Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Meet the requirements of ecological environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

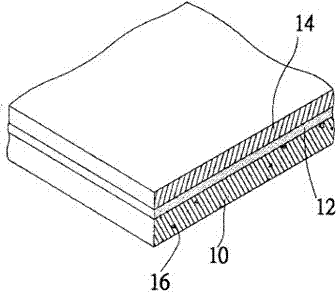

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

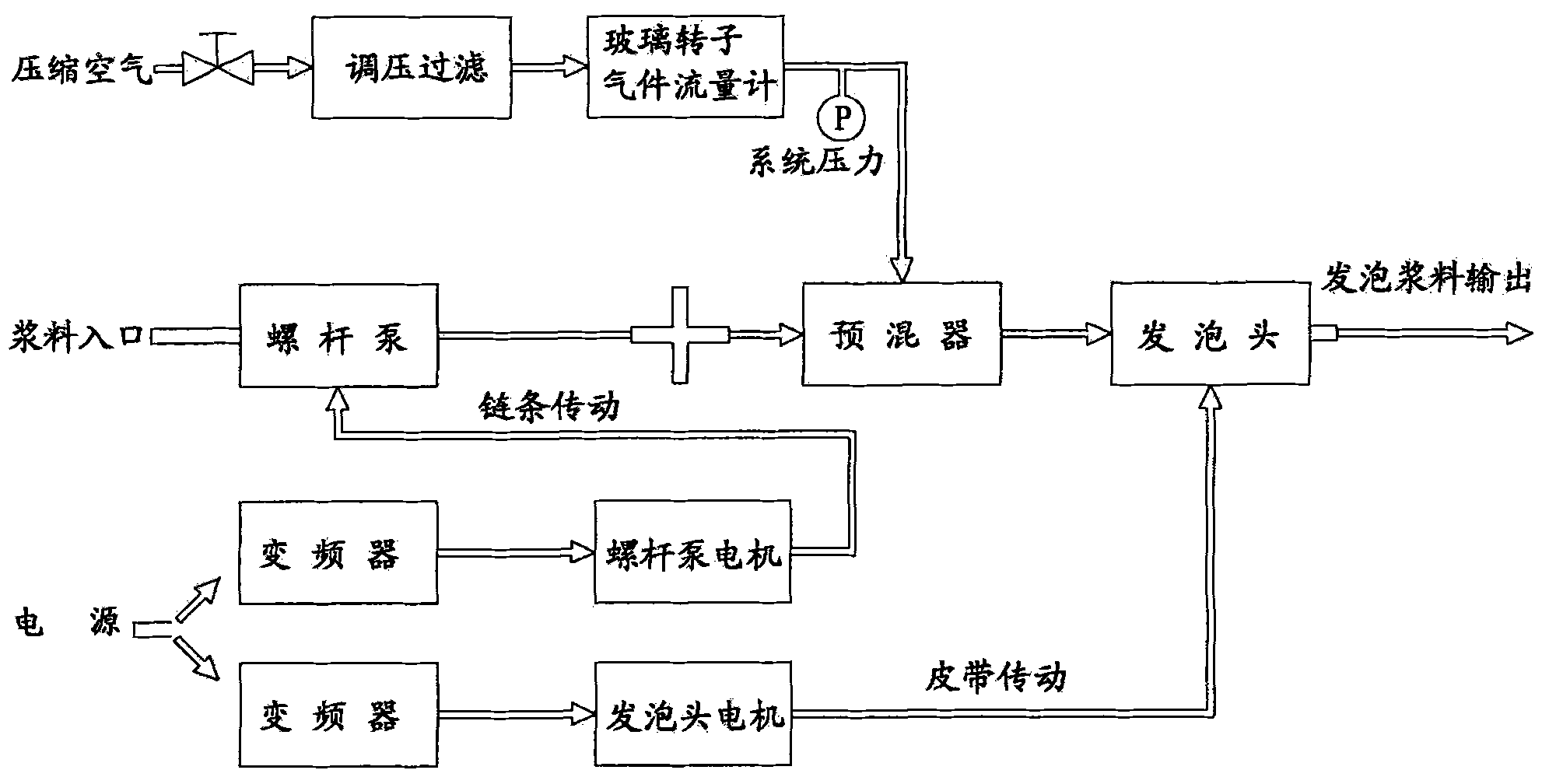

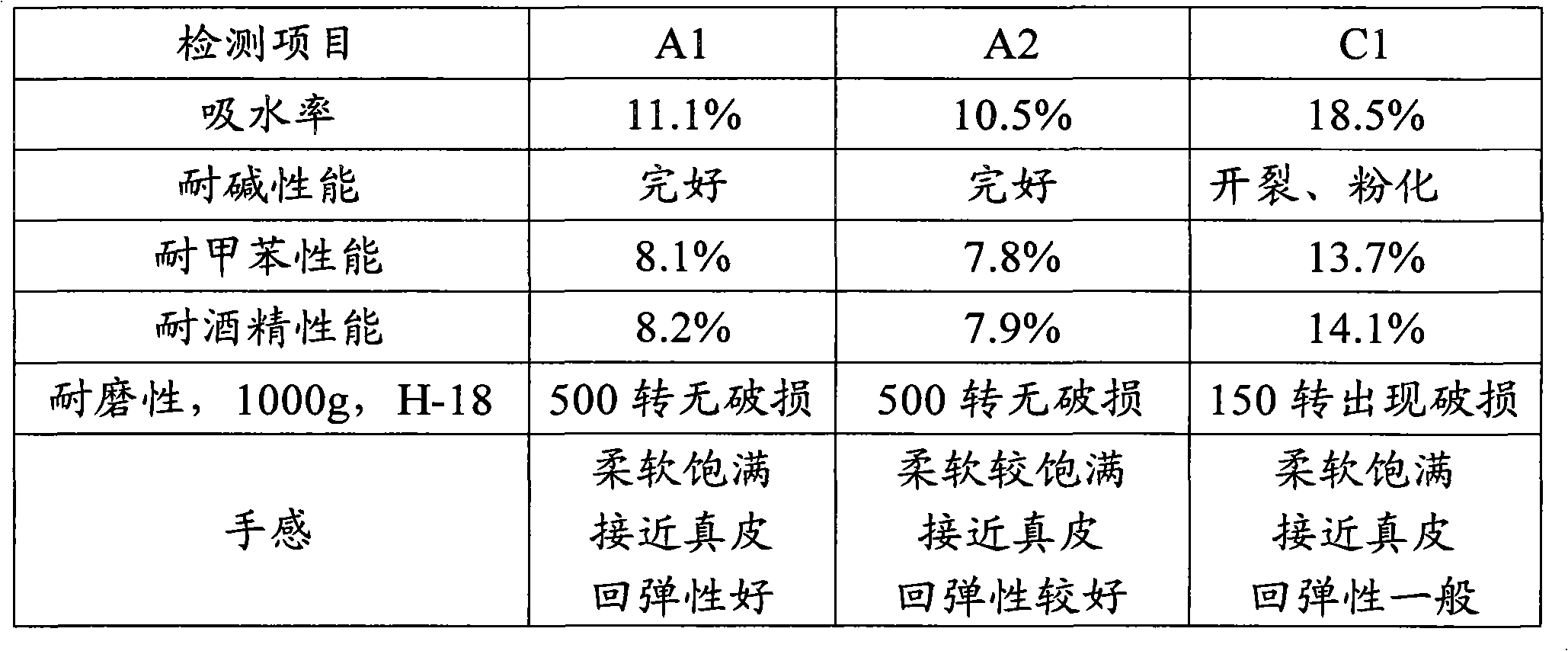

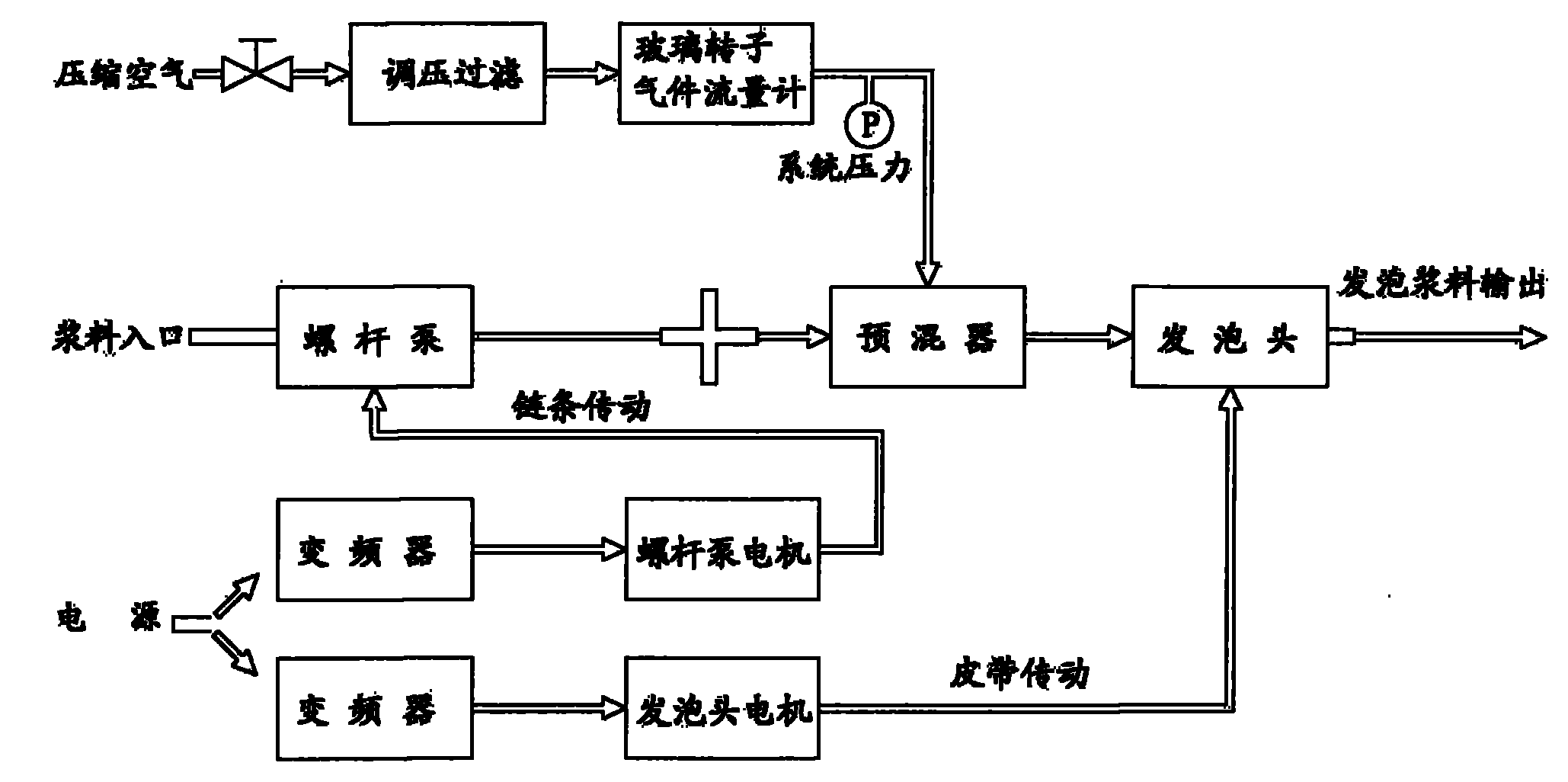

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

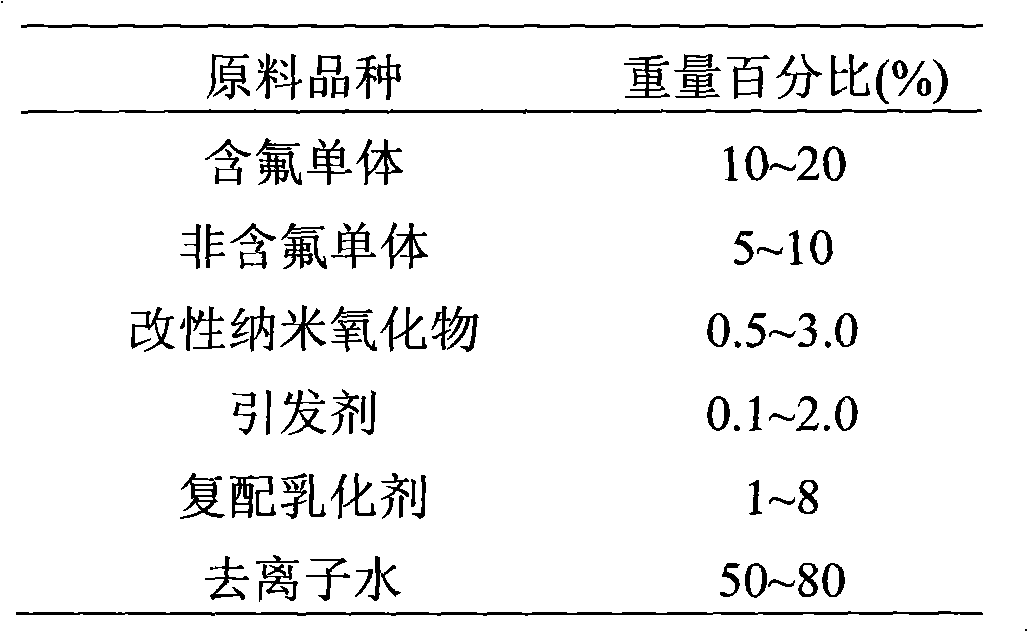

Method for preparing short-chain branch water and oil repellent finishing agent containing modified nano-oxide and fluorine

InactiveCN102041681AImprove securityFeel goodFibre treatmentFunctional monomerEmulsion polymerization

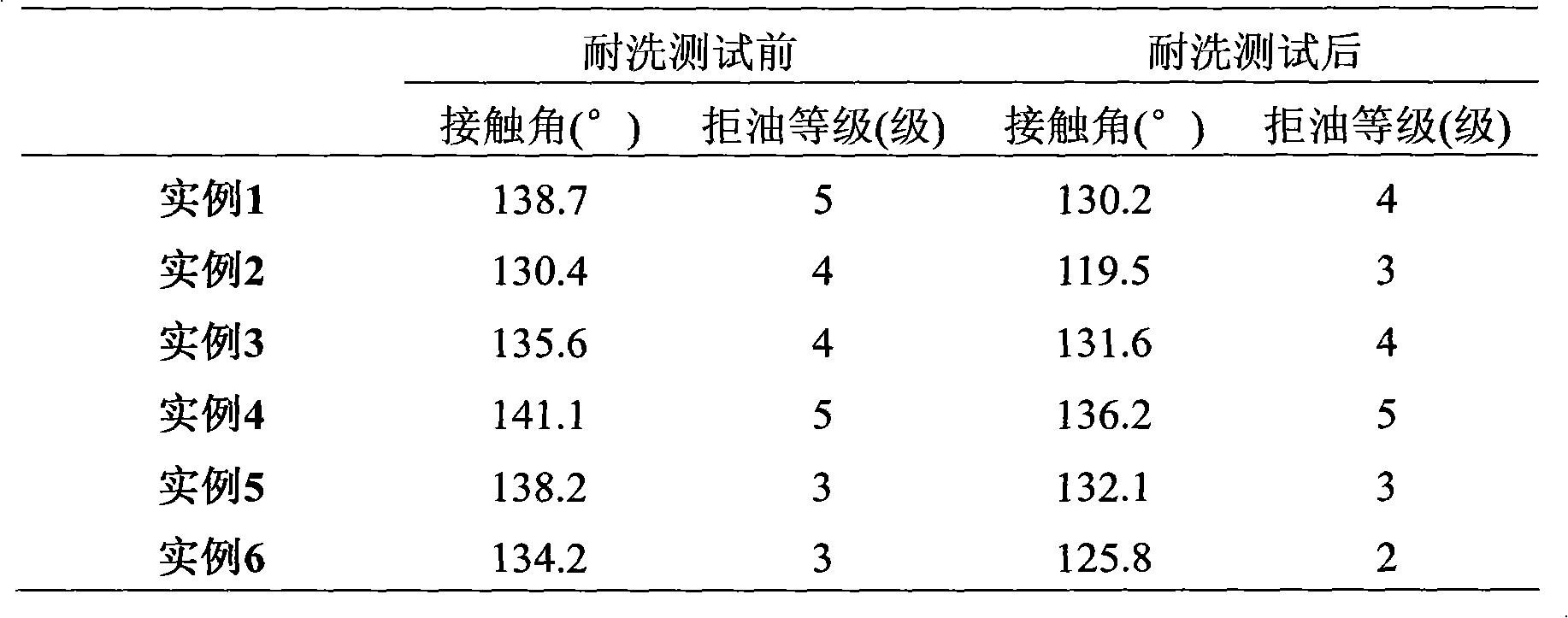

The invention relates to a latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent and a preparation method thereof, belonging to the field of fine chemical industry. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent is prepared by the following steps of: pre-emulsifying short-chain branch perfluoroalkyl acrylate monomer (10-20%), fluorine-free functional monomer (5.0-10%), modified nano-oxide (0.5-3.0%), initiator (0.1-2.0%), compound emulsifier (1.0-8.0%) and deioned water (60-80%); and finally heating for emulsion polymerization. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent can be used for water and oil repellent finishing of animal and plant natural fiber fabric and chemical fiber fabric and has excellent water and oil repellent performance; fabric finished with the finishing agent has good handfeel and excellent endurance performance. Compared with the traditional fluorine-containing finishing agent , the finishing agent disclosed in the invention does not contain components harmful to human bodies and well accords with environmental protection requirement.

Owner:JIANGNAN UNIV

Printing strippable protective ink, and preparation method and application thereof

The invention discloses a printing strippable protective ink, and a preparation method and application thereof. The ink comprises the following components in parts by weight: 50-80 parts of thermoplastic film-forming resin, 20-50 parts of low-viscosity plasticizer, 1-10 parts of filler and pigment, and 1-3 parts of functional assistant. The printing strippable protective ink has 100% solid rate, does not volatilize any solvent, is a green environment-friendly material, and satisfies the increasingly higher ecological environmental requirements. The ink has the advantages of no irritating smell, moderate viscosity and no voids, is not sticky to the printing screen, and is easy for printing operation; the ink can form a film by thermosetting at medium / low temperature, so the energy consumption is low; the thermosetting film has high flexibility, favorable heat resistance, favorable insulativity and favorable acid / alkali resistance, and effectively solves the influence on the resistance when etching the circuit on a transparent conductive film with acid and alkali in the touch screen manufacturing process; and after the conductive film protecting technique is finished in the touch screen manufacturing process, the protective ink layer can be easily stripped, and does not leave any residue, thereby effectively solving the problem of protection of the conducting film in the existing touch screen manufacturing process.

Owner:PANYU NANSHA YAN TIN CHEM

Method for improving color depth and light fastness of natural dye-dyed fabric

ActiveCN104088167AIncrease Shading DepthImprove bonding fastnessDyeing processVegetal fibresChemistryColor depth

The invention relates to a method for improving color depth and light fastness of a natural dye-dyed fabric. The method utilizes an association effect between polyvinylpyrrolidone and natural dye molecules to improve the color depth of the natural dye-dyed fabric; a polyhydric alcohol method is adopted to generate nano ZnO on the surface of the fabric in situ; the excellent anti-ultraviolet performance of nano ZnO is used for improving the light fastness of the natural dye-dyed fabric. With the adoption of the method, the color depth and the light fastness of the natural dye-dyed fabric are obviously improved and the washing-resisting performance of the natural dye-dyed fabric is good.

Owner:CHANGZHOU UNIV

Eucalyptus seedling culture substrate and production process thereof

The invention discloses a eucalyptus seedling culture substrate. The eucalyptus seedling culture substrate comprises the following components in part by weight: 35 to 40 parts of coconut shell powder, 25 to 30 parts of peat, 15 to 20 parts of bentonite, 20 to 25 parts of attapulgite, 0.5 to 0.8 part of soil water-retaining agent, 15 to 20 parts of nutrient substance and 0.2 to 0.3 part of composite strain. A production process of the eucalyptus seedling culture substrate comprises the following steps of: drawing silk from a coconut shell to generate fragments; crushing the fragments; sieving until the granular size is 10 to 20 meshes; performing salt exclusion; mixing 35 to 40 weight parts of the coconut shell powder subjected to the salt exclusion, 15 to 20 weight parts of the nutrient substance and 0.2 to 0.3 weight part of high-temperature-resistant fermenting strain; adding clean water to stir and wet; stacking into a circular truncated cone shape; covering a membrane on the circular truncated cone so as to ferment; and after fermenting completely, adding the peat, the composite strain, the bentonite, the attapulgite and the soil water-retaining agent according to the weight ratio to mix and stir uniformly to prepare into block shapes. The coconut shell powder serves as a main raw material, so the materials are obtained singly and easily, the nutrient ingredients and the content are easy to control, and large-scale standard production can be performed easily.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

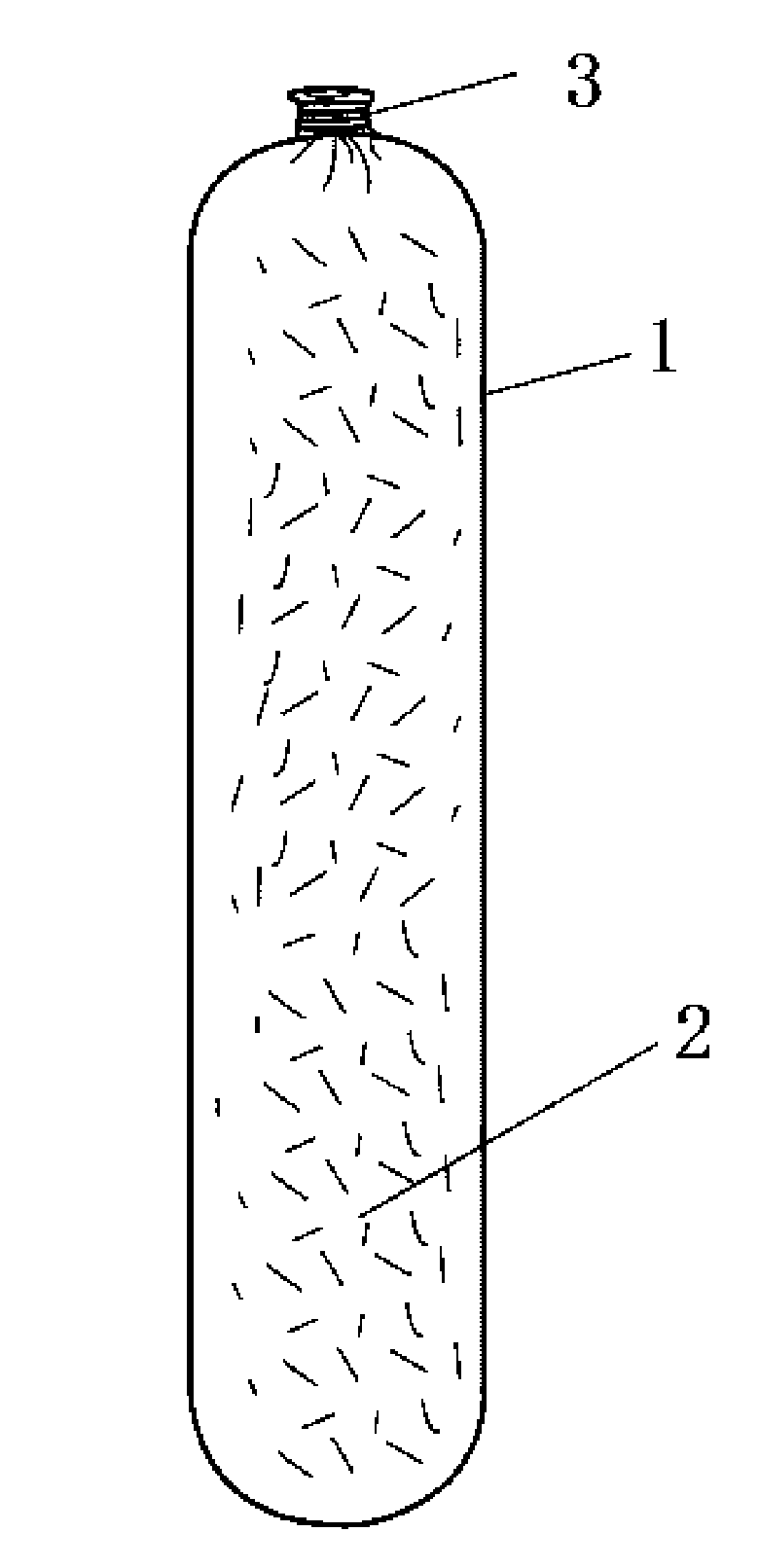

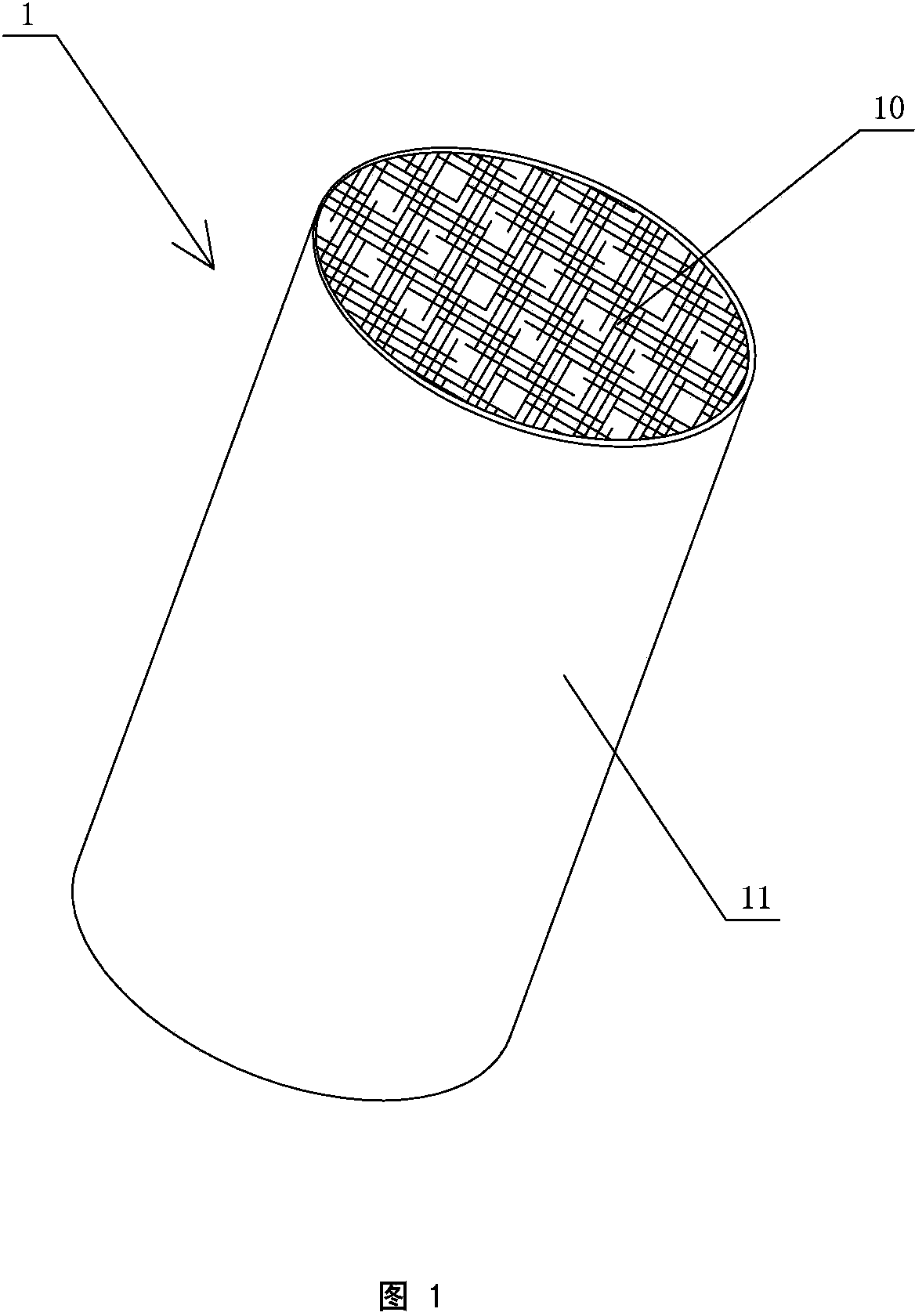

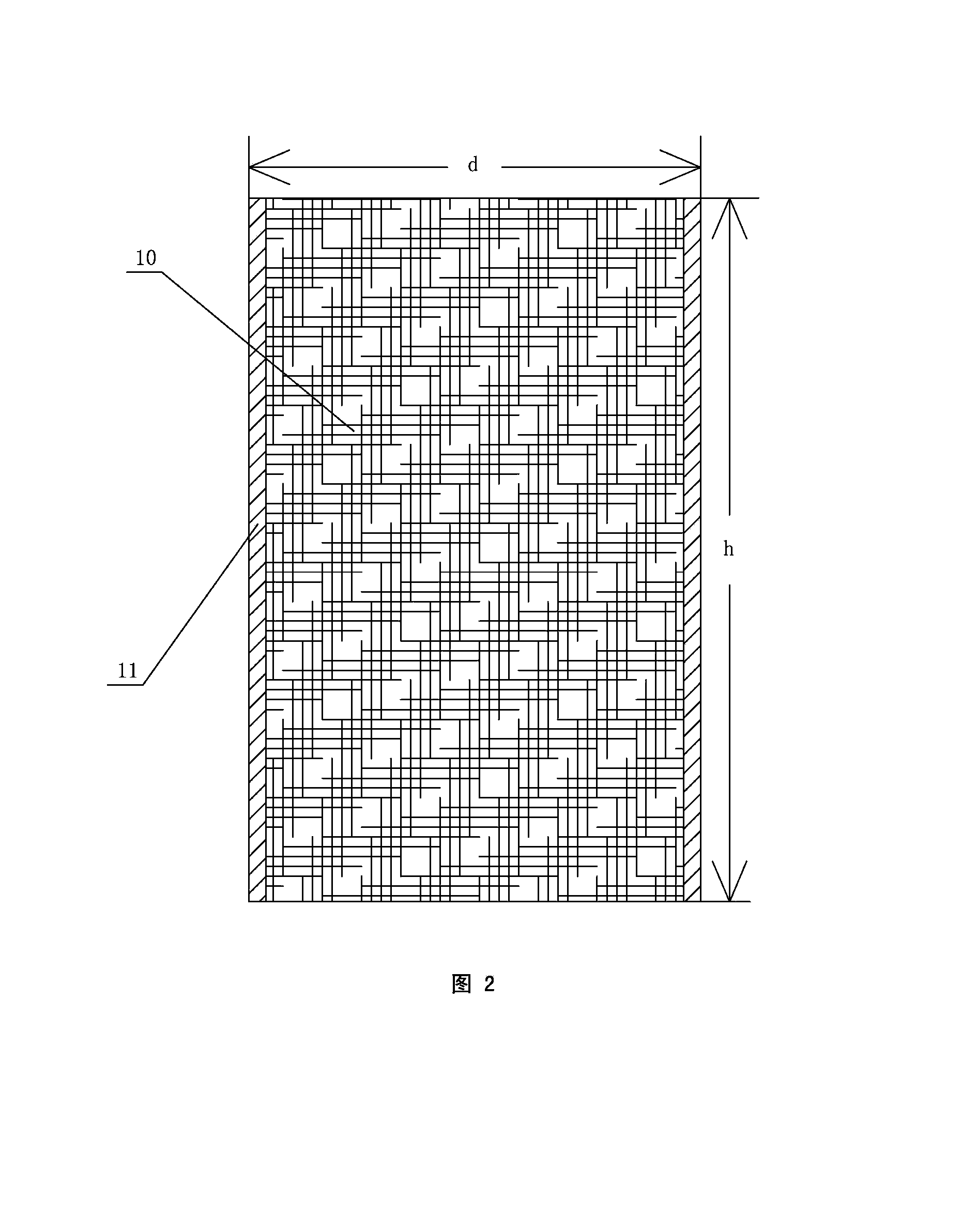

Special matrix for breeding of Chinese fir and production technology thereof

ActiveCN103348903ASingle sourceEasy to obtainCultivating equipmentsSoilless cultivationGrowth plantMolding machine

The invention discloses special matrix for breeding of Chinese fir. The special matrix comprises the following components in parts by weight: 70-80 parts of coir fiber, 10-15 parts of multiple-granular agent, 10-15 parts of plant growth promoting rhinoacteria (PGPR) compound bacterial fertilizer, and 0.1-0.2 parts of humic acid, wherein the matrix forms a block shape; and the production technology of the special matrix comprises the following steps: firstly, carrying out roughening treatment on a coir fiber, adding a little of zymophyte to carry out full fermentation treatment; evenly mixing and stirring 70-80 parts of fermented coir fiber, 10-15% of multiple-granular agent, 10-15% of PGPR compound bacterial fertilizer and 0.1-0.2 parts of humic acid to prepare mixture; pressing the mixture through a molding machine to prepare a fluffy cylindrical block; and taking non-woven fabrics to enclose the peripheral surface of the cylindrical block, so as to form culture medium with upper and lower ports. The proportion of components of the special matrix is fully considered to be suitable for growth of breeding of the Chinese fir; the seedling substrate has an excellent three-phase structure for conserving manure, holding moisture and ventilating.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

Health-care cloth

InactiveCN101343804AHigh far infrared emission effectOvercome limitationsWeft knittingWarp knittingEngineeringNatural fiber

Disclosed is a health care fabric, which relates to health care fabric which is manufactured by the industrial method and contains soybean fibers and bamboo charcoal fibers. The fabric on the market is mainly divided into natural fiber fabrics and artificial fiber fabrics. The costs of the natural fiber fabrics are high, the types of chemical fiber fabrics on the market are multiple, the functions are also various, but the wearing comfort is poor and the function is unitary, the chemical fiber fabrics can not reach the requirements of the customers in function, only the wearing purpose can be satisfied, and the health care and health building can not be achieved. The product can improve the defect of the products on the market. The product components comprise: 40 to 80 parts of soybean fibers by weight and 30 to 60 parts of bamboo charcoal fibers by weight. The product is the health care fabric which can be applied in various fields.

Owner:HEILONGJIANG HUASHEN SCI & TECH DEV

Matrix specially used for phoebe bournei seedling raising and production technology thereof

ActiveCN103355149ASingle sourceEasy to obtainCultivating equipmentsOrganic fertilisersGrowth plantCylindrus

The invention discloses a matrix specially used for phoebe bournei seedling raising. The matrix comprises the following components in percentage by weight: 65-75 of coir fibers, 10-15 of multi-time aggregation agent, 15-20 of plant growth promoting rhinoacteria (PGPR) composite bacterial fertilizer and 0.1-0.2 of humic acid and is block type. A production technology comprises the following steps of roughening the coir fibers, then adding a small amount of zymophyte for full fermentation treatment, uniformly mixing and stirring 80-85 of fermented coir fibers, 10-15 of multi-time aggregation agent, 15-20 of plant growth promoting rhinoacteria (PGPR) composite bacterial fertilizer and 0.1-0.2 of humic acid to obtain a mixture, and pressing the mixture into a fluffy cylindrical block through a shaping machine, and encircling the circumferential surface of the cylindrical block with non-woven cloth to form a culture matrix with a longitudinal through opening. The proportions of the constituent components of the special matrix considers the growth of the phoebe bournei raising seedlings, and the seedling raising matrix has a three-phase structure with high fertilizer preservation property, water retaining performance and ventilating property.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

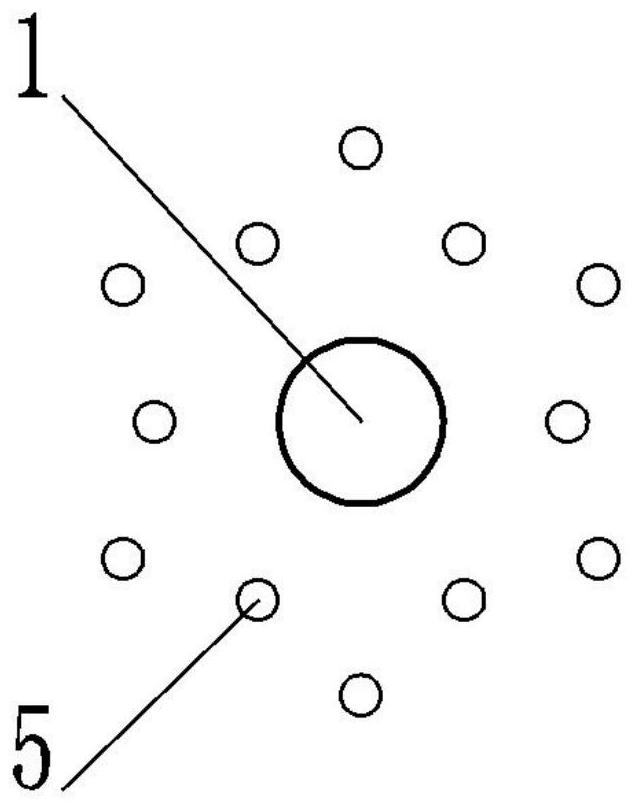

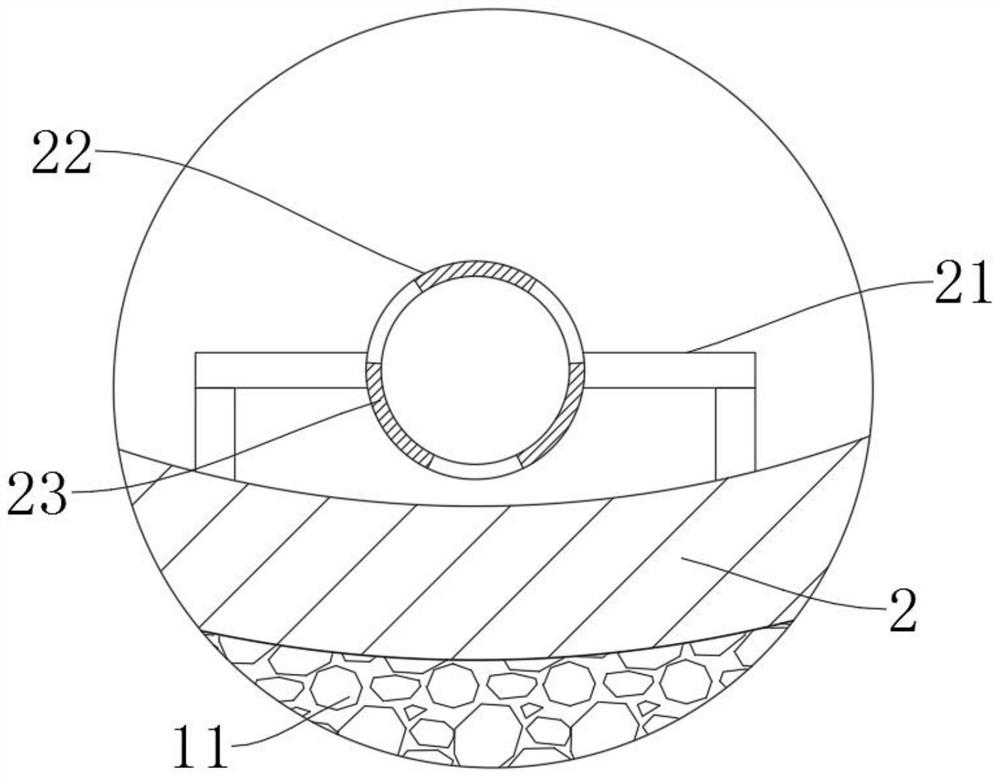

Semi-closed floating type multi-layer ecological culture water tank

PendingCN108575845AMeet the requirements of ecological environmental protectionClimate change adaptationPisciculture and aquariaGratingGroundfish

The invention designs a semi-closed floating type multi-layer ecological culture water tank. The water tank comprises a water tank floating ring, an upper-layer filtering water permeable ring, a watertank upper-edge water partition ring, an upper-layer grating plate, a sealed water tank vertical wall, a middle-layer grating plate, a bottom-layer grating plate, a conical water tank bottom, a sewage discharge filtering cover, a sewage storage tank, an inflation system, a sewage discharge system and a bait feeding system. By using the water tank, planktonic feeding fishes are stocked in an upper-layer culture area, feed eating fishes are stocked in a middle-layer culture area, and bottom fishes are stocked in a bottom-layer culture area. An inflation system is used for conducting inflation and oxygen enrichment on a water area of the water tank, a bait feeding system is used for feeding bait, residual bait enters the bottom-layer culture area to be eaten by the bottom fishes, fish manureand other pollutants are accumulated in the sewage storage tank, and the accumulated pollutants are discharged out through a sewage discharge pump. At the same time, the upper-layer filtering water permeable ring on the upper portion of the water tank body filters surrounding water when the pollutants are discharged, the water then enters the water tank body, only a small amount of water needs tobe supplemented, the culture waste pollutants are extracted from the water area for discharging, the surrounding environment of the culture areas is not influenced, and the requirements for ecological and environmental protection are met.

Owner:魏中成

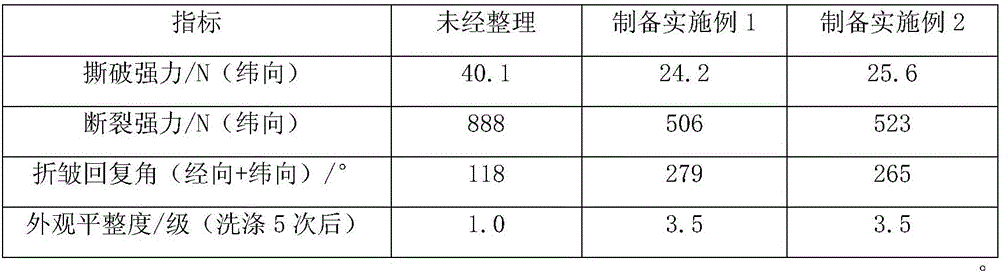

Method for preparing formaldehyde-free non-ironing resin

ActiveCN106496481AMeet the requirements of ecological environmental protectionEasy to useVegetal fibresAlcoholDistillation

The invention relates to a method for preparing formaldehyde-free non-ironing resin, and belongs to the technical field of dyeing-and-printing-industry cotton-fabric post-finishing agents. The method is characterized by including the following steps that (1) urea and a glyoxal solution are reacted for 1 hour to 5 hours under the conditions that pH is 4 to 8, and the temperature is 30 DEG C to 80 DEG C, the temperature is reduced, then the product is standing at the room temperature lower than or equal to 20 DEG C, and a solid intermediate product dyhydroxyl ethylene urea is obtained; (2) the solid dyhydroxyl ethylene urea is dissolved in absolute ethyl alcohol with the mass accounting for 2 times to 5 times of that of the solid dyhydroxyl ethylene urea, then active-group-containing substances are added, wherein the molar ratio of the solid dyhydroxyl ethylene urea to the active-group-containing substances is 1:2-1:3, the mixture is reacted for 1 hour to 6 hours under the conditions that pH is 8 to 12, and the temperature is 30 DEG C to 60 DEG C, the pH of a solution is adjusted to be about 7, ethyl alcohol is removed in a reduced-pressure-distillation mode, a proper amount of water is added, the concentration is adjusted to be the required concentration, and a formaldehyde-free non-ironing resin solution is obtained. According to the formaldehyde-free non-ironing resin solution prepared with the method, the non-ironing finishing effect is good, and the fabric strength losses are small.

Owner:中国纺织科学研究院江南分院

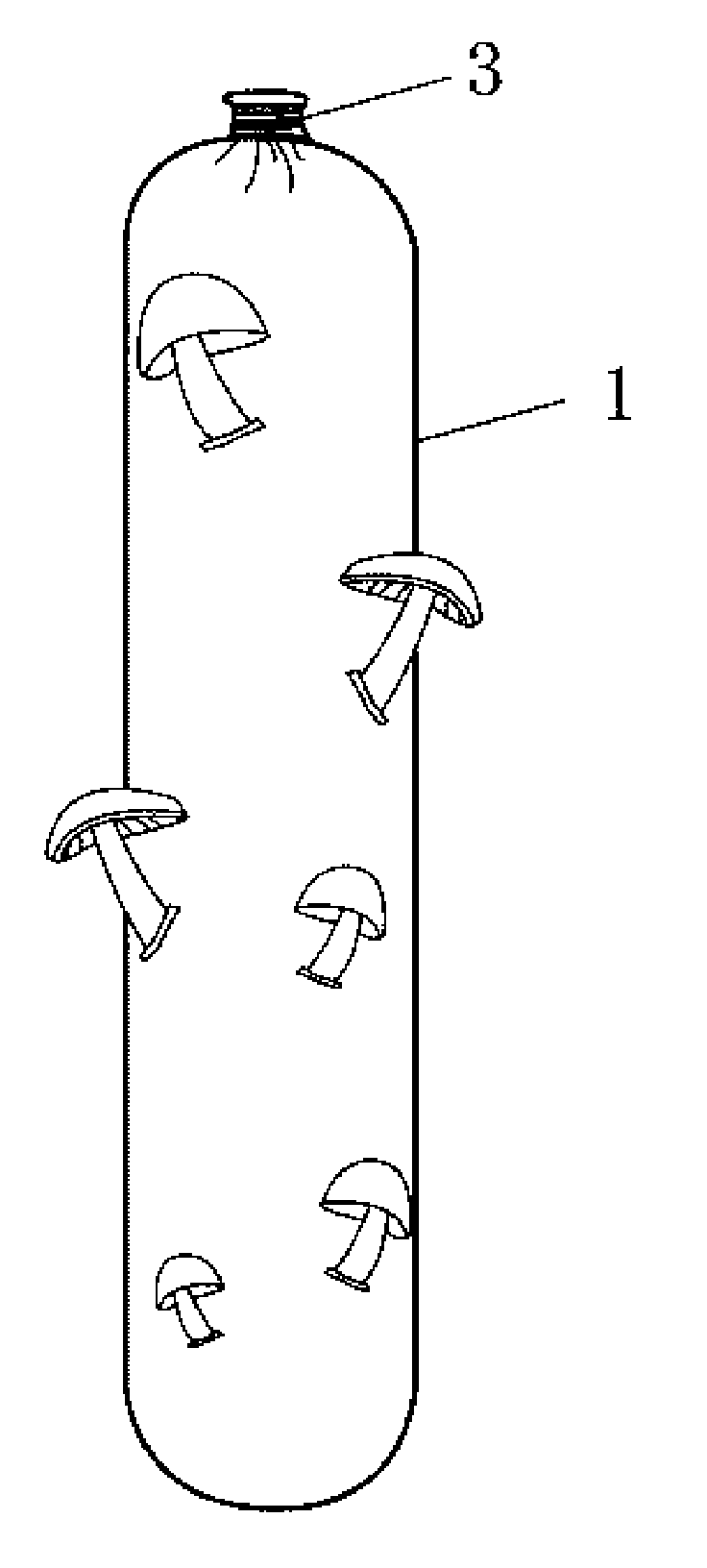

Single-layer cutting-free bag flower mushroom cultivation process

InactiveCN101663955ASignificant technical superiorityReduce usageHorticultureEcological environmentPhacus

The invention relates to a novel single-layer cutting-free bag flower mushroom cultivation process which carries out flower mushroom cutting-free cultivation by a plastic degradation modified cylinderbag of which the single layer is specially processed. After a culture material is charged into the bag to be carried out the phases of disinfection, bacterial fermentation, culture, and the like, a bacterial rod surface film similar to fruiting film ruptured force can be gradually formed; in the fruiting phase, a flower mushroom can directly rupture the film (bag) and fruit by self growing force,the natural growing environments of automatic film rupture and wet inside and dry outside are created for the flower mushroom; the waste of a plurality of plastic resources caused by double-layer bagcultivation is reduced, the white pollution is lowered, and the working procedures of two-step packaging, discoloured water necrosis and decay of an interlayer of two bags, outer bag head cutting after bacterial fermentation maturity, outer bag removal before fruiting, and the like in the double-layer bag cultivation and the bacterial rod loss and mushroom damage caused by the working proceduresare eliminated, thereby achieving the aims of saving power and cost, improving the quality of the flower mushroom and protecting the ecological environment.

Owner:吴方

Process for biologically dyeing wool fabric by virtue of laccase

InactiveCN104032604AHigh fastnessMeet the requirements of ecological environmental protectionBiochemical fibre treatmentDyeing processWoolEcological environment

The invention discloses a process for biologically dyeing wool fabric by virtue of laccase, which belongs to the field of application of bio-enzyme in textile dyeing, and aims at applying the laccase to ecological dyeing of the wool fabric. The wool fabric is colored under the catalytic oxidation action of the laccase on tyrosine components in a wool structure. By virtue of the process, the color of the wool fabric is good in washing resistance, friction resistance and acid resistance. The process is simple, and easy to operate, and is an ecological environment-friendly dyeing method for textile; the consumption of chemicals is reduced.

Owner:JIANGNAN UNIV

Special matrix for camphor tree seedling and production process thereof

ActiveCN103348904AEasy to get materialsHigh degree of ionizationCultivating equipmentsSoilless cultivationHumic acidCoir fiber

The invention provides a special matrix for camphor tree seedling, which is of a block shape and comprises the following components in parts by weight: 80-85 parts of coir fibers, 15-20 parts of a multi-aggregation agent, and 0.1-0.2 part of humic acid. The production process comprises the following steps: roughening the coir fibers, and adding little zymophyte for sufficient fermenting treatment; uniformly mixing and stirring the fermented coir fibers, the multi-aggregation agent and the humic acid to prepare a mixture; compressing the mixture by a molding machine to obtain a fluffy cylindrical block; and enclosing the periphery of the cylindrical block by a non-woven fabric to form a culturing matrix with upper and lower openings. The proportion of the components of the special matrix sufficiently takes the growth of camphor tree seedling, and the seedling matrix has an excellent three-phase structure of fertilizer and water maintenance and ventilation.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

Plastic flat plate and manufacturing method thereof

InactiveCN103481445ASave the trouble of secondary processingSimple processSynthetic resin layered productsFurniture partsMolding machinePlastic materials

The invention discloses a plastic flat plate and a manufacturing method thereof. The plastic flat plate comprises a foamed plastic layer and an appearance skin layer; a plurality of bubbles exist inside the foamed plastic layer, and the foamed plastic layer is formed through injection molding with a foamed plastic material; the appearance skin layer naturally covers at least one of the upper surface and the lower surface of the foamed plastic layer and is formed through injection molding together with the foamed plastic layer with resin by a dual-material co-injection molding machine. The method has the advantages that the trouble of secondary processing that a wood-grain appearance skin is required to be pasted additionally at present can be saved, so that the processing procedure can be simplified, and the use of plastic that replaces wood can be improved effectively, so that the requirements on ecological environmental protection can be met.

Owner:ZHANGJIAGANG JINFENG RUNERFA HARDWARE PLASTIC FACTORY

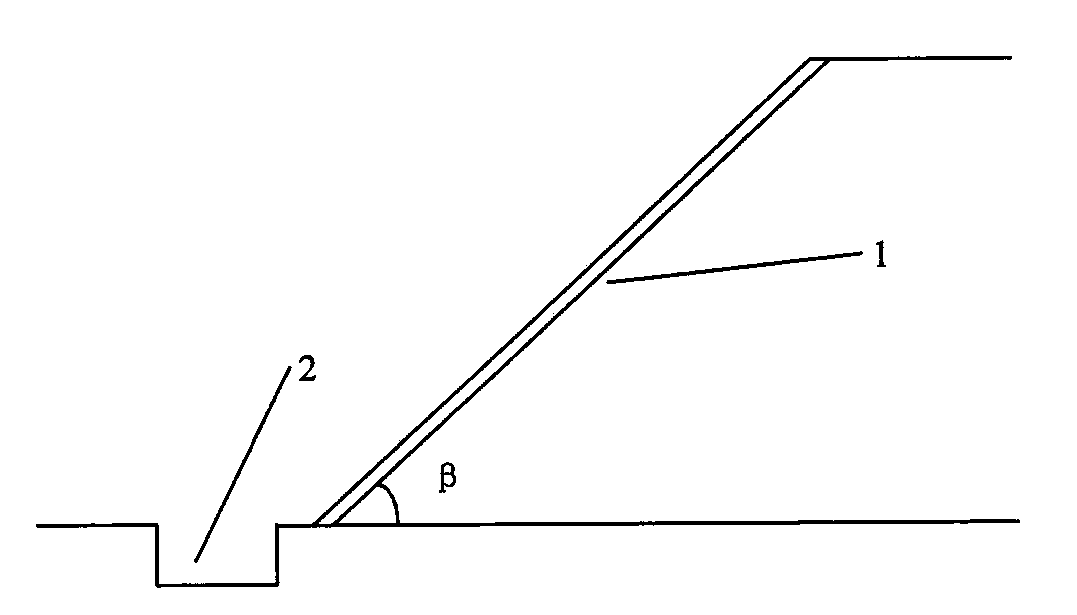

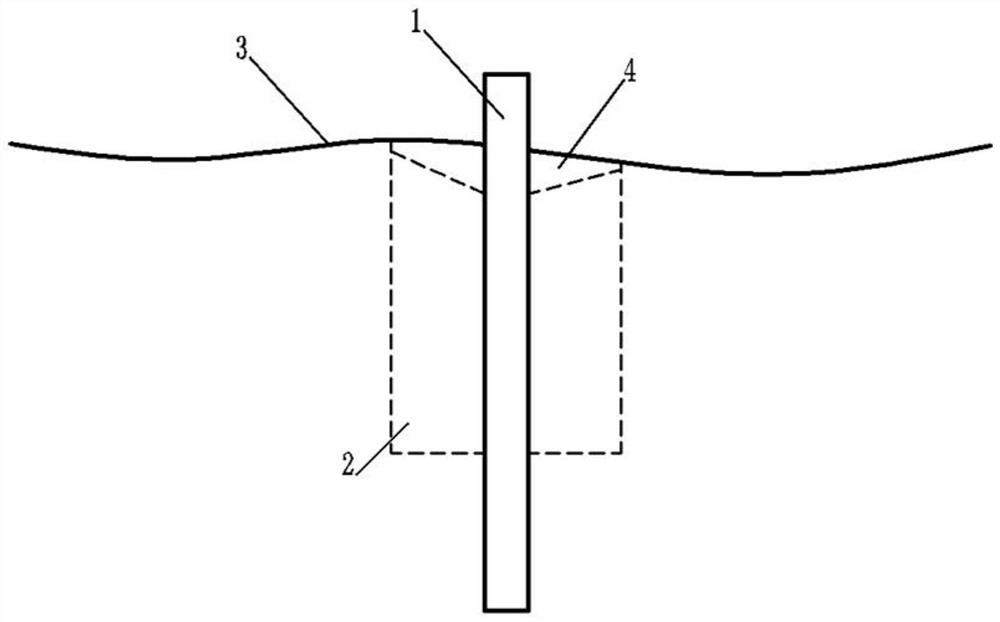

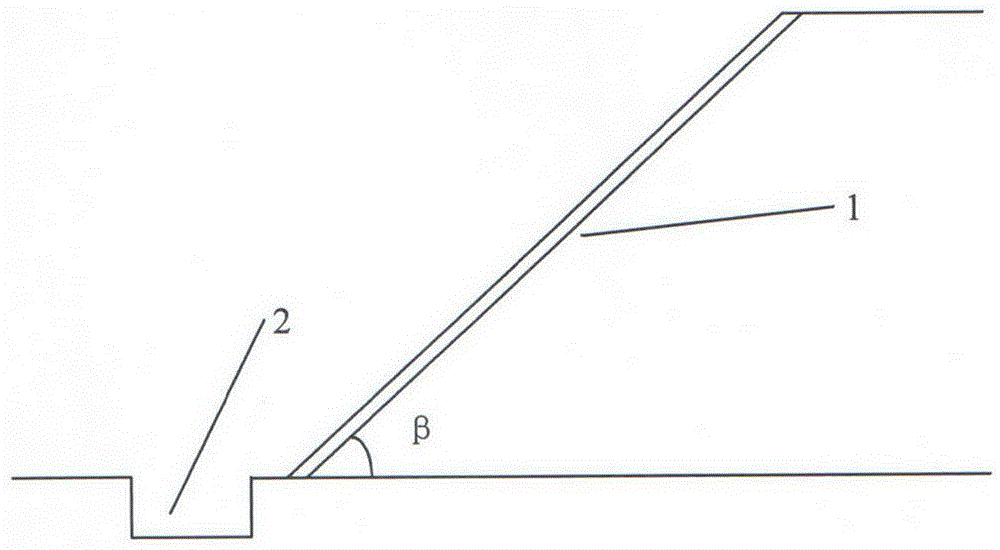

Arid desert region soil engineering slope bandicoot-caused damage prevention and control method

ActiveCN104264696AReduce erosionMeet the requirements of prevention and control of ecological and environmental protectionExcavationsAridHabit

The invention relates to an arid desert region soil engineering slope bandicoot-caused damage prevention and control method. Reinforced concrete grid beams are embedded into a slope foundation layer, and sand gravels are filled in the reinforced concrete grid beams to destroy bandicoot nidification environments so as to achieve slope surface bandicoot-caused damage prevention and control effect. The method is simple, convenient, ecological and long-acting. According to ecological habits, living environments and other characteristics of levee slope bandicoots, a slope surface layer changed foundation structure is adopted, and a loose earth's surface structure which does not facilitate bandicoot nidification is created so as to achieve the purpose of effectively controlling damage caused by the levee slope bandicoots. A concrete grid beam structure is constructed on the ground slope to reinforce a slope soil body and ensure the slope stability. Sand gravel fillers are filled into concrete beam grids so as to inhibit bandicoot nidification and reduce the erosion scouring effect of rainwater. By means of the method, the problem that the bandicoot-caused damage prevention and control effect in the desert environment is low is solved, the ecological environmental protection requirements of a large canal system for slope bandicoot-caused damage prevention and control are met, and technical support is provided for bandicoot-caused damage prevention and control of arid desert region soil engineering facilities.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

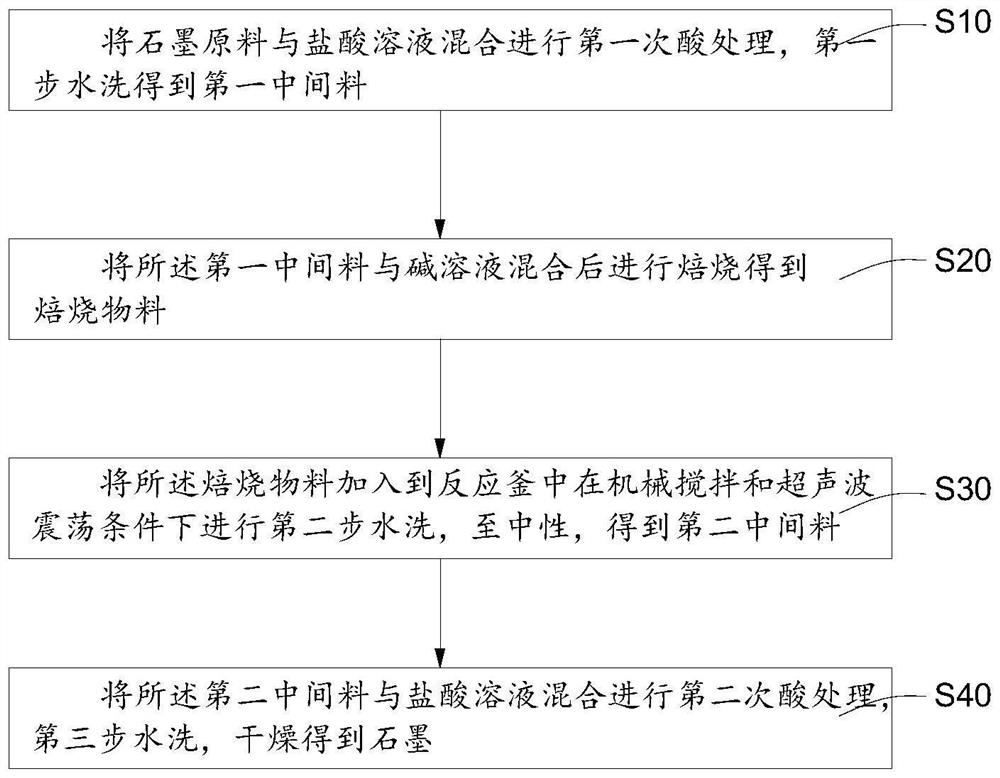

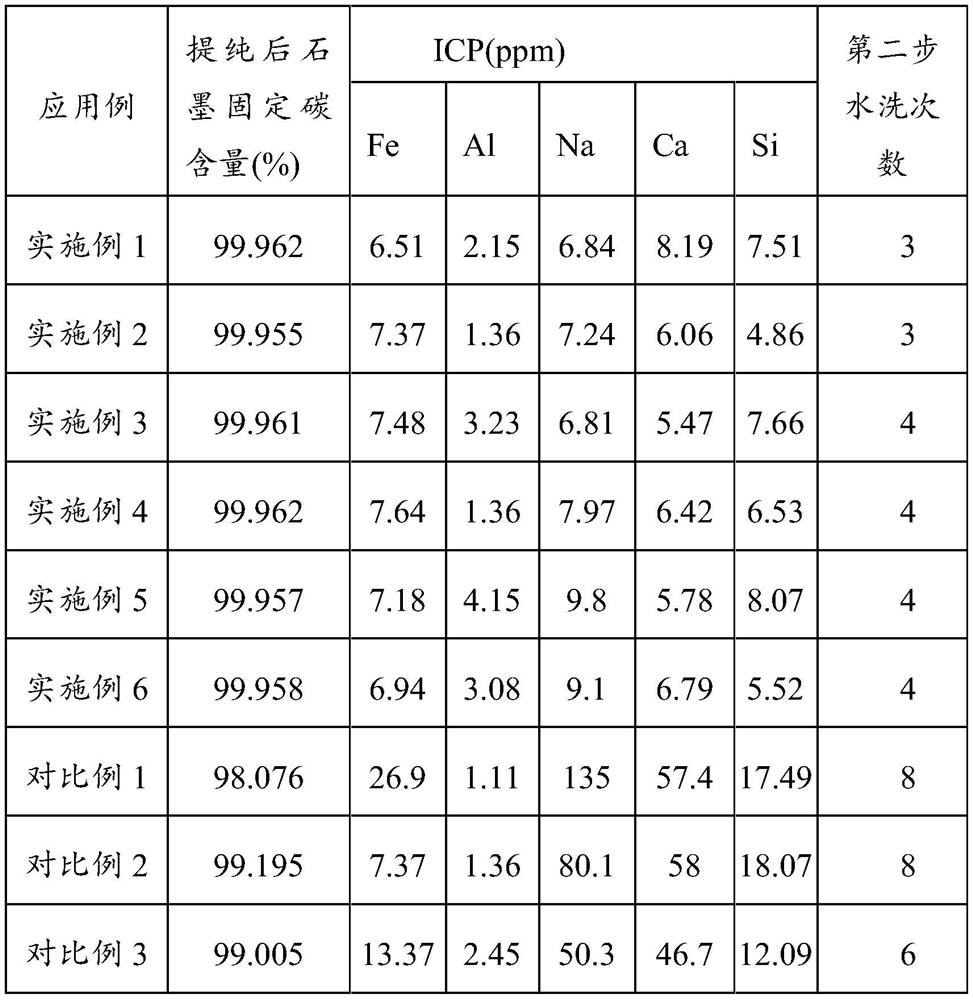

Graphite purification process and graphite

The invention relates to the technical field of graphite purification, in particular to a graphite purification process and graphite. The purification process comprises the following steps: mixing a graphite raw material with a hydrochloric acid solution, carrying out first-time acid treatment, and carrying out first-step water washing to obtain a first intermediate material; mixing the first intermediate material with an alkali solution, and roasting to obtain a roasted material; adding the roasted material into a reaction kettle, and carrying out second-step water washing under the conditions of mechanical stirring and ultrasonic oscillation until the roasted material is neutral, so as to obtain a second intermediate material; mixing the second intermediate material with a hydrochloric acid solution, performing secondary acid treatment, and performing third-step water washing and drying to obtain graphite. According to the graphite purification process, an alkali-acid method purification process is adopted, the process is few, energy consumption is low, cost is low, the amount of generated waste acid and waste alkali is small, a mechanical stirring and ultrasonic water washing method is adopted for roasted materials after roasting, washing of Na, Si and other elements in the roasted materials can be accelerated, the use amount of water in the water washing process can be reduced, and the discharge amount of waste water is reduced.

Owner:BTR NEW MATERIAL GRP CO LTD

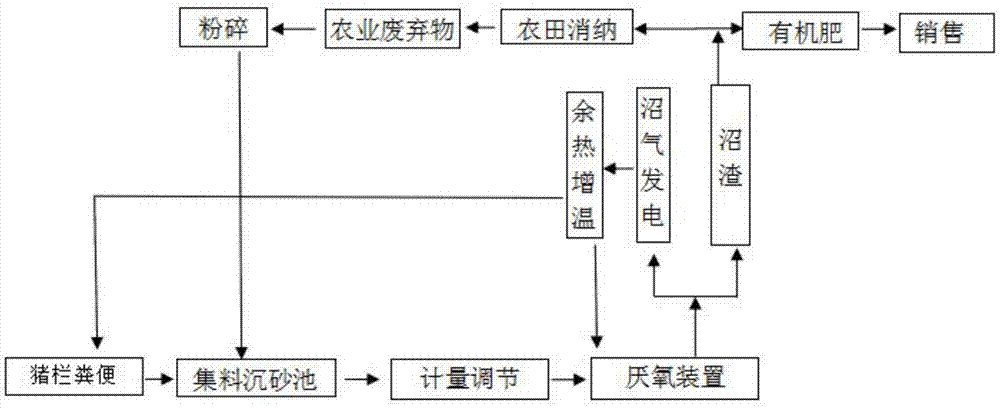

Fermentation treatment method for livestock breeding excrement

InactiveCN107140788AReduce consumptionAvoid pollutionInternal combustion piston enginesWater/sewage treatment with mechanical oscillationsFecesPig breeding

The invention discloses a fermentation treatment method for livestock breeding excrement. The method comprises the following steps: washing the excrement of a pigsty by using water, to obtain primary biogas slurry; stirring and measuring the primary biogas slurry, and pumping into an anaerobic device, fermenting in the anaerobic device; and using marsh gas generated in the fermentation to generate electricity, wherein the waste heat generated in the generation process is used for waste heat warming, and biogas residue after the curing treatment is used for the processes, such as agricultural production. The method is capable of generating the electricity by the marsh gas. The waste heat generated in the generation process is used for warming, and is supplied for the warming of a pig breeding conversation fence, the heating of a fermentation device or the heating of a greenhouse. The energy consumption in the breeding, fermenting and greenhouse planting processes is saved. The method is particularly suitable for the north cold regions and the south regions in winter.

Owner:安徽永志环能科技有限公司

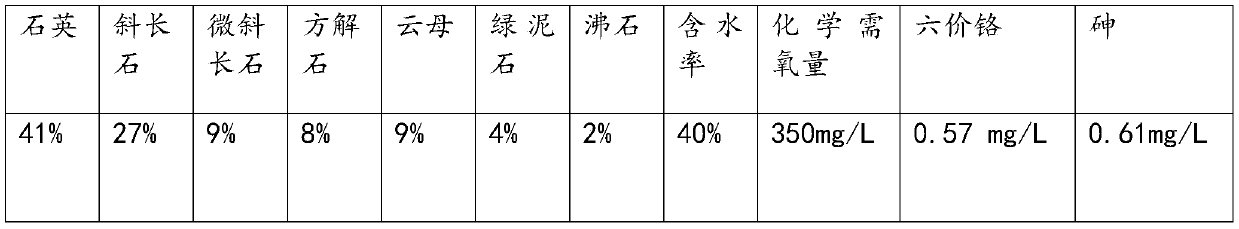

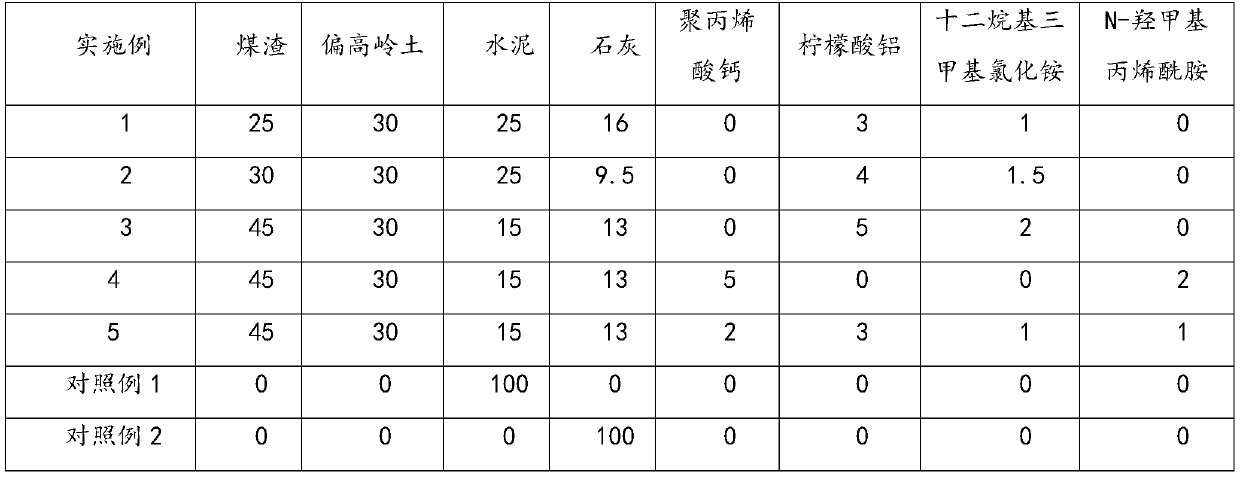

Coal slag metakaolin-based decontaminating and stabilizing material for water-based drilling cuttings as well as decontaminating and stabilizing method thereof

ActiveCN110451905AIncreased unconfined compressive strengthReasonable ratioWater basedResource utilization

The invention discloses a coal slag metakaolin-based decontaminating and stabilizing material for water-based drilling cuttings as well as a decontaminating and stabilizing method thereof, and belongsto the technical field of an environmentally-friendly decontaminating and stabilizing material. The coal slag metakaolin-based decontaminating and stabilizing material for water-based drilling cuttings consists of the following components in percentage by mass: 25.0 to 45.0 percent of coal slag, 11 to 30 percent of metakaolin, 15 to 25 percent of cement, 6 to 13 percent of quick lime, 3 to 5 percent of crosslinking agent and 1 to 2 percent of mineral particle stabilizer. Various materials such as coal slag, the metakaolin and the cement as well as the water-based drilling cuttings are mixed for treating the water-based drilling cuttings , so that generation of percolate by the water-based drilling cuttings or waste coal slag under the erosion and soaking effects can be avoided; the coal slag metakaolin-based decontaminating and stabilizing material for the water-based drilling cuttings is suitable for a subbase layer, an under layer and backfill in the field of road construction, notonly can completely utilize industrial solid waste slag, but also can perform resource utilization on the stabilized drilling waste, namely the water-based drilling cuttings, is applied to road subbase layer, under layer and backfill, and accords with national environmental protection and resource policies.

Owner:鄂尔多斯市固邦环保科技有限公司

After-water-injection vibrating and compacting construction method of desert photovoltaic bracket pile foundation

InactiveCN111719579AImprove bearing capacityImprove anti-overturn performancePhotovoltaic supportsPhotovoltaic energy generationAeolian sandMicrostructure

The invention belongs to the technical field of foundations, and particularly relates to an after-water-injection vibrating and compacting construction method of a desert photovoltaic bracket pile foundation. According to the method, by five steps including site formation, measurement and positioning, piling and pile formation, reinforcement of a sand layer on the periphery of a pile and surface treatment of the sand layer on the periphery of the pile, the solar photovoltaic bracket pile foundation suitable for an aeolian sand site silty-fine sand foundation in a desert area and a corresponding foundation treatment mode are completed. After pile formation, water injection and sand filling are adopted for aeolian sand strata in a certain range on the periphery of the vibrating pile, an original microstructure of aeolian sand is damaged, aeolian sand on the periphery of the pile is reinforced, constraining force and side resistance of the sand layer on the periphery of the pile to the pile are increased, bearing capacity of the pile foundation is increased, pile length is effectively shortened, construction is convenient, engineering quantity is reduced, construction cost is reduced,and economical efficiency is improved.

Owner:POWERCHINA XIBEI ENG

A method for preventing and controlling rodents in soil engineering slopes in arid desert areas

ActiveCN104264696BReduce erosionMeet the requirements of prevention and control of ecological and environmental protectionExcavationsAridBandicoot

The invention relates to an arid desert region soil engineering slope bandicoot-caused damage prevention and control method. Reinforced concrete grid beams are embedded into a slope foundation layer, and sand gravels are filled in the reinforced concrete grid beams to destroy bandicoot nidification environments so as to achieve slope surface bandicoot-caused damage prevention and control effect. The method is simple, convenient, ecological and long-acting. According to ecological habits, living environments and other characteristics of levee slope bandicoots, a slope surface layer changed foundation structure is adopted, and a loose earth's surface structure which does not facilitate bandicoot nidification is created so as to achieve the purpose of effectively controlling damage caused by the levee slope bandicoots. A concrete grid beam structure is constructed on the ground slope to reinforce a slope soil body and ensure the slope stability. Sand gravel fillers are filled into concrete beam grids so as to inhibit bandicoot nidification and reduce the erosion scouring effect of rainwater. By means of the method, the problem that the bandicoot-caused damage prevention and control effect in the desert environment is low is solved, the ecological environmental protection requirements of a large canal system for slope bandicoot-caused damage prevention and control are met, and technical support is provided for bandicoot-caused damage prevention and control of arid desert region soil engineering facilities.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

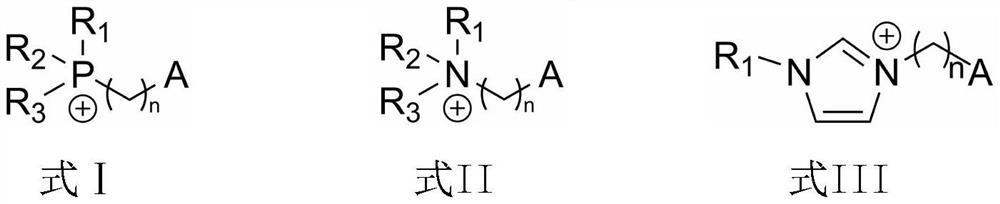

Aluminum material chemical polishing solution and polishing method thereof

ActiveCN114561643AHarm reductionRealize repeated useSolid sorbent liquid separationProcess efficiency improvementMetallurgyIonic liquid

The invention discloses an aluminum material chemical polishing solution and a polishing method thereof.The aluminum material chemical polishing solution is prepared by mixing an ionic liquid, an additive and water, and the using method of the aluminum material chemical polishing solution comprises the steps that the aluminum material chemical polishing solution is prepared firstly, then chemical polishing treatment is conducted on a to-be-polished aluminum material, and finally the used aluminum material chemical polishing solution is recycled. The polishing solution is treated and recycled and is used for the aluminum material polishing procedure again, repeated recycling is achieved, toxic substances such as yellow smoke and irritant gas are not generated in the using process, harm to the human body and the environment is small, meanwhile, due to the fact that the polishing solution can be recycled, low emission and low pollution are achieved, and the polishing solution is environmentally friendly. The polishing solution is composed of ionic liquid with low concentration, most of the ionic liquid is composed of water, the problem that the polishing solution is lost due to the fact that the aluminum material is attached to and taken out of the polishing solution is obviously solved in the using process, a solution in a rinsing bath can be recycled into the polishing bath after polishing and is used for chemical polishing of the aluminum material, cost is saved, and pollution to the environment is avoided.

Owner:SICHUAN UNIV

Eucalyptus seedling culture substrate and production process thereof

The invention discloses a eucalyptus seedling culture substrate. The eucalyptus seedling culture substrate comprises the following components in part by weight: 35 to 40 parts of coconut shell powder, 25 to 30 parts of peat, 15 to 20 parts of bentonite, 20 to 25 parts of attapulgite, 0.5 to 0.8 part of soil water-retaining agent, 15 to 20 parts of nutrient substance and 0.2 to 0.3 part of composite strain. A production process of the eucalyptus seedling culture substrate comprises the following steps of: drawing silk from a coconut shell to generate fragments; crushing the fragments; sieving until the granular size is 10 to 20 meshes; performing salt exclusion; mixing 35 to 40 weight parts of the coconut shell powder subjected to the salt exclusion, 15 to 20 weight parts of the nutrient substance and 0.2 to 0.3 weight part of high-temperature-resistant fermenting strain; adding clean water to stir and wet; stacking into a circular truncated cone shape; covering a membrane on the circular truncated cone so as to ferment; and after fermenting completely, adding the peat, the composite strain, the bentonite, the attapulgite and the soil water-retaining agent according to the weight ratio to mix and stir uniformly to prepare into block shapes. The coconut shell powder serves as a main raw material, so the materials are obtained singly and easily, the nutrient ingredients and the content are easy to control, and large-scale standard production can be performed easily.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

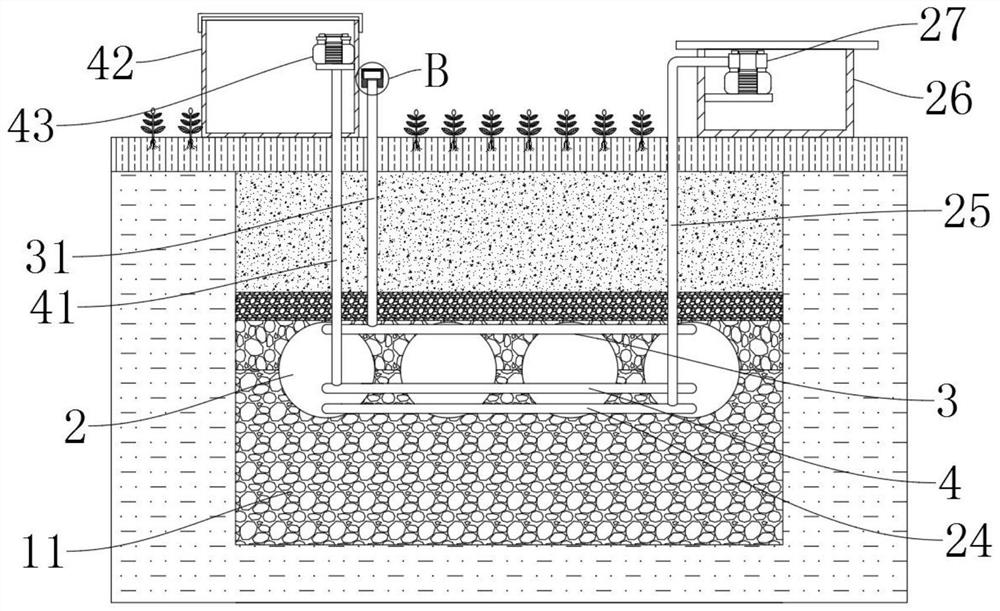

Immersed tube filling type coal mining subsidence land treatment device and method

PendingCN114351677AFacilitate agricultural productionAvoid secondary pollutionArtificial islandsGeneral water supply conservationImmersed tubePollution

The invention discloses an immersed tube filling type coal mining subsidence land treatment device and method, and belongs to the technical field of coal mining subsidence land treatment devices. An immersed tube filling type coal mining subsidence land treatment device comprises immersed tube parts which are laid at equal intervals, and the immersed tube parts which are adjacent end to end are connected through connecting sleeves. By using the immersed pipe fitting for filling, a through water containing space can be formed underground, rainwater can be collected in rainy days, water can be pumped from a water pumping pipe with one end in the immersed pipe fitting through a water pump for irrigation in dry seasons, and agricultural production is facilitated; meanwhile, the exciting quick-setting expansion waste residue cementing material is adopted for filling, the filling material can be obtained locally, self-sufficiency is achieved, a large amount of soil does not need to be filled, local soil resources are saved, meanwhile, the filling material is environmentally friendly, secondary pollution to the subsidence land is avoided, then ploughing is treated and restored, and the ecological and environment-friendly requirements are met.

Owner:山东省煤田地质局第三勘探队

Natural disease and insect prevention ecological planting method for weed and vegetable symbiosis for organic vegetables

InactiveCN111386996ASolve pollutionThe effect of independent growthClimate change adaptationFabaceae cultivationEcological environmentOrganic fertilizer

The invention discloses a natural disease and insect prevention ecological planting method for weed and vegetable symbiosis for organic vegetables. According to the method, plant raw material organicfertilizers with siliceous gels and humus gels are applied to a field as natural ecological fertilizers, weeding, chemical fertilizer application or pesticide spraying is not implemented in the wholegrowth process of vegetables, the plant raw material organic fertilizers are not replenished either, the labor and power can be saved in the planting process, and meanwhile, ecological environments can be protected. Vegetables cultivated by using the method are excellent in quality, stable in yield and safe and healthy.

Owner:唐振海

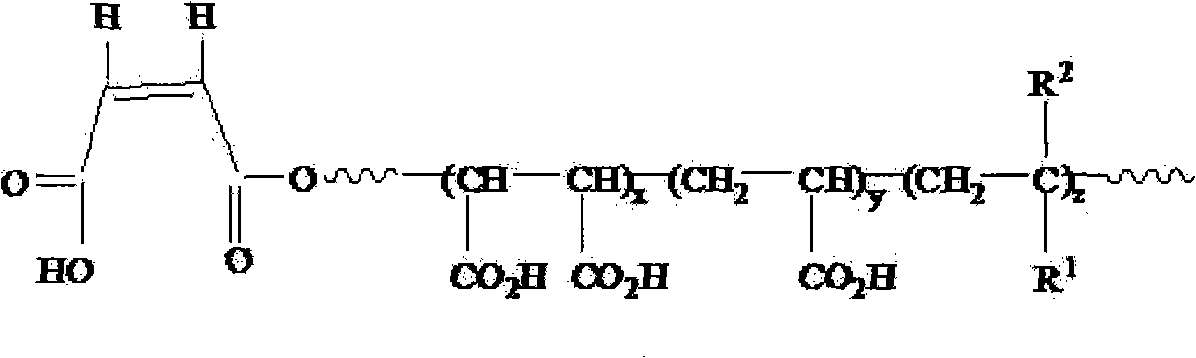

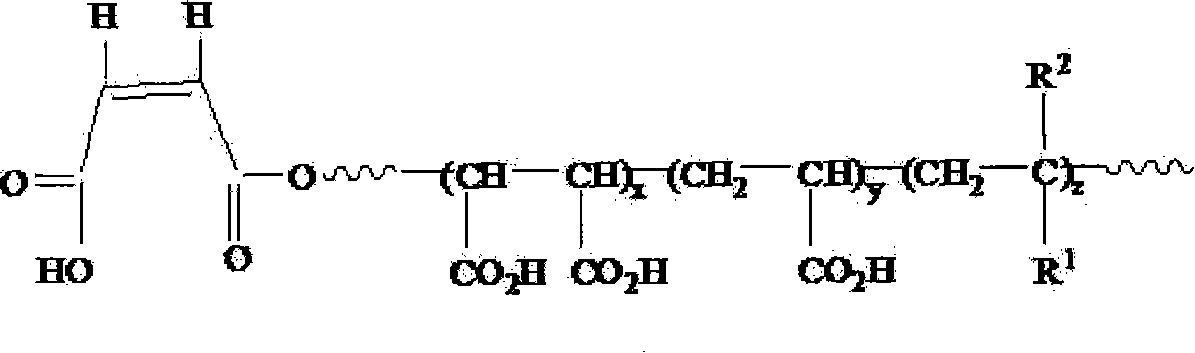

Method for preparing co-polymerized polyocarboxy acid oxymethylene-free anti-creasing finish agent

InactiveCN101307114AOvercome the disadvantage of being expensiveTaking into account the costFibre treatmentRefluxCarvacryl acetate

The invention belongs to the fine chemicals synthesis technical field, and discloses a method for synthesizing a copolymer polycarboxylate series non-formaldehyde crease-resistant finishing agent. The method adopts a clean aqueous solution polymerization technology, and comprises the following steps of: selecting H2O2-maleic anhydride as an initiator to perform a polymerization reaction at a reflux temperature with continuously dropping acrylic acid or an aqueous solution of the acrylic acid and vinyl acetate; synthesizing bipolymers and multi-element copolymers, which are terminated by carboxyl and use maleic anhydride and the acrylic acid as main monomers, through adjusting the proportions of the monomers and the dosage of the initiator. When the non-formaldehyde crease-resistant finishing agent is used as a non-formaldehyde crease-resistant finishing agent for textiles, thereby the crease recovery capability of the textiles can be improved.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

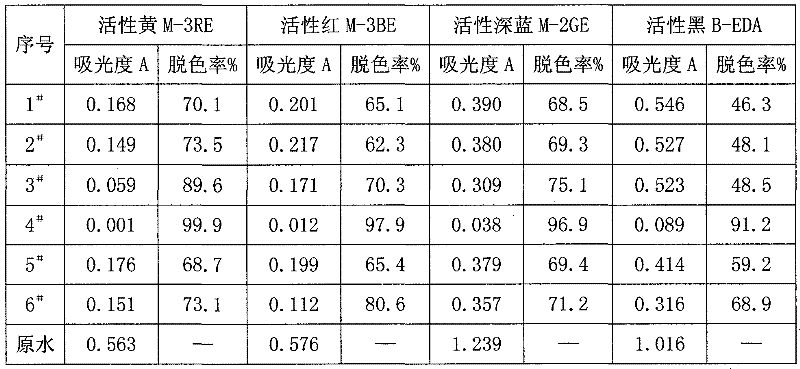

Method for preparing flocculant WK-1 applicable to decolorizing acid dye and reactive dye

InactiveCN101565224BMeet the requirements of ecological environmental protectionEasy to useWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationResource recoveryRoom temperature

The invention relates to the development of a flocculant WK-1 applicable to decolorizing printing and dyeing wastewater of an acid dye and a reactive dye, which belongs to the field of environmental pollution and controlling as well as resources recovery and utilization. A method for preparing the flocculant WK-1 applicable to decolorizing the acid dye and the reactive dye comprises the followingsteps: A, performing acidification on seedy wools with 60-percent sulfuric acid for 1 to 1.5 hours at room temperature to hydrolyze part of the seedy wools, and filtering the redundant sulfuric acid to obtain hydrolysis wool for standby; B, slowly dissolving chitosan of which the deacetylation degree is 85 percent in 100 milliliters of a 1 percent acetum, and stirring the mixture sufficiently to prepare a chitosan acetum; C, adding the hydrolysis wool in to the chitosan acetum gradually, and stirring the mixture for 30 minutes; and D, dropping a 5 percent NaOH solution into the mixture while stirring, adjusting the pH value to between 9 and 10, and continuing to stir the mixture slowly for 20 minutes to obtain a finished product. The method has he advantages of simplicity, practicability,low cost and less discharge capacity, and is a method and a process with greater practical significance.

Owner:NANTONG HUANYU SILK

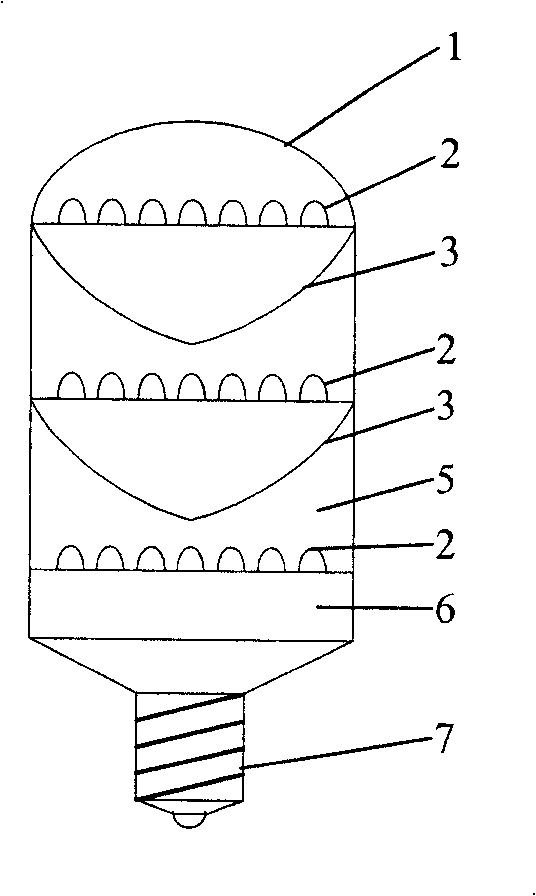

LED bulb for common lighting

ActiveCN100441939CHigh electrical-to-optical conversion efficiencyExtend your lifeMechanical apparatusPoint-like light sourceElectricityElectric light

The invention relates to a general lighting lamp LED, comprising lamp casing, lamp base, screw interface and a LED luminous source array including n layers which contain a plurality of LED in different or same color in each layer, wherein, the lamp casing comprises an integrated lens on the top and a cover lapped in n-1 layers which integrates a shoot and an arched surface in each layer, on the bottom of the cover that lapped as last layer is mounted a lamp base, and the screw interface is installed on the lower part of said lamp base. Said invention uses light source LED which has high electric-light conversion efficiency, super long service life, and environmental protective property, and improves the luminous efficiency by the direction of integrated lens, reflection of non-linear surface, and the optical system of light-gathering wall of the lamp casing, to reach uniform light and light collection. It can extends the layers of LED luminous source array according different power, set different color of each layer of luminous source array according different lamp color, and realizes the dynamic variation of light by control the control circuit in the lamp casing.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Method for preparing co-polymerized polyocarboxy acid oxymethylene-free anti-creasing finish agent

InactiveCN101307114BOvercome the disadvantage of being expensiveImprove appearance indicatorsFibre treatmentRefluxCarvacryl acetate

The invention belongs to the fine chemicals synthesis technical field, and discloses a method for synthesizing a copolymer polycarboxylate series non-formaldehyde crease-resistant finishing agent. The method adopts a clean aqueous solution polymerization technology, and comprises the following steps of: selecting H2O2-maleic anhydride as an initiator to perform a polymerization reaction at a reflux temperature with continuously dropping acrylic acid or an aqueous solution of the acrylic acid and vinyl acetate; synthesizing bipolymers and multi-element copolymers, which are terminated by carboxyl and use maleic anhydride and the acrylic acid as main monomers, through adjusting the proportions of the monomers and the dosage of the initiator. When the non-formaldehyde crease-resistant finishing agent is used as a non-formaldehyde crease-resistant finishing agent for textiles, thereby the crease recovery capability of the textiles can be improved.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

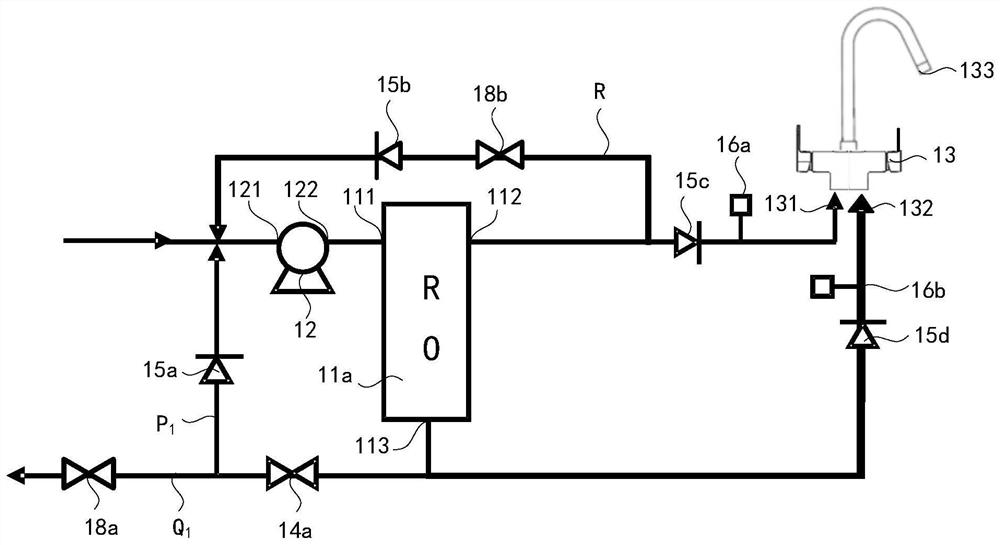

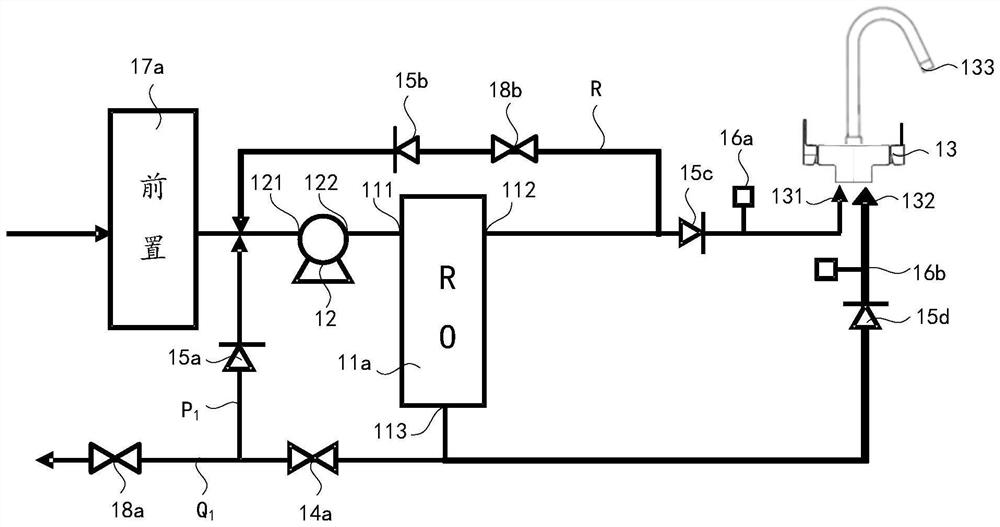

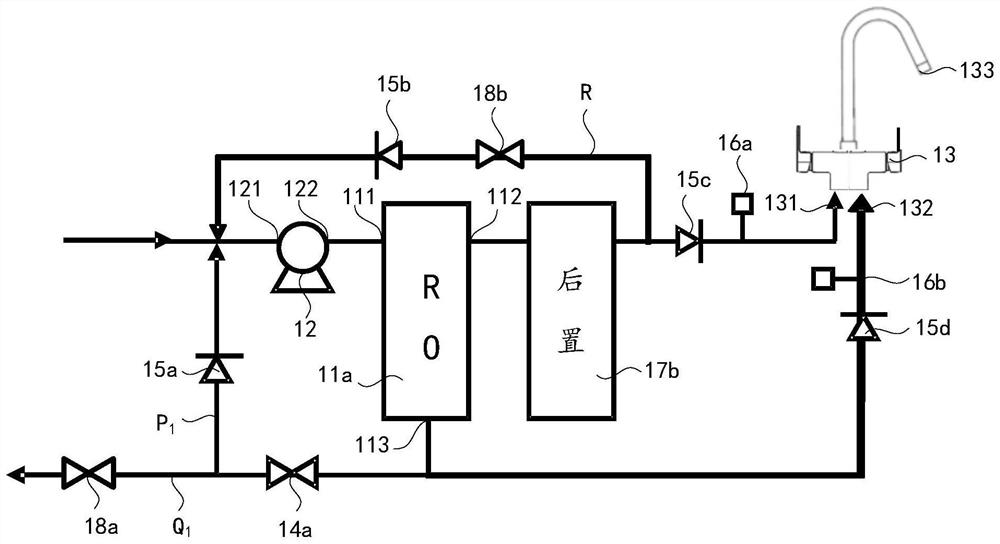

Waterway system and water purifier

InactiveCN114275850AGuaranteed lifeEmission reductionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltrationTap water

According to the water path system, wastewater generated in the water purification process of a reverse osmosis filter element flows back to the front of the reverse osmosis filter element through a pipeline, and the wastewater is mixed with tap water and then enters the reverse osmosis filter element again for secondary filtration. According to the method, the discharge of wastewater can be greatly reduced while the performance and the service life of the reverse osmosis filter element are ensured; meanwhile, wastewater is connected with a domestic faucet, wastewater discharge is completed and wastewater is reutilized when the tap faucet is opened, and the requirement for ecological environmental protection is met; in addition, a waste water direct discharge pipeline is also arranged and is used for direct discharge of waste water when necessary; meanwhile, the system is provided with a pure water backflow branch, purified water flows back to the front end of the reverse osmosis filter element, raw water in front of the reverse osmosis filter element is washed and neutralized, no old water is left, a first cup of water can be drunk, the water quality is stable, and pure and fresh water is provided all the time.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

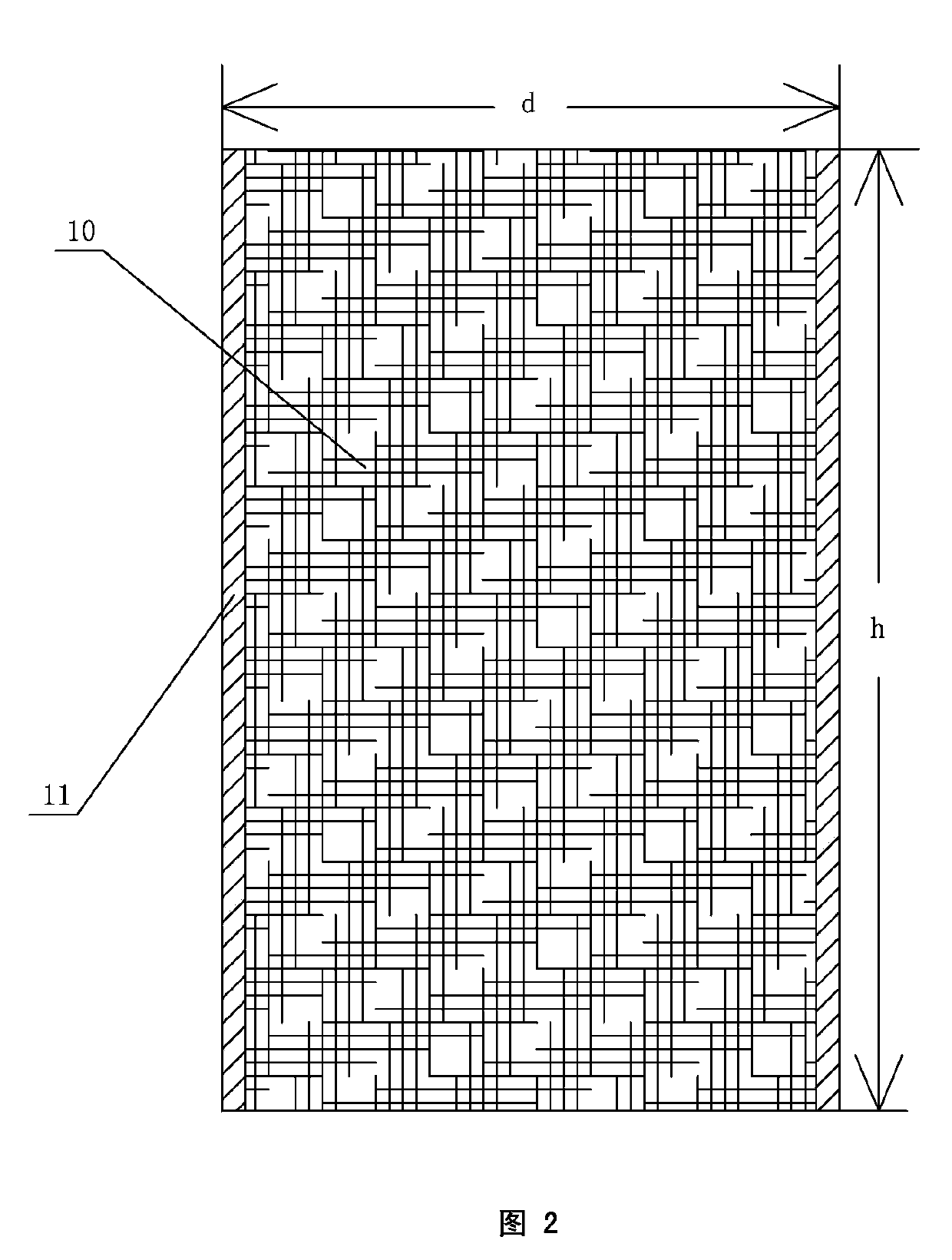

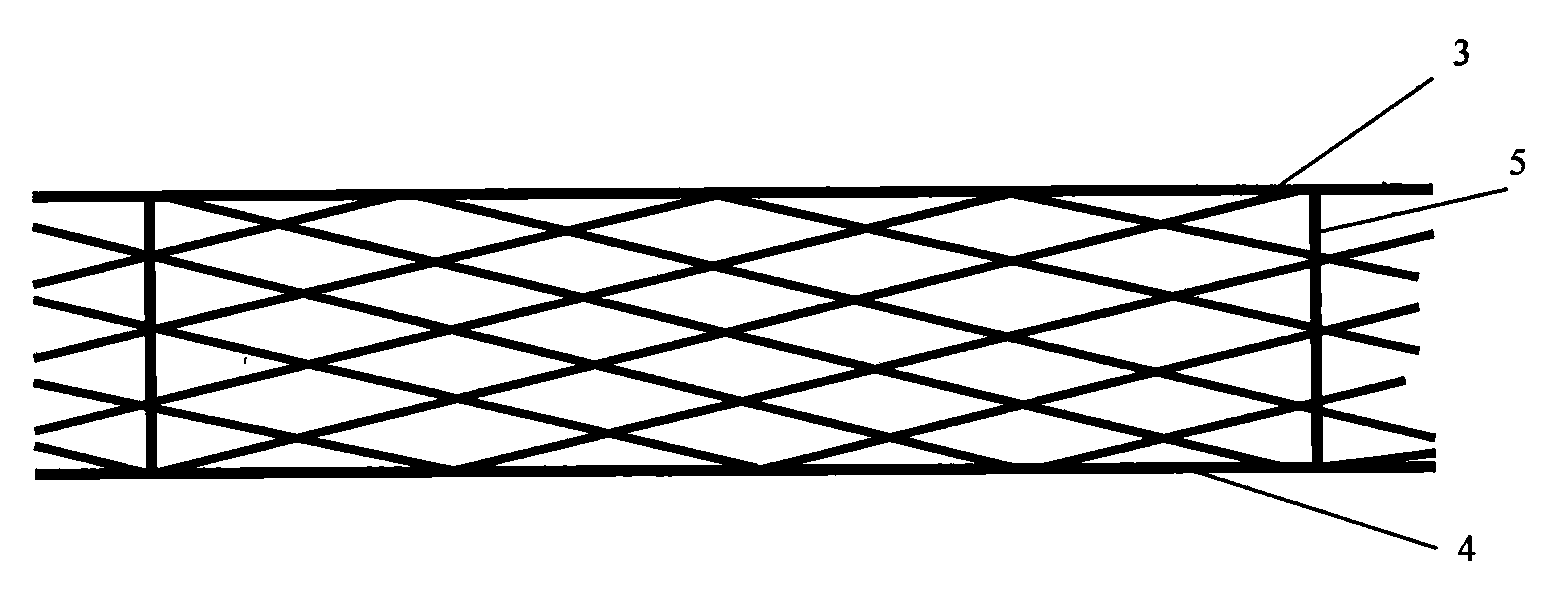

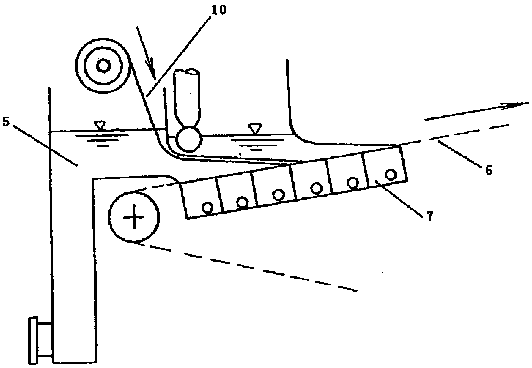

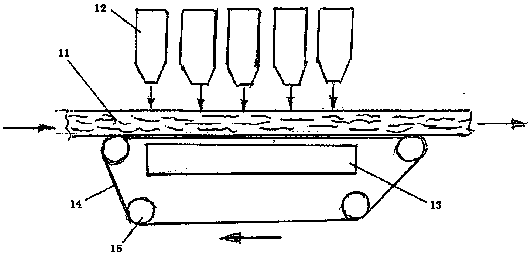

Production process of plant fiber nonwoven filter cloth for wet air puncture drainage reinforcement

ActiveCN105780294BHigh longitudinal and transverse tensile strengthAct as reinforcementWater resource protectionNon-woven fabricsYarnMechanical bond

The invention relates to a production process for a wet-laid air puncture type plant fiber non-woven fabric, which comprises: first opening plant fiber raw materials into single fibers, and then preparing the plant fiber into a suspension slurry; preparing the plant fiber suspension slurry through a wet-laid equipment The plant fiber web is formed; the plant fiber web is punctured by the jet air, so that the fibers in the plant fiber web are entangled with the adjacent fibers or yarns, and form a mechanical bond, and finally the plant fiber web is reinforced; and then dried The final product of plant fiber non-woven fabric is obtained by shaping, hot-rolling reinforcement, and rolling. The invention is specially aimed at plant fibers, and can produce plant fiber non-woven geotextiles that meet the requirements in both strength and water permeability.

Owner:NANJING HYDRAULIC RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com