Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2407results about "Gas generation devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deodorizing and sanitizing employing a wicking device

ActiveUS7285255B2Difficult to cleanAvoid accumulationLavatory sanitoryGaseous substancesCapillary actionChemistry

Owner:ECOLAB USA INC

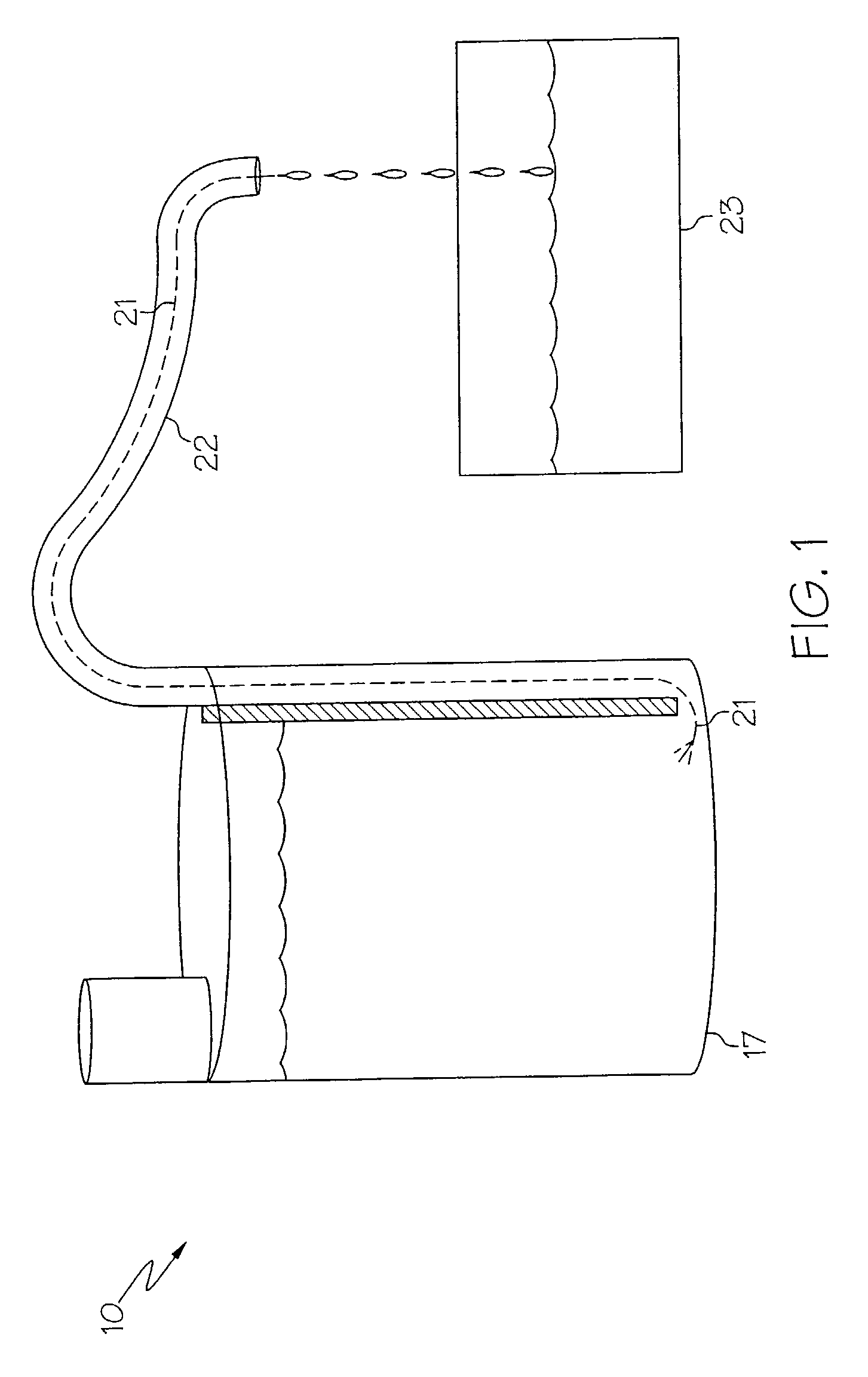

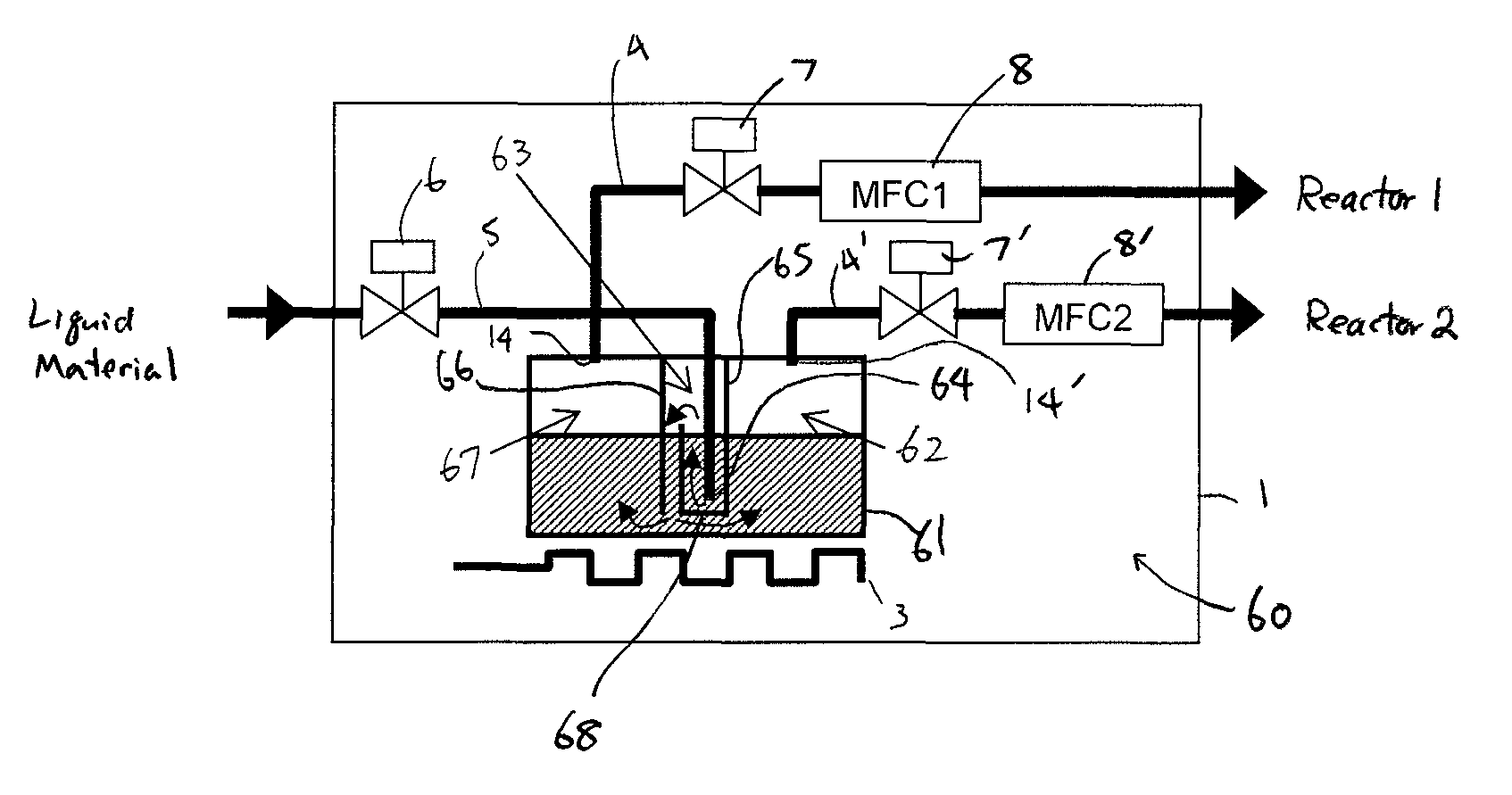

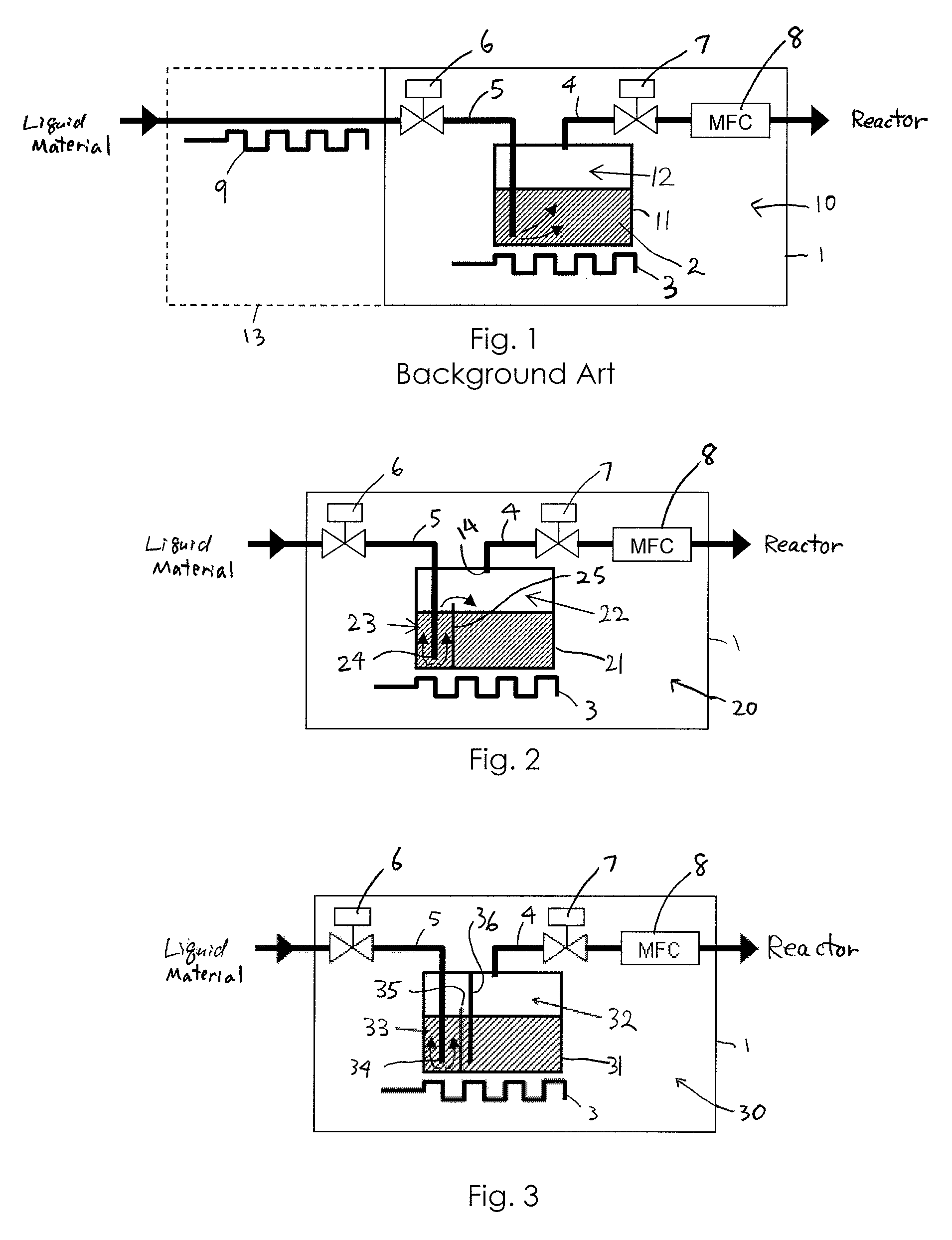

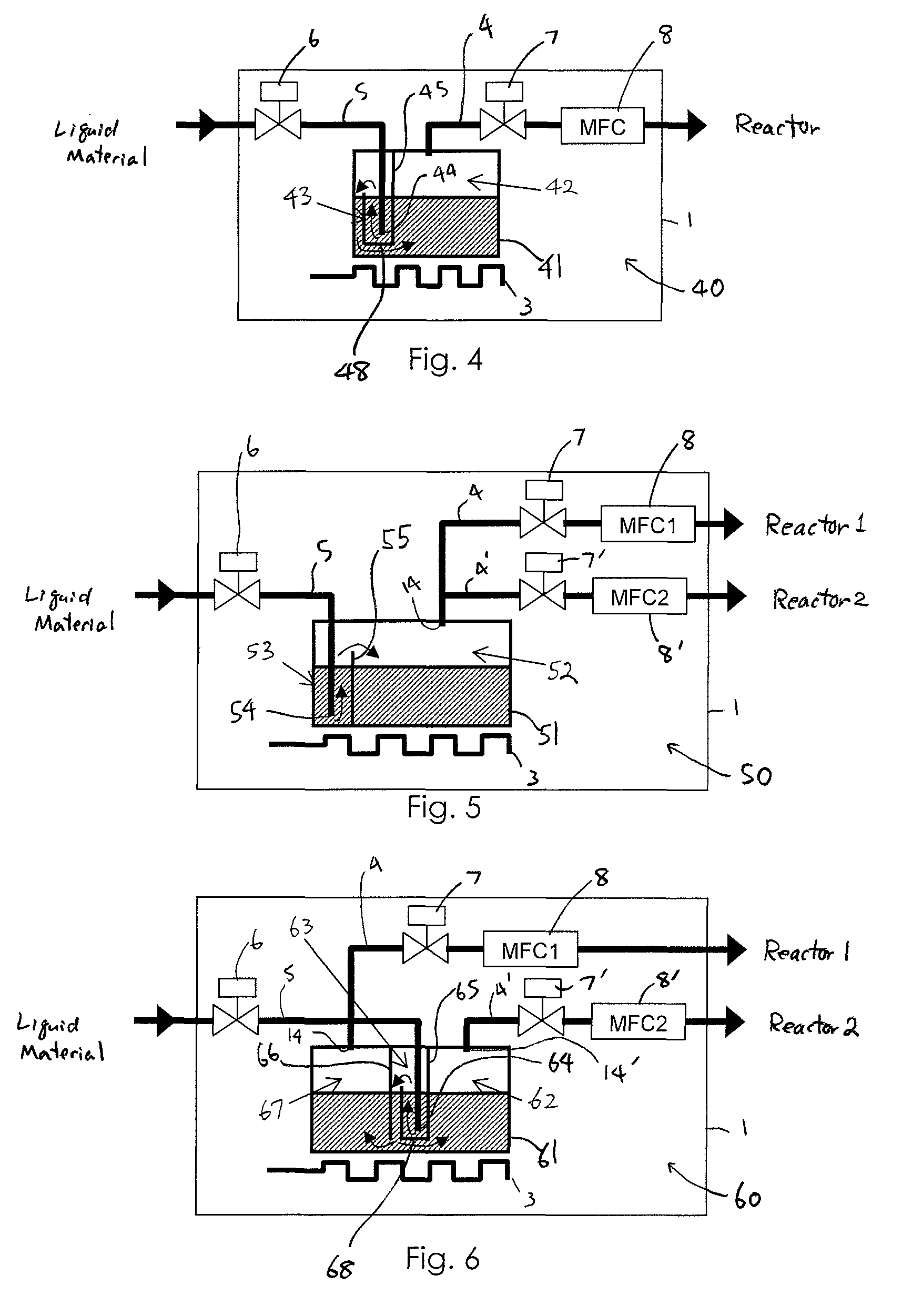

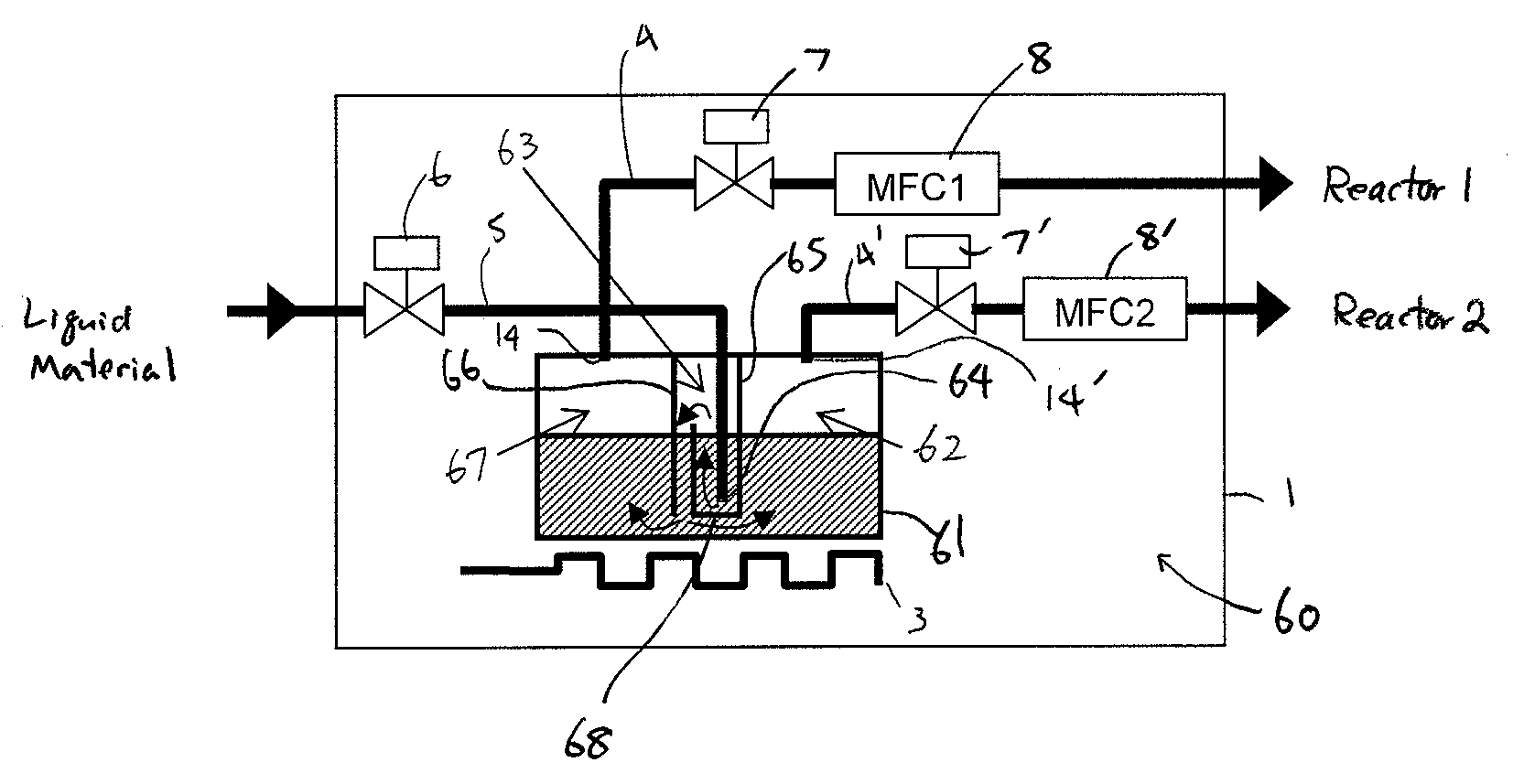

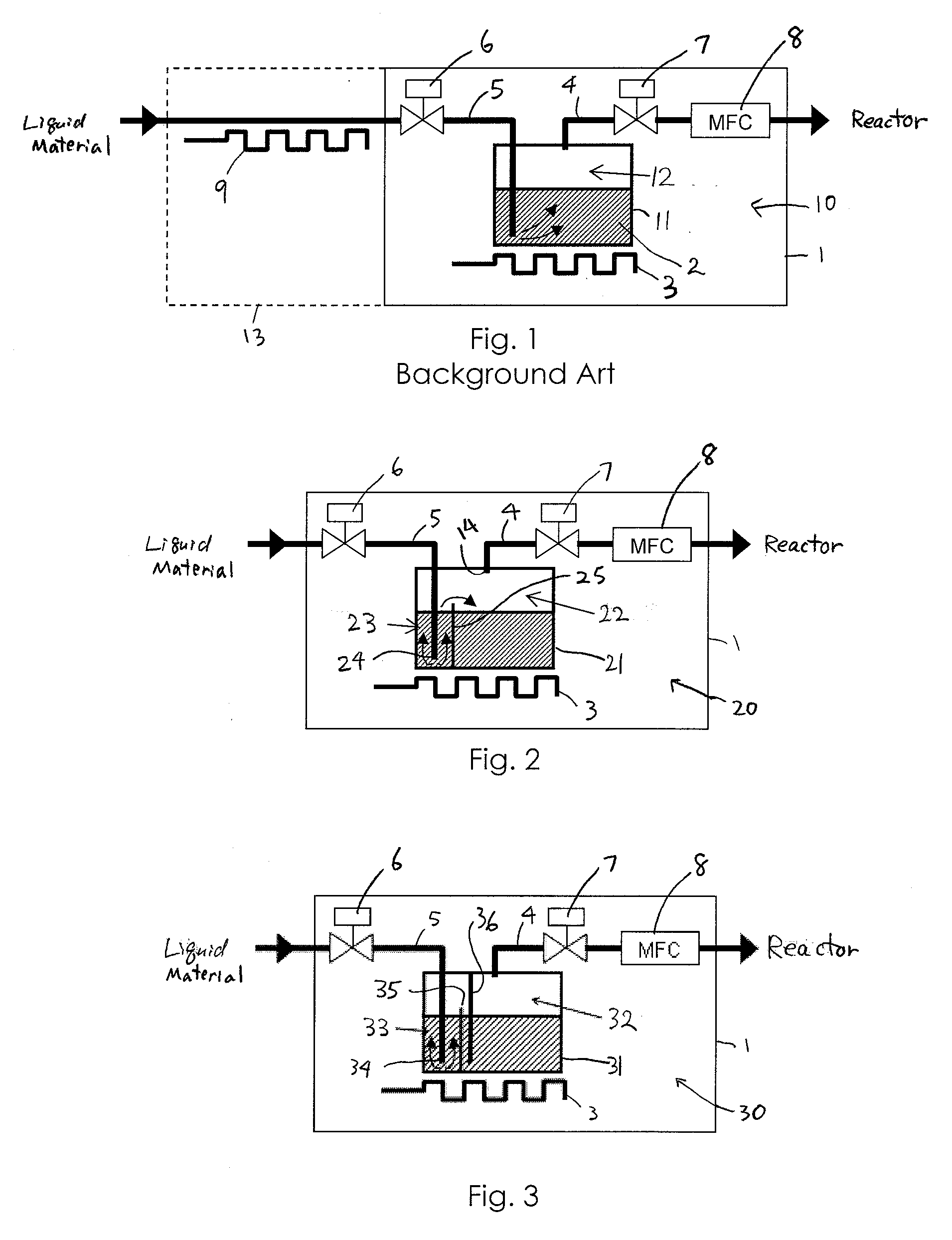

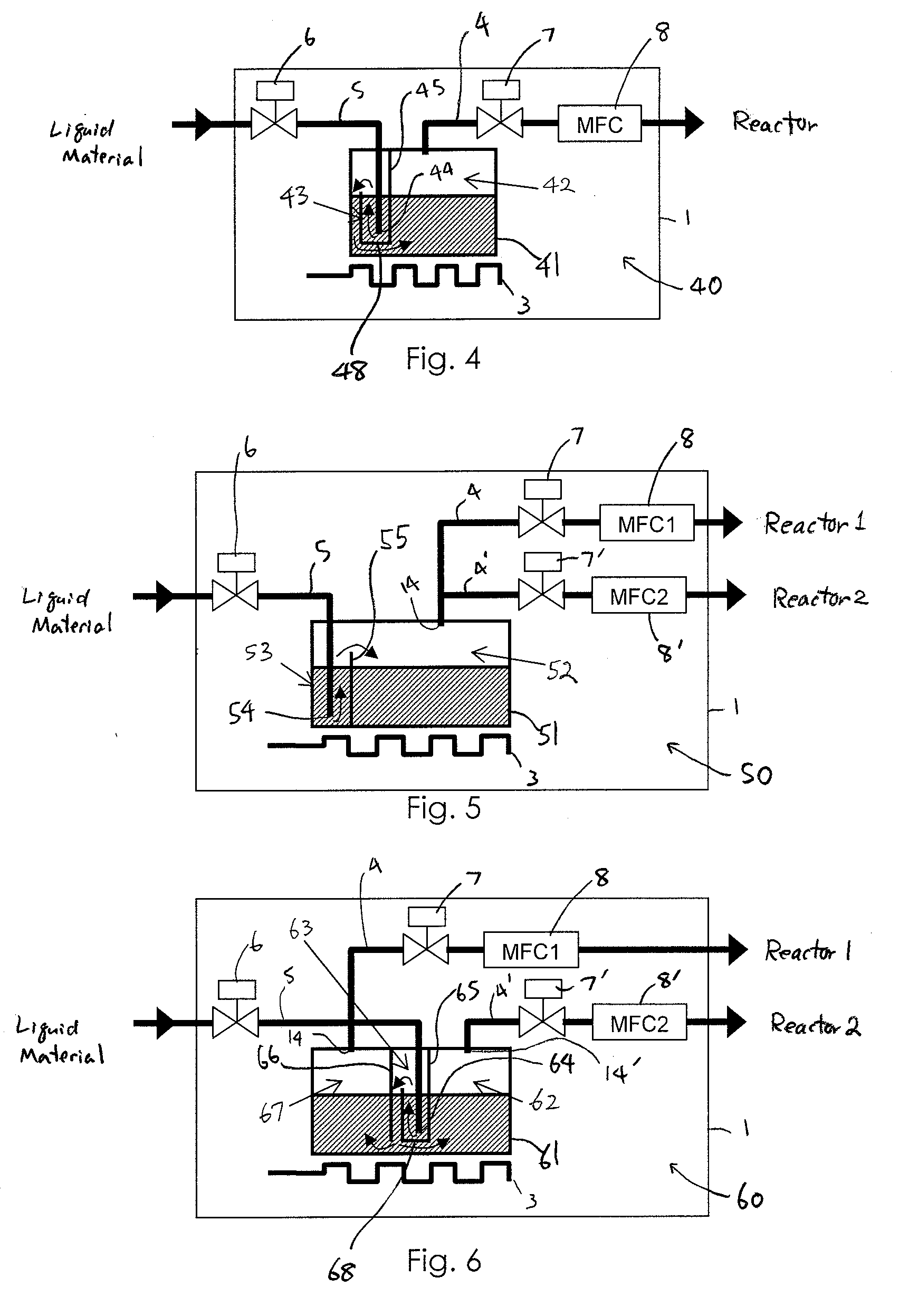

Liquid material vaporization apparatus for semiconductor processing apparatus

ActiveUS7833353B2Reduce the temperatureInhibition is effectiveSteam generation heating methodsSpray nozzlesVaporizationEngineering

A liquid material vaporization apparatus for a semiconductor processing apparatus includes: a vaporization tank; an inner partition wall disposed in the tank for dividing the interior of the tank into a charging compartment and a vaporization compartment which are liquid-communicatable with each other over an upper edge of the inner partition wall. A liquid material charged in the charging compartment overflows over the upper edge of the inner partition wall toward the vaporization compartment to store and vaporize the liquid material in the vaporization compartment.

Owner:ASM JAPAN

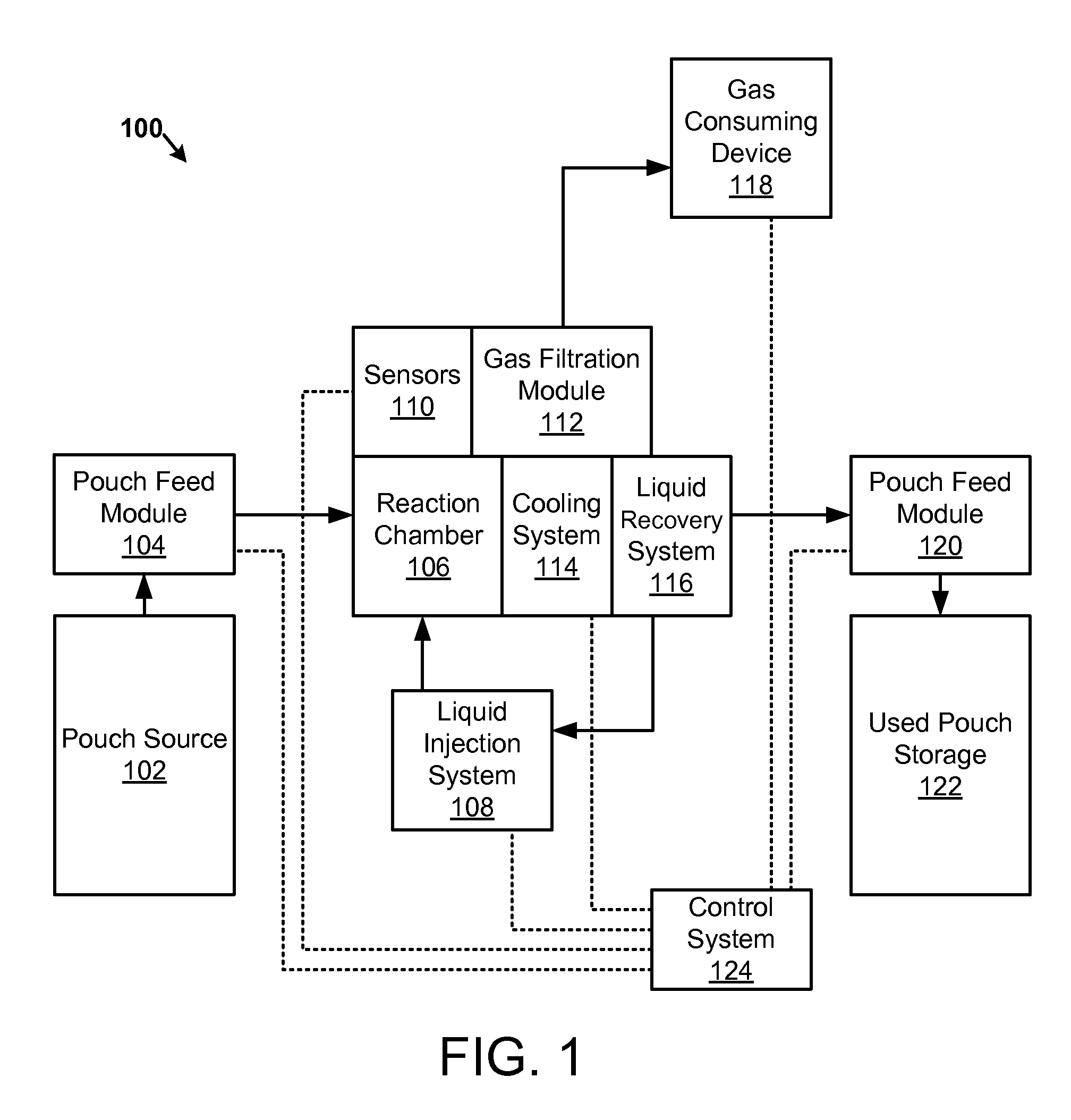

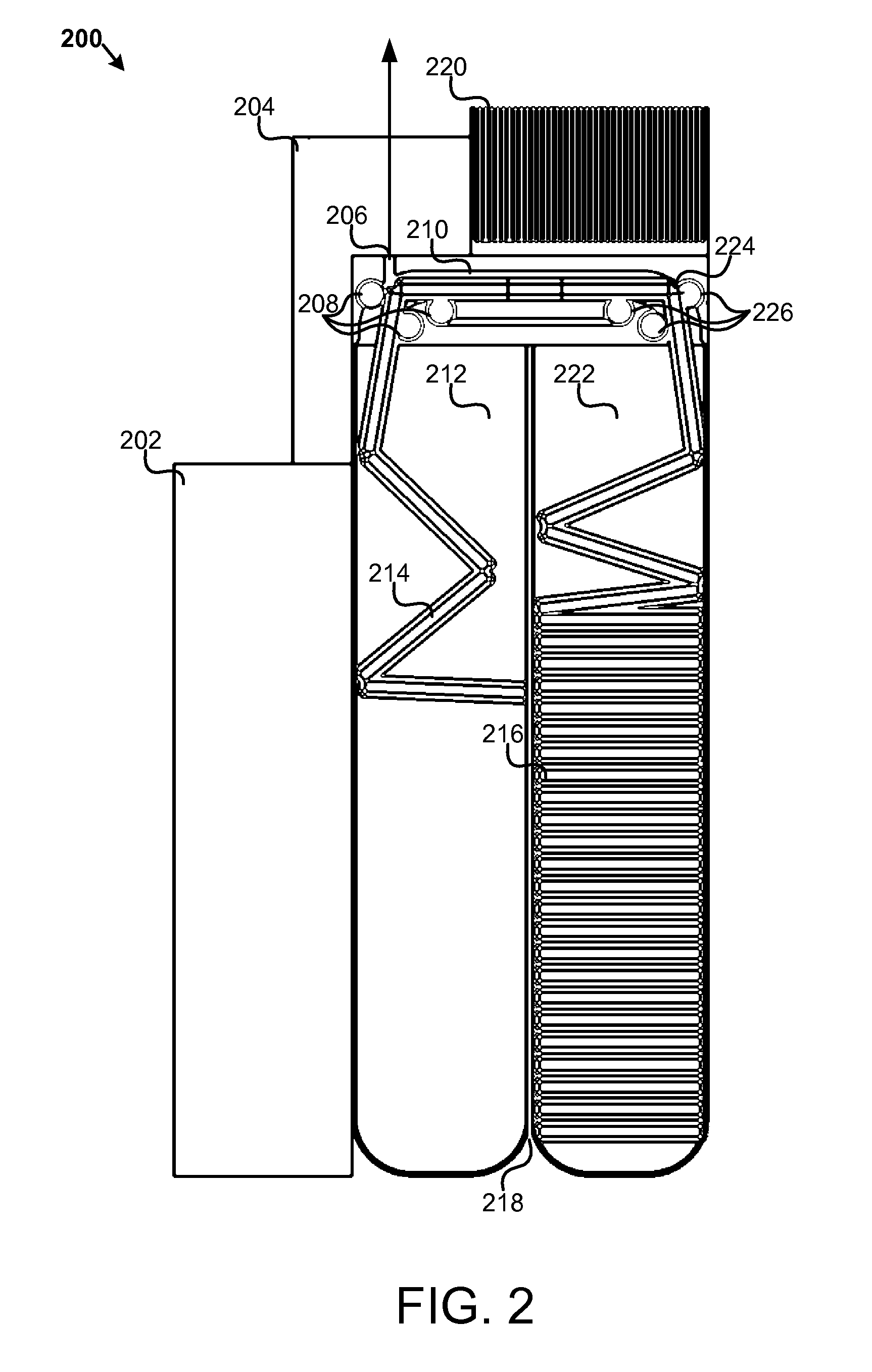

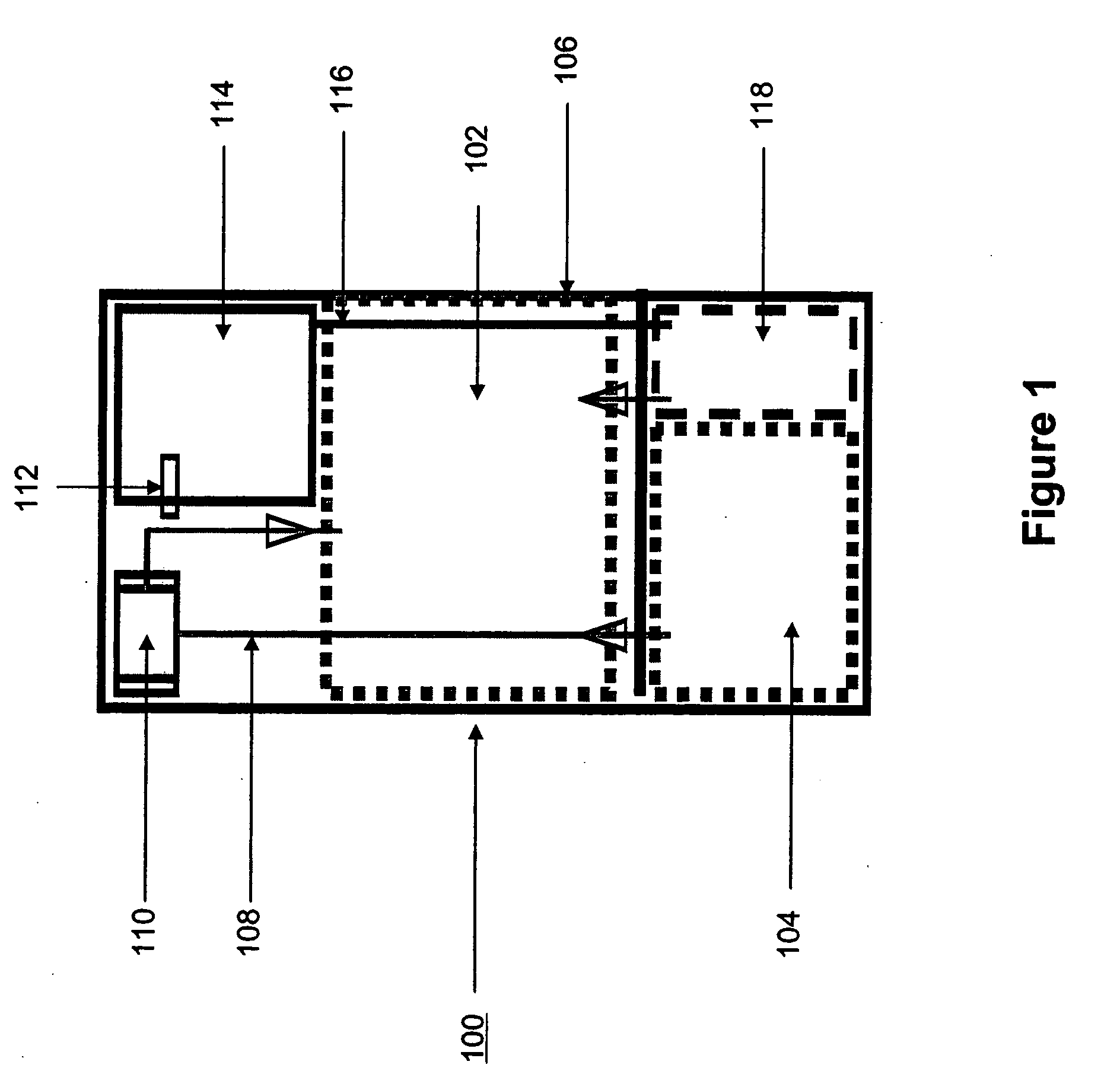

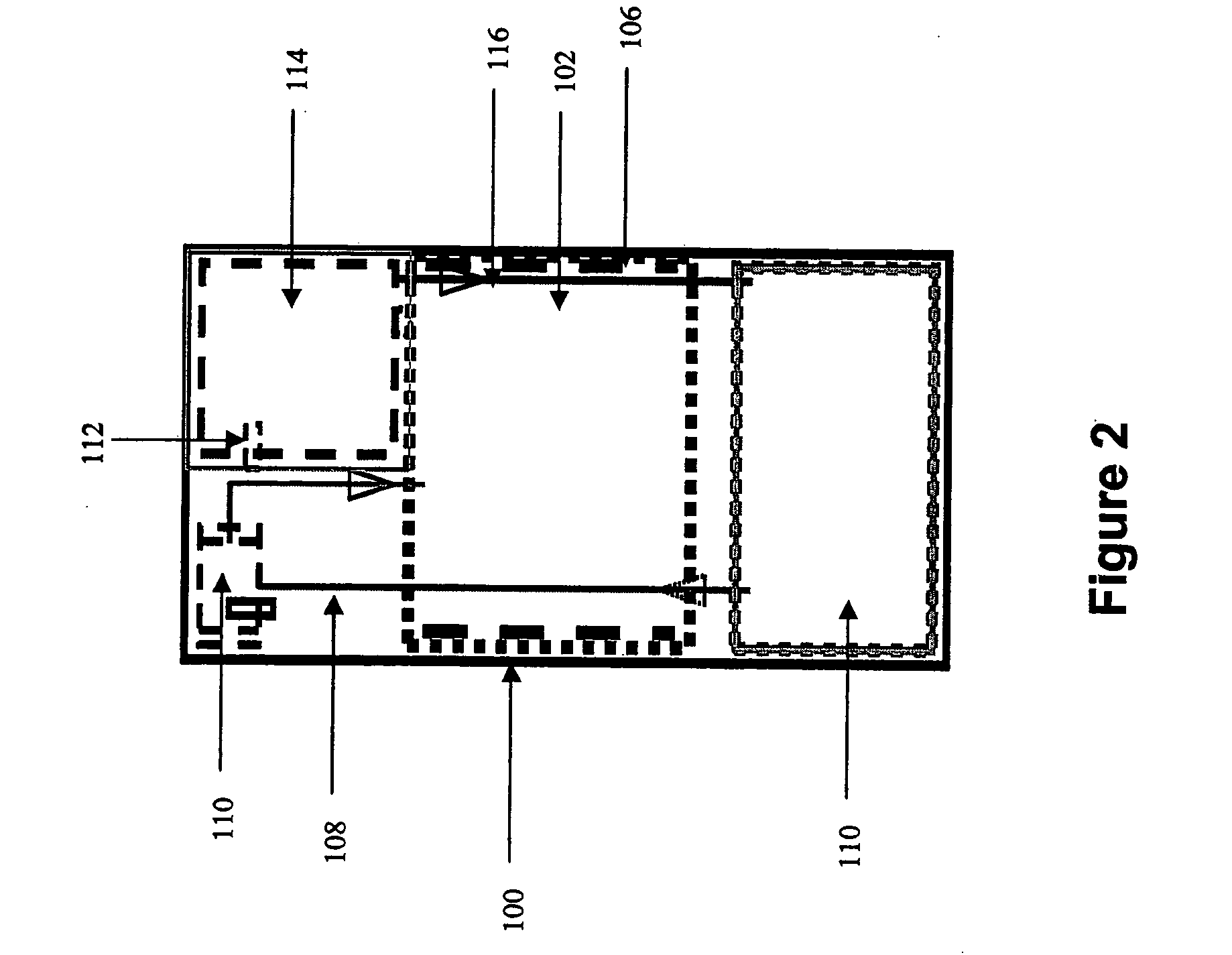

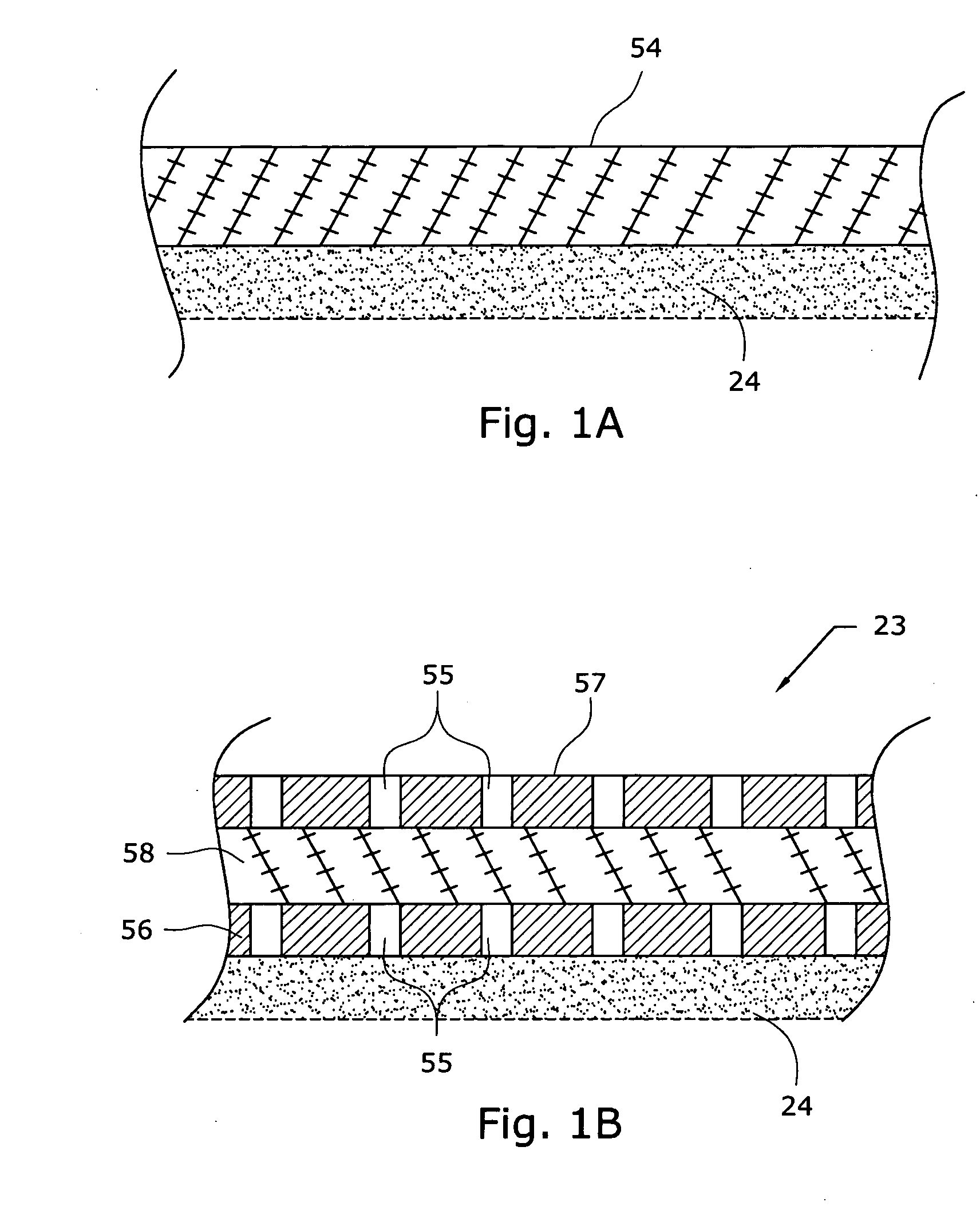

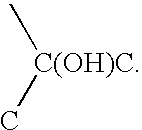

Apparatus, system, and method for generating a gas from solid reactant pouches

An apparatus, system, and method are disclosed for generating a gas. One or more liquid permeable pouches each define a cavity that contains a solid anhydrous reactant, such as a chemical hydride. A reaction chamber made of a heat, chemical and / or pressure resistant material receives the one or more pouches from a pouch feeder that transfers the one or more pouches into the reaction chamber successively at a feed rate. One or more liquid sources inject a liquid reactant into the reaction chamber so that the liquid reactant contacts a portion of the one or more pouches. The one or more liquid sources inject the liquid reactant at an injection rate that corresponds to the feed rate. A gas outlet releases a gas, such as hydrogen, oxygen, ammonia, borazine, nitrogen, or a hydrocarbon, that is produced by a reaction between the solid reactant and the liquid reactant.

Owner:TRULITE INC

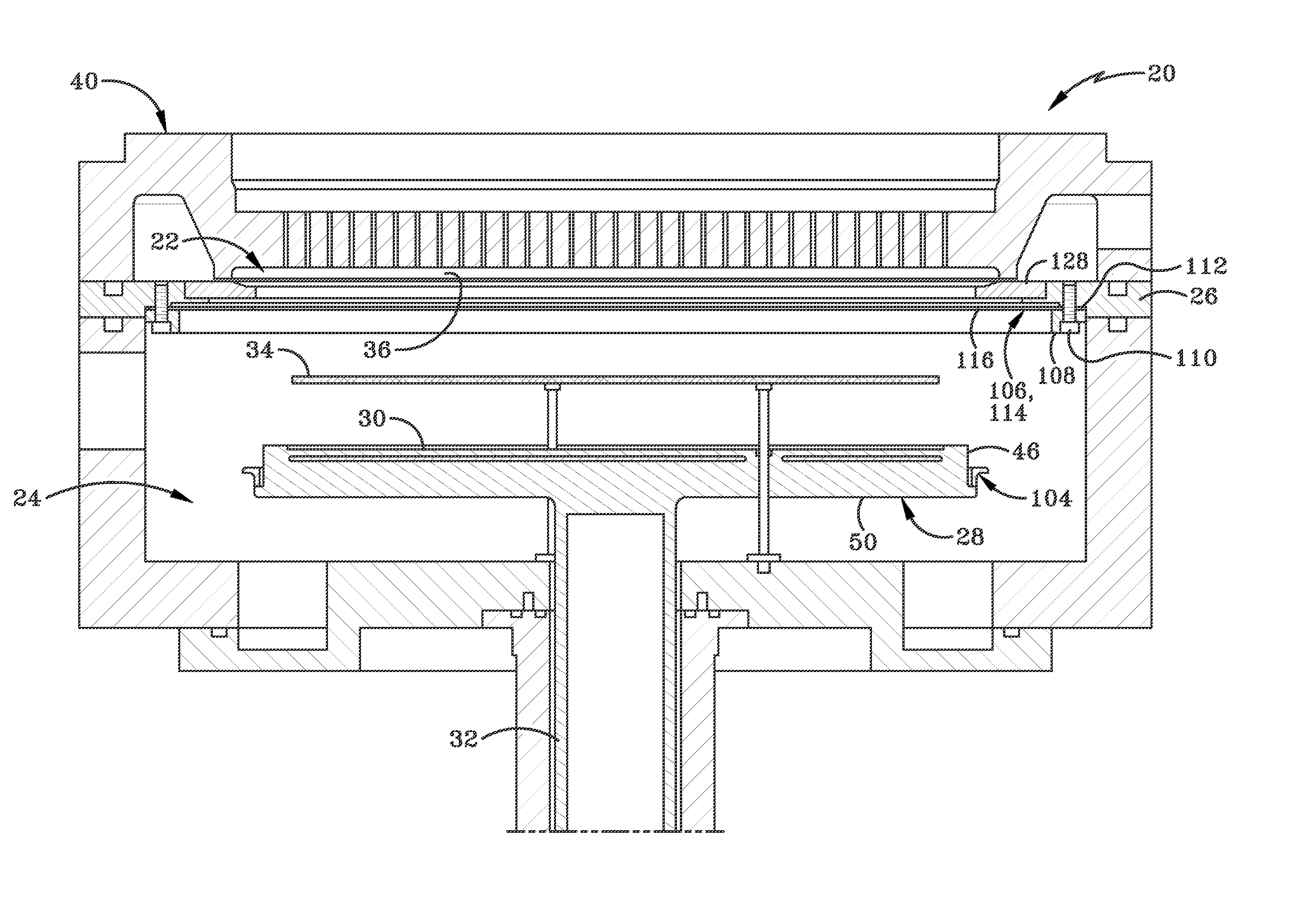

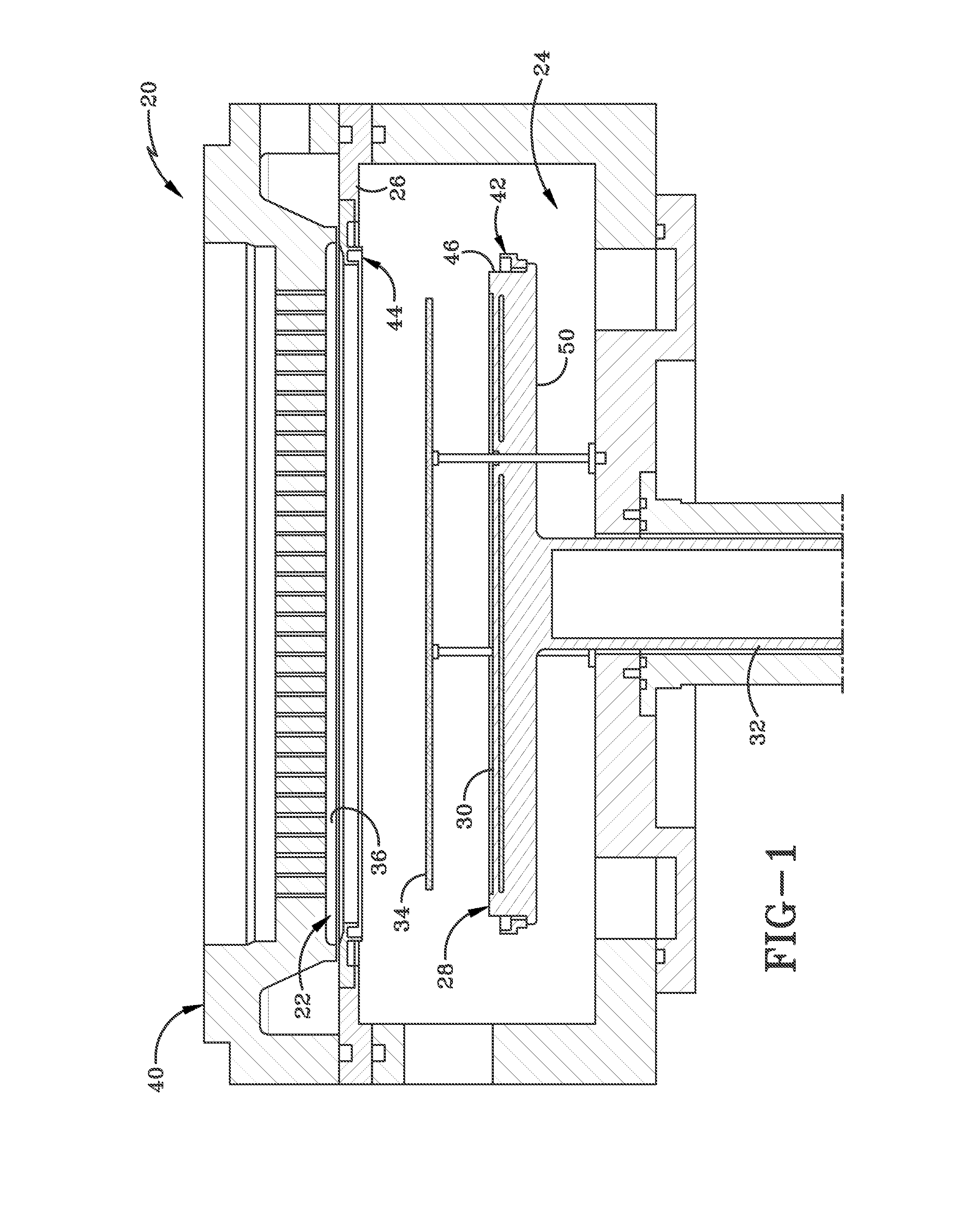

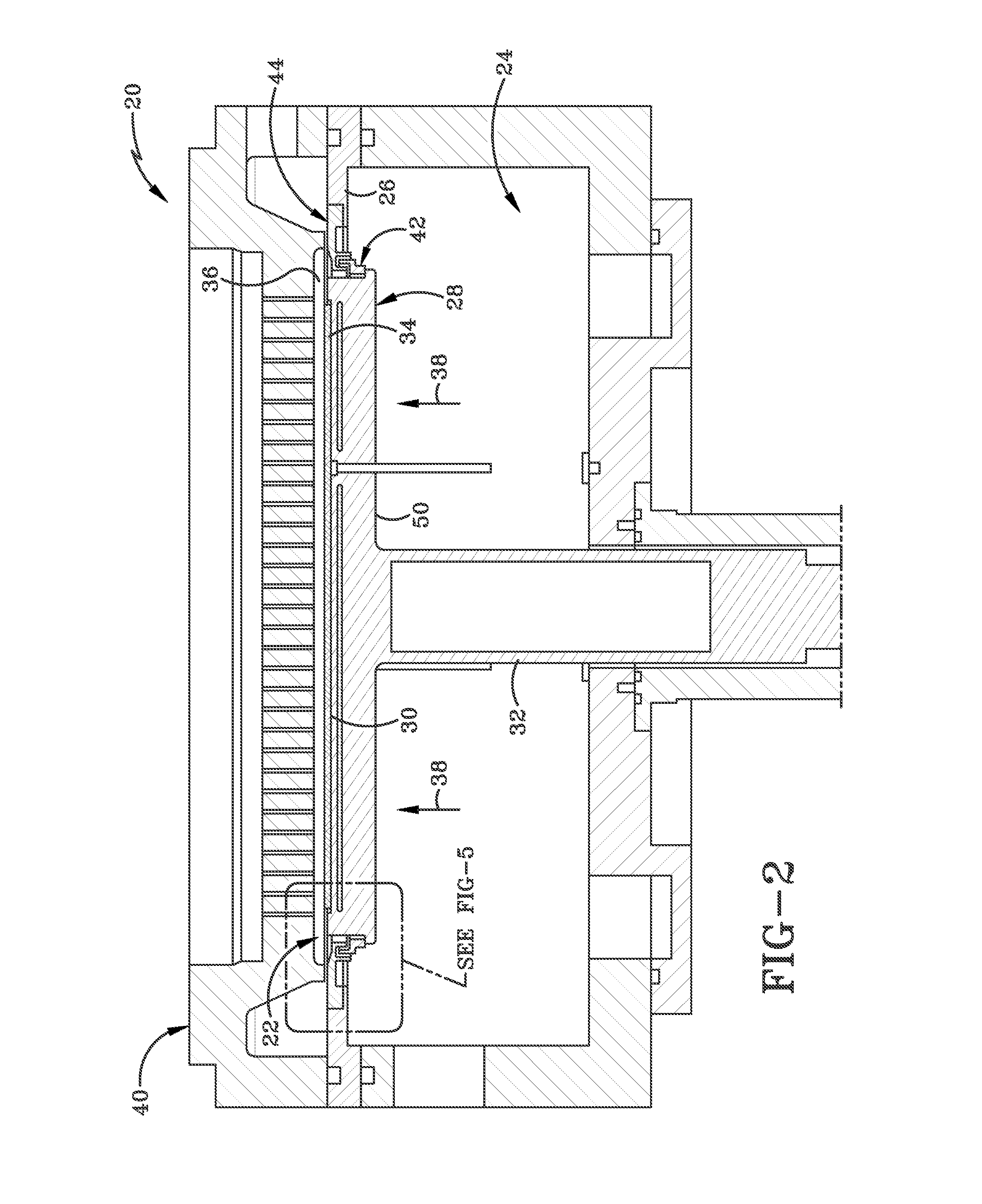

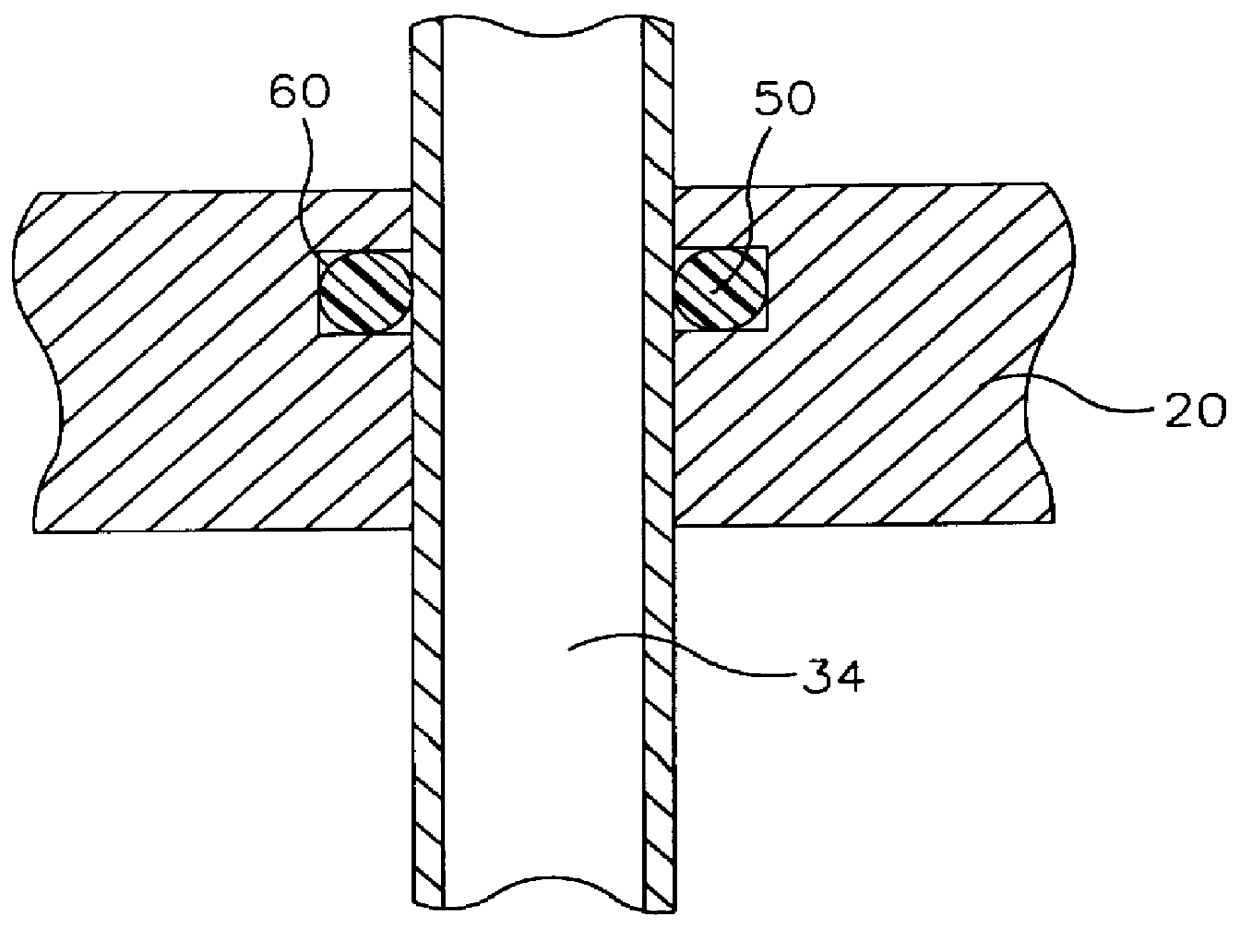

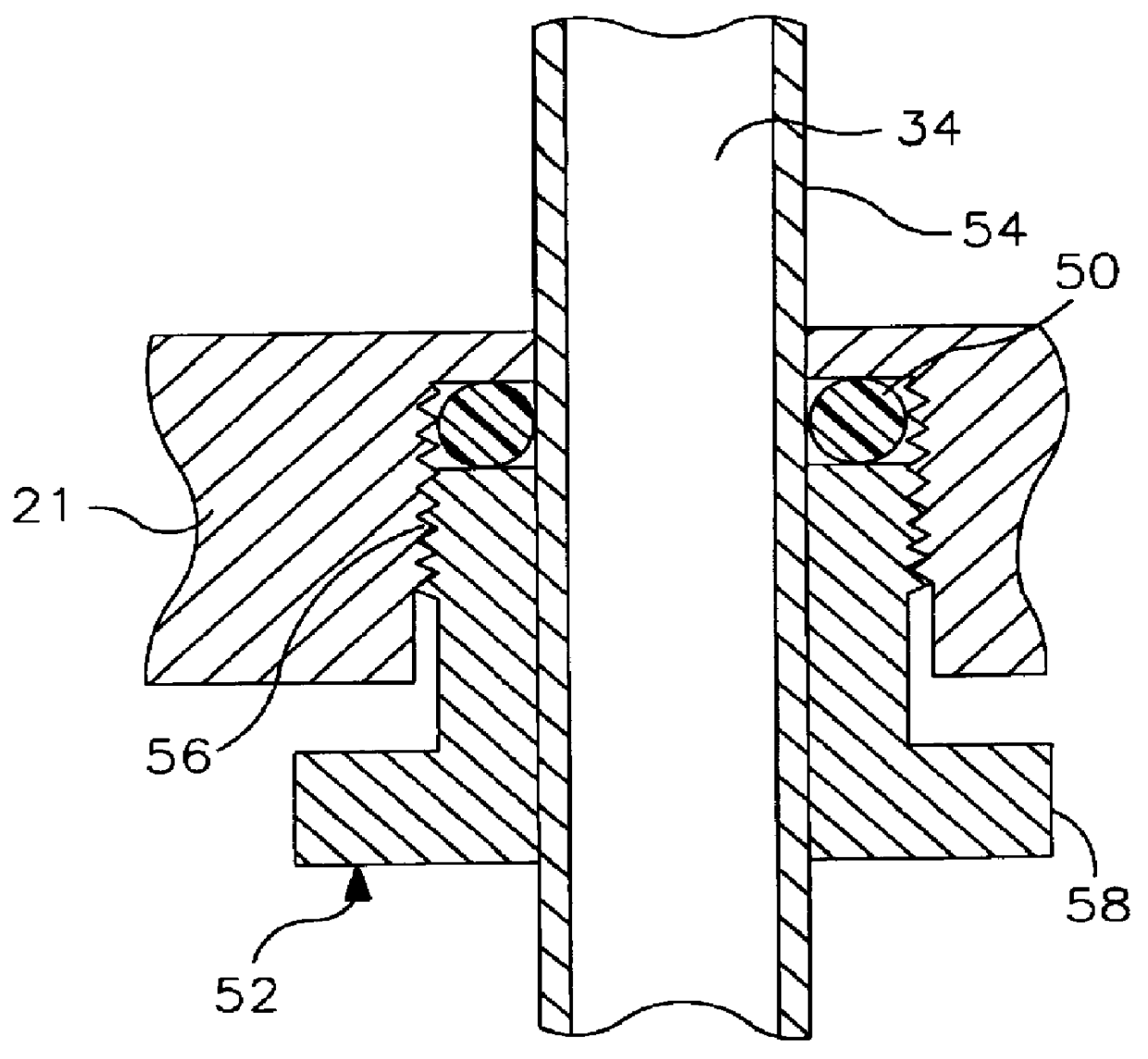

Chamber sealing member

ActiveUS20130129577A1Semiconductor/solid-state device manufacturingChemical/physical/physico-chemical processesSusceptorMechanical engineering

A reaction chamber including an upper region for processing a substrate, a lower region for loading a substrate, a susceptor movable within the reaction chamber, a first sealing member positioned on a perimeter of the susceptor, a second sealing member positioned between the upper region and the lower region, wherein the first and second sealing members are selectively engaged with one another to limit communication between the upper region and the lower region.

Owner:ASM IP HLDG BV

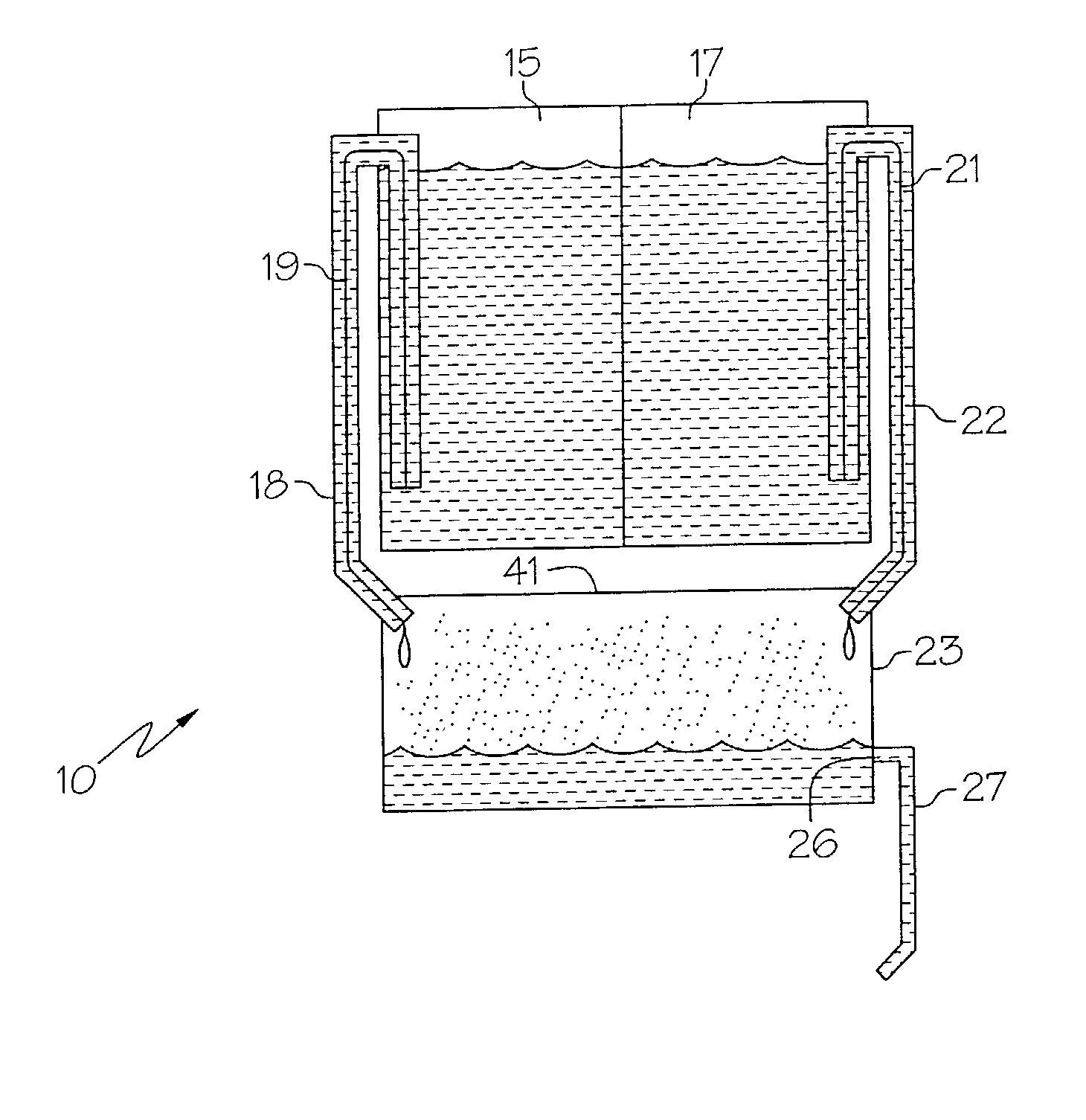

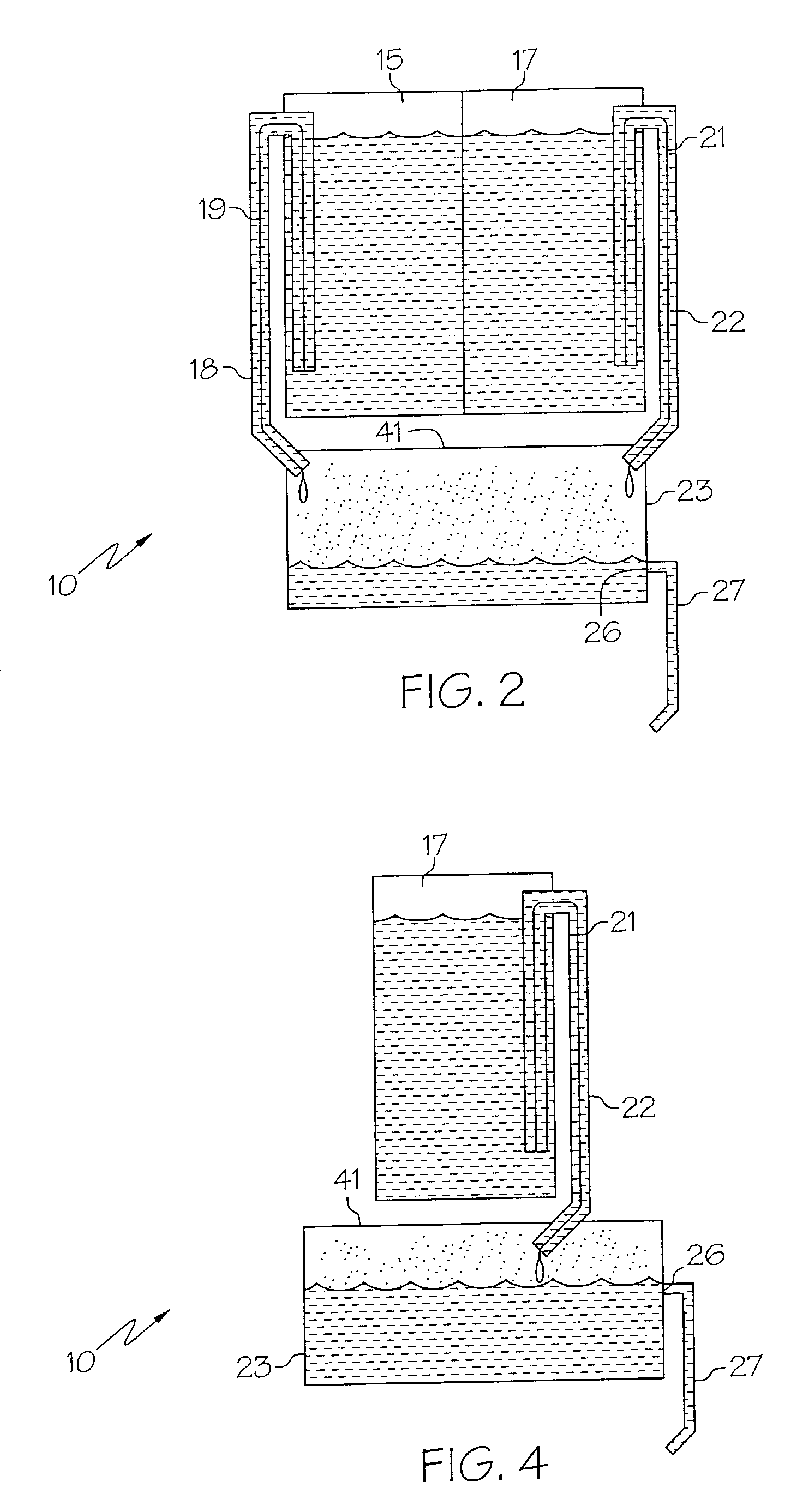

Liquid material vaporization apparatus for semiconductor processing apparatus

ActiveUS20080173240A1Reduce the temperatureLow thermal conductivitySteam generation heating methodsSpray nozzlesVaporizationEngineering

A liquid material vaporization apparatus for a semiconductor processing apparatus includes: a vaporization tank; an inner partition wall disposed in the tank for dividing the interior of the tank into a charging compartment and a vaporization compartment which are liquid-communicatable with each other over an upper edge of the inner partition wall. A liquid material charged in the charging compartment overflows over the upper edge of the inner partition wall toward the vaporization compartment to store and vaporize the liquid material in the vaporization compartment.

Owner:ASM JAPAN

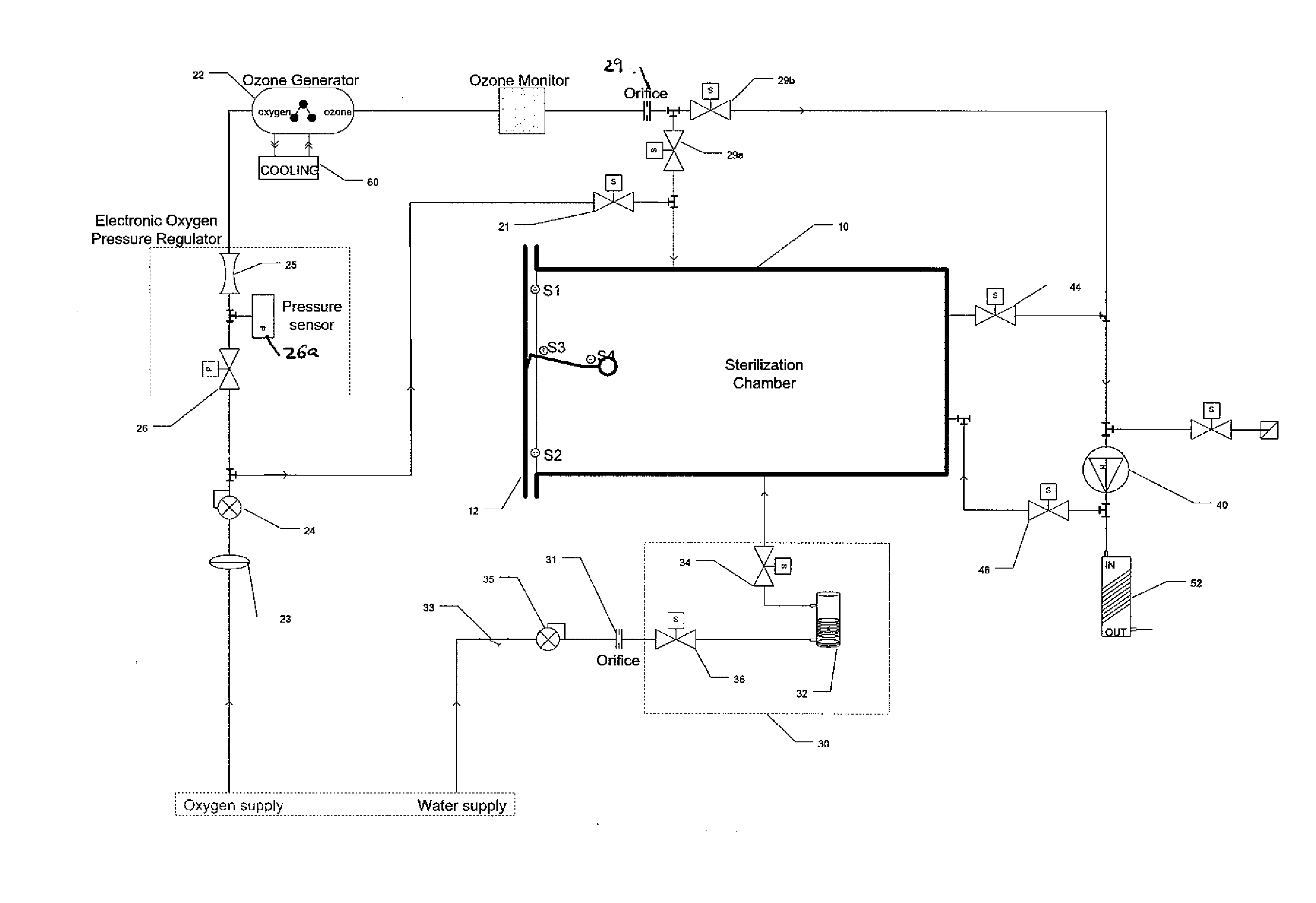

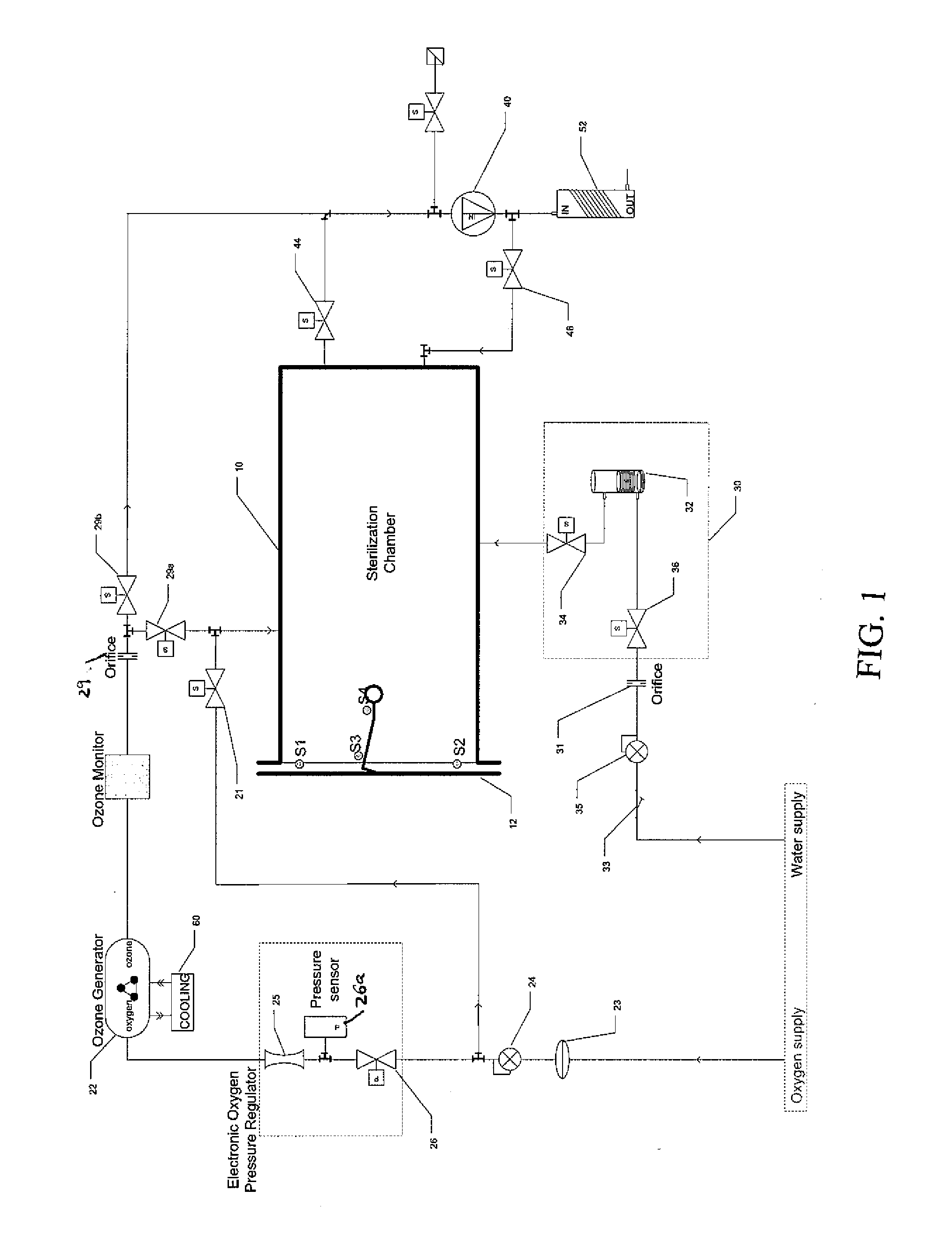

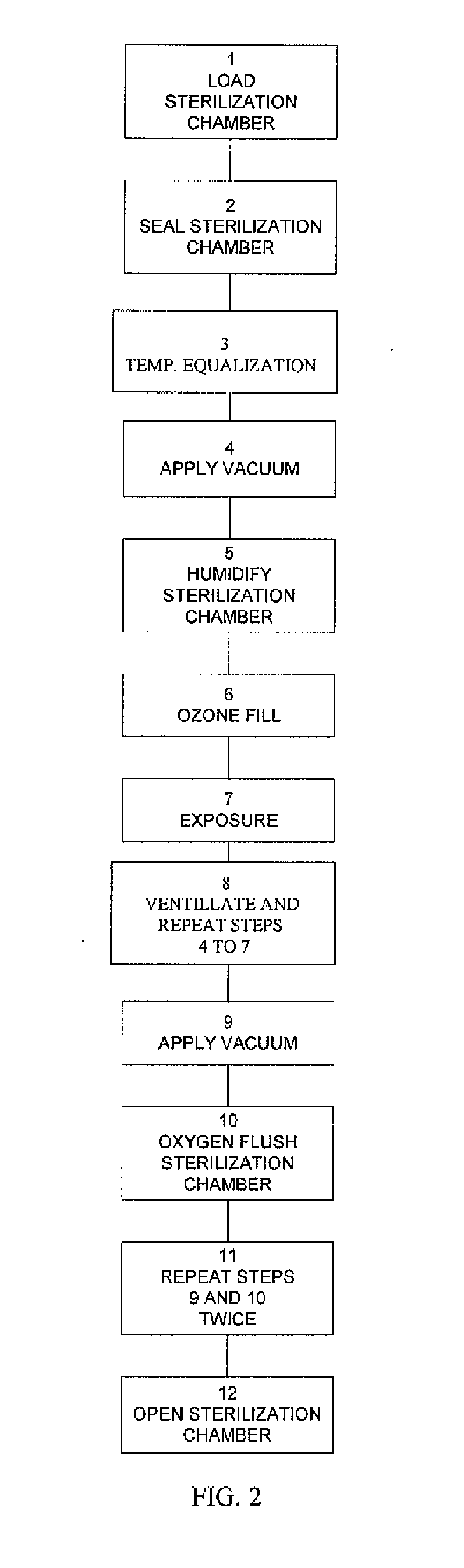

Method and apparatus for ozone sterilization

InactiveUS20070258855A1Avoid condensationPrevent water condensationElectrolysis componentsExhaust apparatusVacuum pressureWater vapor

The present invention provides a method and apparatus for sterilizing articles using an ozone-containing gas, where condensation of water from the sterilization atmosphere during the sterilization process is substantially prevented. The inventive sterilization method includes providing a sterilization chamber and placing an article into the sterilization chamber. The sterilization chamber is sealed prior to equalizing the temperature of the article and the atmosphere in the sterilization chamber. A vacuum is applied to achieve a preselected vacuum pressure in the sterilization chamber. Once the vacuum pressure is set, water vapour is supplied to the sterilization chamber. Ozone-containing gas is then supplied to the sterilization chamber and the sterilization chamber remains sealed for a preselected treatment period, where the sterilization chamber remains sealed throughout the whole process. Finally, vacuum in the sterilization chamber is released.

Owner:STRYKER CORP

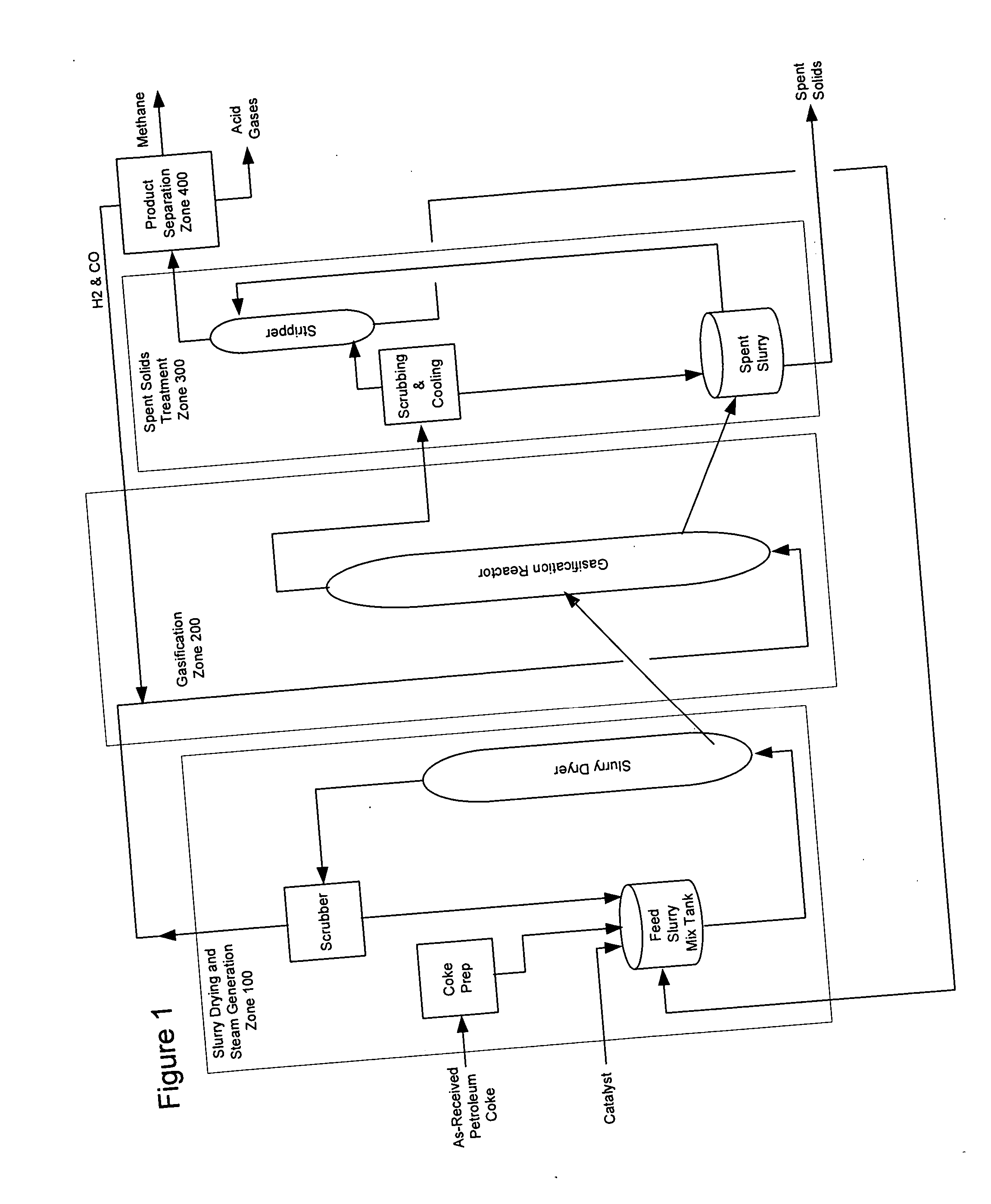

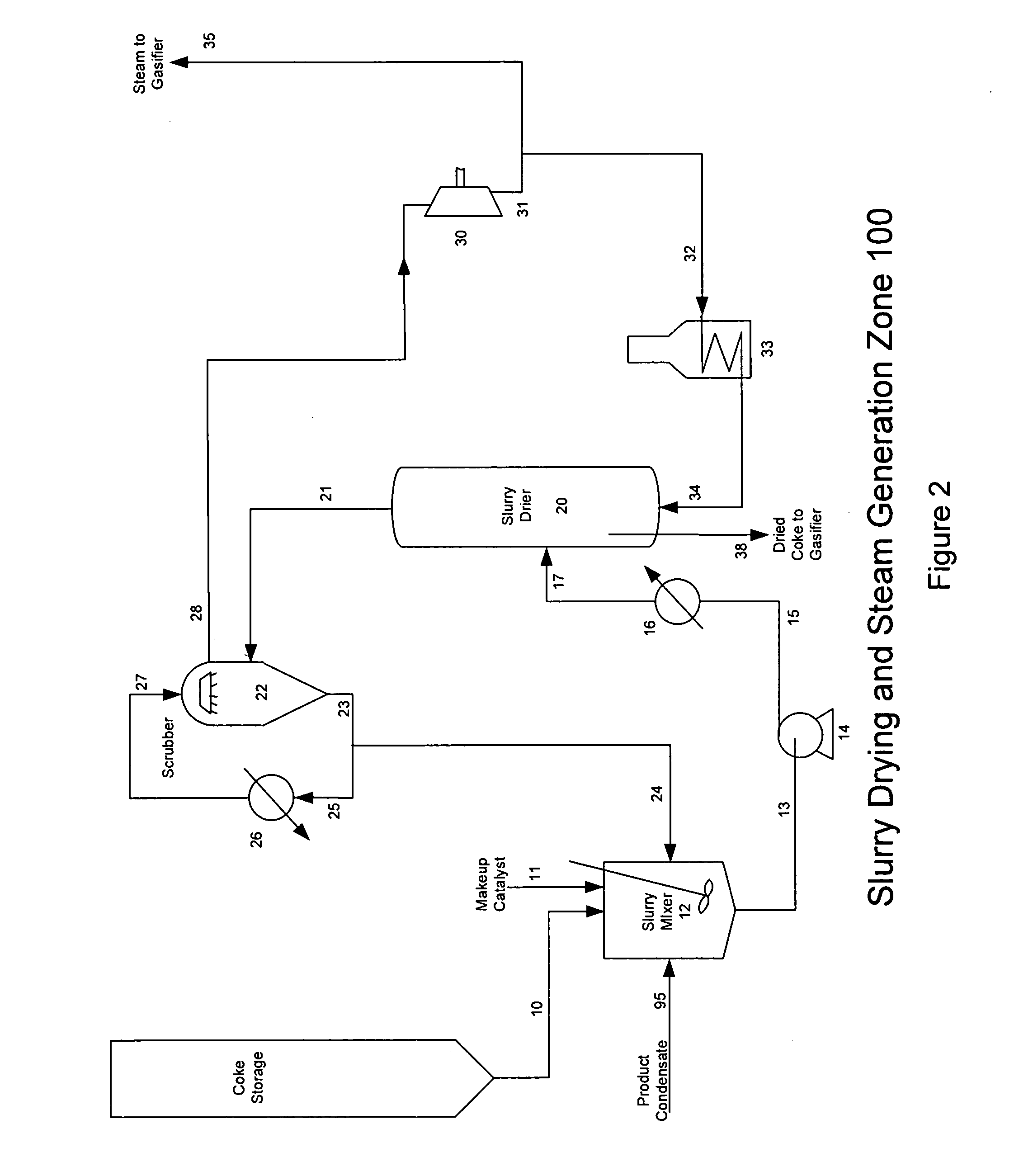

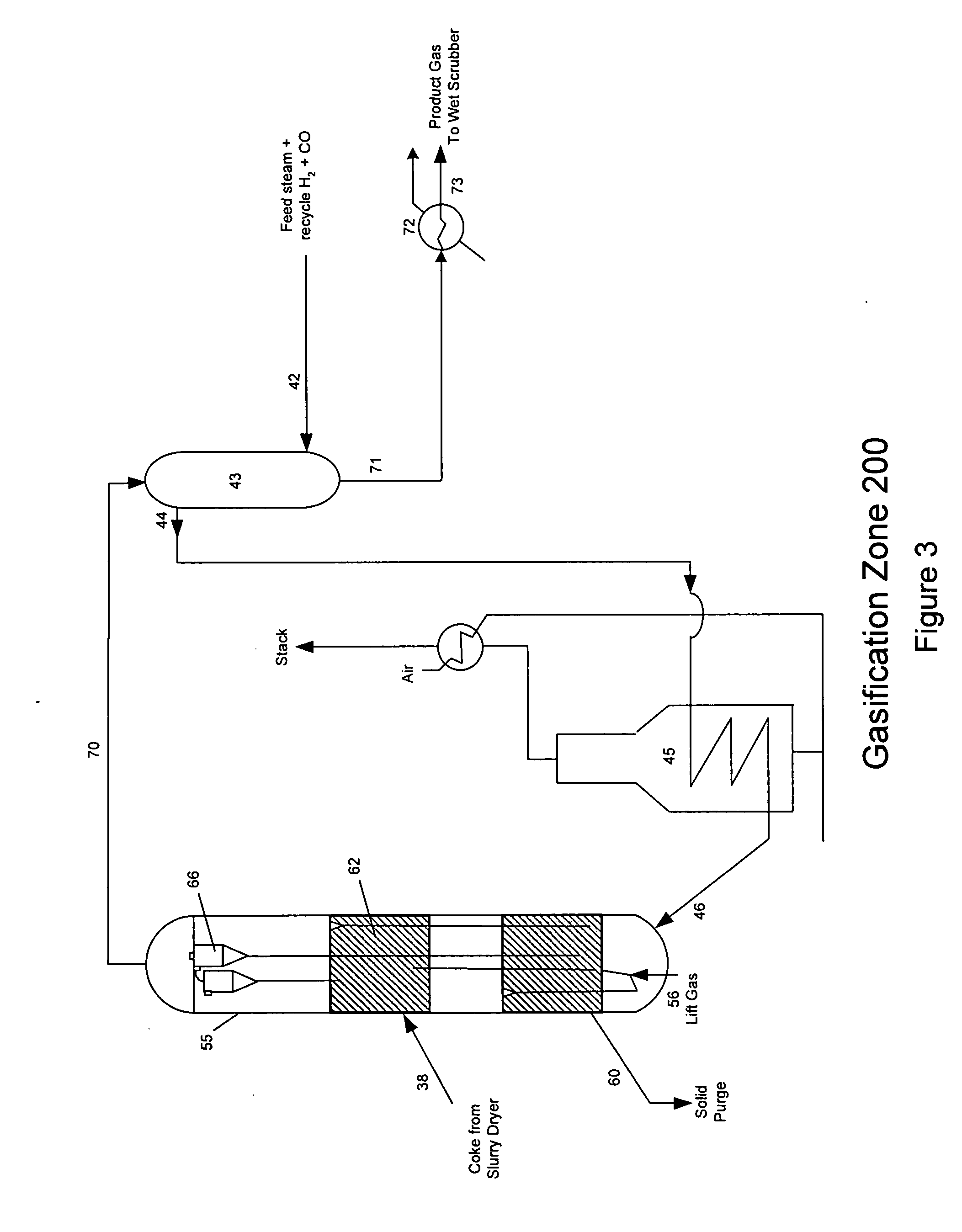

Catalytic steam gasification of petroleum coke to methane

The present invention provides a catalytic steam gasification process for gasifying petroleum coke. The solids composition within the gasification reactor of the disclosed invention is maintained by controlling the catalyst composition of the feed. The process utilizes sour water from the raw gasification product gases to recover and recycle catalyst. Fine particles generated in the handling of coke are advantageously utilized to increase the efficiency of the process.

Owner:SURE CHAMPION INVESTMENT LTD

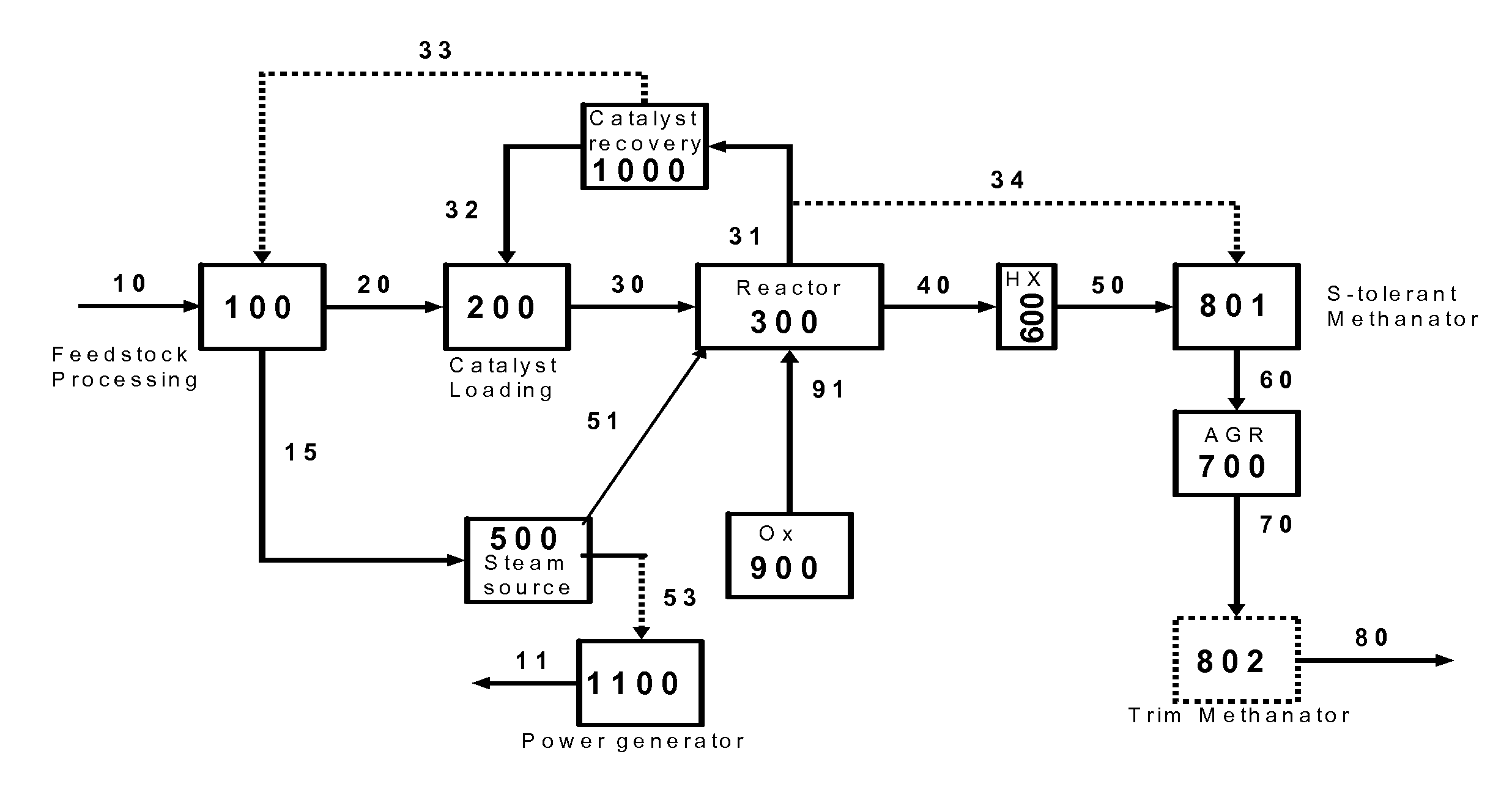

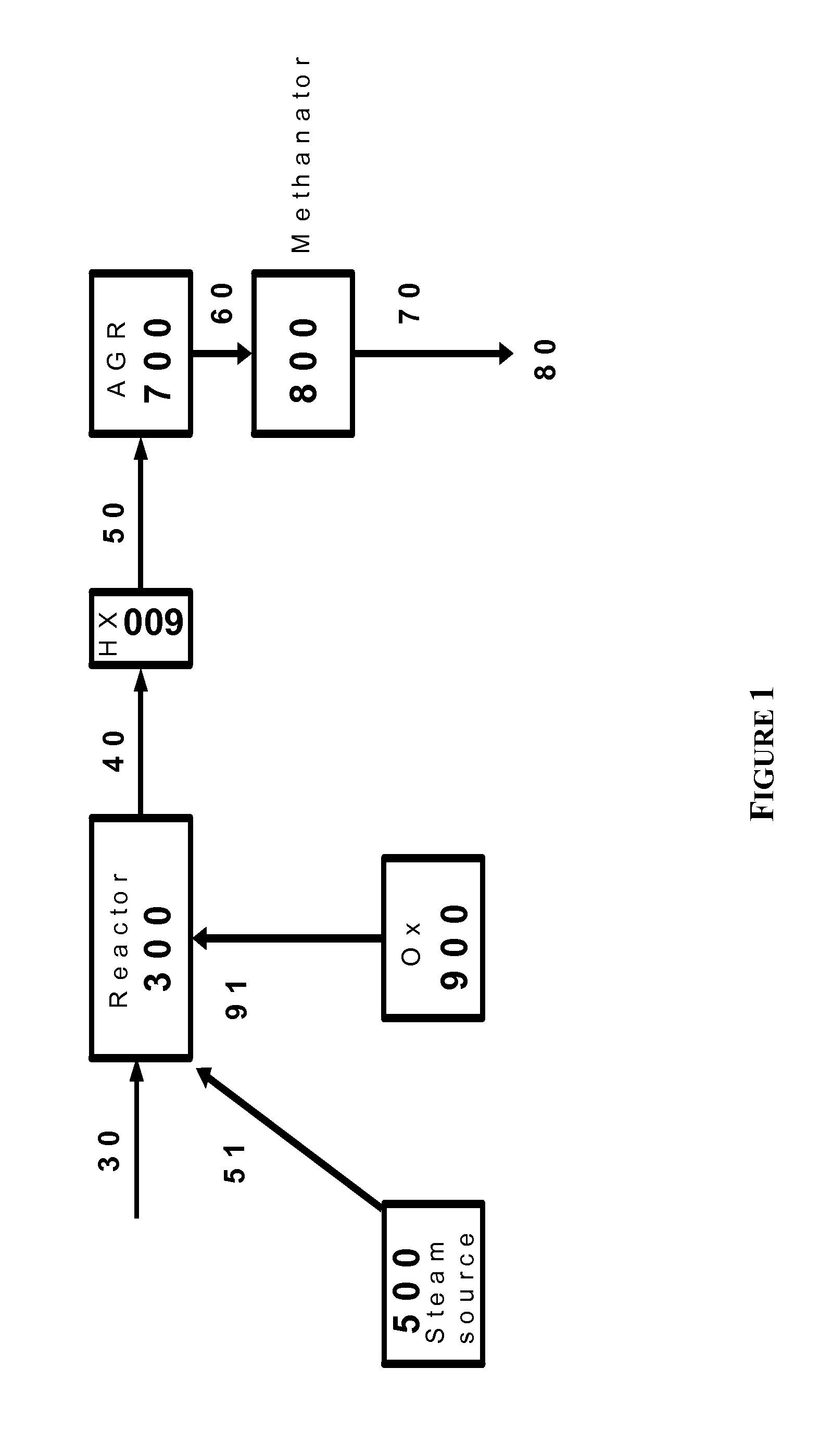

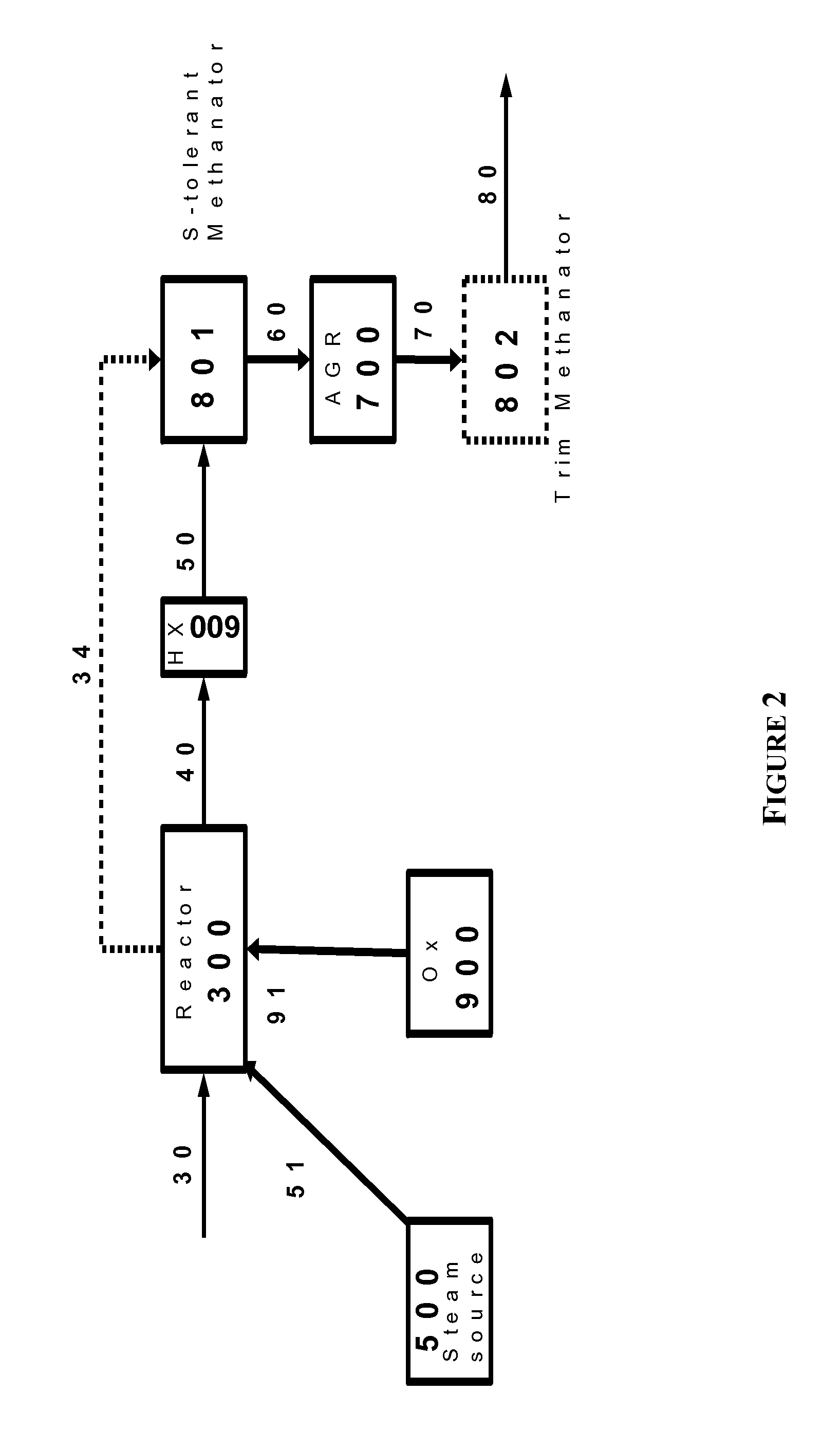

Processes for Gasification of a Carbonaceous Feedstock

The present invention relates to processes for preparing gaseous products, and in particular, methane via the catalytic gasification of carbonaceous feedstocks in the presence of steam and an oxygen-rich gas stream. The processes comprise using at least one catalytic methanator to convert carbon monoxide and hydrogen in the gaseous products to methane and do not recycle carbon monoxide or hydrogen to the catalytic gasifier.

Owner:SURE CHAMPION INVESTMENT LTD

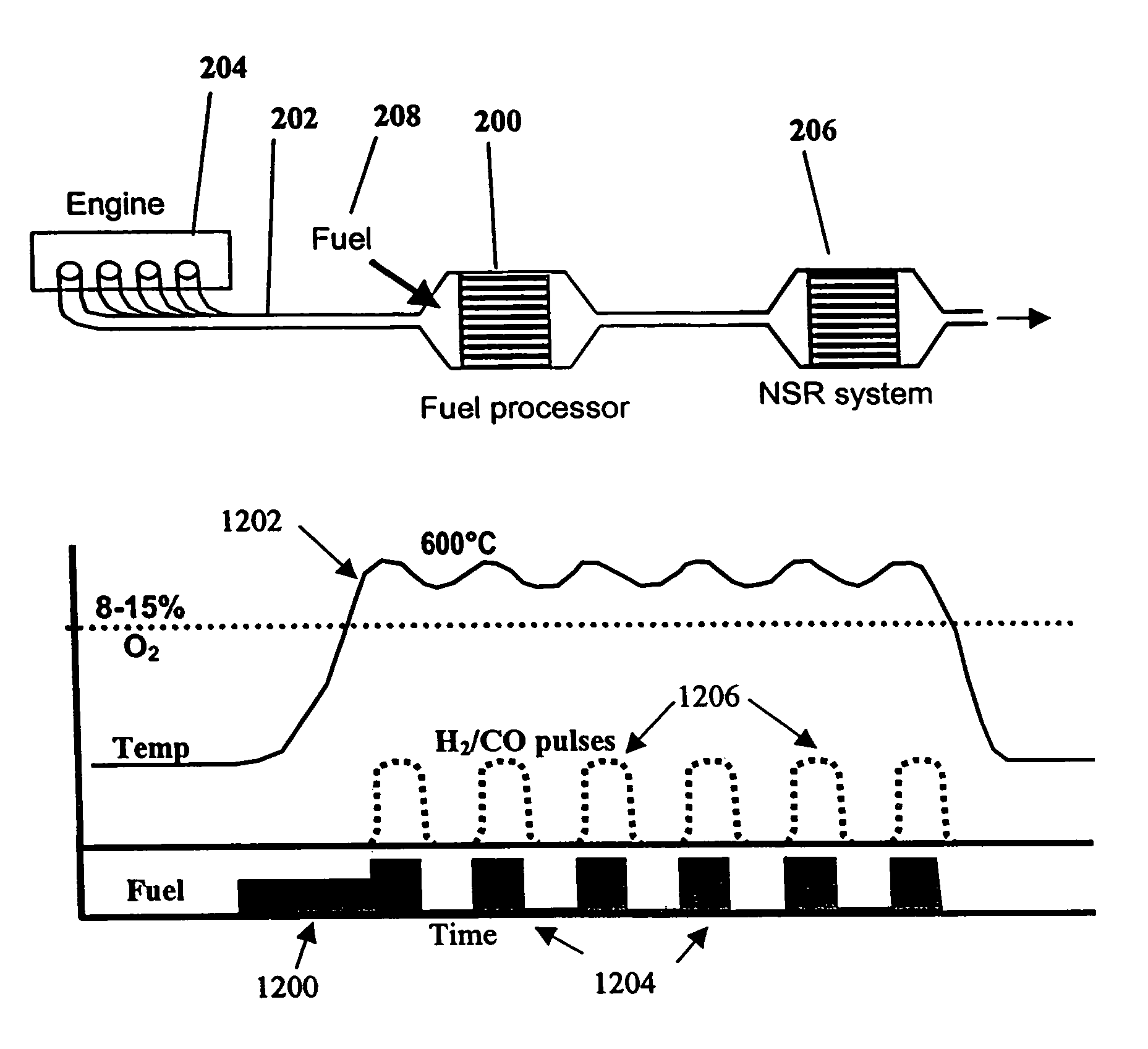

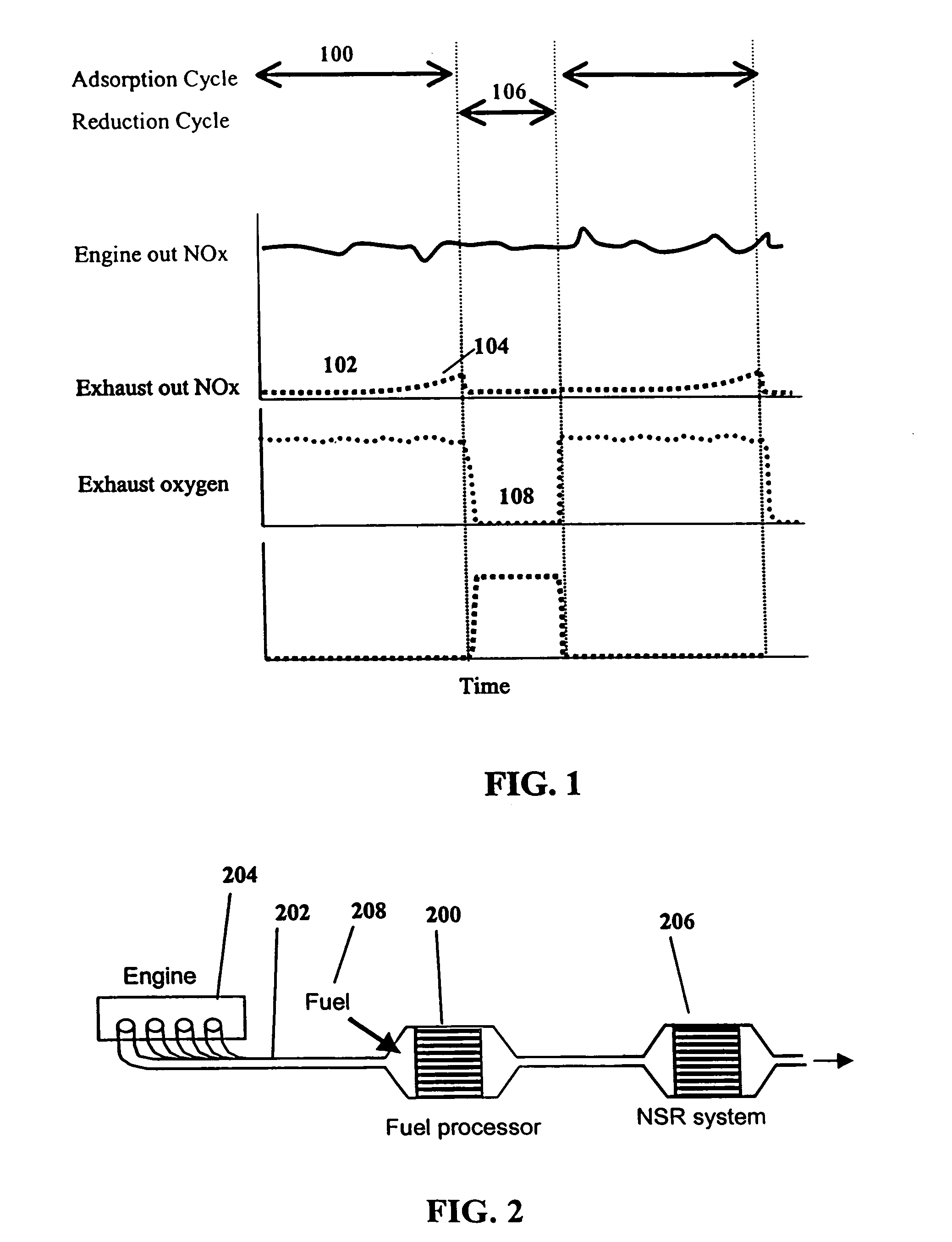

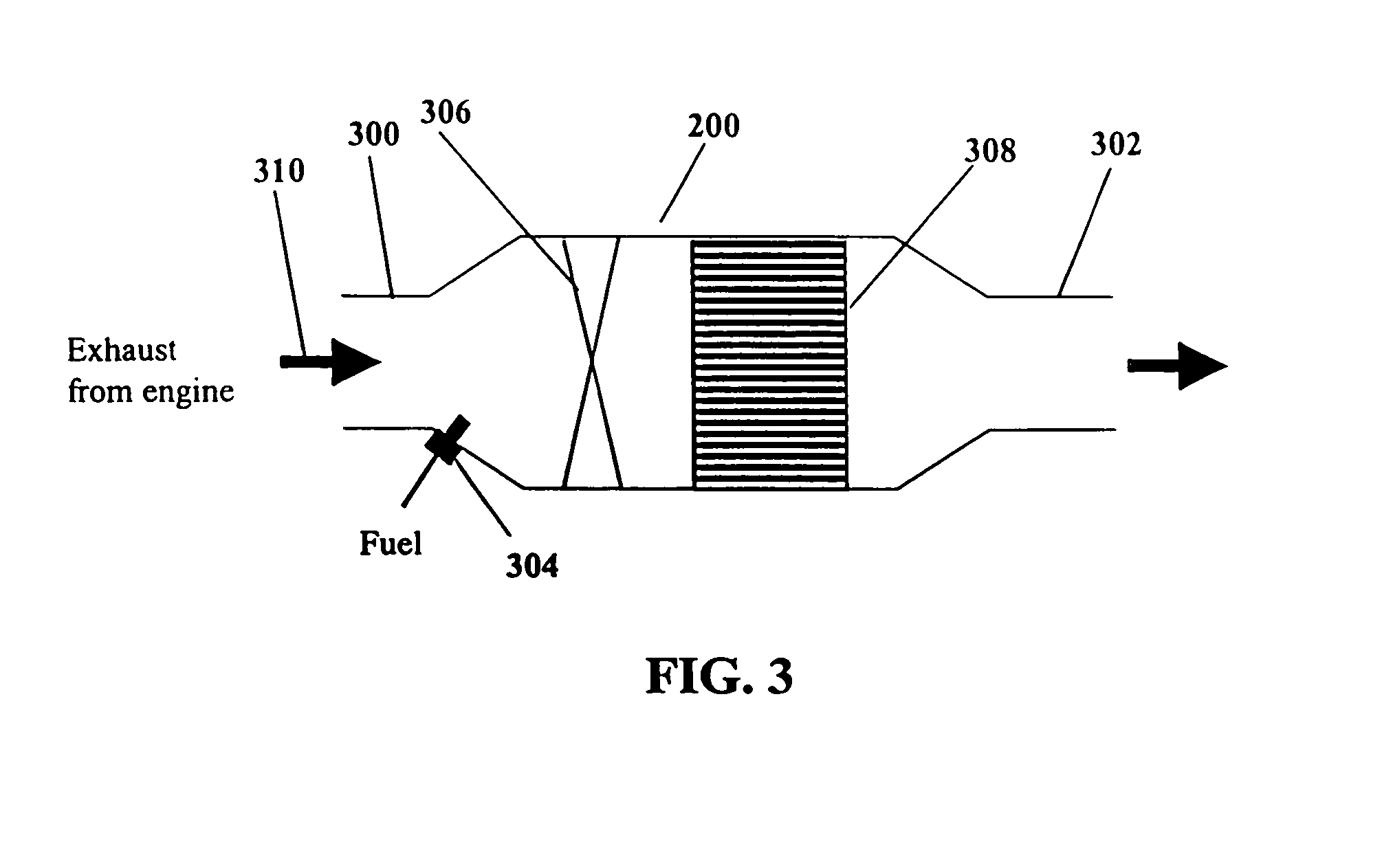

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

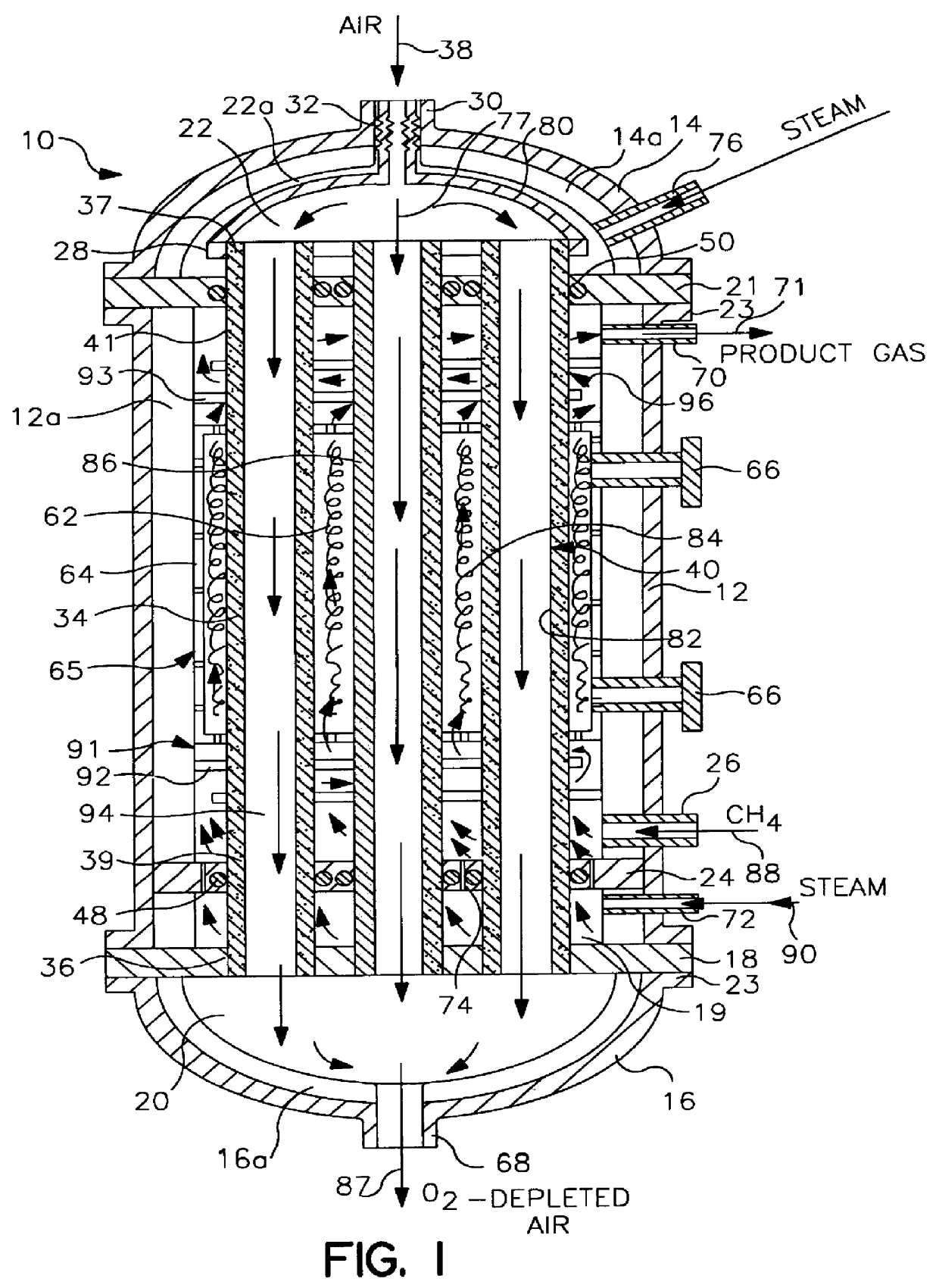

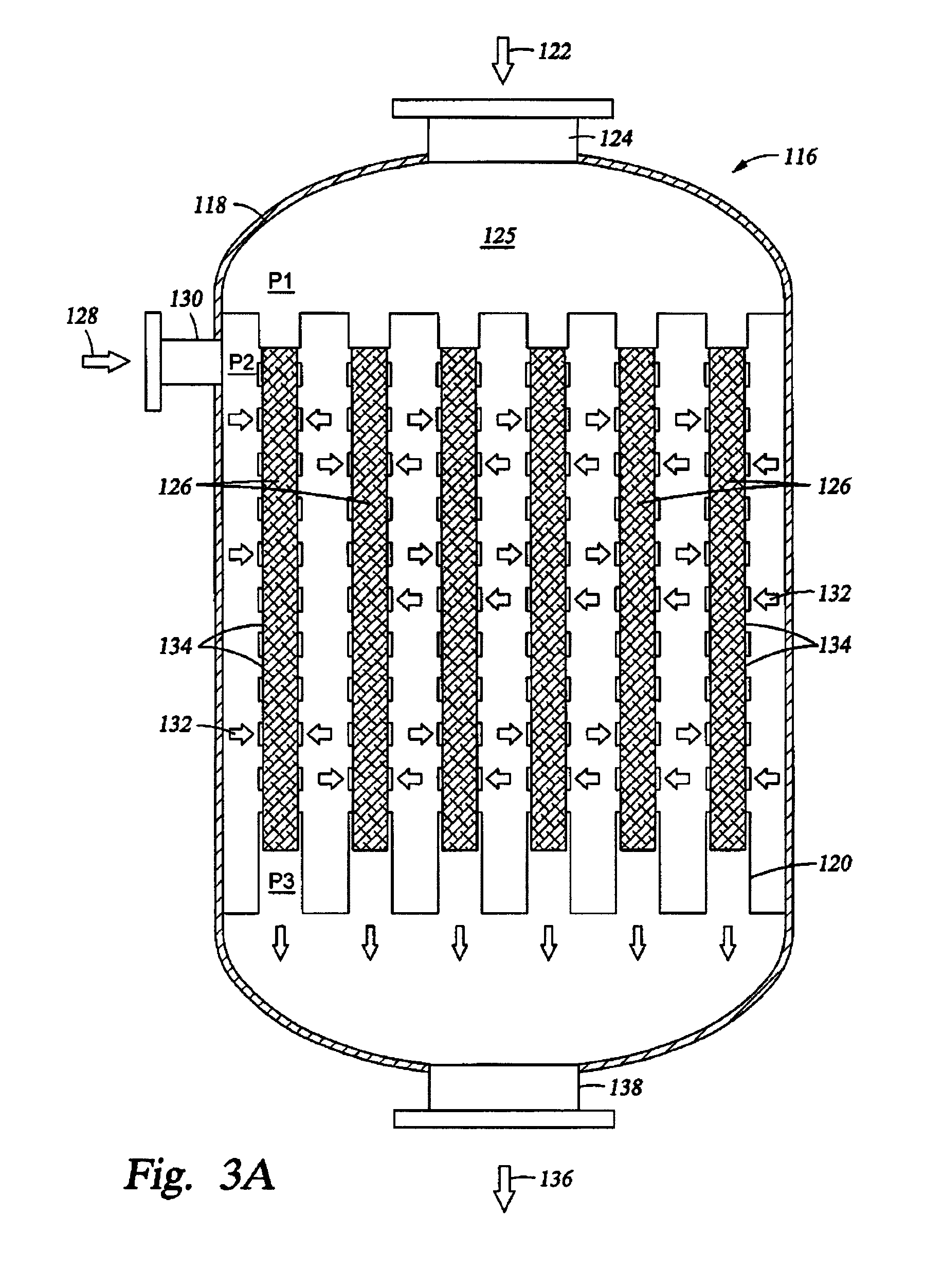

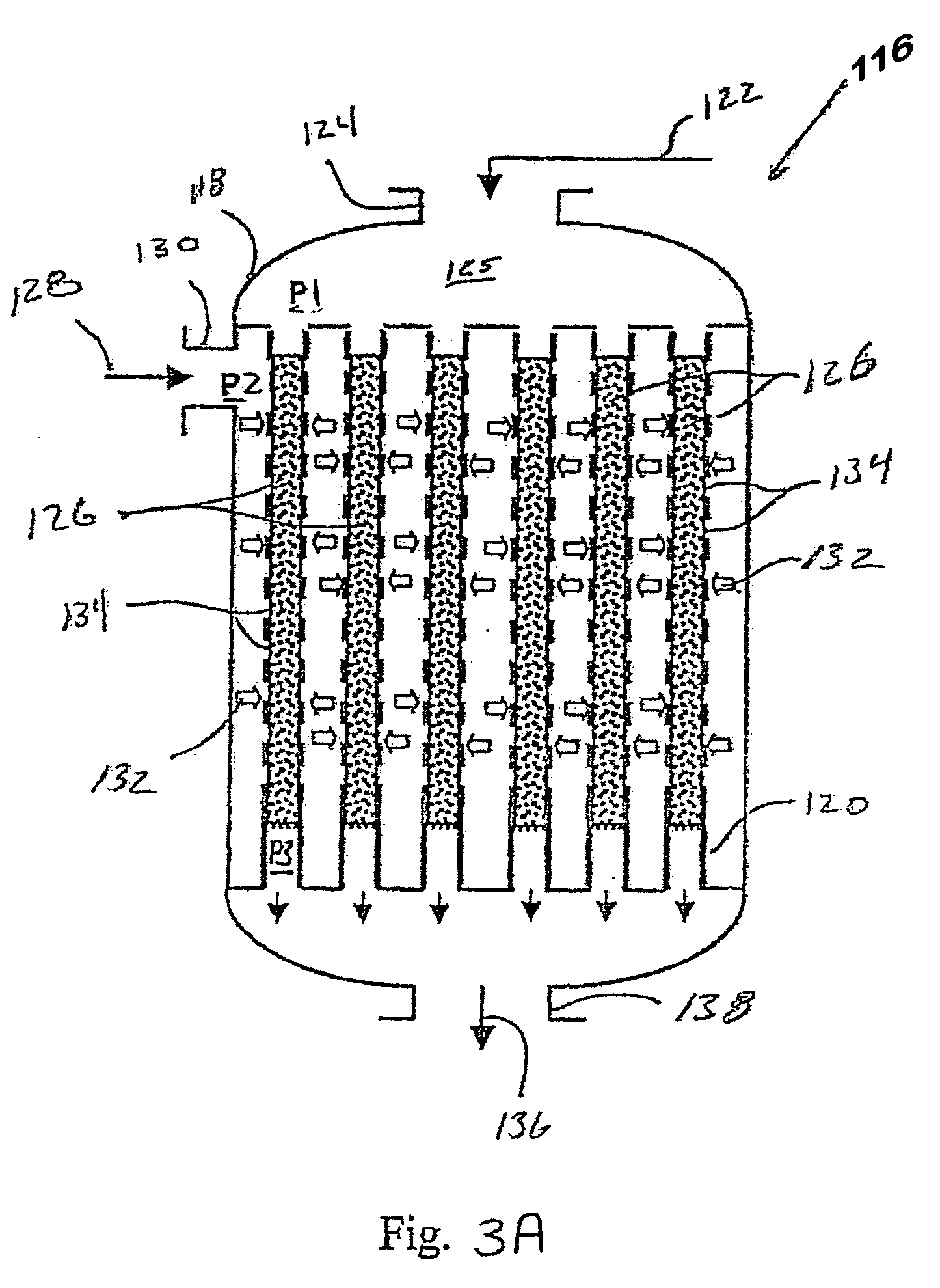

Tube and shell reactor with oxygen selective ion transport ceramic reaction tubes

InactiveUS6139810AIncrease oxygen fluxDecreasing anode side partial oxygen pressureIsotope separationHydrogen/synthetic gas productionPtru catalystElectrical conductor

A reactor comprising: a hollow shell defining a hermetic enclosure; a plurality of tube sheets disposed within said hermetic enclosure, a first one of said plurality of tube sheets defining a first chamber; at least one reaction tube each having a first end and an opposing second end, said first end being fixedly attached and substantially hermetically sealed to one end of said plurality of tube sheets and opening into said first chamber, the second end being axially unrestrained; each of said reaction tubes is comprised of an oxygen selective ion transport membrane with an anode side wherein said oxygen selective ion transport membrane is formed from a mixed conductor metal oxide that is effective for the transport of elemental oxygen at elevated temperatures and at least a portion of said first and second heat transfer sections are formed of metal; each of said reaction tubes includes first and second heat transfer sections and a reaction section, said reaction section disposed between said first and second heat transfer sections; a reforming catalyst disposed about said anode side of said oxygen selective ion transport membrane; a first process gas inlet; a second process gas inlet; and, a plurality of outlets.

Owner:STANDARD OIL CO +1

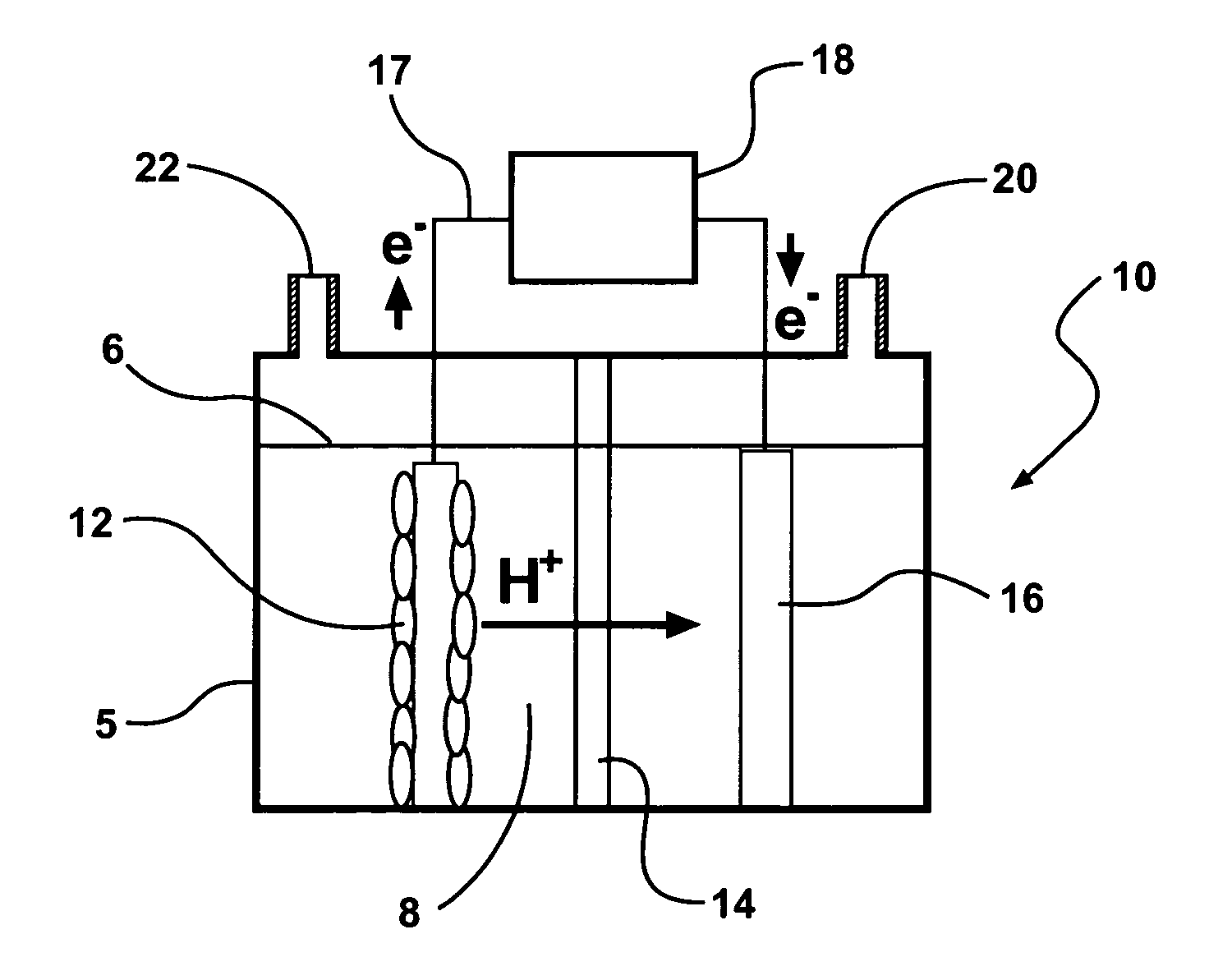

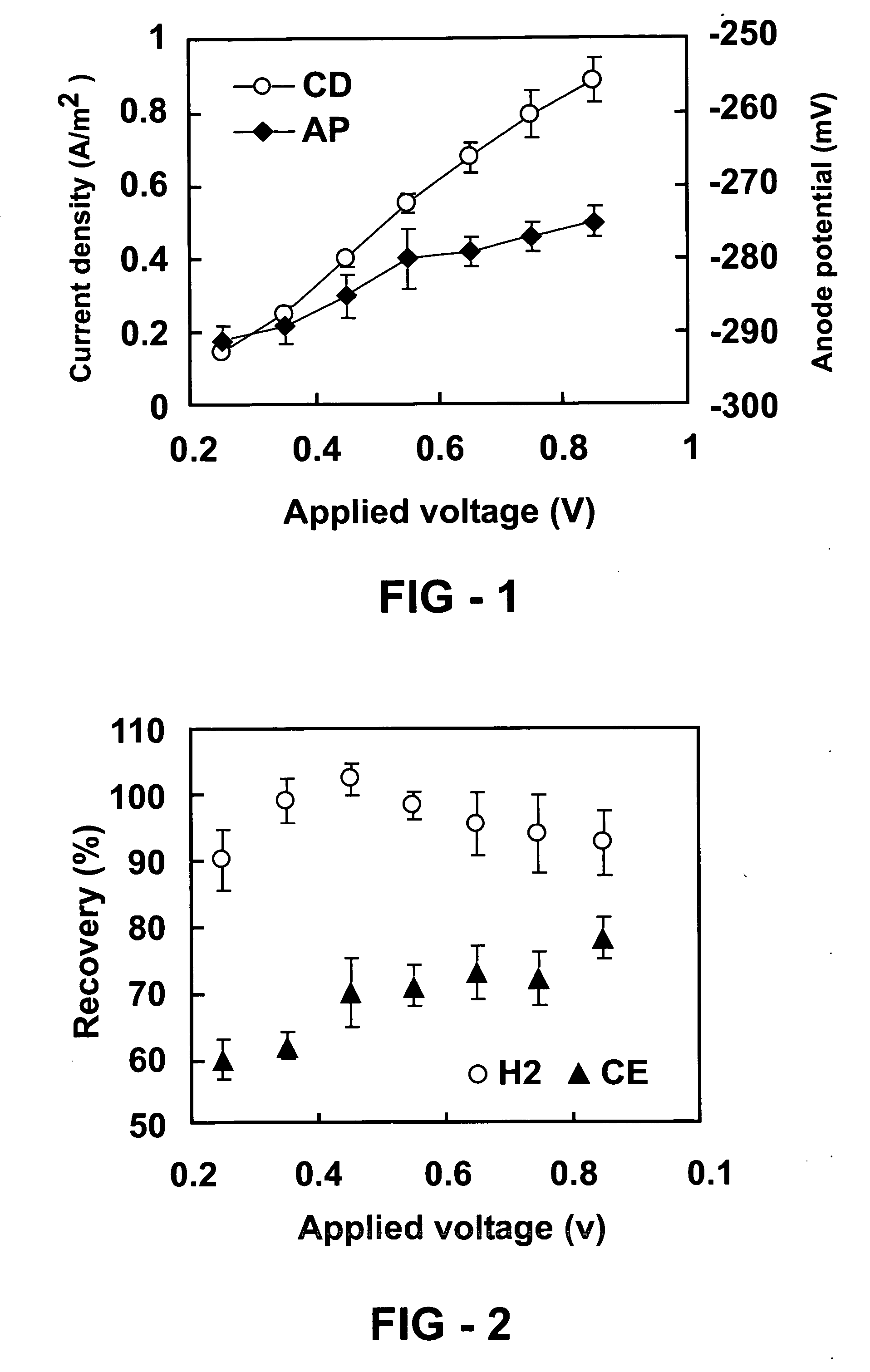

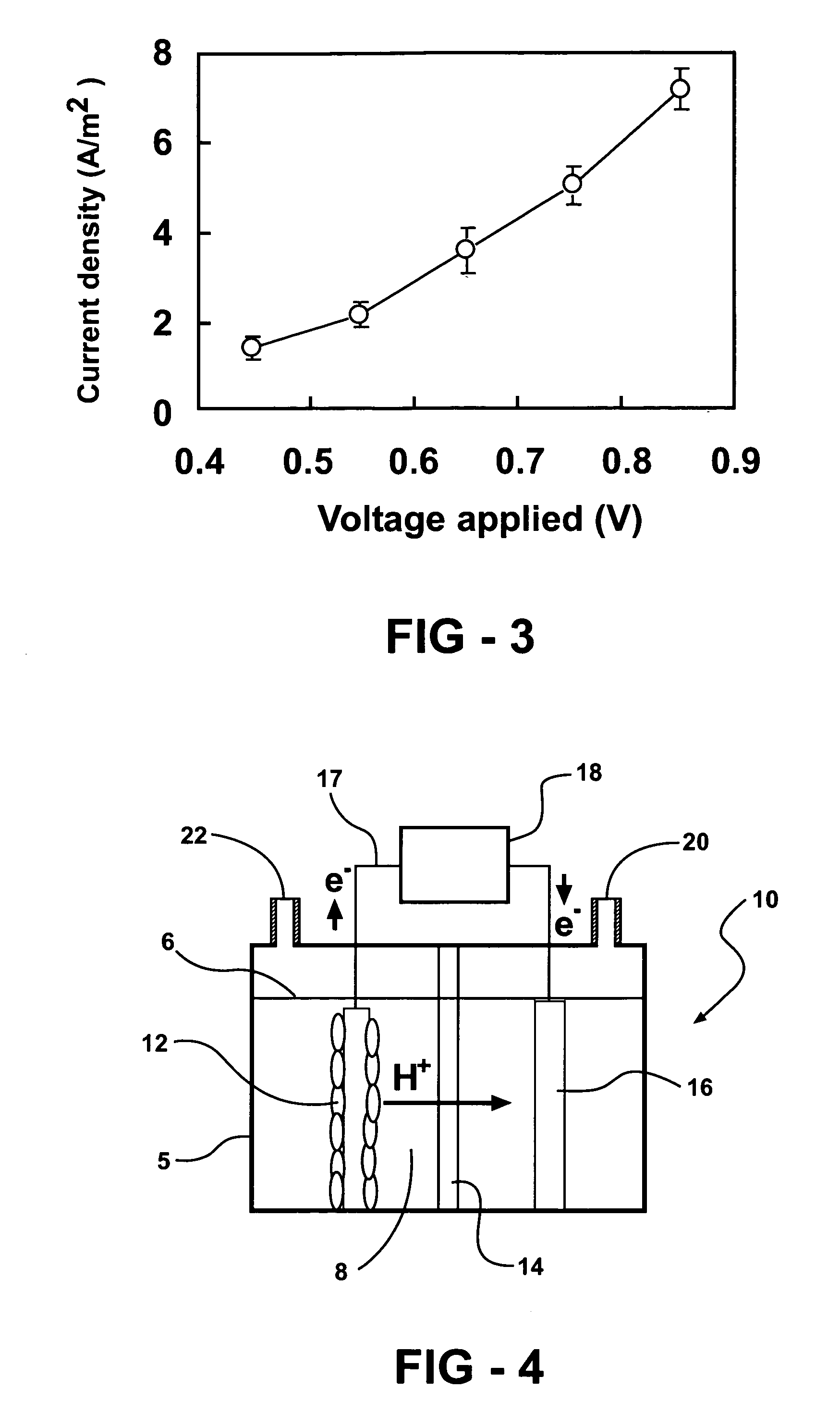

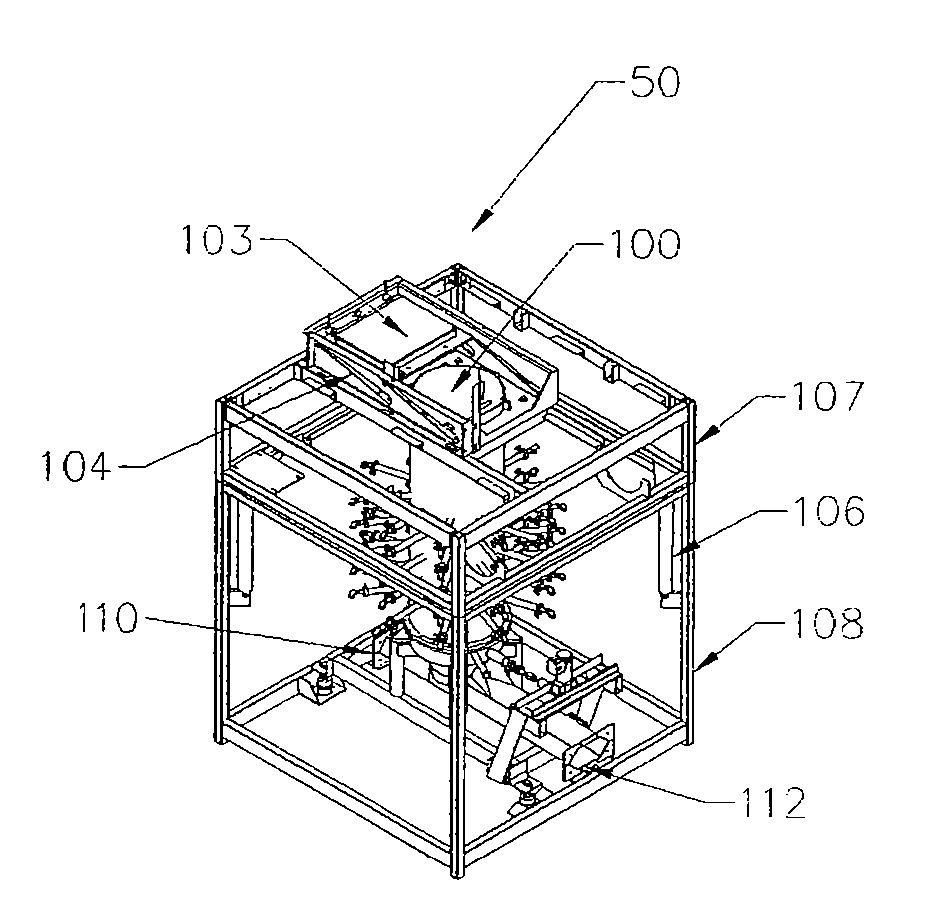

Bio-electrochemically assisted microbial reactor that generates hydrogen gas and methods of generating hydrogen gas

ActiveUS20060011491A1Provide supportGrowth inhibitionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityHydrogen

Systems and processes for producing hydrogen using bacteria are described. One detailed process for producing hydrogen uses a system for producing hydrogen as described herein, the system including a reactor. Anodophilic bacteria are disposed within the interior of the reactor and an organic material oxidizable by an oxidizing activity of the anodophilic bacteriais introduced and incubated under oxidizing reactions conditions such that electrons are produced and transferred to the anode. A power source is activated to increase a potential between the anode and the cathode, such that electrons and protons combine to produce hydrogen gas. One system for producing hydrogen includes a reaction chamber having a wall defining an interior of the reactor and an exterior of the reaction chamber. An anode is provided which is at least partially contained within the interior of the reaction chamber and a cathode is also provided which is at least partially contained within the interior of the reaction chamber. The cathode is spaced apart at a distance in the range between 0.1-100 centimeters, inclusive, from the anode. A conductive conduit for electrons is provided which is in electrical communication with the anode and the cathode and a power source for enhancing an electrical potential between the anode and cathode is included which is in electrical communication at least with the cathode. A first channel defining a passage from the exterior of the reaction chamber to the interior of the reaction chamber is also included.

Owner:PENN STATE RES FOUND +1

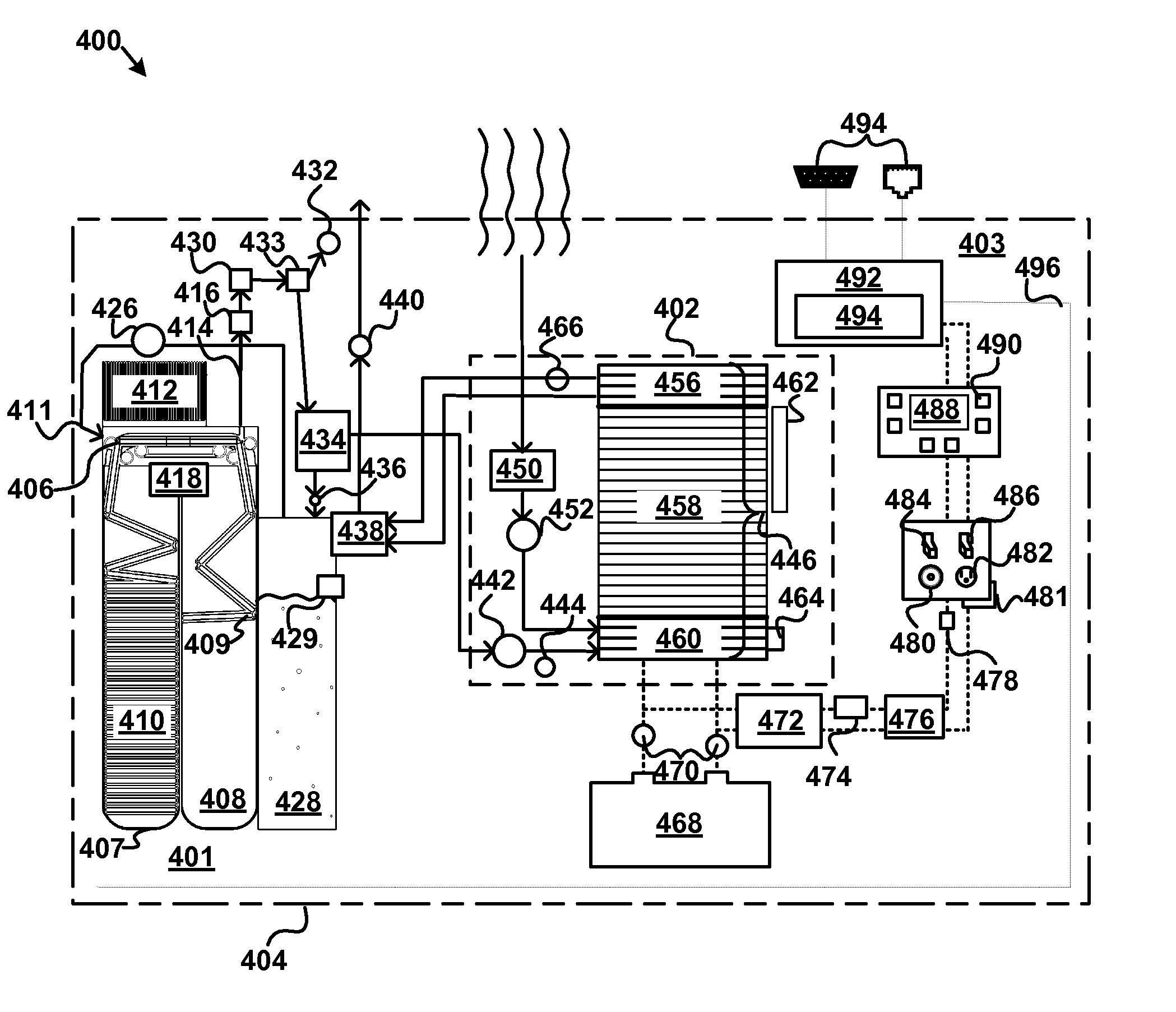

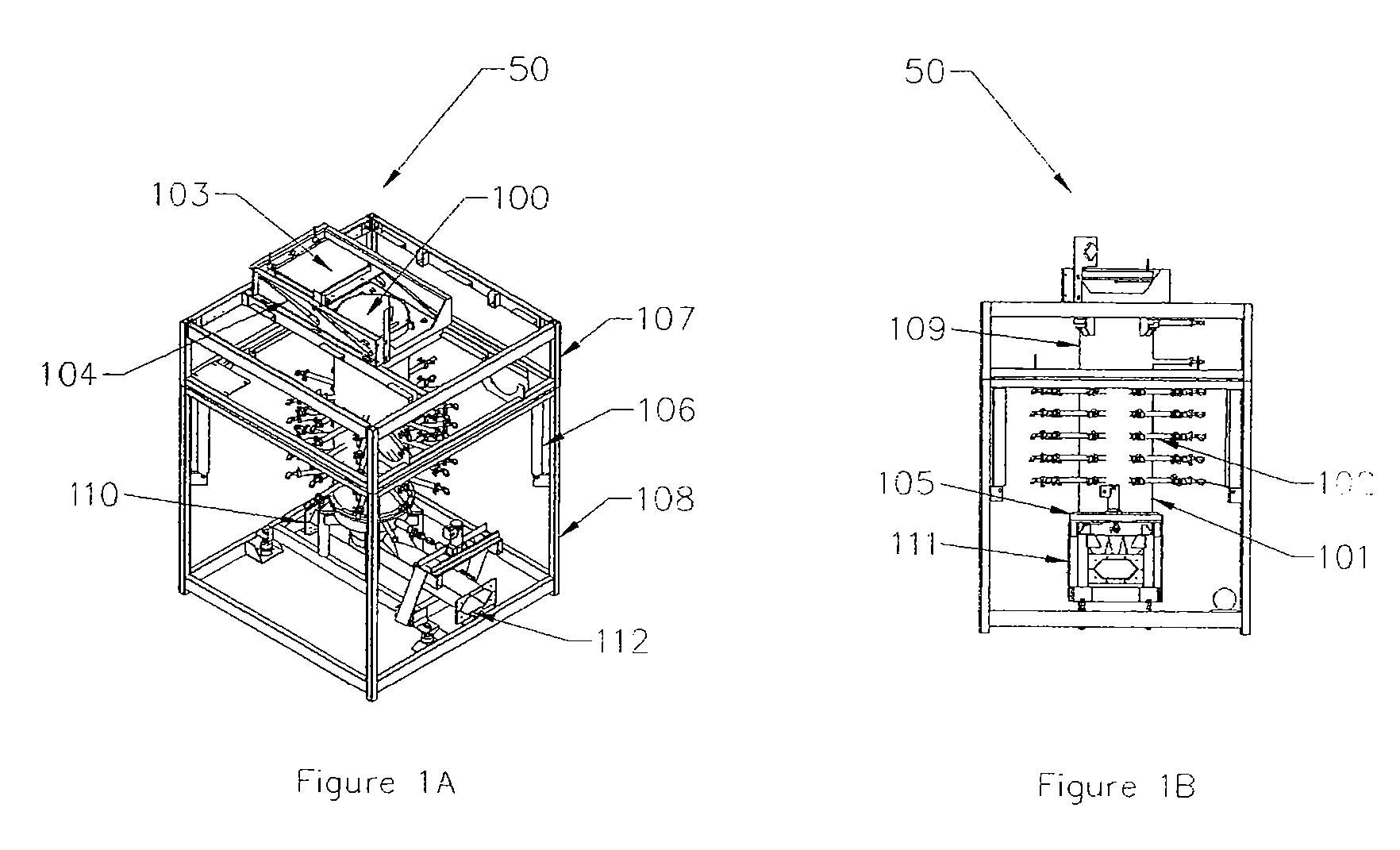

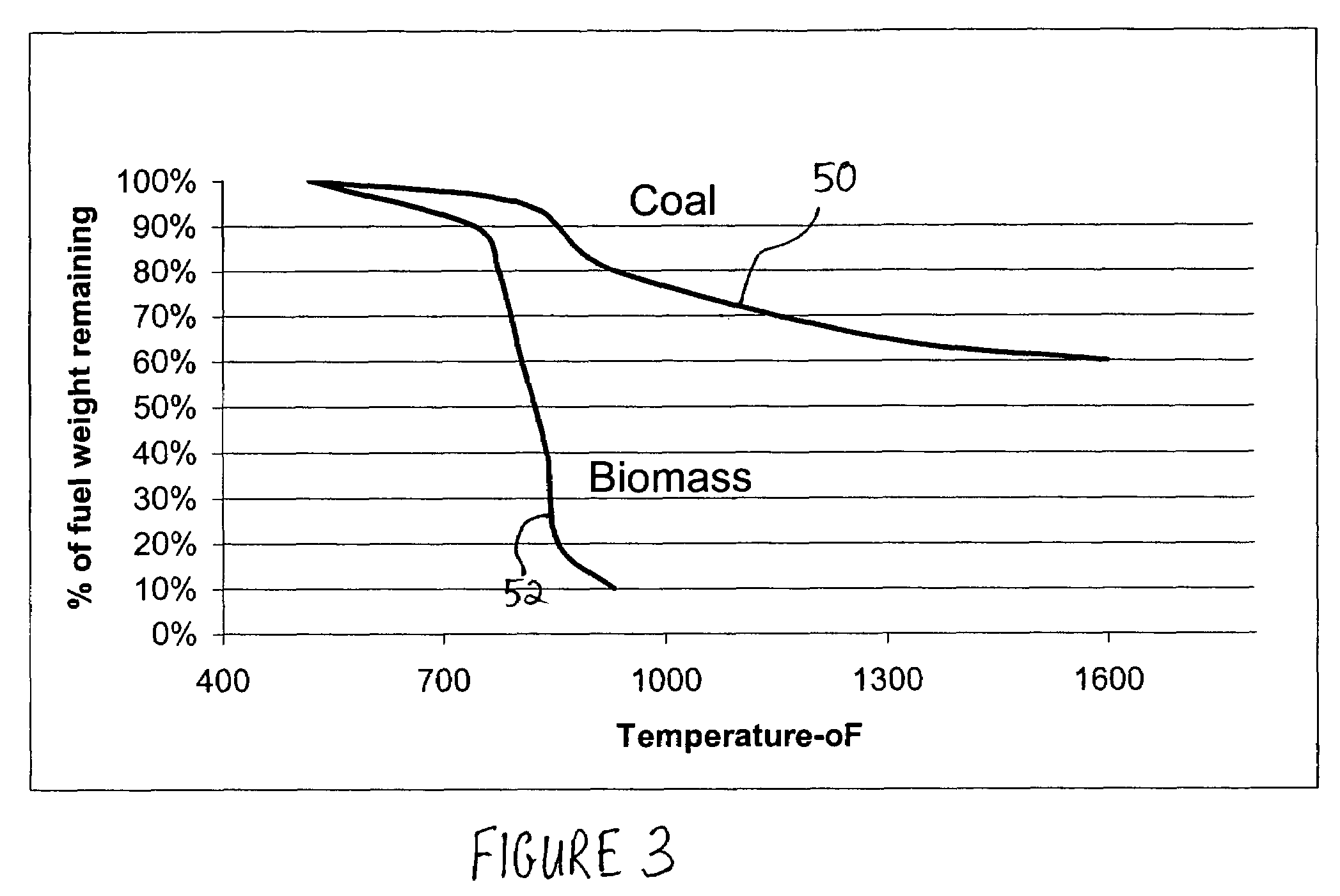

Method and Apparatus for Automated, Modular, Biomass Power Generation

ActiveUS20070006528A1Increasing fuel-bed bulk densityRestrict movementHydrogenDispersed particle filtrationElectric power systemFossil fuel

Method and apparatus for generating a low tar, renewable fuel gas from biomass and using it in other energy conversion devices, many of which were designed for use with gaseous and liquid fossil fuels. An automated, downdraft gasifier incorporates extensive air injection into the char bed to maintain the conditions that promote the destruction of residual tars. The resulting fuel gas and entrained char and ash are cooled in a special heat exchanger, and then continuously cleaned in a filter prior to usage in standalone as well as networked power systems.

Owner:COMMUNITY POWER CORP

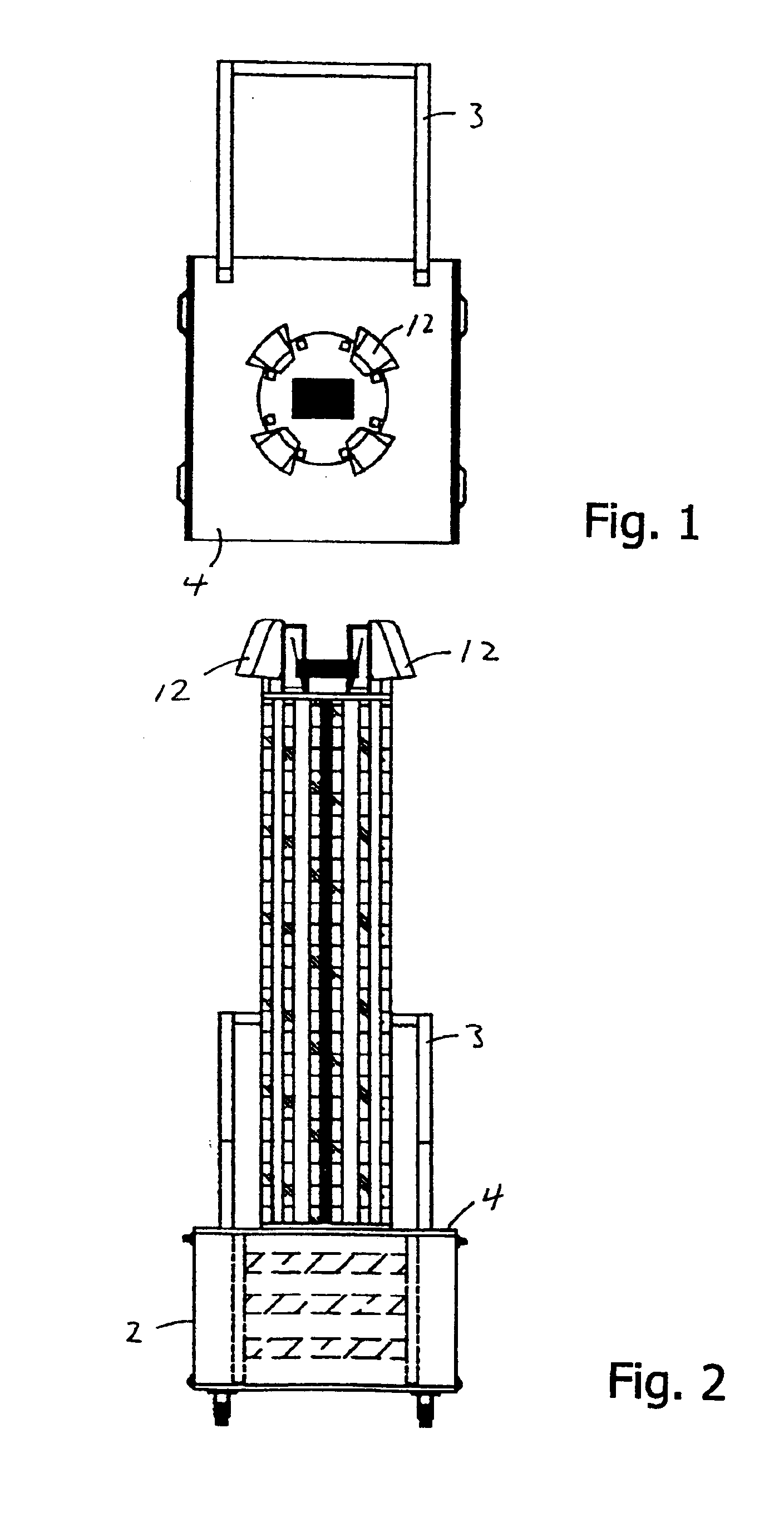

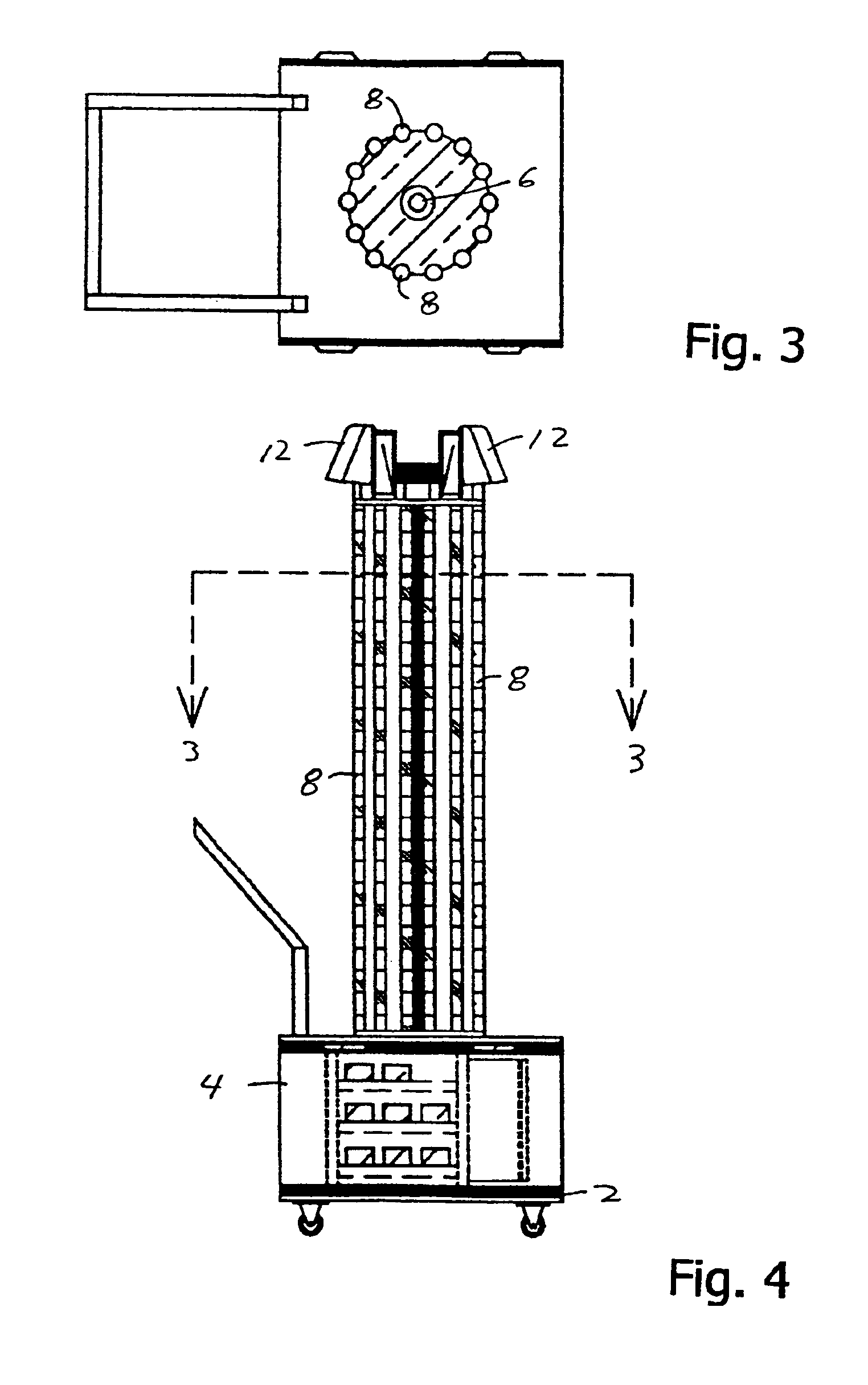

Ultraviolet area sterilizer and method of area sterilization using ultraviolet radiation

An ultraviolet area sterilizer (UVAS) is mobile or stationary. The UVAS is positioned in a room, such an operating room or intensive care unit. Motion detectors sense movement, to assure that personnel have evacuated the space to be sterilized. Subsequently, UV-C generators, such mercury bulbs, generate UV-C from multiple locations within the room or other enclosed space. Multiple UV-C sensors scan the room, and determine the area reflecting the lowest level of UV-C back to the sensors. The device calculates the time required to obtain a bactericidal dose of UV-C reflected back to the sensors. Once an effective bactericidal dose has been reflected to all the sensors, the unit notifies the operator and shuts down.

Owner:UVAS

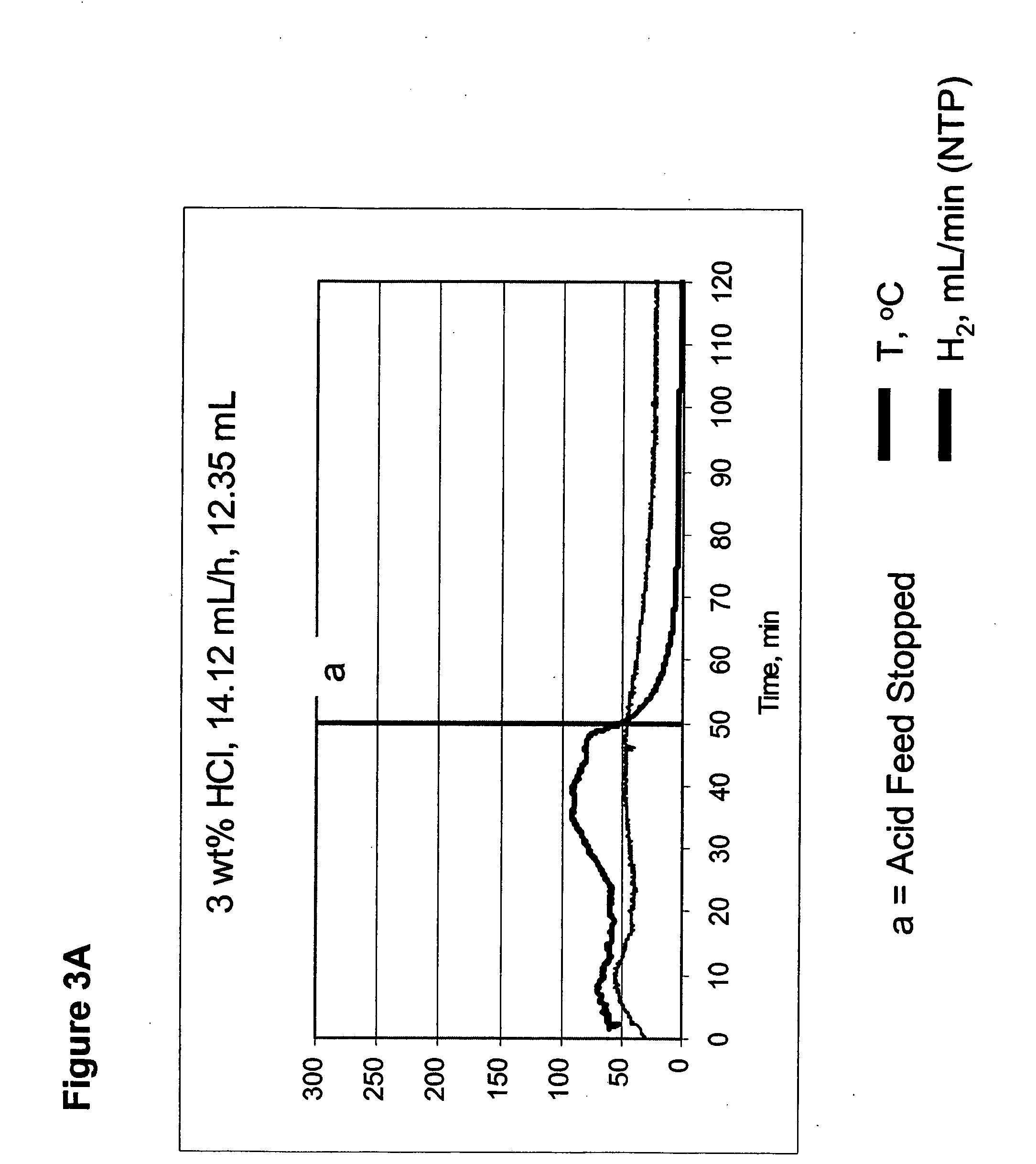

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

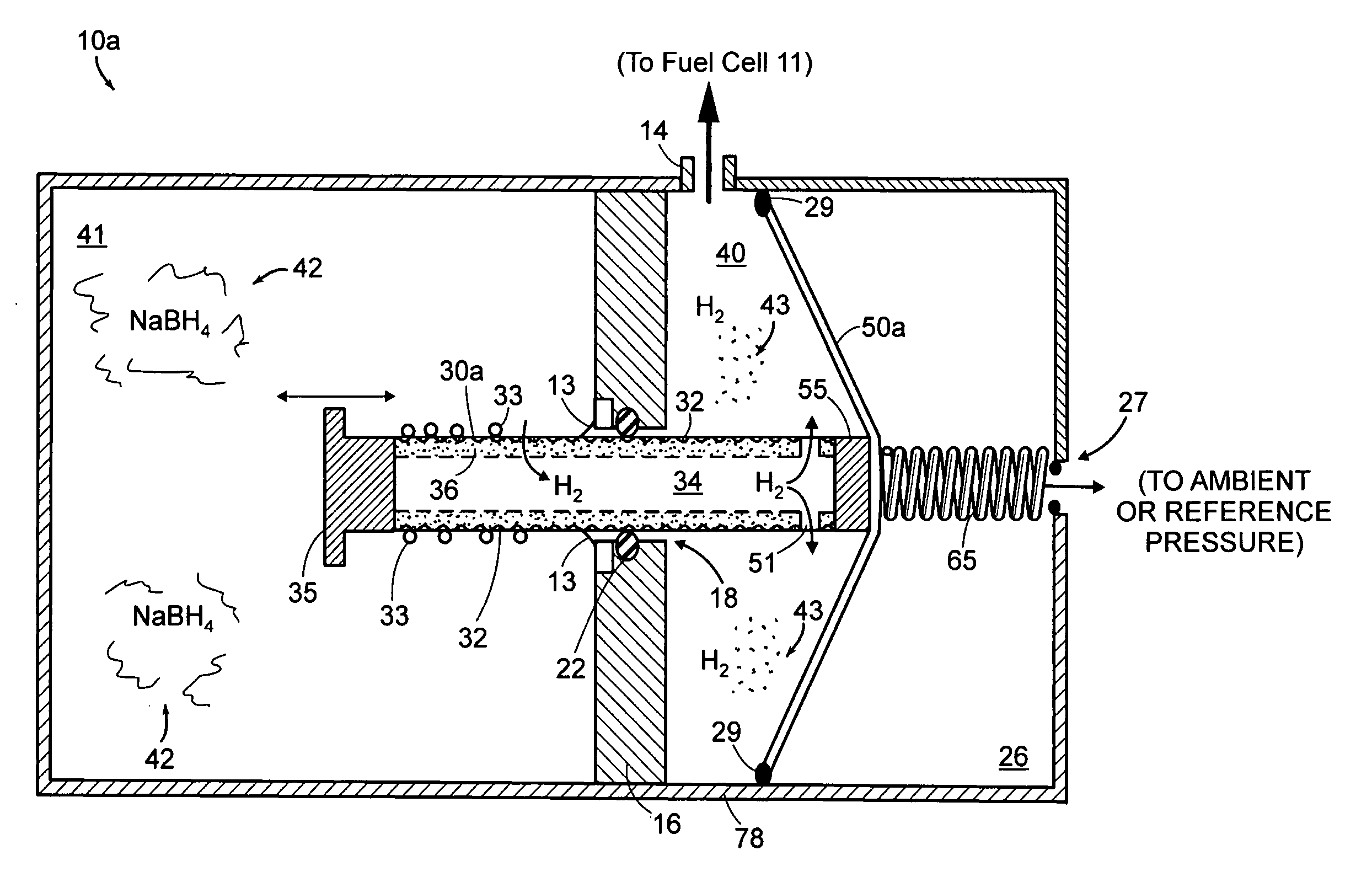

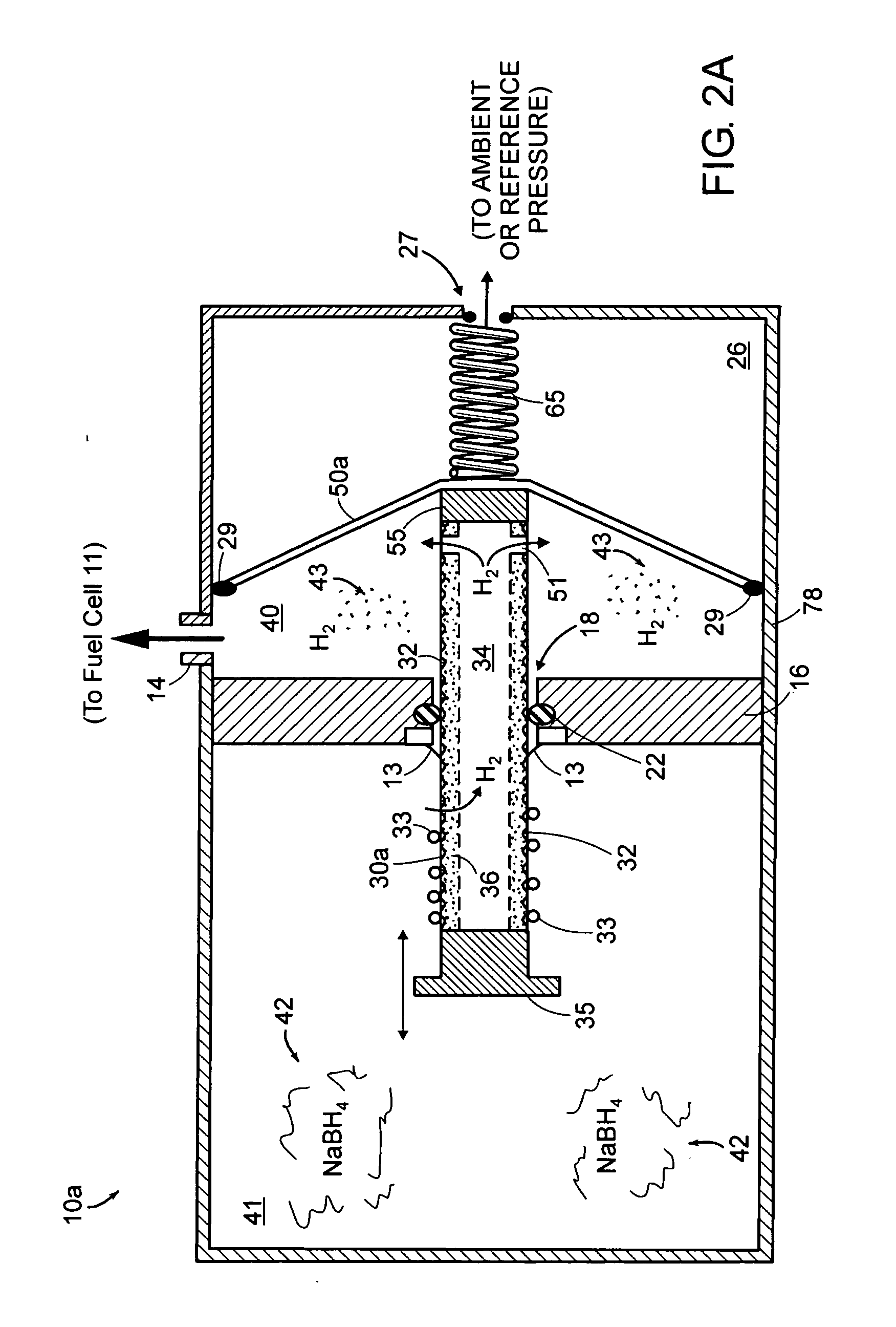

Self-regulating gas generator and method

ActiveUS20050158595A1Increase and decreases gas production rateExtend your lifeReactant parameters controlMultiple metal hydridesHydrogenFuel cells

A self-regulating gas generator that, in response to gas demand, supplies and automatically adjusts the amount of gas (e.g., hydrogen or oxygen) catalytically generated in a chemical supply chamber from an appropriate chemical supply, such as a chemical solution, gas dissolved in liquid, or mixture. The gas generator may employ a piston, rotating rod, or other element(s) to expose the chemical supply to the catalyst in controlled amounts. The gas generator may be used to provide gas for various gas consuming devices, such as a fuel cell, torch, or oxygen respiratory devices.

Owner:ENCITE LLC

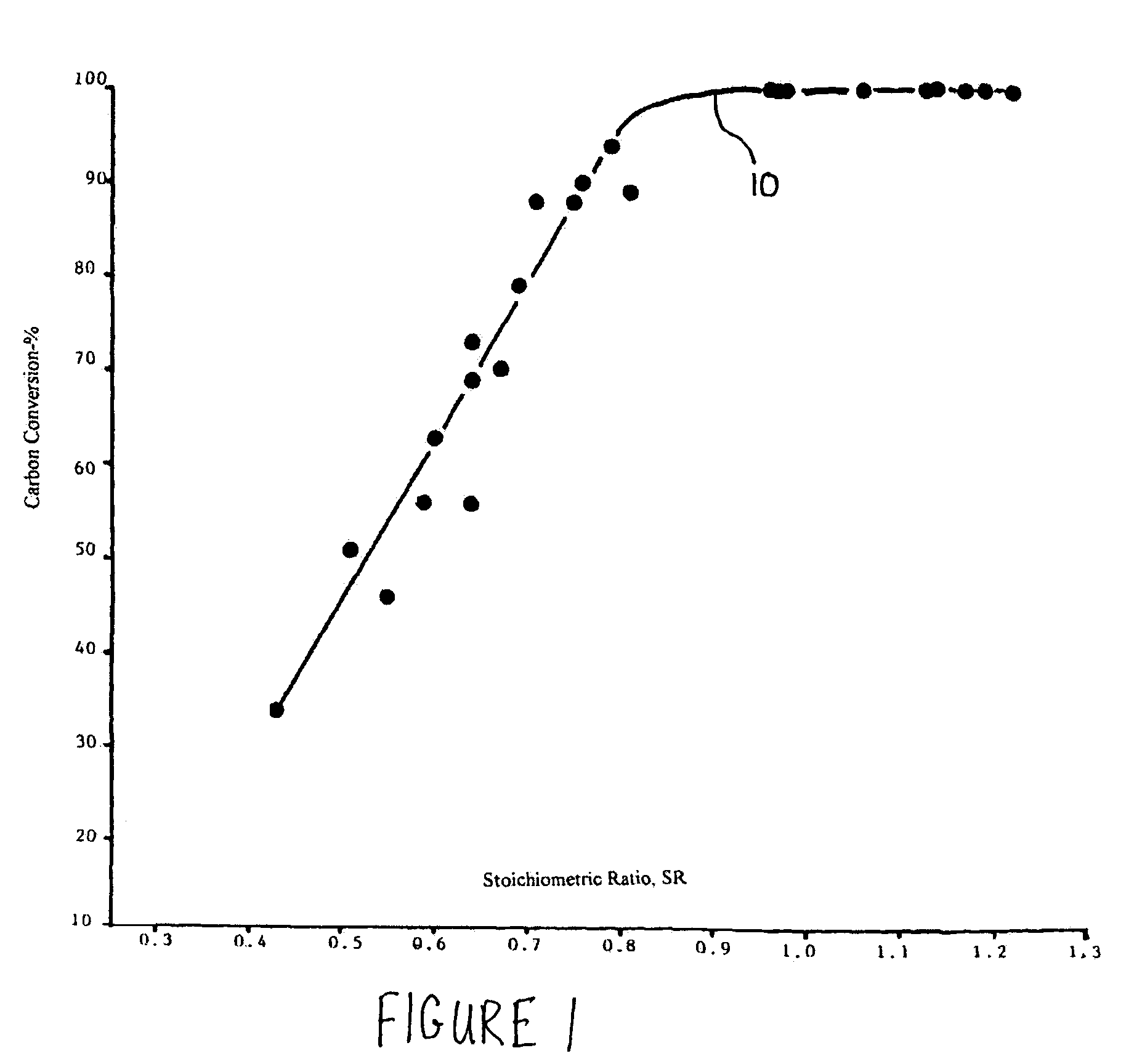

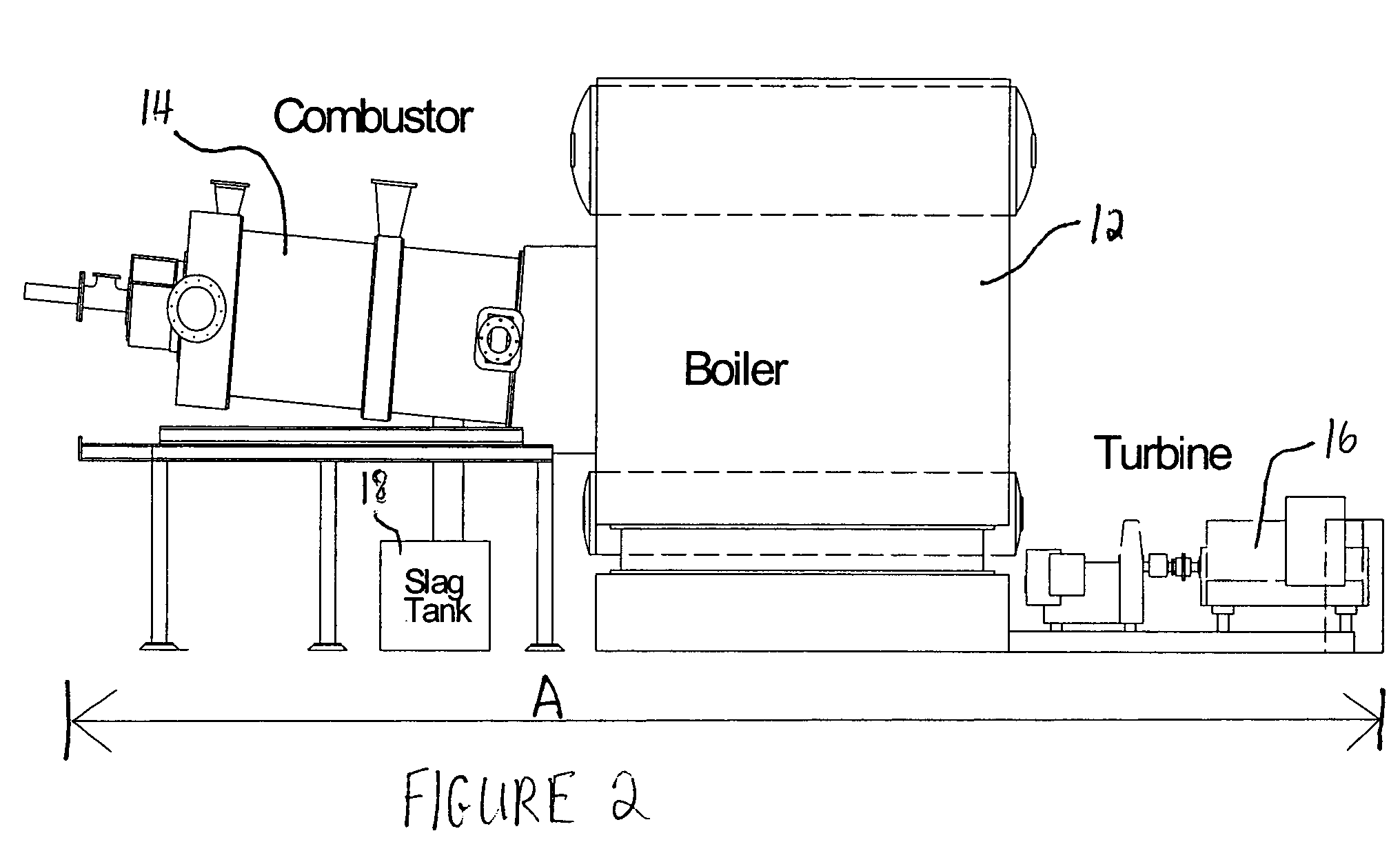

Production of hydrogen and removal and sequestration of carbon dioxide from coal-fired furnaces and boilers

InactiveUS7282189B2Increase ratingsValue maximizationOrganic chemistryNitrogen compoundsHydrogenProcess engineering

Methods for reducing and eliminating carbon dioxide from the emissions of solid fuel fired power plants, particularly coal fired power plants, and to sequester the carbon dioxide, typically by using existing equipment. In some embodiments, the methods involve pyrolyzing the solid fuel to remove volatile matter and using the volatile matter to produce hydrogen. Additionally, the methods may involve burning the solid fuel or pyrolized solid fuel at very fuel rich stoichiometric conditions. Sequestration may include the production of a carbon dioxide-containing solution and the pumping of the solution into the ground, particularly in areas high in limestone.

Owner:ZAUDERER BERT

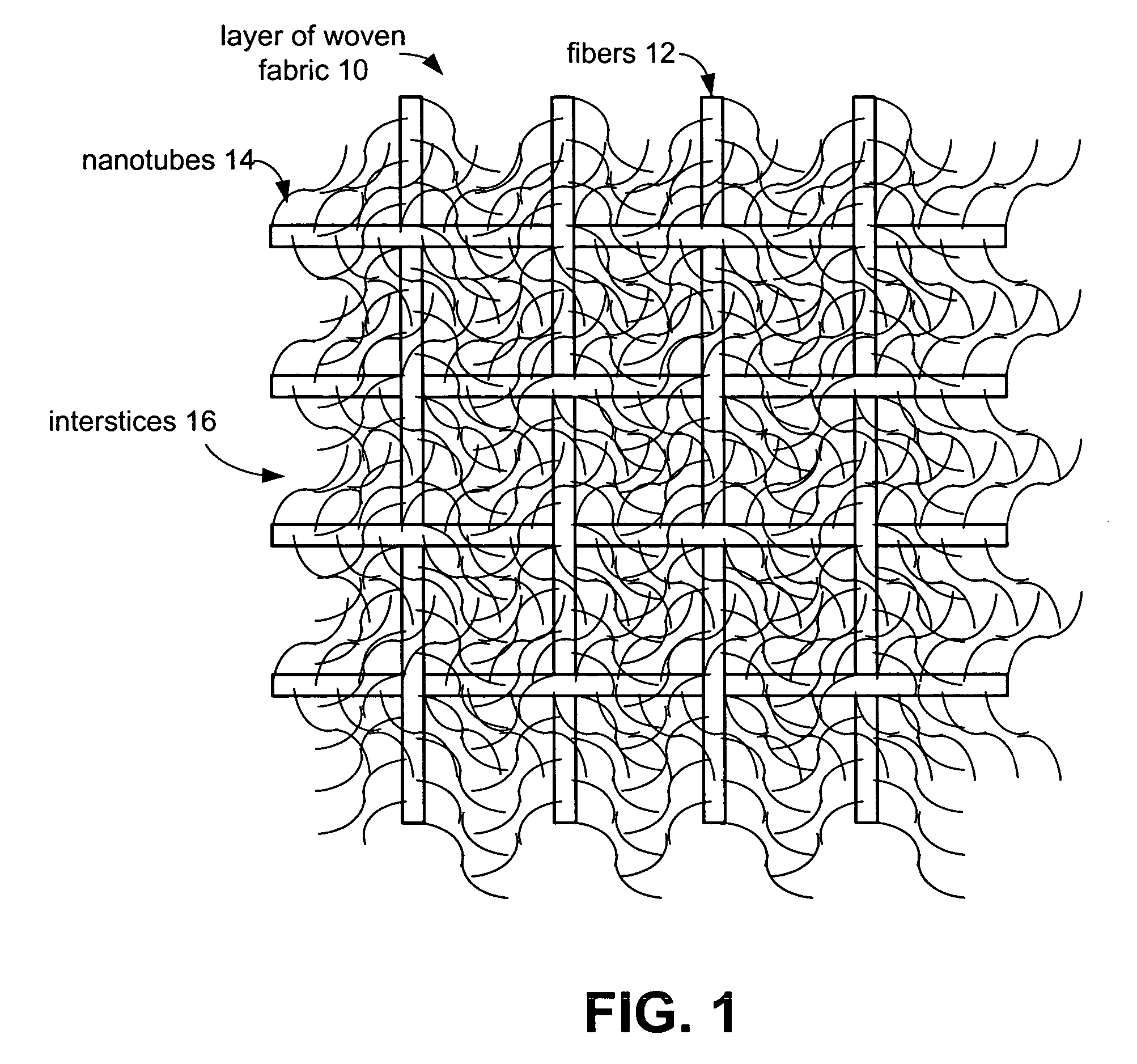

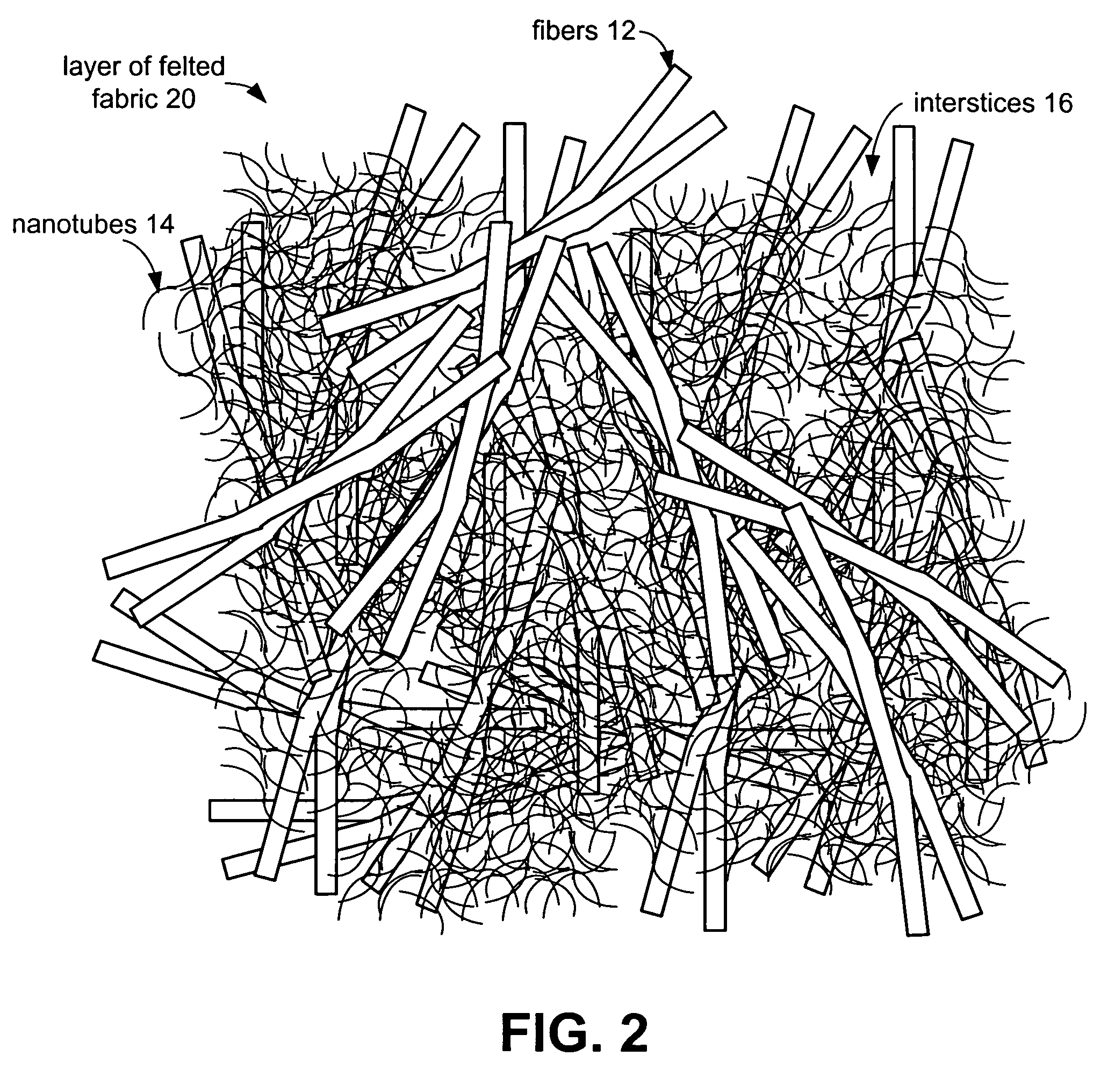

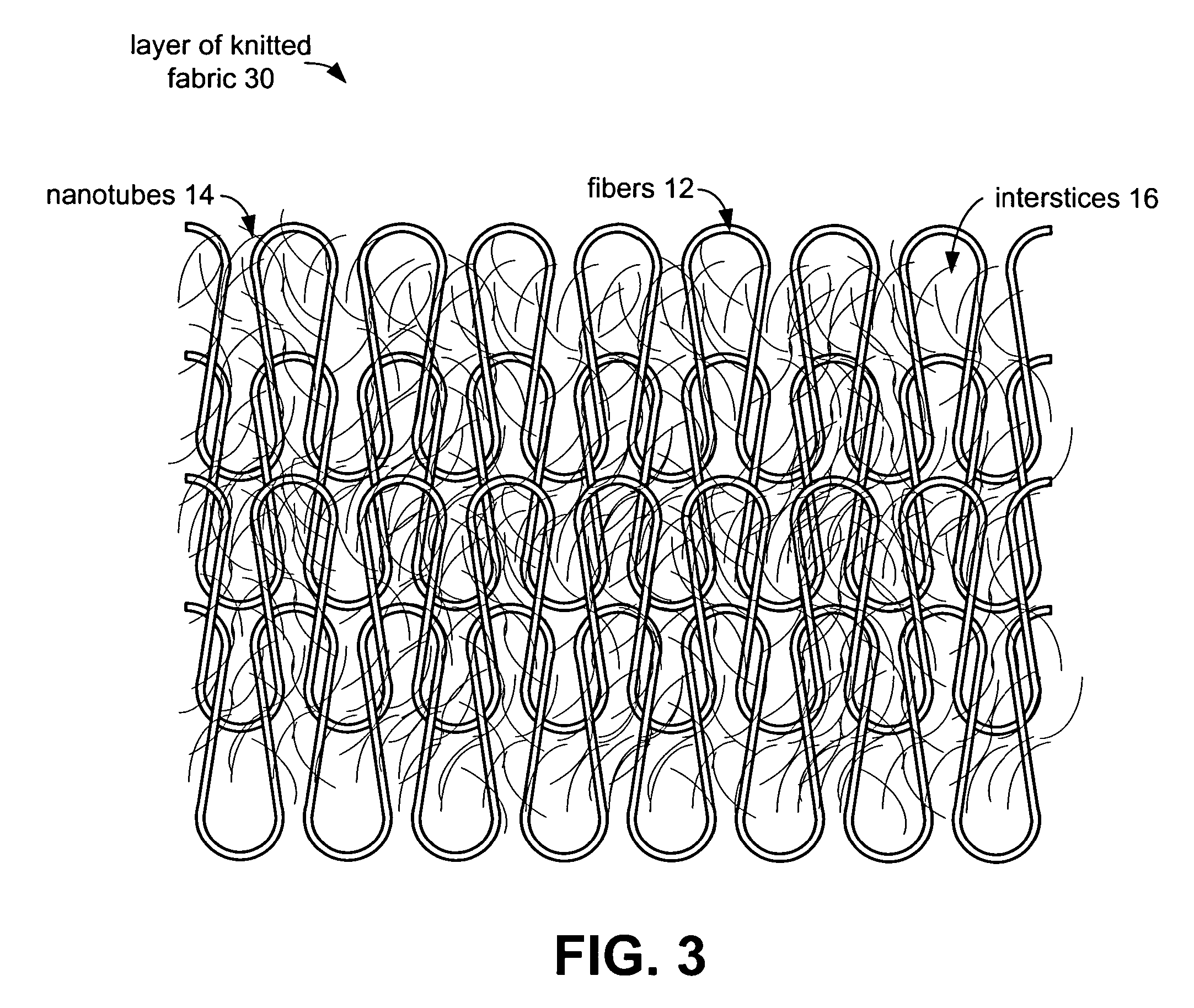

Ballistic fabrics with improved antiballistic properties

ActiveUS20060062944A1Good physical propertiesImprove propertiesMaterial nanotechnologyWarp knittingFiberYarn

The present invention provides fabrics that have unique mechanical, chemical, electrical, and thermal properties. The fabrics comprise layers of woven, knit or felted fibers, yarns or tow. Interstitially synthesized nanotubes, such as single-walled or multi-walled carbon nanotubes, enhance the fabric's antiballistic properties. These nanotubes may also insulate, semi-conduct or super-conduct electrical charges, or provide enhanced thermal properties of these fabrics which can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

Fuel supply for a fuel cell

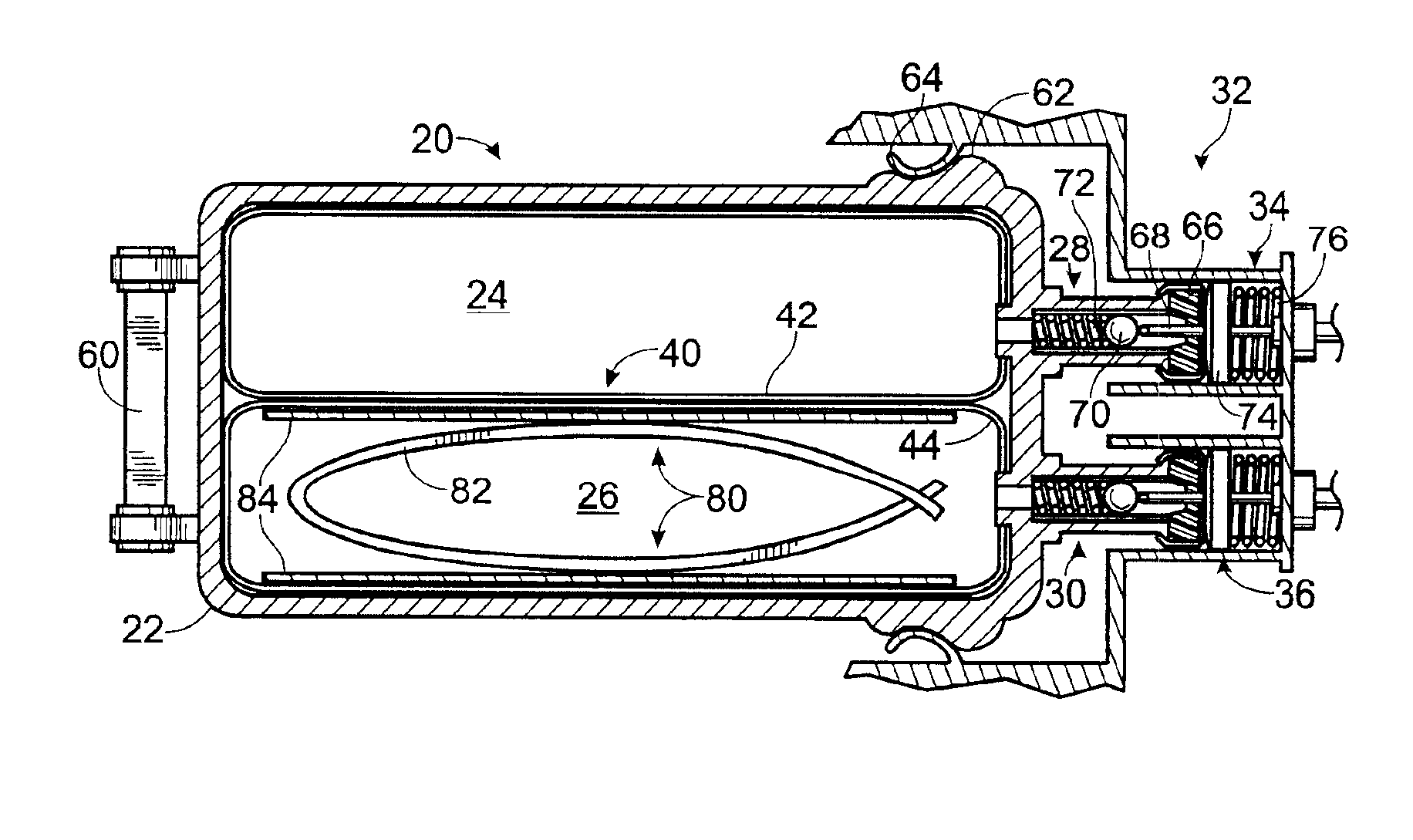

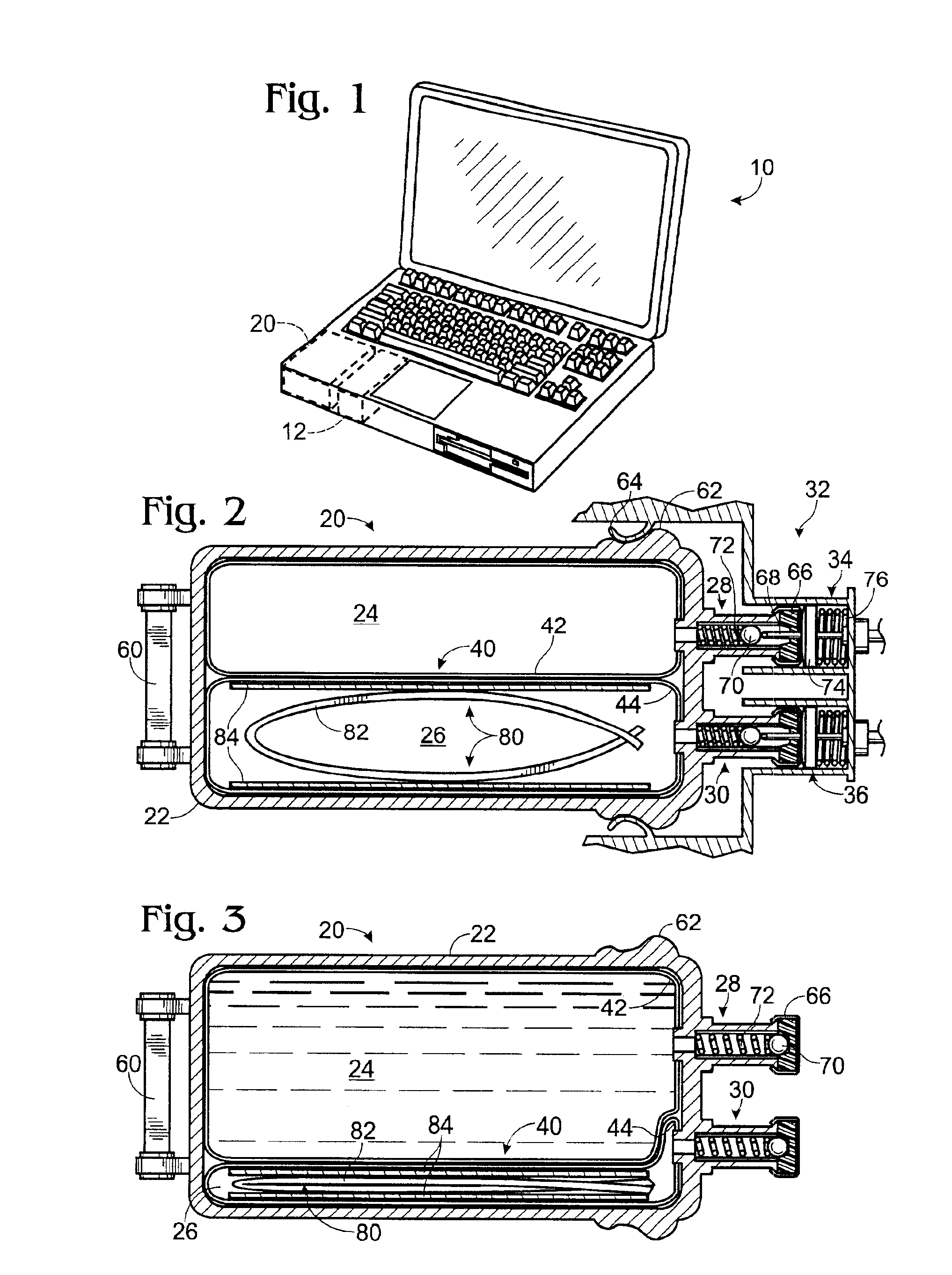

InactiveUS6924054B2Lower the volumeIncrease volumeInternal combustion piston enginesReactant parameters controlFuel cellsFuel supply

The present invention concerns a fuel supply for a fuel cell. The fuel supply includes a fuel storage area configured to hold a fuel solution, a fuel solution outlet configured to pass the fuel solution from the fuel storage area, a waste storage area, a waste inlet configured to pass waste into the waste storage area, and a movable barrier separating the fuel storage area and the waste storage area. The movable barrier is configured to move as fuel solution is passed from the fuel storage area and waste solution is passed into the waste storage area to simultaneously decrease the volume of the fuel storage area and increase the volume of the waste storage area.

Owner:INTELLIGENT ENERGY LTD

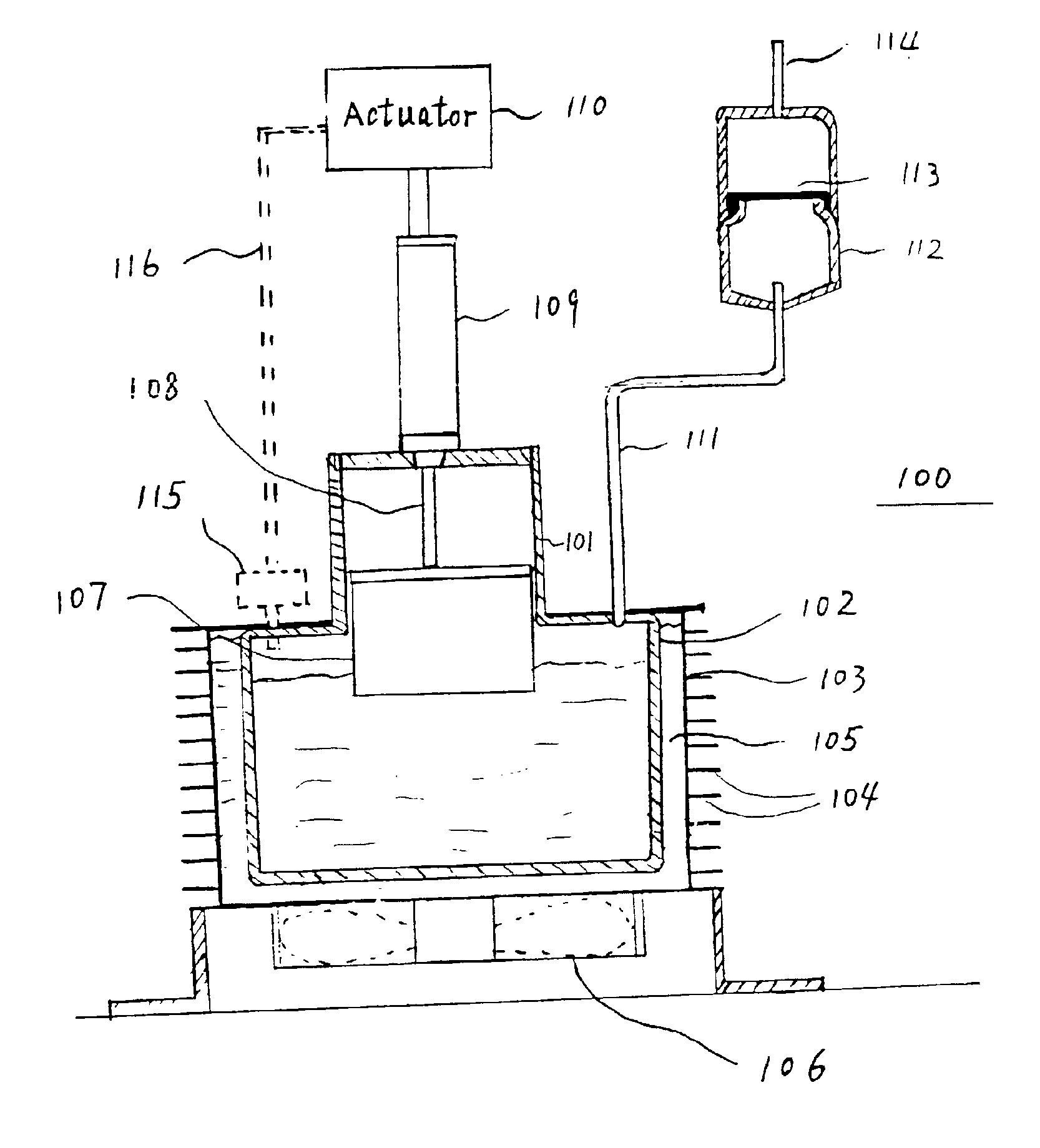

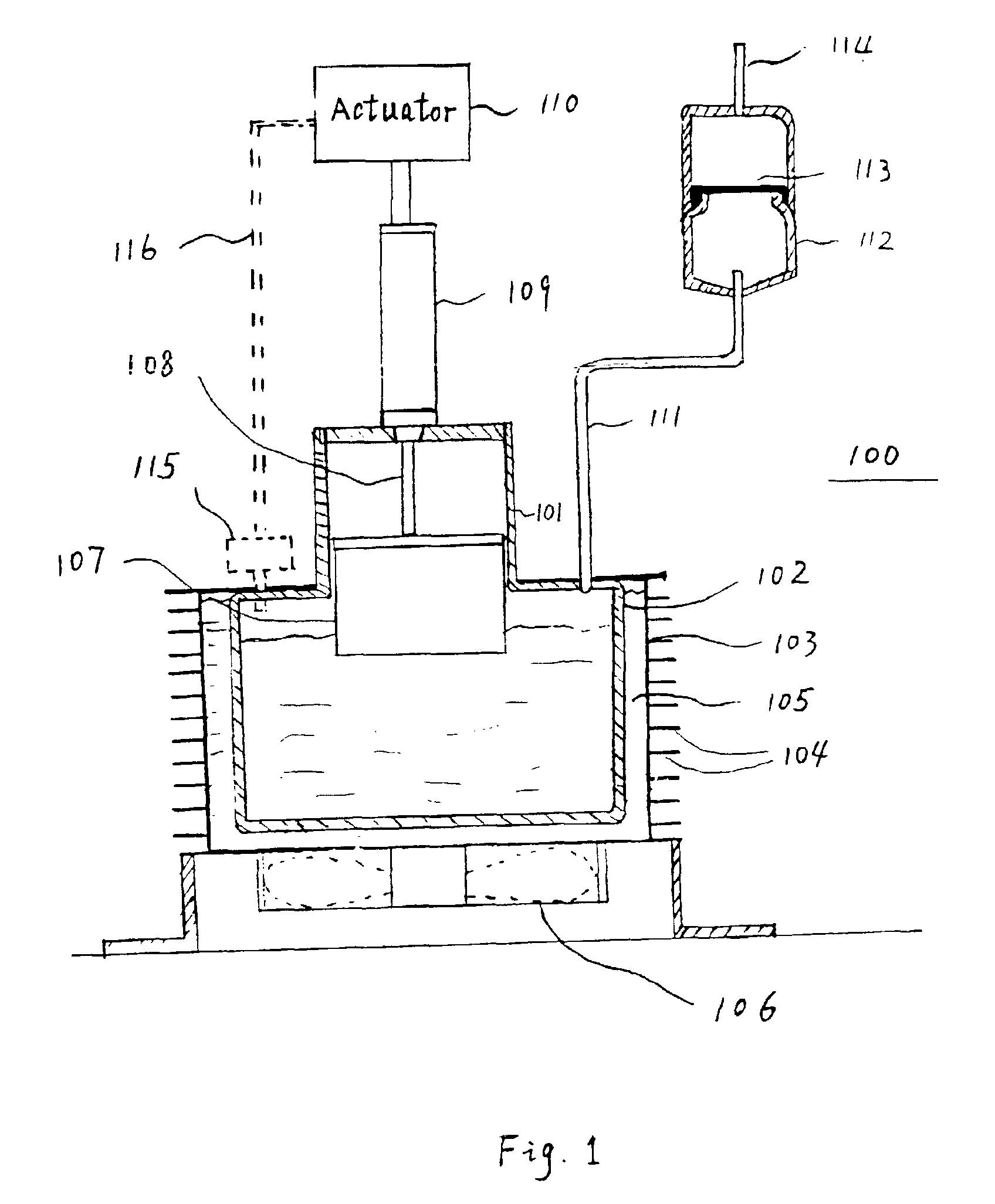

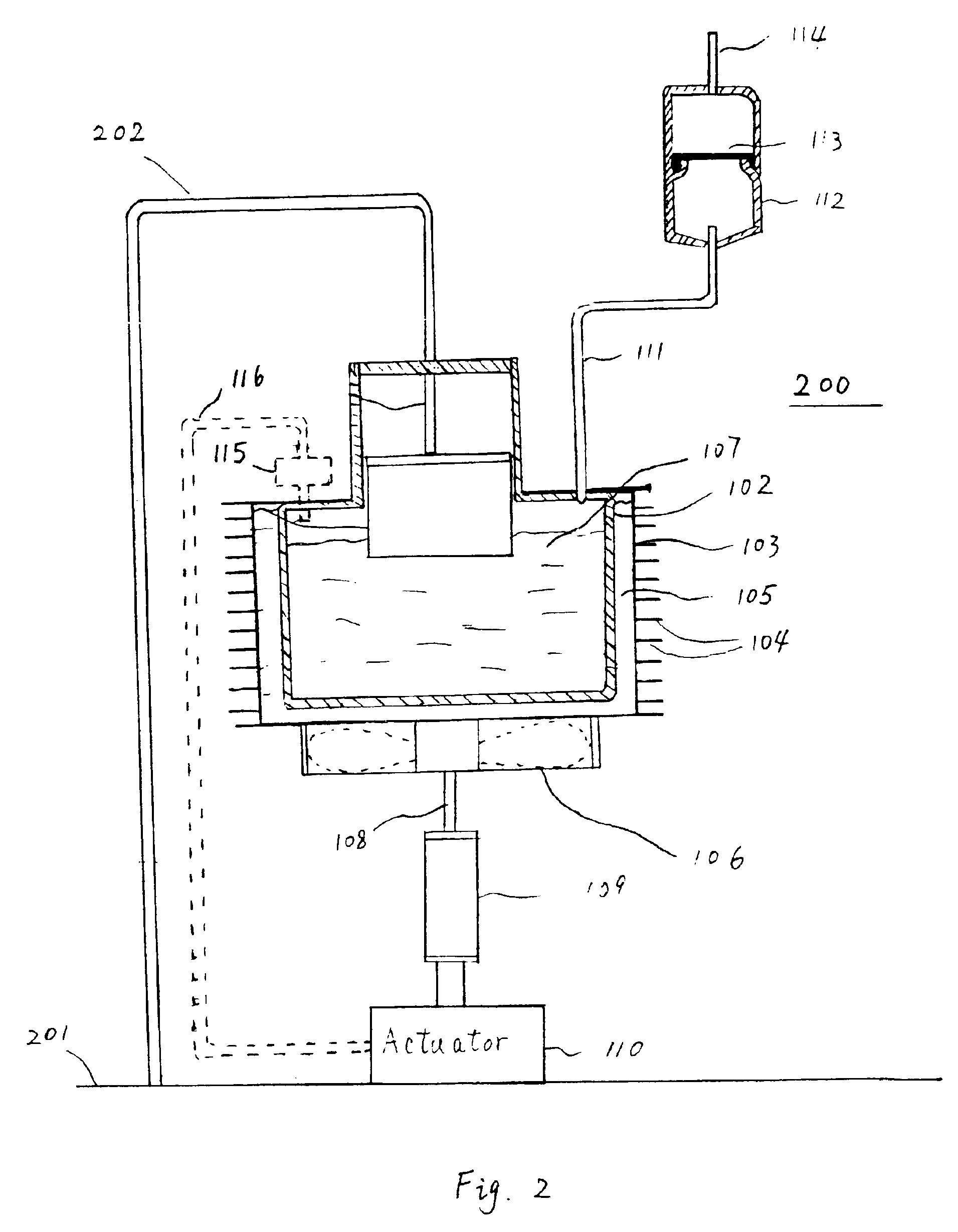

Self-regulating hydrogen generator

InactiveUS6939529B2Increase and decrease hydrogen generation rateIncrease rate of hydrogen generationPhysical/chemical process catalystsHydrogen productionGeneration processGeneration rate

A hydrogen generating system regulates its rate of hydrogen generation by monitoring one or more parameters of the hydrogen generation process and then providing relative movement between the fuel tank and the catalyst chamber so as to increase or decrease the rate of hydrogen generation.In the disclosed embodiments, the catalyst chamber is disposed in a tank containing the fuel. The relative movement provided moves the catalyst chamber toward the fuel solution so as to increase the rate of hydrogen generation and moves the catalyst chamber away from the fuel solution to decrease such generation. Advantageously, such self-regulation can be provided without an external power source and can be varied to meet the requirements of different commercial applications. The overall system can be readily fabricated using commercially available parts.

Owner:PROTONEX TECH CORP

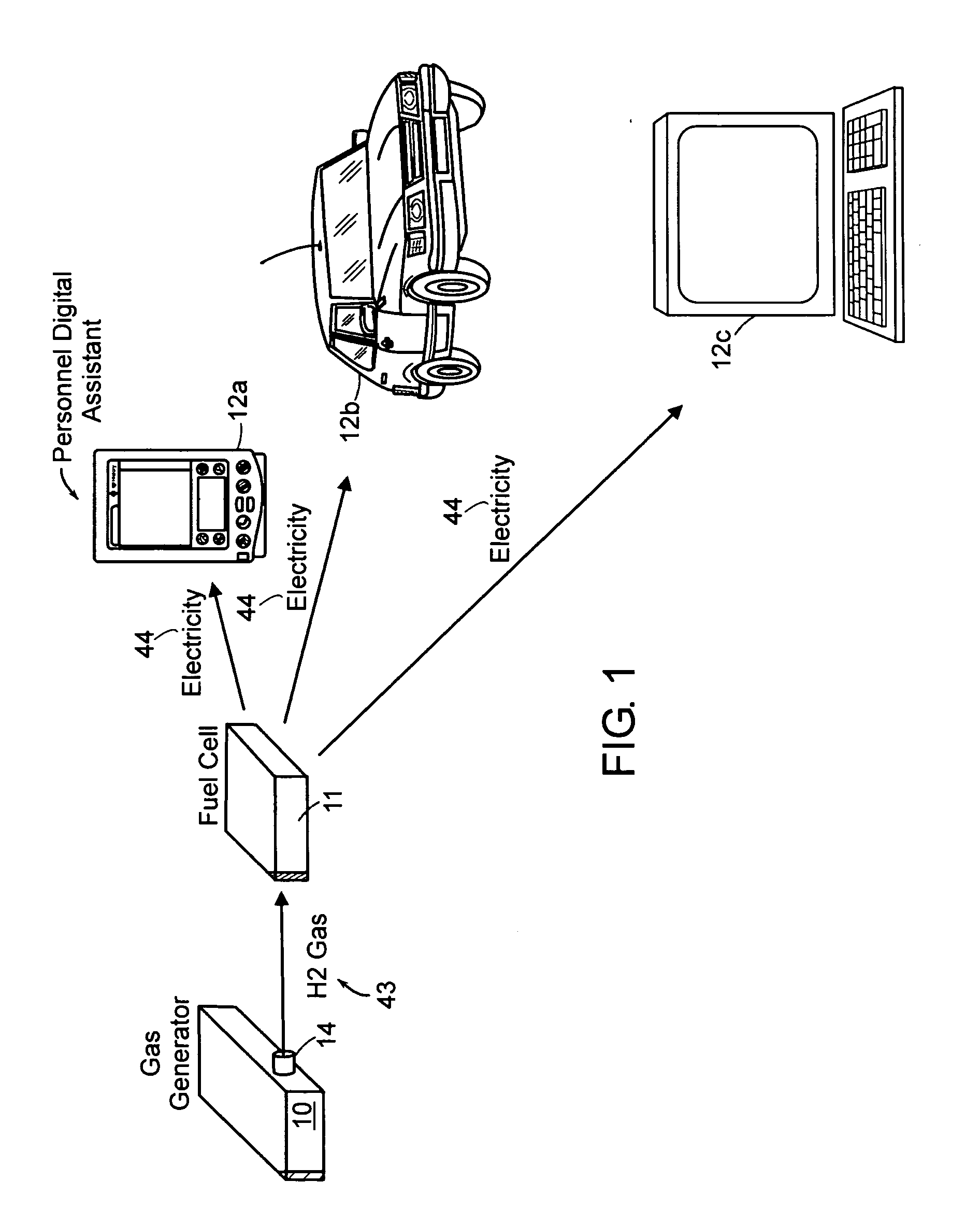

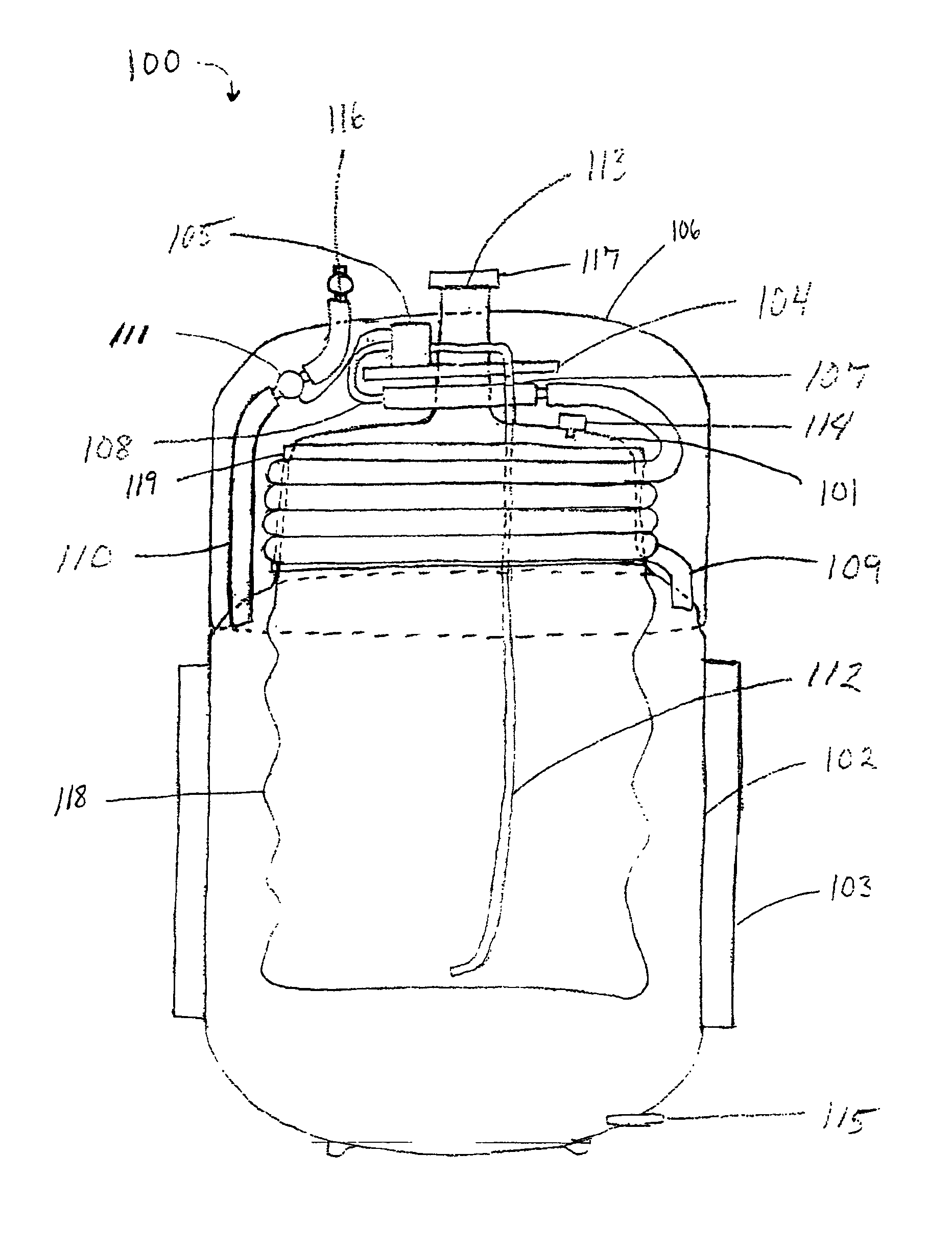

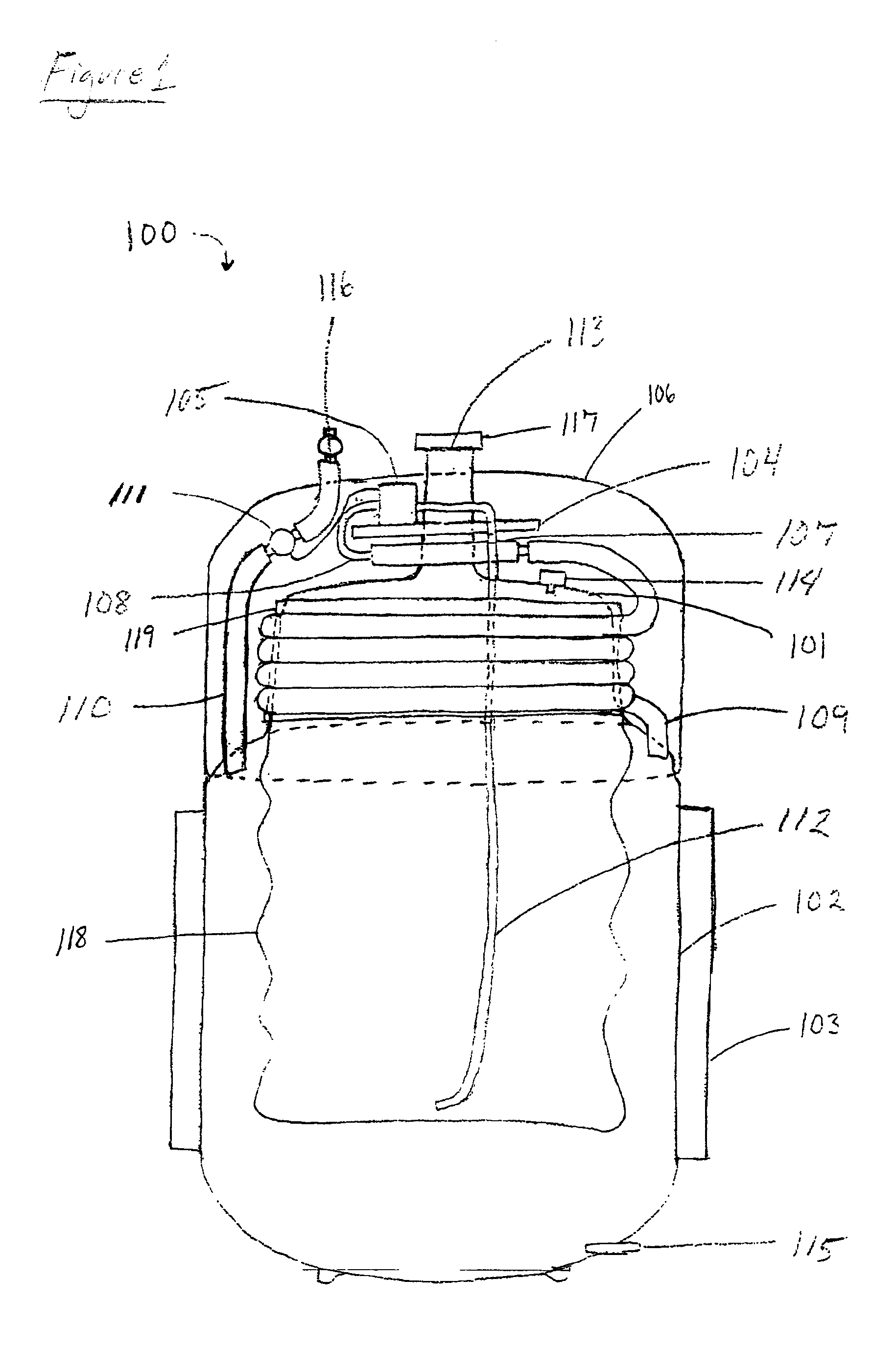

Portable hydrogen generator

A hydrogen generation system includes a fuel container, a spent fuel container, a catalyst system and a control system for generating hydrogen in a manner which provides for a compact and efficient construction while producing hydrogen from a reaction involving a hydride solution such as sodium borohydride.

Owner:SILICON VALLEY BANK

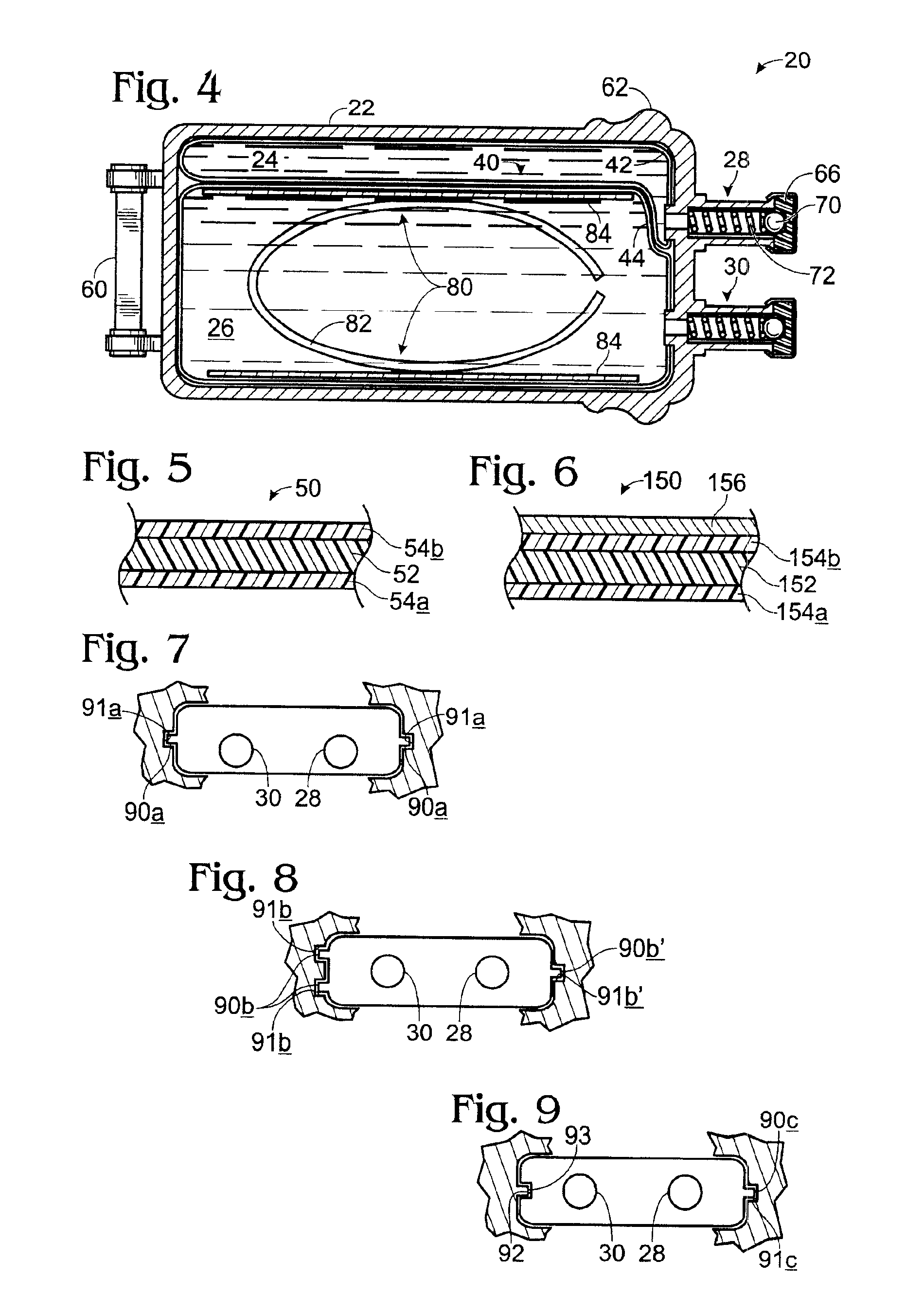

Hydrogen-generating fuel cell cartridges

ActiveUS20060174952A1Minimize fluctuationDiaphragm valvesReactant parameters controlHydrogen pressureNuclear engineering

The present application is directed to a gas-generating apparatus and various pressure regulators or pressure-regulating valves. Hydrogen is generated within the gas-generating apparatus and is transported to a fuel cell. The transportation of a first fuel component to a second fuel component to generate of hydrogen occurs automatically depending on the pressure of a reaction chamber within the gas-generating apparatus. The pressure regulators and flow orifices are provided to regulate the hydrogen pressure and to minimize the fluctuation in pressure of the hydrogen received by the fuel cell. Connecting valves to connect the gas-generating apparatus to the fuel cell are also provided.

Owner:INTELLIGENT ENERGY LTD

Air freshening compositions, articles comprising same and methods

An air freshening composition including porous carrier particles having a perfume composition entrapped therein, and a second component selected from an inert filer, hygroscopic agent, binder, coating material, moisture providing agent, and mixtures thereof. The composition may further comprise various optional components such as free perfumes, colorants, disintegrants, water swelling agents, porosity modifiers and mixtures thereof. A method for processing the compositions into a solid article includes the steps of entrapping a perfume in the porous carrier particles, heating and incorporating a carrier or binder material. The compositions may be further processed by optionally incorporating a powder inert filler and forming articles from the mixture. The articles may be formed from the compositions through prilling, extrusion, or compaction amongst other techniques. The air freshening articles and compositions will provide a sustained and controlled release of the perfume compositions over a long period of time without the use of a heat to activate the release. Articles of manufacture including the air freshening articles and various packaging are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

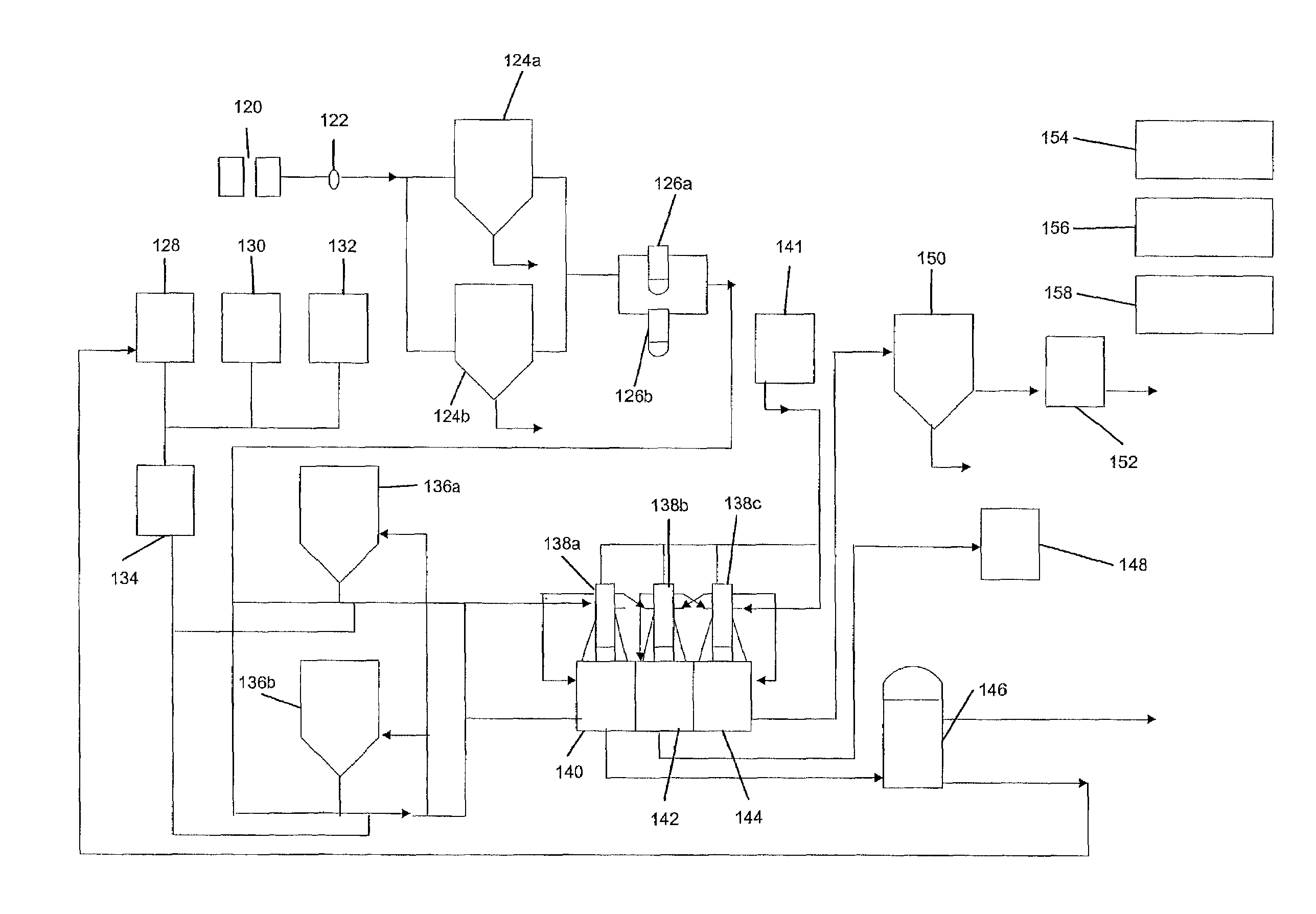

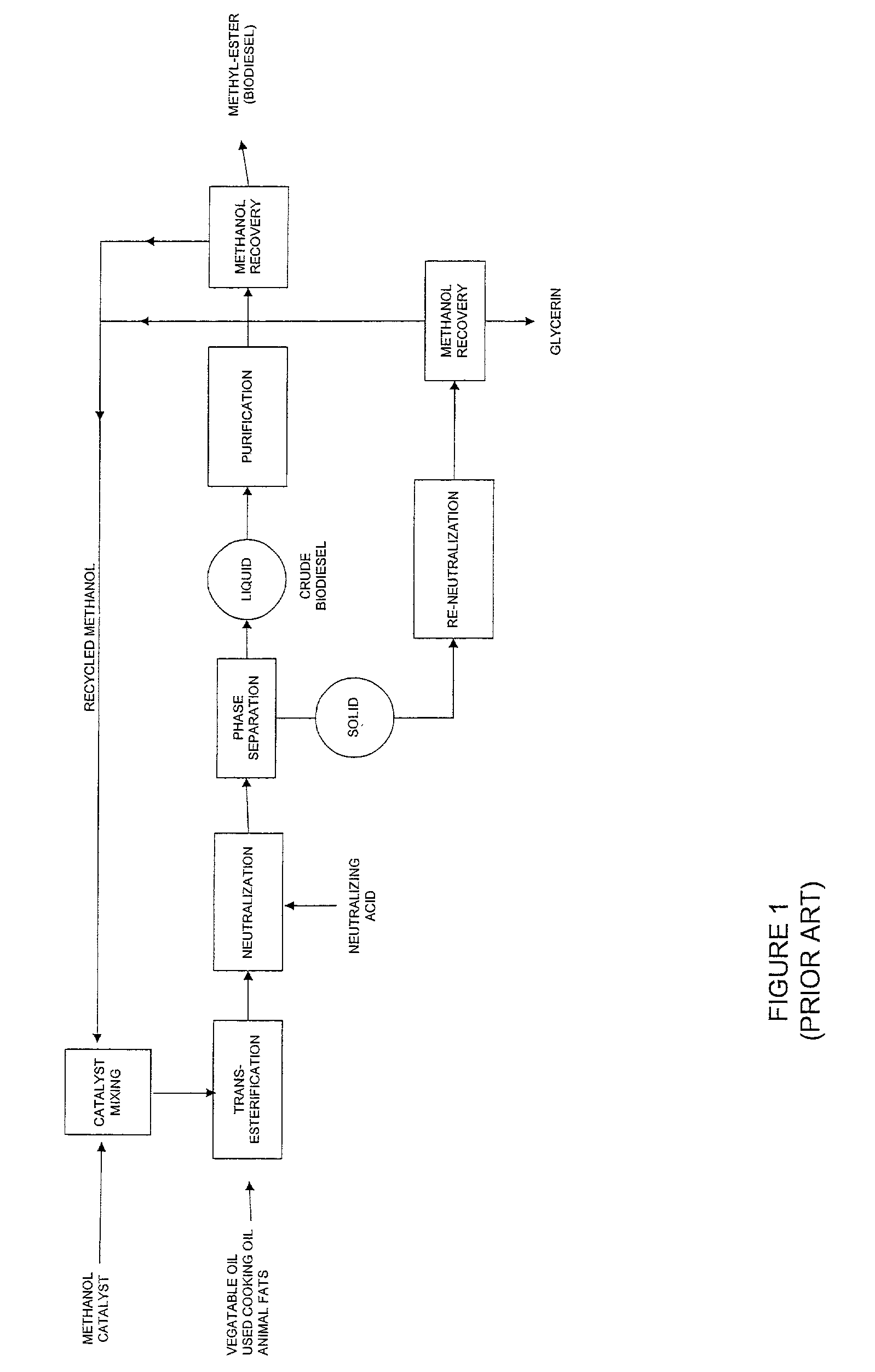

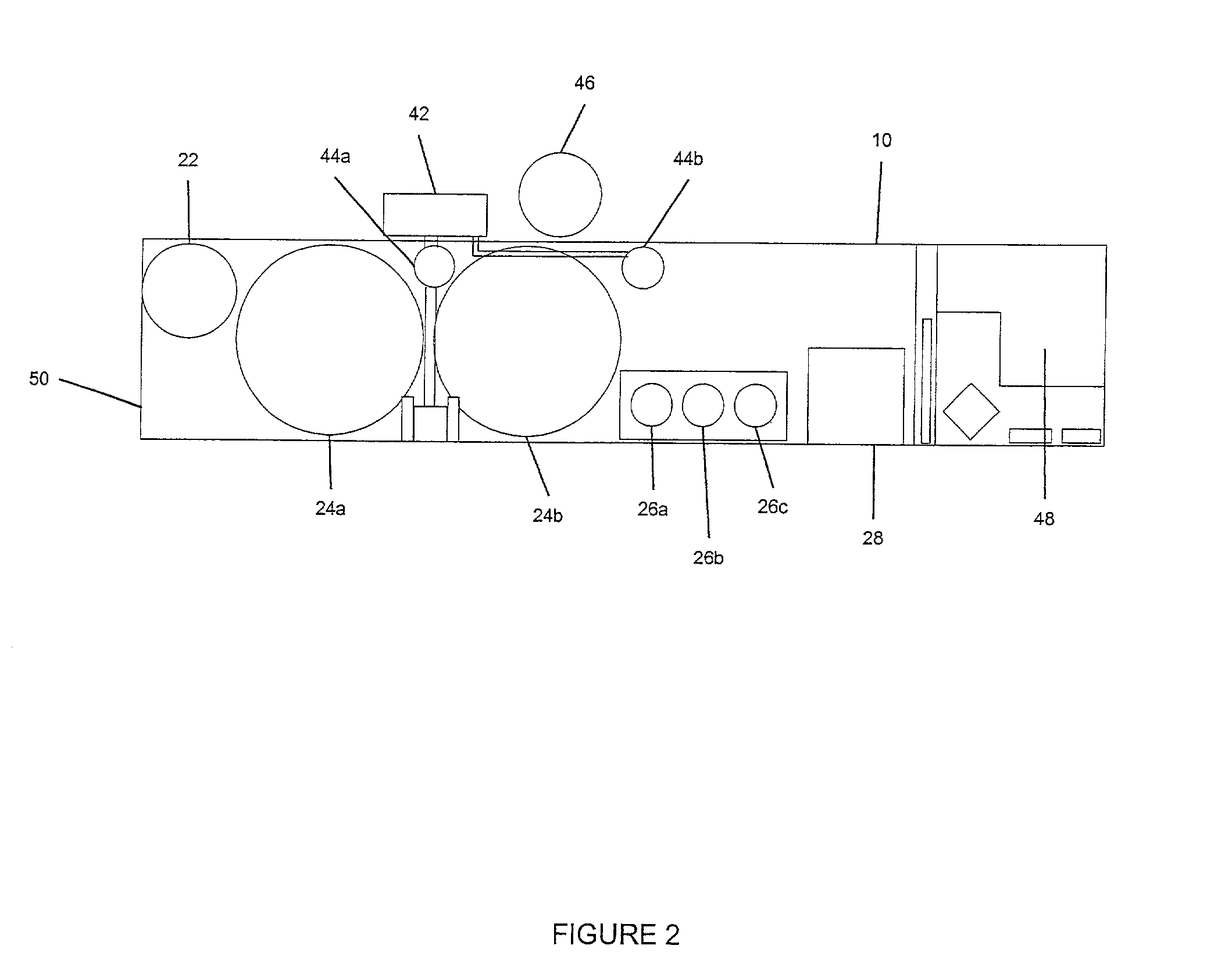

Biodiesel production unit

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

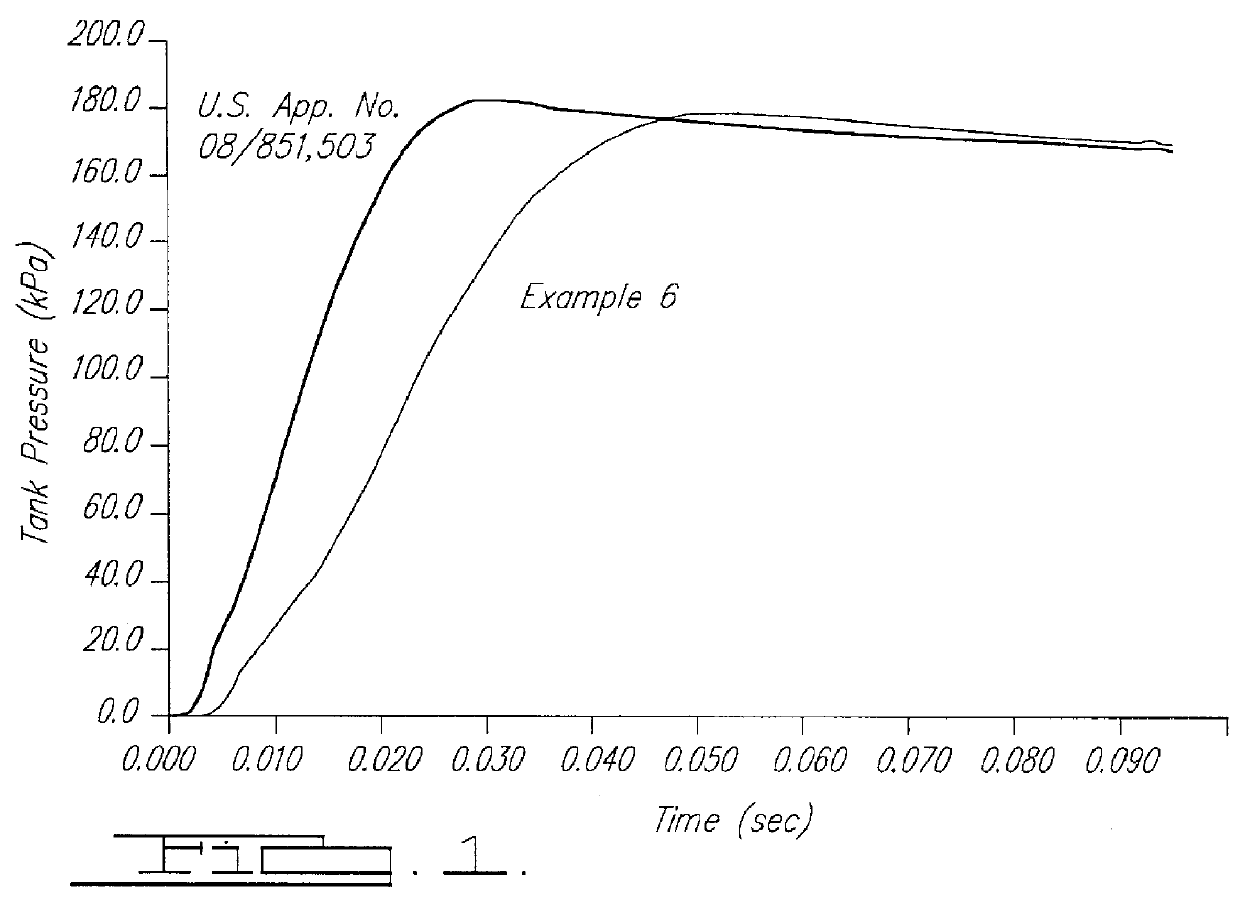

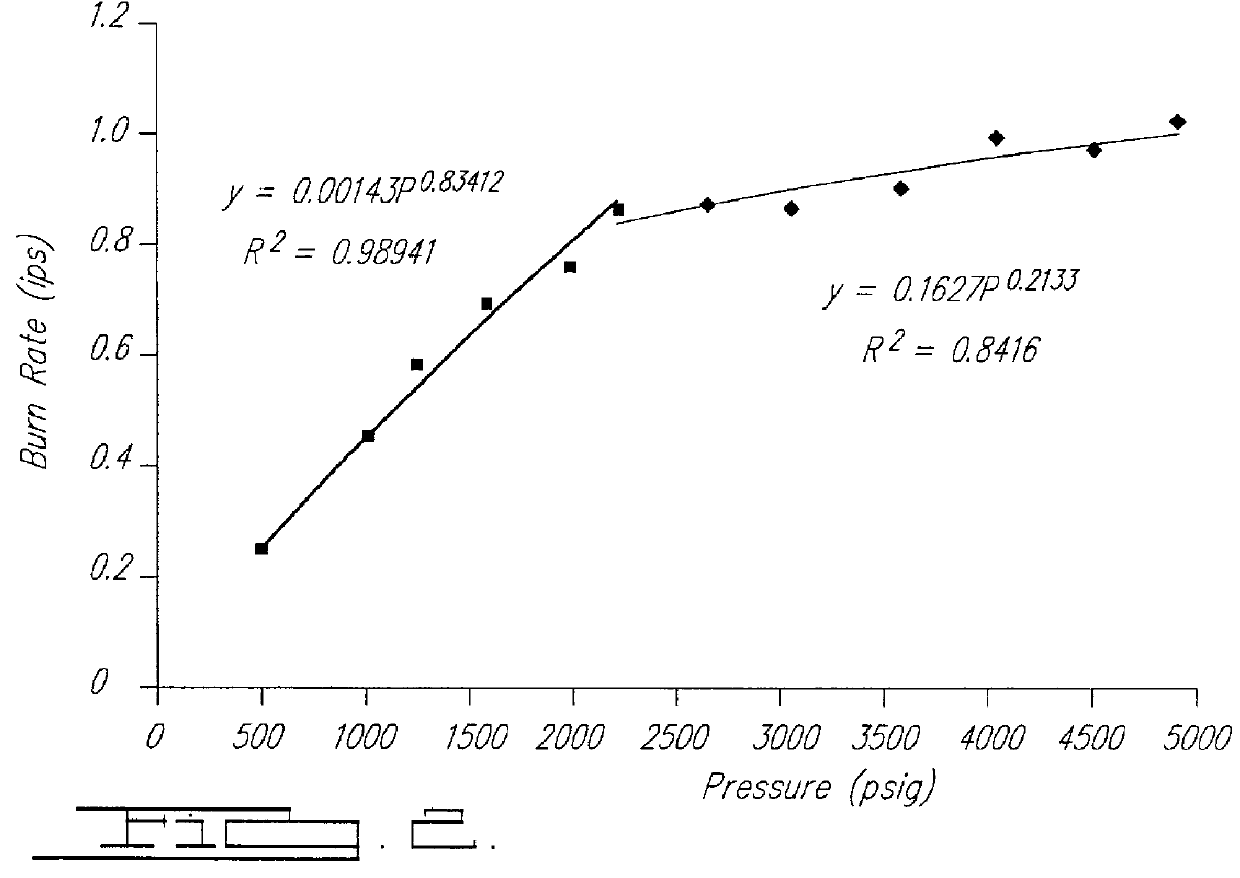

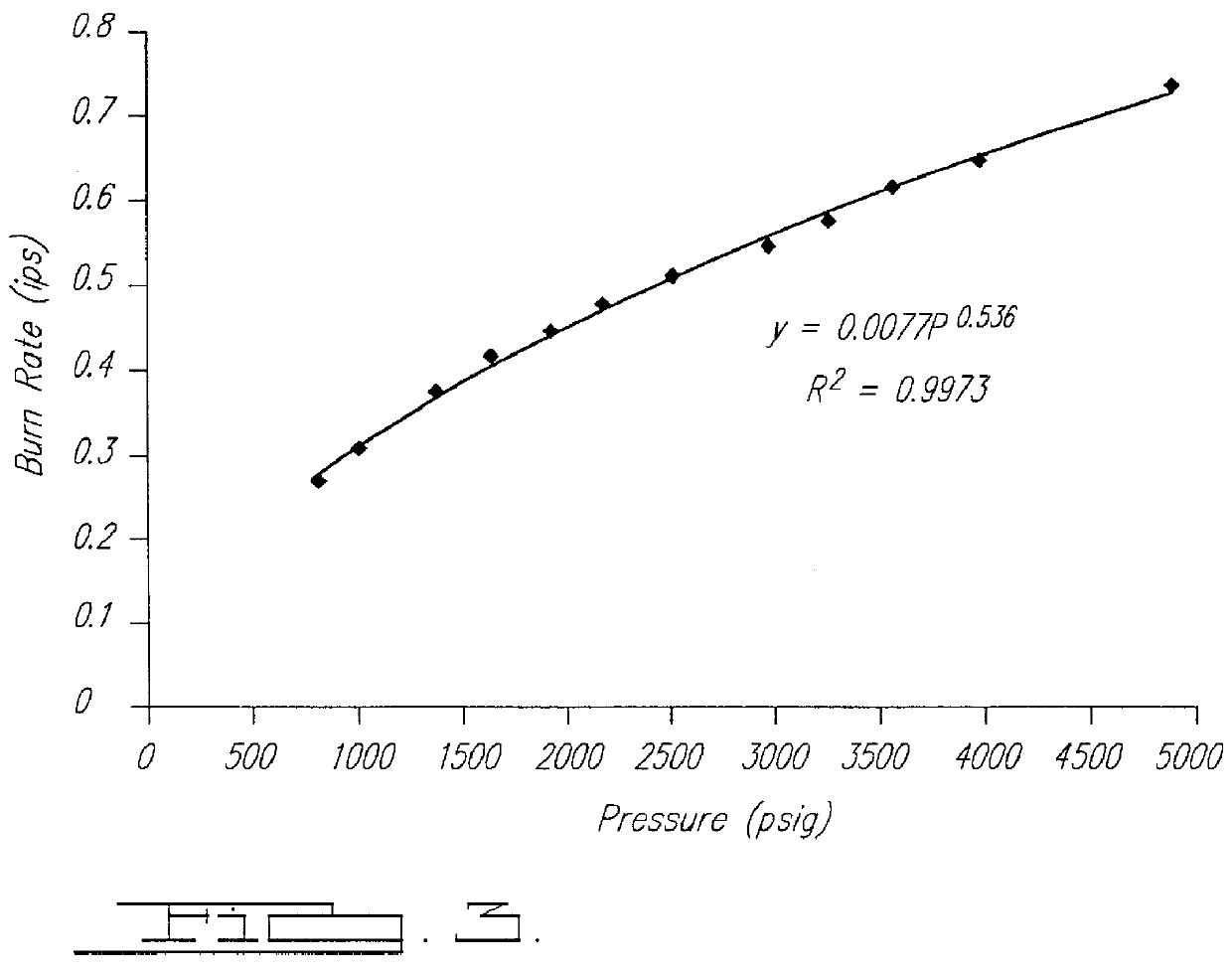

Smokeless gas generant compositions

Thermally stable gas generant compositions incorporate a combination of one or more primary nonazide high-nitrogen fuels selected from a group including tetrazoles, bitetrazoles, and triazoles, and salts thereof; and one or more secondary nonazide high nitrogen fuels selected from azodicarbonamide and hydrazodicarbonamide. The primary and secondary fuels are combined with phase-stabilized ammonium nitrate that when combusted, results in a greater yield of gaseous products per mass unit of gas generant, a reduced yield of solid combustion products, lower combustion temperatures, and acceptable burn rates, thermal stability, and ballistic properties. These compositions are especially suitable for inflating air bags in passenger-restraint devices.

Owner:AUTOMOTIVE SYST LAB

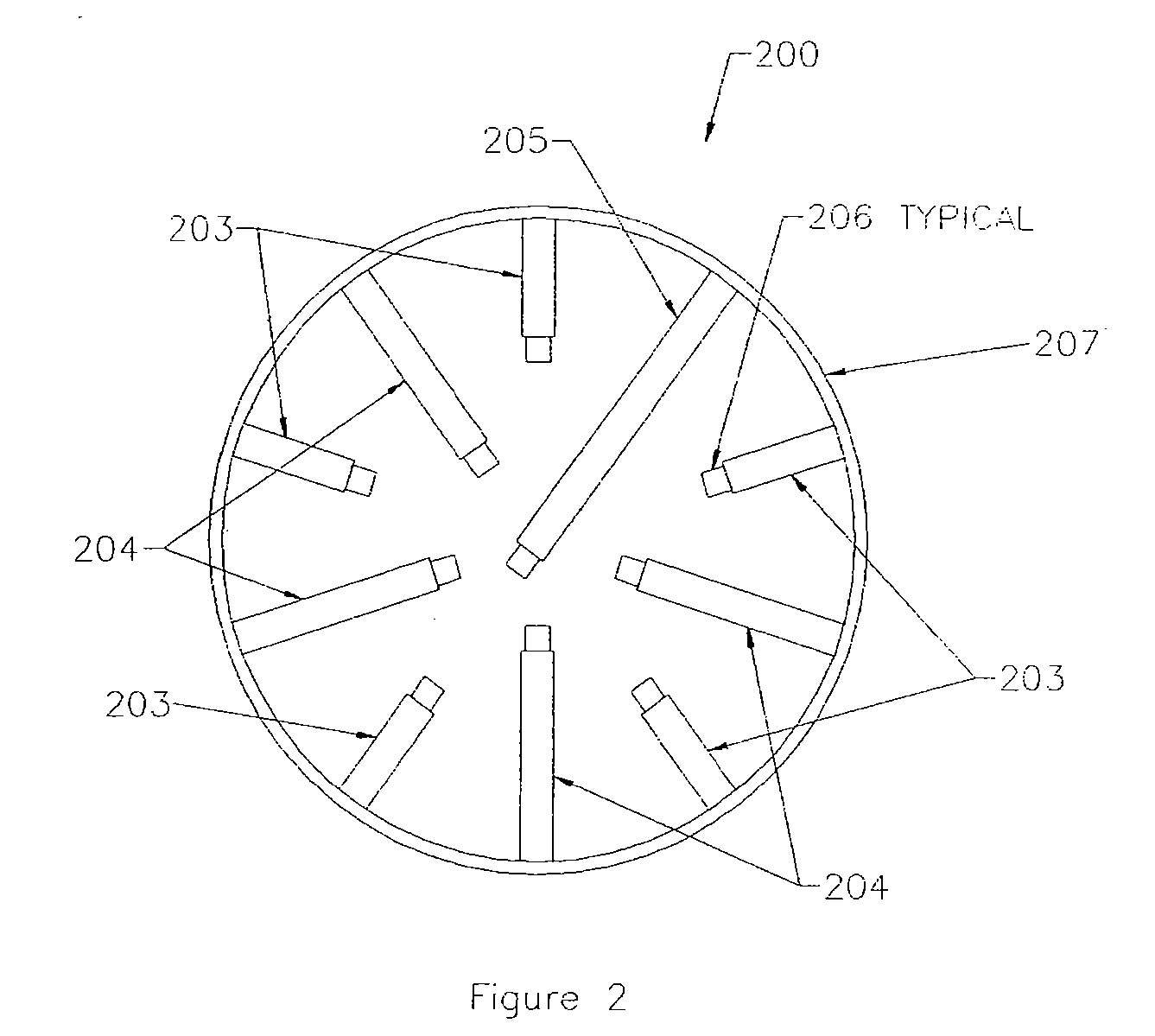

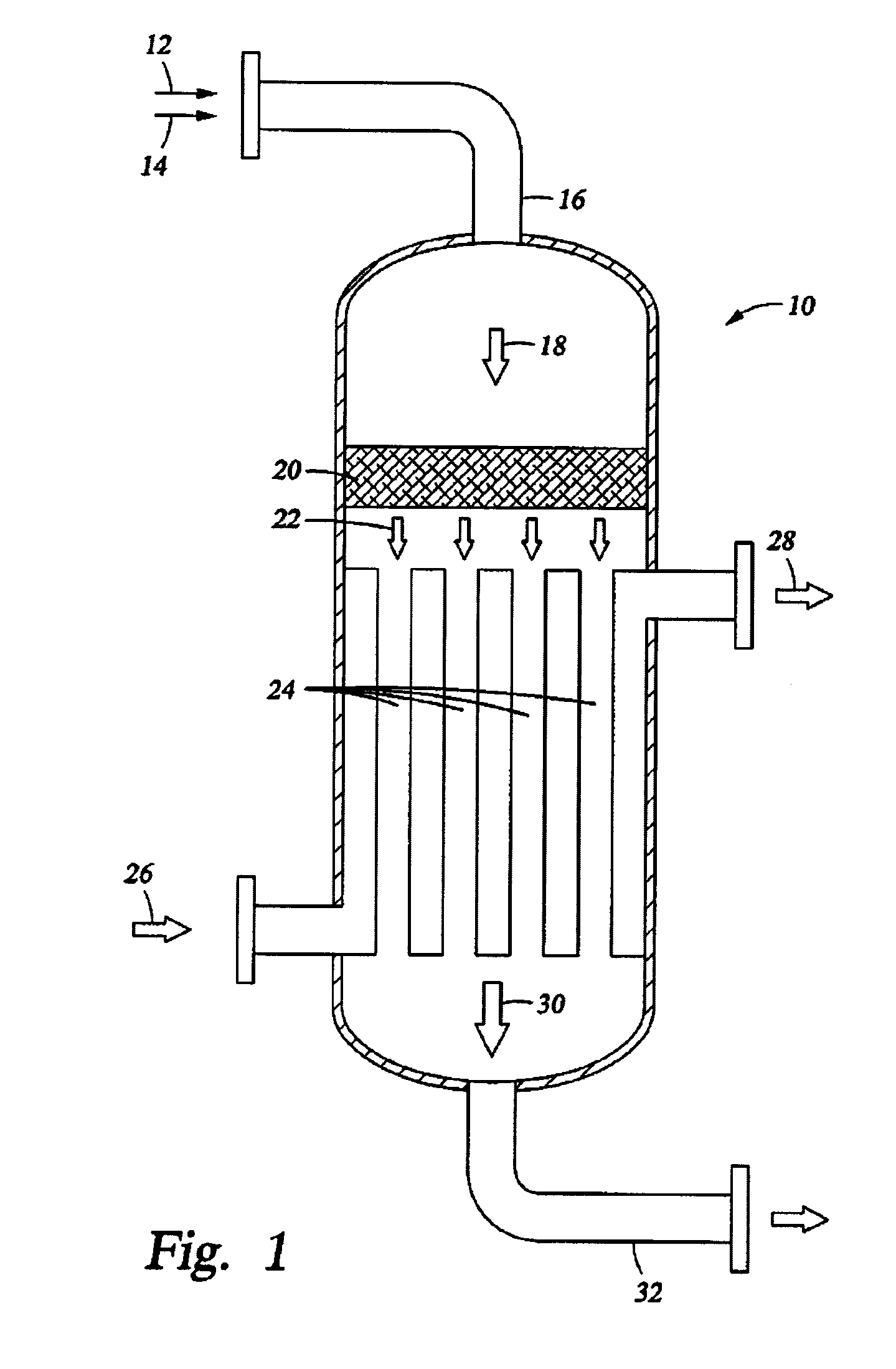

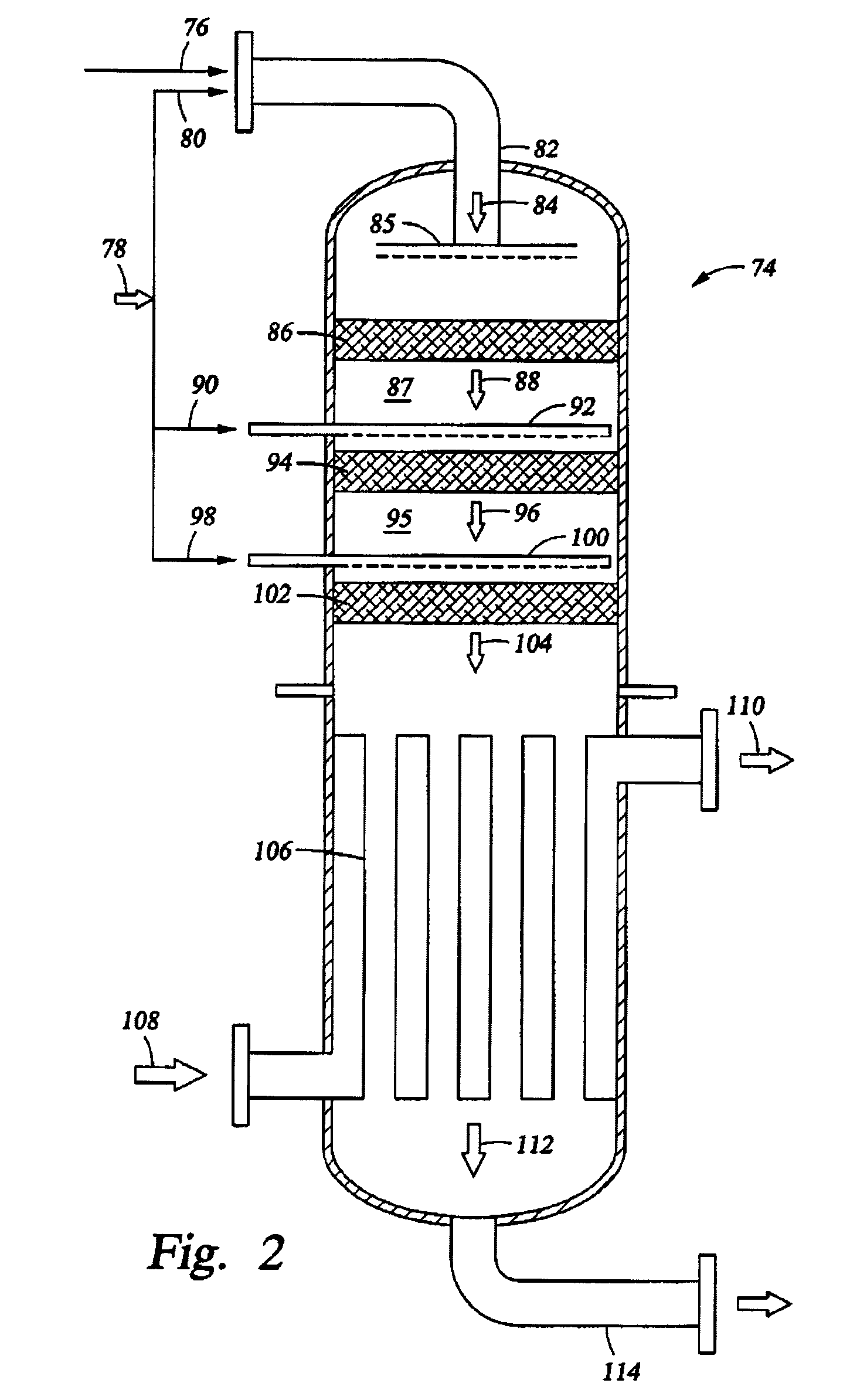

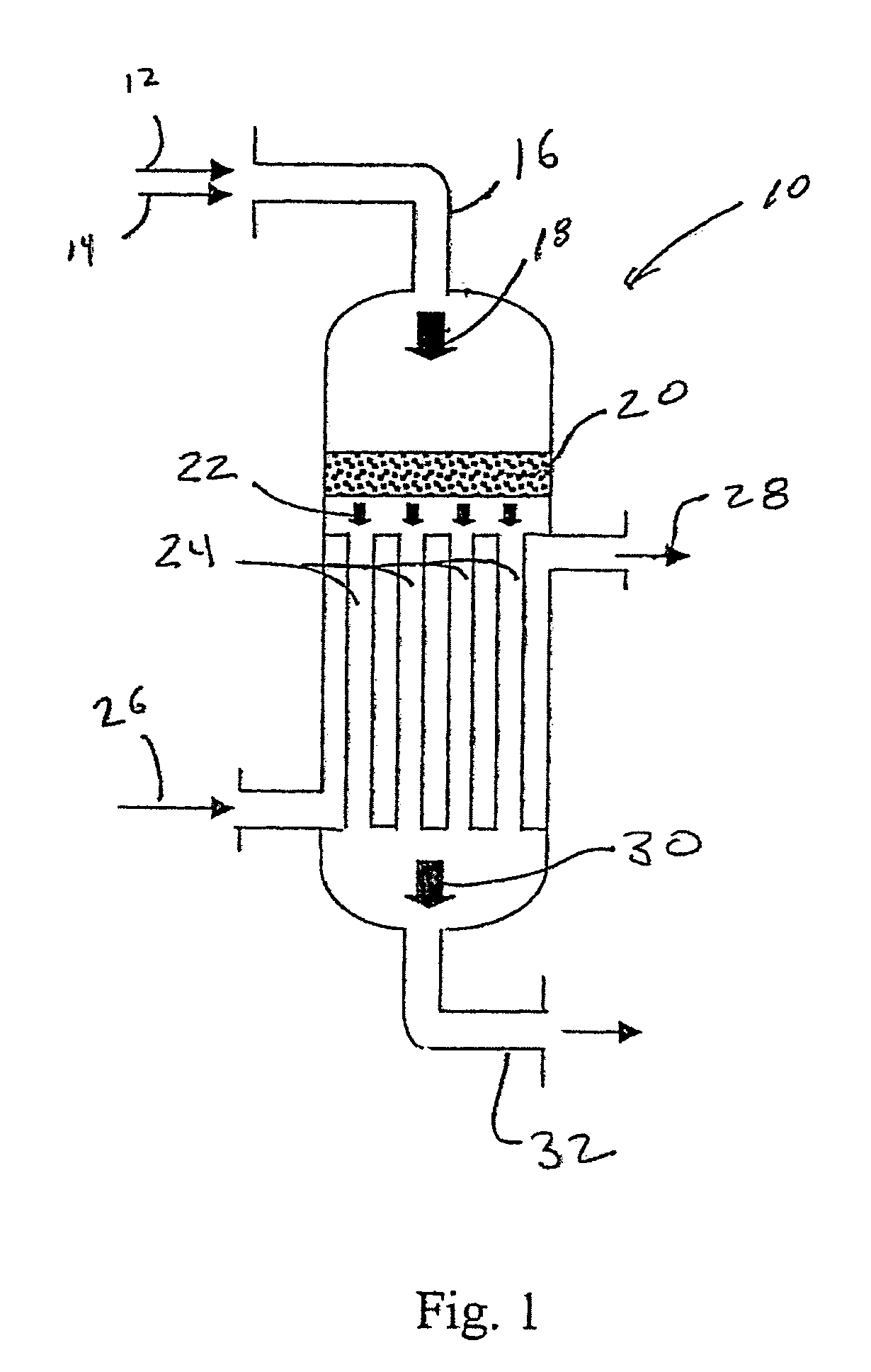

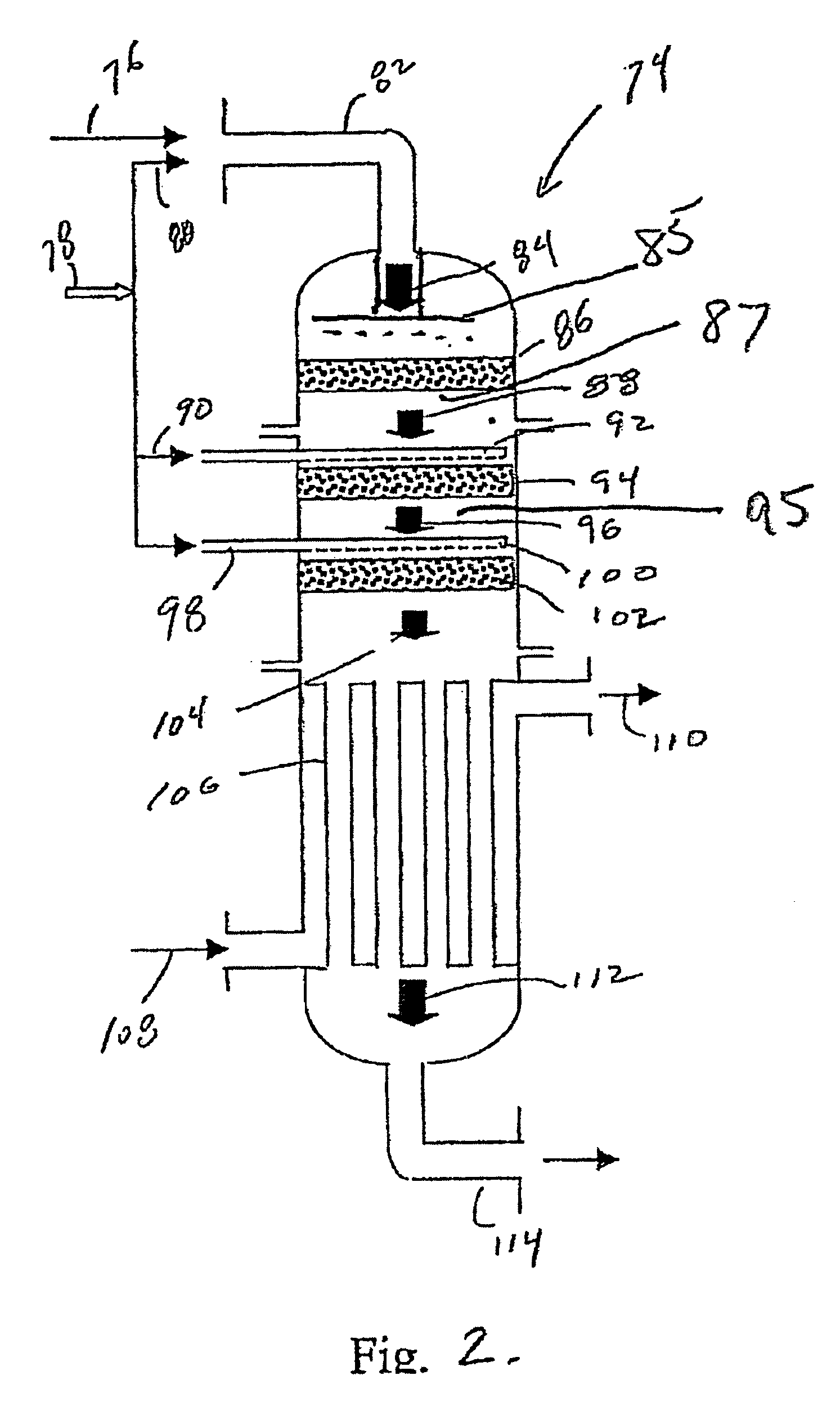

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS7261751B2Low selectivityRisk of explosion can be minimizedHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisPartial oxidationFixed bed

Owner:PHILLIPS 66 CO

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS20060029539A1Risk of explosion can be minimizedIncrease the molar ratioHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisForming gasPartial oxidation

This invention relates to methods for reacting a hydrocarbon, molecular oxygen, and optionally water and / or carbon dioxide, to form synthesis gas. The preferred embodiments are characterized by delivering a substochiometric amount of oxygen to each of a multitude of reaction zones, which allows for optimum design of the catalytic packed bed and the gas distribution system, and for the optimization and control of the temperature profile of the reaction zones. The multitude of reaction zones may include a series of successive fixed beds, or a continuous zone housed within an internal structure having porous, or perforated, walls, through which an oxygen-containing stream can permeate. By controlling the oxygen supply, the temperatures, conversion, and product selectivity of the reaction can be in turn controlled and optimized. Furthermore the potential risks of explosion associated with mixing hydrocarbon and molecular oxygen is minimized with increased feed carbon-to-oxygen molar ratios.

Owner:PHILLIPS 66 CO

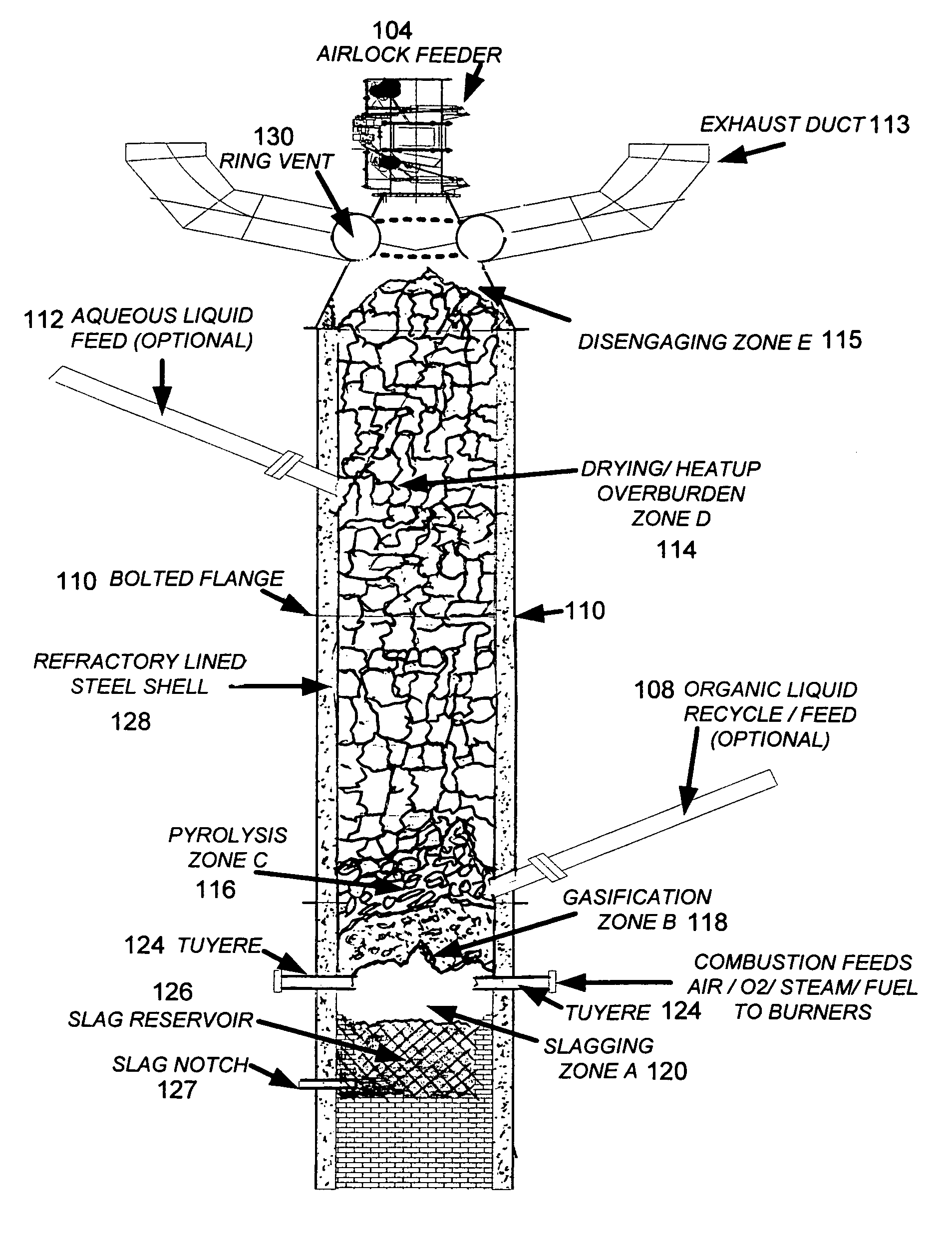

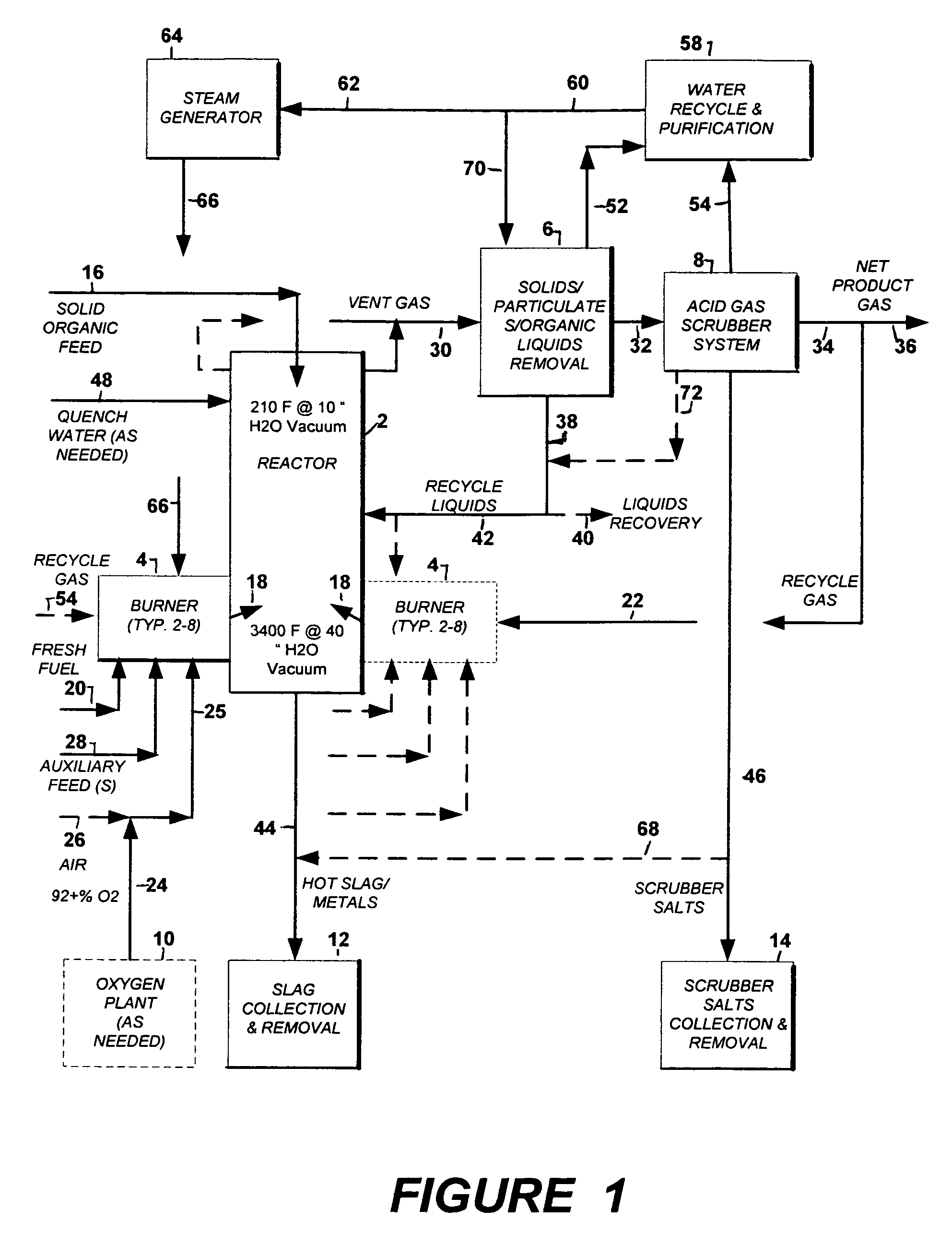

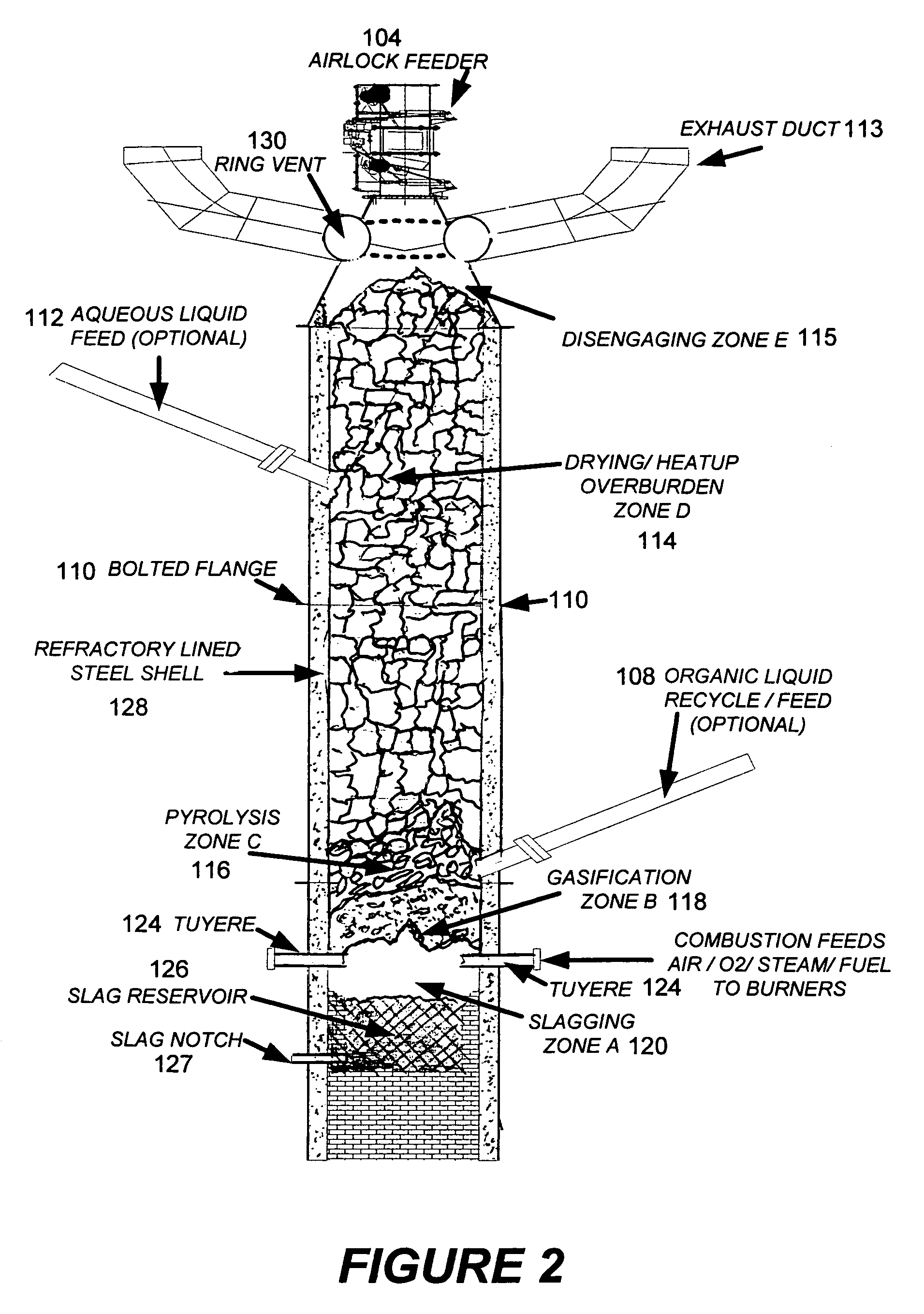

Process for pyrolytic heat recovery enhanced with gasification of organic material

InactiveUS7452392B2Improve throughputInhibition formationGas modification by gas mixingWaste based fuelThermal energyForming gas

This invention is a reactor and a process for the conversion of organic waste material such as municipal trash, sewage, post-consumer refuse, and biomass to commercially salable materials.The invention produces the following:1. Maximum energy conversion from the organic material2. High volume consumption of the organic feed material3. Less pollution of gaseous products than prior art systems4. Solid residuals for disposal are minimal and non-hazardous.The conversion is accomplished by combining anaerobic gasification and pyrolysis of the feed organic material and making it into synthetic gas. The synthetic gas is a mixture of hydrocarbons (CxHy), hydrogen, and carbon monoxide with small amounts of carbon dioxide and nitrogen. An essential feature of the invention is a hot driver gas, devoid of free oxygen and rich in water, which supplies the entire thermal and chemical energy needed for the reactions. This hot driver gas is produced by complete sub-stoichiometric combustion of the fuel (CxHy) before it enters the reactor.

Owner:NICK PETER A +4

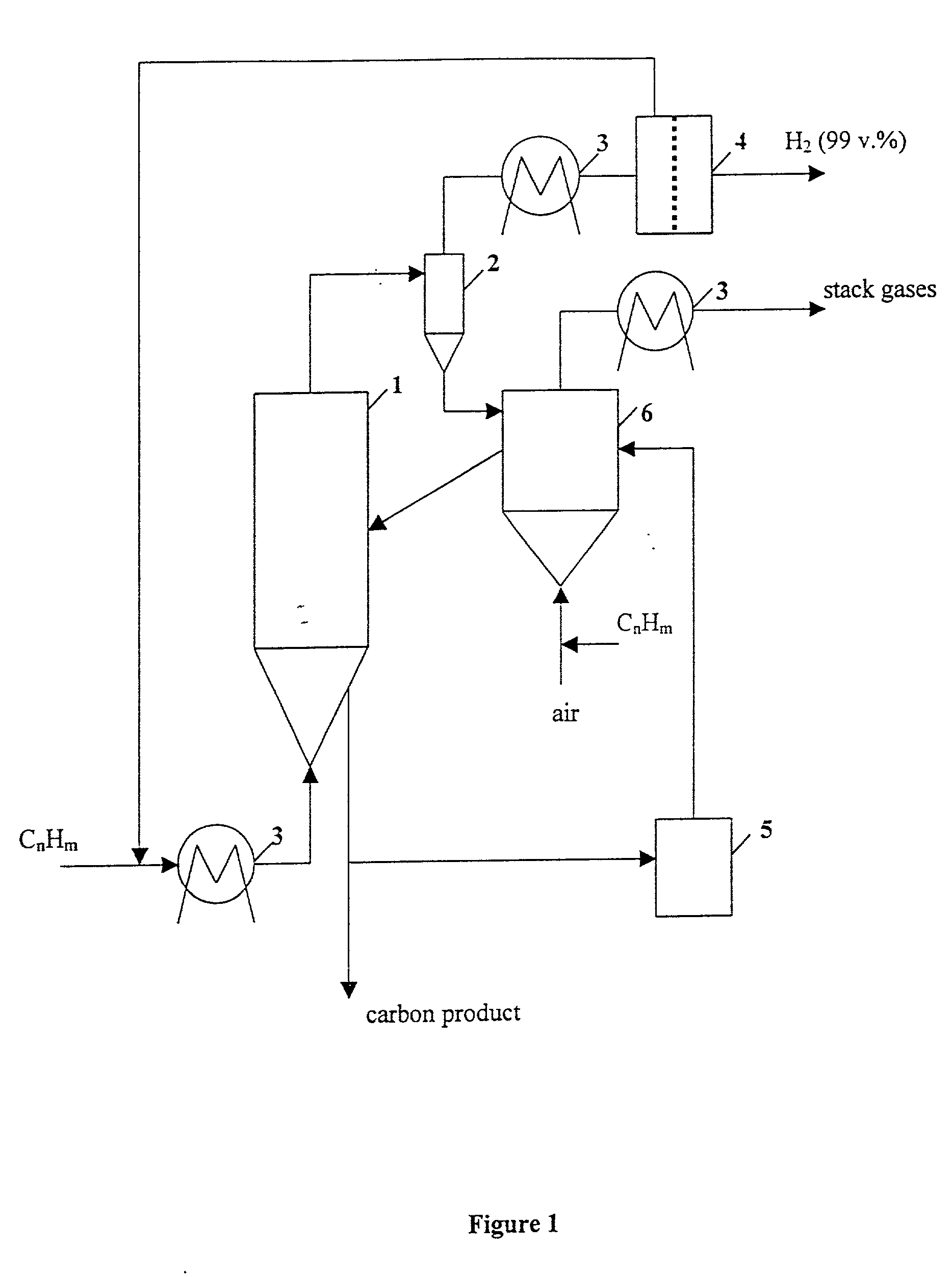

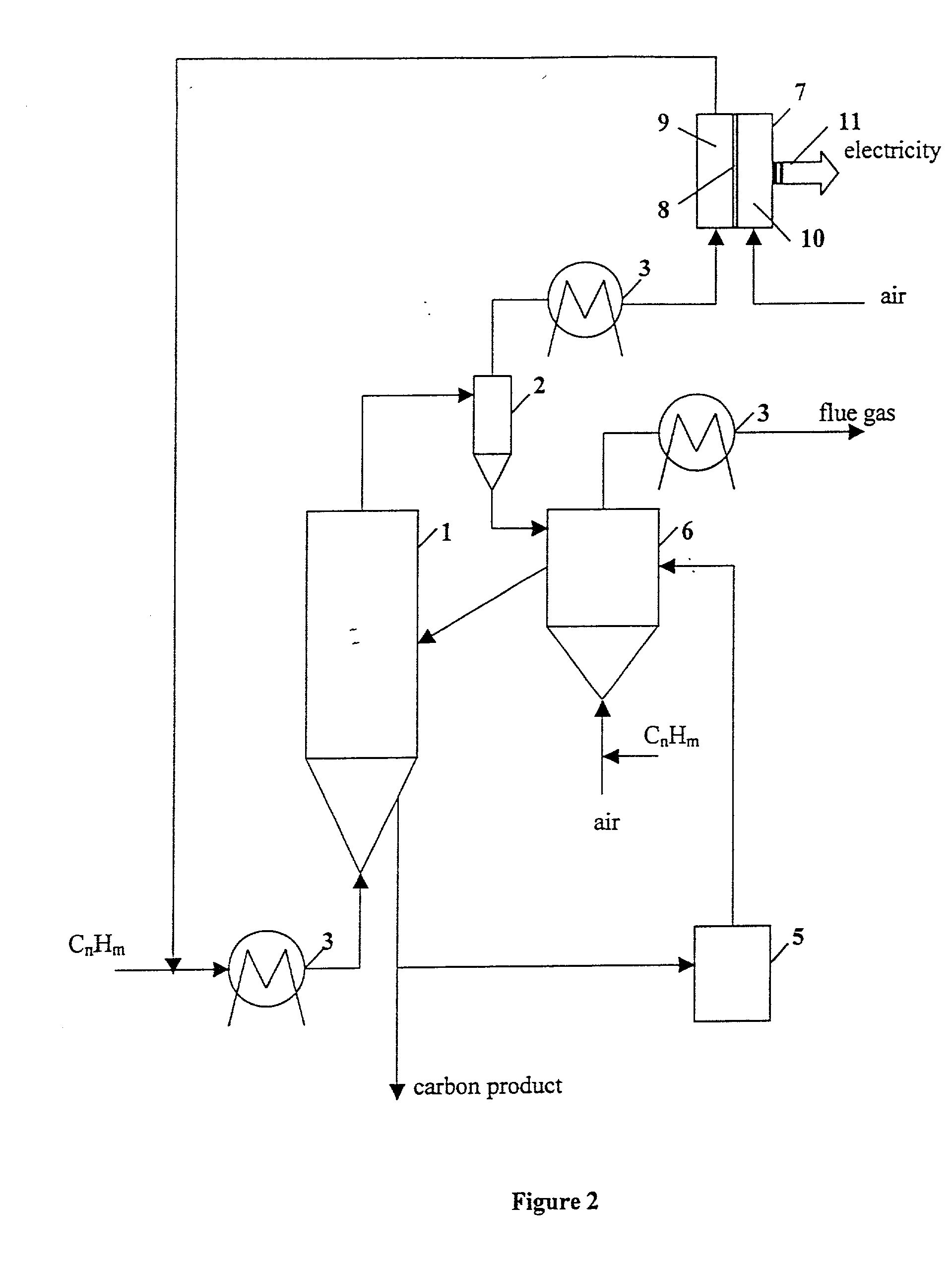

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

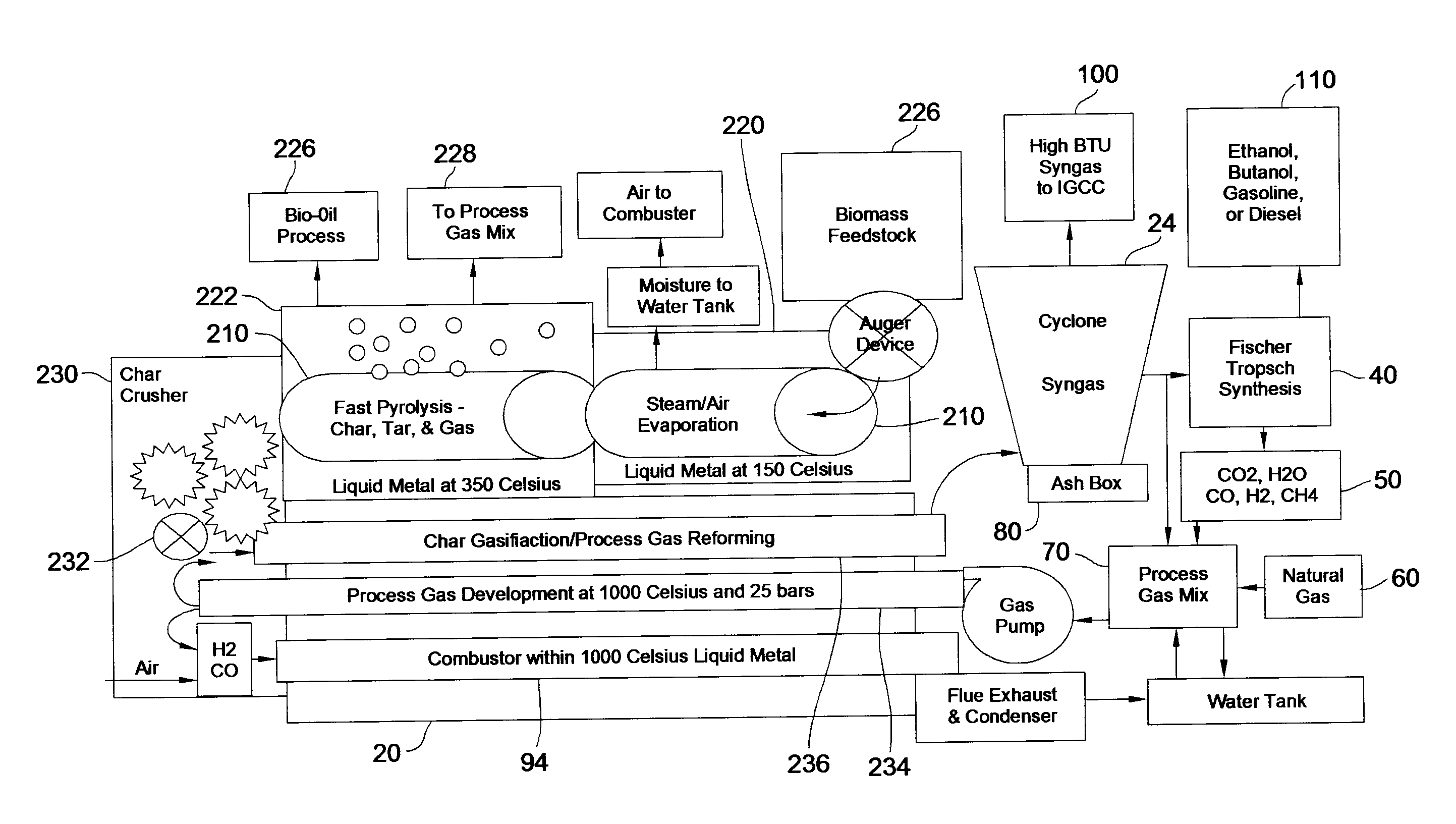

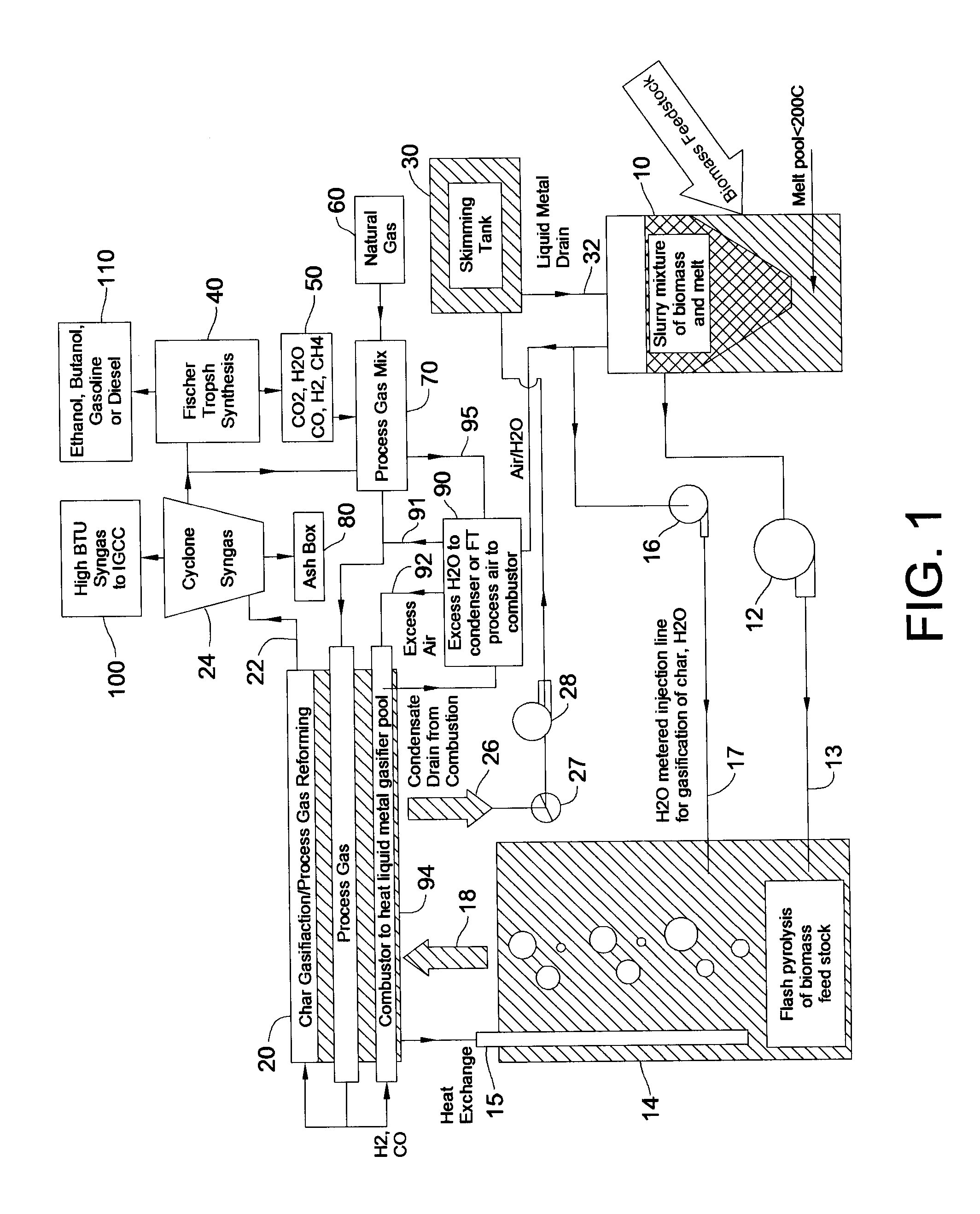

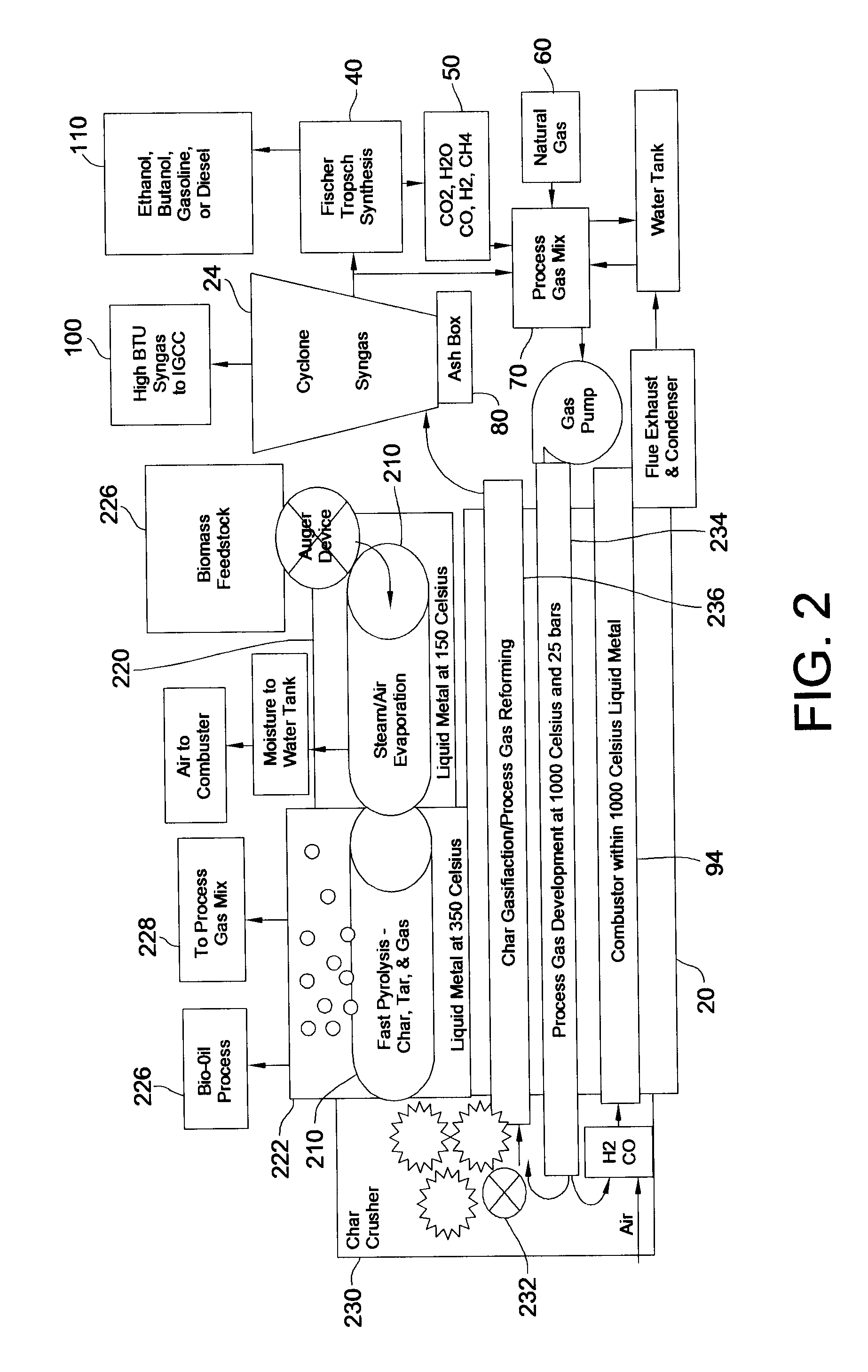

Method and apparatus to protect synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS20080307703A1Improve efficiencyLittle heating lossWaste based fuelRetortsSyngasThermodynamics

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

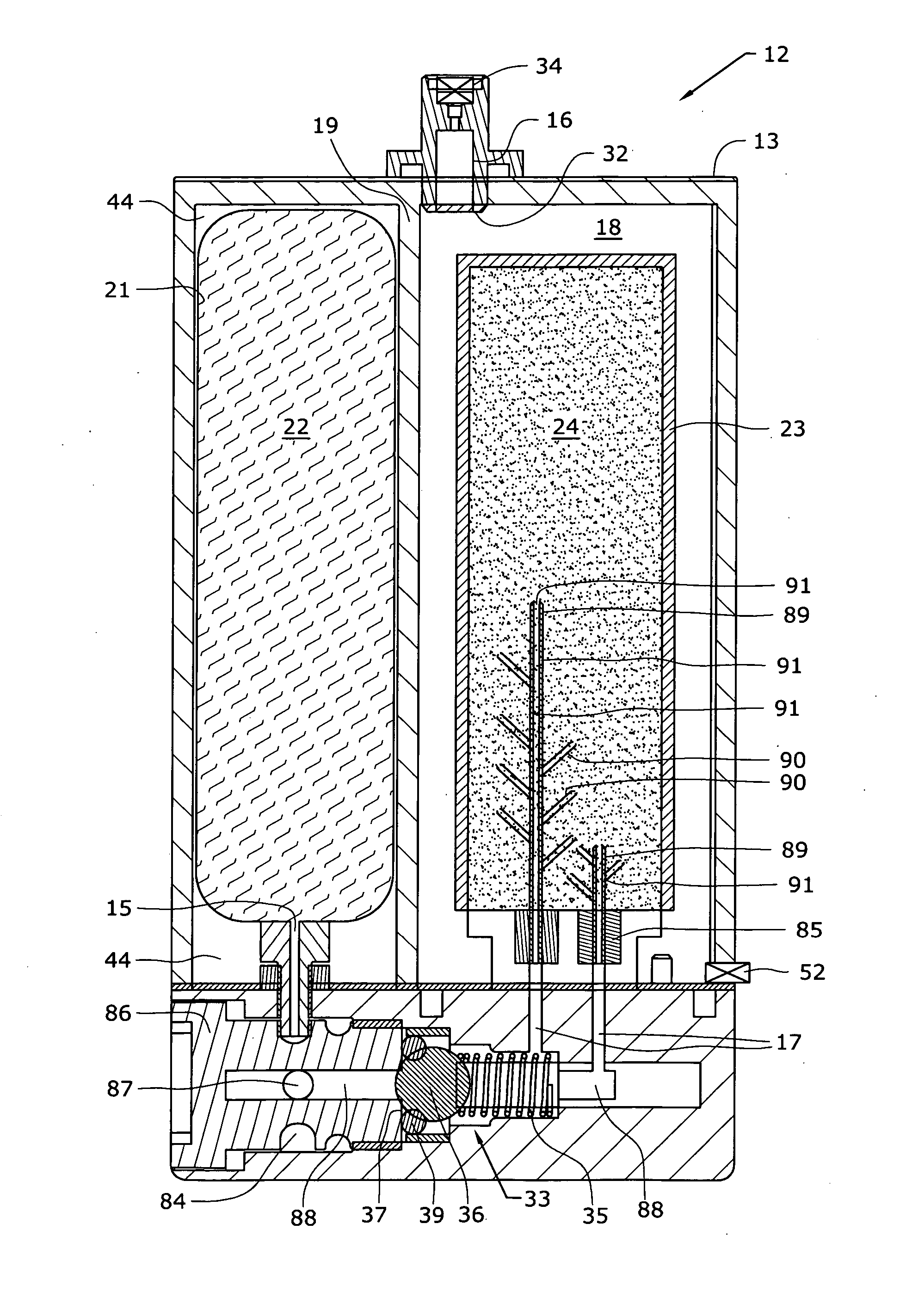

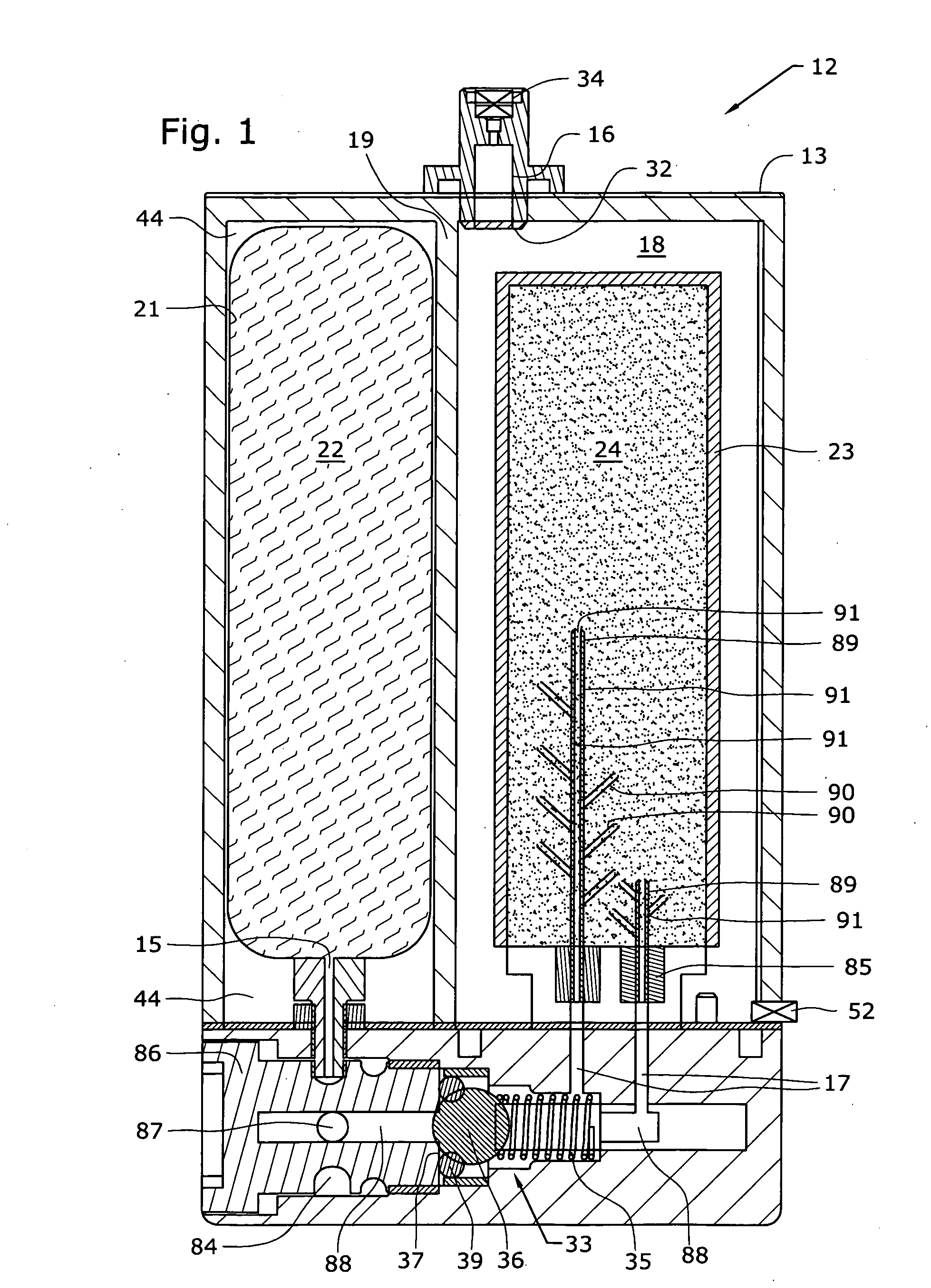

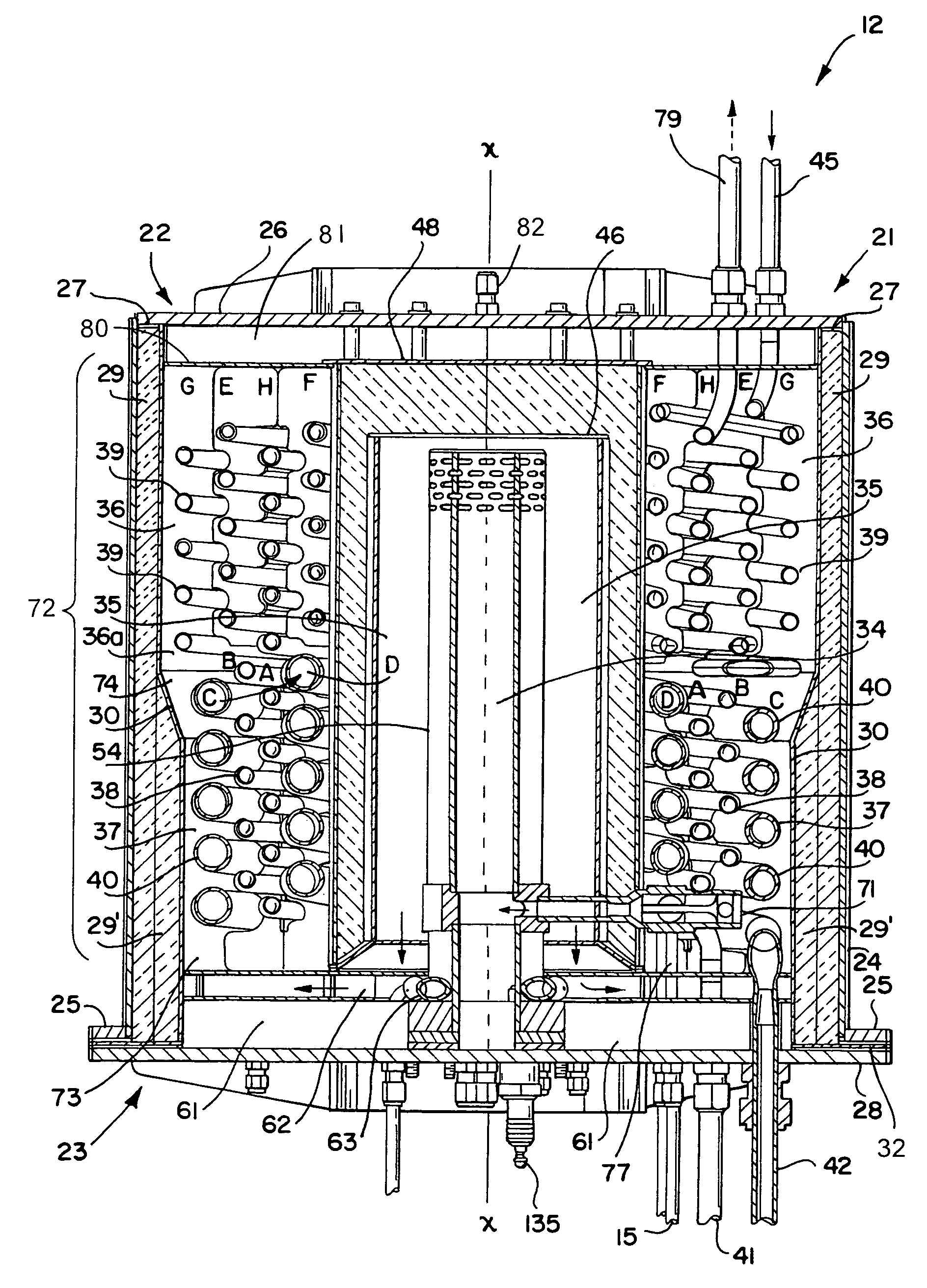

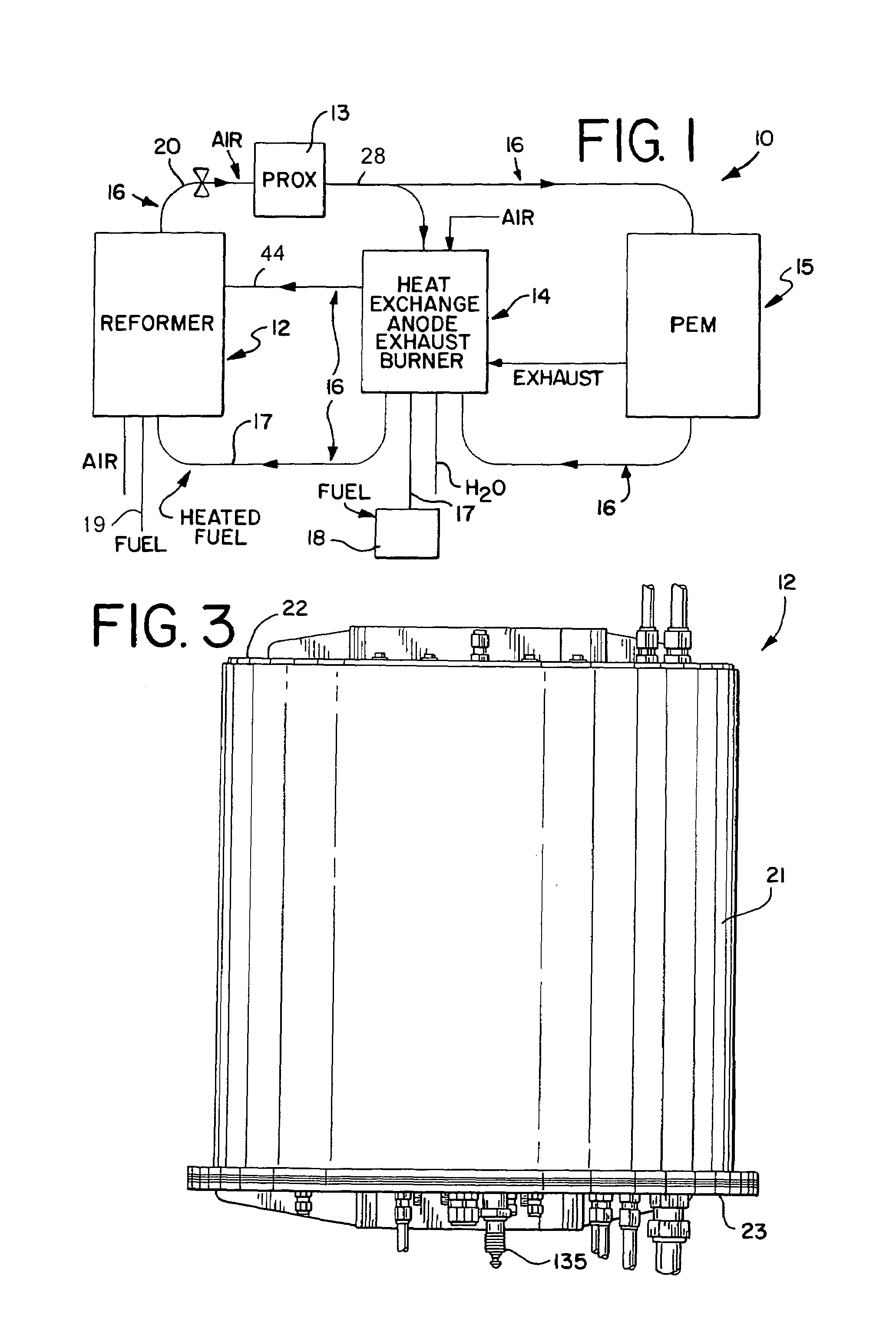

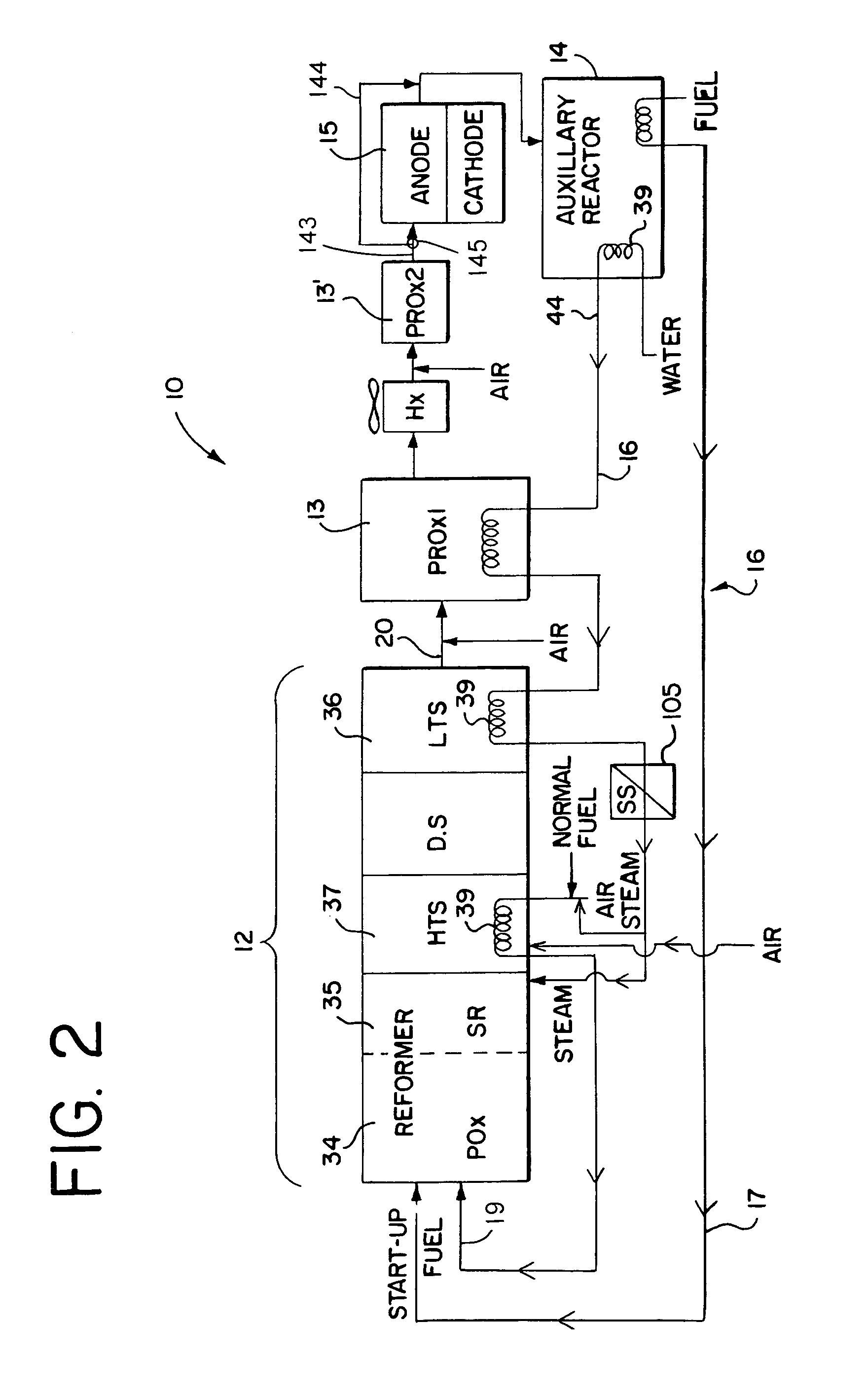

Integrated reformer and shift reactor

A hydrocarbon fuel reformer for producing diatomic hydrogen gas is disclosed. The reformer includes a first reaction vessel, a shift reactor vessel annularly disposed about the first reaction vessel, including a first shift reactor zone, and a first helical tube disposed within the first shift reactor zone having an inlet end communicating with a water supply source. The water supply source is preferably adapted to supply liquid-phase water to the first helical tube at flow conditions sufficient to ensure discharge of liquid-phase and steam-phase water from an outlet end of the first helical tube. The reformer may further include a first catalyst bed disposed in the first shift reactor zone, having a low-temperature shift catalyst in contact with the first helical tube. The catalyst bed includes a plurality of coil sections disposed in coaxial relation to other coil sections and to the central longitudinal axis of the reformer, each coil section extending between the first and second ends, and each coil section being in direct fluid communication with at least one other coil section.

Owner:NUVERA FUEL CELLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com