Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1070 results about "Functional composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

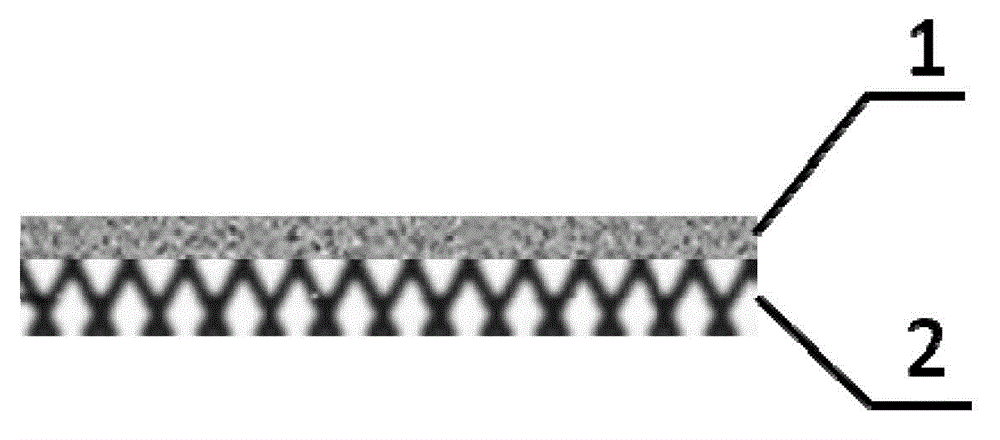

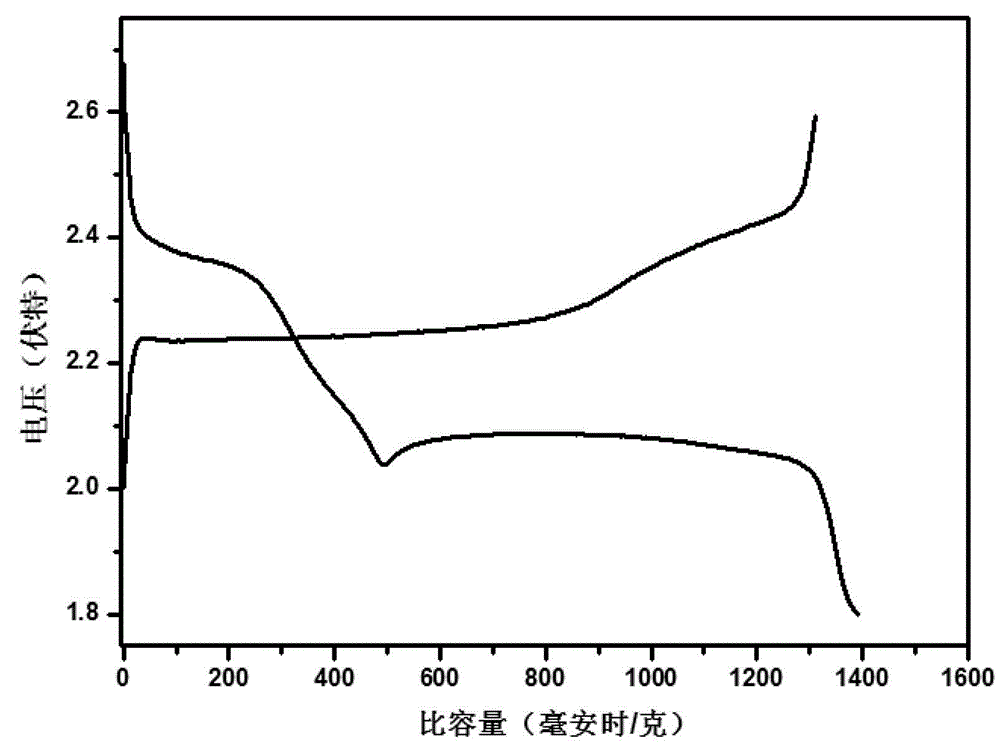

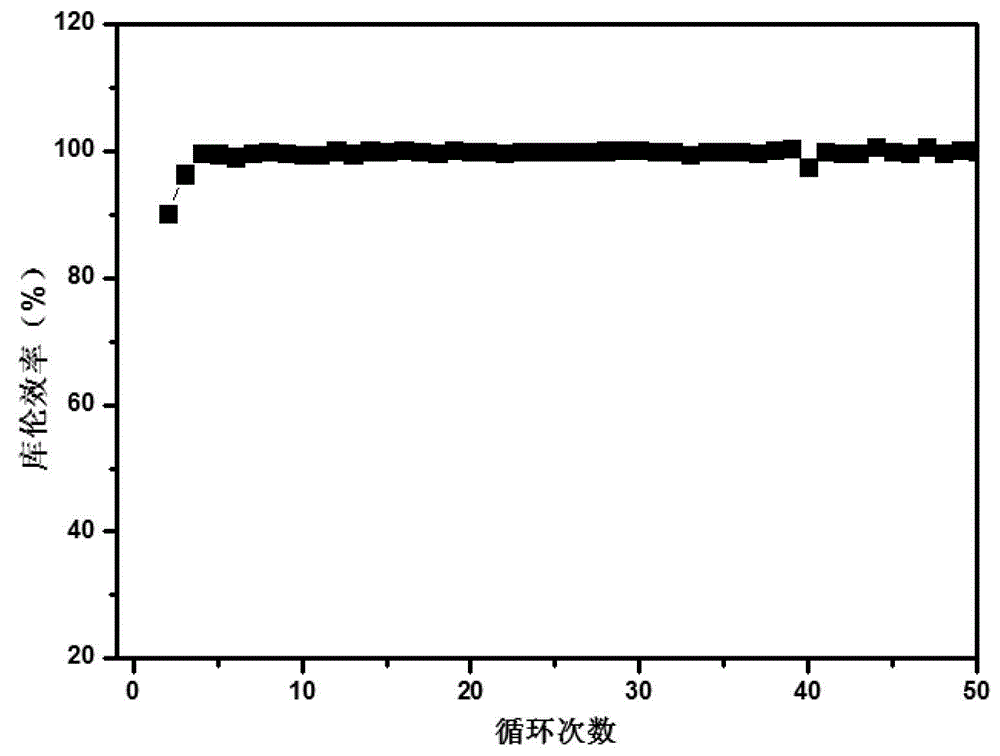

Functional composite membrane for lithium-sulfur battery and preparation method of functional composite membrane

InactiveCN105140447AImproved magnification performanceImprove ionic conductivityLi-accumulatorsCell component detailsLithium–sulfur batteryConductive materials

The invention relates to a functional composite membrane for a lithium-sulfur battery and a preparation method of the functional composite membrane. The composite membrane comprises a membrane for the lithium-sulfur battery and a functional modified layer, wherein the functional modified layer is located on the membrane for the lithium-sulfur battery, and comprises an electronic conductive material and / or inorganic oxides. Compared with the lithium-sulfur battery employing an ordinary battery membrane, the lithium-sulfur battery employing the functional composite membrane with the modified layer has a relatively high specific discharge capacity; the shuttle effect of the lithium-sulfur battery can be suppressed; the coulombic efficiency of the battery is improved; and the cycle performance of the battery is improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

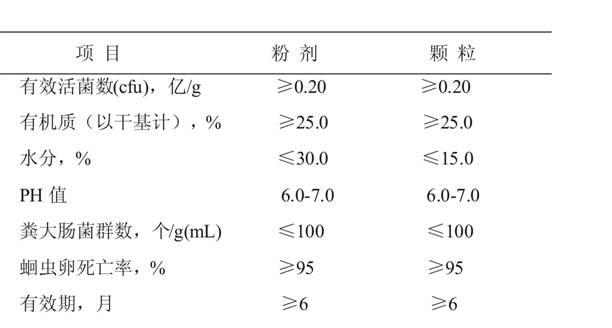

Bio-organic fertilizer produced by using livestock manure

ActiveCN102219570ASimple structureImprove conversion rateBio-organic fraction processingFungiLivestock manureAgricultural science

The invention provides an efficient active bio-organic fertilizer produced by using livestock manure and a preparation method thereof. The preparation method comprises the following steps: pre-treating the livestock manure, straw and peat; mixing the livestock manure, straw and peat at a weight ratio of (3-5):(1-2):(1-2); adding a composite ageing bactericide based on the condition that the weight ratio of the mixture to the high-concentrated organic material ageing bactericide is (5000-10000):(1-2), evenly mixing, and then carrying out composting fermentation for 7-10 days, wherein during the composting fermentation, the material needs to be stirred 1-2 times each day; and mixing the material decayed by fermentation with a functional composite bactericide which is generated by single fermentation at a weight ratio of (5000-1000):(1-2), granulating and drying at low temperature so as to obtain the high-efficiency and active bio-organic fertilizer. The process is relatively simple, is easy to operate, and can be used for lowering the product cost is low, saving energy and turning wastes into wealth, thereby being beneficial to promotion of benign ecological circulation and environment conservation; and by utilizing the fertilizer, the quality of the product is good, thereby obviously improving the yield and quality of agricultural products.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

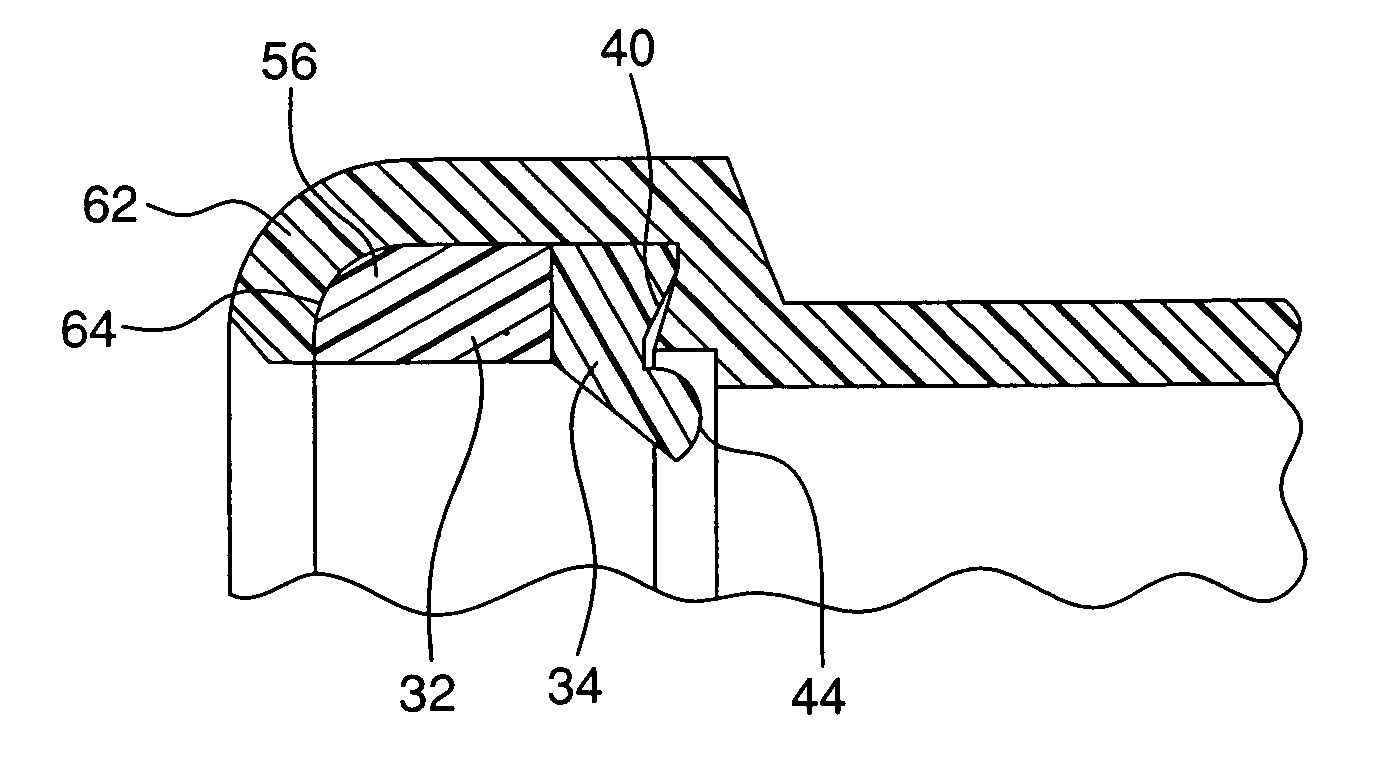

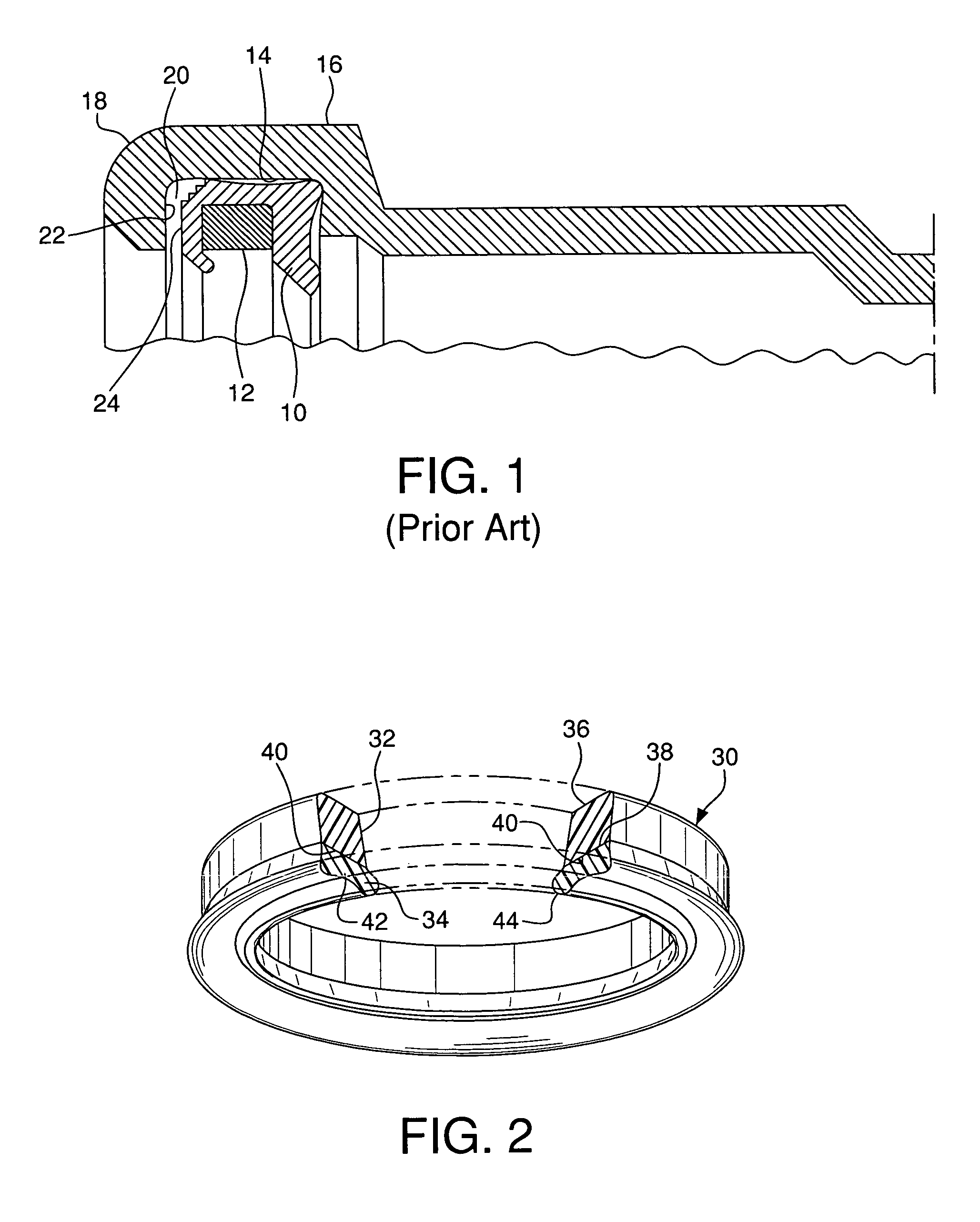

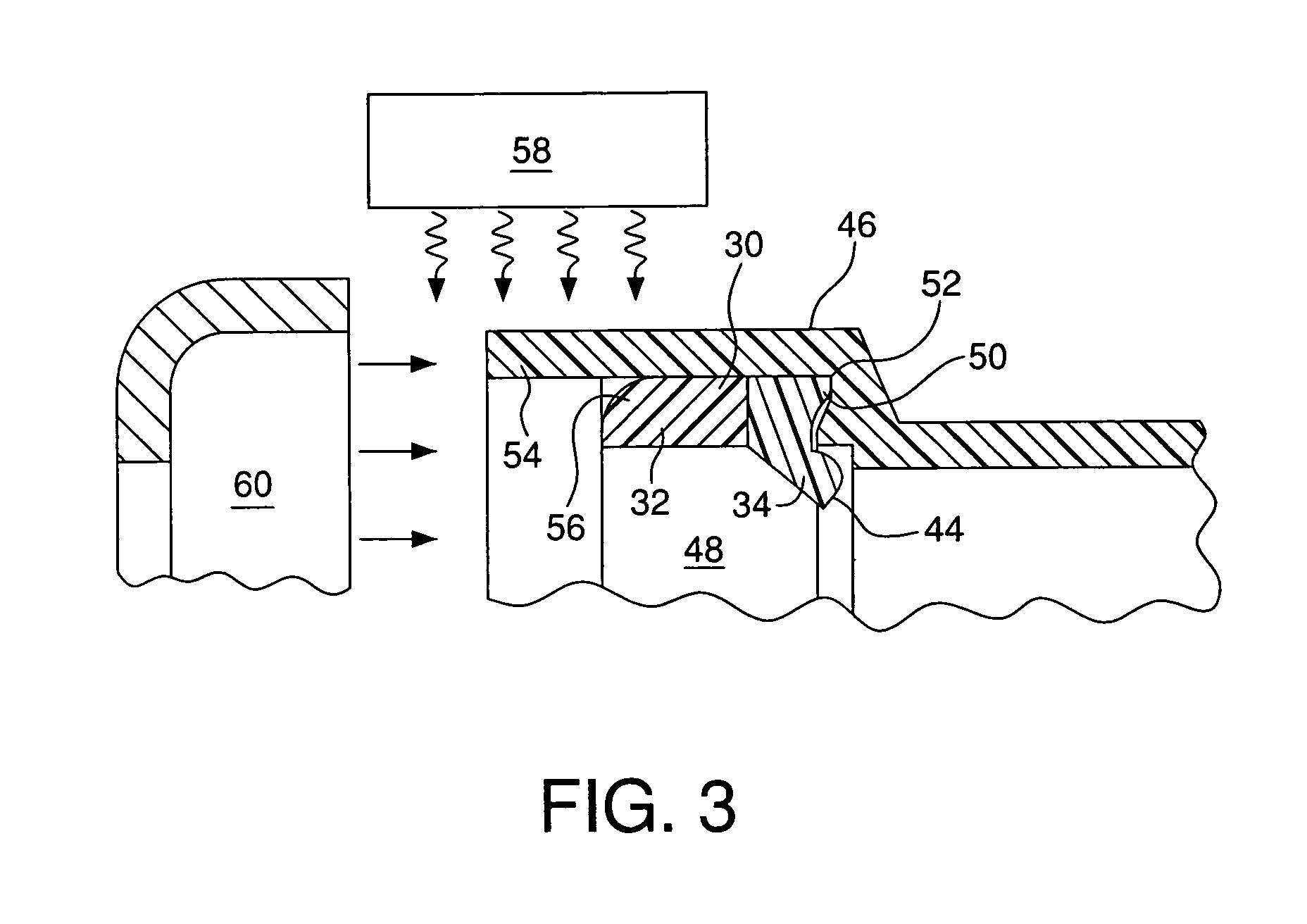

Socket with dual-functional composite gasket

InactiveUS7140618B2Eliminate disadvantagesEliminate gapsSleeve/socket jointsEngine sealsLeading edgeElastomer

A gasketed pipe joint including a dual-functional, composite gasket, which in addition to forming a seal between a pipe bell and a spigot provides a molding surface for forming a bent retainer in the hub of the pipe or fitting. The dual-functional composite gasket comprises a first axially disposed portion formed of a non-elastomeric, substantially rigid, substantially non-resilient plastic material and has a first leading edge and a first trailing edge, and a second axially disposed portion, adjacent the first axially disposed portion, formed of an elastomeric material. Preferably, the gasket comprises a major portion of the non-elastomeric, substantially rigid, substantially non-resilient plastic and a minor portion of the elastomeric material.

Owner:TIGRE USA

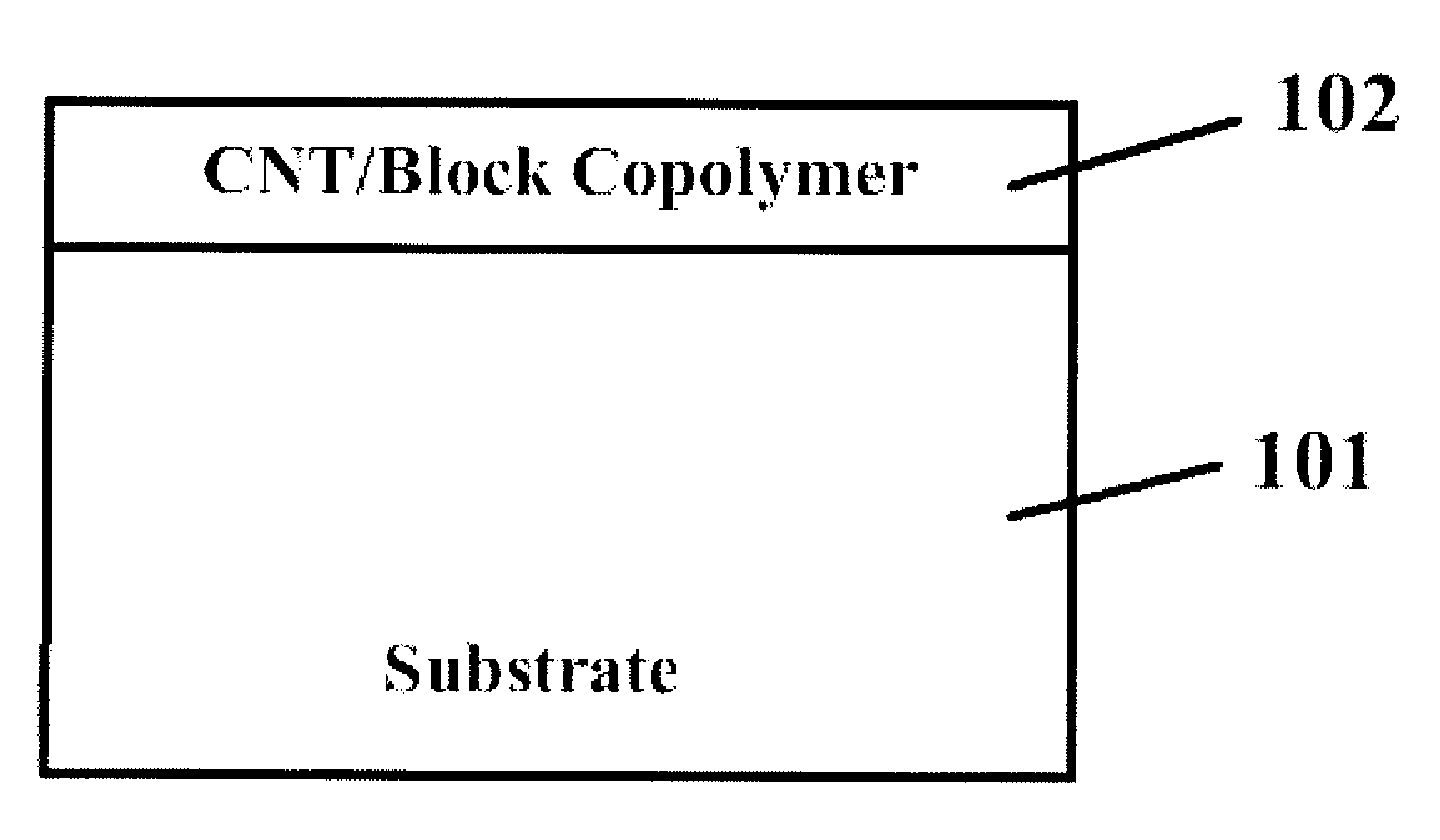

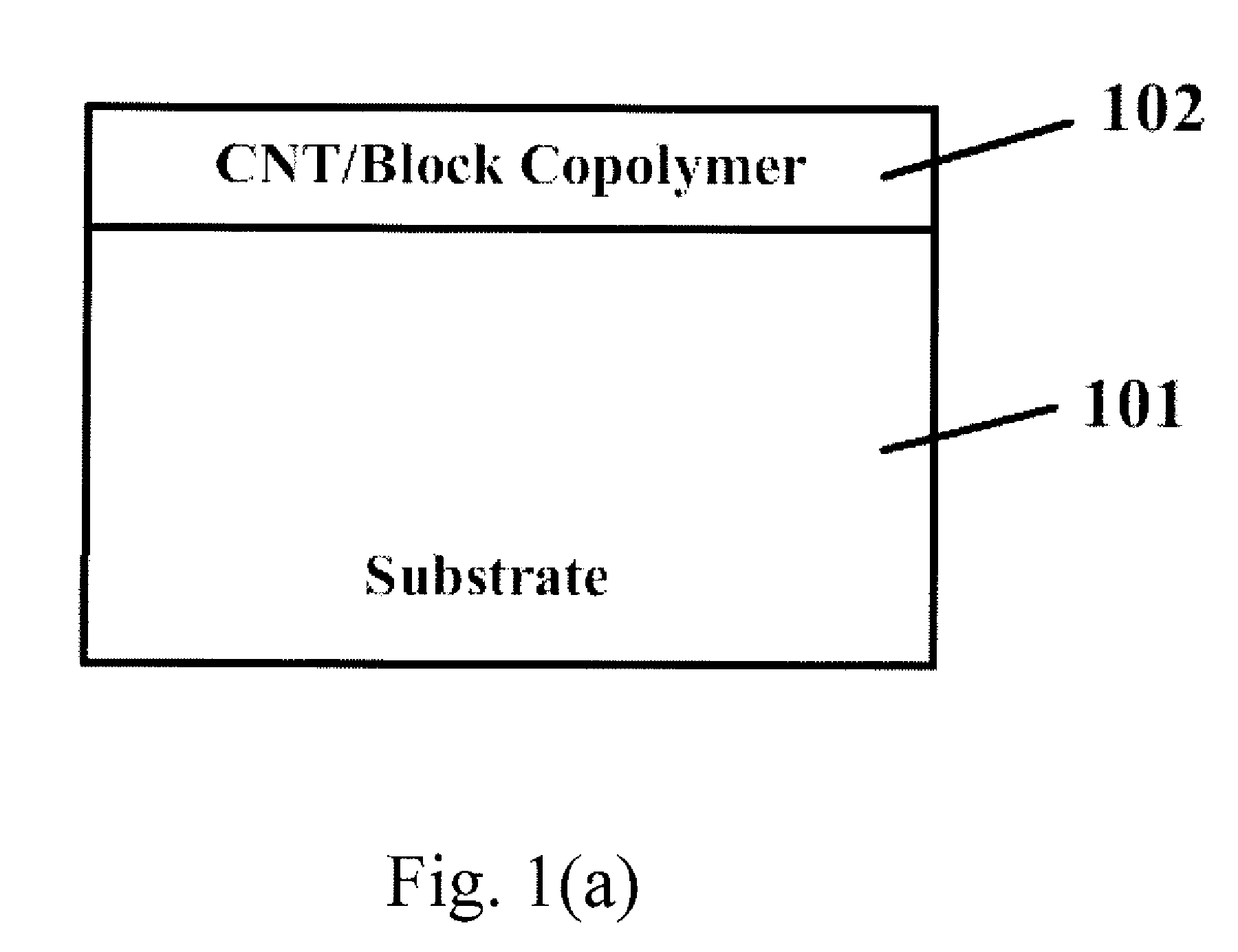

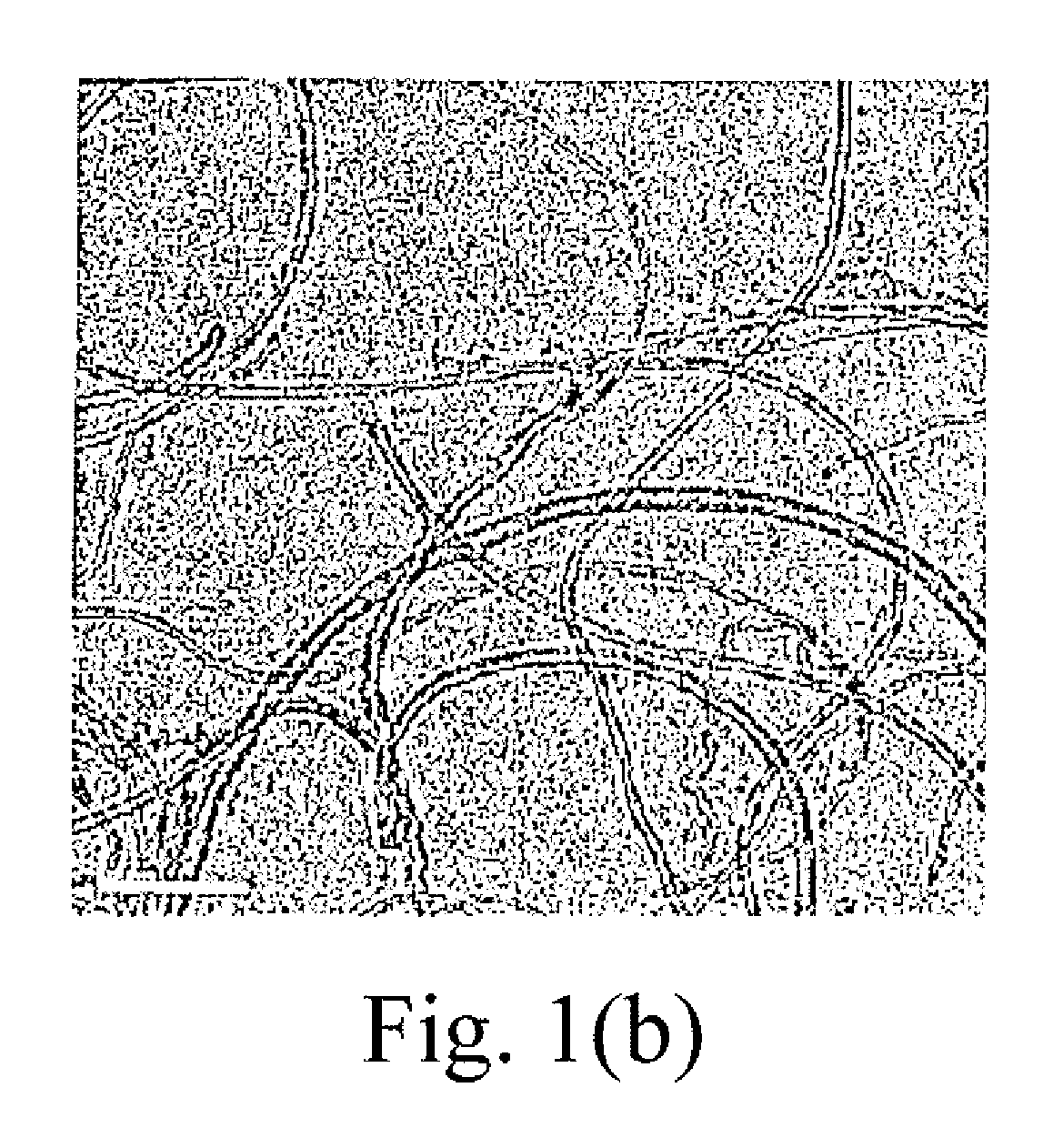

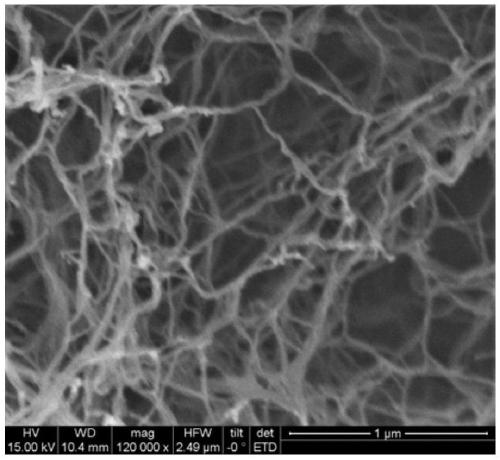

Dispersions of carbon nanotubes in copolymer solutions and functional composite materials and coatings therefrom

A dispersion includes a plurality of non-chemically modified carbon nanotubes, a soluble block copolymer providing at least one block of a conjugated polymer and at least one block of a non-conjugated polymer, and at least one solvent. At 25° C. exclusive of any mechanical force and after one hour, at least 90% of the plurality of carbon nanotubes exist in the dispersion as isolated carbon nanotubes. The components of the dispersion can be combined with a polymer miscible with the block copolymer to form a carbon nanotube polymer composite upon removal of the solvent. The dispersion can be cast on a substrate and then dried to form a coating, including forming a superhydrophobic coating on the substrate. The non-conjugated polymer of the block copolymer or another miscible conjugated polymer including a copolymer can include functionalities that non-covalently attach to the carbon nanotube surface, such as for manipulating carbon nanotube properties including for enhanced solubility or enhanced biocompatibility.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Chemically resistant radiation attenuation barrier

ActiveUS7196023B2Protective equipmentSynthetic resin layered productsCountermeasureMarine engineering

A unique and novel multi-functional composite fabric and fabrication process for use during chemical, biological, radiological and nuclear countermeasure (CBRNC) events is disclosed. The composite fabric combines the performance characteristics of chemically resistant films and radiation attenuating polymer matrices. The composite fabric offers universal protection against a wide range of military chemical agents, toxic industrial chemicals and materials (TICS and TIMS), biological agents, as well as certain ionizing and non-ionizing forms of radiation. The composite fabric is heat sealable and can be fabricated utilizing hermetically seal seams, and has application in protective clothing and equipment, indoor and outdoor covers, containment systems, bags, drapes, gowns, remains pouches, etc.

Owner:MERIDIAN RES & DEV

Method for preparing functional composite microsphere with multi-layer core-shell structure and application thereof

InactiveCN101735413ADifferent Surface ElectricityWith strengthDrilling compositionPolymer scienceMicrosphere

The invention discloses a method for preparing functional composite microsphere with a multi-layer core-shell structure and application thereof, and relates to the technical fields of functional macromolecular microsphere preparation and petroleum exploitation, in particular to the technical field of deep profile control water shutoff during high water-cut period of petroleum exploitation. The functional composite microsphere is prepared by a dispersion polymerization method which comprises the following steps: forming a core part by polymerization of a styrene monomer, and forming a cation shell part by copolymerization of acrylamide, the cation monomer and a crosslinking agent; and forming an anion shell part by copolymerization of acrylamide, anion monomer and the crosslinking agent. The functional composite microsphere is characterized in that the size of the microsphere is between 1,500 and 2,000nm and the microsphere is white solid powder or polymer emulsion; the expansion multiplying power of the microsphere is improved by 20 to 50 times after 5-day hydration; and therefore, the functional composite microsphere can be used for effective plugging at the pore throat of a bottom high permeability zone during high water-cut period of the petroleum exploitation.

Owner:JIANGNAN UNIV

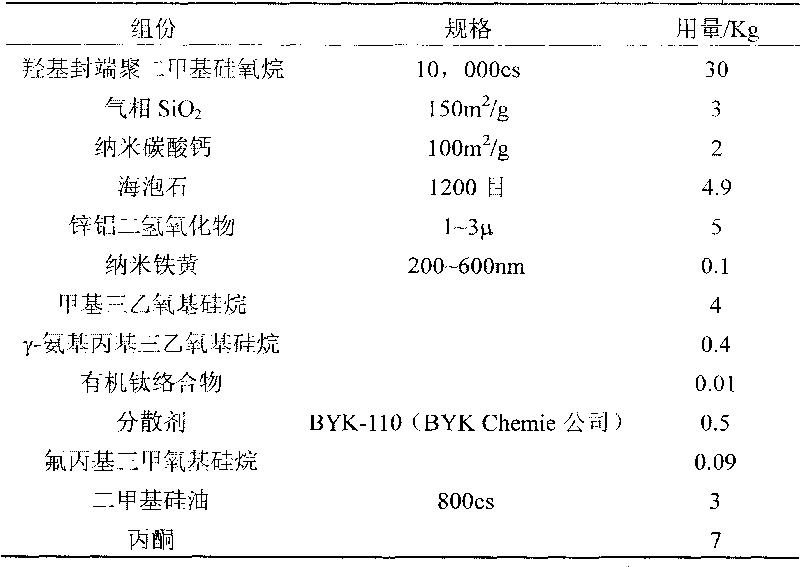

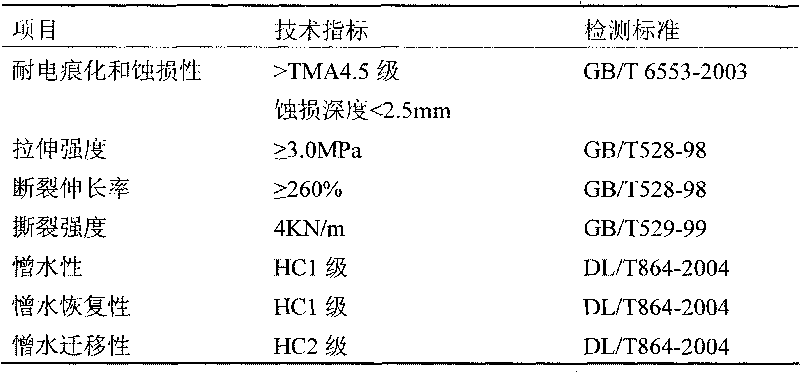

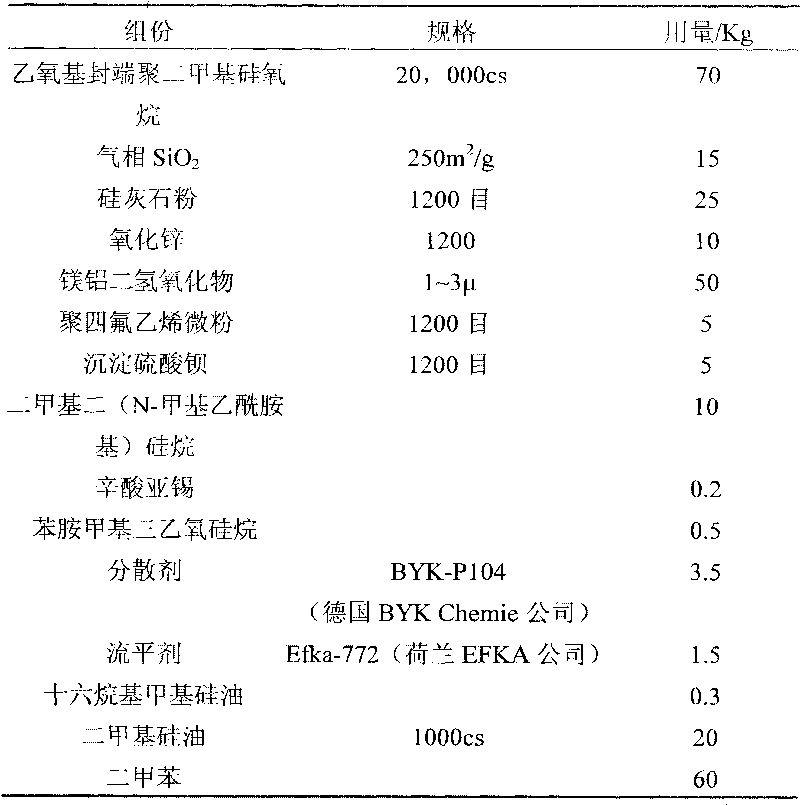

Tracking-proof corrosion-proof room temperature silicon disulfide rubber composite

ActiveCN101747630AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsCoatingsRoom temperatureDiluent

The invention relates to a tracking-proof corrosion-proof room temperature silicon disulfide rubber composite which has the following formula: 30-70 parts of polysiloxane by weight, 5-40 parts of reinforced filler by weight, 10-70 parts of electric corrosion resistance stabilizer by weight, 5-15 parts of auxiliary agent by weight and 10-80 parts of diluent by weight. The tracking-proof corrosion-proof room temperature silicon disulfide rubber composite provided by the invention has favourable tracking-proof corrosion-proof performance, has higher tensile strength, breaking elongation and tearing strength as well as favourable surface hydrophobicity, hydrophobicity transference and hydrophobicity restoration and is a functional composite capable of effectively preventing and curing pollution flashover.

Owner:CHINA ELECTRIC POWER RES INST +3

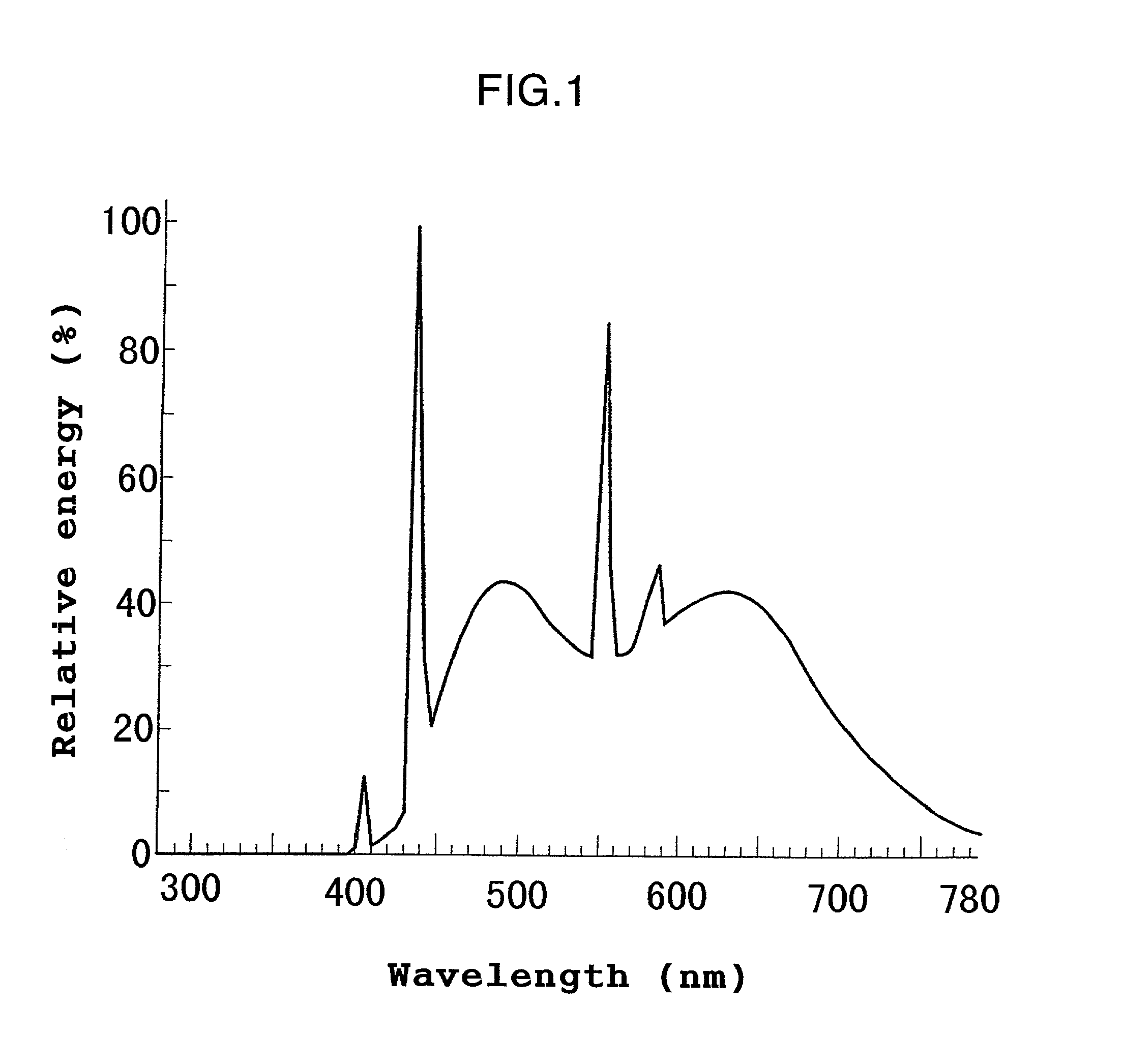

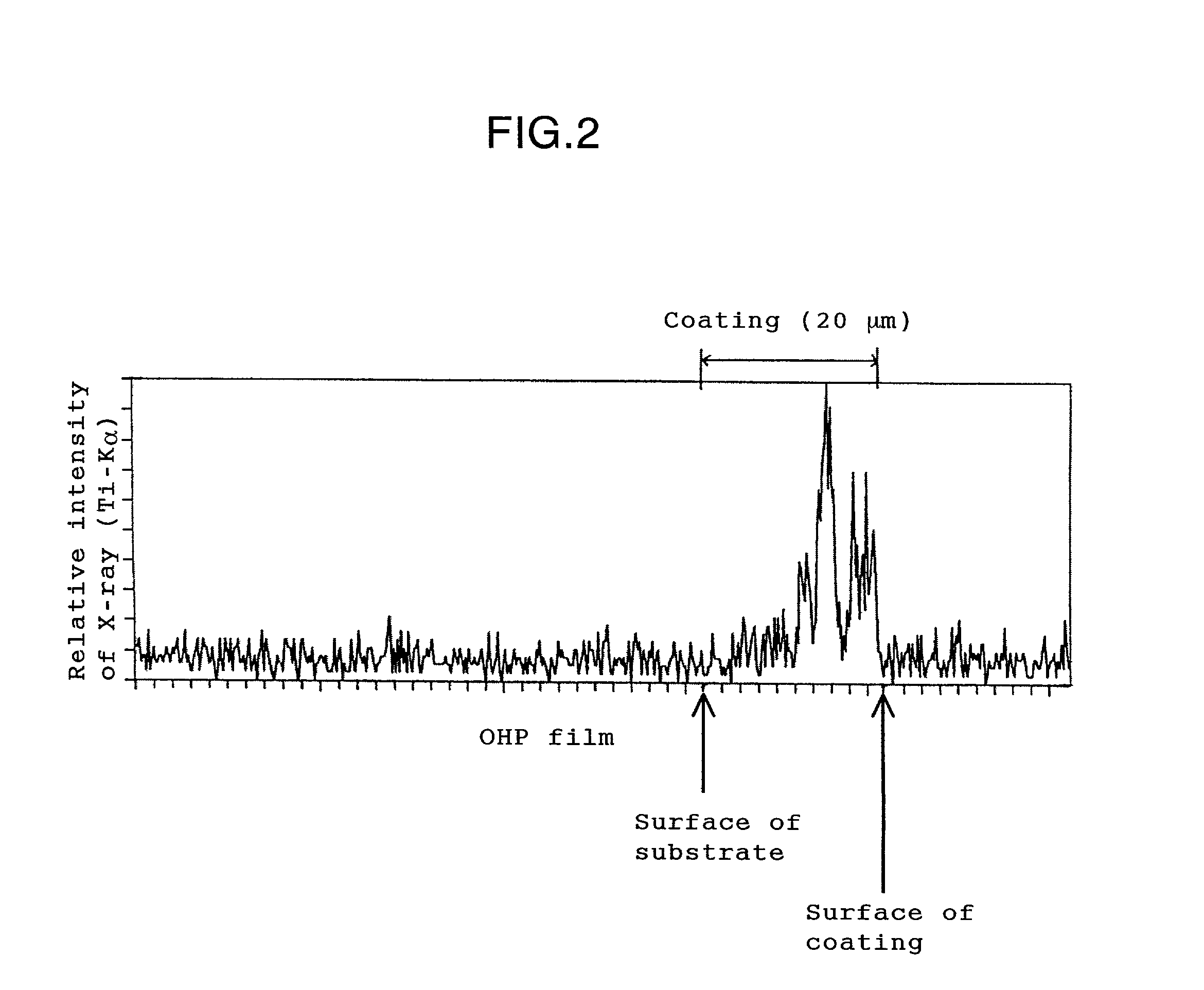

Photocatalyst composition

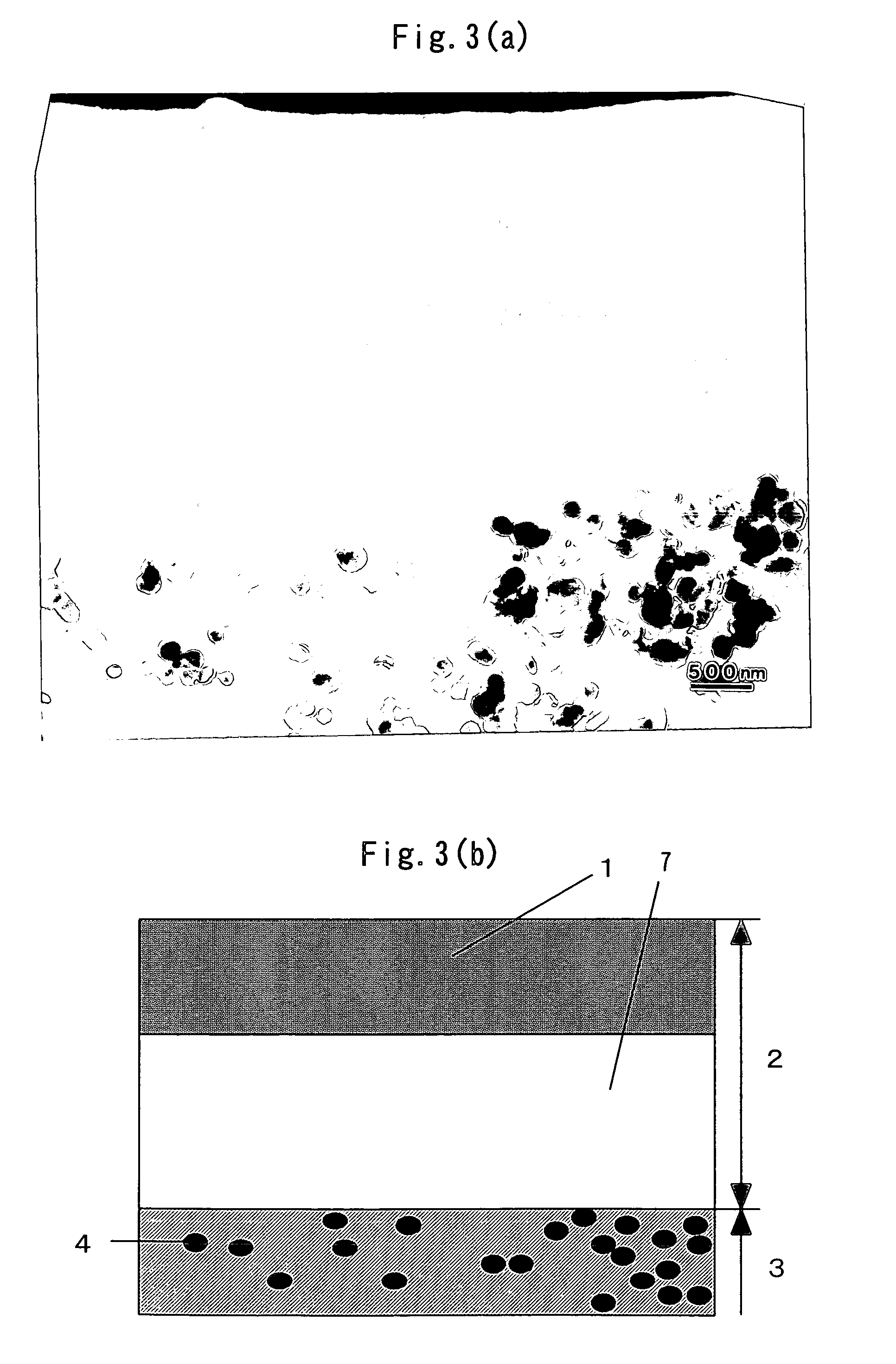

InactiveUS7211543B2Improve balanceIncrease flexibilityInorganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical compoundOxygen

A photocatalyst composition which comprises (A) modified photocatalyst particles, the modified photocatalyst particles (A) being prepared by subjecting particles of a photocatalyst to a modification treatment with at least one modifier compound selected from the group consisting of different compounds each of which independently comprises at least one structural unit selected from the group consisting of a triorganosilane unit, a monooxydiorganosilane unit and a dioxyorganosilane unit; and (B) a binder component comprising a phenyl group-containing silicone optionally containing an alkyl group. A film formed using the above-mentioned photocatalyst composition, a functional composite comprising a substrate and the above-mentioned film formed on the substrate, and a shaped article produced by shaping the above-mentioned photocatalyst composition.

Owner:ASAHI KASEI KK

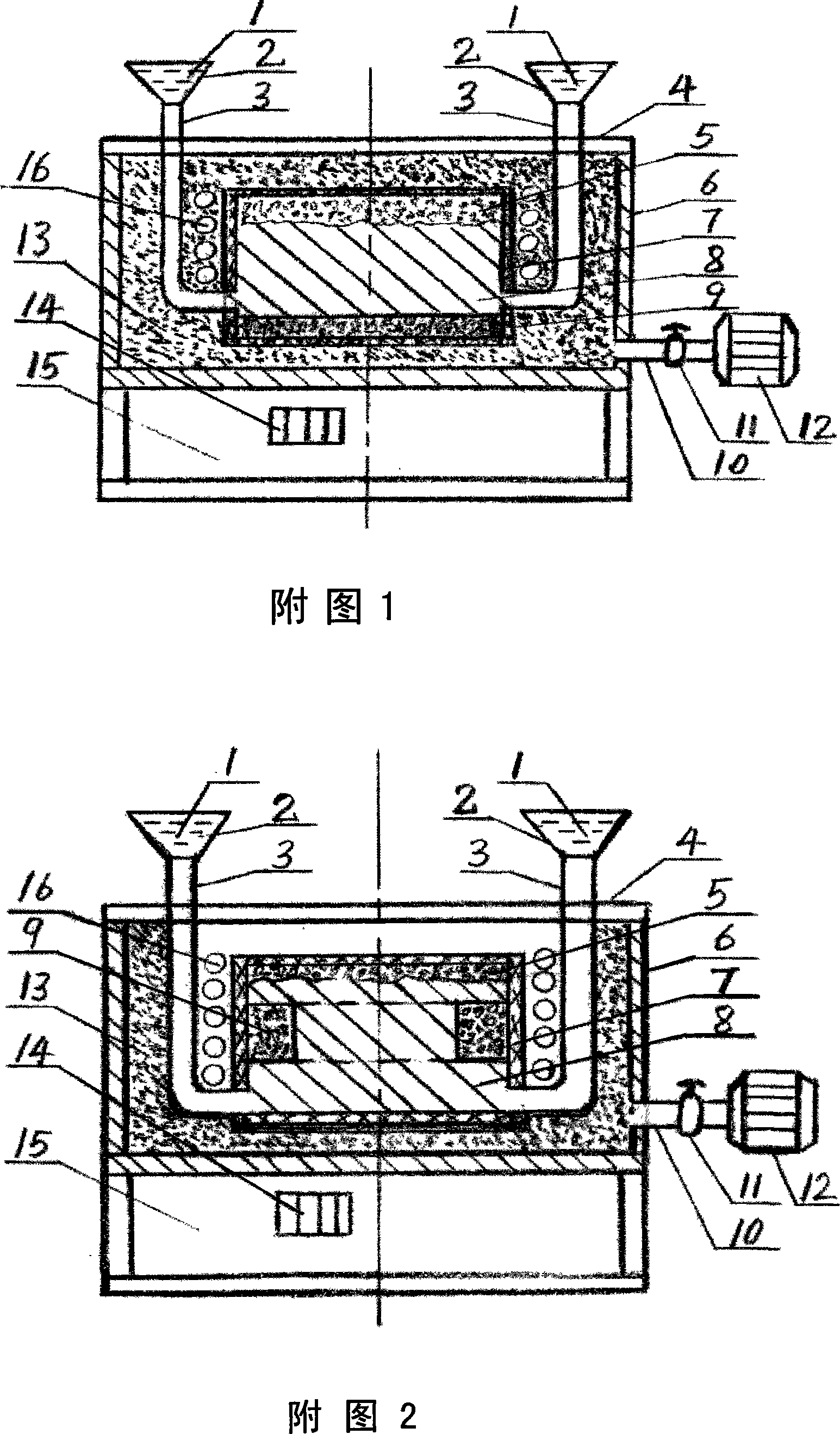

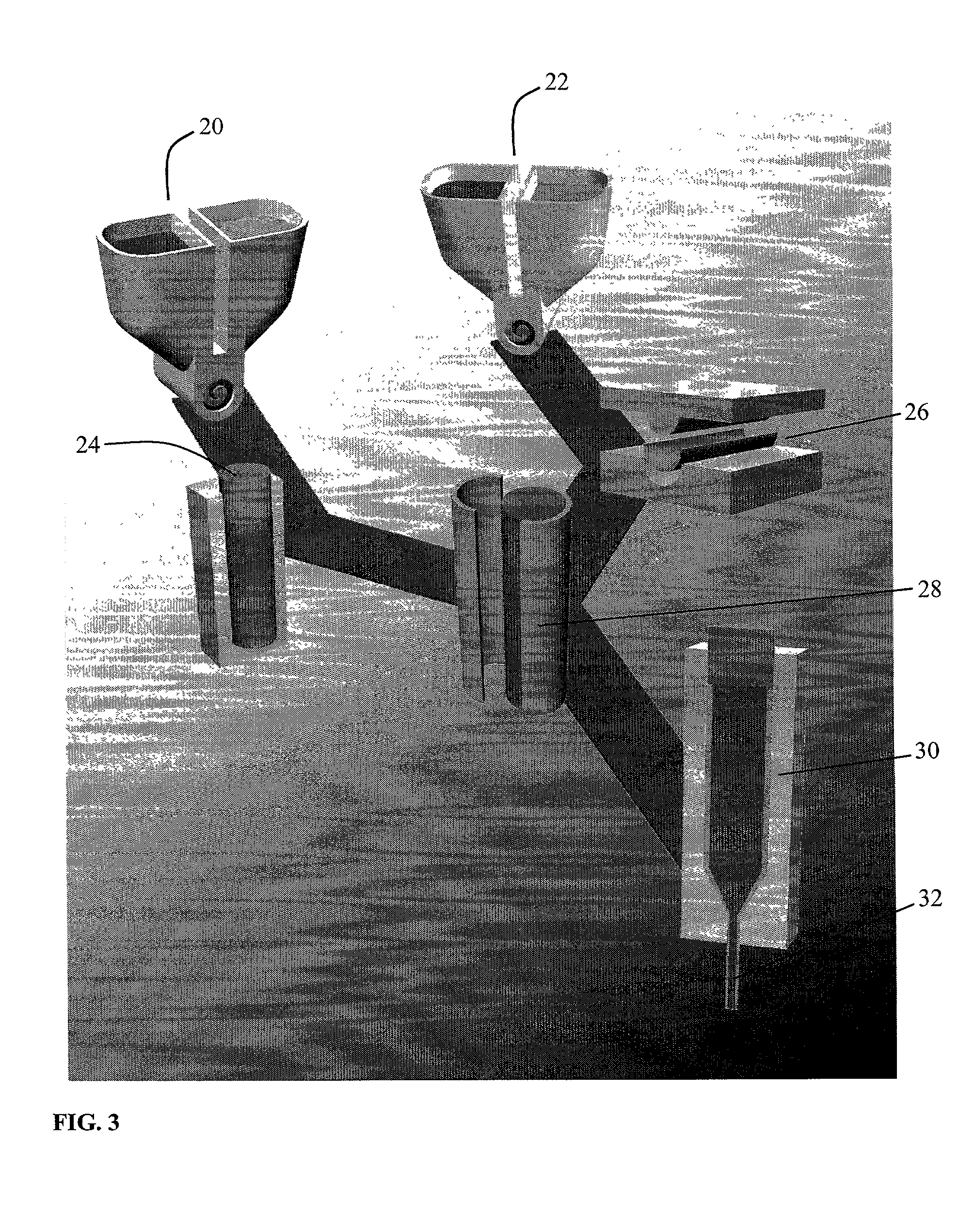

Reinforcing phase metallic gradient composite material manufacturing process and equipment thereof

The present invention discloses process and apparatus for preparing composite material with gradient reinforcing phase. The composite material is prepared through fixing reinforcing alloy blocks in the required positions of the foamed plastic model, vacuum vibrating molding, heating the alloy blocks to 100-1200 deg.c with one outside electromagnetic induction heater, pouring base metal liquid, which infiltrates into the gaps of alloy powder to form great thickness gradient alloy layer with special function in the required positions of the base metal. The process has only once heating, no oxidation of the reinforcing alloy material, and raised flowability and permeability of the metal liquid, and is suitable for thick casting with two phases of different materials in high combination strength and high quality.

Owner:丁家伟 +1

Chemically resistant radiation attenuation barrier

ActiveUS20050191918A1Enhance layeringProtective equipmentSynthetic resin layered productsManufacturing technologyRadiation attenuation

A unique and novel multi-functional composite fabric and fabrication process for use during chemical, biological, radiological and nuclear countermeasure (CBRNC) events is disclosed. The composite fabric combines the performance characteristics of chemically resistant films and radiation attenuating polymer matrices. The composite fabric offers universal protection against a wide range of military chemical agents, toxic industrial chemicals and materials (TICS and TIMS), biological agents, as well as certain ionizing and non-ionizing forms of radiation. The composite fabric is heat sealable and can be fabricated utilizing hermetically seal seams, and has application in protective clothing and equipment, indoor and outdoor covers, containment systems, bags, drapes, gowns, remains pouches, etc.

Owner:MERIDIAN RES & DEV

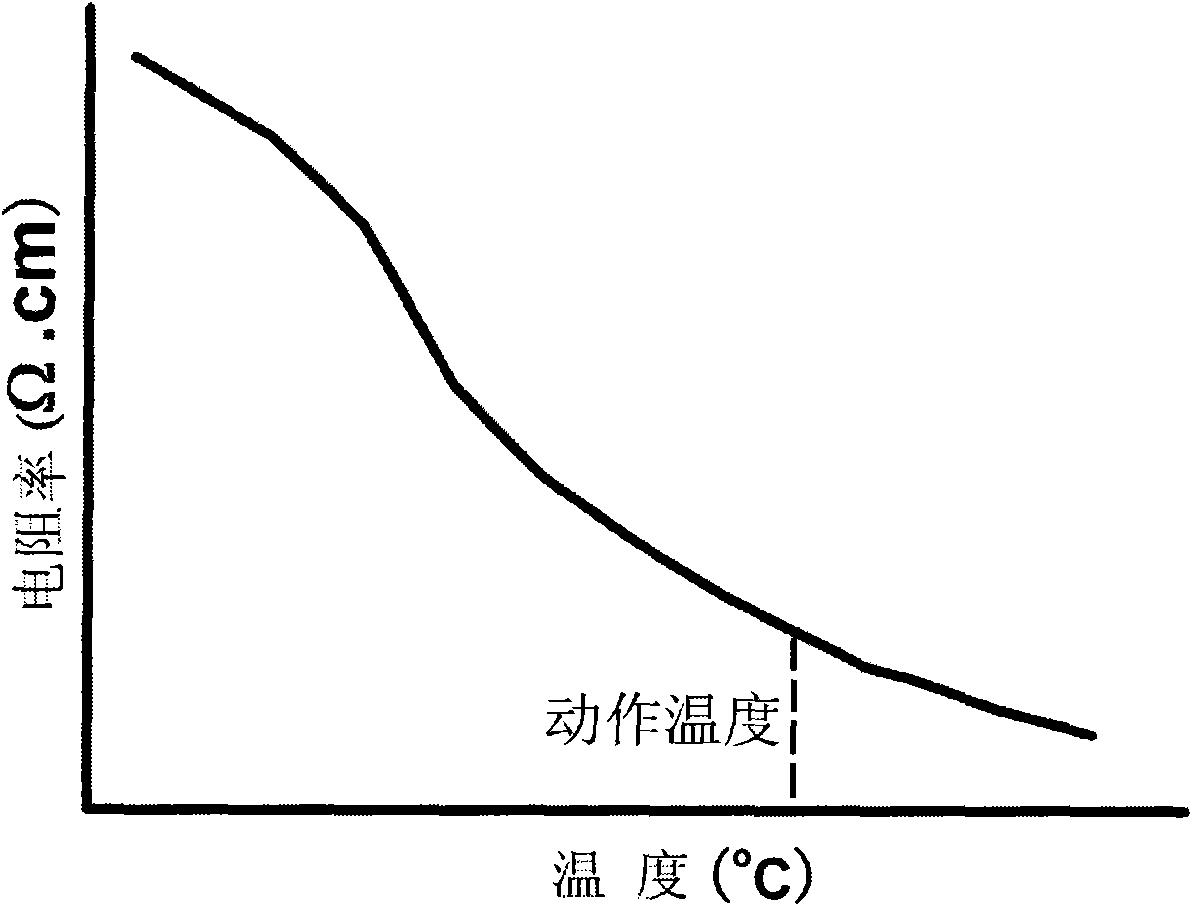

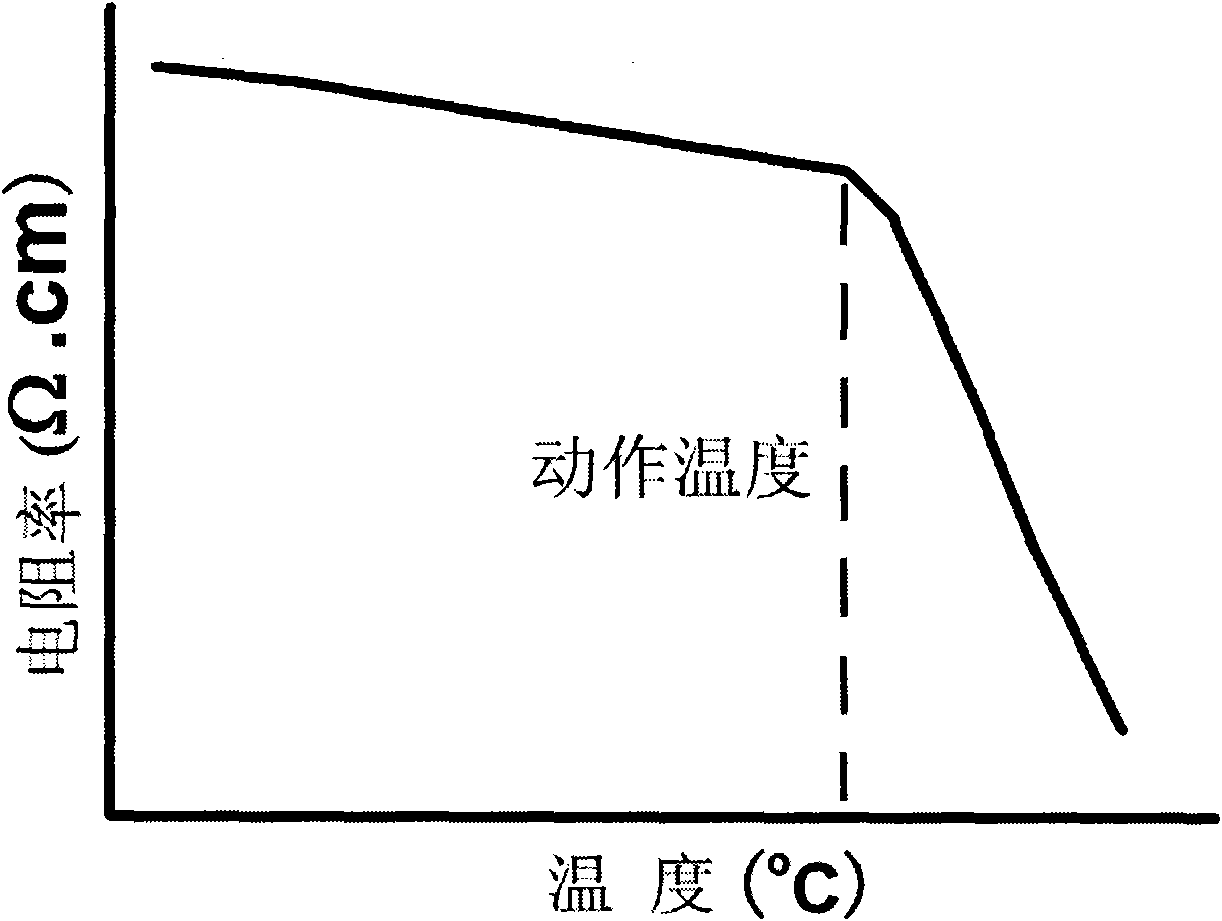

Negative temperature coefficient polymer composite material for temperature sensing cable and preparation method

InactiveCN101654530AImprove structural stabilityGood repeatabilityNegative temperature coefficient thermistorsNegative temperatureThermoplastic elastomer

The invention relates to a negative temperature coefficient polymer composite material for temperature sensing cables and a preparation method, belonging to the field of the preparation of macromolecule functional composite material and process technology of polymers; the invention has the characteristics that: rubber or thermoplastic elastomers are combined with different auxiliary polymers, conducting particles are added to prepare the macromolecule composite material with the characteristic of negative temperature coefficient. The material has the characteristics that the resistance changeis low below the room temperature and operating temperature, and then is rapidly reduced after reaching the operating temperature, and overcomes the disadvantages that the traditional NTC macromolecule composite material has obvious resistance change below the room temperature and the operating temperature, and the resistance change is low close to the operating temperature, so as to lead the prepared temperature sensing cables to have high sensitivity, to have little effect to environment temperature and good repetitiveness.

Owner:TSINGHUA UNIV

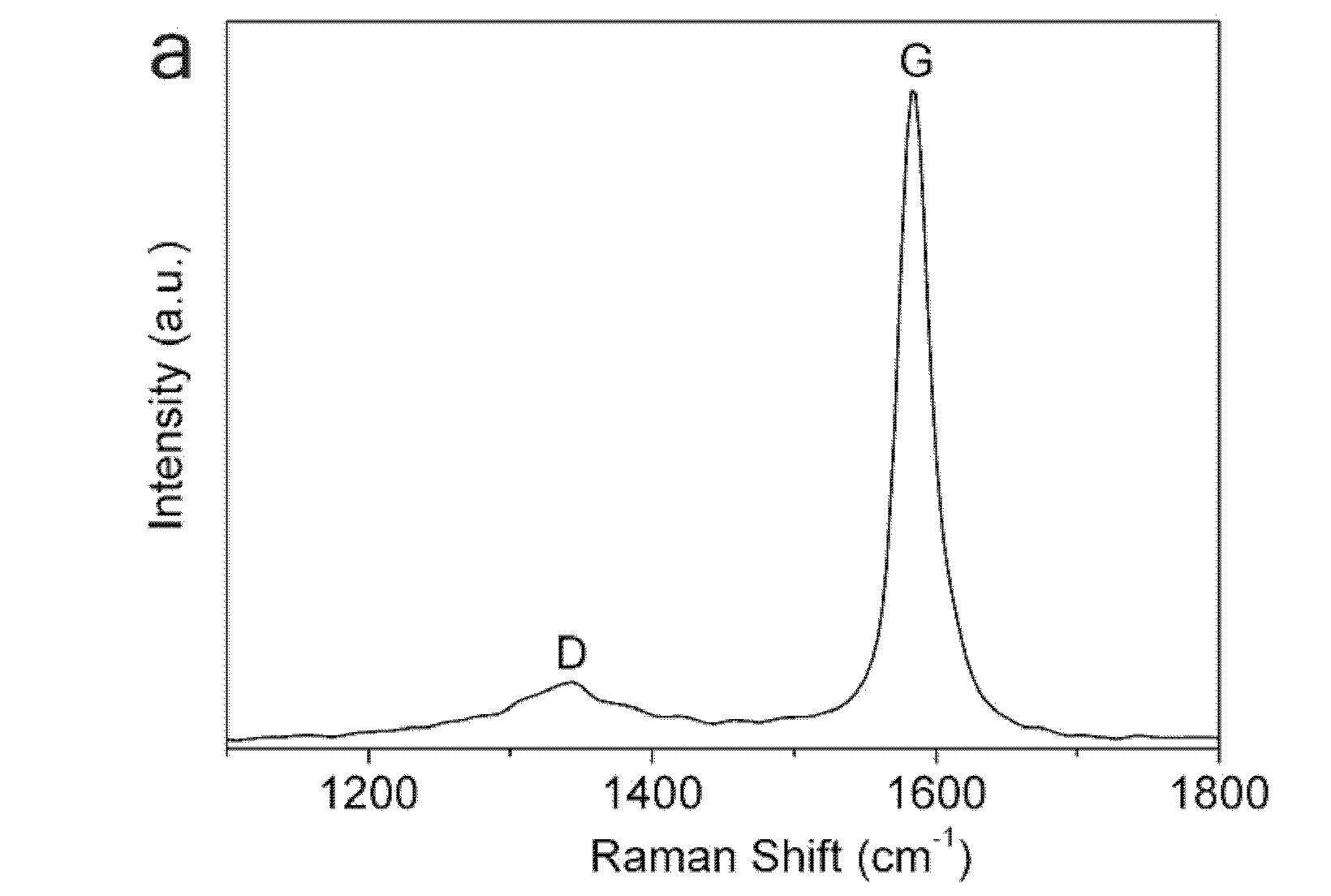

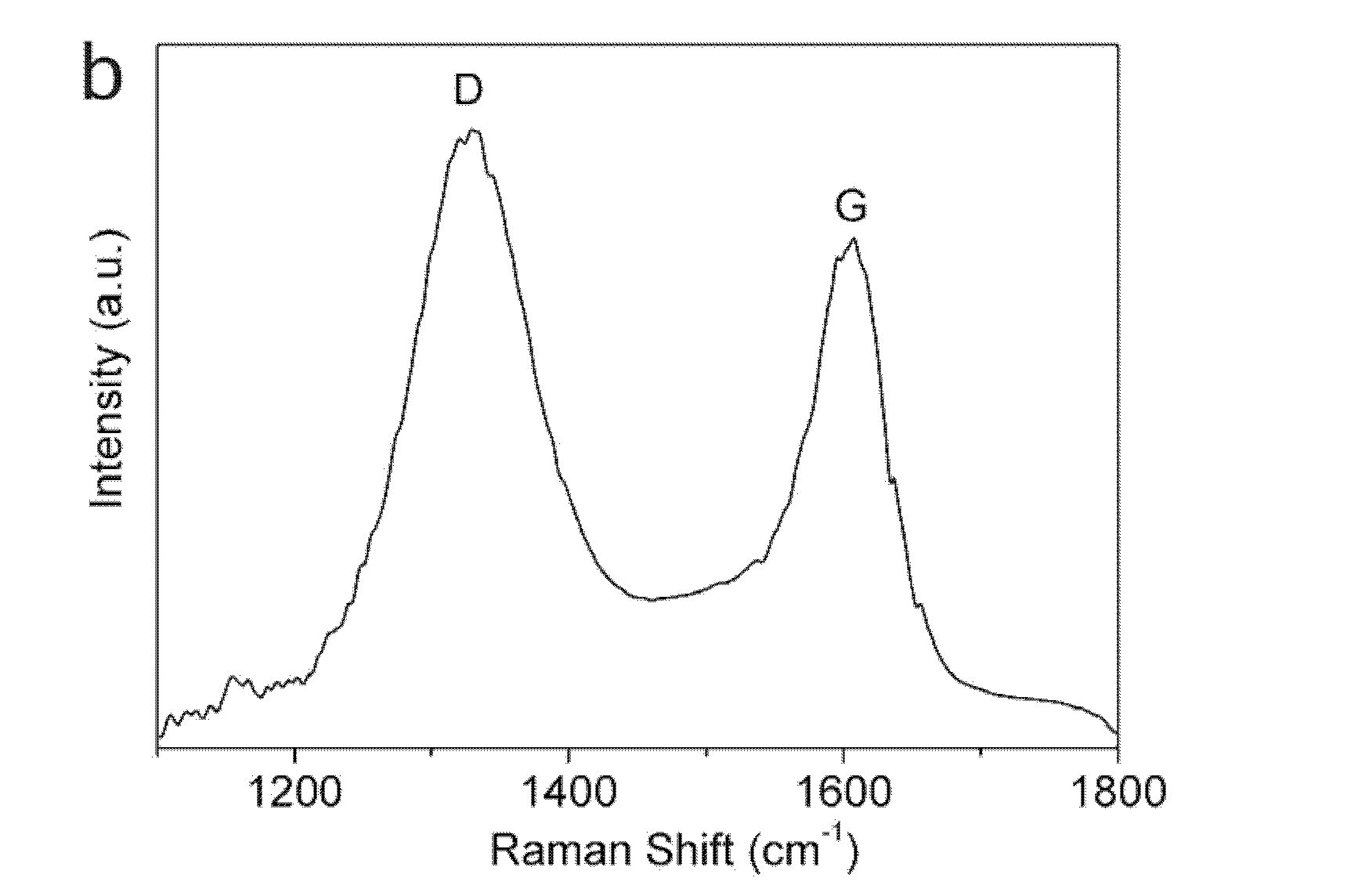

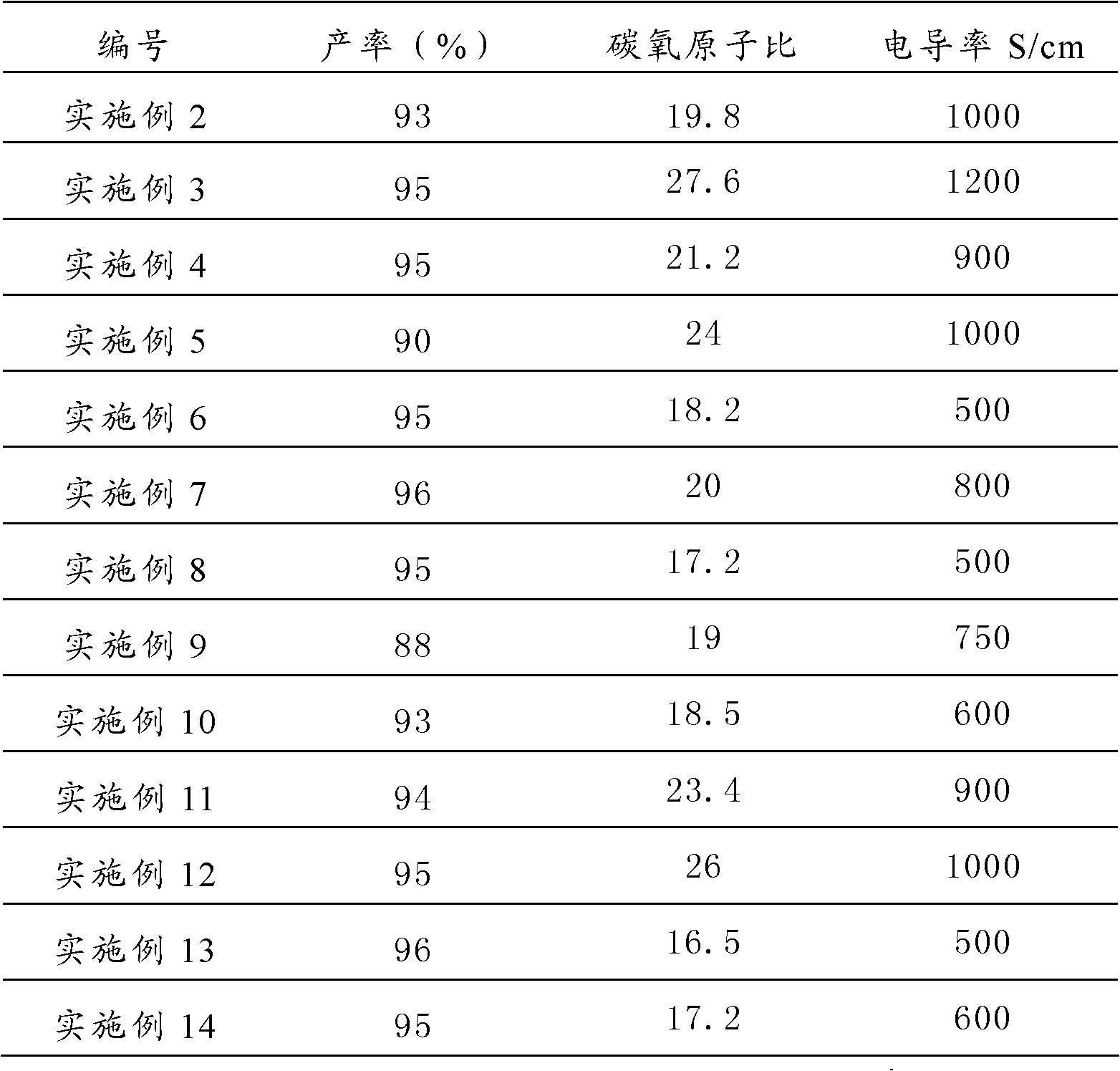

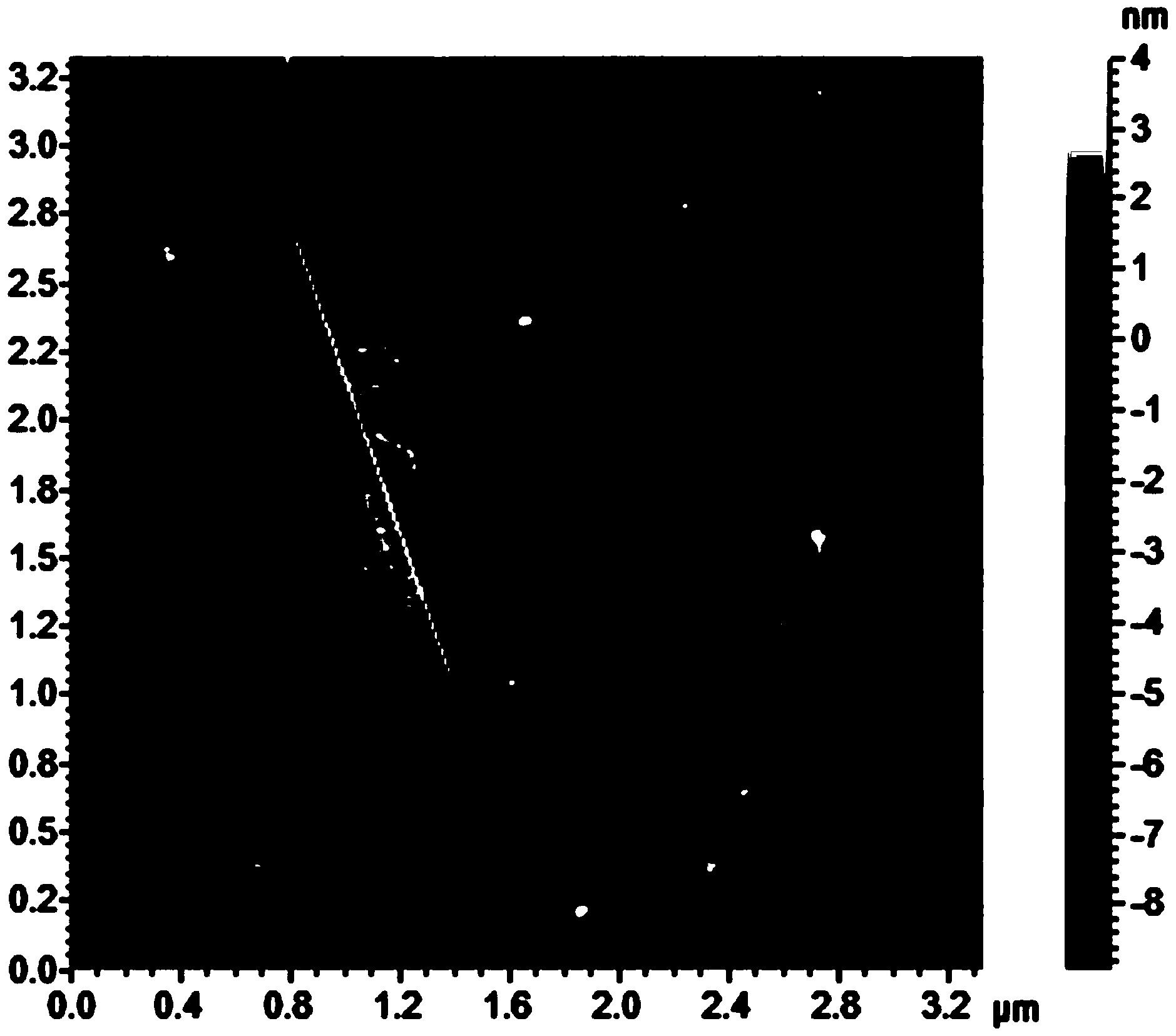

Method for preparing graphene

ActiveCN102757038AQuality improvementIncrease productionGrapheneNanotechnologyGas phaseLithium-ion battery

The invention provides a method for preparing graphene. The method includes that graphite reacts in acid solution with an oxidant to obtain the graphene. Compared with the prior art, the method has the advantages that the graphene prepared by the method is good in quality, yield is greatly increased and productivity is greatly improved as compared with a mechanical exfoliation method, an epitaxial growth method and a chemical vapor deposition method; the quality of the graphene is greatly enhanced, structural defects of the graphene are greatly reduced, and electrical conductivity of the graphene is obviously improved as compared with a solution-phase oxidation reduction method; and the preparation process is simple, conditions are mild, cost is low, and large-scale production is realized easily. In addition, the graphene prepared by the method has an extremely broad prospect in fields of lithium ion batteries, super-capacitors, functional composites, transparent conductive thin films, microelectronic devices and the like.

Owner:NINGBO MORSH TECH

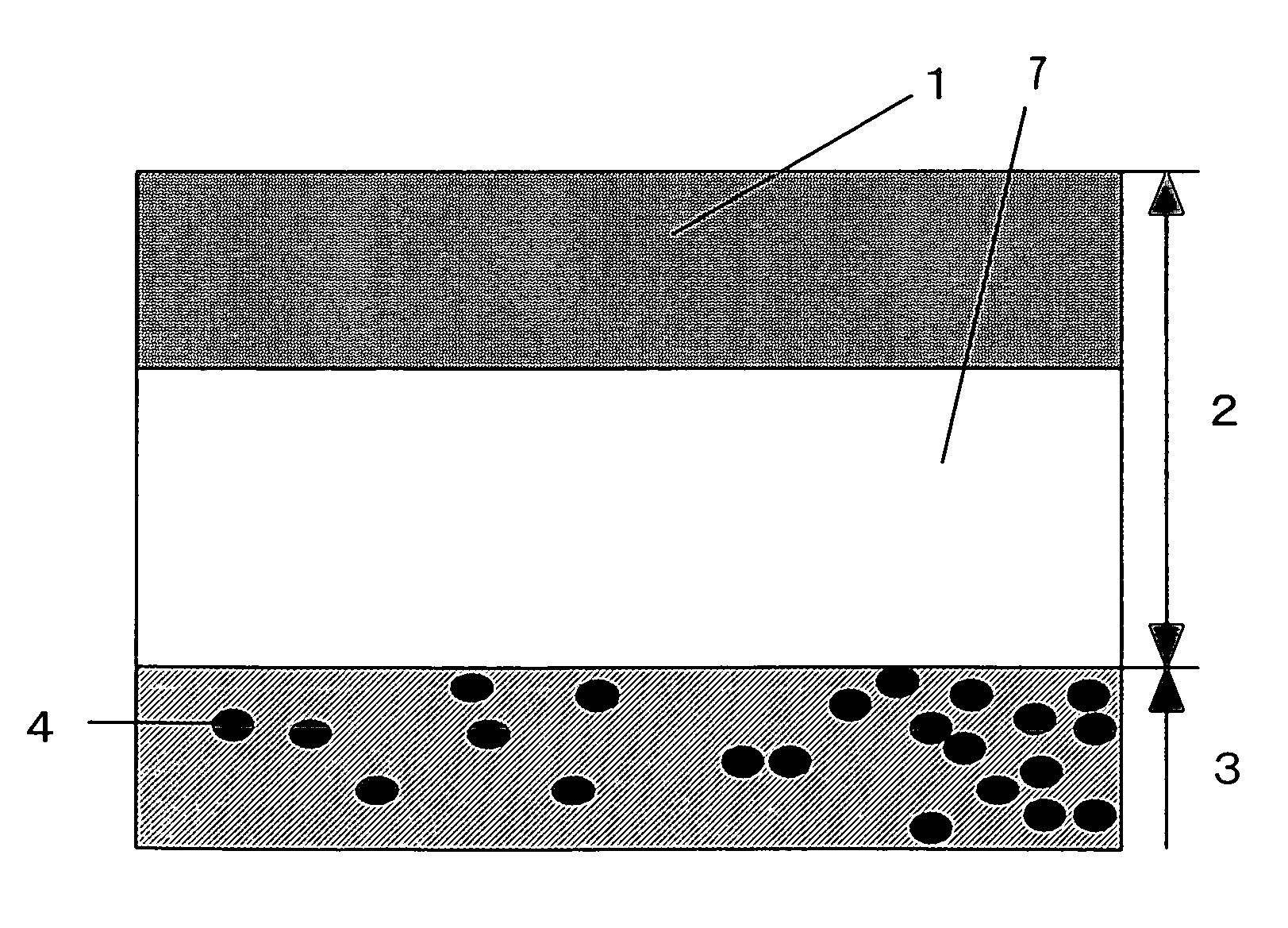

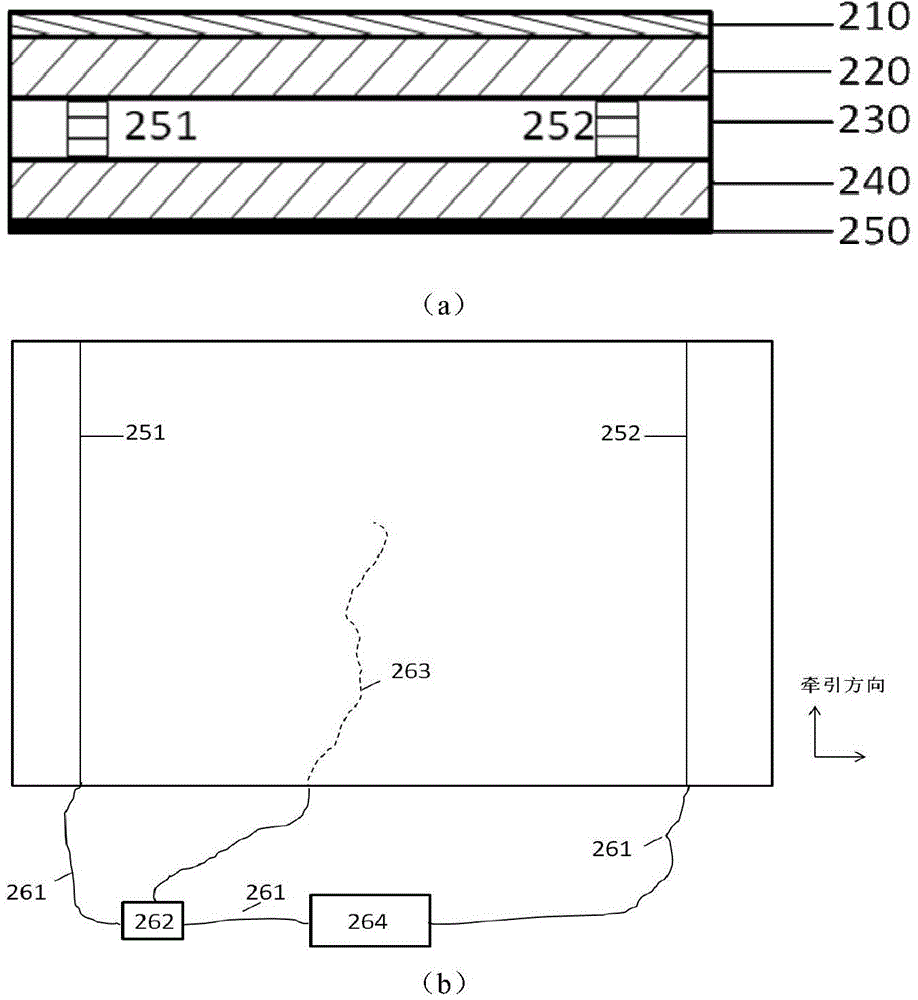

Double-effect composite membrane used for lithium sulphur battery and preparation method thereof

ActiveCN108461694AImprove the utilization rate of active substancesImprove stabilityCell component detailsHigh energyLithium–sulfur battery

The invention provides a double-effect composite membrane used for a lithium sulphur battery and a preparation method thereof. The membrane is composed of a functional composite layer and porous insulating film. The functional composite layer is a composite of conductive carbon base materials, polar materials and a binder, wherein the mass fraction of the conductive carbon base materials and polarmaterials is 5%-90% and 5%-90% respectively. The preparation method comprises the steps that the conductive carbon base materials and the polar materials are used for preparing the functional composite layer, the functional composite layer is loaded on the porous insulating film, and surface loading capacity of the functional composite layer is 0.1-3.0 mg cm-2. The composite membrane in the lithium sulphur battery regulates and controls reaction and deposition behaviors of active substances in different charge-discharge stages and significantly improves the utilization and stability of the active substances of the lithium sulphur battery. Compared with ordinary commercial polymer battery membranes, the composite membrane prolongs the cycle life of the lithium sulphur battery and improvesspecific energy, positive discharge capacity and coulombic efficiency. The method is simple in operation, is beneficial to large-scale preparation, and facilities wide commercial application of the high-energy density lithium sulphur battery.

Owner:TSINGHUA UNIV

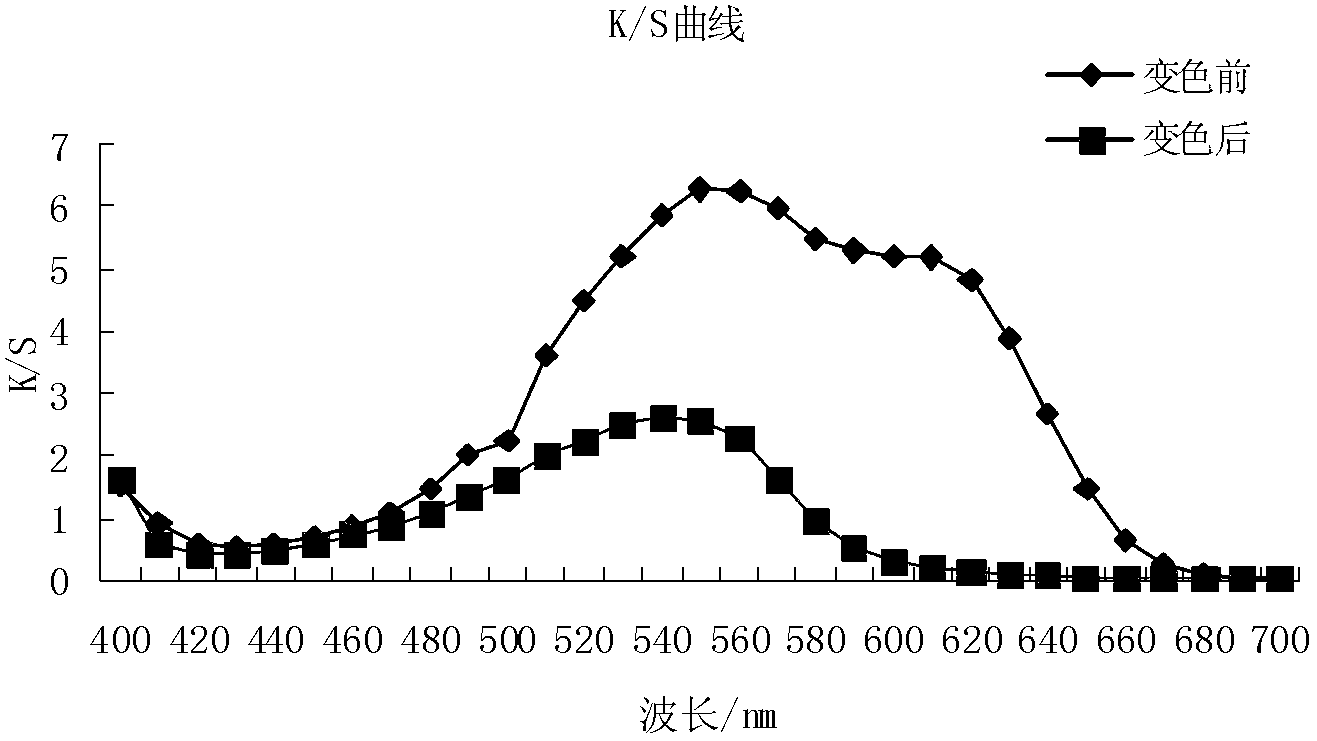

Thermosensitive discoloring energy-storage material and preparation method thereof

InactiveCN102827597AOvercoming the Liquid Leakage Problem of Phase ChangesOvercome the defect of high discoloration temperatureHeat-exchange elementsTenebresent compositionsMelamineStorage material

The invention discloses a thermosensitive discoloring energy-storage material and a preparation method of the thermosensitive discoloring energy-storage material, belonging to the field of functional composite materials. The invention aims at solving the technical problem of forming a thermosensitive discoloring energy-storage microcapsule by using crystal violet lactone as a leuco body, using bisphenol A as a color developing agent, and using the compound of tetradecanol and hexadecanol as a solvent; mixing the leuco body, the color developing agent, the solvent and an appropriate amount of dispersant cationic dyes to form a core material; using a melamine resin formed by formaldehyde-melamine as a wall material; and covering the core material by the wall material. The thermosensitive discoloring energy-storage material disclosed by the invention can not only reversibly discolor along with the change of temperature, but also absorb and dissipate energy; and the thermosensitive discoloring energy-storage material is compact in structure, uniform in particle size and long in service life, and can be widely used in the fields of civil textiles, industry cloths, construction and building materials, printing, anti-faking and the like.

Owner:TIANJIN POLYTECHNIC UNIV

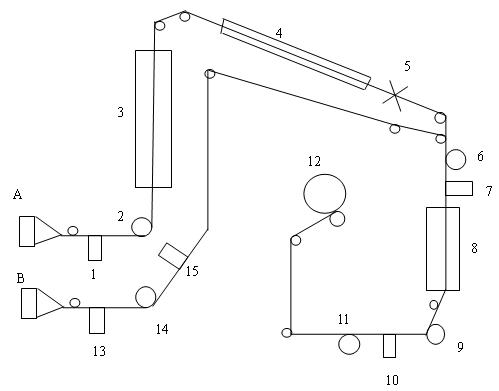

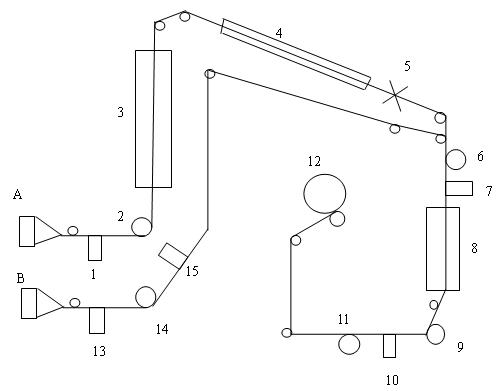

Method for preparing functional composite woolly elastic fiber

The invention relates to a method for preparing functional composite woolly elastic fiber, comprising the following steps: (1) preparing uvioresistant fine-denier polyester pre-oriented yarn (a) with the method of adding uvioresistant masterbatch; (2) carrying out composite spinning with low viscosity polyester (PET) or modified PET and polyethylene terephthalate (PTT) to prepare fully-drawn self-winding composite elastic fiber (b); and (3) stretching and false twisting the uvioresistant fine-denier polyester pre-oriented yarn (a) on a false-twisting texturing machine, converging the uvioresistant fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) in the position of a second roller, combining the uvioresistant the fine-denier polyesterpre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through an interlacing machine, shaping the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through a second heating box, and winding the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) into a composite yarn, contracting the PET / PTT self-winding composite elastic fiber with the elasticity and the contractibility in the core layer of the composite woolly elastic fiber to show the elasticity of the composite yarn, and making the uvioresistant fine-denier polyester pre-oriented yarn to float on the surface layer of the composite yarn to show the uvioresistant performance of the composite yarn. Therefore, the uvioresistant composite woolly elastic fiber is prepared.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

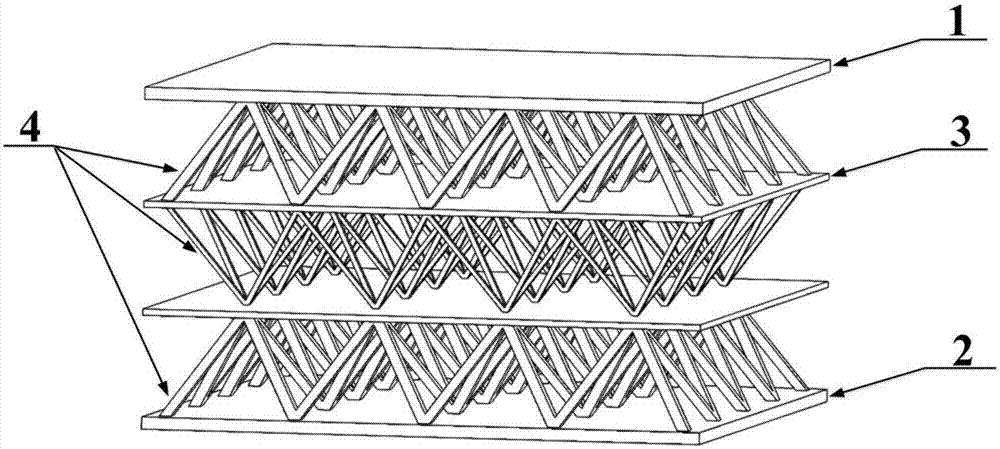

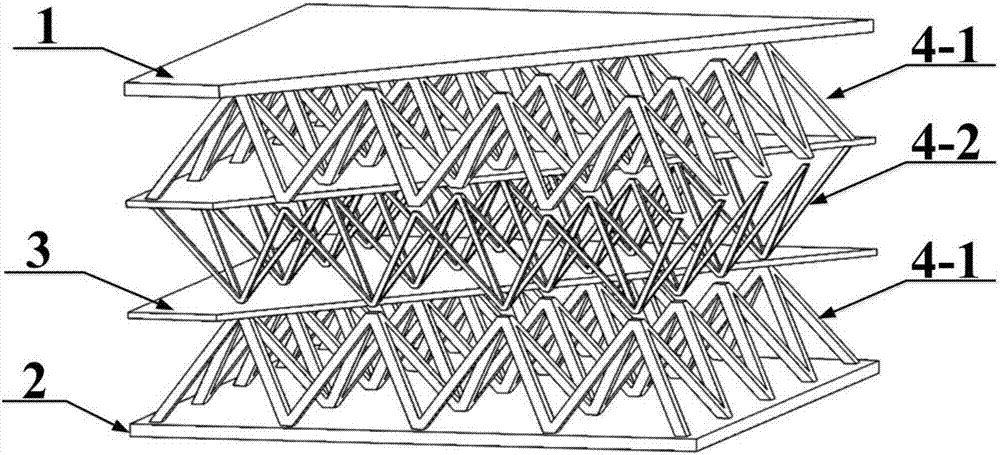

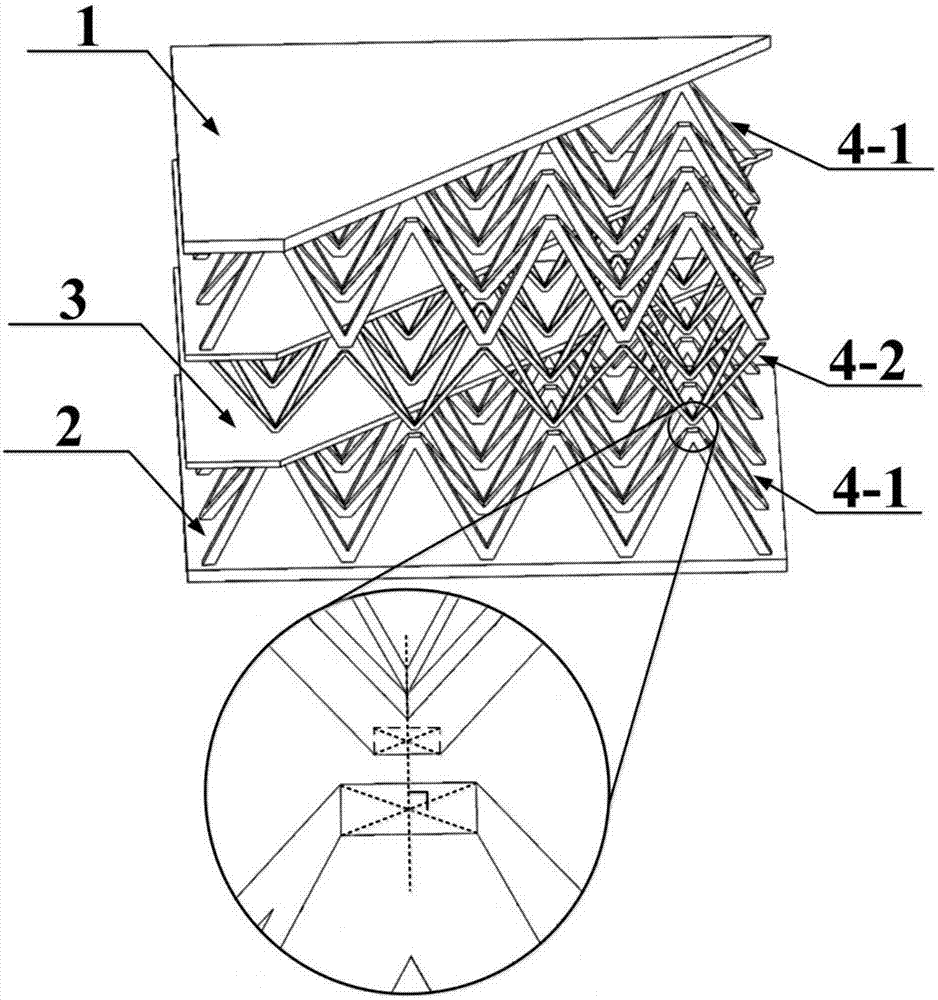

Multilayer gradient lattice sandwich panel and preparation method thereof

The invention discloses a multilayer gradient lattice sandwich panel and a preparation method thereof. Two punched diamond plates with different thicknesses are treated with mold pressing and folding technologies, two pyramid lattice core layers with different core rod part side lengths are prepared, the two core layers are welded with metal panels or partition boards in a circularly interphase distribution form, and the multilayer gradient lattice sandwich panel is obtained. Compared with a non-gradient multilayer lattice structure, the multilayer gradient lattice structure has the advantages that deformation difference among different core layers under the explosion load is greatly reduced, buckling deformation of the core layers are sufficiently utilized, influence of the rear panel by explosion shock is reduced by 50%, and a better protection function is realized. Besides, the characteristic of high porosity of the lattice structure is reserved, and further function composite is facilitated. The sandwich panel has broad application prospects in the fields of safety protection, military and the like by means of the excellent energy adsorption mechanism, low density, high specific strength and specific stiffness and multifunctional composite potentials.

Owner:三亚哈尔滨工程大学南海创新发展基地

Method for mixing preparation of carbon nano tube/polymer composites

InactiveCN101717540AEmbodies structural designabilityImprove effective utilizationThermoplasticCarbon nanotube

The invention provides a method for the mixing preparation of carbon nano tube / polymer composites, relating to the technical field of the preparation of functional polymer materials and apparatus. The preparation process comprises the following steps of: dispersing carbon nano tubes in a solvent in advance to form a stable supernatant solution; pouring in thermoplastic resin particles which are distributed at intervals of a certain particle diameter, and fully and evenly mixing by sonic oscillation so that the surfaces of the polymer particles are fully coated with the carbon nano tubes; drying and removing the solvent to form a mixed system of the carbon nano tubes and the polymer particles, filling in a mold, heating to melt the thermoplastic resin, integrating the melt thermoplastic resin and carbon nano tube networks under the pressure, and cooling and demolding to obtain carbon nano tube / polymer composites. The method has the advantages of simple process, good material structure control and low cost, and can be used for designing and manufacturing functional composites with specific transport network structures by selecting different types of resin substrates and molding process conditions based on operating requirements, thereby having great design freedom.

Owner:SHENYANG JIANZHU UNIVERSITY

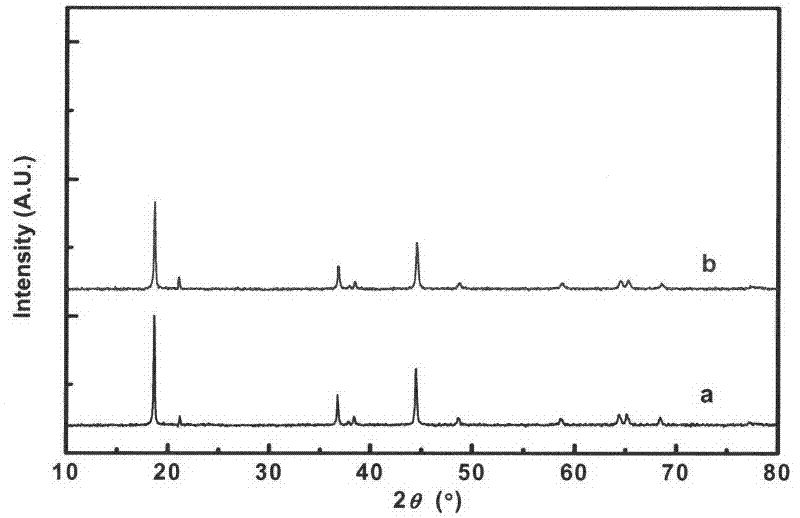

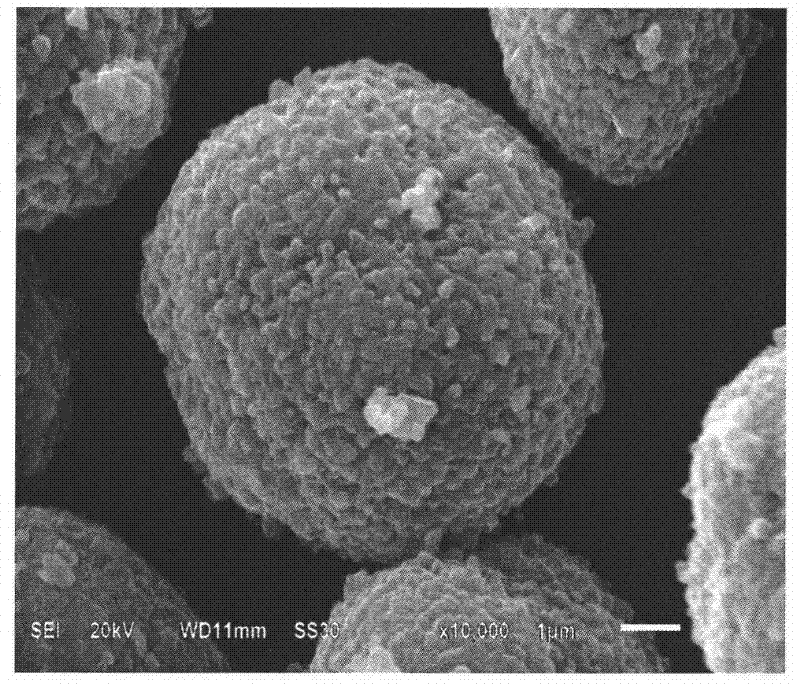

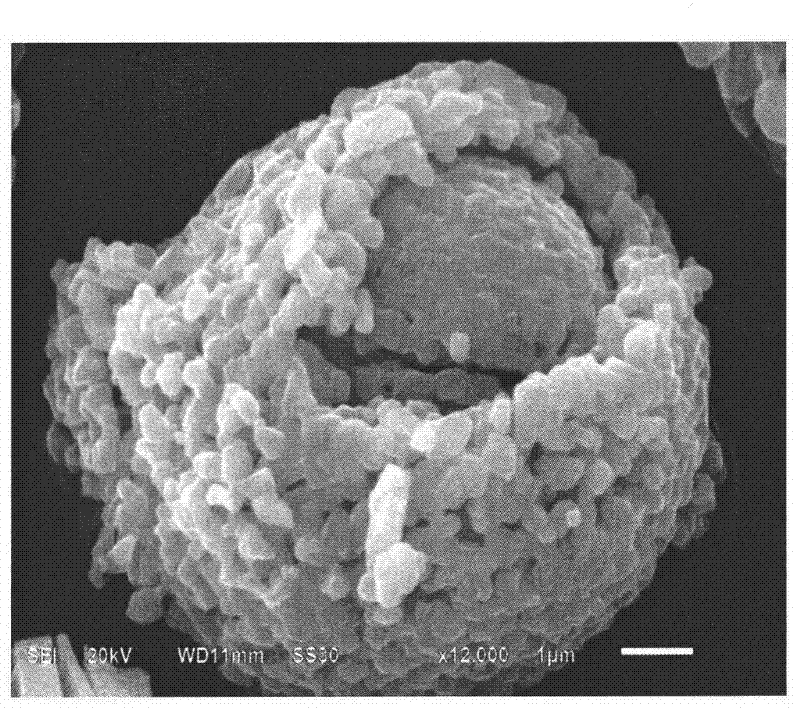

Spherical compound lithium-rich multielement cathode material with core shell structure and preparation method thereof

The invention discloses a preparation method of a spherical compound lithium-rich multielement cathode material with a core shell structure. The cathode material has a general formula of Li1+m[(NixCoyMn1-x-y)1-n(Ni0.25Mn0.75)n]1-mO2. The spherical compound lithium-rich multielement cathode material breaks through traditional idea of cladding or doping to improve material performance, and acquires better integrated performance through material structure design by realizing nuclear casing functional composition and complementation. The material combines advantages of nuclear and casing, has high energy density and good rate capability and excellent cyclical stability, and is simply prepared, at low cost and easy for industrialized production; therefore, the material has promising development prospect.

Owner:XIANGTAN UNIV

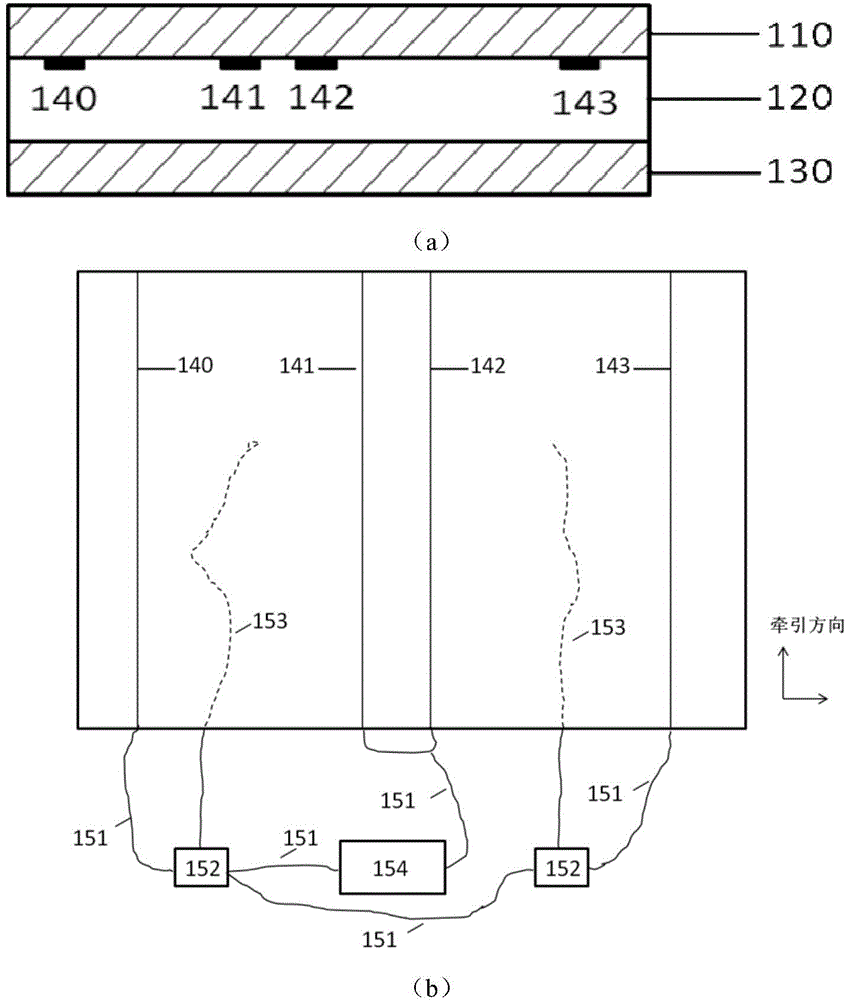

Electrically-induced-heating functional composite water-proof material and preparation method thereof

The invention discloses an electrically-induced-heating functional composite water-proof material and a preparation method thereof. The electrically-induced-heating functional composite water-proof material comprises two water-proof substrate layers and an electric heating layer positioned between the water-proof substrate layers, wherein the electric heating layer is made of an electric heating material; at least two intercepting bars are paved in the electric heating layer or between the electric heating layer and the water-proof substrate layers at certain distances. The preparation method of the electrically-induced-heating functional composite water-proof material comprises the following steps: fixing the intercepting bars on the surface or inside of the electric heating layer; compounding the water-proof substrate with the upper and lower surfaces of the electric heating layer in sequence or simultaneously. The electrically-induced-heating functional composite water-proof material has the same water-proofing performance as the conventional water-proof material, and has a heating function; the voltage is adjustable between 1.5V and 220V, and the surface temperature is adjustable between 5 DEG C and 160 DEG C; the heating time is 5-600 seconds before a set temperature is reached; in a heating process, far infrared waves in wave bands of 4-15 micrometers are released in the heating process, and the releasing equivalent of the far infrared waves is up to 50-95 percent.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

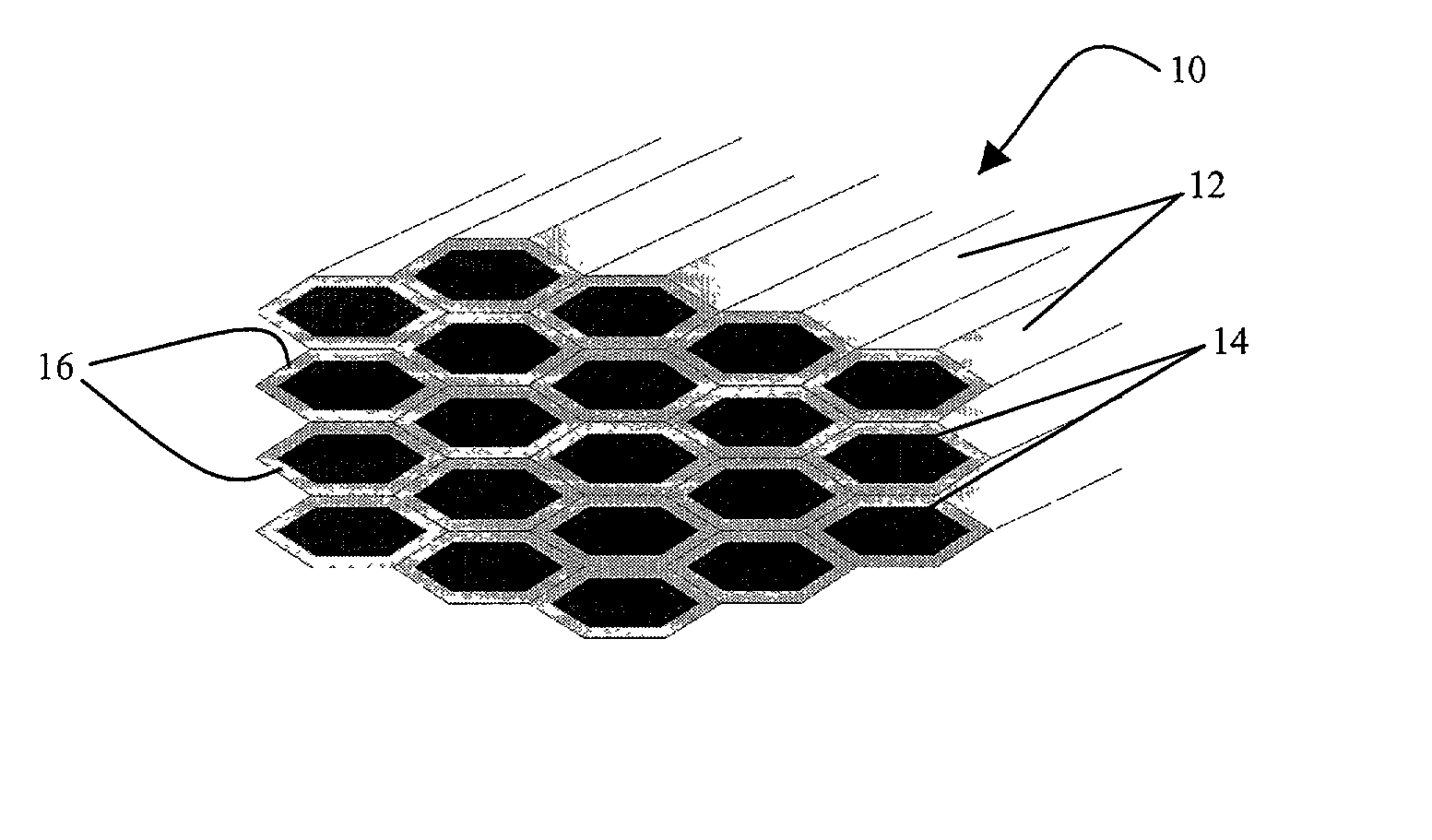

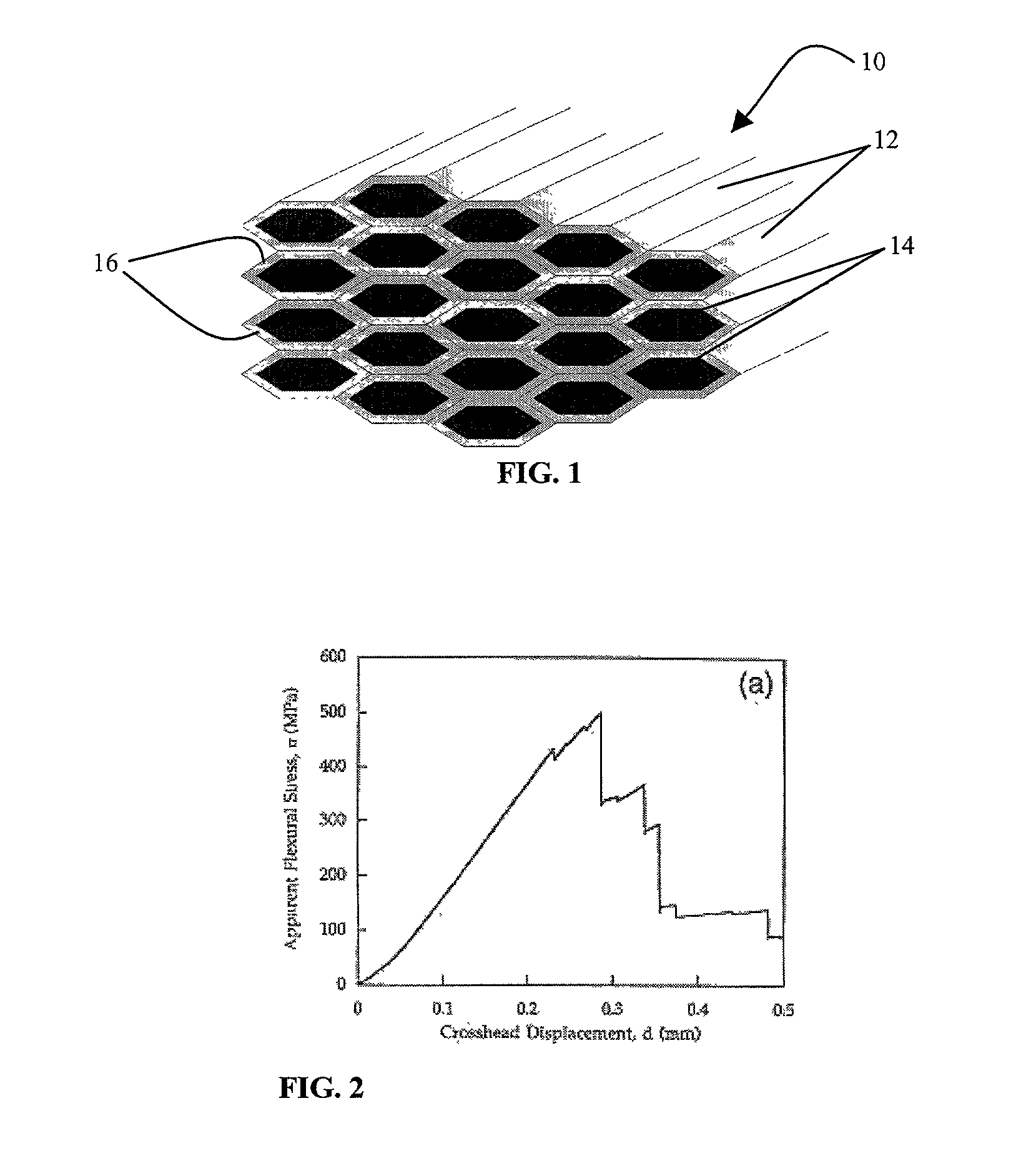

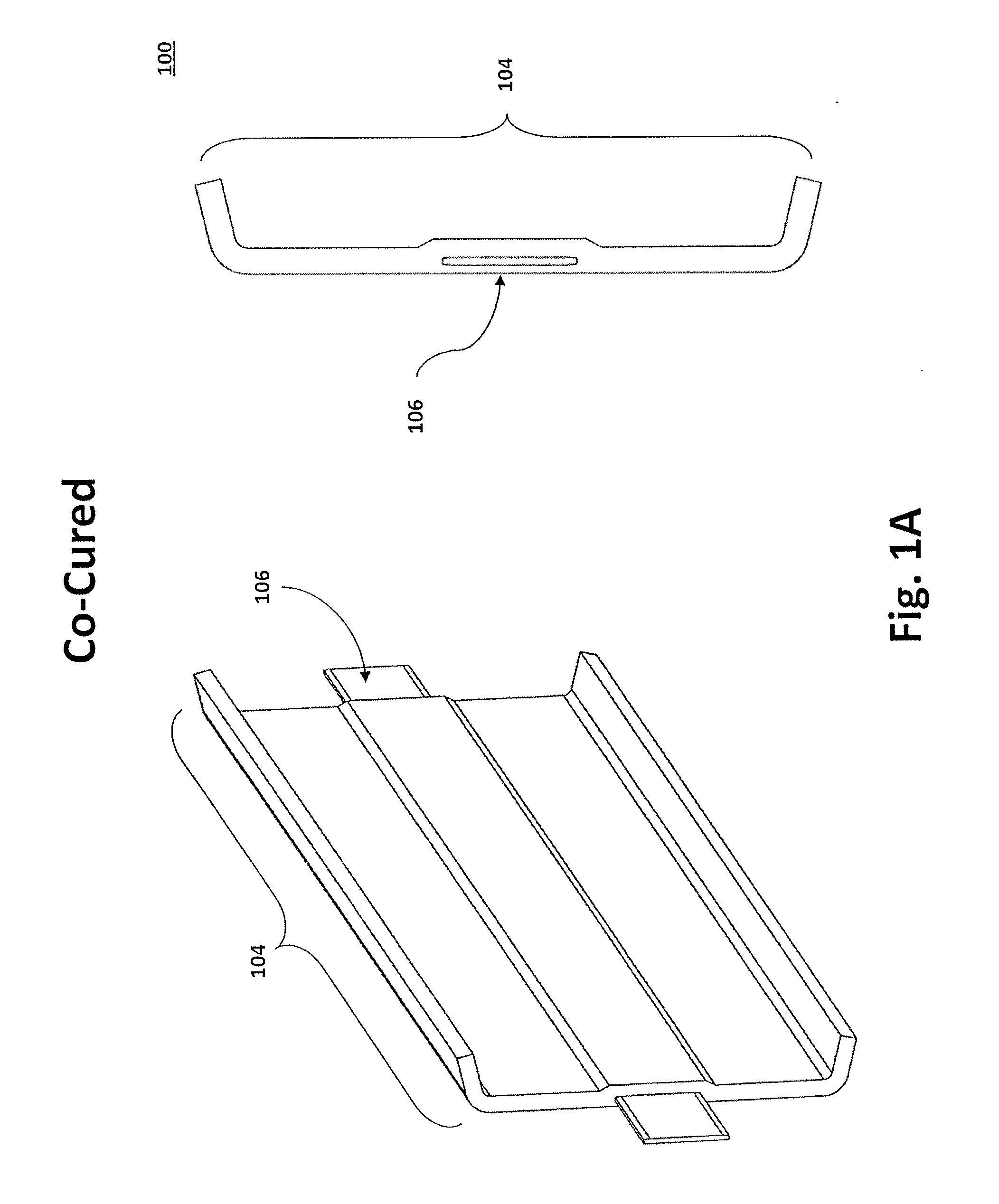

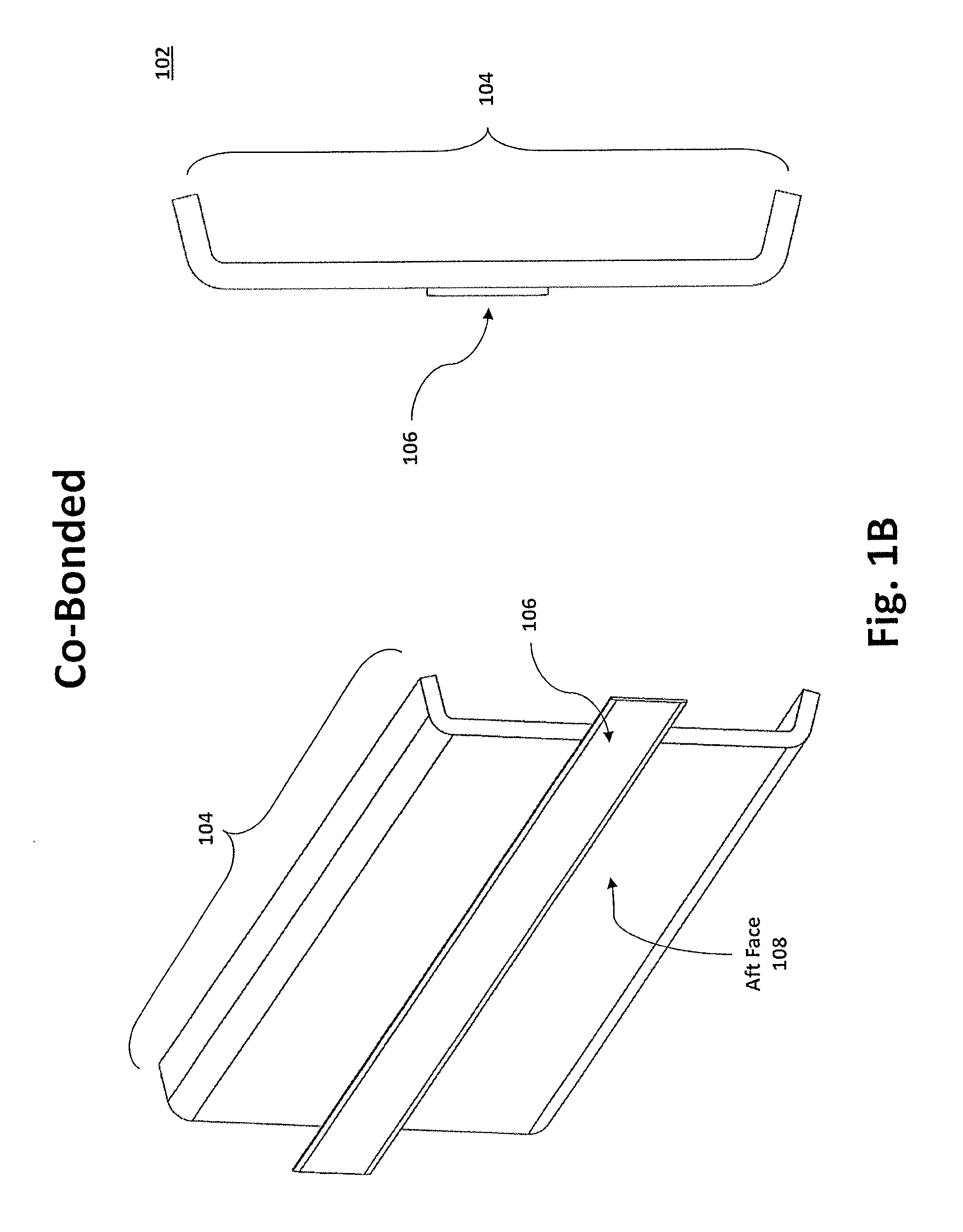

Multi-functional composite structures

InactiveUS20020127384A1Enhanced structural benefitEasy polingFibreboardPiezoelectric/electrostrictive device material selectionDiscrete functionsFunctional composite

Fibrous monolith processing techniques to fabricate multifunctional structures capable of performing more than one discrete function such as structures capable of bearing structural loads and mechanical stresses in service and also capable of performing at least one additional non-structural function.

Owner:ADVANCED CERAMICS

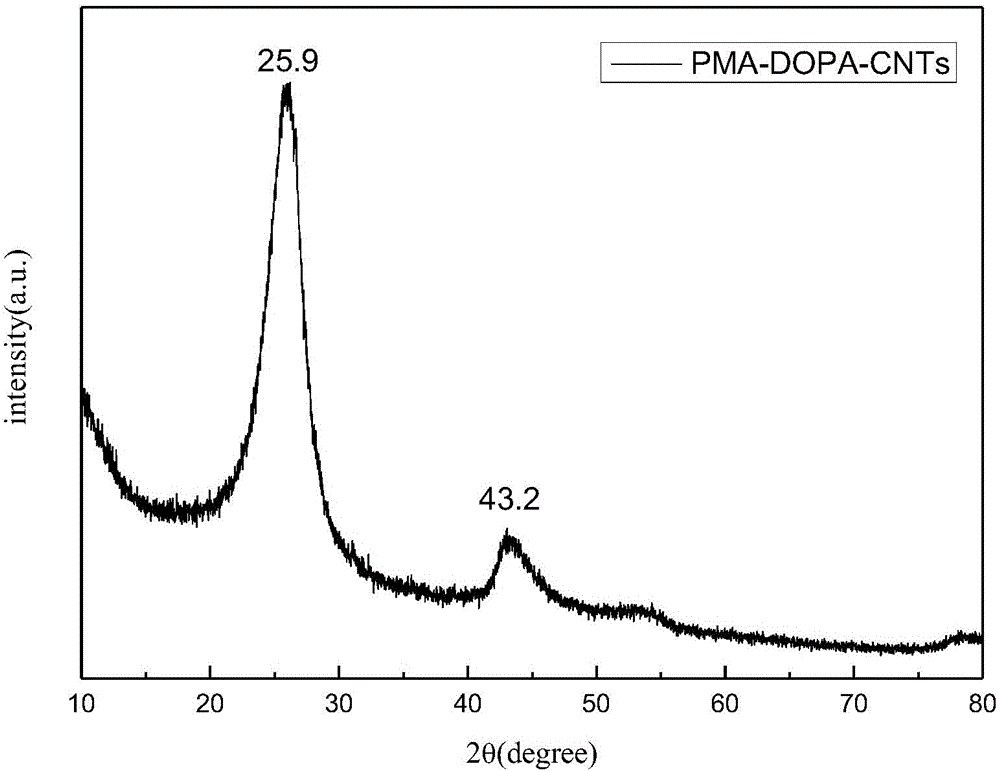

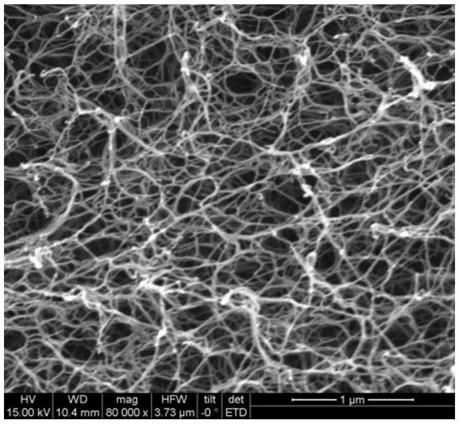

Preparation method for heteropoly acid functional composite material adopting dopamine modified carbon nano tube as carrier

ActiveCN104477881ADoes not damage the structureNon-destructive propertiesMaterial nanotechnologyCarbon nanotubeFunctional composite

The invention relates to the technical field of nanometer materials, and particularly discloses a preparation method for heteropoly acid functional composite material adopting a dopamine modified carbon nano tube as a carrier. The preparation method comprises the following steps: first, utilizing dopamine to generate oxypolymerization reaction in a Tris-HC1 buffer solution at the room temperature to modify the surface of a carbon nano tube to obtain a poly-dopamine modified carbon nano tube; then adopting an impregnation method to load heteropoly acid on the surface of the poly-dopamine modified carbon nano tube; reacting for certain time so as to obtain the heteropoly acid loading dopamine modified carbon nano tube composite material finally. The preparation method is conducive to realizing uniform and directional loading of heteropoly acid on one hand, improves the utilization ratio and the application range of the carbon nano tube on the other hand, is simple in steps and low in cost, can be reused, and has potential application prospect in the fields of fuel cells, sensors, electric coloration devices and the like.

Owner:HUBEI ENG UNIV

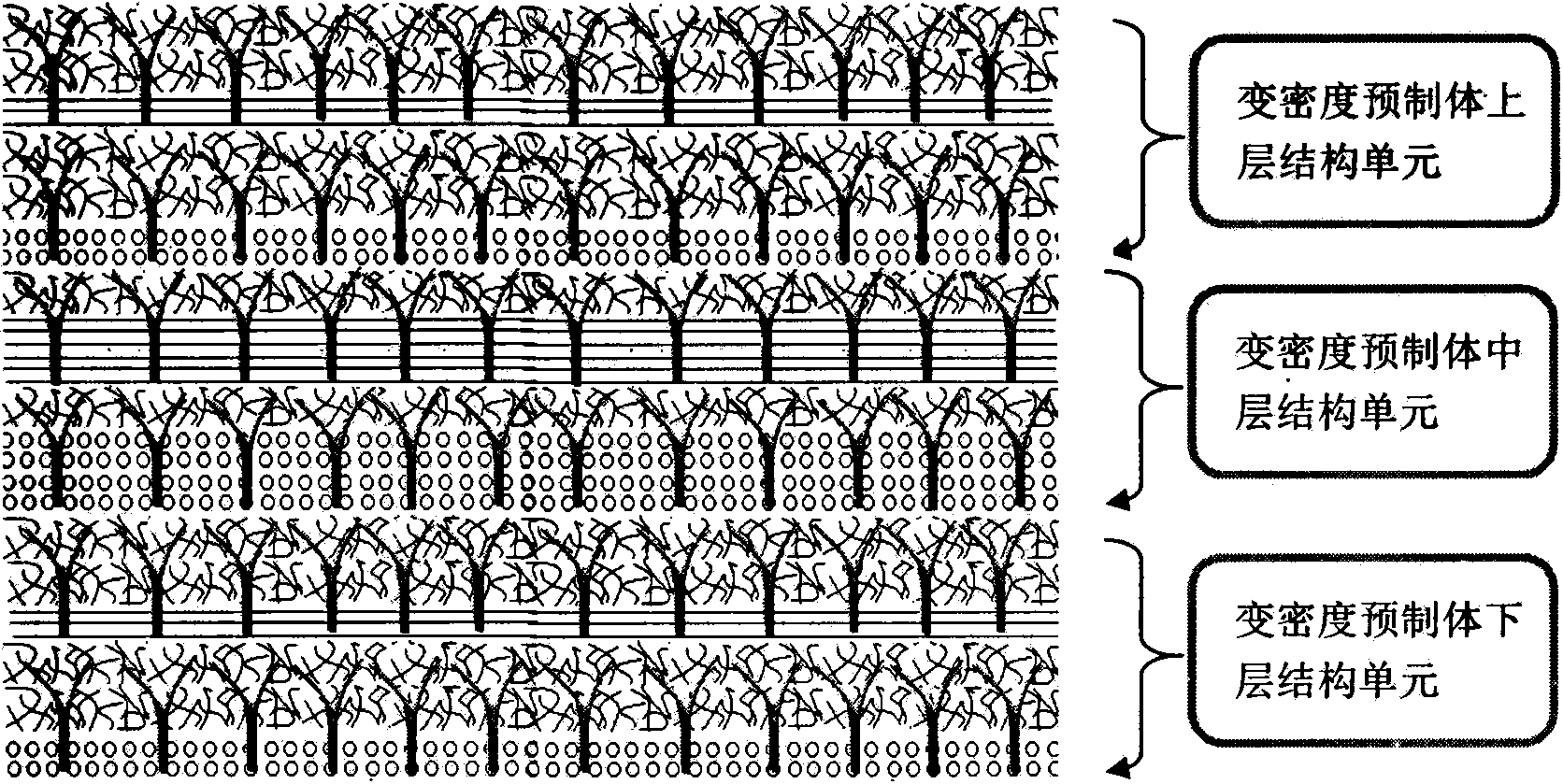

Carbon-fiber needled preformed body with gradiently-changed body density

The invention discloses a carbon-fiber needled preformed body with gradiently-changed body density. The preformed body is formed by continuously needling three layers of carbon-fiber needled preformed bodies in a multi-angle and layer-by-layer crossed manner, wherein the density of the preformed body at a middle layer is larger than the densities of the preformed bodies at an upper layer and a lower layer, and each preformed body is formed by compositing a layer of weftless carbon cloth paved in a 0-degree / 90-degree angle with a layer of mesh tire and continuously needling in the layer-by-layer manner. The preformed body has the advantages of short preparation cycle and low production cost in carbon / carbon sedimentation technological process, and a carbon / carbon composite material produced from the preformed body has excellent performances of wear resistance, high temperature resistance, low expansion coefficient, high heat conductivity, good heat shock resistance, light weight and the like. The high-performance carbon-fiber needled preformed body is a novel functional composite structure product and has wide application prospects in the fields of aviation, space flight, civil construction, military and the like due to the specific structure and advanced production process.

Owner:JIANGNAN UNIV

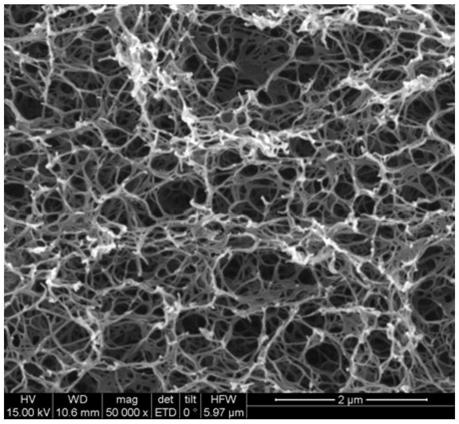

Kevlar aerogel film, and preparation method and application thereof

The invention discloses a Kevlar aerogel film, and a preparation method and application thereof. The Kevlar aerogel film has a communicating three-dimensional network-like porous structure formed by mutual overlapping of Kevlar nanofibers. The preparation method comprises: dissolving Kevlar fibers to form a Kevlar nanofiber sol; applying the Kevlar nanofiber sol to a substrate, and then transferring the substrate to a coagulation bath, and performing a sol-gel process and a subsequent solvent replacement process to form a Kevlar gel film; and finally, conducting drying to obtain the Kevlar aerogel film. The Kevlar aerogel film of the invention has high specific surface area and porosity, good flexibility, thermal stability and chemical stability, and the preparation process is simple, andis easy for continuous large-scale production. The Kevlar aerogel film can be directly used as a dielectric material, a sound insulation material, a heat insulation material, a filter film material, etc., and can also be used as a substrate of a flexible functional composite material.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

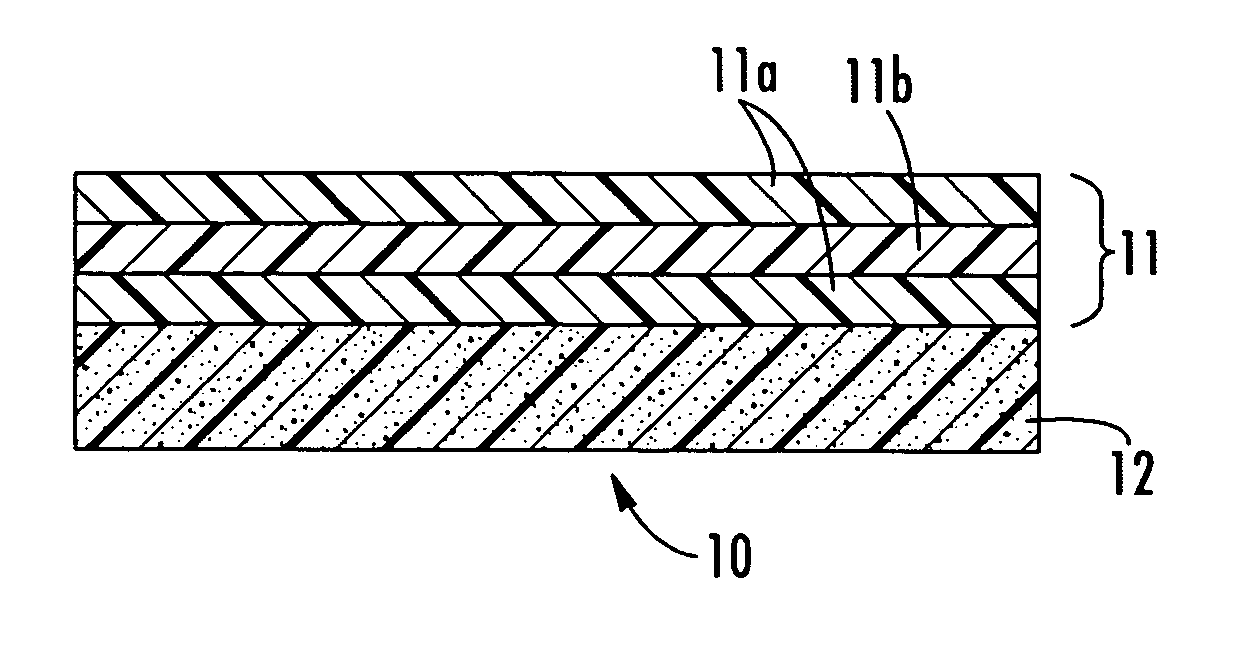

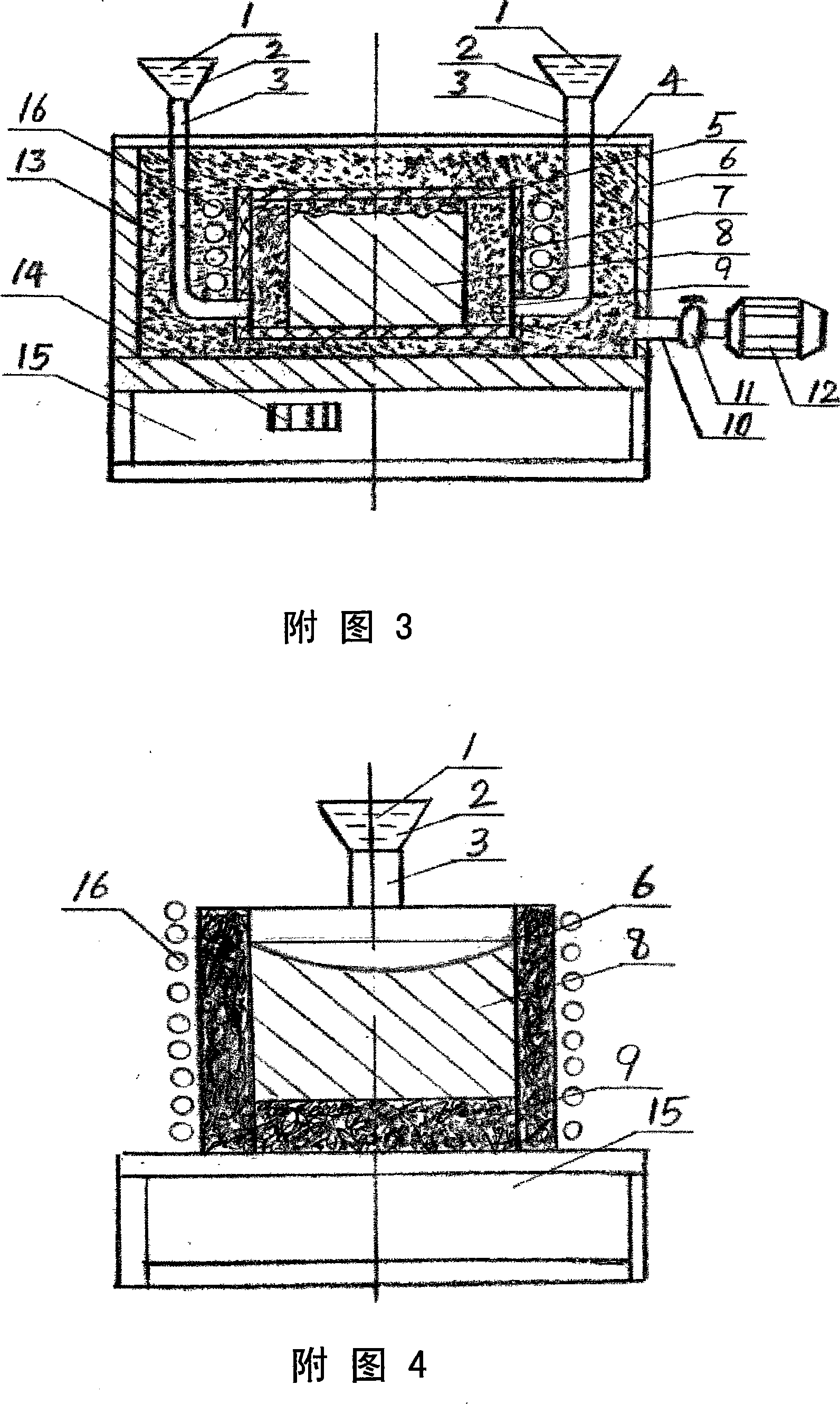

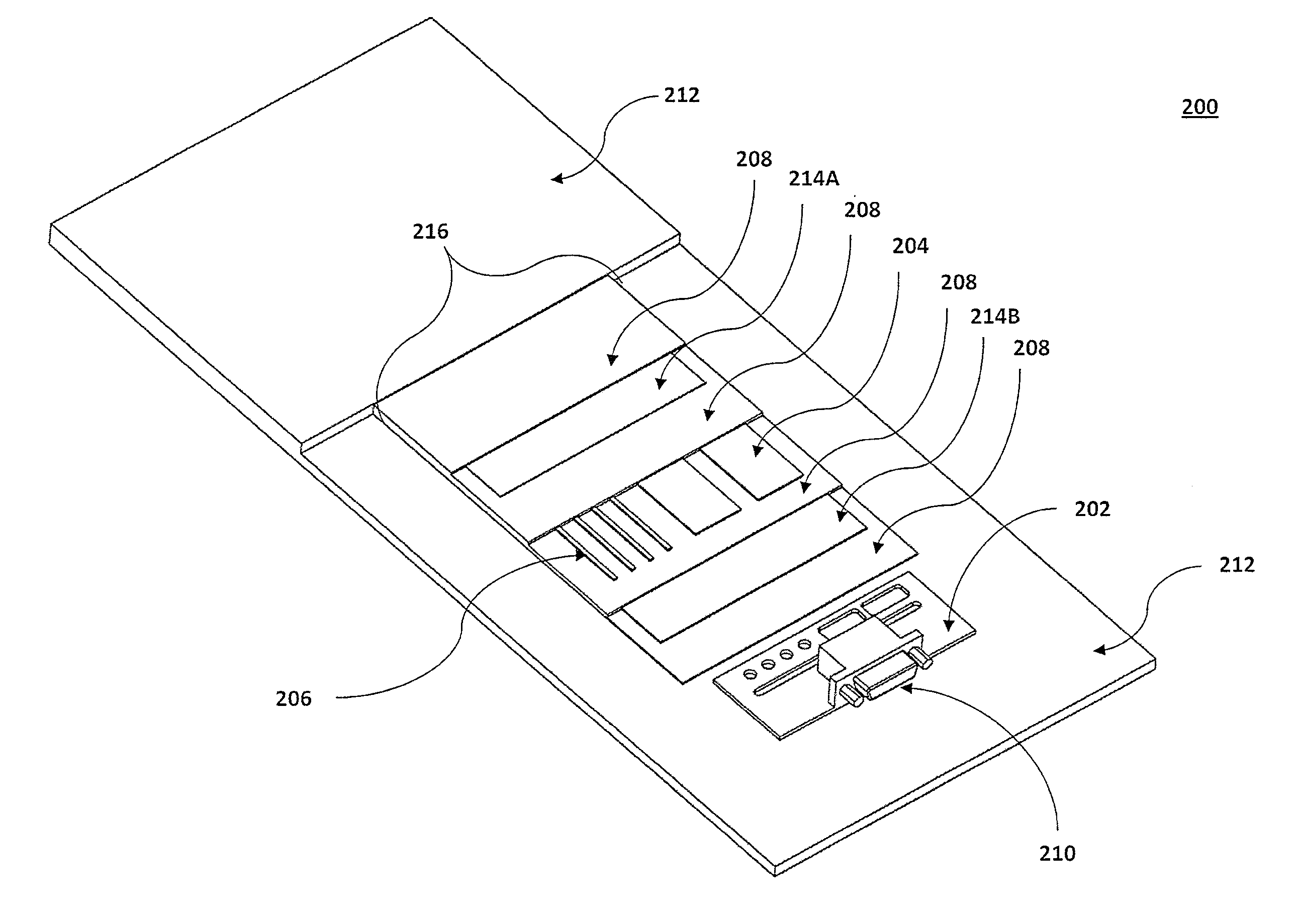

Multi-functional composite structures

ActiveUS20150344138A1Easy to implementCurrent distributionHeater elementsEnergy efficient board measuresElectrical conductorFunctional composite

A multi-functional composite system, the multi-functional composite system comprising a core, a plurality of structural composite fiber layers, a matrix material, a composite conductor assembly, the composite conductor assembly having one or more conductors disposed between two or more insulating layers, and an electric power source electronically coupled with said composite conductor assembly, the electric power source is configured to pass electric current through at least one of said one or more conductors.

Owner:AURORA FLIGHT SCI CORP

Soil-acidification-resistant organic fertilizer additive and preparation method thereof

ActiveCN102627514AEffective nitrificationRaise pH by 1-2 unitsFertilizer mixturesEcological environmentFood chain

The invention relates to a soil-acidification-resistant organic fertilizer additive and a preparation method thereof. The additive is prepared through the steps of mainly using zeolite powder, low-grade calcium magnesium phosphate fertilizer, waste resource shells, calcium silicon powder and humic acid powder as raw materials, mixing, fermenting, curing, drying, crushing and scientifically combining and mixing with spray-dried embedded functional composite microbial agent microcapsules. After organic fertilizers added with the additive are applied into acid / acidified soil, the physical fertility, the biological fertility and the chemical fertility of the soil can be improved and the acid resistance of the soil is improved. The additive and the fertilizer with the additive are safe, effective and highly functional. The application of the additive removes the threat of acid / acidified soil to the agricultural production, the ecological environment and the human health from the angle of nutritionists of a food chain.

Owner:徐州市芭田生态有限公司

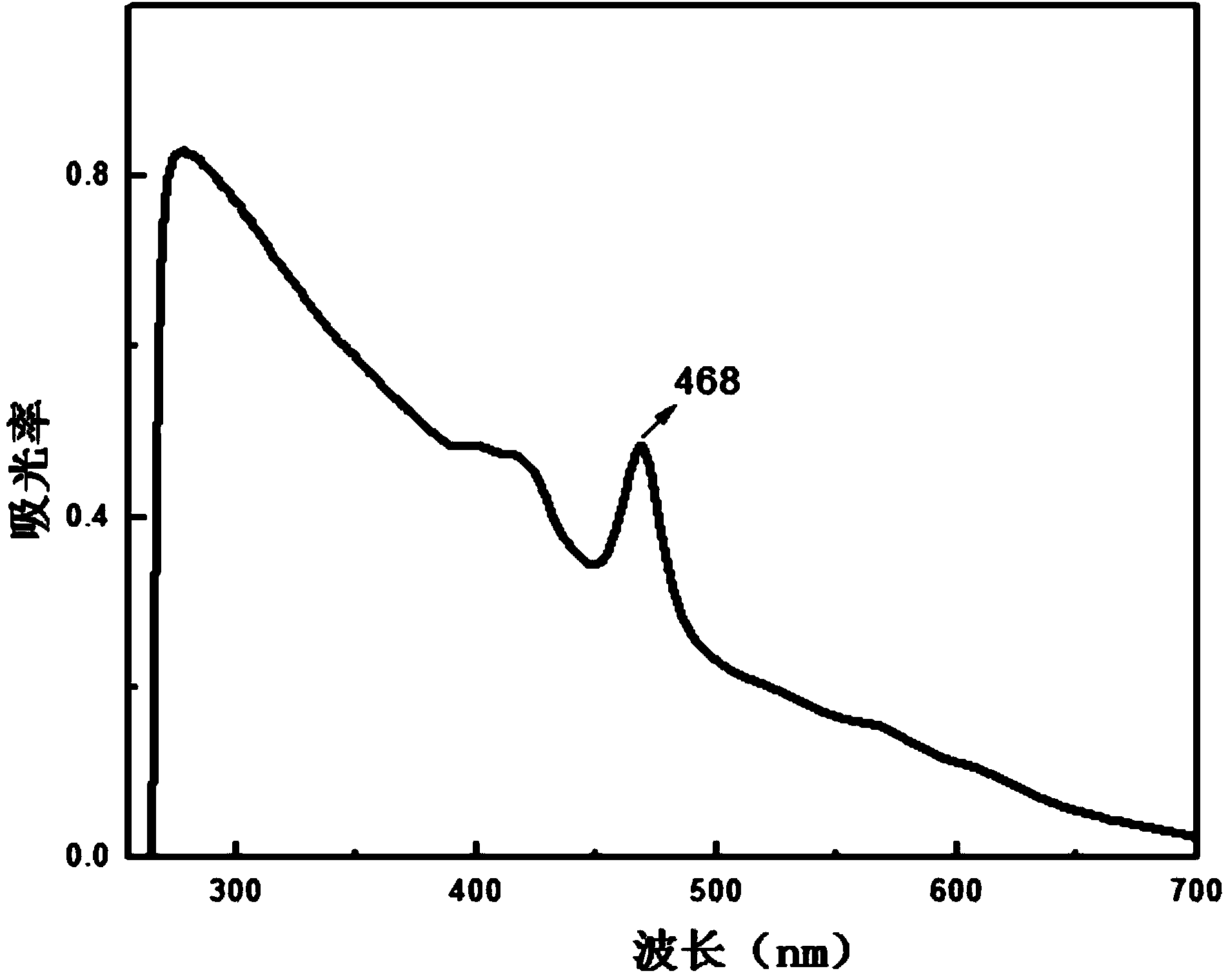

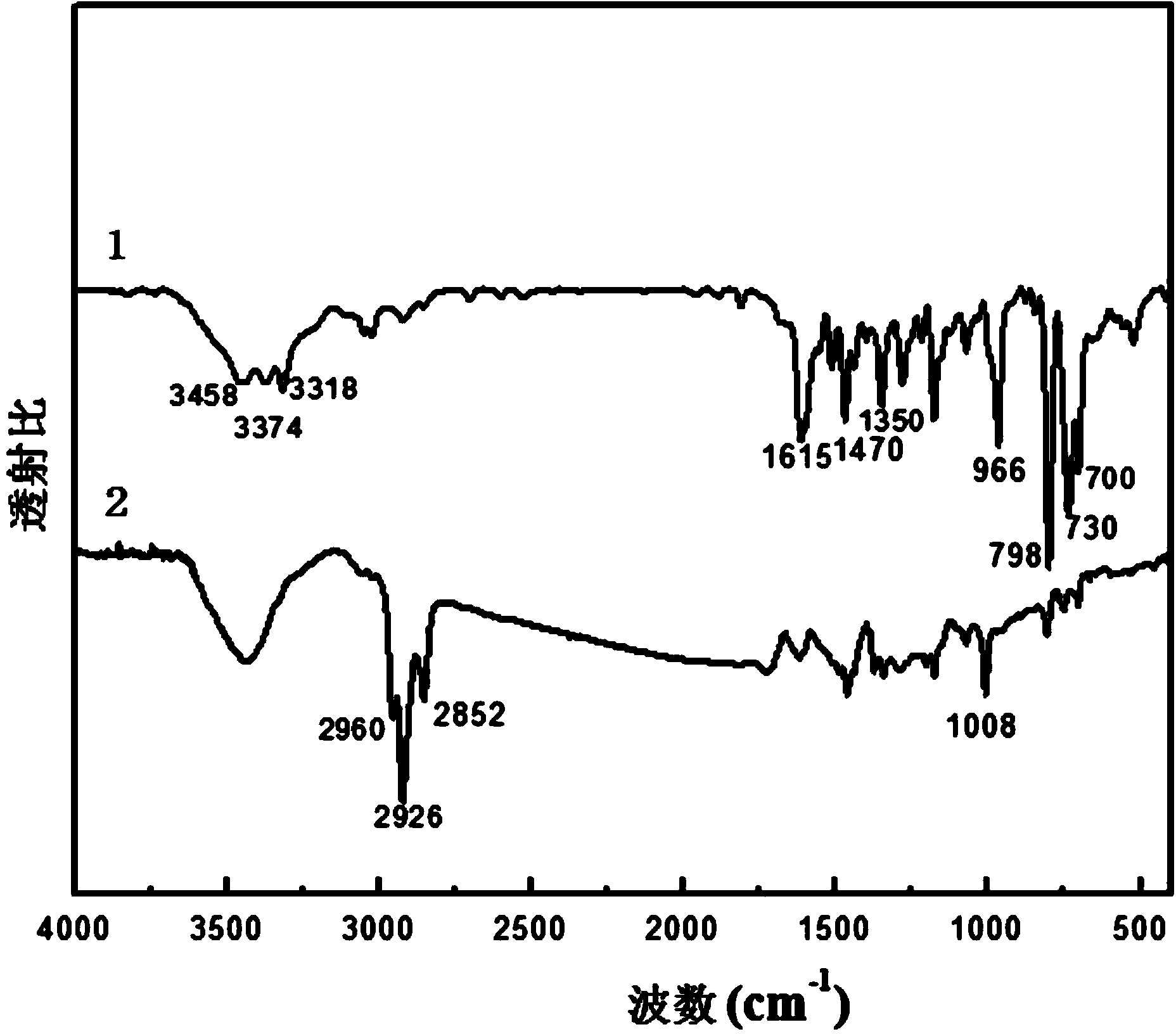

Manufacturing method of graphene-porphyrin modified electrode and application of electrode

InactiveCN103852505ASensitive detectionStable detectionMaterial electrochemical variablesManganese porphyrinCoordination complex

The invention relates to a manufacturing method of a graphene-porphyrin modified electrode and application of the electrode, aiming to solve the problems of complex operation, long time and relatively high price in the conventional method for detecting the content of ascorbic acid in a living body. The method comprises the following steps: I, preparing pre-oxidized graphene; II, preparing a graphene oxide solid; III, preparing acyl-chlorinated graphene; IV, preparing tetraphenylporphyrin; V, preparing 5-(4-nitro)-10,15,20-triphenyl porphyrin; VI, preparing 5-(4-amino)phenyl-10,15-20-triphenyl porphyrin; VII, preparing a pure manganese porphyrin coordination compound; VIII, preparing a functional composite material of graphene oxide and porphyrin; IX, modifying a glassy carbon electrode. The modified electrode has excellent interference resistance, stability and reproducibility, and can be taken as a biosensor for detecting ascorbic acid in practical samples.

Owner:HARBIN INST OF TECH

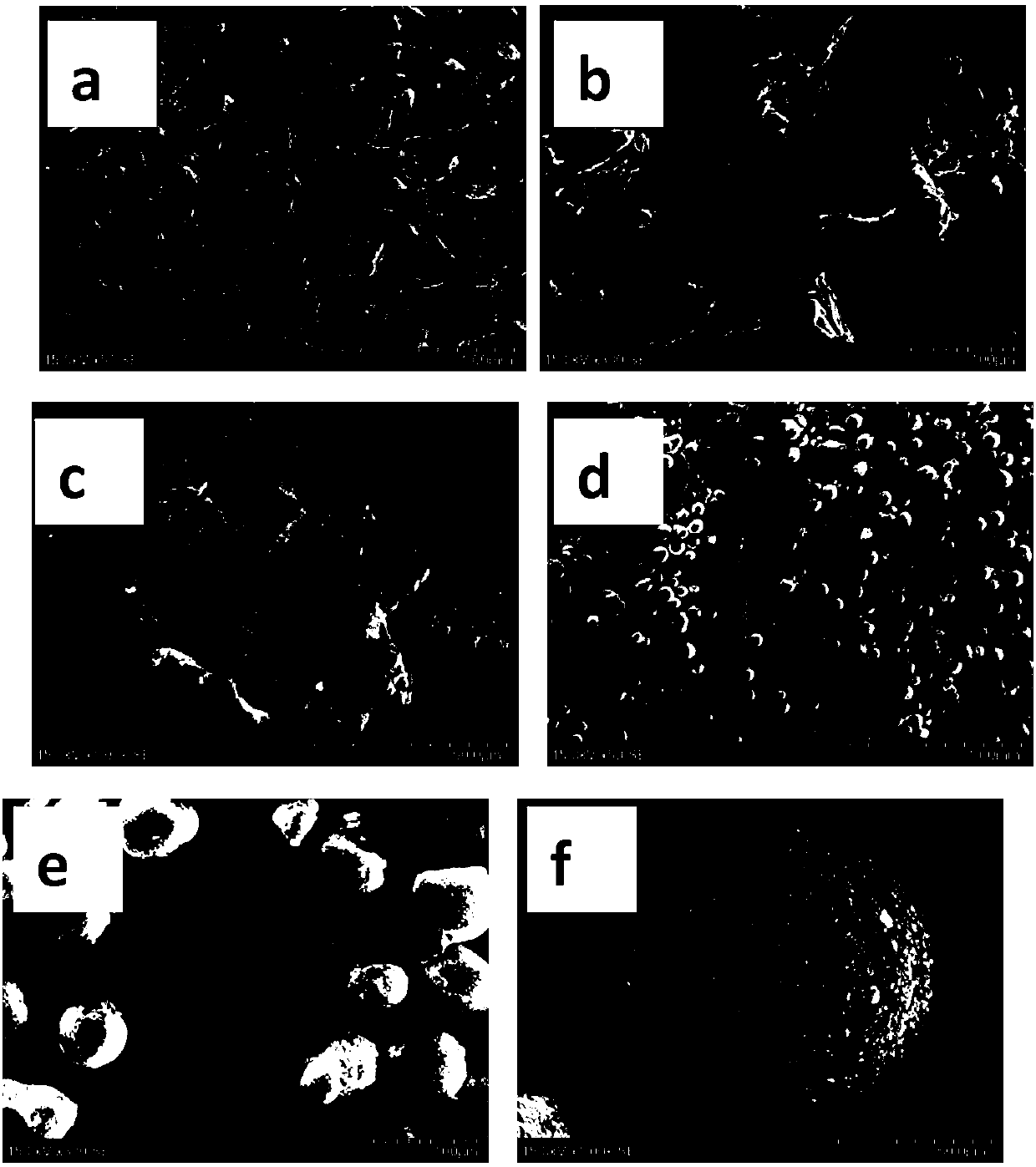

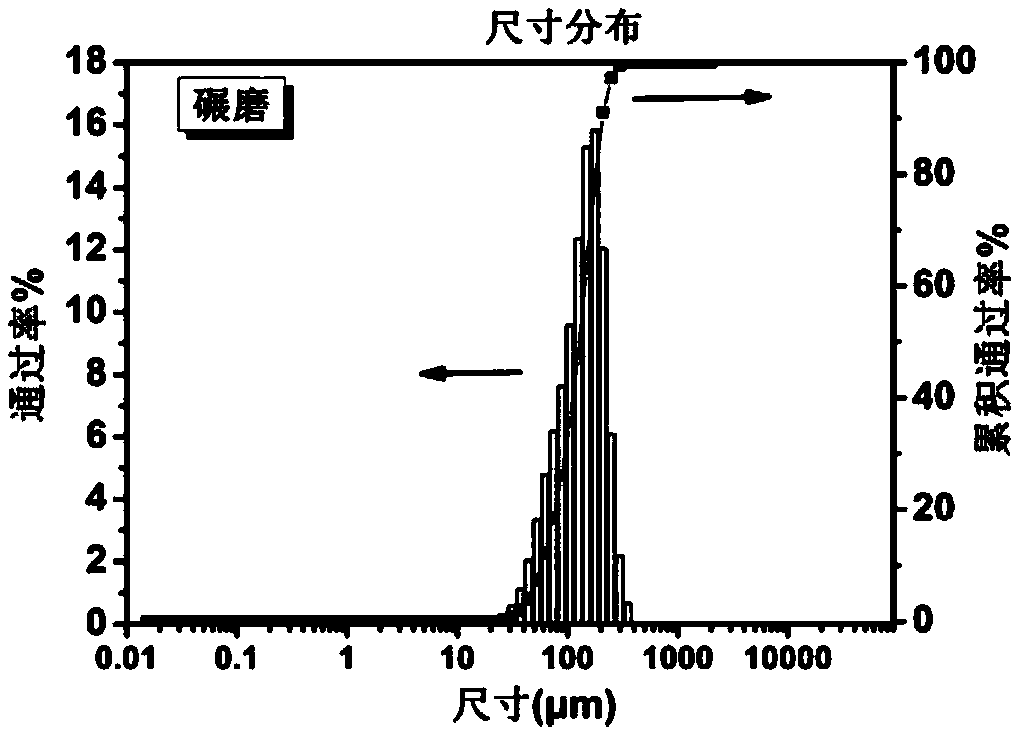

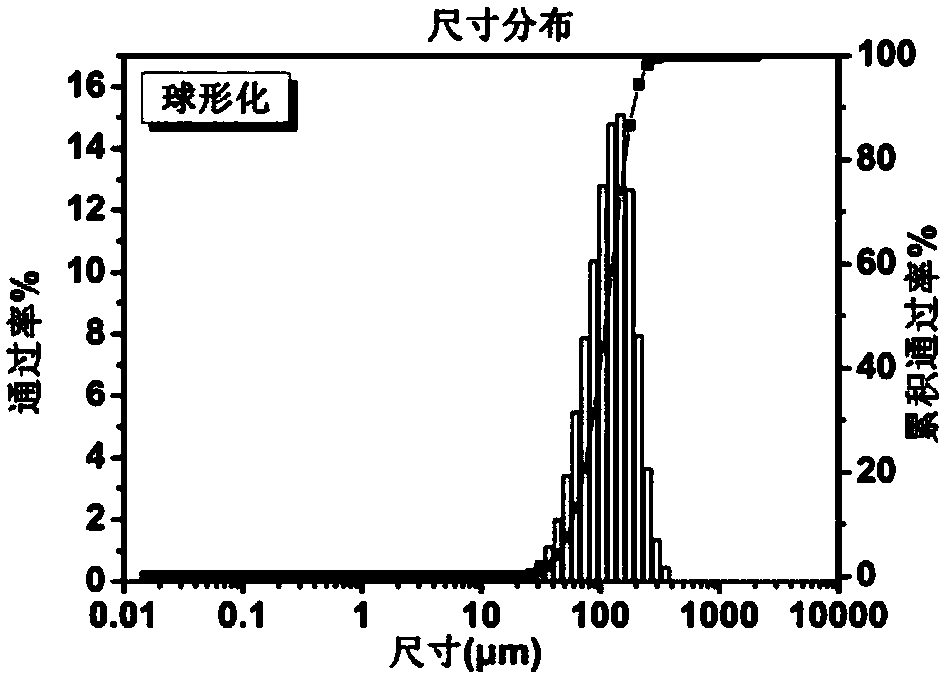

Polymer-based micron/nano functional composite spherical powder and preparing method thereof

ActiveCN107825621AStrong shear stressMiniaturizationHeat deflection temperatureSelective laser sintering

The invention belongs to the field of macromolecules, and particularly relates to polymer-based micron / nano functional composite spherical powder and a preparing method thereof. According to the method, polymer-based micron / nano functional composite ultrafine powder compact in combination and uniform in scattering is obtained through solid-phase shearing grinding, and the powder grain size rangesfrom 30 microns to 200 microns; the above functional composite powder is evenly scattered in a scattering agent to be heated to the temperature above the heating deformation temperature of the functional composite powder for spheroidization treatment; and then heated suspension liquid is cooled, filtered, washed, dried and screened, and the functional composite spherical powder is obtained. The method is simple in operation, economical and environment-friendly, and large-scale preparing of the polymer-based micron / nano functional composite spherical powder can be achieved. The beneficial effects that the degree of sphericity is high, size distribution is narrow, the inner structure is uniform, and mobility and stacking density are high are achieved. The functional composite powder preparedthrough the method can meet the selective laser sintering requirement and can also be applied to the fields of the biomedical engineering, super capacitors, coatings, cosmetics and the like.

Owner:SICHUAN UNIV

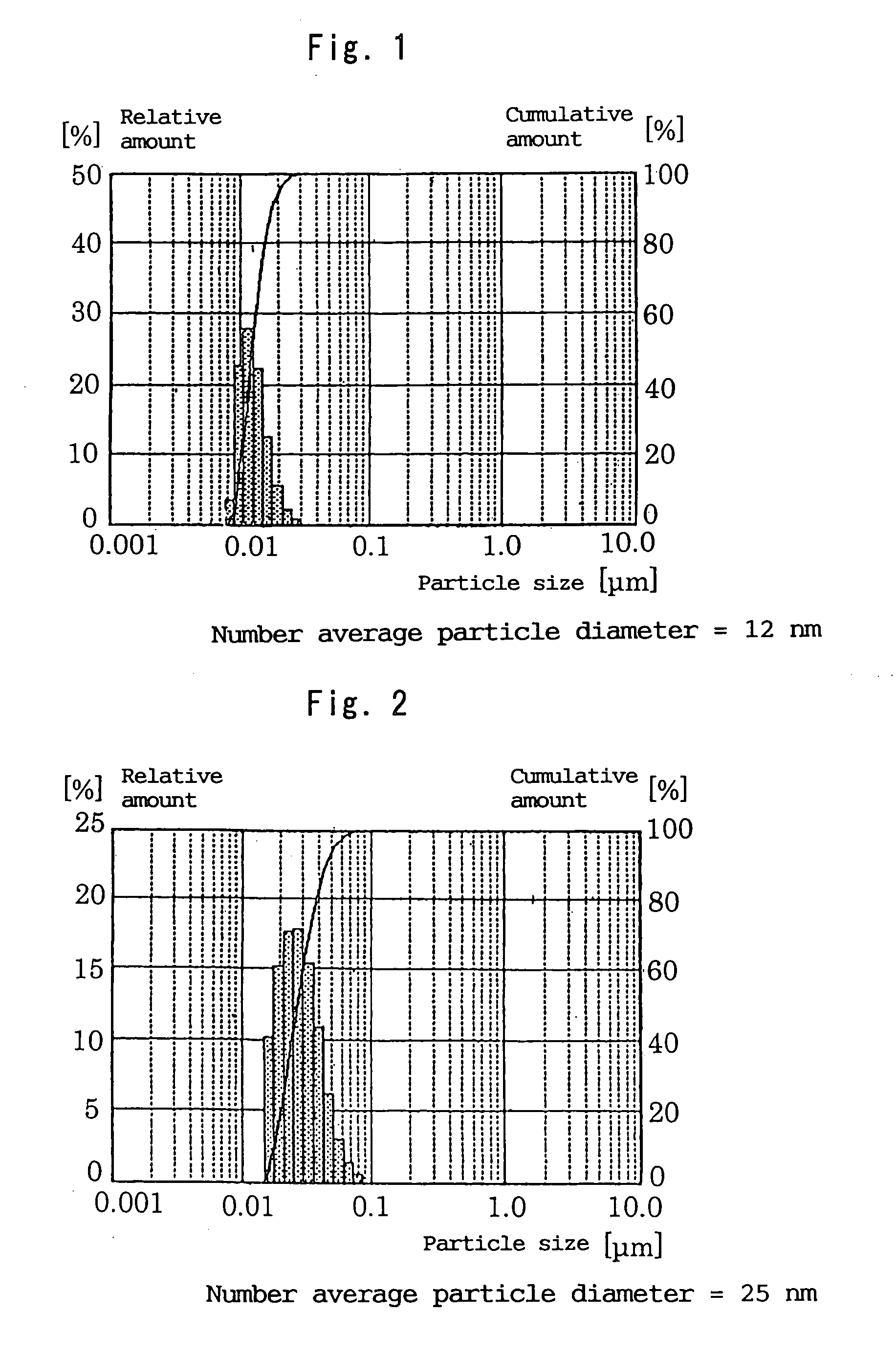

Modified photocatalyst sol

InactiveUS7030058B1Prevent surfaceInorganic chemistryOther chemical processesCrystallographyLiquid medium

Disclosed is a modified photocatalyst sol comprising a liquid medium having dispersed therein particles of a modified photocatalyst, wherein the modified photocatalyst particles are prepared by subjecting particles of a photocatalyst to a modification treatment with at least one modifier compound selected from the group consisting of different compounds each of which independently comprises at least one structural unit selected from the group consisting of a monooxydiorganosilane unit, a dioxyorganosilane unit and a difluoromethylene unit, and wherein the modified photocatalyst particles have a specific volume mean particle diameter. Also disclosed is a modified photocatalyst composition comprising the modified photocatalyst sol and a functional substance. Also disclosed are a film formed using the above-mentioned modified photocatalyst sol or modified photocatalyst composition, a functional composite comprising the film and a substrate covered with the film, and a shaped article produced by shaping the above-mentioned modified photocatalyst composition.

Owner:ASAHI KASEI KK

Functional composite face fabric and producing method thereof

The present invention relates to a new-type functional composite face fabric with several functions of resisting static electricity, resisting radiation, resisting bacteria, killing bacteria, filtering toxic material and protecting health, etc. Said composite face fabric includes functional fibre layer, adhered base layer or surface layer face fabric, the above-mentioned all the layers and combined together by means of physical, chemical or mechanical method so as to obtain the invented product.

Owner:上海兰度科技有限公司

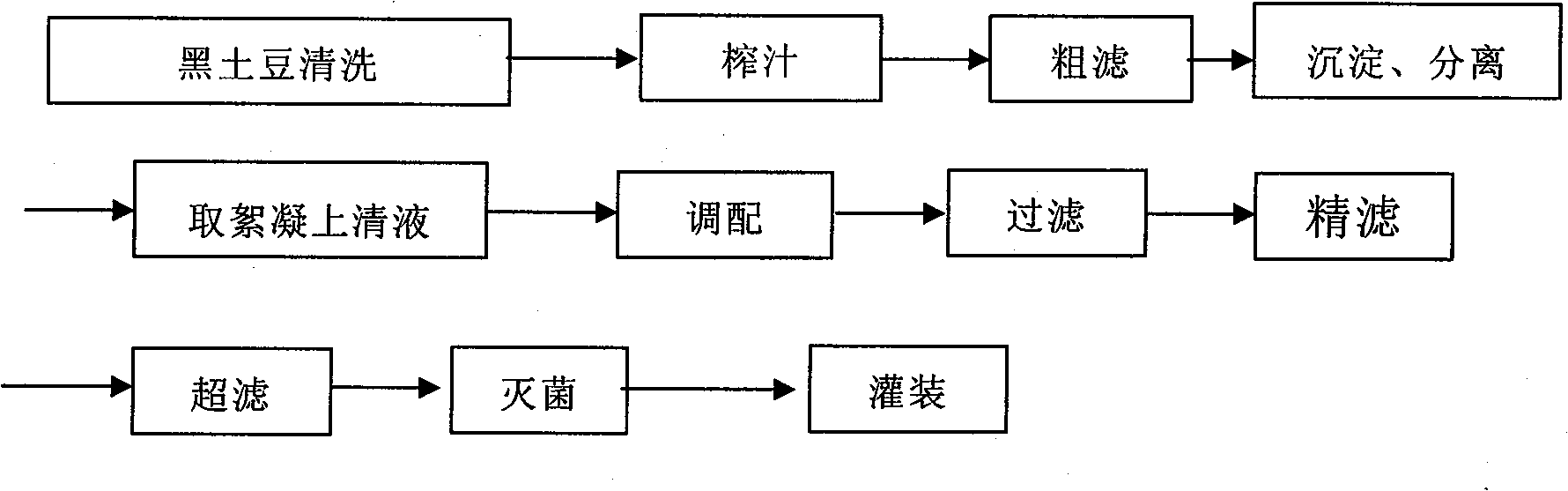

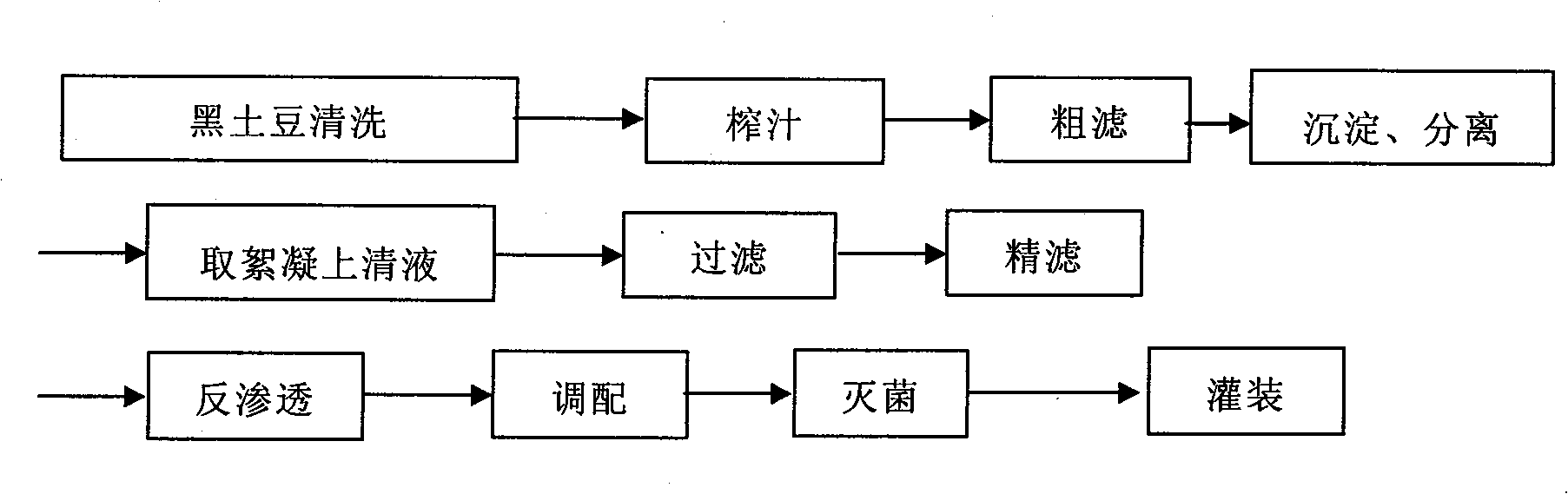

Method for preparing beverage, fruit wine and fruit vinegar by using black potato containing anthocyanin

InactiveCN102132924AMicroorganism based processesAlcoholic beverage preparationFruit wineAdditive ingredient

The invention relates to a method for preparing beverage, fruit wine and fruit vinegar by using black potato containing anthocyanin. The method comprises the steps of: juicing black potato used as raw material, adding an antioxidant, roughly filtering, precipitating, taking supernatant, flocculating, settling, finely filtering, and carrying out ultrafiltration to obtain black potato original juice; or carrying out concentrating, blending and sterilizing and the like to obtain beverage or concentrated beverage; the black potato fruit wine is prepared by the steps of fermenting, filtering, storing and ageing, blending, sterilizing and filling; black potato fruit vinegar is prepared by adding acetobacter and fermenting again on the basis of the preparation steps of the black potato wine. The black potato beverage, fruit wine and fruit vinegar can be directly eaten, and also can be mixed with other ingredients which are both medicine and food to be prepared into functional composite beverage; and the composite beverage not only contains protein, amine acid, vitamins, anthocyanin, various minerals and trace elements which are also contained in single beverage, but also has the effects brought by composite ingredients, and is functional beverage which can improve immunity and resist cancers, oxidation, depression and ageing.

Owner:王尧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com