Process and device for overall standard-reached treatment for oil-gas field drilling waste

A technology for drilling waste and oil and gas fields, which is applied in the field of overall compliance treatment of drilling waste in oil and gas fields. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

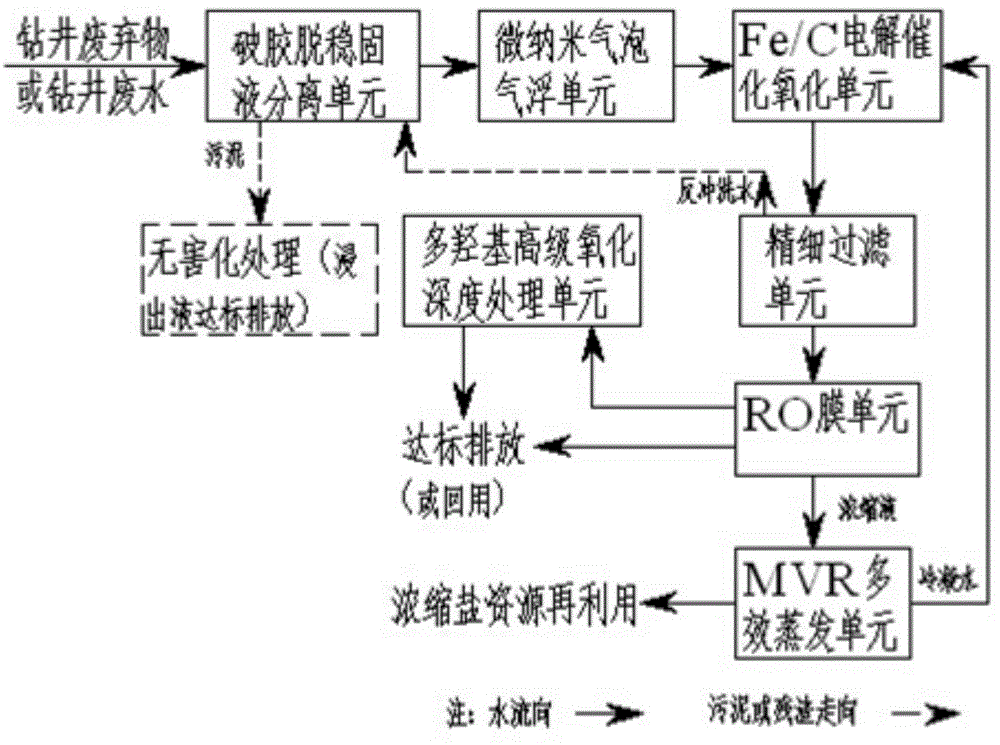

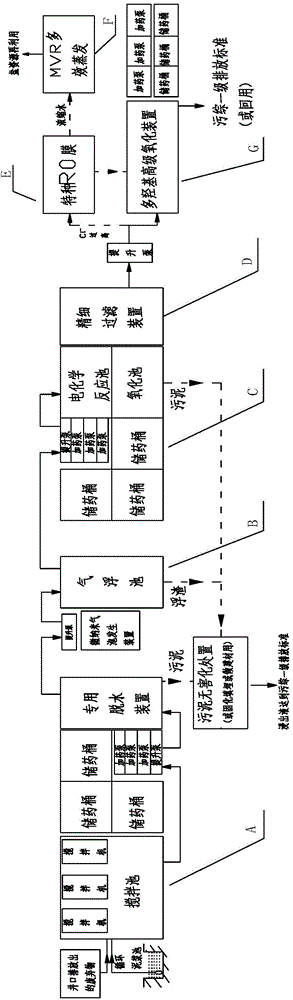

[0030] A process for the overall up-to-standard treatment of drilling waste in oil and gas fields, including the following steps:

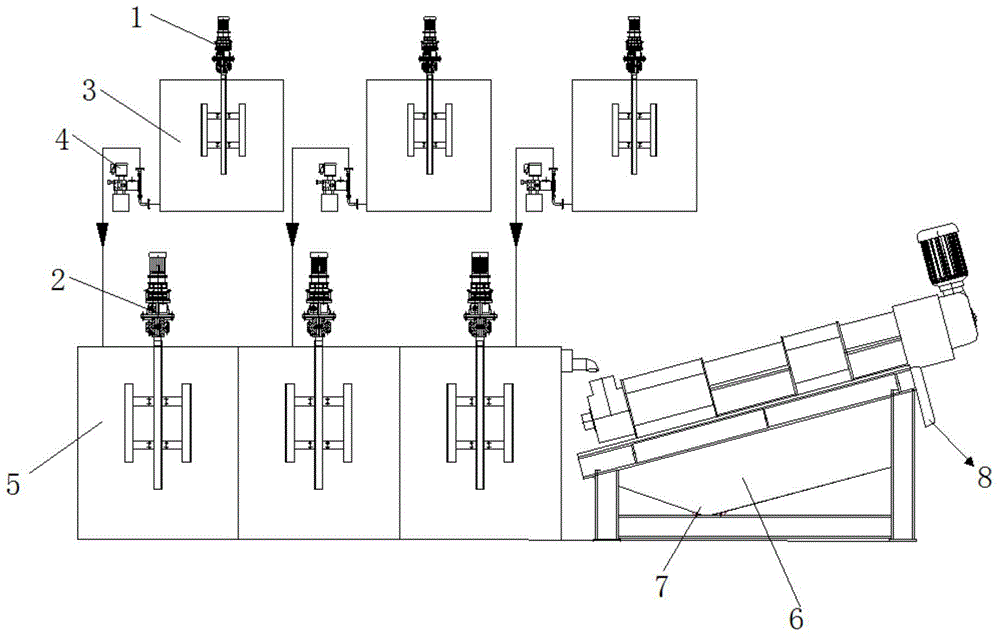

[0031] 1. Gel breaking and destabilization, solid-liquid separation pretreatment unit: Drilling waste can be directly pumped into the gel breaking treatment equipment with a screw pump. Different drilling fluid systems are added with different amounts of gel breaking treatment agents, and they are quickly broken under special stirring. The glue is destabilized, and the special stacked screw dehydration device makes the solid-liquid separation of the high-solid content material and liquid complete, and the sludge dewaterability is good, creating favorable conditions for subsequent disposal. The step of gel breaking and destabilization and solid-liquid separation pretreatment is very critical. The quality of the treatment effect directly affects the difficulty and operation cost of the subsequent process, and is one of the main factors determining th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com