Method for constructing oil drilling waste mud solidification pool

A waste mud and oil drilling technology, which is applied in the direction of buildings, building types, underwater structures, etc., can solve the problems that the pool does not play an anti-seepage role, pollutes the surrounding environment, waste mud overflows, etc., and achieves long-term protection without leakage , low curing cost, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

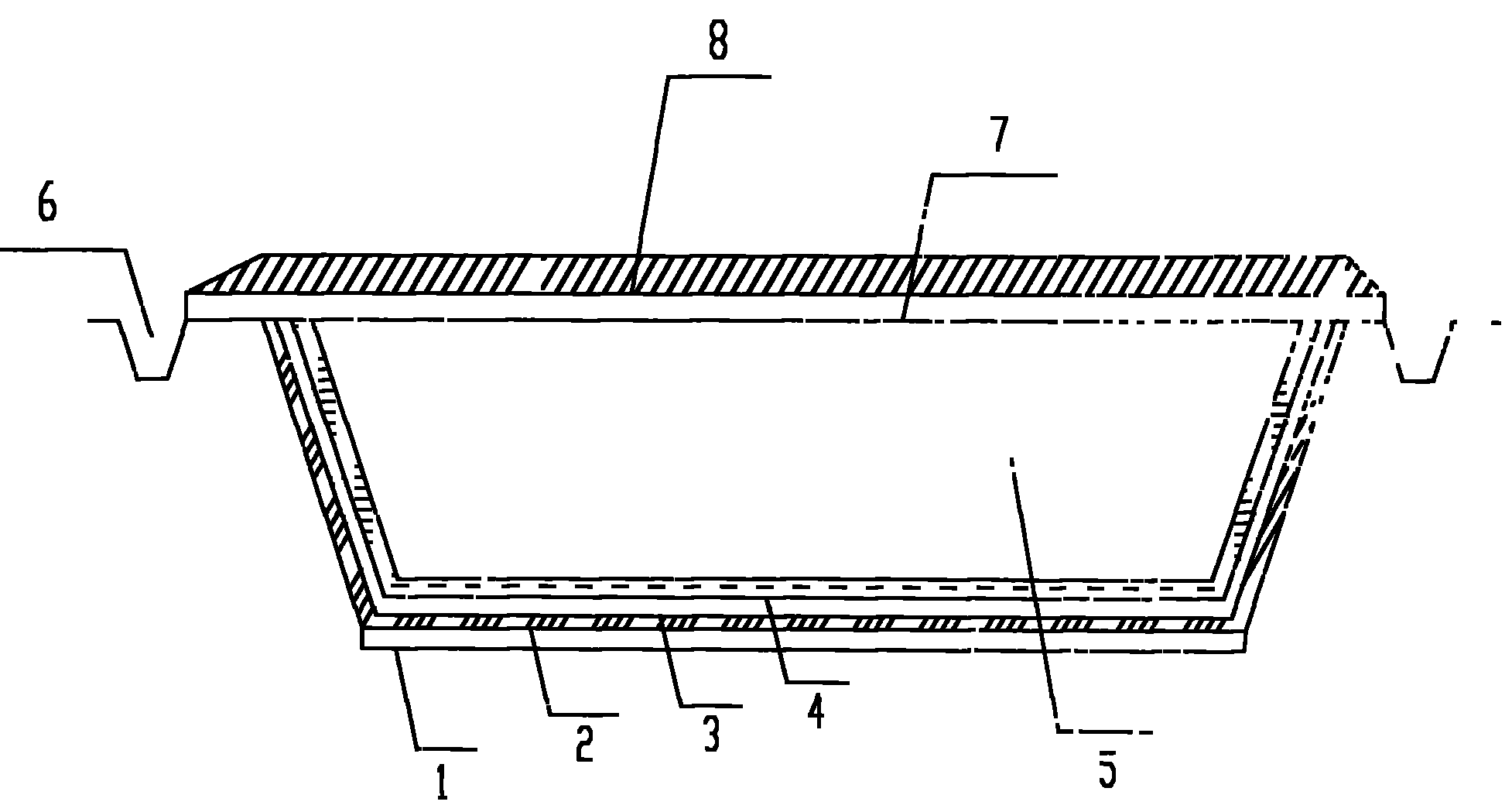

[0037] The invention discloses a method for constructing an oil drilling waste mud solidification pool, which comprises the following steps: a. Excavating an earthen pool and compacting the pool body; b. Removing sharp debris on the inner wall of the earthen pool, and laying a clay layer on the bottom of the earthen pool 1, the clay layer 1 is compacted; c, the bottom layer of non-woven geotextile 2, the polyethylene geomembrane 3 and the surface layer of non-woven geotextile 4 are sequentially laid on the inner wall of the earthen pond to form a three-layer structure, and the surface of the non-woven geotextile is Fill the waste mud 5 in the layer 4, and use the three-layer structure to wrap the waste mud 5; d, lay a concrete layer 7 on the three-layer structure wrapped with the waste mud 5; e, cover the concrete layer 7 with a Layer cooked soil 8.

Embodiment 2

[0039] As the best implementation mode of the present invention is as follows: with reference to figure 1 , the present invention includes: a, excavating the earthen pond, and tamping the pond body; b, removing the sharp debris on the inner wall of the earthen pond, and laying a clay layer 1 at the bottom of the earthen pond, and compacting the clay layer 1; c, on the inner wall of the earthen pond Lay non-woven geotextile bottom layer 2, polyethylene geomembrane 3 and non-woven geotextile surface layer 4 in sequence to form a three-layer structure, fill waste mud 5 into the non-woven geotextile surface layer 4, and use the three-layer The structure wraps the waste mud 5; d, laying a concrete layer 7 on the three-layer structure wrapped with the waste mud 5; e, covering a layer of mellow soil 8 on the concrete layer 7. After any of the steps a-e, a drainage ditch 6 is dug outside the pool, and the concrete layer 7 is extended to the drainage ditch 6 . In the concrete layer 7,...

Embodiment approach

[0042] (1) Excavate the solidification pool according to the terrain, try to be within 50m of the sewage pool, the depth of the pool is 2.5-3m, the length and width are not more than 20m, and the slope of the slope is 45°-60°.

[0043] (2) Compact the bottom and sides of the pool, remove sharp debris, and use 20cm of clay at the bottom and compact it.

[0044] (3) High-density polyethylene geomembrane 3 (1.5mm) uses upper and lower layers of non-woven geotextiles as the protective layer. Before laying the geomembrane, lay the geotextile, and then lay a layer of geotextile. The geotextile joints are lapped. The amount of contact is between 20-30cm.

[0045] (4) Lay high-density polyethylene geomembrane 3 and the welding sequence extends from the height of the pool to the lower part. The overlap between the two membranes is between 10-20cm. The joint must be clean and free of water drops, so as not to affect the welding quality. The welding adopts hot-press fusion welding, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com