Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

293 results about "Drilling waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modular pressure control and drilling waste management apparatus for subterranean borehole operations

ActiveUS7207399B2Waste water treatment from quariesWater/sewage treatment with mechanical oscillationsDegasserDisposal waste

Owner:MI

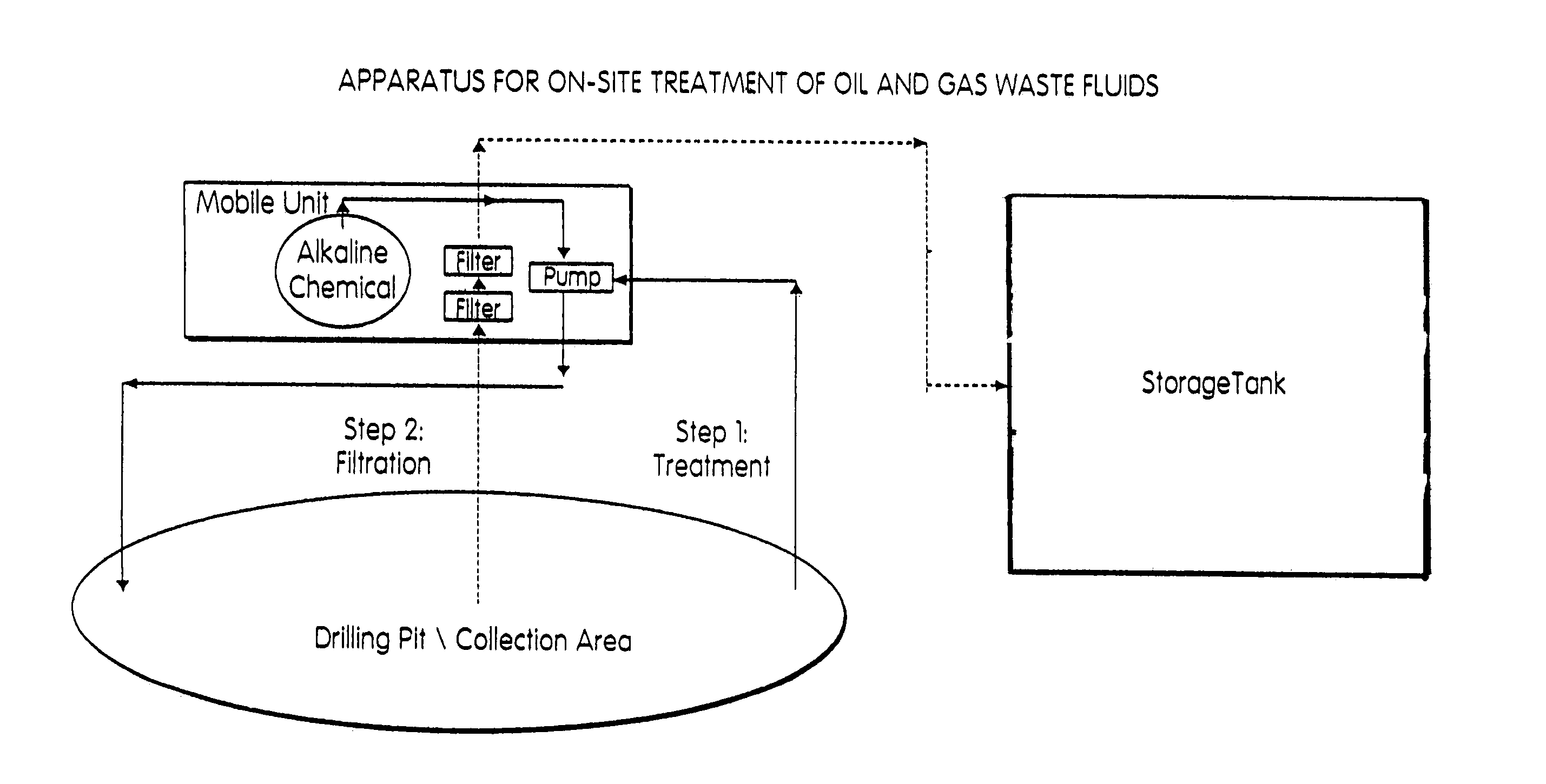

Method for on-site treatment of oil and gas well waste fluids

InactiveUS7022240B2Economic treatmentRaise the pHTreatment involving filtrationCentrifugal force sediment separationSites treatmentLiquid waste

An apparatus and method for on-site treatment and reclamation of oil and gas well waste water or fracturing fluids. The mobile treatment process and apparatus provide both chemical precipitation and filtration to treat the drilling fluid waste to a technically and environmentally acceptable level allowing for reuse. Alkaline treating agents are applied to the drilling waste fluids, as they are pumped through the treatment apparatus, to increase the pH of the fluid waste to a preferred pH range and to also cause selective soluble contaminants in the fluids to form a precipitate. The waste fluid is allowed to clarify as the precipitate of insoluble contaminants, through flocculation, settle and form a sludge at the bottom of the drilling pit. The clarified fluids are then filtered to satisfy applicable industry and environmental requirements.

Owner:FLUID RECOVERY SERVICES

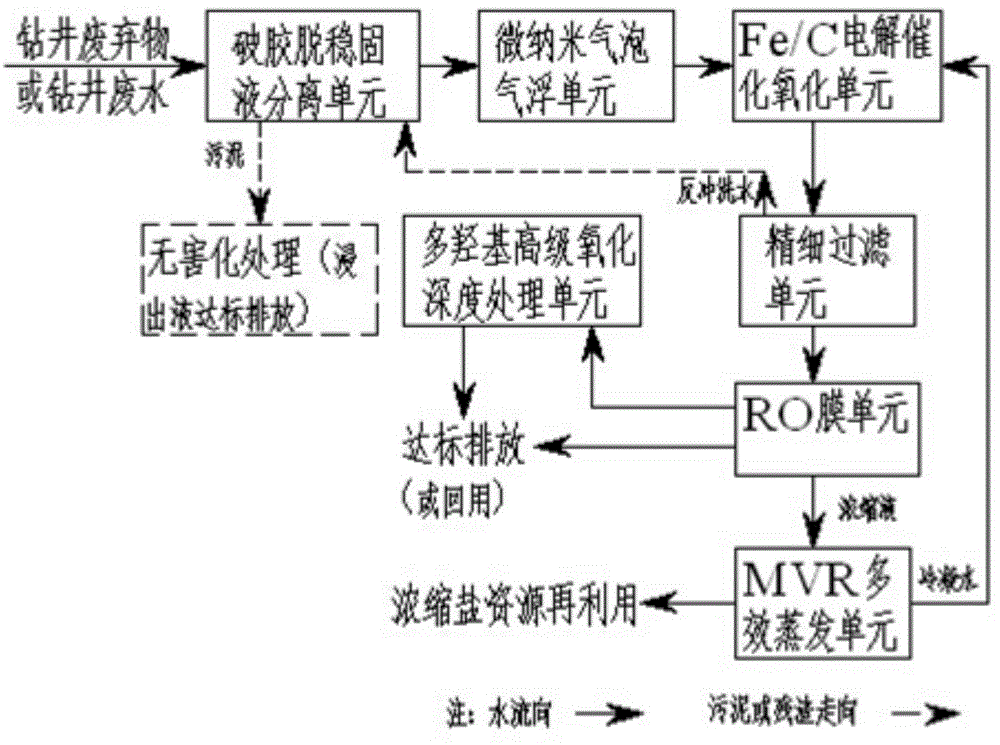

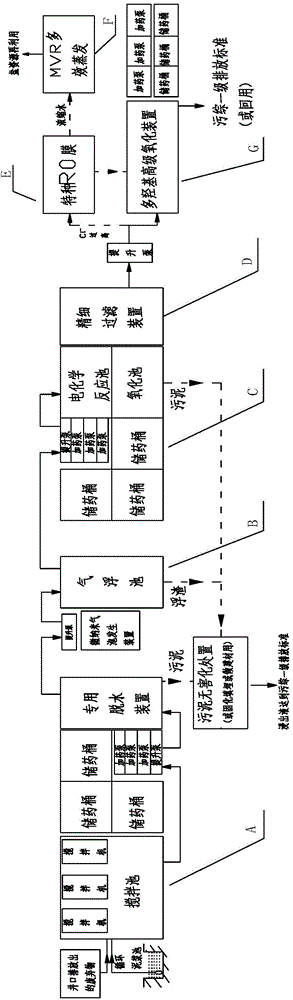

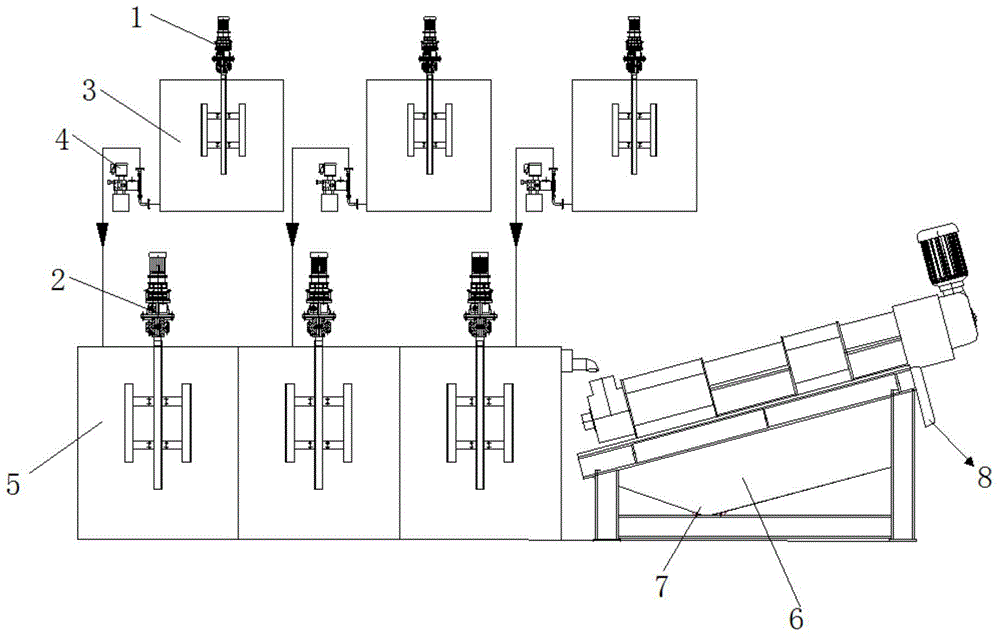

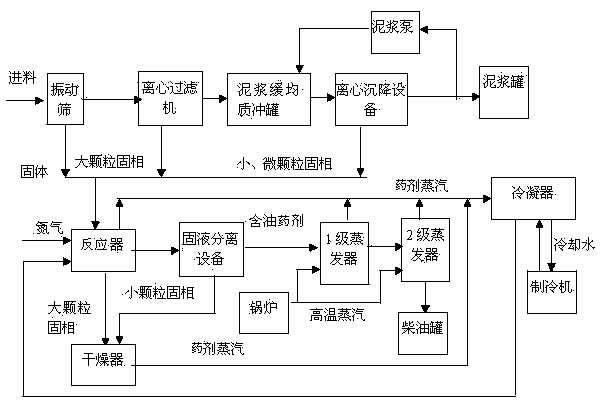

Process and device for overall standard-reached treatment for oil-gas field drilling waste

ActiveCN104355476AReduce processing timeFacilitate skid-mounted assemblyMultistage water/sewage treatmentMicro nanoElectrolysis

The invention discloses a process and a device for overall standard-reached treatment for oil-gas field drilling waste. The process comprises the following steps of: (1) gel breaking and destabilization and solid-liquid separation treatment; (2) micro-nano bubble air-floatation oil removal treatment; (3) Fe / C electrolysis catalytic oxidation; and (4) polyhydroxy advanced oxidation deep treatment. According to the process and the device disclosed by the invention, the drilling waste is totally treated to reach the standard or partially reused for preparing mud, and a solid phase (sludge and drillings), a liquid phase (drilling wastewater), chloride ions (salts) and the like are completely treated to reach the standards; the leachate generated after the treatment for the solid phase (sludge and drillings) and the treated liquid phase (drilling wastewater) reach Class A of 'Integrated Wastewater Discharge Standard' for discharge to be discharged; the chloride ions in the drilling wastewater reach 'Standards for Irrigation Water Quality' (GB5084-92) after the treatment. Meanwhile, the treatment process flow is simplified, the wastewater is recycled, and energy consumption is saved.

Owner:CHENGDU GUOSHENG ENVIRONMENTAL PROTECTION TECH

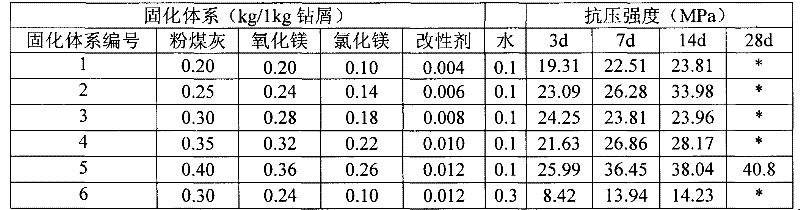

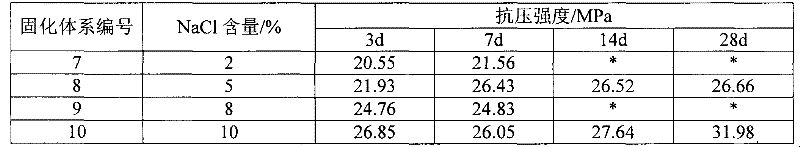

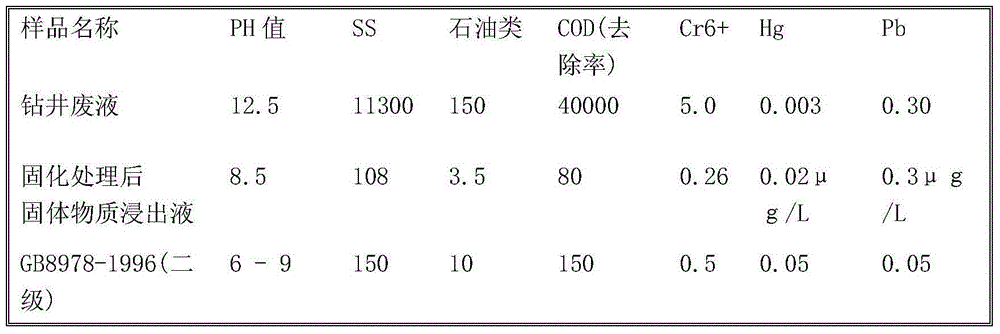

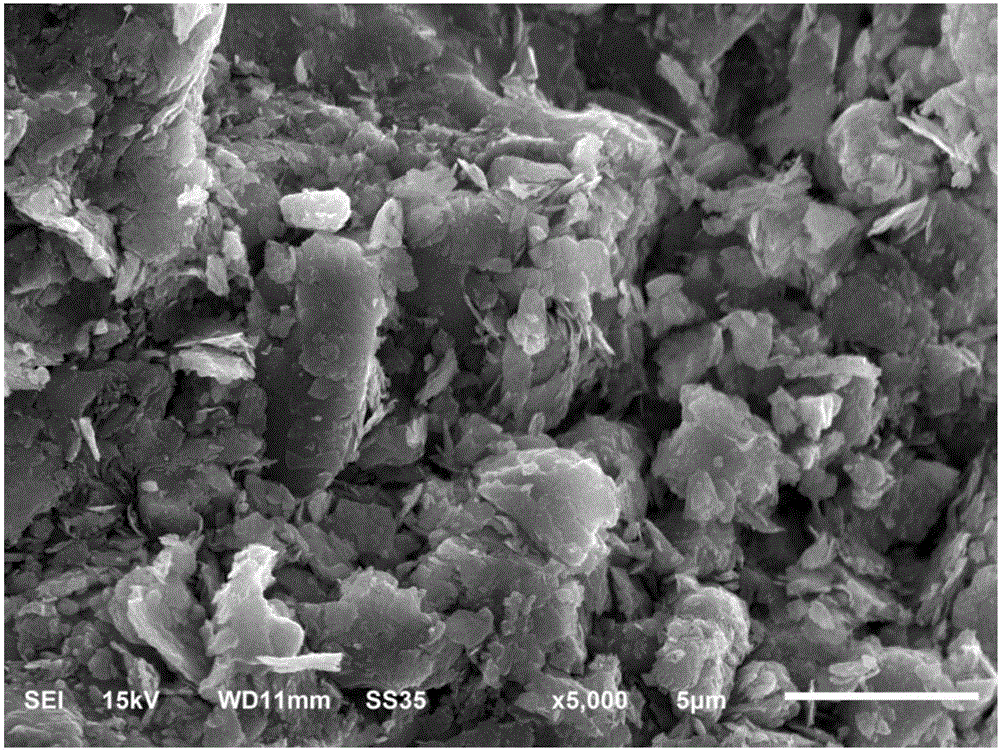

Method and process for high strength curing of drilling waste

InactiveCN102180641AAchieve stabilization/curingHigh compressive strengthSolid waste managementTO-18Chloride

The invention relates to a method and a process for the high strength curing of drilling waste, in particular to a curing agent and a curing process. The curing agent consists of the following components in percentage by weight: 30 to 35 percent of magnesia, 20 to 25 percent of magnesium chloride, 30 to 35 percent of fly ash, 0.8 to 1 percent of modifier and 10 to 18 percent of water. The curing process comprises the following steps of: uniformly mixing the drilling waste, light burned magnesia, the fly ash and the modifier, adding magnesium chloride aqueous solution into the mixture, quickly mixing, putting into a die, performing compaction molding, demolding, and naturally curing at the environment temperature. The compression strength of a product after the product is cured for 28 days can reach 40MPa, the compression strength of the drilling waste with 10 percent of salt after the drilling waste is cured for 28 days can reach 32MPa, and extract heavy metal ions meet the environment-friendly requirement. The cured product has high compression strength and comprises 40 to 60 percent of drilling waste, and the cured drilling waste has high stability and recycling value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

A treatment method for deep well polysulfide mud drilling wastewater

InactiveCN102295359AImprove processing efficiencyAchieve primary treatment standardsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationWater filter

The invention relates to a treatment method for deep-well polysulfide slurry drilling waste water, belonging to the technology for treating waste water of oil and gas field. The method comprises the following steps of: (1) coagulation treatment: pumping the drilling waste water into a coagulation reactor, and orderly adding inorganic coagulant, coagulant aids and flocculating agent; (2) secondaryflocculation: pumping the waste water processed in the coagulation treatment step into a secondary flocculation reactor, and directly adding secondary flocculation flocculant, coagulant aids and flocculating agent; (3) absorption treatment: pumping the waste water processed in the flocculation step into an active carbon adsorptive filtration reactor; (4) oxidation treatment: pumping the water filtered by the active carbon into an oxidation reactor for oxidation, and adding oxidant. The method takes the active carbon absorption and the oxidation treatment with inorganic chlorate type strong oxidizer as technical core processes, each index of the treated water can meet the level-1 technical standard requirements of a 'comprehensive sewage discharge standard' GB8978-1996.

Owner:CHINA PETROCHEMICAL CORP +1

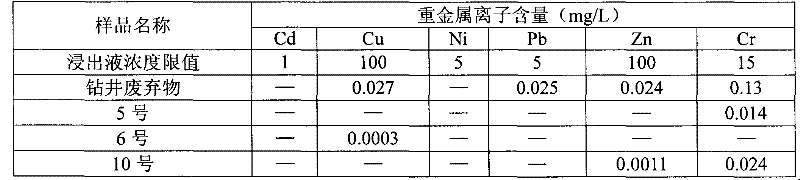

Drilling wastes recycling method

ActiveCN105347609AAdapt to dispersionAdapt to mobilityWaste water treatment from quariesWater treatment compoundsSludgeEvaporation

The invention belongs to the technical field of sewage processing, and concretely relates to a drilling wastes recycling method. The method comprises the following steps: performing primary purifying, removing rock debris and sandstones; performing destabilizing and flocculating treatment, conglomerating the suspending granules into a flocculent body; performing solid-liquid separating, using a separated sludge for profile control of a water injection well in an oil field; performing biological treatment on the separated sewage to reduce COD, carrying out microfiltration and ultrafiltration processing for removing a suspension and a colloid as well as reducing SDI, performing reverse osmosis to obtain fresh water for reuse, evaporating concentrated water obtained by reverse osmosis and crystallization, reusing the fresh water obtained by evaporation, and reusing the common salt and potassium chloride obtained by crystallization as an additive of a drilling fluid. The method realizes harmlessness and recycling of the drilling wastes, eliminates pollution on surrounding environment, and is in favor of protection of resources such as soil, air and underground water at periphery of a well field. The method can be widely used in a recycling treatment process of the drilling wastes in the oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

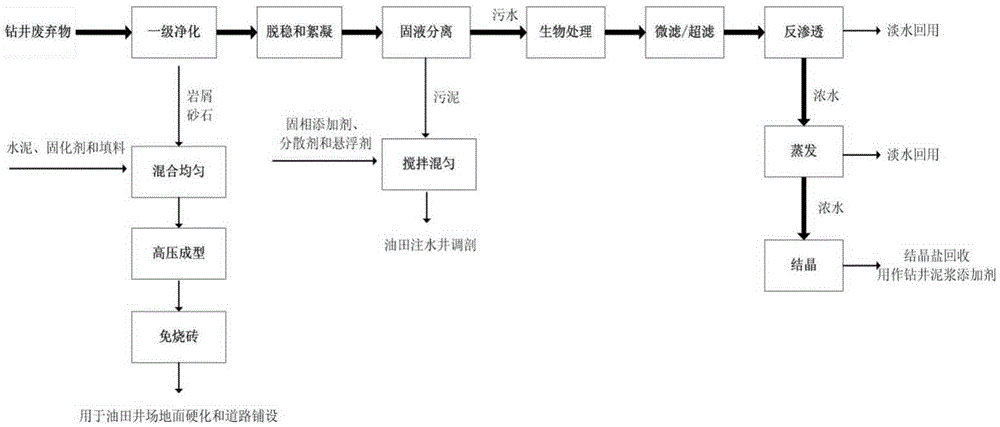

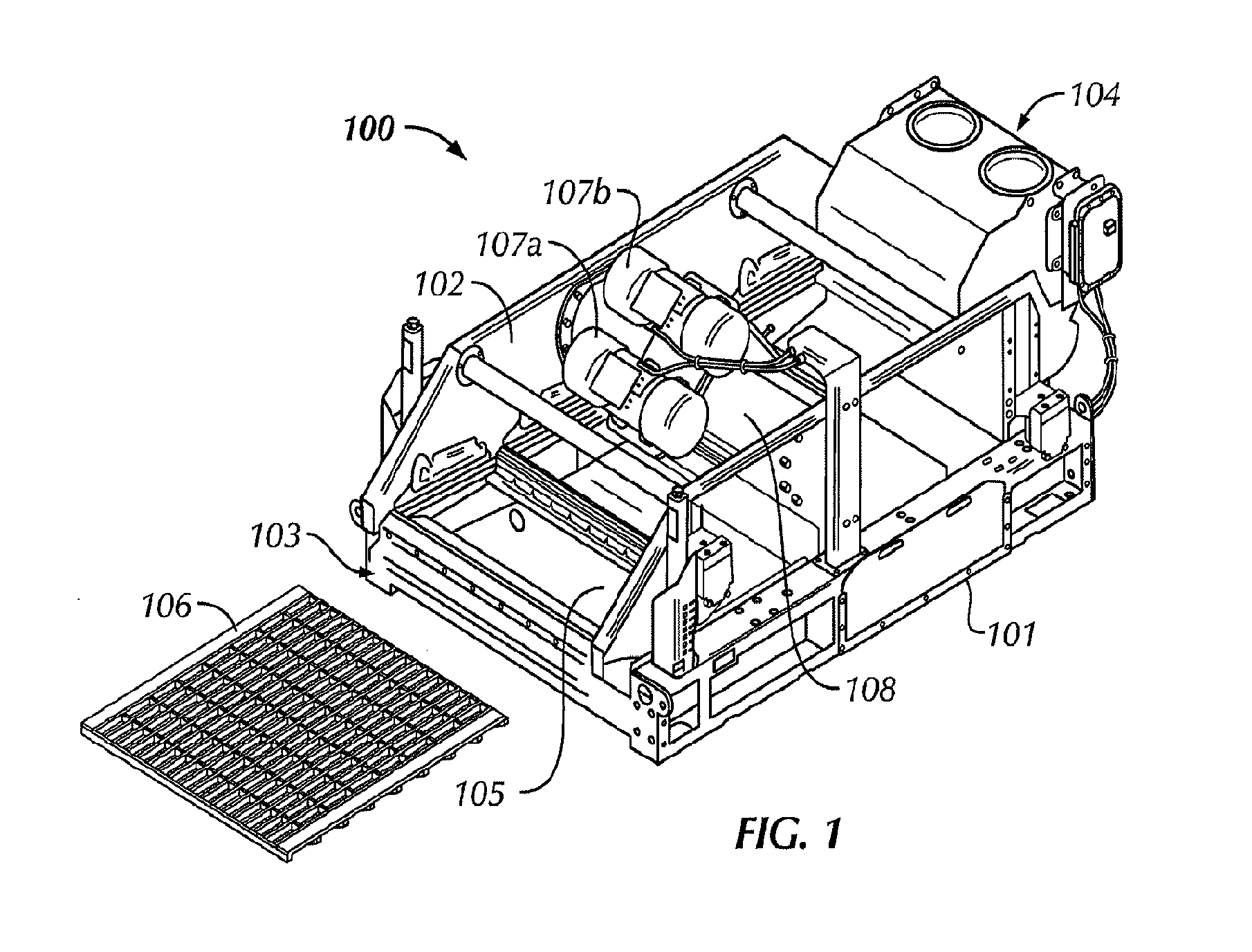

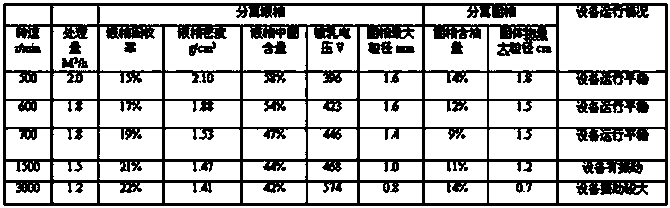

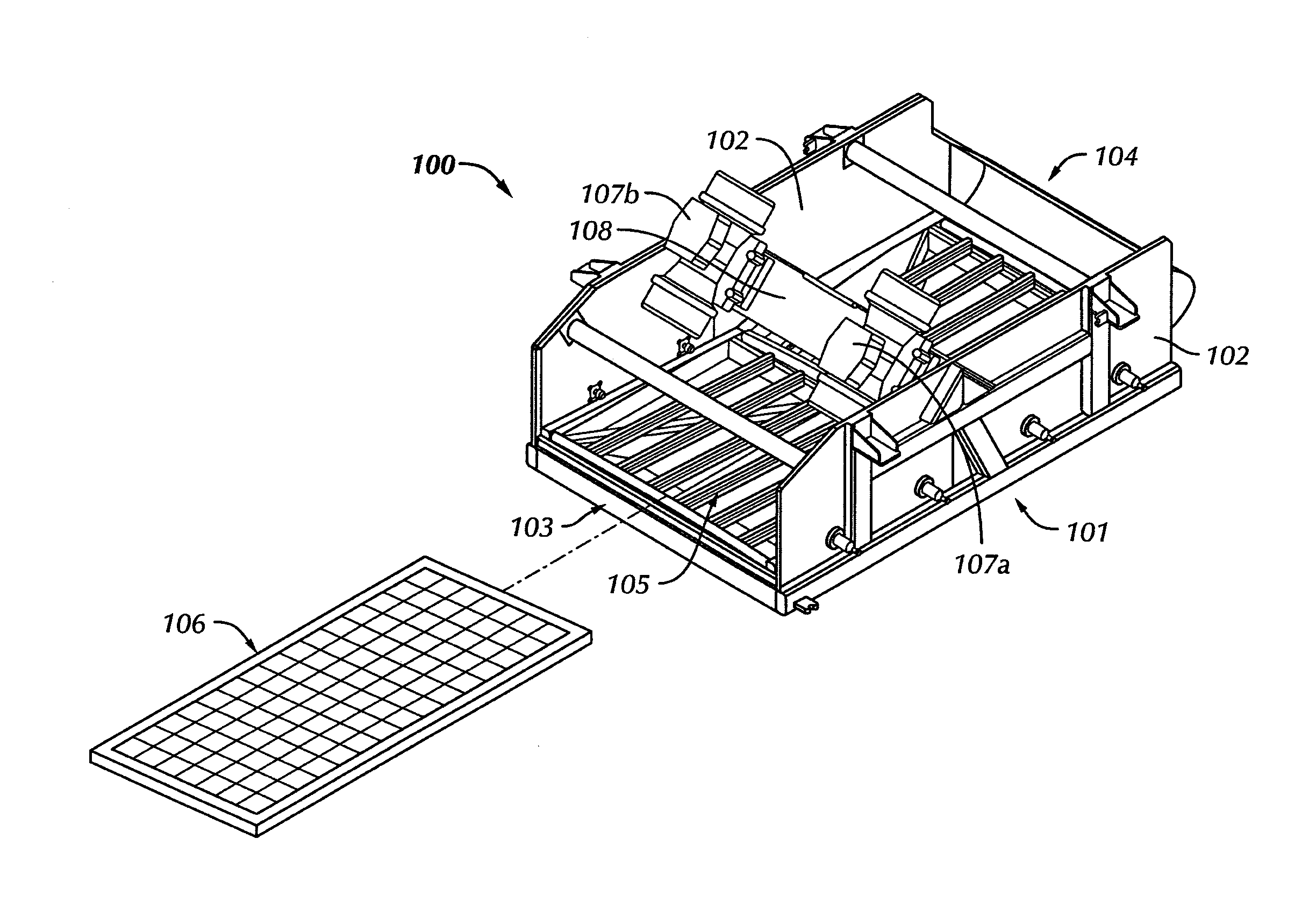

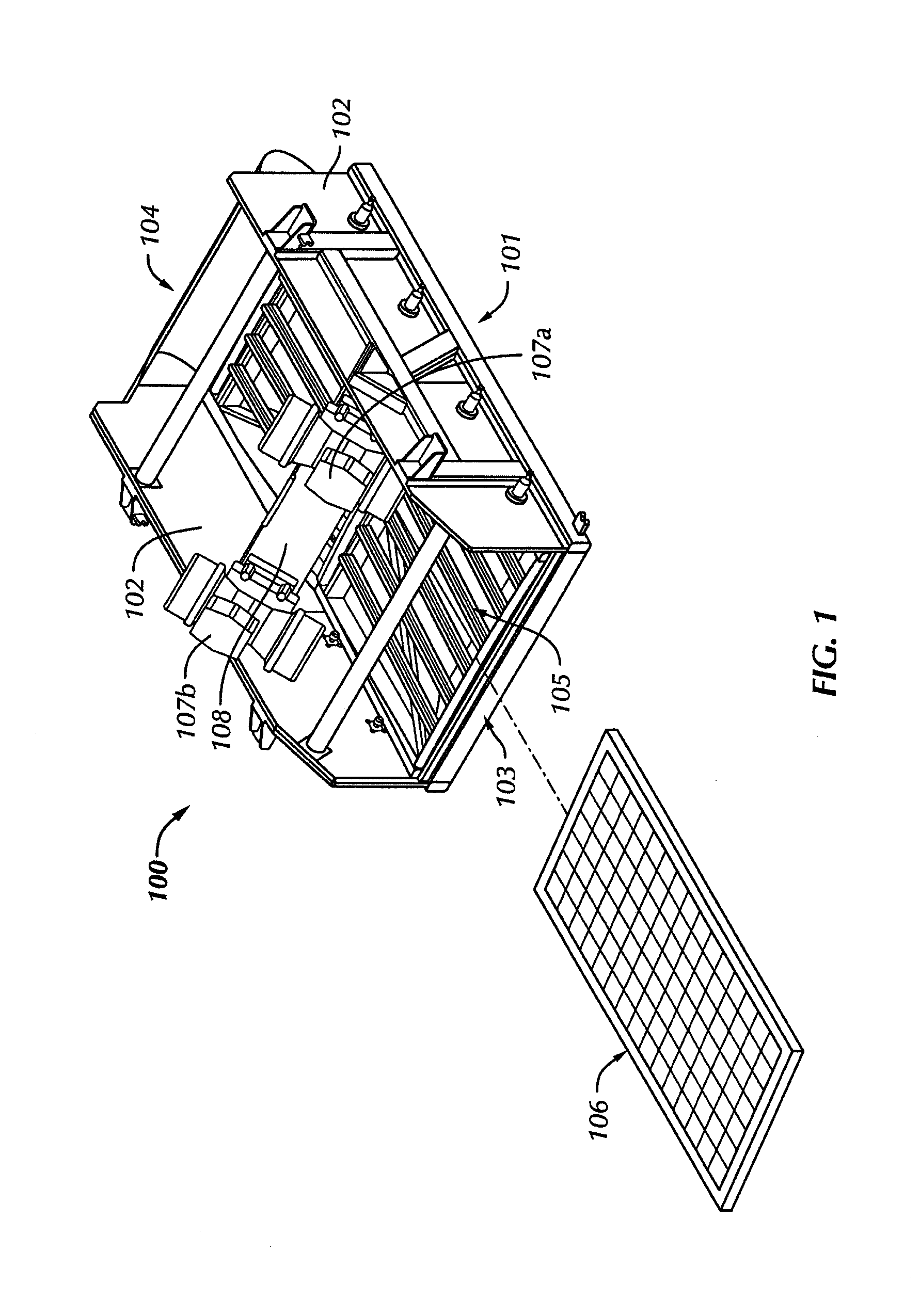

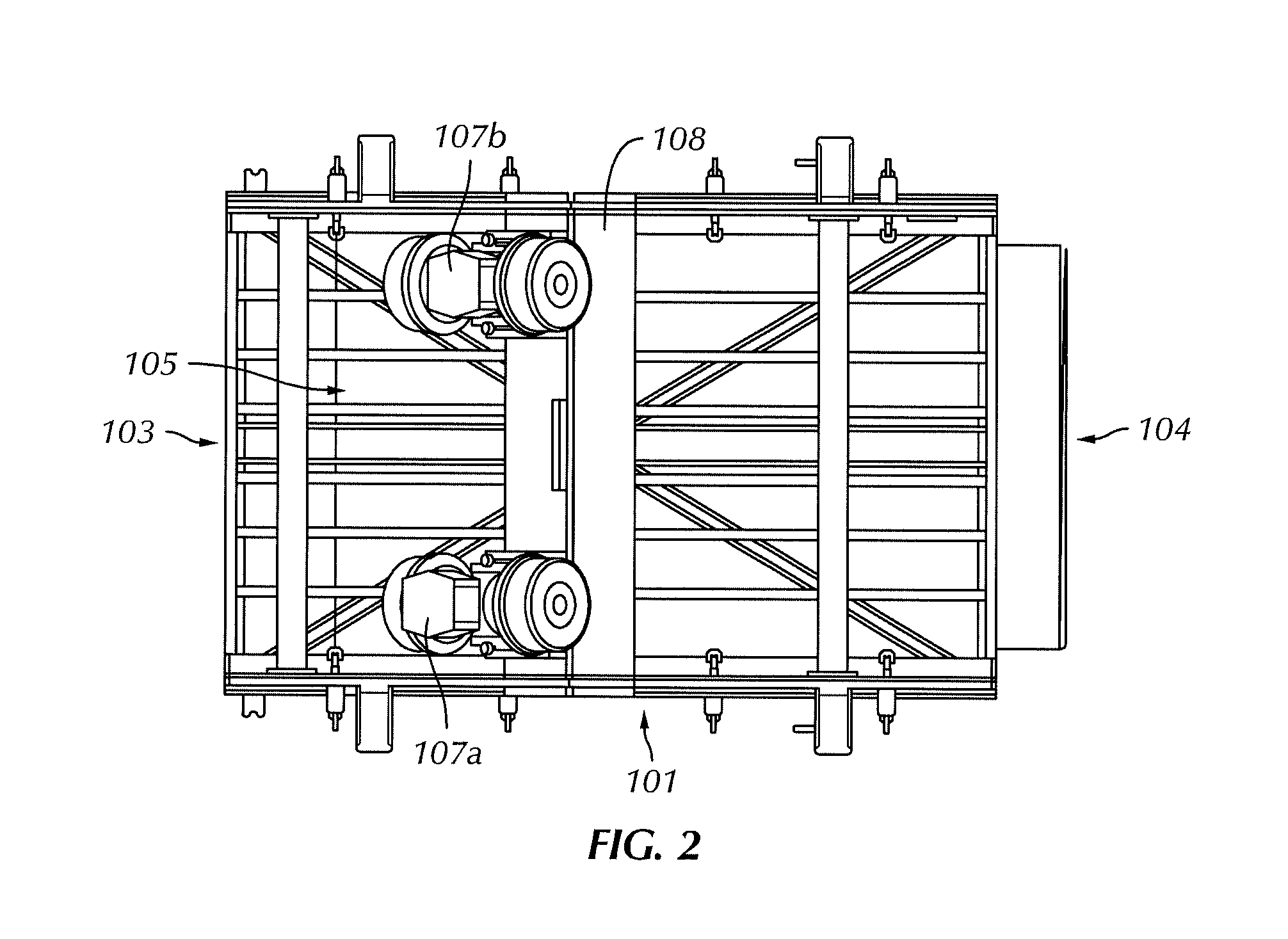

Vibratory separator motion

A vibratory separator (100) including a first actuator (107A) coupled to a basket (105) and a second actuator (107B) coupled to the basket. Additionally, the vibratory separator (100) includes a motion control switch operatively connected to at least one of the first and second actuators (107A, 107B) and configured to modulate motion generated by the first and second actuators between a first elliptical motion and a second elliptical motion. Also, a method of processing drilling waste, the method including flowing drilling waste over a screen of a vibratory separator and imparting a first elliptical motion to the screen. The method further includes monitoring the flow of drilling waste over the screen, determining an overload condition exists, and adjusting the motion to a second elliptical motion based on the determined load condition.

Owner:MI

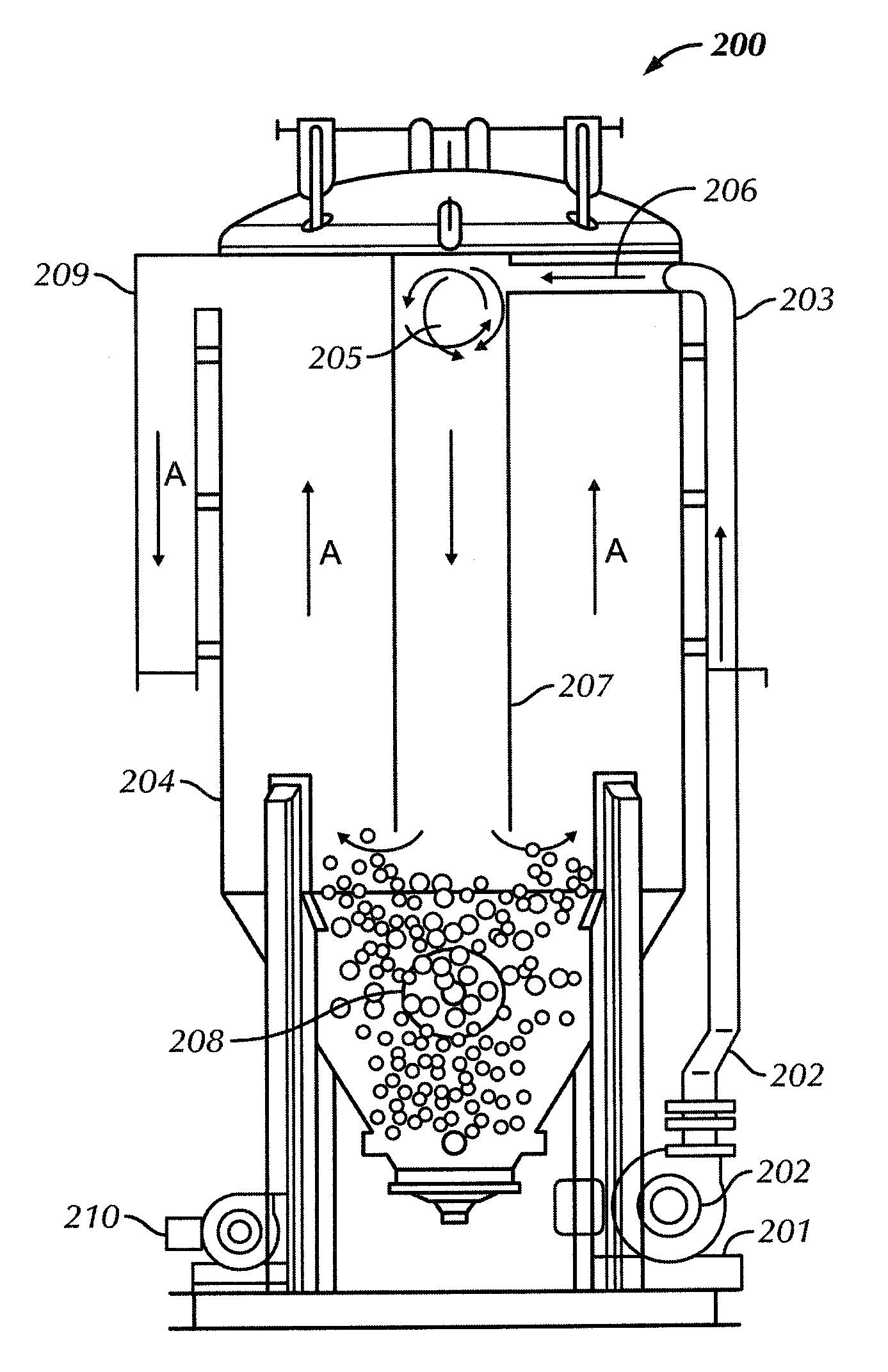

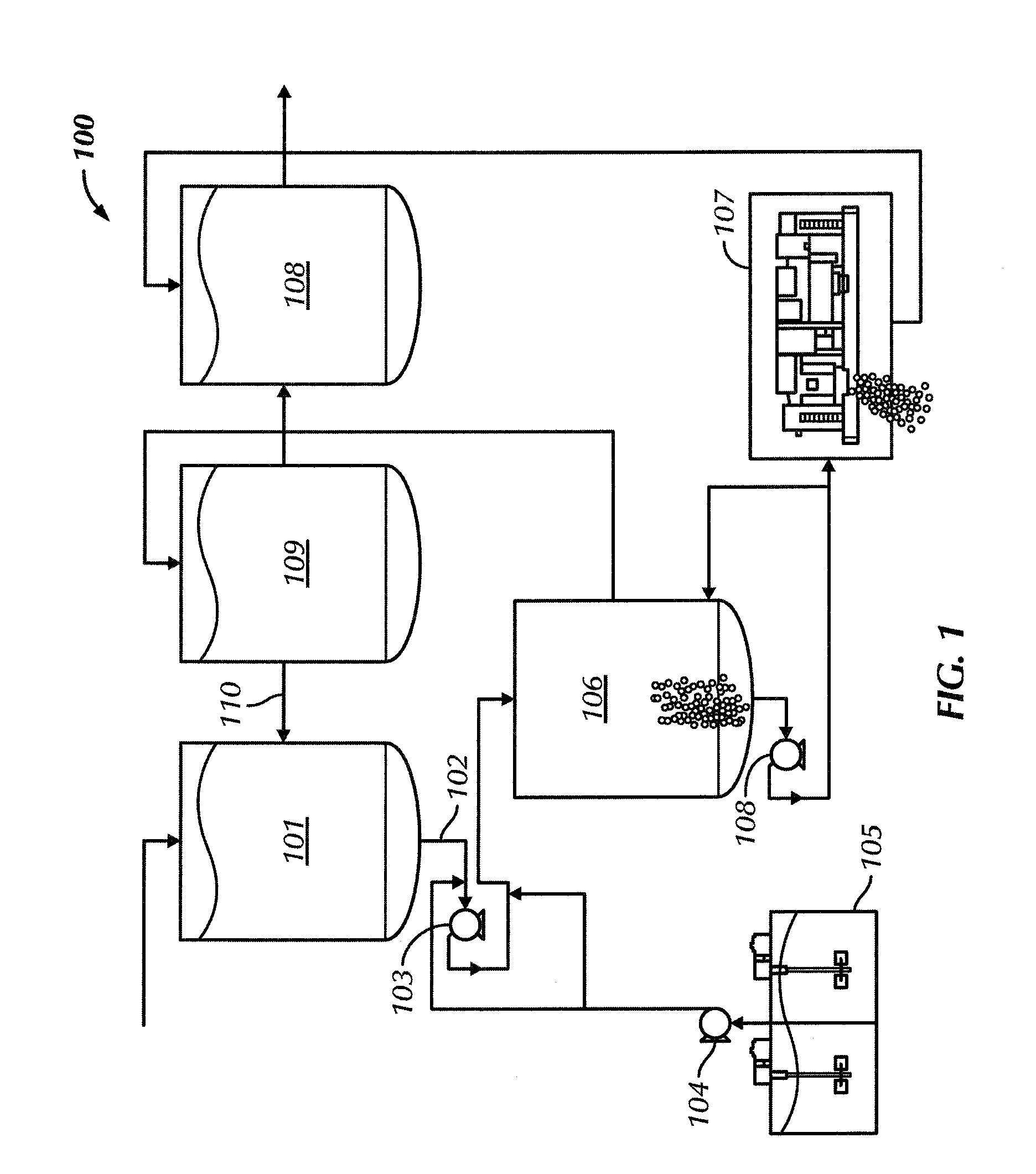

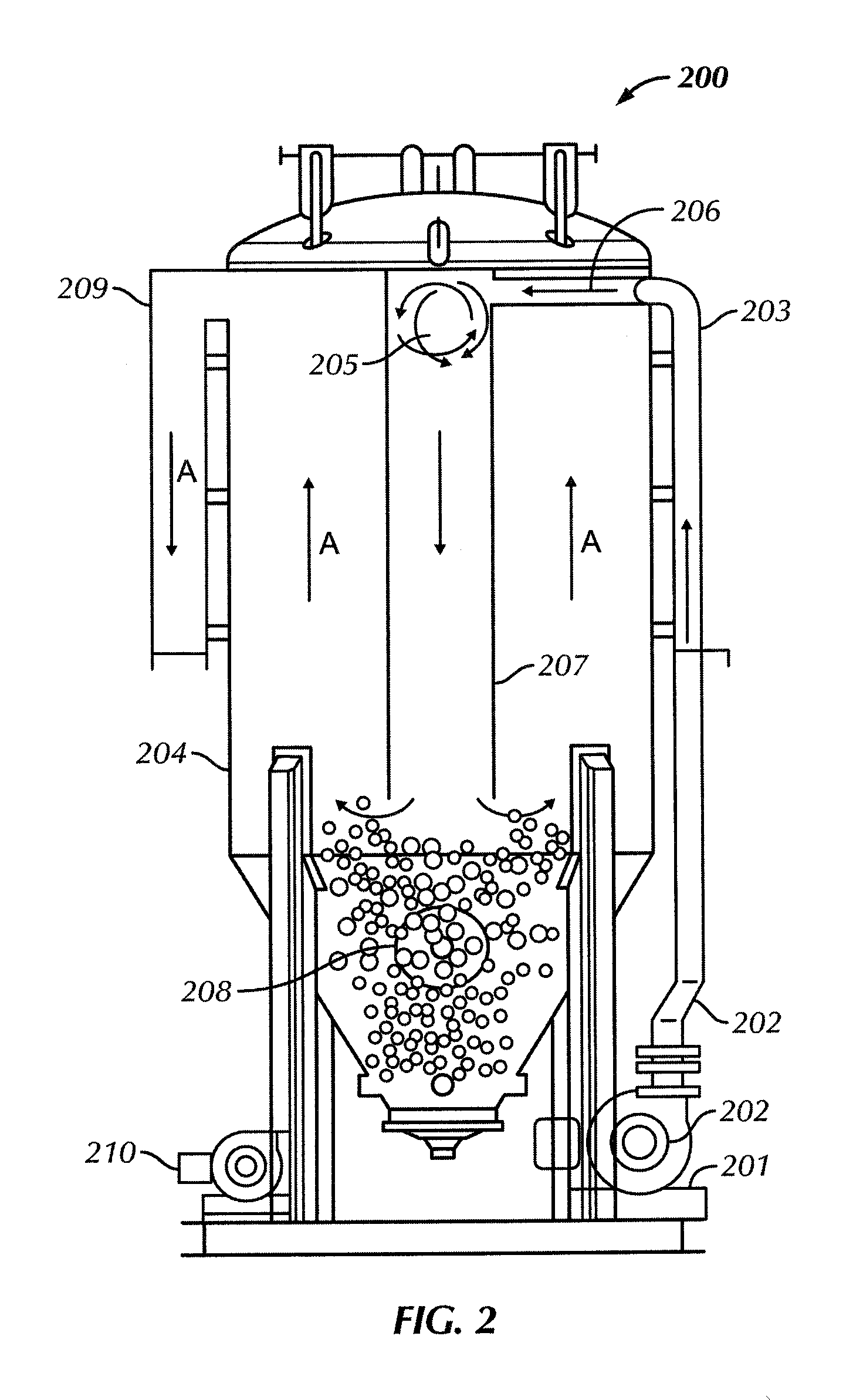

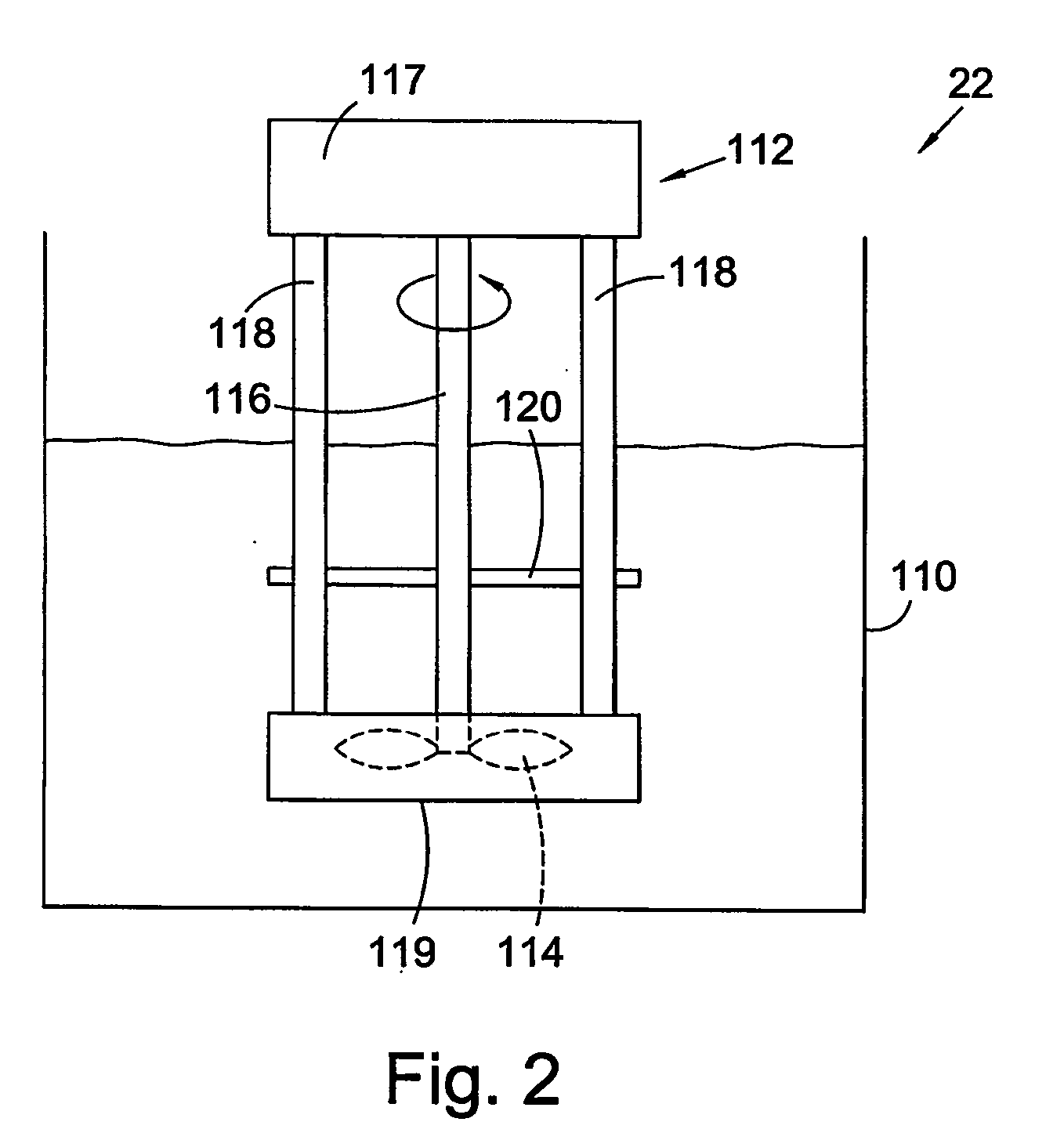

Dewatering system

A system for processing drilling mud, the system including a primary separation tank having an inlet for receiving drilling waste and an outlet in fluid communication with a feed line, and an injection pump in fluid communication with a polymer tank and the feed line. The system also includes a clarifying tank in fluid communication with the feed line and a first collection tank, wherein effluent from the clarifying tank is discharged into the first collection tank, and a centrifuge in fluid communication with the clarifying tank and a second collection tank, wherein effluent from the centrifuge is discharged into the second collection tank.

Owner:MI

Treatment process for drilling waste sludge in oil and gas field

ActiveCN103435241AThe process steps are simpleHigh oil removal efficiencyWaste water treatment from quariesBiological sludge treatmentThree levelSurface layer

The invention discloses a treatment process for drilling waste sludge in oil and gas field, relating to the technical field of pollution treatment of petroleum and gas exploration drilling. The treatment process comprises the following steps of a. culturing and domesticating microbial degradation bacteria to obtain degradation strains; b. mixing the drilling waste sludge and the degradation strain obtained in the step a according to a proportion of 100:(0.3-0.5) in parts by weight; c. mixing the mixture obtained in the step b with soil according to a proportion of 1:(1.5-3) in parts by weight; d. covering the surface layer of the mixture formed in the step c with soil; e. cultivating plants in the soil of the step d. By using the method, the problems of secondary pollution, high cost and complex operation existing in the conventional treatment technology are effectively solved, and the treated mixture meets the national soil quality three-level standard after the drilling waste sludge plant-soil-microorganism are subjected to innocent treatment together.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

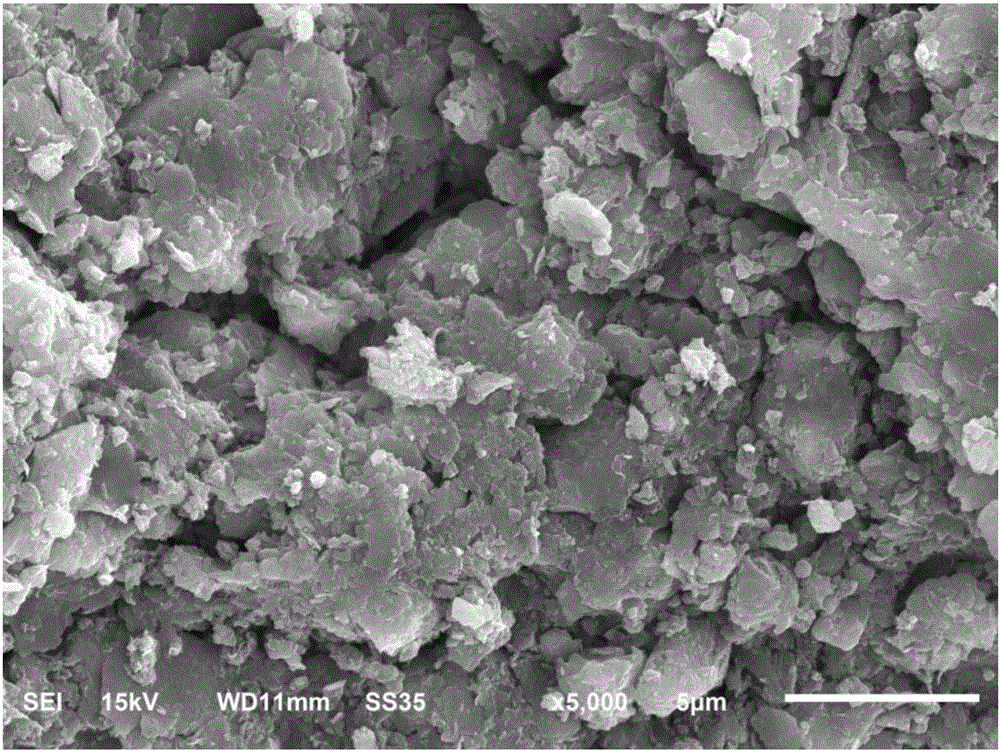

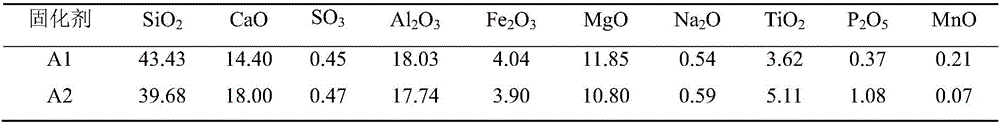

Harmless treatment method for drilling wastes of oil and gas fields

ActiveCN105107824AEfficient conversionWith water absorption and thickening effectSolid waste disposalLiquid wasteChemical oxygen demand

The invention provides a harmless treatment method for drilling wastes of oil and gas fields. The harmless treatment method comprises the steps that solid-liquid separation of waste drilling fluid is conducted, a water treatment agent is added in the solid-liquid separation process, and liquid water directly returns to drilling mud of the oil and gas fields to be reused after mechanical reinforcement to the solid-liquid separation is conducted; collecting equipment is adopted for collecting solid wastes such as rock debris and residual mud in waste mud; the collected solid wastes are placed in a mixer, and a solidification enhancement treatment agent comprising a RDH-1 solidification agent and a RDH-2 solidification agent is added into the mixer, so that the solidification enhancement treatment agent and the solid wastes containing a certain amount of water are mixed fully and evenly. The harmless treatment method is capable of effectively transferring harmful ingredients in wastes to substances small in harm or harmless substances, or reducing the leaching rate of the wastes, adjusting the PH value of a leaching solution of a solidified body of the waste mud and decreasing chemical oxygen demand (COD) and the chroma of suspended solids (SS), so that heavy metal ions contained in the treated solid wastes meet the requirement of a discharging index which environmental protection allows.

Owner:北京融达环科新材料科技有限公司

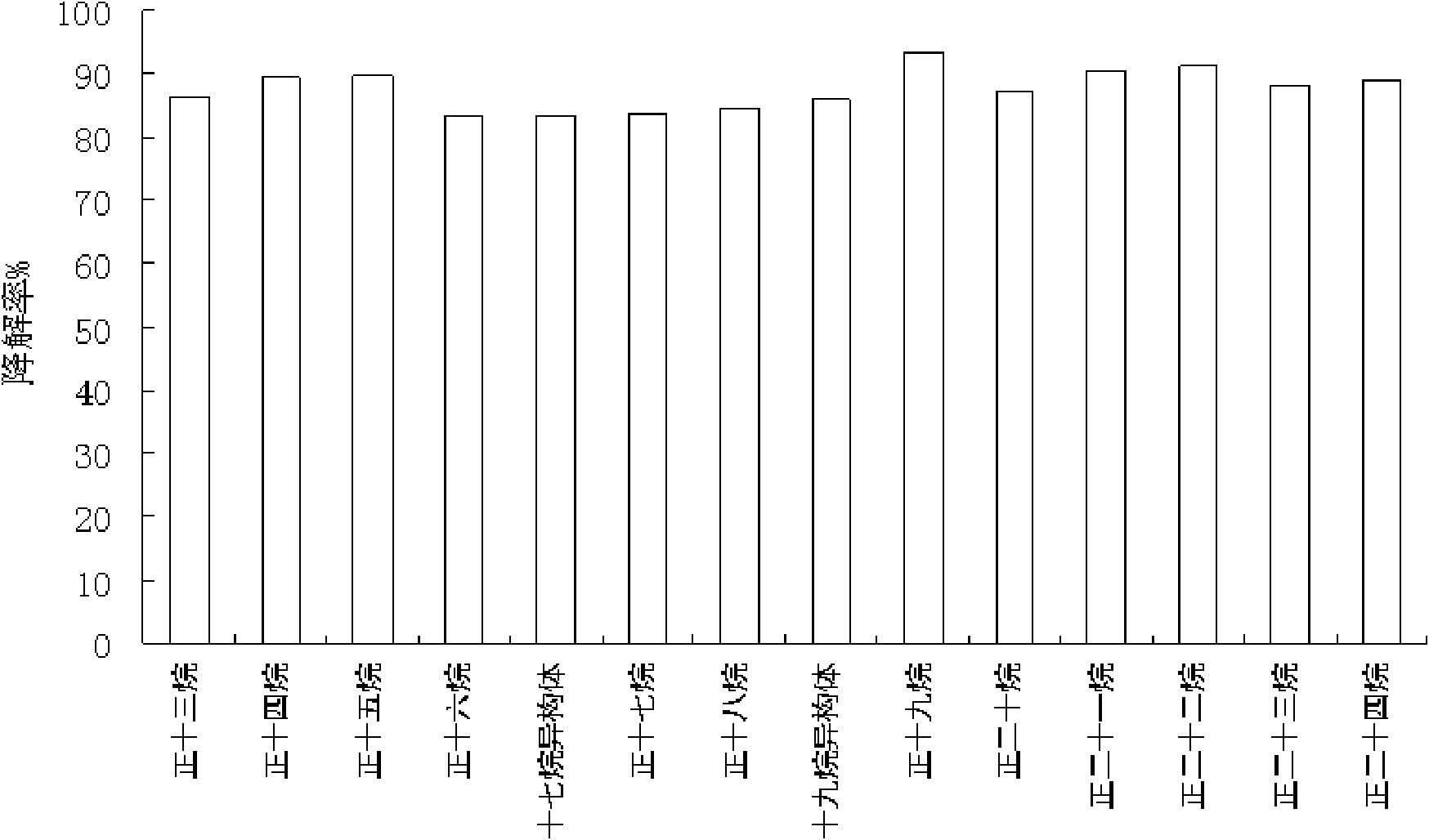

Process for recycling oil-based mud and oil bases from oil-based mud drilling wastes

The invention belongs to the treatment field of oil-based mud or oil-based drilling cuttings in the well drilling of shale gas, tight gas and conventional oil gas fields, and in particular relates to a treatment recycling process for synchronously recycling the oil-based mud and oil bases from oil-based mud drilling wastes. The treatment recycling process is characterized by comprising the following steps: performing centrifugal separation on the oil-based mud; recycling the oil-based mud in a deep desorption manner via reagents at a normal temperature; and performing mixed distillation on the reagents containing oil and recycling the condensed reagents. According to the reaction process, the harmless treatment of the oil-based mud or the oil-based drilling cuttings can be realized, wherein the content of the oil in a final solid-phase product is less than 1%; the majority of oil ingredients in the oil-based mud or the oil-based drilling cuttings can be recycled, wherein the recycling rate of the oil bases is greater than 90%. The adopted reaction reagents can be almost recycled for reutilization, wherein the loss of the reagents is less than 2%. In addition, the treatment procedures are all performed under a normal temperature and a normal pressure, so that the treatment time is short; the secondary pollution is nearly avoided. The treatment recycling process is low in equipment investment and operation cost. Thus, the treatment recycling process is obvious in environmental, social and economic benefits.

Owner:四川博盛永业工程技术有限公司

Method for treating oil field drilling waste water

ActiveCN102030435AImprove biodegradabilityImprove surface activityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationChemical oxygen demandPolyacrylamide

The invention relates to a method for treating oil field drilling waste water, which comprises the following major steps: A) adding activated carbon and ferric trichloride, ferric sulfate or other ferric salt to oil field drilling waste water, and introducing ozone to perform a catalytic ozonization reaction; and B) after ozonization, adding polyacrylamide flocculant to the outlet water to enablethe activated carbon and ferric hydroxide to be subject to coagulative precipitation, and separating the water and precipitates. By using the method provided by the invention, the COD (Chemical Oxygen Demand) (2000-10000mg / L) removal rate of the oil field drilling waste water can be increased from 10% or so to 50-70% by ozone oxidation.

Owner:北京中科国益环保工程有限公司

Drilling waste-fly ash-shale base sintering product and preparation method

InactiveCN102167562AReduce pollutionImprove resource utilizationCeramic materials productionClaywaresLand resourcesToxic industrial waste

The invention relates to a sintering product, and belongs to the field of waste resource recycling. The drilling waste-fly ash-shale base sintering product is characterized in that the sintering product is prepared by sintering the following raw materials, by mass, 10 to 30% of drilling waste, 10 to 30% of fly ash, 35 to 65 % of shale, and 2 to 5 % of fluxing toughening agent. The drill waste is prepared by drying and grinding the drilling waste mud. The fluxing toughening agent is a mixture of feldspar and mica at a mass ratio of 1-2:1. The sintering product utilizes the industrial waste, like the drilling waste, the fly ash, etc., thus protecting environment and saving land resources. The sintering product has the advantages of low density and high strength.

Owner:WUHAN UNIV OF TECH

Waste solid cleaning

InactiveUS20070056611A1Increase oil extractionEfficient trappingMixing methodsTransportation and packagingDrill cuttingsMicroemulsion

This invention relates to a method and apparatus for removing oil from oil-contaminated waste. In particular, the present invention relates to the removal of oil from drilling wastes such as drill cuttings and oil slops, and other industrial oily wastes such as refinery and interceptor wastes by forming a microemulsion of reduced particle size oil-contaminated material.

Owner:MARTIN ANDREW JOHN

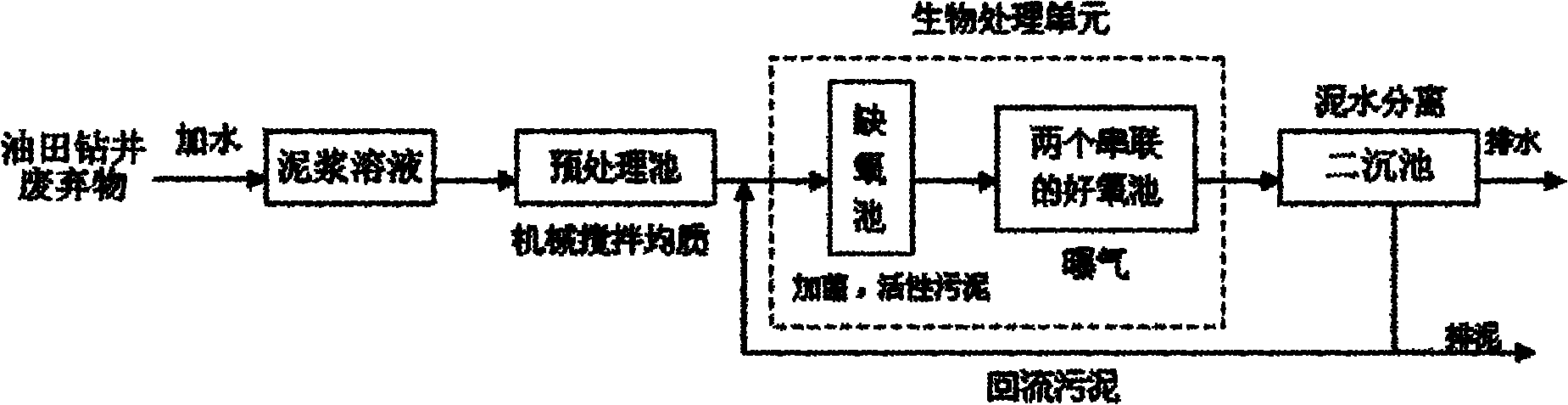

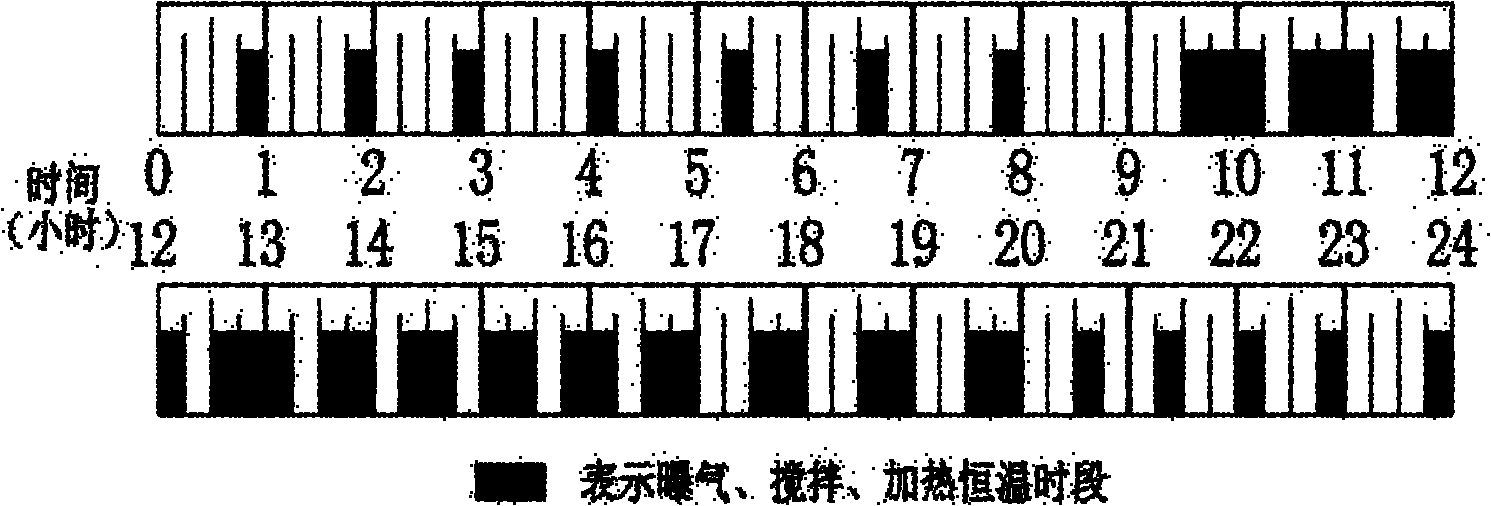

Biological treatment method of oilfield drilling waste

ActiveCN102108000AEnhanced biological treatmentEasy to handleSludge processingTreatment with aerobic and anaerobic processesEnvironmental engineeringHydrocarbon

The invention relates to a biological treatment method of oilfield drilling waste. Specifically, microorganisms are utilized to degrade hydrocarbons pollutants in the drilling waste, so as to treat the oilfield drilling waste.

Owner:CHINA NAT OFFSHORE OIL CORP +2

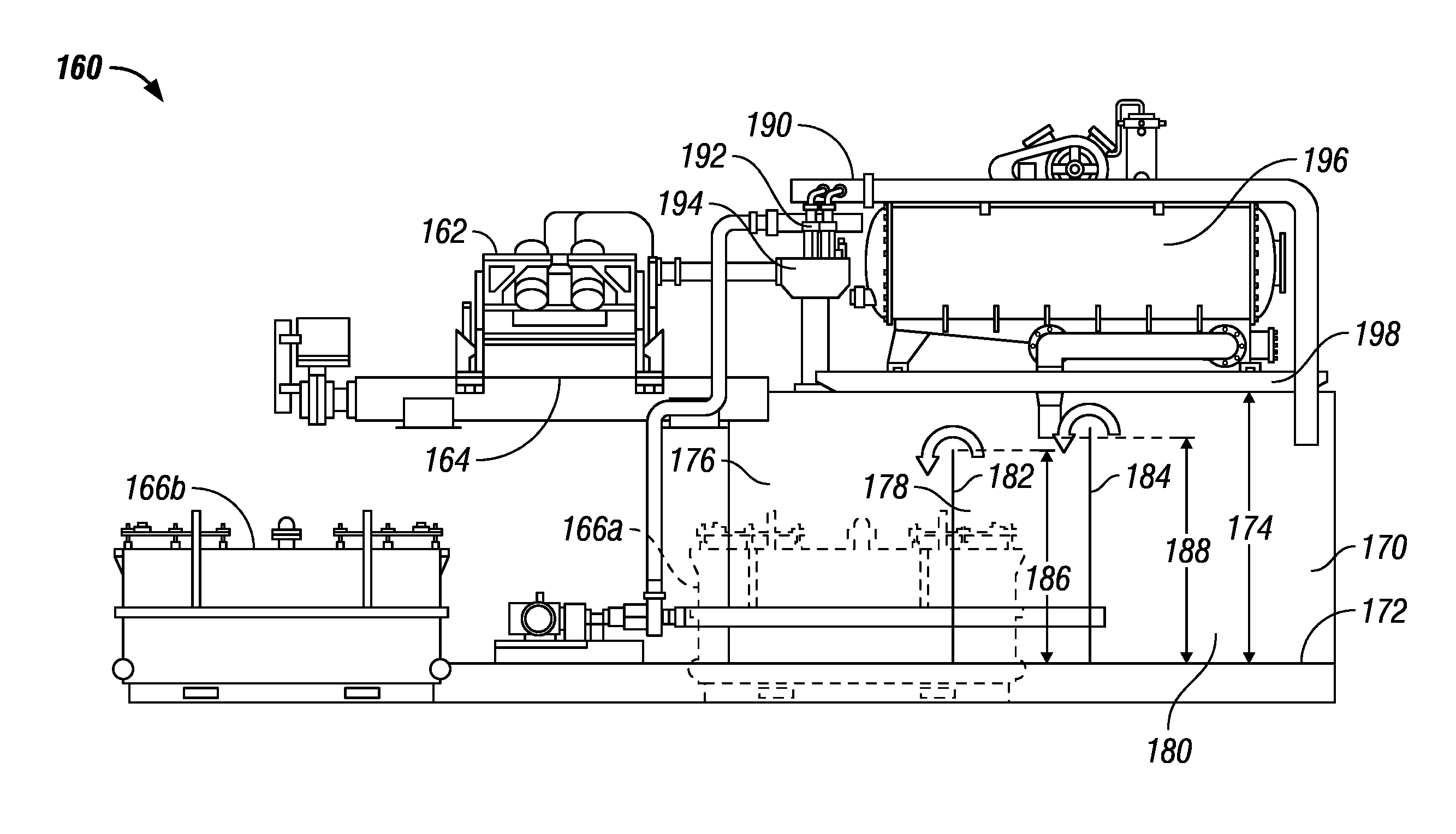

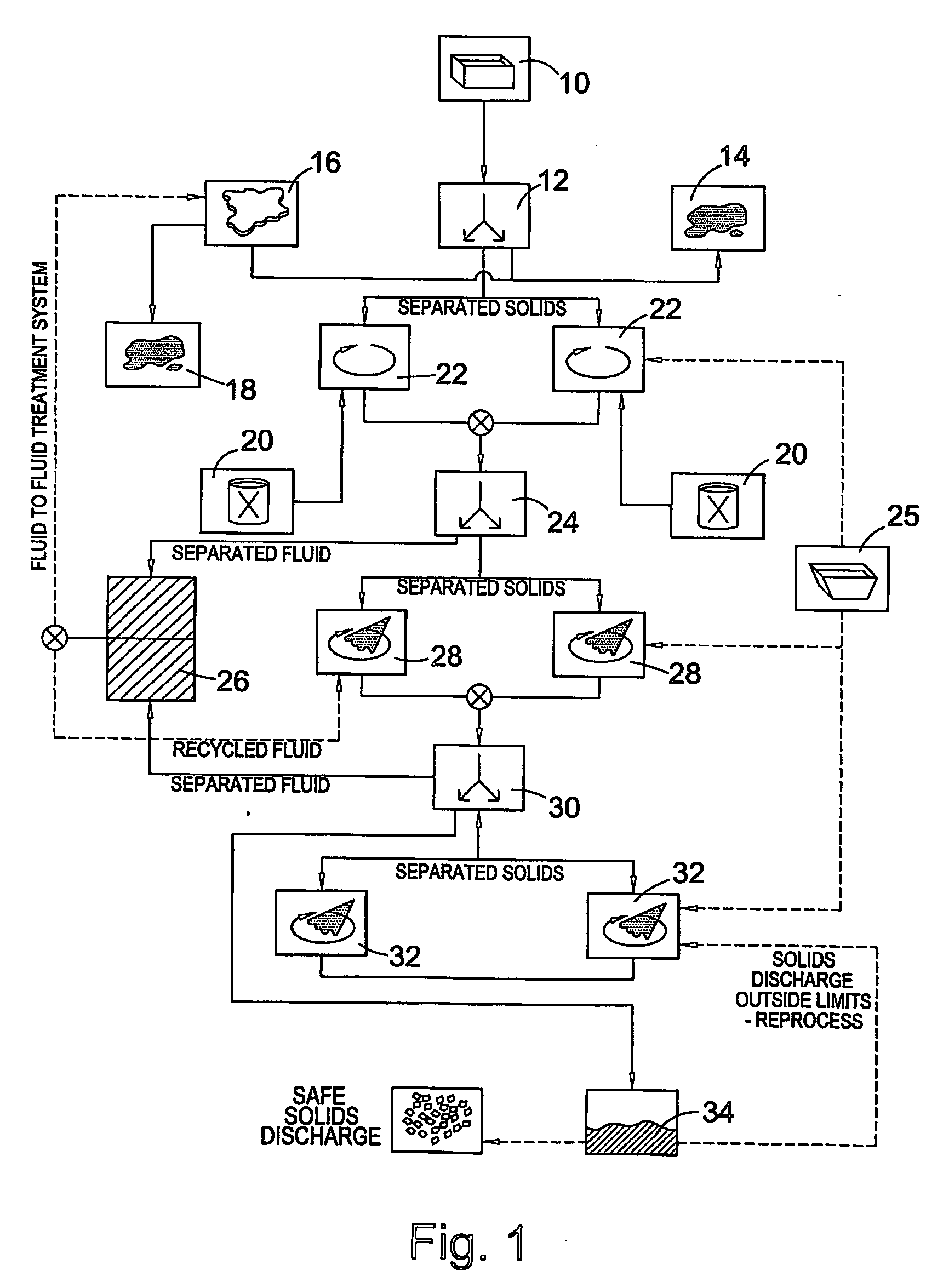

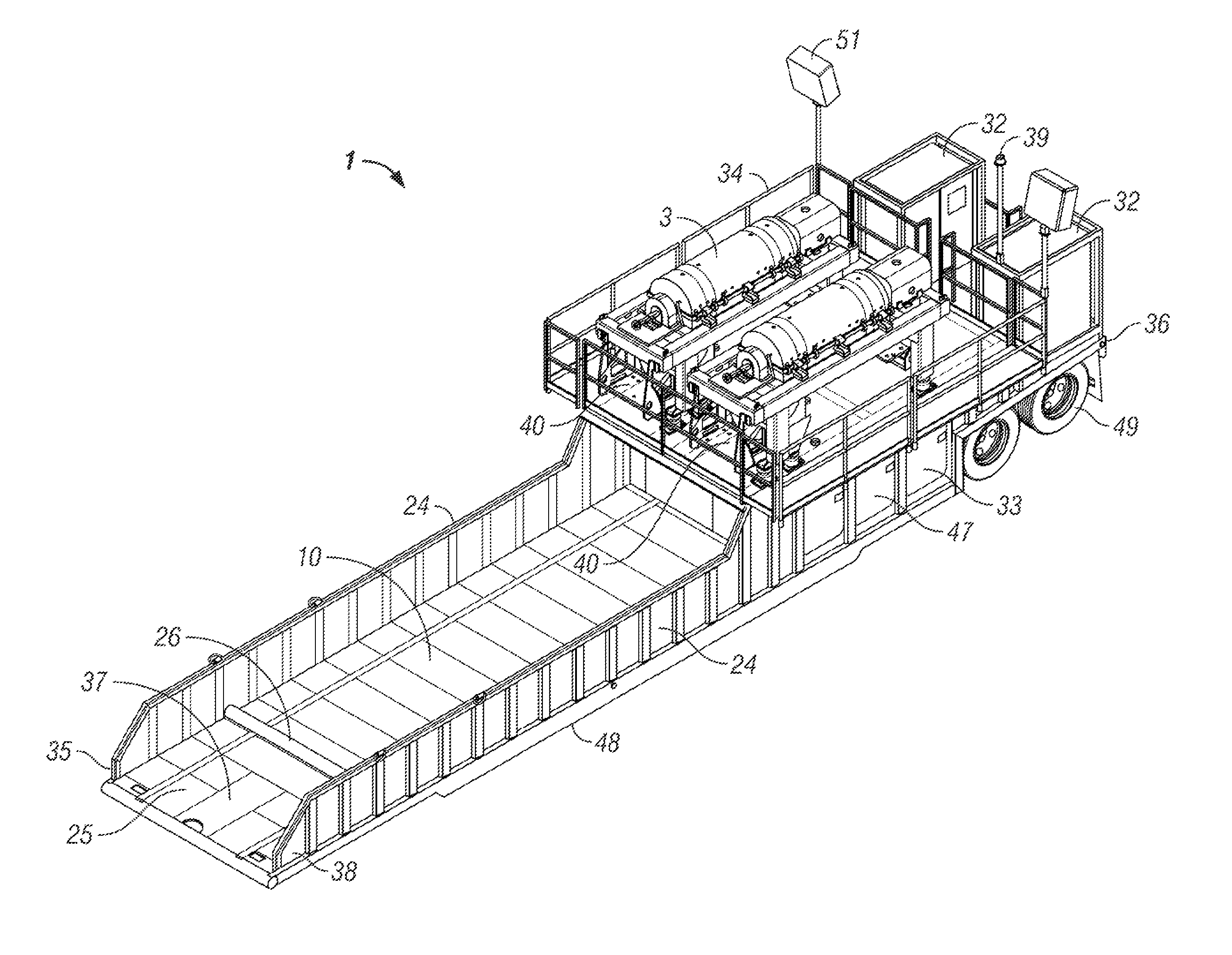

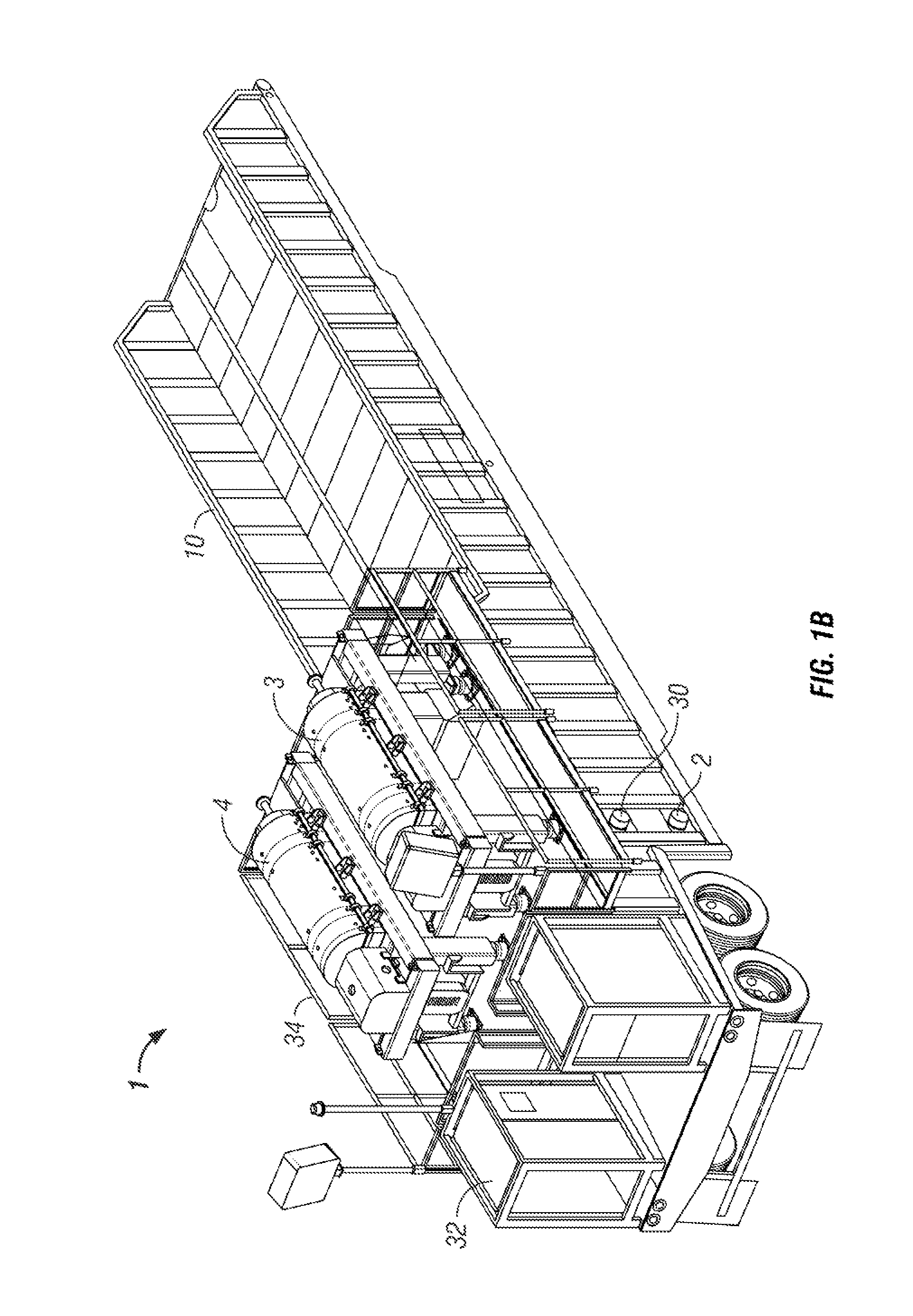

Drilling waste management system

A mobile drilling waste management system including a trailer having at least one centrifuge and a solids catch tank receiving solids separated from drilling fluid by one or more of the centrifuges. And a method of reclaiming drilling fluid including pumping drilling fluid contaminated with solids onto a trailer, separating the contaminant solids from the drilling fluid with at least one centrifuge located on the trailer, directing the contaminant solids to a solids catch tank located on the trailer, and pumping the drilling fluid off of the trailer.

Owner:MI

Novel processing method for oil field drilling waste water

InactiveCN101113040ASolve processing problemsReduce processing costsWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationWell drillingOil field

The invention relates to a wastewater purification treatment technique field. The novel wastewater treatment method for oil field drilling of the invention is that: first coagulation pretreatment to drilling wastewater is carried out, and ferrum series and aluminum series inorganic flocculating agents or ferrum aluminum series complex flocculating agent or the combination of the flocculating agents are adopted, then the solid and liquid is separated, and the treated liquid after coagulation pretreatment enters into chemical oxidation process and then is discharged, finally qualified treated wastewater is acquired.

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD

Equipment and method for cooperative treatment of drilling solid waste by using cement kiln

PendingCN109265028AReduce consumptionEasy to handleCement productionIncinerator apparatusCement kilnPollution

The invention discloses equipment and method for cooperative treatment of drilling solid waste by using a cement kiln. The equipment comprises the cement rotary kiln, a drilling waste storage and treatment closed system, a waste gas collecting and sealing treatment system and a waste water and waste liquid collecting and treatment system. The drilling waste is oil-based mud drilling rock debris oroil-containing soil, and the systems are fully closed. According to the equipment and method, the cement kiln is used for cooperative treatment of the oil-based mud drilling rock debris and the oil-containing soil, people only need to conduct adaptive reconstruction on an existing cement production line and pollution control facilities of the existing cement production line, the oil-based mud drilling rock debris and the oil-containing soil can serve as full-substitute materials, waste oil substances can serve as part of fuel to replace coal powder, and the consumption of fire coal and silicon materials of ton products can be reduced. Besides, emission of the pollutants can not be increased, hazardous solid waste of the similar kind can be effectively treated, and the purposes of recycling, reduction and harmless treatment of the hazardous solid waste are achieved.

Owner:乐山华宇欣和石油科技有限公司

Drilling waste management system

A mobile drilling waste management system including a trailer having at least one centrifuge and a solids catch tank receiving solids separated from drilling fluid by one or more of the centrifuges. And a method of reclaiming drilling fluid including pumping drilling fluid contaminated with solids onto a trailer, separating the contaminant solids from the drilling fluid with at least one centrifuge located on the trailer, directing the contaminant solids to a solids catch tank located on the trailer, and pumping the drilling fluid off of the trailer.

Owner:MI

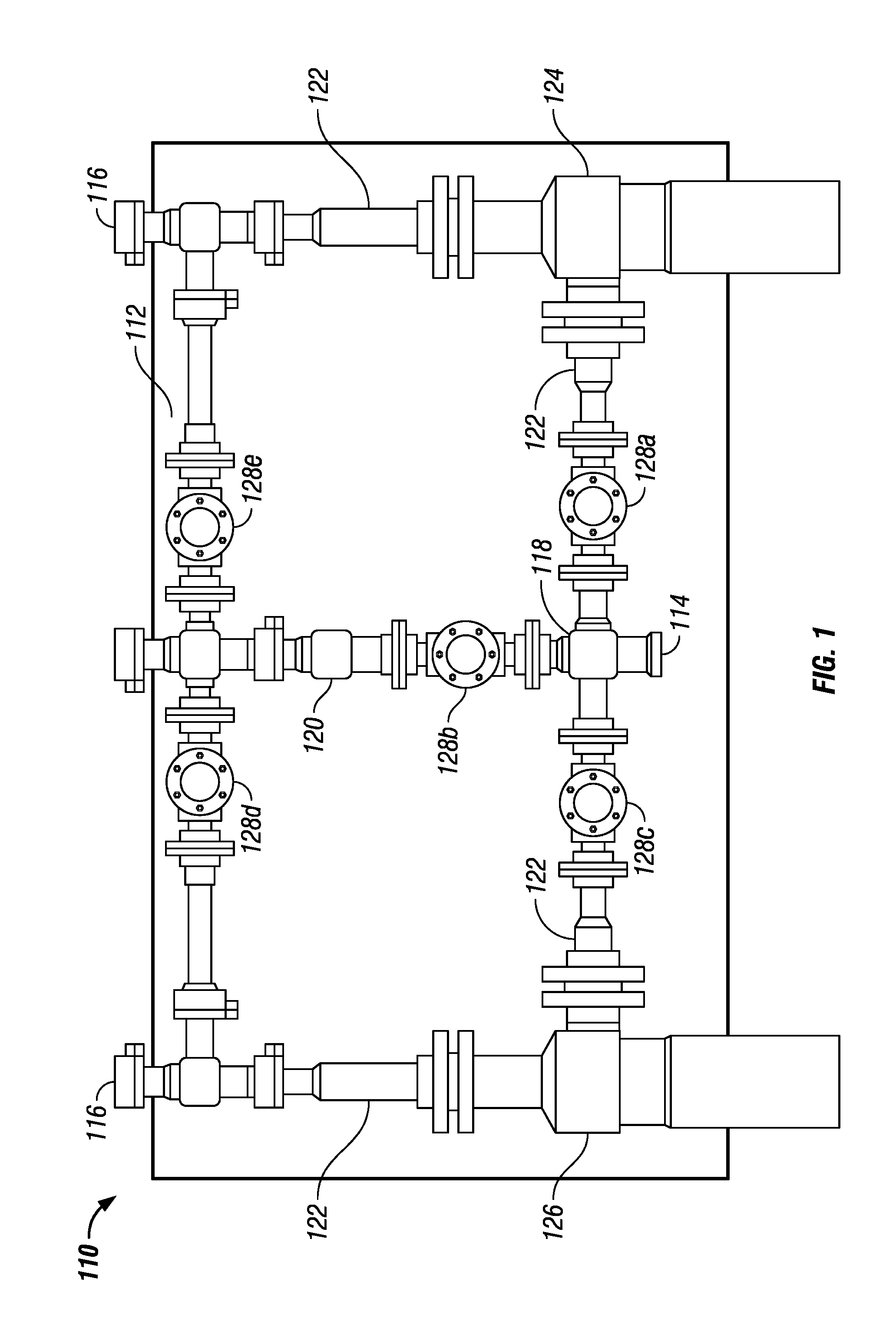

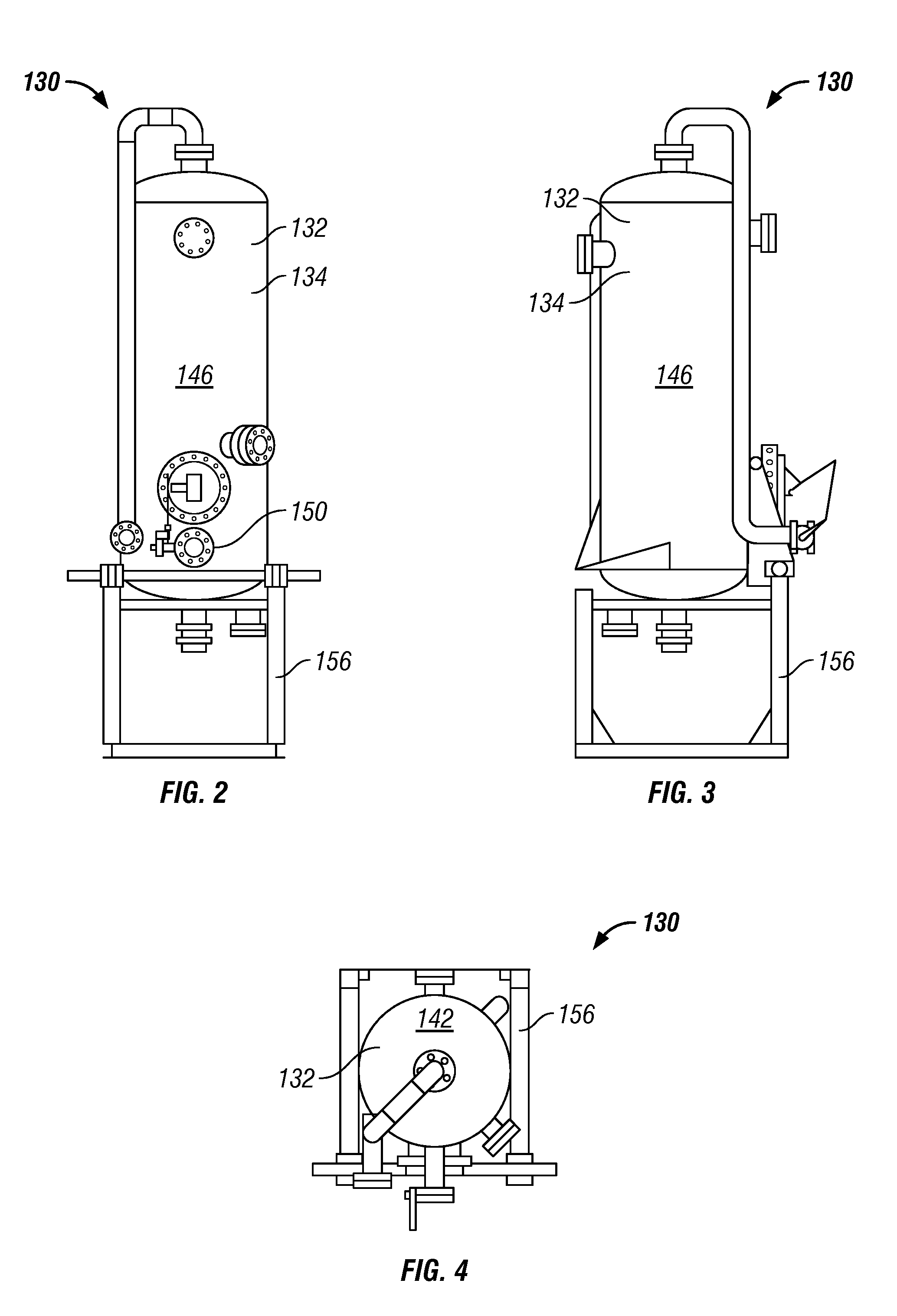

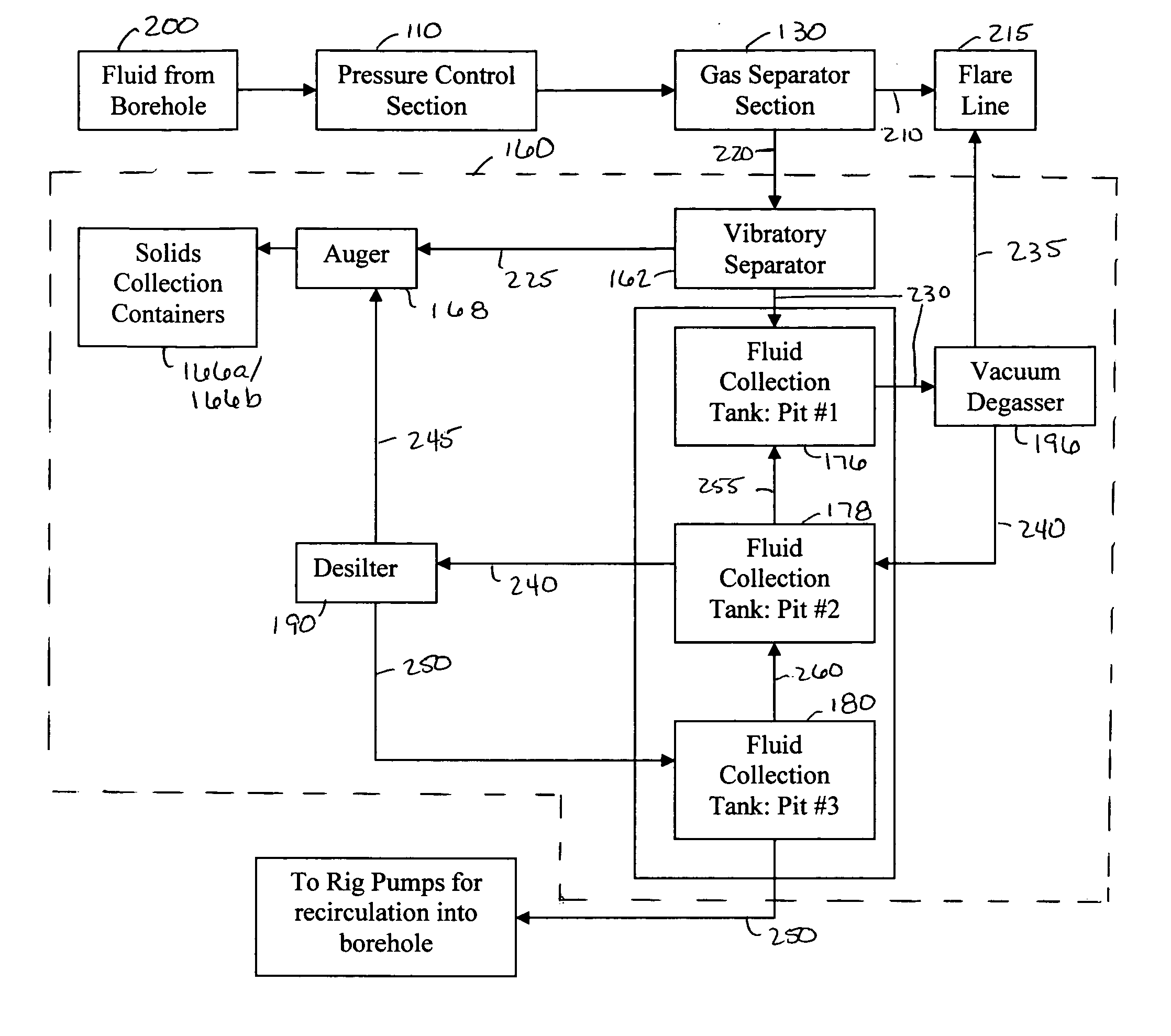

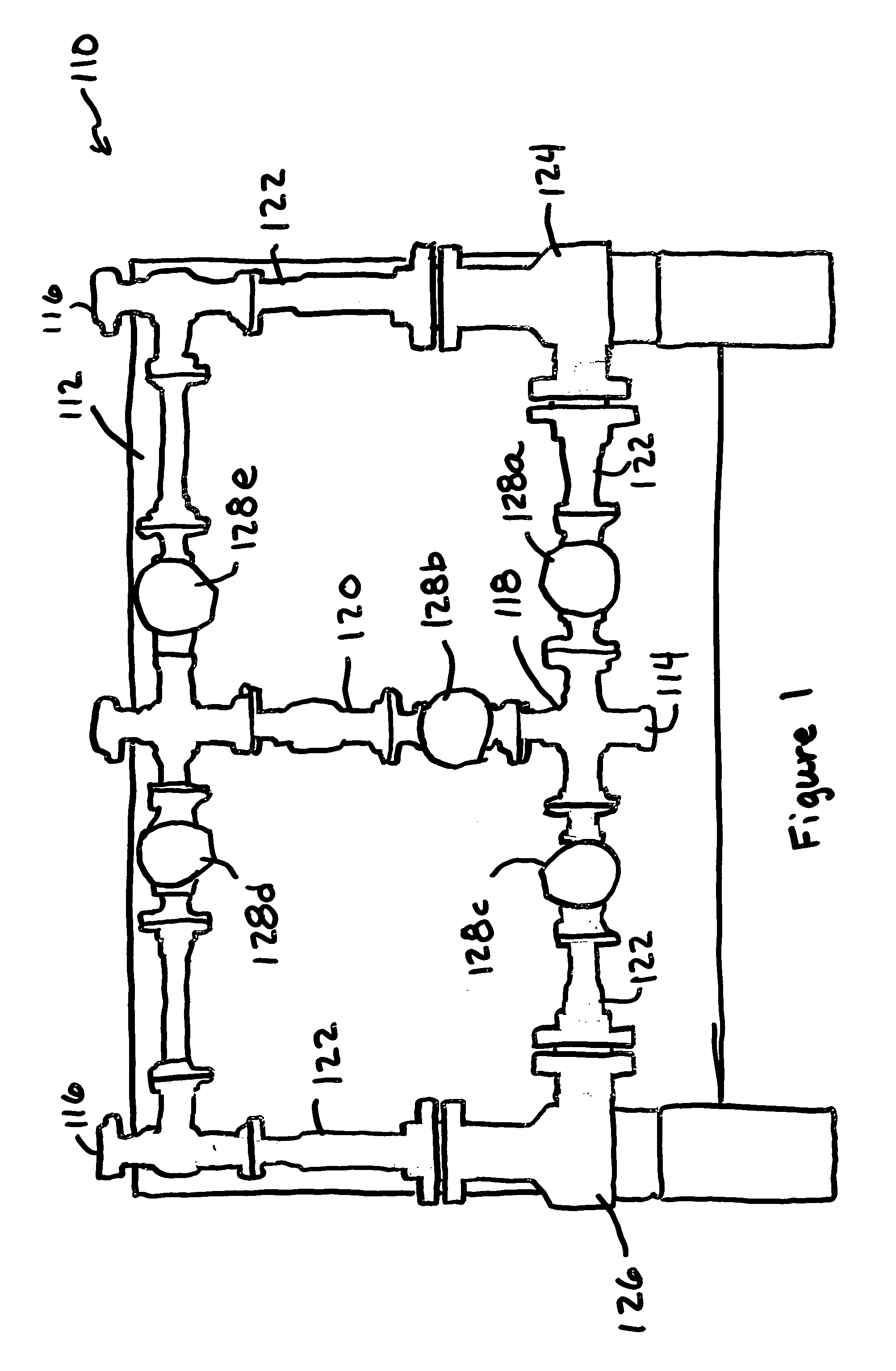

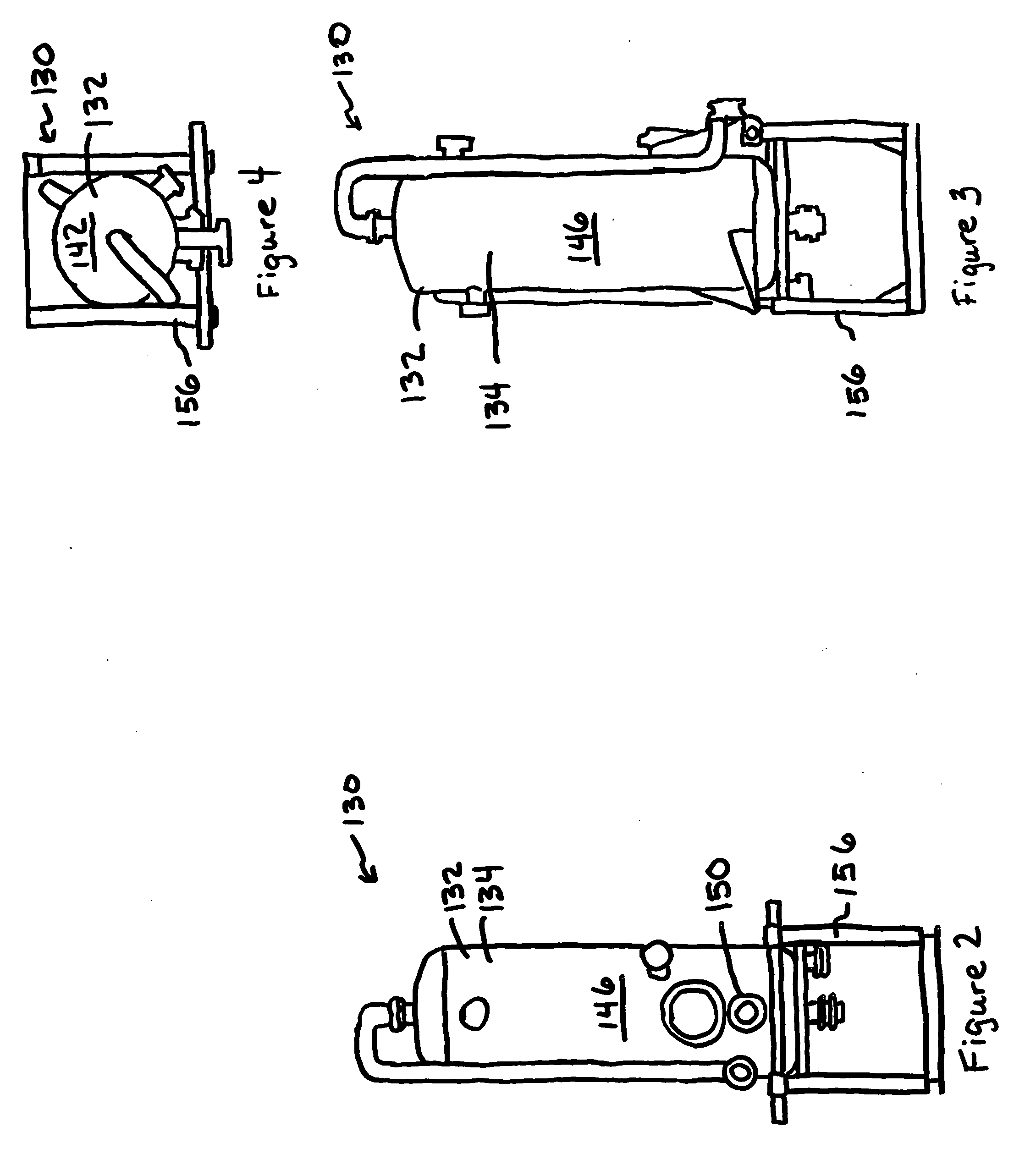

Modular pressure control and drilling waste management apparatus for subterranean borehole operations

ActiveUS20060124524A1Keep the pressureWaste water treatment from quariesLiquid degasificationDegasserDisposal waste

A modularly segmented apparatus for precise borehole pressure control, removing waste from borehole fluid, and recirculating the cleaned borehole fluid includes a pressure control section, a gas separator section, and a waste management section. In the pressure control section, a pressure manifold interconnects a plurality of chokes. A plurality of valves are used to direct the contaminated fluid through one of the chokes, which maintains a precise and predetermined pressure in the system. The manifold, chokes, and valves are mounted on a skid for easy transport. In the gas separator section, a gas separator is used to remove a majority of the gases present in the contaminated borehole fluid. In the waste management section, a vibratory separator removes large solid contaminants from the degassed fluid. The solids are directed to a solids collection container for further treatment or disposal. The fluid is directed to a first pit, which may be one partitioned are of a larger collection tank. Fluid from the first pit is directed to a degasser which removes additional gases in the fluid and directs the fluid to a second pit. Fluid from the second pit is directed to a desilter, which removes additional solids and directs the fluid to a third pit. The solids from the desilter are directed to the solids collection container. Fluid from the third pit is directed to active rig pumps for recirculation into the borehole.

Owner:MI

Chemical-biological stabilization process for repairing soils and cuttings contaminated with oils and petroleum derivatives

The present invention describes a process utilized for the remediation of soils and petroleum drilling wastes contaminated with hydrocarbons, which consists in stabilization by application and mixing in specific proportions of calcium oxides and organic conditioners. It is possible to treat materials with concentrations of at least seven percent (dry weight) of hydrocarbons petroleum hydrocarbons (TPH) and reduce the concentration to 1-1.5% TPH. Furthermore, residual toxicity is completely eliminated in the treated material, vegetative growth is stimulated, the treated material does not present significant concentrations of hydrocarbons leachates and it passes all criteria to be considered not a dangerous waste (CRETI or TCLP).

Owner:UNIVERSIDAD JUAREZ AUTONOMA DE TABASCO

Methods to increase force and change vibratory separator motion

A vibratory separator including a frame, a basket disposed on the frame, and a motor configured to impart a vibratory motion to the basket. Additionally, the vibratory separator includes an adjustable speed drive operatively coupled to the motor to control a vibratory motion imparted to the basket. Also, a method of processing drilling waste including generating a first vibratory motion on a vibratory separator using at least one motor, and adjusting the first vibratory motion using an adjustable speed drive to generate a second vibratory motion.

Owner:MI

Oil base drill chip processing method

InactiveCN104373065AHigh recovery rateImprove wetting abilityFlushingDrilling compositionEnvironmental resistancePetroleum

The invention relates to an oil base drill chip processing method, belongs to the field of environment protection, and particularly belongs to the technical field of drilling waste processing in oil and natural gas industry. The method comprises the following steps of: (1) demulsification: adding demulsifying agents accounting for 0.4 percent to 1.0 percent of the mass of oil base drill chips into the oil base drill chips in a stirring state; (2) cleaning: adding a non-ionic surfactant solution accounting for 10 percent to 30 percent of the mass of the oil base drill chips and an anionic surfactant solution accounting for 20 percent to 30 percent of the mass of the oil base drill chips into the demulsified oil base drill chips in the first step in the stirring state to obtain an oil-water-solid mixture; (3) separation: carrying out centrifugal separation on the mixture in the step (2); and (4) processing by hydrocarbon degradation bacteria: regulating the pH of the separated oil base drill chips and then adding nutrients, nutrient providers, bulking agents and the hydrocarbon degradation bacteria. The method has the advantages that the oil recovery rate is higher than 94 percent; the oil content of the drill chips is less than 0.3 percent; the operation is simple; the equipment investment is low; and reclamation and harmlessness are realized.

Owner:CHINA PETROCHEMICAL CORP +1

Shale gas well drilling waste-oil-based mud curing material

InactiveCN105776780AHigh strengthImprove stabilityWaste water treatment from quariesFixation/solidifcation sludge treatmentWell drillingOil field

The invention discloses a shale gas well drilling waste-oil-based mud curing material.The problem that a drilling waste-oil-based mud environment is polluted is effectively solved, and comprehensive utilization of solid waste of an oil field is achieved.The material is low in leaching and small in pollution, waste resources are comprehensively utilized, and sustainable development of economy is promoted.The shale gas well drilling waste-oil-based mud curing material is prepared from, by mass, 10%-50% of oil-based mud, 30%-70% of sand, 0.1%-10% of curing agent and 0.1%-10% of water.

Owner:南京乾庚新材料科技有限公司 +1

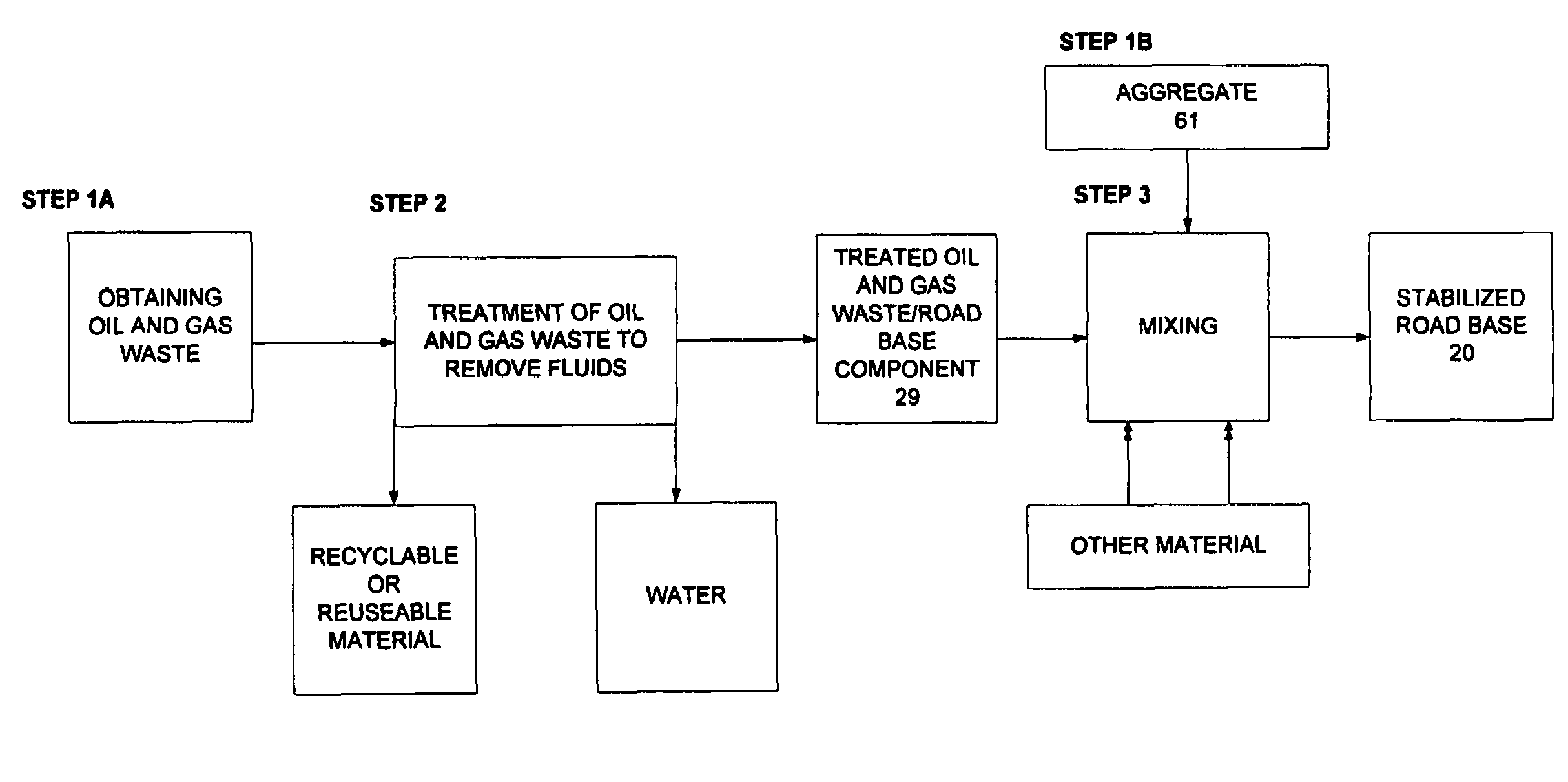

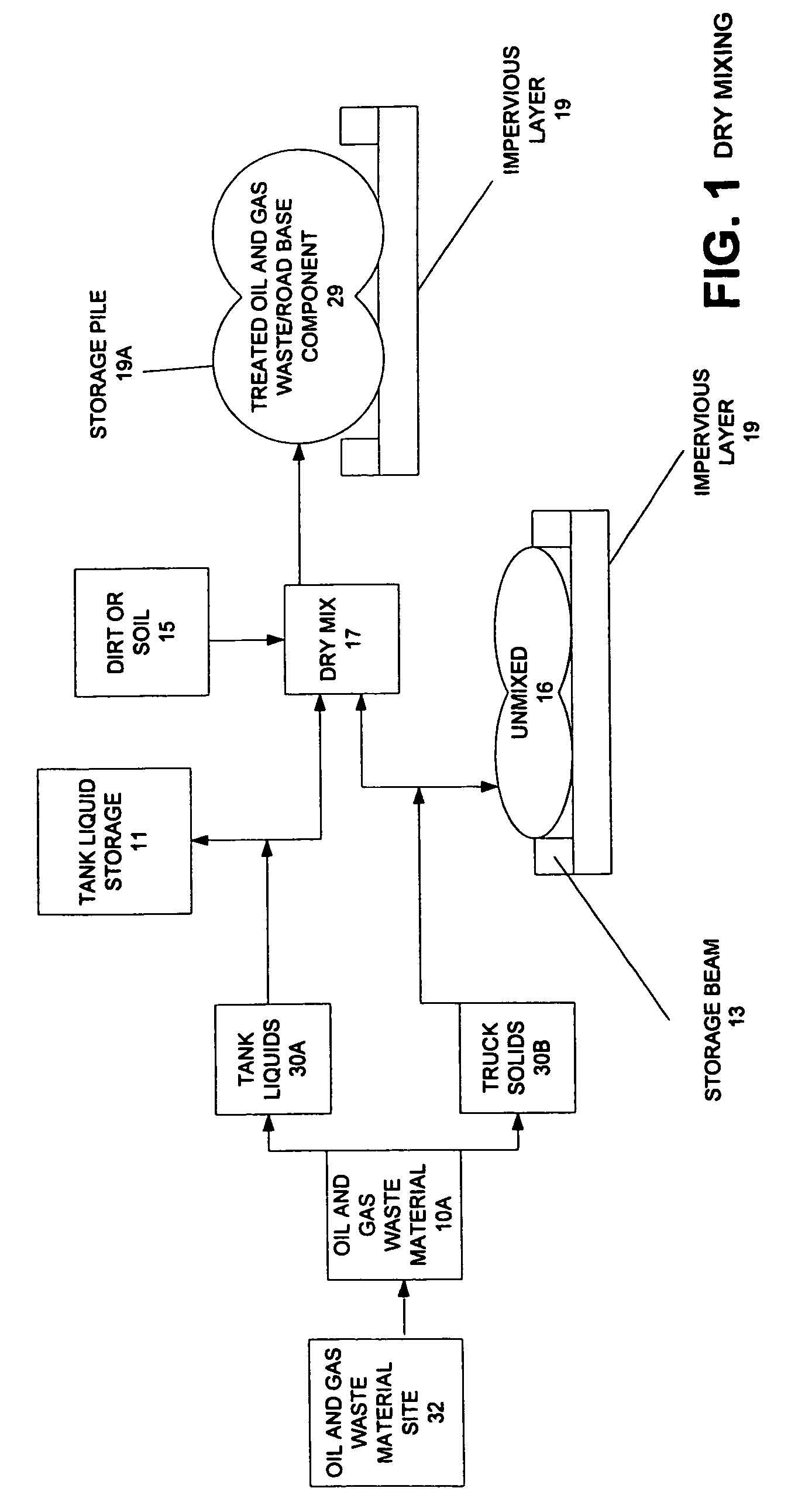

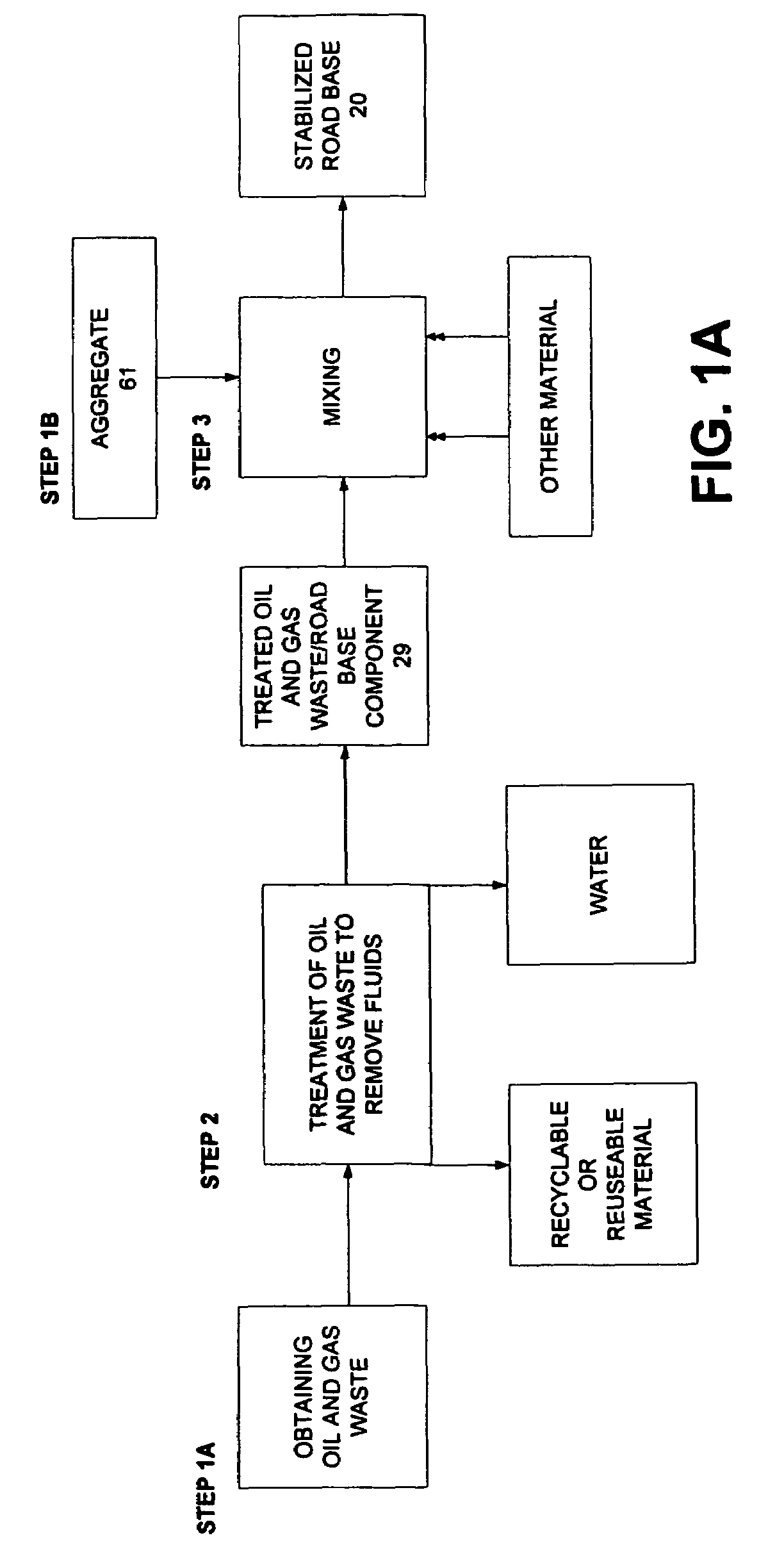

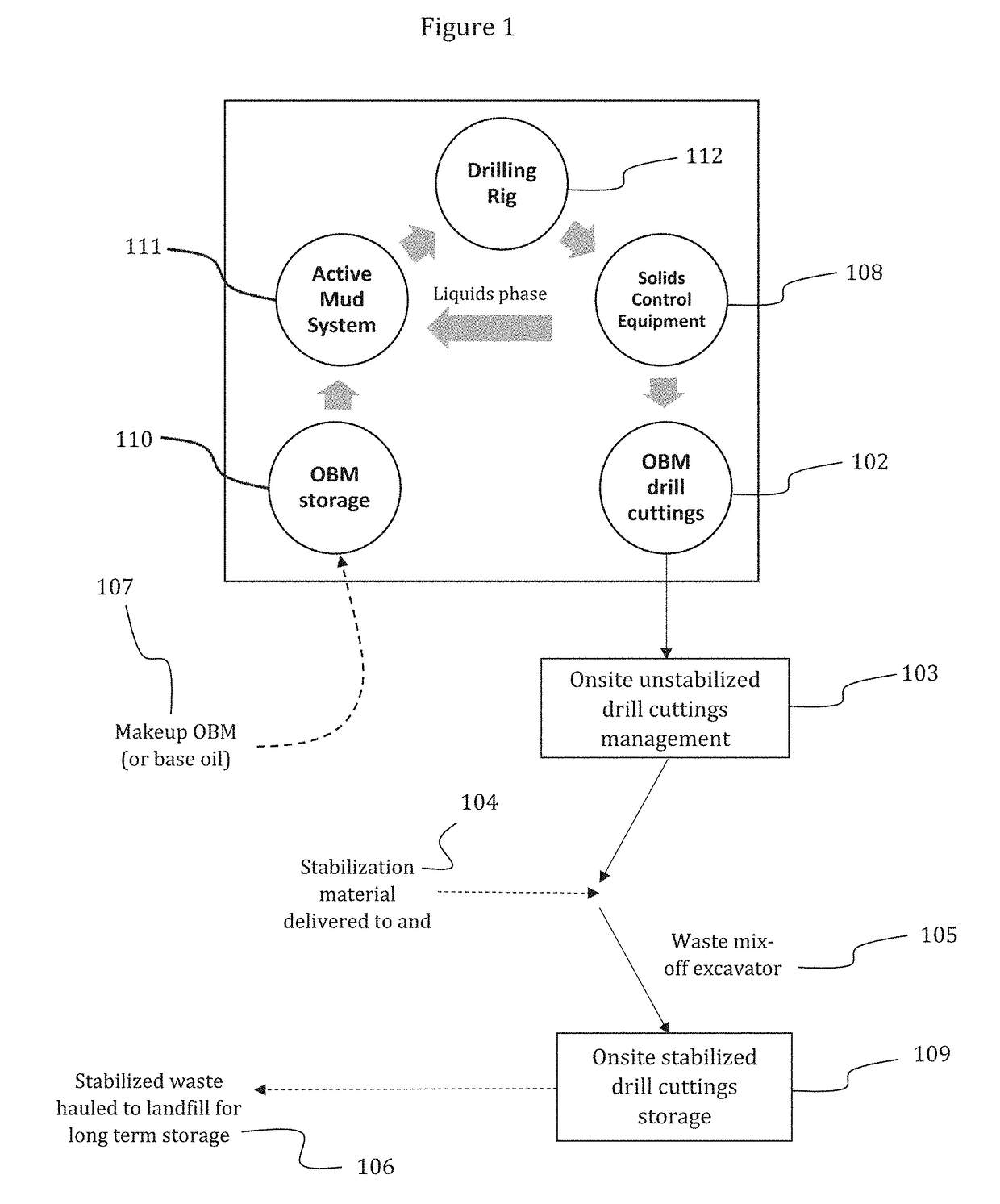

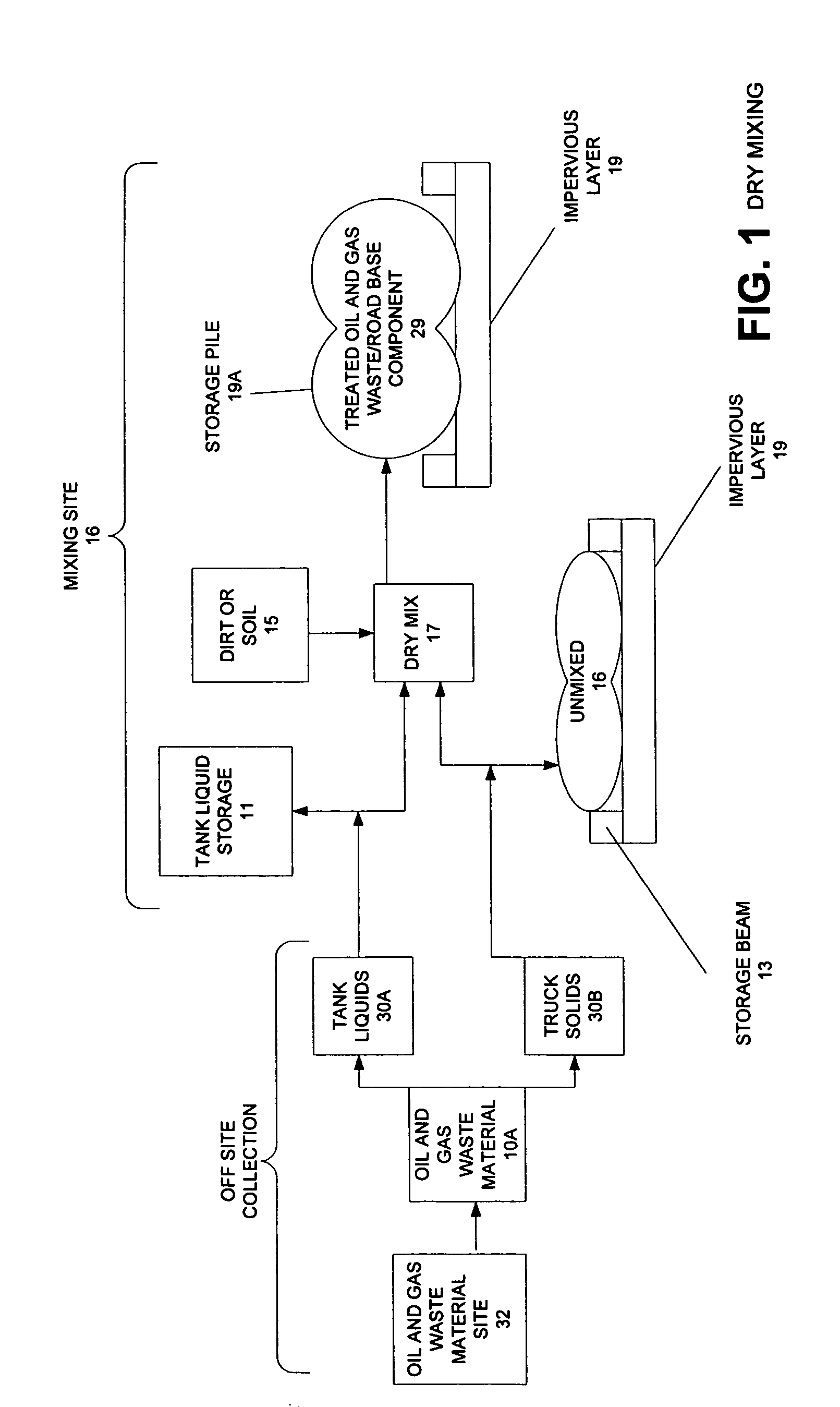

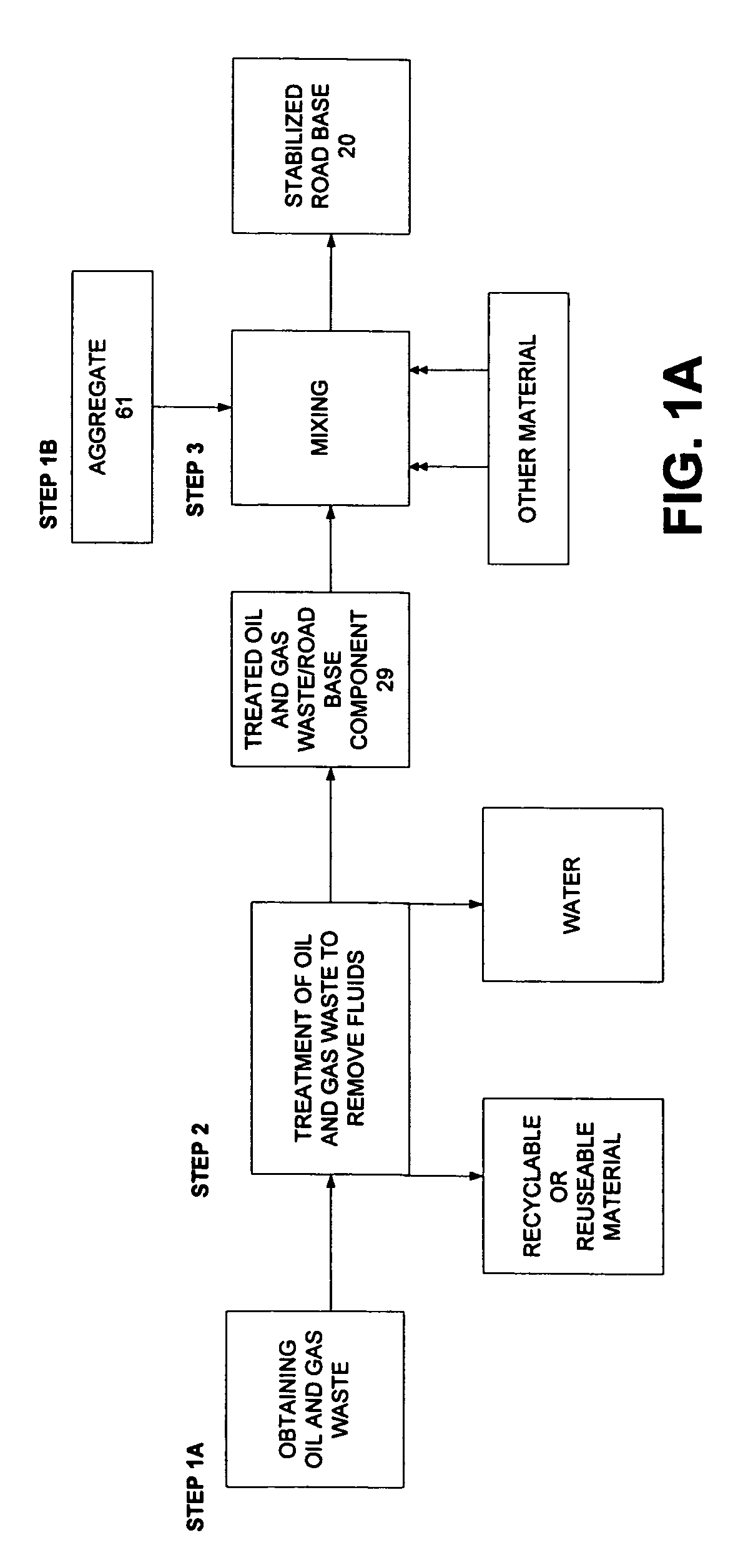

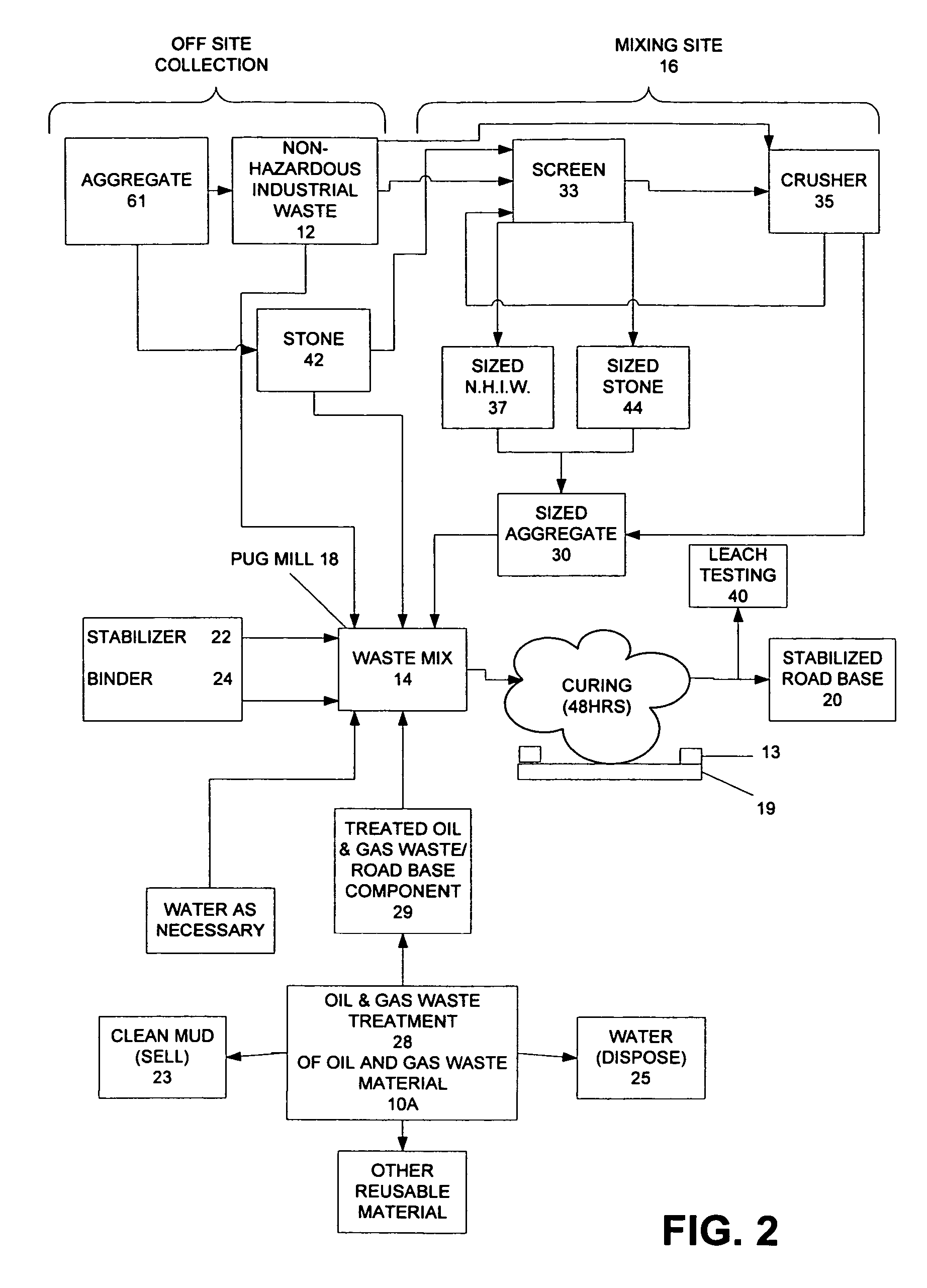

Method for making a road base material using treated oil and gas waste material

The present invention provides a novel method to produce grade road base material using recycled oilfield waste, called “oil and gas waste,” more specifically, drilling waste and aggregate and a novel road base material. Hydration and mixing of the waste materials along with an aggregate will form an environmentally safe, structurally sound road base material. An asphalt emulsifier may be included in the binder to manufacture asphalt stabilized road base. The entire method is a cold batch process.

Owner:MVC ENVIRONMENTAL INC

Methods to increase force and change vibratory separator motion

A vibratory separator including a frame, a basket disposed on the frame, and a motor configured to impart a vibratory motion to the basket. Additionally, the vibratory separator includes an adjustable speed drive operatively coupled to the motor to control a vibratory motion imparted to the basket. Also, a method of processing drilling waste including generating a first vibratory motion on a vibratory separator using at least one motor, and adjusting the first vibratory motion using an adjustable speed drive to generate a second vibratory motion.

Owner:MI

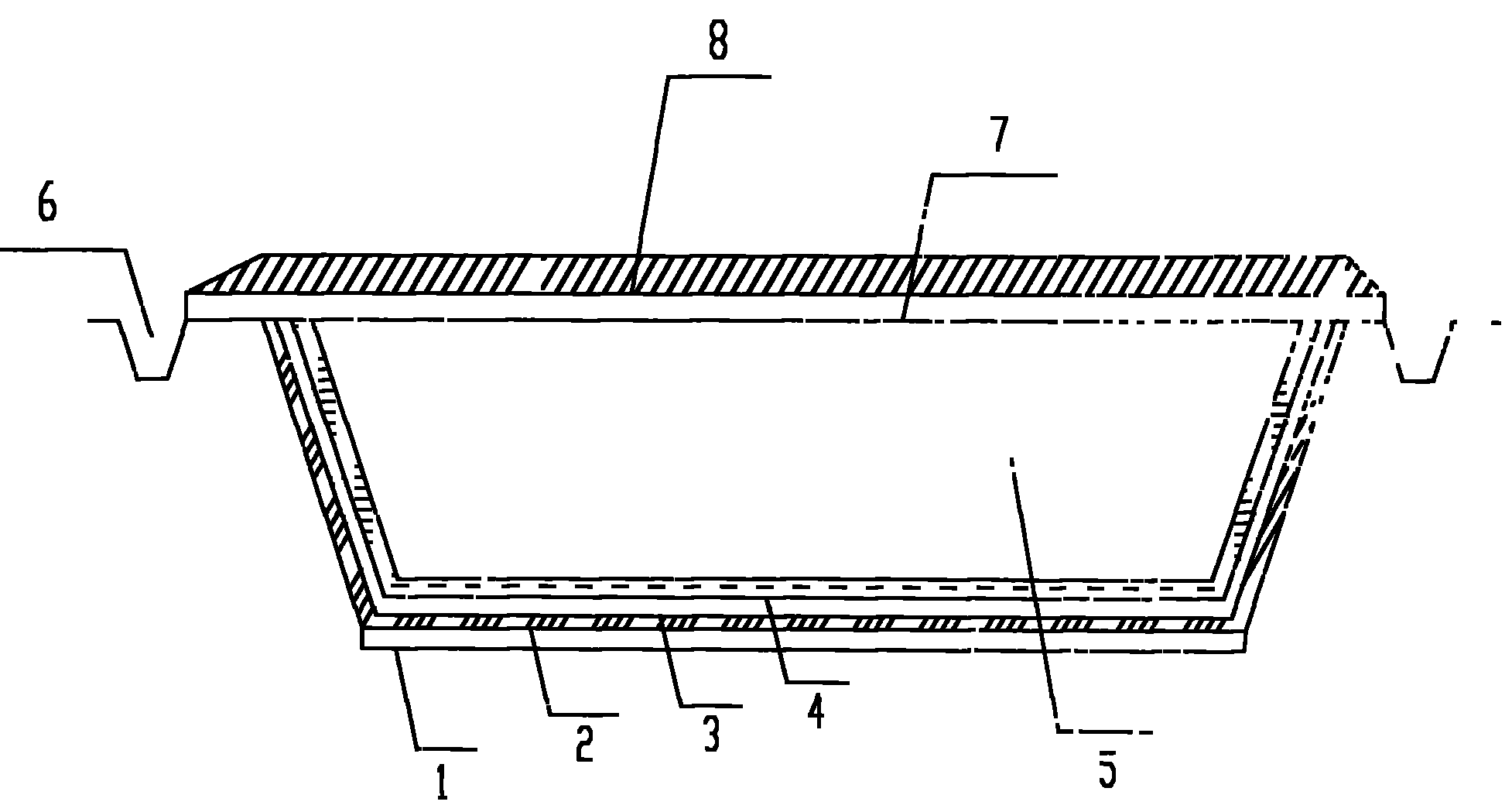

Method for constructing oil drilling waste mud solidification pool

ActiveCN101979781AImprove anti-seepage effectWill not puncture the polyethylene geomembraneArtificial islandsUnderwater structuresGeomembraneWell drilling

The invention provides a method for constructing an oil drilling waste mud solidification pool and relates to the technical field of oil and gas exploration drilling pollution control. A scheme of the method comprises the following steps of: excavating the solidification pool on site, wherein the slope of a pool wall is 45 to 60 DEG, and the pool height is 2.0 to 2.5 m; performing seepage control on a pool bottom by adopting clay-(non-woven geotextile)-(high-density polyethylene geomembrane)-(non-woven geotextile); continuously packaging solid waste to a top part by using the clay-(non-woven geotextile)-(high-density polyethylene geomembrane)-(non-woven geotextile); and capping the top part by using C20 concrete so as to prevent a solidified body from seeping. The process is simple and easy, the cost investment is small, the construction period is short, and the drilling waste mud is propelled to be solidified rapidly and timely so as to effectively prevent the waste mud from overflowing and polluting the environment in the drilling operation process.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

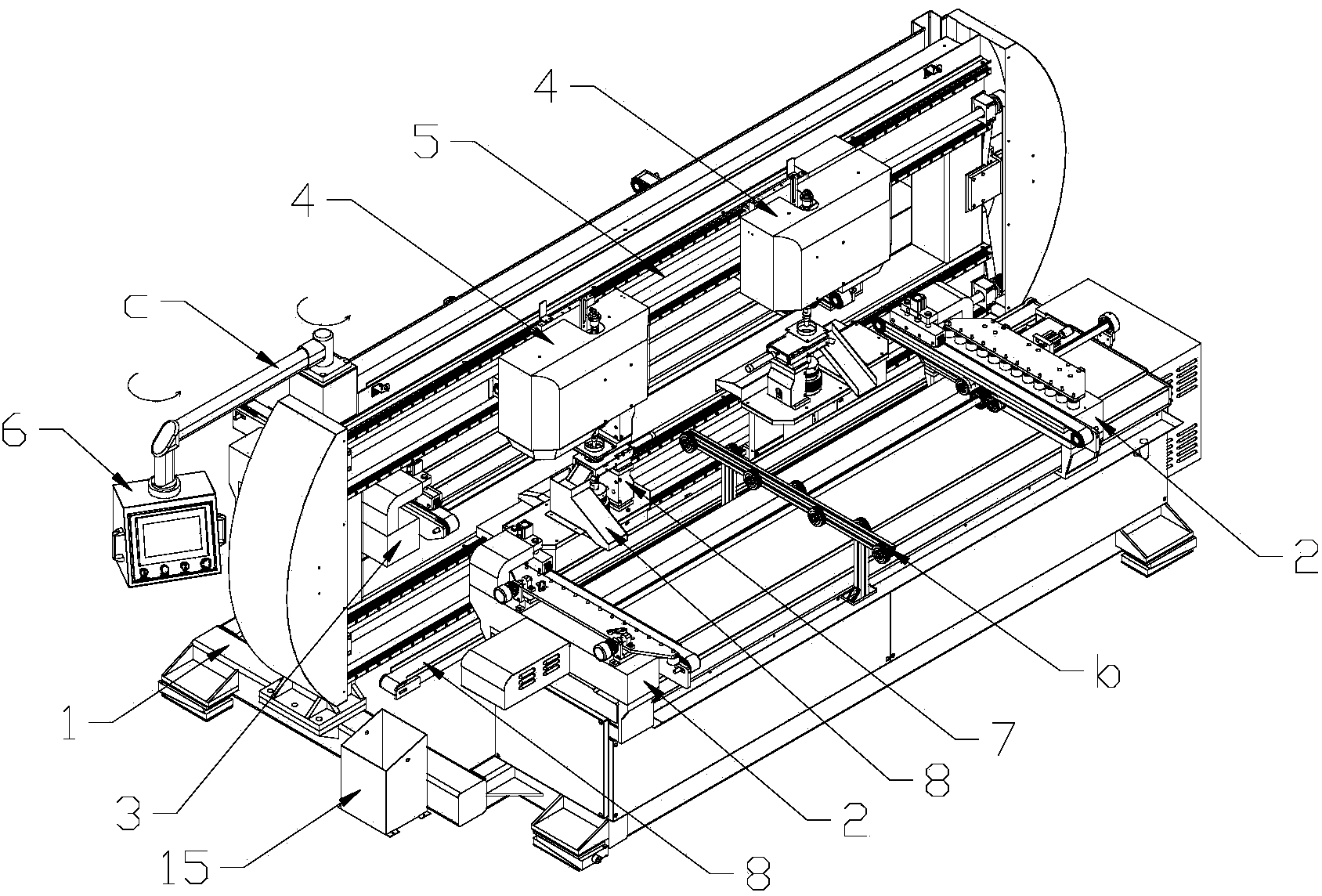

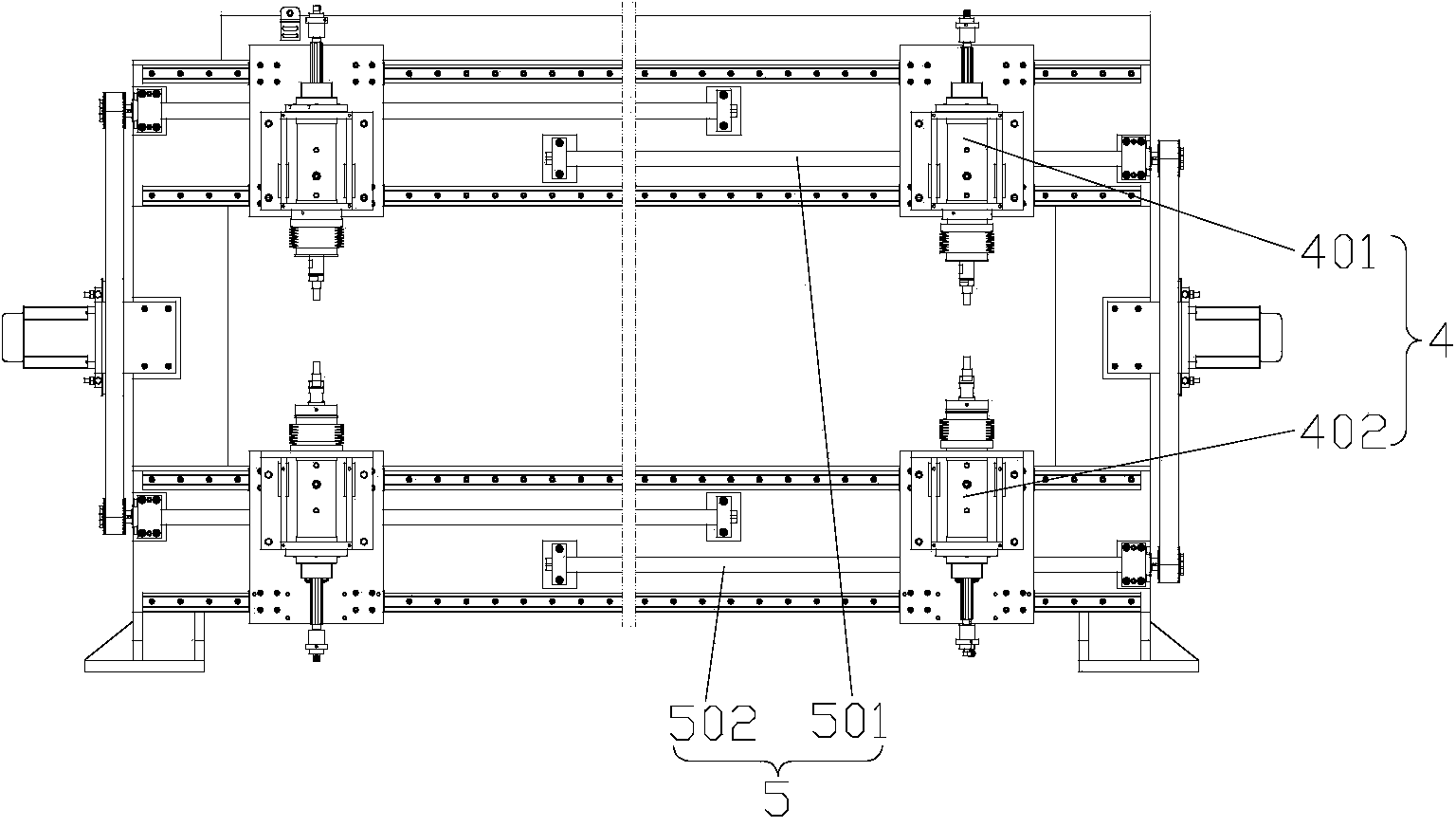

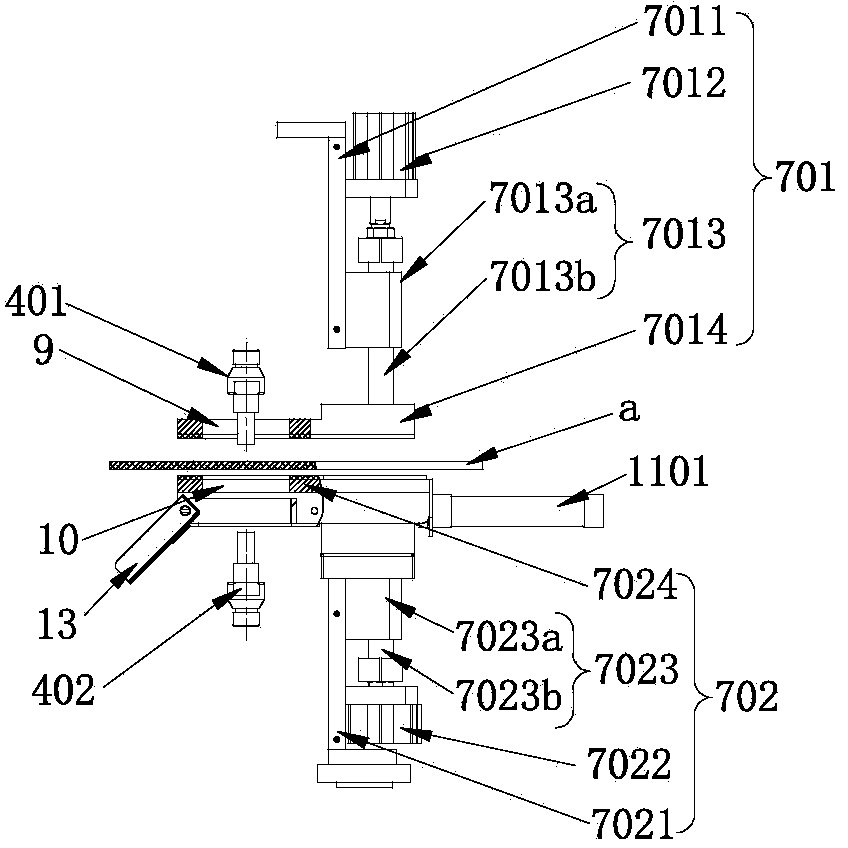

Horizontal glass drilling machine

InactiveCN103862581AAvoid breakingTo prevent the corresponding harm caused by it, etc.Working accessoriesStone-like material working toolsAssembly lineEngineering

The invention discloses a horizontal glass drilling machine. The horizontal glass drilling machine comprises a base, wherein a first conveying mechanism, a second conveying mechanism and a portal frame are arranged on the base; an operation box(s) are / is arranged on the base and / or the portal frame; the to-be-machined glass conveying track of the first conveying mechanism and the to-be-machined glass conveying track of the second conveying mechanism are in the same straight line; the portal frame is erected between the first conveying mechanism and the second conveying mechanism and is arranged along the horizontal and vertical directions of the to-be-machined glass conveying tracks; a drilling mechanism is arranged on a horizontal guide rail of the portal frame and can move on the horizontal guide rail along the horizontal direction; an up-down pressing device which is used for clamping and fixing to-be-machined glass and a waste collecting mechanism which is used for conveying drilling waste out of the horizontal glass drilling machine and collecting the drilling waste are arranged on the drilling mechanism. The drilling efficiency is high, and glass drilling assembly line operation is conveniently formed; the probability of subsequent assembly, disassembly and maintenance of the drilling machine is reduced, and the drilling assembly line operation is carried out favorably; the horizontal glass drilling machine is energy-saving and environment-friendly.

Owner:HUNAN SANXING LEIYANG GLASS MACHINERY

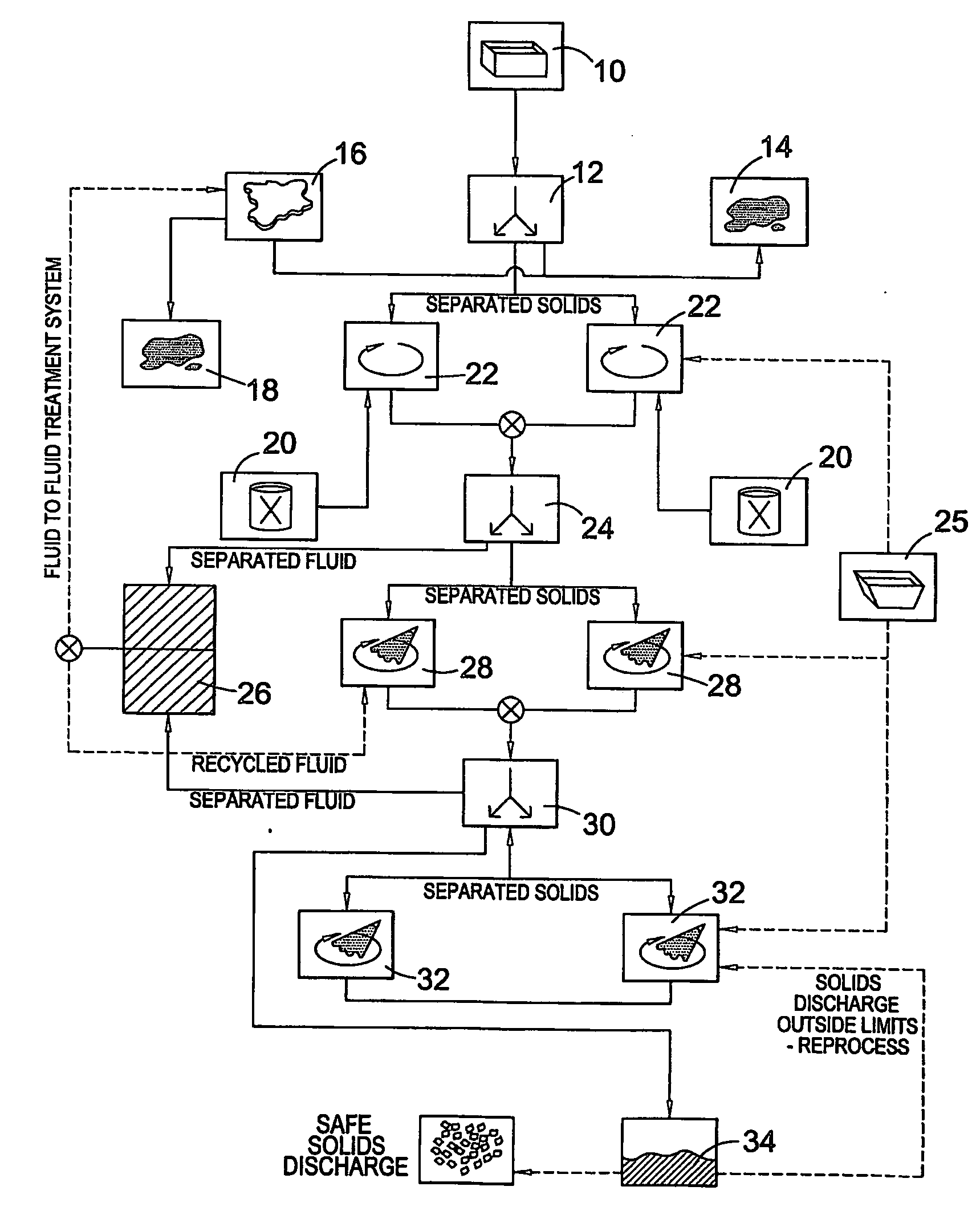

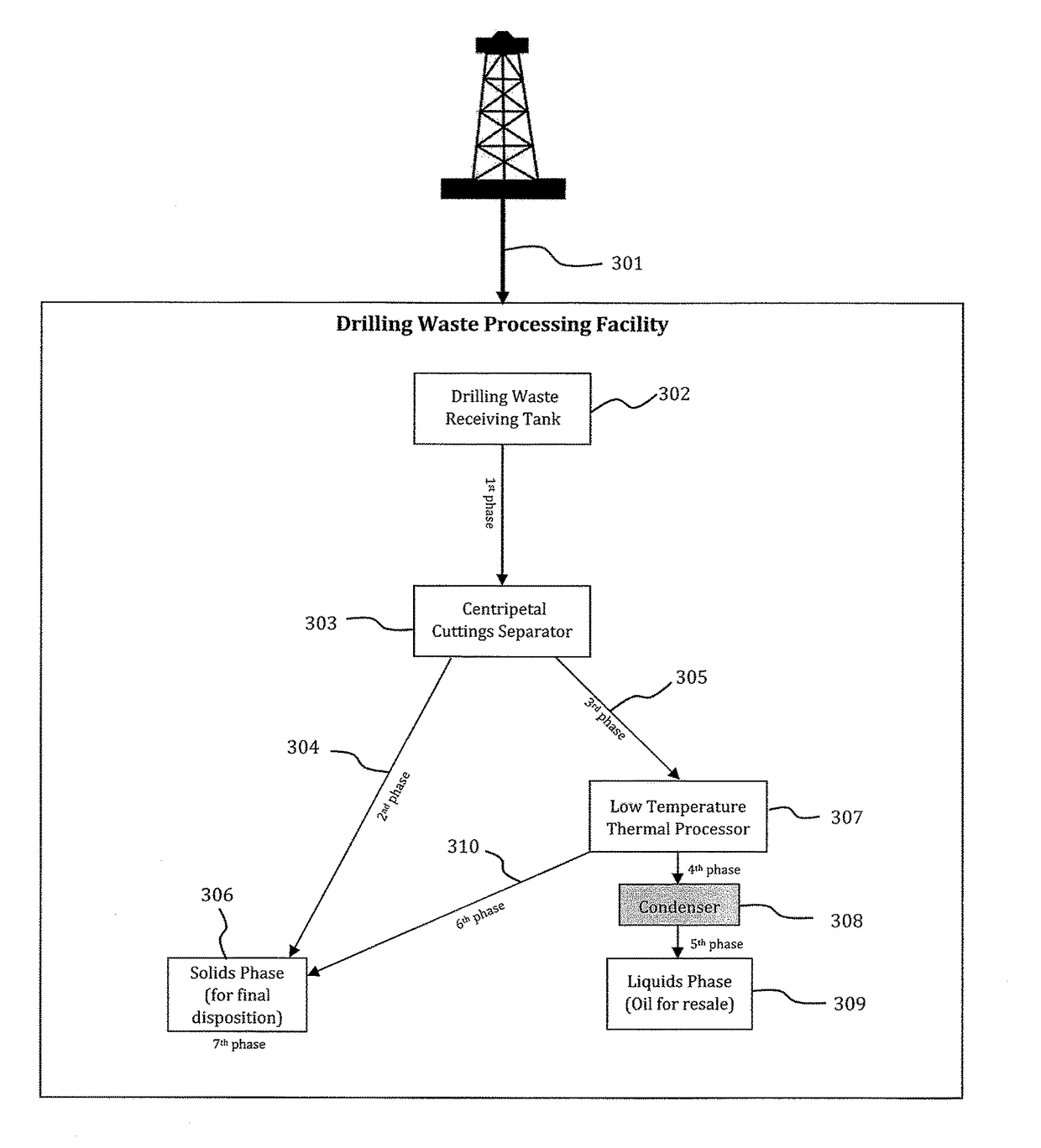

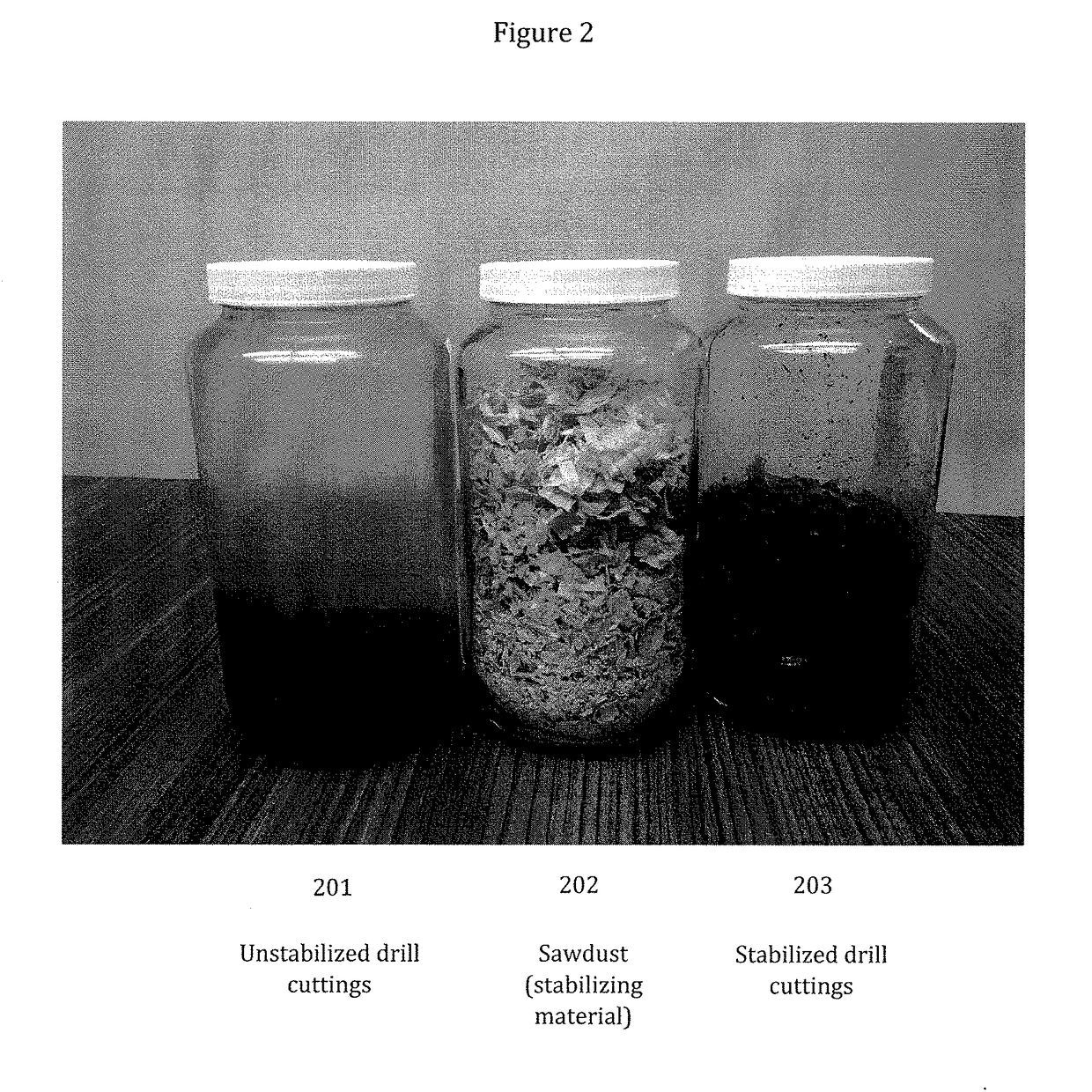

Multi-stage drilling waste material recovery process

ActiveUS20170298703A1Enhanced liquidEnhanced solid recoveryDrying solid materials with heatDrying solid materials without heatComponents of crude oilHeat treated

A process for removing free liquids from oil base mud contaminated drill cuttings waste. A process is described wherein a high gravity centripetal separator and low temperature thermal process are cooperatively used to enhance the mechanical and thermal separation methods, resulting in improved efficiency of the hydrocarbon and water removal process. A process is also described wherein the oil base mud contaminated drill cuttings waste is heated to strip volatile constituents and excess water from the oil base mud contaminated drill cuttings to further enhance the mechanical and thermal separation methods resulting in improved efficiency of the hydrocarbon and water removal process. A less expensive process is also described where the oil base mud contaminated drill cuttings waste is heated to strip volatile constituents and excess water from the oil base mud contaminated drill cuttings to further enhance the recoverable liquids phase during mechanical separation. A conventional stripping process for oil base mud is also utilized.

Owner:RECOVERY ENERGY SERVICES INC

Method for making a road base material using treated oil and gas waste material

The present invention provides a novel method to produce grade road base material using recycled oilfield waste, called “oil and gas waste,” more specifically, drilling waste and aggregate and a novel road base material. Hydration and mixing of the waste materials along with a binder, will achieve an irreversible pozzolanic chemical reaction necessary for stabilization into a road base. An asphalt emulsifier may be included in the binder to manufacture asphalt stabilized road base. The entire method is a cold batch process.

Owner:MVC ENVIRONMENTAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com