Functional composite material

A functional composite material and functional technology, applied in metal material coating process, thin material treatment, liquid chemical plating, etc., can solve the problem of limiting heat transfer of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

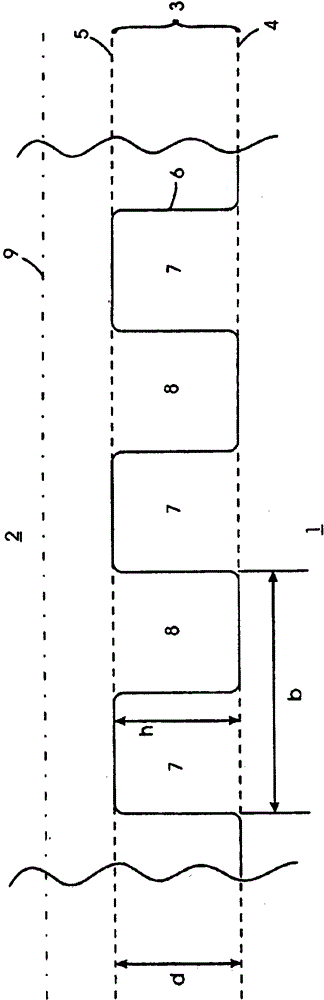

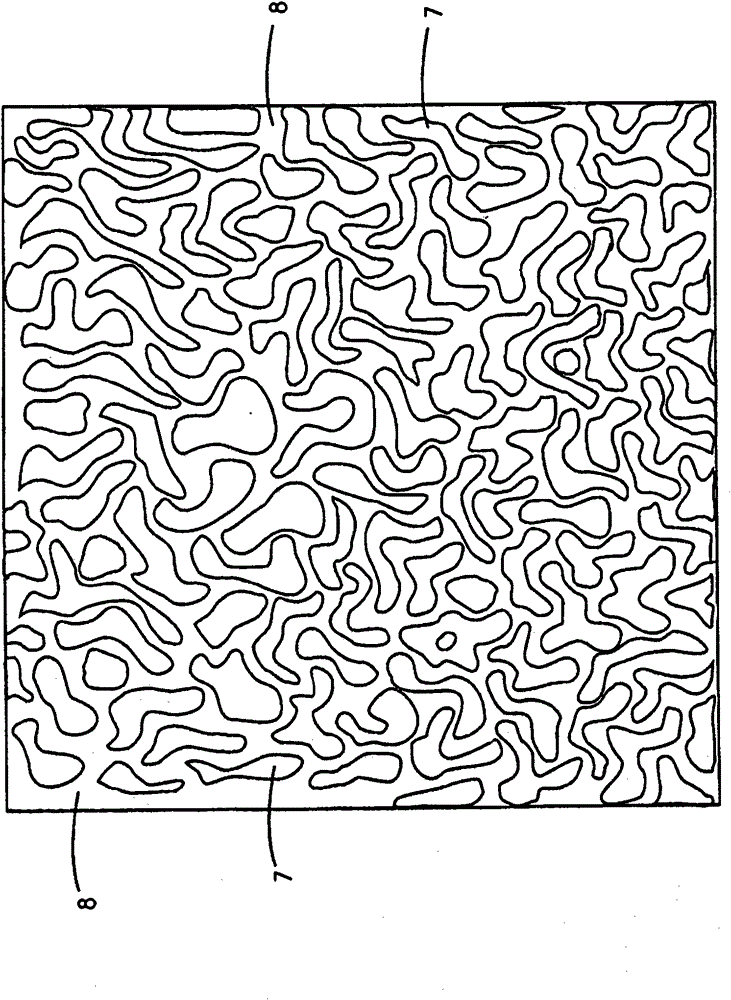

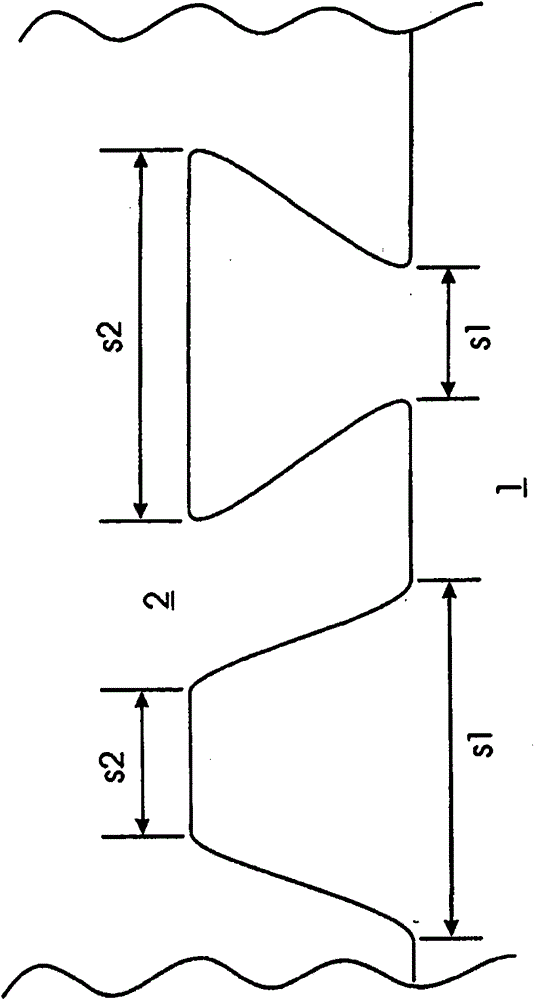

[0029] figure 1 A base body 1 is shown which comprises a deposited functional surface material 2 which completely covers the base body. The surface of the base body facing the surface layer has a series of shaped portions 7 and gaps 8 between the shaped portions. The combination of the shaped part and the gap forms a structured boundary layer 3 which has a crosslinking depth d. The crosslinking depth denotes the distance between the lower boundary 4 and the upper boundary 5 of the structured boundary layer. The crosslinking depth corresponds to the distance between the highest and lowest planes of the shaped part.

[0030] The height h of each individual profile corresponds substantially to the crosslinking depth d of structured boundary layer 3 . The surfaces of the shaped parts and the gaps between them form the material boundary 6 produced between the base body and the surface material 2 , at which material boundary the surface material and the material of the base body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com