Electromagnetic-induction heating high-temperature fused salt heat carrier furnace

An electromagnetic induction heating and heat carrier furnace technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex structure of heat carrier furnaces, low energy utilization efficiency, and serious environmental pollution. Achieve the effects of extensive application expansion, strong heat carrying capacity, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] For better understanding and implementation, the present invention will be described in detail below in conjunction with the attachment:

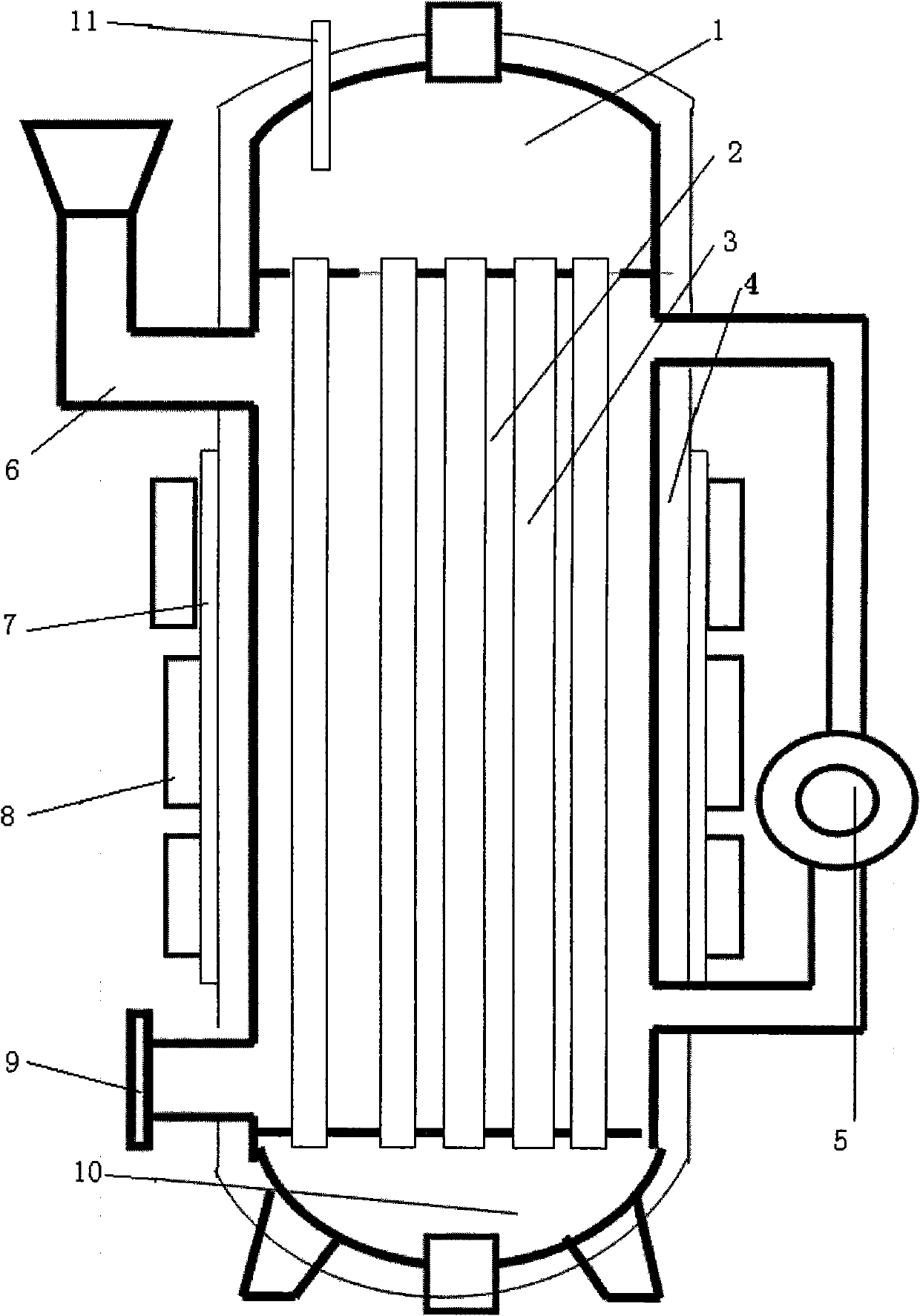

[0015] Examples, see figure 1 The upper medium chamber 1, the lower medium chamber 10 and the heat carrier chamber 2 are made of corrosion-resistant and heat-resistant alloy steel castings or welded parts, and the three are welded and connected; the heat exchange tube bundle 3 is arranged in the heat carrier chamber 2, and the upper medium chamber 1 is sealed and connected with the lower medium chamber 10 and the heat exchange tube bundle 3 to form a heat exchanger. The inside of the heat exchanger is a fluid medium or a gas medium. It is sealed and isolated, and the liquid-phase molten salt is in the heat carrier warehouse 2, which constitutes the heat carrier furnace; the heat-insulation layer 4 is located outside the heat-carrier furnace body, and the outer layer of the heat-insulation layer 4 in the heat carrier chamber 2 section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com