Grouting method of waterproof curtain of burnt rock covering on working surface to be mined of coal mine

A water-proof curtain and working face technology, which is applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve the problems that the slurry is difficult to fully diffuse and overlap, the burnt rock grouting curtain has poor anti-seepage effect, and the water blocking rate is not high. , to achieve the effects of small leakage, improved water-proof performance, and good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

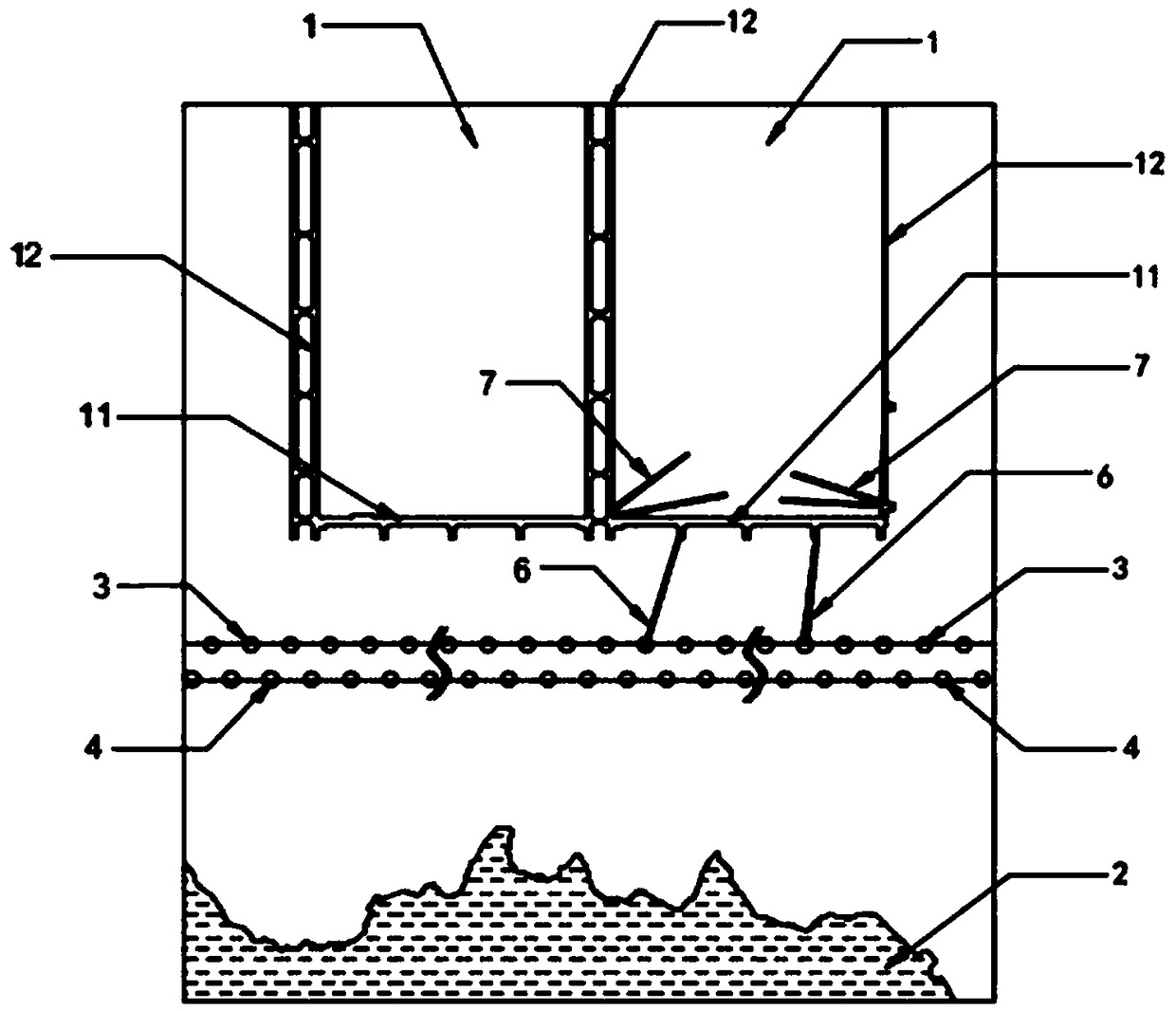

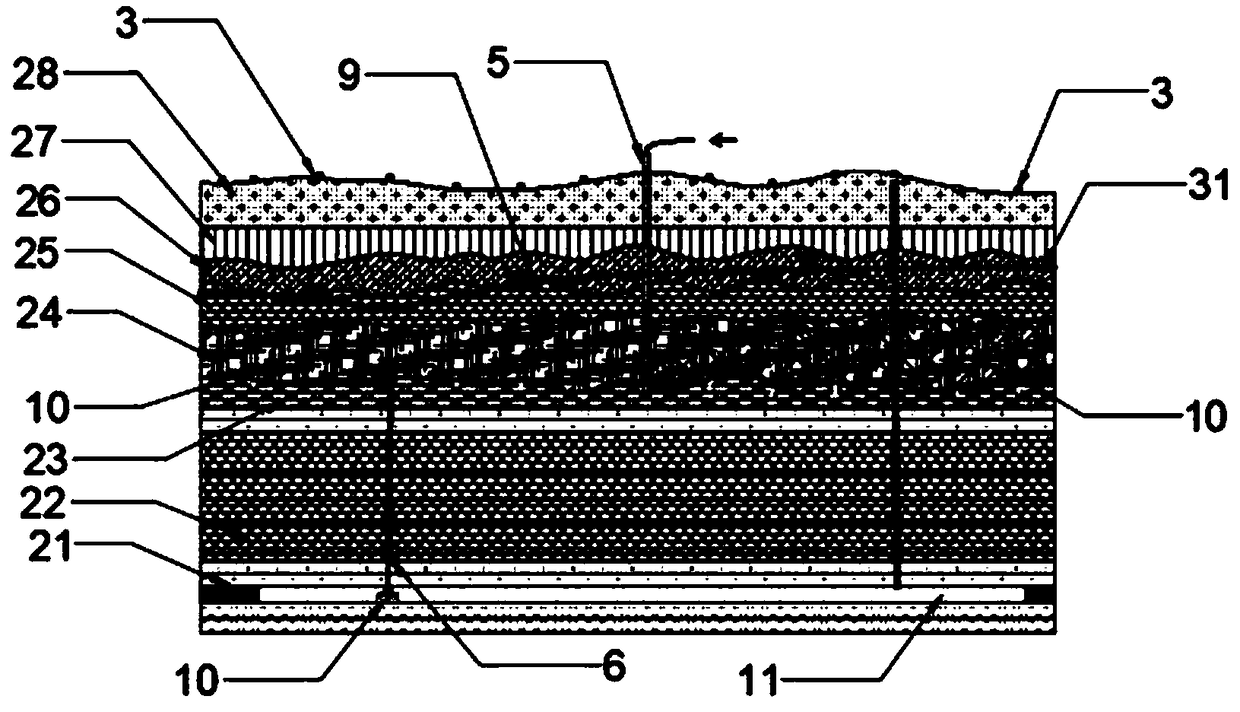

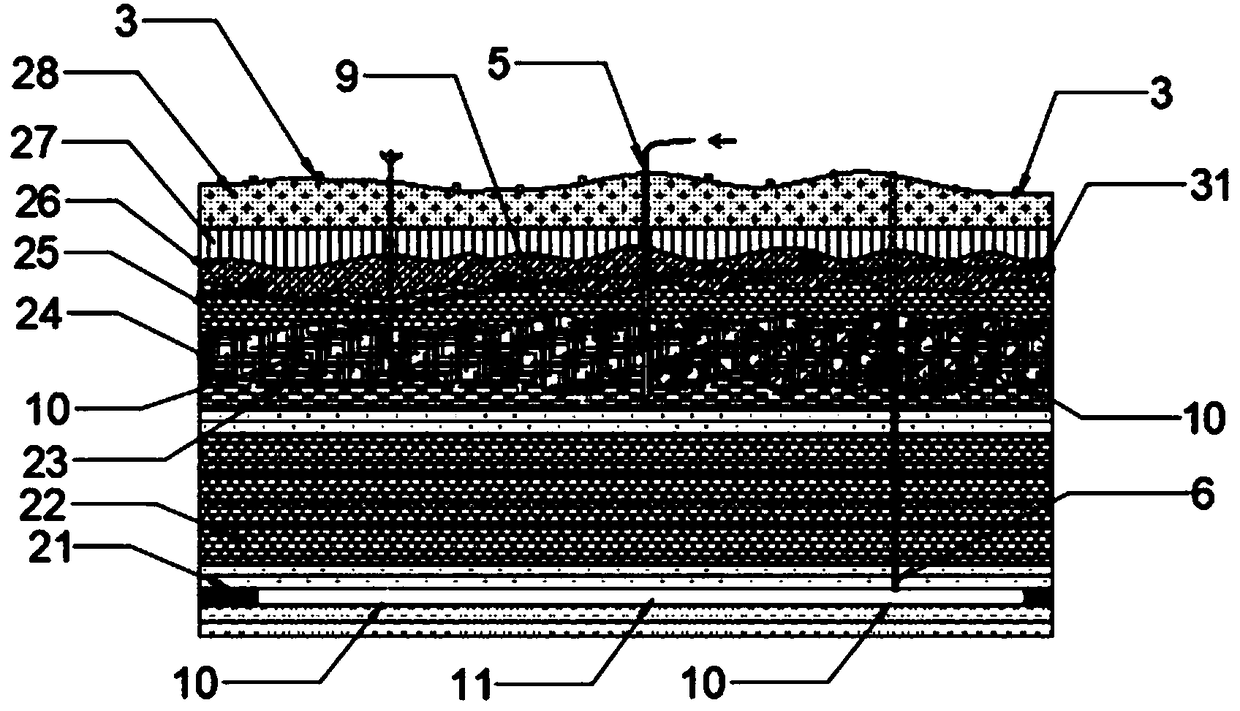

[0044] A mine in the northern Shaanxi mining area is a coal seam of the Jurassic Yan'an Formation. The coal seam structure is simple and the dip angle is small, which is a near-horizontal coal seam. Due to the development of surface gullies, the multi-layer coal in the minefield has burning phenomenon. Main mining seam 4 -2 The average coal thickness is about 3.63m, and the middle part of the minefield is 4 -2 Coal burnt rocks are in direct contact with reservoirs, 4 -2 coal below 5 -2 Coal is a complete coal seam that has not been burned. 4 -2 Coal-burned metamorphic rock is recharged by reservoir water and has strong water-rich properties, with a distance of 5 -2 Coal about 75m, 5 -2 Coal thickness is about 6m, 5 -2 After the coal face is mined, the water-conducting fracture zone will develop to 4 -2 coal burnt rock, 4 -2 Water in burnt rocks in the coal-fired area contributes to the lower part 5 -2 The threat to the safety of coal working face is great. for 5 -2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com