Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192 results about "Adjustable-speed drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adjustable speed drive (ASD), also known as variable-speed drive (VSD), describes equipment used to control the speed of machinery. Many industrial processes such as assembly lines must operate at different speeds for different products. Where process conditions demand adjustment of flow from a pump or fan, varying the speed of the drive may save energy compared with other techniques for flow control.

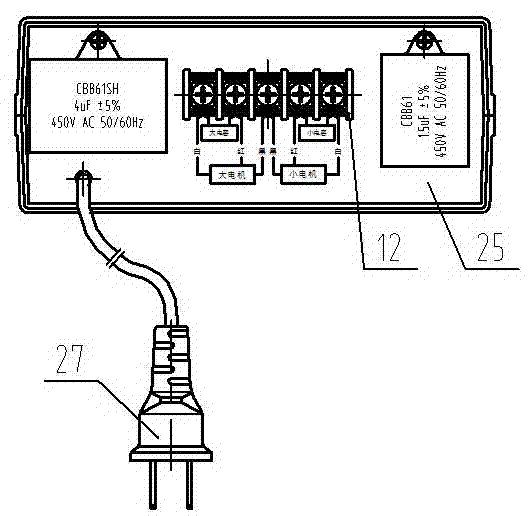

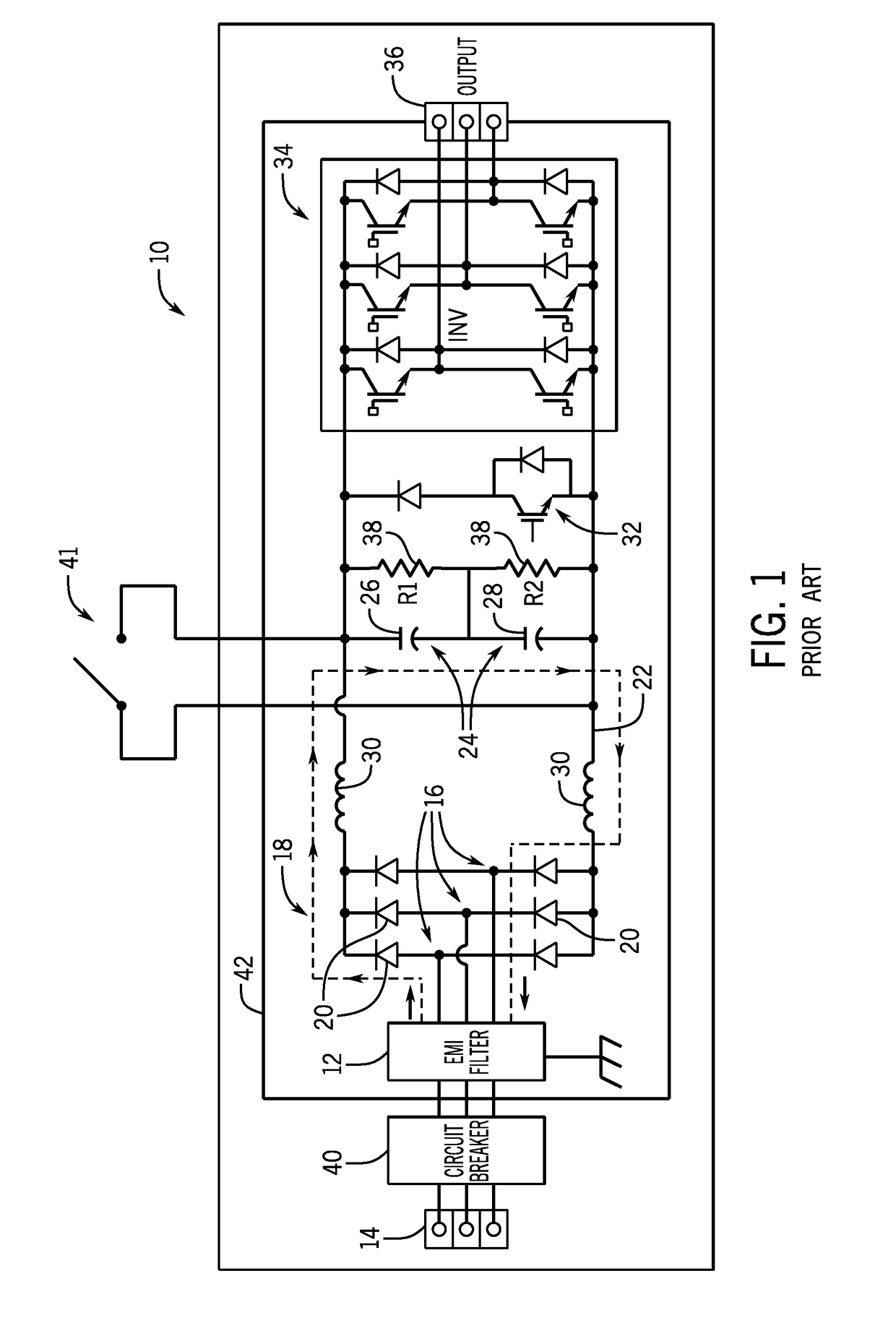

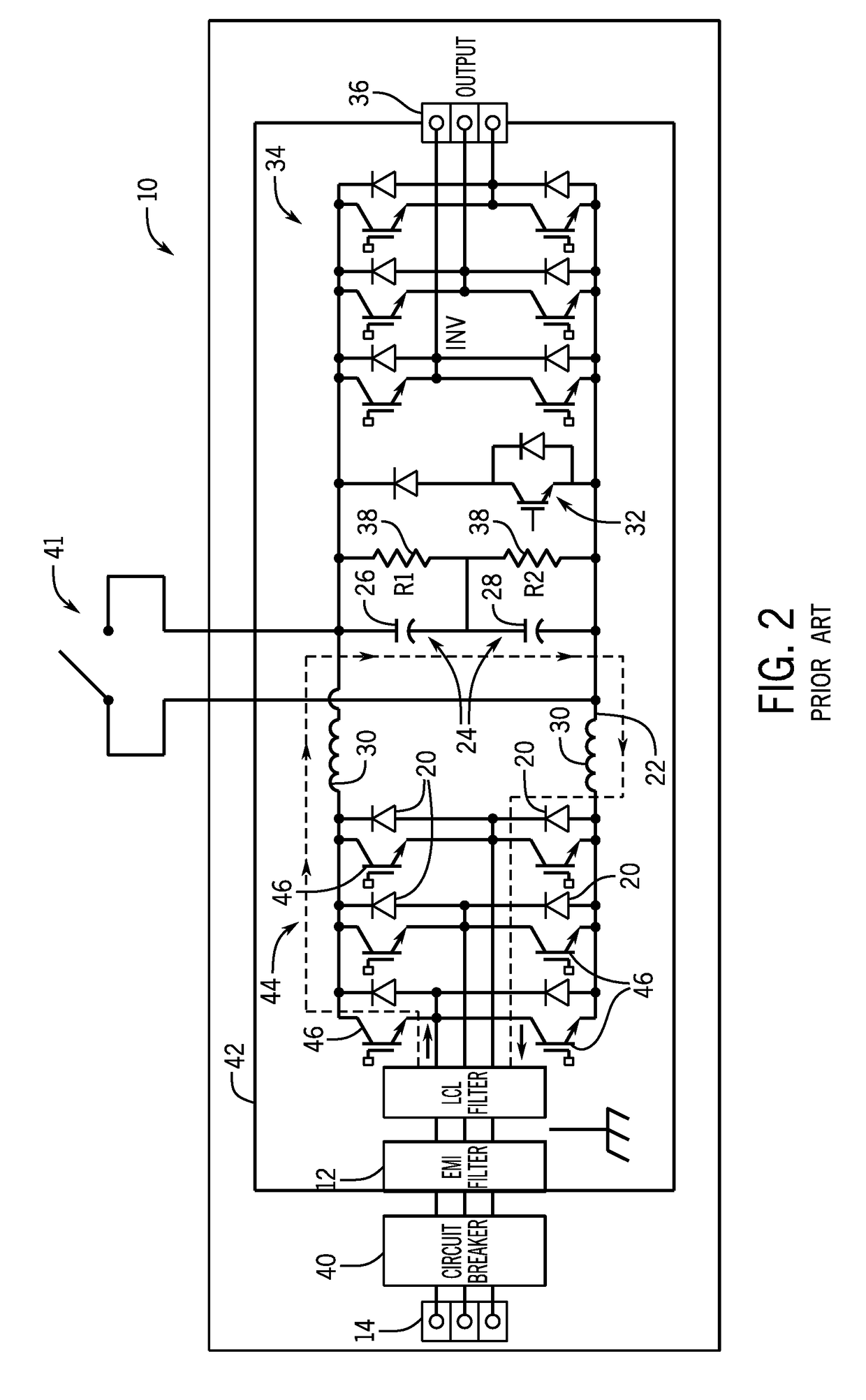

Synchronous and bi-directional variable frequency power conversion systems

InactiveUS6850426B2Facilitate easeLow costAc-dc conversion without reversalDc-dc conversionDigital controlAC power

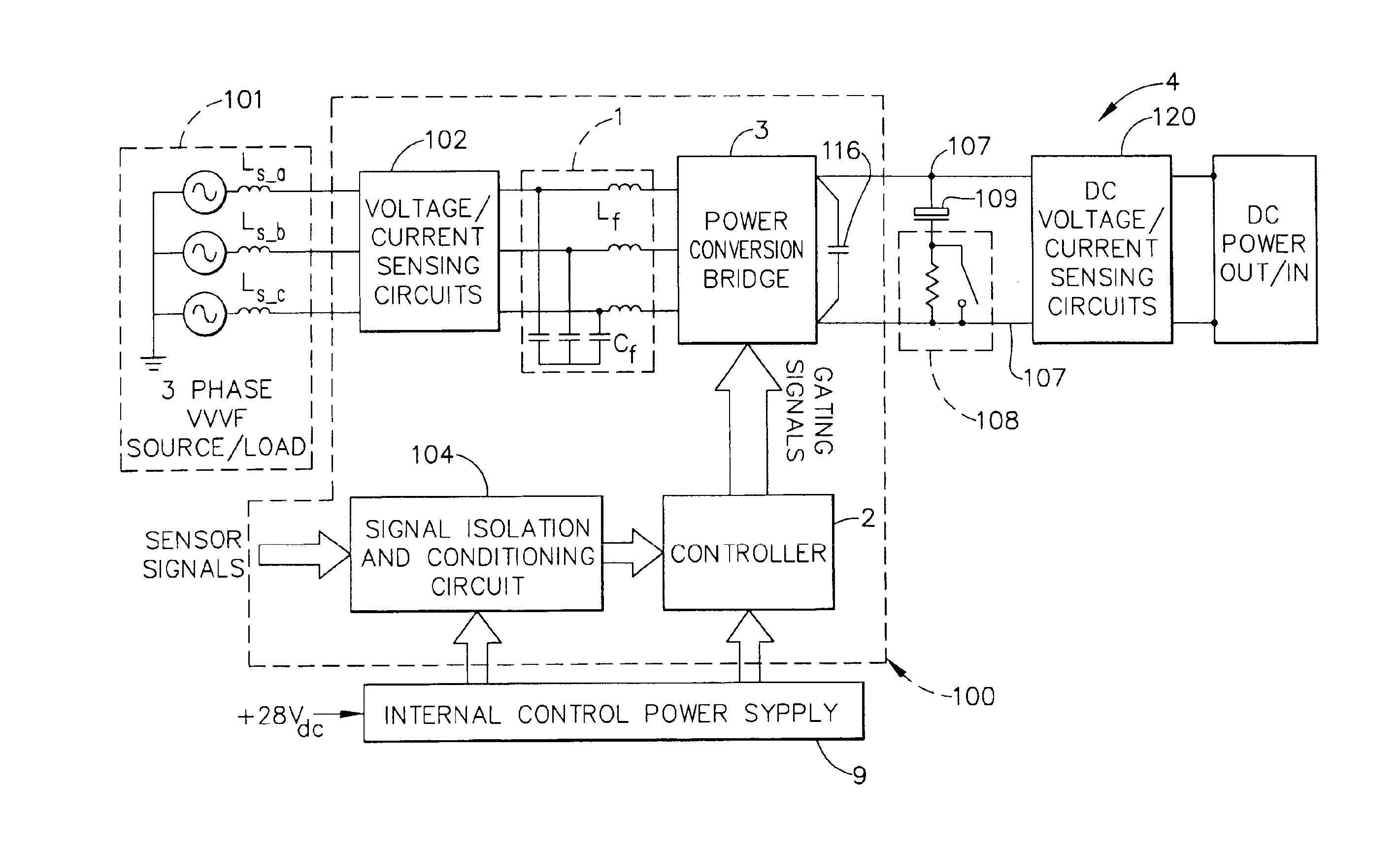

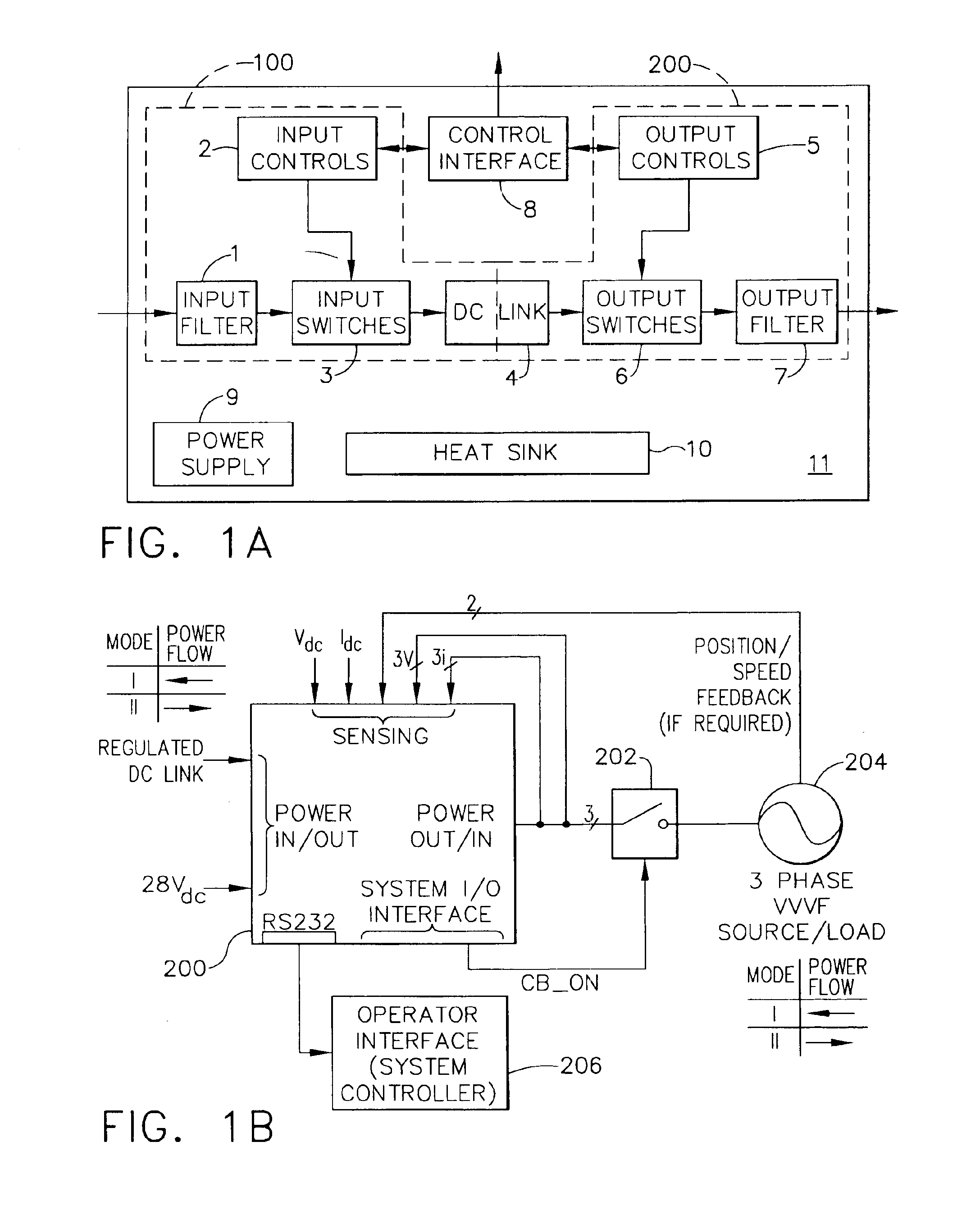

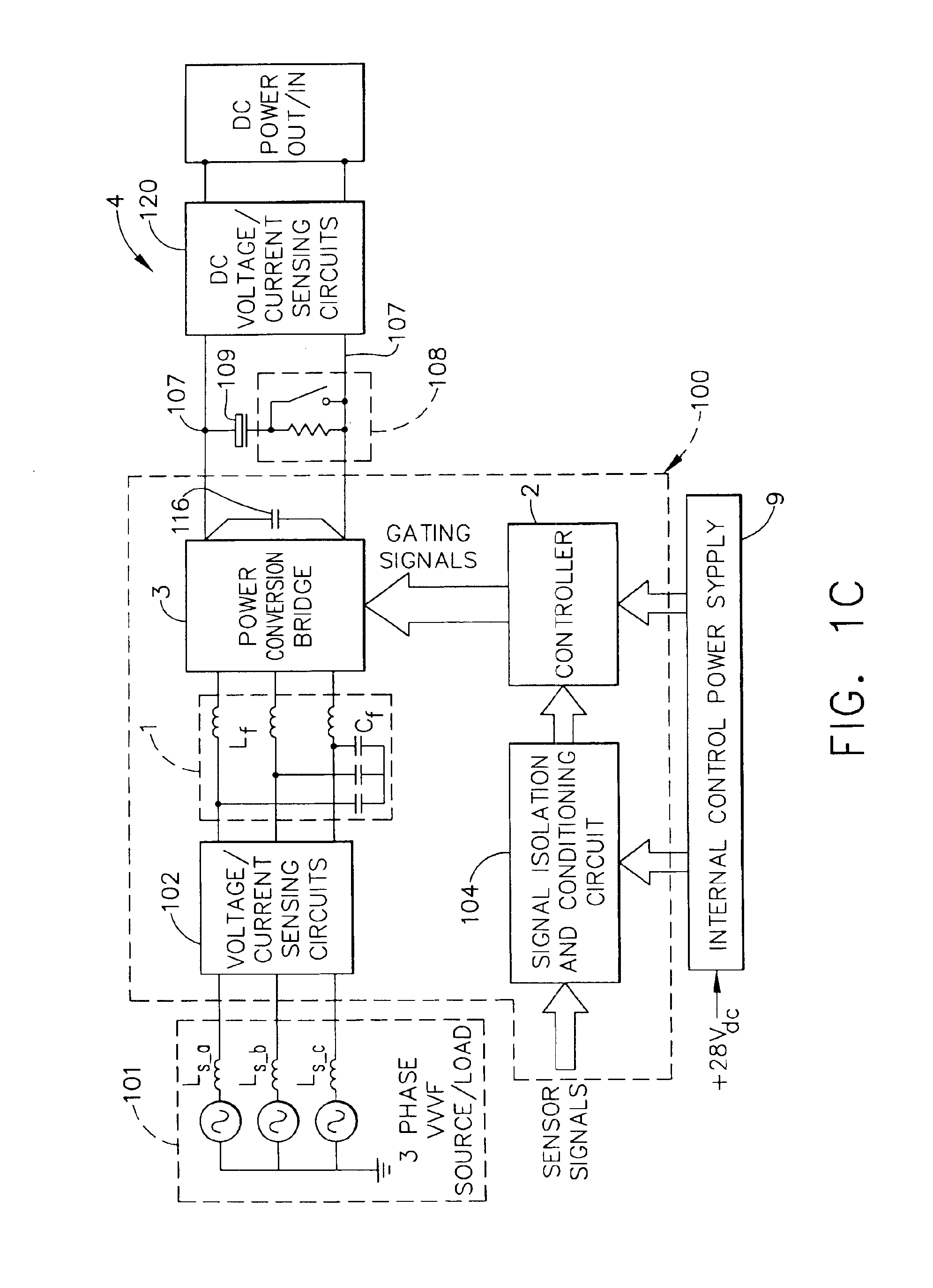

A synchronous bi-directional active power conditioning system (11) suitable for wide variable frequency systems or active loads such as adjustable speed drives which require variable voltage variable frequency power management systems is disclosed. Common power electronics building blocks (100, 200) (both hardware and software modular blocks) are presented which can be used for AC-DC, DC-AC individually or cascaded together for AC-DC-AC power conversion suitable for variable voltage and / or wide variable frequency power management systems. A common control software building block (2, 5) includes a digital control strategy / algorithm and digital phase lock loop method and apparatus which are developed and implemented in a digital environment to provide gating patterns for the switching elements (3, 6) of the common power-pass modular power electronics building blocks (100, 200).

Owner:HONEYWELL INT INC

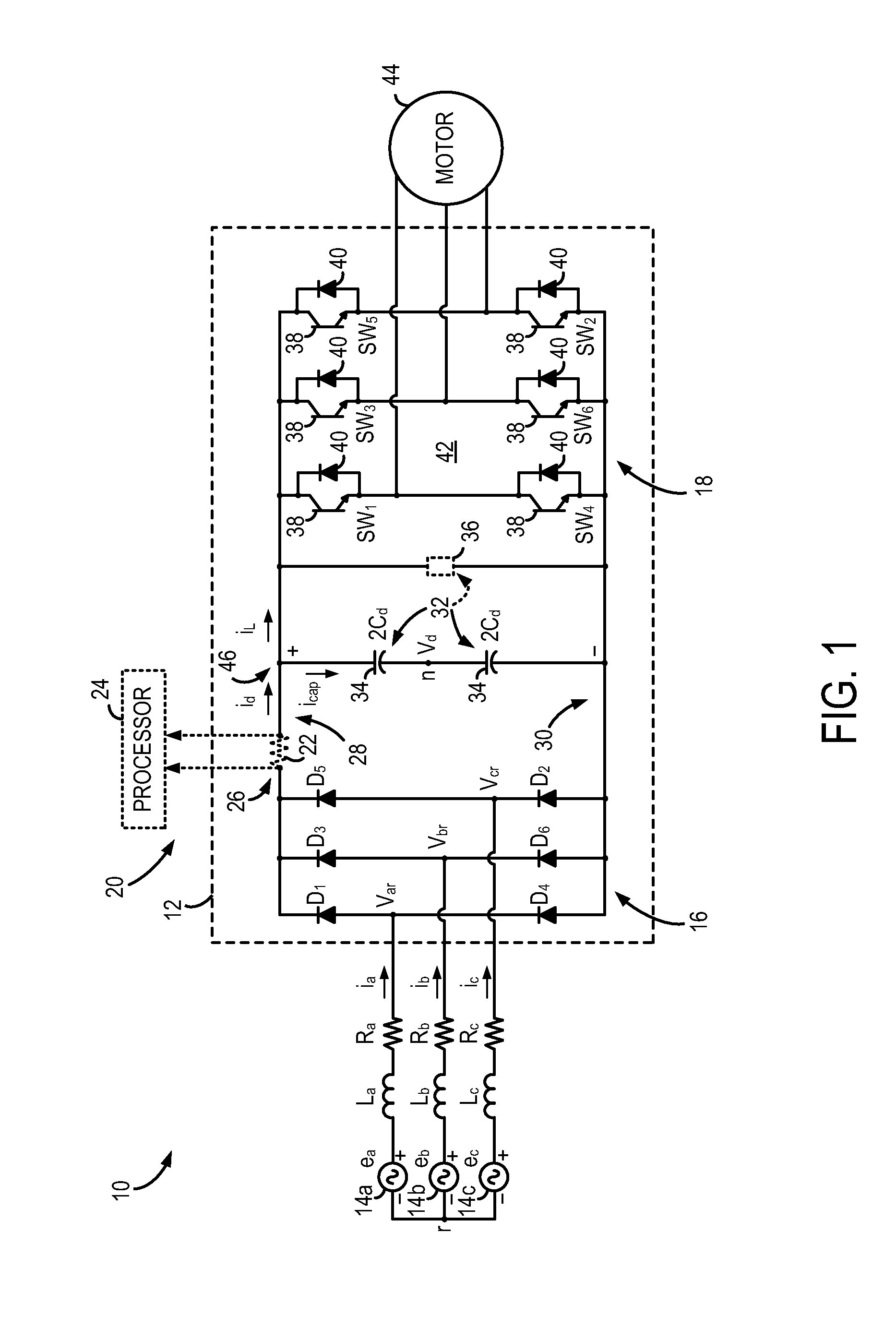

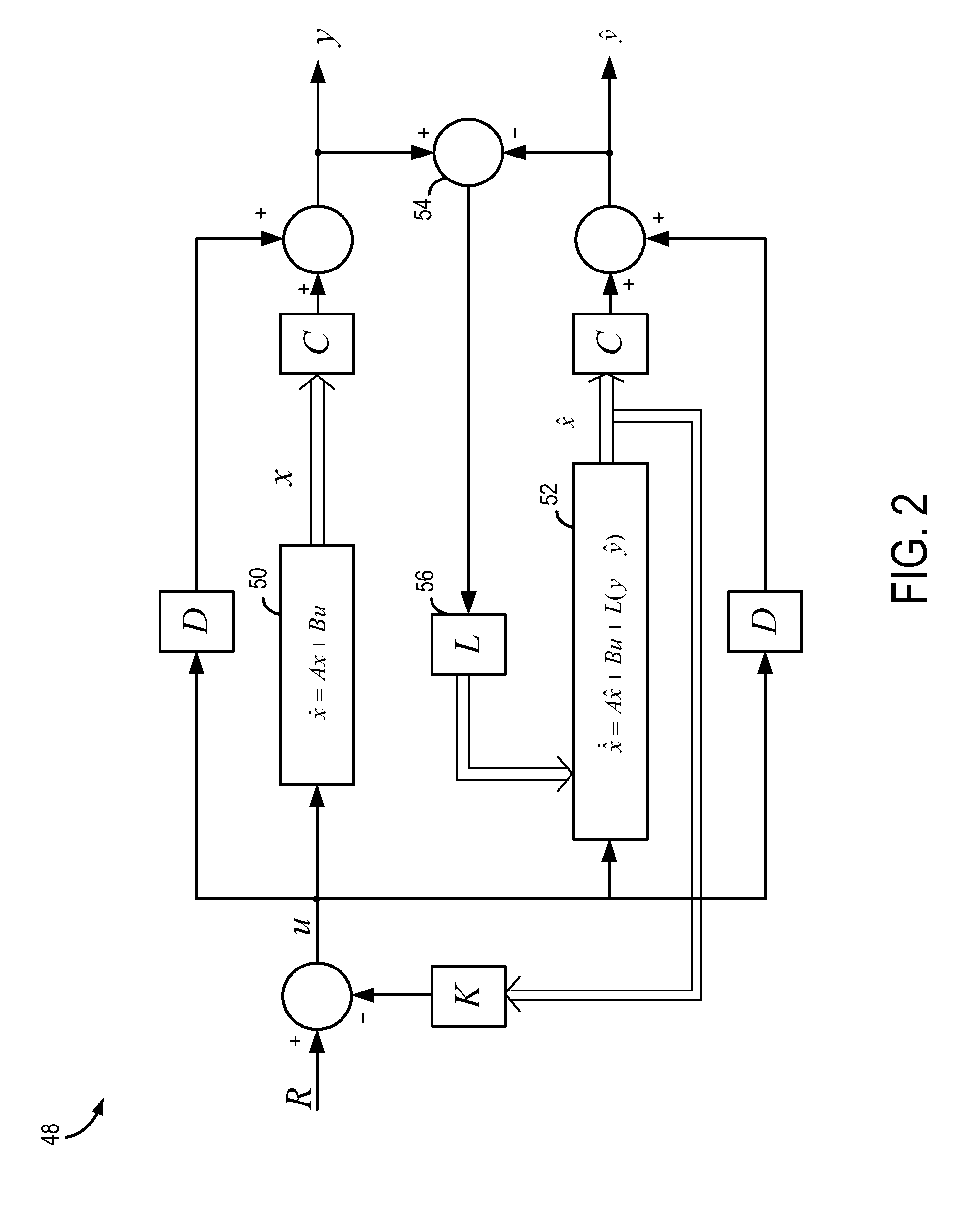

System and method for detecting phase loss and diagnosing DC link capacitor health in an adjustable speed drive

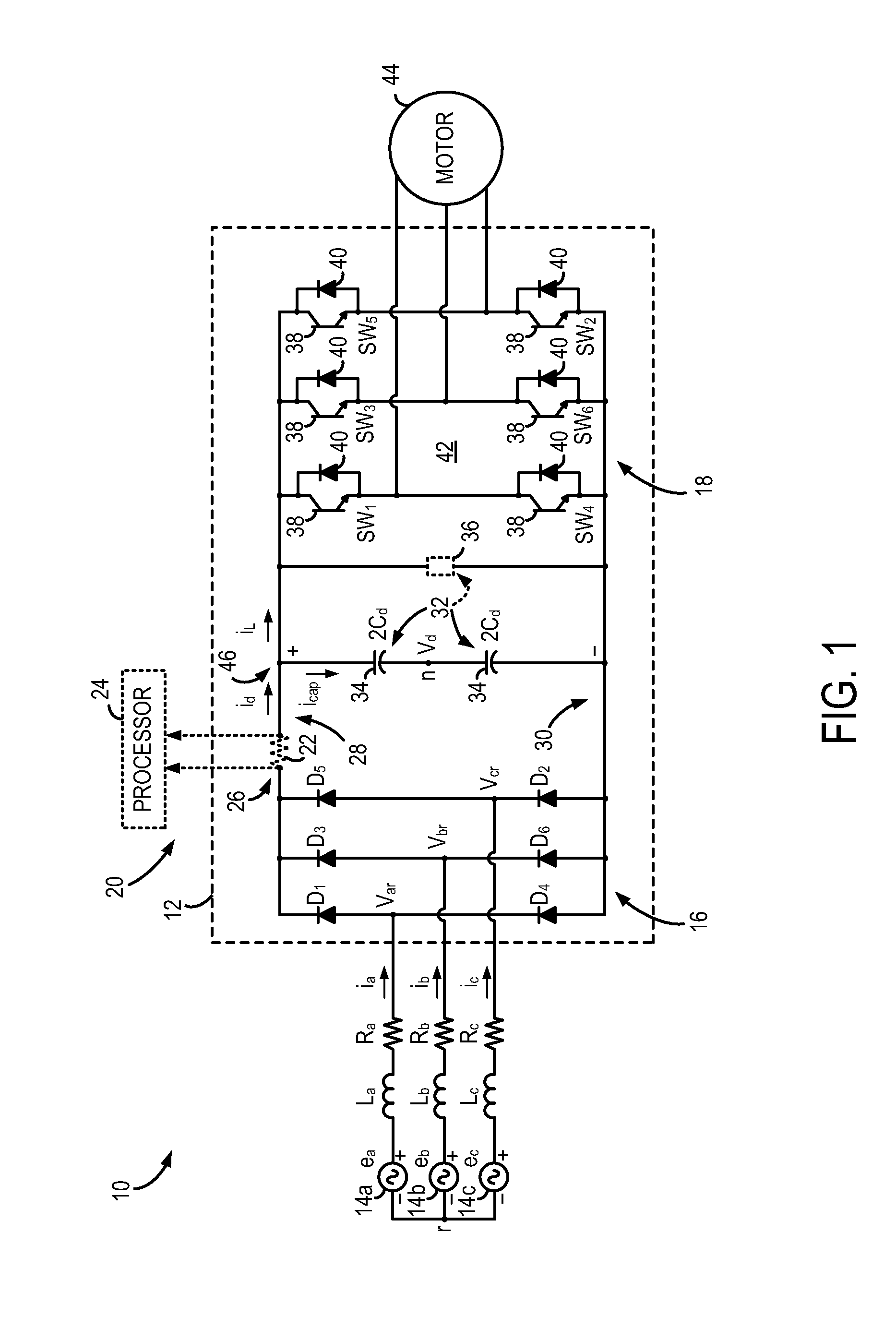

A system and method for detecting input phase loss in an adjustable speed drive (ASD) includes an input unit to detect operating data from the ASD. The operating data includes a DC link current of the ASD. The system also includes a state observer that is adapted to receive the operating data from the input unit and extract a DC link capacitor current of the ASD using the DC link current. The system also includes a controller programmed to compare the extracted DC link capacitor current to a predetermined fault range and generate a fault indication of an input phase loss if the extracted DC link capacitor current is within the predefined fault range. The controller is also programmed to calculate an estimated lifespan of the DC link capacitor based on the extracted DC link capacitor current.

Owner:EATON INTELLIGENT POWER LIMITED

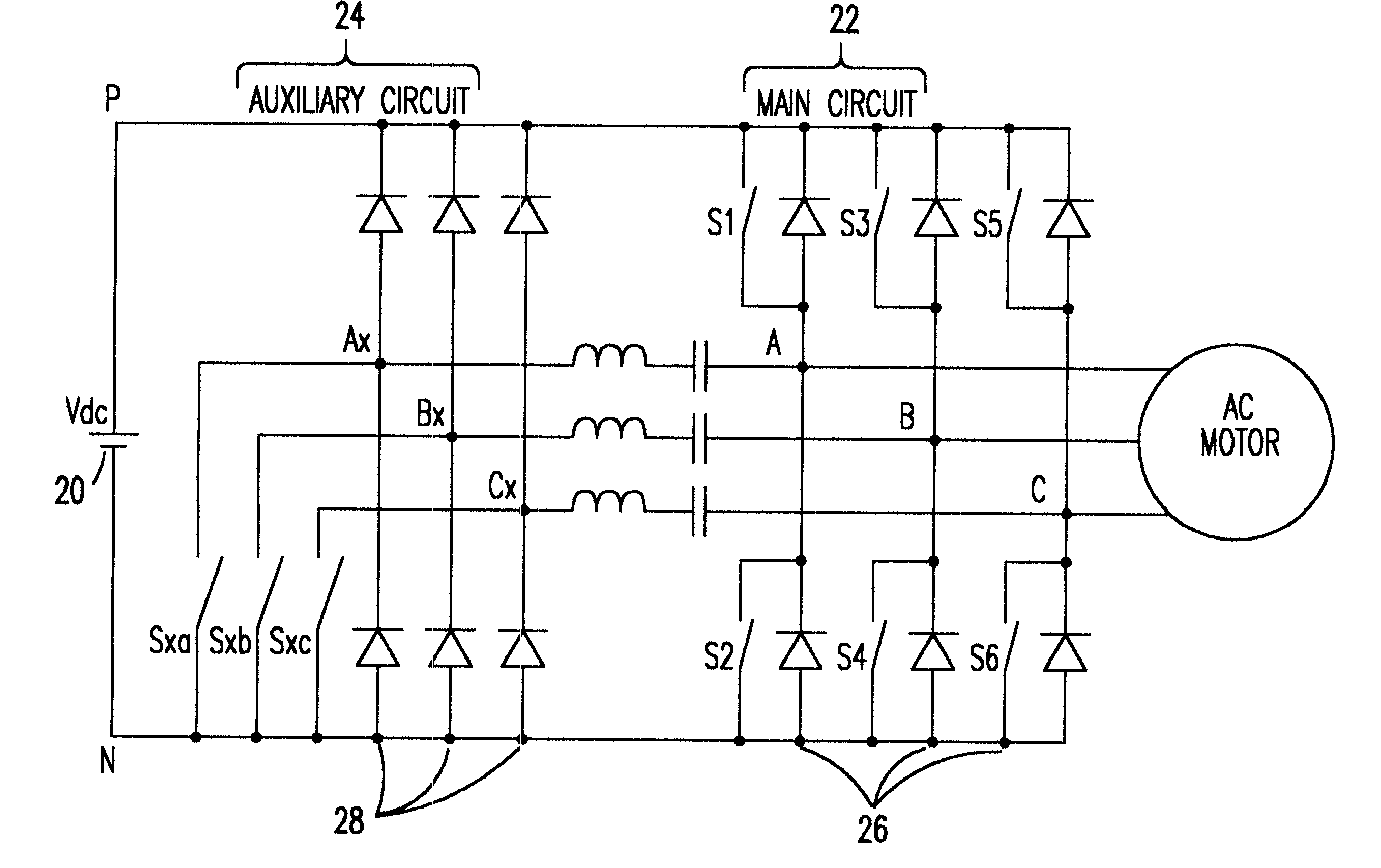

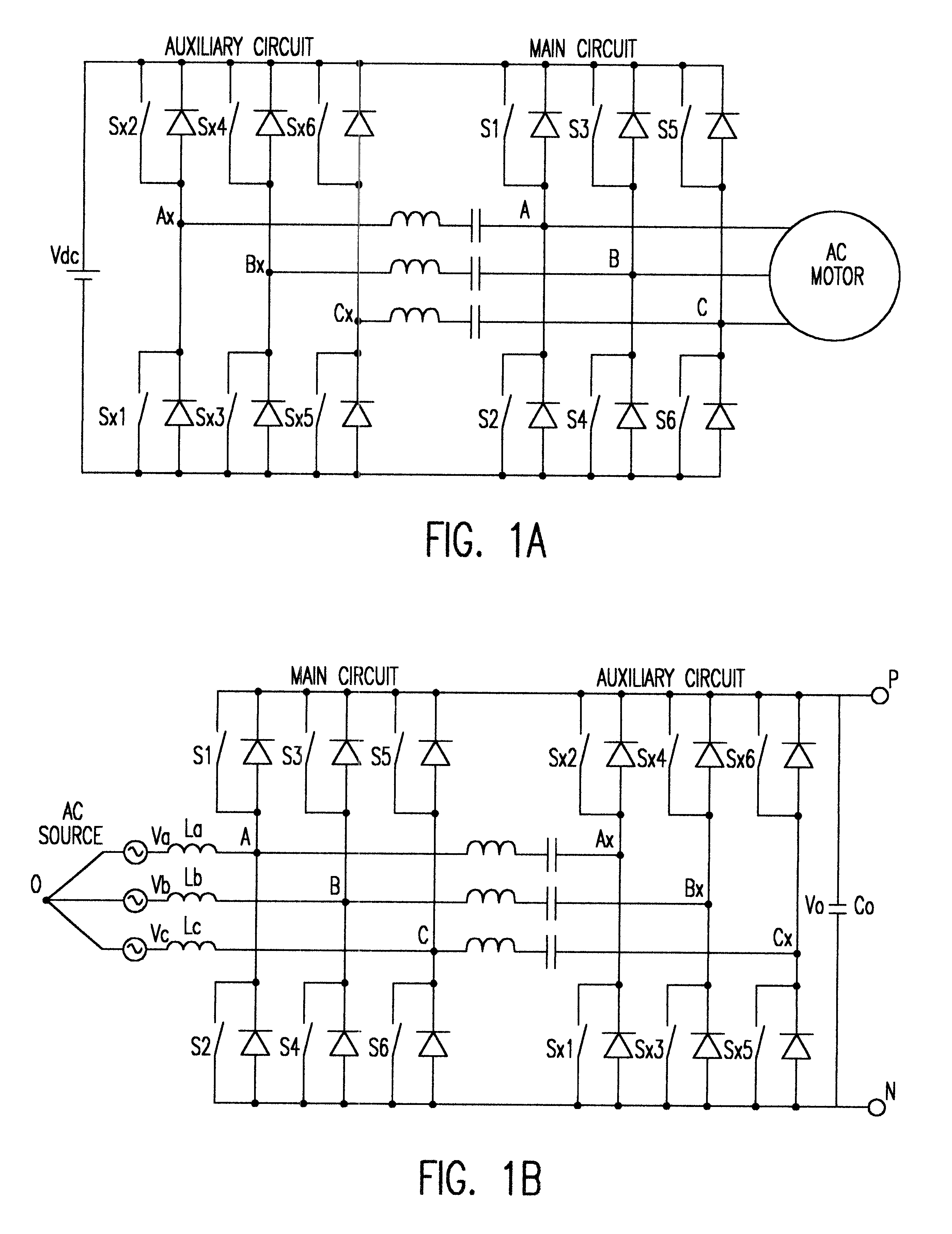

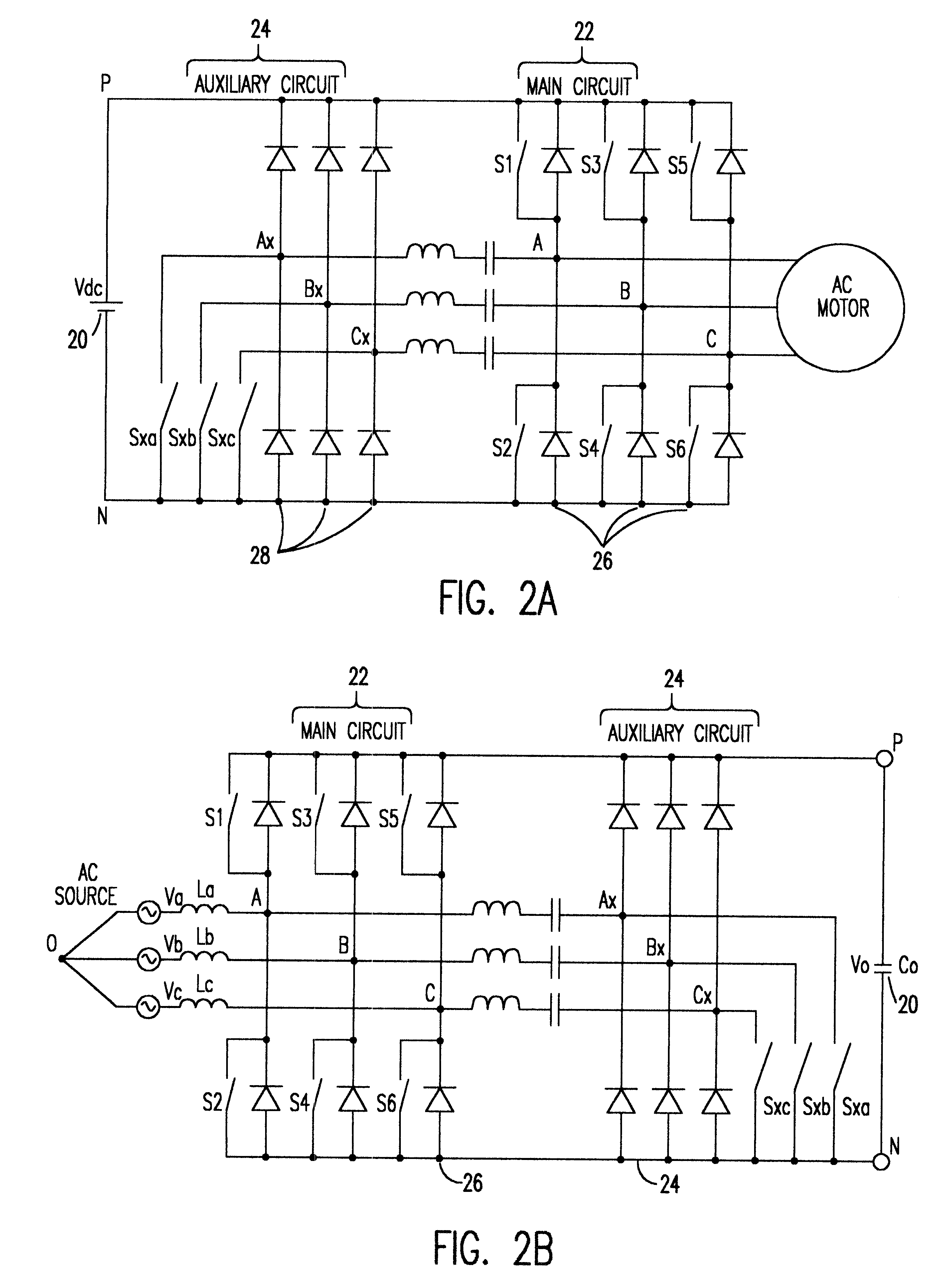

Three-phase zero-current-transition (ZCT) inverters and rectifiers with three auxiliary switches

InactiveUS6337801B2Dc-ac conversion without reversalConversion with reversalSoft switchingCombustion

Zero current transition (ZCT) topologies are presented for three-phase inverters and rectifiers. Such devices are used for example in AC adjustable speed drives for so-called zero-emission vehicles (i.e., electric and hybrid combustion / electric automobiles). Compared to existing three-phase ZCT techniques, the number of auxiliary switches is reduced from six to three, while not altering the necessary device rating. Correspondingly, the number of gate-drivers for the auxiliary switches is also reduced to three. Meanwhile, the merits of the existing three-phase ZCT techniques are still retained, i.e., all the main switches and the auxiliary switches are turned on and turned off under zero-current conditions, and the independent commutation for each main switch is achieved. The desired soft-switching features are achieved. Therefore, this invention will contribute to more cost-effective, reliable, and efficient high-performance three-phase inverters and rectifiers.

Owner:VIRGINIA TECH INTPROP INC

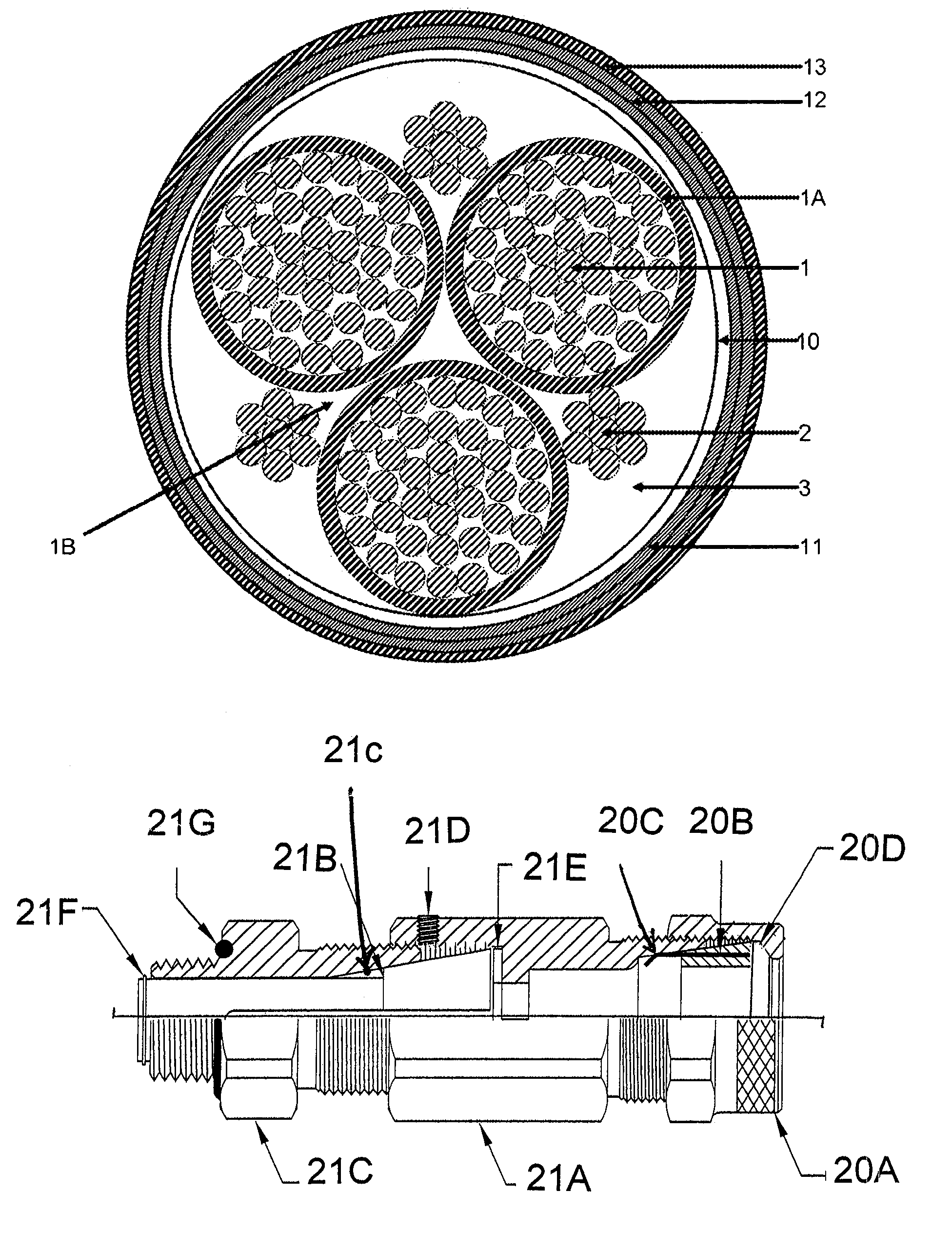

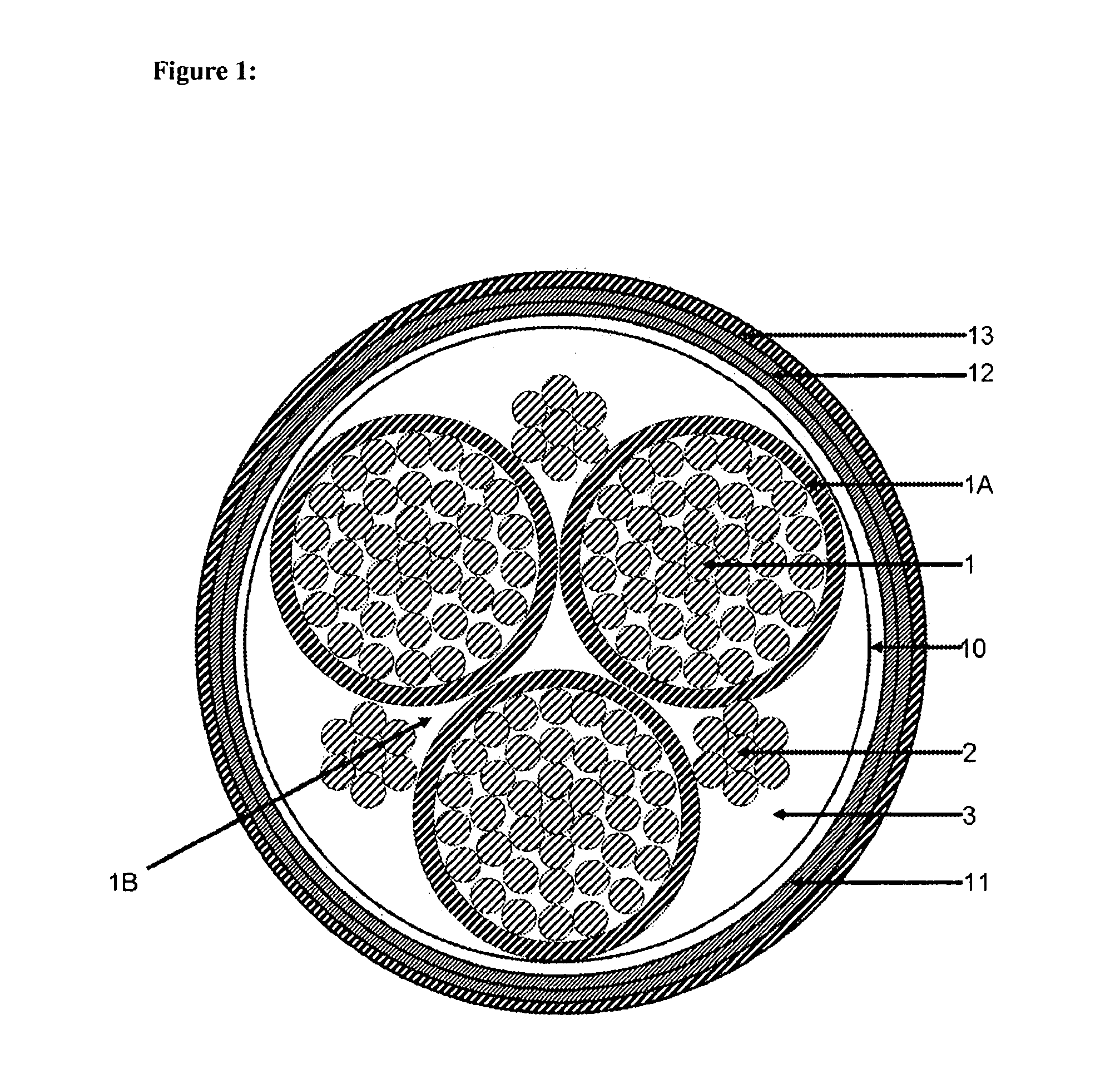

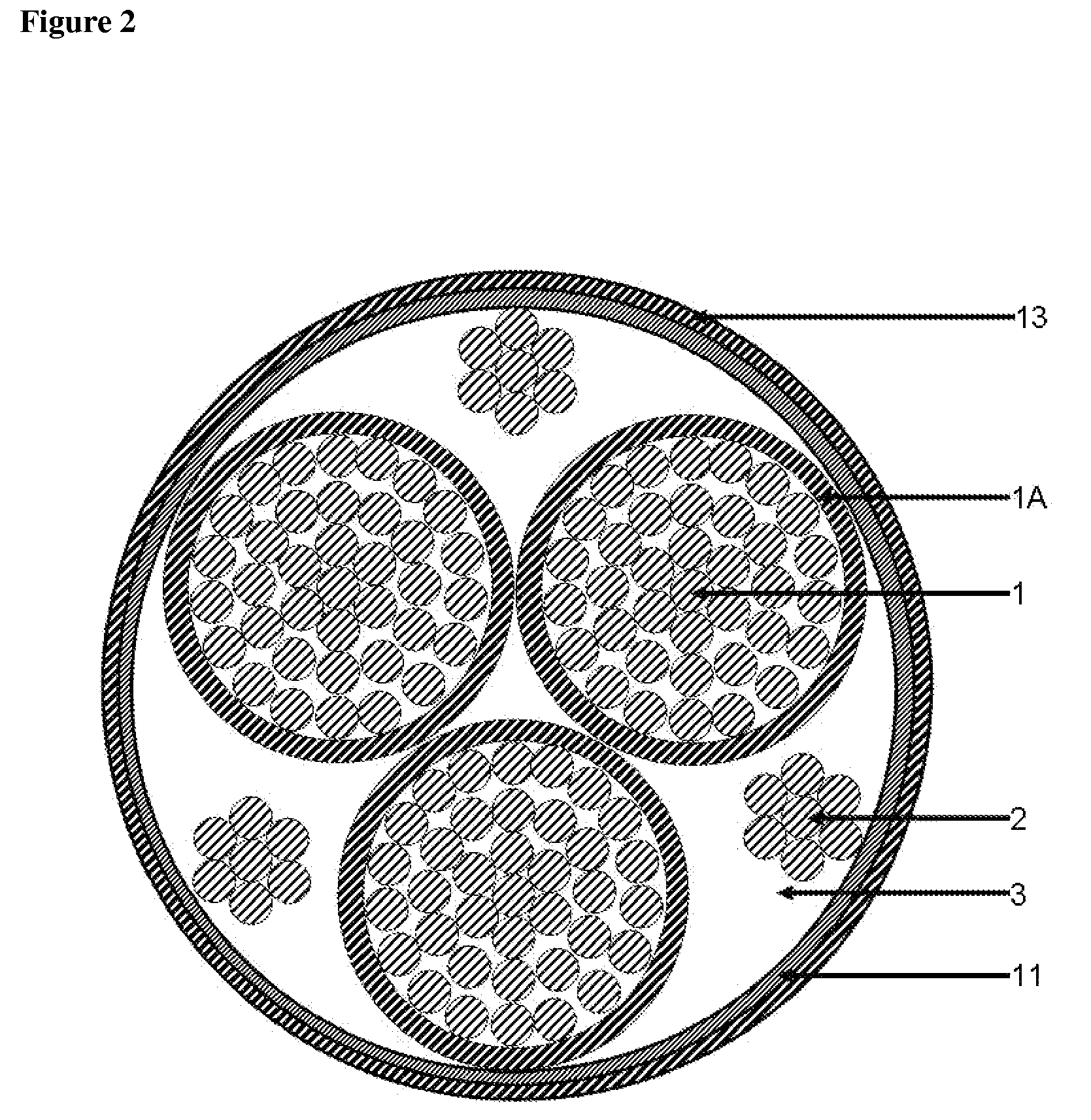

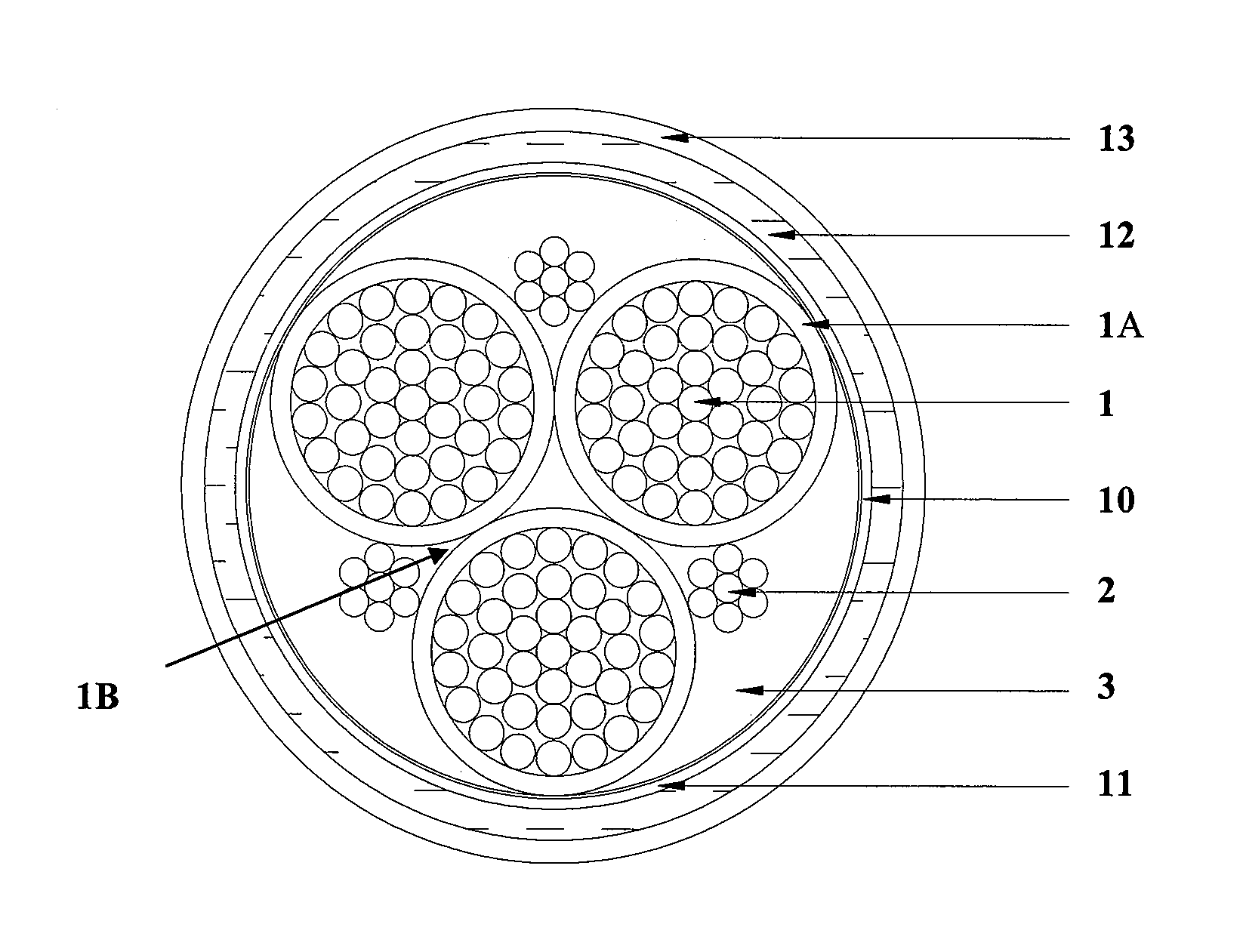

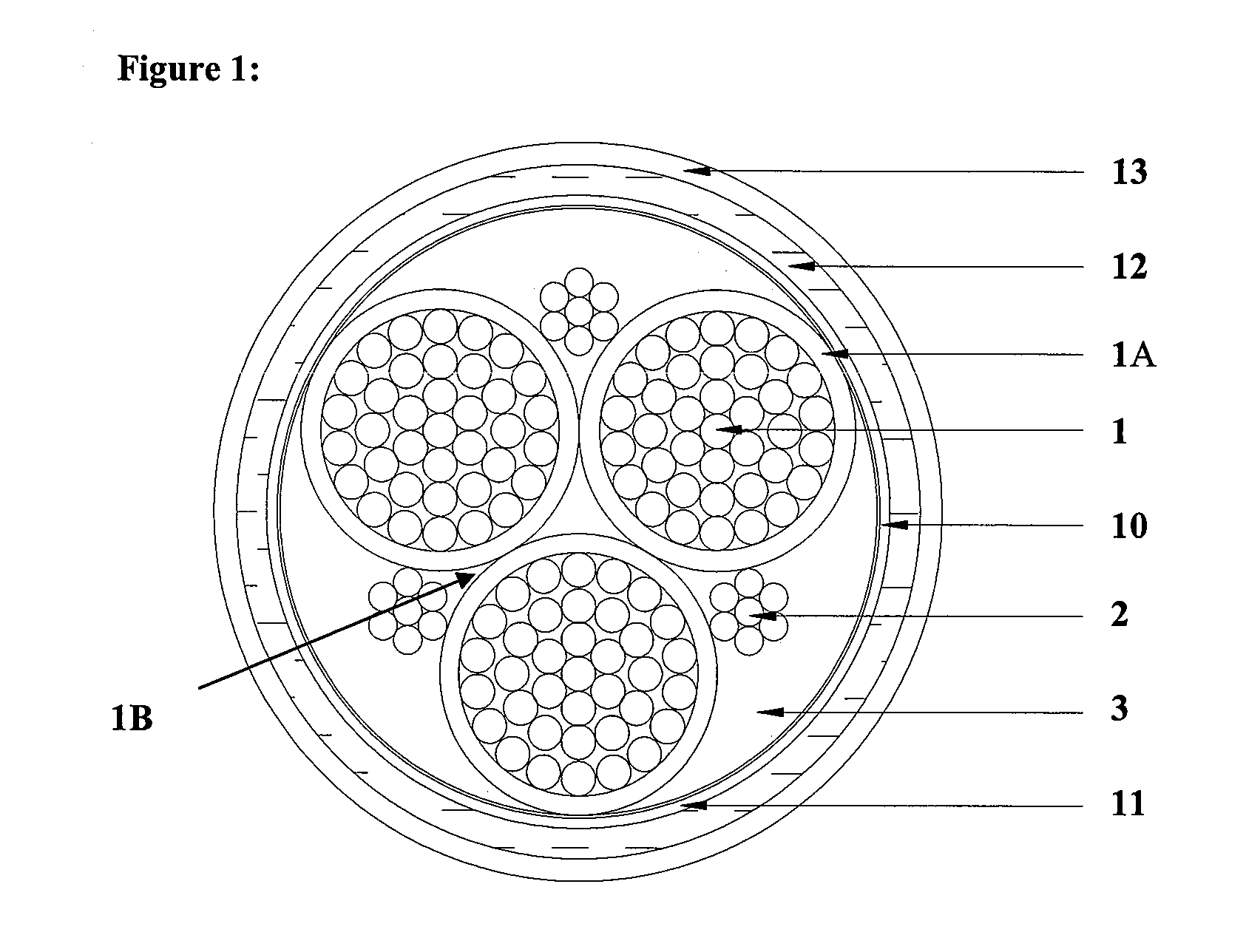

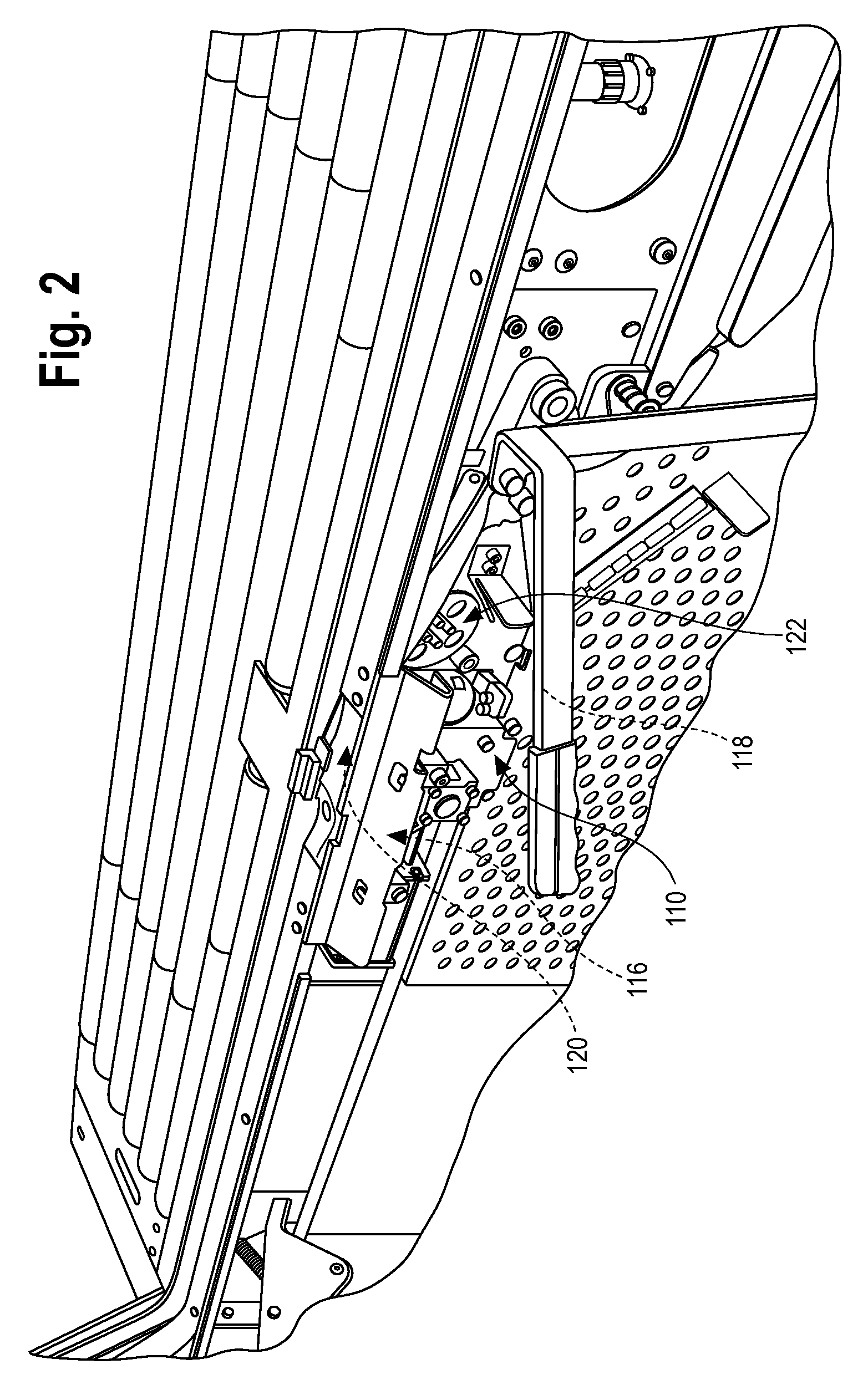

Adjustable speed drive/variable frequency drive cable, connector and termination system

A cable and termination system for use with adjustable speed drives, including flexible tray cables and metal-clad cables, and terminations coupled therewith. The cables generally include three phase conductors, three ground conductors and fillers, and are wrapped with copper tape and other elements. The terminations coupled with the cables include a plurality of connectors and flexible, tinned-copper braids which act as the shield termination for the copper tape. More detailed and other embodiments of the present invention are disclosed in the specification hereof.

Owner:SERVICE WIRE

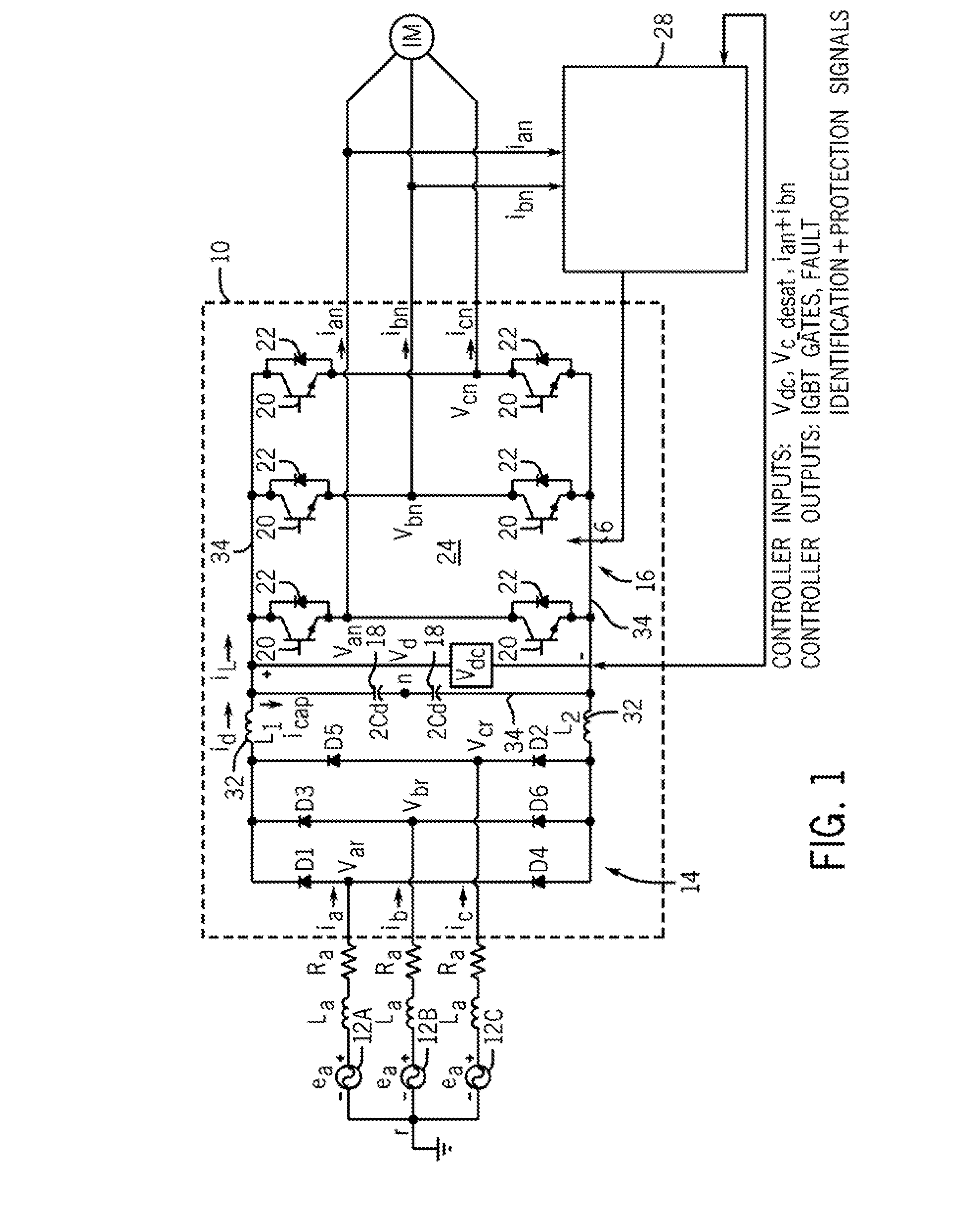

System and method for ground fault detection and protection in adjustable speed drives

A system and method for detecting ground faults in an AC motor drive is disclosed. A fault detection and protection system for an AC motor drive includes current sensors to measure first and second phase output currents, a voltage sensor to measure a DC link voltage, and a desaturation control circuit to determine a voltage and associated current across PWM inverter switches for a third phase of the output. A controller compares the first and second phase currents, the measured DC link voltage, and the voltage across the PWM inverter switches on the third phase, to a plurality of thresholds. The controller detects a ground fault on one of the first, second, and third phases of the three phase output to the AC motor based on the comparisons of the first and the second phase currents, the DC link voltage, and the voltage across the switches to the thresholds.

Owner:EATON INTELLIGENT POWER LIMITED

Adjustable Speed Drive Cable and Shield Termination

ActiveUS20070107921A1Power cables with screens/conductive layersInsulated cablesThree-phaseAdjustable-speed drive

The product of the present invention comprises flexible tray cables and metal-clad cables designed for use with adjustable speed drives, and terminations coupled therewith. The cables comprise, generally, three phase conductors, three ground conductors and fillers, and are wrapped with copper tape and other elements. The terminations comprise a plurality of connectors and a plurality of flexible, tinned-copper braids acting as the shield termination for the copper tape. More detailed and other embodiments of the present invention are disclosed in the specification hereof.

Owner:SERVICE WIRE

Bearing current reduction assembly

InactiveUS6984906B1Rotor to stator currents through the bearings are reduced or eliminatedLow costAssociation with grounding devicesMechanical energy handlingEngineeringAdjustable-speed drive

An electric motor with an adjustable speed drive includes a bearing current reduction assembly including a charge concentrator providing a higher electric field concentration through a clearance between an inner bearing cap and a rotor shaft than occurs within a bearing. Accordingly, damaging rotor to ground currents through a bearing are reduced or eliminated. The charge concentrator is disposed on either the rotor shaft or the inner bearing cap, or both.

Owner:GENERAL ELECTRIC CO

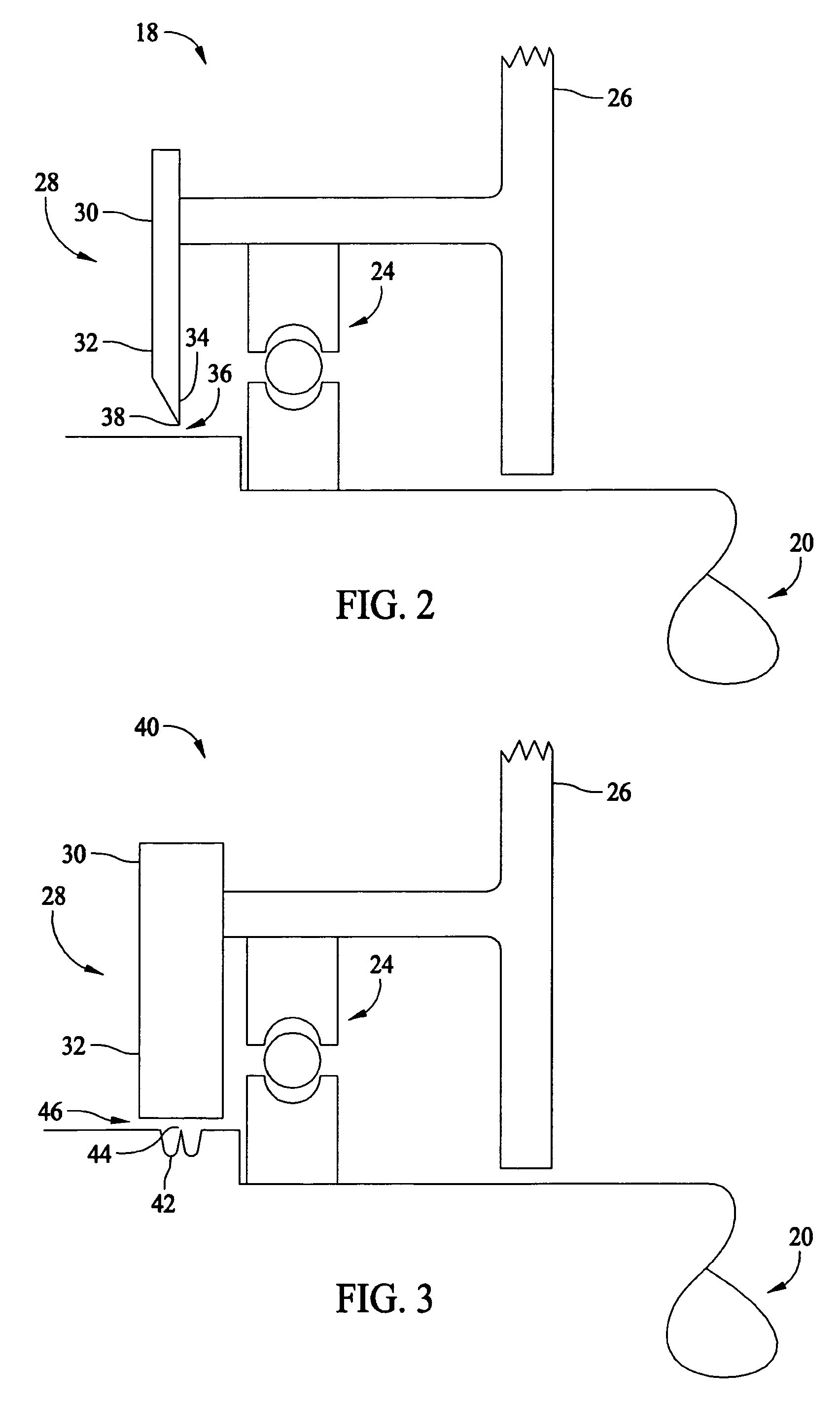

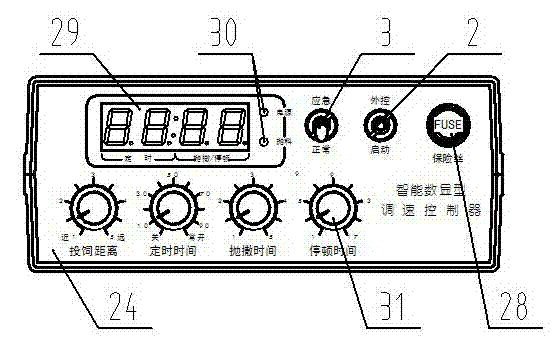

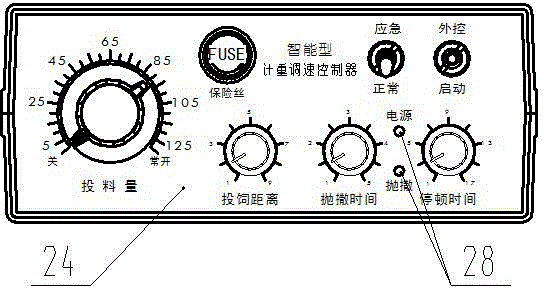

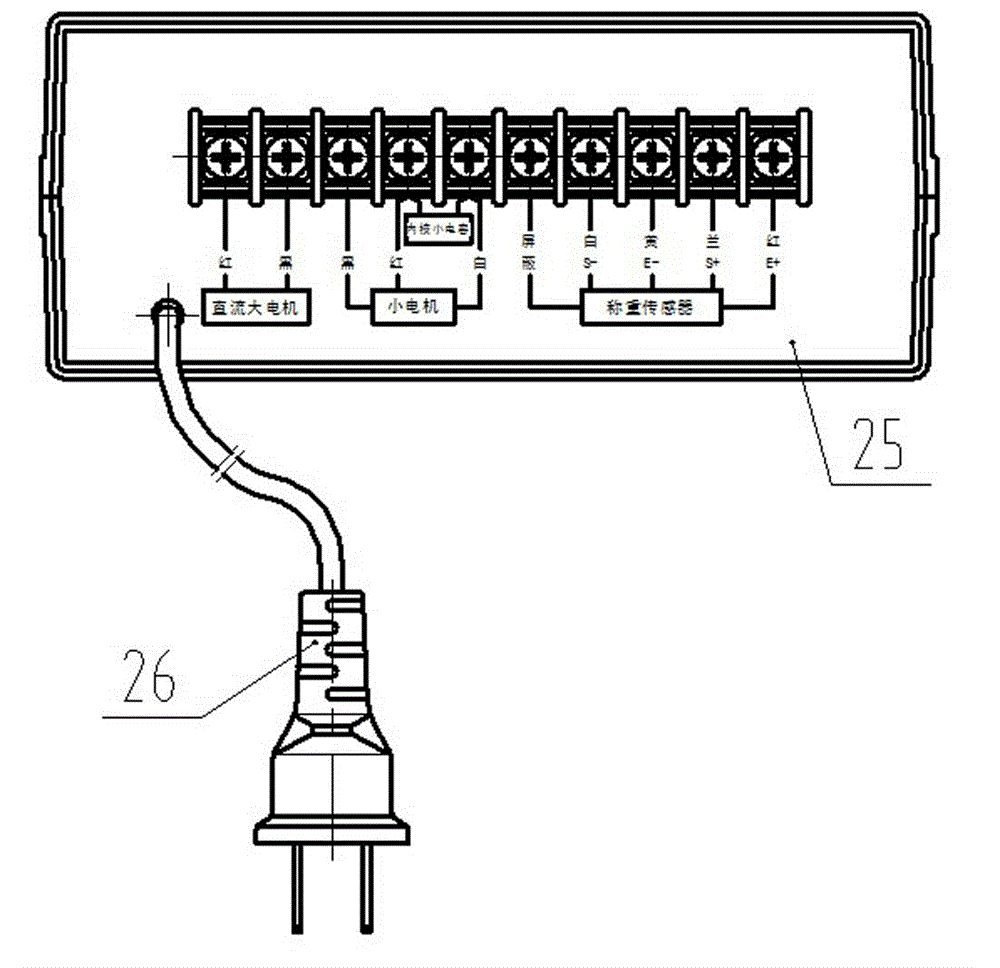

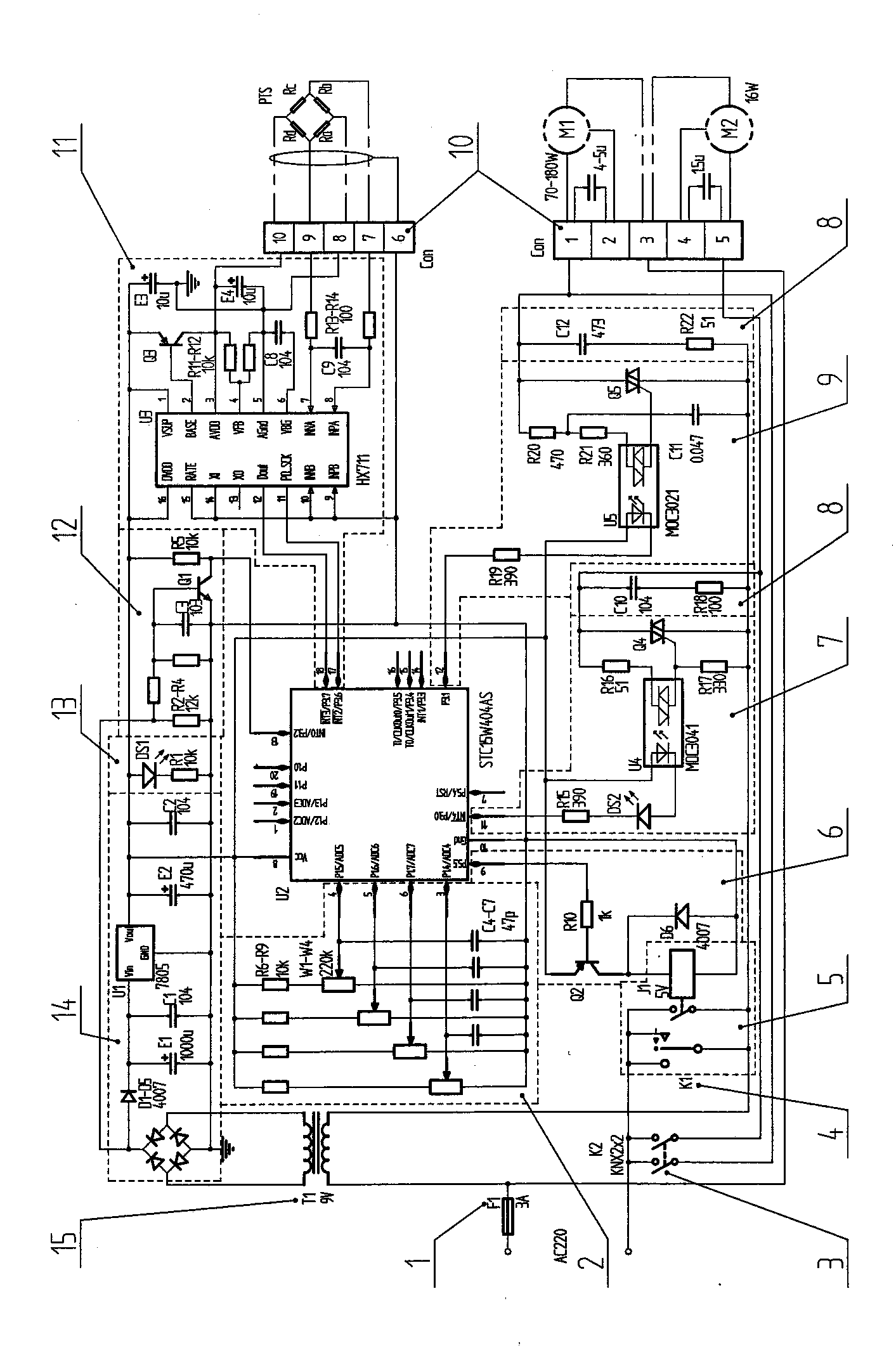

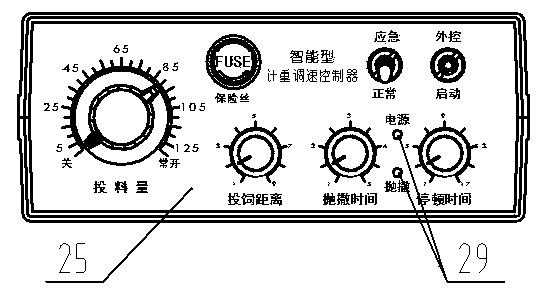

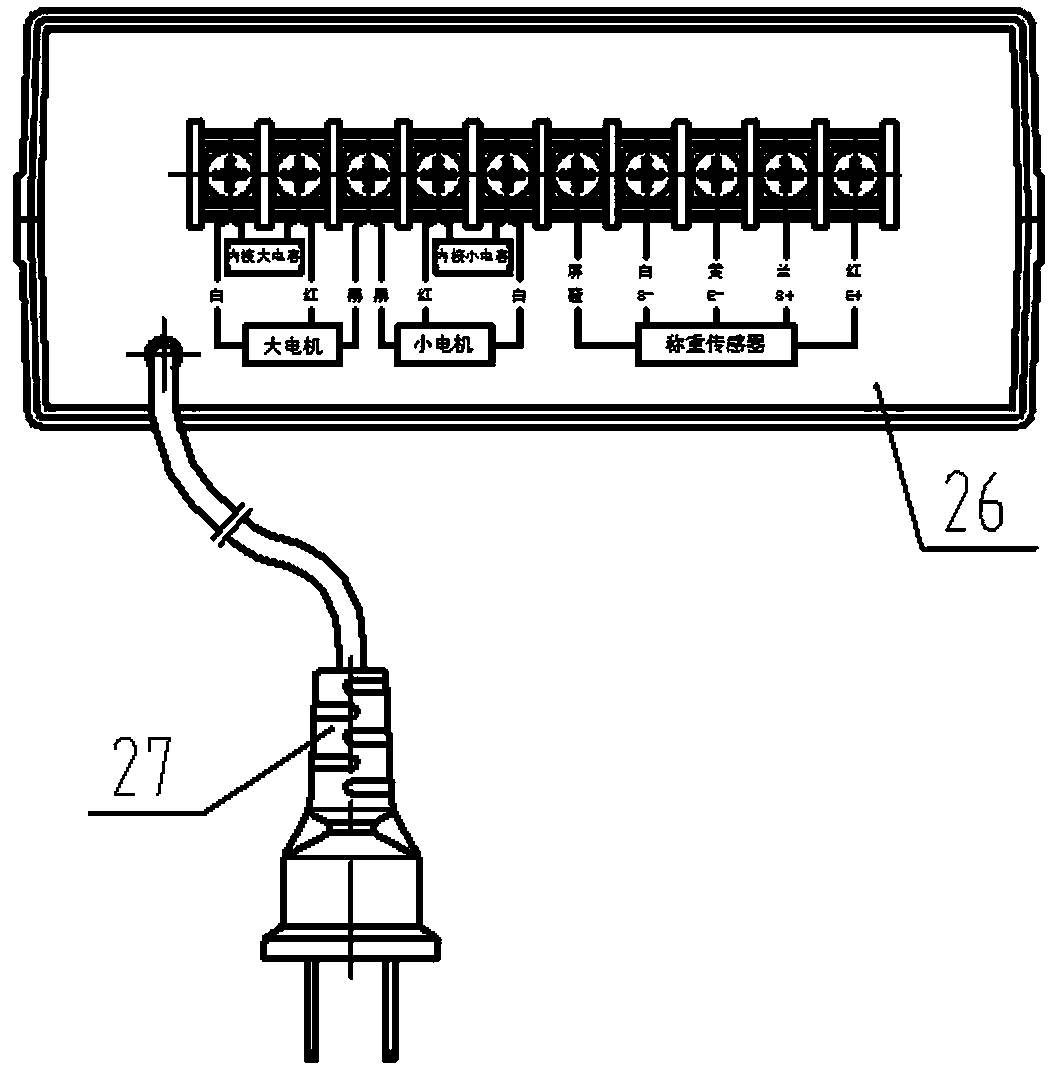

Intelligent digital display stepless speed regulation controller for feeder

InactiveCN103929098AMeet needsEliminate demandPisciculture and aquariaElectric motor speed/torque regulationMicrocomputerMicrocontroller

The invention discloses an intelligent digital display stepless speed regulation controller for a feeder. The intelligent digital display stepless speed regulation controller is formed by connecting a safety circuit (1), a reset switch (2), a self-locking circuit (4), a transformer (15) T1, a rectification voltage-stabilizing circuit (5), a power source indicating circuit (6), an input setting circuit (7), a relay J1 driving protective circuit (14), a relay J2 driving circuit protective circuit (9), a material fling indicating circuit (8), a relay J1, a relay J2, a speed regulation driving output circuit (10), an output protective circuit (11), an emergency switch (3), a wiring terminal (12), a driving display circuit (13) and a zero cross detection circuit (17) in an electric-loop mode. According to the intelligent digital display stepless speed regulation controller, a single chip microcomputer with an AD interface is adopted as a core control component, input setting is easy, and the intelligent digital display stepless speed regulation controller has the advantages of being good in control performance, stepless in speed regulation, synchronous in output, high in working reliability, and simple in structure, and facilitating production and adjusting.

Owner:JIANGSU HENGSHENYANG MACHINERY

DC bus clamp circuit to prevent over voltage failure of adjustable speed drives

ActiveUS20100177452A1Reduced power ratingReducing electrical transientAC motor controlElectric motor controlOvervoltageCapacitance

The present invention relates to a protective circuit to provide over voltage protection for an ASD. The protective circuit provides the benefits of fewer components with lower power ratings than existing protective circuits. The protective circuit may be incorporated directly in the ASD for continuous protection or mounted externally and connected to the ASD under operating conditions that require the circuit. This flexibility for mounting the protective circuit allows the capacitor of the protective circuit to be sized either in relation to capacitive elements on the DC bus within the ASD or according to external capacitance observed at the output of the ASD. In addition, the circuit is only operative during an overvoltage condition allowing for power ratings lower than would be required for continuous operation.

Owner:ROCKWELL AUTOMATION TECH

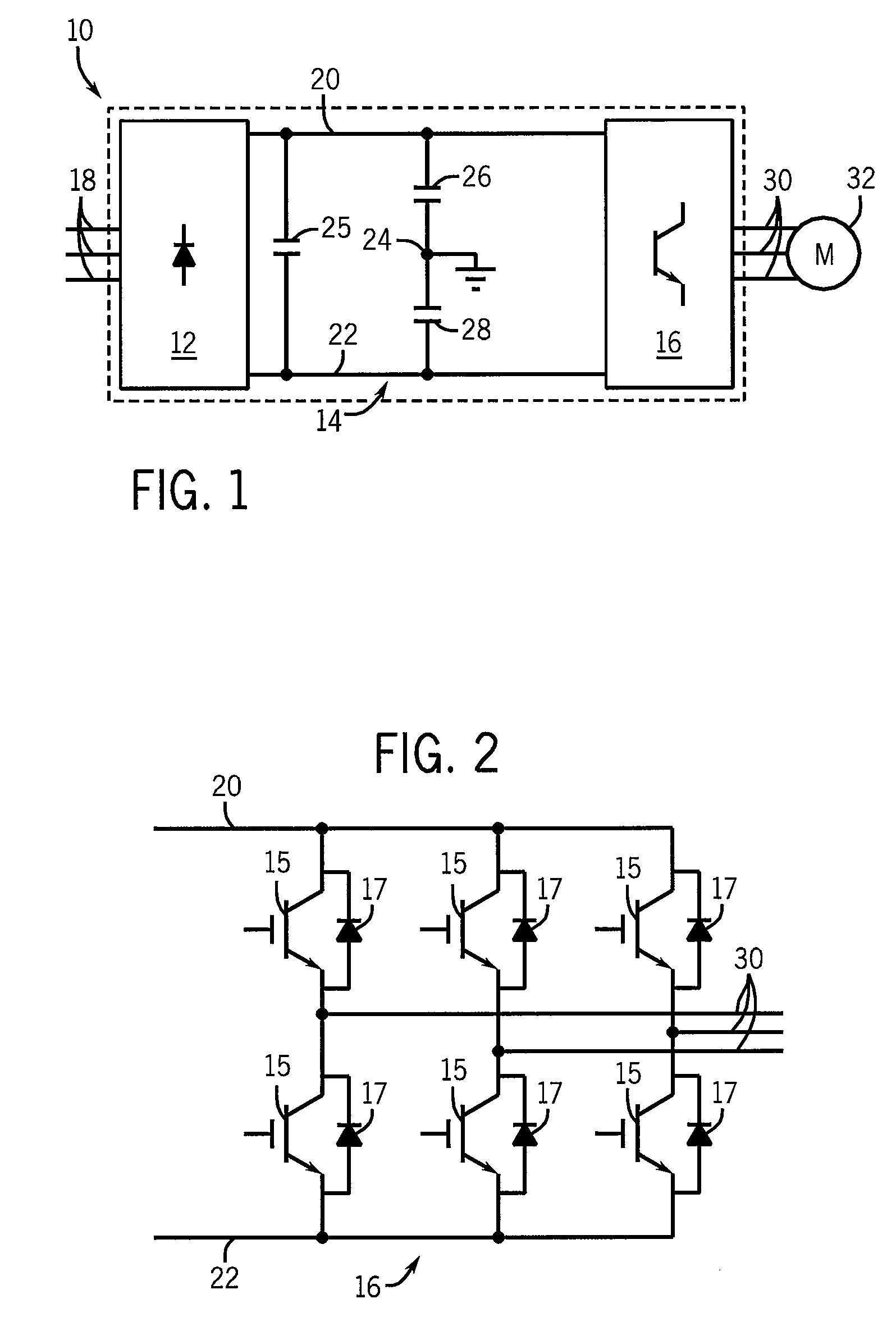

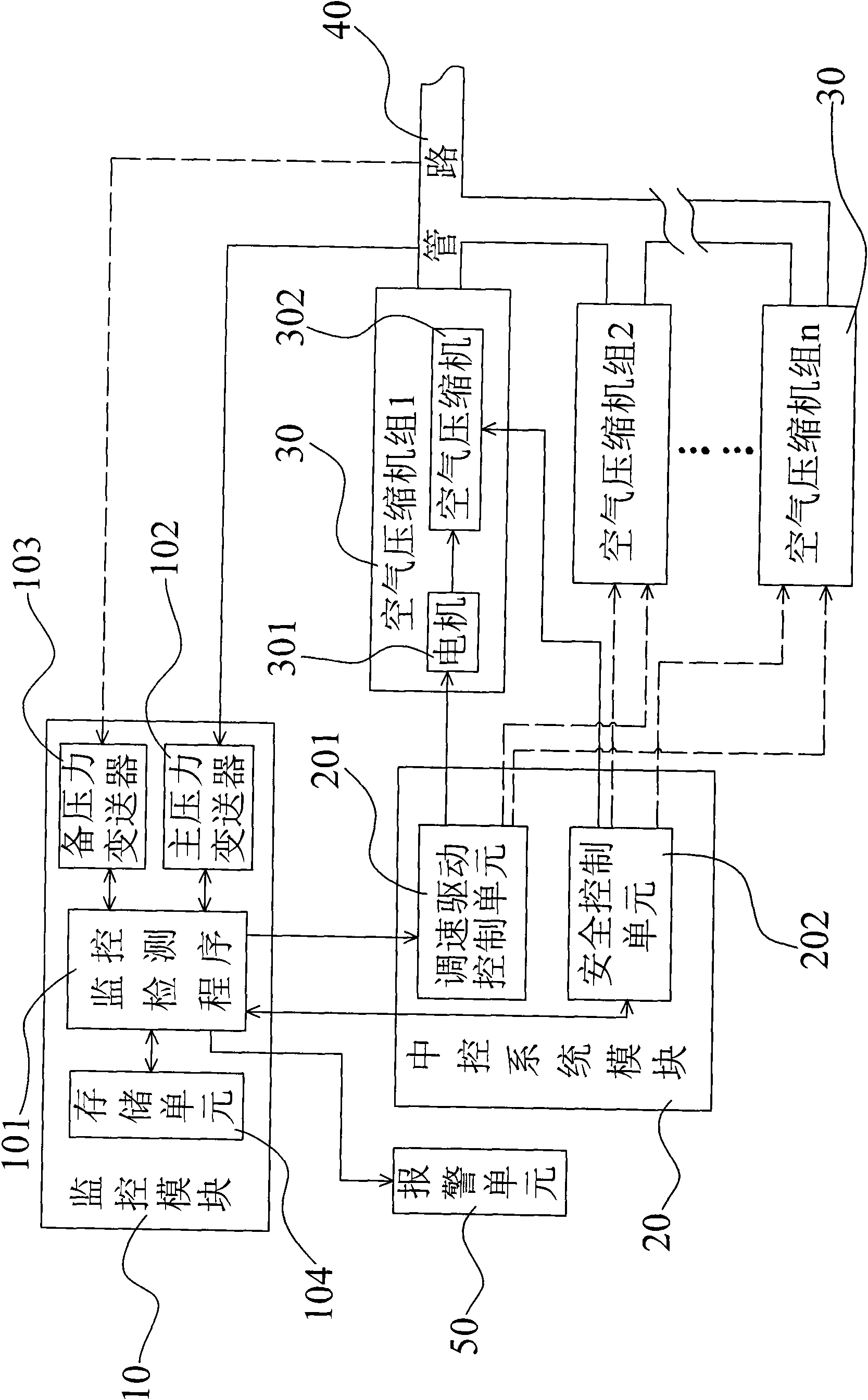

System and method for energy-saving control of compressor unit

InactiveCN101526080ARealize the purpose of energy savingRealize multiple air compressor units to achieve energy savingProgramme controlComputer controlControl systemSafety control

The invention discloses a system for energy-saving control of an air compressor unit, which comprises a monitor module, a central control system module and an air compressor unit, wherein the monitor module comprises a main pressure transmitter, a spare pressure transmitter, a monitoring detection program and a storage unit; the central system module is connected with the monitor module and the air compressor unit respectively and comprises a safety control unit and a regulation speed drive control unit; and the air compressor unit consists of a motor and an air compressor, the motor is connected with the regulation speed drive control unit and the air compressor respectively, and the air compressor is connected with the safety control unit and a pipeline. The monitor module detects the pressure in the pipeline and processes data detected in time to allow the central system module to regulate and control the air compressor unit according to pressure trend analysis. The invention has the advantages of diagnosing pressure change trend and making quick and timely response to possible pressure loss, thereby saving energy.

Owner:BEIJING FENGDY S&T

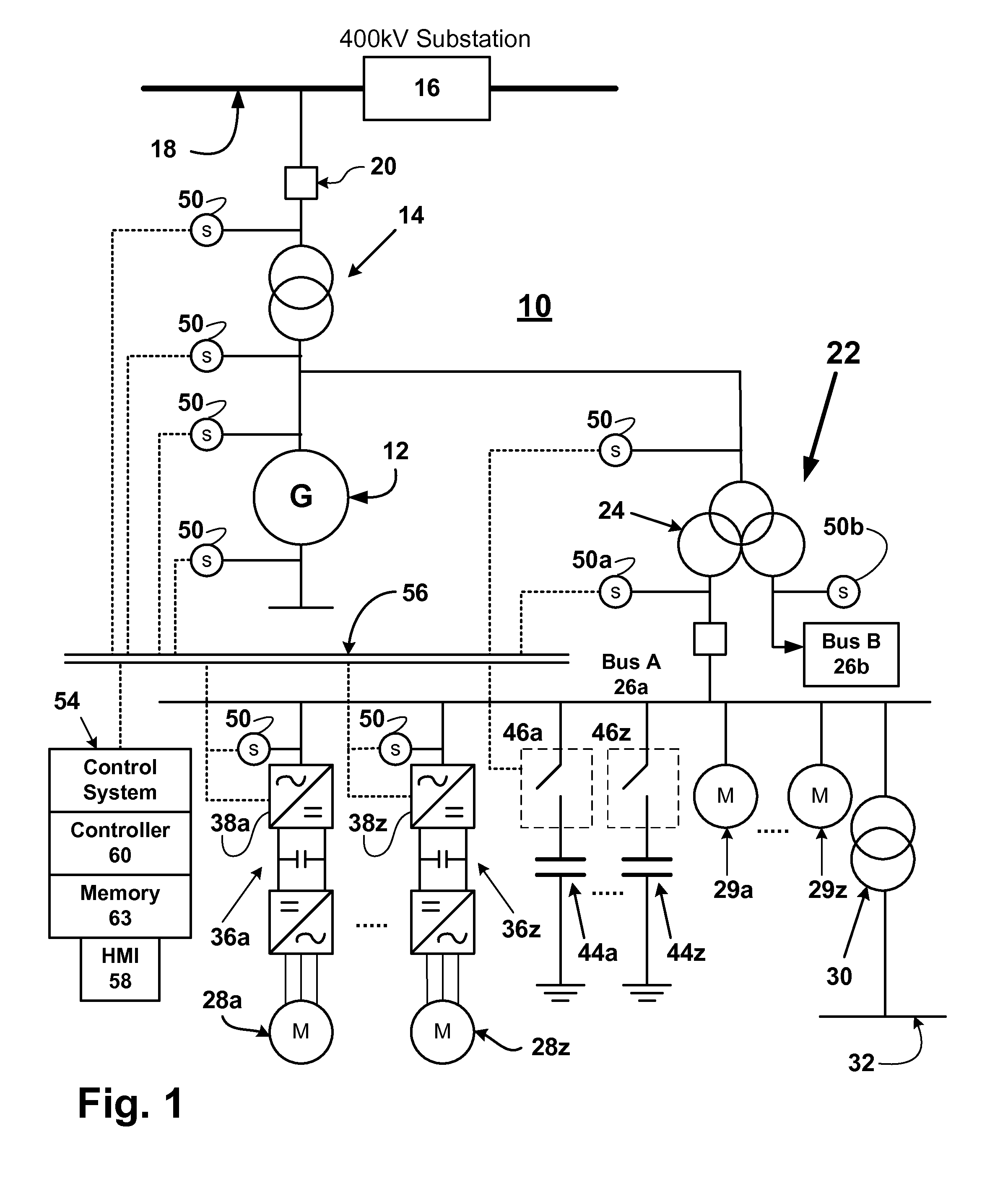

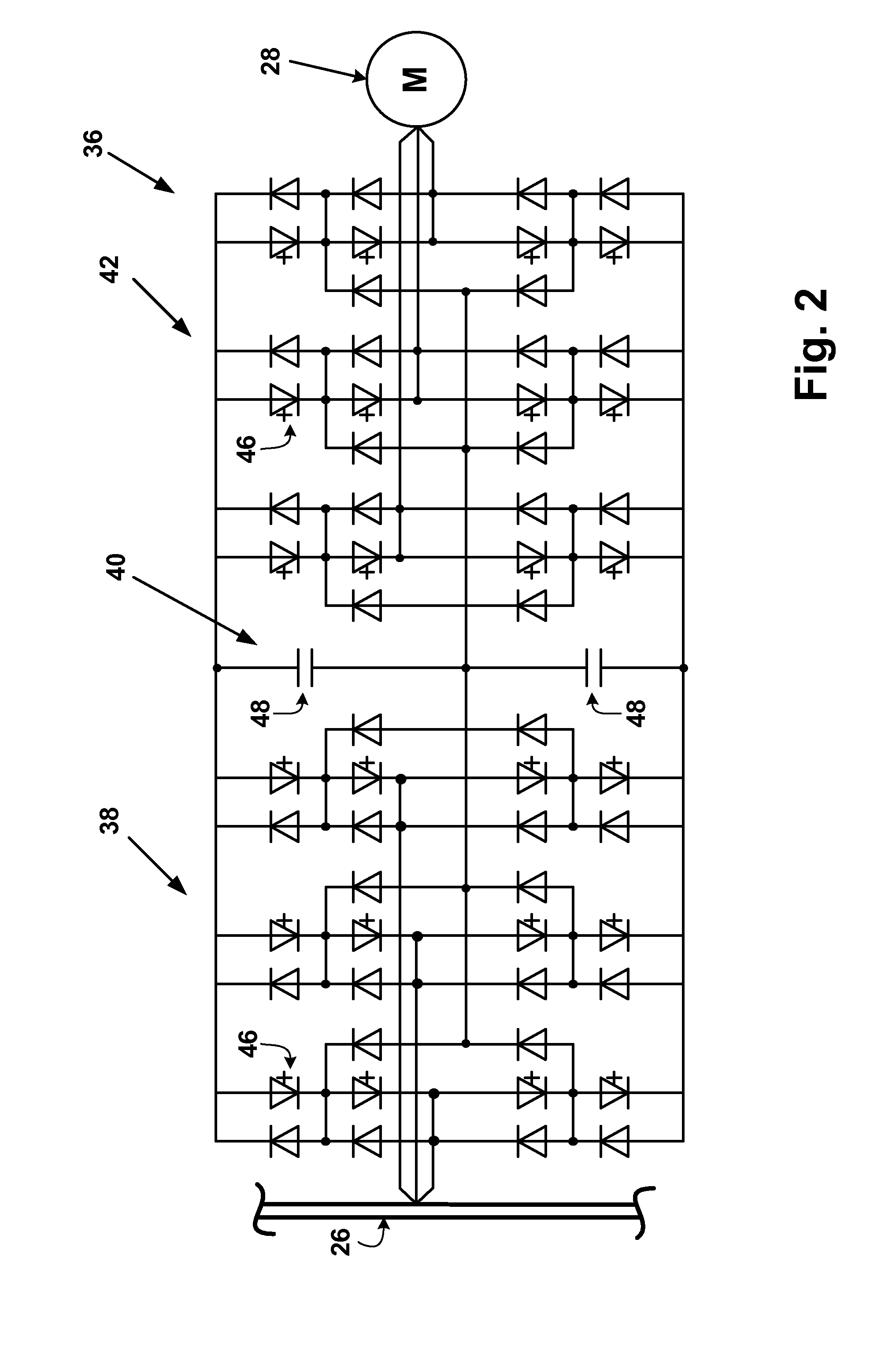

Method and apparatus for improving the operation of an auxiliary power system of a thermal power plant

Apparatus and method for controlling power in an auxiliary power system of a thermal power plant having a generator and one or more auxiliary buses. The apparatus includes adjustable speed drives and capacitance sources for connection to the one or more auxiliary buses and sensors for measuring voltage and reactive power on the one or more auxiliary buses. A controller is operable to control the adjustable speed drives and the capacitance sources to control the power factor of the auxiliary power system, while providing steady state voltage regulation and dynamic voltage support.

Owner:ABB RES LTD

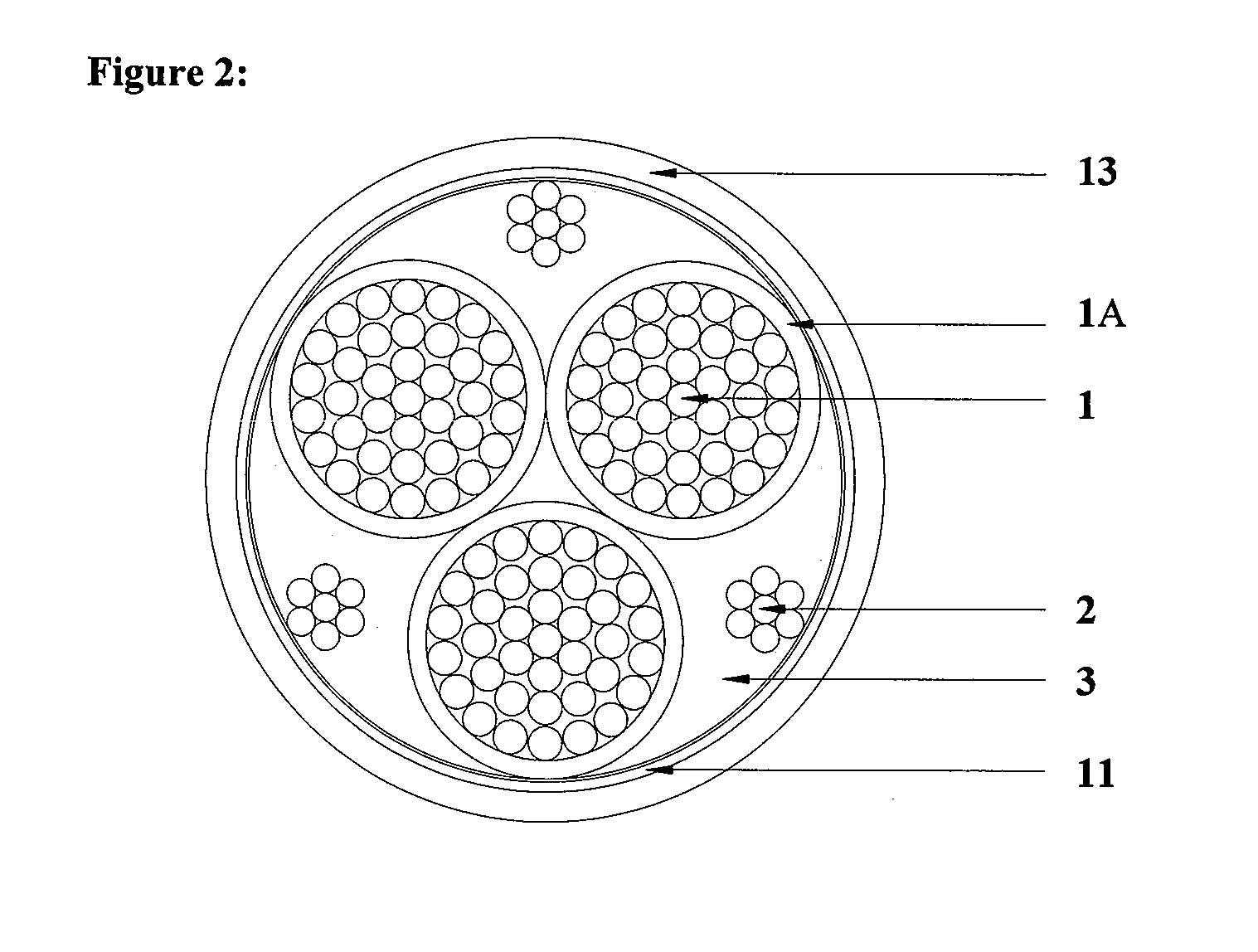

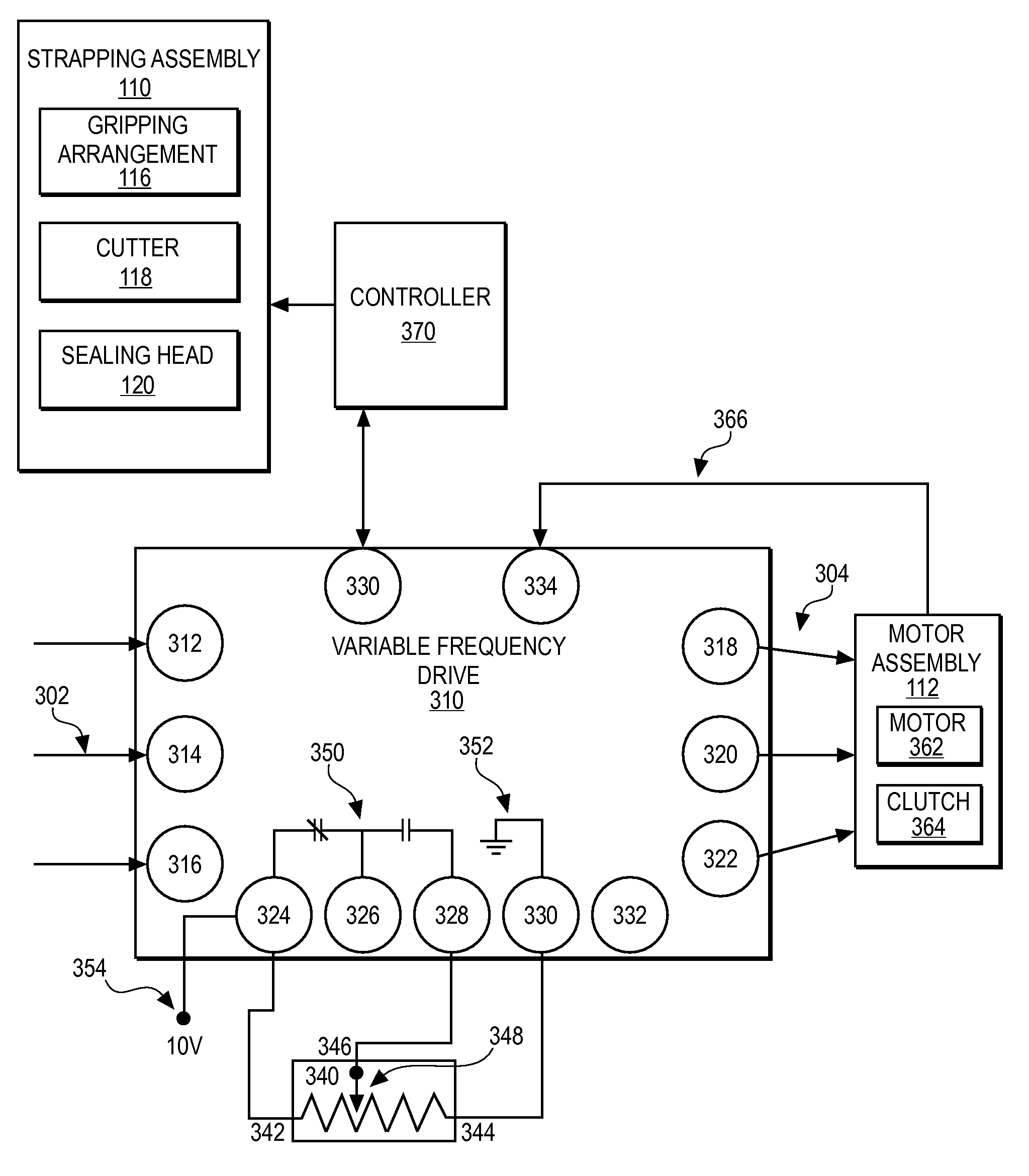

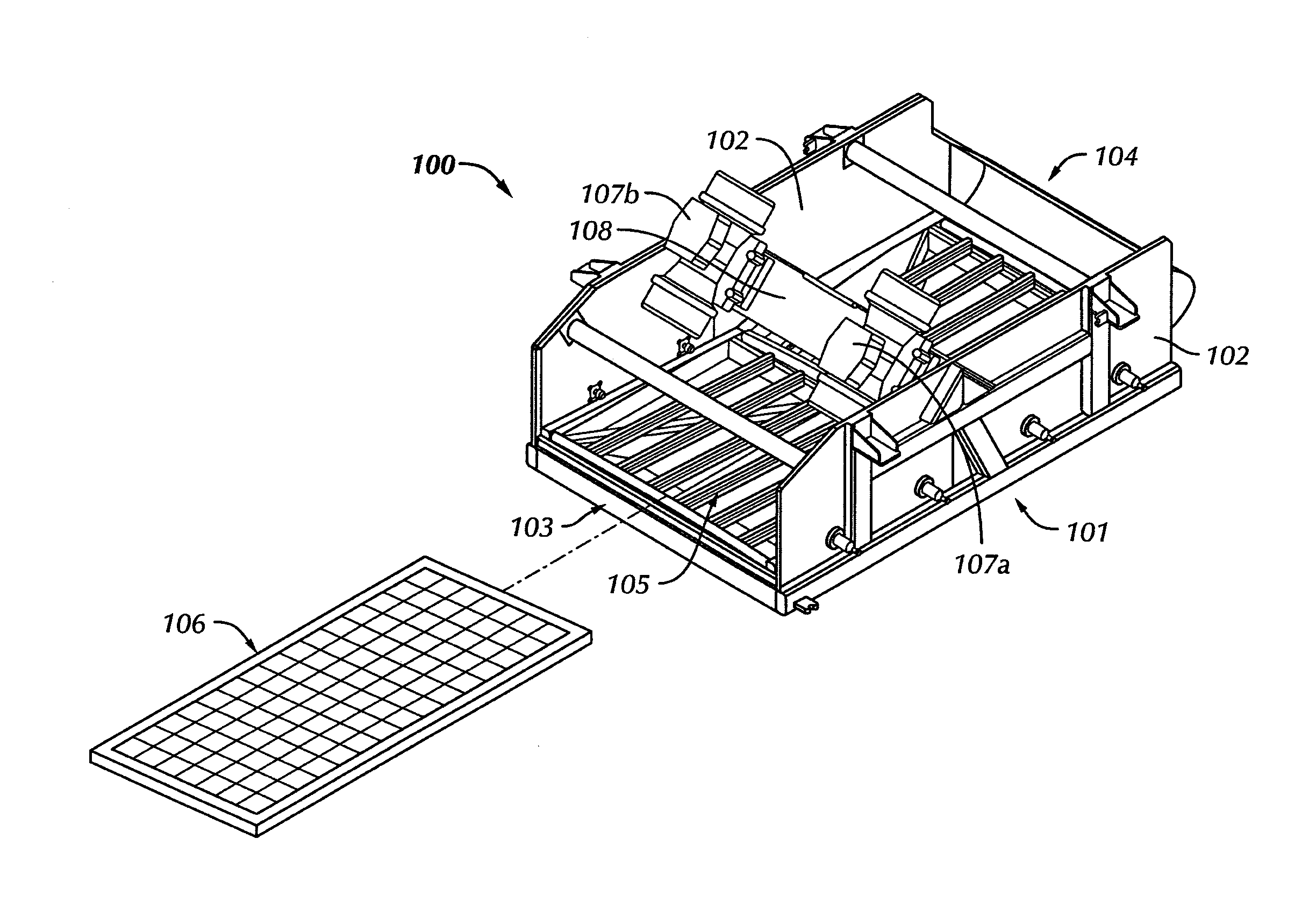

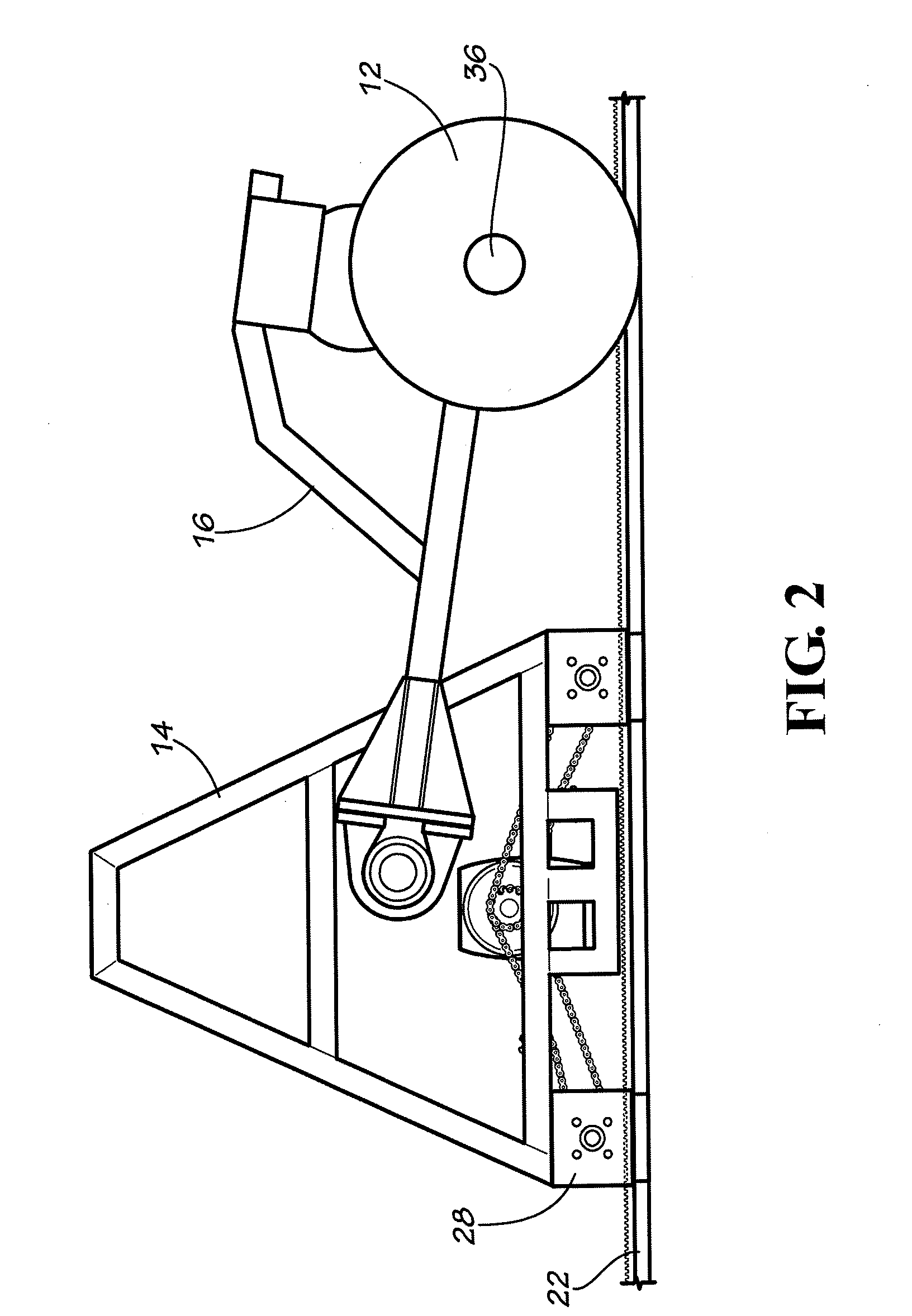

Tension control system and method for tensioning a strapping material around a load in a strapping machine

A strapping machine is provided to feed a strap around a load, position, tension and seal the strap around the load. The strapping machine includes a surface to support the load in the strapping machine; a strap chute to carry a strap around the load and release the strap from the strap chute; a motor assembly to convey the strap around the strap chute, retract the strap material around the load, and tension the strap around the load; and an adjustable speed drive capable of receiving a first reference signal and a second reference signal, and configured to actuate the motor assembly to apply a first amount of torque to the strap when receiving the first reference signal and to apply a second amount of torque to the strap when receiving the second reference signal. The strapping machine also includes a controller configured to operate the adjustable speed drive in a first mode while conveying the strap around the strap chute and retracting the strap material around the load, and a second mode while tensioning the strap around the load. In the first mode, the adjustable speed drive actuate the motor assembly to apply the first amount of torque to the strap, and in the second mode, the adjustable speed drive actuates the motor assembly to apply the second amount of torque to the strap.

Owner:SIGNODE IND GRP

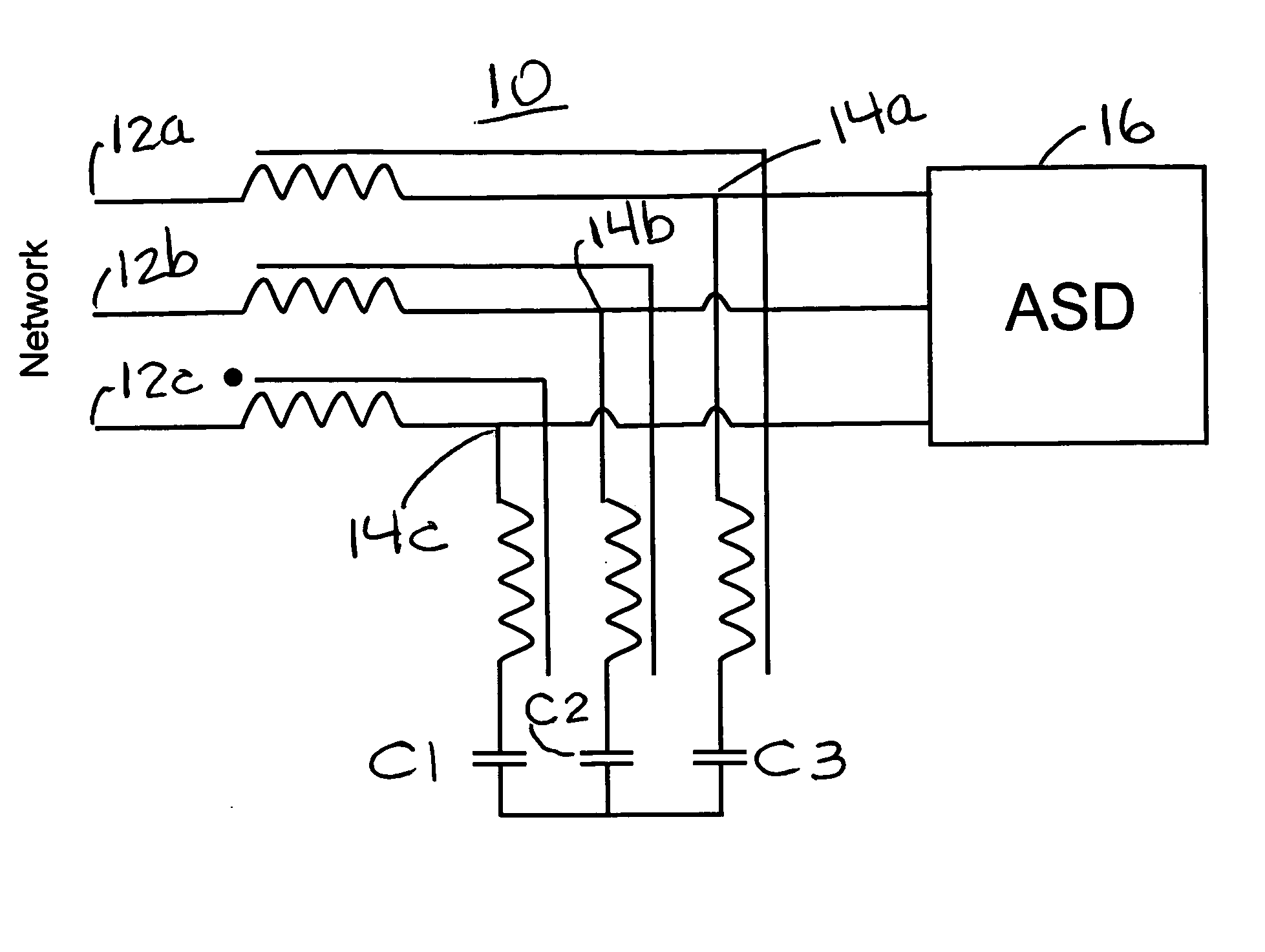

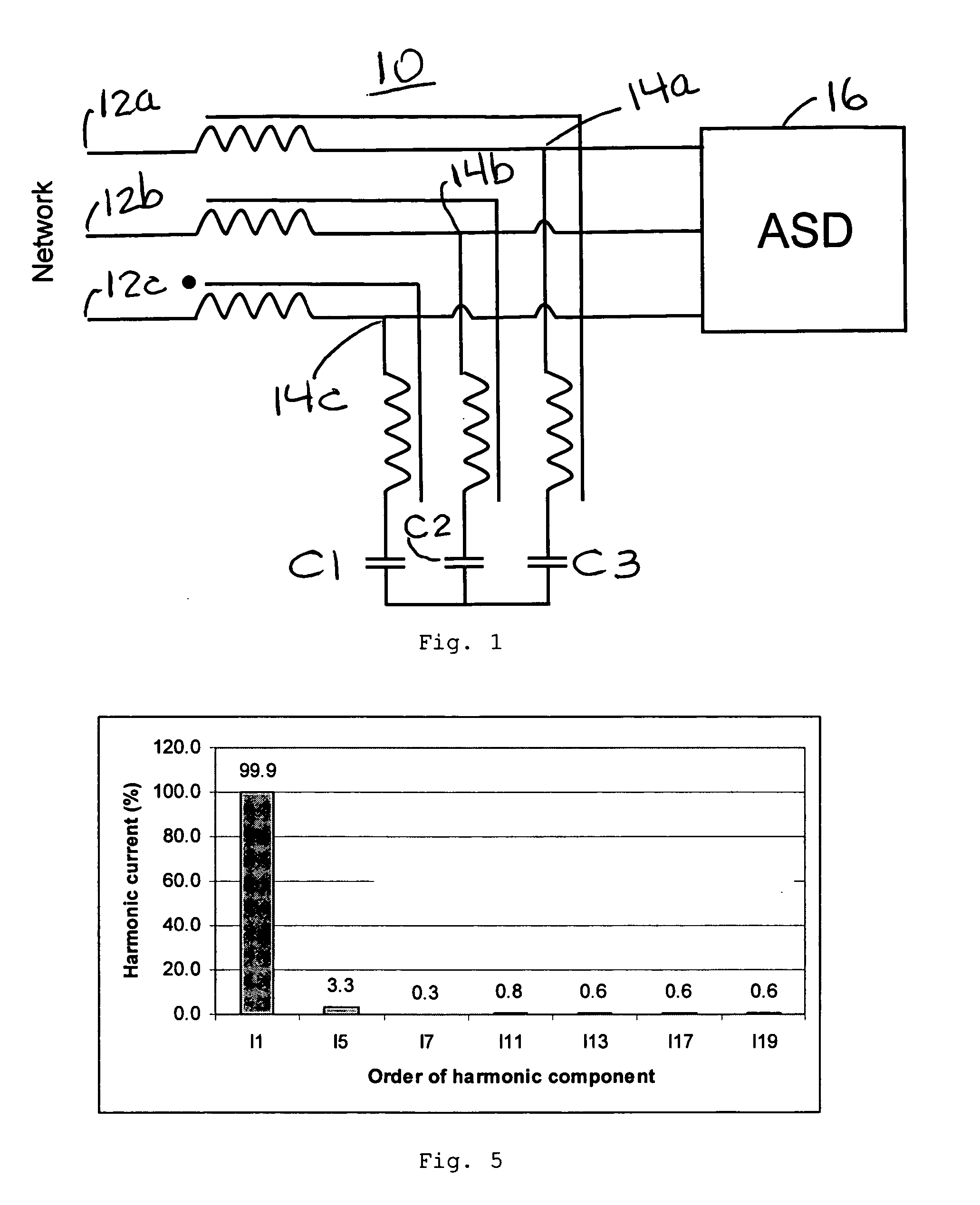

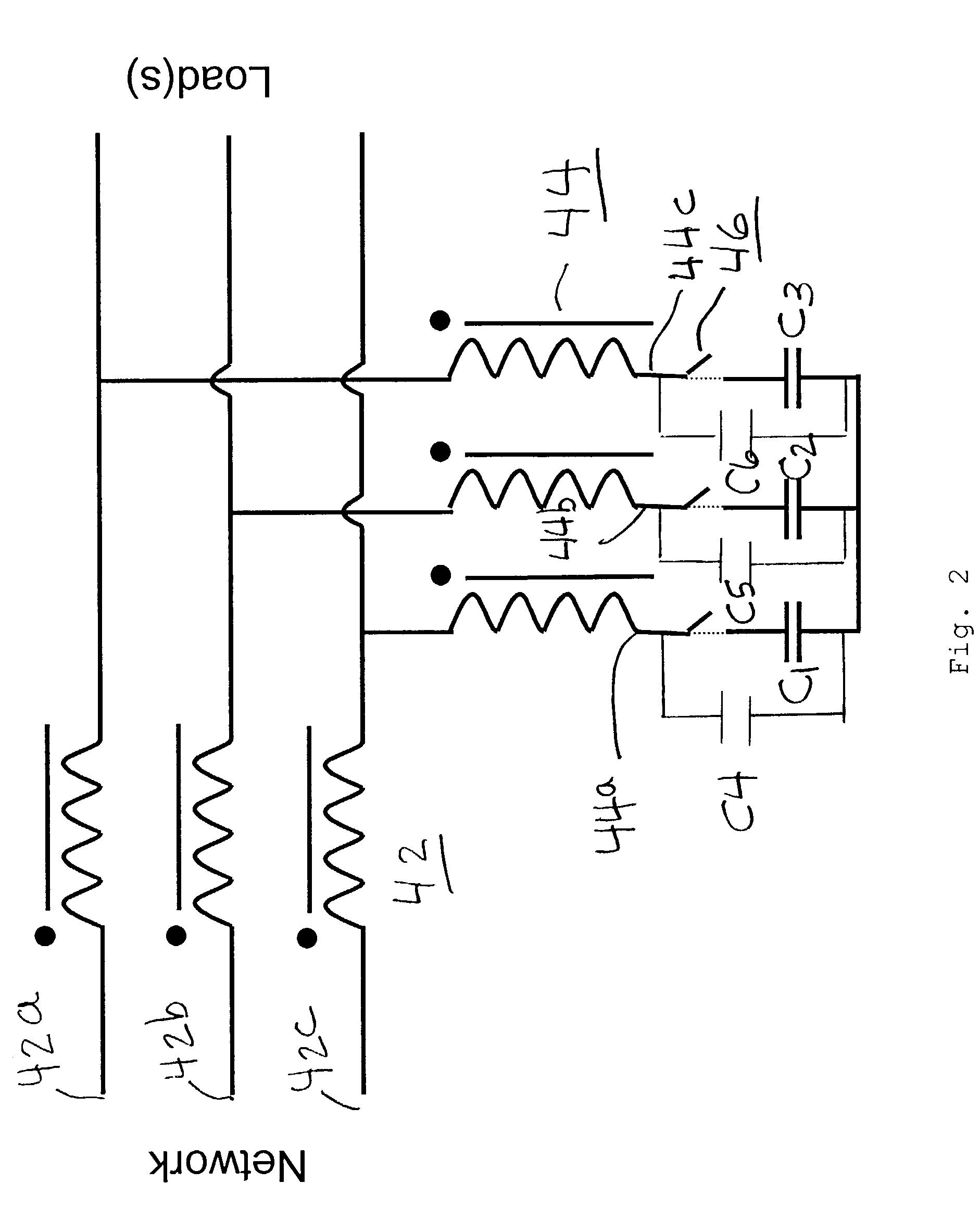

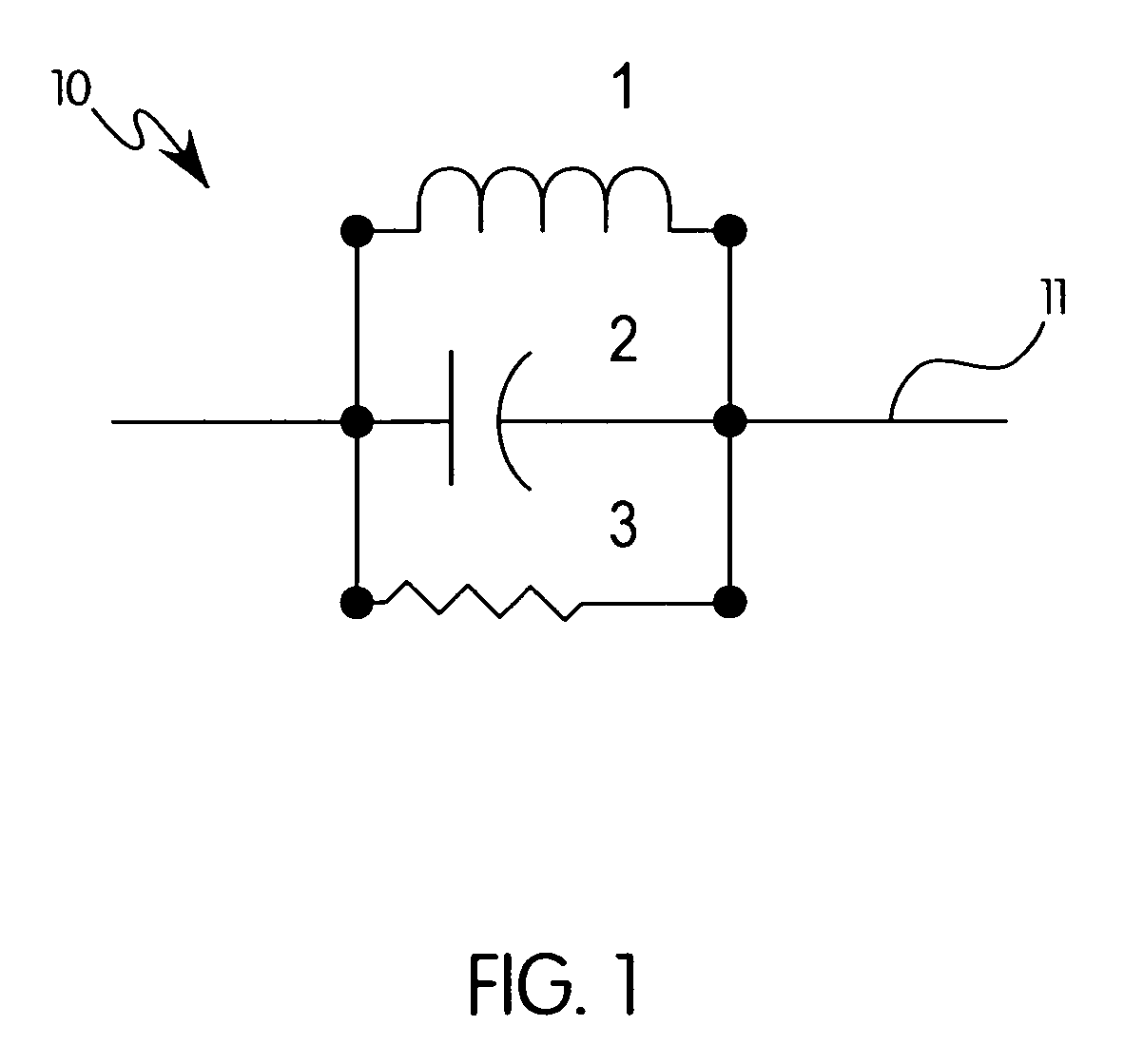

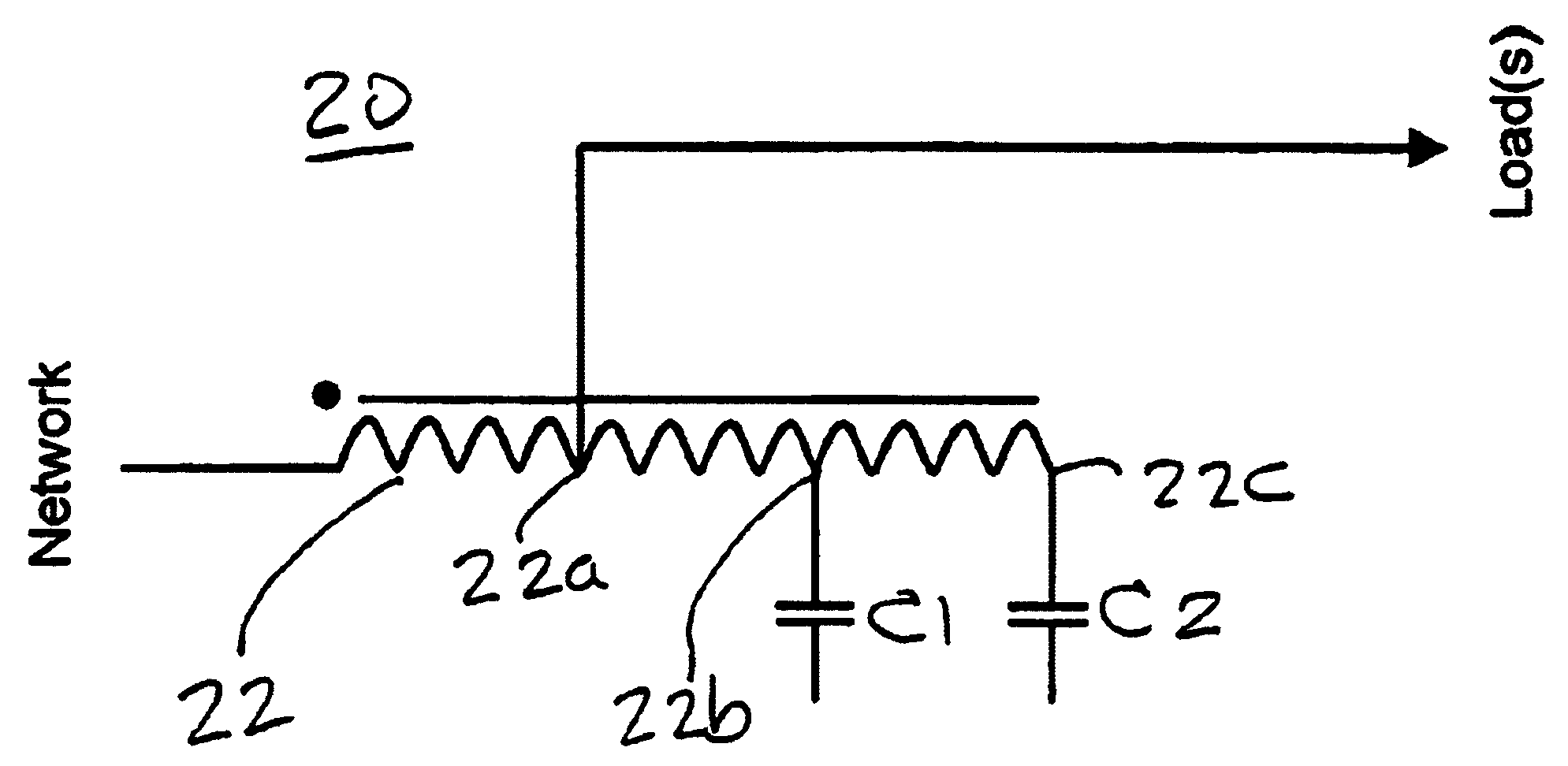

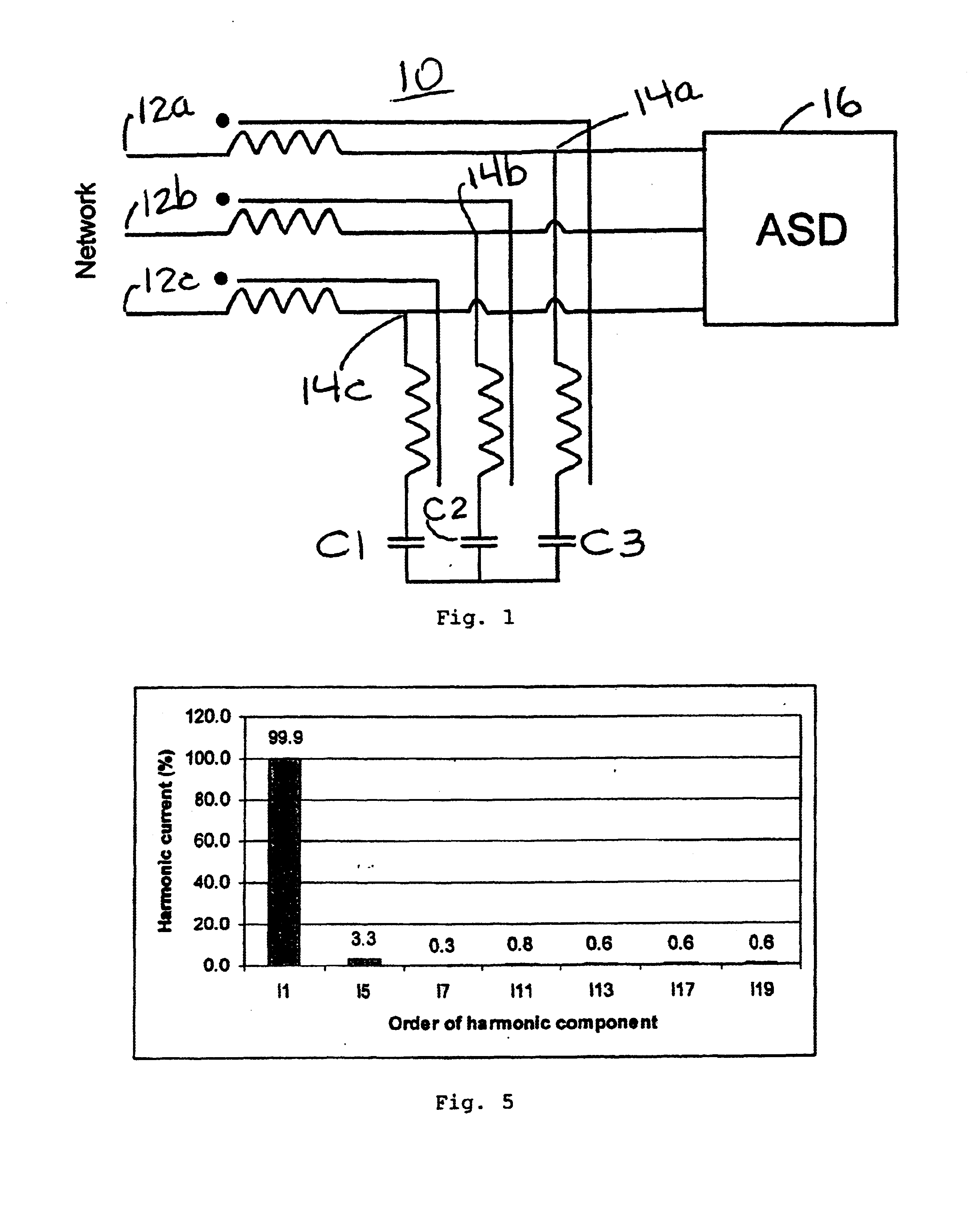

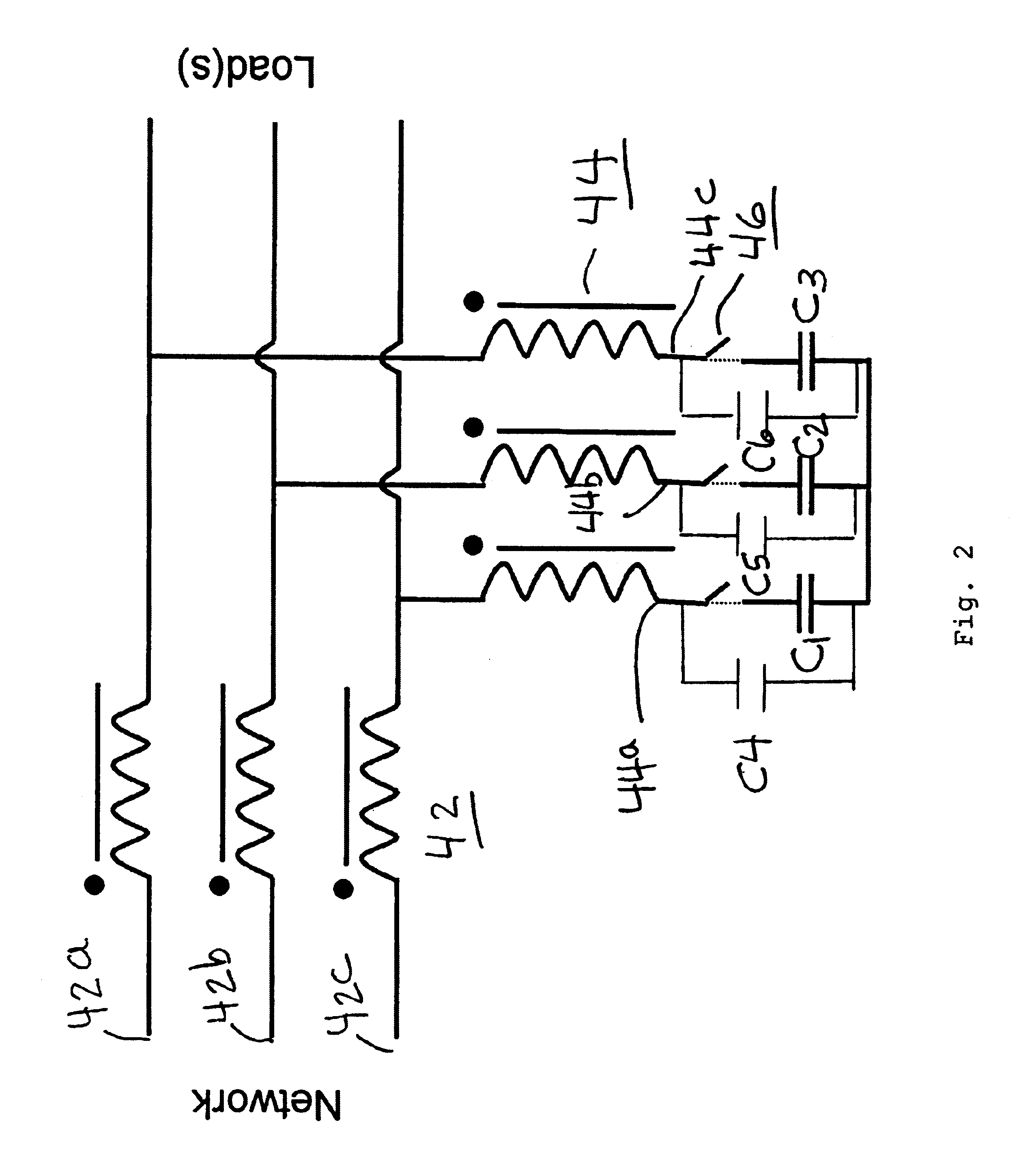

Harmonic mitigating filter

InactiveUS20040066253A1Multiple-port networksCurrent interference reductionHarmonicDistribution system

A filter for mitigating harmonics in an electrical distribution system. In one embodiment the filter has one winding that is connected to the power distribution system which may be a three phase system and capacitors are connected to other end of the winding in either a delta or y-connection. There is one tapping on the winding for connection to a load which may an adjustable speed drive. In another embodiment the filter has two or more separate reactors. In either embodiment a switch may be in series with the capacitors and capacitors may be connected in parallel with the series combination of switch and capacitors.

Owner:ABB (SCHWEIZ) AG

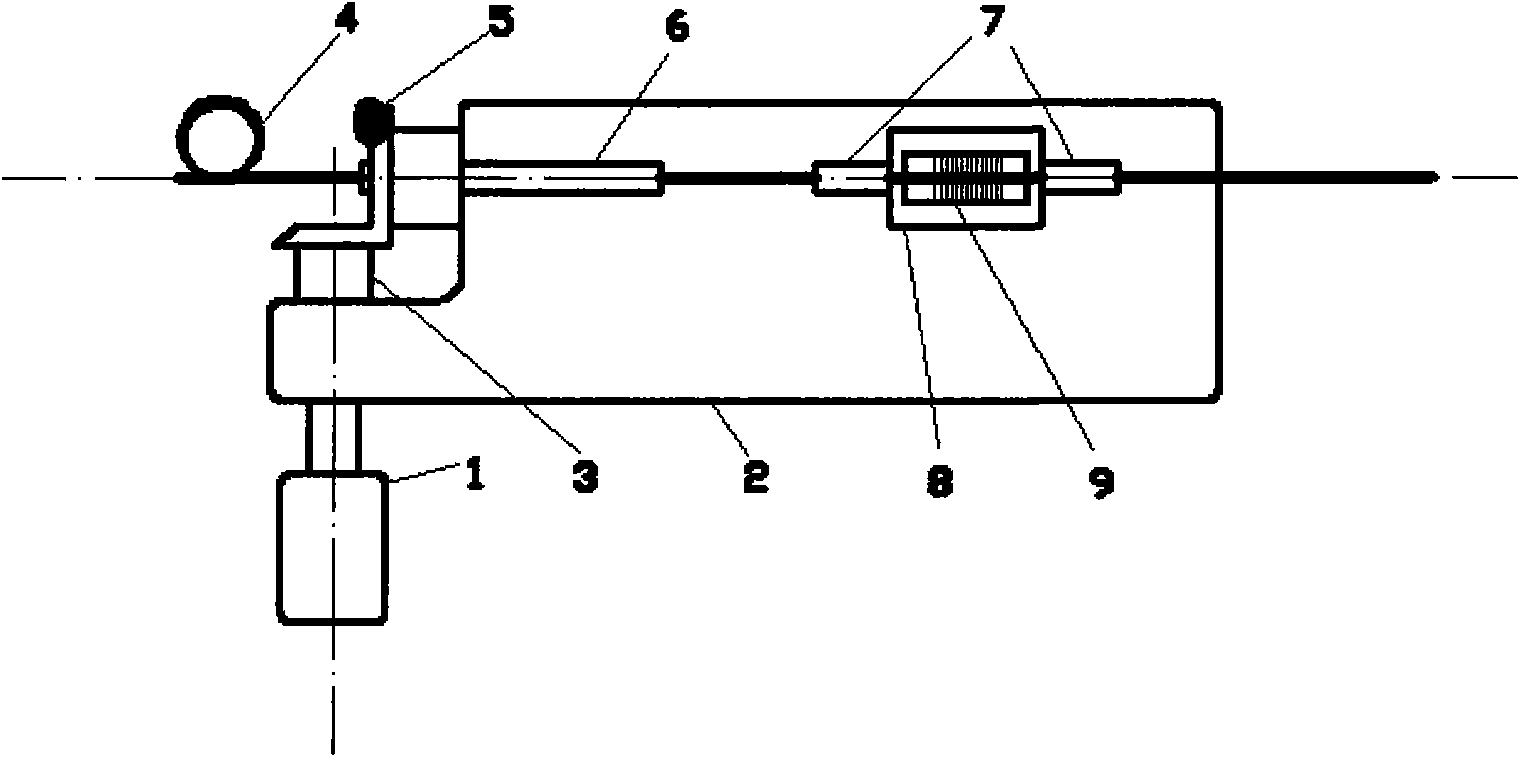

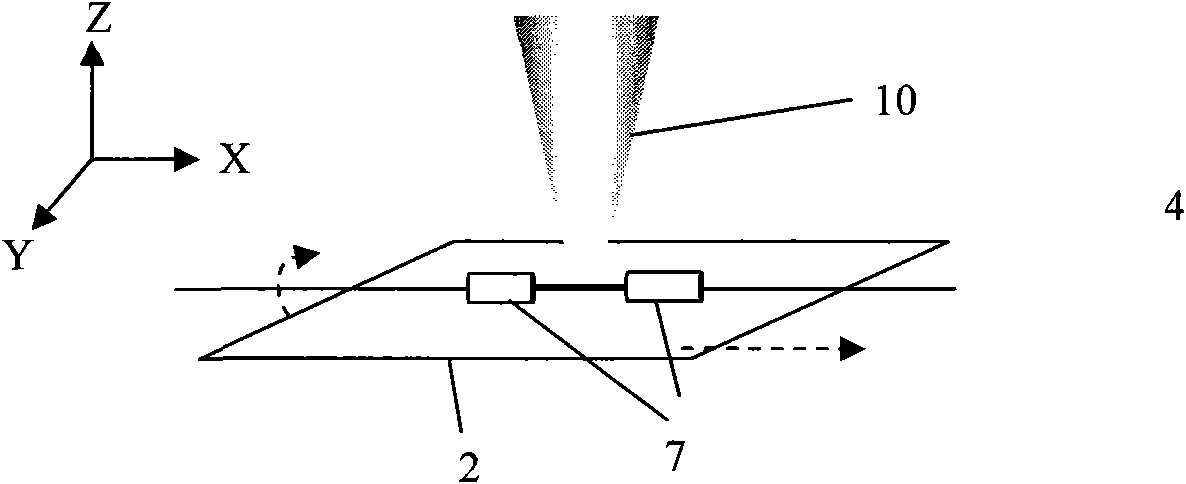

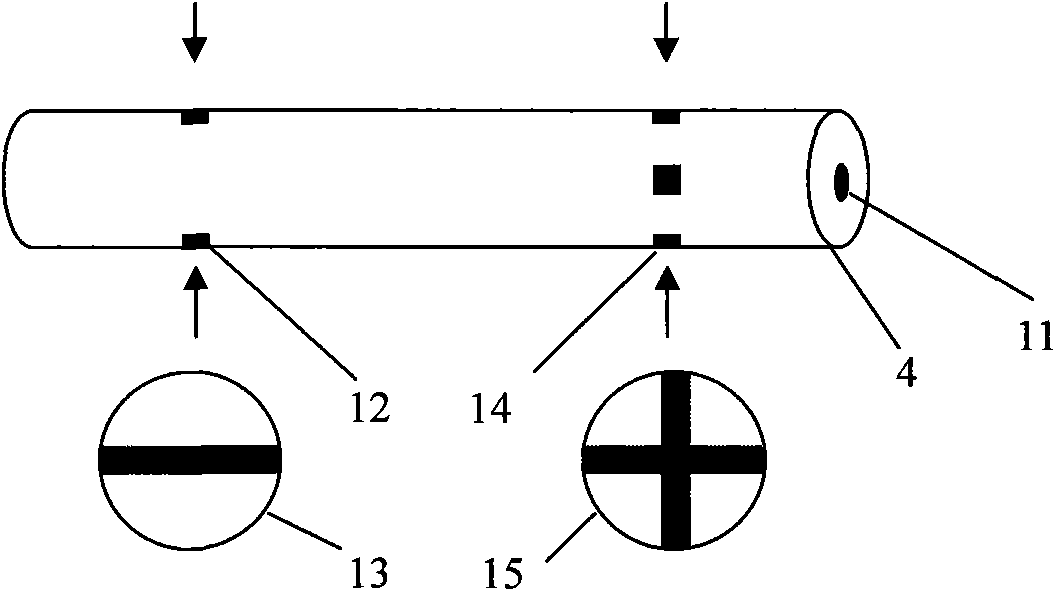

Method and device for microprocessing rotary optical fiber

InactiveCN101879659AEasy to assembleEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesMicrometerProcess region

The invention provides a method and a device for microprocessing rotary optical fiber. An adjustable-speed driving motor of the device arranged on a base drives an optical fiber clamp to rotate through a variable-speed phase changer, the optical fiber simultaneously passes through the optical fiber clamp and an optical fiber positioning device, the optical fiber clamp drives the clamped optical fiber to rotate, the processed region of the optical fiber is positioned in the center of the optical fiber positioning device, and is exposed to an external processing source through a processing window, and the processing source is laser or focused ion beams. The deice can control the rotation drifting of the rotary optical fiber within a range of 2 micrometers, has the characteristics of simple assembly, easy operation, high precision and low drifting, and can be used for microprocessing under a high-precision microscope. The invention belongs to the field of laser microprocessing.

Owner:WUHAN UNIV OF TECH

Adjustable speed drive with integrated solid-state circuit breaker and method of operation thereof

A power conversion circuit having a solid-state circuit breaker integrated therein is disclosed. With a disconnect switch between a utility source and the power conversion apparatus described for meeting UL489, the power conversion circuit includes an input connectable to an AC source, a rectifier circuit connected to the input to convert an AC power input to a DC power, and a DC link coupled to the rectifier circuit to receive the DC power therefrom. The rectifier circuit comprises a plurality of phase legs each including thereon an upper switching unit and a lower switching unit, wherein at least one of the upper and lower switching units on each phase leg comprises a bi-directional switching unit that selectively controls current and withstands voltage in both directions, so as to provide a circuit breaking capability that selectively interrupts current flow through the rectifier circuit, while maintaining original power conversion functionalities.

Owner:EATON INTELLIGENT POWER LIMITED

System and method for detecting phase loss and diagnosing DC link capacitor health in an adjustable speed drive

A system and method for detecting input phase loss in an adjustable speed drive (ASD) includes an input unit to detect operating data from the ASD. The operating data includes a DC link current of the ASD. The system also includes a state observer that is adapted to receive the operating data from the input unit and extract a DC link capacitor current of the ASD using the DC link current. The system also includes a controller programmed to compare the extracted DC link capacitor current to a predetermined fault range and generate a fault indication of an input phase loss if the extracted DC link capacitor current is within the predefined fault range. The controller is also programmed to calculate an estimated lifespan of the DC link capacitor based on the extracted DC link capacitor current.

Owner:EATON INTELLIGENT POWER LTD

Multiple Motors Driving a Single Compressor String

ActiveUS20100135825A1Improve electricity efficiencySave energySolidificationLiquefactionMotor driveElectric machine

Systems and methods of driving a compressor are provided. The compressor can be driven by multiple electric motors, which can be controlled by an adjustable speed drive (ASD) to increase efficiency. A torque controller may also be included.

Owner:KELLOGG BROWN & ROOT LLC

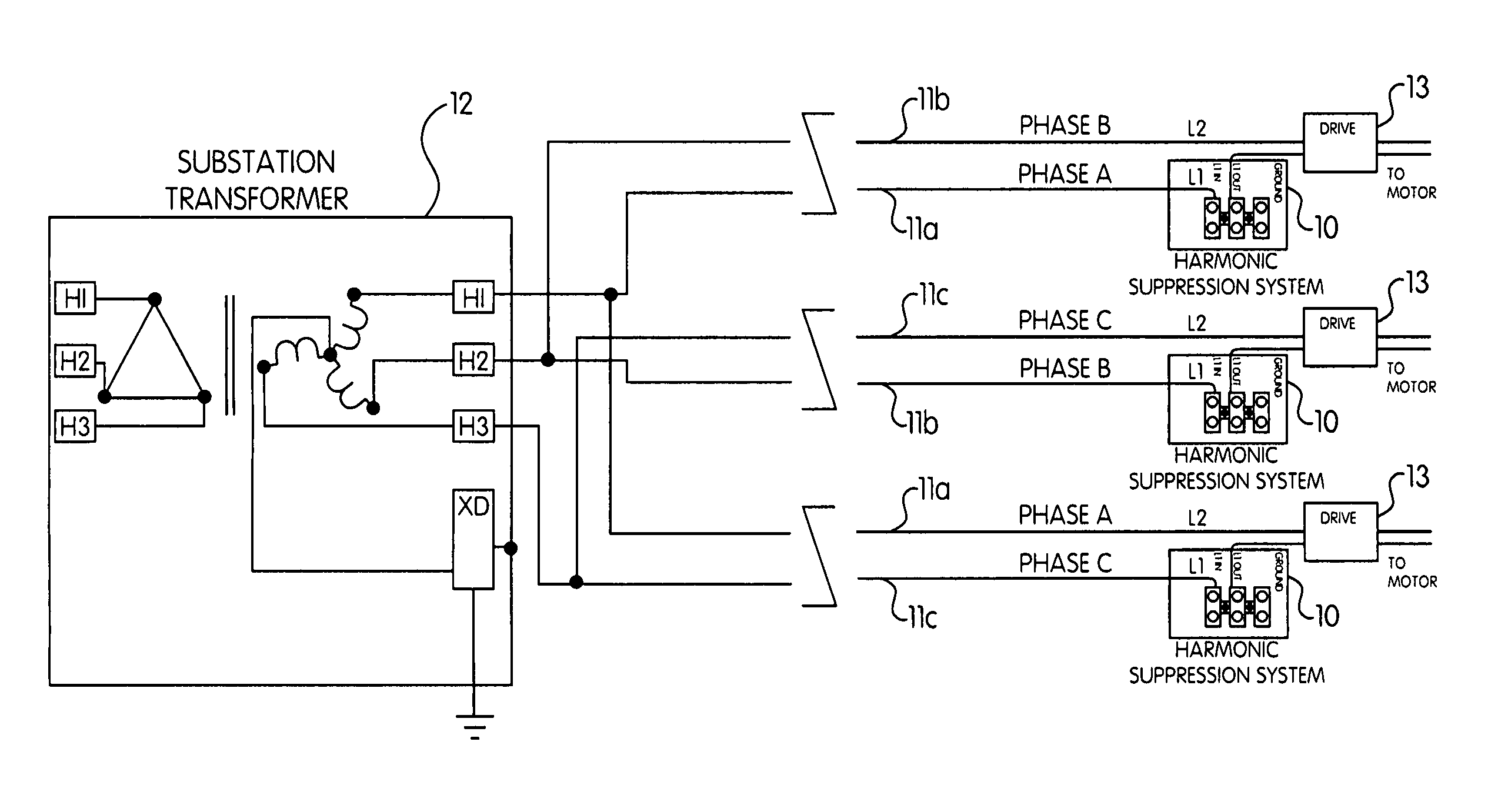

Electrical harmonic suppression system and enclosure for the same

ActiveUS20080211315A1Eliminate harmonic currentInhibition formationSubstation/switching arrangement detailsDc circuit to reduce harmonics/ripplesElectricityThird harmonic

In an electrical distribution system for supplying power from an AC source to an adjustable-speed drive connected in a single-phase manner, a device for substantially eliminating harmonic currents in the supply lines of said system. The device includes a completely-passive parallel resonant circuit having three passive electrical branches connected in parallel and also having an almost infinite impendence at a third harmonic frequency of a fundamental frequency of said AC source to prevent the formation of only said third harmonic frequency so that there is no third harmonic current to remove or dissipate as heat. The three passive electrical branches comprise a first branch consisting of a capacitor, a second branch consisting of a reactor, and a third branch consisting of a resistor. The parallel resonant circuit is electrically connected to at least one supply line.

Owner:JEFFERSON ELECTRIC LLC

System and method for tensioning

ActiveUS20080072539A1Binding material applicationPackaging automatic controlEngineeringAdjustable-speed drive

A strapping machine is provided to feed a strap around a load, position, tension and seal the strap around the load. The strapping machine includes a surface to support the load in the strapping machine; a strap chute to carry a strap around the load and release the strap from the strap chute; a motor assembly to convey the strap around the strap chute, retract the strap material around the load, and tension the strap around the load; and an adjustable speed drive capable of receiving a first reference signal and a second reference signal, and configured to actuate the motor assembly to apply a first amount of torque to the strap when receiving the first reference signal and to apply a second amount of torque to the strap when receiving the second reference signal. The strapping machine also includes a controller configured to operate the adjustable speed drive in a first mode while conveying the strap around the strap chute and retracting the strap material around the load, and a second mode while tensioning the strap around the load. In the first mode, the adjustable speed drive actuate the motor assembly to apply the first amount of torque to the strap, and in the second mode, the adjustable speed drive actuates the motor assembly to apply the second amount of torque to the strap.

Owner:SIGNODE IND GRP

Methods to increase force and change vibratory separator motion

A vibratory separator including a frame, a basket disposed on the frame, and a motor configured to impart a vibratory motion to the basket. Additionally, the vibratory separator includes an adjustable speed drive operatively coupled to the motor to control a vibratory motion imparted to the basket. Also, a method of processing drilling waste including generating a first vibratory motion on a vibratory separator using at least one motor, and adjusting the first vibratory motion using an adjustable speed drive to generate a second vibratory motion.

Owner:MI

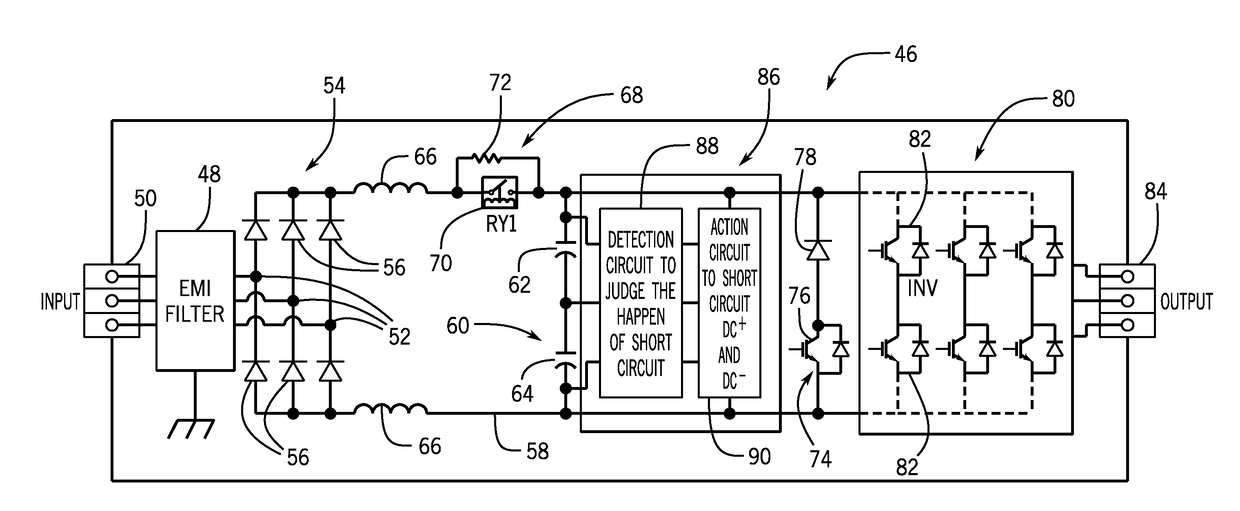

System and method for capacitor fault energy interruption in adjustable speed drives

ActiveUS20180062557A1Control damageAC motor controlElectric motor controlCapacitor voltageAdjustable-speed drive

An adjustable speed drive (ASD) circuit includes a rectifier bridge to convert an AC power input to a DC power, a DC link coupled to the rectifier bridge to receive the DC power, a DC link capacitor bank comprising at least first and second capacitors connected to the DC link, each capacitor having a capacitor voltage thereacross, and a protection circuit including a detection circuit configured to detect a short circuit on one or more of the first and second capacitors of the DC link capacitor bank and generate an action signal upon detection of a short circuit on one or more of the first and second capacitors of the DC link capacitor bank. The ASD circuit also includes an action circuit in operable communication with the detection circuit and configured to cause a short circuit across the DC link upon receiving the action signal from the detection circuit.

Owner:EATON INTELLIGENT POWER LTD

Harmonic mitigating filter

A filter for mitigating harmonics in an electrical distribution system. In one embodiment the filter has one winding that is connected to the power distribution system which may be a three phase system and capacitors are connected to other end of the winding in either a delta or y-connection. There is one tapping on the winding for connection to a load which may an adjustable speed drive. In another embodiment the filter has two or more separate reactors. In either embodiment a switch may be in series with the capacitors and capacitors may be connected in parallel with the series combination of switch and capacitors.

Owner:ABB (SCHWEIZ) AG

Methods to increase force and change vibratory separator motion

A vibratory separator including a frame, a basket disposed on the frame, and a motor configured to impart a vibratory motion to the basket. Additionally, the vibratory separator includes an adjustable speed drive operatively coupled to the motor to control a vibratory motion imparted to the basket. Also, a method of processing drilling waste including generating a first vibratory motion on a vibratory separator using at least one motor, and adjusting the first vibratory motion using an adjustable speed drive to generate a second vibratory motion.

Owner:MI

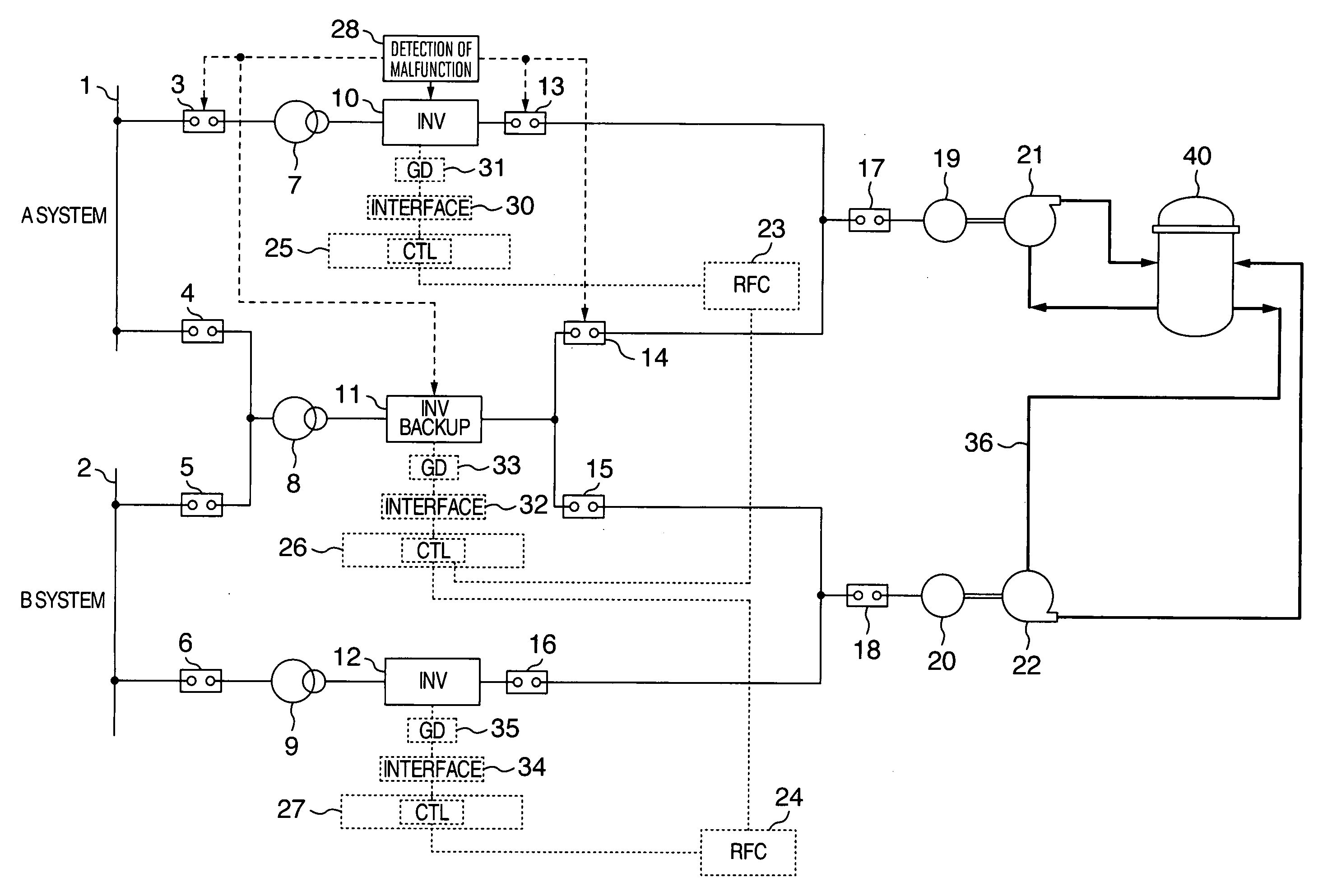

Adjustable speed drive system for primary loop recirculation pump

ActiveUS20060256912A1Guaranteed uptimeRapid and safeSpecific fluid pumpsBatteries circuit arrangementsPower inverterNuclear reactor

An adjustable speed drive system for a primary loop recirculation pump capable of keeping a PLR pump operating even if a single malfunction occurred in a main adjustable speed drive circuit portion. The drive system for the primary loop recirculation pump has a backup main adjustable speed drive circuit portion, and a breaker for switching between an incoming destination and an outputting destination of the backup main adjustable speed drive circuit portion. A control signal of an inverter control portion is switched to control an inverter included in the backup main adjustable speed drive circuit portion, and when a malfunction occurred in the adjustable speed drive main circuit, by switching to the backup main adjustable speed drive circuit portion, the primary loop recirculation pump of a nuclear reactor is continuously controlled and operated.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

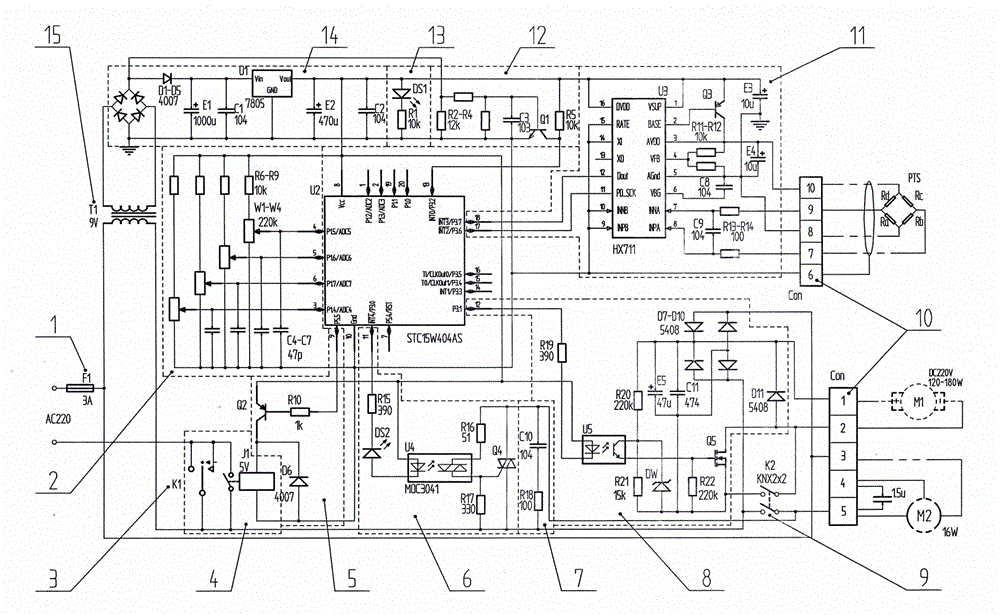

Intelligent stepless-speed-regulation weighing feeder controller for driving DC 220V feed throwing motor

InactiveCN103955154AMeet needsIncrease profitProgramme controlComputer controlMicrocomputerMicrocontroller

The invention discloses an intelligent stepless-speed-regulation weighing feeder controller for driving a DC 220V feed throwing motor. The controller is formed by connecting a safety circuit (1), an input setting circuit (2), a reset switch (3), a self-locking circuit (4), a relay J1 driving protection circuit (5), a feed throwing indicating driving output circuit (6), an output protection circuit (7), a speed regulation driving output circuit (8), an emergency switch (9), a connection terminal (10), a weighing detection circuit (11), a zero-cross detection circuit (12), a power indicating circuit (13), a commutating and voltage-stabilizing circuit (14),a transformer T1(15), a single-chip microcomputer U2(18) and a relay J1 into an electrical circuit. As the single-chip microcomputer with an AD port is used as a core control element, input setting is simple; the feed throwing amount is used for controlling the length of available machine time instead of a timer, so that accurate feed throwing is achieved, and the utilization rate of feed is increased; besides, the controller has the advantages of being good in controlling performance and easy to operate.

Owner:JIANGSU HENGSHENYANG MACHINERY

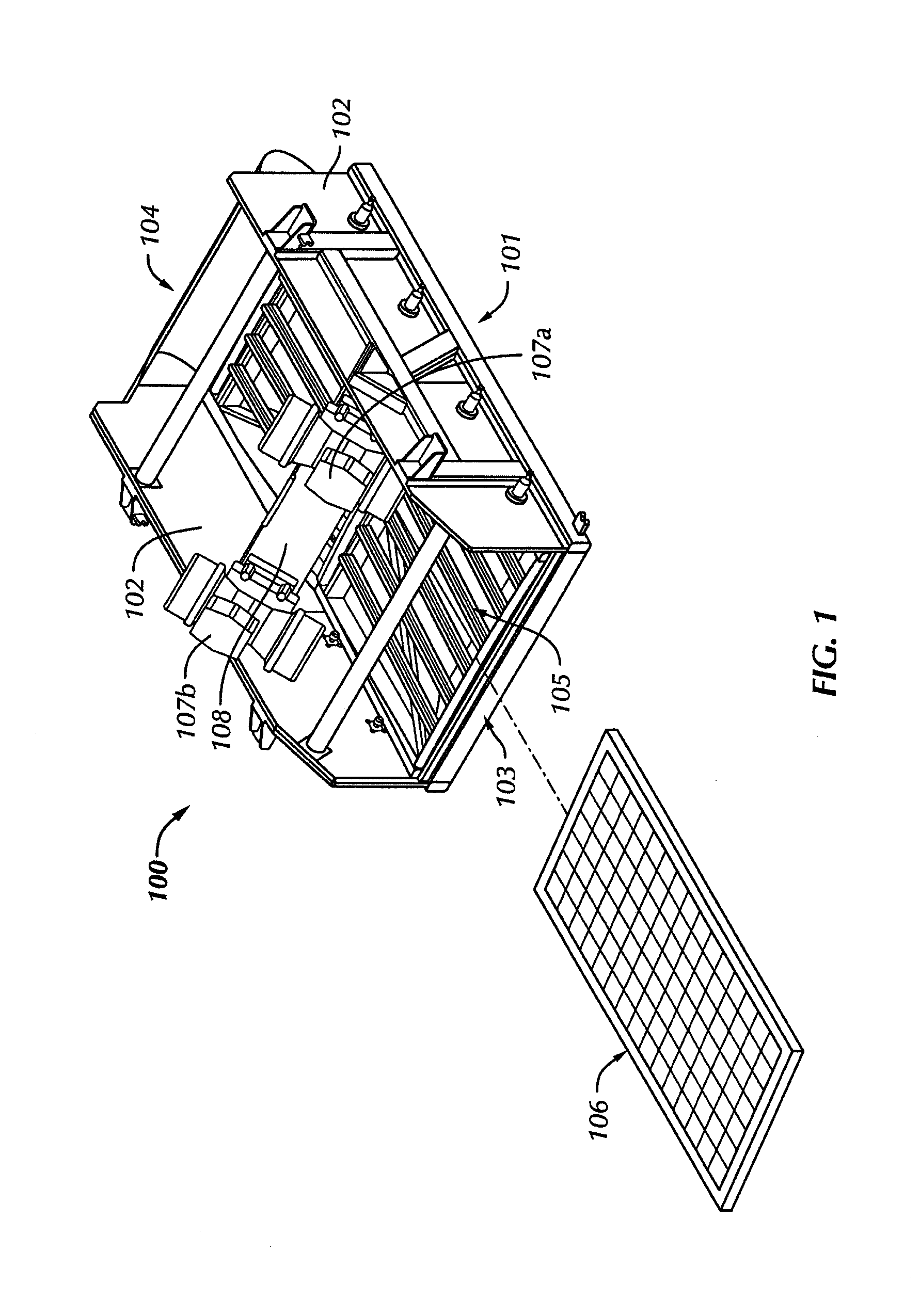

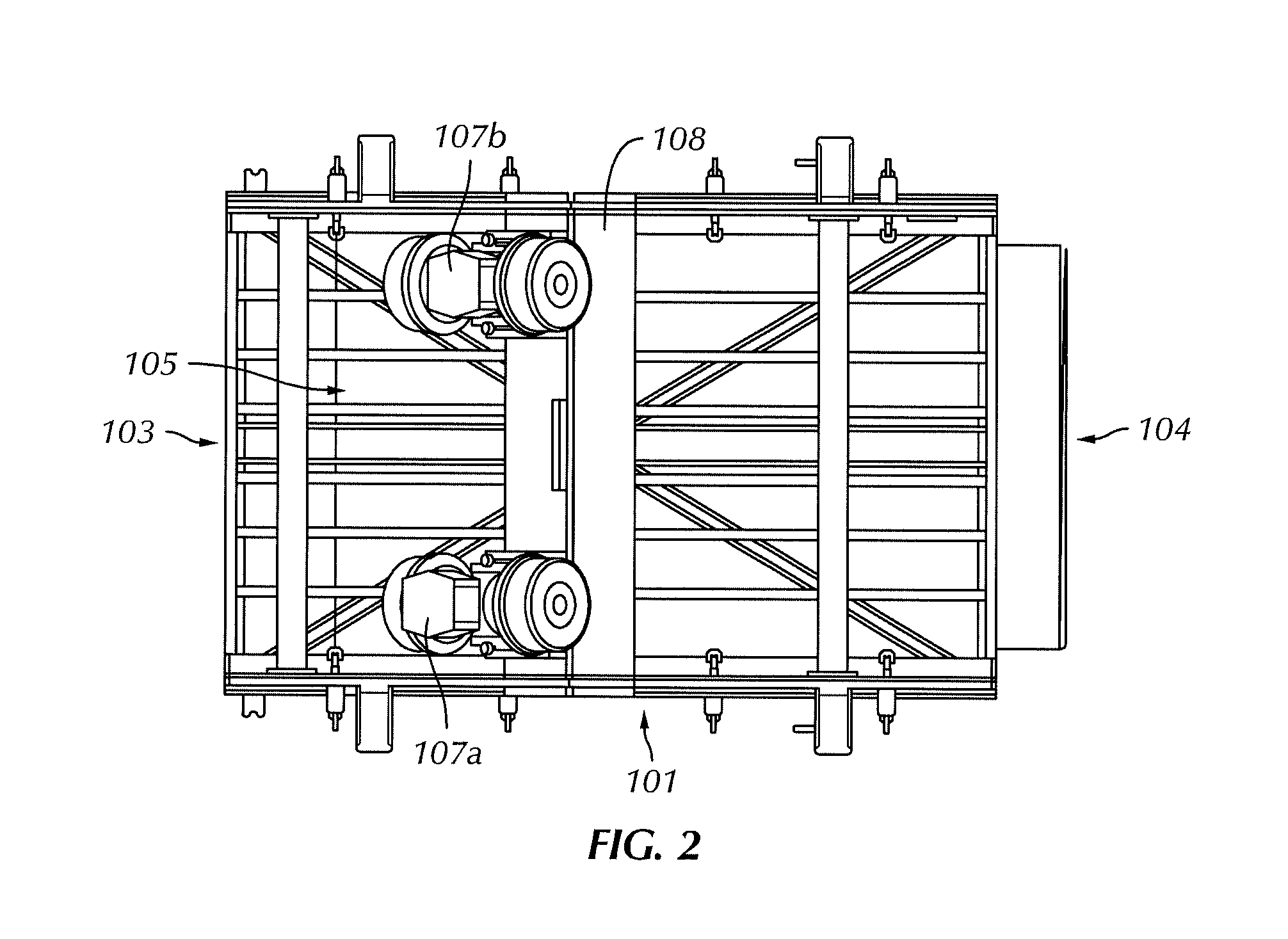

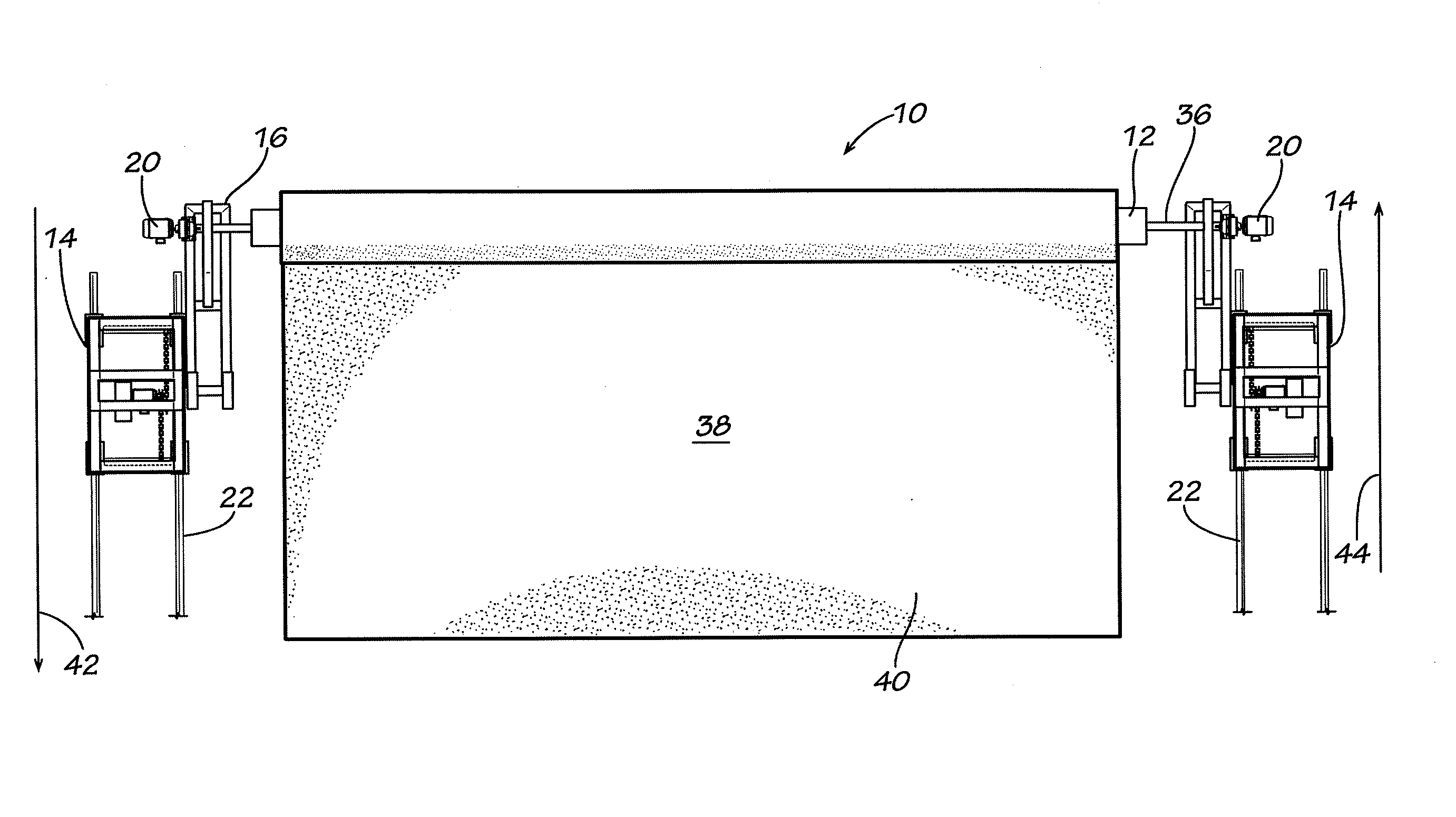

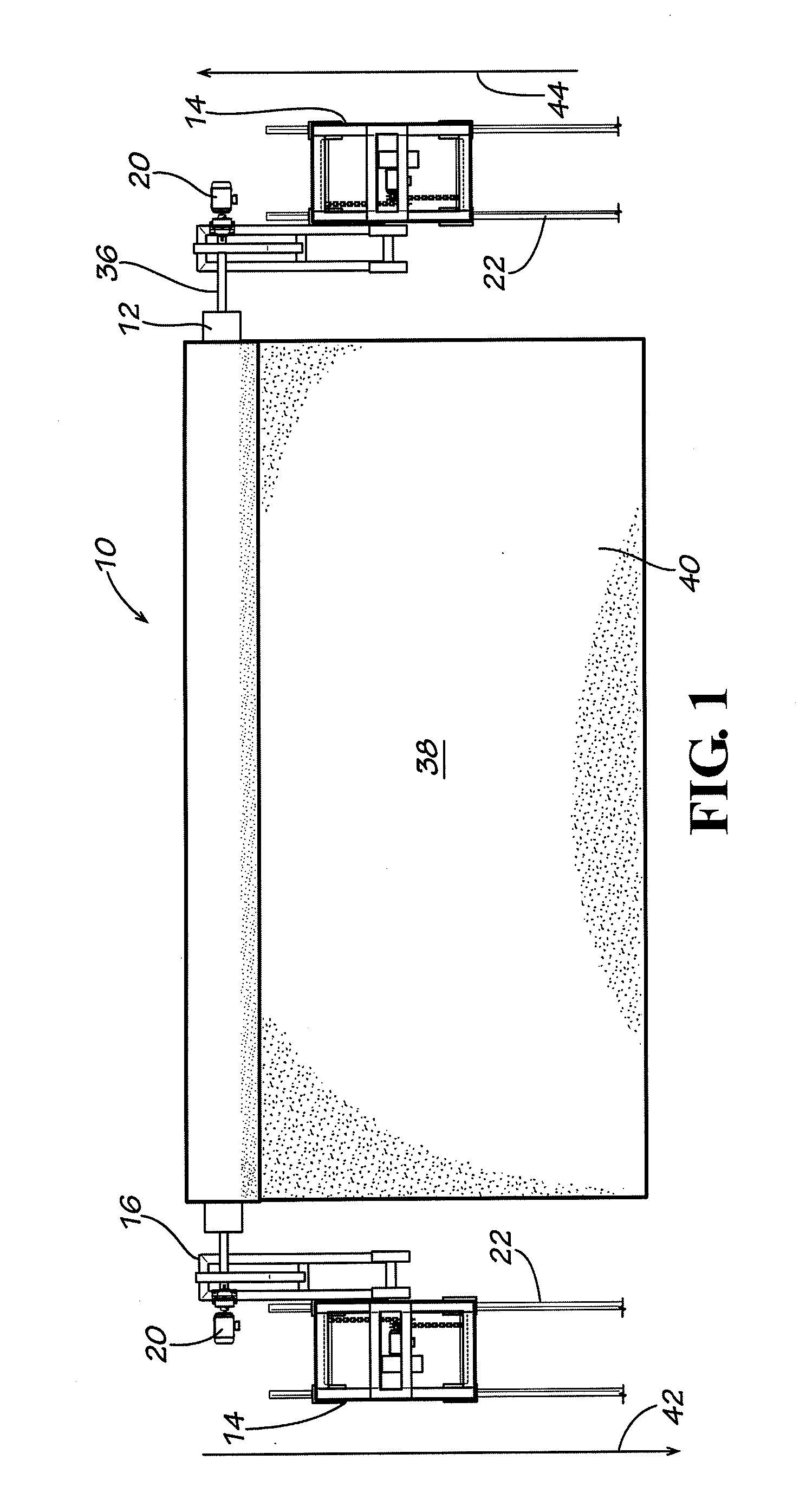

System and Method for Storage and Temporary Installation of Secondary Flooring Surface

Systems and methods of rolling and unrolling secondary flooring surfaces, such as tall pile turf, are provided. The system includes a core onto which the secondary flooring surface is rolled, the core being coupled on both ends to a frame that moves along a track mounted on or in a primary surface. The system includes a drive system that allows for the conversion of a primary surface into a secondary flooring surface in a relatively short period of time. The drive system includes core adjustable speed drive units for controlling the speed and torque of the motors that drive the core, as well as frame adjustable speed drive units for controlling the speed of the movement of the frames along the tracks. The core adjustable speed drive units control the torque of the core motors during roll up and control the speed of the core motors during roll out.

Owner:APT ADVANCED POLYMER TECH CORP

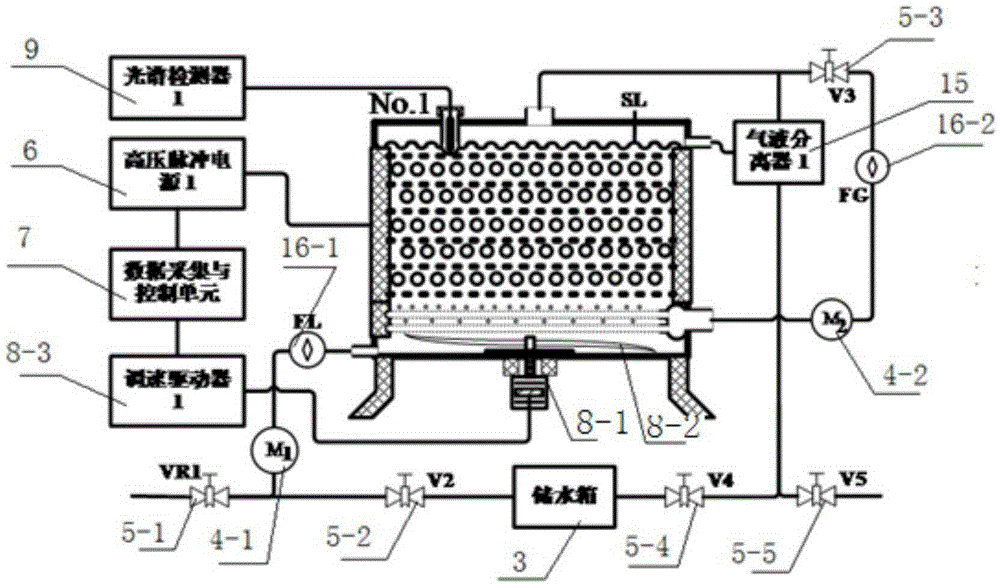

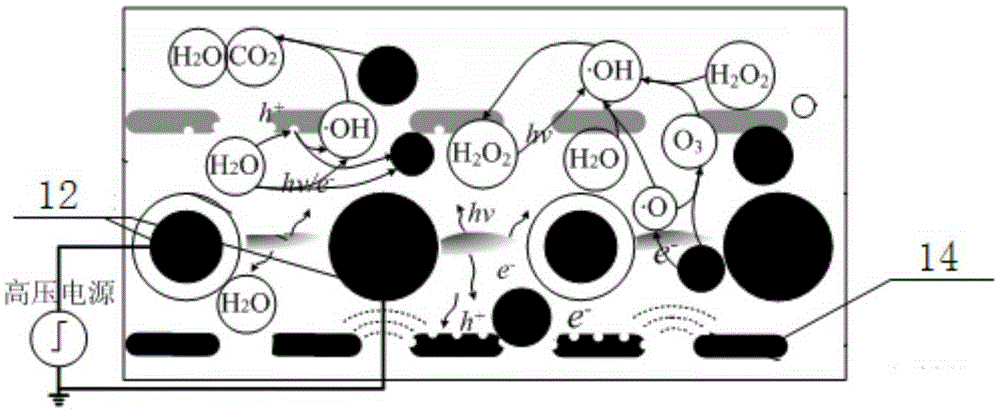

Motor regulation and control underwater dense bubble dielectric barrier discharge reactor

ActiveCN105198034AFacilitated DiffusionEnhanced mass transferWater/sewage treatment by irradiationWater/sewage treatment by oxidationWater storage tankData acquisition

The invention discloses a motor regulation and control underwater dense bubble dielectric barrier discharge reactor. The motor comprises a base, a shell installed on the base, a water storage tank, a pump assembly, a valve assembly, a high-voltage pulse power supply, a data collection and control unit, a mechanical agitation device used for generating underwater dense bubble two-phase flow, a spectrum detector and a liquid level sensor. A dielectric barrier discharge electrode array, a punched net board and an aeration device are arranged in the shell. The dielectric barrier discharge electrode array is connected with the high-voltage pulse power supply. The liquid level sensor and the spectrum detector are connected with the input end of the data collection and control unit. The output end of the data collection and control unit is connected with the pump assembly, the valve assembly, the high-voltage pulse power supply and a speed regulation driver. Water treatment channel selection and gas circulation are achieved by the pump assembly and the valve assembly under control of the data collection and control unit. High-flow wastewater can be treated by the reactor, discharge is easy, a discharge area is large, treatment efficiency is high, and cost is low.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

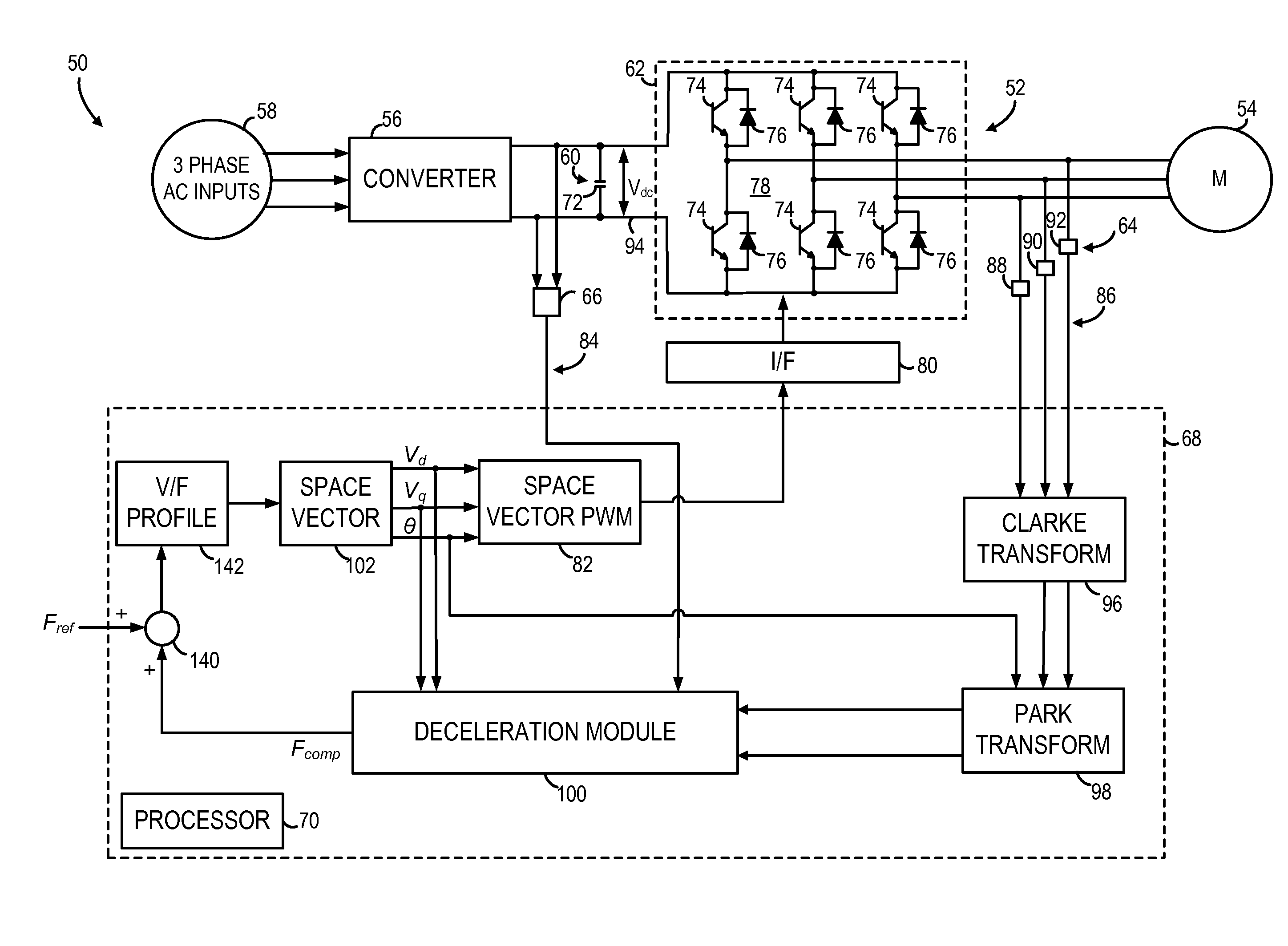

System and method for controlling regenerating energy in an adjustable speed drive

ActiveUS20150002072A1Motor/generator/converter stoppersElectric motor controlPower inverterControl system

A system and method for controlling an adjustable speed drive (ASD) to decelerate an AC load during a generating mode of operation is disclosed. The ASD includes a capacitor and an inverter coupled to a DC link. A current sensor system is coupled to an output of the inverter. The ASD further includes a control system programmed to calculate an energy of the capacitor, generate a reference power using the calculated capacitor energy, and calculate a feedback power from realtime current signals received from the current sensor system. The control system compares the feedback power to the reference power, defines a frequency offset based on the comparison, generates a speed command using the frequency offset, and outputs the speed command to the inverter to maintain a smooth DC link voltage during deceleration.

Owner:EATON INTELLIGENT POWER LIMITED

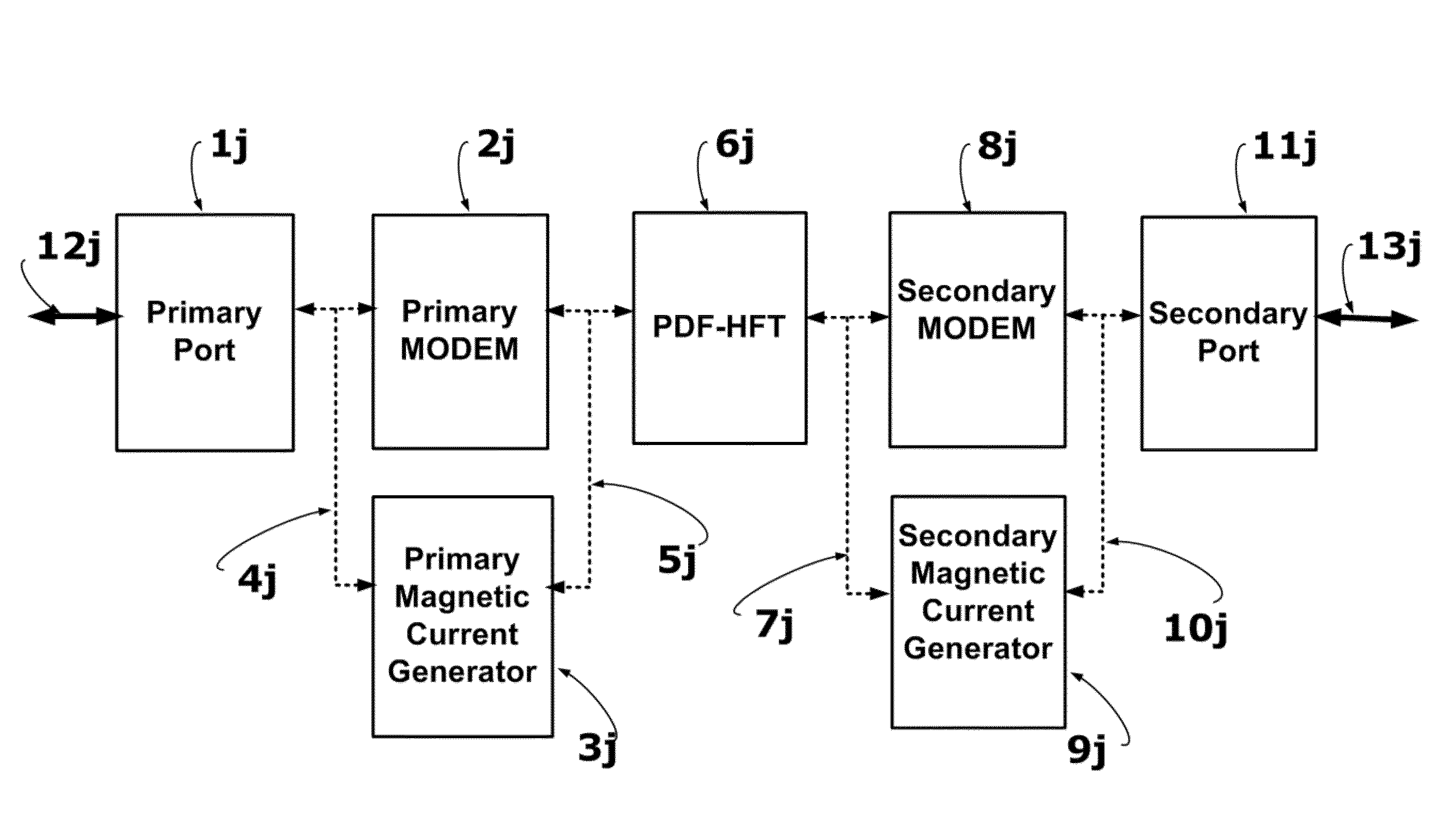

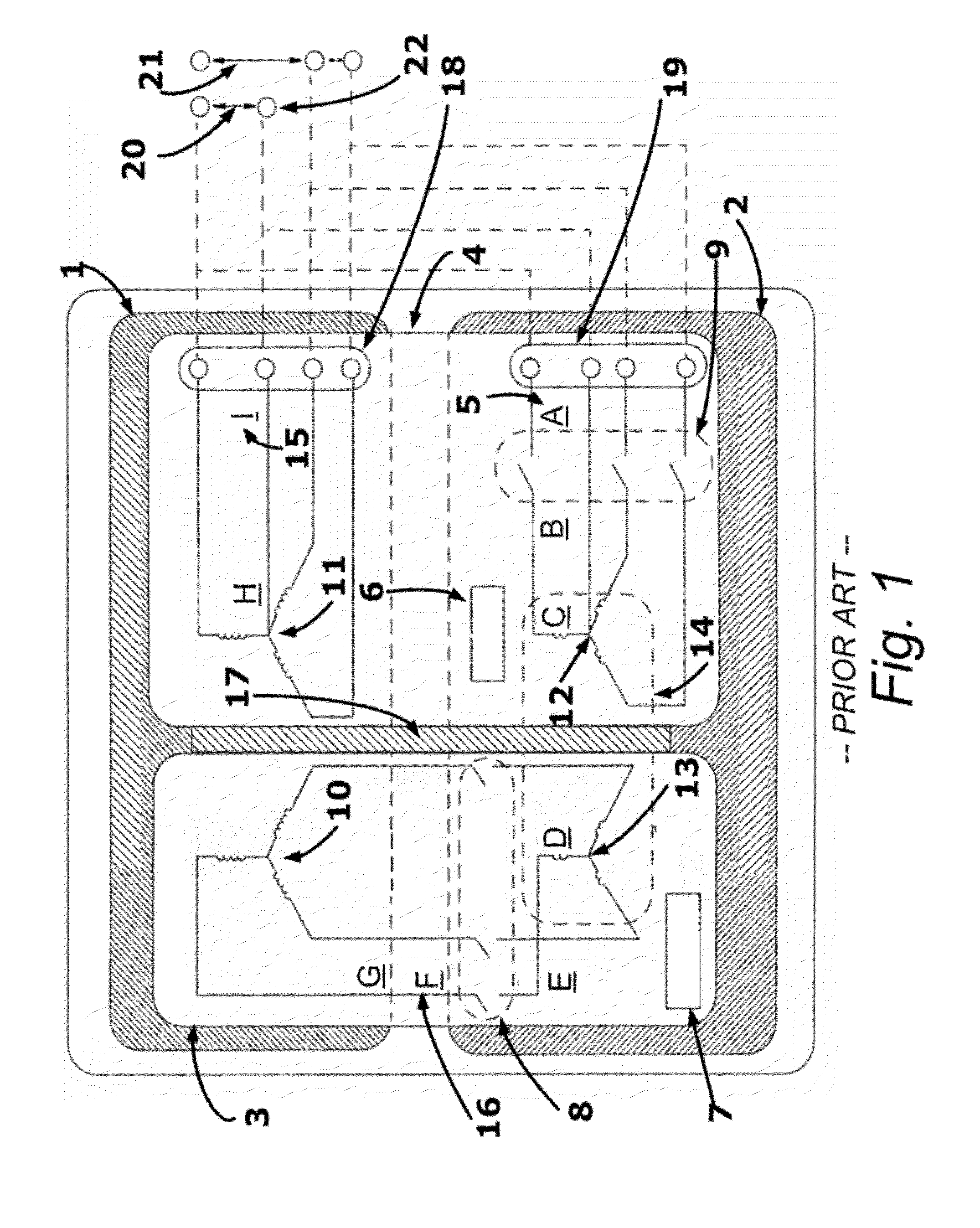

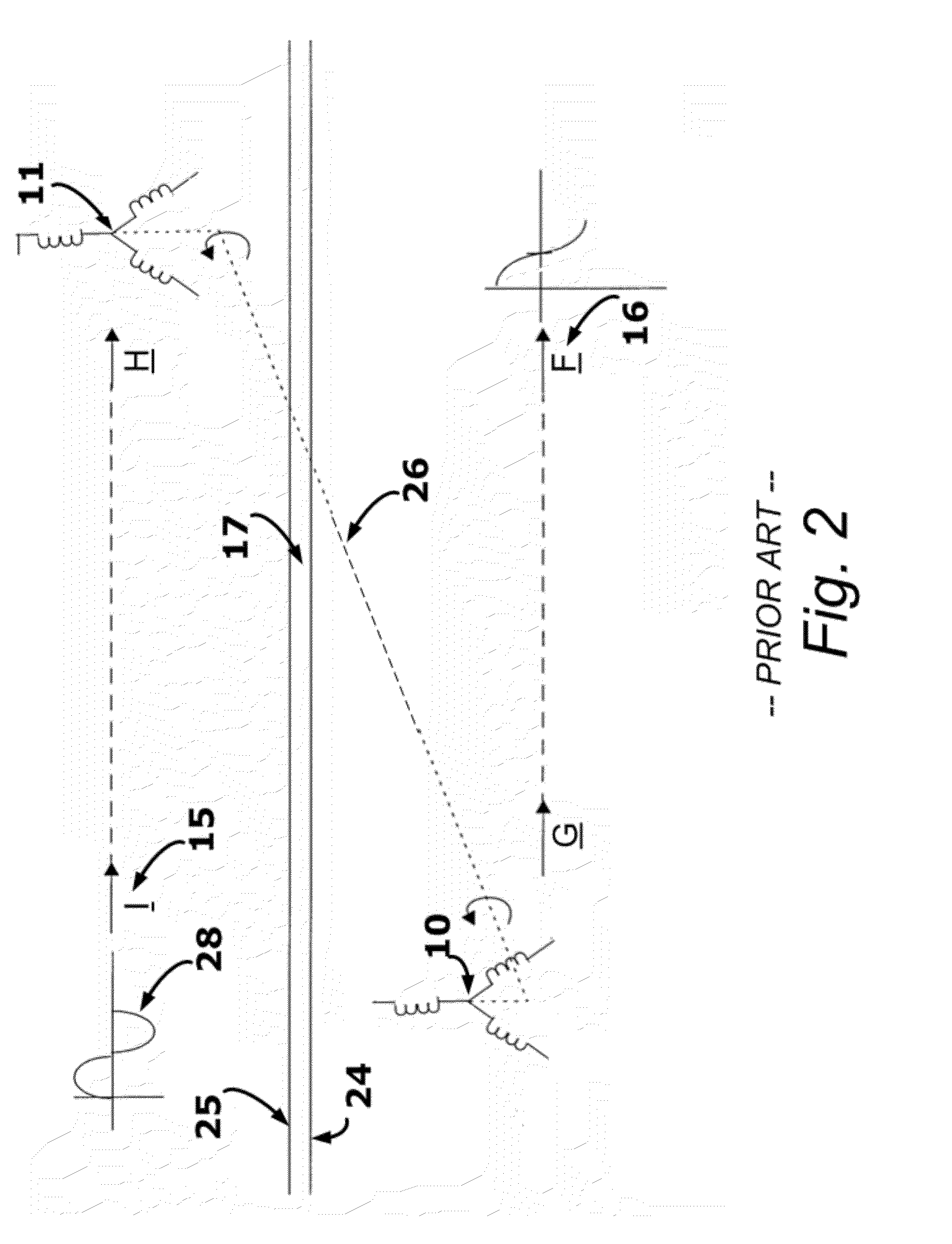

Brushless multiphase self-commutation control (or BMSCC) And Related Inventions

The Brushless Multiphase Self-Commutation Controller or BMSCC is an adjustable speed drive for reliable, contact-less and stable self-commutation control of electric apparatus, including electric motors and generators. BMSCC transforms multiphase electrical excitation from one frequency to variable frequency that is automatically synchronized to the movement of the electric apparatus without traditional estimation methods of commutation and frequency synthesis using derivatives of electronic, electro-mechanical, and field-oriented-control. Instead, BMSCC comprises an analog electromagnetic computer with synchronous modulation techniques to first establish magnetic energy and then dynamically share packets of magnetic energy between phase windings of a multiphase, position dependent flux, high frequency transformer by direct AC-to-AC conversion without an intermediate DC conversion stage.

Owner:KLATT FREDERICK WILLIAM

Intelligent stepless speed-regulation controller of metering feeder

InactiveCN103901905AMeet needsIncrease profitPisciculture and aquariaSpeed/accelaration control using electric meansMicrocomputerMicrocontroller

Owner:JIANGSU HENGSHENYANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com