Spherical compound lithium-rich multielement cathode material with core shell structure and preparation method thereof

A technology of core-shell structure and positive electrode material, which is applied in the field of spherical core-shell structure composite lithium-rich multi-element positive electrode material and its preparation, can solve the problems of affecting the specific discharge capacity of the material, affecting the cycle performance of the material, and poor rate performance, etc., to achieve Cost-friendly and environmentally friendly, suitable for large-scale industrialization, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

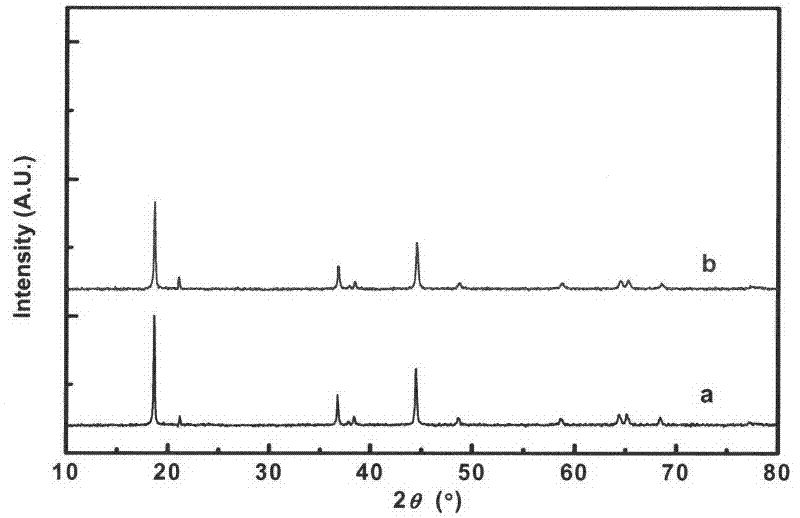

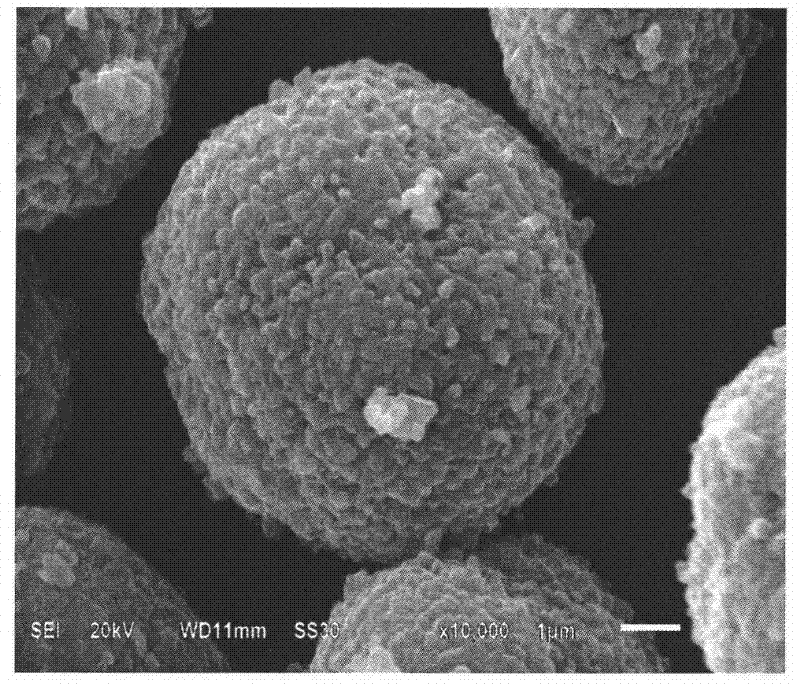

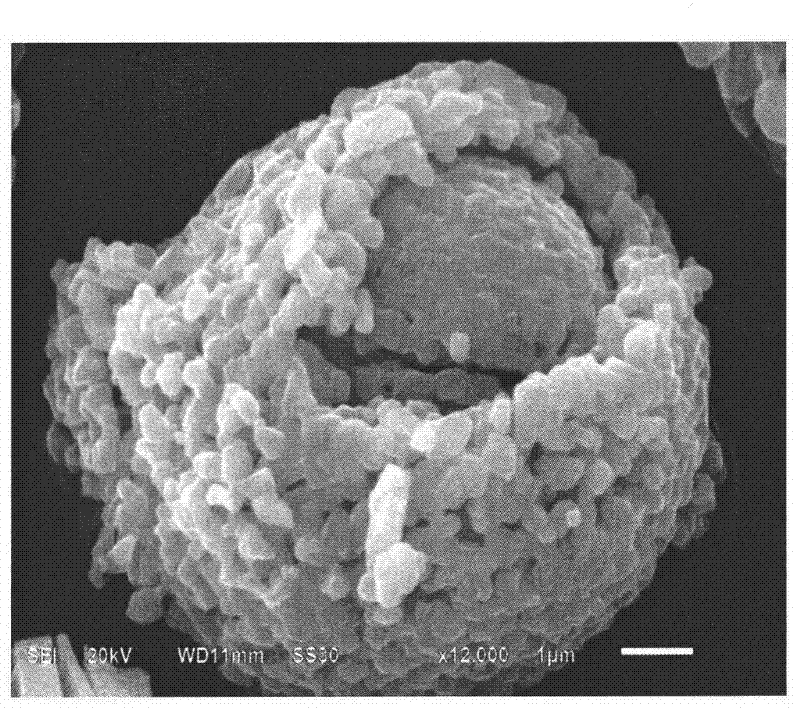

Embodiment 1

[0025] (1) Nickel sulfate, manganese sulfate, and cobalt sulfate are mixed according to the ratio of Ni:Mn:Co (molar ratio)=1:1:1, dissolved in deionized water, and mixed with a total metal ion concentration of 2.0mol / L. Salt solution A; Nickel sulfate, manganese sulfate are mixed by Ni:Mn (molar ratio)=1:3 ratio, dissolve in deionized water, be mixed with the mixed salt solution B that total metal ion concentration is 2.0mol / L; Prepare respectively Na at a concentration of 2.0 mol / l 2 CO 3 Alkaline solution and ammonia water with a concentration of 0.8mol / L.

[0026] (2) the mixed salt solution A, Na prepared in step (1) 2 CO 3 Alkali solution and ammonia water are fed into the reaction kettle in parallel through a constant flow pump, the stirring speed is controlled at 1000rpm, the reaction temperature is 55°C, the pH value is 8.0, and the reaction time is 12h. The spherical core [Ni 1 / 3 mn 1 / 3 co 1 / 3 ]CO 3 .

[0027] (3) The mixed salt solution B, Na 2 CO 3 Alkali...

Embodiment 2

[0032] (1)-(3) are the same as in Example 1.

[0033] (4) The precursor obtained in step (3) is filtered, washed, dried, and Li 2 CO 3 After the ratio of the moles of lithium to the total moles of Ni, Mn and Co is 1.37:1, after uniform mixing, it is pre-fired at 500°C for 8 hours in an air atmosphere, and then heated to 850°C for 12 hours to obtain a core-shell structure composite type. Lithium-rich multi-element cathode material Li 1.15 [(Ni 1 / 3 mn 1 / 3 co 1 / 3 ) 0.6 (Ni 0.25 mn 0.75 ) 0.4 ] 0.85 o 2 .

[0034] Electrochemical tests show that the first discharge specific capacity is 258mAh / g in the voltage range of 0.1C and 2.0-4.8V; the capacity retention rate after 100 cycles at 0.2C and 2.0-4.6V is 96.7%; at 0.5C , 1C, and 2C rates, the reversible capacities are 215mAh / g, 180mAh / g, and 168mAh / g, respectively, showing good electrochemical performance.

Embodiment 3

[0036] (1) Nickel sulfate, manganese sulfate, and cobalt sulfate are mixed according to the ratio of Ni: Mn: Co (molar ratio) = 4: 4: 2, dissolved in deionized water, and mixed with a total metal ion concentration of 2.0mol / L. Salt solution A; Nickel sulfate, manganese sulfate are mixed by Ni: Mn (molar ratio)=1: 3 ratio, dissolve in deionized water, be prepared into the mixed salt solution B that total metal ion concentration is 2.0mol / L; Prepare respectively Concentration is 4.0mol / l NaOH alkaline solution and concentration is 4.0mol / L ammonia water.

[0037] (2) Add the mixed salt solution A, NaOH alkali solution and ammonia water prepared in step (1) into the reactor filled with nitrogen protection in parallel through a constant flow pump, control the stirring speed to 1000rpm, and the reaction temperature to be 55°C and The value is 11.0, the reaction time is 24h, and the spherical inner core [Ni 0.4 mn 0.4 co 0.2 ](OH) 2 .

[0038] (3) Add the mixed salt solution B,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com