Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1265 results about "Vinyl polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl polymers are a group of polymers derived from vinyl monomers of the type CH₂=CHR. Their backbone is an extended alkane chain ...-CH₂-CHR-CH₂-CHR-..). In popular usage, "vinyl" refers only to polyvinyl chloride (PVC).

PVA hydrogel

InactiveUS7235592B2Improve physical stabilityGood physical propertiesOrganic chemistryMixing methodsPolymer sciencePolymer

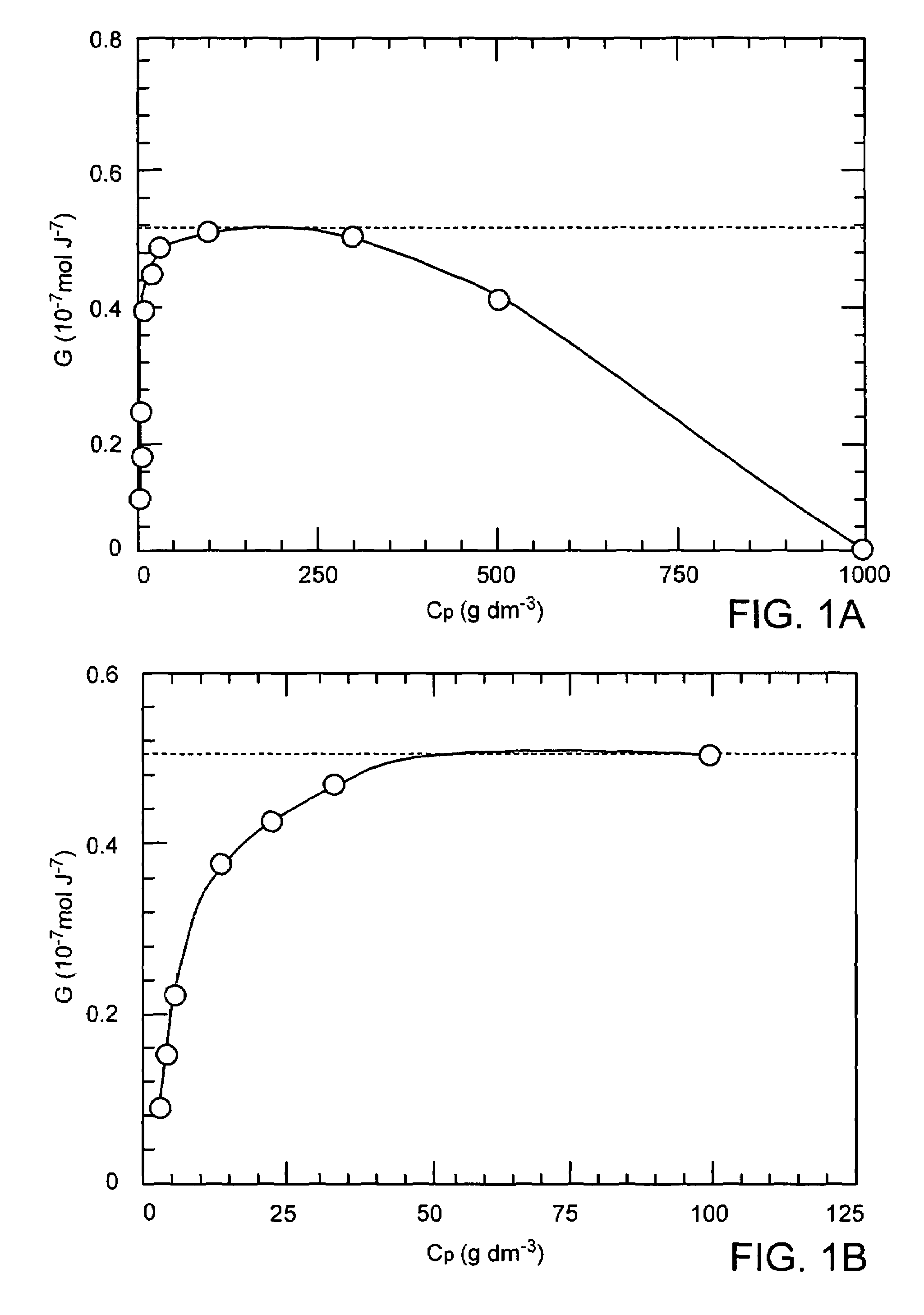

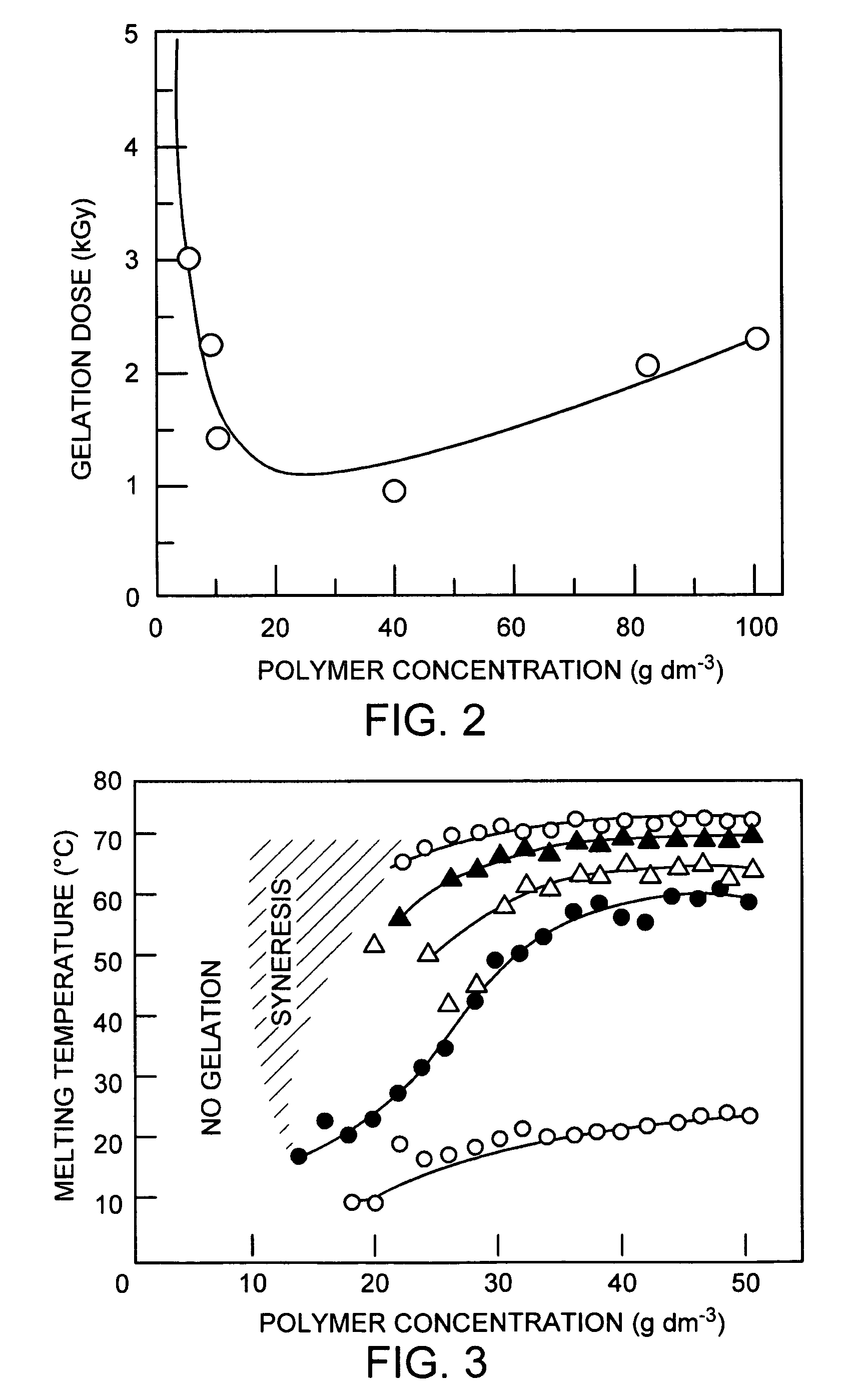

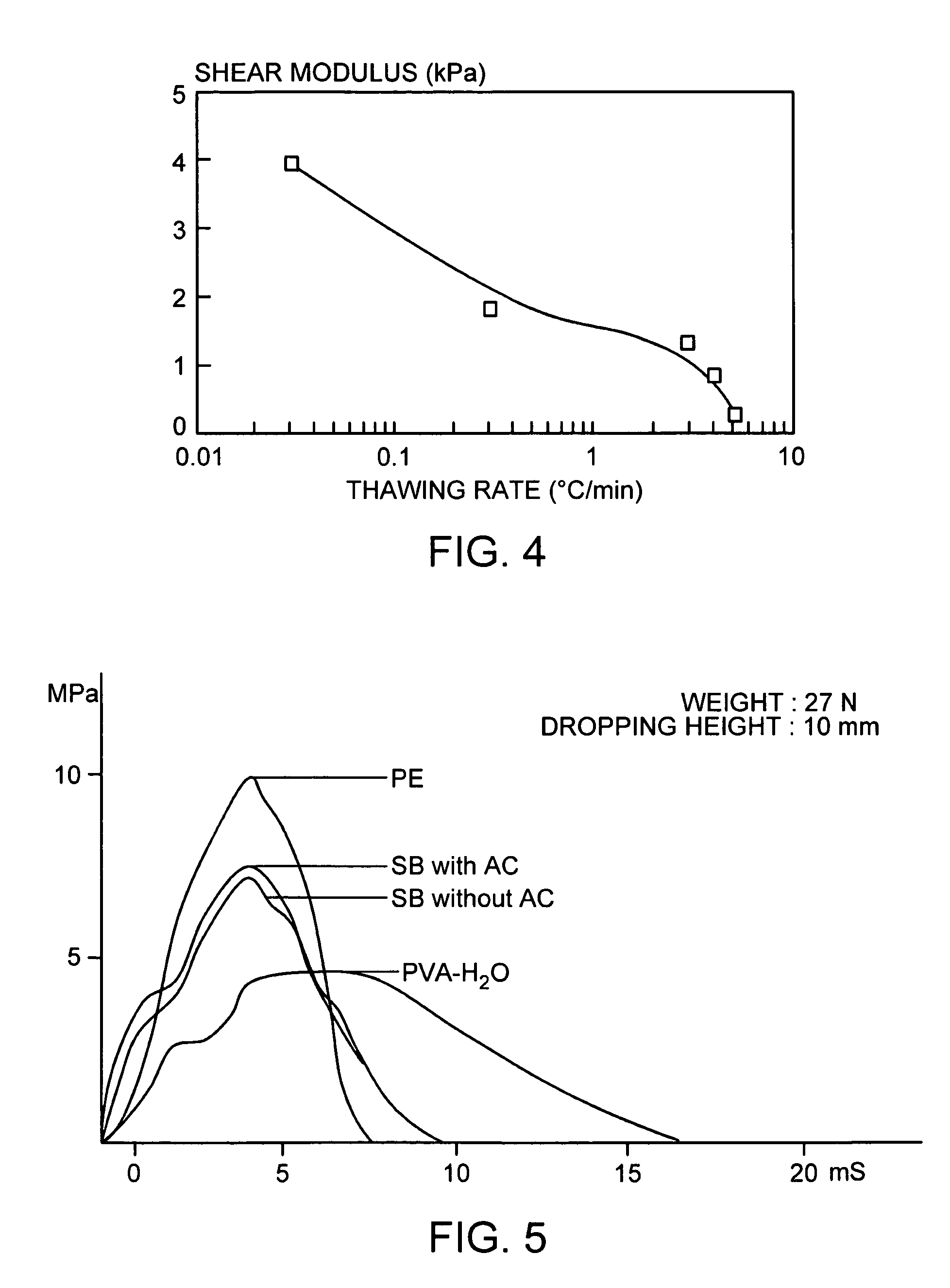

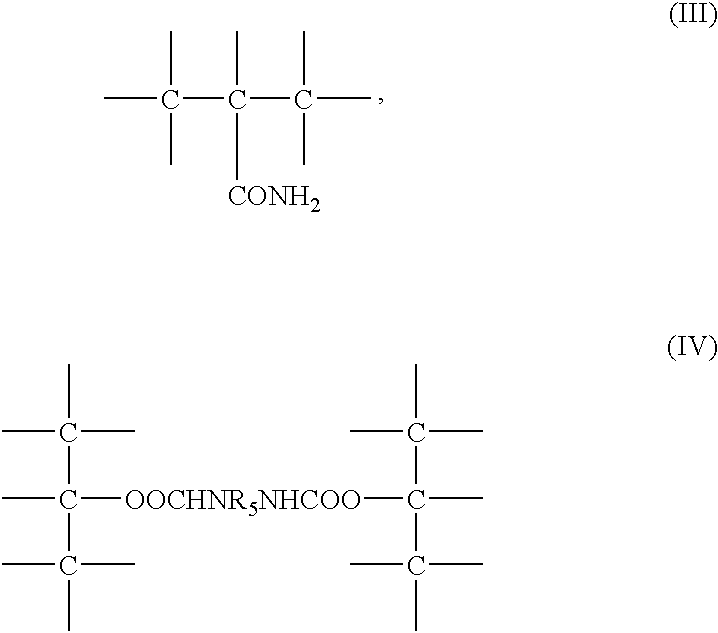

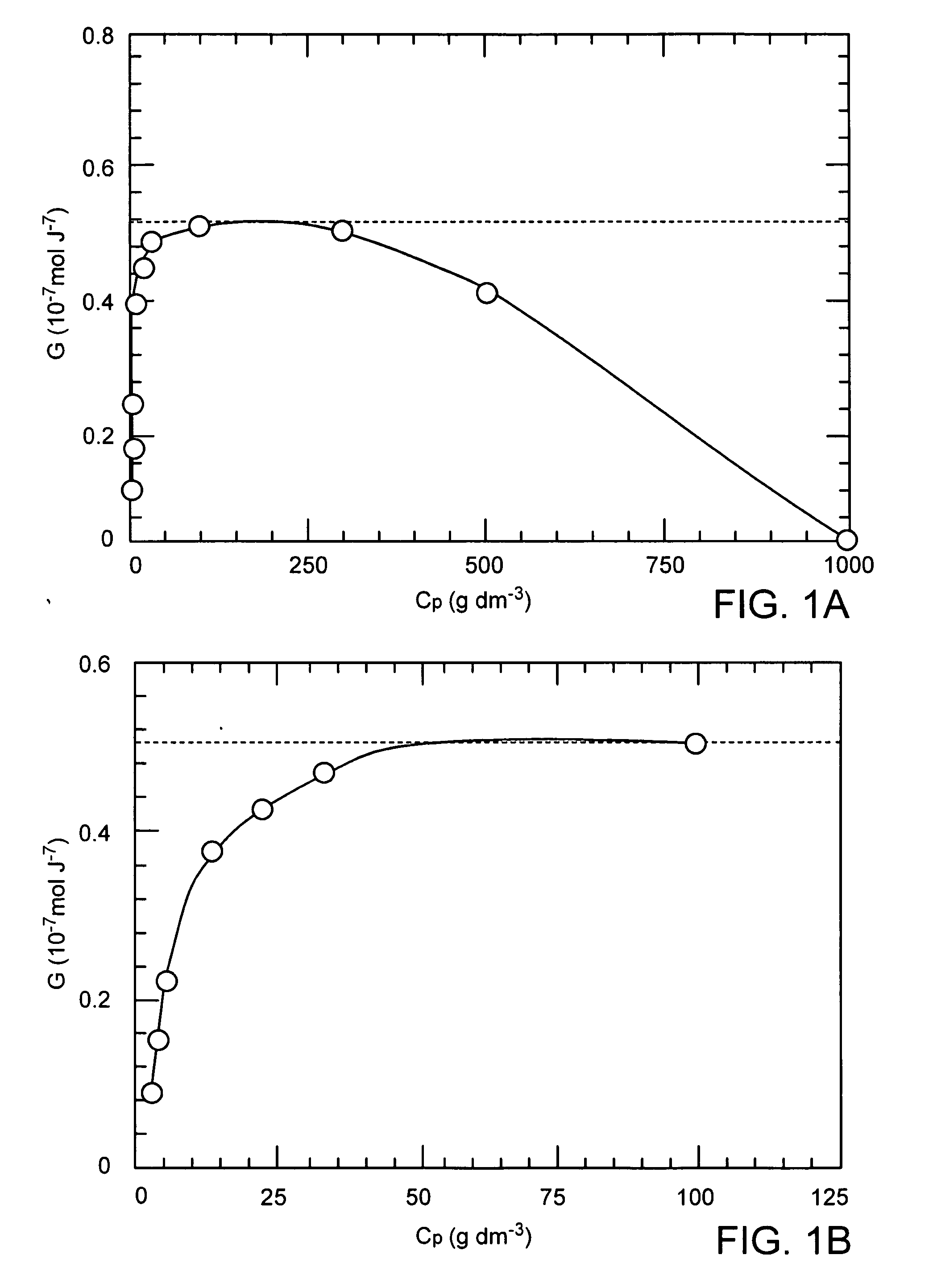

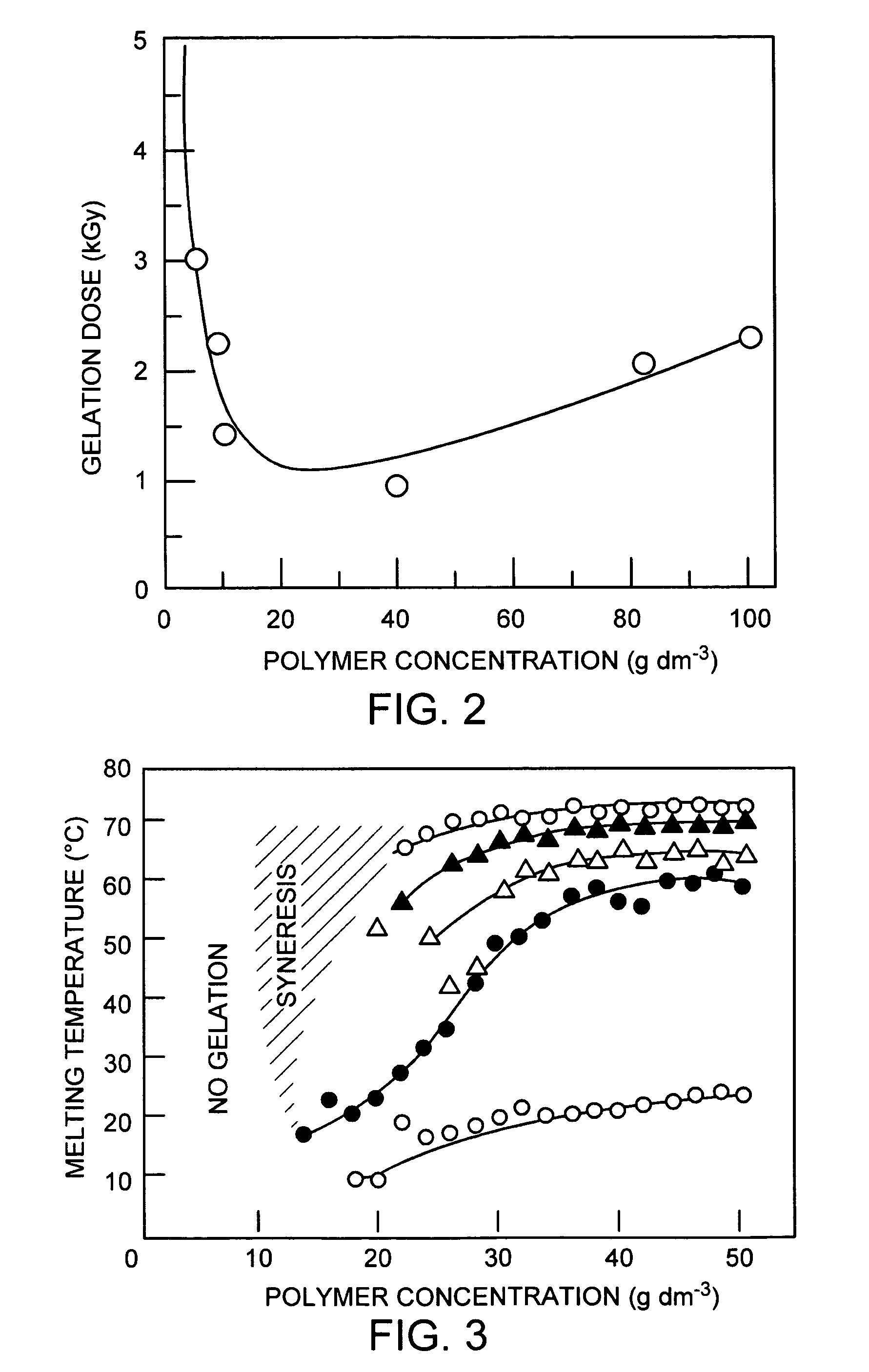

The present invention provides methods of making covalently crosslinked vinyl polymer hydrogels having advantageous physical properties, and covalently crosslinked vinyl polymer hydrogel compositions made by such methods, as well as articles of manufacture comprising such covalently crosslinked vinyl polymer hydrogel compositions. The physical properties of the produced hydrogels can be adjusted by varying controlled parameters such as the proportion of physical associations, the concentration of polymer and the amount of radiation applied. Such covalently crosslinked vinyl polymer hydrogels can be made translucent, preferably transparent, or opaque depending on the processing conditions. The stability of the physical properties of the produced vinyl polymer hydrogel can be enhanced by controlling the amount of covalent crosslinks.

Owner:ZIMMER GMBH

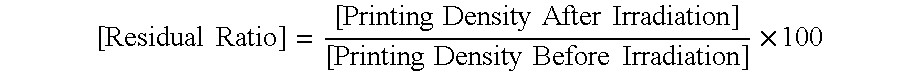

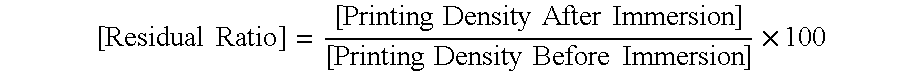

Water-based ink for ink-jet recording

A water-based ink for inkjet printing comprising a water dispersion of vinyl polymer particles prepared by containing a pigment in a vinyl polymer prepared by copolymerizing a monomer mixture comprising (a) a salt-forming group-containing monomer, (b) a macromer, and (c) a monomer copolymerizable with the salt-forming group-containing monomer and the macromer; and a process for preparing a water-based ink for inkjet printing comprising a water dispersion of vinyl polymer particles prepared by containing a pigment in a vinyl polymer, comprising dissolving in an organic solvent a vinyl polymer prepared by copolymerizing a monomer mixture comprising (a) a salt-forming group-containing monomer, (b) a macromer, and (c) a monomer copolymerizable with the salt-forming group-containing monomer and the macromer; adding a pigment to the resulting solution; pre-kneading the mixture; thereafter adding a neutralizing agent and water and kneading the mixture, to give an oil-in-water dispersion; and distilling off the organic solvent from the resulting kneaded product.

Owner:KAO CORP

Film-forming compositions and methods

InactiveUS6838078B2Reduce bacterial loadLess irritatingCosmetic preparationsBiocideWater dispersibleActive agent

Film-forming compositions, as well as methods of making and using, wherein the compositions include an optional active agent, water, a surfactant, and a water-soluble or water-dispersible vinyl polymer comprising amine group-containing side-chains and a copolymerized hydrophobic monomer; wherein the amine equivalent weight of the polymer is at least about 300 grams polymer per equivalent of amine group.

Owner:3M INNOVATIVE PROPERTIES CO

Electrospun electroactive polymers

InactiveUS20060057377A1Easy to set upFast and easy to runMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyPolyesterFiber

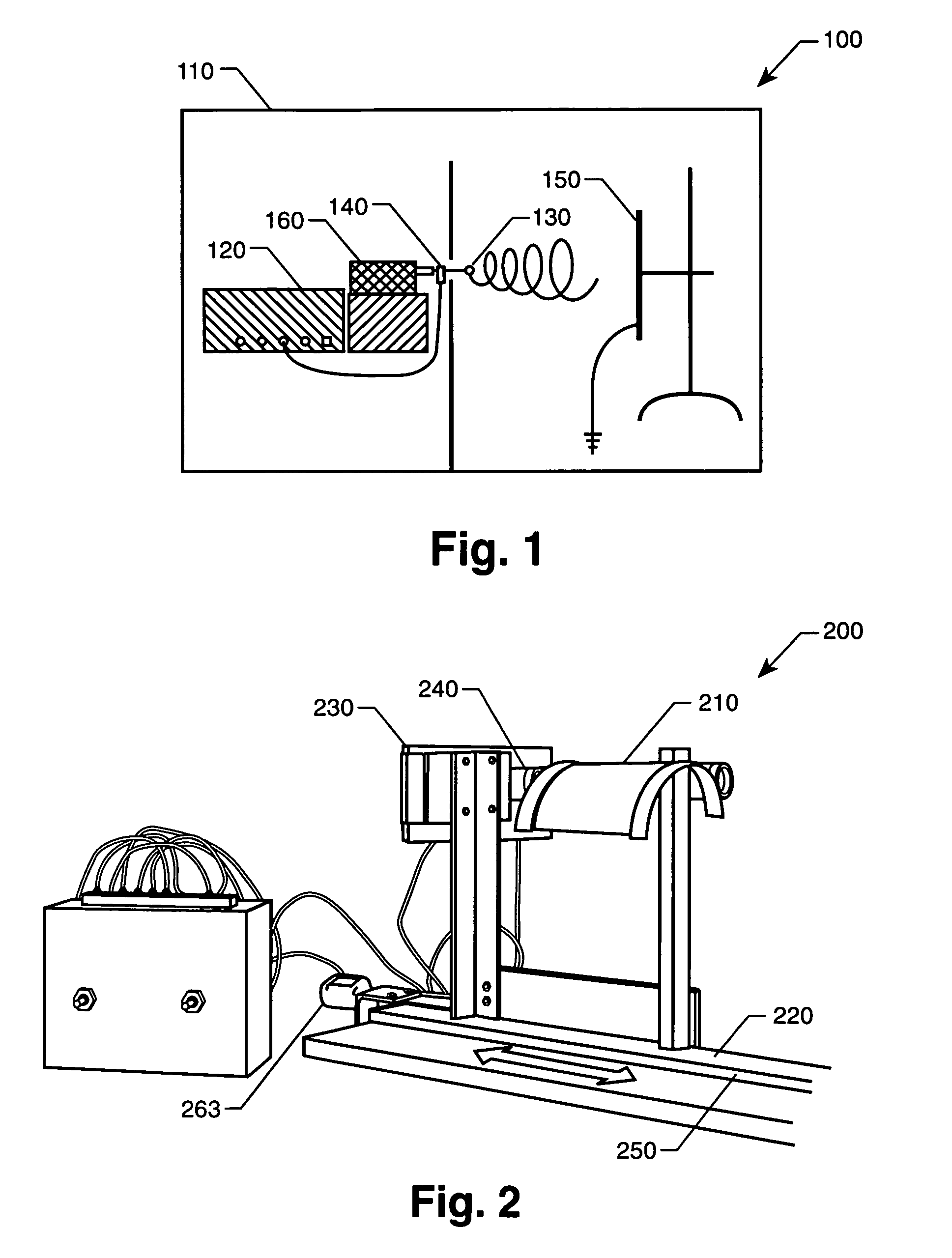

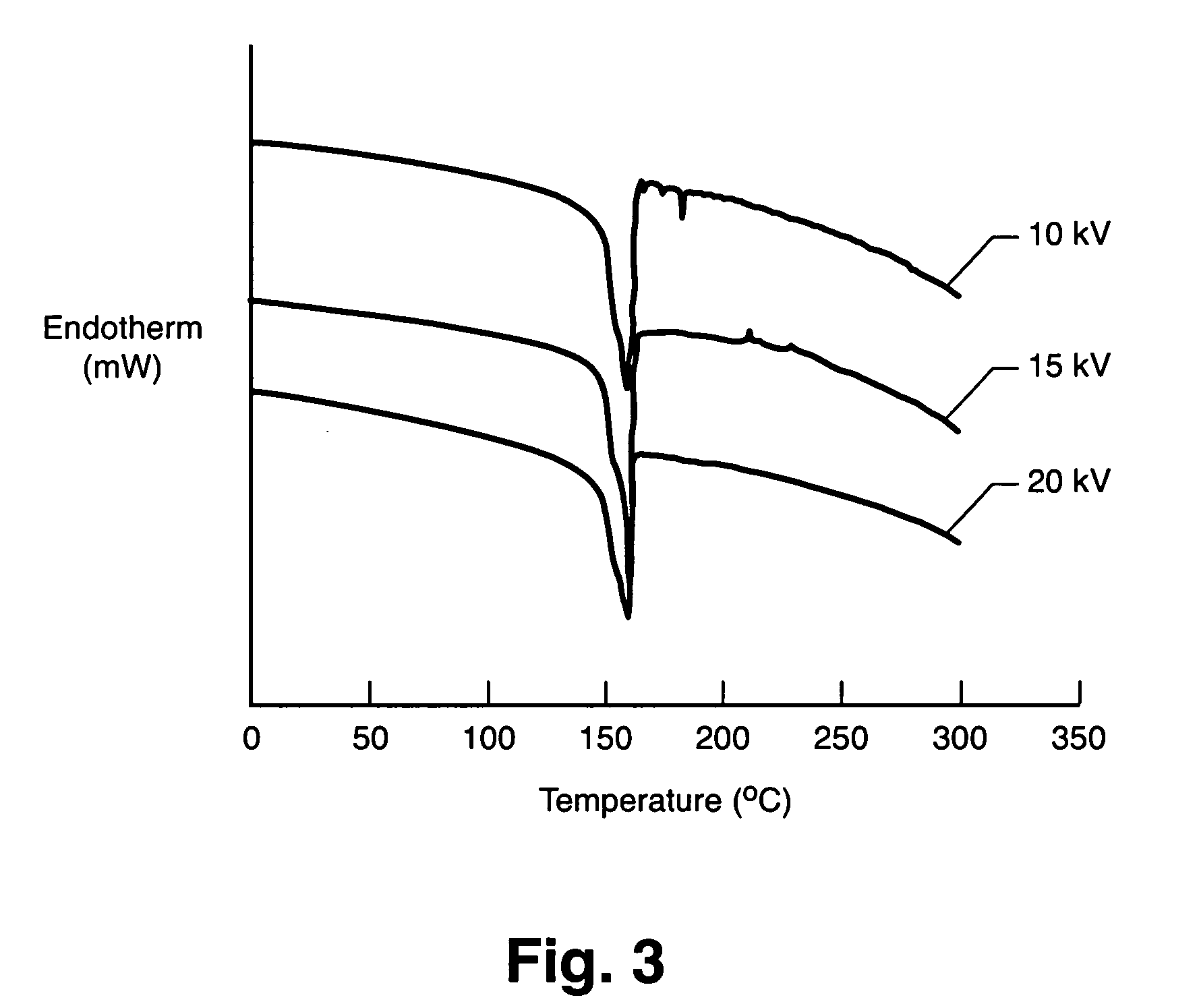

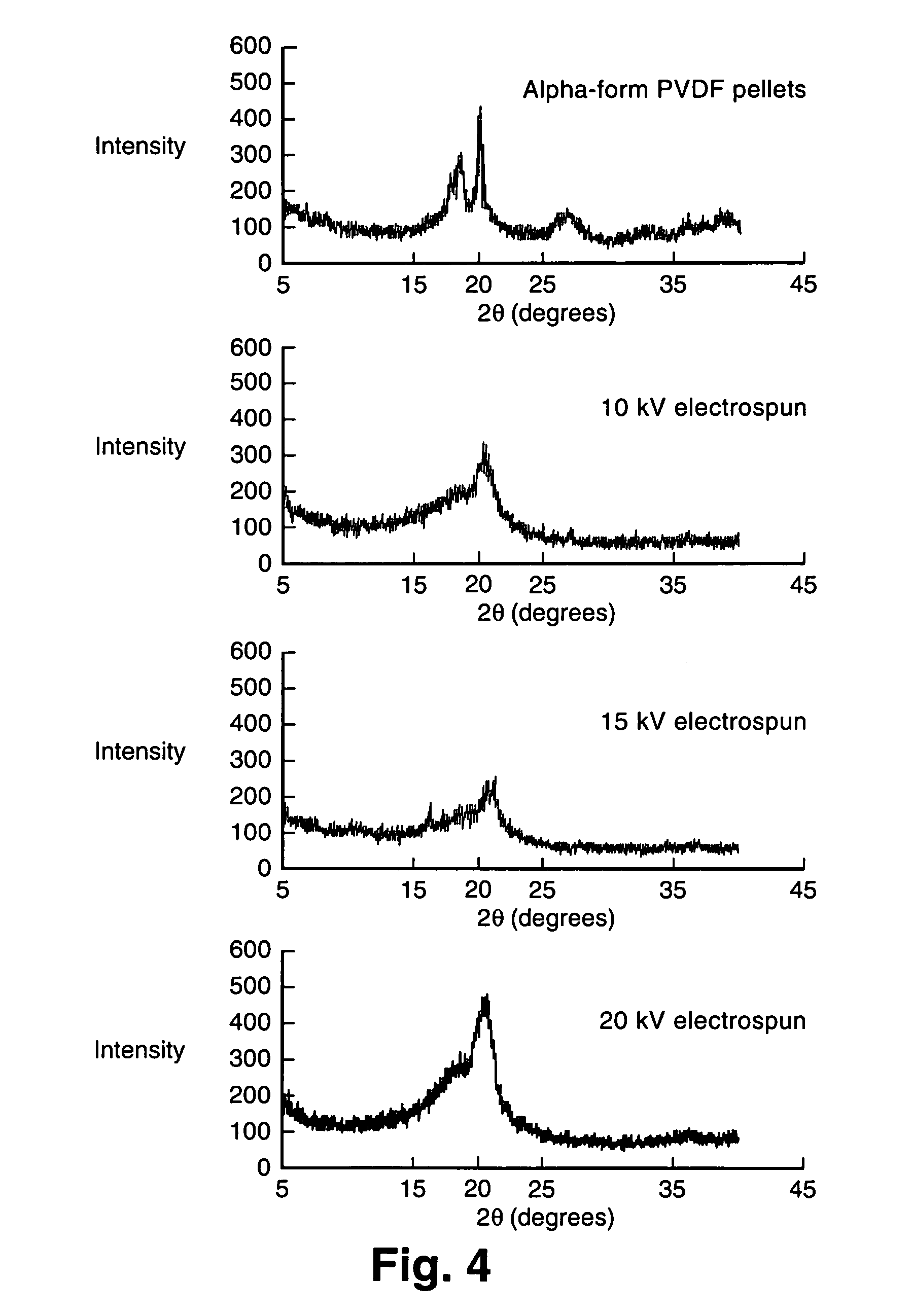

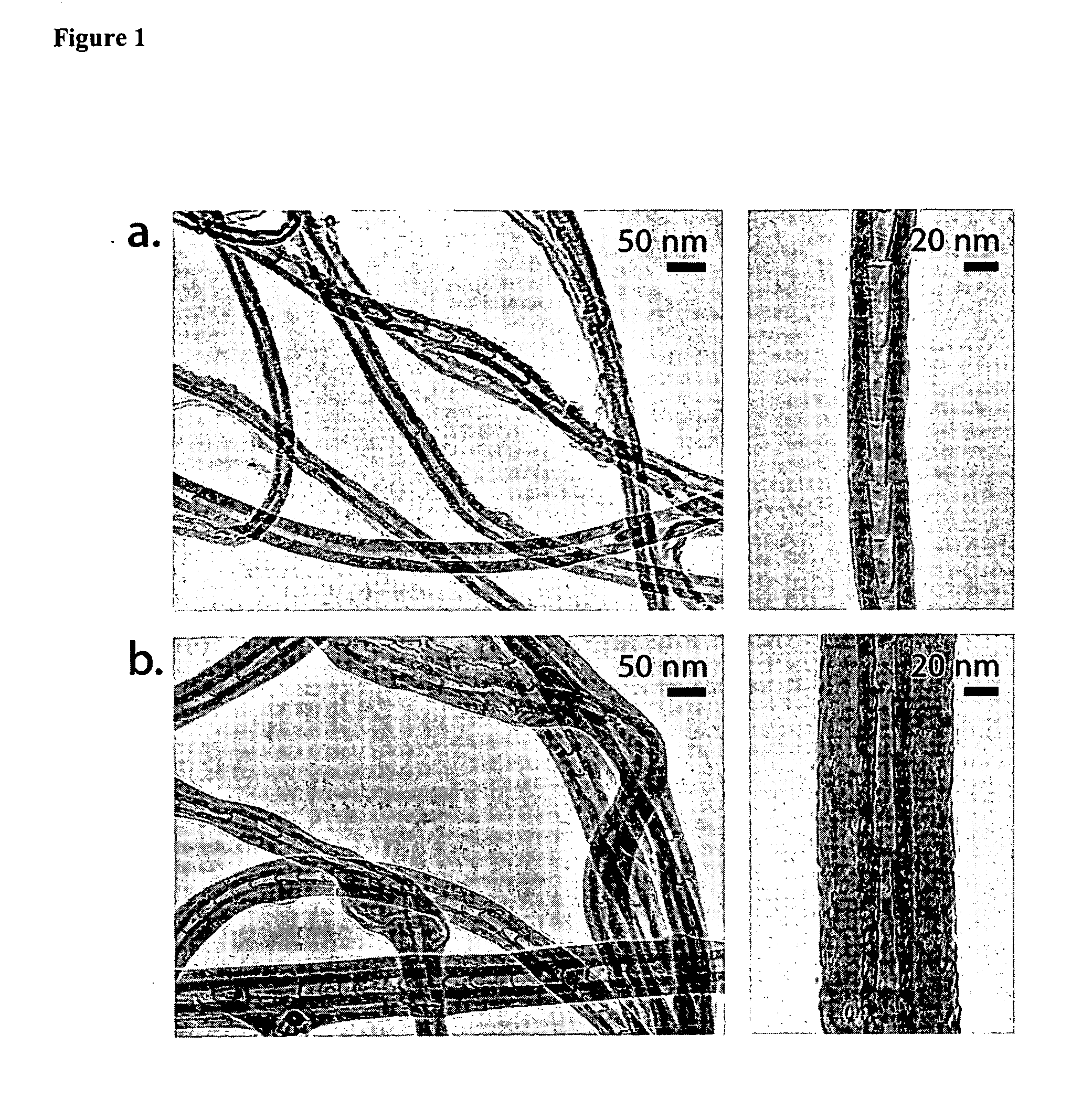

Electroactive polymers are produced via electrospinning. The induction of electroactivity via electrospinning can be utilized with one or more soluble polymers with polarizable moieties. Suitable polymer classes include but are not limited to polyimides, polyamides, vinyl polymers, polyurethanes, polyureas, polythioureas, polyacrylates, polyesters, and biopolymers. Any one or more solvents sufficient to dissolve the one or more polymers of interest and make a spinnable solution can be utilized. The polymer can be electrospun into fiber and fibrous nonwoven mat. The electroactive polymer can be doped with inclusions, such as nanotubes, nanofibers, and piezoceramic powders for dielectric enhancement The availability of electroactive polymer fibers and fibrous nonwoven mat will enable many new applications for electroactive polymers.

Owner:NASA +2

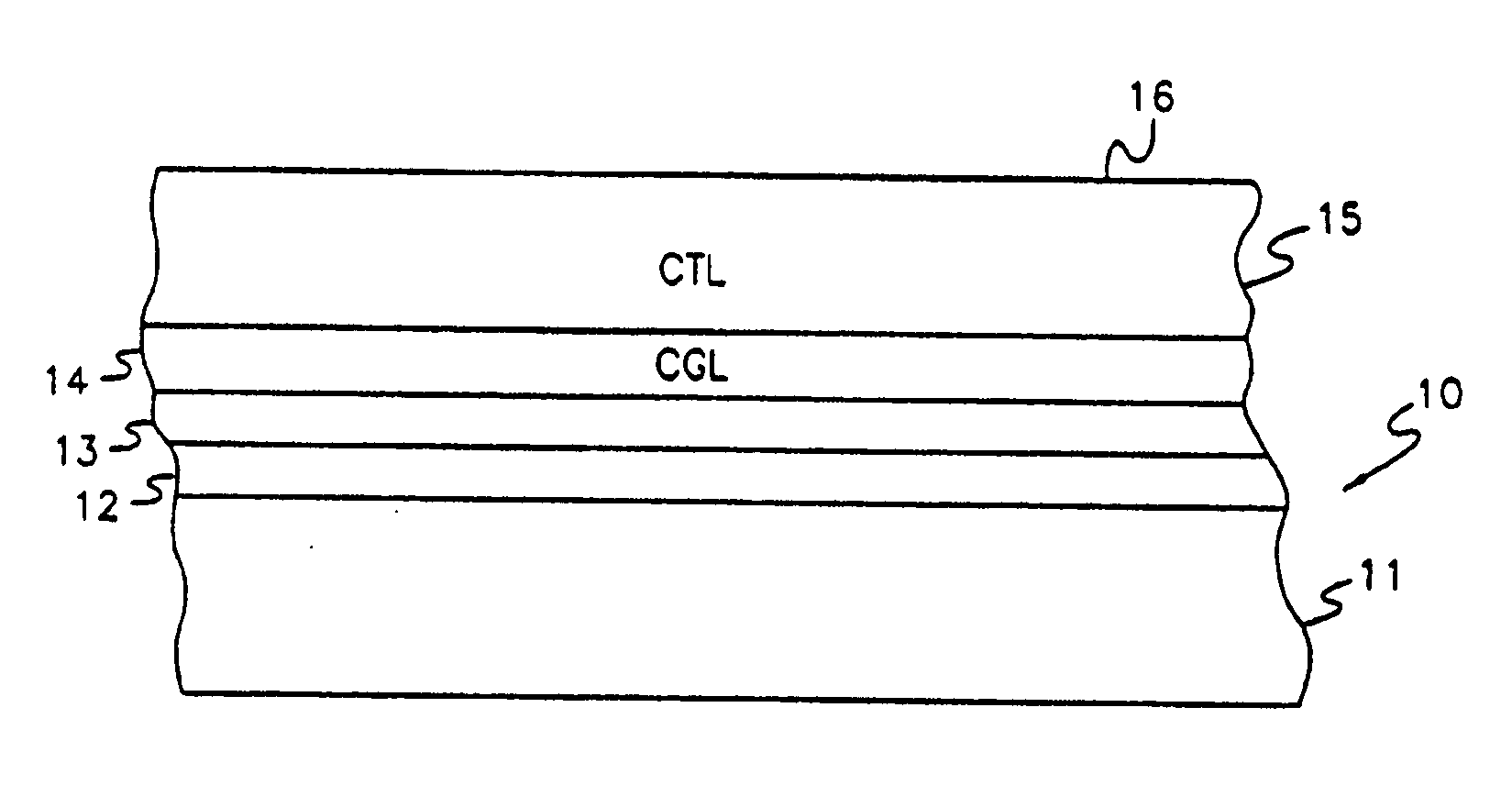

Vinyl polymer photoconductive elements

InactiveUS20070026332A1Improve the immunityThick and uniformElectrographic process apparatusElectrographic processes using charge patternElectrical resistance and conductanceCharge carrier

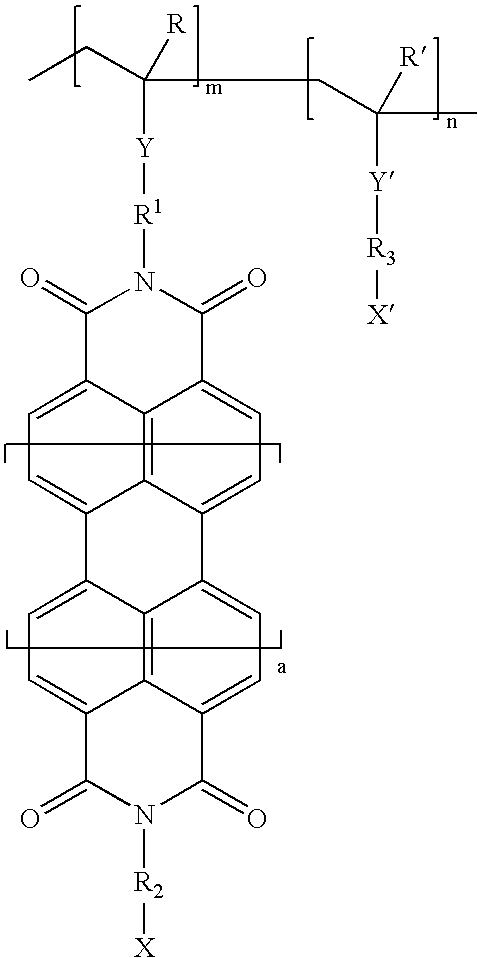

The present invention is a photoconductive element that includes an electrically conductive support, an electrical barrier layer disposed over said electrically conductive support, and disposed over said barrier layer, a charge generation layer capable of generating positive charge carriers when exposed to actinic radiation. The barrier layer includes a vinyl polymer with aromatic tetracarbonylbisimide side groups and crosslinking sites.

Owner:EASTMAN KODAK CO

Ethylene-Based Polymers And Articles Made Therefrom

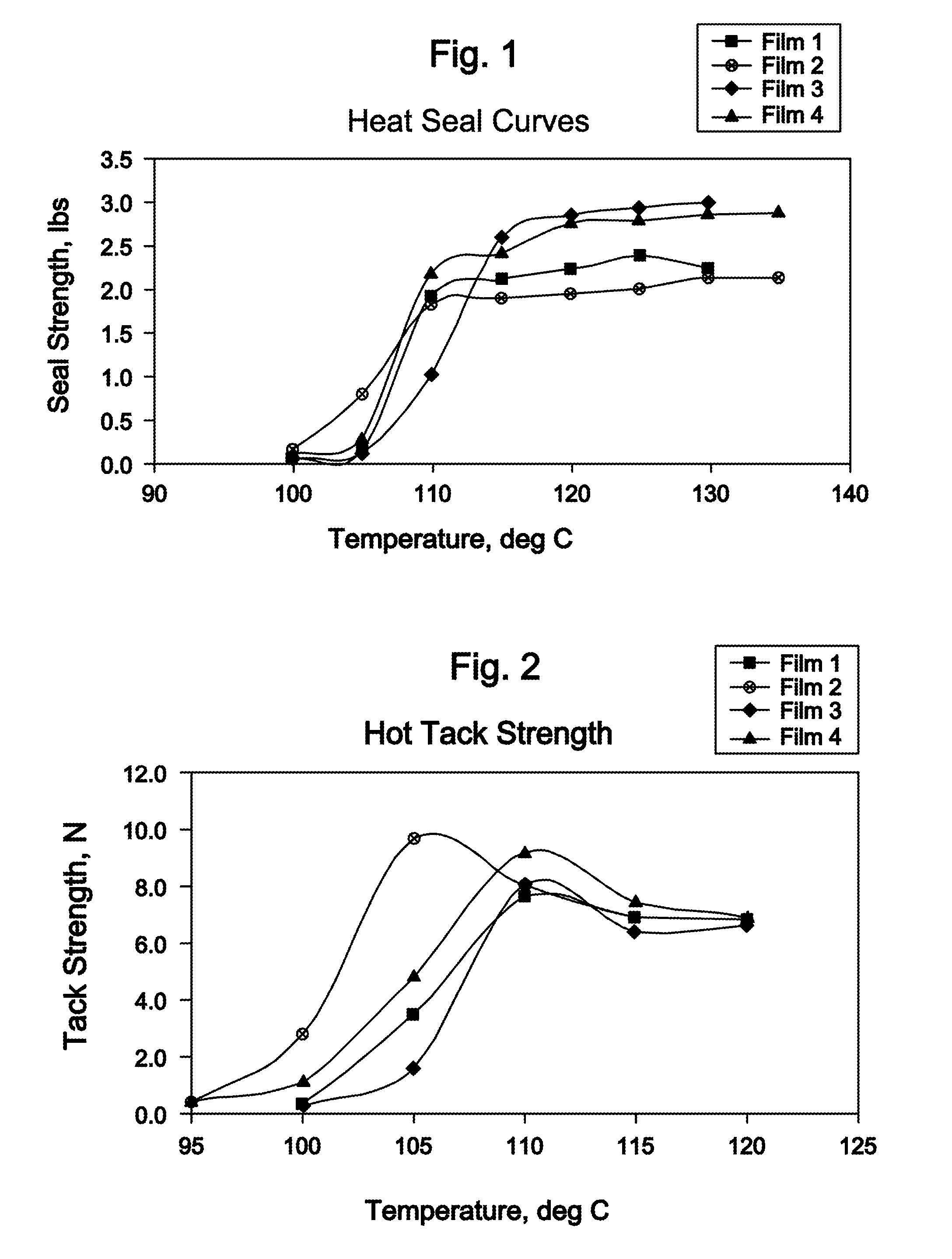

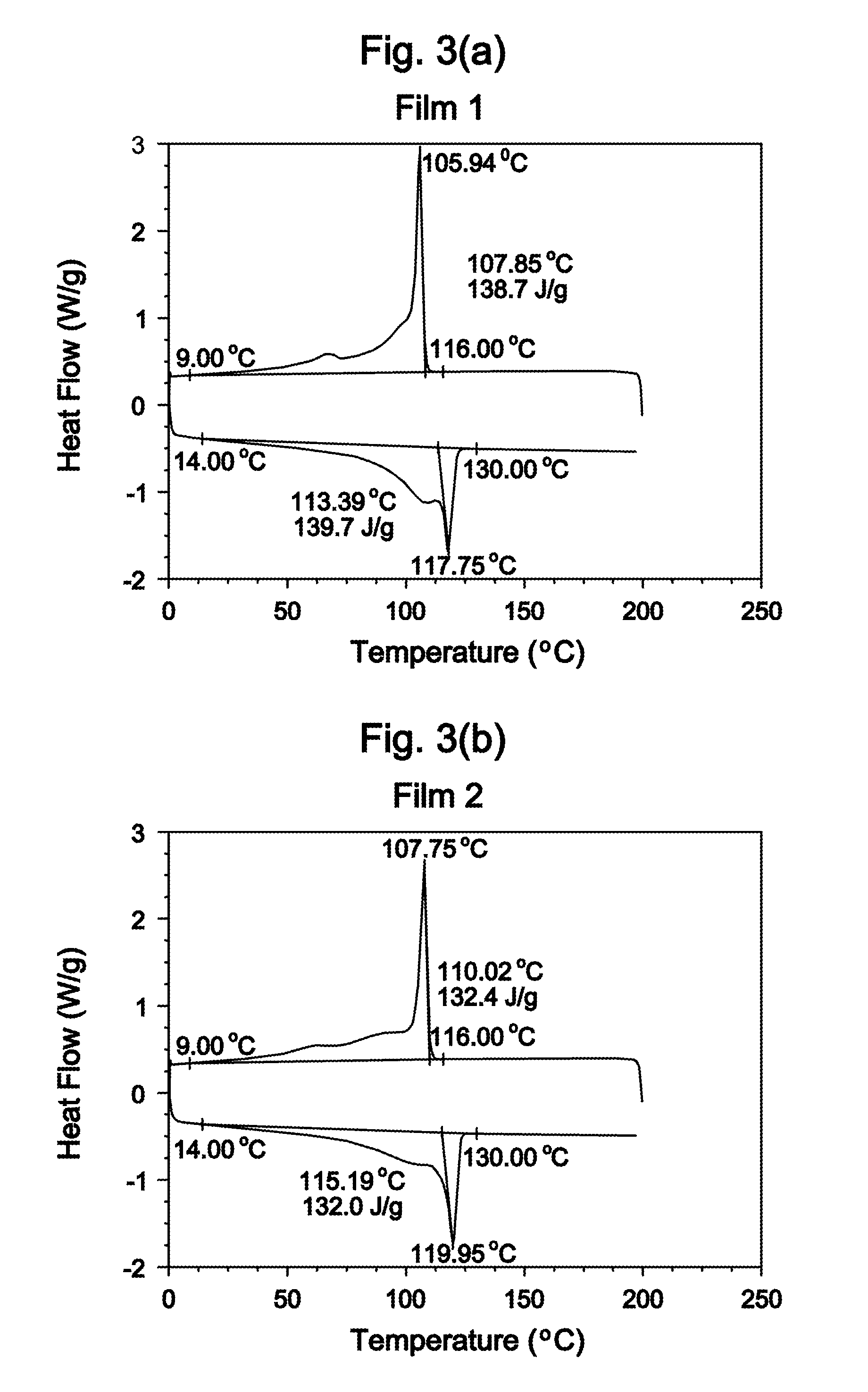

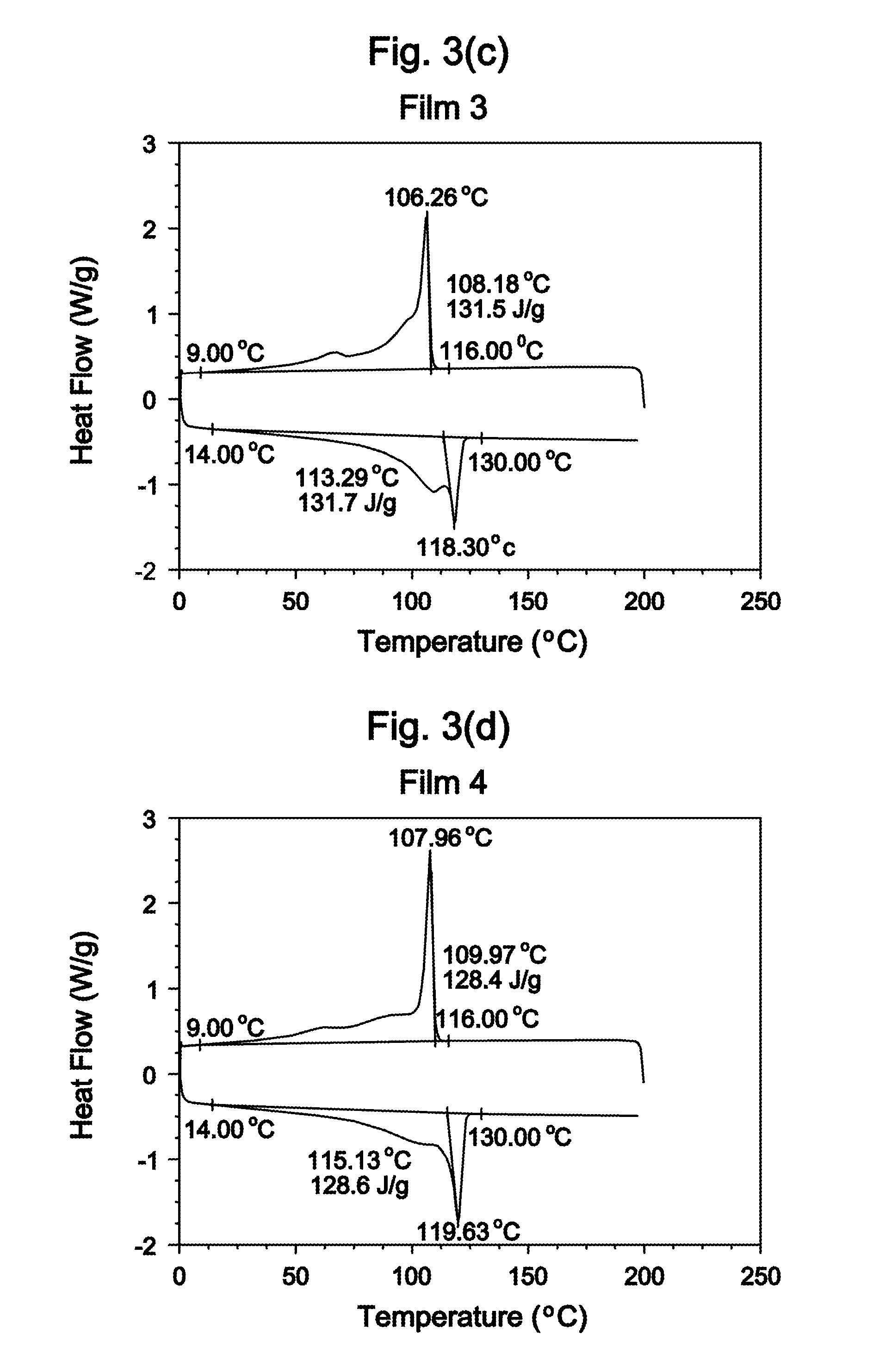

ActiveUS20090192270A1Good physical propertiesDrop clarityPersonal careSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

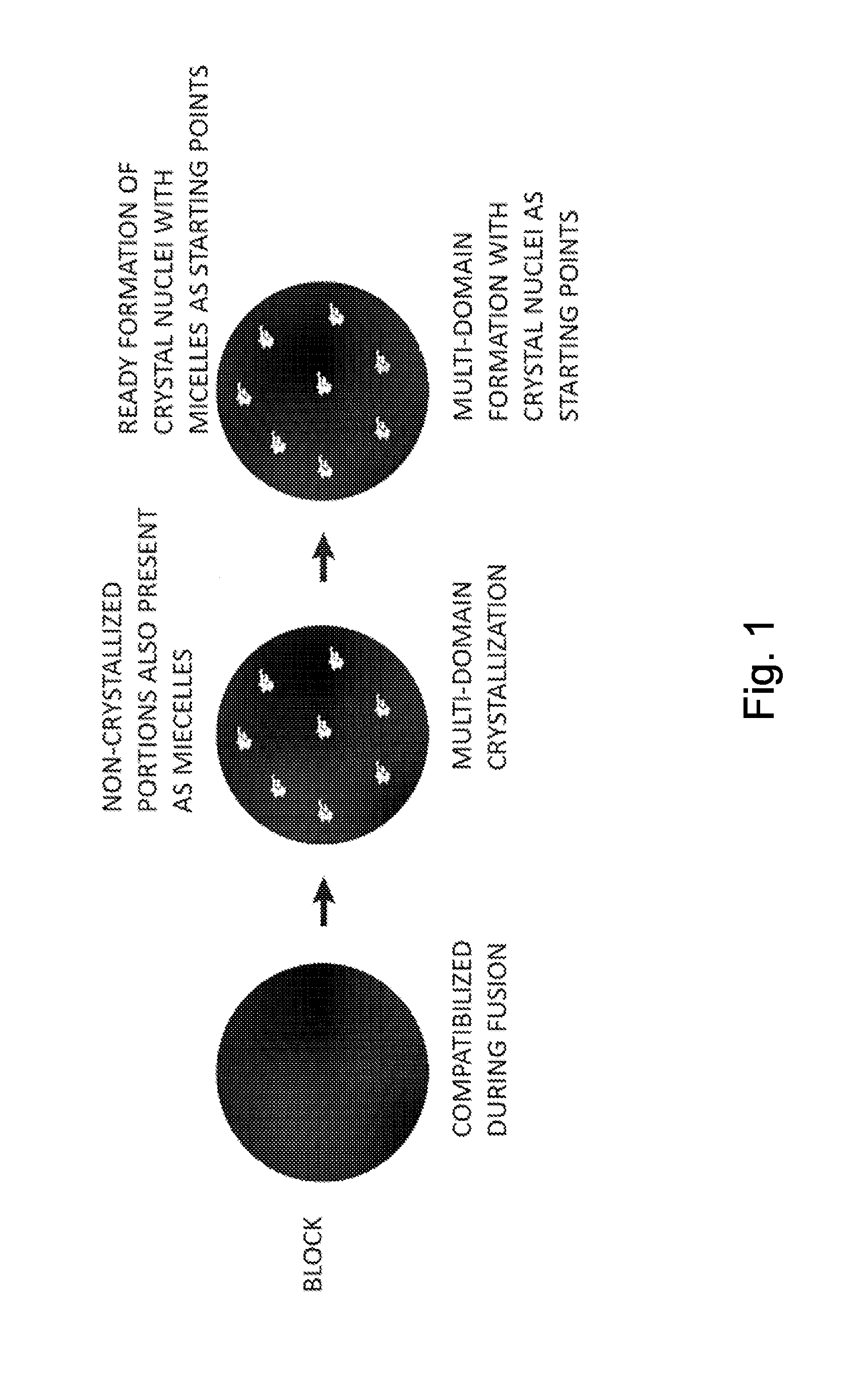

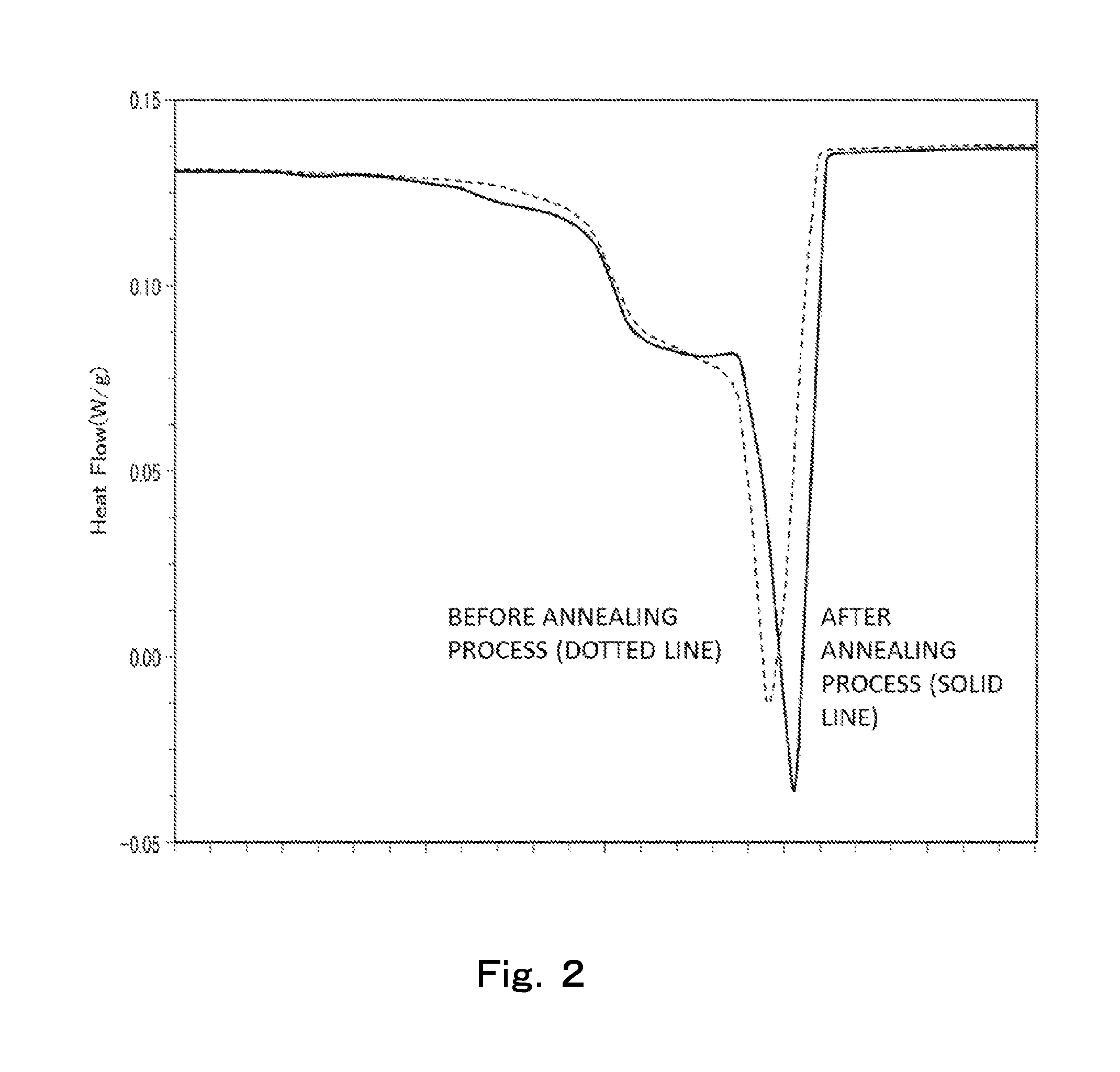

Provided are ethylene-based polymer compositions, articles made therefrom, and methods of making the same. Ethylene-based polymer compositions include blends of a linear low density polyethylene prepared with metallocene catalyst and a low density polyethylene. The linear low density polyethylene may optionally have about five mole percent or less of monomer units derived from an alpha-olefin comonomer. Articles composed of such ethylene-based polymer compositions, such as blown films, exhibit favorable physical properties, including excellent optical properties and retained strength i.e., mitigation of expected decline in physical strength due to LDPE addition.

Owner:EXXONMOBIL CHEM PAT INC

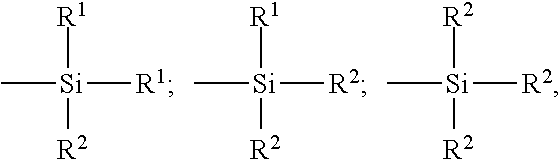

Curing composition

InactiveUS20060135709A1Good rubber physical propertyImprove heat resistancePolymer scienceWeather resistance

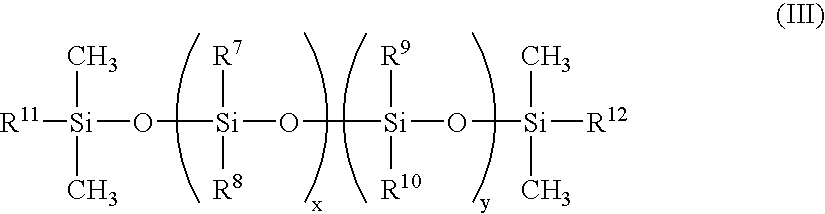

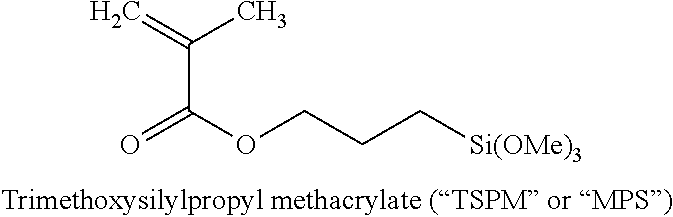

The present invention is a curable composition comprising a vinyl polymer having at least one crosslinkable silyl group on average and a compound having an α,β- or α,γ-diol structure in the molecule. The curable composition of the present invention can be used for obtaining a cured product which has superior weather resistance and heat resistance, and good rubber physical properties such as low stress and high elongation therefrom.

Owner:KANEKA CORP

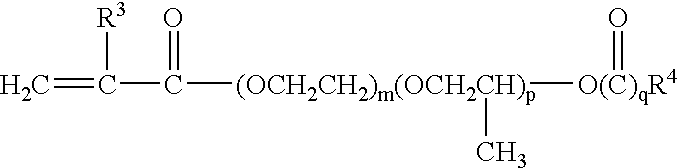

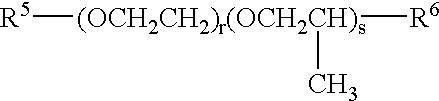

Water-in-oil emulsions with ethylene oxide groups, compositions, and methods

Water-in-oil emulsions, compositions, and methods that include a vinyl polymer that includes ethylene oxide-containing side chains and alkyl-Y-containing side chains, wherein Y is O or NR, wherein R is H or CH3, and wherein the alkyl group of the alkyl-Y-containing side chain has at least 4 carbon atoms on average in a cyclic, branched-, or straight-chain configuration and optionally including one or more heteroatoms.

Owner:3M INNOVATIVE PROPERTIES CO

Functionalized vinyl polymer nanoparticles

Owner:MICHELIN RECH & TECH SA

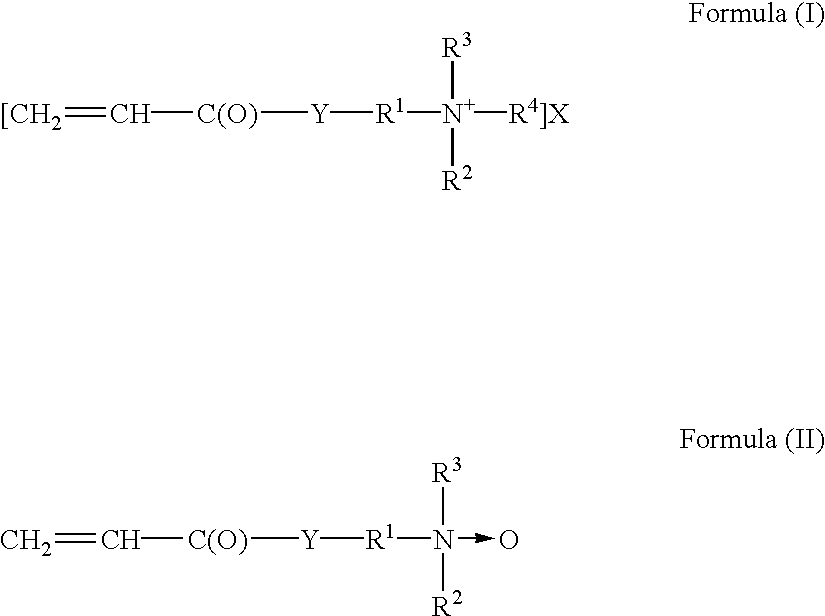

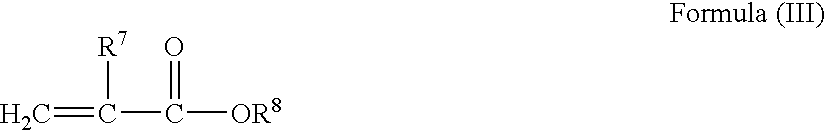

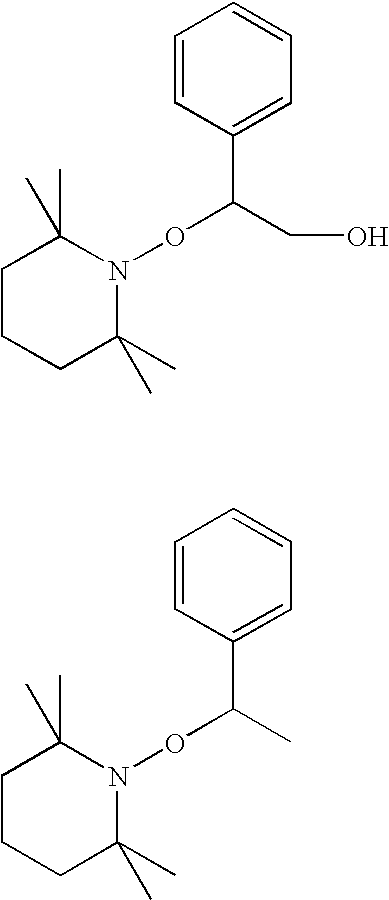

Functional groups-terminated vinyl polymers

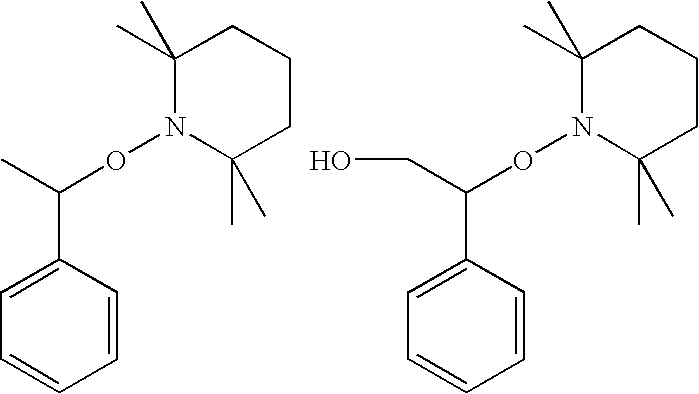

A vinyl polymer which has at least one terminal functional group per molecule and has a ratio of weight average molecular weight to number average molecular weight of less than 1.8 as determined by gel permeation chromatography, said terminal functional group being a crosslinking silyl group, an alkenyl group, or a hydroxyl group. Curable compositions containing this vinyl polymer is easy to handle.

Owner:KANEKA CORP

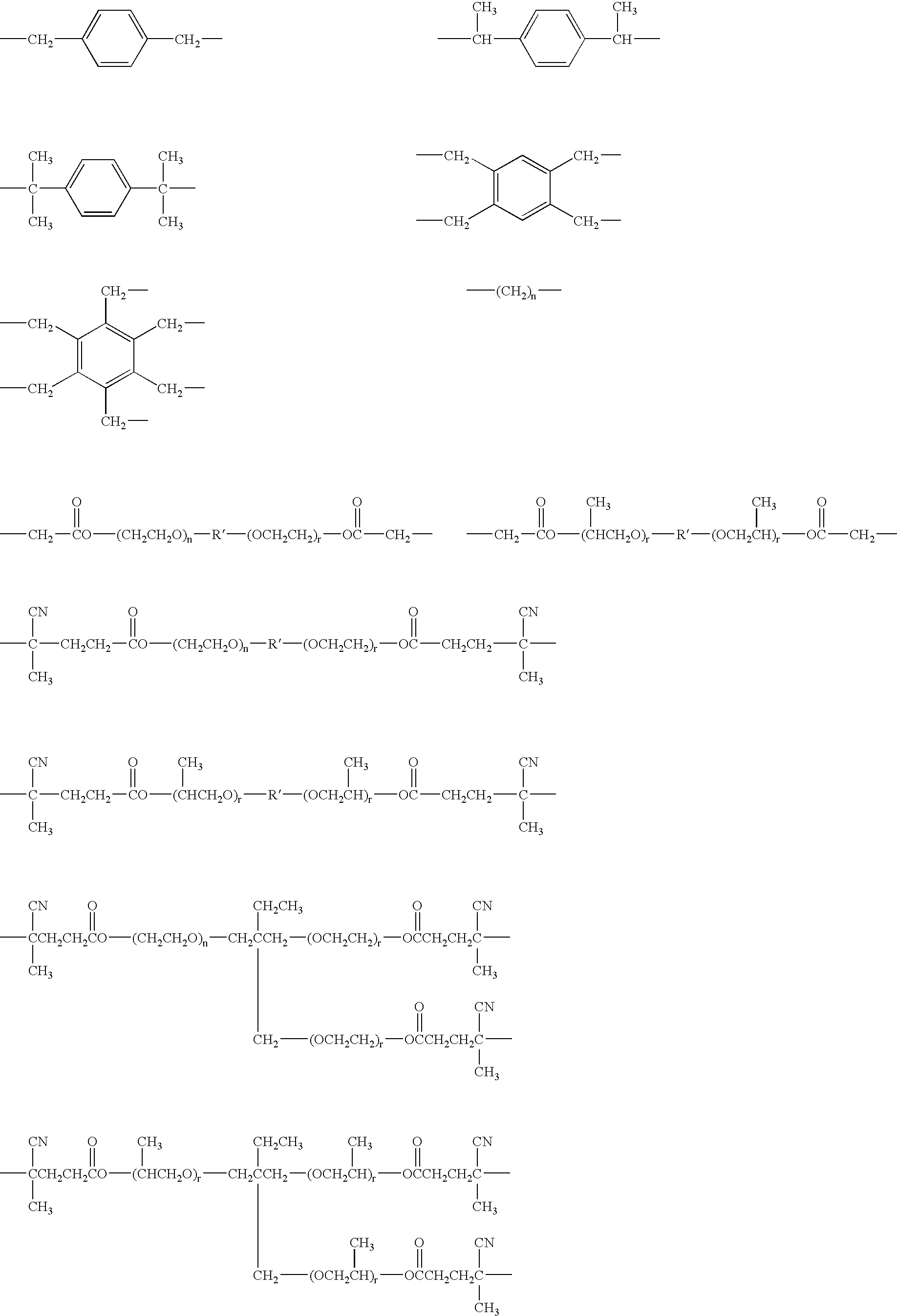

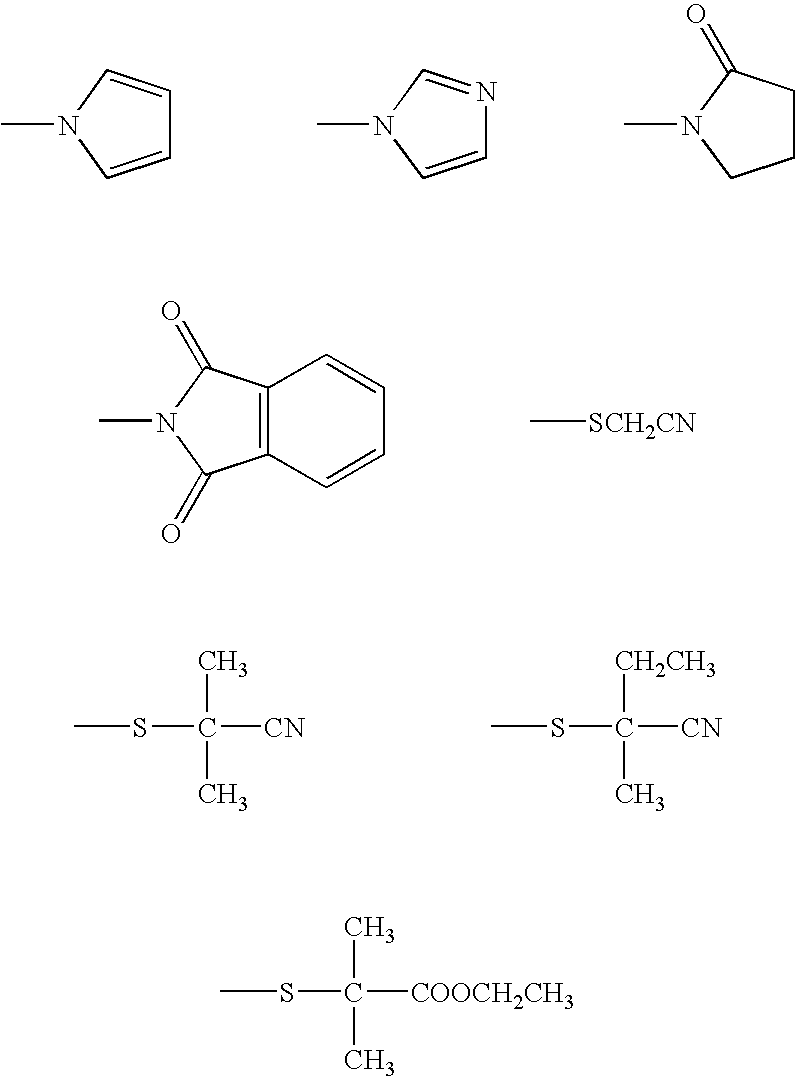

Amphiphilic diblock, triblock and star-block copolymers and their pharmaceutical compositions

This invention relates to novel amphiphilic diblock, triblock copolymers and star-shaped block copolymers comprising a biodegradable polymer covalently attached at the polymer ends, to a hydrophilic vinyl polymer, via divalent sulfur atom; to a process for producing the block polymers; to a polymerization process which comprises subjecting the monomers capable of radical polymerization to radical polymerization in the presence of a macromolecular biodegradable chain-transfer agent; and to pharmaceutical compositions comprising the block copolymers loaded with therapeutic agents.

Owner:PALADIN LABS INC

Pharmaceutical dental formulation for topical application of metronidazole benzoate, chlorhexidine gluconate and local anesthetic

Pharmaceutical dental gel preparation comprising of metronidazole benzoate, chlorhexidine gluconate, and local anesthetic as the active ingredient; glycol as the solvent medium; a carboxyvinyl polymer, cross-linked polymer of acrylic acid copolymerized with polyalkylsucrose as a gelling agent.

Owner:J B CHEM & PHARMA

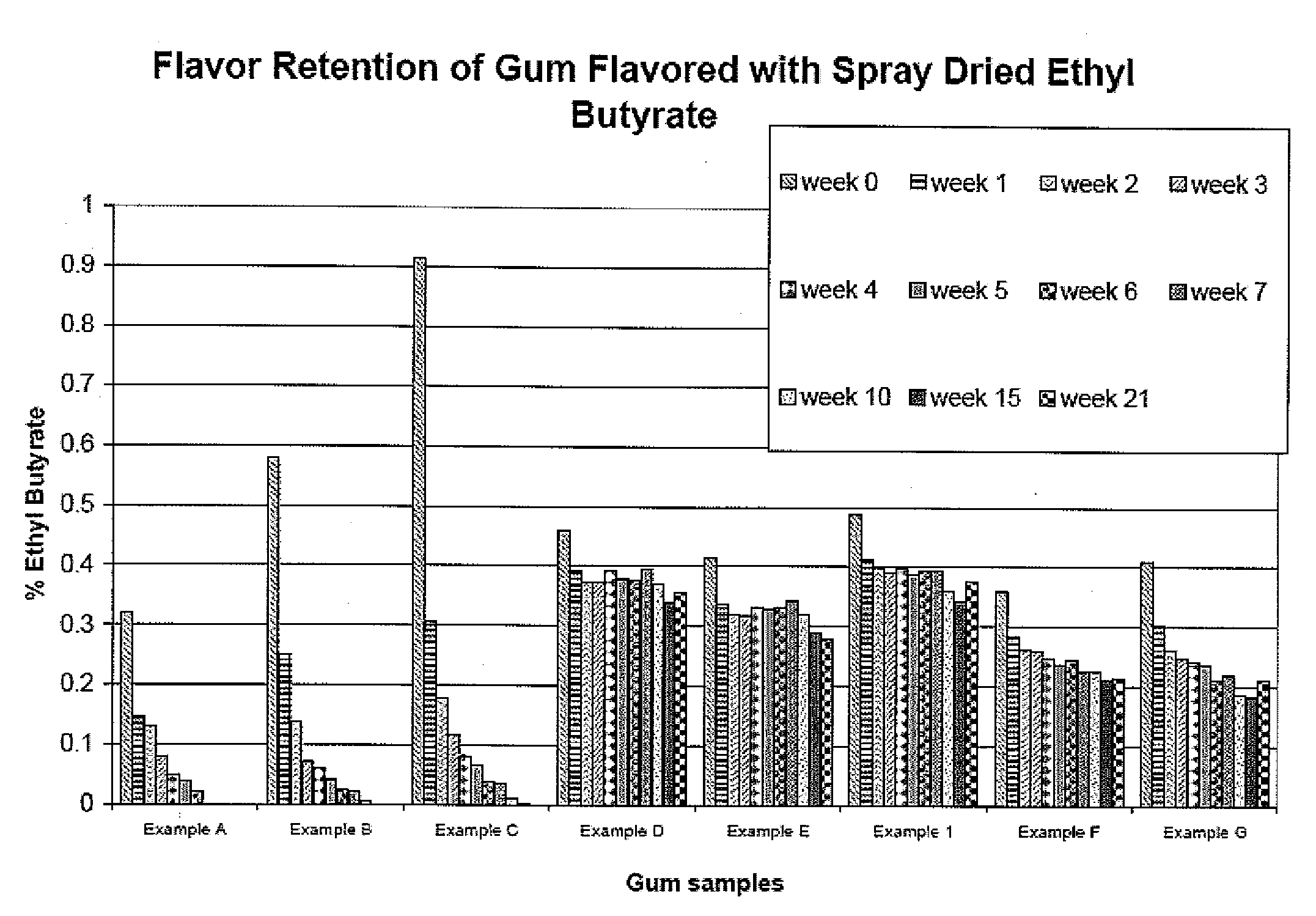

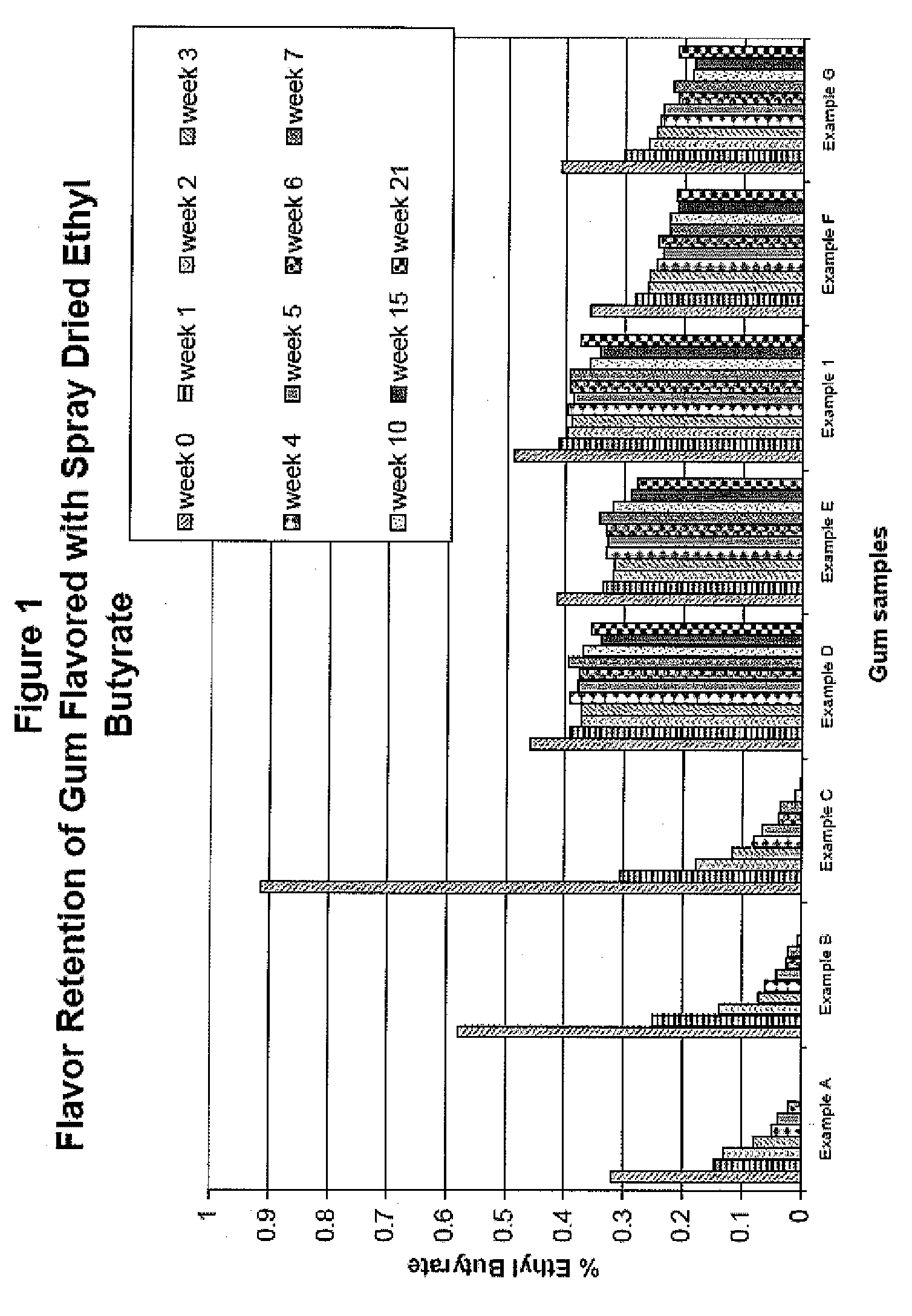

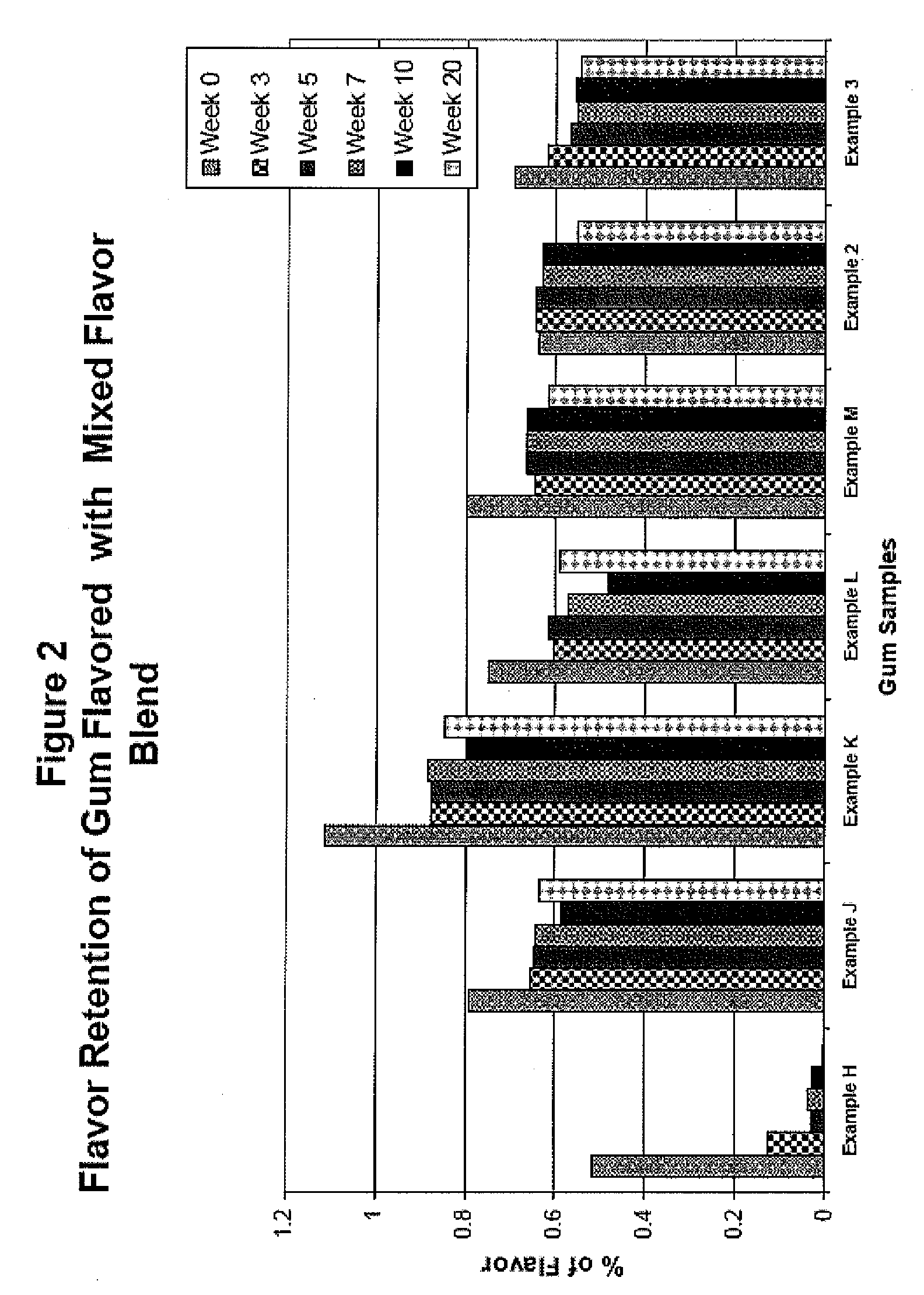

Long-duration encapsulated flavors and chewing gum using same

InactiveUS20070231424A1Easy to keepIncreases flavor durationSugar food ingredientsChewing gumCORN SYRUP SOLIDSFood flavor

A chewing gum composition comprises about 5% to about 95% gum base, about 5% to about 96% bulking and sweetening agents, and about 0.1% to about 15% flavor, wherein at least part of the flavor is a long-duration flavor material comprising a vinyl polymer encapsulated matrix. The matrix itself includes about 30% to about 60% acacia gum, about 30% to about 60% corn syrup solids having a DE of between about 24 and about 44 or equivalent hydrogenated starch hydrolysates, and about 2% to about 20% hydrocolloid material, with the acacia gum and corn syrup solids or hydrogenated starch hydrolysates together comprising at least 80% of the matrix. The vinyl polymer comprises between about 30% and about 80% of the long-duration flavor material.

Owner:WM WRIGLEY JR CO

Toner

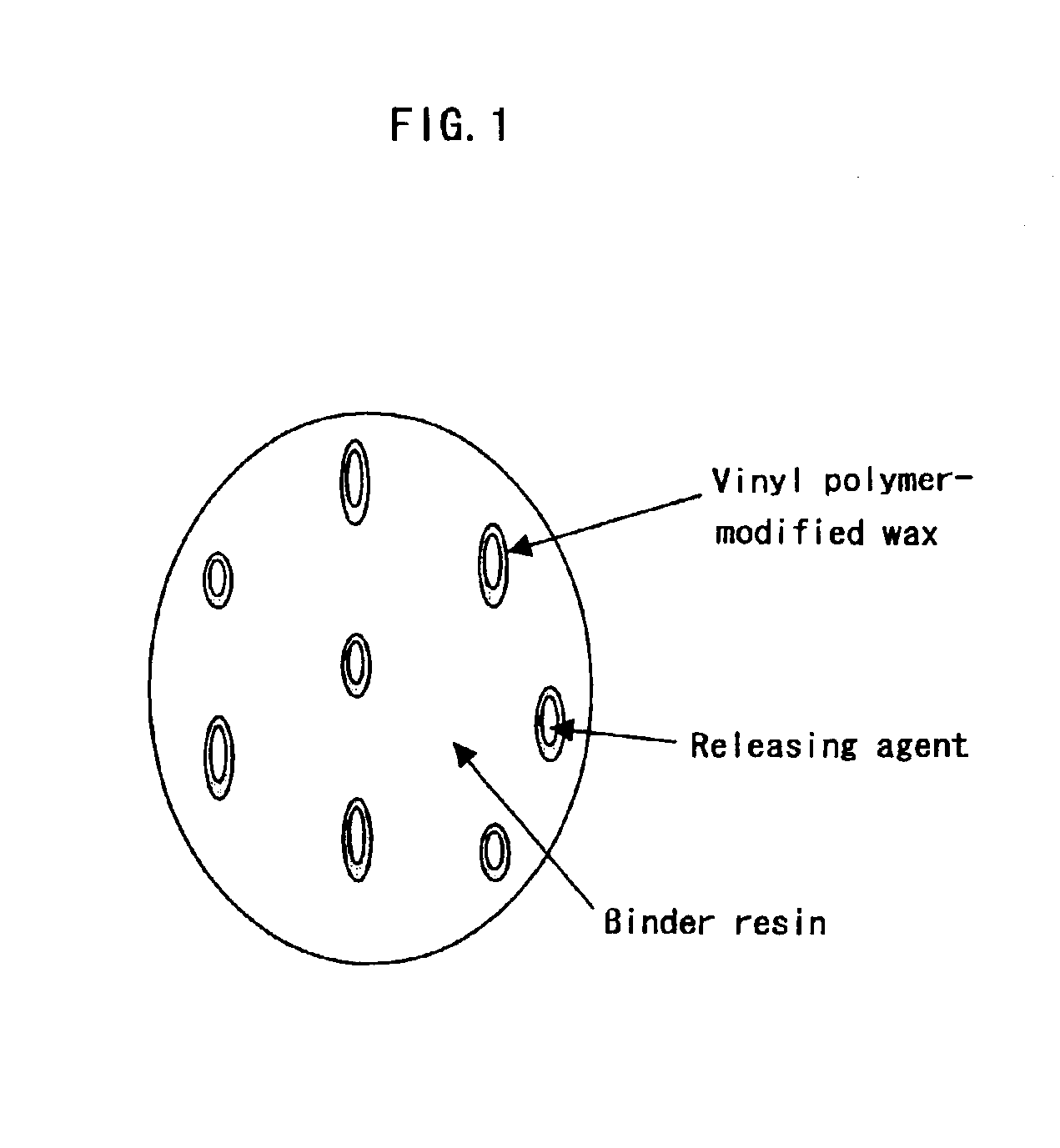

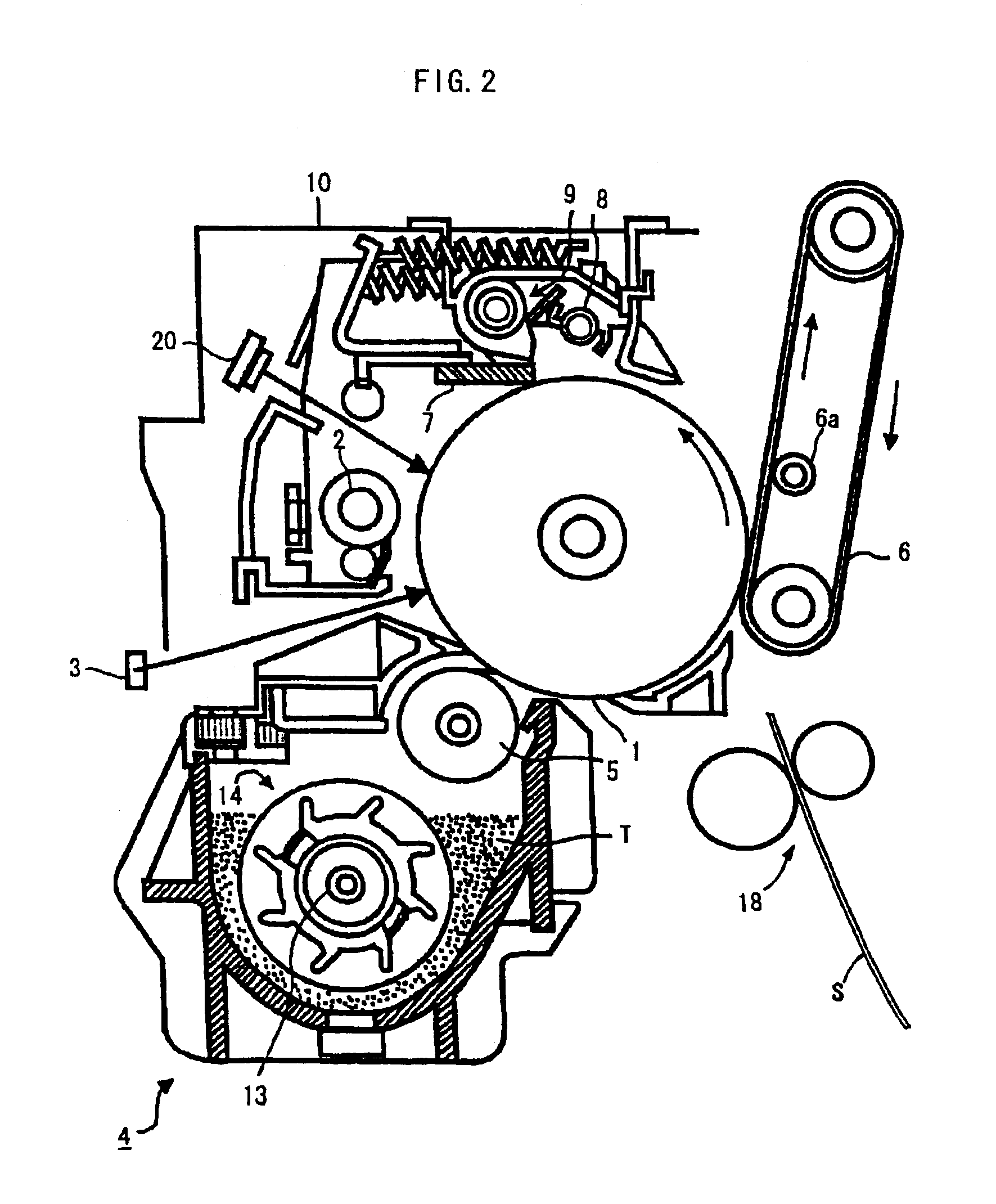

A toner, particularly a color toner suitable for full-color image formation through a substantially oil-less heat-pressure fixing device, is formed from at least a binder resin, a colorant and a wax. The binder resin comprises a polyester-based resin selected from the group consisting of (a) a polyester resin, (b) a hybrid resin having a polyester unit and a vinyl polymer unit, and (c) a mixture of these resins. The wax is characterized by including a structural unit including an OH group, an amide, or an ester group at a specific position.

Owner:CANON KK

PVA hydrogel

InactiveUS20060079597A1Improve physical stabilityGood physical propertiesOrganic chemistryMixing methodsPolymer sciencePolymer

The present invention provides methods of making covalently crosslinked vinyl polymer hydrogels having advantageous physical properties, and covalently crosslinked vinyl polymer hydrogel compositions made by such methods, as well as articles of manufacture comprising such covalently crosslinked vinyl polymer hydrogel compositions. The physical properties of the produced hydrogels can be adjusted by varying controlled parameters such as the proportion of physical associations, the concentration of polymer and the amount of radiation applied. Such covalently crosslinked vinyl polymer hydrogels can be made translucent, preferably transparent, or opaque depending on the processing conditions. The stability of the physical properties of the produced vinyl polymer hydrogel can be enhanced by controlling the amount of covalent crosslinks.

Owner:ZIMMER GMBH

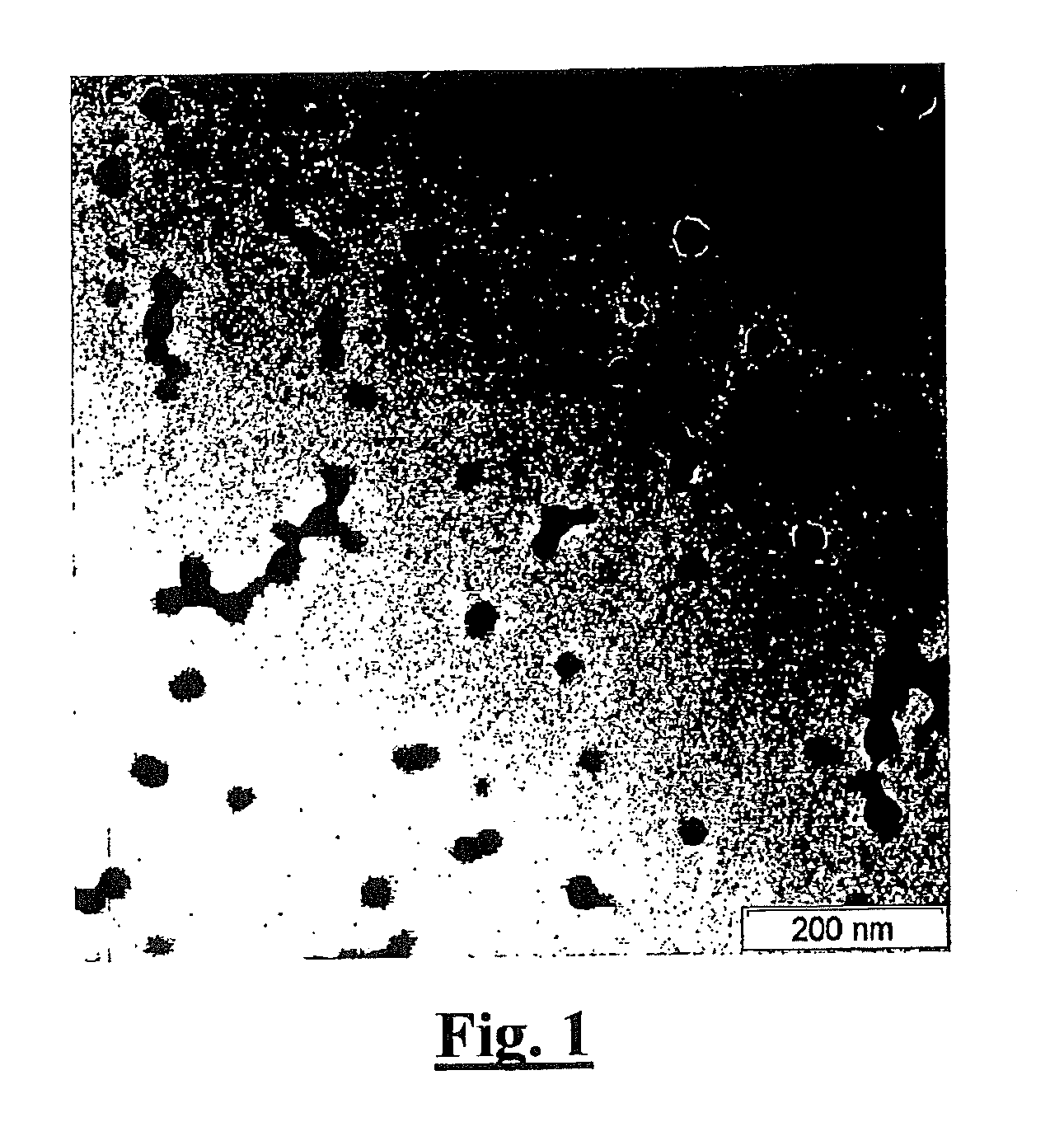

Initiated chemical vapor deposition of vinyl polymers for the encapsulation of particles

ActiveUS20070104860A1Quality improvementClear processPretreated surfacesChemical vapor deposition coatingGas phaseConformal coating

One aspect of the present invention relates to an all-dry encapsulation method that enables well-defined polymers to be applied around particles of sizes down to the nanoscale. In certain embodiments, the methods are modified forms of initiated chemical vapor deposition (iCVD) using a thermally-initiated radical polymerization to create conformal coatings around individual particles while avoiding agglomeration. The present invention also enables the coating of particle surfaces with a range of functional groups via direct incorporation of the functionality into the monomers used or indirectly through a subsequent modification of the surface of a coated particle. In certain embodiments, the method produces high quality functional polymer coatings.

Owner:MASSACHUSETTS INST OF TECH

Elastomeric compositions

A composition comprising: (i) at least one low molecular weight polyolefin; (ii) at least one block copolymer obtainable by selectively hydrogenating a block copolymer having terminal polymeric blocks of a vinyl aromatic monomer and a mid-block prepared originally with an olefin and subsequently hydrogenated; (iii) at least one polypropylene; and (iv) at least one plastomer, wherein the plastomer is an ethylene based polymer having a density of 0.86 g / cc to about 0.910 g / cc or a propylene based polymer having a heat of fusion (Hf) of 70 J / g or less.

Owner:EXXONMOBIL CHEM PAT INC

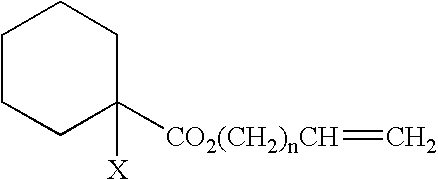

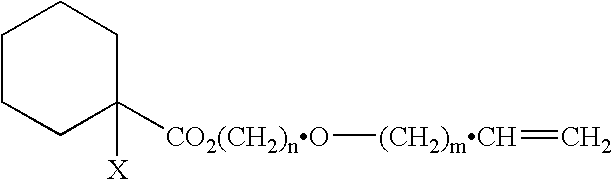

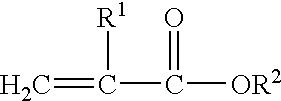

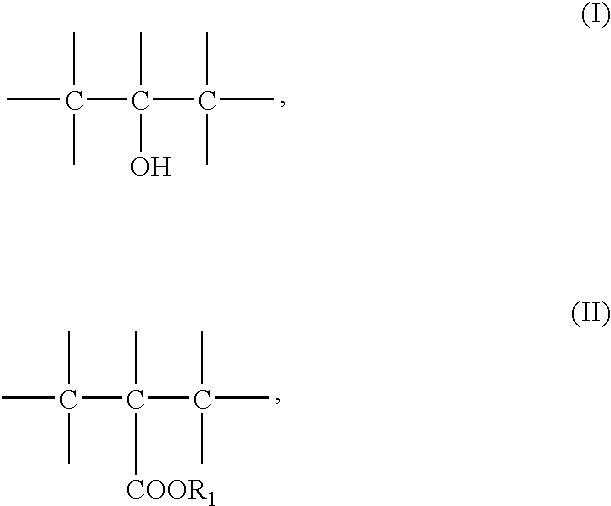

Polymer and curable composition

InactiveUS6964999B1Easy to useHigh terminal functionalityOrganic non-macromolecular adhesiveHydrogenEmulsion

A vinyl polymer having at least one terminal group of the general formula (1) per molecule;—OC(O)C(R)═CH2 (1)wherein R represents hydrogen or an organic group containing 1 to 20 carbon atoms;a curable composition containing said polymer;an aqueous emulsion containing either said polymer or said curable composition;a pressure sensitive adhesive composition and a pressure sensitive adhesive each comprising said curable composition or aqueous emulsion.

Owner:KANEKA CORP

Desalting adjunct chemistry

InactiveUS6120678AImproves separation of waterReduce decreaseDewatering/demulsification with chemical meansLiquid separation by electricityChemical treatmentMeth-

Improved performance in the phase separation of aqueous brines from hydrocarbons within an electrostatic desalter operation is obtained by the addition to the crude oil emulsions entering the desalter of an effective asphaltene dispersing amount of an alkyl phenol-formaldehyde liquid resin polymer, optionally in the presence of a lipophilic / hydrophilic vinylic polymer. The preferred resin is a nonyl phenol-formaldehyde resin having a molecular weight of from 1,000-20,000, and the preferred vinylic polymer is a copolymer of lauryl (meth)acrylate and hydroxyethyl (meth)acrylate. Best results from the electrostatic desalter are obtained when also using a demulsifier chemical treatment along with the asphaltene dispersing treatments. Desalter efficiency is increased and desalter brine effluent quality is greatly increased.

Owner:ECOLAB USA INC +1

Low density ethylene-based polymers with broad molecular weight distributions and low extractables

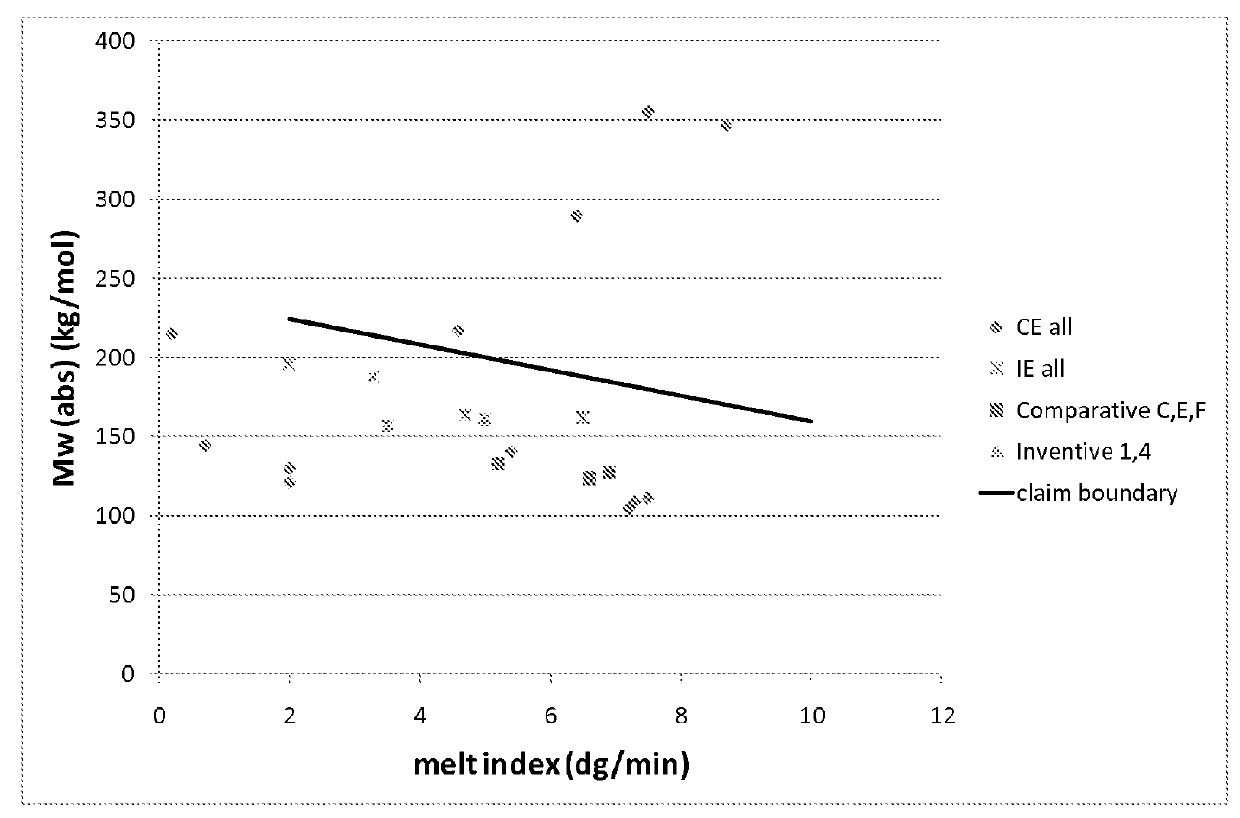

The invention provides an ethylene-based polymer comprising the following properties: a) a melt index (12)>2.0 dg / min; b) a Mw(abs) versus 12 relationship: Mw(abs)<A+B(I2), where A=2.40×105 g / mole, and B=−8.00×103 (g / mole) / (dg / min); and c) a G′ versus 12 relationship: G′>C+D(I2), where C=127.5 Pa, and D=−1.25 Pa / (dg / min). The invention also provides an ethylene-based polymer comprising the following properties: a) a melt index (12)>2.0 dg / min; b) a G′ versus 12 relationship: G′>C+D(I2), where C=127.5 Pa, and D=−1.25 Pa / (dg / min) c) a chloroform extractable (Clext) versus G′ relationship: Clext.<E+FG′, where E=0.20 wt %, and F=0.060 wt % / Pa; and d) a “weight fraction (w) of molecular weight greater than 106 g / mole, based on the total weight of polymer, and as determined by GPC(abs),” that meets the following relationship: w<I−J(I2), where I=0.080, and J=−4.00×10−3 min / dg.

Owner:DOW GLOBAL TECH LLC

Toner for developing electrostatic latent image, toner cartridge, developer, developer cartridge, image forming method, and image forming apparatus

InactiveUS6924073B2Excellent low temperature fixabilityIncrease resistanceDevelopersElectrographic processes using charge patternWaxLatent image

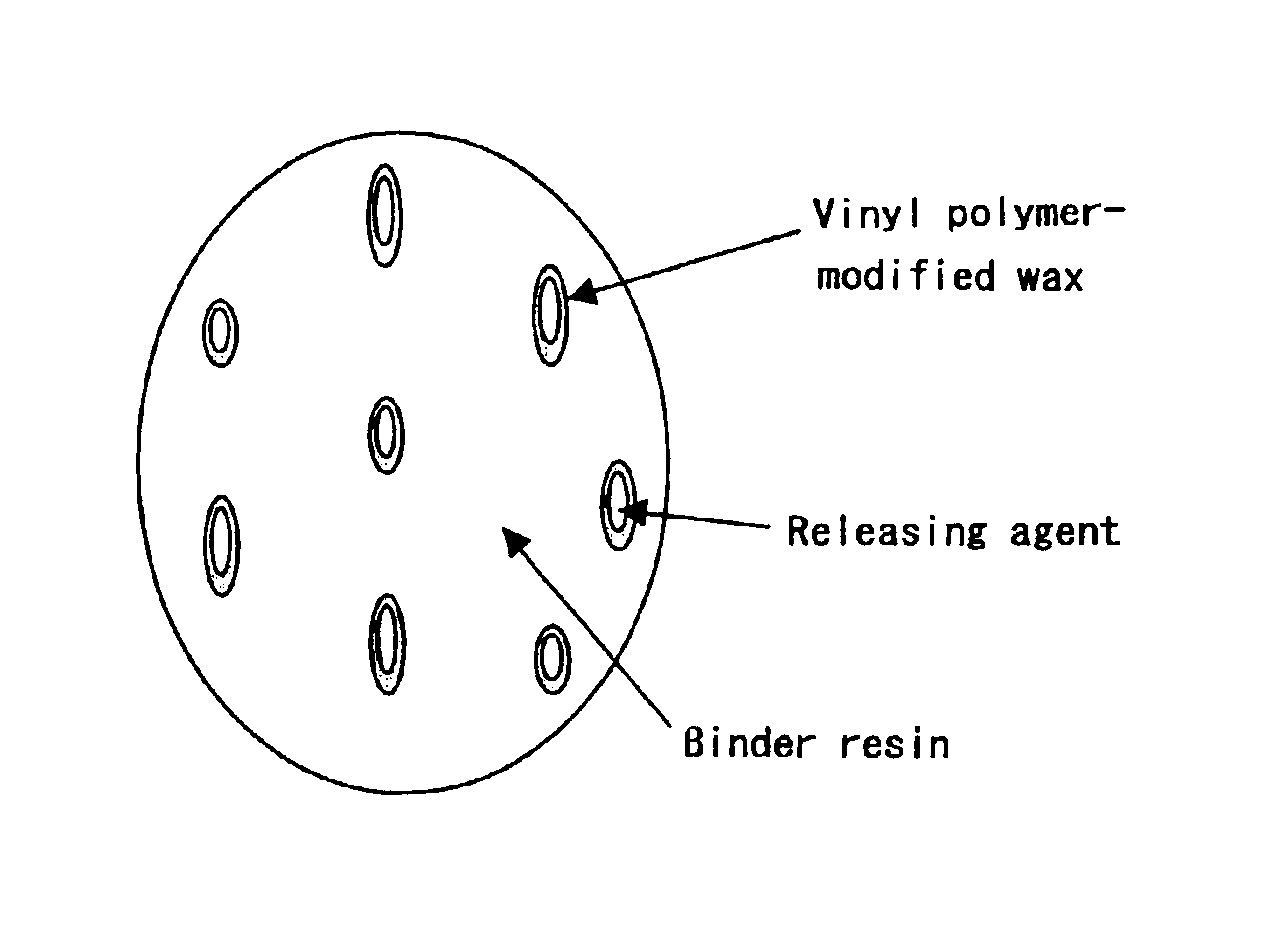

A toner for developing an electrostatic latent image, comprising a colorant, a releasing agent and a binder resin, wherein said binder resin comprises a first, non-linear resin, a second, linear resin, and a modified wax comprising a wax moiety and a vinyl polymer moiety having an ester group content of 8 to 30% by weight based on the weight of the vinyl polymer moiety.

Owner:RICOH KK

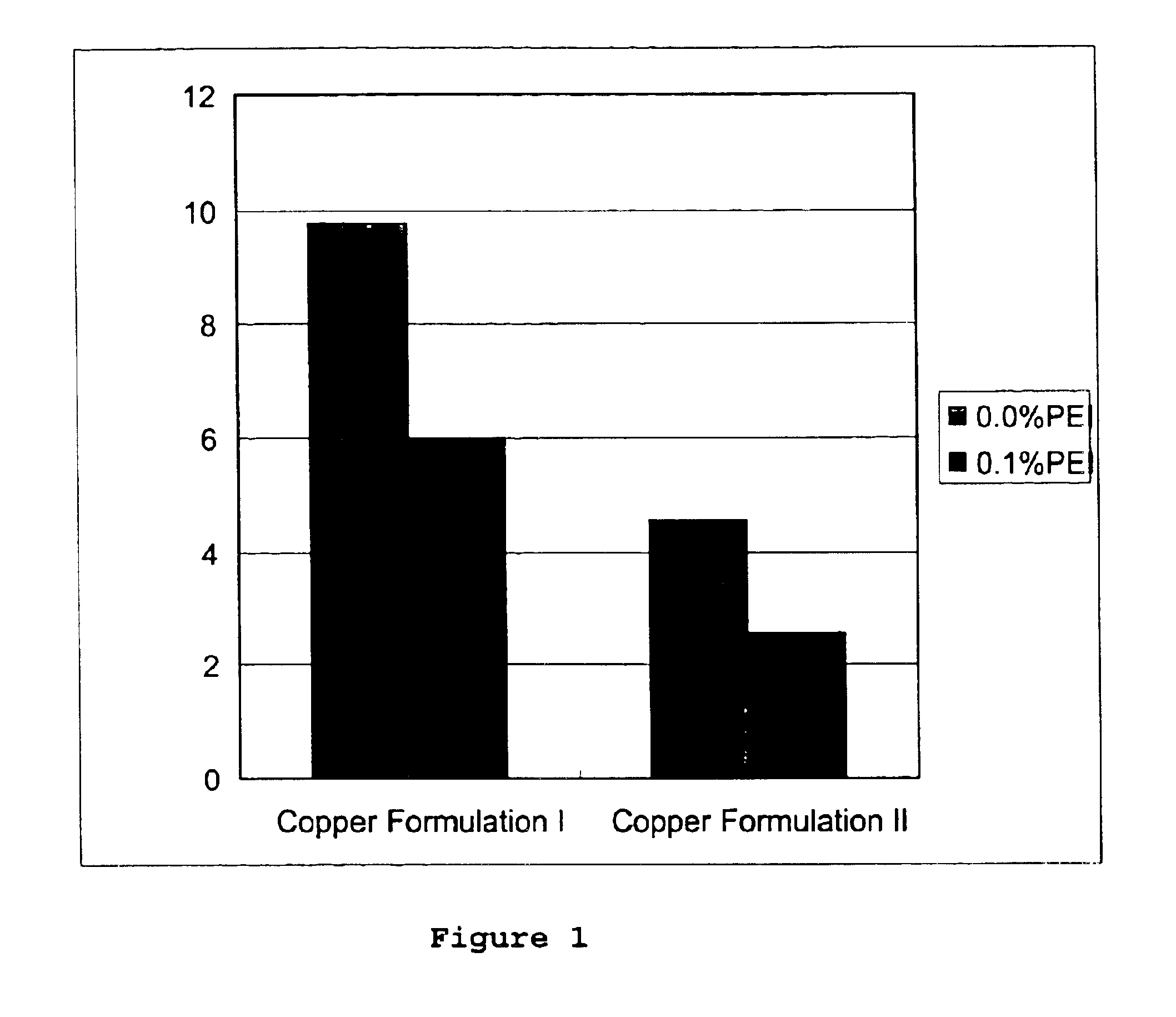

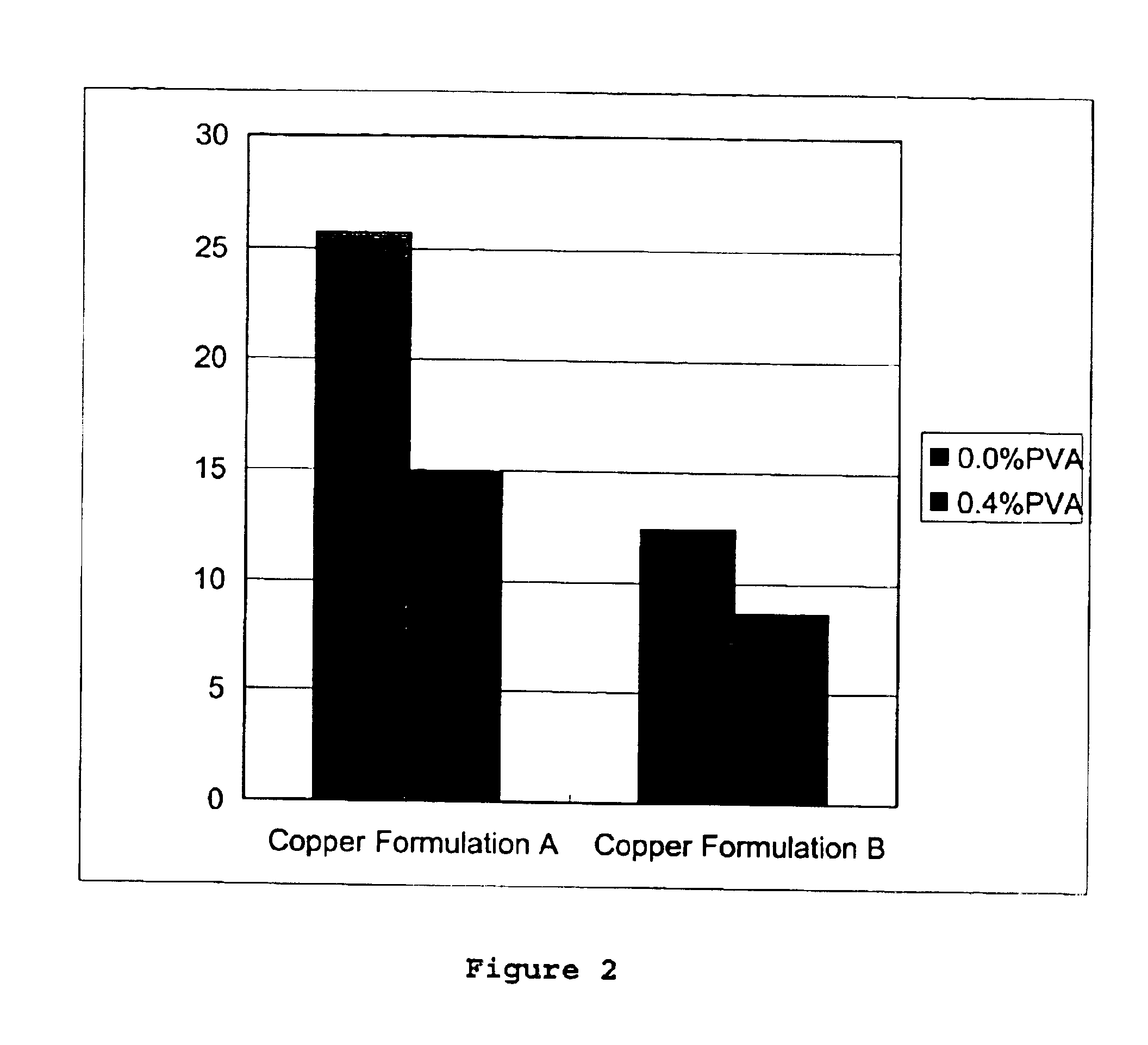

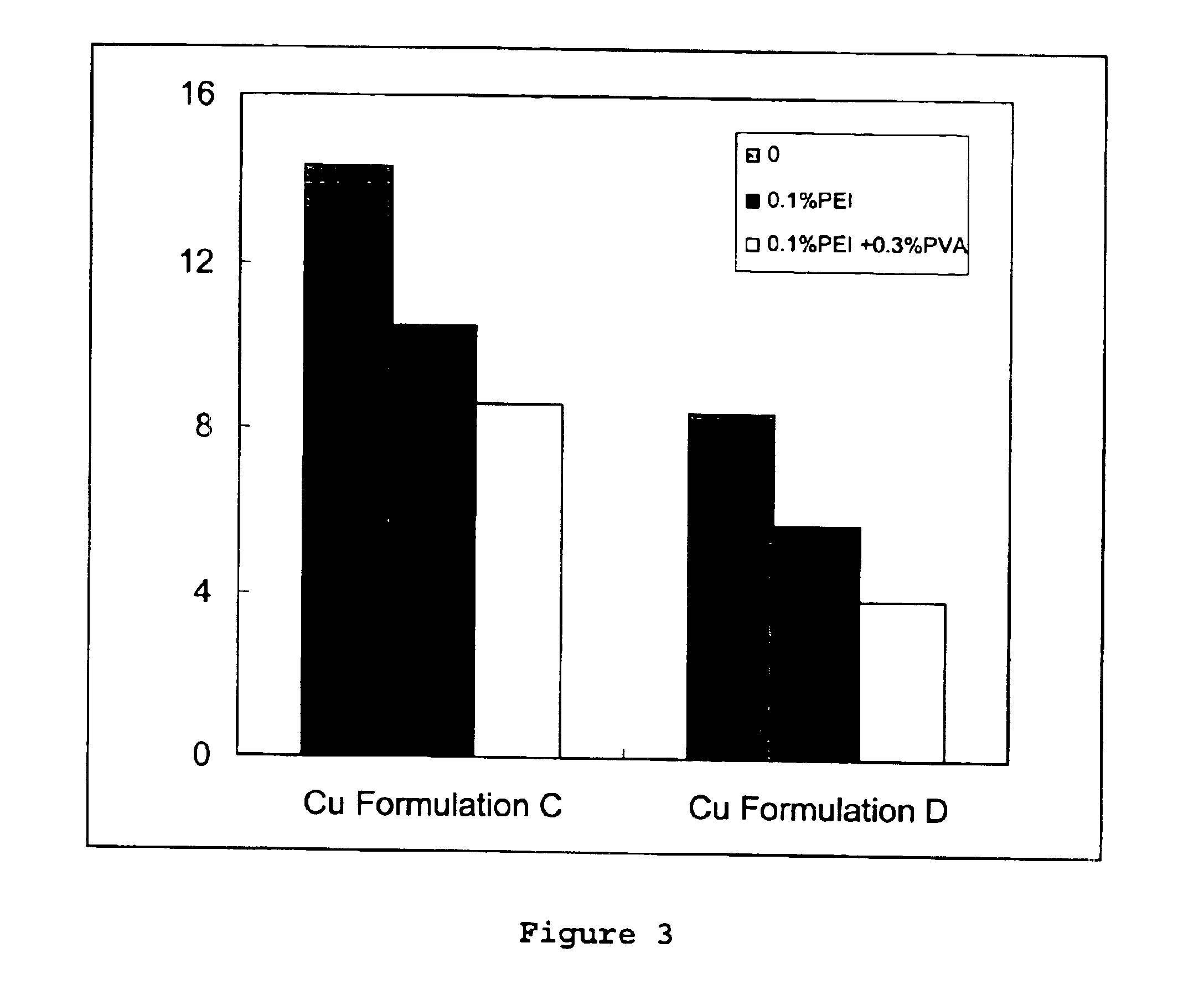

Polymeric wood preservative compositions

The present invention relates to a method and a wood preserving composition which comprises mixtures of a metal compound, complexing agents selected from ethanolamines, polyethylenimine, ammonia or a mixture of these compounds, and a vinyl based polymer selected from poly(vinyl alcohol) (PVA), poly(acrylamide) (PA), poly(N-vinyl pyrrolidone) (PVP) and poly(N-isopropyl acrylamide) (PNIPAM). The resulting metal amine solution can then be used to formulate a variety of metal-based cellulosic material preserving products.

Owner:OSMOSE

Intumescent Seal

InactiveUS20090326117A1Reduce riskHigh mechanical elasticity and resistanceOther chemical processesEngine diaphragmsOrganic Boron CompoundsPassive fire protection

A flexible intumescent seal for passive fire protection has a base material that consists of a blend comprising at least one thermoplastic polymer, expandable graphite and at least one acid generating compound. The acid generating compound is an organic boron compound and the at least one thermoplastic polymer is a vinyl polymer and / or copolymer. The seal may be formed by extrusion, drawing, molding or injection of the blend.

Owner:BENUSSI GIAMPAOLO +2

Method for producing toner particles

Owner:CANON KK

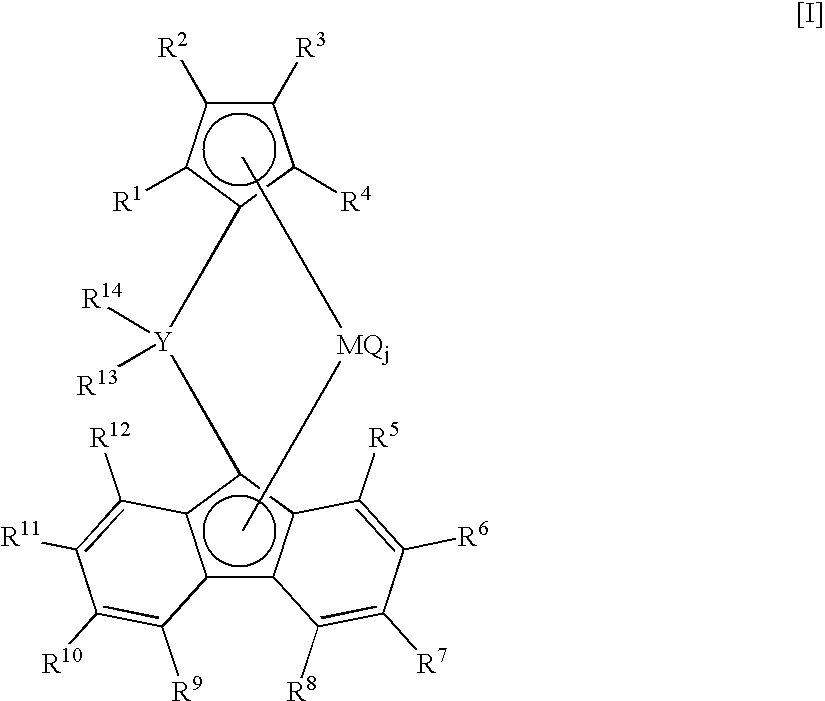

Crosslinked metallocene compound for olefin polymerization and method of polymerizing olefin with the same

InactiveUS20060161013A1High polymerization activitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

The bridged metallocene compound or the olefin polymerization catalyst which comprises the compound, enables high polymerization activity in polymerizing one or more monomers selected from ethylene and α-olefins. The bridged metallocene compound contains specific substituted cyclopentadienyl and fluorenyl groups which are linked via carbon or silicon atoms. In the method for the preparation of polyolefins, one or more monomers, preferably ethylene as an essential monomer, selected from ethylene and α-olefins are copolymerized in the presence of the olefin polymerization catalyst comprising the bridged metallocene compound, so that an ethylene based polymer with an ethylene content of more than 50 mol % is obtained.

Owner:MITSUI CHEM INC

Glycerin triester plasticizer

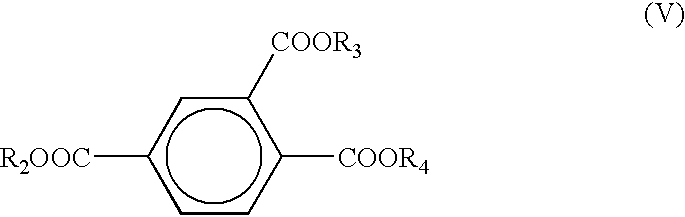

InactiveUS6652774B2Improve heat resistanceReduce volatilityOrganic compound preparationOther chemical processesArylPolymer resin

The present invention provides a phthalate-free plasticizer for polymer resins. The phthalate-free plasticizer according to the invention includes a mixture of different triesters of glycerin, at least one of which meets the formula:wherein at least two of R1, R2, and R3 are different alkyl or aryl groups. Phthalate-free plasticizers according to the invention can be made by esterifying glycerin with a mixture of acids in the presence of a catalyst. Preferably, the mixture of acids includes at least two selected from the group consisting of alkyl acids and aryl acids, with each acid in the mixture containing up to about 11 carbon atoms, and more preferably from about 4 to about 9 carbon atoms each. The plasticizer according to the invention can be used to modify the properties of a wide variety of polymers including vinyl polymers, rubbers, polyurethanes, and acrylics, and has superb thermostability and low volatility.

Owner:POLYMER ADDITIVES INC DBA VALTRIS SPECIALTY CHEM

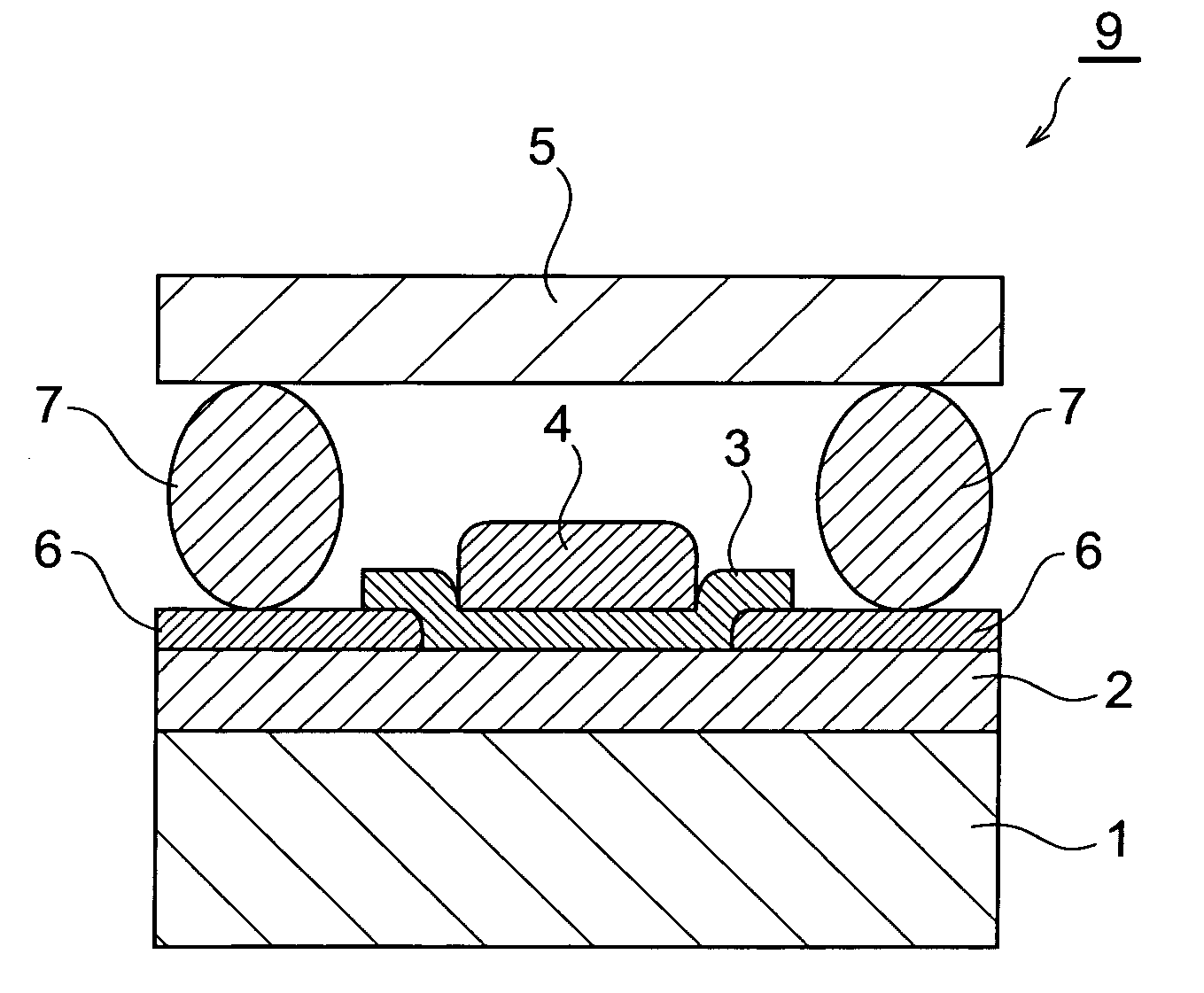

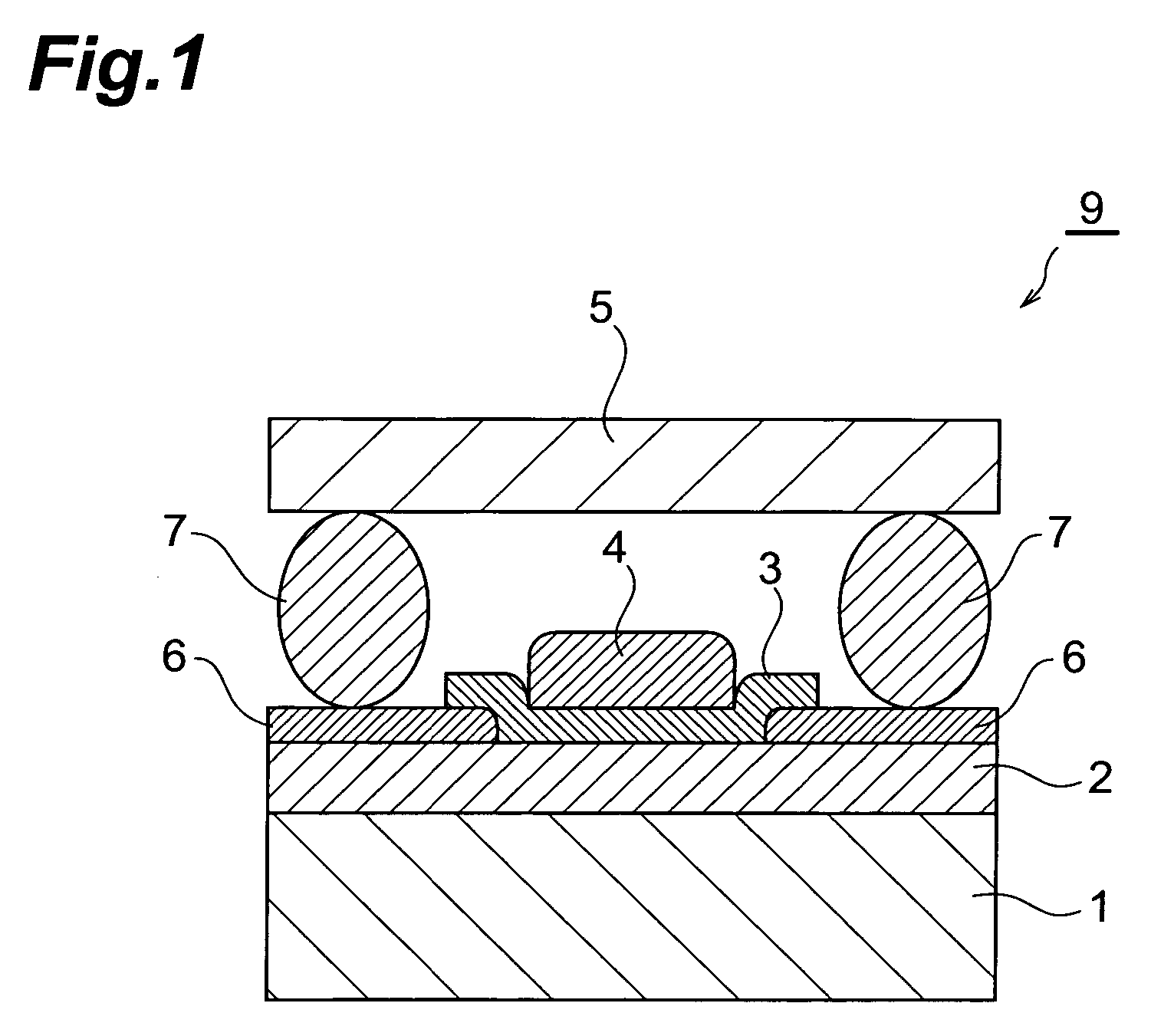

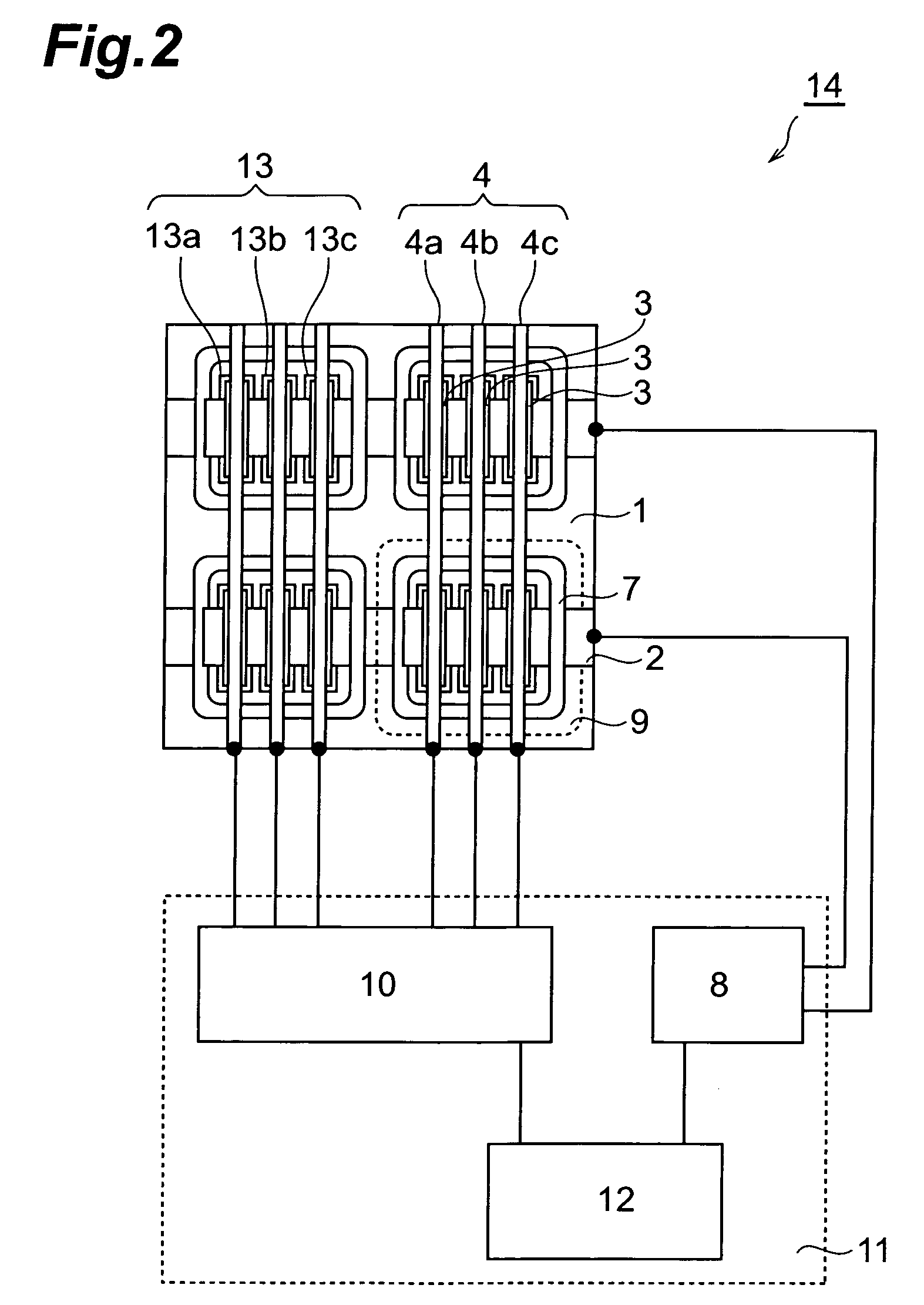

Organic el device and organic el display

InactiveUS20060238110A1Emission highProlong lifeStyryl dyesDischarge tube luminescnet screensOrganic layerVinyl polymer

An organic EL element of the present invention comprises a substrate, an electrode layer, an organic layer, and an electrode layer, whereas the organic layer 3 contains a vinyl polymer obtained by polymerizing a polymerizable monomer containing a compound represented by formula (1) or (2): wherein each of L1 and L2 is a bivalent group; each of X1, X2, X3, X4, X5, and X6 is alkyl group or the like; each of a and e is 0 or 1; each of b, f, g, and h is an integer of 0 to 3; c is an integer of 0 to 2; and d is an integer of 0 to 4.

Owner:FUTABA CORPORATION

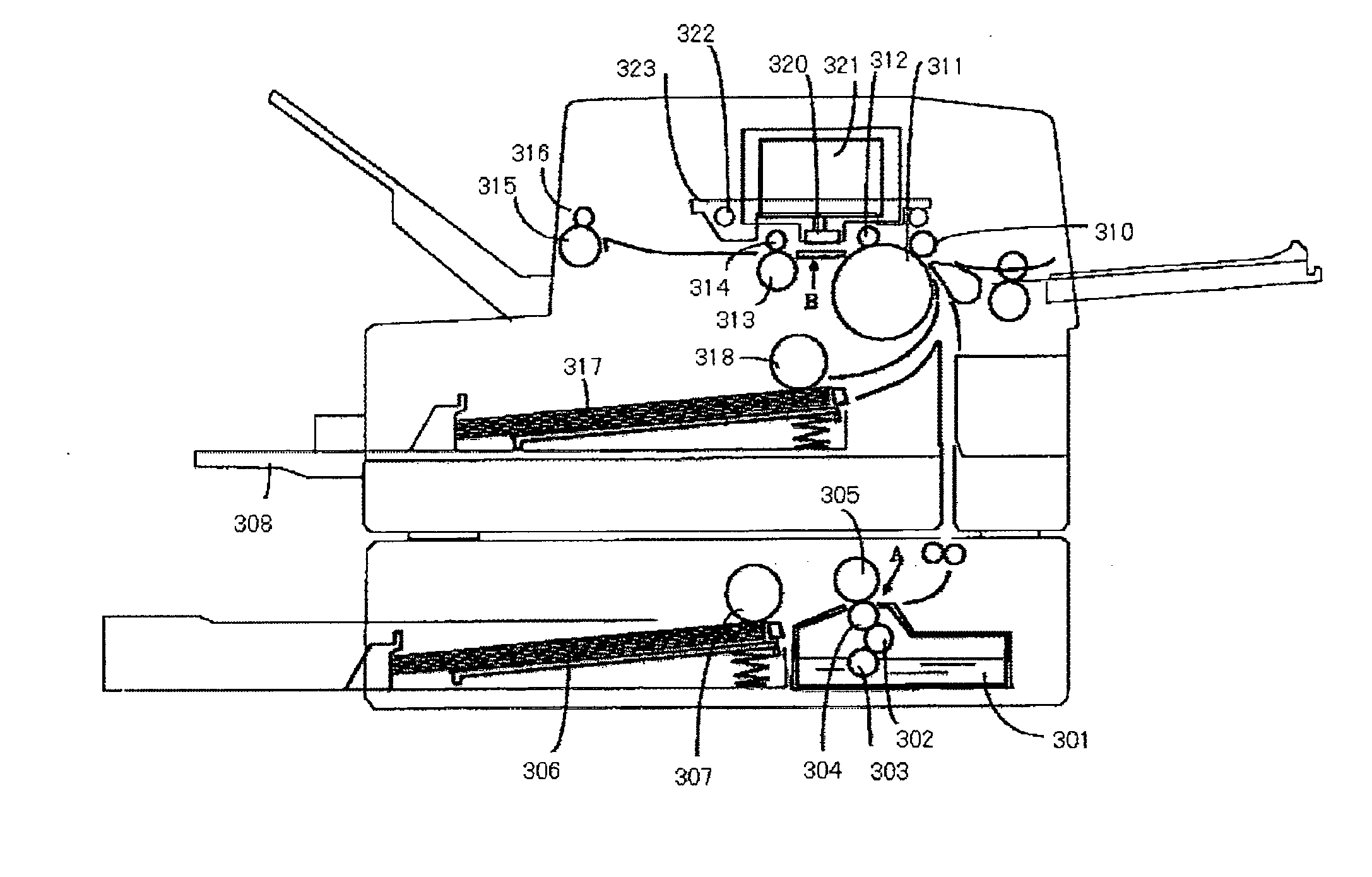

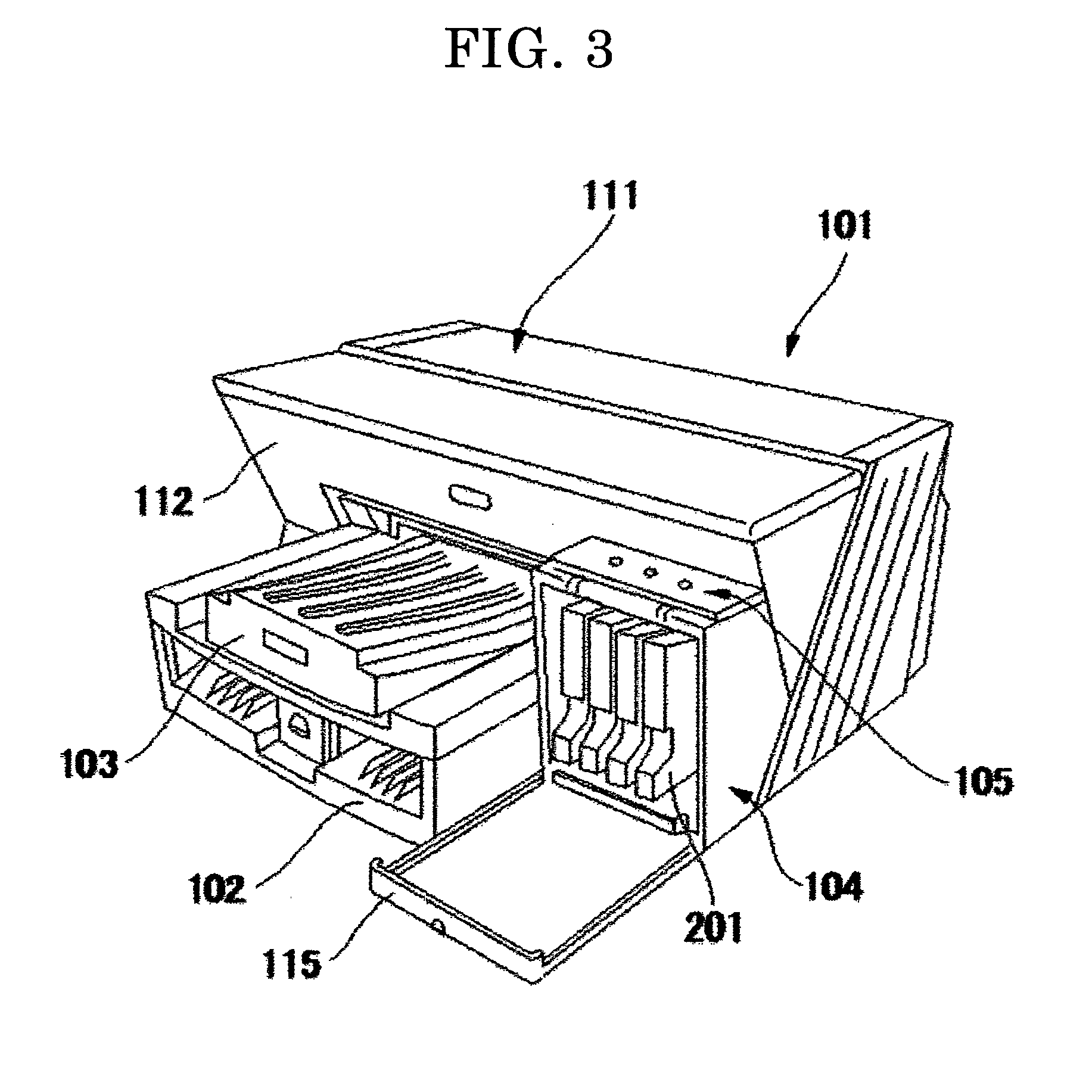

Inkjet ink, ink cartridge, inkjet recording apparatus, inkjet recording method and image forming apparatus

ActiveUS20110164086A1Improve image qualityLess loadMeasurement apparatus componentsDuplicating/marking methodsOrganic solventImaging quality

The present invention provides an inkjet ink which is excellent in image quality and high-speed printing on plain paper, in storage stability and in ejection stability and gives less load on a maintenance device for an inkjet recording apparatus; and an ink cartridge, an inkjet recording apparatus, and an inkjet recording method, using the inkjet ink. An inkjet ink containing a water dispersion of pigment-containing water-insoluble vinyl polymer particles; a water-soluble organic solvent; and water, wherein an ink residue from the inkjet ink has a viscosity of 3,000 mPa·s or less, the ink residue is obtained by leaving the inkjet ink to stand at a temperature of 25° C. and a humidity of 15% until substantially no mass change occurs, and wherein the inkjet ink, pH of which is adjusted to 7 with an acid, has a viscosity of 500 mPa·s or more.

Owner:RICOH KK

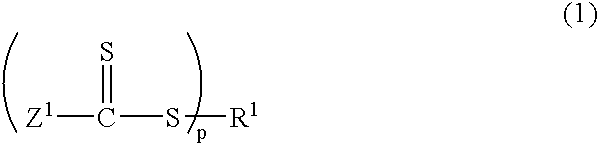

Polyurethane polymer

InactiveUS20040171765A1Good chemical resistanceImprove chlorine resistanceMonocomponent polyurethanes artificial filamentHeat resistanceReversible addition−fragmentation chain-transfer polymerization

Provided is a polyurethane polymer which is excellent in oil resistance, weatherability, light resistance, heat resistance, hot water resistance, hydrolysis resistance, strength, chlorine resistance, and chemical resistance, and which can be produced simply and economically. The polyurethane polymer is produced by polymerizing at least two components: a vinyl polymer (A) having a mercapto group at each end of the molecular chain produced by a reversible addition-fragmentation chain transfer polymerization method, and an organic polyisocyanate (B). Also provided are polyurethane-based materials containing the polyurethane polymer, and polyurethane elastic fiber.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com