Kevlar aerogel film, and preparation method and application thereof

A Kevlar gel and aerogel technology, which is applied in the field of nanoporous materials, can solve the problems of long preparation period, difficult to realize industrialization, and incapable of continuous large-scale preparation, and achieves high porosity, easy continuous, The effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Another aspect of the embodiments of the present invention also provides a method for preparing a Kevlar aerogel film, comprising:

[0025] (1) Dissolving macroscopic Kevlar fibers to form Kevlar nanofiber sol;

[0026] (2) coating the Kevlar nanofiber sol on a substrate, transferring it to a coagulation bath, and replacing it with a solvent to form a Kevlar gel film;

[0027] (3) drying the Kevlar gel film to obtain a Kevlar aerogel film.

[0028] In a more preferred embodiment, step (1) can specifically include: adding Kevlar fiber to potassium hydroxide, potassium tert-butoxide or other strong alkaline substances in a mass ratio of 1:0.2~1:1 to polar Among the solvents, polar solvents include but are not limited to dimethyl sulfoxide, magnetic stirring at a certain temperature (20 ~ 70 ° C), until a uniform dispersion is formed, according to different needs, prepare 0.1wt% ~ 10.0wt% respectively of Kevlar nanofiber sols.

[0029] In a more preferred embodiment, in...

Embodiment 1

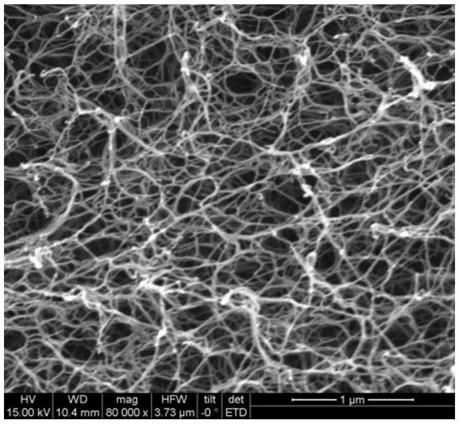

[0048] Add 2.0 g of Kevlar fiber and 0.4 g of potassium hydroxide to the sample bottle, then add 98.0 g of dimethyl sulfoxide, close the bottle cap tightly, and stir magnetically at 25°C until a uniform dispersion is formed; The droplets were added to the glass slide, and the spin coater was used for spin coating for 30 s, and the spin coating speed was 500 rpm; the sample after spin coating was quickly transferred to deionized water, and after gelation, the Kevlar hydrogel film fell off the glass slide substrate. Solvent replacement of the above hydrogel with absolute ethanol followed by supercritical CO 2 After drying, a flexible self-supporting Kevlar aerogel film was obtained. Figure 1a The SEM photograph of the Kevlar aerogel film obtained in this example is shown, and other parameters are shown in Table 1.

Embodiment 2

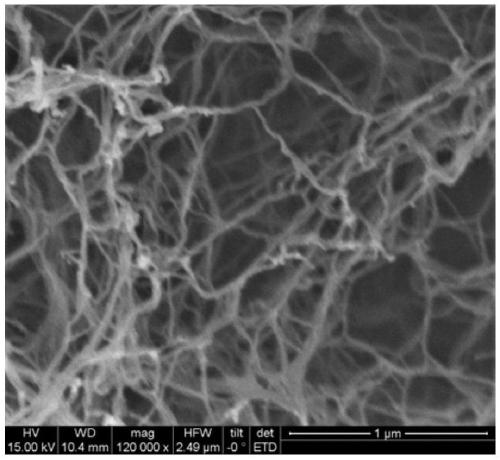

[0050] Add 2.0g Kevlar fiber and 1.0g potassium hydroxide to the sample bottle, then add 98.0g dimethyl sulfoxide, close the bottle cap tightly, and stir magnetically at 20°C until a uniform dispersion is formed; The droplets were added to the glass slide, and the spin coater was used for spin coating for 30 s, and the spin coating speed was 1000 rpm; the sample after spin coating was quickly transferred to anhydrous ethanol, and after gelation, the Kevlar gel film fell off the glass slide substrate. , supercritical CO 2 After drying, a flexible and self-supporting Kevlar aerogel film was obtained. Figure 1b The SEM photograph of the Kevlar aerogel film obtained in this example is shown, and other parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com