Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Rapid and safe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for inducing hypothermia

InactiveUS20050203598A1Improve the protective effectPromote resultsLighting and heating apparatusIce productionParticulatesSlurry

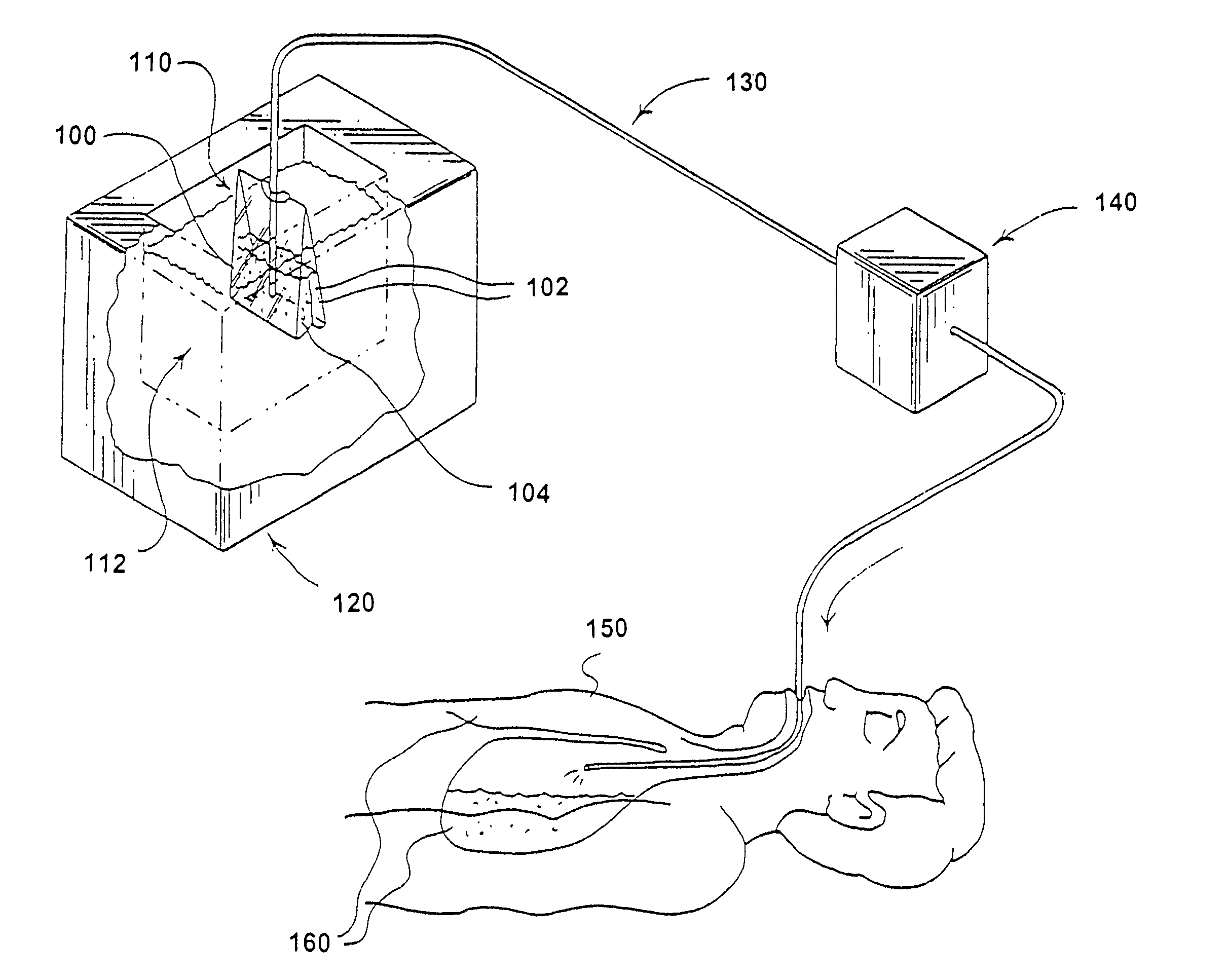

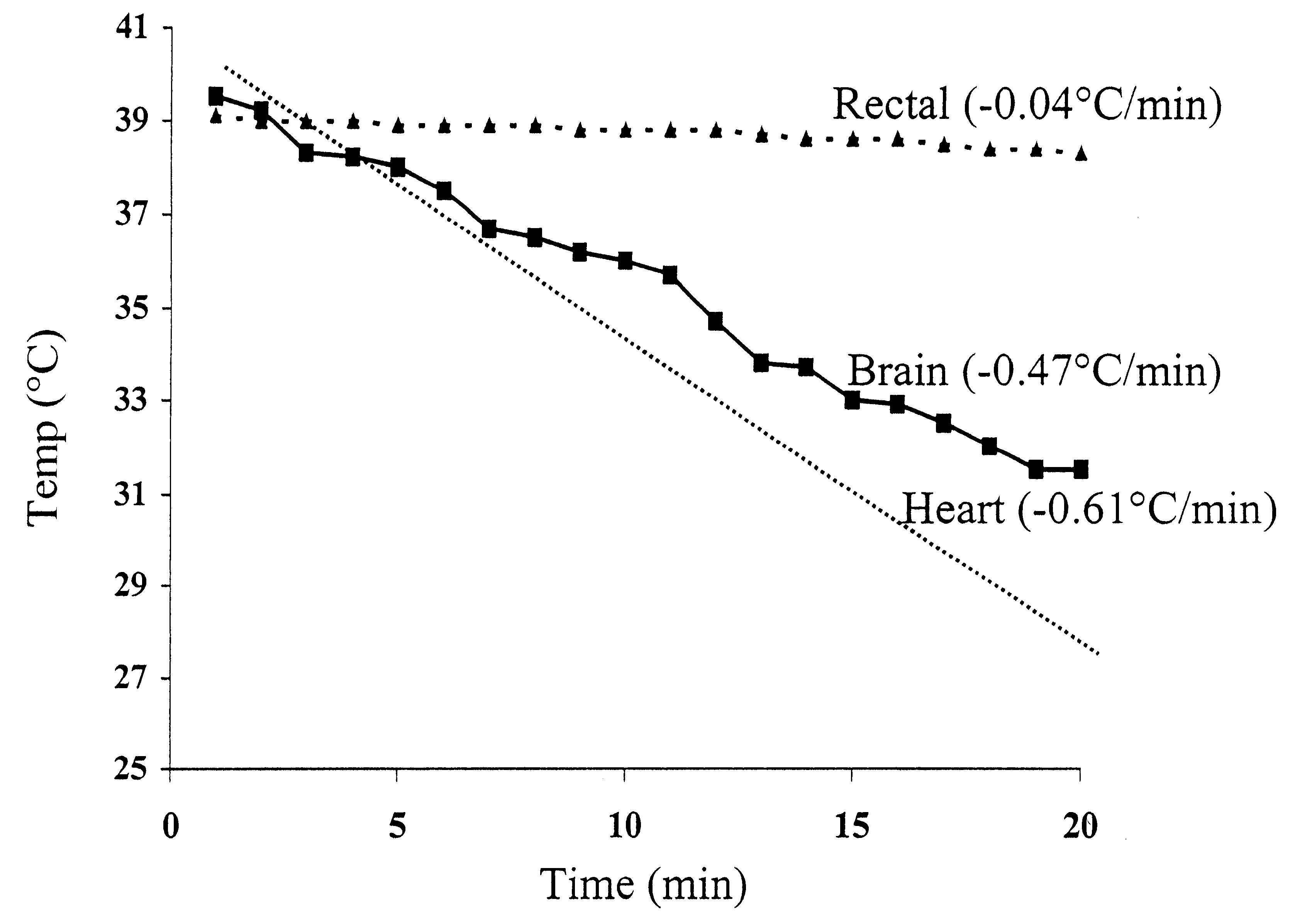

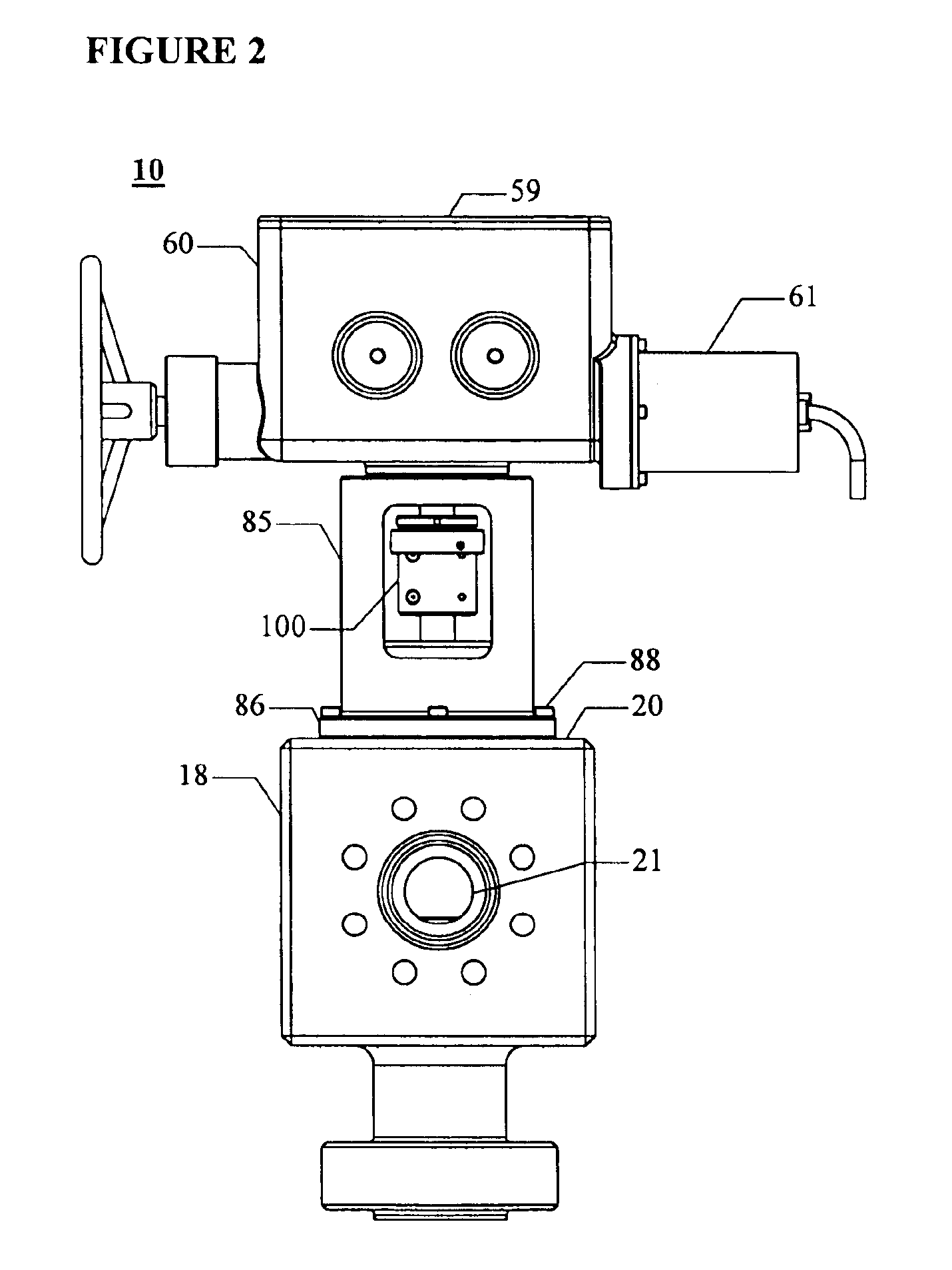

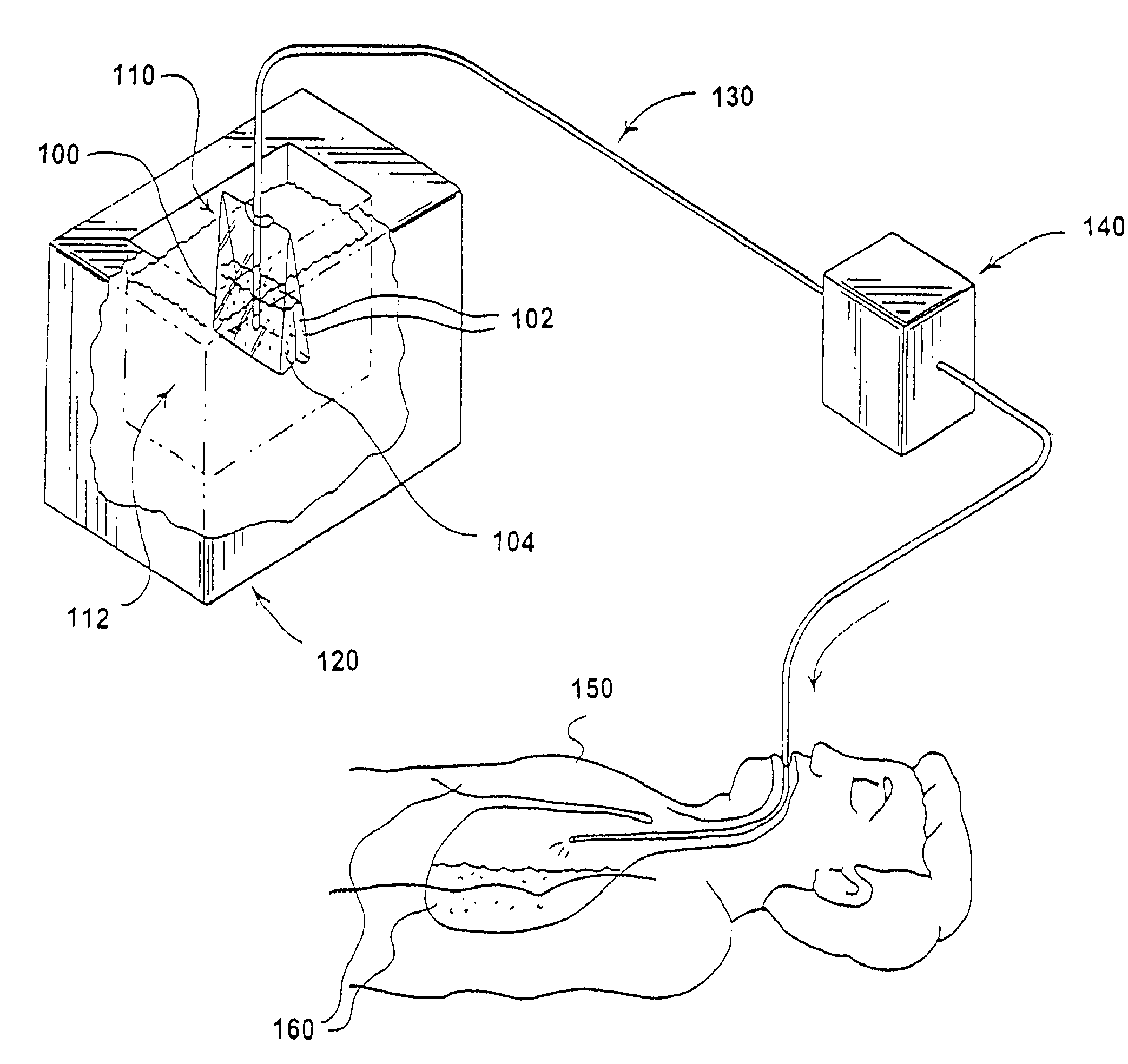

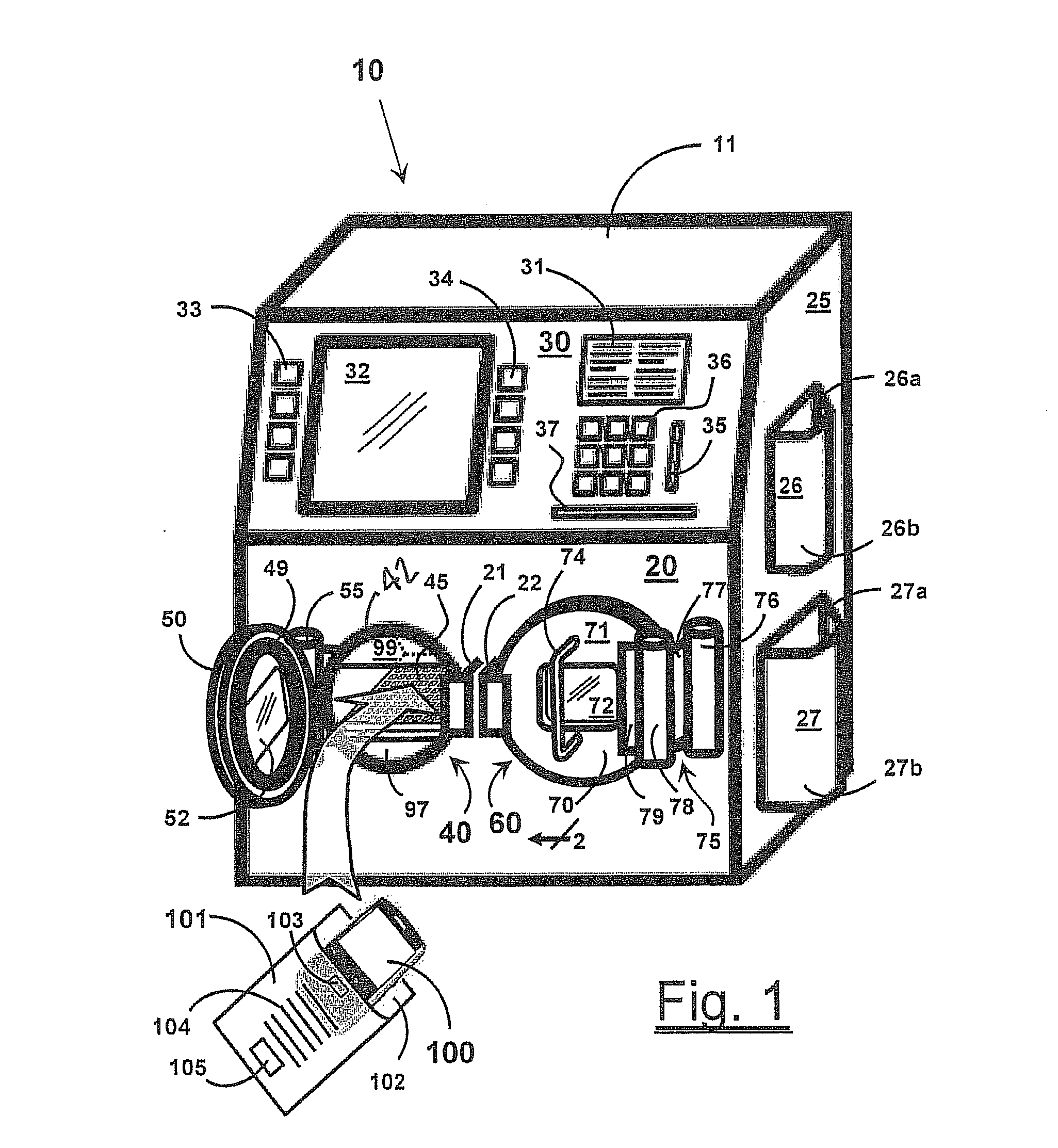

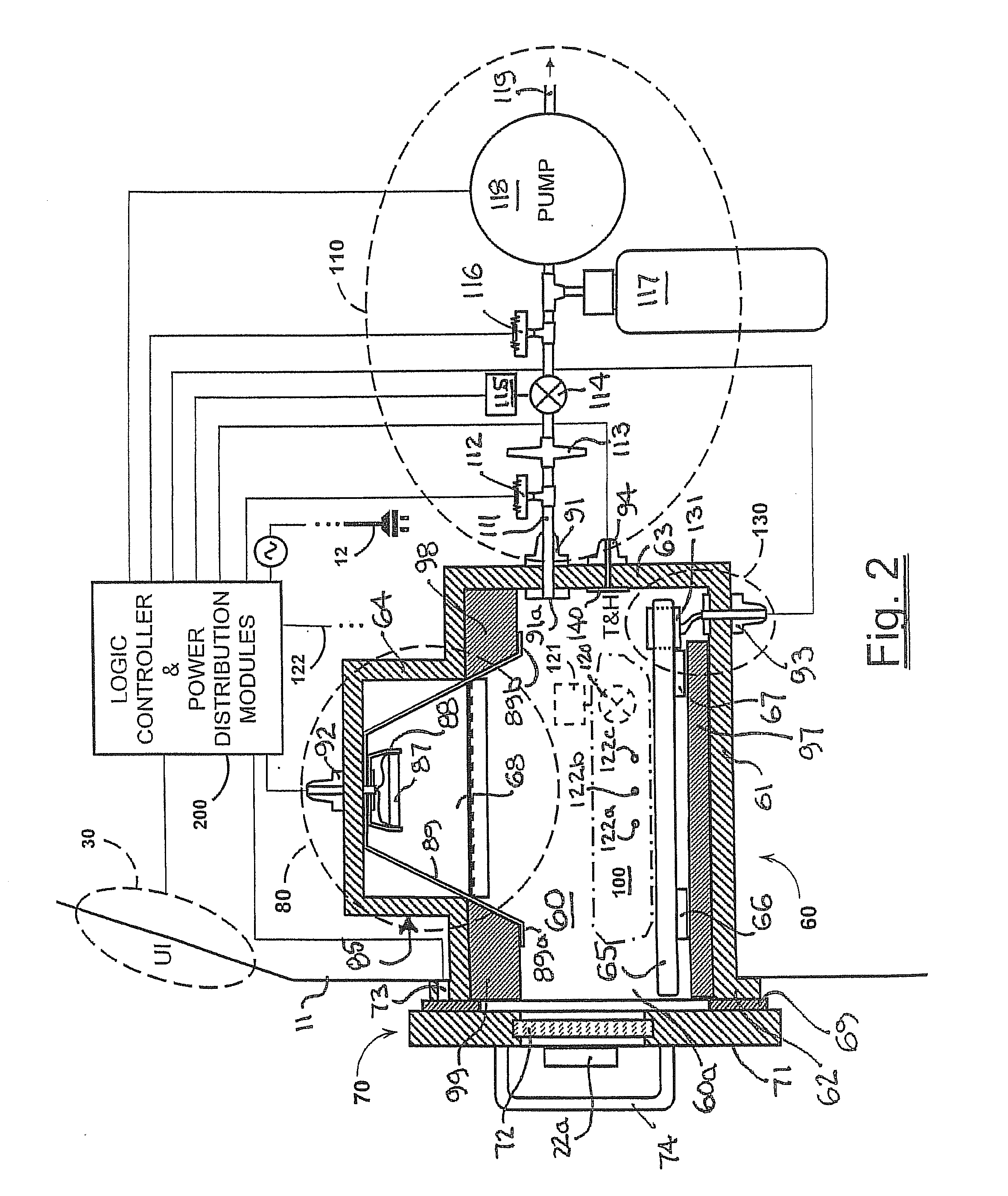

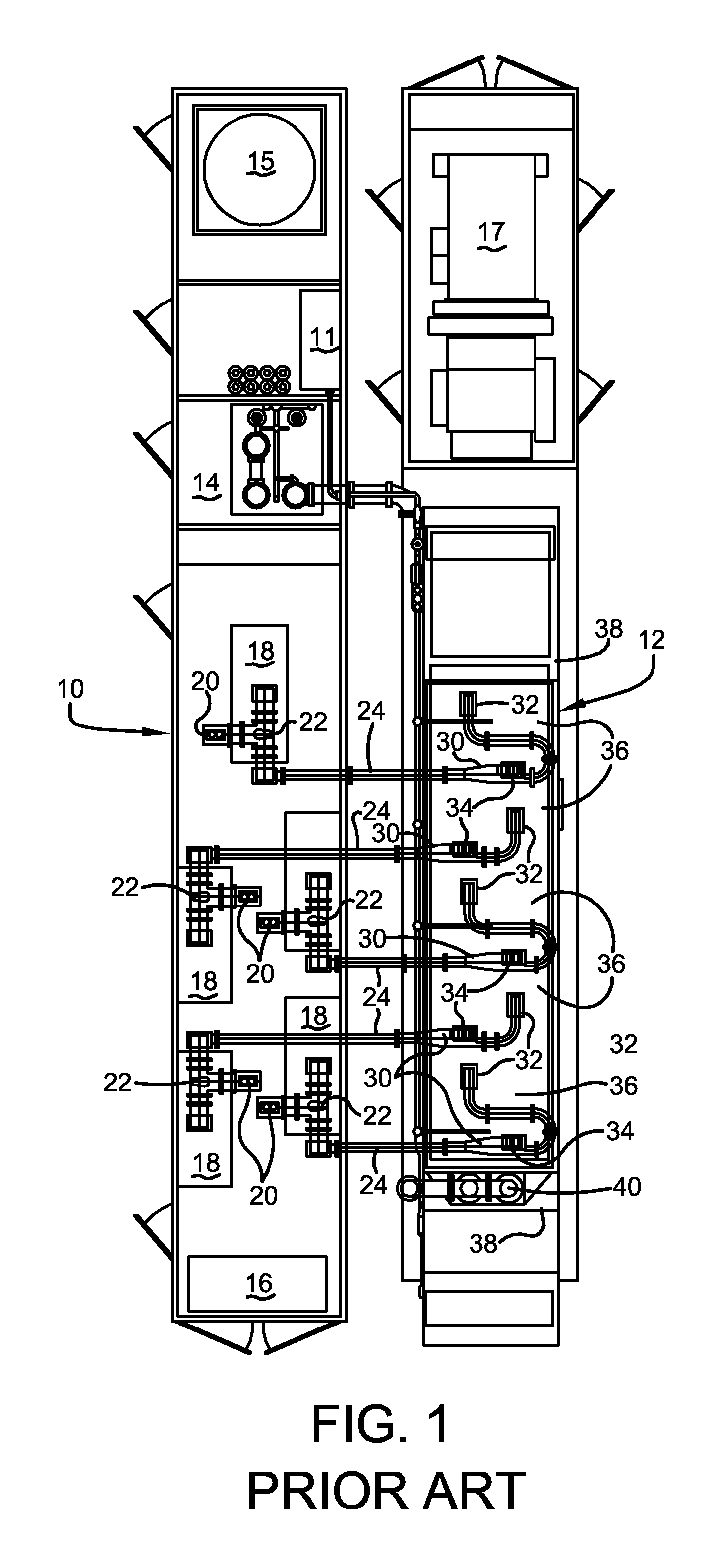

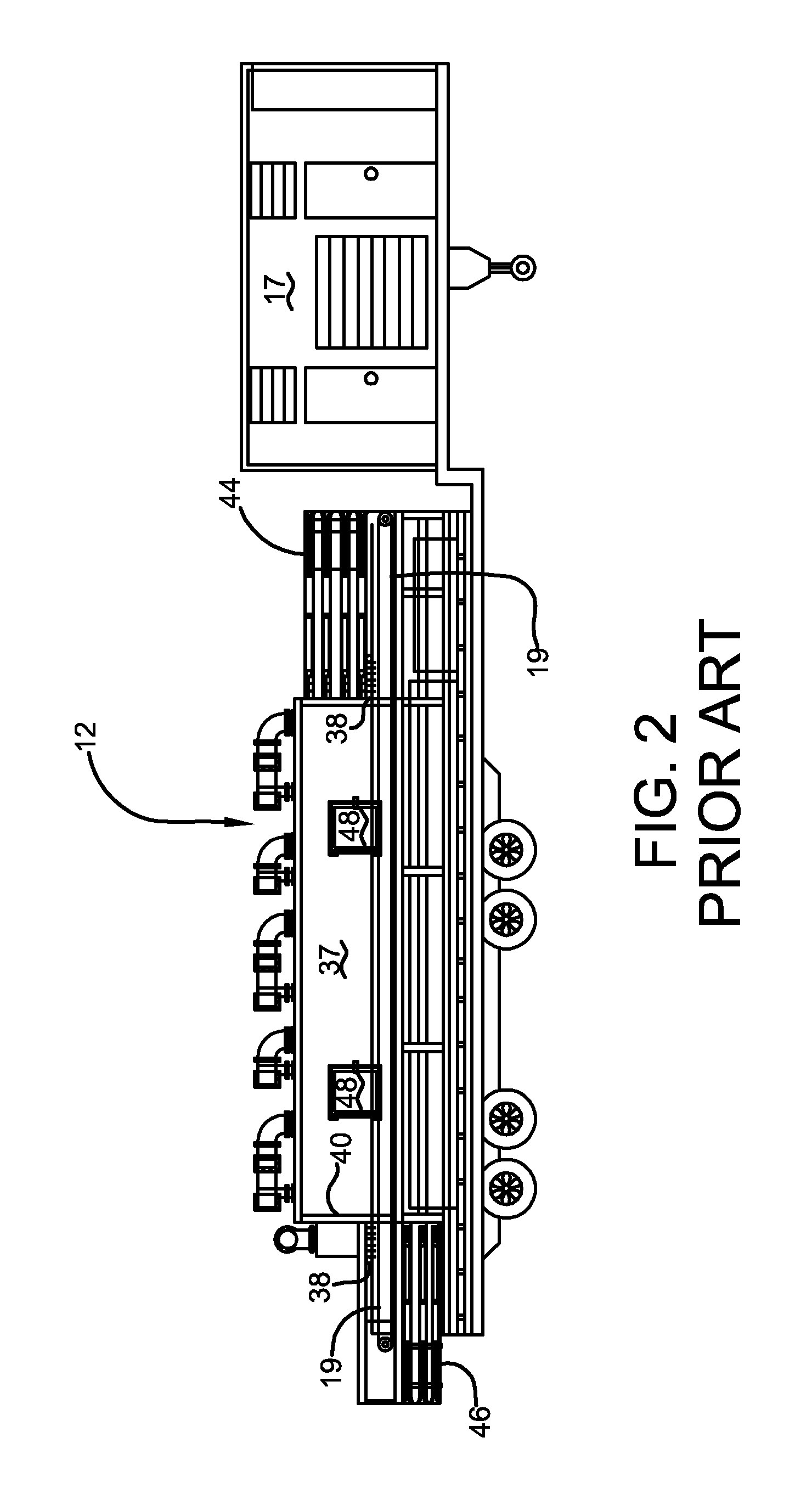

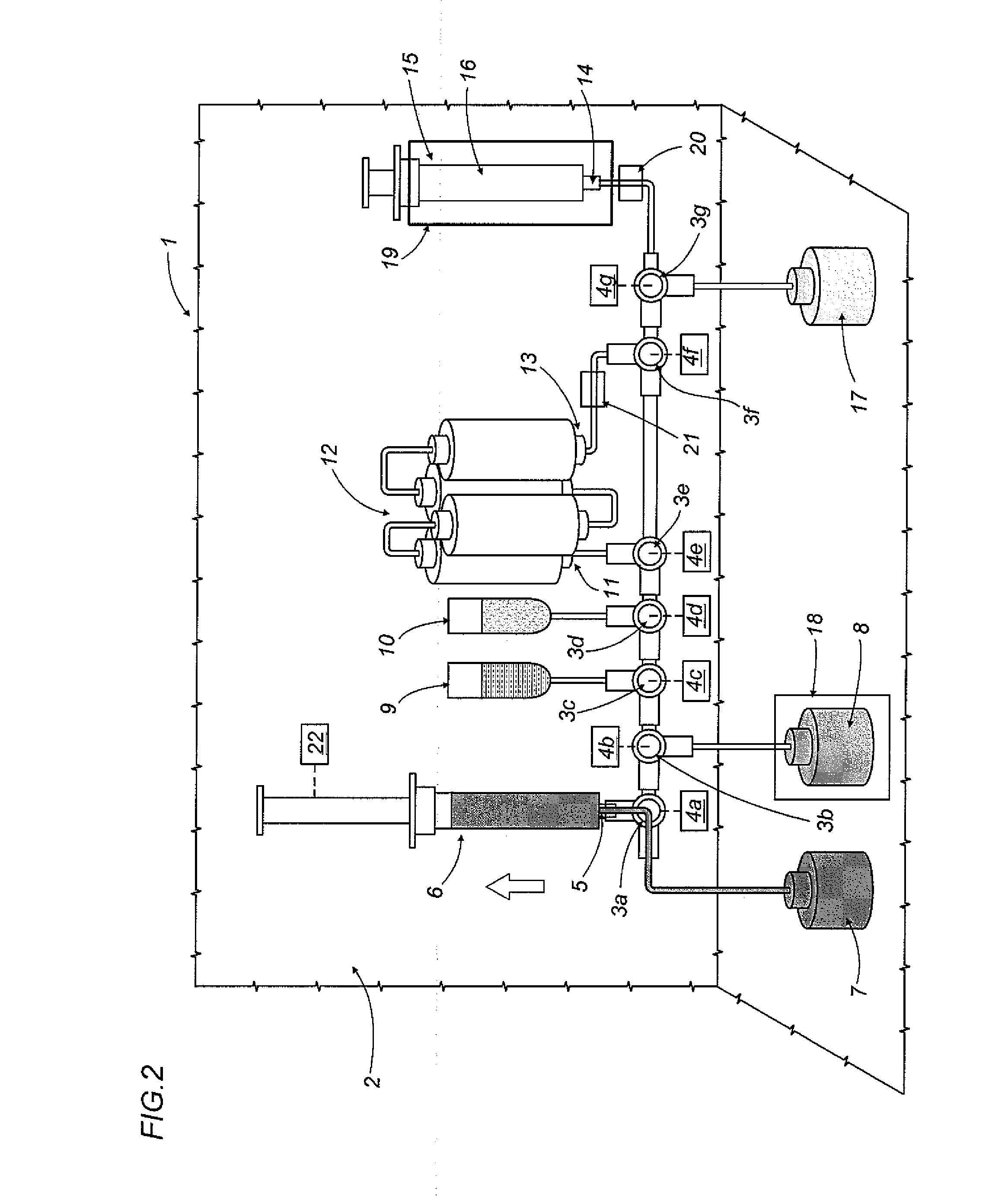

Systems for phase-change particulate slurry cooling equipment and methods to induce hypothermia in a patient through internal and external cooling are provided. Subcutaneous, intravascular, intraperitoneal, gastrointestinal, and lung methods of cooling are carried out using saline ice slurries or other phase-change slurries compatible with human tissue. Perfluorocarbon slurries or other slurry types compatible with human tissue are used for pulmonary cooling. And traditional external cooling methods are improved by utilizing phase-change slurry materials in cooling caps and torso blankets.

Owner:UNIVERSITY OF CHICAGO

Method for inducing hypothermia

InactiveUS6962601B2Simple methodImprove the protective effectOther chemical processesLighting and heating apparatusParticulatesSlurry

Systems for phase-change particulate slurry cooling equipment and methods to induce hypothermia in a patient through internal and external cooling are provided. Subcutaneous, intravascular, intraperitoneal, gastrointestinal, and lung methods of cooling are carried out using saline ice slurries or other phase-change slurries compatible with human tissue. Perfluorocarbon slurries or other slurry types compatible with human tissue are used for pulmonary cooling. And traditional external cooling methods are improved by utilizing phase-change slurry materials in cooling caps and torso blankets.

Owner:UNIVERSITY OF CHICAGO +1

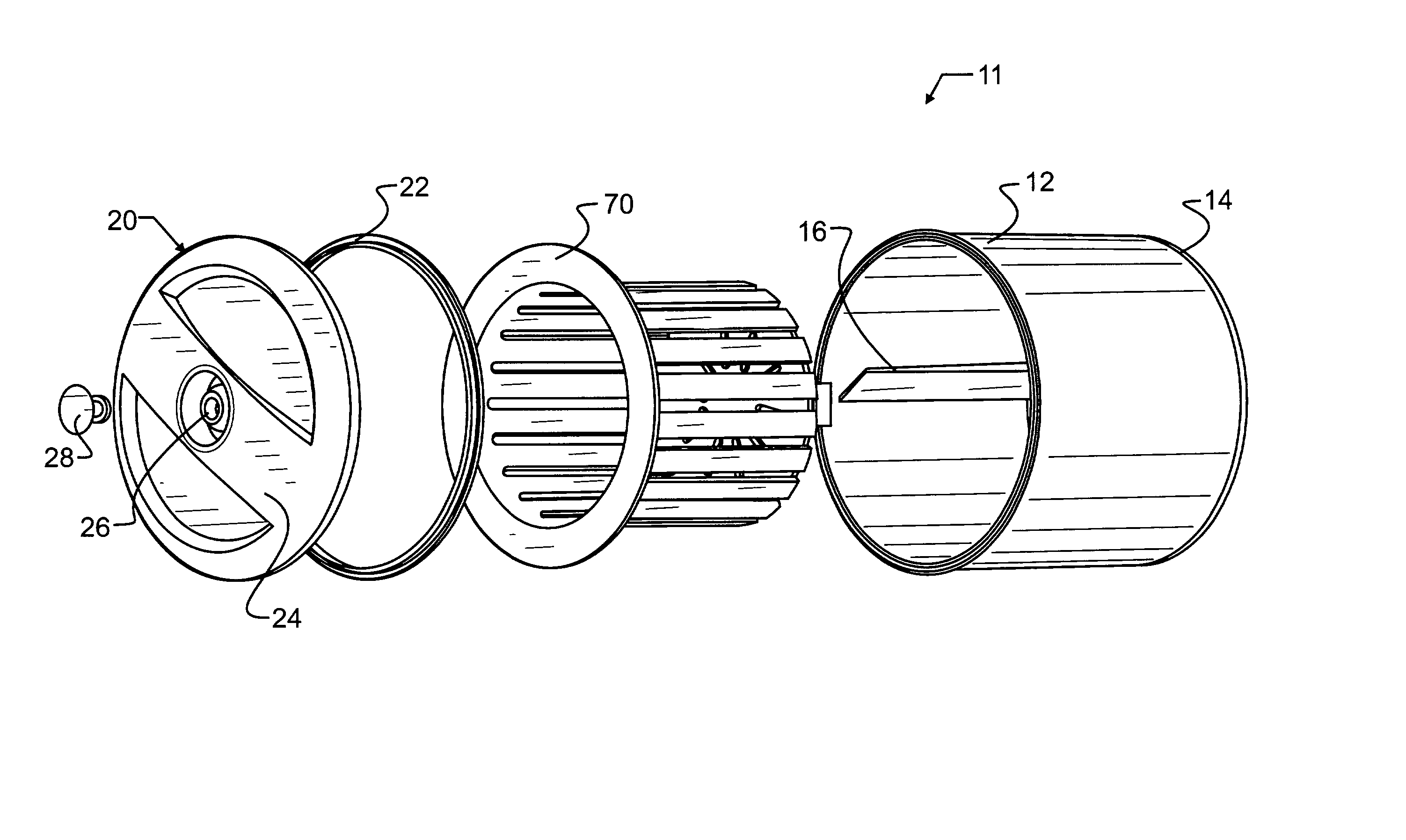

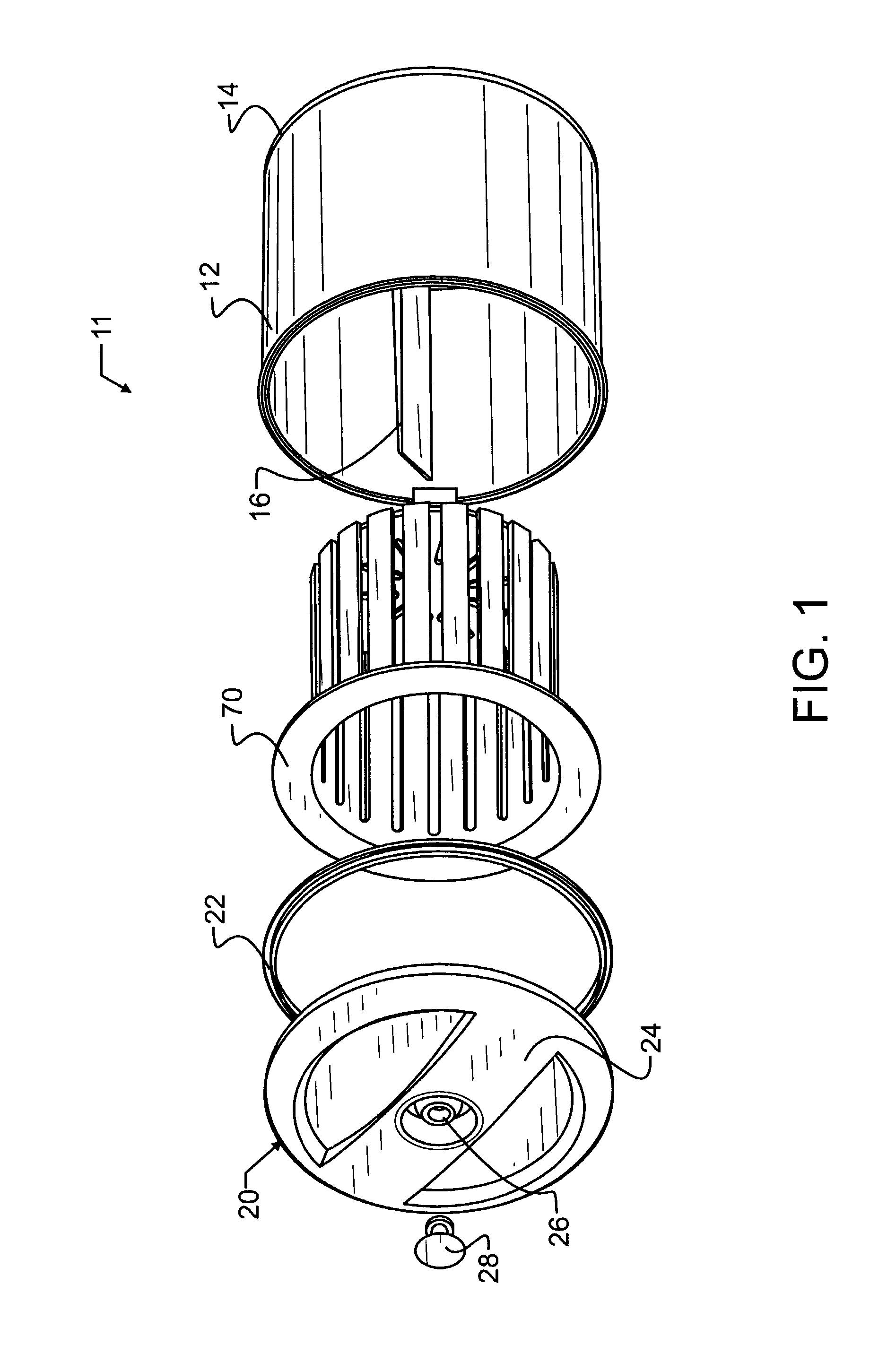

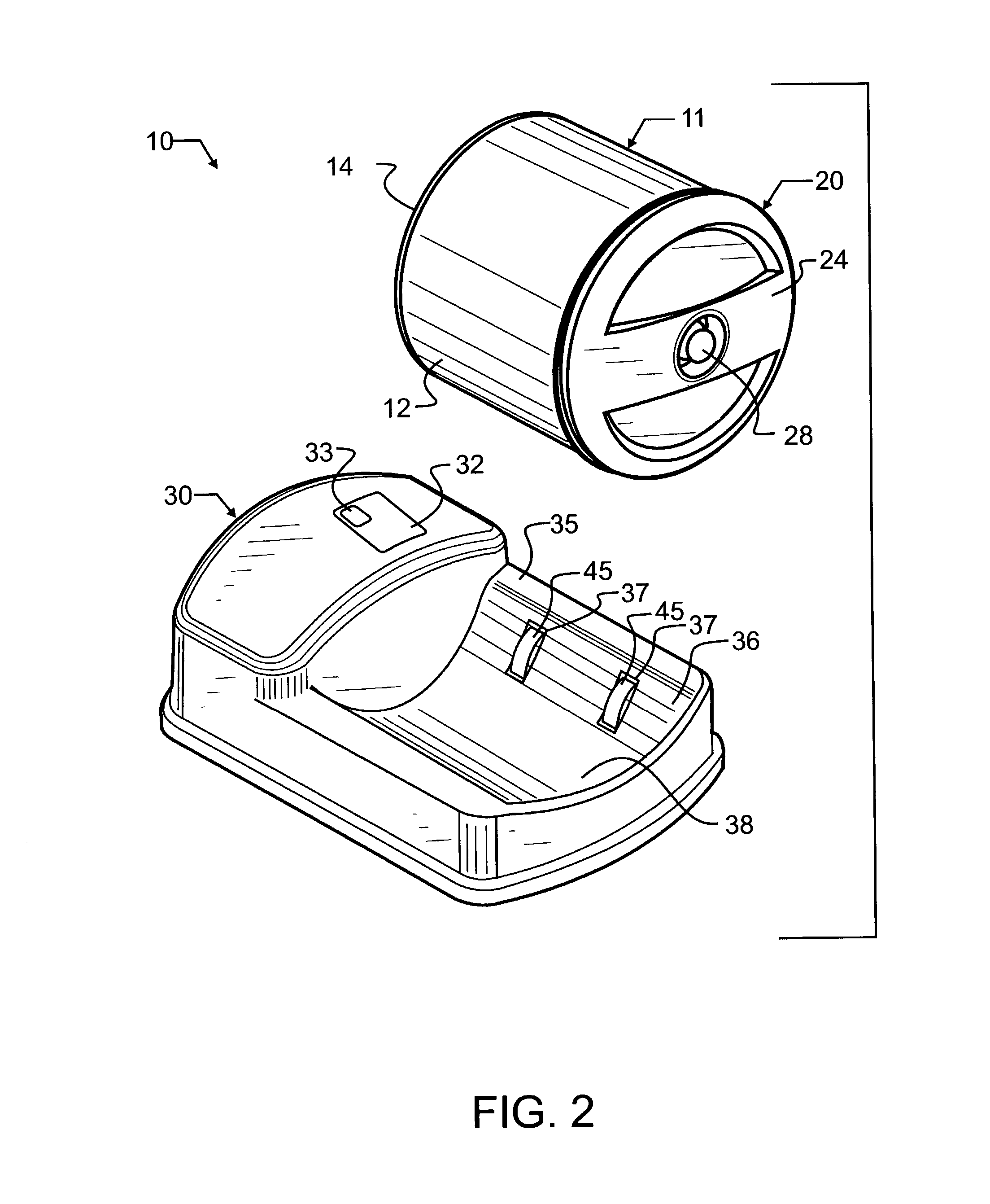

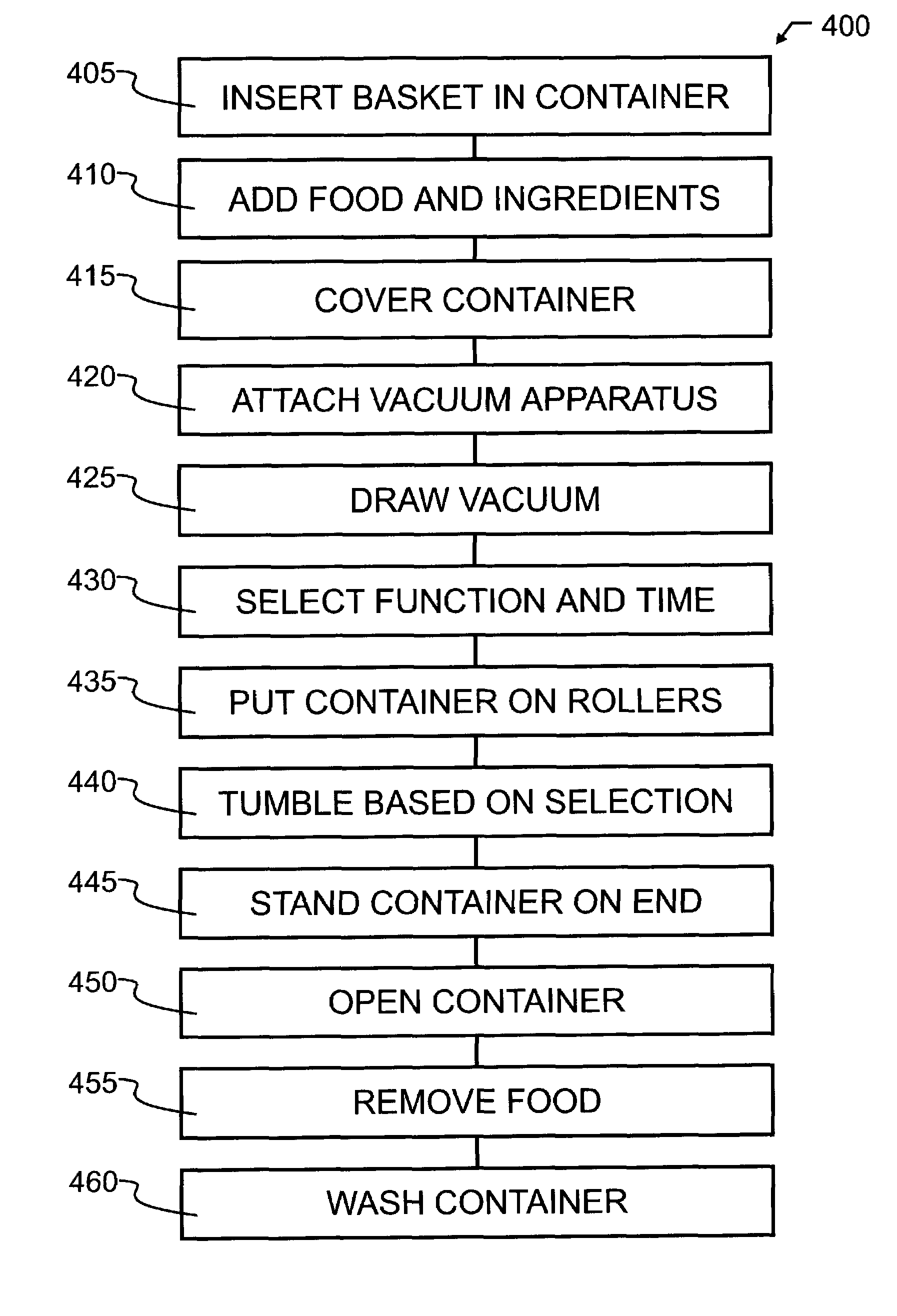

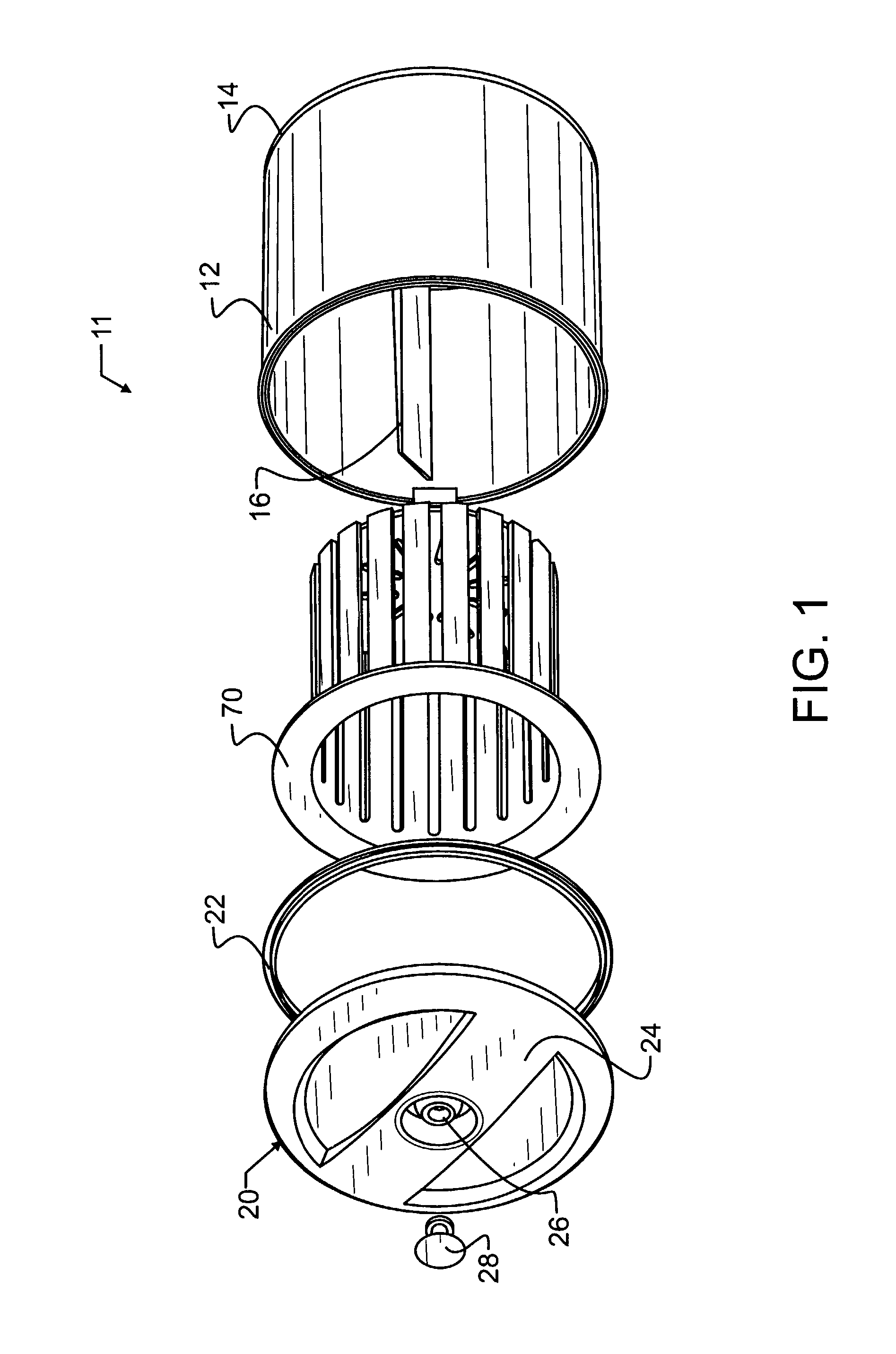

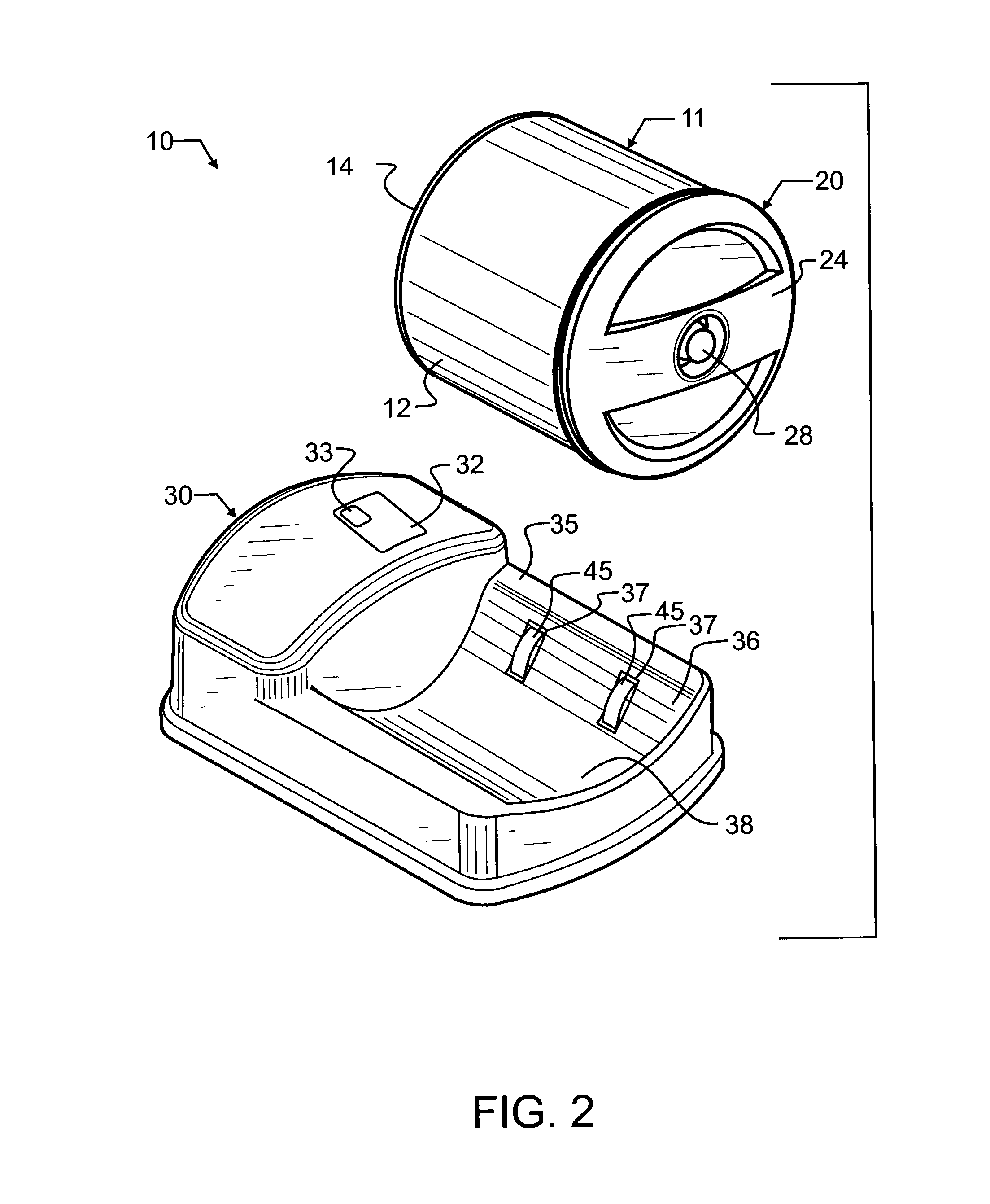

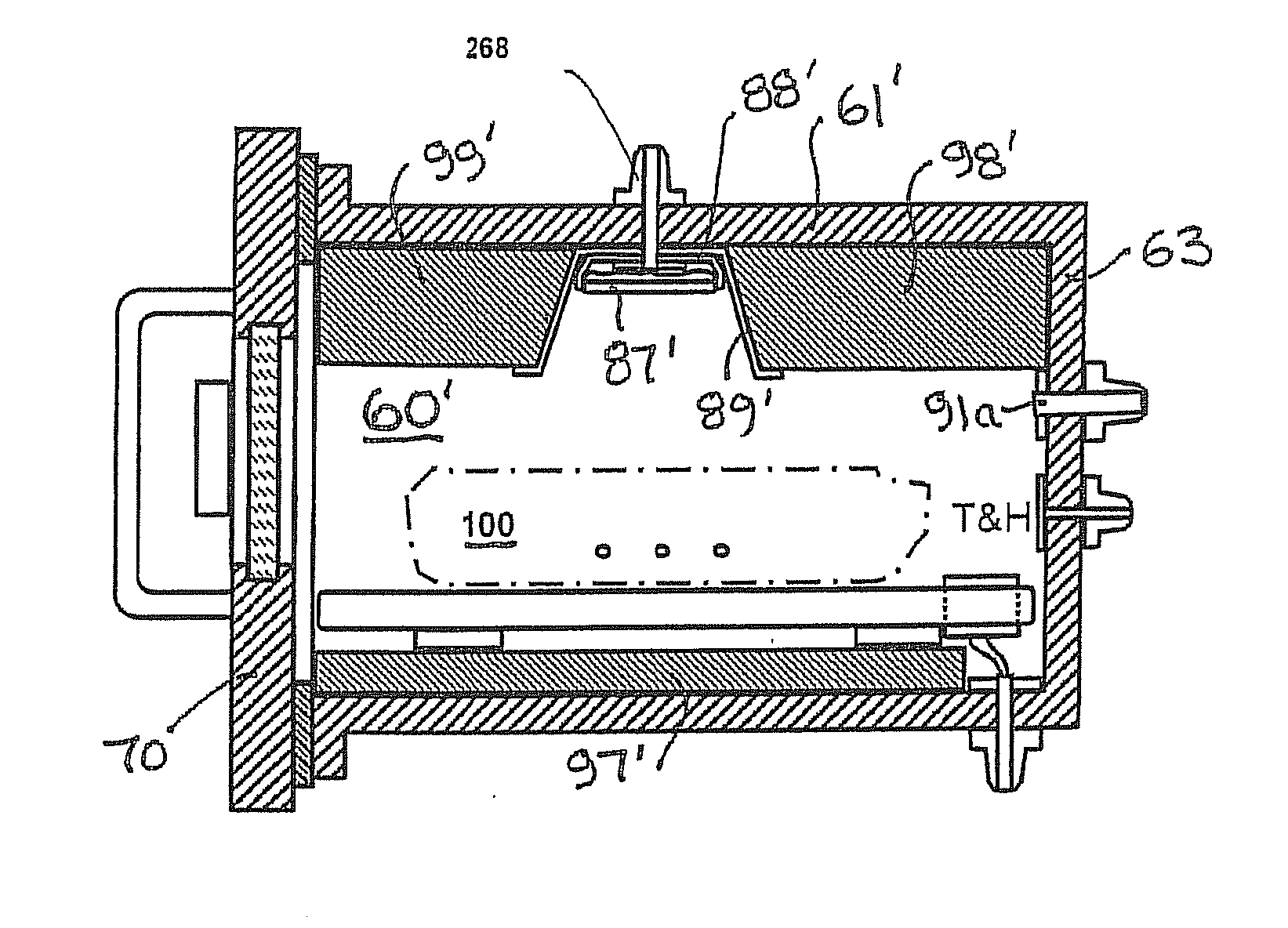

Food tumbler

InactiveUS20030085234A1Simple processImprove securityGrain huskingRotating receptacle mixersMechanical engineeringFood item

A counter-top appliance has a food container with internal fins extending inward from the outer wall at an angle offset from radial. The food container is coupled to a motor for rotation in either of two directions. One direction of rotation produces a scooping, elevating and subsequent discharge of liquid and fluent materials such as might be useful for washing or breading, while the second direction of rotation presents a surface adapted for massaging meat during marinating. The food container is preferably sealed through vacuum, and has a simple geometry which greatly facilitates thorough cleaning of the container. Meats, produce, pasta, and other diverse foods are processed using the counter-top appliance, and a method for processing one or a sequential set of foods is disclosed.

Owner:PAUMEN DECEASED LAWRENCE J +2

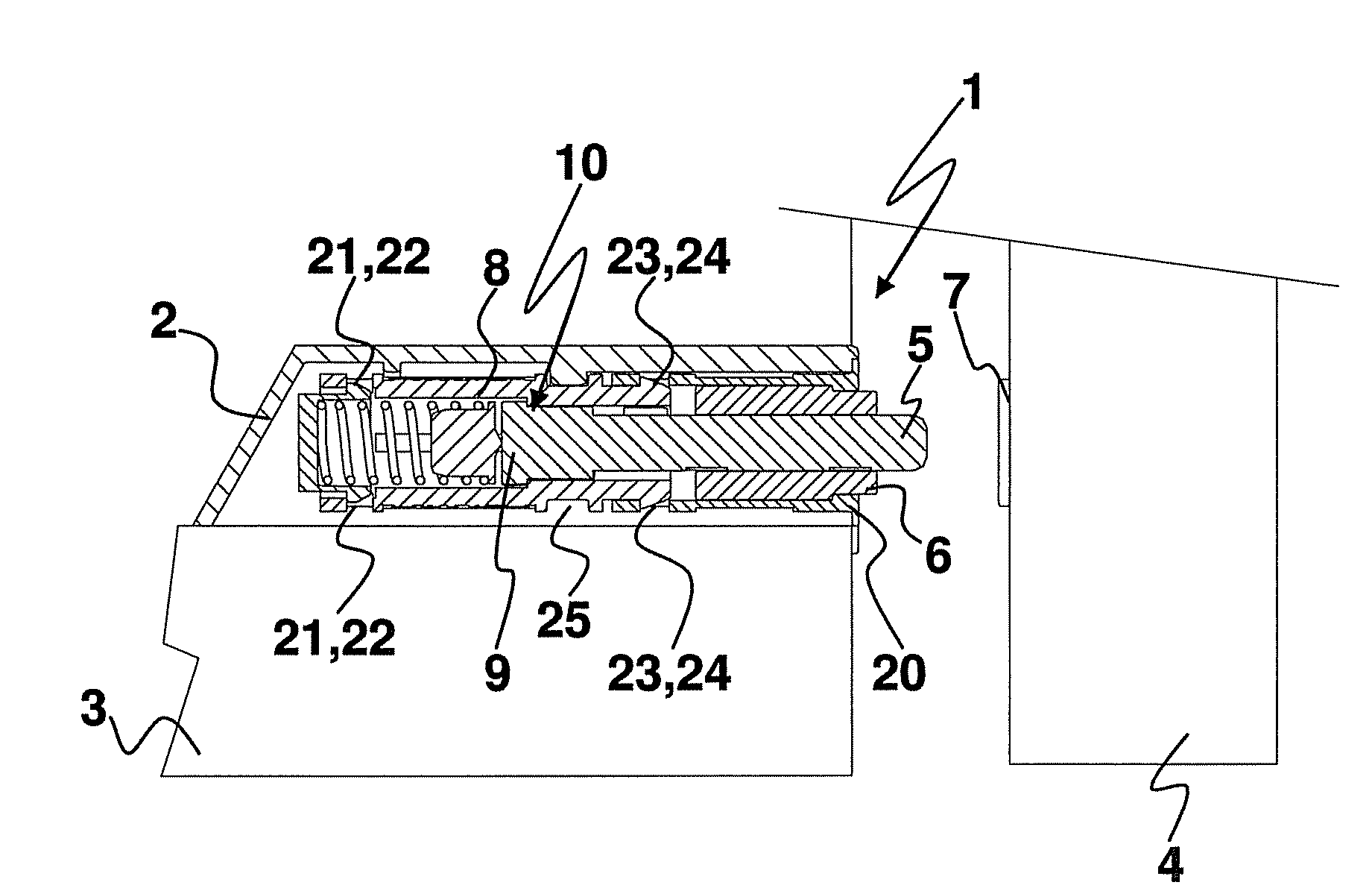

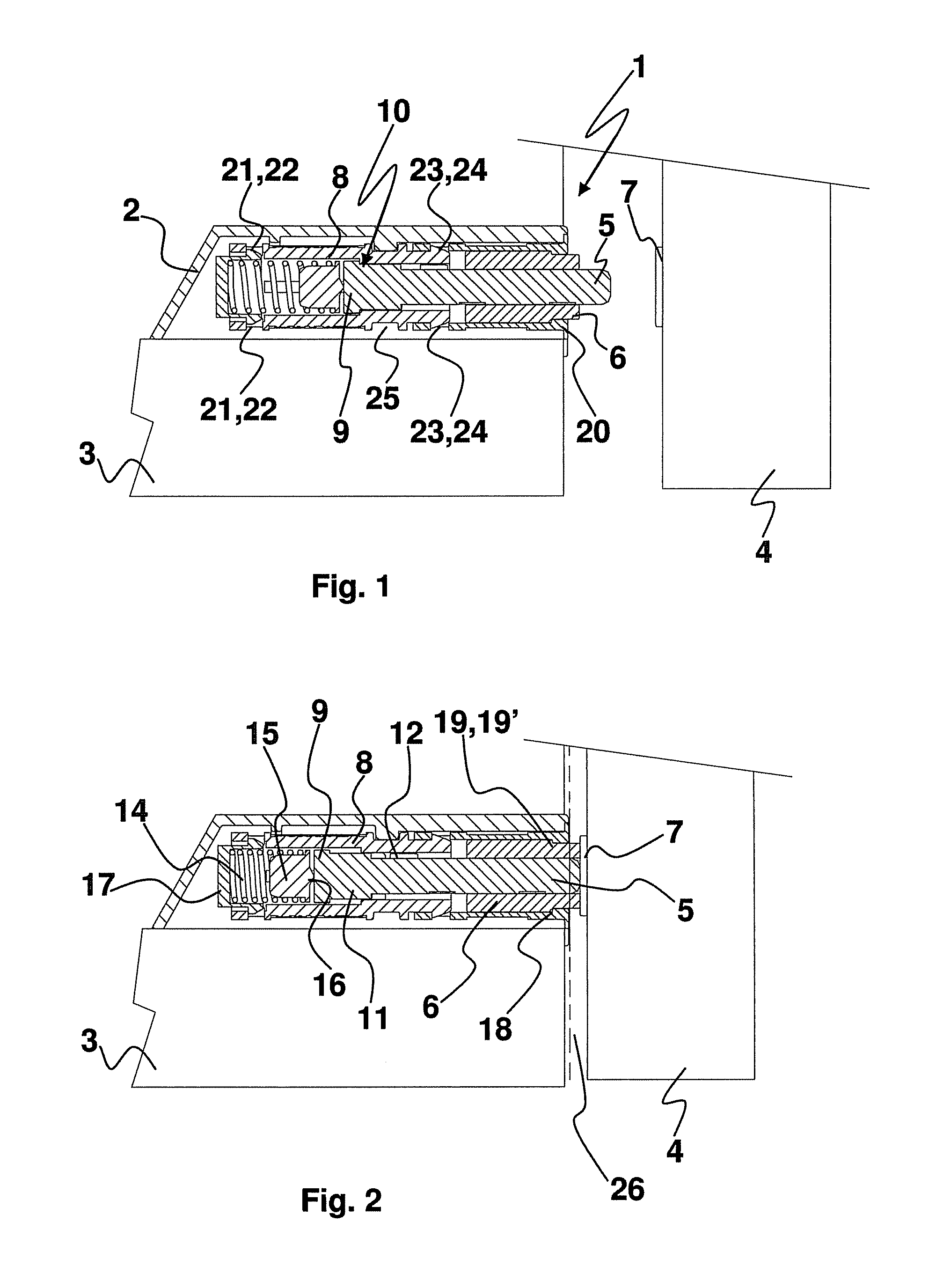

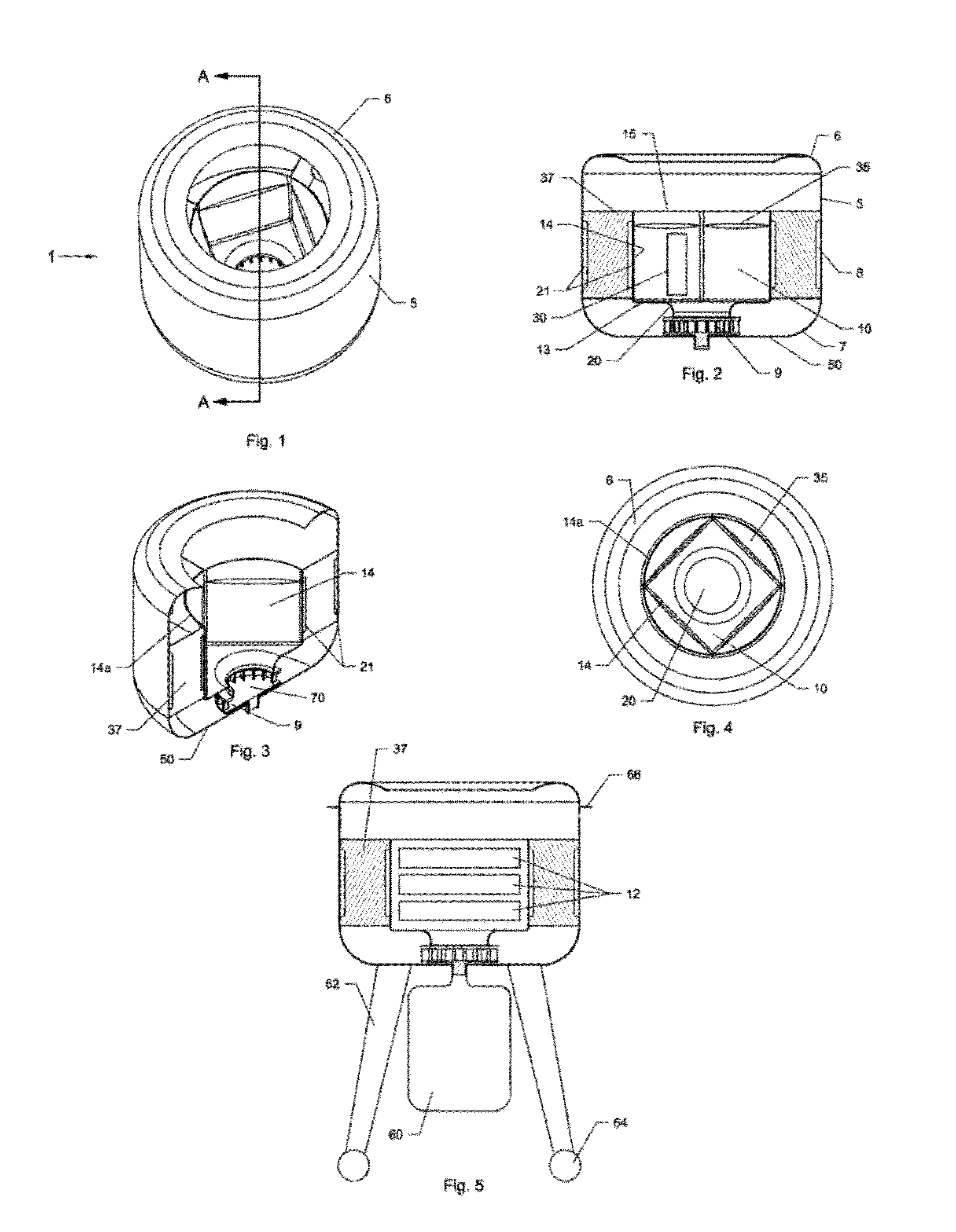

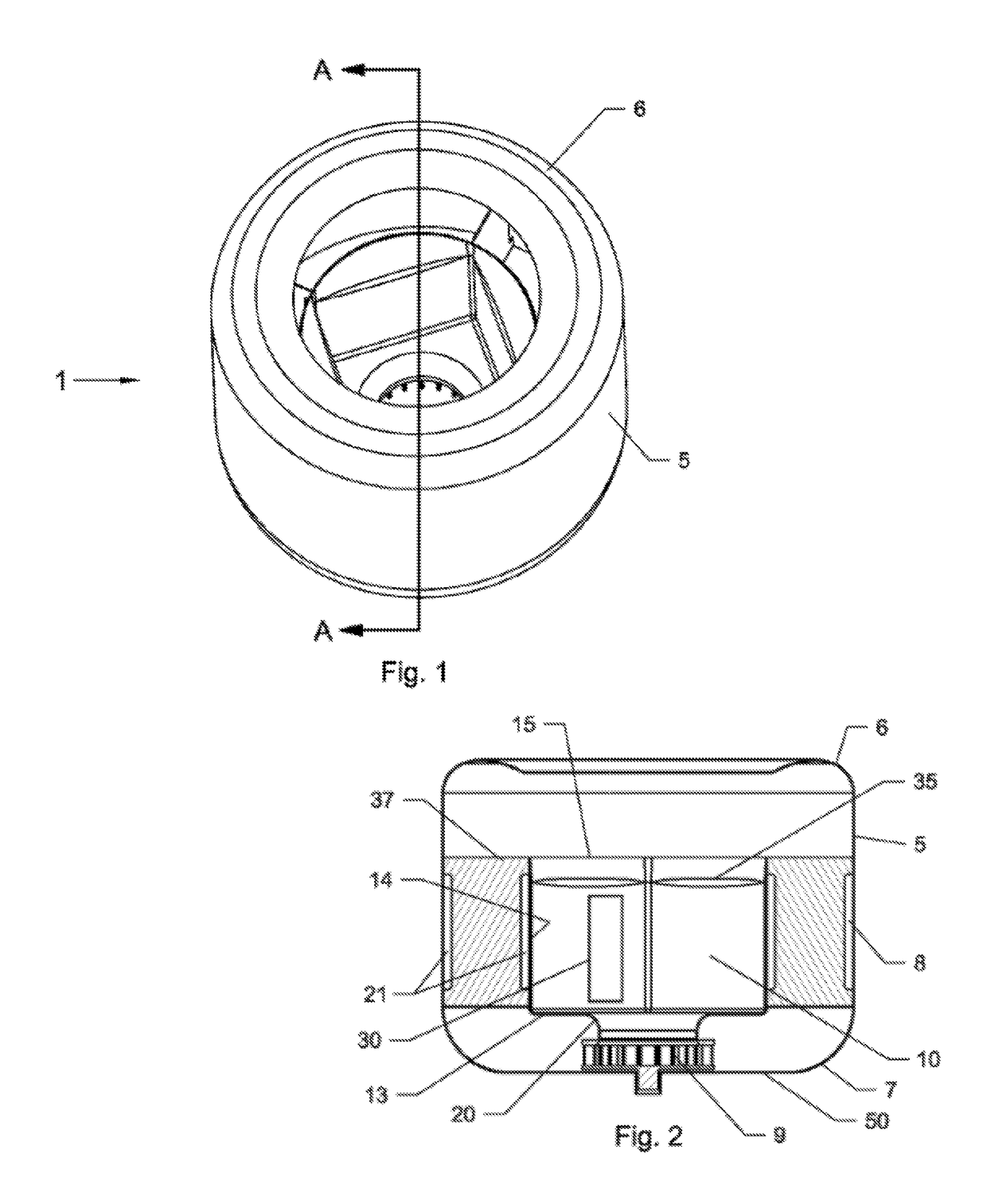

Closing and opening device of the snap type for a moveable part of a piece of furniture

InactiveUS20090307869A1Easy to assembleRapid and safeBuilding braking devicesWing fastenersBiomedical engineering

A magnetic fitted ratchet device assembled in rapid, safe and cost-effective manner. Advantageously, the device according to the invention is provided with suitable elastic protrusions and corresponding slots, provided on the surface of some of its components having a tubular shape, preferably cylindrical, which allow its rapid and safe assembly.

Owner:ARTURO SALICE

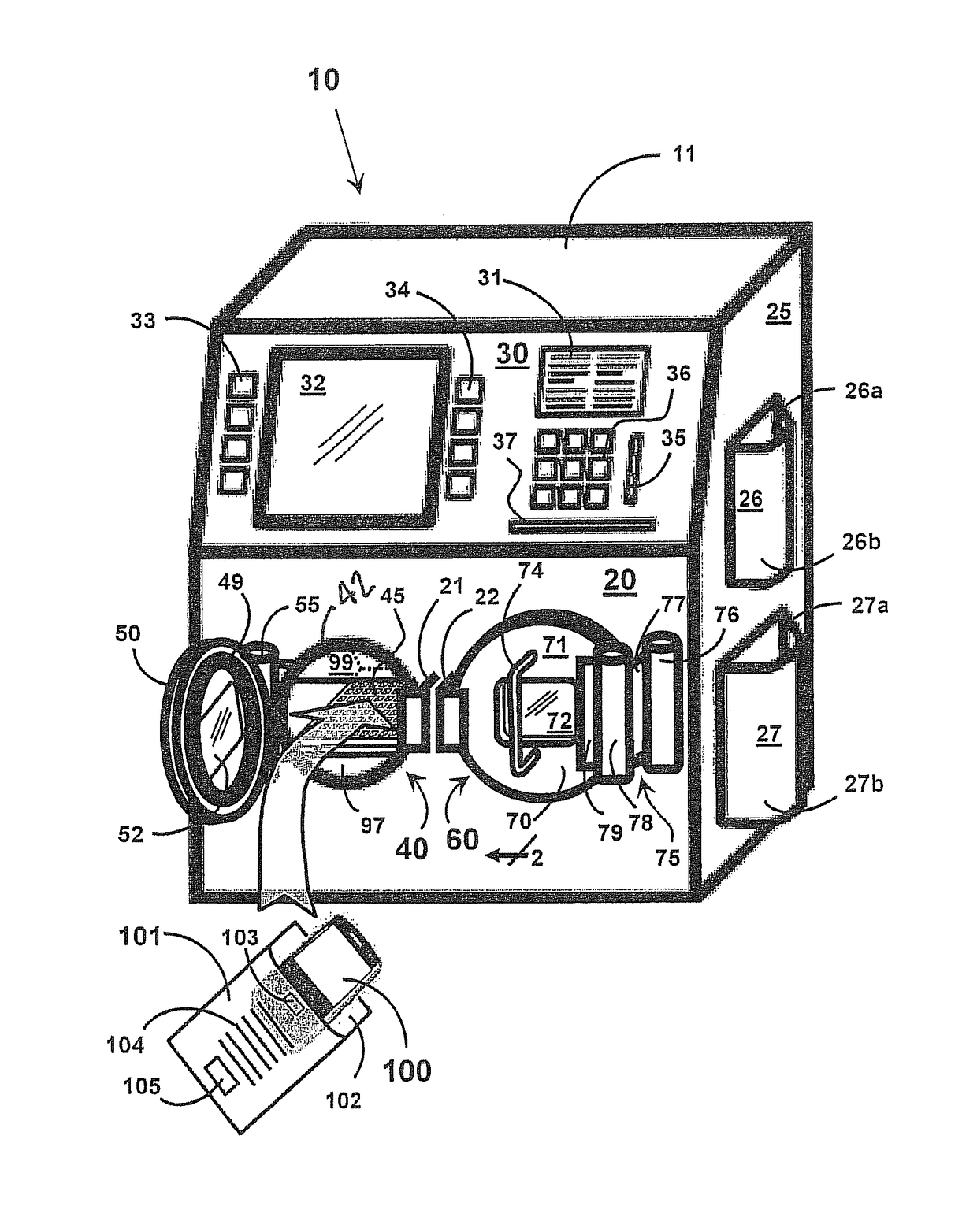

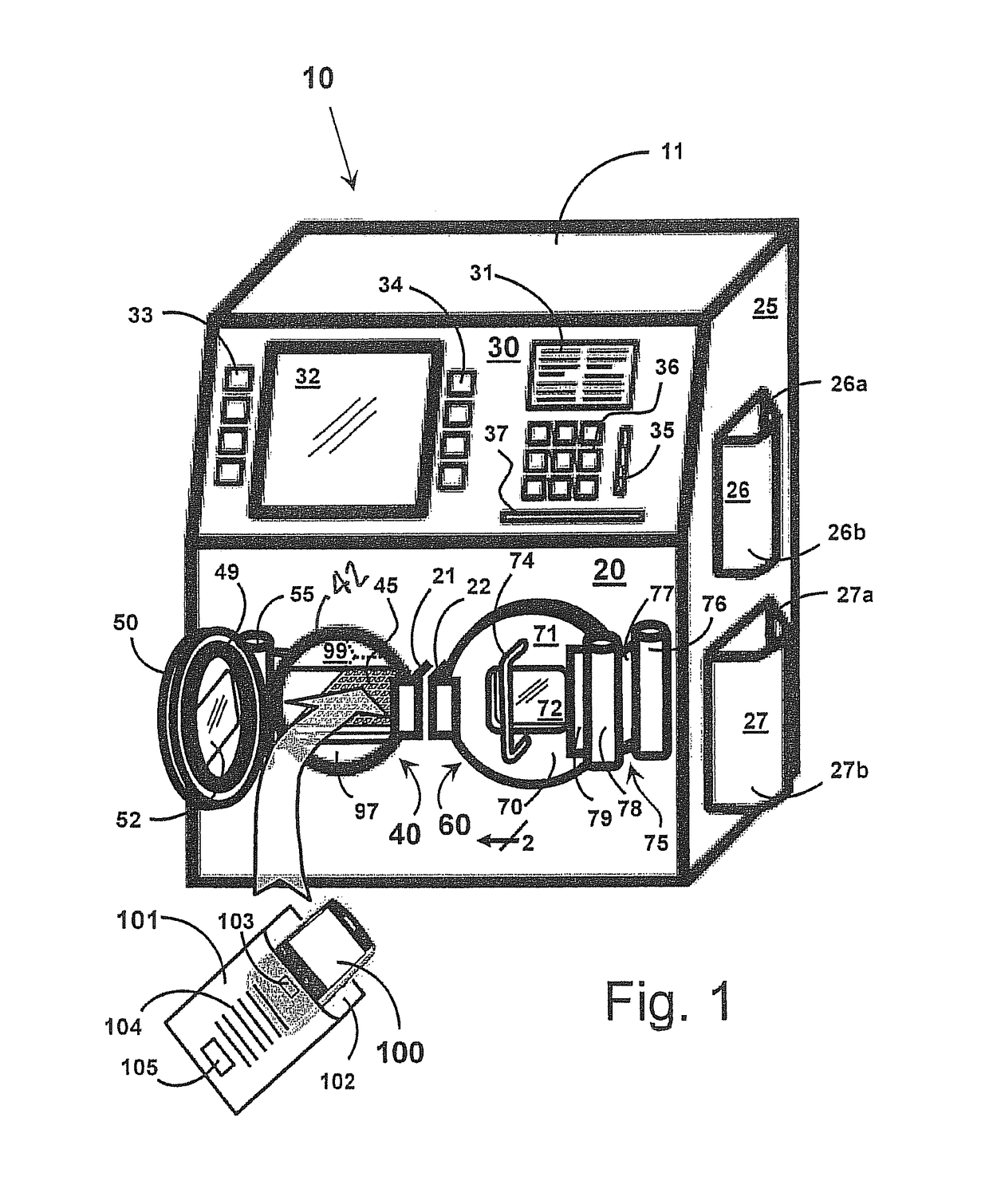

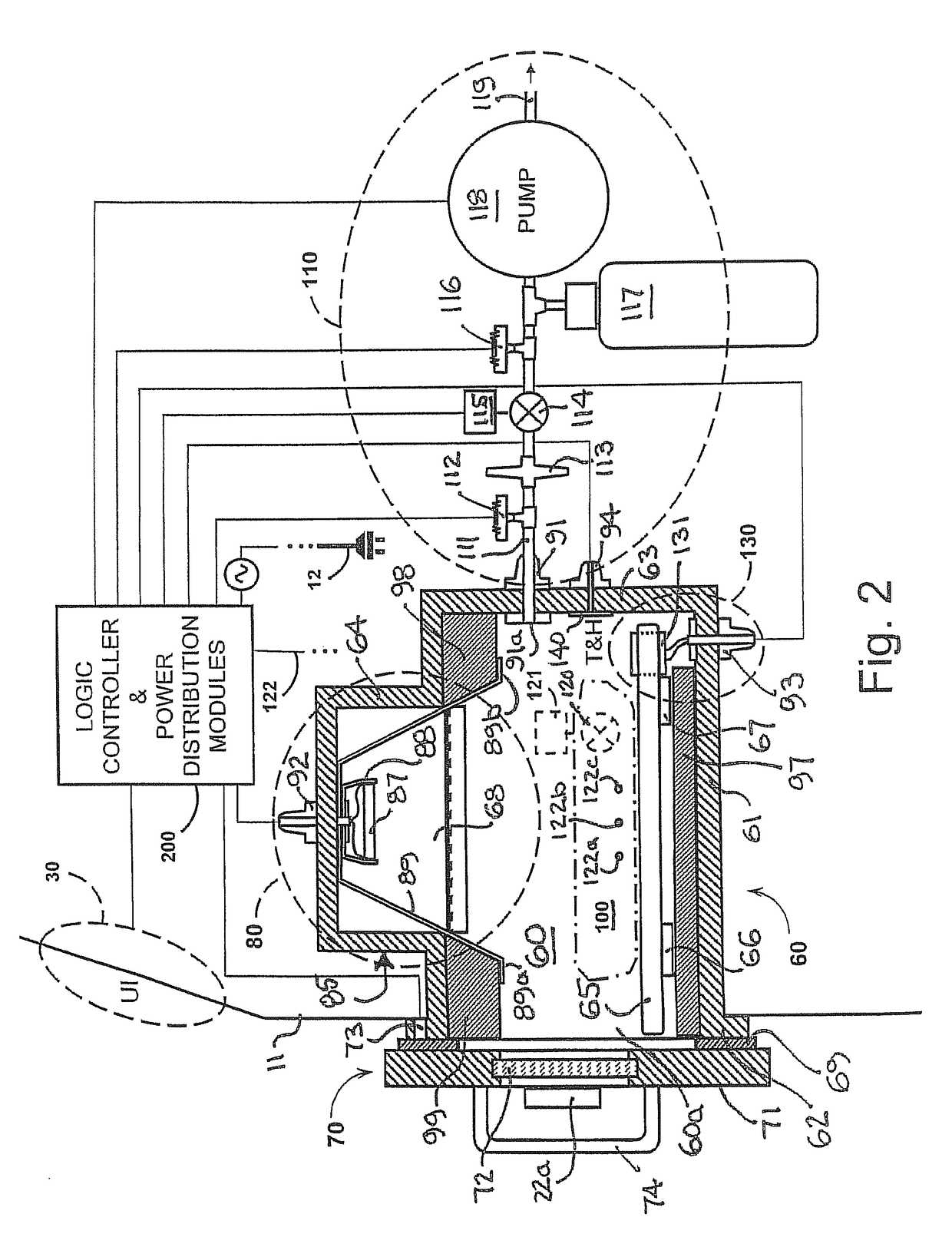

Method for inducing hypothermia

InactiveUS7422601B2Rapid and safeStart fastLighting and heating apparatusIce productionParticulatesSlurry

Systems for phase-change particulate slurry cooling equipment and methods to induce hypothermia in a patient through internal and external cooling are provided. Subcutaneous, intravascular, intraperitoneal, gastrointestinal, and lung methods of cooling are carried out using saline ice slurries or other phase-change slurries compatible with human tissue. Perfluorocarbon slurries or other slurry types compatible with human tissue are used for pulmonary cooling. And traditional external cooling methods are improved by utilizing phase-change slurry materials in cooling caps and torso blankets.

Owner:UNIVERSITY OF CHICAGO

Modular actuator system for valves and chokes

ActiveUS6883614B2Rapidly and safely and efficiently interchangedSimple and easyOperating means/releasing devices for valvesDrilling rodsLinear motionCoupling

The invention contemplates a simple coupling means for interfacing linear acting actuator shafts with valves or hydraulic chokes. The coupling means of the present invention allows either an actuator or an interconnected valve or choke to be rapidly, safely, and efficiently interchanged with a replacement part. The present invention is broadly applicable to a wide variety of actuator types having rectilinear motion outputs and to a large variety of valve and choke types which are operated by linear motions, including gate valves with or without balanced stems.

Owner:ADS SERVICES LLC

Method for inducing hypothermia

InactiveUS20090125087A1Rapid and safeStart fastLighting and heating apparatusIce productionParticulatesSlurry

Systems for phase-change particulate slurry cooling equipment and methods to induce hypothermia in a patient through internal and external cooling are provided. Subcutaneous, intravascular, intraperitoneal, gastrointestinal, and lung methods of cooling are carried out using saline ice slurries or other phase-change slurries compatible with human tissue. Perfluorocarbon slurries or other slurry types compatible with human tissue are used for pulmonary cooling. And traditional external cooling methods are improved by utilizing phase-change slurry materials in cooling caps and torso blankets.

Owner:UNIVERSITY OF CHICAGO

Food tumbler

InactiveUS7229656B2Simple processImprove securityGrain huskingRotating receptacle mixersEngineeringMechanical engineering

A counter-top appliance has a food container with internal fins extending inward from the outer wall at an angle offset from radial. The food container is coupled to a motor for rotation in either of two directions. One direction of rotation produces a scooping, elevating and subsequent discharge of liquid and fluent materials such as might be useful for washing or breading, while the second direction of rotation presents a surface adapted for massaging meat during marinating. The food container is preferably sealed through vacuum, and has a simple geometry which greatly facilitates thorough cleaning of the container. Meats, produce, pasta, and other diverse foods are processed using the counter-top appliance, and a method for processing one or a sequential set of foods is disclosed.

Owner:PAUMEN DECEASED LAWRENCE J +2

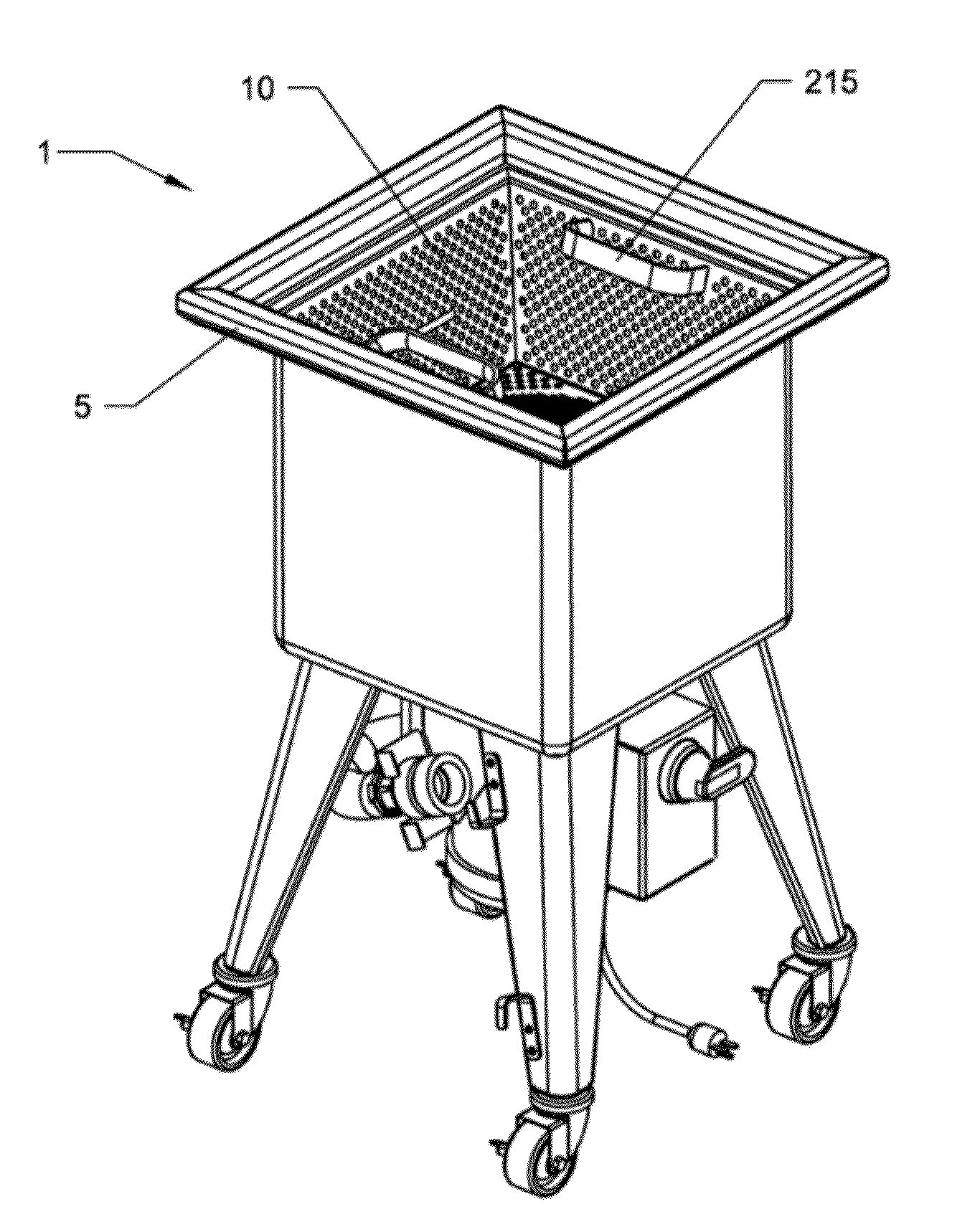

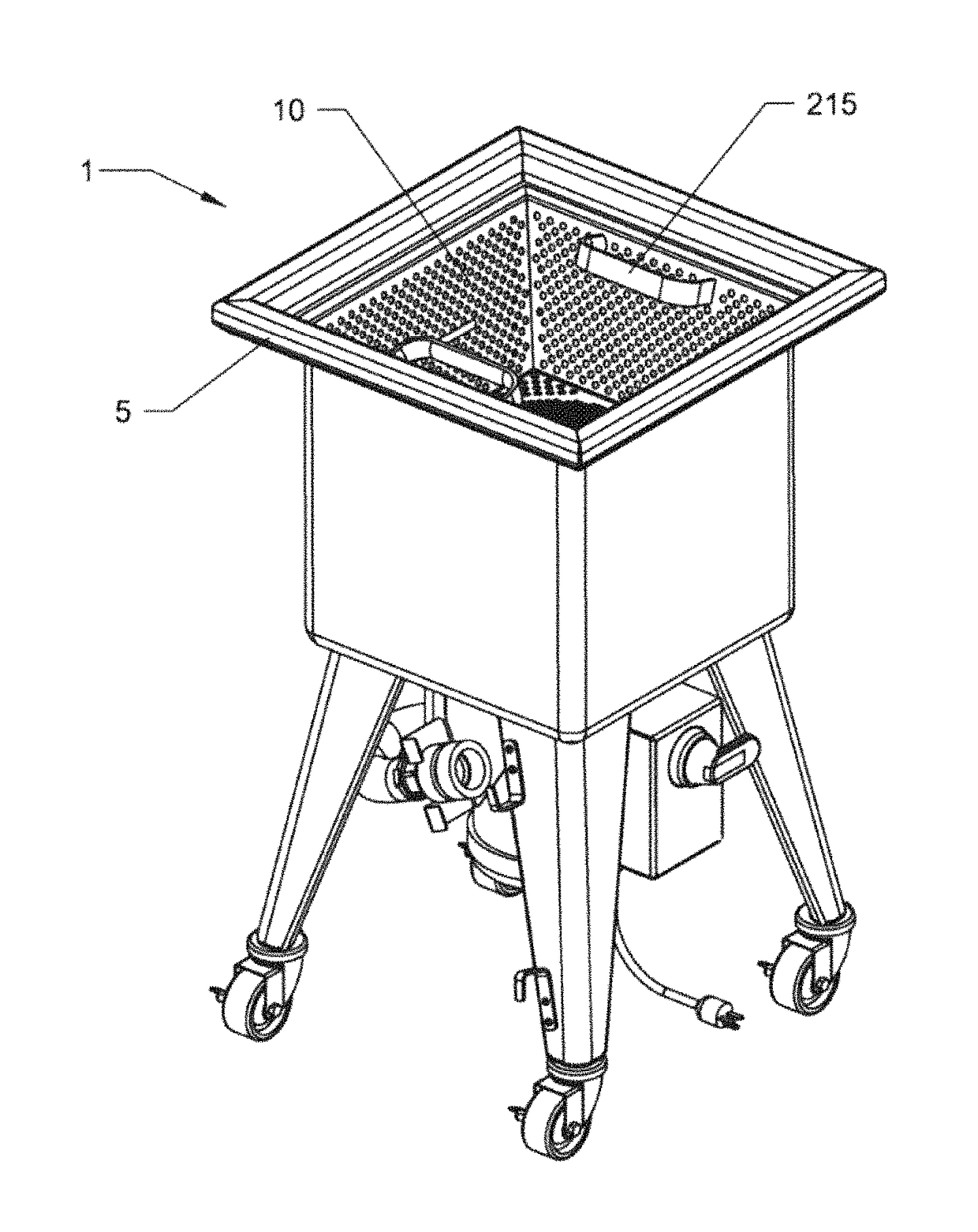

Rapid Rescue of Inundated Cellphones

ActiveUS20150226481A1Fast and effective drying systemOptimize locationDrying using combination processesDrying solid materials with heatThermal energyBiological activation

A system and method for providing fast and effective drying for inundated wireless telecommunications handsets by a combination of technologies that induce a negative pressure atmosphere together with controlled thermal energy at levels that is significant yet relatively harmless to handset components and memory. The combination is such that the embodiments generally restore full handset functionality (to the extent recoverable) within thirty minutes from activation of the particular station for treatment of an inundated handset. Related business methods of the embodiments include the derivation of revenue through licensing and marketing agreements with service center owners or the operators of other retail establishments such as courier mail centers.

Owner:REVIVE ELECTRONICS

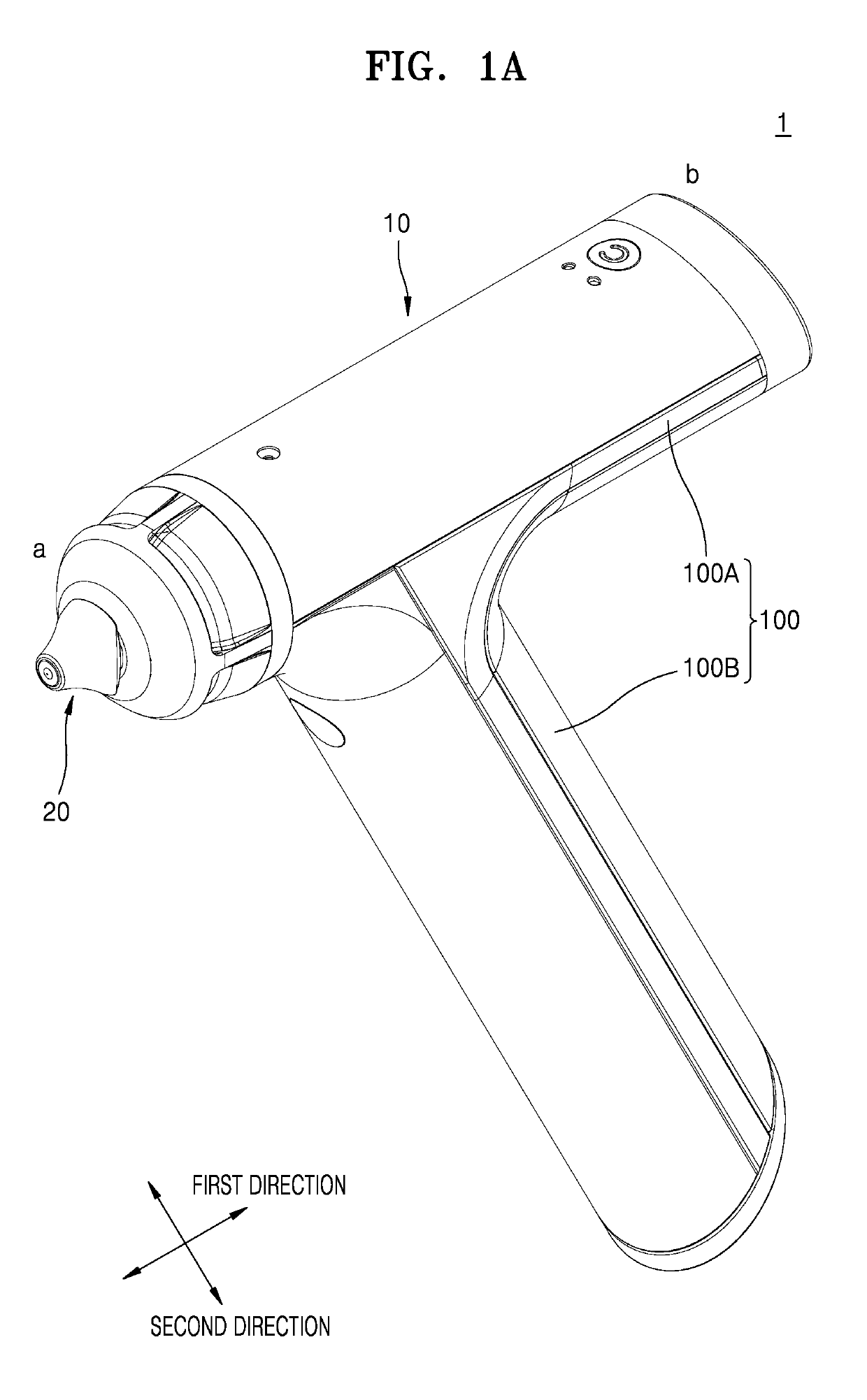

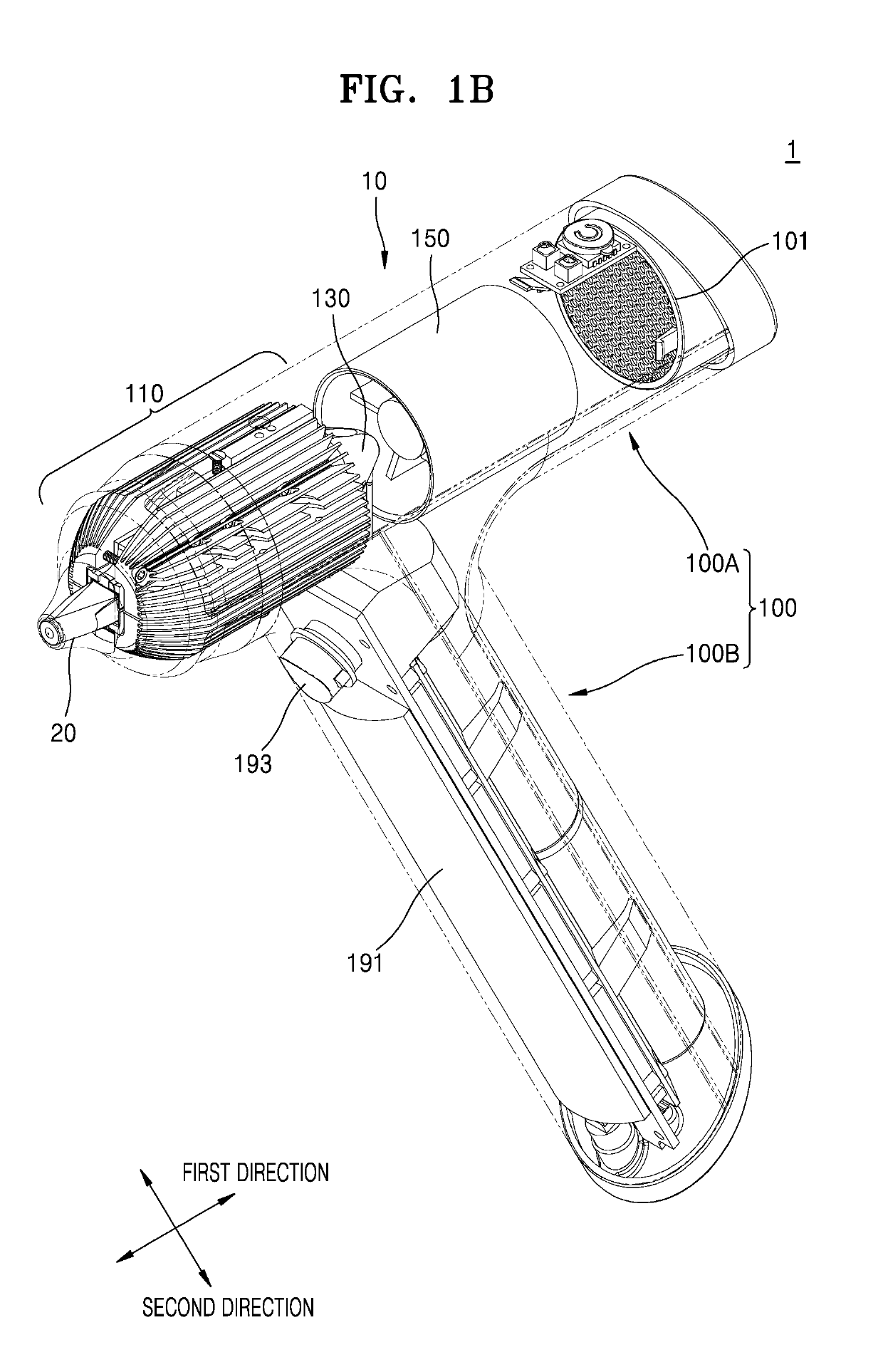

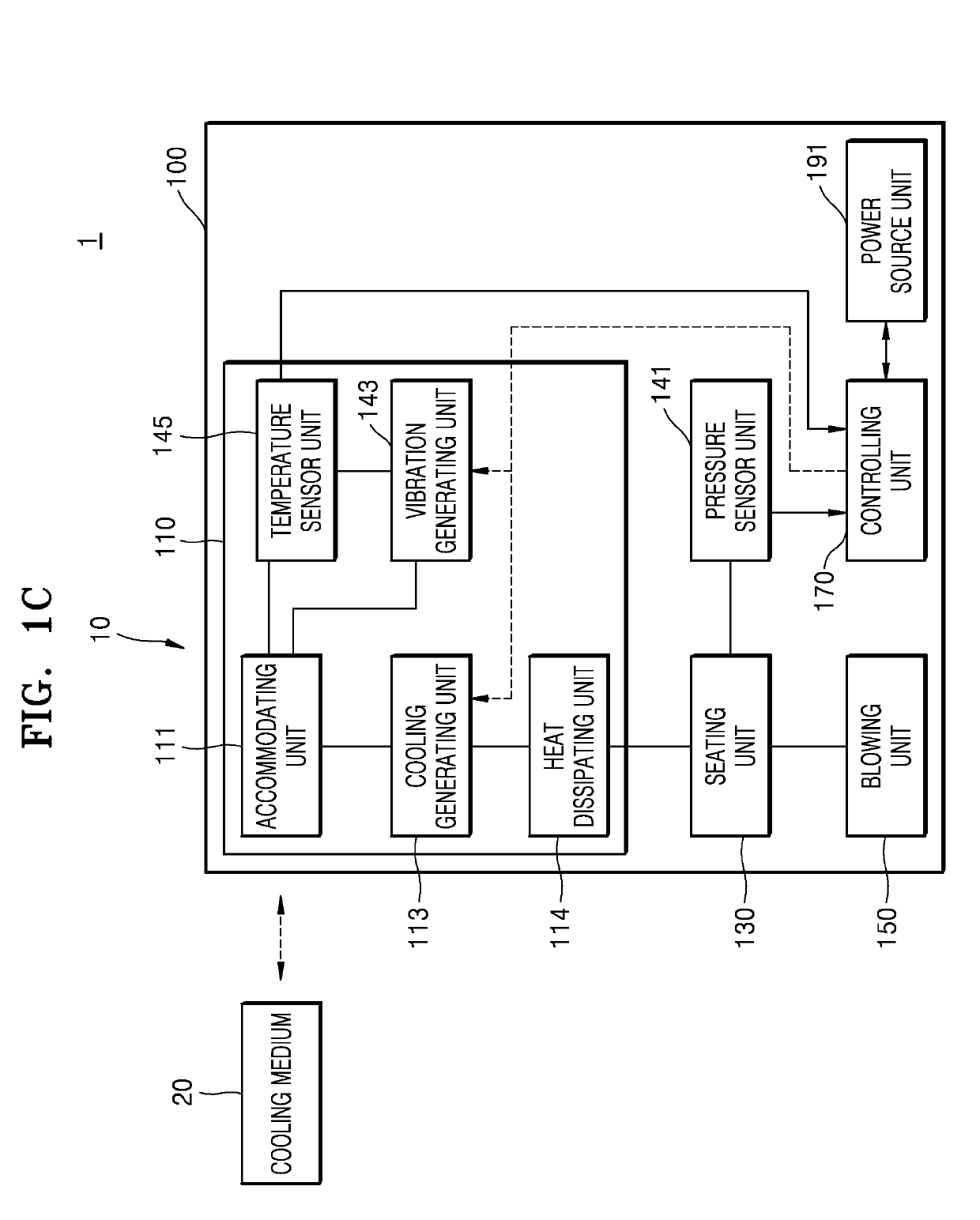

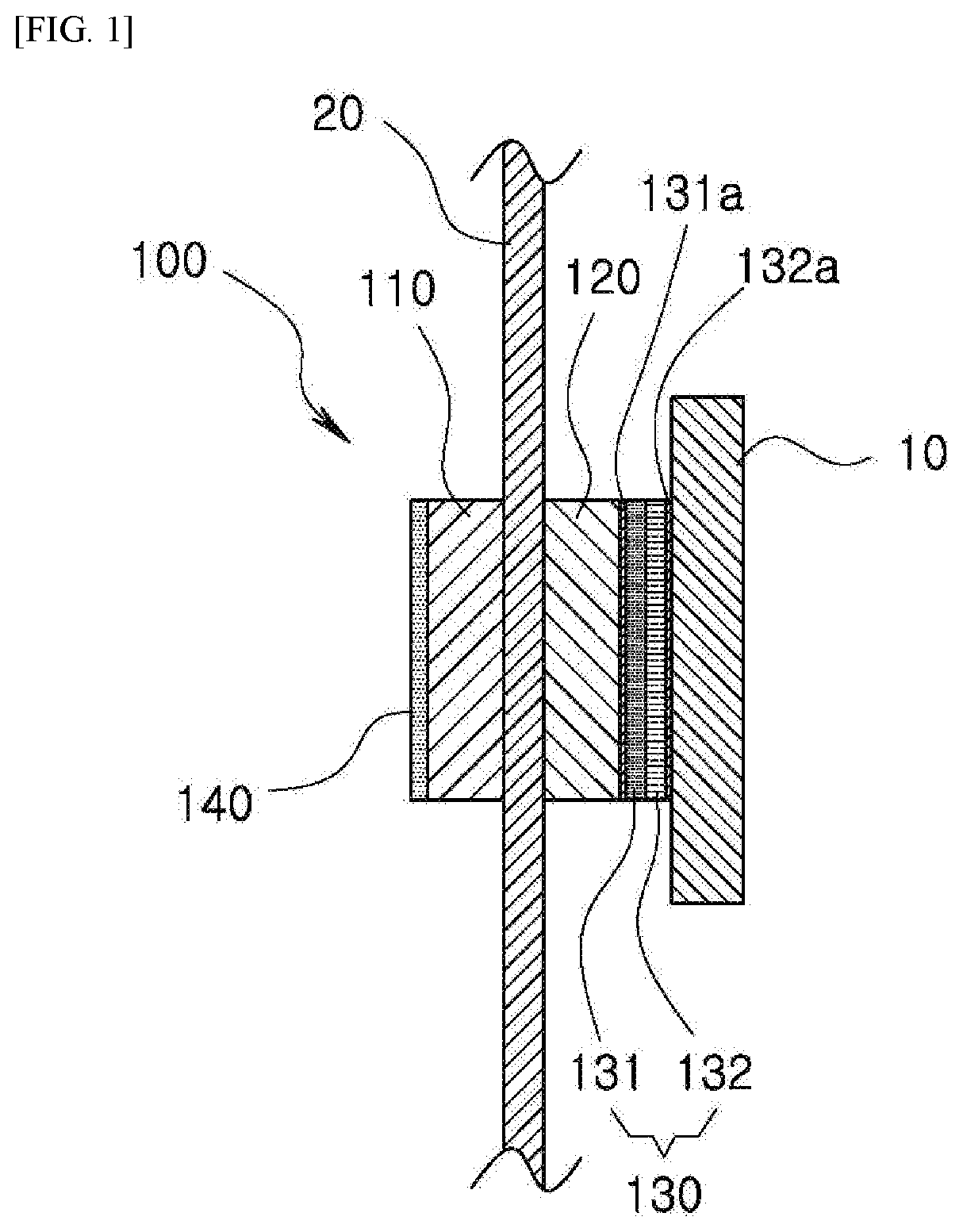

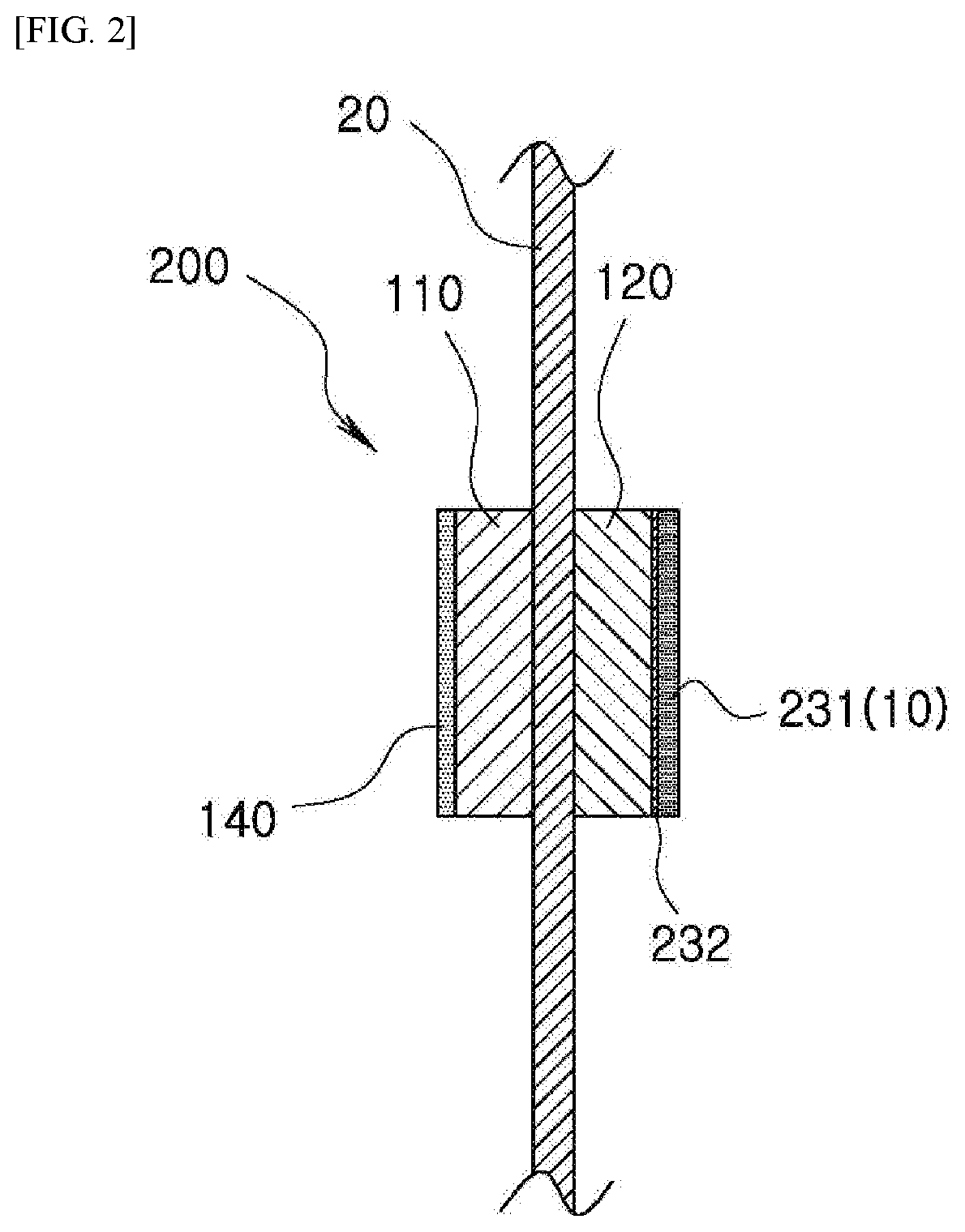

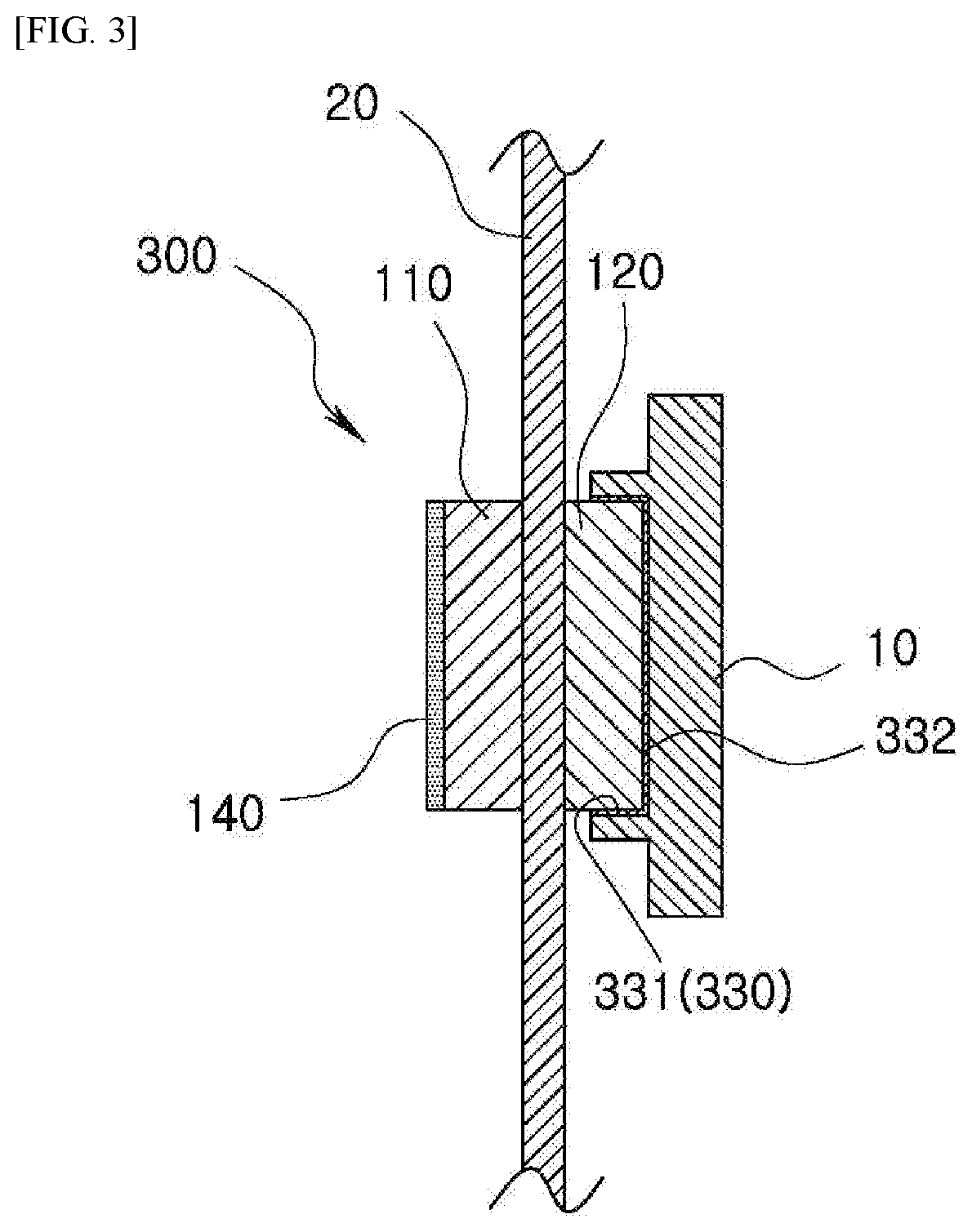

Device and method for cooling living tissue

The present disclosure provides a device and a method for cooling living tissues for a medical purpose and other purposes. The cooling device comprises: a container configured to accommodate a cooling medium, the container including a plurality of divided members each having a contact surface which is thermally coupled with the cooling medium; a cooling generator configured to provide cooling energy to the container, and disposed on another surface of the divided member other than the contact surface; and a lubricating member provided to the contact surface of the divided member, wherein the container is configured to be thermally coupled with the cooling medium via the lubricating member.

Owner:RECENSMEDICAL INC

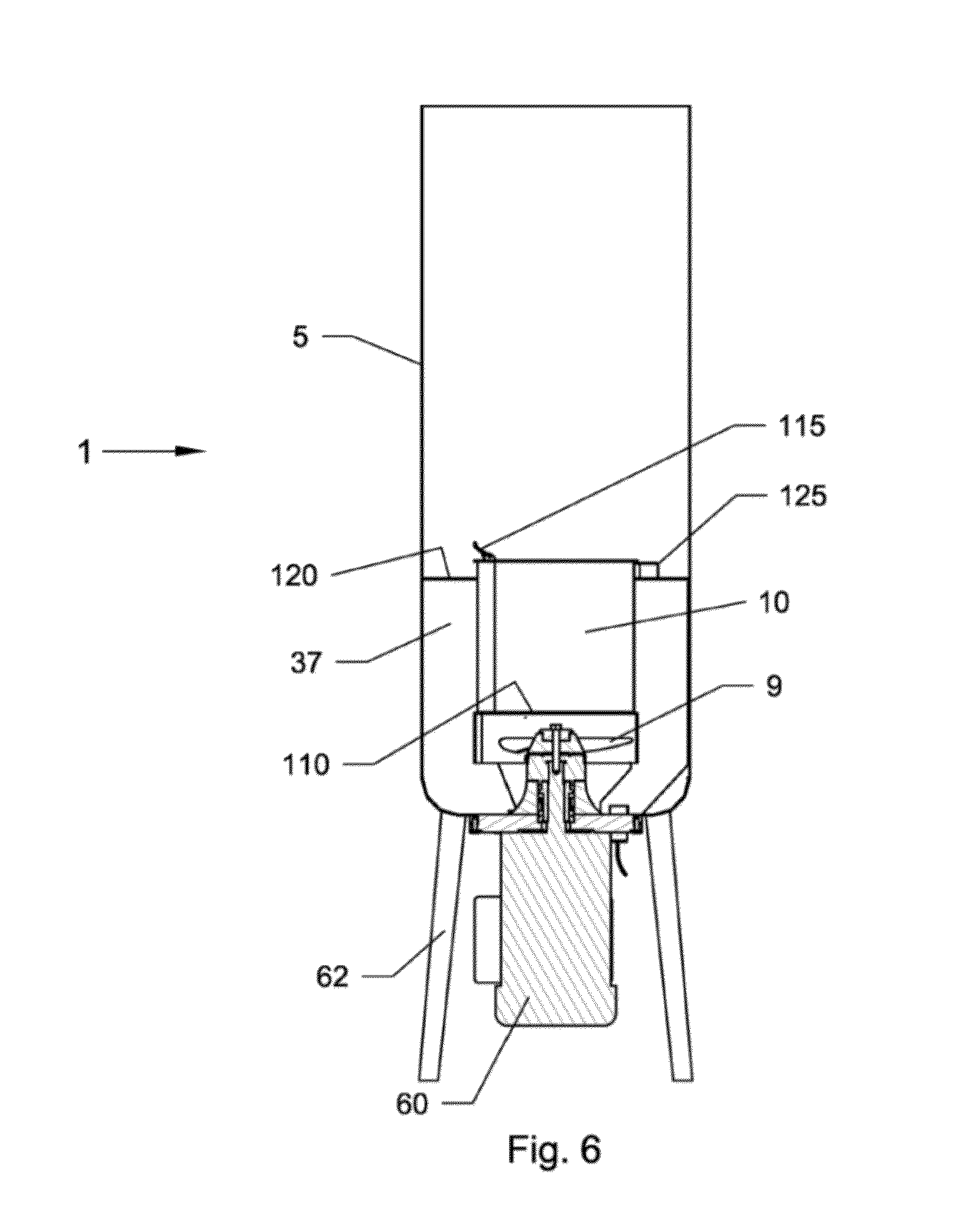

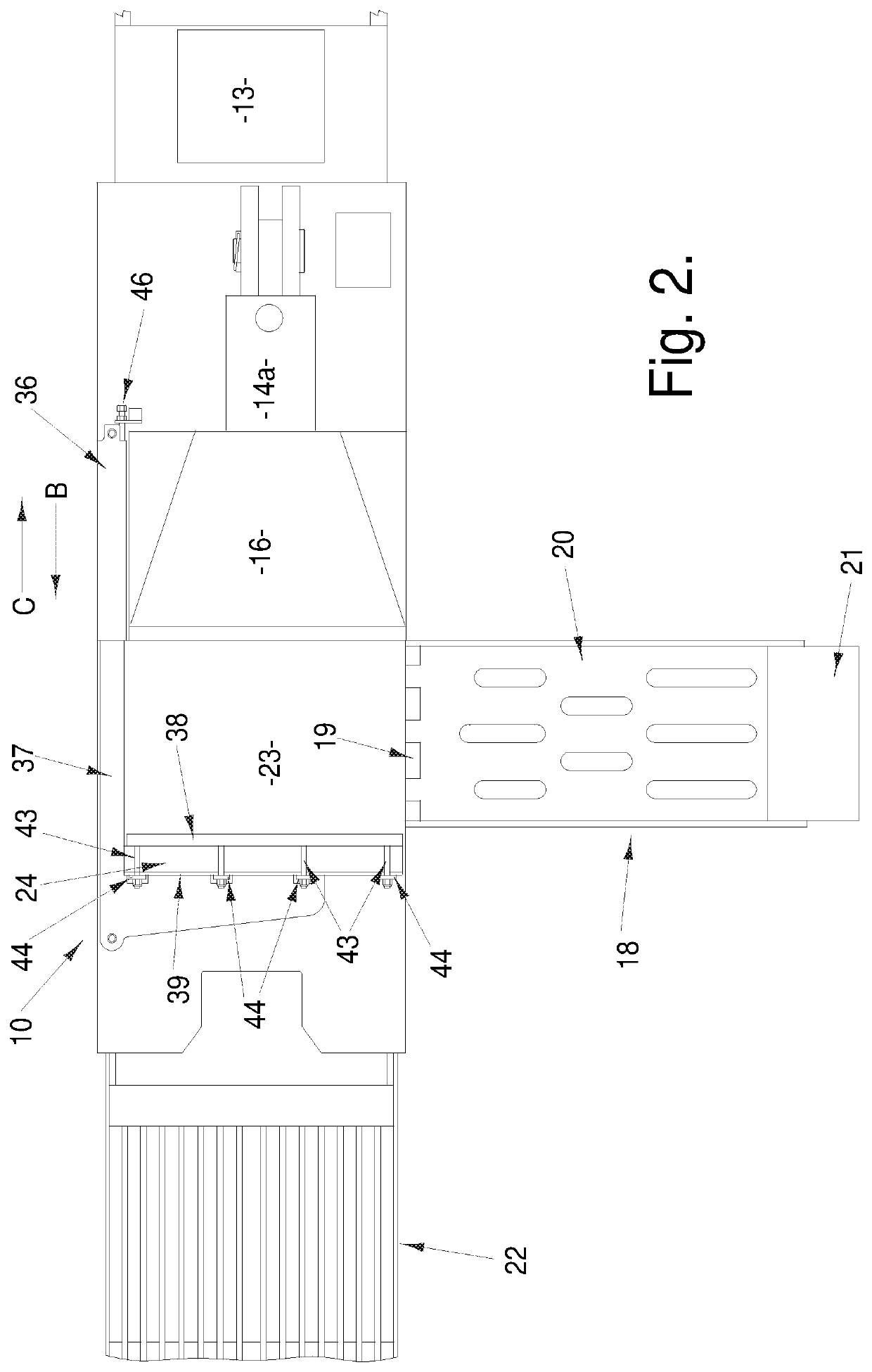

Defrost apparatus and method thereof

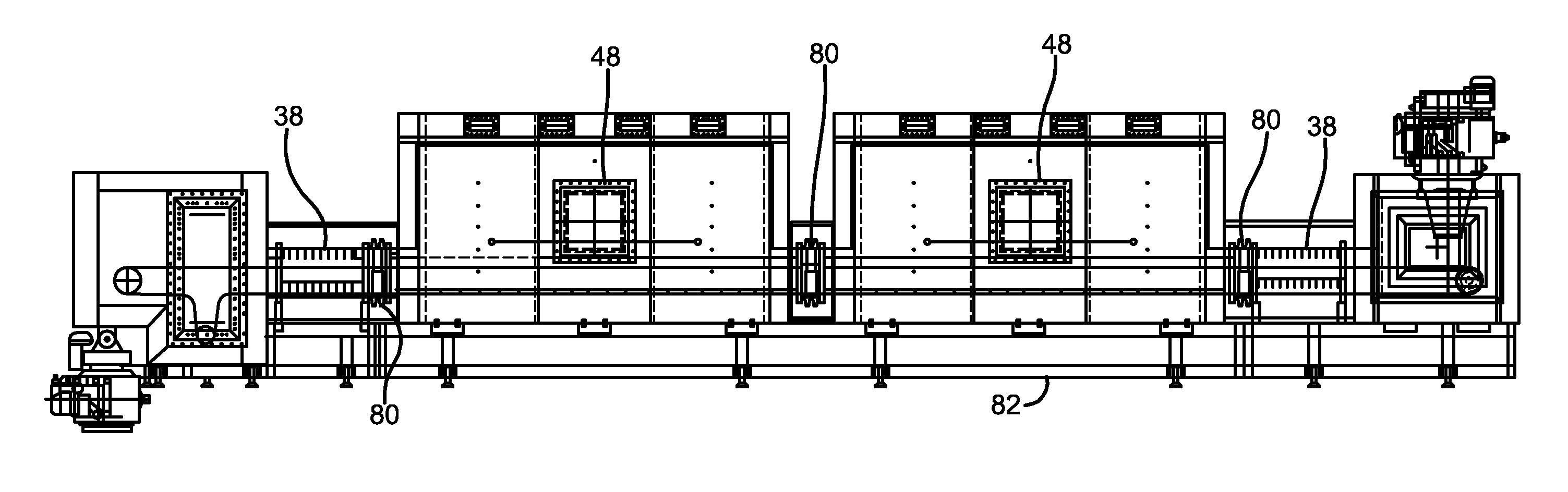

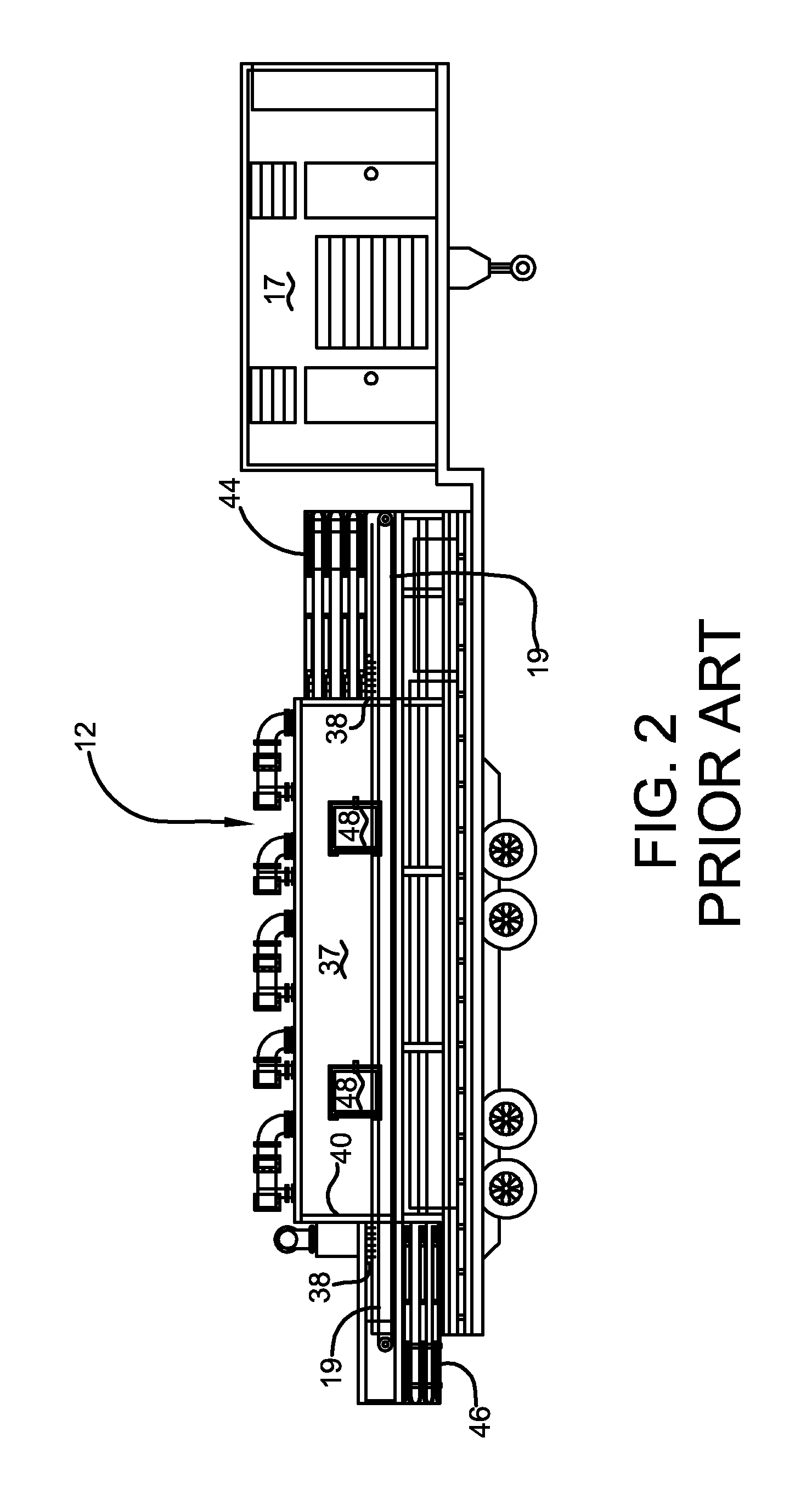

ActiveUS20150007588A1Safely and rapidly defrostingEffectively defrost such itemsDomestic cooling apparatusLighting and heating apparatusMotion systemBiomedical engineering

An apparatus and a method of defrosting frozen items, is provided. The apparatus and method utilizes a fluid flow system and method, such as a fluid-push / pull system in which generally an entire volume of fluid is pushed or pulled through a cavity in which frozen items are located and / or a continuous motion system in which fluid is circulated within a fluid tank of the system.

Owner:UNIFIED BRANDS

Rapid rescue of inundated cellphones

ActiveUS9709327B2Fast and effective drying system and methodOptimize locationDrying solid materials without heatDrying chambers/containersThermal energyBiological activation

A system and method for providing fast and effective drying for inundated wireless telecommunications handsets by a combination of technologies that induce a negative pressure atmosphere together with controlled thermal energy at levels that is significant yet relatively harmless to handset components and memory. The combination is such that the embodiments generally restore full handset functionality (to the extent recoverable) within thirty minutes from activation of the particular station for treatment of an inundated handset. Related business methods of the embodiments include the derivation of revenue through licensing and marketing agreements with service center owners or the operators of other retail establishments such as courier mail centers.

Owner:REVIVE ELECTRONICS

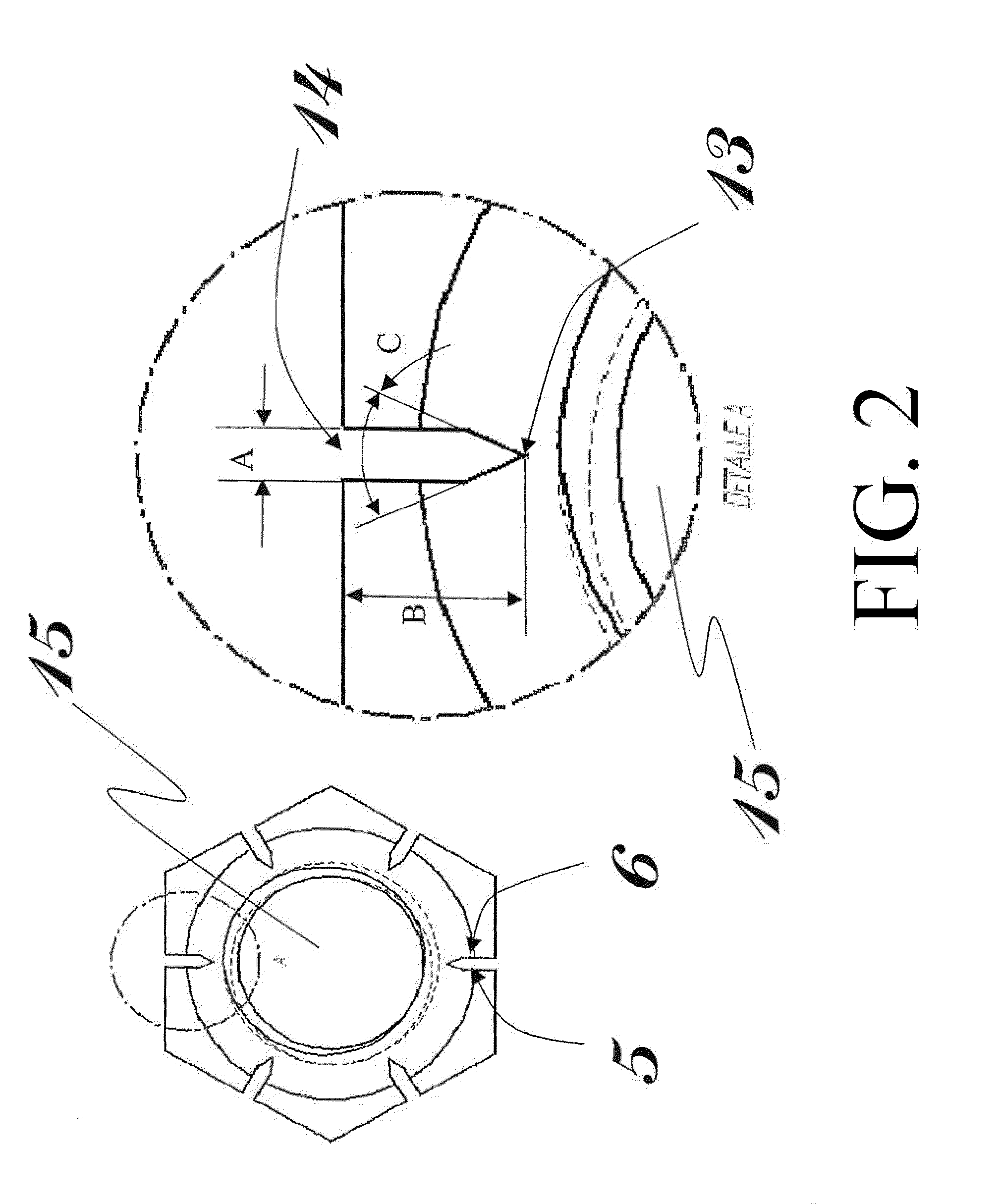

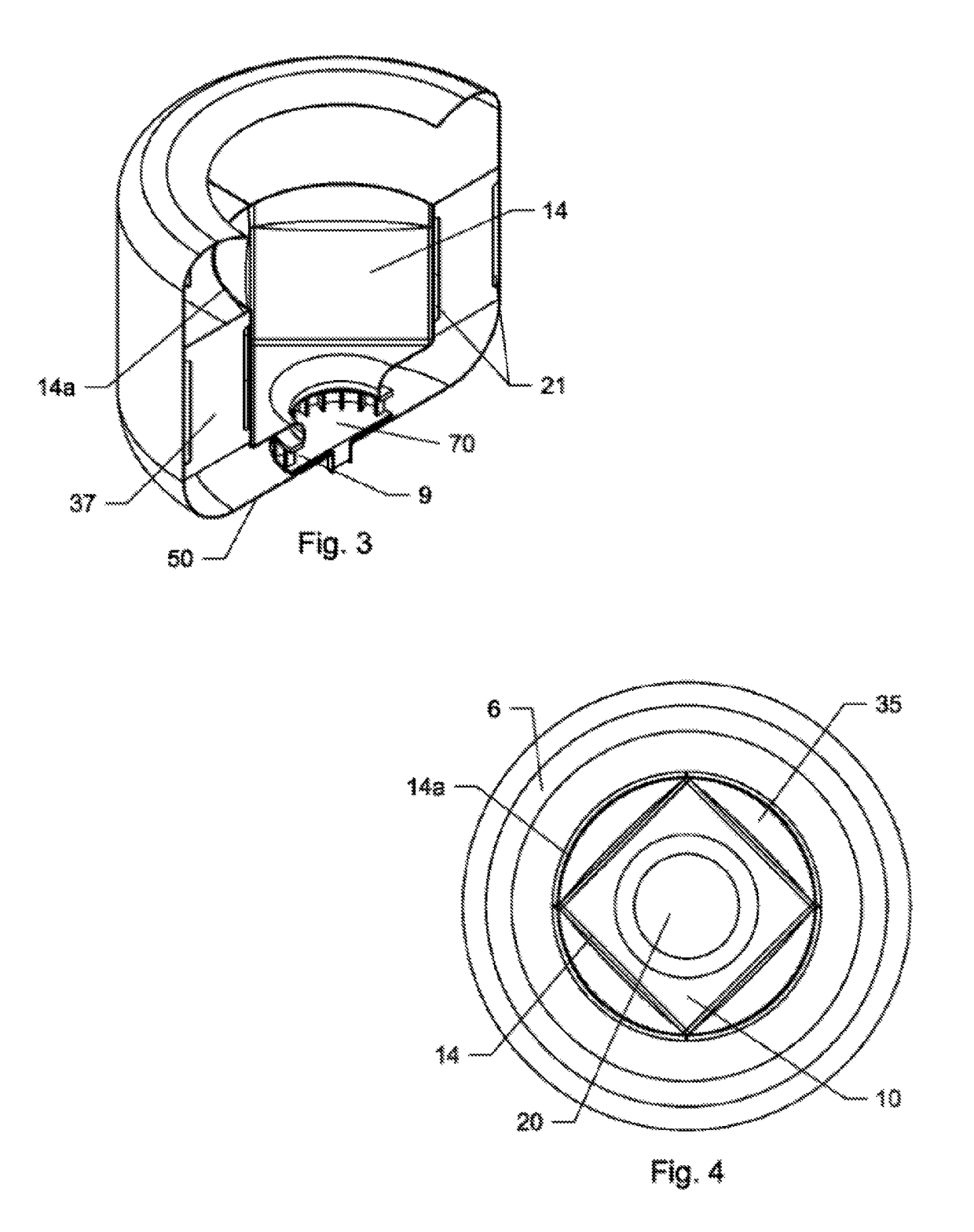

Fast Extraction Threaded Nut

The present invention relates to a fast extraction threaded nut intended to be used on a threaded bolt or male member wherein the fast extraction threaded nut comprises at least an outer face and an axial bore as to allow insertion of a male member or like, wherein the fast extraction threaded nut and the threaded bolt have tightening means with common geometry, and the fast extraction threaded nut and the threaded bolt or male member are intended to join or connect two elements that need to be attached or coupled to each other, wherein the fast extraction threaded nut comprises in at least the outer face a notch of variable section and the notching is formed by at least two faces wherein the maximum cross-section of the notch is positioned in the outer area and the minimum section is positioned prior to the axial bore at such a distance that allows for the generation of an increase area which extensively grows until reaching the inner surface of the axial bore where the common tightening means is formed thus generating the split of the fast extraction threaded nut.

Owner:ABASOLO VALLEJO +1

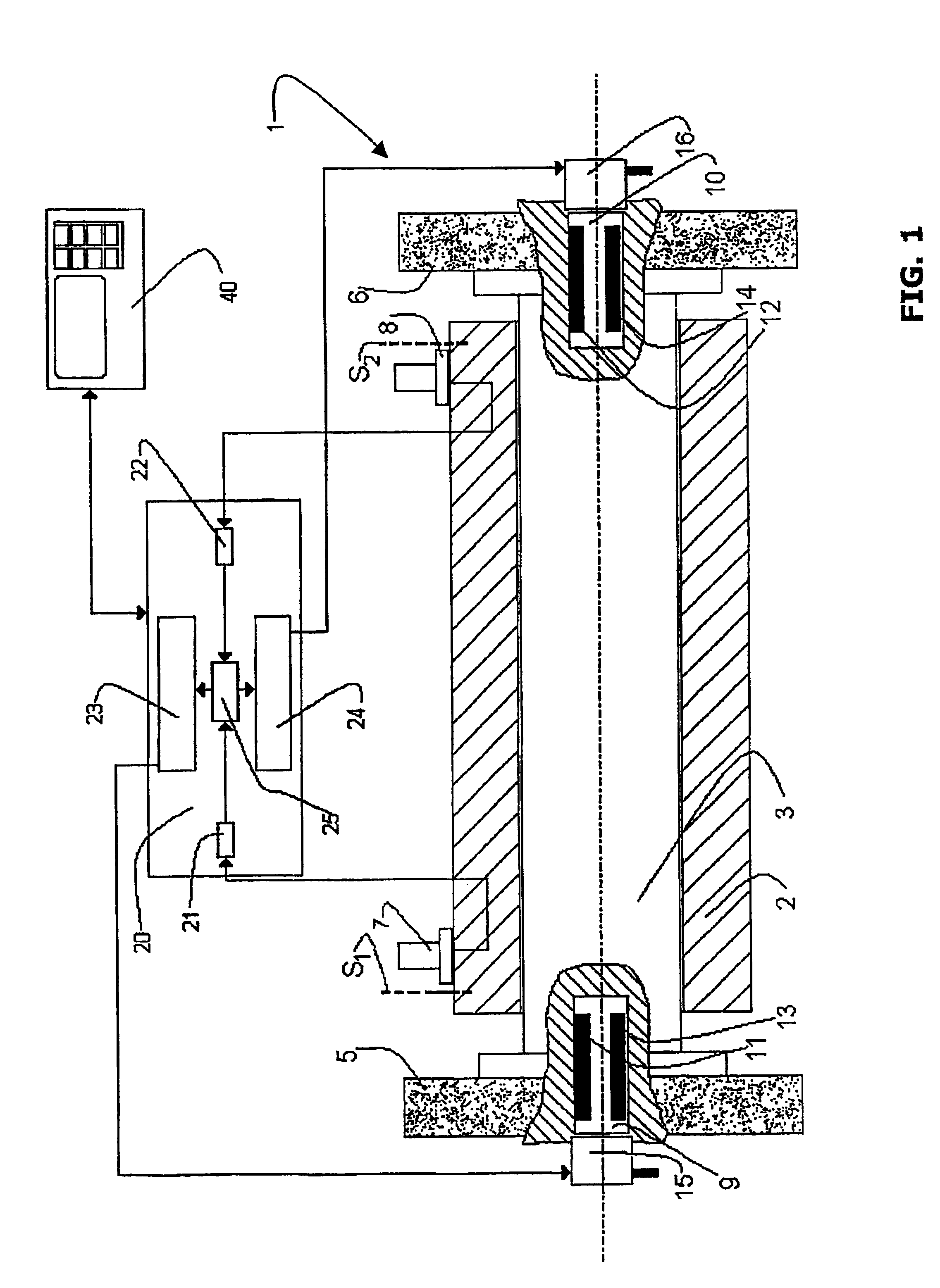

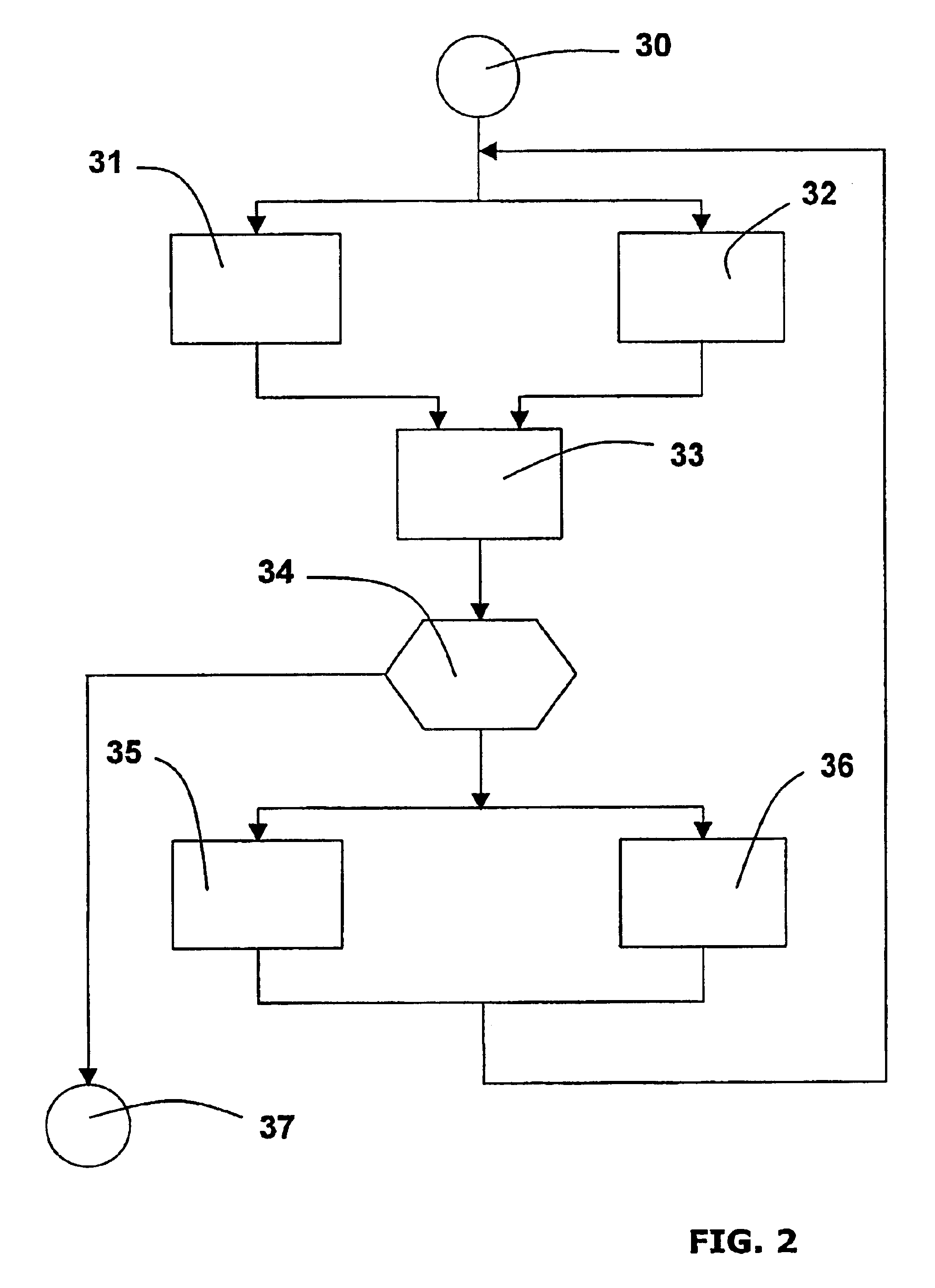

Method and apparatus for the dynamic balancing of a rotating structure

InactiveUS6879882B2Flexibility of useRapid and safeSampled-variable control systemsComputer controlComputer moduleEngineering

A method and an apparatus for balancing an elongate structure (1) rotating about an axis, like a spindle (3) carrying two grinding wheels (5, 6), wherein two vibration-detecting sensors (7, 8) and associated balancing devices (9, 10) with movable masses (11-14) are arranged at two checking sections (S1, S2) spaced out along the axis of rotation. Processing and control means (20) control the balancing devices on the basis of one or more signals (VC; VC1, VC2) achieved as combination(s) of the vibrations, in module, detected by both the sensors.

Owner:MARPOSS SPA

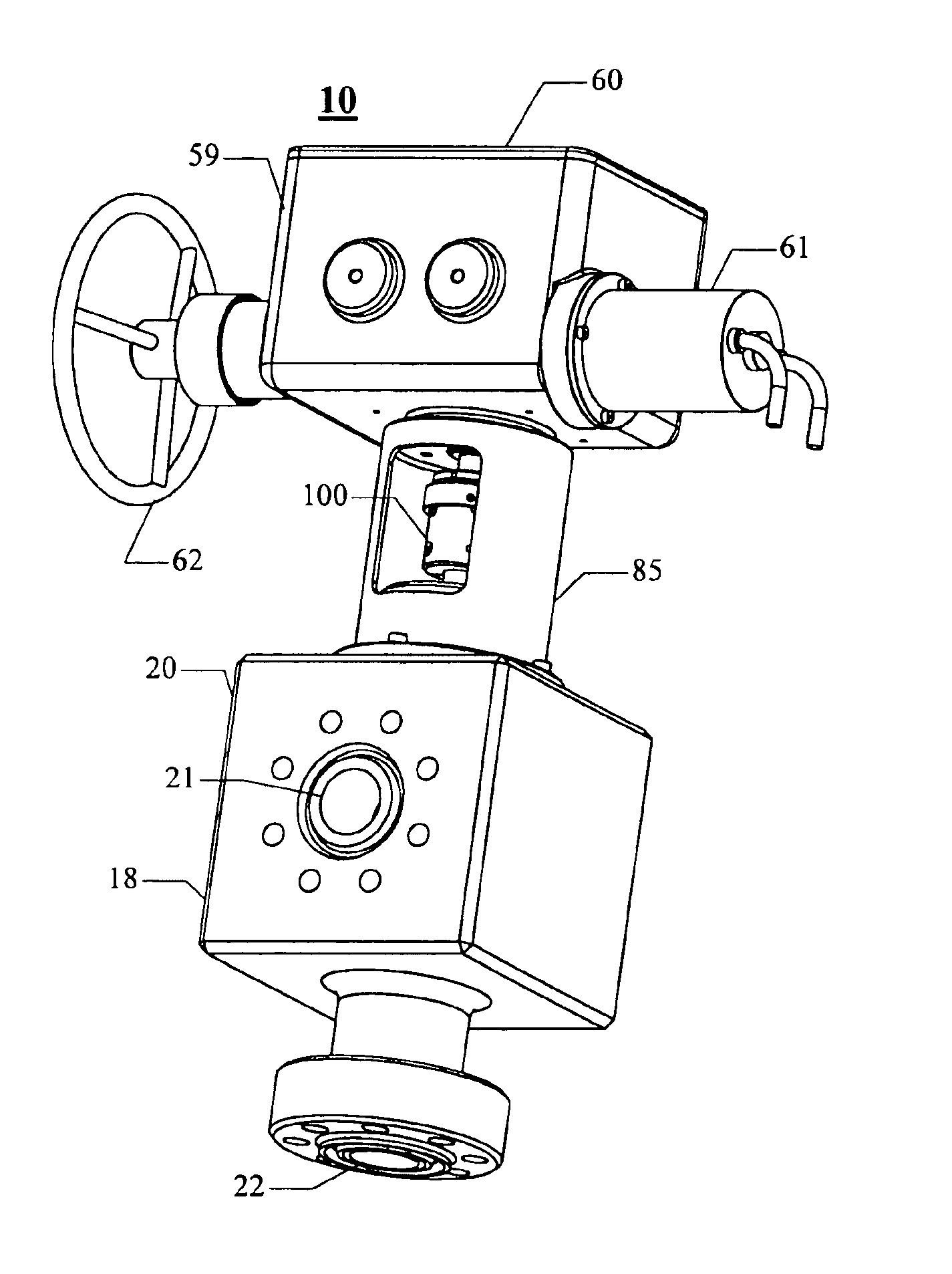

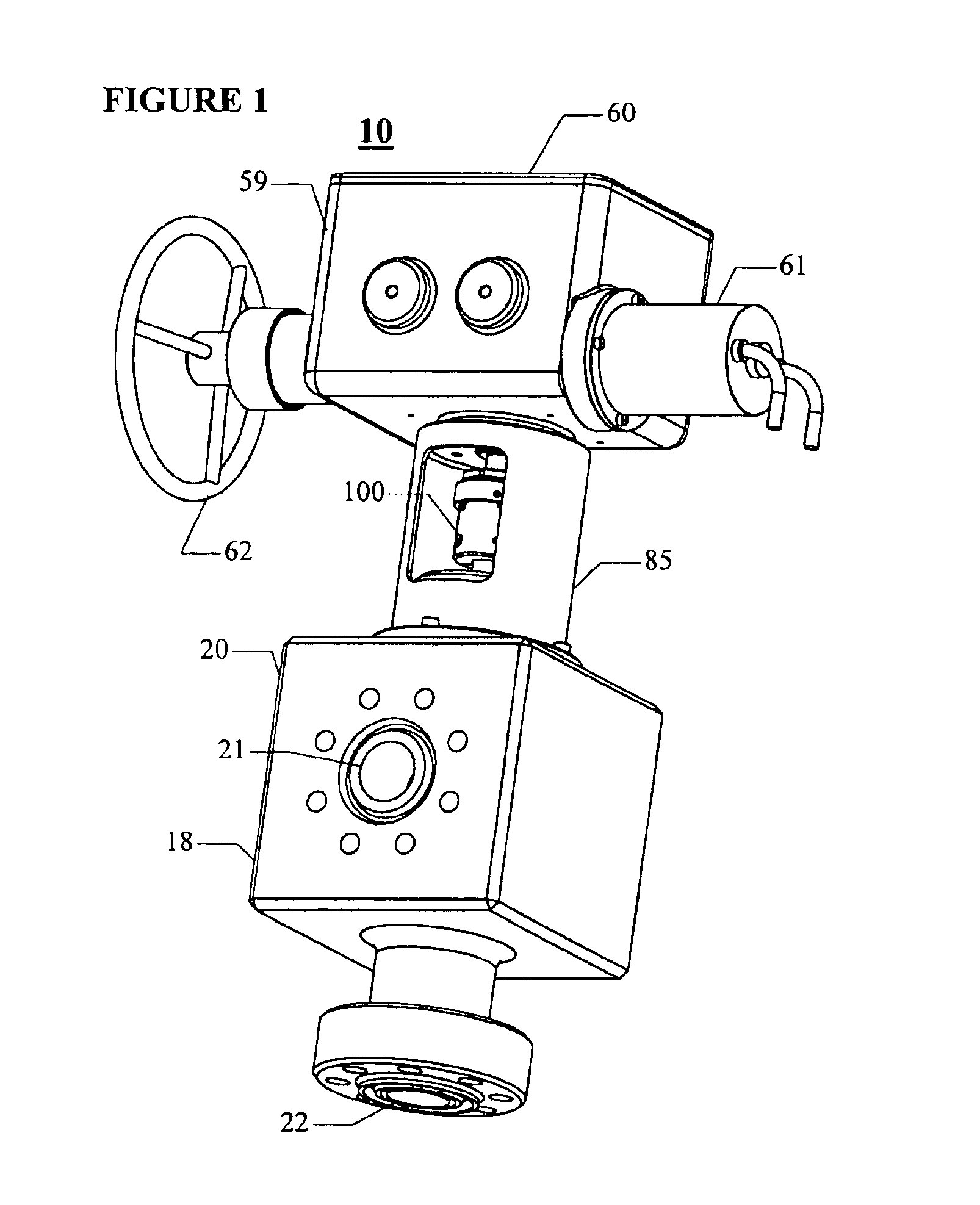

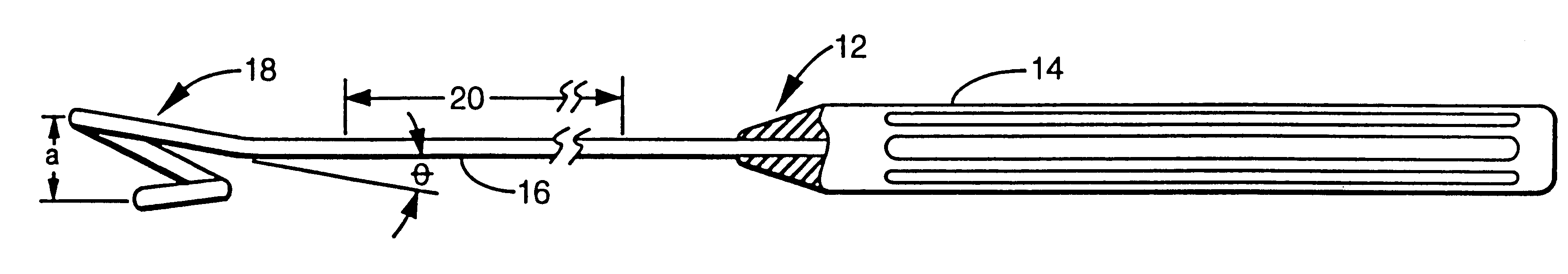

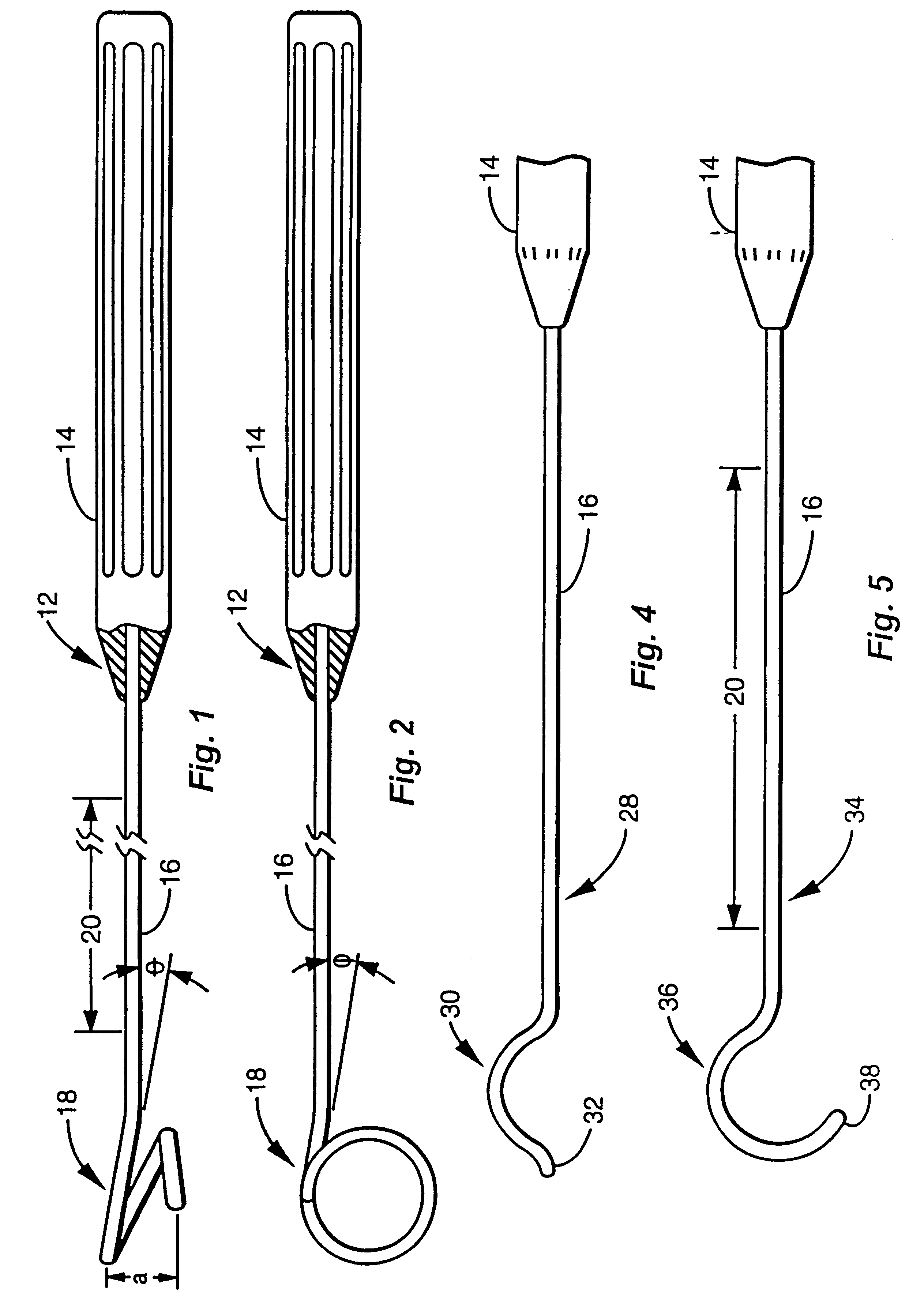

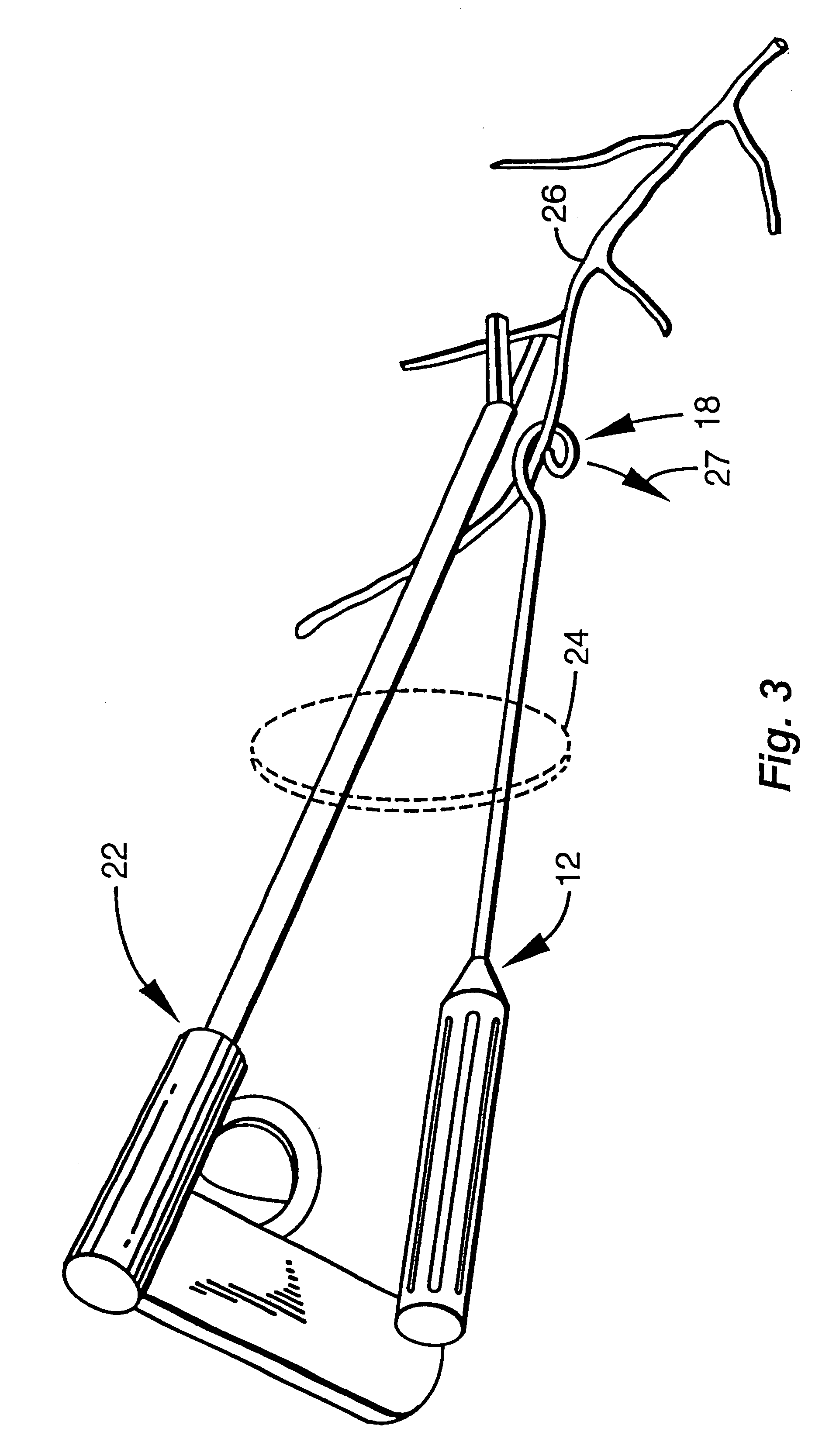

Surgical instrument for facilitating the detachment of an artery and the like

InactiveUS6280455B1Minimal bleedingReducing eliminating needCannulasSurgical instruments for heatingVisibilityMammary artery

A surgical instrument is configured to aid in performing a procedure of detaching an internal mammary artery (IMA) and the like, from the connecting tissues and side branch vessels which surround the artery in its native location, wherein the detaching procedure is preliminary to the performing of a coronary artery bypass grafting procedure and wherein the IMA is detached via a minimally invasive thoracotomy. To this end, an elongated slender rod includes a handle at its proximal end and an artery engaging loop, arc, fork configuration, or hook at its distal working end. Embodiments may incorporate electrosurgical capability or electrical insulation. A surgeon thus has means for harvesting an intact and undamaged graft vessel from its native location through a minimally invasive incision with enhanced speed, visibility, and freedom of motion.

Owner:LASALLE CAROL +1

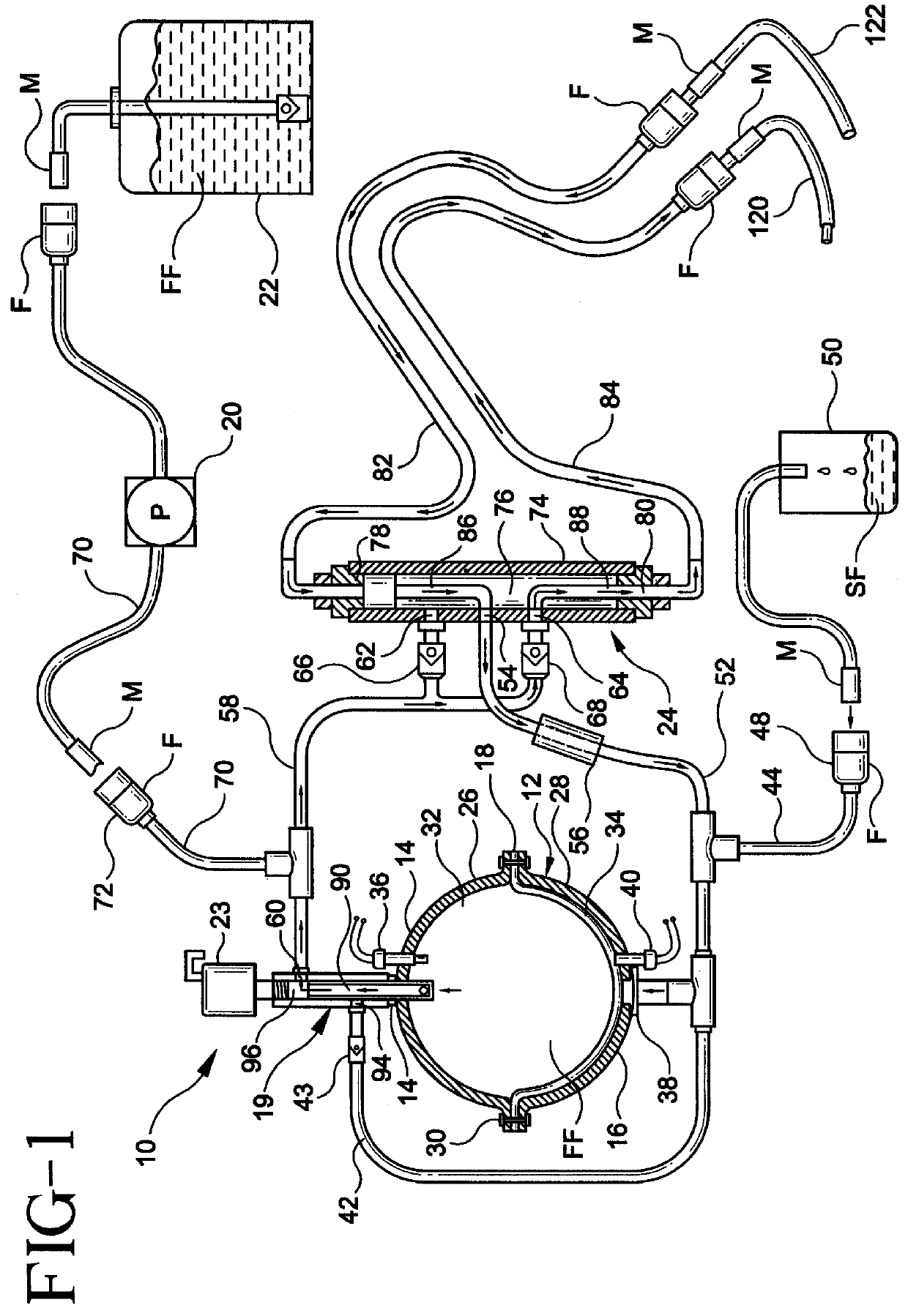

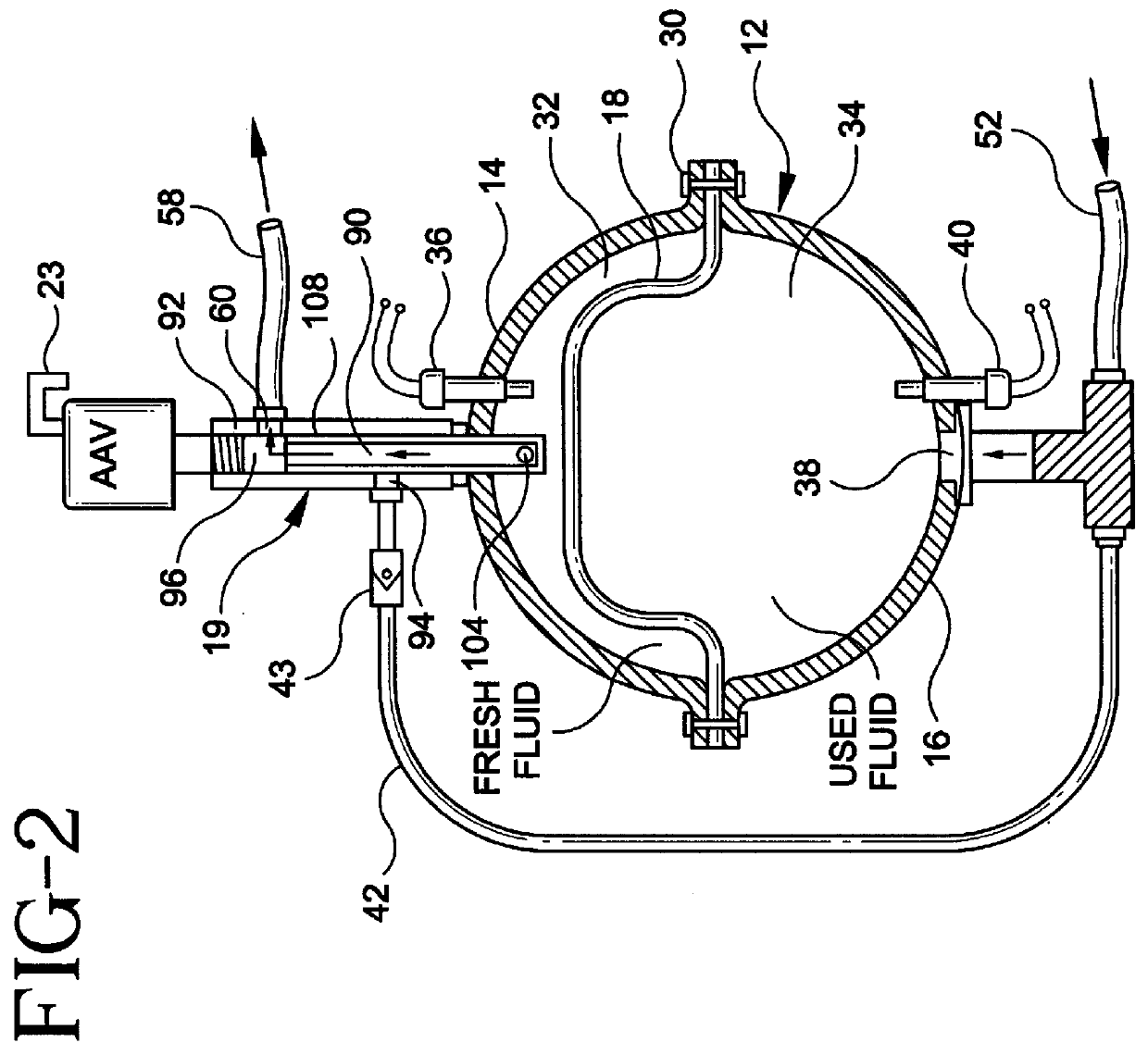

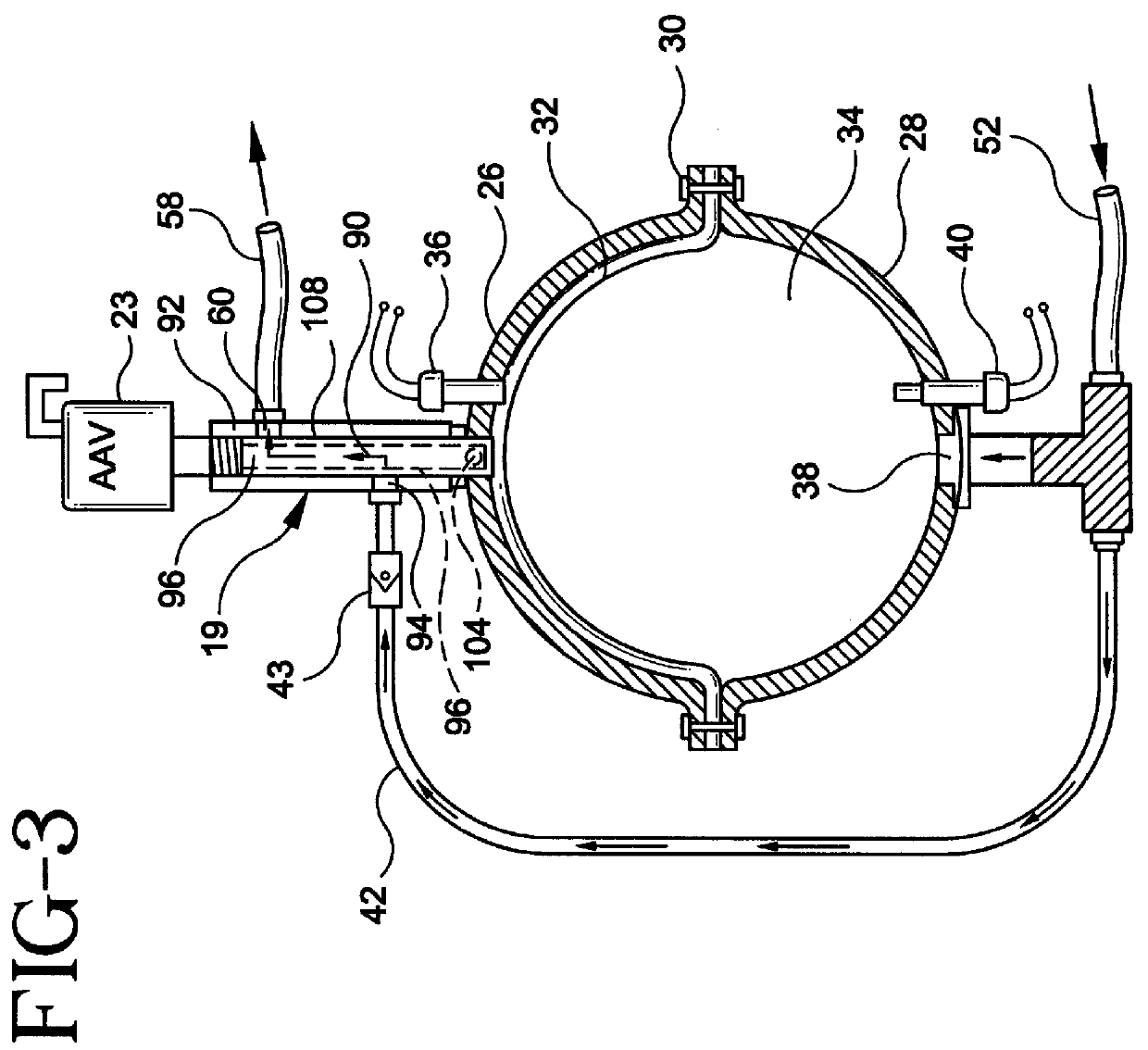

Fluid exchange apparatus

InactiveUS6082416AEffective and inexpensive meanRapid and safeCrankshaftsLiquid fillingEngineeringHydraulic fluid

A system and method for exchanging used hydraulic fluid with fresh hydraulic fluid in an accessed hydraulic fluid system. The system including a fluid exchange assembly having a fluid receptacle and an interior fluid separation member, which may be a distendable diaphragm member. The exchange system further includes features of automatic fluid flow alignment, an exchange mode indicating system, and a bypass system for removing at least a portion of the exchange system during a bypass mode of operation.

Owner:VIKEN JAMES P

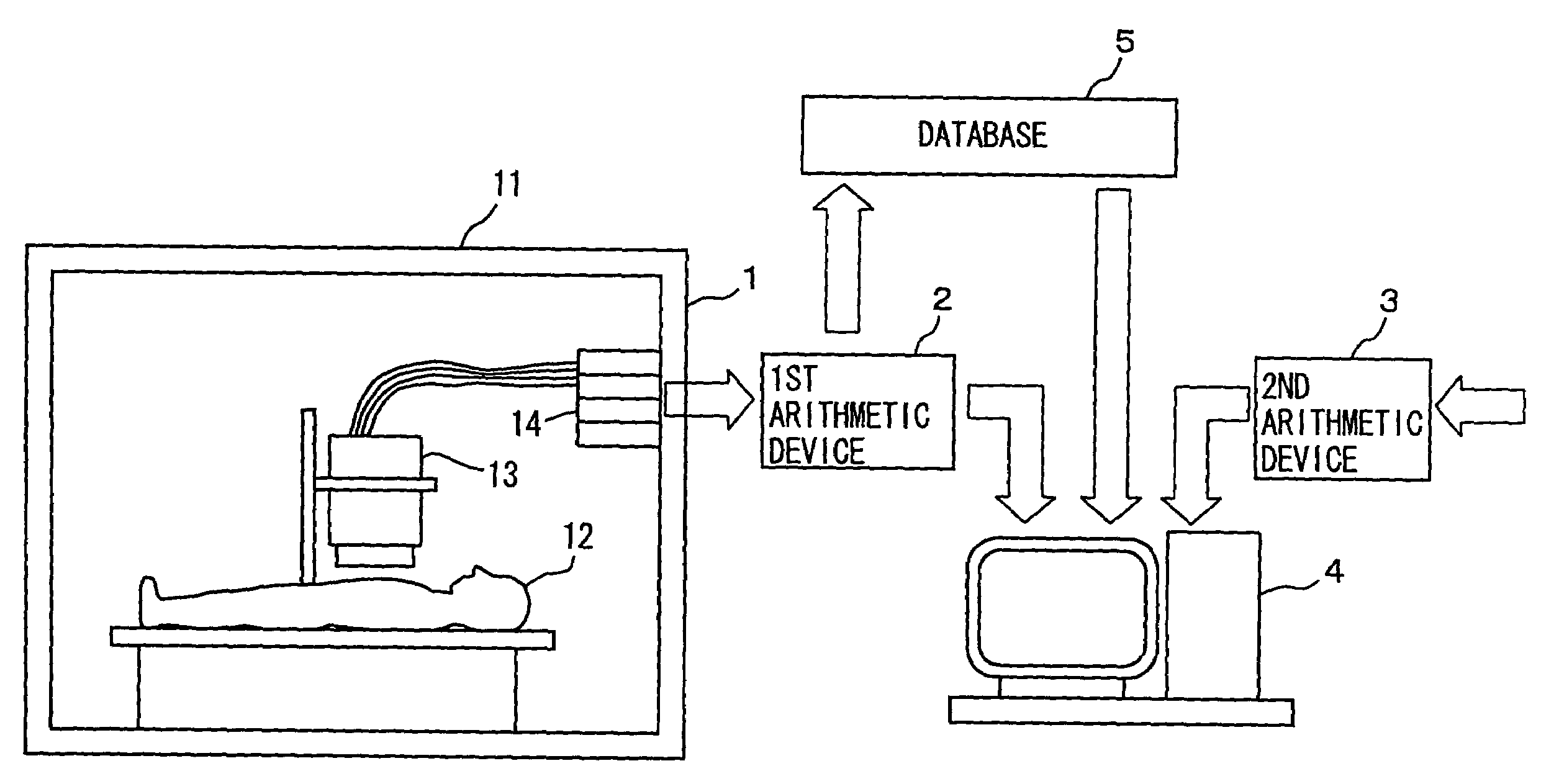

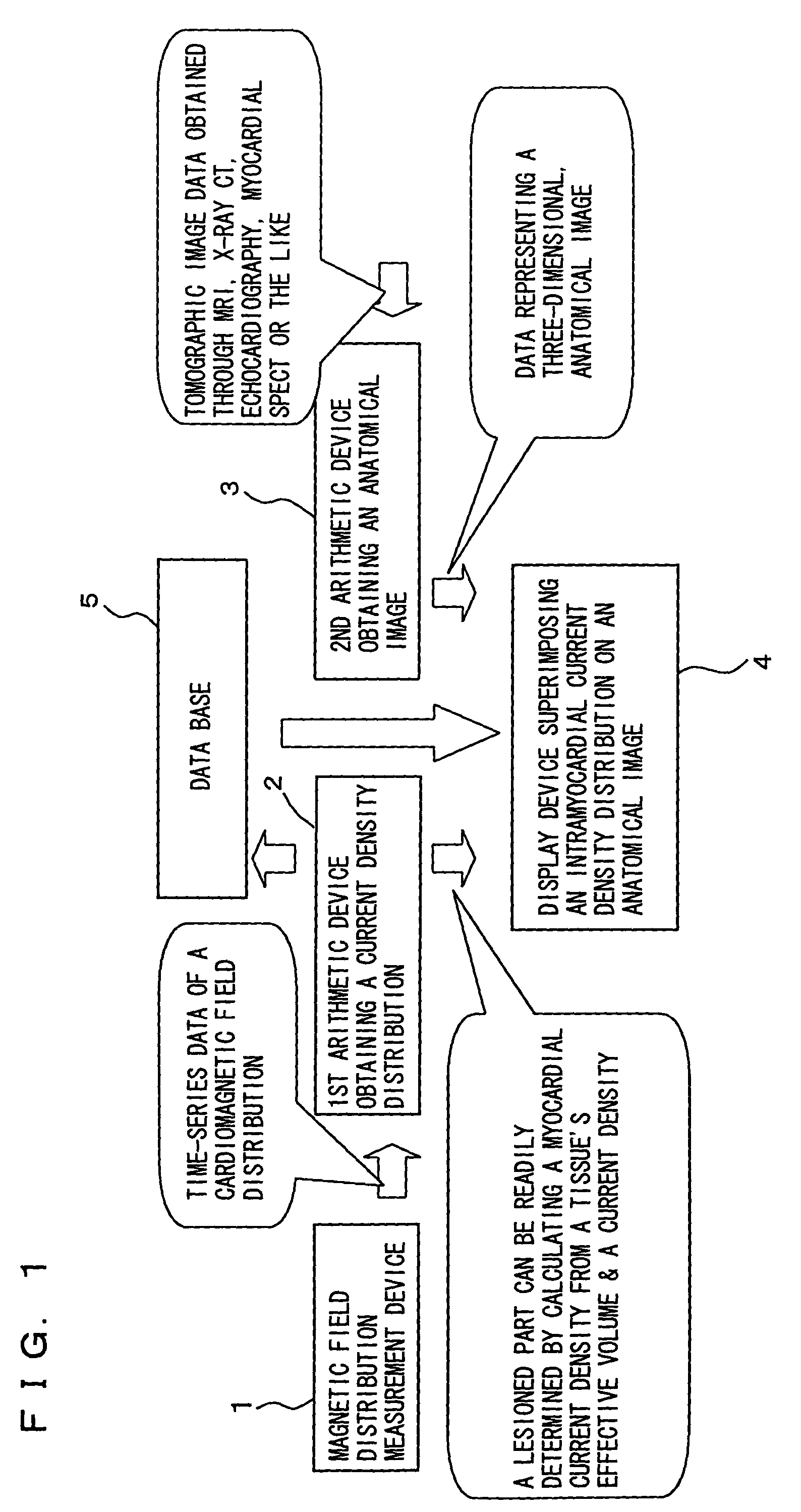

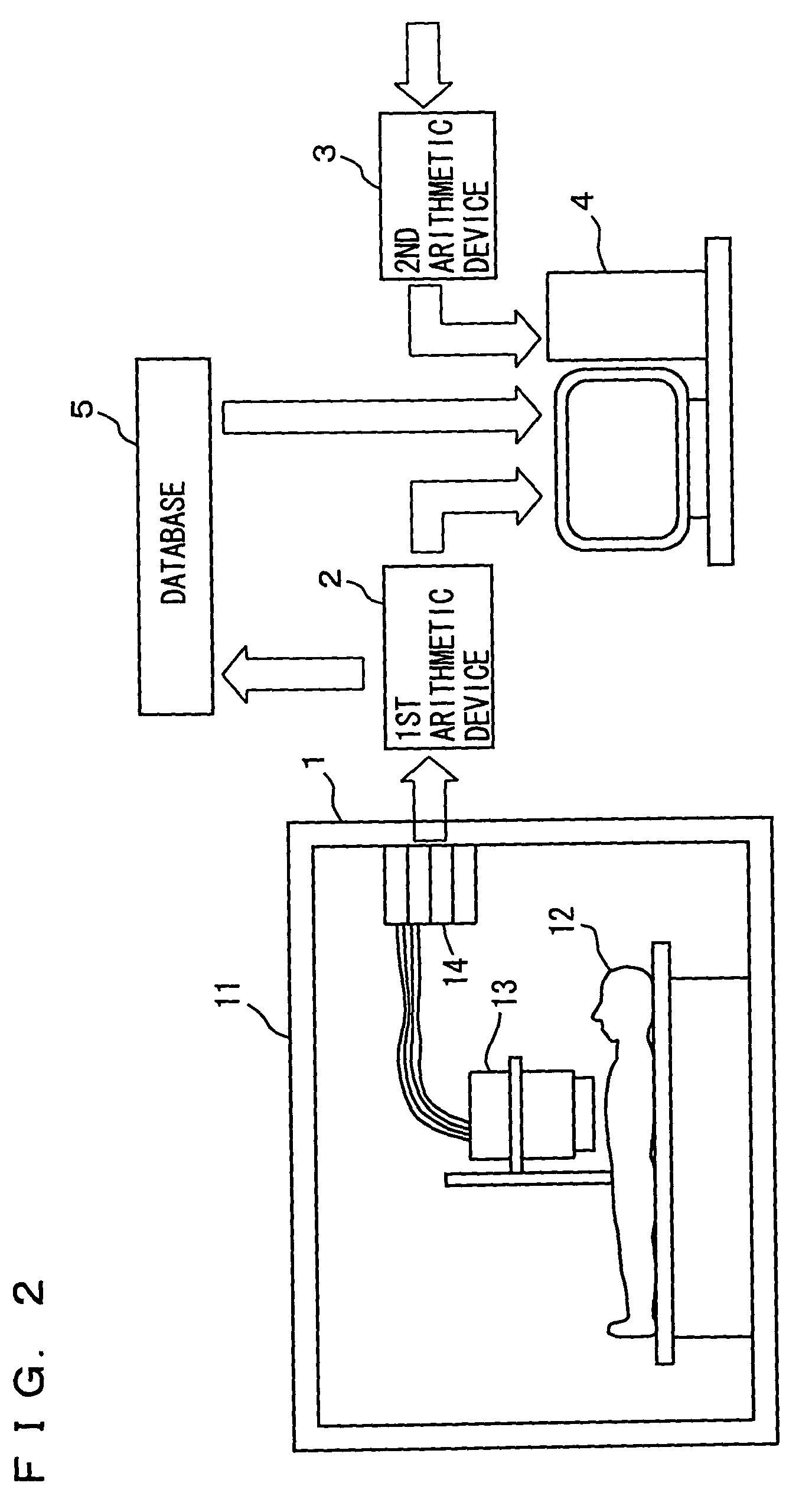

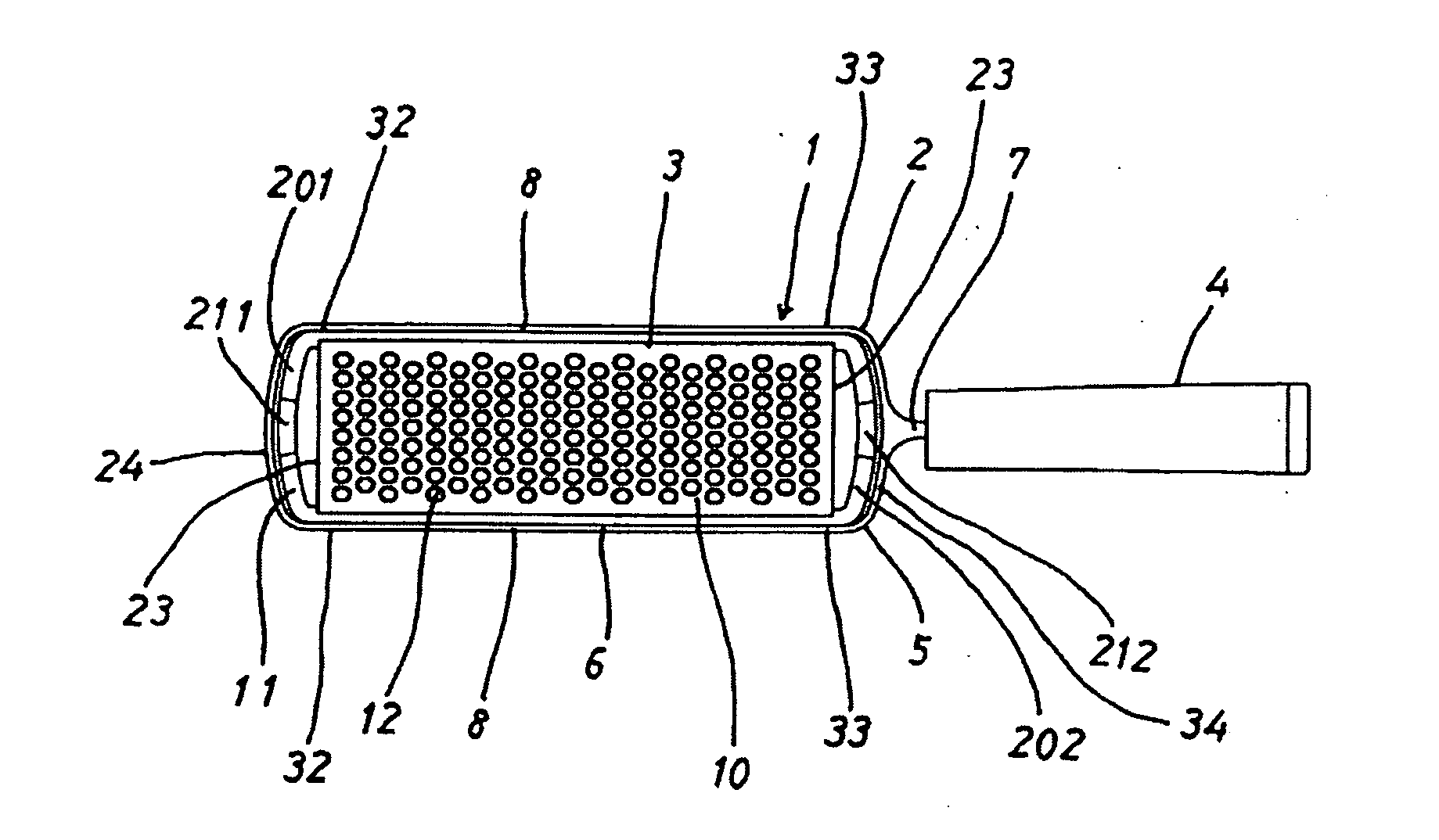

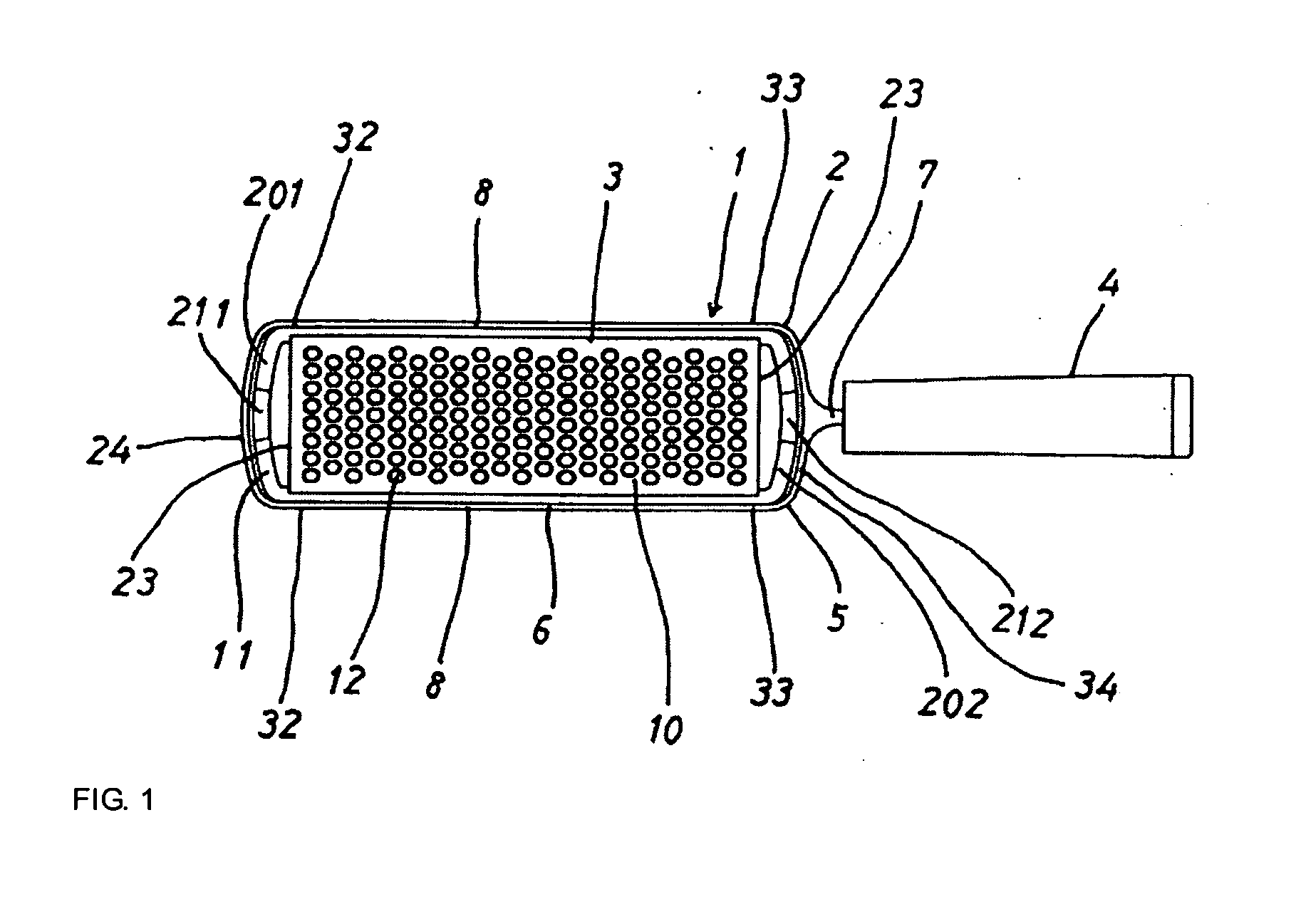

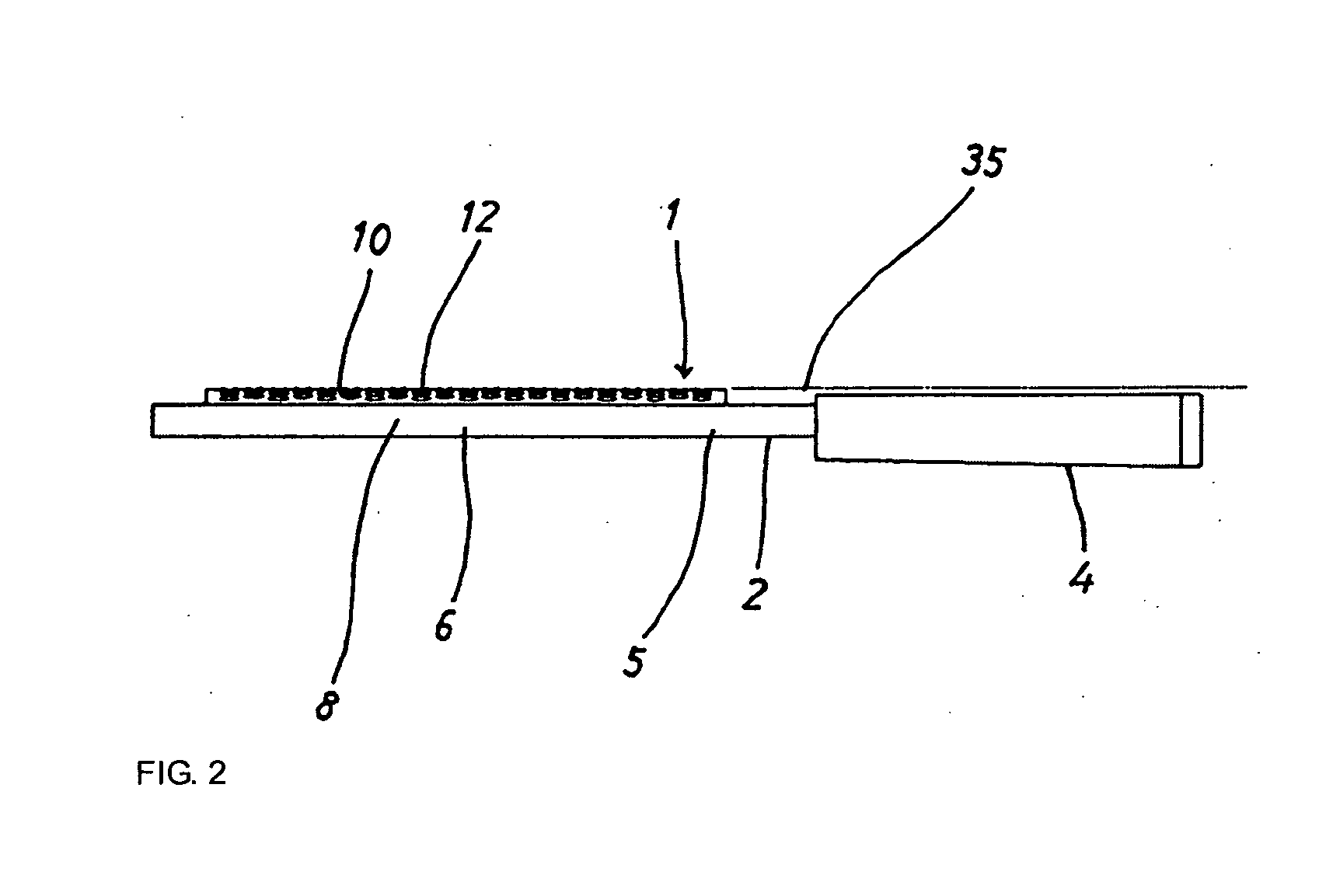

Liable cardiac muscle diagnosing apparatus and liable cardiac muscle analyzing method by magnetic field measurements

InactiveUS7144376B2Improve accuracyRapid and safeUltrasonic/sonic/infrasonic diagnosticsMedical simulationMeasurement devicePower flow

A magnetic field distribution measurement device (1) provides a non-contact magnetic measurement on a subject's chest at a plurality of coordinates and forms therefrom time-series magnetic field distribution data. A first arithmetic device (2) in response generates image data representing a three-dimensional, intramyocardial current density distribution. A second arithmetic device (3) receives a plurality of tomographic image data separately obtained by a tomographic diagnosis apparatus and processes the data to generate three-dimensional, anatomical image data. A display device (4) receives these data and displays on an anatomical image an image representing an intramyocardial current density. Thus in a ventricle a lesioned or viable part of myocardium can be readily identified in location, size, geometry and level. Furthermore, the anatomical image may be replaced with an image representing a normal stimulation propagation circuit and serving as a template.

Owner:JAPAN SCI & TECH CORP +1

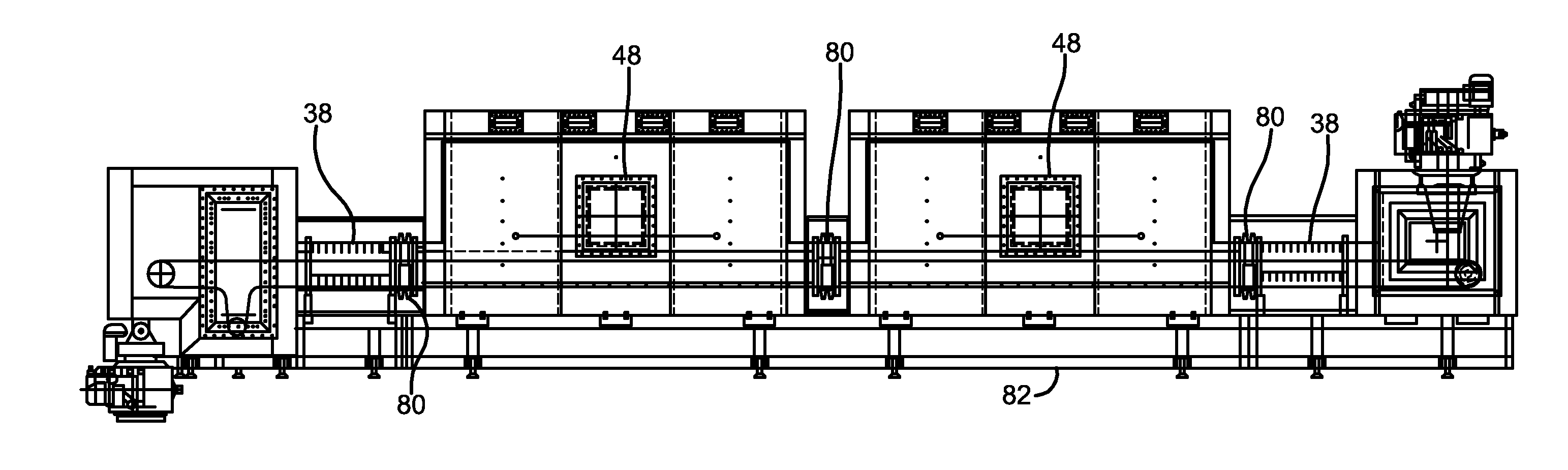

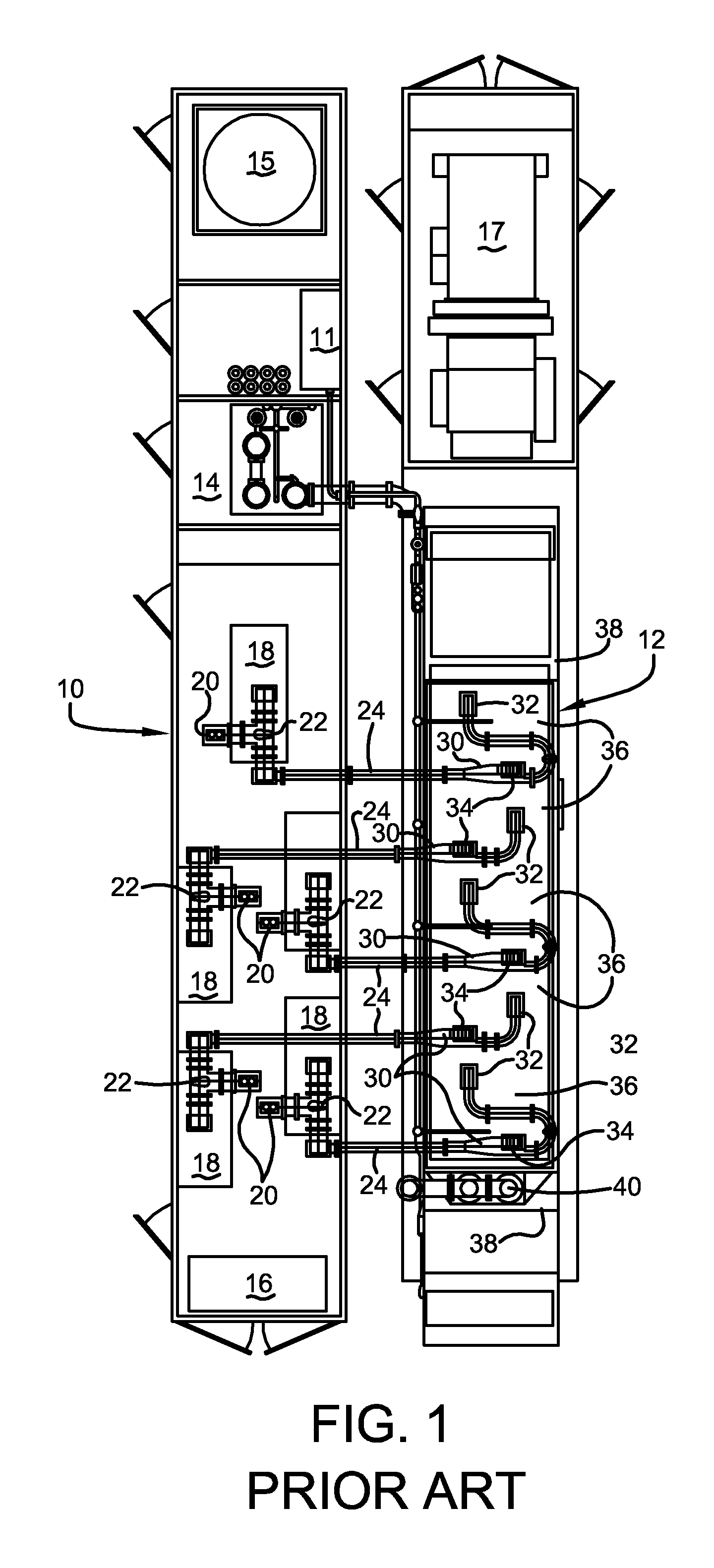

Method and apparatus for microwave dissociation of organic compounds

ActiveUS20110215092A1Promote absorptionReduce energy consumptionHydrocarbonsMicrowave heatingSolid carbonLiquid hydrocarbons

The invention described herein generally pertains to a process for reducing an organic-containing material into lower molecular weight gaseous hydrocarbons, liquid hydrocarbons and solid carbon constituents, said process including the steps of: feeding a sample of said organic-containing material into an infeed system, wherein the infeed system contains a non-flammable blanketing purge gas; transferring the material into at least one microwave applicator containing the purge gas in a pressurized state above local atmospheric pressure to insure that no air migrates into said microwave applicator which might cause a fire or explosion hazard; exposing the material in said microwave applicator to at least two sources of microwaves from at least a pair of divaricated waveguide assemblies for a period of time sufficient to volumetrically reduce said material into said constituents, a frequency of said microwaves between approximately 894 MHz and approximately 1000 MHz and without an external heat source, the microwaves entering the at least one applicator out-of-phase to each other by using unequal lengths of waveguide between the microwave generator and the at least one applicator; the microwaves entering the at least one applicator through at least one applicator diffuser matrix for each divaricated waveguide, which includes at least four essentially parallel beveled entry channels (preferably six slotted, beveled entry channels per applicator diffuser); and collecting byproduct constituents.

Owner:NOVAK JUDITH

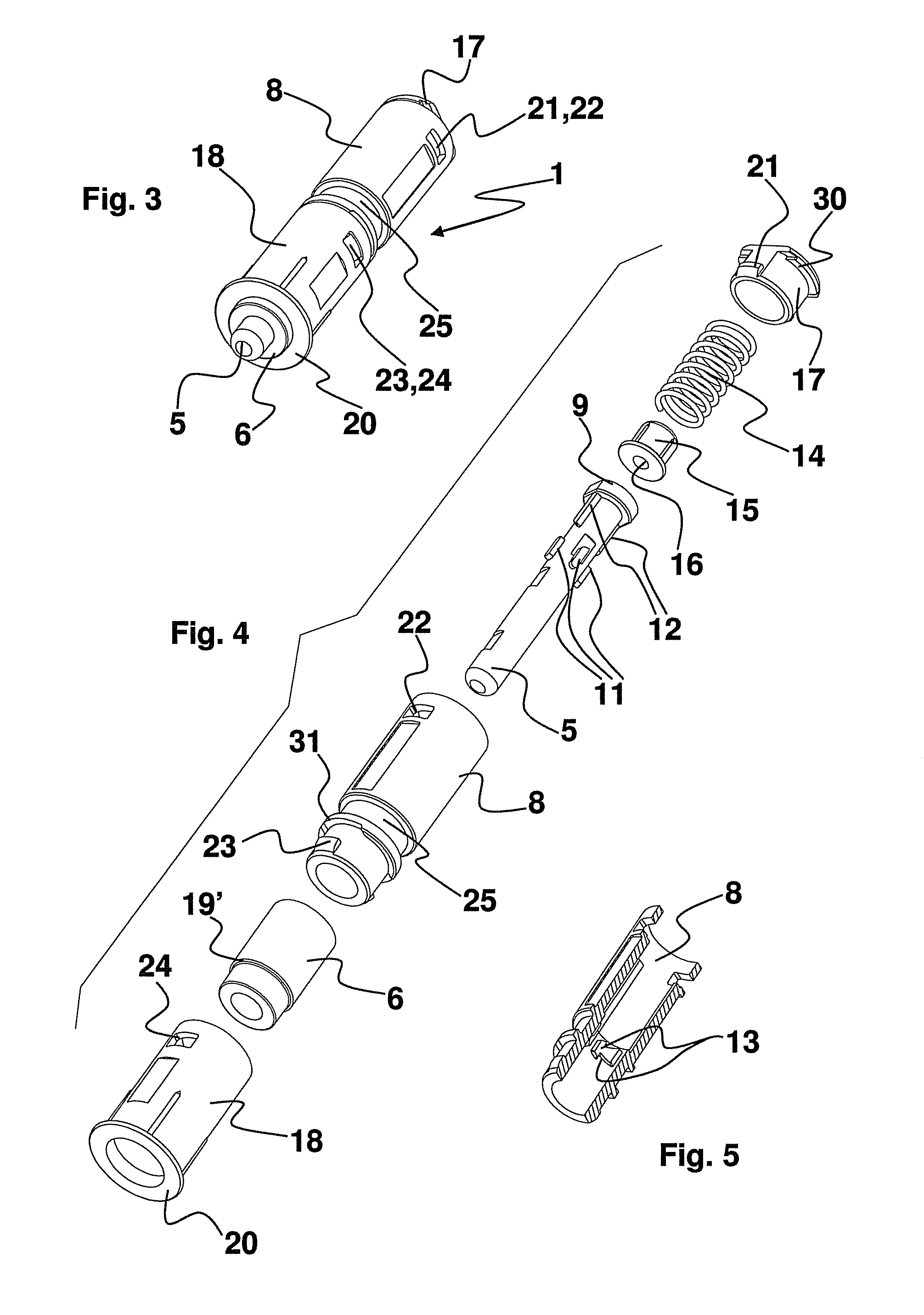

Apparatus and method for preparing medicines containing radioactive substances

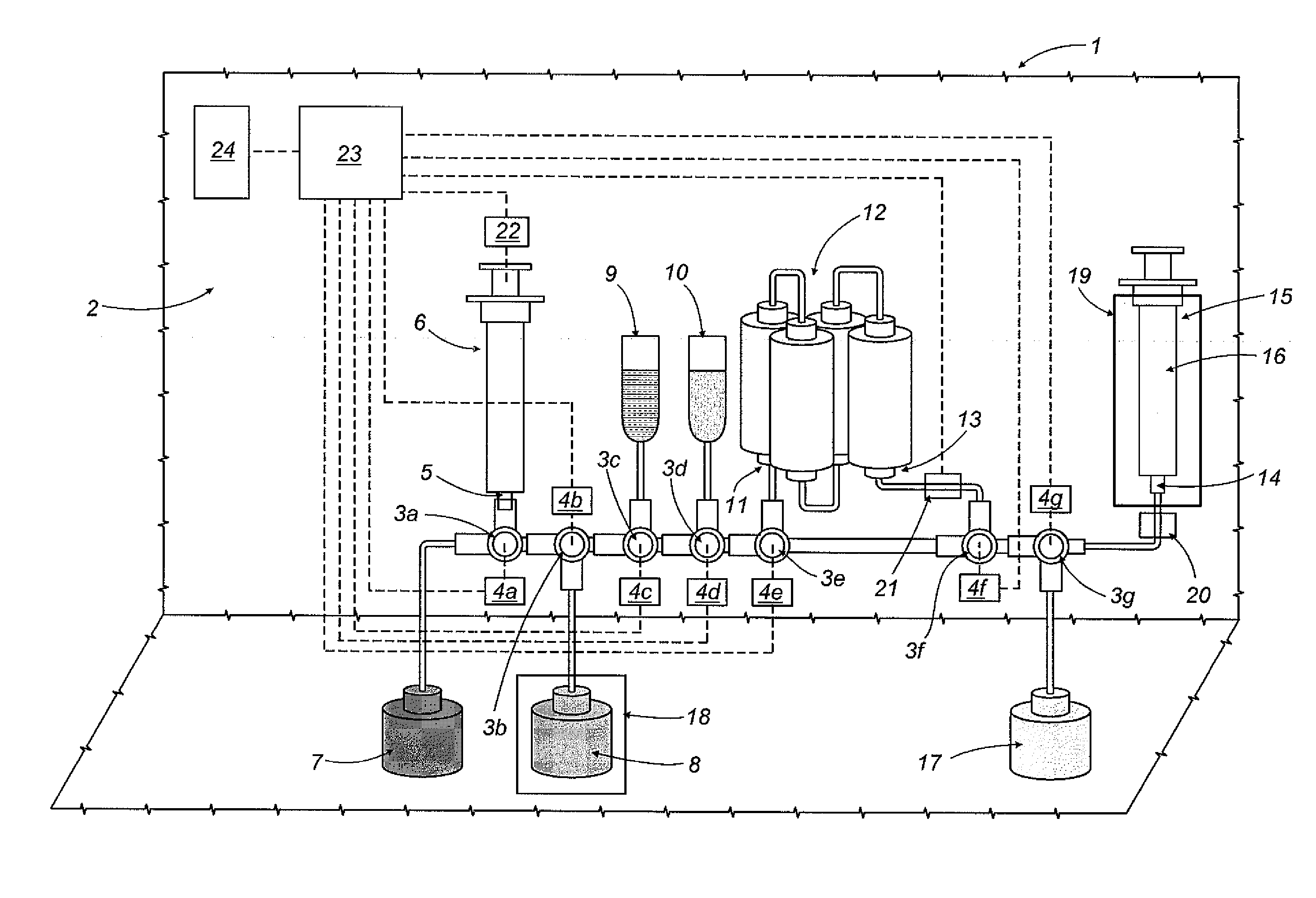

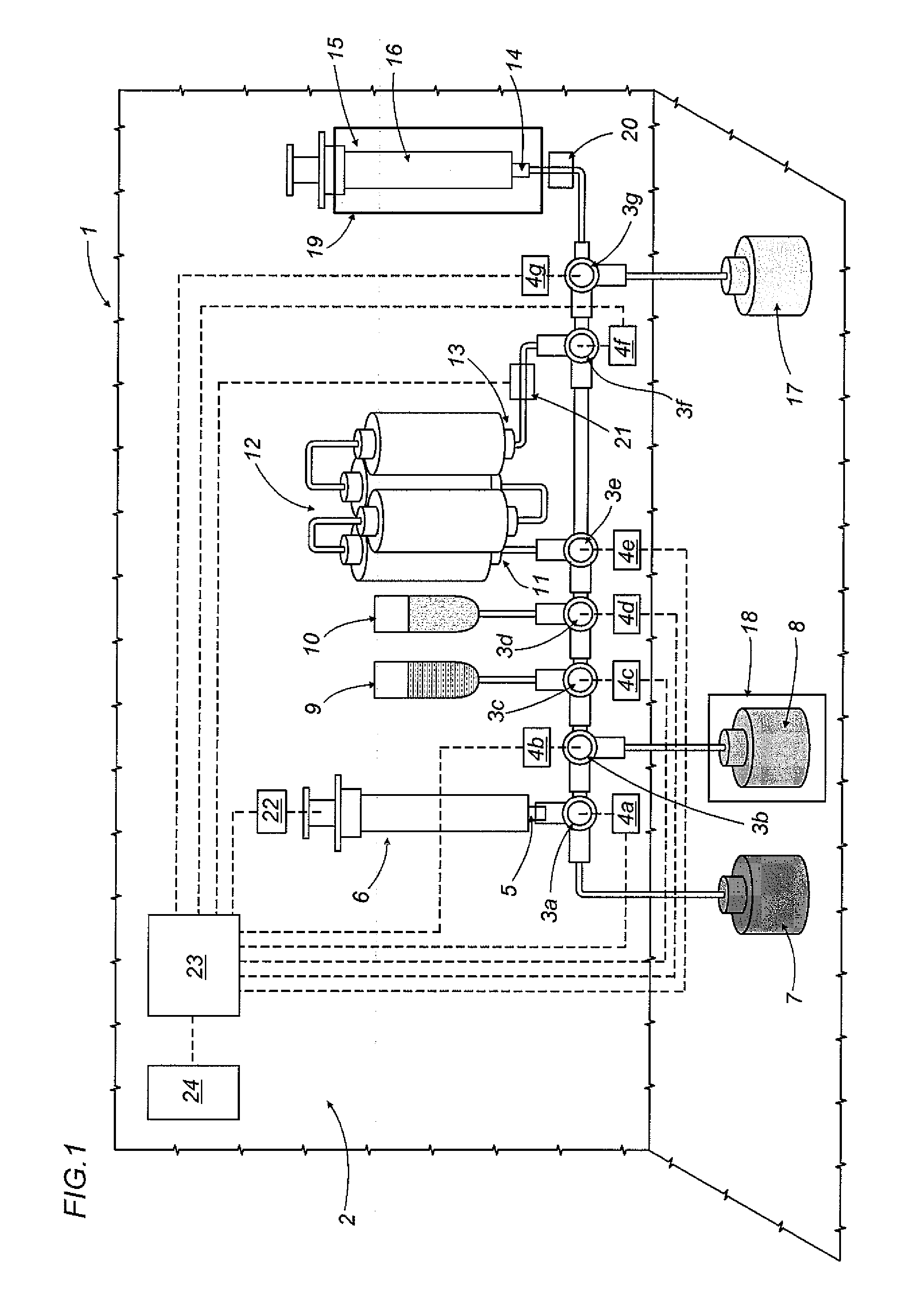

InactiveUS20110020224A1Rapid and easy to useRapid and safeRadioactive preparation carriersPeptide preparation methodsChromatographic separationMedicine

An apparatus (1) for preparing medicines containing radioactive substances, more specifically injectable medicines containing beta-emitting substances, in which a radioactive element is combined, in a mixture, with a protein to be labelled using the radioactive element; the mixture is then subjected to a chromatographic separation step which separates the mixture and isolates the medicine (16).

Owner:PHILOGEN SRL LLC

Method and apparatus for microwave dissociation of organic compounds

ActiveUS8283616B2Promote absorptionReduce energy consumptionHydrocarbonsMicrowave heatingSolid carbonMicrowave

The invention describes a process for reducing an organic-containing material into lower molecular weight gaseous hydrocarbons, liquid hydrocarbons and solid carbon constituents, by using out-of-phase microwaves which enter the applicator through at least one applicator diffuser matrix. The matrix includes essentially parallel beveled entry channels.

Owner:NOVAK JUDITH

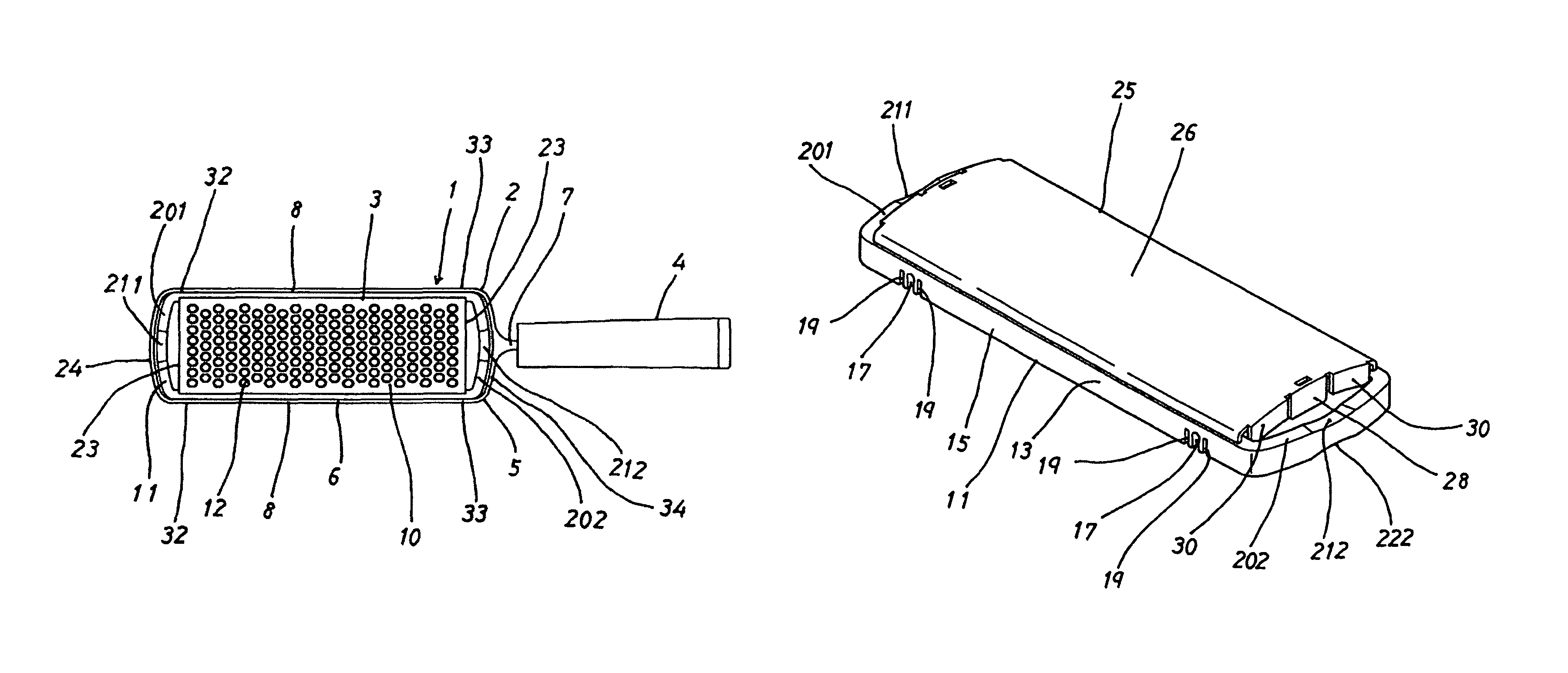

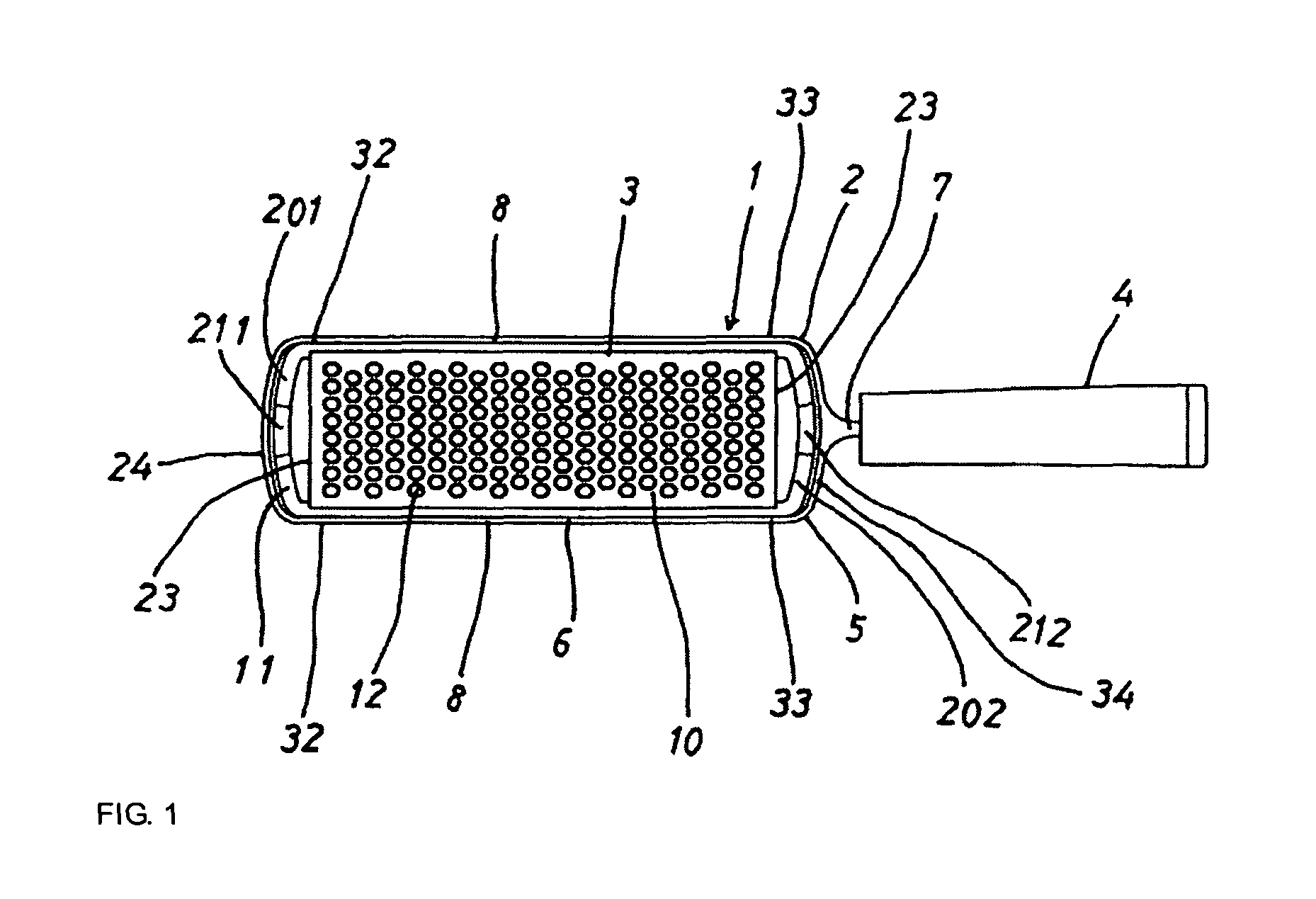

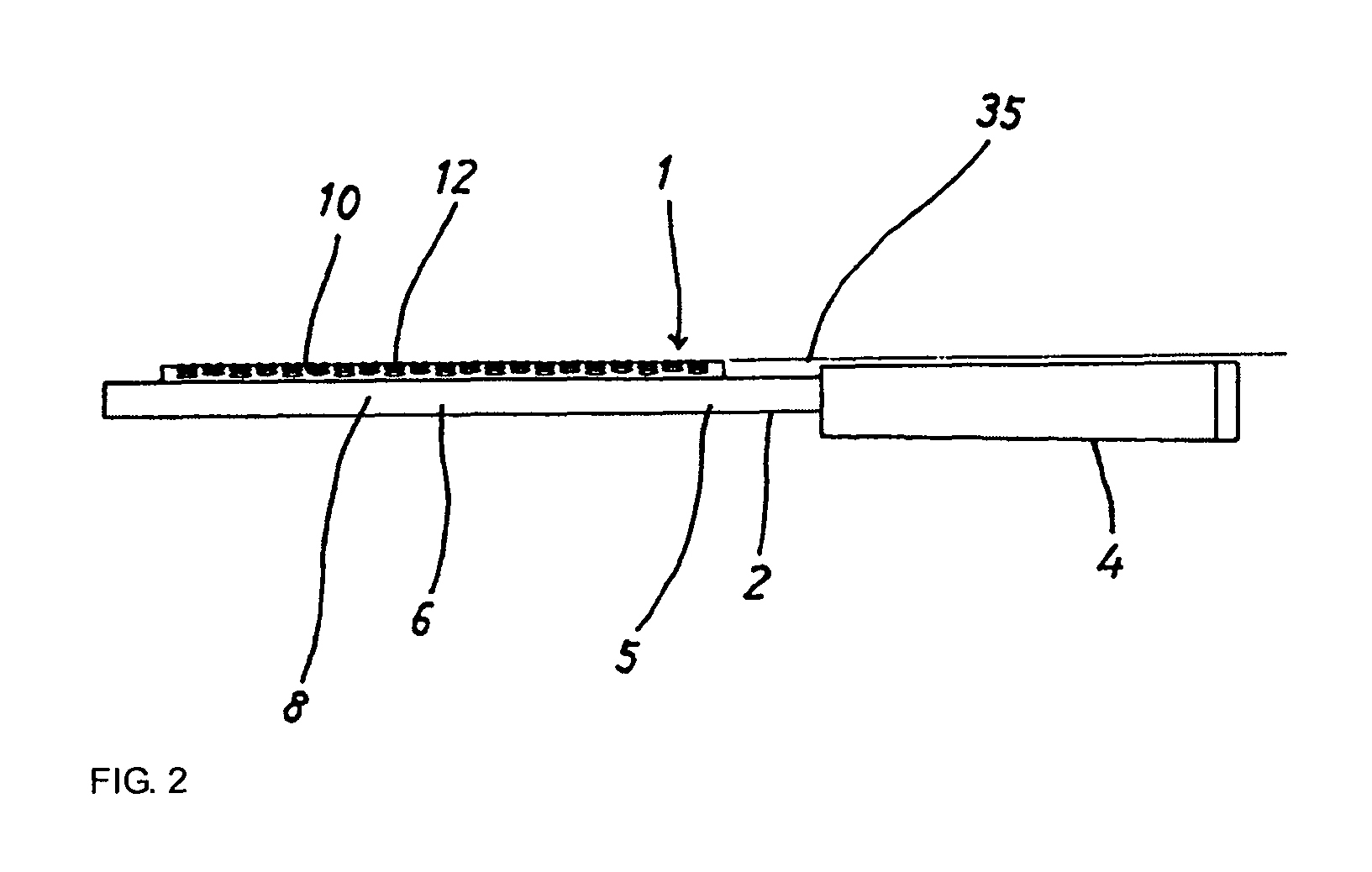

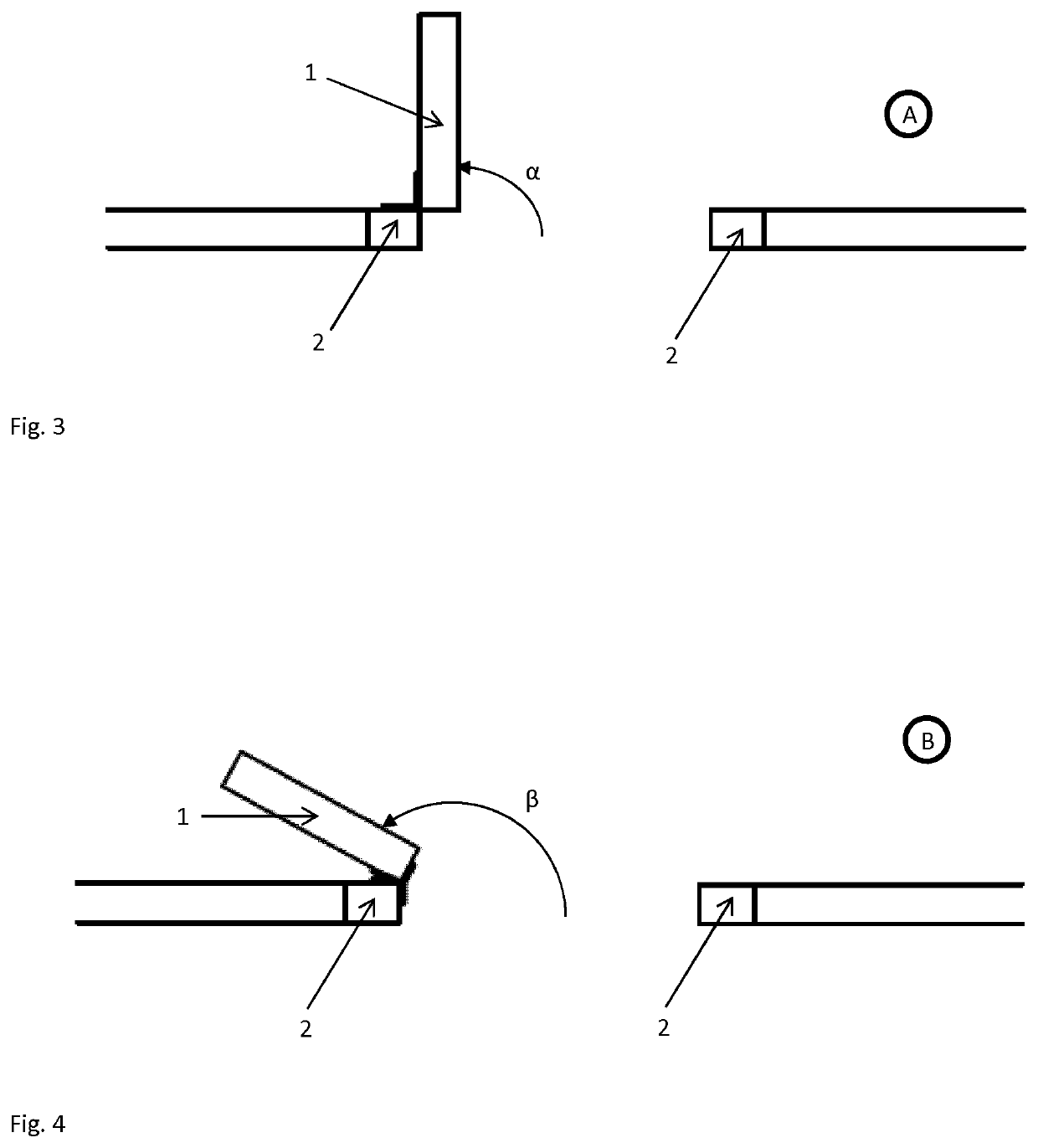

Food preparation device

ActiveUS8857747B2Rapid and safeEasy to separateHand equipmentsGrain treatmentsFood preparationFood science

A food preparation plate is replaceable and engagement means for retaining the food preparation plate are present between the food preparation plate and a retaining part. The food preparation plate can move in translation in a direction perpendicular to a plane constituted by the retaining part. Two places on the back side of the food preparation plate that is retained in the retaining part can be simultaneously pressed in the direction of the front side by the digits of different hands; and by simultaneously pressing those two places with digits of different hands, the food preparation plate is moved in translation in the direction of the front side thereof, so as to release the engagement means and allow the food preparation plate to be detached.

Owner:KAI R&D CENT CO LTD

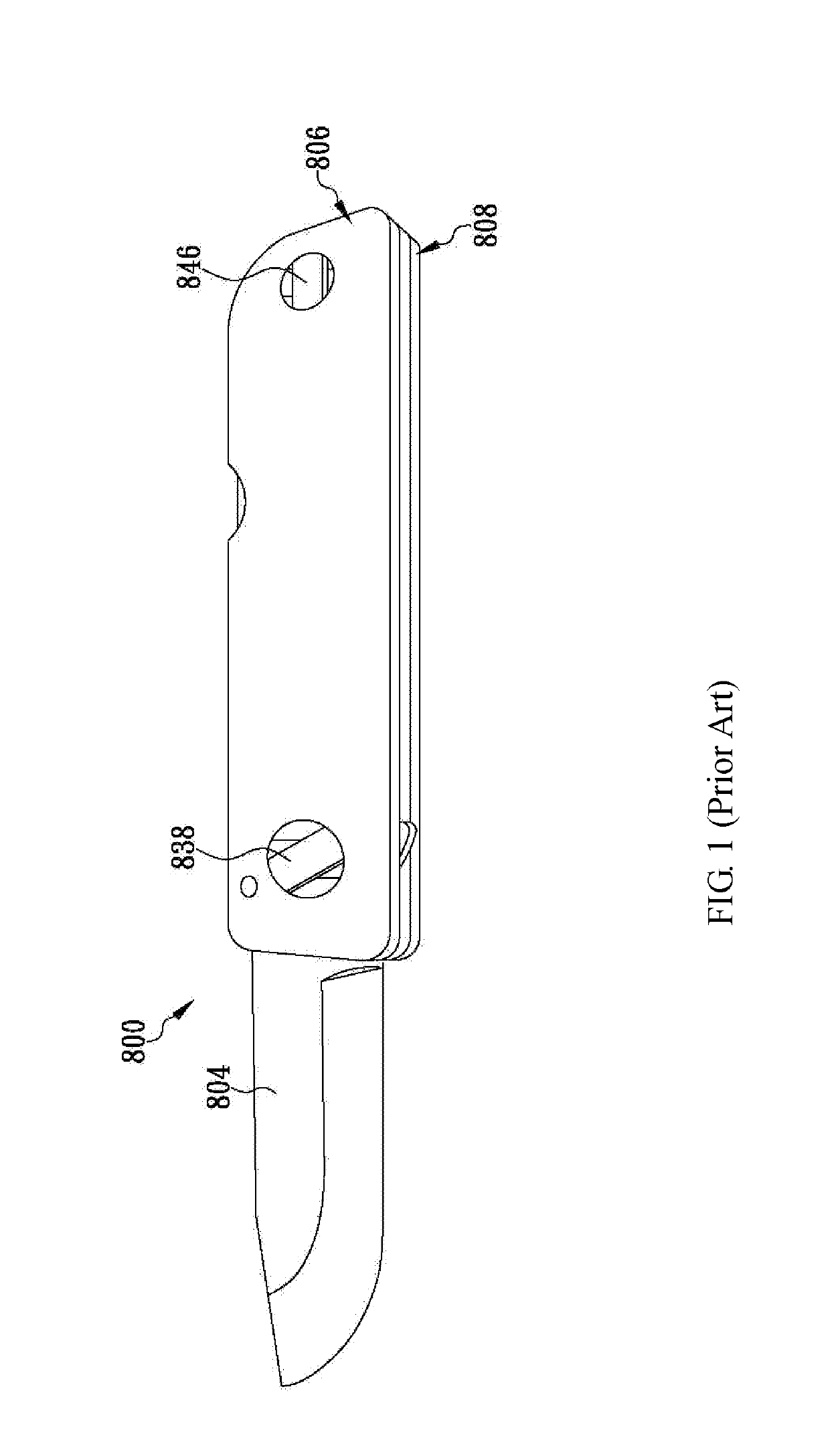

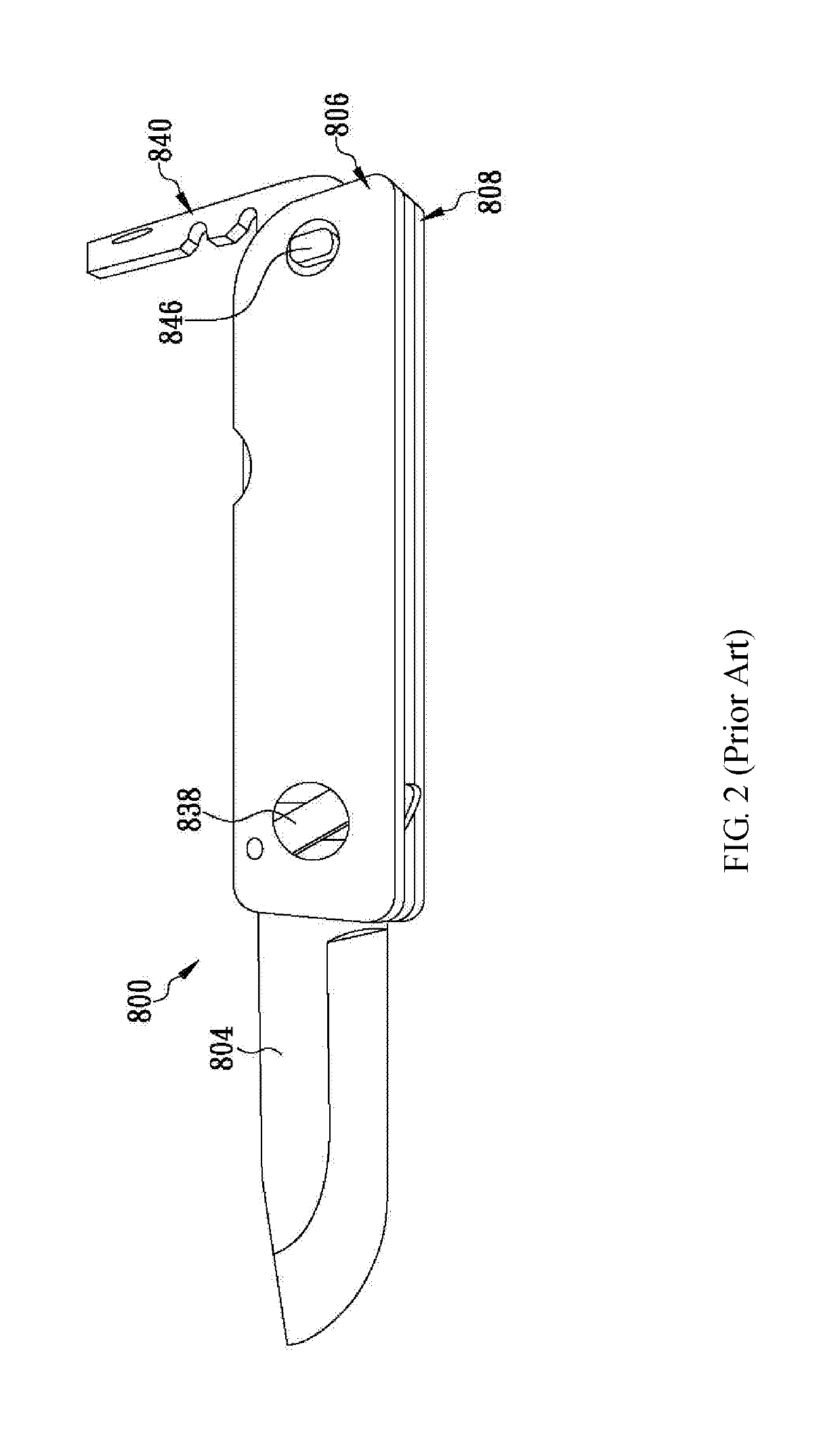

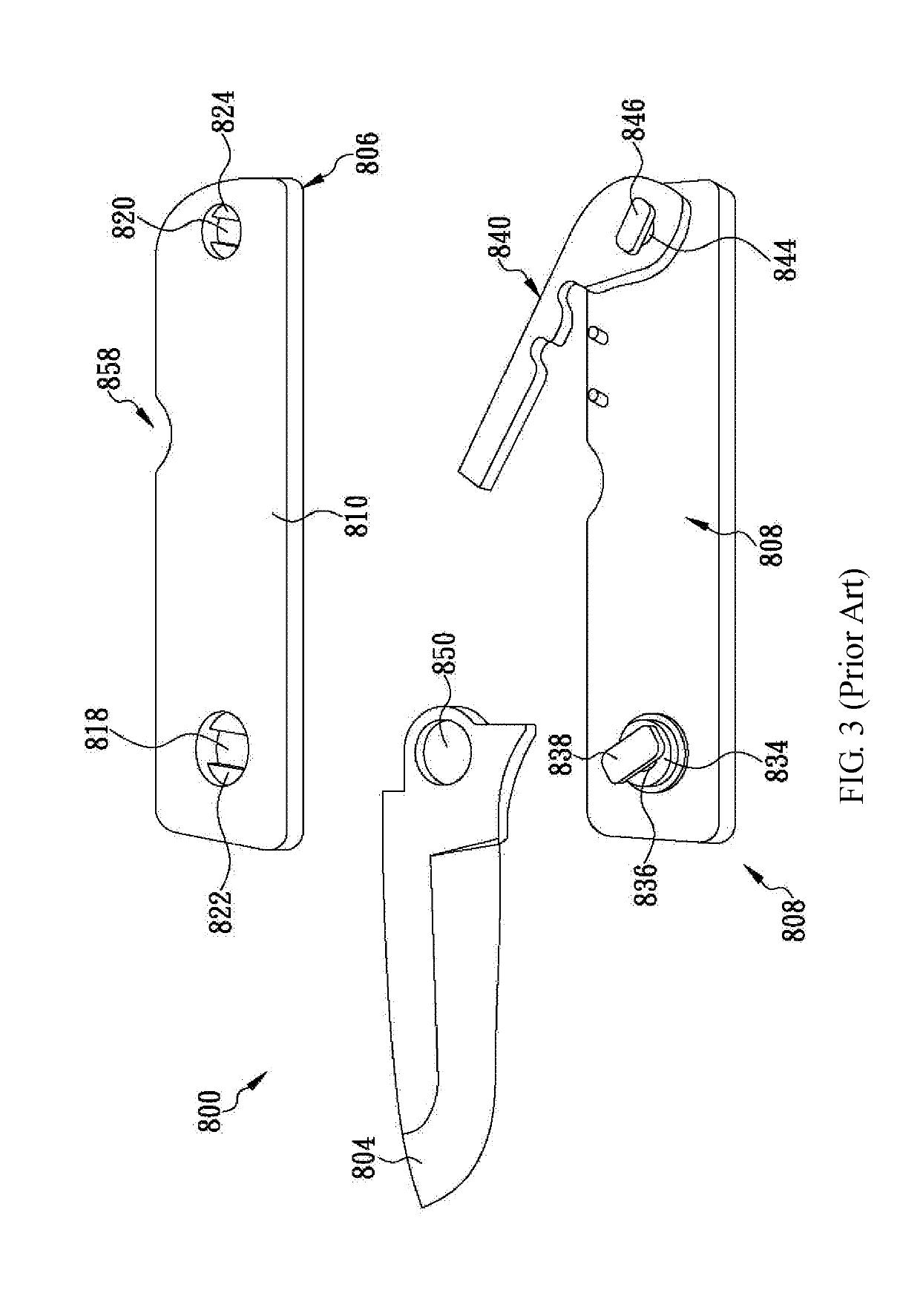

Folding knife configured for safe and rapid disassembly and reassembly

ActiveUS20190217488A1Rapid and safeGreat convenience and safety of useMetal working apparatusKnife bladesEngineering

A folding knife configured for safe and rapid disassembly and reassembly includes an upper handle portion having two engaging grooves respectively adjacent to its two ends, and a lower handle portion having an engaging and pivotally connecting shaft and an engaging and locking shaft respectively adjacent to its two ends. The two shafts are engageable in the engaging grooves respectively. A blade is mounted around the engaging and pivotally connecting shaft and rotatable into and out of a space between the handle portions. A pushable locking member is rotatably connected to the engaging and locking shaft and can be pushed to allow or prevent disengagement between the engaging and locking shaft and the corresponding engaging groove. Thus, user only has to push the pushable locking member, the upper handle portion and the blade will be in a detachable from or securely connected to the lower handle portion as a whole.

Owner:LO YEN FEN

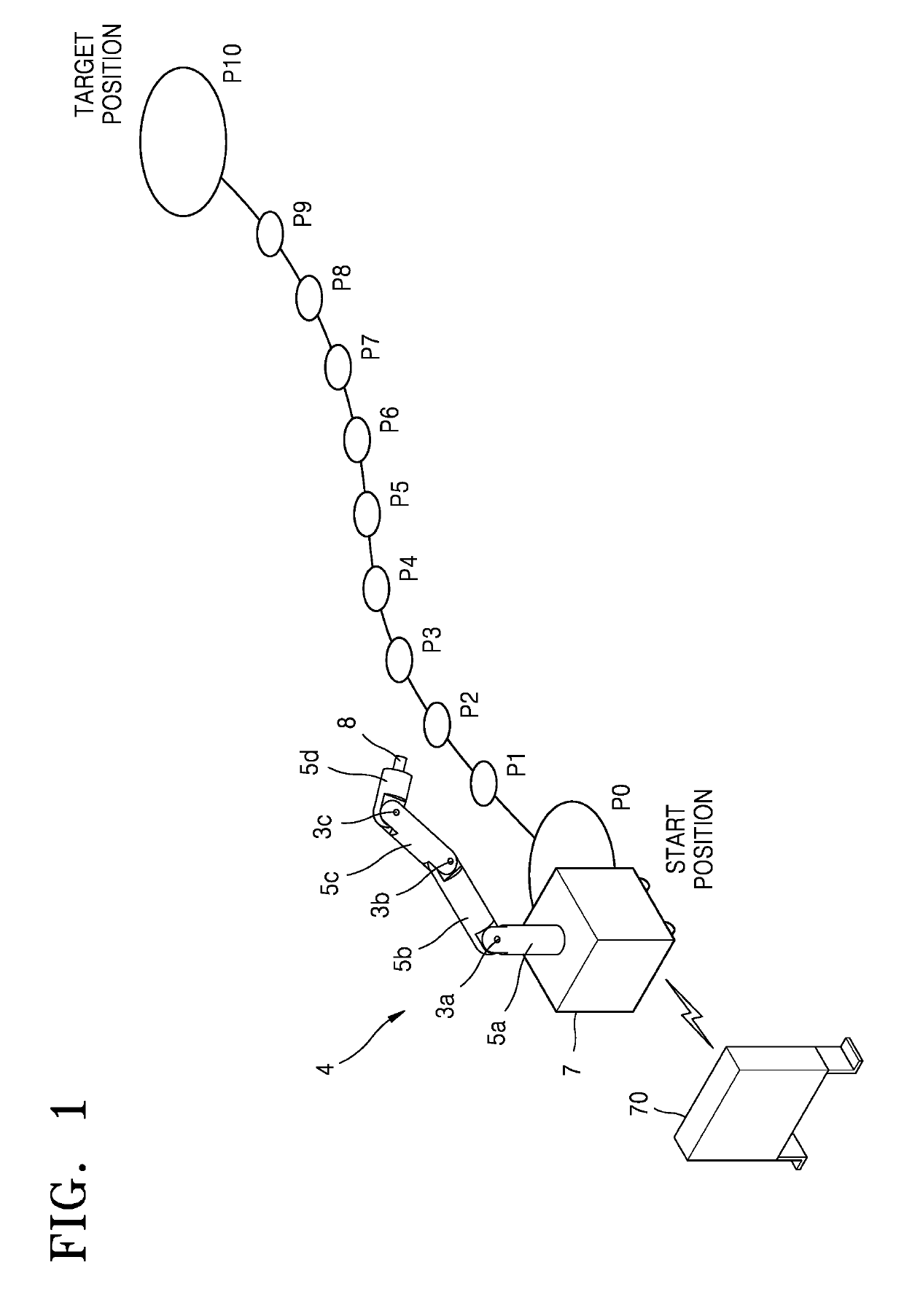

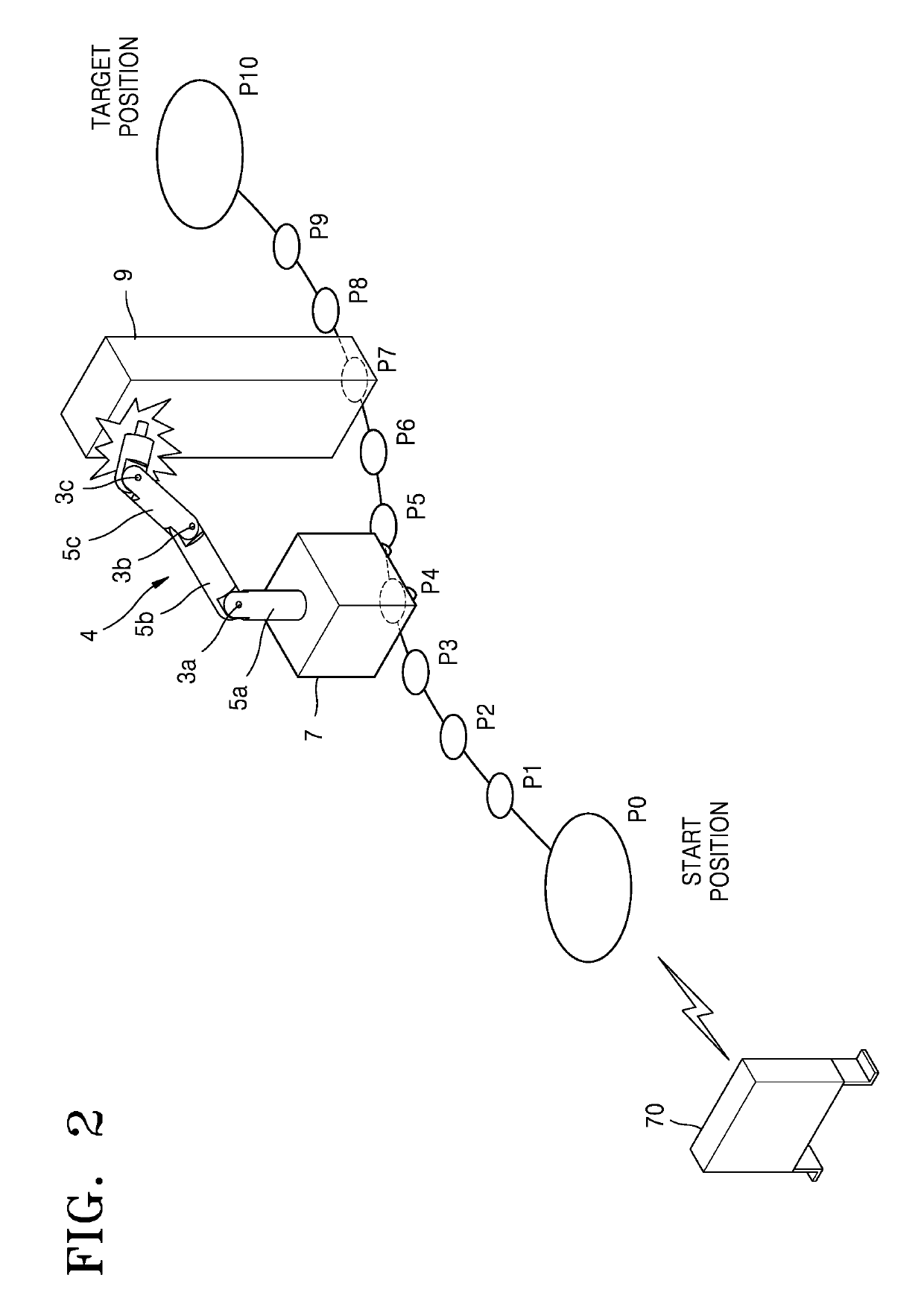

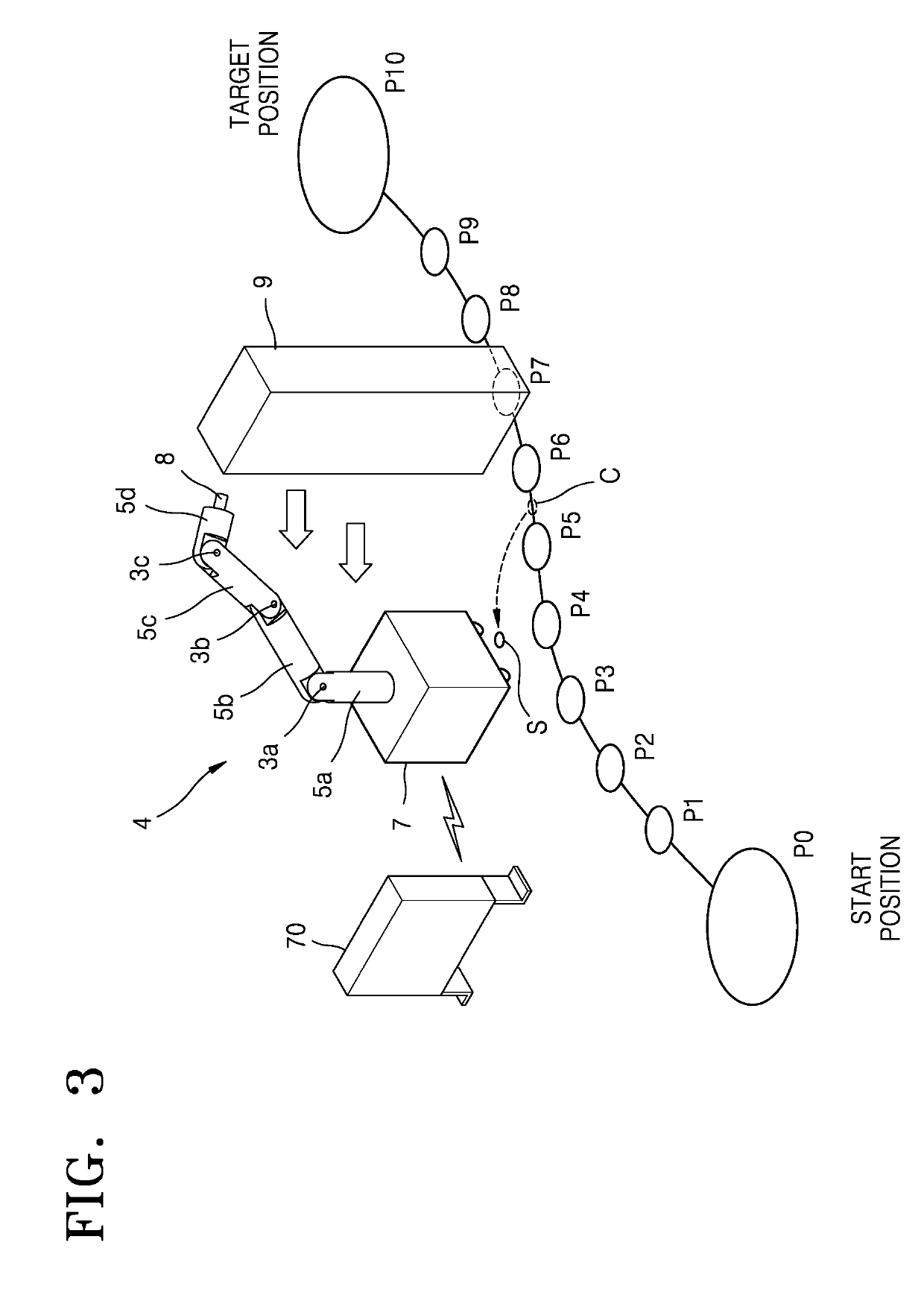

Robot control system and method of controlling a robot

ActiveUS20190193269A1Effectively respondRapid and safeProgramme-controlled manipulatorPosition/course control in two dimensionsRobot control systemCalculator

A robot control system for controlling a robot including an actuator is provided. The robot control system includes: a collision detector configured to detect a collision occurring between the robot and an external object during movement of the robot, a driving controller configured to control the actuator, a position calculator configured to calculate at least one of collision position coordinate information indicating a collision position where the collision occurs and pushed position coordinate information indicating a pushed position to which the robot is pushed by a collision force generated from the collision, and a restart coordinate setter configured to set the collision position or a position included in a preset moving path of the robot and spaced apart from the collision position as a restart position for restarting a moving operation of the robot, based on a result of the calculation by the position calculator.

Owner:HANWHA CORP

Food preparation device

ActiveUS20120180323A1Easy to separateSafe removalKitchen equipmentHand equipmentsFood preparationFood science

A food preparation plate is replaceable and engagement means for retaining the food preparation plate are present between the food preparation plate and a retaining part. The food preparation plate can move in translation in a direction perpendicular to a plane constituted by the retaining part. Two places on the back side of the food preparation plate that is retained in the retaining part can be simultaneously pressed in the direction of the front side by the digits of different hands; and by simultaneously pressing those two places with digits of different hands, the food preparation plate is moved in translation in the direction of the front side thereof, so as to release the engagement means and allow the food preparation plate to be detached.

Owner:KAI R&D CENT CO LTD

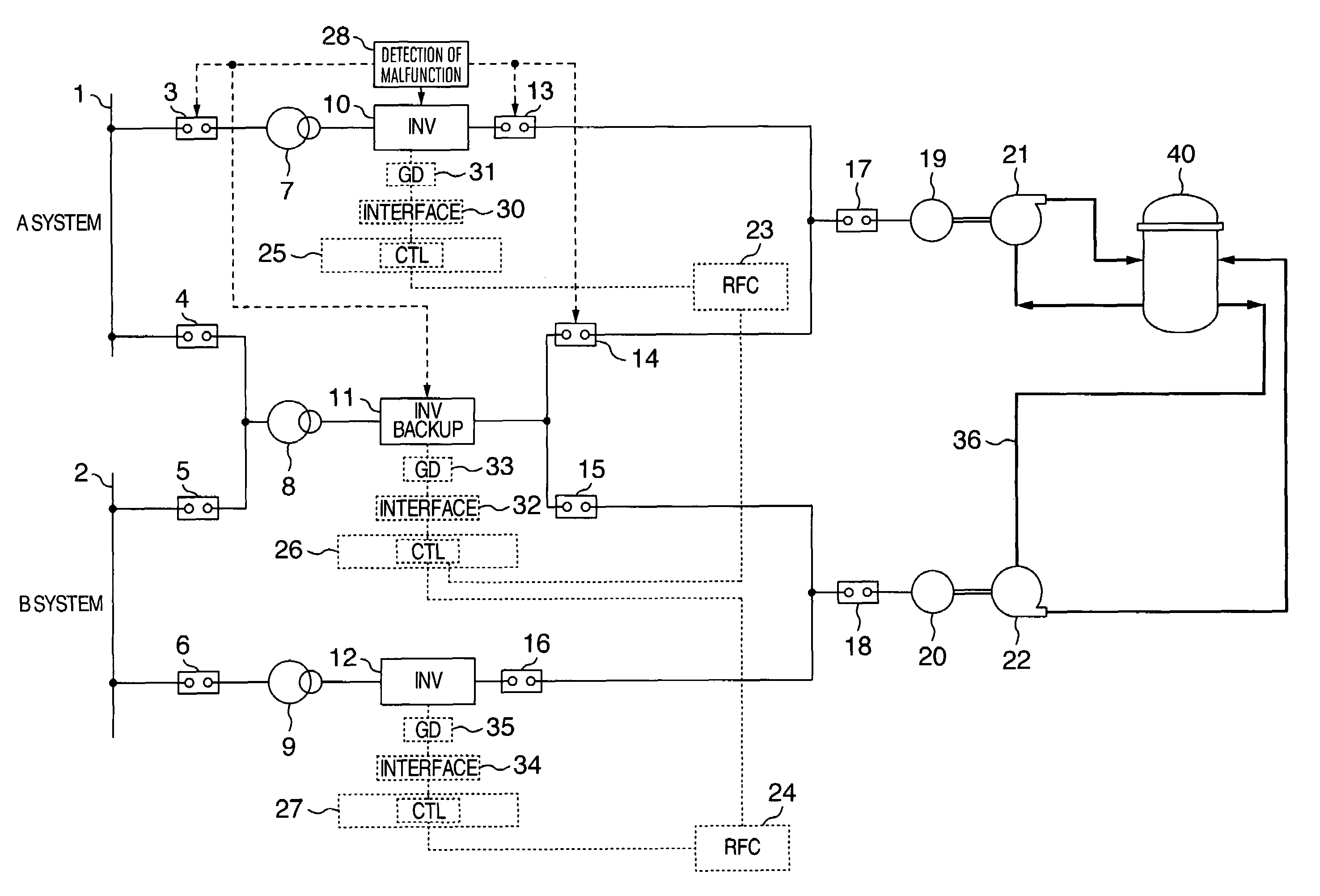

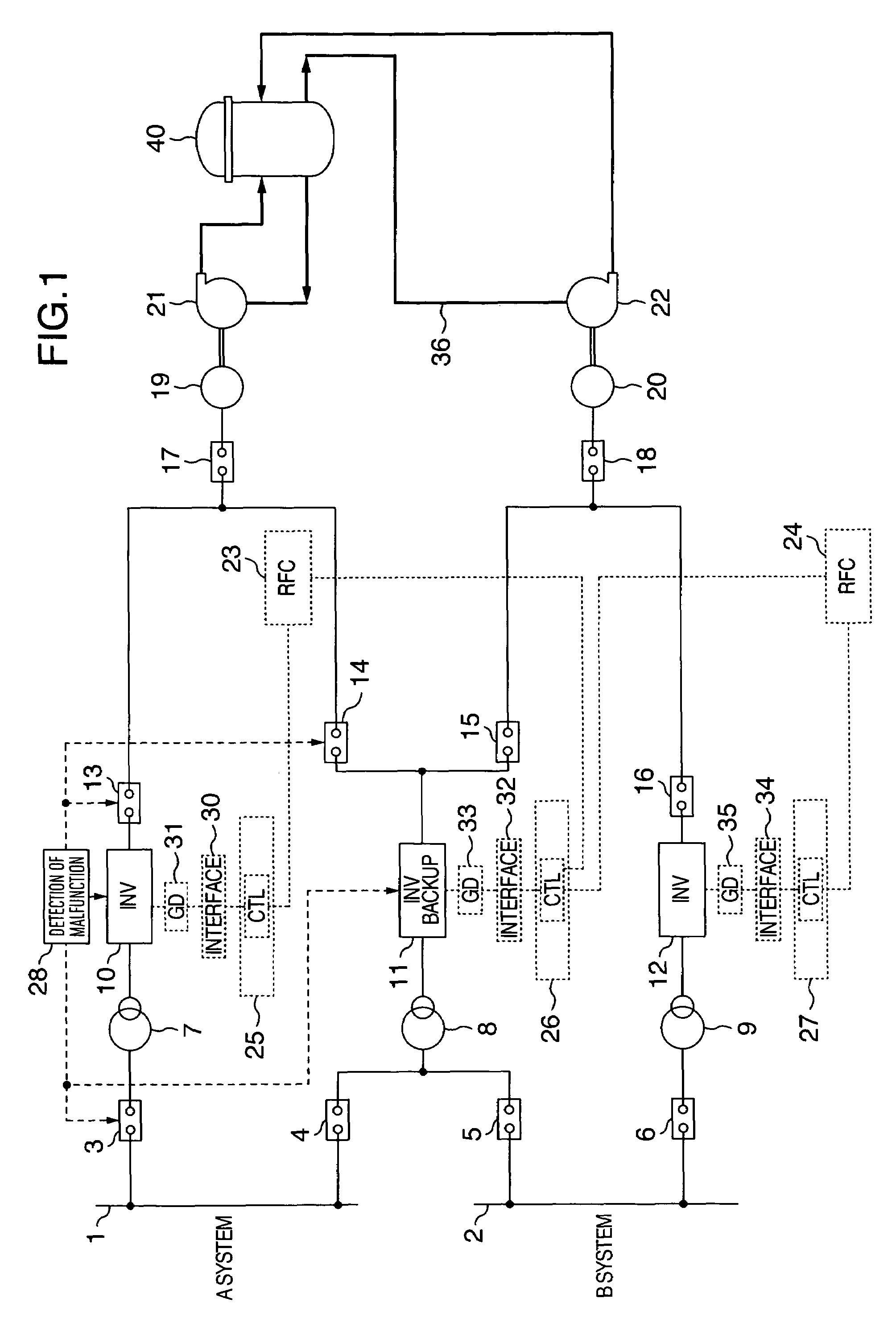

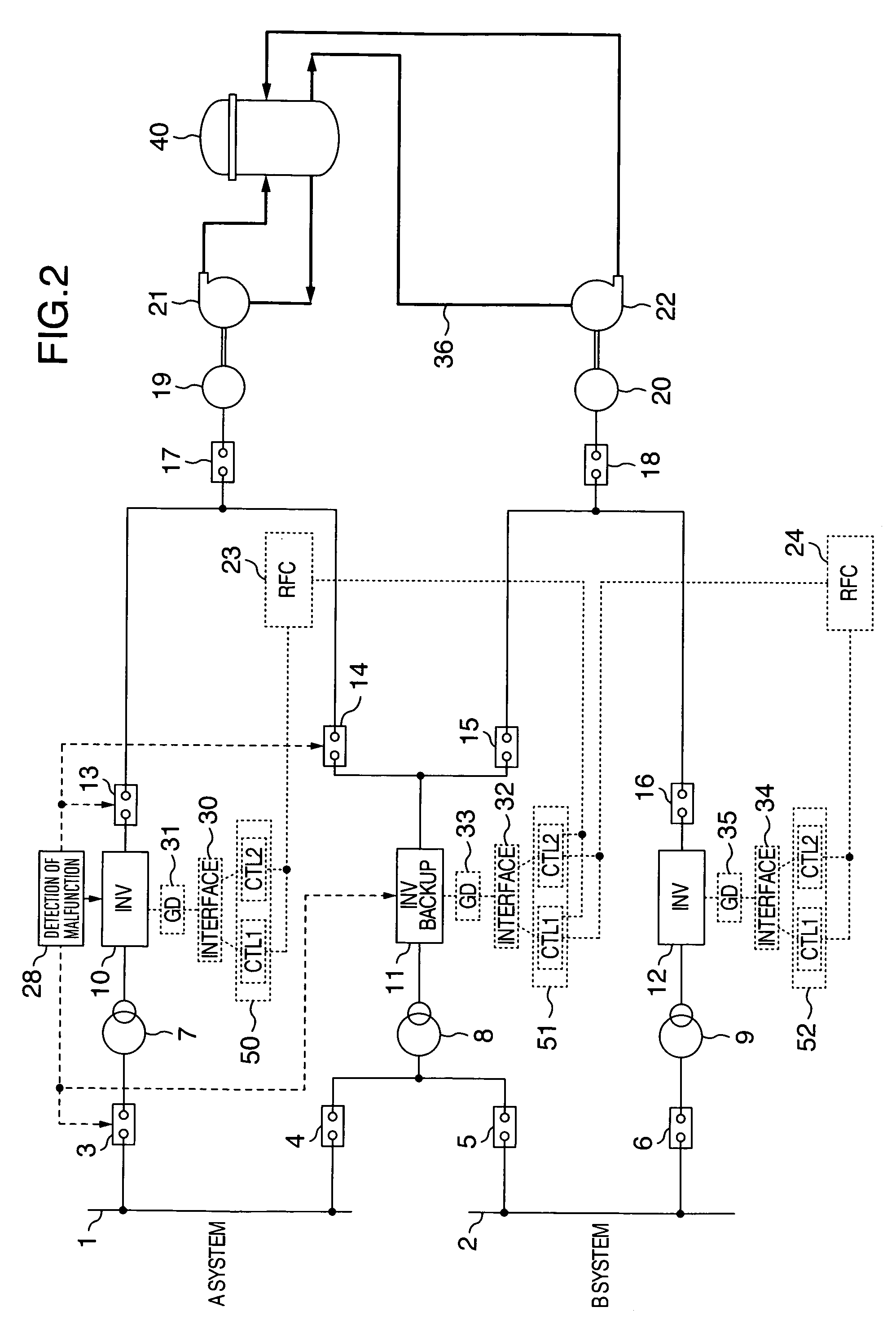

Adjustable speed drive system for primary loop recirculation pump

ActiveUS7429807B2Guaranteed uptimeRapid and safeSpecific fluid pumpsBatteries circuit arrangementsNuclear reactorControl signal

Owner:HITACHI-GE NUCLEAR ENERGY LTD

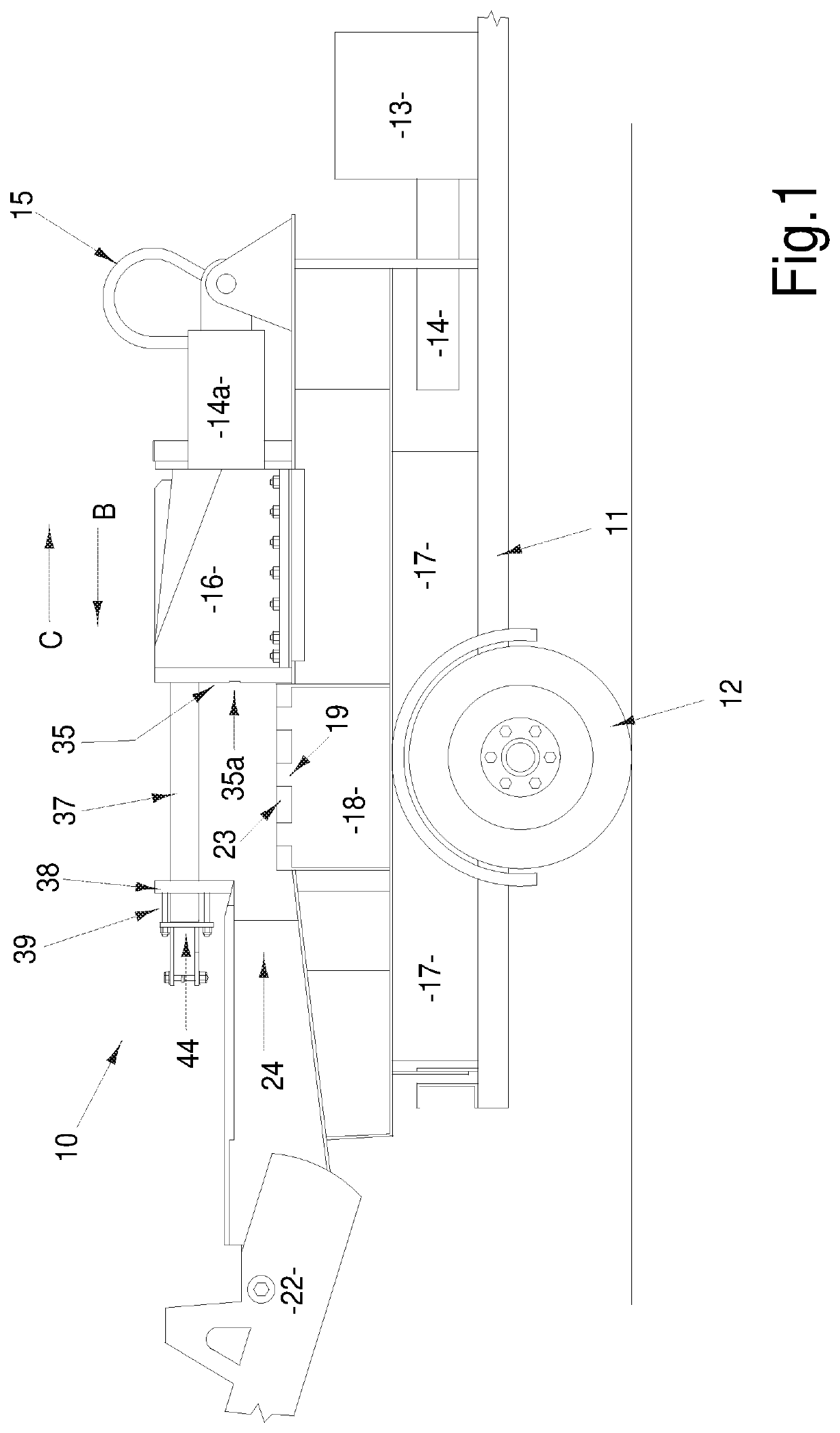

Wood Splitter

InactiveUS20220234241A1Minimal handlingRapid and safeWood splittingAgricultural engineeringWoodchips

A wood splitter which includes a supporting surface for receiving a section of wood to be split; the supporting surface having a cutting box on one side and a reciprocating moving head on the other side; the cutting box providing a series of spaced stationary knives through which the wood can be forced, to cut the wood, said stationary knives including a horizontal knife along the uppermost margin of the cutting box; the moving head being arranged to be reciprocable towards the cutting box so as to engage wood placed on the supporting surface and push said wood through the cutting box, and then away from the cutting box to allow a fresh piece of wood to be placed on the supporting surface; a top plate connected to the moving head by a connecting arm and movable between a first position in which the lower edge of the top plate overhangs said horizontal knife and a second position in which the top plate is raised vertically relative to the cutting box and is moved horizontally away from the supporting surface.

Owner:TASKPOWER NZ LTD

Defrost apparatus and method thereof

ActiveUS9723864B2Safely and rapidly defrostingEffectively defrost such itemsFood preservationThermometer applicationsEngineeringMotion system

An apparatus and a method of defrosting frozen items, is provided. The apparatus and method utilizes a fluid flow system and method, such as a fluid-push / pull system in which generally an entire volume of fluid is pushed or pulled through a cavity in which frozen items are located and / or a continuous motion system in which fluid is circulated within a fluid tank of the system.

Owner:UNIFIED BRANDS

Fast extraction threaded nut

The present invention relates to a fast extraction threaded nut intended to be used on a threaded bolt or male member wherein the fast extraction threaded nut comprises at least an outer face and an axial bore as to allow insertion of a male member or like, wherein the fast extraction threaded nut and the threaded bolt have tightening means with common geometry, and the fast extraction threaded nut and the threaded bolt or male member are intended to join or connect two elements that need to be attached or coupled to each other, wherein the fast extraction threaded nut comprises in at least the outer face a notch of variable section and the notching is formed by at least two faces wherein the maximum cross-section of the notch is positioned in the outer area and the minimum section is positioned prior to the axial bore at such a distance that allows for the generation of an increase area which extensively grows until reaching the inner surface of the axial bore where the common tightening means is formed thus generating the split of the fast extraction threaded nut.

Owner:ABASOLO VALLEJO +1

Swing door operator

InactiveUS20200332586A1More energy efficientMore energyPower-operated mechanismRevolving doorClassical mechanics

The present invention relates to a swing door operator adapted for employing a first predetermined speed trajectory, or a first and a second predetermined speed trajectory in sequence, when opening a swing door leaf (1). The first predetermined speed trajectory comprises the swing door leaf (1) being moved from a closed position (C) to a first open position (A). The second predetermined speed trajectory comprises the swing door leaf (1) being moved from the first open position (A) to a second open position (B) at a reduced kinetic energy setting. The first speed trajectory is initiated in response to an opening command or an evacuation command received by the swing door operator. The second speed trajectory is initiated in response to an evacuation command received by the swing door operator when the door leaf (1) arrives at the first open position (A).

Owner:ASSA ABLOY ENTRANCE SYST

Ornament attachable and detachable apparatus

A technical object of the present invention is to provide an ornament attachable and detachable apparatus which may attach and detach an ornament without piercing a product. To this end, the ornament attachable and detachable apparatus for attaching and detaching an ornament to and from a product according to the present invention includes: a first magnet positioned on an inner surface of the product; a second magnet of which a portion is positioned on an outer surface of the product to correspond to the first magnet and which has a different polarity from the first magnet; and a mounting portion mounting the ornament on another portion of the second magnet.

Owner:SEMA GLOBAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com