Novel multipurpose composite insulation board and construction method and processing device thereof

A technology of composite thermal insulation and thermal insulation board, which is applied in the direction of thermal insulation, floor slabs, building components, etc. It can solve the problems of high labor intensity, too thin floor heating pipes, complicated procedures, etc., and achieve the effect of reducing labor intensity, improving work efficiency, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

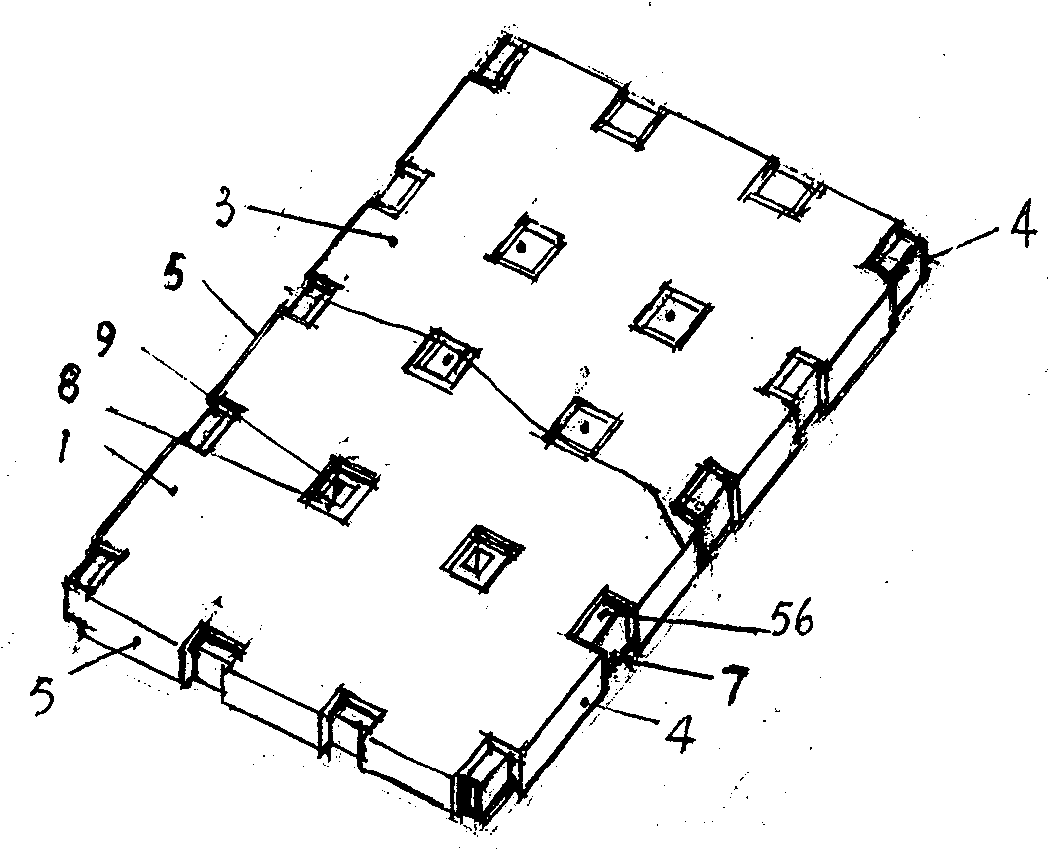

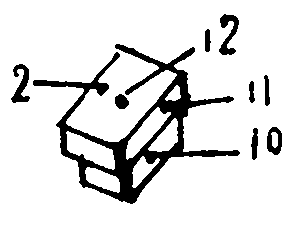

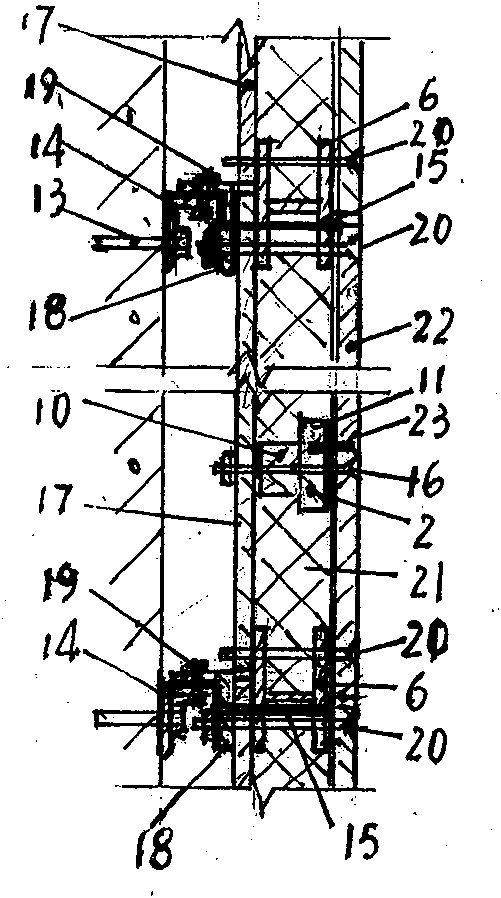

[0058] An example of a new type of multi-purpose composite insulation board, such as figure 1 As shown, it is not only suitable for the insulation of interior and exterior walls, floors and roofs of industrial and civil buildings, but also can be used for formwork and insulation of cast-in-place reinforced concrete walls, floors and roof panels. It is characterized in that it is composed of a rectangular or square insulation board 1 with a thickness of 20-120 mm and a length x width of 600-2800 x 600-1000 mm, and a reinforced connection anchor support seat 2 reserved in the insulation board and pasted on the insulation board. The aluminum foil reflective layer 3 on the upper surface is formed. It includes a composite thermal insulation board without reinforced connection anchor support seat 2; it also includes 2 to 6 22×22mm (or 18×18mm) square or Φ22mm (or Φ18mm) circles that are long in the longitudinal direction in the transverse direction of the board. A composite thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com