Shoe sole dryer

A dryer and drying channel technology, applied in the field of dryers, can solve the problems of inconvenience affecting people's lives, heavy work of cleaning staff, and easy to cause health problems, so as to reduce the probability of injury, lighten the weight, and reduce heavy work The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

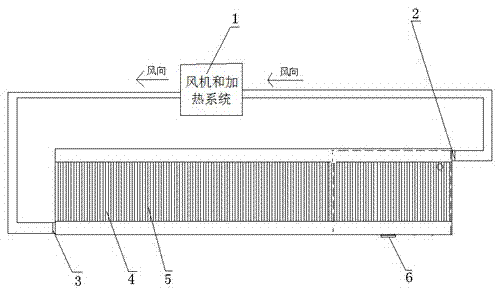

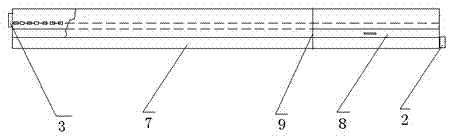

[0022] like figure 1 and figure 2 As shown, a shoe sole dryer includes a fan and a heating device, an air suction port, an air outlet, a drying channel, a drain tank, a first water collection tank, a second water collection tank and a barrier sheet, and the heating device is arranged at The air outlet of the fan is connected to the air outlet at one end of the drying channel through a pipe, and the other end of the drying channel is provided with an air suction port, and the air suction port is connected to the air inlet of the fan through a pipe. An airtight barrier is arranged in the drying channel to divide the drying channel into a suction air channel and an air outlet channel. The surface of the drying channel is provided with a drainage groove, and the bottom of the air outlet channel is provided with a first A water collection tank, a second water collection tank is arranged at the bottom of the suction air duct.

[0023] In this embodiment, the length, width and hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com