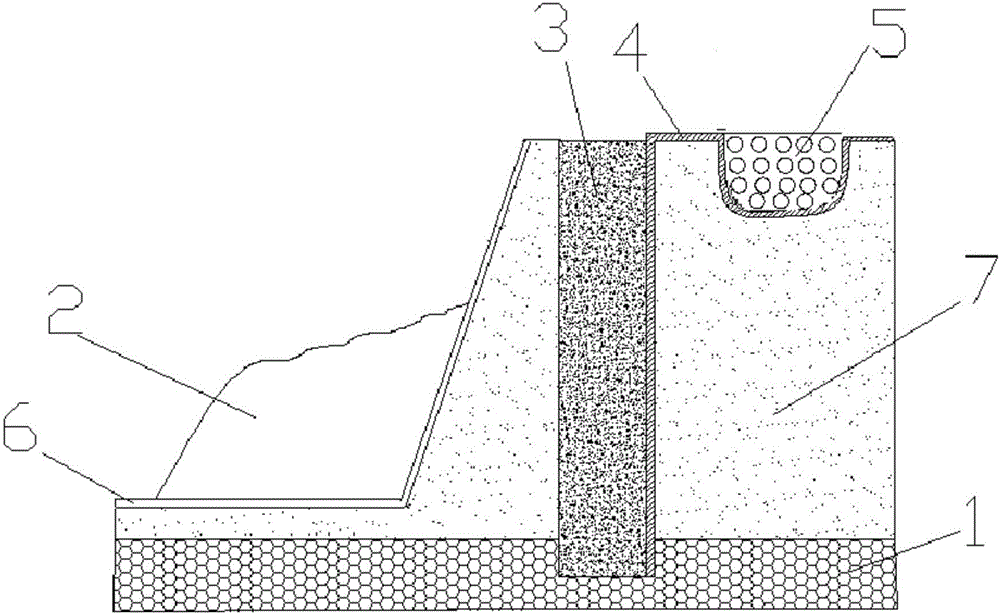

GCL vertical anti-seepage wall and preparation method thereof

An anti-seepage wall and waterproof blanket technology, applied in geotextiles, protection devices, buildings, etc., can solve problems such as high project cost, pollute soil and groundwater, and affect project quality, achieve good overall anti-seepage performance, and improve anti-seepage. Good performance and anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further elaborated below in conjunction with specific preferred embodiments. It should be understood that the preferred embodiments are only for the convenience of understanding the solutions of the present invention, and are not intended to limit the scope of protection.

[0022] A preparation method for an anti-seepage wall, comprising the steps of:

[0023] (1) Excavation of trenches: Excavate trenches with a width of 70cm around the garbage dump, and the trenches go deep vertically to 50cm below the impermeable layer. exudate

[0024] (2) Lay powder type sodium bentonite waterproof blanket (GCL) on the inner wall of the backwater surface of the groove, and the grammage of the powder type GCL is 3800g / m 2 ; The powder-type GCL is composed of two layers of geotextile layers and a bentonite layer between the two layers of geotextile layers;

[0025] What needs to be explained here is: powder-type GCL has a fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com