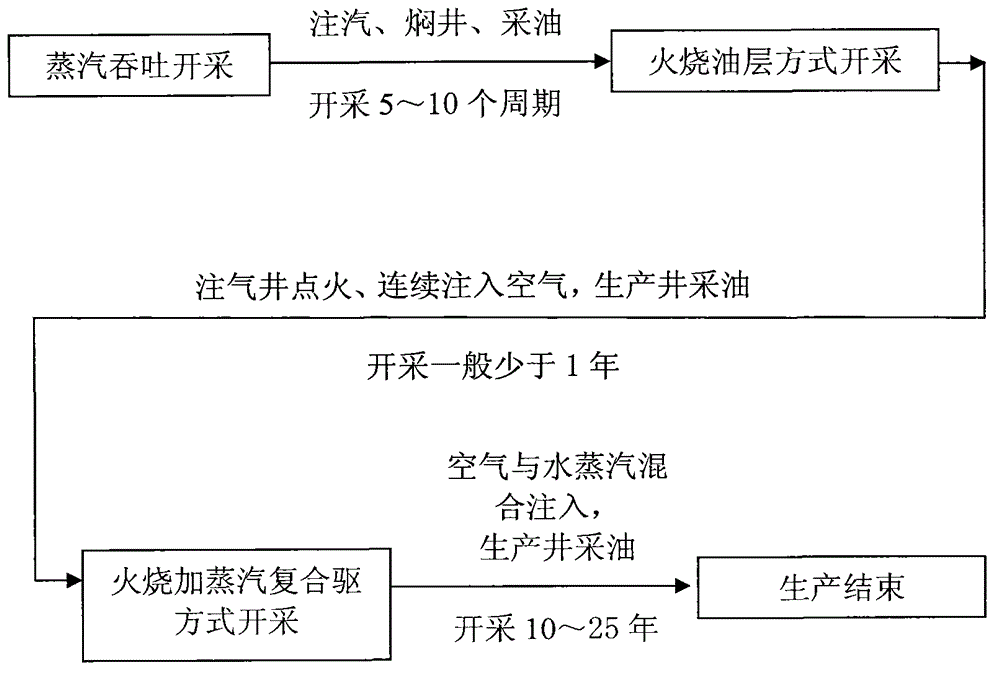

Method for using combustion and vapor combination flooding to exploit thick oil

A combined mining and composite flooding technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as inability to form effective thermal communication, fluid blockage, and high viscosity of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

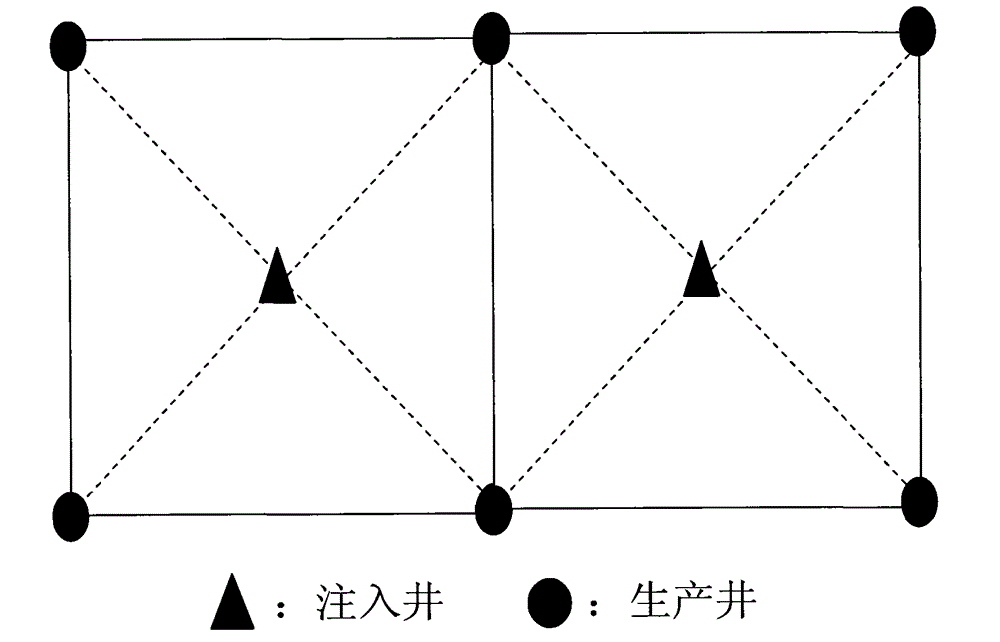

Embodiment 1

[0076]The buried depth of the oil layer in Oilfield 1 is -800~-1000m, and the average oil layer thickness is 42.1m. The average porosity is 25.5%, and the average permeability is 780mD. The viscosity of crude oil is high, and the average viscosity of degassed crude oil at 50°C is 300-2000mPa·s. Five-point well pattern with a well spacing of 71m. In the early stage, the steam huff and puff development was mainly used. At present, the formation pressure is low, with an average of only 1.2MPa, the underground water storage is large, the stepping water rate is only 32.3%, and the remaining oil saturation between wells is 44.5%.

[0077] (1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.35, reservoir thickness>10.0m, reservoir porosity>0.2, reservoir permeability>200mD, crude oil viscosity<100000mPa·s.

[0078] (2) Firstly, the interwell temperature is ...

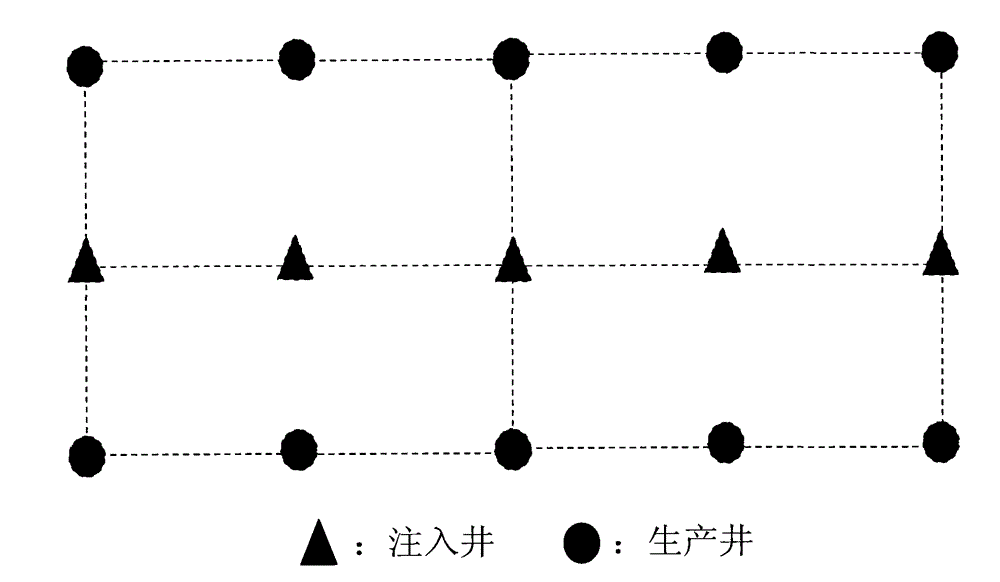

Embodiment 2

[0083] Oilfield 2 oil layer buried depth is -1640~-1740m, average oil layer thickness is 69.7m. The average porosity is 21.2%, and the average permeability is 1376mD. The viscosity of crude oil is high, and the average viscosity of degassed crude oil at 50°C is 2000-3500mPa·s. Row-column well pattern with a well spacing of 105m. In the early stage, the steam huff and puff development was mainly used. At present, the formation pressure is low, only 2-3MPa, the underground water storage is large, the stepping water rate is only 27.6%, and the remaining oil saturation between wells is 46.3%.

[0084] (1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.35, reservoir thickness>10.0m, reservoir porosity>0.2, reservoir permeability>200mD, crude oil viscosity<100000mPa·s.

[0085] (2) Firstly, the interwell temperature is evaluated for the oil reservoir wher...

Embodiment 3

[0090] Oilfield 3 oil layer has a buried depth of -875--1015m and an effective thickness of 42-70m. The average porosity is 25.0%, and the average permeability is 1335mD. The viscosity of crude oil is high, and the average viscosity of degassed crude oil at 50°C is 59834mPa·s. Vertical well-horizontal well combination, the well spacing is 70m. In the early stage, steam huff and puff development was mainly used. At present, the formation pressure is low, only 2.0MPa, the underground water storage is large, the water recovery rate is 65%, and the remaining oil saturation between wells is the highest at 56%.

[0091] (1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.35, reservoir thickness>10.0m, reservoir porosity>0.2, reservoir permeability>200mD, crude oil viscosity<100000mPa·s.

[0092] (2) Firstly, the interwell temperature is evaluated for the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com