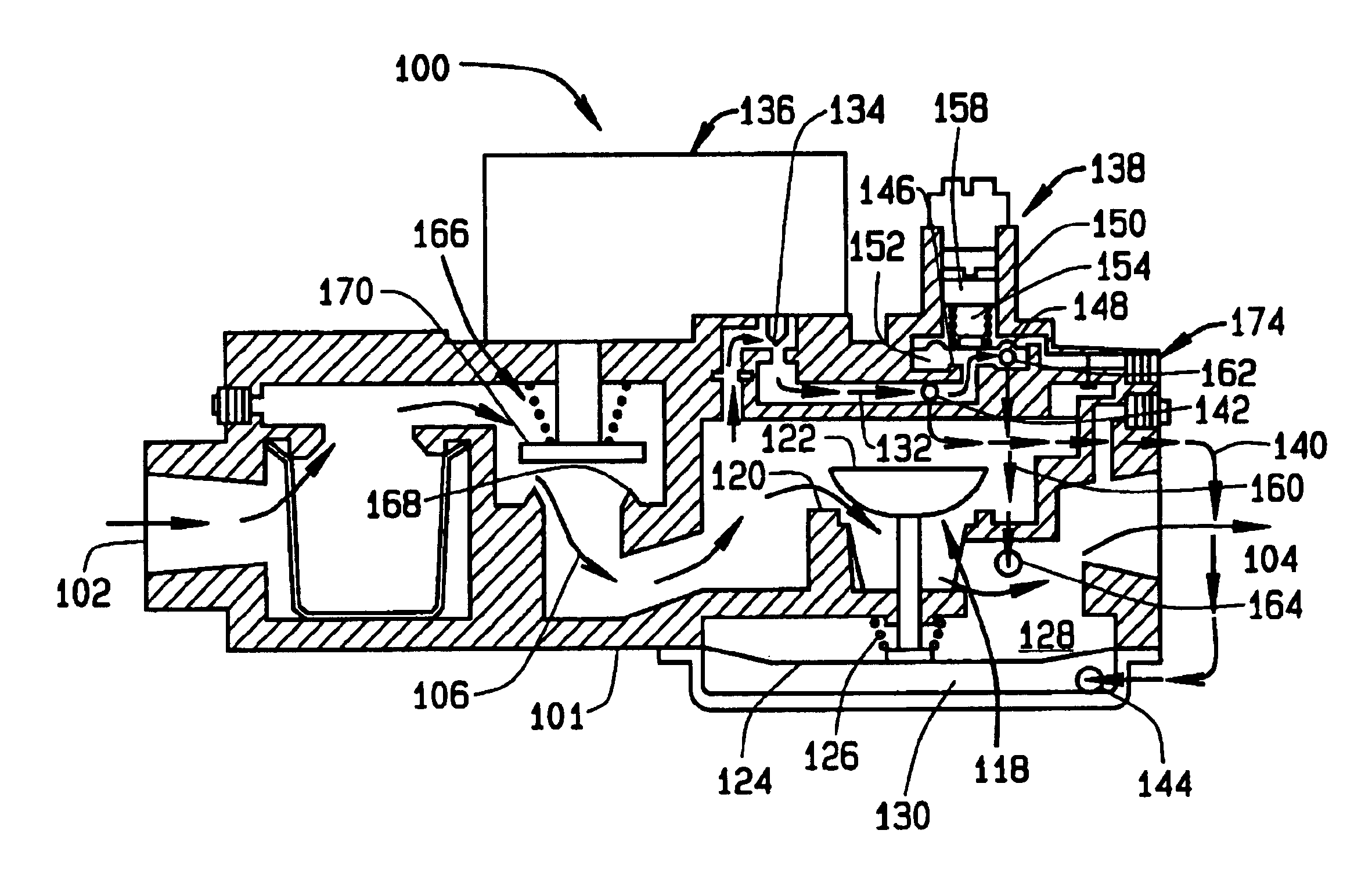

Auxiliary reactor for a hydrocarbon reforming system

InactiveUS6986797B1Thermal non-catalytic crackingFluidized bed combustionCombustorNuclear engineering

An auxiliary reactor for use with a reformer reactor having at least one reaction zone, and including a burner for burning fuel and creating a heated auxiliary reactor gas stream, and heat exchanger for transferring heat from auxiliary reactor gas stream and heat transfer medium, preferably two-phase water, to reformer reaction zone. Auxiliary reactor may include first cylindrical wall defining a chamber for burning fuel and creating a heated auxiliary reactor gas stream, the chamber having an inlet end, an outlet end, a second cylindrical wall surrounding first wall and a second annular chamber there between. The reactor being configured so heated auxiliary reactor gas flows out the outlet end and into and through second annular chamber and conduit which is disposed in second annular chamber, the conduit adapted to carry heat transfer medium and being connectable to reformer reaction zone for additional heat exchange.

Owner:POWERTAP HYDROGEN FUELING CORP

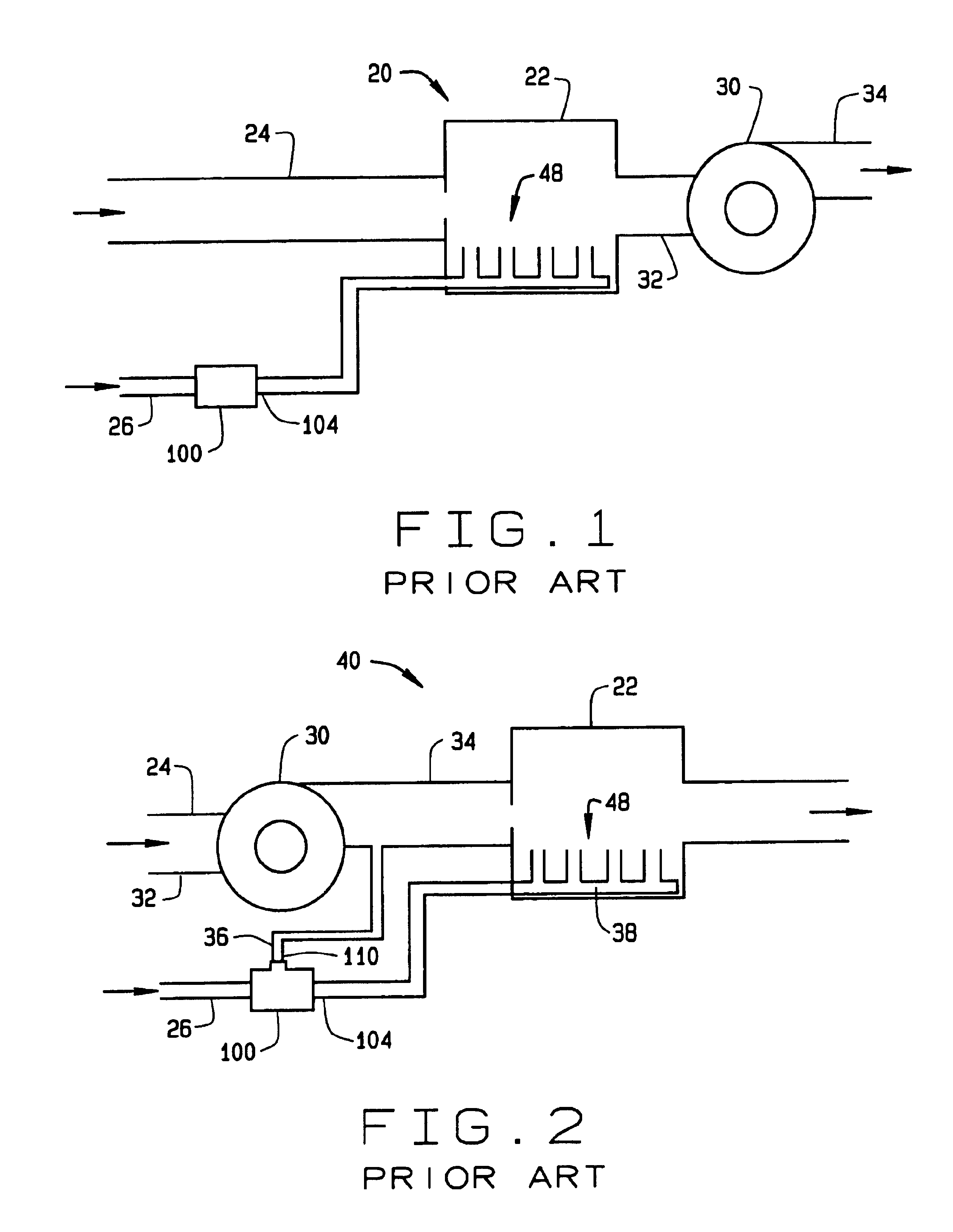

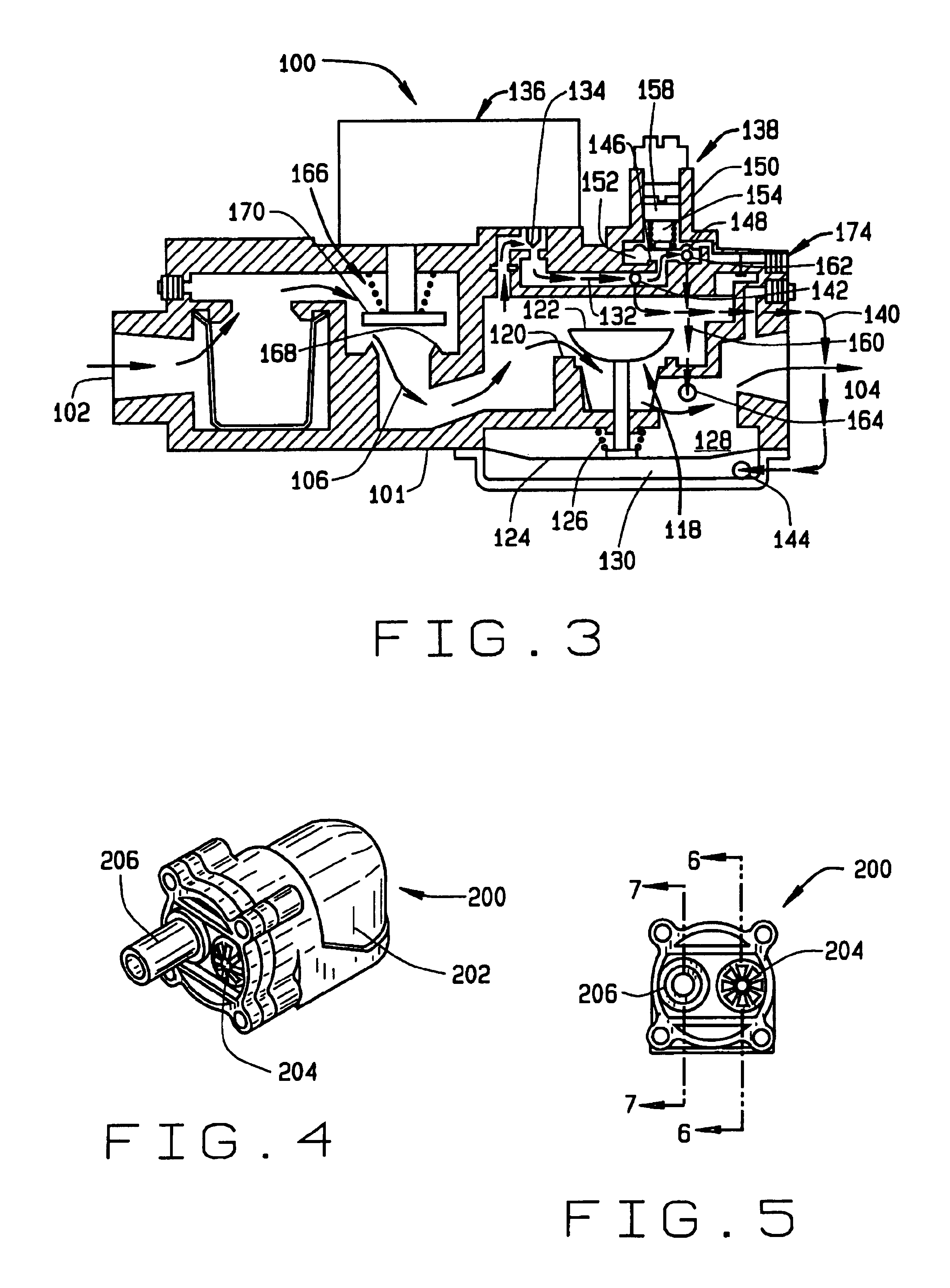

System and methods for modulating gas input to a gas burner

InactiveUS6918756B2Simply and reliably controlledLow costFluidized bed combustionFuel supply regulationMotor driveEngineering

An improved gas appliance having a burner, a gas valve through which the flow of combustion gas to the burner is controlled, and a motor driven blower that supplies combustion air to the burner. The improvement includes means for increasing gas flow through the gas valve as blower speed increases, and decreasing gas flow through the gas valve as blower speed decreases, based on a pressure signal generated independently of combustion air pressure. This improvement allows a constant ratio of gas to air to be maintained in the burner while a combustion flow rate varies dependent on the blower motor revolutions per minute. Thus input pressures of combustion can be controlled at low cost.

Owner:EMERSON ELECTRIC CO

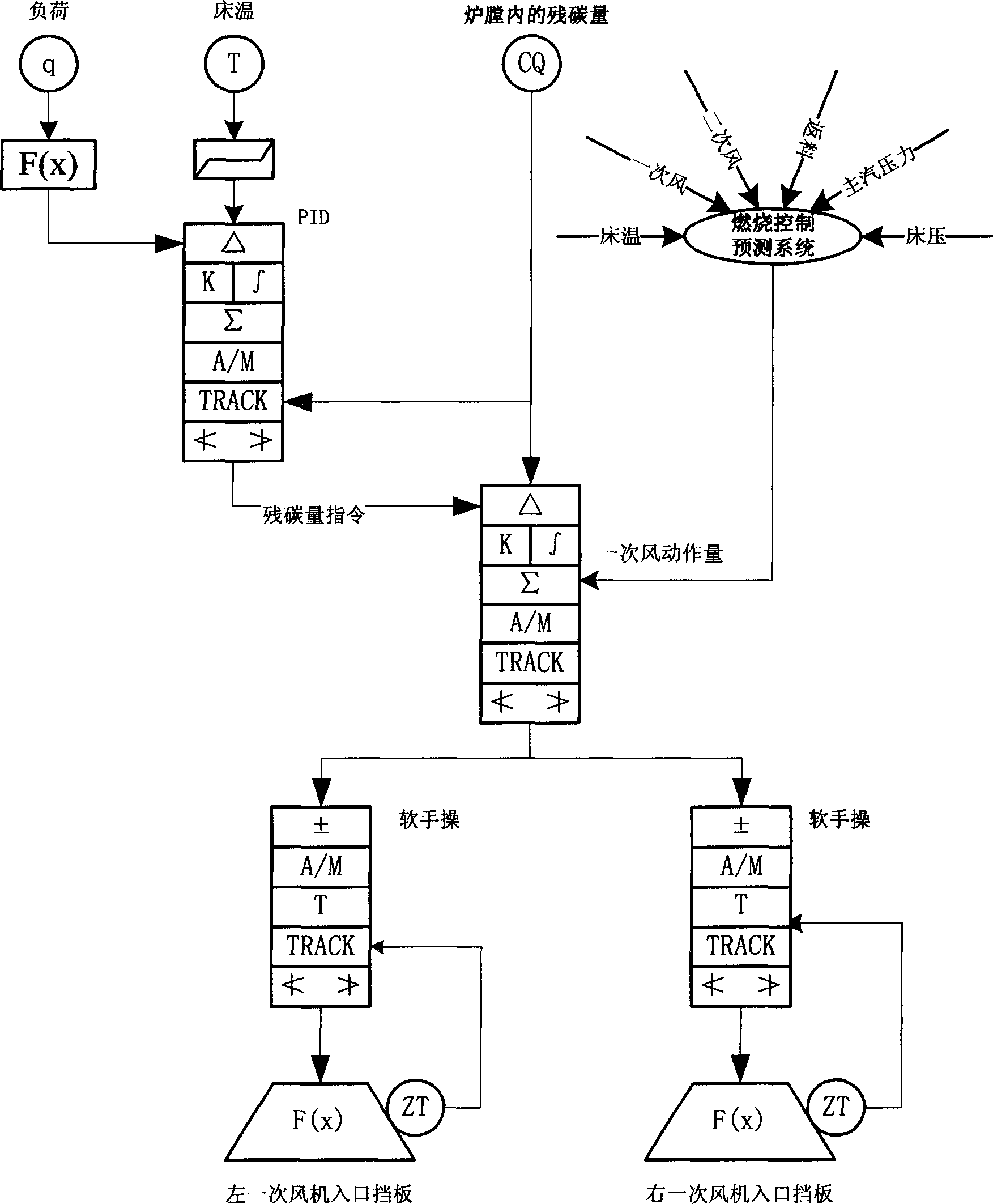

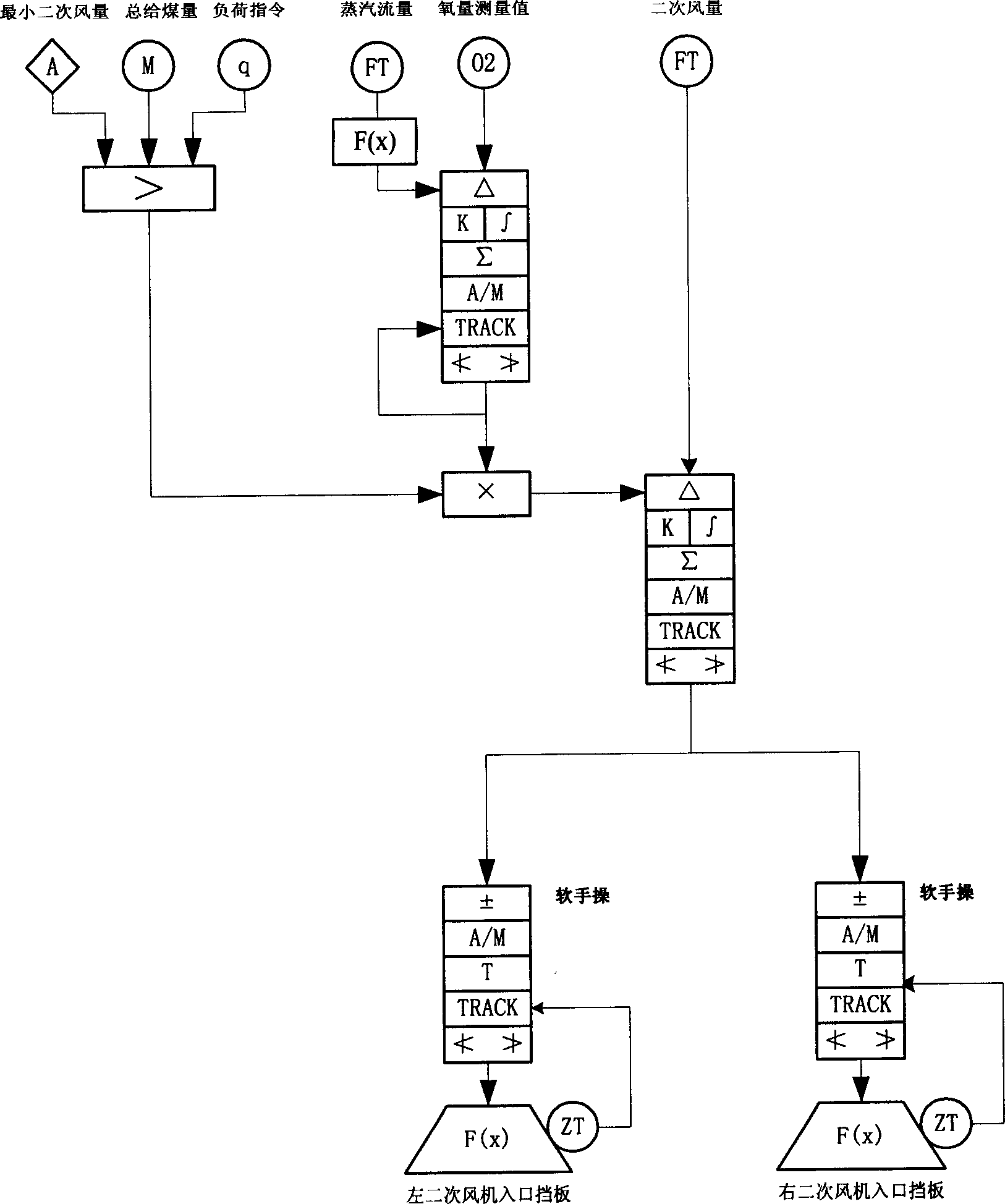

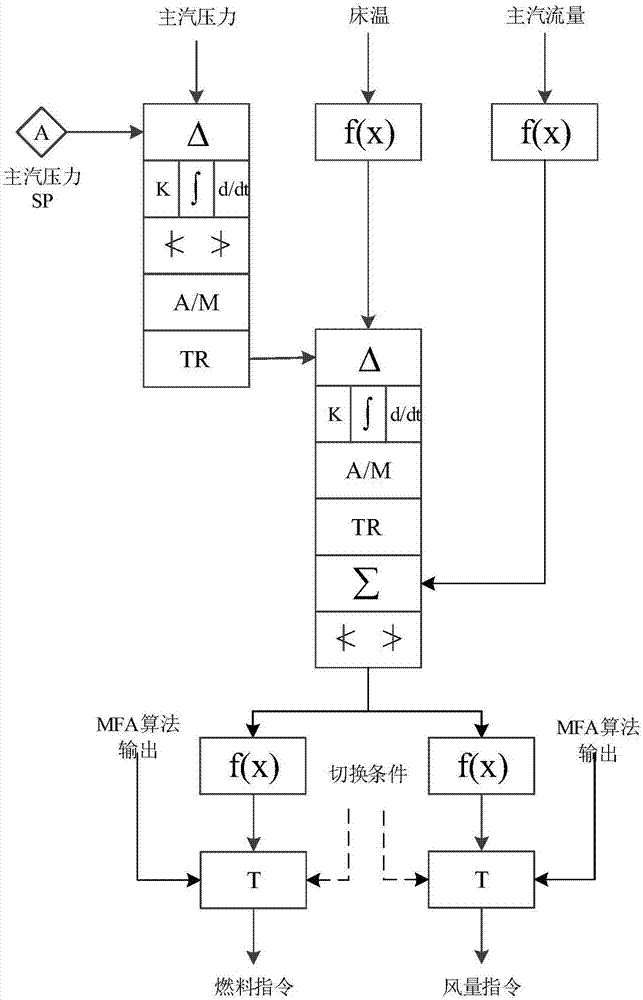

Method for controlling optimized burning in circulating fluid bed boiler

ActiveCN1916492AMeet instantaneous needsBalance and stabilityFluidized bed combustionApparatus for fluidised bed combustionCirculating fluidized bed boilerPower grid

A method for controlling combustion of circulation fluidized bed boiler includes using turbine to regulate load and using boiler to regulate pressure as well as using control system to receive load command when machine set is under coordination control system; carrying out uncoupling operation on load, main steam pressure, bed temperature and bed pressure of fluidized bed boiler when turbine load is changed greatly; and controlling carbon residual content in firepot for realizing energy balance control of machine set.

Owner:南京科远智慧能源投资有限公司

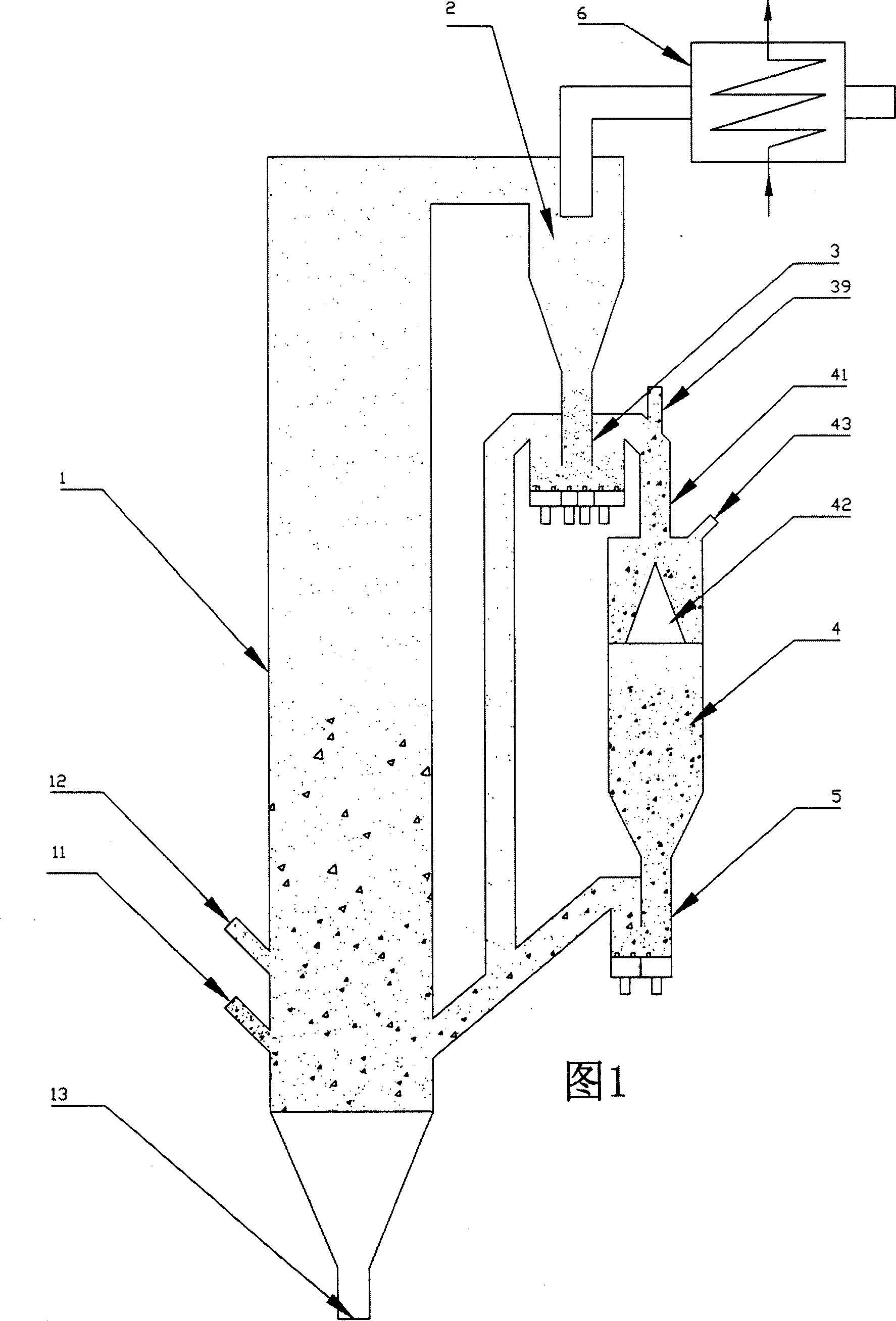

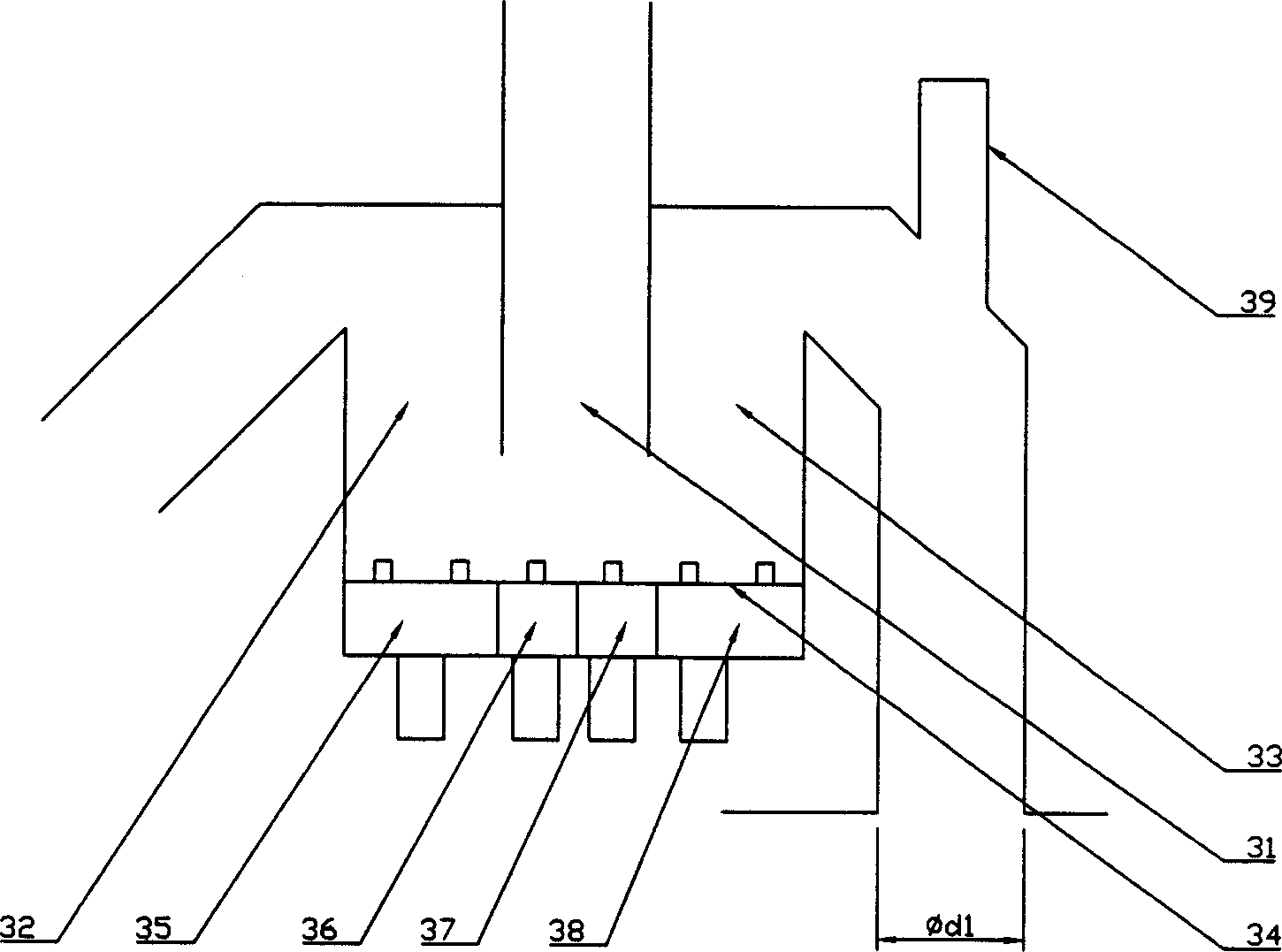

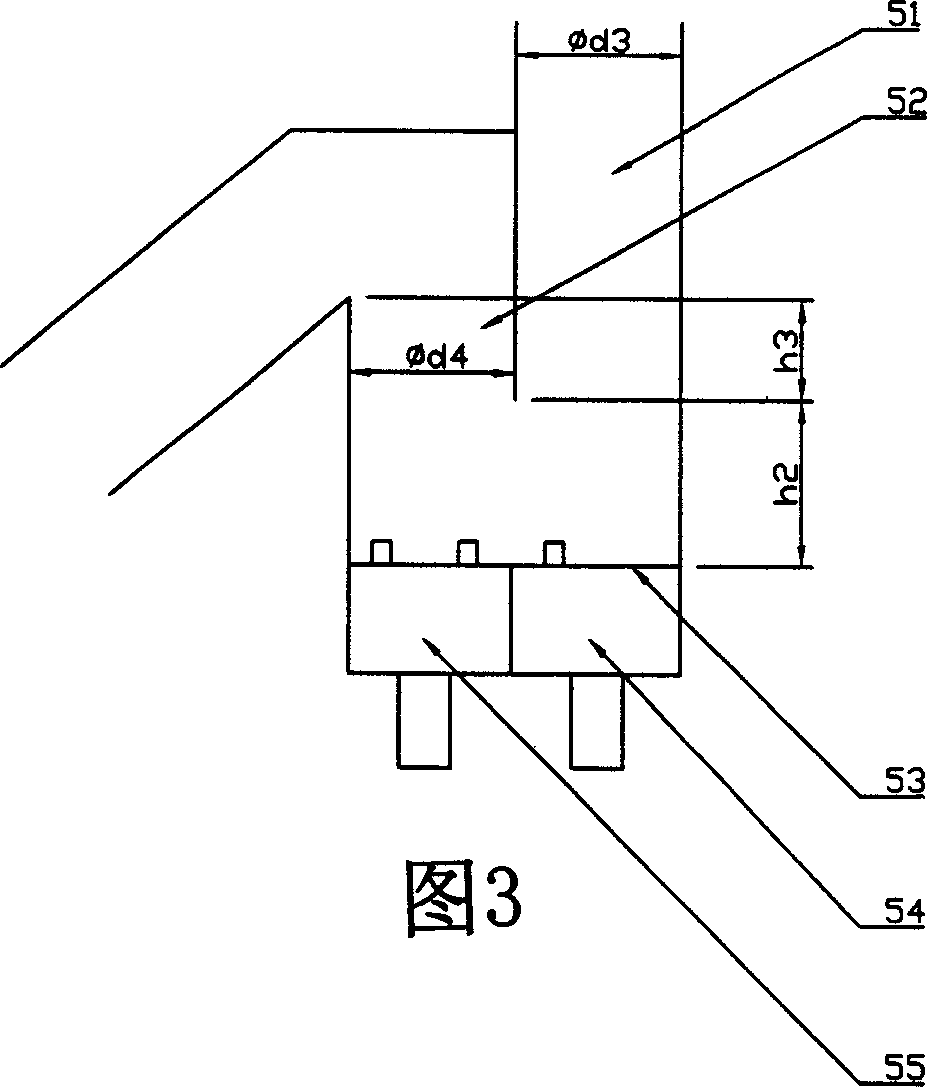

Method for producing both gas and steam, and boiler of circulating fluid bed with pyrolysis vaporizer

InactiveCN1727750AReduce solid impuritiesReduce tar contentFluidized bed combustionCombined combustion mitigationCombustion chamberEngineering

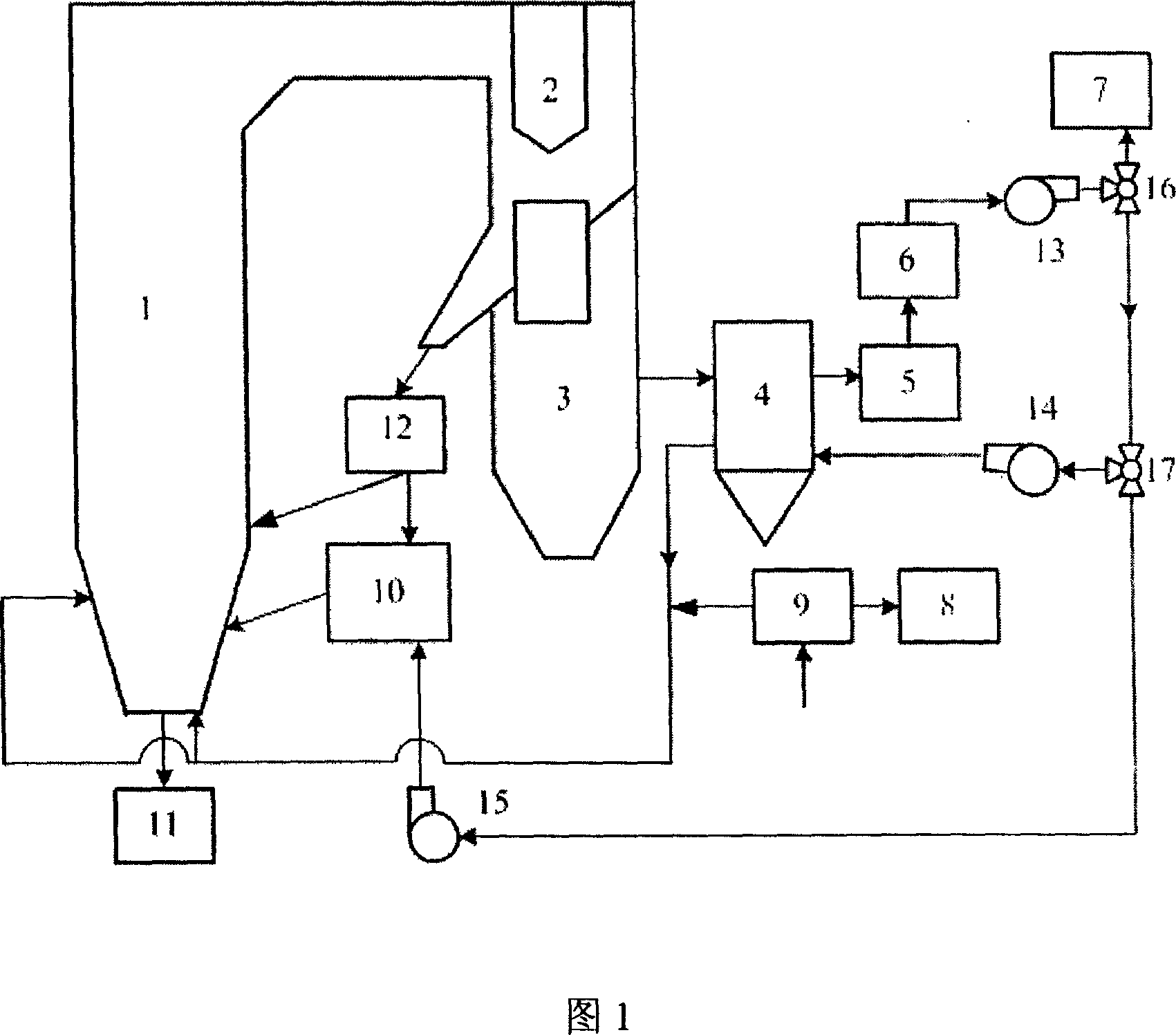

The present invention relates to a gas-steam joint production method and circulating fluidized-bed boiler. It includes the following portions: fluidized-bed combustion chamber, cyclone separator, hot ash distributor, pyrolysis gasification chamber, heat exchanger and differential bed material-retuning device. Said invention also provides its concrete technological process, it can be used as steam boiler, and can implement gas-steam joint production.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

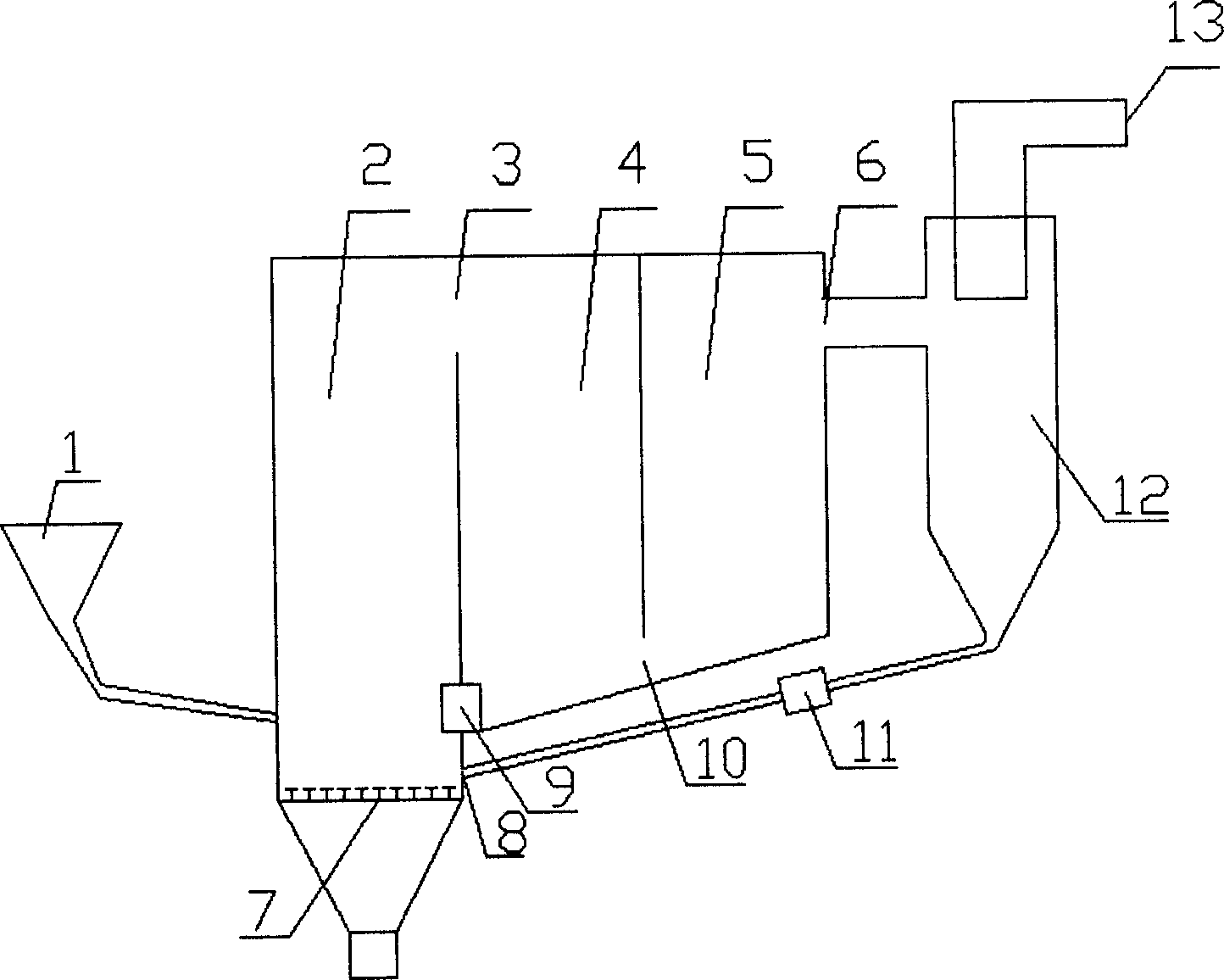

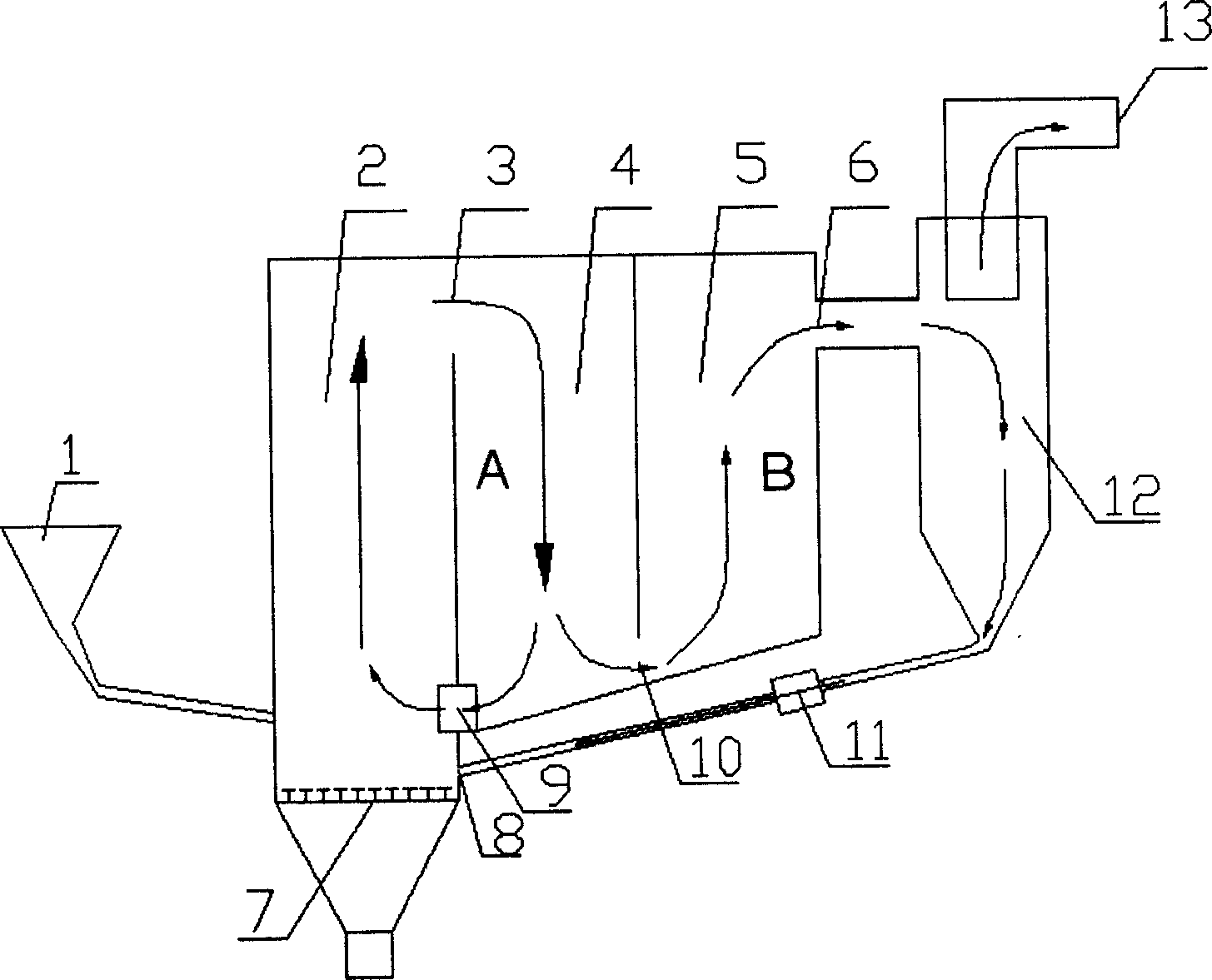

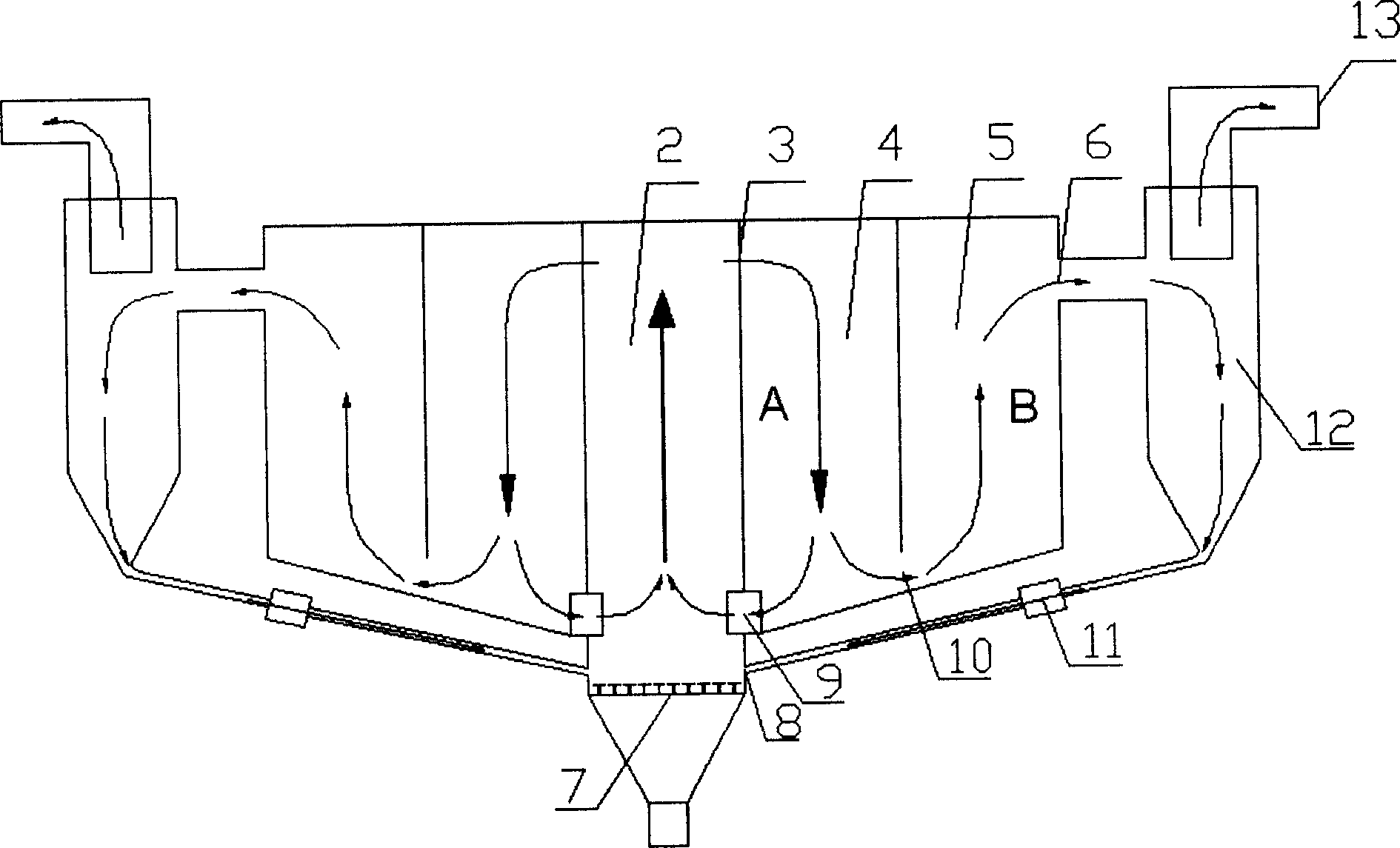

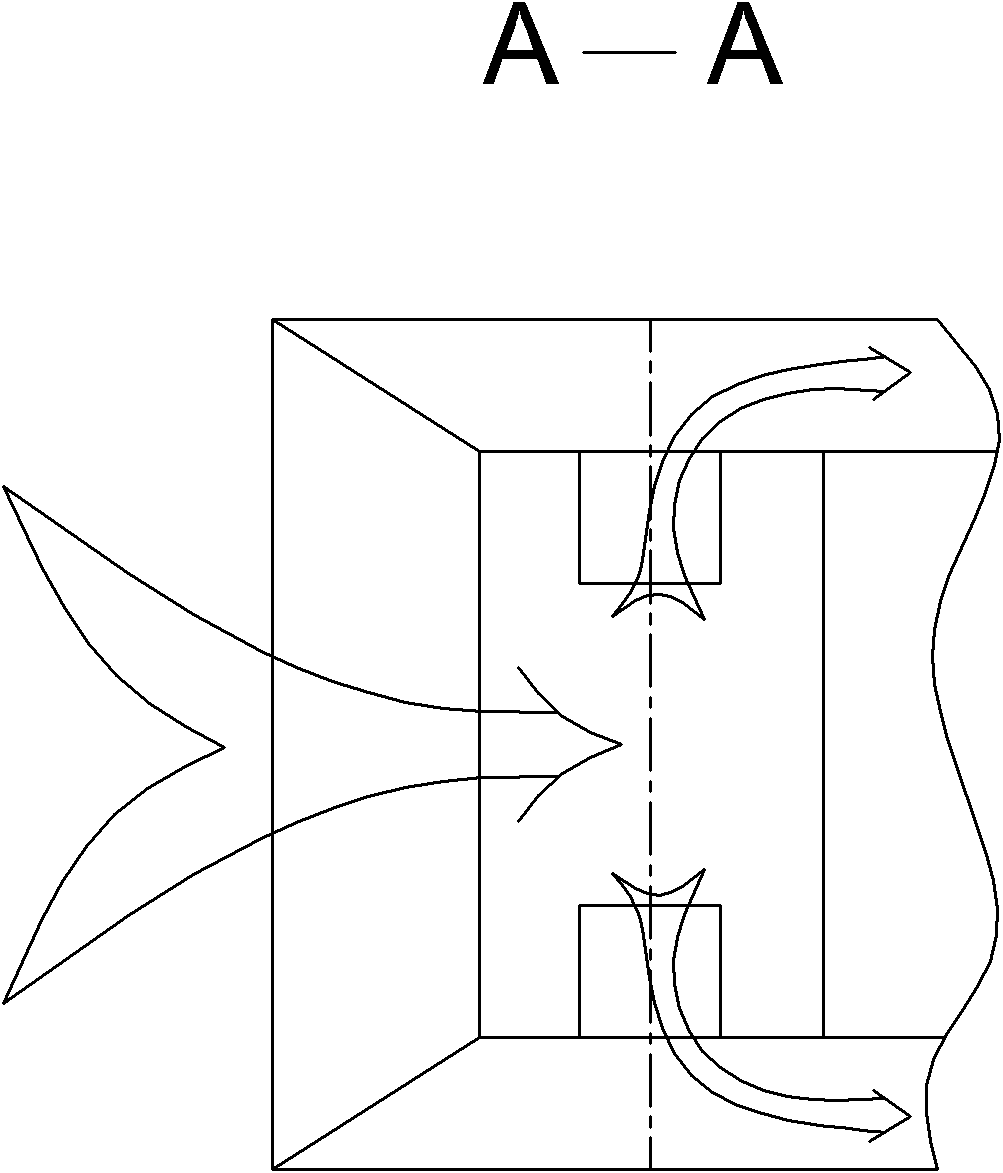

Horizontal circulating fluidized bed burning equipment and its circulating burning method

ActiveCN1786565ALow costReduce construction costsFluidized bed combustionIncinerator apparatusGas solidSingle stage

The invention relates to horizontal type circulating fluid bed combustion equipment and its circulating combustion method. It belongs to inferior fuel combustion equipment and combustion method. It is made up of main combustion chamber, multistage subsidiary combustion chamber, and gas solid separator. It can change the national single stage vertical type circulating structure of the circulating fluid bed, effectively reduce boiler height, and reduce the cost. In the combustion equipment, the material is formed two stages or more material circulating. So the combustion efficiency is high. The combustion equipment has the all advantages of the circulating fluid bed. And it can use inferior fuel such as inferior coal, solid waste, and so on. So its fuel adaptability is wide. It is the high efficiency combustion equipment with cleaning combustion, compact structure, and long using life.

Owner:TSINGHUA UNIV

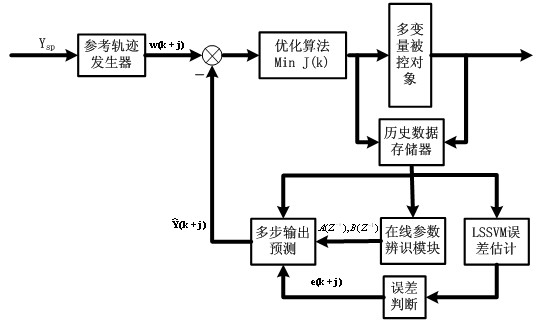

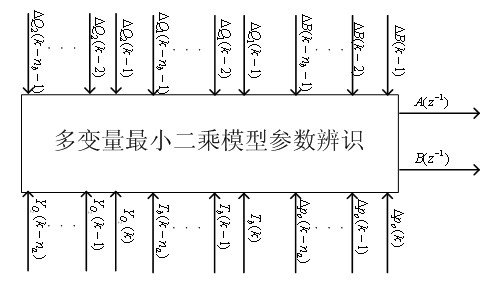

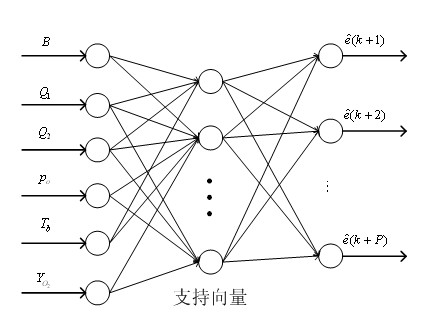

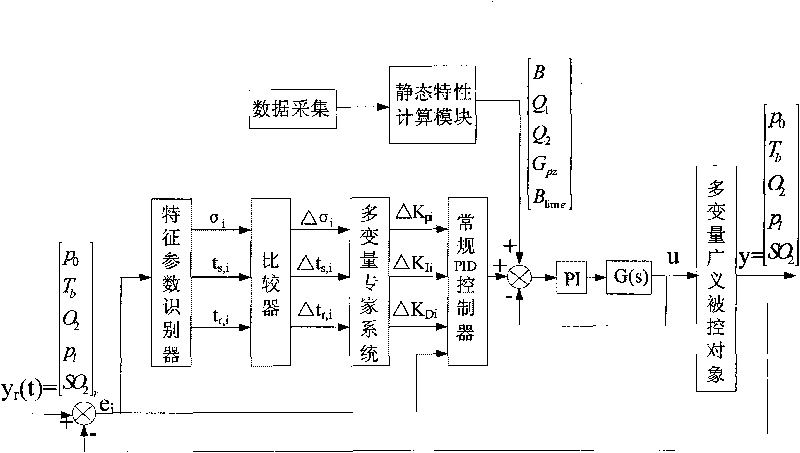

Combustion process multivariable control method for CFBB (circulating fluidized bed boiler)

InactiveCN102494336AImprove robustnessSolving time-varying problemsFluidized bed combustionApparatus for fluidised bed combustionSteam pressureData acquisition

The invention discloses a combustion process multivariable control method for a CFBB (circulating fluidized bed boiler), which is realized in the following procedures: in each control period, collecting operational parameters of the boiler through data collecting equipment and storing the operational parameters in a data storage module; utilizing the history data in a memorizer to on-line identify the CARIMA model and present P step future moment predominant values such as process output variable main steam pressure, material bed temperature and flue gas oxygen content through a model on-lineparameter identification module of GPC (generalized prediction control); performing error compensation to the process future moment prediction output through an error estimation module of an LSSVM (least square support vector machine); and referring the reference trace obtained by a trace generator, performing rolling optimization in GPC for the process future moment prediction output, and calculating through the optimized algorithm to enable the process actual output to reach the set value. The method provided by the invention solves the time varying problem of the model parameter, and enables the control system to have stronger robustness.

Owner:ZHEJIANG UNIV

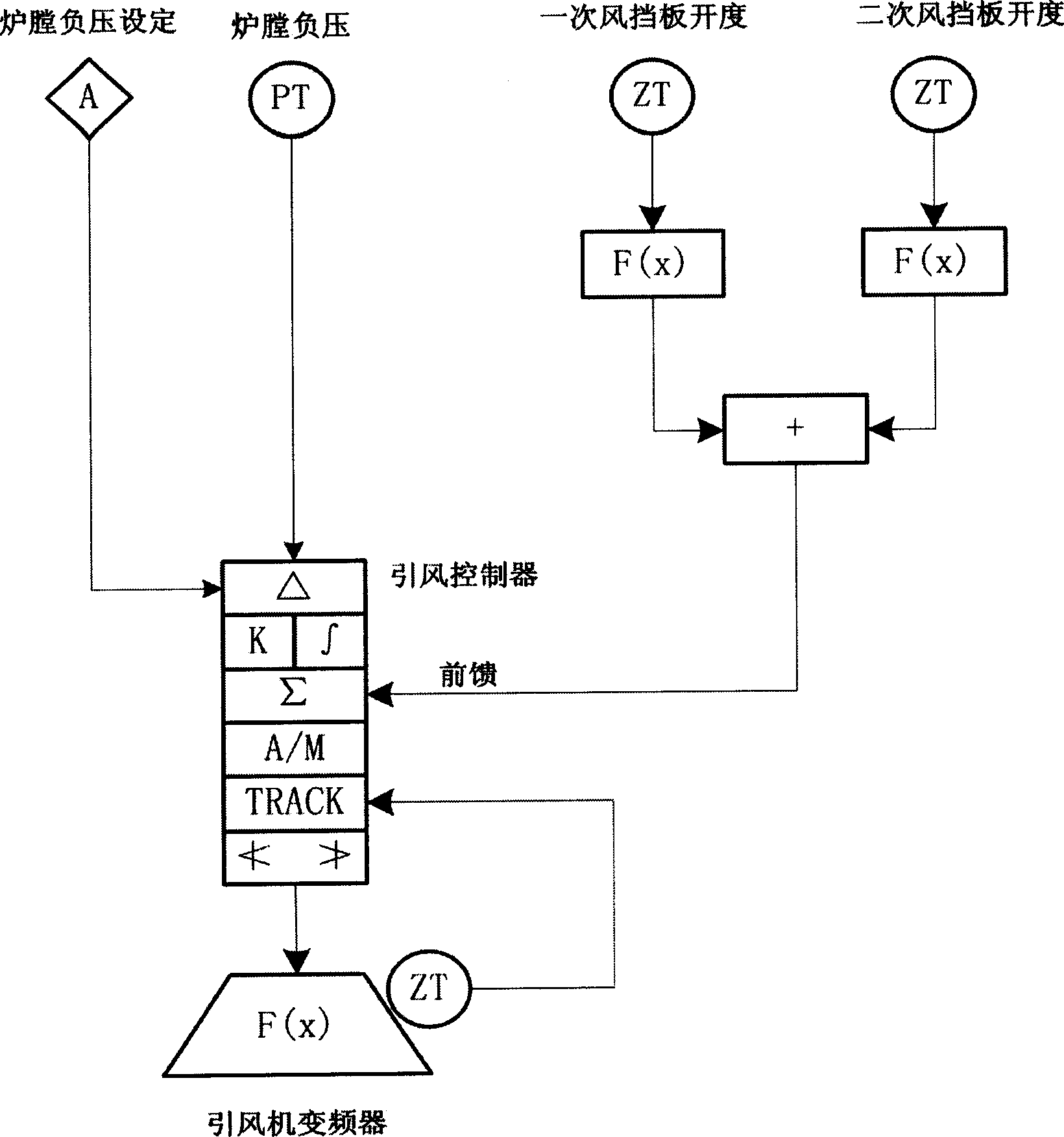

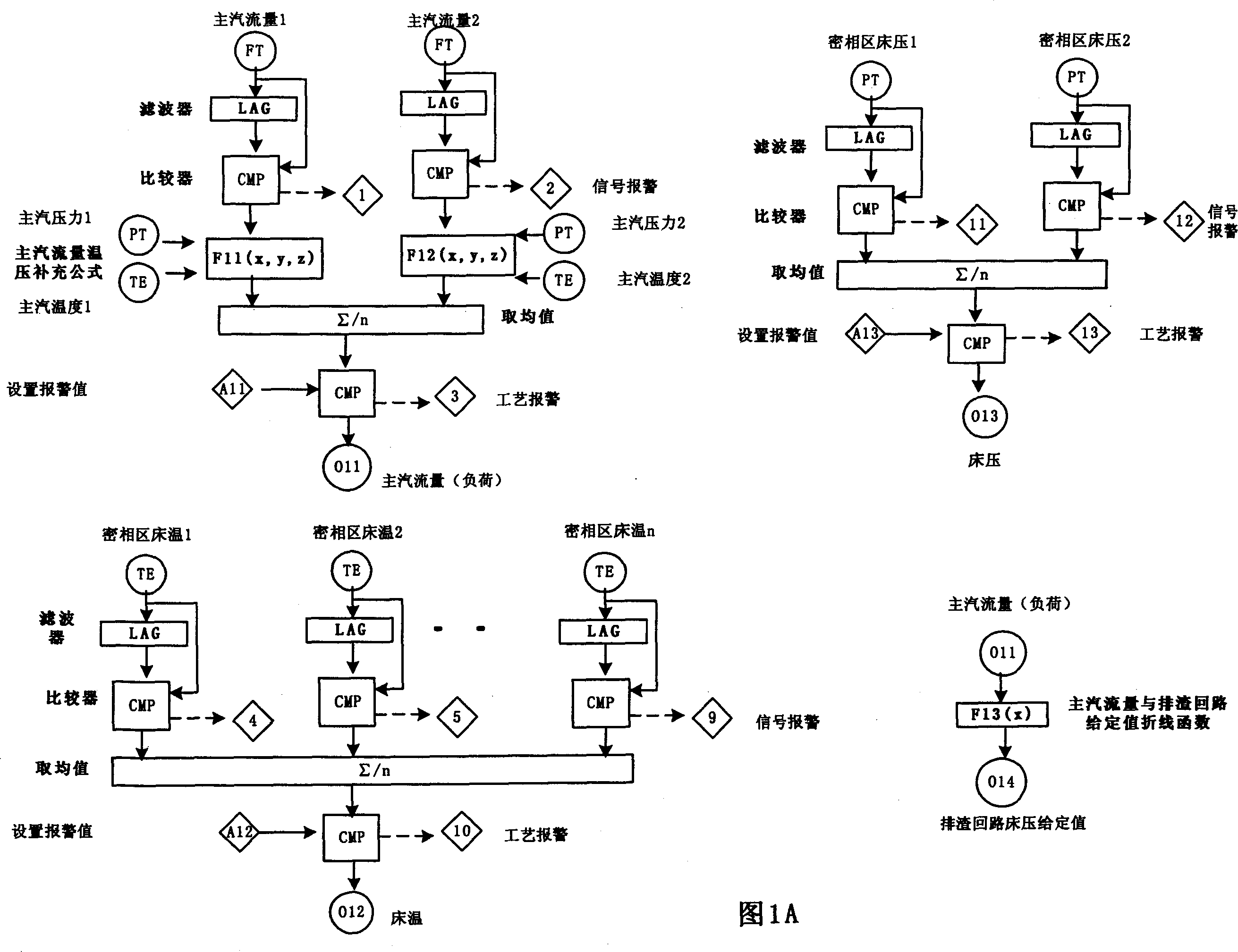

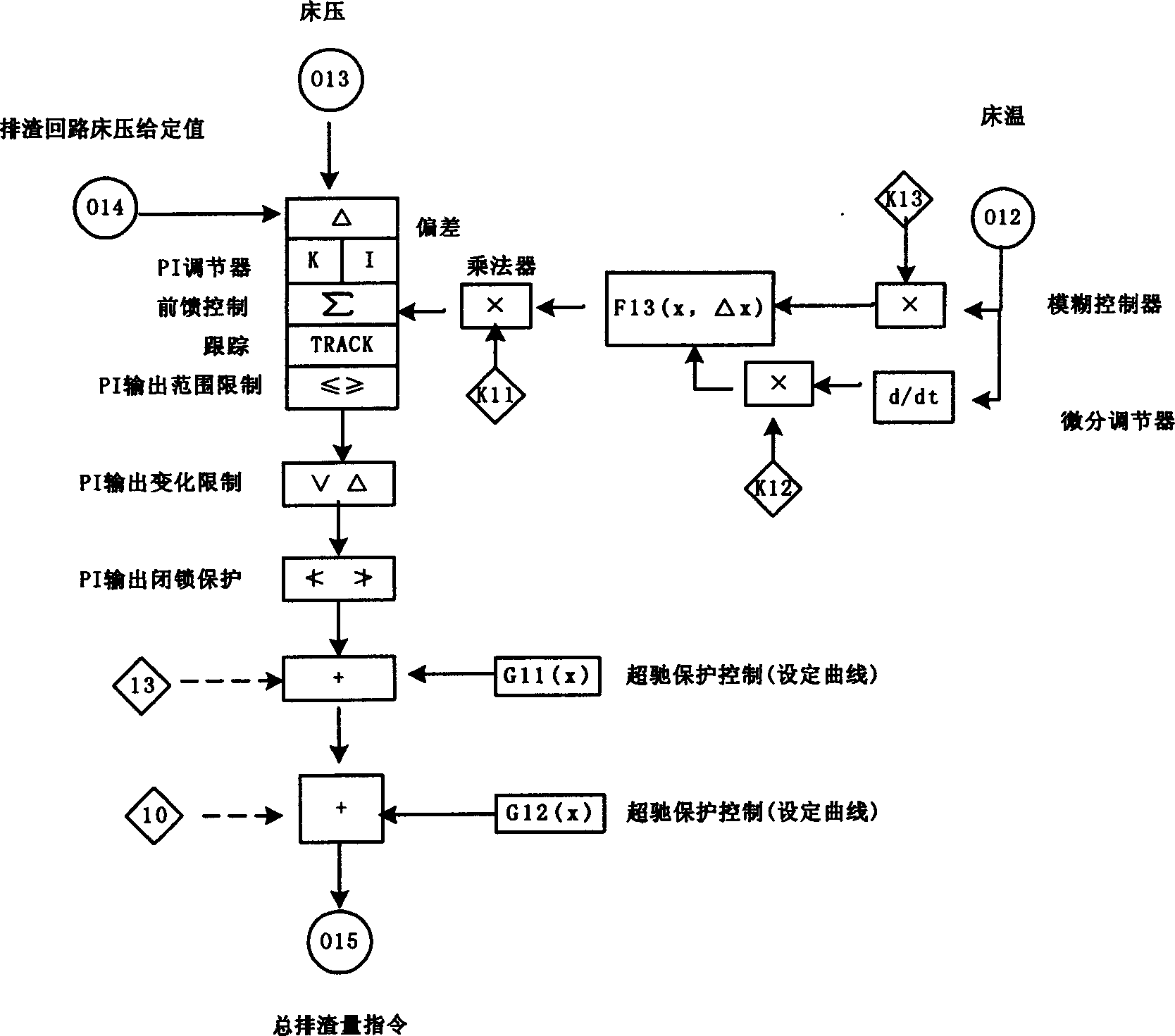

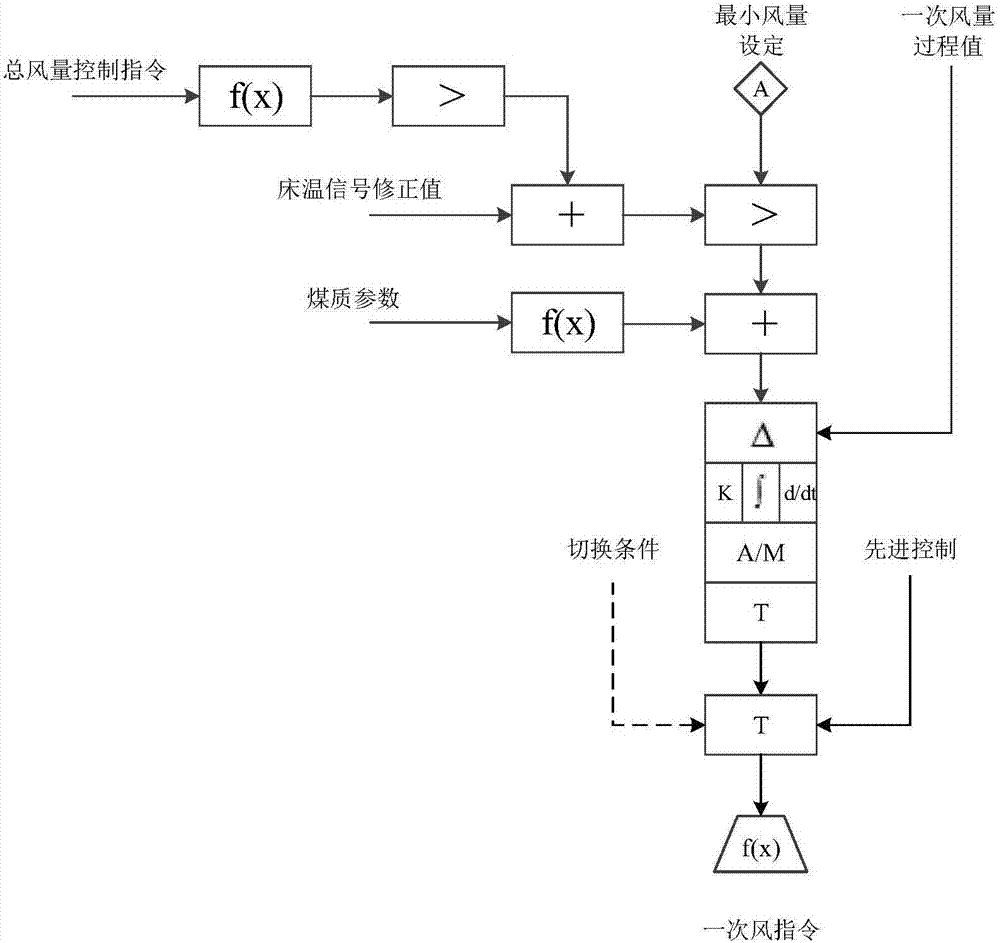

Automatic regulating system for combustion process of circulating fluid bed in boiler

InactiveCN1480682ATake full advantage of precisionContinuous and stable investmentFluidized bed combustionApparatus for fluidised bed combustionAuto regulationCombustion system

An automatic regulation system for the combustion of circulating fluidized-bed boiler (CFBB) features that it has several regulation loops for the discharged cinder quantity, primary blowing rate, supplied coal quantity, secondary blowing rate and draught air volume, which are based on the coordination between fluidizing, combustion and heat exchange, the expert system, fuzzy control and composite cascaded PI regulation are combined, and the protecting tactics such as override protection, output restriction and lock distribution choosing and tracking are used.

Owner:BEIJING HOLLYSYS

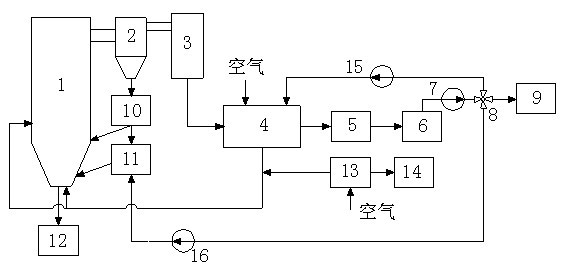

Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

InactiveCN102425789ALow costZero pollution dischargeSolidificationFluidized bed combustionProcess engineeringPollution

The invention discloses a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction system for solving the problem of low-cost CO2 emission reduction of an industrialized coal-fired boiler. A micro oxygen rich combustion mode using mixed gas of air, oxygen and recycled smoke as a combustion aid is adopted, wherein the mixed gas contains about 25 percent of oxygen, 30 to 40 percent of recycled smoke and the balance of air; and in the micro oxygen rich combustion mode, the concentration of the CO2 gas in the generated smoke is 30 to 40 percent, and the CO2 in the smoke is removed by adopting a physical adsorption technology. The invention also provides a system device for implementing the method. By considering oxygen making cost, energy consumption and optimal comprehensive effect of separating CO2 by physical adsorption and combining the micro oxygen rich concept and the circulating fluidized bed combustion technology, desulfuration, denitration, decarburization and zero pollution emission at lower cost can be realized. The invention has the advantages of good economic efficiency, simple process, low energy consumption, high automation degree in operation process and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

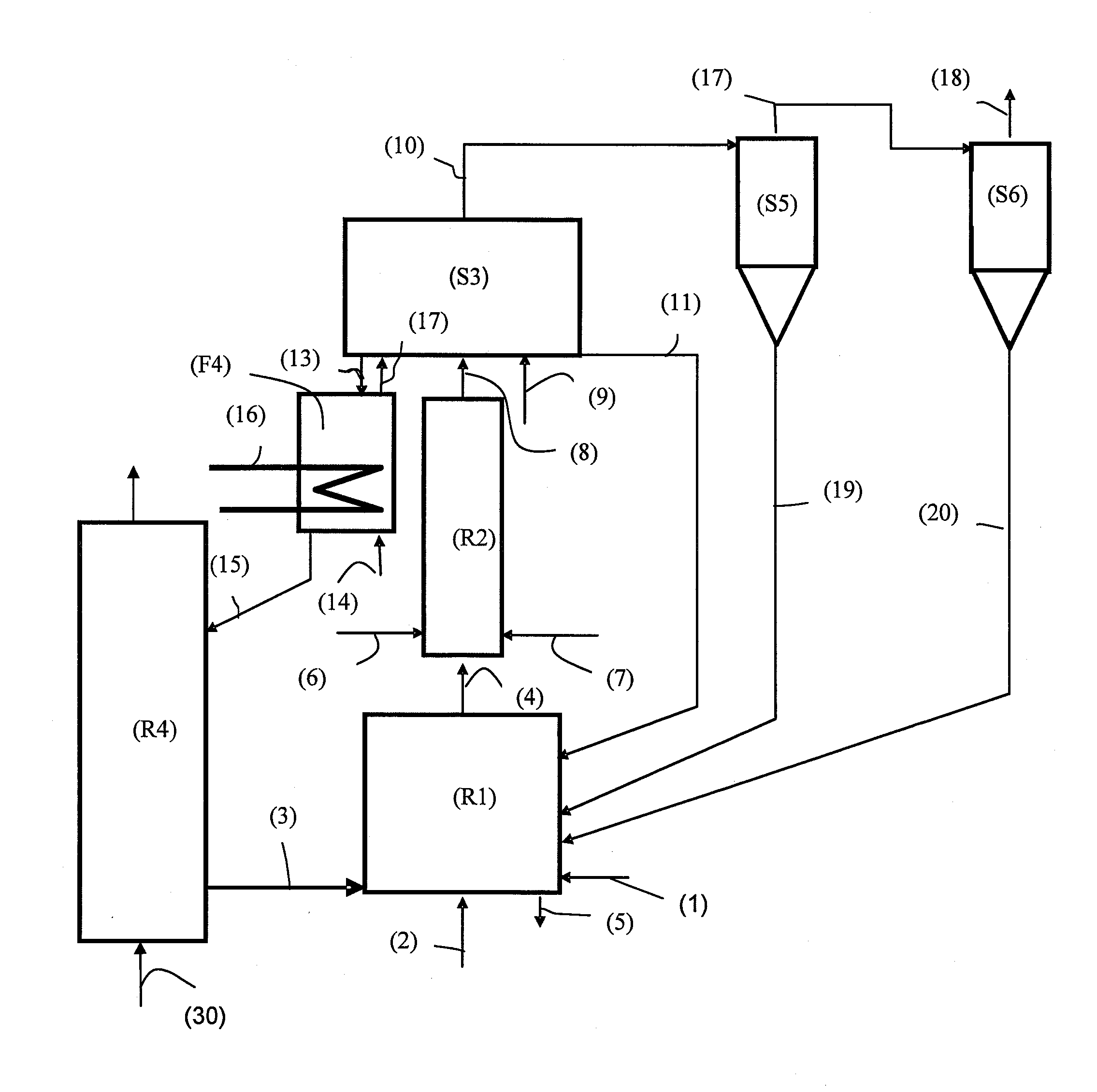

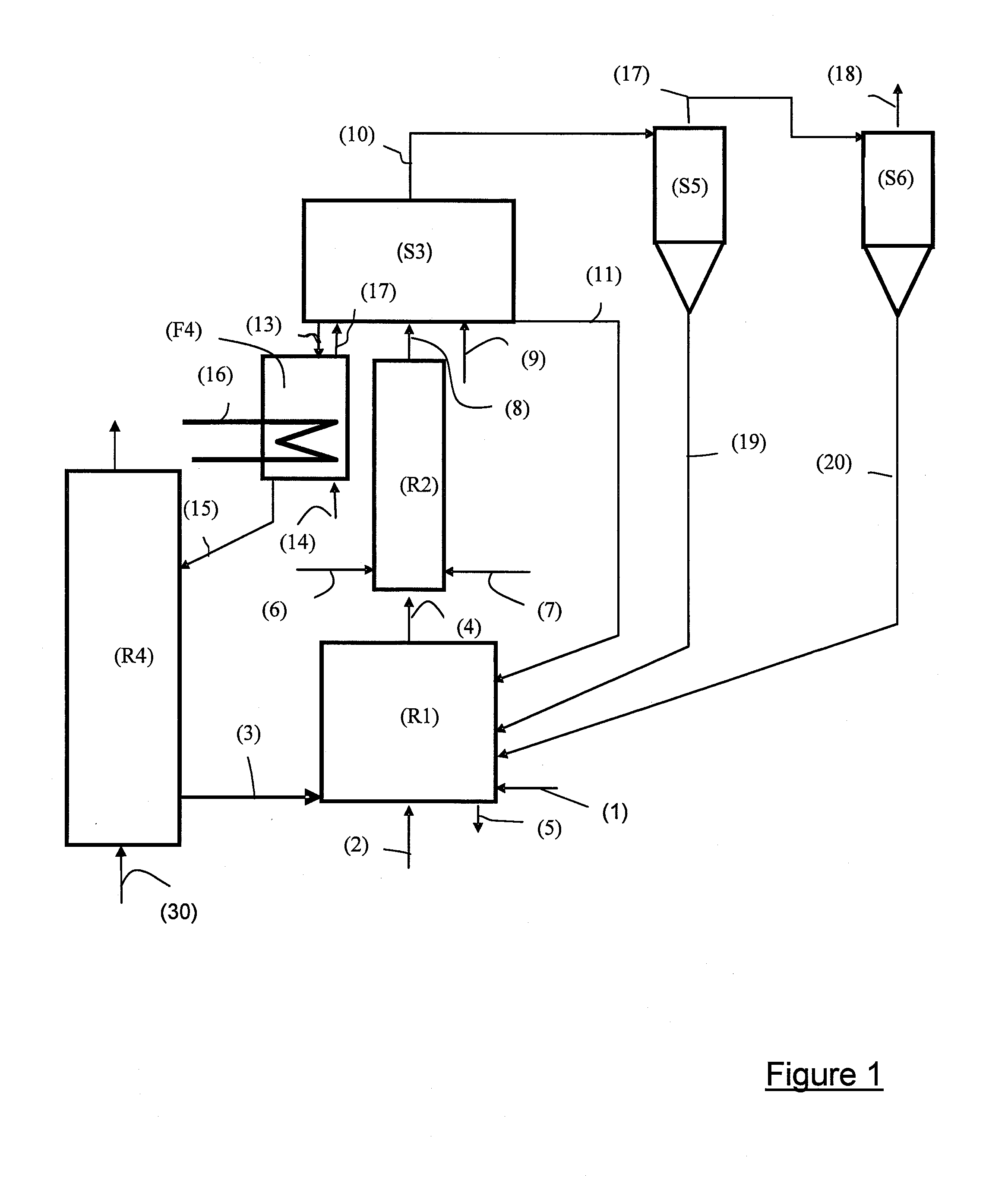

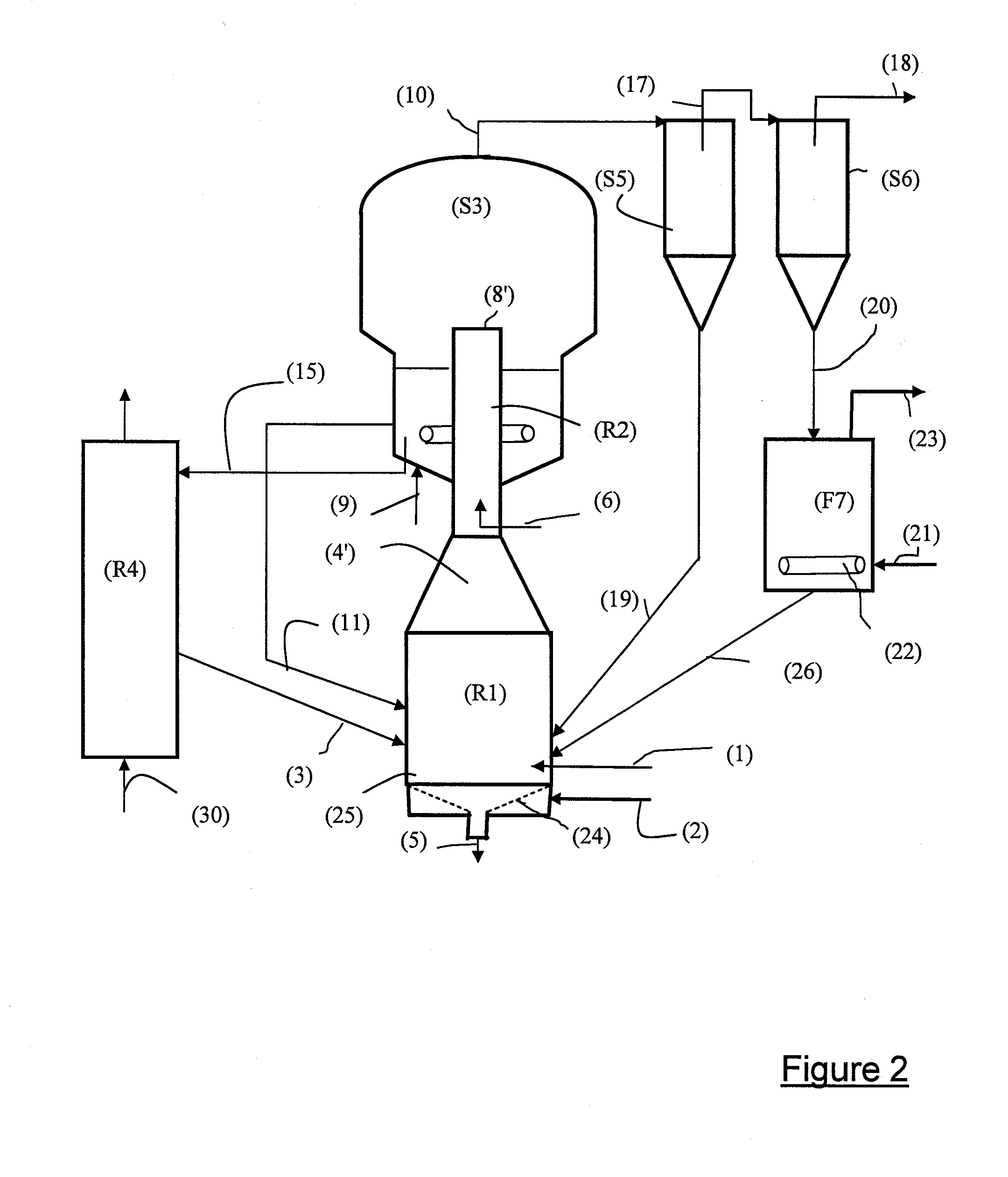

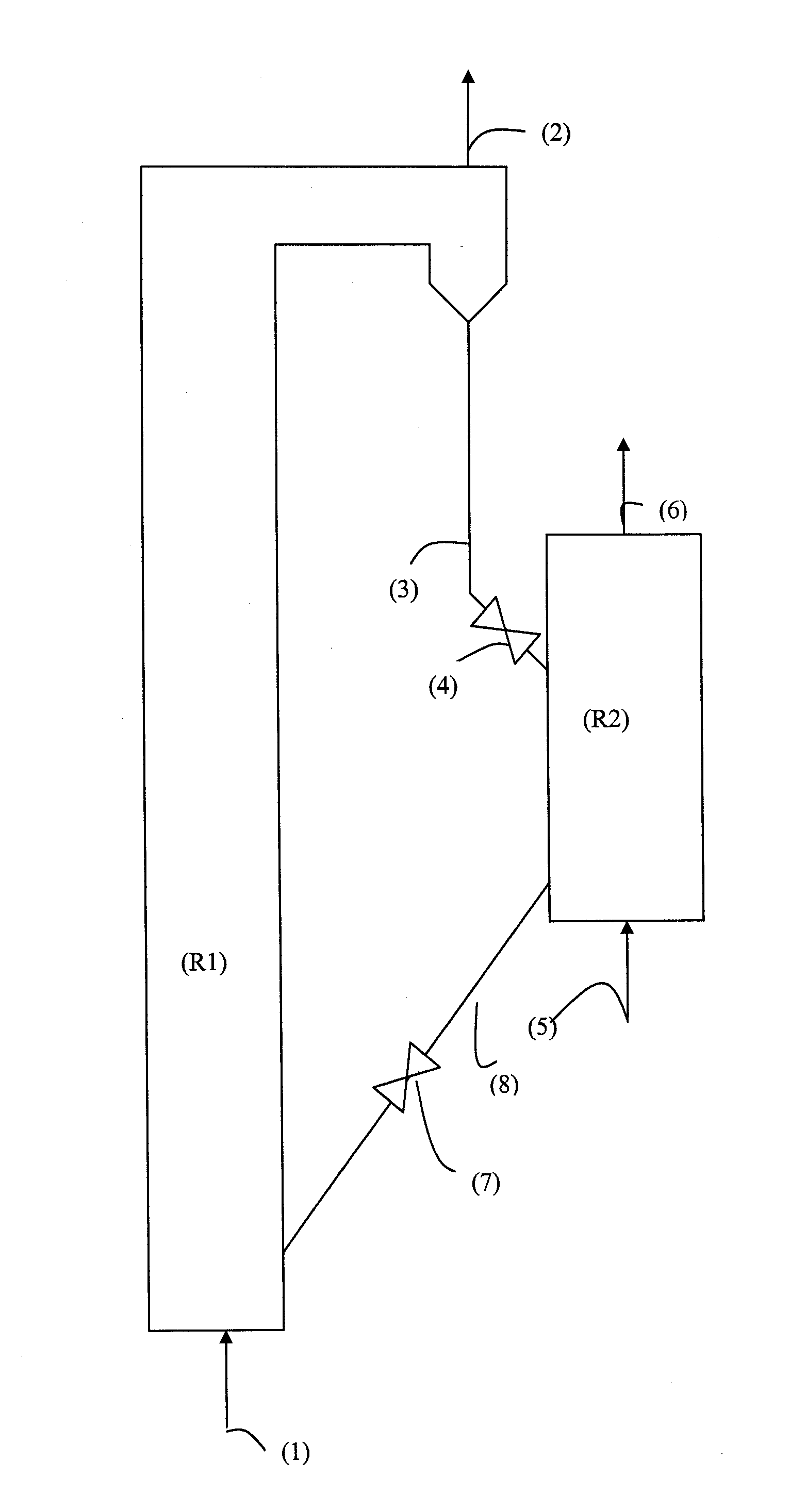

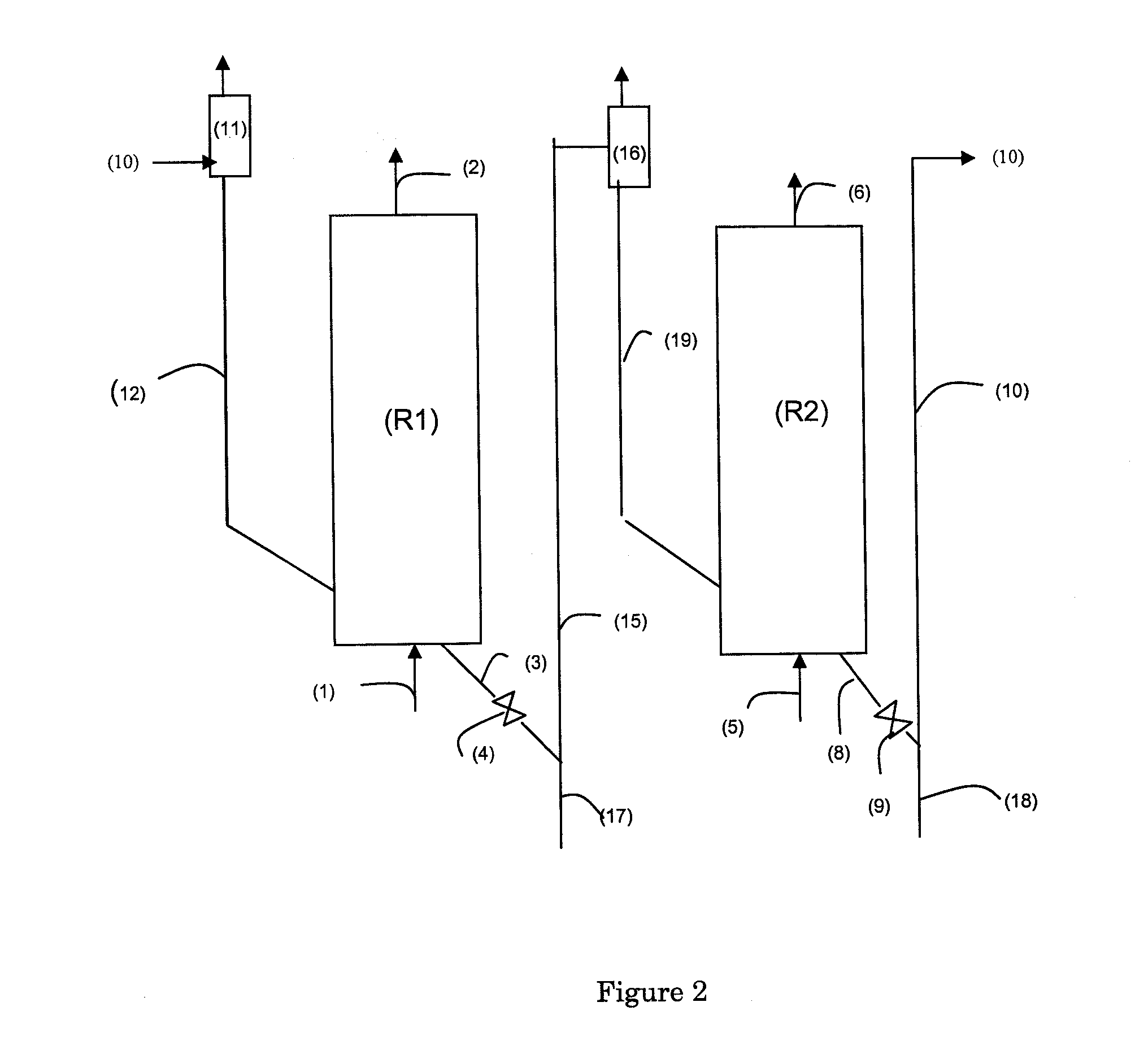

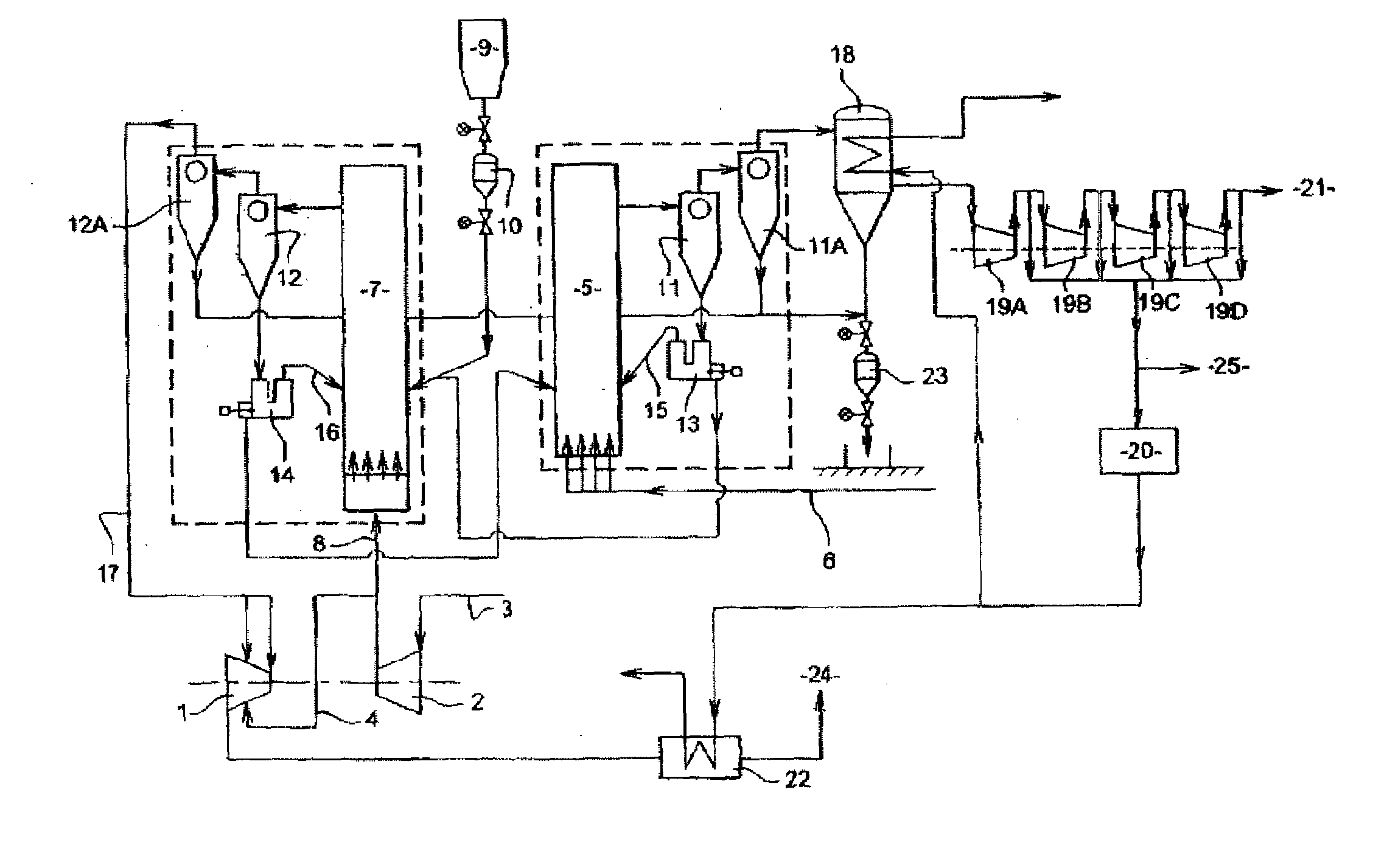

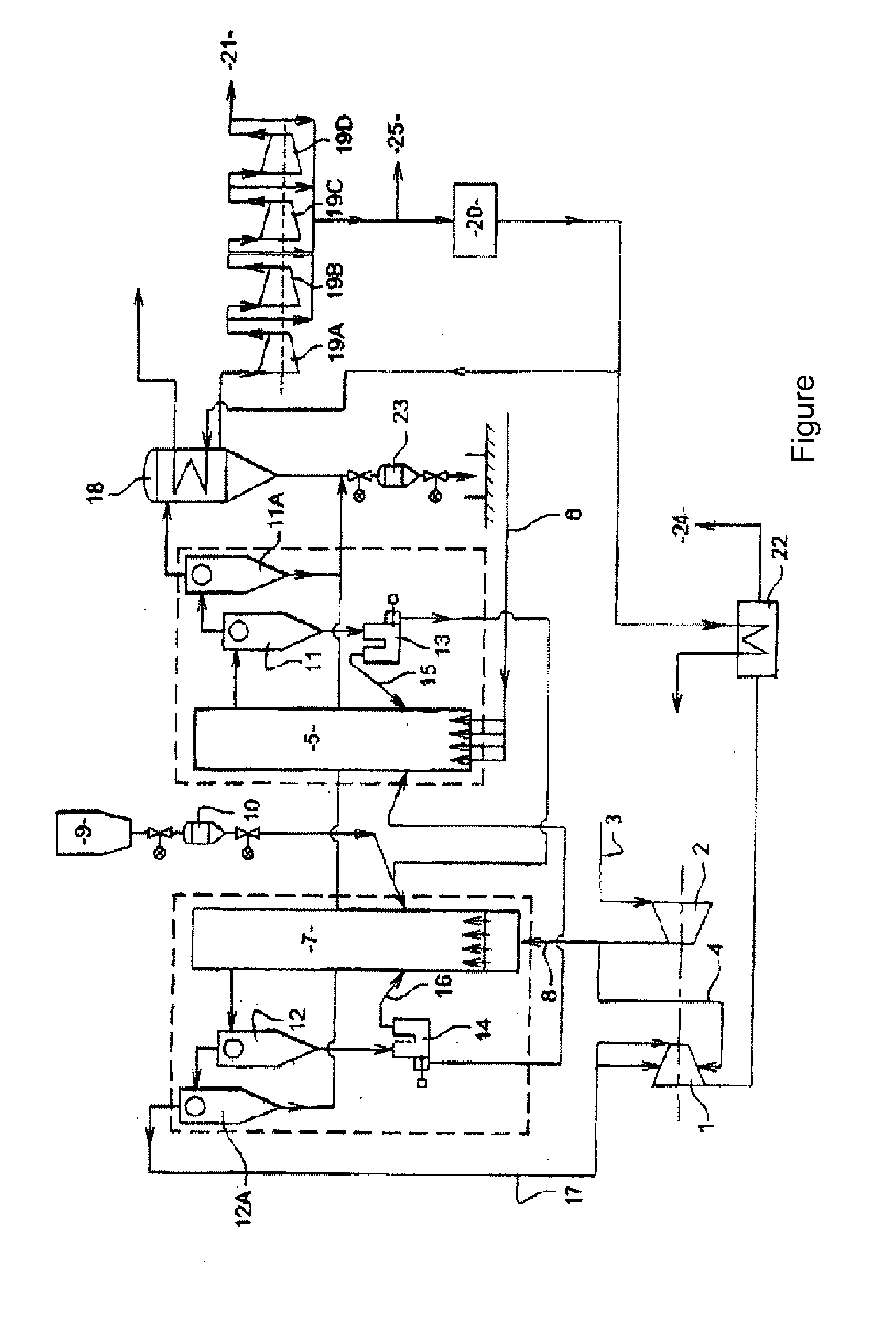

Chemical looping combustion method with a reaction zone including a gas-solid separation zone and plant using same

ActiveUS20130149650A1Small flowFluidized bed combustionFurnace componentsReaction zoneOxidation zone

The object of the invention is a combustion method for a solid feed using a chemical loop wherein an oxygen-carrying material circulates, said method comprising at least:contacting the solid feed particles in the presence of metallic oxide particles in a first reaction zone (R1) operating in dense fluidized bed mode,carrying out combustion of the gaseous effluents from first reaction zone (R1) in the presence of metallic oxide particles in a second reaction zone (R2),separating in a separation zone (S3) the unburnt particles and the metallic oxide particles within a mixture coming from second reaction zone (R2),re-oxidizing the metallic oxide particles in an oxidation zone (R4) prior to sending them back to first zone (R1).

Owner:TOTALENERGIES ONETECH +2

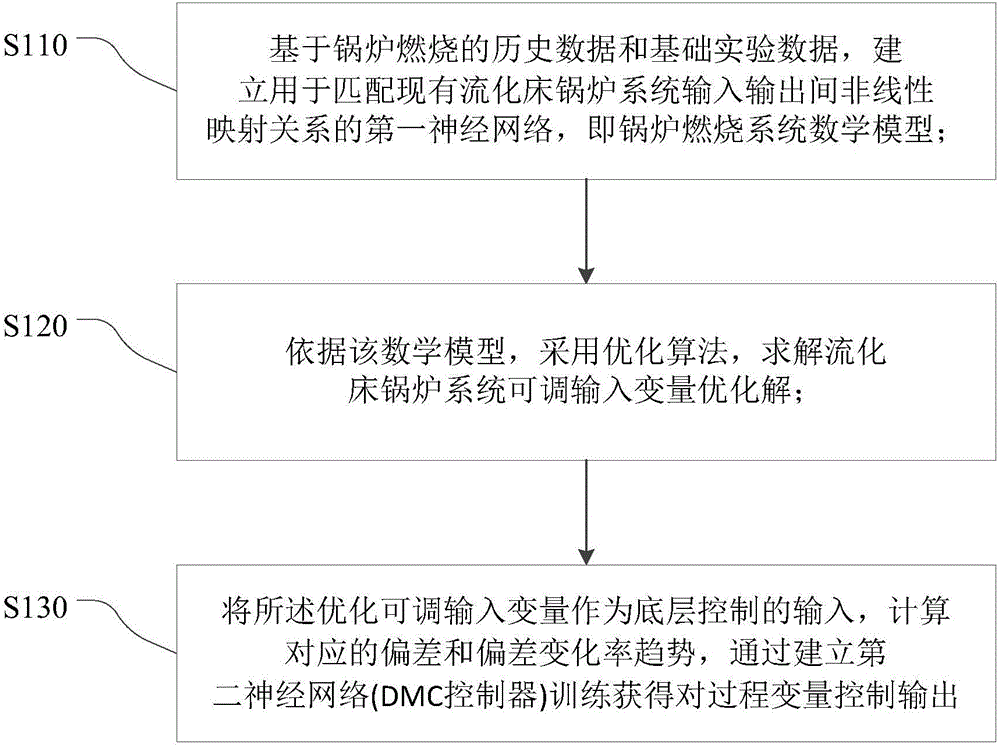

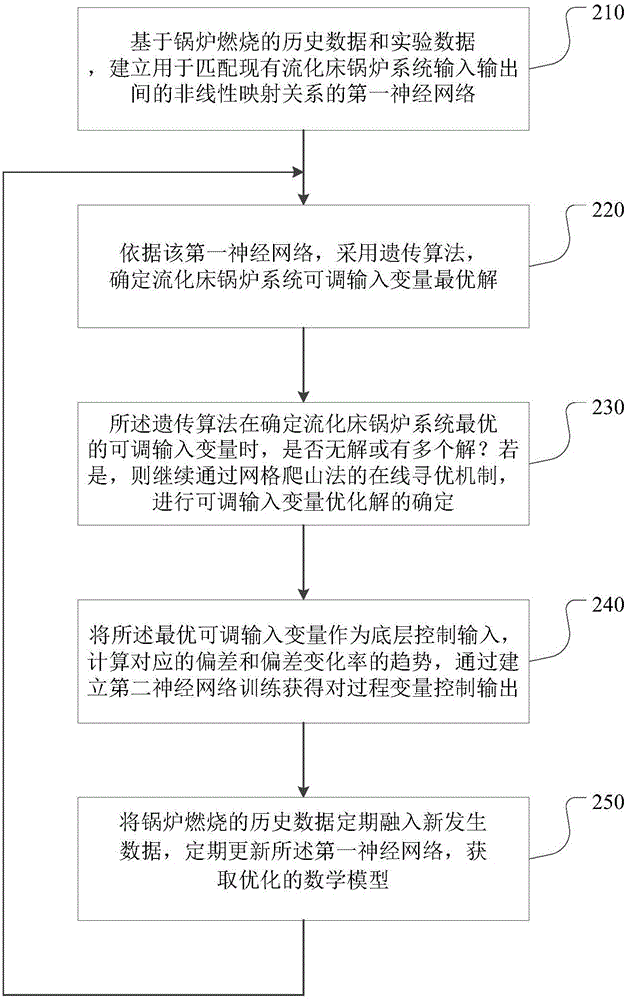

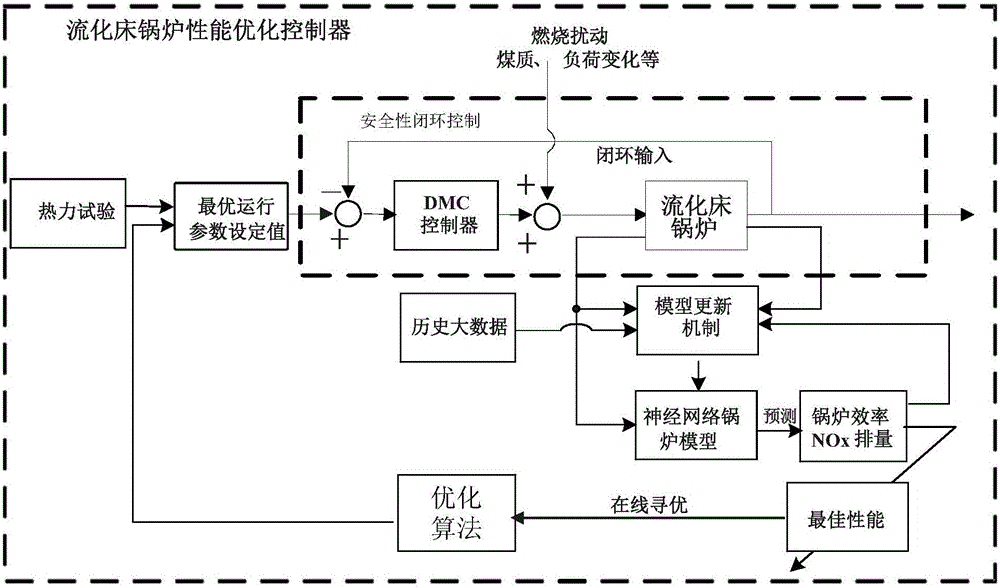

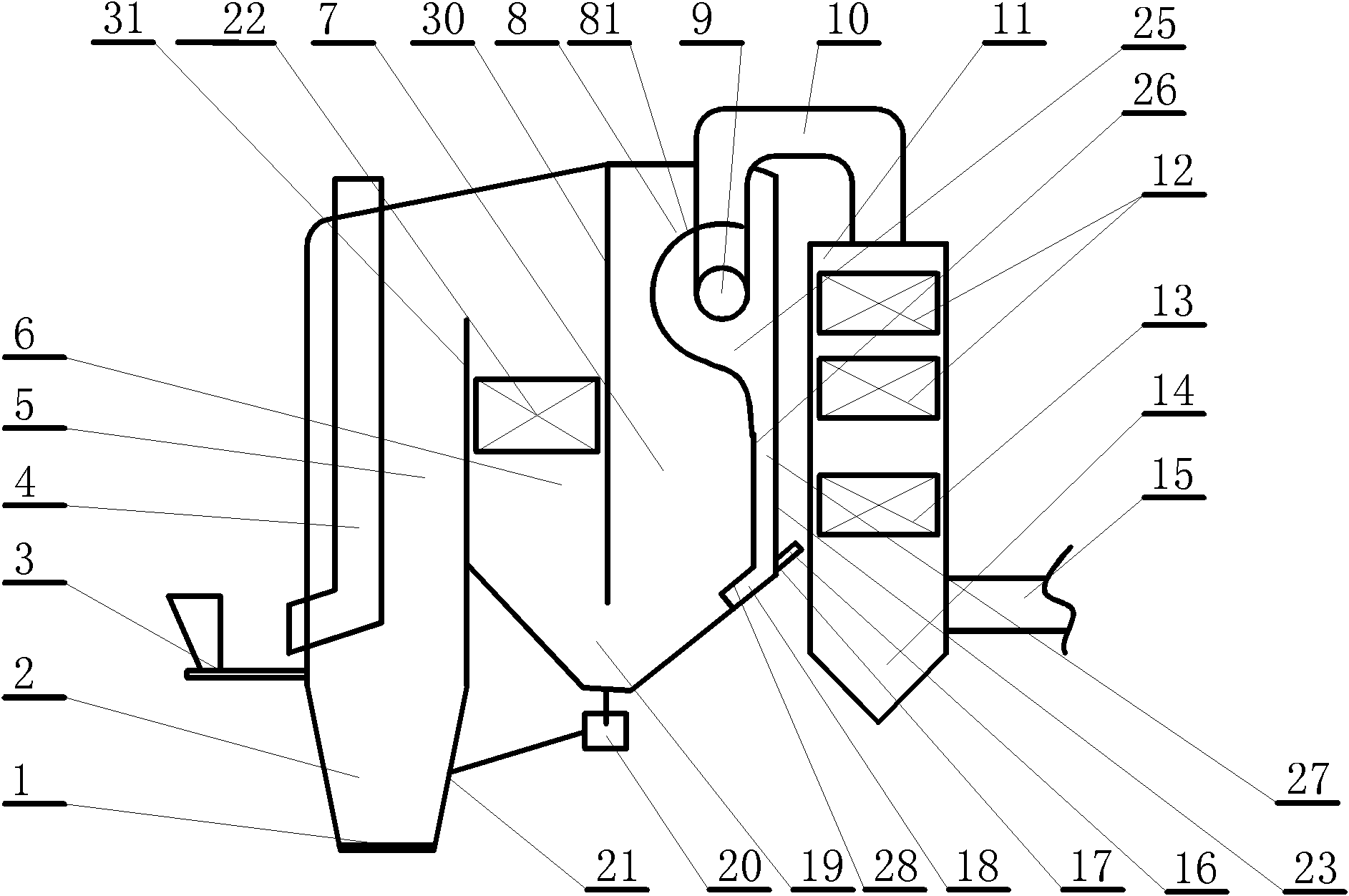

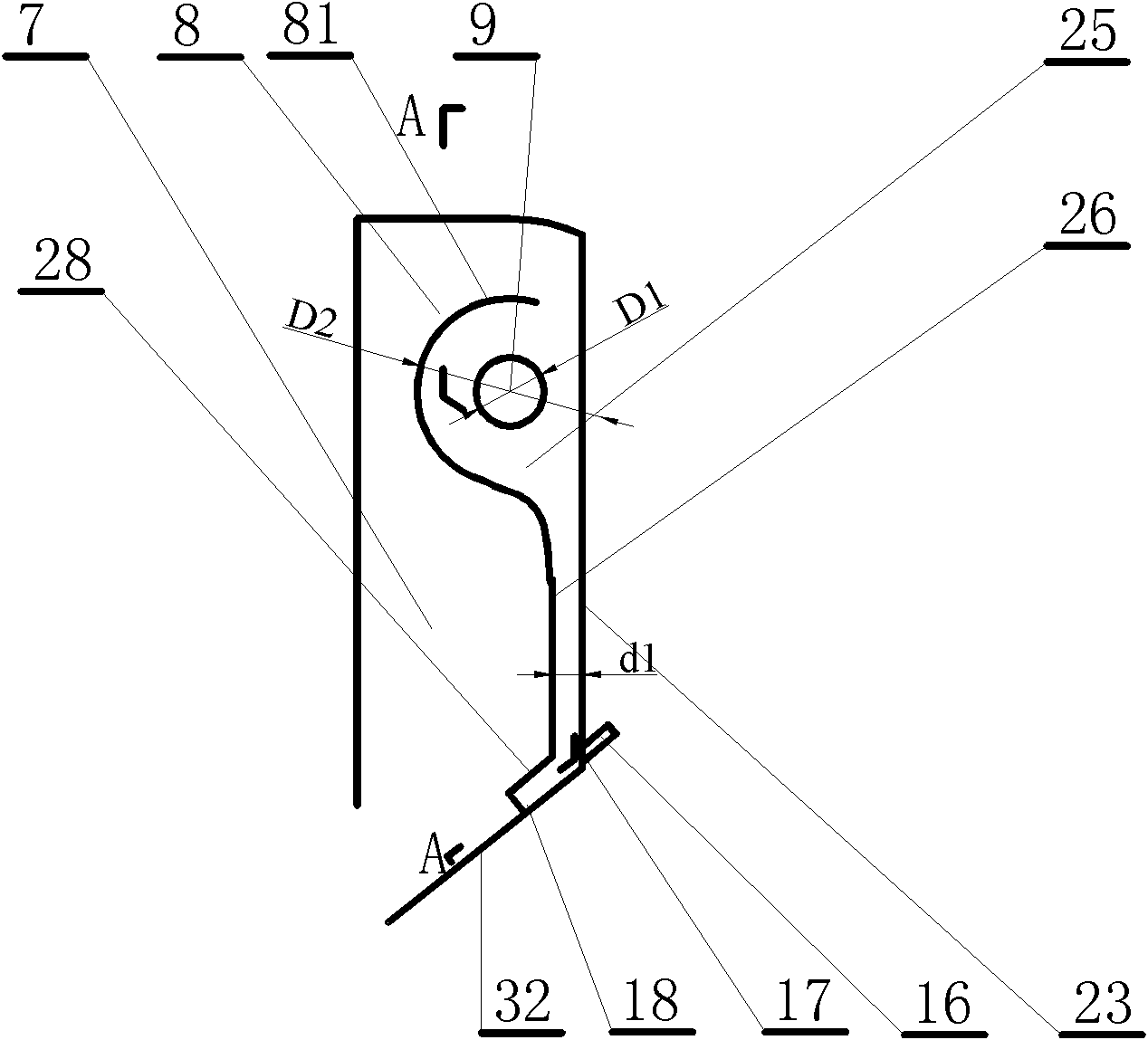

Method and system for optimizing and controlling combustion performance of circulating fluidized bed boiler in real time

ActiveCN105020705AGuaranteed uptimeImprove performanceFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention provides a method and system for optimizing and controlling combustion performance of a circulating fluidized bed boiler in real time. The method for optimizing and controlling combustion performance of the circulating fluidized bed boiler in real time includes the steps that based on historical data of combustion of the boiler, a first neural network used for being matched with a nonlinear mapping relation between the input and the output of an existing fluidized bed boiler system is established; according to the first neural network, the adjustable input variable of the input of the fluidized bed boiler system is determined; and the adjustable input variable serves as the bottom layer control input, the trends of corresponding deviation and the deviation change rate are calculated, and a second neural network is established for training and acquiring the process variable control output. By the adoption of the method and system, the boiler efficiency is improved, the power supply coal consumption is lowered, coking and slag bonding are prevented or treated, NOx emission is reduced, and the safety, the reliability and the economical efficiency of operation of the boiler are further improved.

Owner:INNER MONGOLIA RUITE TECH

Horizontal type circulating fluidized bed boiler with horizontal cyclone separator

ActiveCN102537943ALow costReduce construction costsFluidized bed combustionReversed direction vortexCycloneCombustion chamber

The invention relates to a horizontal type circulating fluidized bed boiler with a horizontal cyclone separator, belonging to combustion equipment of inferior fuels such as inferior coal, solid waste, sludge or biomass and the like, and the horizontal type circulating fluidized bed boiler is particularly suitable for fluidized combustion of a biomass boiler with less ash content. The horizontal type circulating fluidized bed boiler consists of a main combustion chamber, a secondary combustion chamber, a burnout chamber and a tail gas flue, and a horizontal cyclone separator is arranged in the burnout chamber. The horizontal type circulating fluidized bed boiler in the invention changes a single-stage vertical circulating structure of a vertical circulating fluidized bed, can effectively reduce the height of a boiler and reduce the requirement for building height of a factory, meanwhile, the horizontal cyclone separator is integrated in the burnout chamber, the structure is more compact, thereby being beneficial to miniaturization of a circulating bed boiler and reducing the cost effectively. The horizontal type circulating fluidized bed boiler has all the advantages of a circulating fluidized bed and can combust fuels such as inferior coal, solid waste, municipal and industrial sludge, biomass and the like, has wide fuel adaptability and is high-efficiency combustion equipment with clean combustion, a compact structure and long service life.

Owner:TSINGHUA UNIV +1

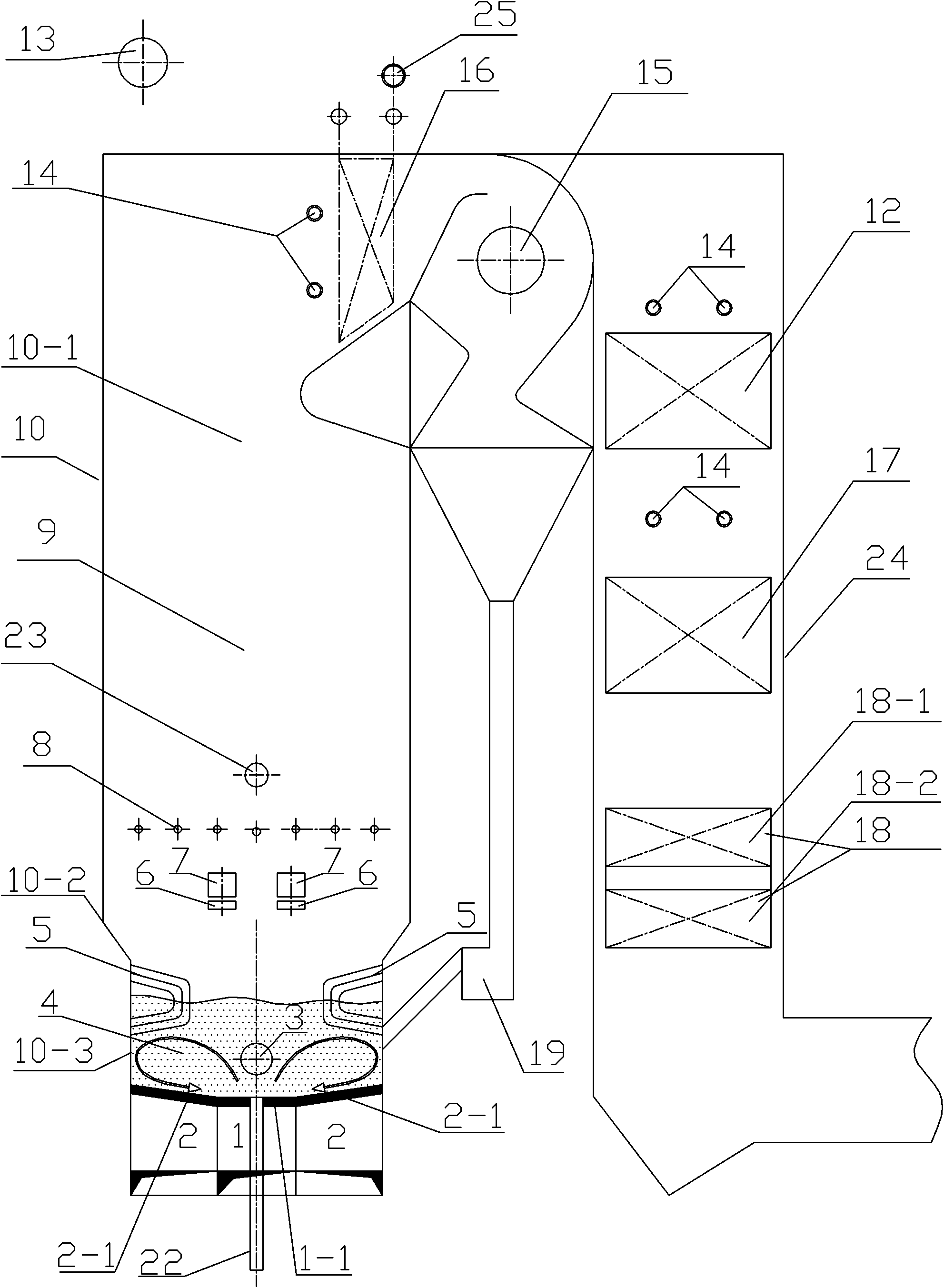

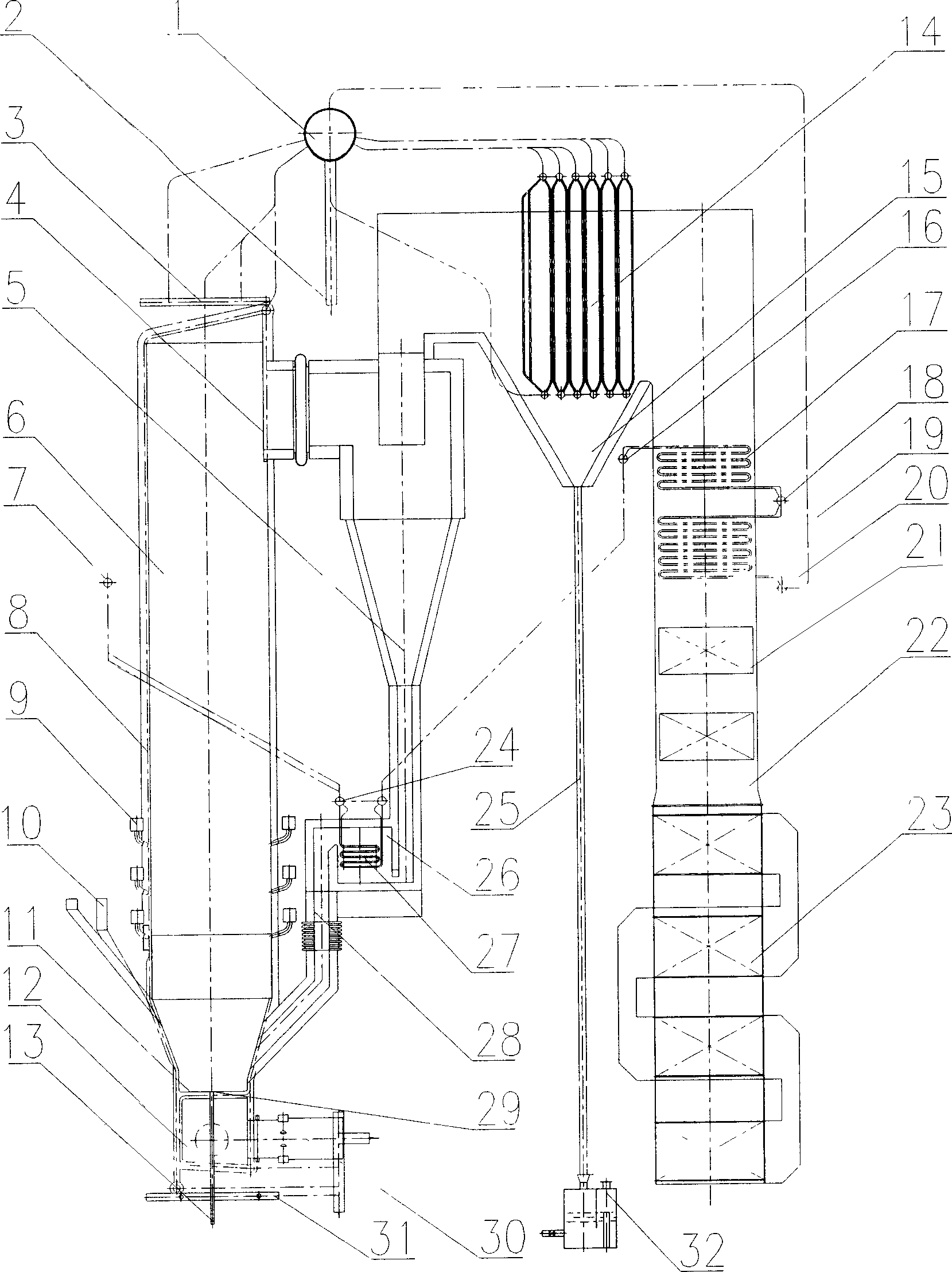

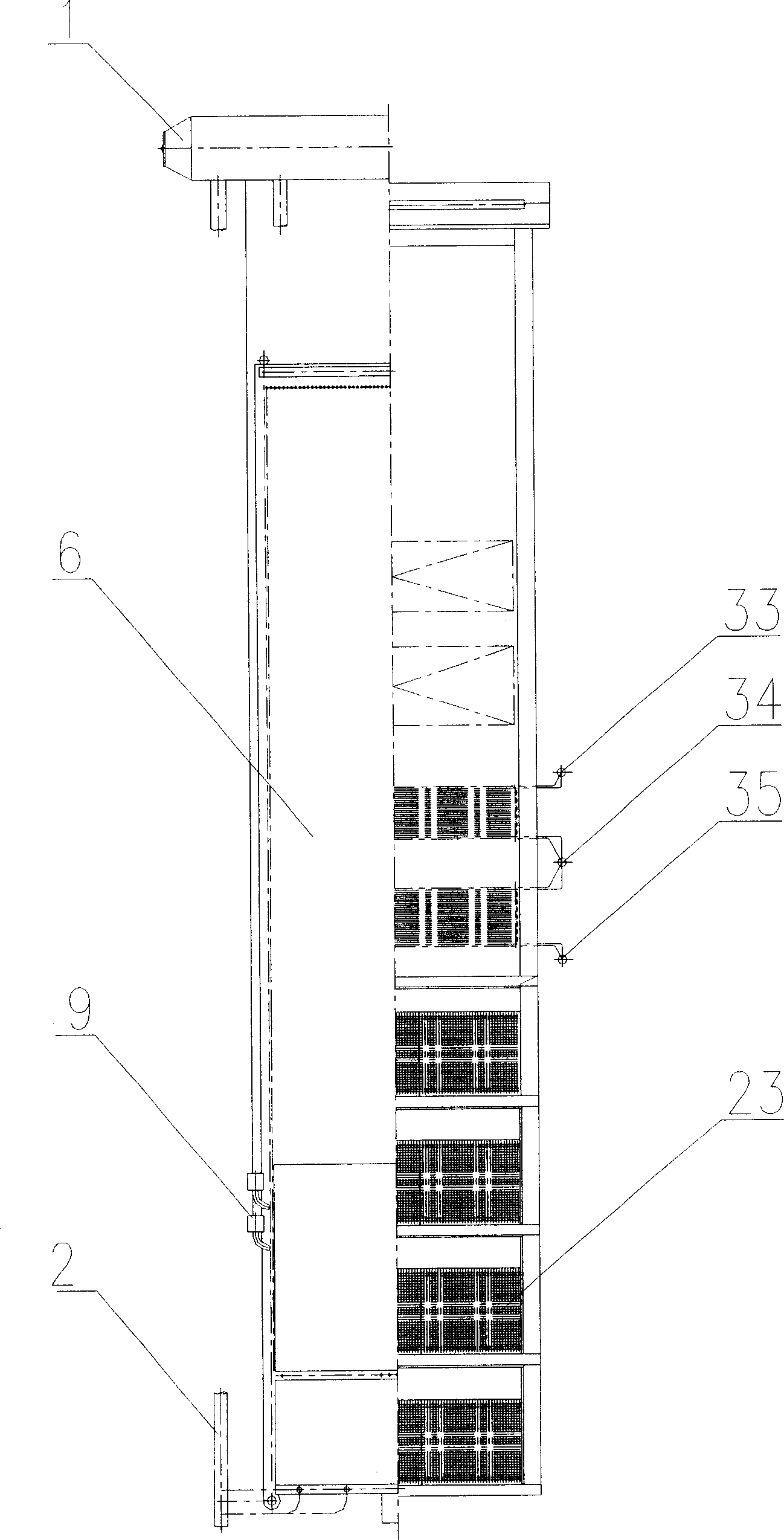

A membrane-type water-cooled wall four-flue biomass circulating fluidized bed boiler

InactiveCN102297423AIncrease profitGuaranteed uptimeFluidized bed combustionCombustion technology mitigationSuperheaterHeat energy

A membrane water-cooled wall four-flue biomass circulating fluidized bed boiler, including a drum, a furnace, a cyclone separator, a return device, a second flue, a third flue, a fourth flue, an economizer, and a dust collector appliance, induced draft fan, chimney. The furnace, the second flue and the third flue are surrounded by membrane water-cooled walls; in the lower part of the furnace and the inner surface of the flue gas outlet, the cyclone separator and the inner surface of the flue gas outlet, the second flue and the third flue Refractory castables are laid around the connecting parts of the flue; a medium-temperature screen superheater is arranged at the upper end of the second flue; high-temperature and low-temperature convection superheaters are spaced in the third flue; the middle wall adopts a tapered wall structure; low-temperature convection superheater The first water spray desuperheater and the second water spray desuperheater are respectively arranged between the high temperature convection superheater and the medium temperature screen convection superheater. The invention improves the combustion heat energy utilization rate of the biomass fluidized bed boiler, reduces the wear and alkali metal corrosion of the inner wall of the flue by high-speed and high-temperature flue gas, and enhances the wear resistance of the wall surface.

Owner:JIANGSU SIFANG BOILER +1

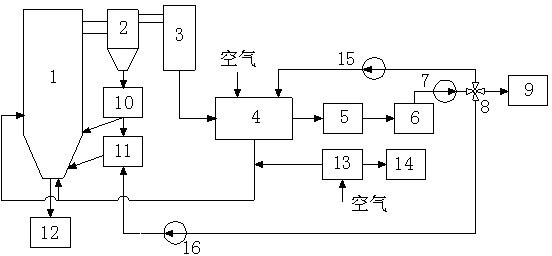

Boiler system of circulating fluid bed burning in oxygen enrichment

InactiveCN1959208AOvercome the problem of difficult temperature controlIncrease concentrationFluidized bed combustionIndirect carbon-dioxide mitigationHigh concentrationFluidized bed

A circulation fluidized-bed boiler of rich-oxygen combustion type is prepared as utilizing circulation fluidized-bed boiler with external fluidized bed heat exchanger to carry out combustion in mode of mixing mixture gas of high concentration oxygen from air separate and recirculation smoke from boiler tail with fuel, controlling load and firepot temperature of said boiler by regulating flow rate of fly ash particles entering into external fluidized bed heat exchanger.

Owner:HUAZHONG UNIV OF SCI & TECH

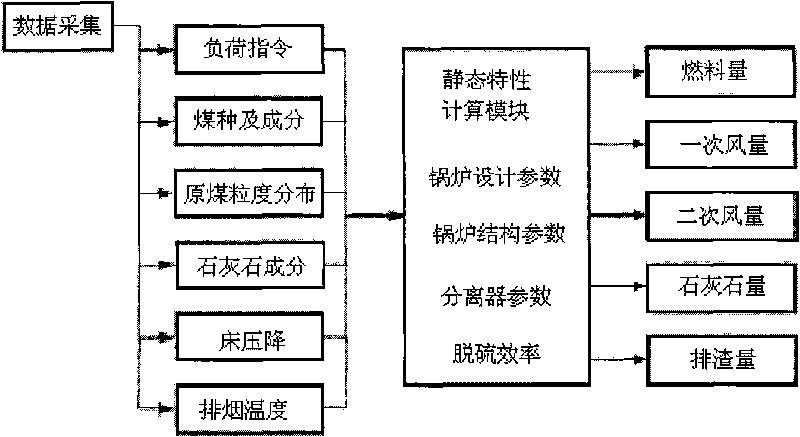

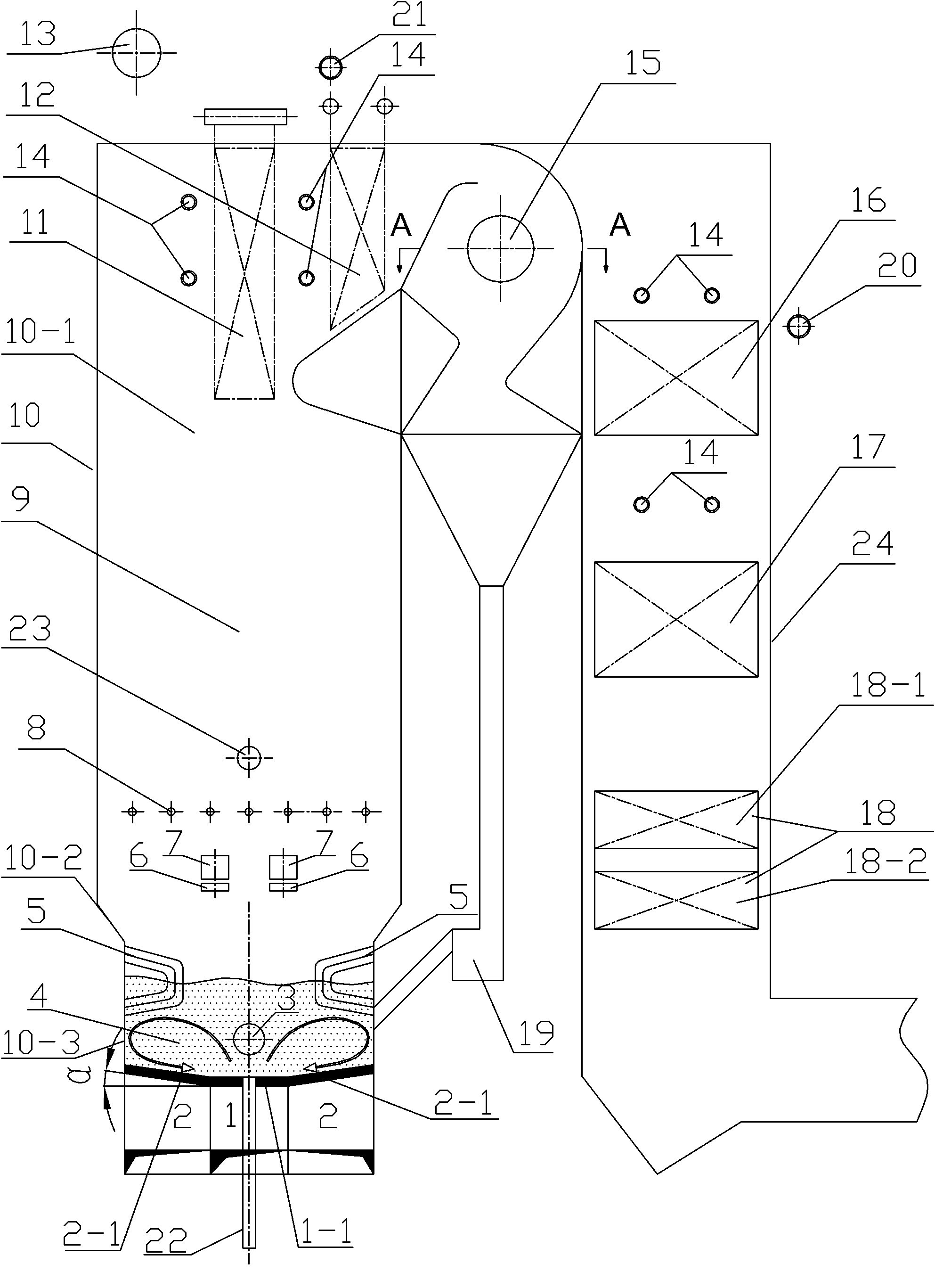

Control method of combustion system of circulating fluidized bed boiler

InactiveCN101713536AReal-time and accurate adjustment commandRealize combustion automatic controlFluidized bed combustionApparatus for fluidised bed combustionAir volumeAutomatic control

The invention relates to a control method of a combustion system of a circulating fluidized bed boiler, which adopts multivariable expert intelligent self-calibration PID control and is provided with an on-line calculation module for the static characteristics of the circulating fluidized bed boiler. The on-line calculation module for the static characteristics of the circulating fluidized bed boiler calculates the coal supply quantity, the limestone quantity and the deslagging quantity for realizing the optimizing combustion of the boiler under different loads, the primary air quantity and the secondary air quantity are optimized and proportioned and are used as load feedforward signals which are applied to a main steam pressure control loop, a limestone quantity control loop, a bed pressure drop control loop, a bed temperature control loop and an oxygen quantity control loop, and each control loop adopts an expert intelligent self-calibration PID controller to form a multivariable combustion control system of a CFB boiler. The invention is provided with the calculation module for the static characteristics of the circulating fluidized bed boiler, which can accurately send out each regulation quantity instruction at real time and realize automatic control; the multivariable expert system is in consideration of the nonlinearity and the strong-coupling property of the combustion system of the boiler and ensures the performance robustness of the control system; and meanwhile, the PID parameters are automatically regulated according to the change of the characteristics of a controlled object, so the automatic combustion control system of the circulating fluidized bed boiler has stable robustness.

Owner:TAIYUAN UNIV OF TECH

Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

InactiveCN101949535AProlonged combustion residence timeSolve cokingFluidized bed combustionApparatus for fluidised bed combustionCombustionLow speed

The invention relates to a low-ratio biomass circulating fluidized bed boiler and a combustion method thereof, relating to a circulating fluidized bed boiler and a combustion method thereof and solving the problems of difficult feeding, grate slagging, bed material coking, tempering and output reduction, and the like existing in the operation of traditional grate furnaces and circulating fluidized bed boilers. A middle air chamber corresponds to the middle of a dense-phase area at the lower part, lateral grid plates are arranged between a lateral air chamber and the dense-phase area at the lower part, and a medium-temperature steam-cooled cyclone separator is arranged at the joint between a flue shaft at the tail part and a health outlet of a boiler body, respectively communicated with the flue shaft and the health outlet and communicated with the dense-phase area at the lower part through a material returner. The method adopts a negative-pressure feeding manner so that the fluidization air velocity of a high-speed area of the dense-phase area at the lower part is 4-5 m / s, the fluidization air velocity of a low-speed area is 1.5-2.0 m / s, the temperature of the dense-phase area at the lower part is 650-780 DEG C, and the material circulation ratio is below 10. The invention is suitable for the biomass circulating fluidized bed boiler for an electric power plant.

Owner:湖南博茂节能环保科技有限公司

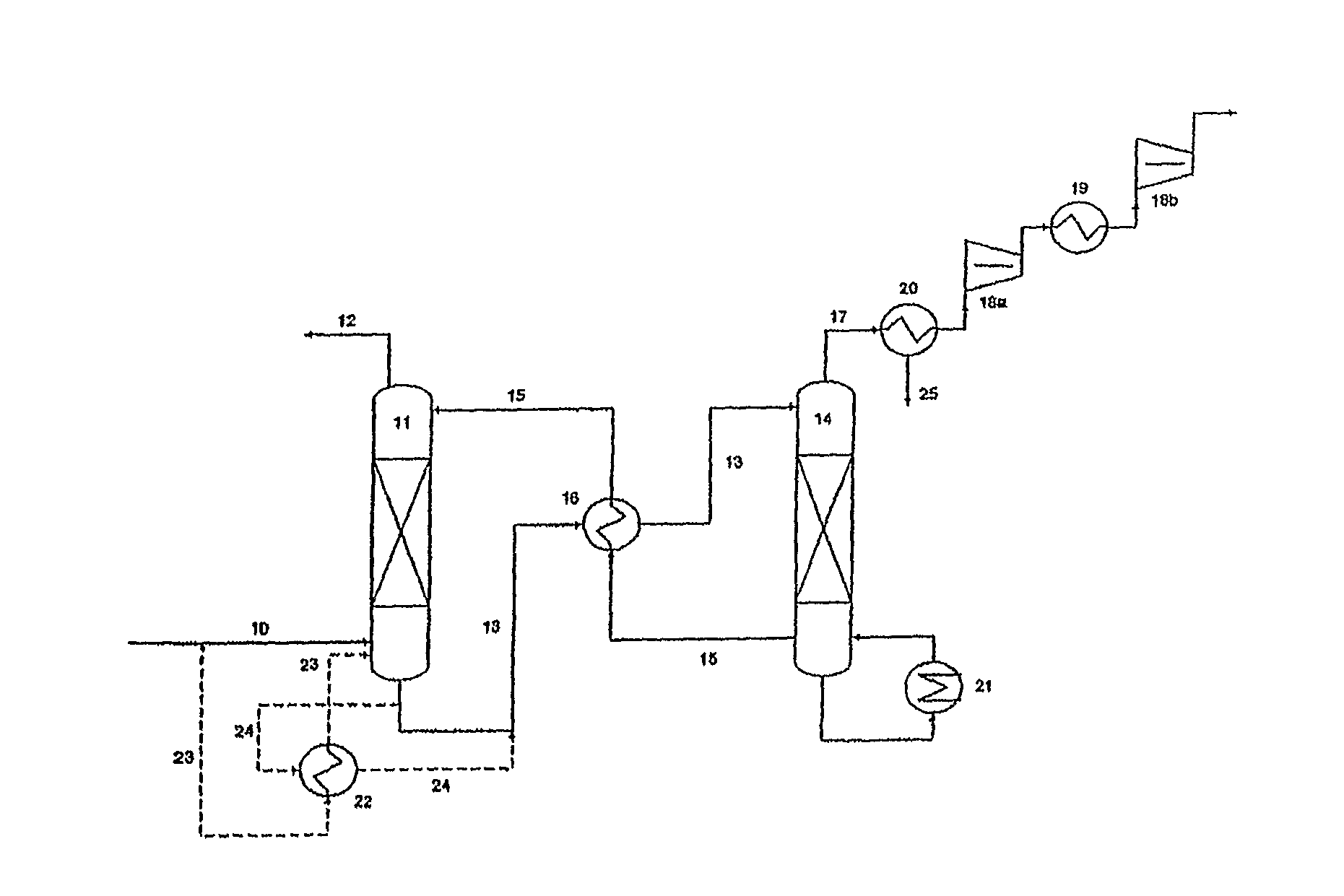

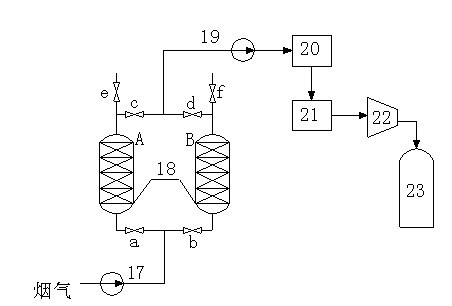

Oxygen production method and plant using chemical looping in a fluidized bed

The invention relates to a method and to a plant for producing high-purity oxygen, said method comprising a chemical loop wherein circulates a fluidized bed material having the capacity to release gaseous oxygen through oxygen partial pressure lowering, at a temperature ranging between 400° C. and 700° C. The oxygen thus produced can be used in applications such as oxycombustion methods, production of syngas under pressure or FCC catalyst regeneration.

Owner:INST FR DU PETROLE

Fluidized bed boiler control and combustion optimization system

ActiveCN107023825AOptimize operating parametersImprove controlFluidized bed combustionApparatus for fluidised bed combustionFluidized bedOxygen content

The invention discloses a fluidized bed boiler control and combustion optimization system. The problem that a fluidized bed boiler system is not easy to control for a long time is solved. According to a method, a control strategy of combining an advanced control algorithm and a conventional control algorithm is adopted, and continuous, economical and stable operating of the boiler system is guaranteed; multivariable model-free adaptive control is adopted, and decoupling control of the fuel quantity and the air supply quantity over the bed temperature under the variable load work condition is achieved; and a nerual network technique is adopted for building a boiler combustion prediction model, online calculation of the boiler efficiency and NOX and SOX emissions is achieved, a multi-objective optimization function is constructed according to the prediction result, a combustion self-optimization algorithm is adopted, the flue gas oxygen content and the bed temperature are optimized constantly so as to adapt to work condition changes, and a fluidized bed boiler can operate in an optimal combustion area.

Owner:XIAN IBL TECH DEV +1

Straw circulation fluidized-bed combustion boiler

InactiveCN1912461AGood load regulation performanceAvoid corrosionFluidized bed combustionCombined combustion mitigationAir preheaterCombustion chamber

A recirculation fluidized bed combustion boiler of straw is prepared as setting material feed mouth and residue extraction mouth on firepot, setting cooling device being connected to ignition combustion chamber and refeeder with secondary wind opening at bottom of firepot, using water cooling wall with top and bottom collection boxes as side wall of firepot, connecting outlet of firepot to separation device being connected to refeeder and two stages of thermo reduction devices separately, connecting one stage of thermo reduction device to a overheat unit with economizer and preheater as well as setting steam pocket and water supply pipe at top of firepot.

Owner:SHANDONG GUODIAN TECH CONSULTING +1

Plant for the generation of electricity

InactiveUS20090072538A1Easy to captureInhibit productionFluidized bed combustionGas turbine plantsElectricityCyclone

A plant for generating electricity includes a gas turbine, a compressor driven by the gas turbine, a reduction reactor configured to reduce metal oxides, fed with a fuel and having a first circulating fluidized bed, a first cyclone configured to separate the metal oxide solids, and feeding at least a portion of the metal oxide solids to the reduction reactor via a first connecting line, an oxidation reactor configured to oxidize the metal oxides having a second circulating fluidized bed and fed only with pressurized air from the compressor, and a second cyclone configured to separate the metal oxide solids and feeding at least a portion of the metal oxide solids to the oxidation reactor via a second connecting line.

Owner:GENERAL ELECTRIC TECH GMBH

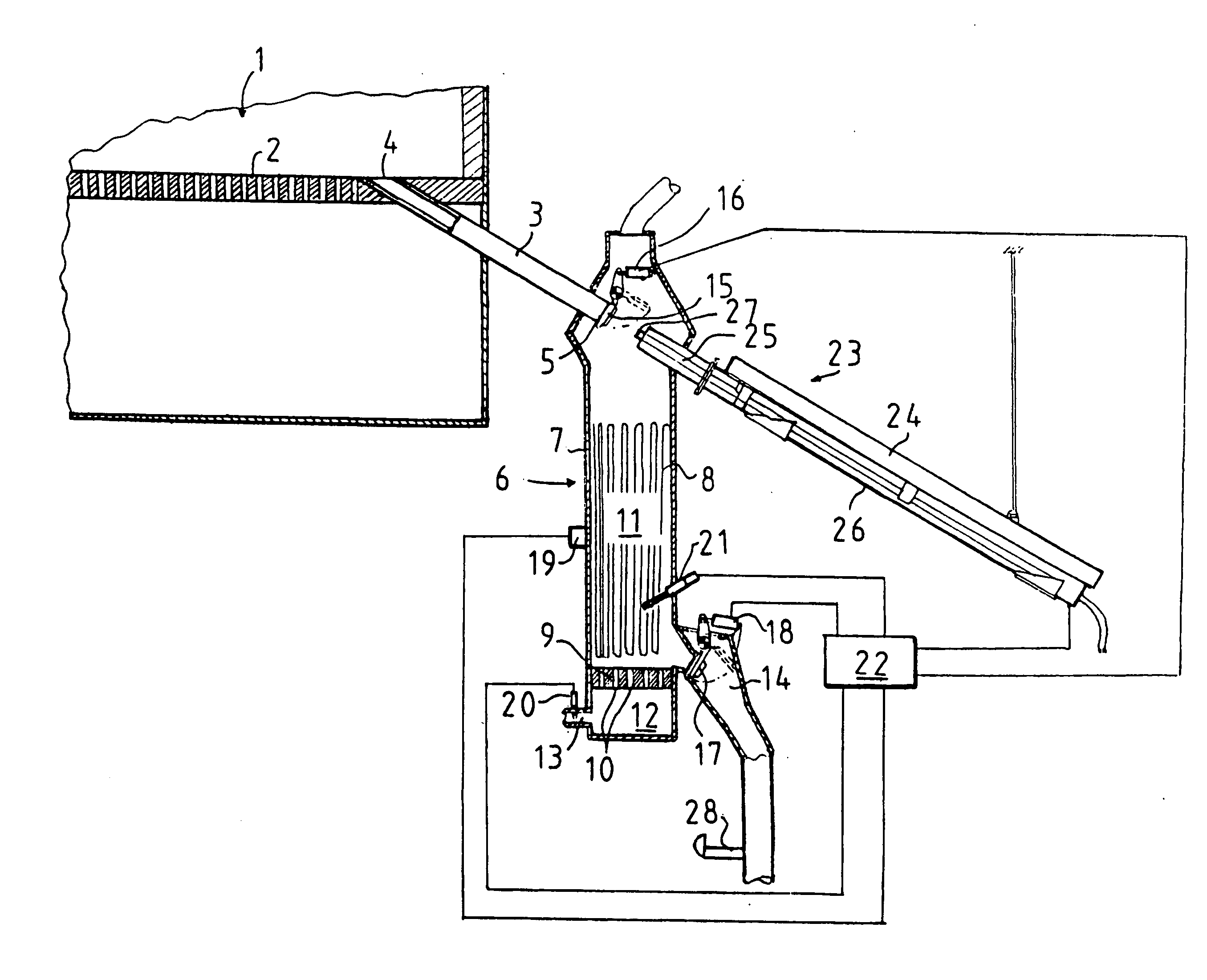

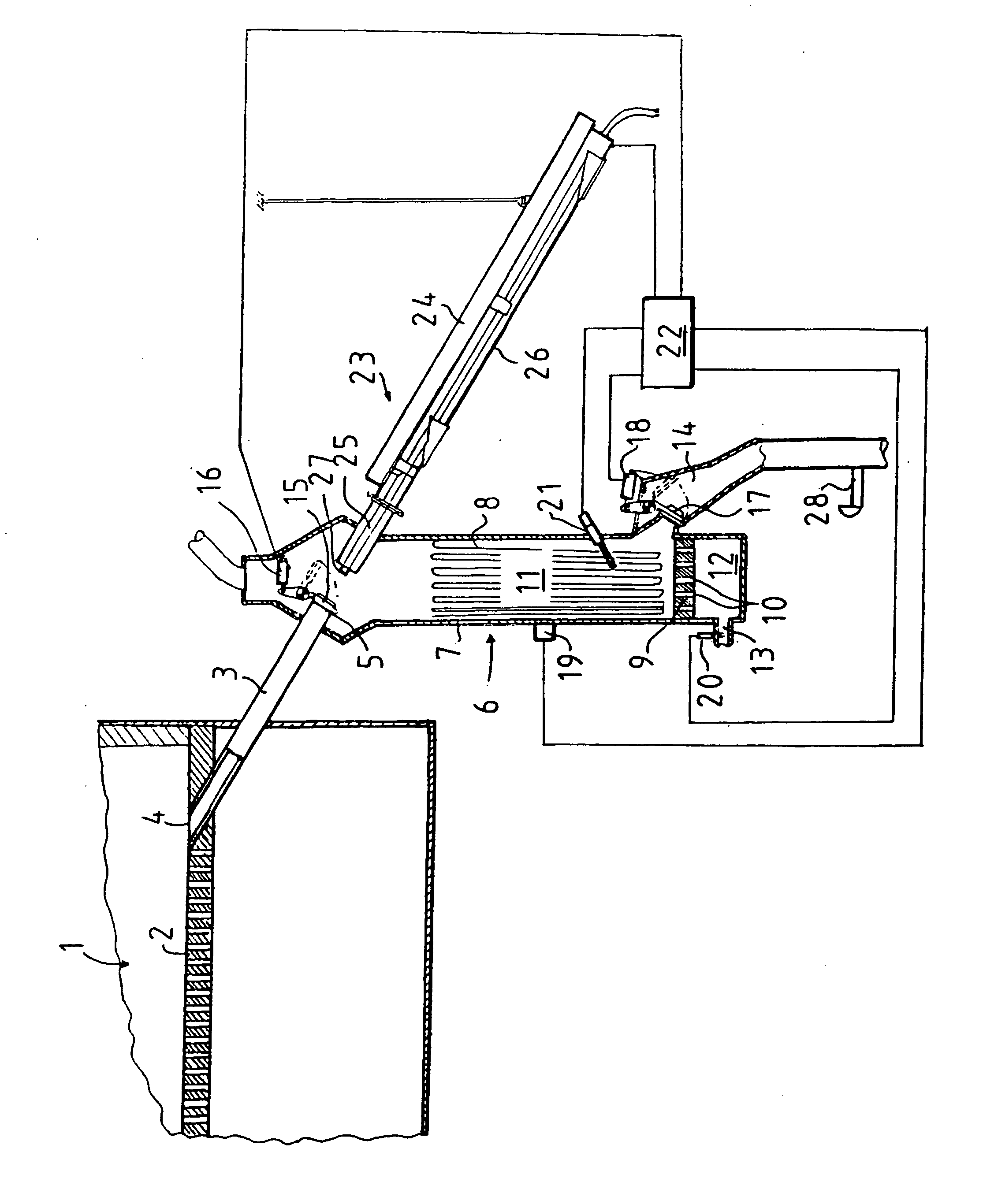

Method And Apparatus For Cooling A Material To Be Removed From The Grate Of A Fluidized Bed Furnace

InactiveUS20080199821A1Improve automationQuantity of charge is controlledFluidized bed combustionGasification processes detailsElectricityLimit value

The invention relates to a method and an apparatus for cooling a material to be removed from the grate of a fluidized bed furnace. Material at a high temperature is passed from the grate of the fluidized bed furnace into a fluidized bed cooler in charges of a given size by measuring the quantity of the material accumulating in the fluidized bed cooler. When the quantity of the material in the cooler has reached a predetermined limit value, the supply of material into the fluidized bed cooler is prevented. The charge is cooled in the fluidized bed cooler by fluidization air and via heat transfer into a cooling liquid circulation system and the temperature of the charge is measured. The charge is removed when the temperature of the charge has fallen to a predetermined limit value. The second end (5) of a supply conduit (3) is provided with a supply valve (15) actuated by a power means (16). A discharge conduit (14) is provided with a discharge valve (17) actuated by a second power means (18). Quantity detection means (19, 20) are provided to produce quantity data regarding the amount of material in a fluidized bed space (11), and temperature measuring means (21) are provided to produce temperature data. A control device (22) controls the first power means (16) to open and close the supply valve (15) and the second power means (18) to open and close the discharge valve (17) on the basis of the quantity data and temperature data and the predetermined limit values of quantity and temperature so that the loading of material into the fluidized bed space and its cooling and removal from the fluidized bed space take place in a charge-by-charge and cyclic manner.

Owner:OUTOTEC OYJ

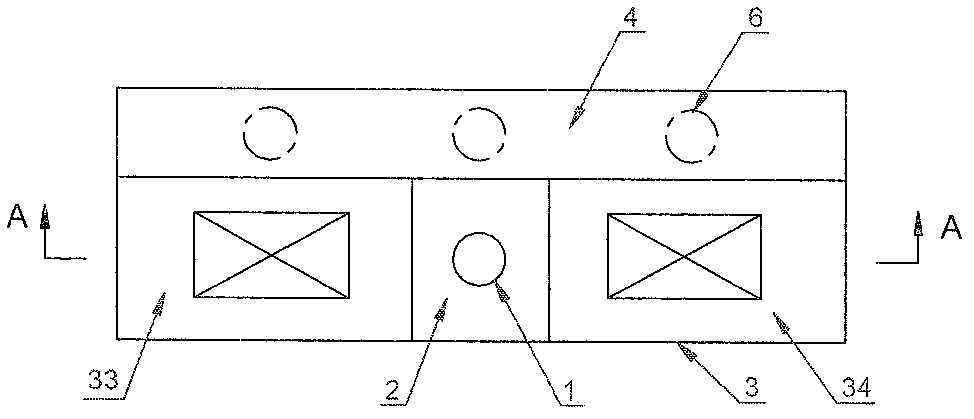

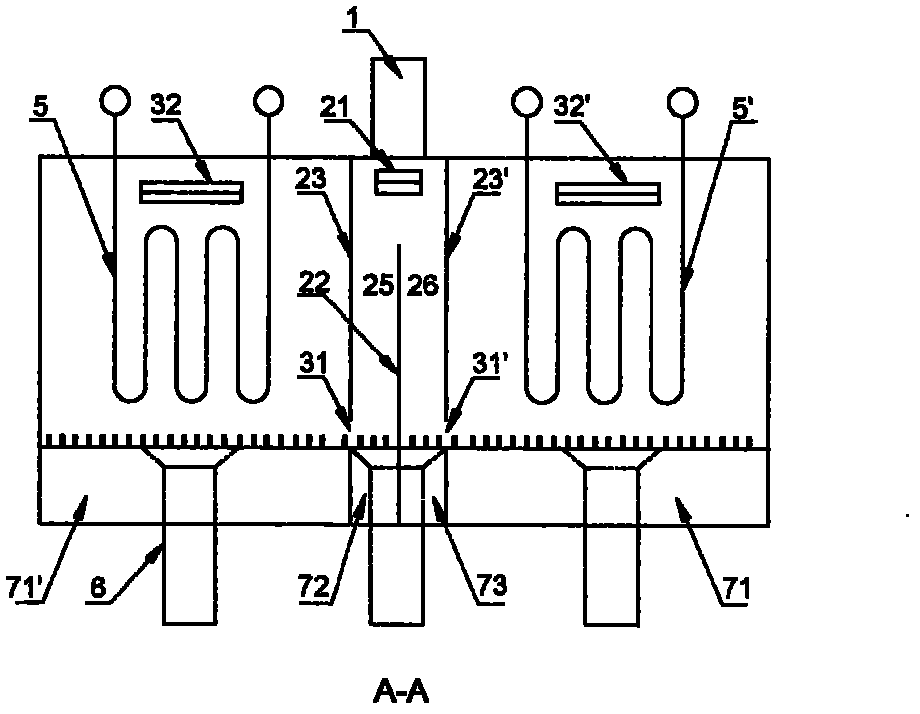

Compact parallel connection type external fluidized bed heat exchanger

ActiveCN102840578AImprove heat exchange capacityImprove heat transfer efficiencyFluidized bed combustionApparatus for fluidised bed combustionConnection typeFluidized bed

The present invention discloses a compact parallel connection type external fluidized bed heat exchanger, and relates to a fluidized bed heat exchange technology. The compact parallel connection type external fluidized bed heat exchanger comprises a material inlet, a material dispenser, two heat exchange chambers arranged in a parallel connection manner, and a material returning chamber. According to the compact parallel connection type external fluidized bed heat exchanger of the present invention, a pneumatic way is adopted to precisely control the amounts of circulating ash entering the two parallel heat exchange chambers, such that independent adjustments and controls of heat exchange powers of the two heat exchange chambers according to requirements can be achieved; with arrangement of the two heat exchange chambers in the parallel connection manner, heat exchange of the two heat exchange chambers has high heat transfer temperatures and high heat transfer pressures, such that a heat exchange efficiency between high temperature circulating particles and the heat exchange pipe bundles is improved while uniformity of the returned material of the large-size hearth and stability of the bed temperature are improved; and with the compact integration design, structure arrangement and operation adjustment of the large circulating fluidized bed boiler are flexible.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Automatic control method of 300 MW grading circulating fluidized bed units

ActiveCN101225955AKeep the economy runningAvoid cokingFluidized bed combustionLiquid fuel feeder/distributionAir volumeAutomatic control

The invention relates to an automatic control method of 300MW grade circulating fluid bed unit, which sets the automatic control methods for the coordination of machine and furnace, the deviation of single bed pressure and double bed pressure, the water level of the deaerator and the condenser, the secondary air quantity / oxygen quantity and the secondary air pressure, the boiler bed temperature, the fuel flow and the limerock feeding during making the first 300 MW circulating fluid bed unit as the localization of manufactures, meanwhile, the 300 MW circulating fluid bed unit has the advantages of stable operation, safety, reliable and remarkable economic operation passing through the coordination and control for the system.

Owner:云南电力试验研究院(集团)有限公司

Processes and systems for producing heat for rapid thermal processing of carbonaceous material

InactiveUS20120137939A1Rapid heat treatmentFluidized bed combustionDirect heating destructive distillationHeat carrierGrating

Embodiments of processes and systems for producing heat for rapid thermal processing of carbonaceous material are provided. The process comprises the steps of contacting bubbles of an oxygen containing gas advancing through a fluidized bubbling bed with a grating to form smaller bubbles. The fluidized bubbling bed is contained in a reheater and comprises inorganic heat carrier particles and char. The reheater is operating at combustion conditions effective to burn the char into ash and heat the inorganic heat carrier particles to form heated inorganic particles. The heated inorganic particles are advanced to a reactor.

Owner:ENSYN RENEWABLES

Apparatuses for controlling heat for rapid thermal processing of carbonaceous material and methods for the same

ActiveUS20130078581A1Rapid heat treatmentMaterial becomes quickFluidized bed combustionContinuous combustion chamberInorganic particleHeat carrier

Embodiments of apparatuses and methods for controlling heat for rapid thermal processing of carbonaceous material are provided herein. The apparatus comprises a reactor, a reheater for forming a fluidized bubbling bed comprising an oxygen-containing gas, inorganic heat carrier particles, and char and for burning the char into ash to form heated inorganic particles. An inorganic particle cooler is in fluid communication with the reheater. The inorganic particle cooler comprises a shell portion and a tube portion. The inorganic particle cooler is configured such that the shell portion receives a portion of the heated inorganic particles and the tube portion receives a cooling medium for indirect heat exchange with the portion of the heated inorganic particles to form partially-cooled heated inorganic particles.

Owner:ENSYN RENEWABLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com