Anti-freezing mortar special for aerated bricks

A kind of aerated brick and mortar technology, applied in the field of building materials, can solve problems such as imperfect composition and performance, sudden drop in strength and other performance, poor heat preservation and temperature resistance, etc., achieve good microporous structure and bulk density, improve frost resistance, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

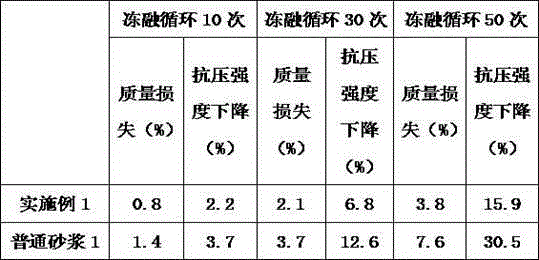

Examples

Embodiment 1

[0023] A special mortar for frost-resistant aerated bricks, made of the following substances by weight:

[0024] 35 parts of slag, 30 parts of cement, 25 parts of river sand, 0.6 parts of water reducing agent, 0.5 parts of air-entraining agent, 1.5 parts of antifreeze, 4 parts of vitrified microspheres, 4 parts of kapok fiber, 2.5 parts of rare earth oxide, 7 parts Modified concave-convex soil.

[0025] Further, the slag is composed of iron slag and zinc slag, and its crushed particle size is not greater than 3mm.

[0026] Further, the cement is Portland cement with a label of 42.5.

[0027] Further, the river sand is composed of 50% fine sand with a particle size of 0.25-0.35 mm and 50% medium sand with a particle size of 0.35-0.50 mm.

[0028] Further, the water reducer is a naphthalene powder water reducer.

[0029] Further, the air-entraining agent is composed of a rosin resin-based air-entraining agent and an alkylbenzenesulfonate-based air-entraining agent.

[0030] ...

Embodiment 2

[0038] A special mortar for frost-resistant aerated bricks, made of the following substances by weight:

[0039] 38 parts of slag, 33 parts of cement, 26 parts of river sand, 1 part of water reducer, 0.6 parts of air-entraining agent, 1.5 parts of antifreeze, 5 parts of vitrified microbeads, 4 parts of kapok fiber, 4 parts of rare earth oxide, 6 parts Modified concave-convex soil.

[0040] Further, the slag is composed of magnesium slag and copper slag, and the particle size after crushing is not greater than 3mm.

[0041] Further, the cement is 52.5 Portland cement.

[0042] Further, the river sand is composed of 40% fine sand with a particle size of 0.25-0.35mm and 60% medium sand with a particle size of 0.35-0.50mm.

[0043] Further, the water reducer is composed of aliphatic powder water reducer and polycarboxylic acid powder water reducer.

[0044] Further, the air-entraining agent is composed of alkylbenzene sulfonate air-entraining agent and fatty alcohol sulfonate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com