Automatic boiler combustion control system of circulating fluid bed

An automatic control system, a technology of circulating fluidized bed, which is applied in the directions of fluidized bed combustion equipment, fuel burned in a molten state, combustion method, etc., can solve the explosion of the boiler steam-water system, the uncertainty of the load change is large, and the combustion efficiency of the boiler is reduced. and other problems, to achieve the effect of reducing the risk of steam turbine water shock, advanced and reasonable algorithm design, and improved operation safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

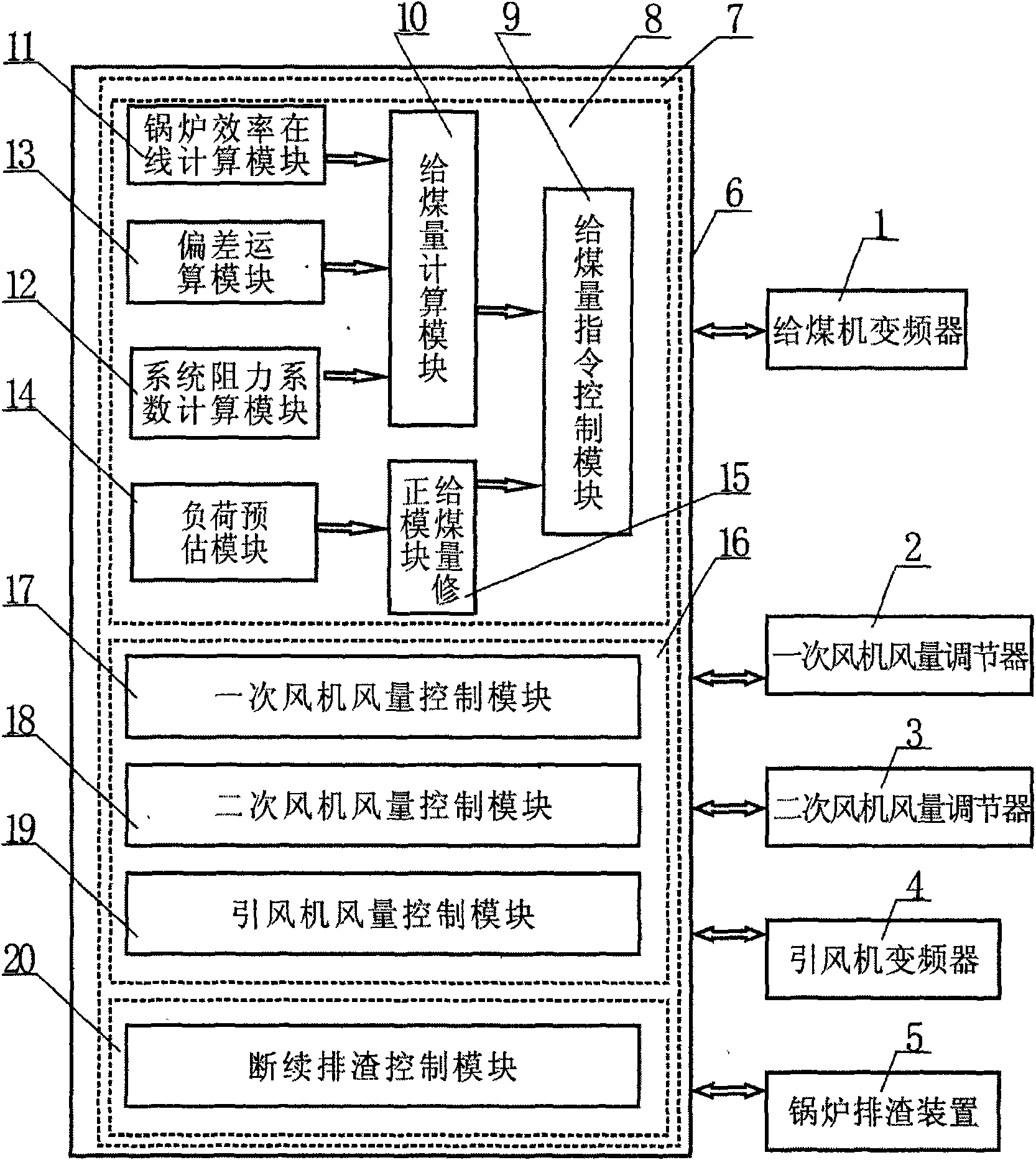

[0028] like figure 1 As shown, the circulating fluidized bed boiler combustion automatic control system includes two parts: hardware and control program software. 4. Boiler slag discharge device 5 and computer 6. Coal feeder inverter 1 is used to adjust the speed of the coal feeder feeding coal to the boiler to control the amount of coal fed; primary fan air volume regulator 2, secondary fan air volume adjustment The device 3 and the induced draft fan frequency converter 4 are used to adjust the air supply volume of the fan to the boiler; the boiler slag discharge device 5 discharges the ash after boiler combustion intermittently; the computer 6 is used to receive control parameters and calculate according to the control parameters Coal supply volume, air supply volume, and form control instructions to control coal feeder frequency converter 1, primary fan air volume regulator 2, secondary fan air volume regulator 3, induced draft fan frequency converter 4, and boiler slag dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com