A deep heat recovery device and method for boiler flue gas

A heat recovery device, boiler flue gas technology, applied in preheating, feed water heaters, fluid heaters, etc., can solve the problems of huge initial investment in flue gas waste heat recovery equipment, insufficient heat recovery depth, and limited heat exchange capacity. Achieve the effect of increasing equivalent heat capacity, increasing water vapor content, and deep heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

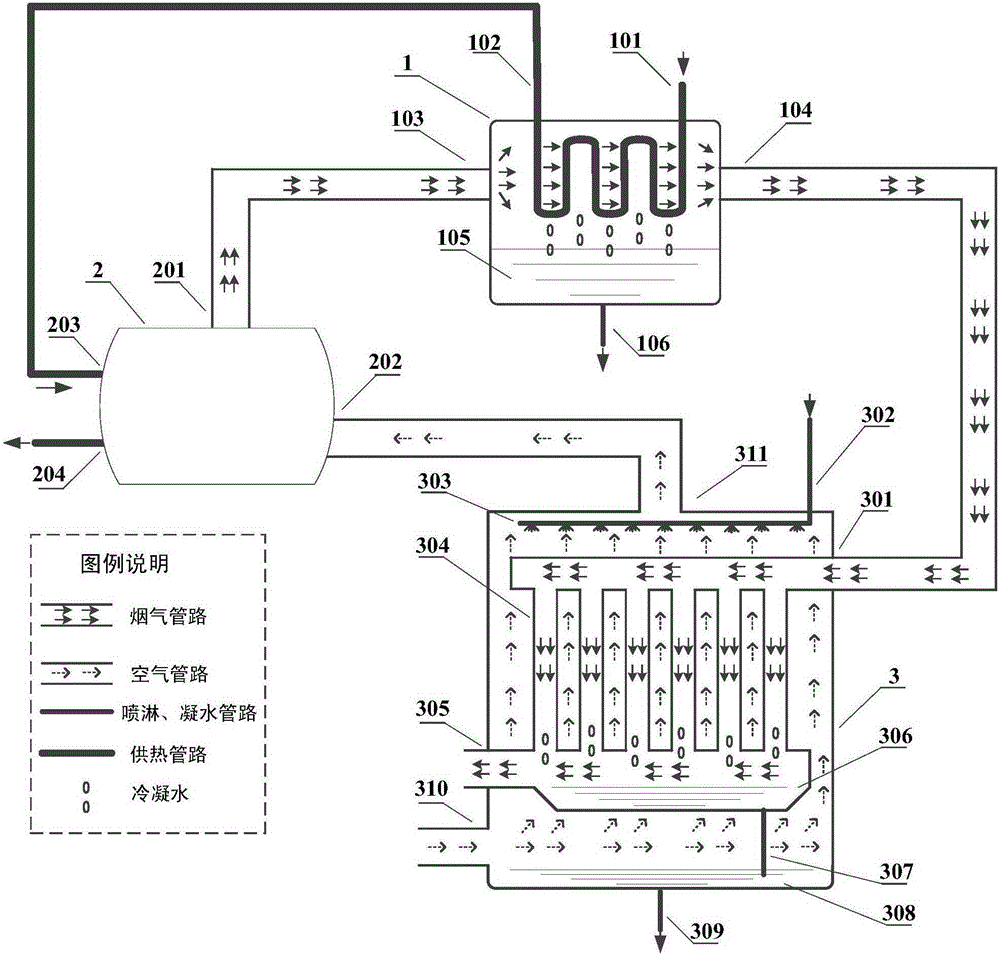

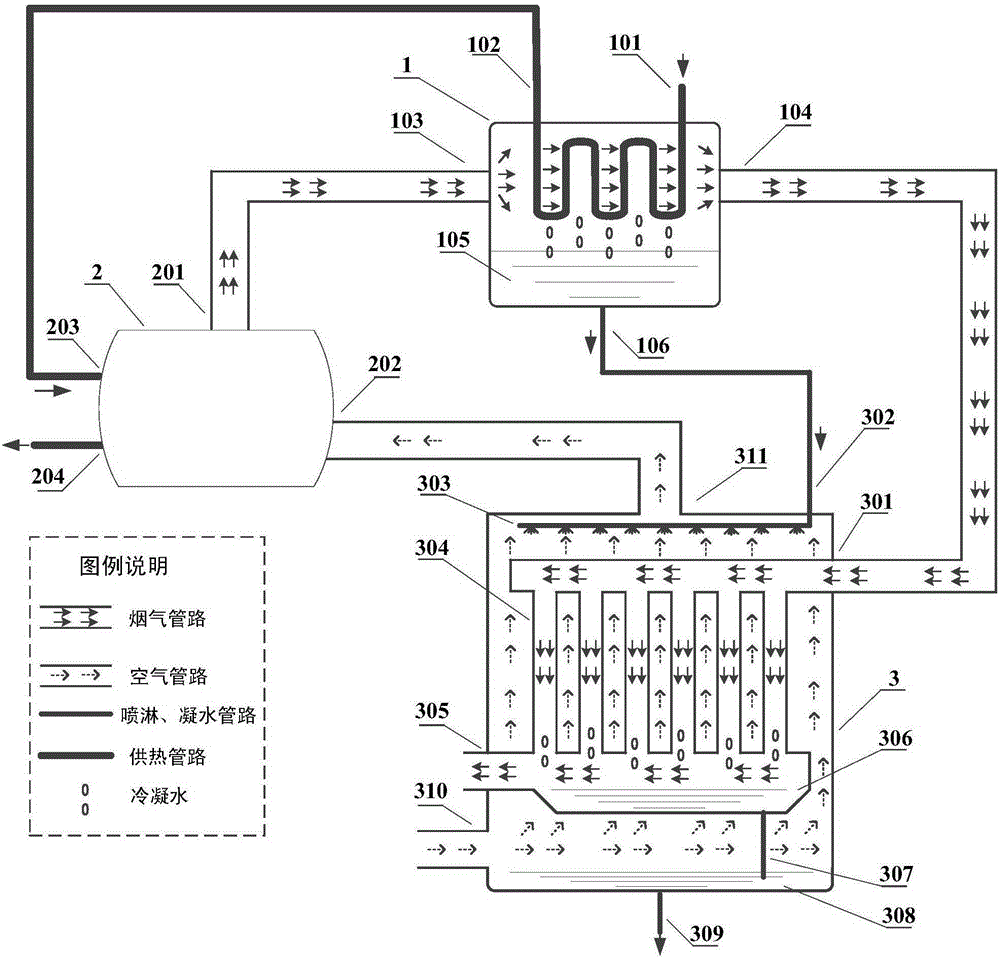

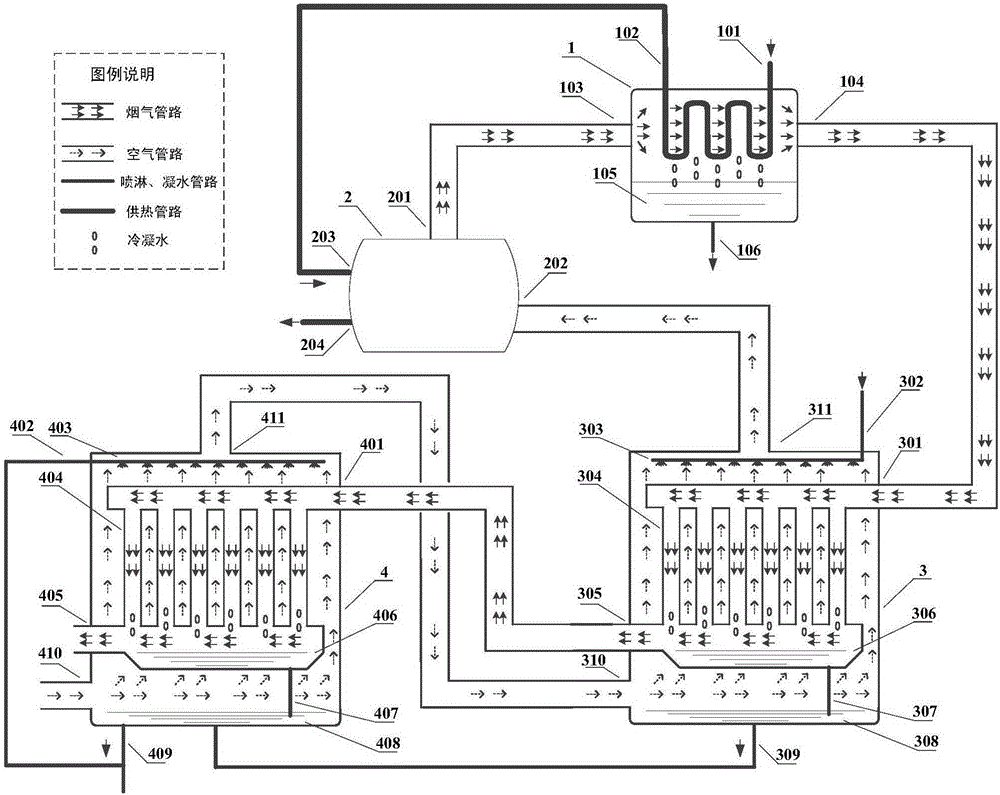

[0034] A boiler flue gas deep heat recovery device provided by the present invention comprises a flue gas-return water heat exchanger 1, a boiler 2 and N-stage heat recovery devices arranged in series, wherein N≥1; the flue gas-return water exchanger Heater 1 includes primary network return water inlet 101, primary network return water outlet 102, return water heat exchanger flue gas inlet 103, return water heat exchanger flue gas outlet 104, return water heat exchanger condensate tank 105 and return water exchanger Heater outlet 106; said boiler 2 includes boiler flue gas outlet 201, boiler air inlet 202, boiler return water outlet 203 and boiler hot water outlet 204; said boiler flue gas outlet 201 and return water heat exchanger flue gas inlet 103 The return water outlet 102 of the primary network is connected to the boiler return water port 203 , the condensate tank 105 of the return water heat exchanger and the drain port 106 of the return water heat exchanger are located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com