Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

837results about How to "Good toughening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

Full-biodegradable polylactic acid composite material and preparation method thereof

The invention discloses a full-biodegradable polylactic acid composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 40-93 parts of polylactic acid, 5-40 parts of flexibilizer, 1-10 parts of plasticizer, 1-30 parts of vegetable fibre, 0.1-2 parts of antioxygen and 0.1-1 part of silane coupling agent. In the invention, the vegetable fibre composite polylactic acid is modified, which can enhance the mechanical property and the heat resistance of the polylactic acid material, and moreover, the polylactic acid material can be fully degraded, and the raw materials of the polylactic acid material are renewable and abundant; a lateral feed mode is applied to the fiber, therefore, the damage of a screw to the fibre is smaller, the strengthening and toughening effects of the fibre are better. Polydiethylene glycol sebacate (PBS), grafted with a polylactic acid copolymer, serves as the flexibilizer, which not only greatly improves the compatibility of the PBS and the polylactic acid but also can improve the toughness and the heat resistance of the composite material.

Owner:CHERY AUTOMOBILE CO LTD

SiCf/SiC ceramic-based composite material with composite interfaces

InactiveCN107540400AIncrease temperatureGood toughening effectAntioxidant capacityOxidation resistant

A SiCf / SiC ceramic-based composite material with composite interfaces is characterized by comprising CVD-SiC coating, a PIP-SiC matrix, the composite interfaces and SiC fiber, wherein the CVD-SiC coating is silicon carbide coating prepared through a chemical vapor deposition method, and has the thickness of 100-500 microns; the composite interfaces are formed by alternately and periodically overlapping any two or three of a BN interface, a ZrO2 interface, an LaPO4 interface and an SiC interface, and the cycle period frequency is 3-5 times; the PIP-SiC matrix is silicon carbide formed through in-situ pyrolysis of polycarbosilane; the SiC fiber accounts for 40-60% of the composite material by volume, a pyrolytic carbon layer with the thickness of 5-20 nanometers is formed on the surface thereof. A preparation method comprises the following steps: preparing multiple layers of composite interfaces on the surface of the silicon carbide fiber by different preparation processes, then fillingthe SiC matrix by a PIP method, and finally preparing the surface SiC coating by a CVD method. The SiCf / SiC ceramic-based composite material prepared through the preparation method provided by the invention is high in toughness and strong in antioxidant capacity, and the preparation process is simple.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Toughened thermosetting resin and its preparation method

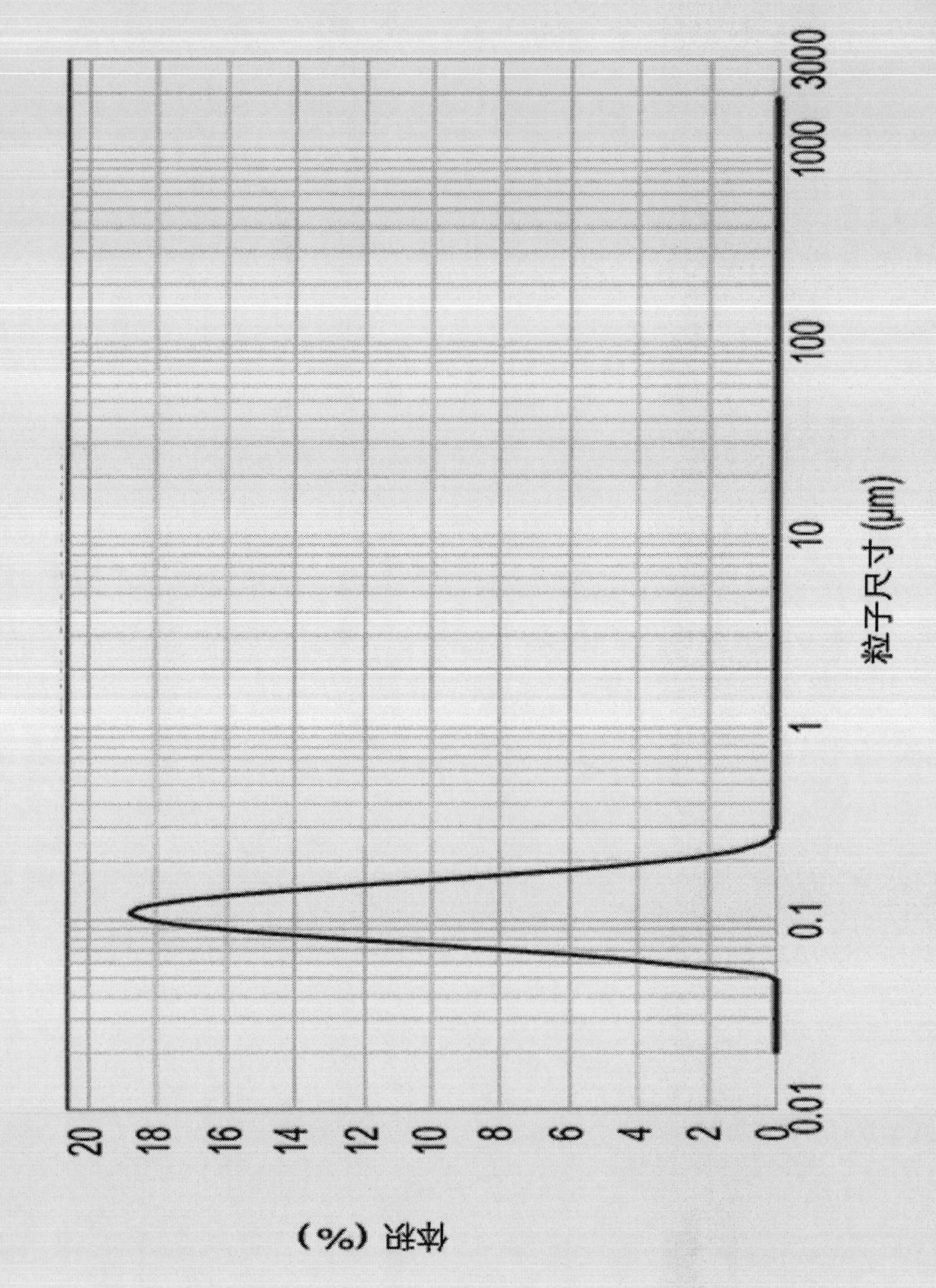

The toughened thermosetting resin contains thermosetting resin and rubber granules whose mean grain size is 20-500 nm. Said resin is obtained by mixing the fully-vulcanized powder rubber whose mean grain size is 20-500 nm and thermosetting resin prepolymer and making their mixture undergo the process of solidification treatment. Said resin possesses obvious toughened effect, excellent impact resistance and high strength, modulus and heat resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite material sliding bearing with base of high-temp polymer

InactiveCN1431406AImprove thermal conductivityGood toughening effectBearing componentsFiberPolymer science

This invention discloses a high-temp polymer matrix compound material sliding bearing which is processed according to conventional formation method with the compound material made of high-temp polymer matrix resin with functional additives, reinforced fiber and agent. The said matrix resin is made by teflon mixed with and / or polyamide and modified and the said function additives are nm or mm level mineral nonmetal fillers in which, at least one kind is particle of nm level. This invention provides a low friction ratio, good wearness, long working time, high PV, value, self lubricating compound material sliding bearing.

Owner:UNIV OF JINAN

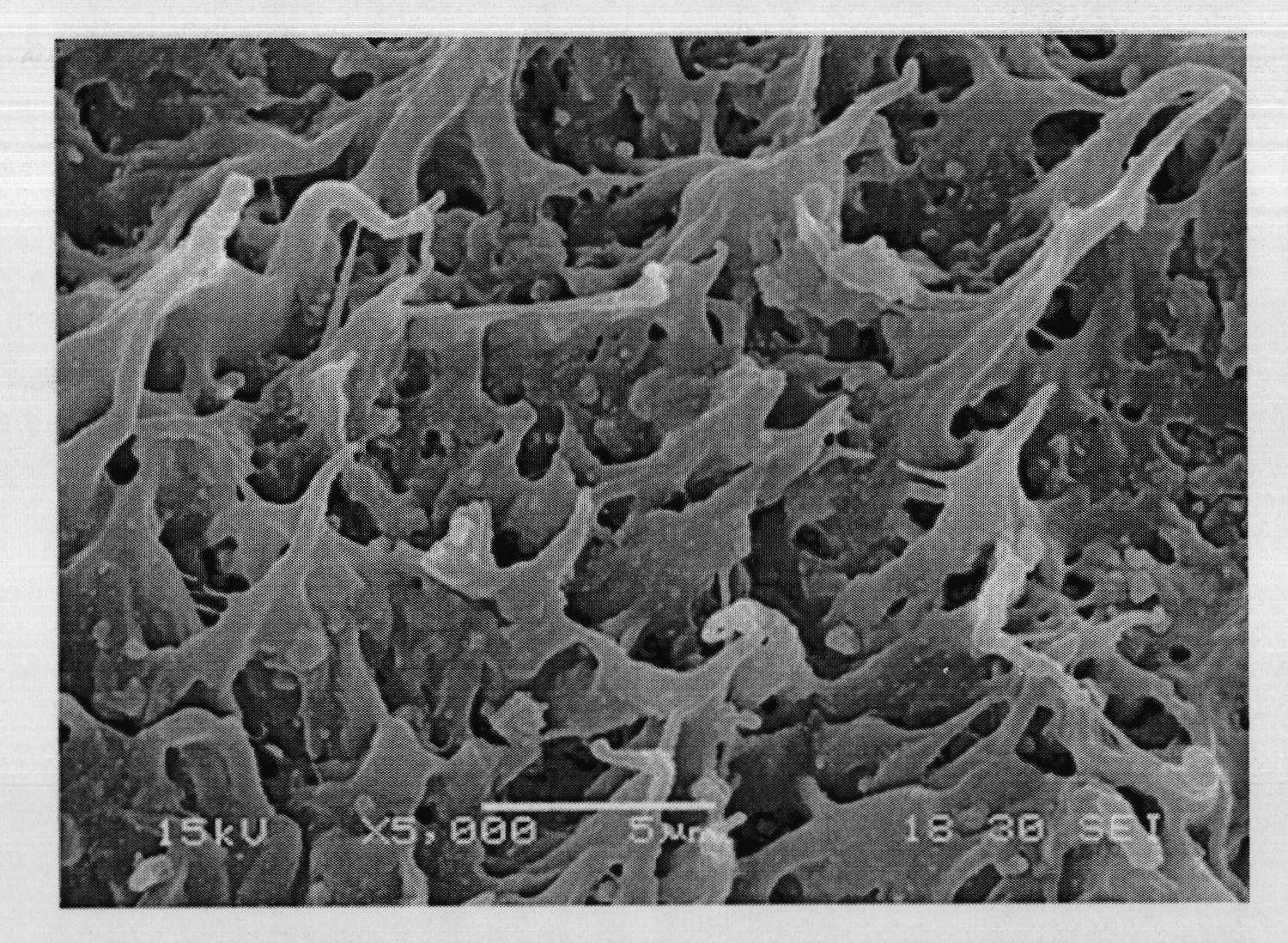

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

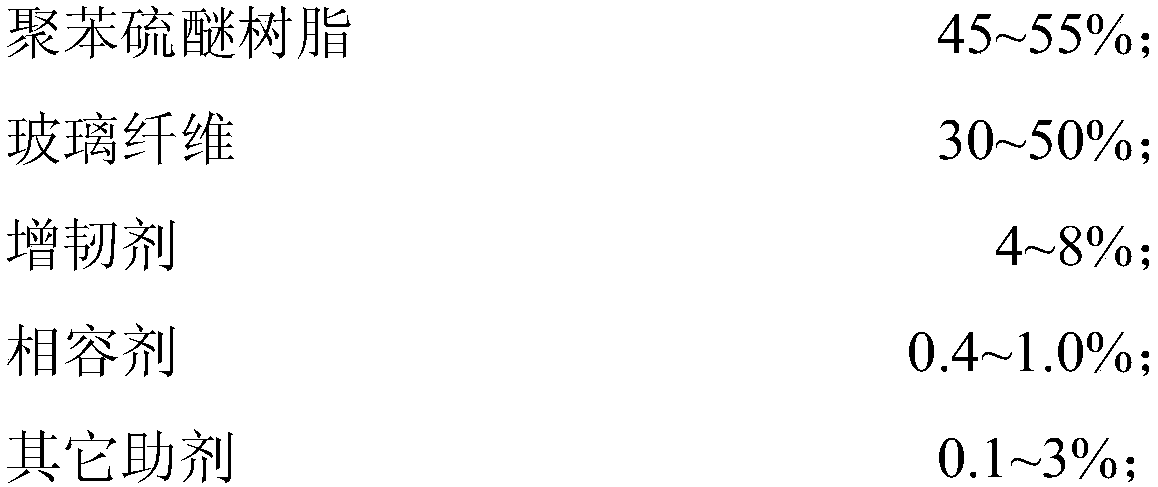

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

Wear-resistant and heatproof modified polyurethane rubber cable material

InactiveCN105602238AImprove performanceGood wear resistance and heat resistancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl alcohol

The invention discloses a wear-resistant and heatproof modified polyurethane rubber cable material which comprises the following raw materials: modified polyurethane, acrylate rubber, ethylene-propylene-diene monomer, nitrile butadiene rubber, epoxy resin, polyether glycol, toluene diisocynate, polyvinyl alcohol, diisobutyltin dilaurate, polyvinyl chloride, hydroxyl-terminated polybutadiene, hydroxyl-terminated polyalcohol, isocyanate, vinyltriethoxysilane, dibutyltin dilaurate, silicone oil, a carbon nanotube, organic modified montmorillonoid, nano alumina powder, talc powder, bamboo carbon fiber, chlorinated paraffin, silicon dioxide, zinc oxide, stearic acid, nano aluminum hydroxide, a flame retardant, an anti-aging agent, a plasticizer, an antioxidant and an accelerant. The modified polyurethane rubber cable material disclosed by the invention has excellent wear-resistant and heatproof properties.

Owner:ANHUI DUJIANG CABLE GROUP

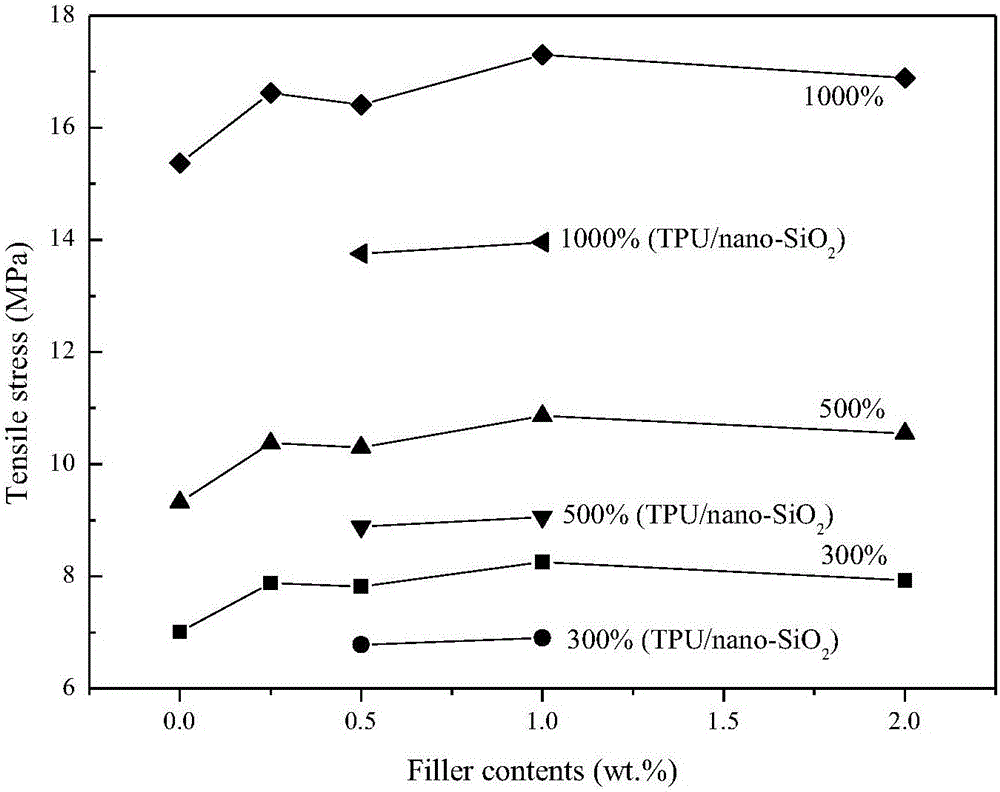

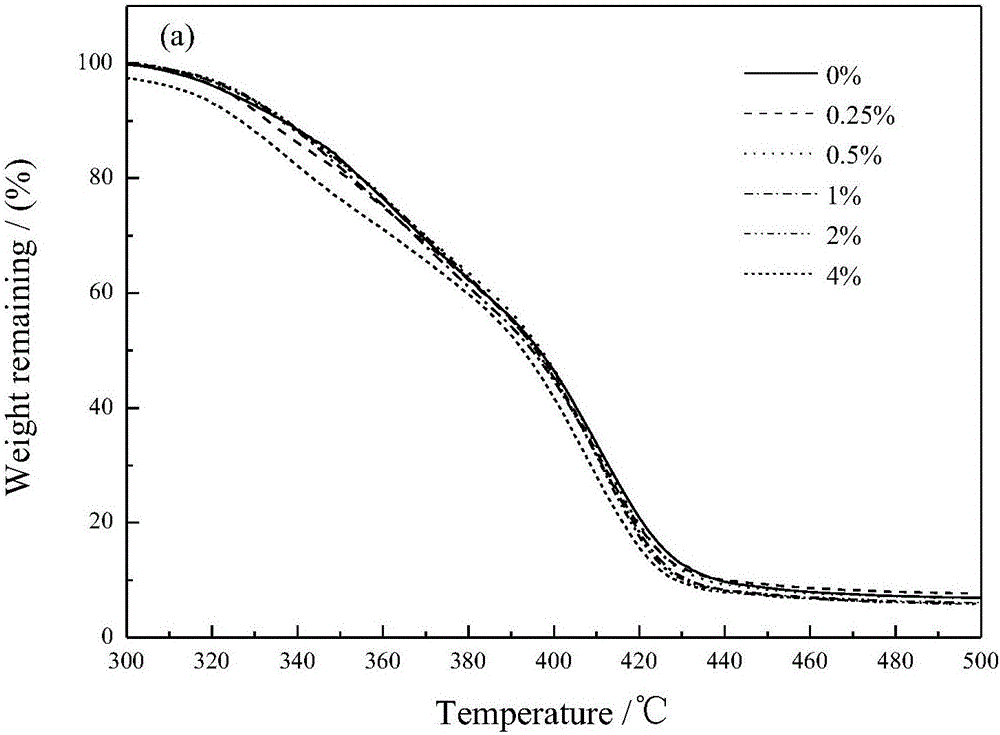

Graphene-silica hybrid material and method for preparing polyurethane based nanocomposite

The invention relates to a melt blending modification of polyurethane resin material, in particular to a graphene-silica hybrid material and a method for preparing a polyurethane based nanocomposite. The graphene-silica hybrid material is obtained through reaction of graphene oxide, silicon dioxide and 3- aminopropyltriethoxysilane; functional 3-aminopropyltriethoxysilane monomers is a bridge for linking silica and graphene oxide; the nanocomposite is obtained by by a melt blending method by using graphene-silica hybrid material as a filler and polypropylene resin as a matrix. The polymer matrix and filler of the invention have rich sources and low cost; the mutual barrier effect of graphene-silica to inhibit the aggregation of each other is given full play to, and obvious synergistic strengthening and toughening effect is applied on the TPU substrate. The preparation method is simple, easy to operate, and can be widely used; and the obtained nanocomposite has excellent mechanical properties and thermal properties.

Owner:XIHUA UNIV

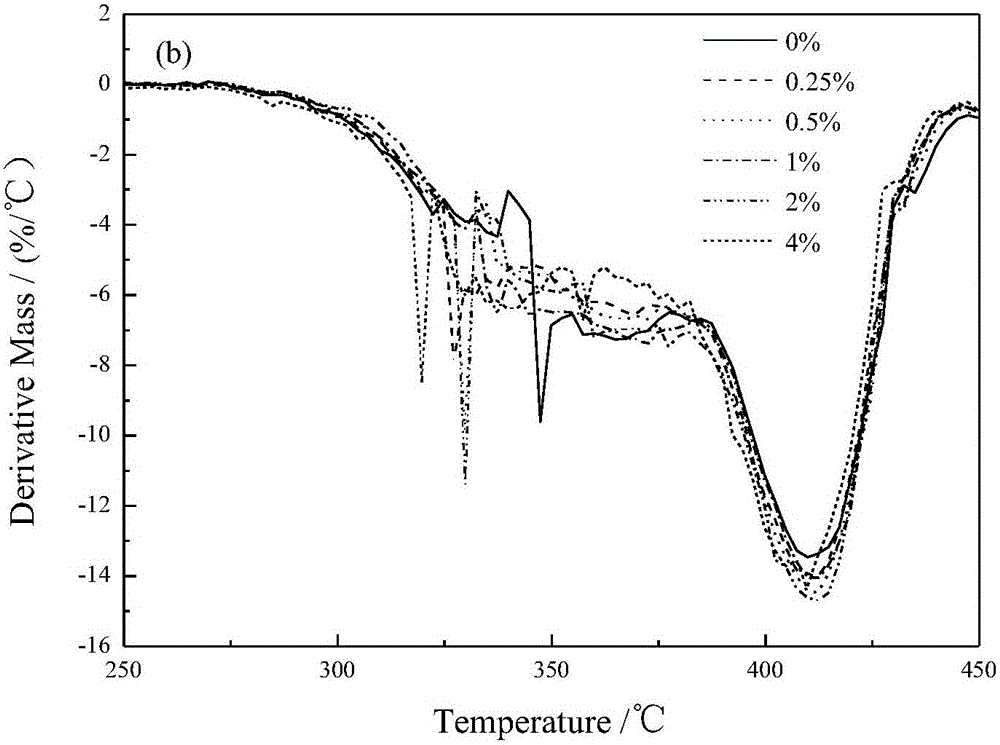

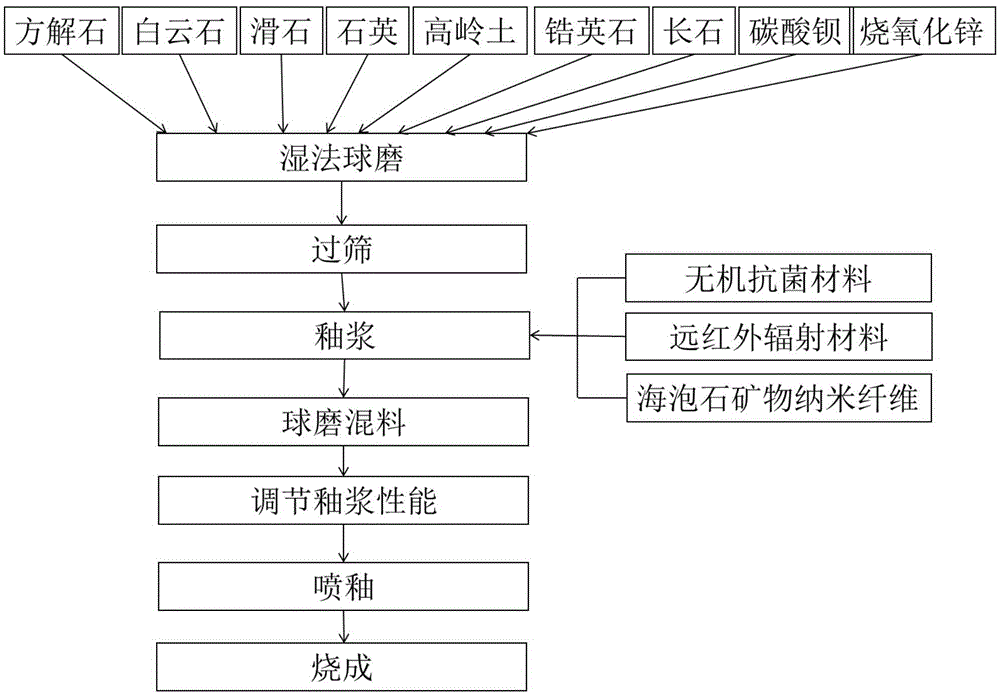

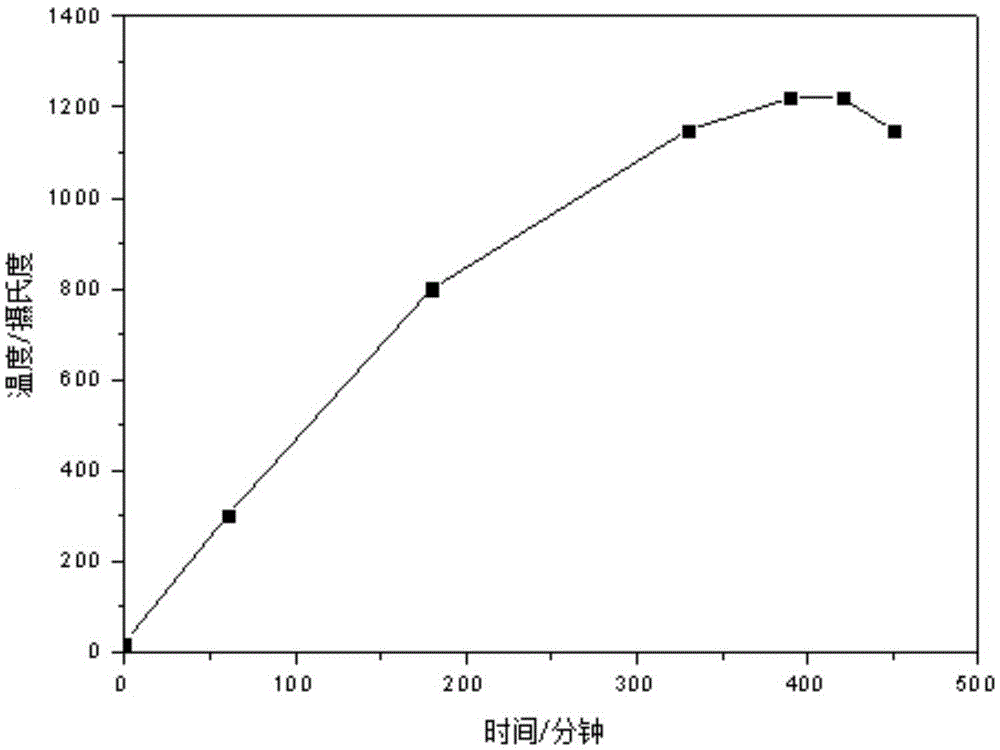

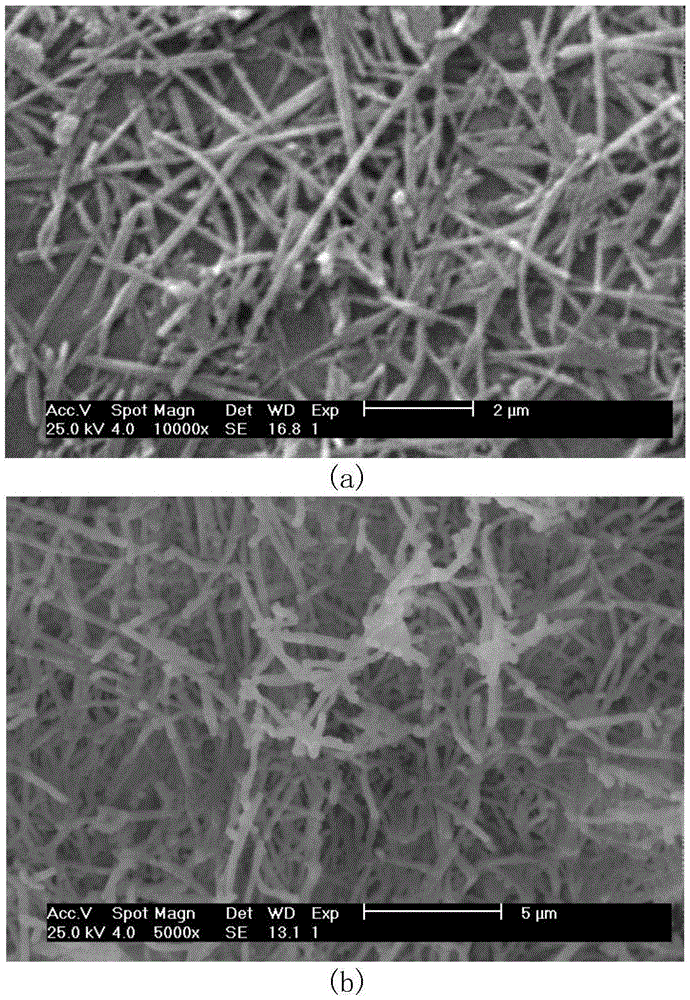

Easy-to-clean and antibacterial sanitary ceramic and preparation method thereof

The invention provides an easy-to-clean and antibacterial sanitary ceramic and a preparation method thereof. The ceramic is prepared from, by mass, 77-97 parts of ceramic glaze, 1-5 parts of inorganic antibacterial material, 5-15 parts of far infrared radiation material and 1-3 parts of sepiolite mineral nano-fiber. The inorganic antibacterial material is an inorganic composite antibacterial agent or inorganic silver antibacterial agent. The far infrared radiation material is a compound of a natural mineral material and a rare earth material. The sepiolite mineral nano-fiber is a product obtained after sepiolite is crushed through an air-current mill. The easy-to-clean performance and the antibacterial performance of the sanitary ceramic are obviously improved, and antibacterial and easy-to-clean functionalization of a glaze surface is achieved on the basis that production cost is not increased.

Owner:HEBEI UNIV OF TECH

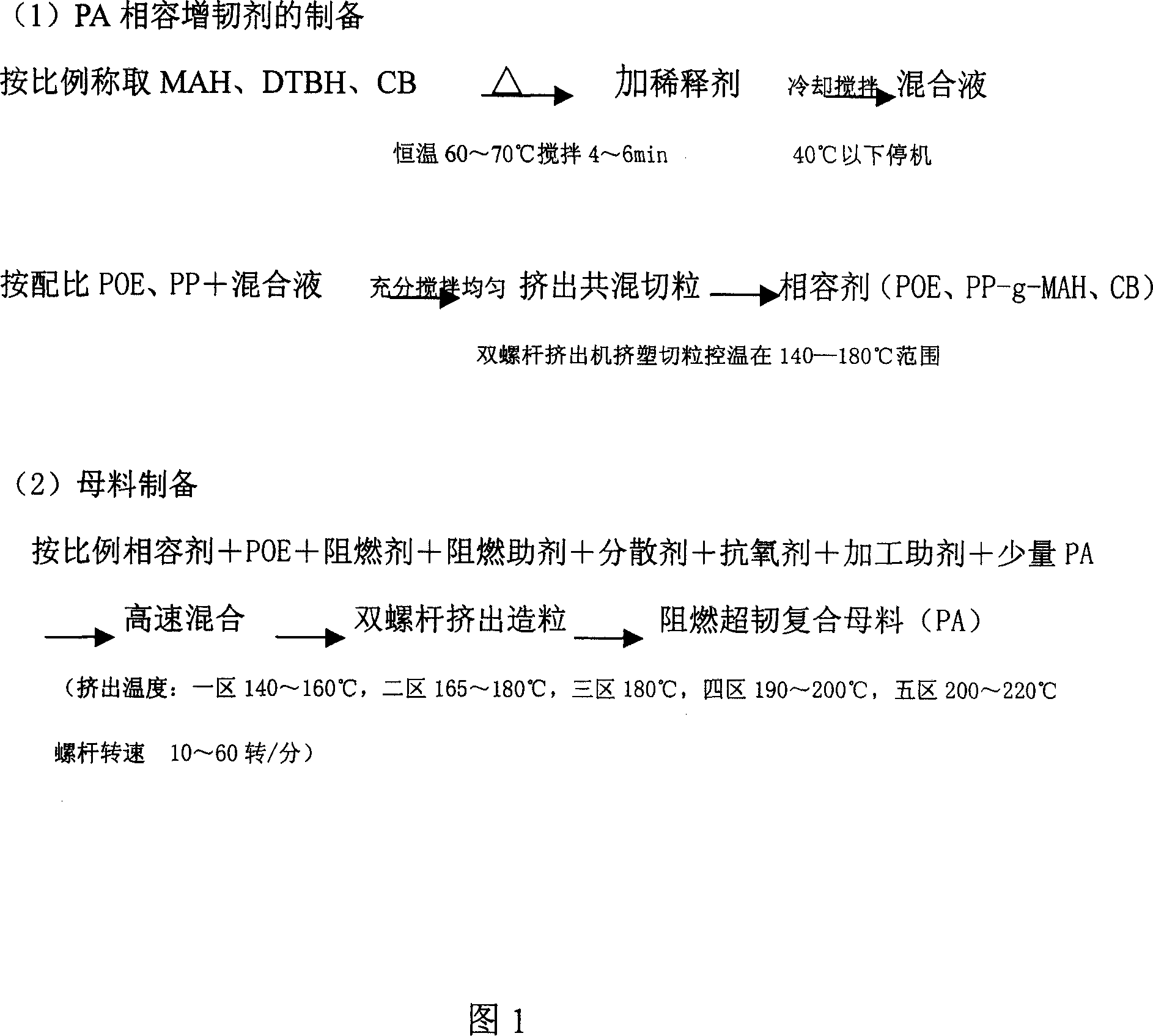

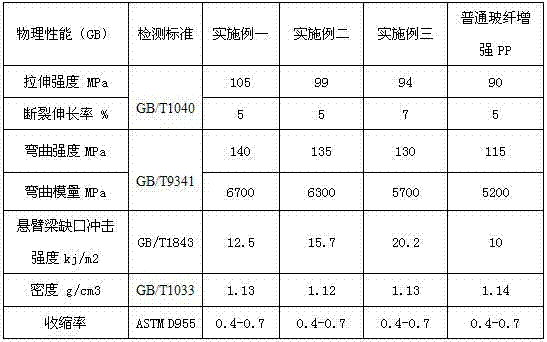

Production of super-toughened fire-retardant composite modified nylon mother material

Production of composite fire-retardant and ultra-toughed modified Nylon base material is carried out by preparing Nylon compatible toughening agent, weighing maleic anhydride, bis-penta vulcanizing agent and grafting accessory proportionally, adding into diluting agent, agitating, cooling to normal temperature to prepare into mixed liquid, extruding for multi-polymer of ethane-octylene, poly-propylene and mixed liquid by bi-screw extruder, granulating to obtain Nylon compatible toughening agent, extruding for multi-polymer of ethane-octylene, fire-retardant agent, dispersant, antioxidant and processing accessory, and granulating to obtain final product. It's convenient, cheap, fast and efficient and saves resources.

Owner:张发饶

Reinforced polypropylene composite material and preparation method thereof

InactiveCN103589058ARaw materials are easy to getSolving Recycling ProblemsPolypropylene compositesGlass fiber

Owner:ORINKO NEW MATERIAL CO LTD

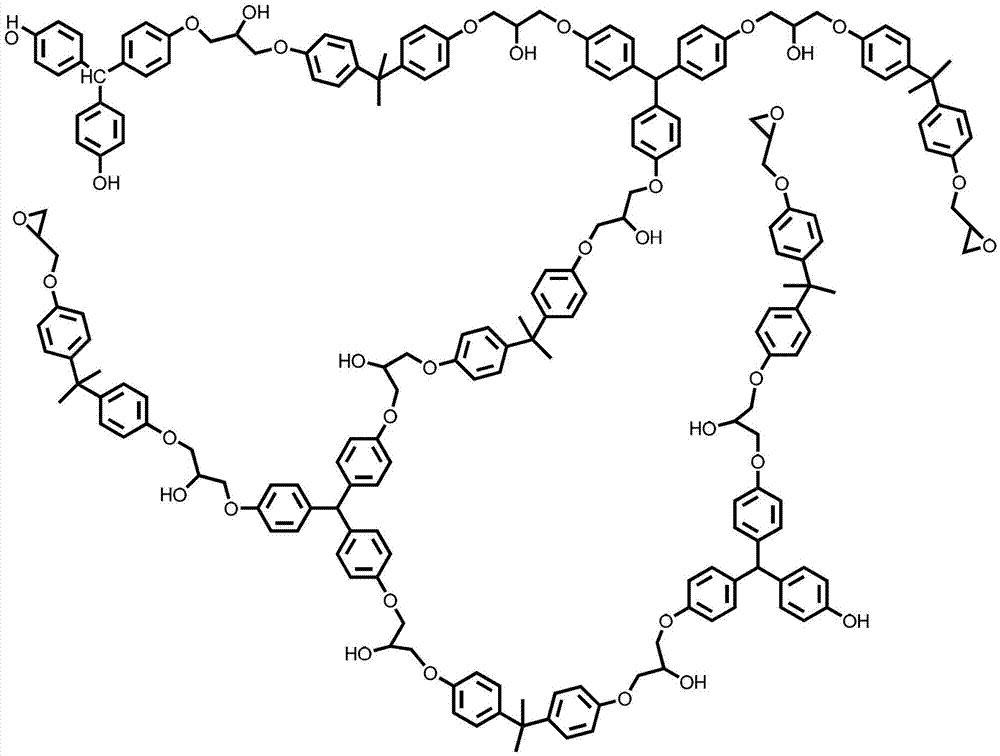

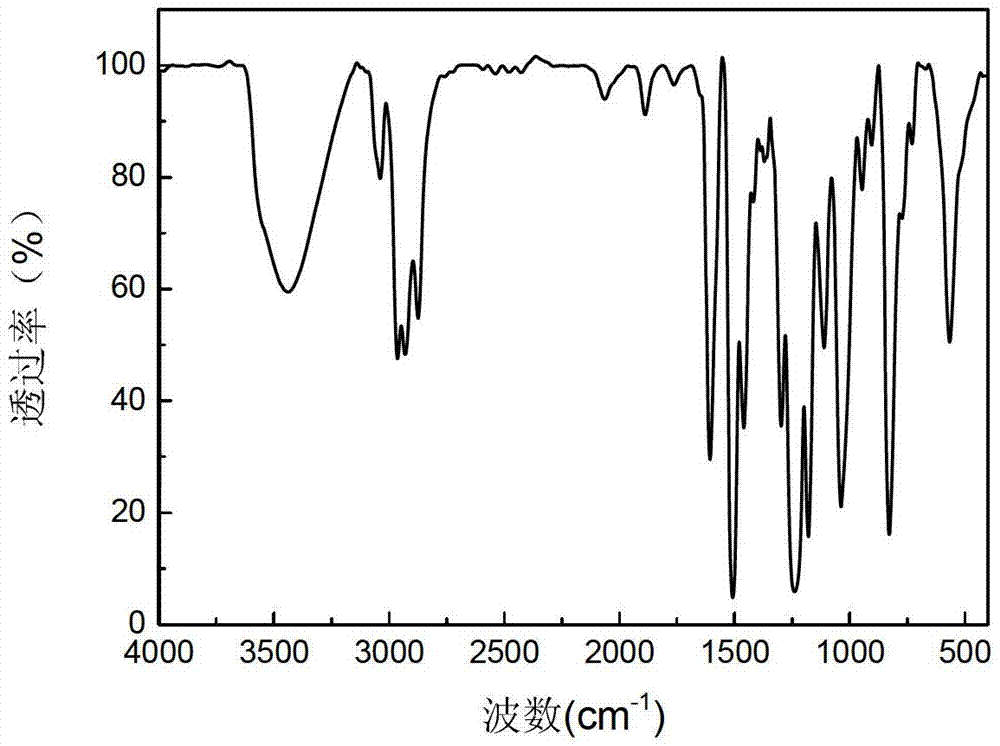

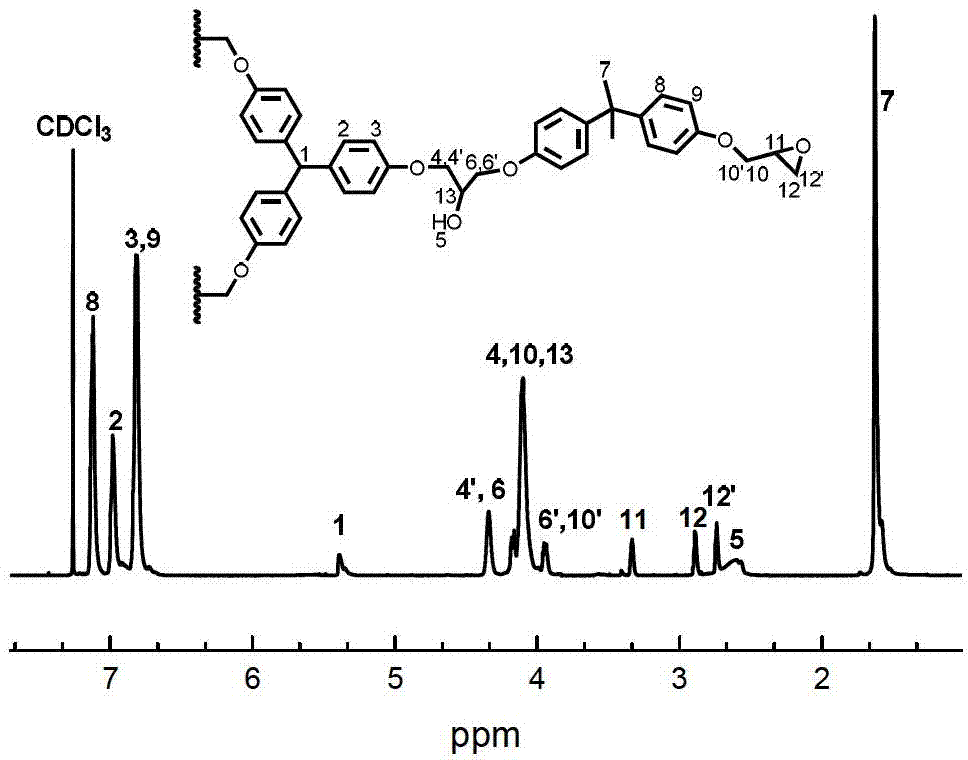

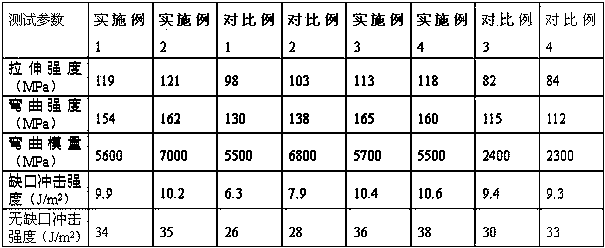

Epoxy resin material used for toughening and reinforcing of hyperbranched polyether type epoxy resin and preparation method thereof

The invention relates to an epoxy resin material used for toughening and reinforcing of hyperbranched polyether type epoxy resin and a preparation method thereof. An epoxy resin / hyperbranched polyether type epoxy hybrid material is formed by utilizing bisphenol A linear epoxy resin as a base material, utilizing the hyperbranched polyether type epoxy resin as a superstrong toughening agent and adding a curing agent and an accelerant. The weight of the hyperbranched polyether type epoxy polymer occupies 3-50% of that of epoxy resin. The hyperbranched polyether type epoxy polymer is obtained by utilizing triphenol methane as a first monomer and E51 as a second monomer and conducting one-step combination through a proton transfer polymerization method. Impact strength of the epoxy resin material reaches 35.2kJ / <2>, elongation at break reaches 11%, tensile strength reaches 89.2MPa, bending strength reaches 145.6MPa, and glass-transition temperature reaches 142 DEG C. The performance indexes are greatly improved compared with that of bisphenol A epoxy resin.

Owner:BEIJING UNIV OF CHEM TECH

High strength and toughness 3Y-TZP composite ceramic and preparation method thereof

The invention discloses a high strength and toughness 3Y-TZP composite ceramic and a preparation method thereof. The 3Y-TZP composite ceramic consists of 3Y-TZP, a SiC crystal whisker and Sr2Nb2O7; and the preparation method of the 3Y-TZP composite ceramic comprises the steps of preparing and mixing Sr2Nb2O7 powder, ball milling, profiling, degumming and sintering. The composite ceramic is obtained by sintering the SiC crystal whisker and a Sr2Nb2O7 ferroelectric material second-phase addictive which are introduced into the 3Y-TZP. The ceramic material with high strength and toughness can be obtained by adjusting the contents of the SiC crystal whisker and the Sr2Nb2O7 and optimizing a microwave sintering process under the synergistic effect of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. The invention has reasonable components and simple preparation process and simultaneously achieves the effects of strengthening and toughening by adopting a synergistic technology of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. In addition, the invention is applicable for industrial production, effectively improves the mechanical property of the 3Y-TZP ceramic and widens the application field of the 3Y-TZP ceramic.

Owner:CENT SOUTH UNIV

SiCf/SiC ceramic-based composite material with composite interface and preparation method of SiCf/SiC ceramic-based composite material

The invention discloses a SiCf / SiC ceramic-based composite material with a composite interface. The SiCf / SiC ceramic-based composite material with the composite interface has the characteristic of comprising a CVD-SiC coating, a PIP-SiC matrix, the composite interface and SiC fiber, wherein the CVD-SiC coating is a silicon carbide coating which is prepared by using a chemical vapor deposition method and has a thickness of 100-500 [mu]m, the composite interface is formed through alternate cyclic overlapping of arbitrary two or three of a BN interface, a ZrO2 interface, a LaPO4 interface and a SiC interface, and the cyclic number is 3-5 times; and the PIP-SiC matrix is silicon carbide formed through in-situ pyrolysis of polycarbosilane, the volume of the SiC fiber accounts for 40-60% of thevolume of the composite material, and a pyrolytic carbon layer of 5-20 nm thick is formed on the surface. The preparation method comprises the steps: preparing the multi-layer composite interface on the surface of the silicon carbide fiber by using different preparation processes, then filling a SiC matrix by using a PIP method, and finally preparing a surface SiC coating by using a CVD method. The prepared SiCf / SiC ceramic-based composite material has high toughness, high oxidation resistance and a simple preparation process.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

PLA modified material applied to 3D printing of large casting molds, and method of PLA modified material

InactiveCN106009572AEasy to degradeNon-irritatingAdditive manufacturing apparatusEnvironmental resistancePolymer science

The invention relates to the technical field of high polymer materials, the technical field of 3D printing, and the field of 3D casting, in particular to a PLA modified material applied to 3D printing of large casting molds, and a method of the PLA modified material. The invention provides the PLA modified material applied to 3D printing of large casting molds, and the PLA modified material comprises the following components: polylactic resin, an inorganic filler, a plasticizer, a flexibilizer, a coupling agent, a chain extender, an antioxidant, an anti-hydrolysis agent, a compatilizer, and a lubricant. To overcome defects in the prior art, the invention creatively develops the PLA modified material specially applied to 3D printing of large casting molds, and the PLA modified material has the advantages of being low in shrinking percentage, good in dimensional stability, high in strength, not liable to be affected with damp, low in price, easy to degrade, environment-friendly, non-toxic, non-irritant, non-pollution and the like.

Owner:NINGXIA KOCEL MOLD

Composite material toughened ceramisite concrete and preparation method thereof

ActiveCN105541212AImprove toughnessImprove isotropic performanceSolid waste managementFiberAggregate (composite)

The invention belongs to the field of preparation of concrete, and in particular relates to composite material toughened ceramisite concrete and a preparation method thereof. The composite material toughened ceramisite concrete comprises the following components in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slagpowder, 20-40 parts of silica fume, 700-900 parts of recycled coarse aggregates, 500-800 parts of ceramisites, 3-4 parts of a water reducing agent, 100-200 parts of water, 10-20 parts of polyacrylate, 20-30 parts of a toughening composite material, 0.05-0.1 part of sodium gluconate, and 10-15 parts of triethanolamine, wherein the toughening composite material is prepared from the following raw materials in parts by weight: 1.2-1.8 parts of modified silicon dioxide nanotubes, 22-28 parts of a styrene-butadiene-styrene block copolymer, 46-50 parts of activated wood powder fibers, 3.5-5 parts of a silane coupling agent, 3.0-3.5 parts of a solubilizing agent, 4-6 parts of a filler and 180-220 parts of water. The concrete has good toughness, isotropy, fatigue resistance, compactness, crack resistance, shock resistance and permeability resistance, and is a high-performance concrete toughening material, and the 28-day compression strength of the prepared concrete can reach 30-60MPa, so that the concrete is suitable for building bearing structures.

Owner:福建省东霖建设工程有限公司

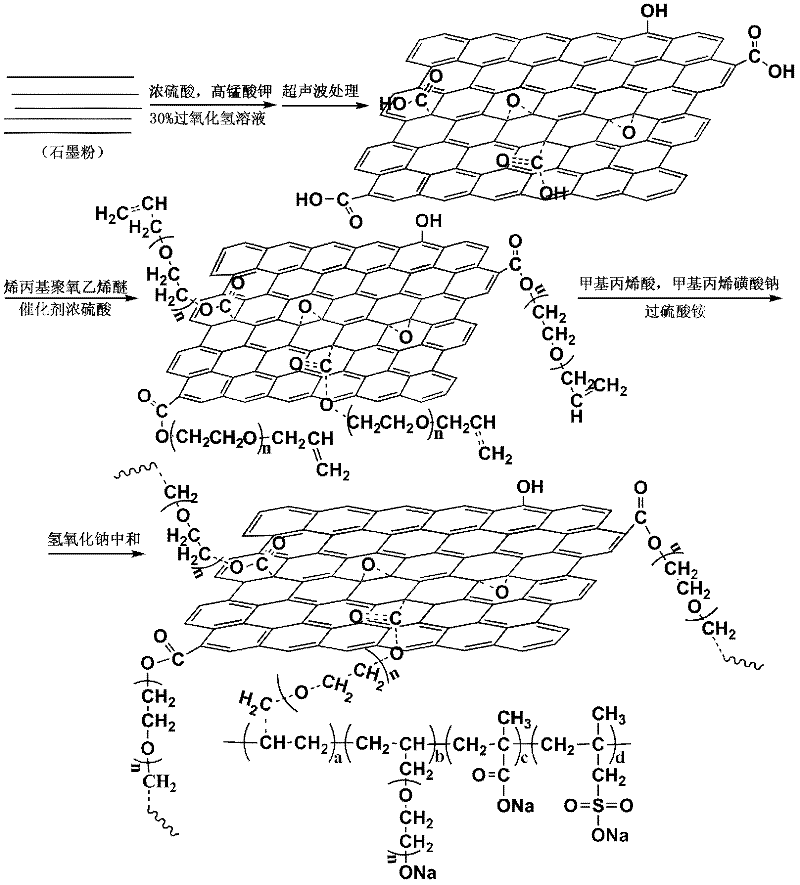

Preparation method of strengthening and toughening polycarboxylate water reducing agent

The invention relates to a preparation method of a strengthening and toughening polycarboxylate water reducing agent. The method comprises the following steps of: oxidizing graphite powder by using concentrated sulfuric acid and potassium permanganate, then carrying out ultrasonic separation to obtain graphene oxide structurally containing carboxyl, hydroxyl, epoxy group and the like, and then, subjecting graphene oxide and allyl polyoxylethylene ether to esterification reaction under the action of ultrasonic; then carrying out free radical copolymerization reaction with methacrylic acid and sodium methylacrylsulfonate under the initiation of ammonium persulfate to obtain the strengthening and toughening polycarboxylate water reducing agent. The method provided by the invention has the innovation points as follows: a graphene oxide structure is introduced to the molecule of the polycarboxylate water reducing agent through oxidation, separation, esterification and free radical copolymerization reaction, so that the strength of concrete is increased by the high water-reducing rate of the water reducing agent, and in addition, the graphene also has strengthening and toughening effects for the concrete.

Owner:河北圣通建材科技有限公司

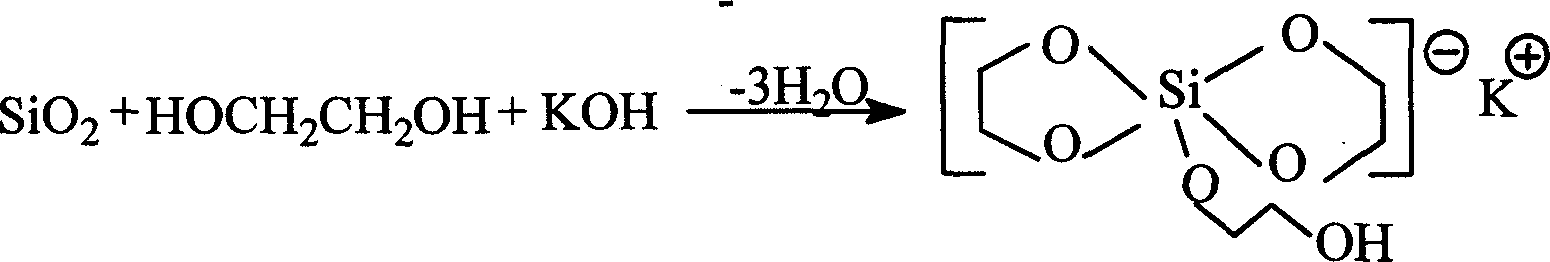

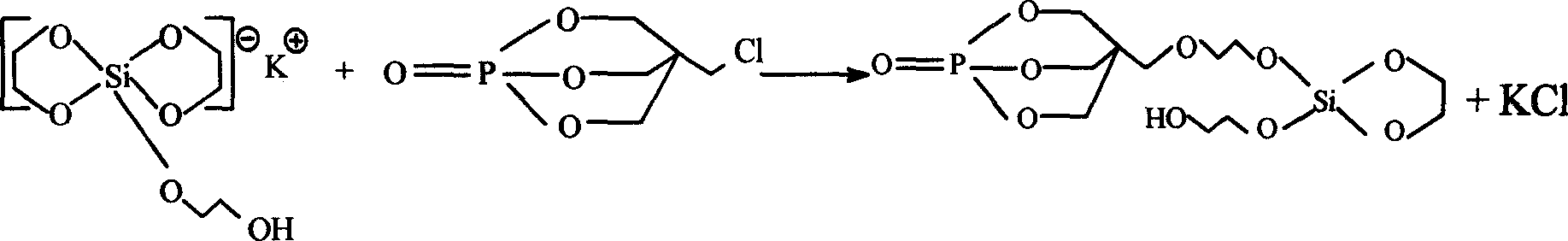

Double-ring cage shape substituted silsesquioxane and its preparation method and uses

InactiveCN101007824AGood toughening effectImprove permeabilityGroup 5/15 element organic compoundsEpoxyAdjuvant

The invention discloses a bicyclo ring cage substituted sesquialter oxosilane and the method for preparing the same and its application. The compound possesses high sesquialter constructure, the core is cage sesquialter oxosilane, the eight apical angle are 1- oxo- 1- phosphora- 2, 6, 7- trioxa bicyclo [2, 2, 2]- 4- methylene sorbate. The method comprises: dissloving catalyst and solvent, adding bicyclo ring cage coordination silicon, reacting while stirring at room temperature; heating to 60- 70 Deg .C, stopping reaction, sucting, distilling part of solvent from filtering liquid and putting it in fridge for cooling, a large amount of crystal will be generated two days later, putting it at room temperature for 1 hour to make the ethandiol crystal disslove, sucting and drying the crystal at 60 Deg. C. The epoxide resin adjuvant is characterized by ability of increasing toughness, fire-retardancy, heat-proof quality, abradability, weatherability and anti ultraviolet absorption for epoxide resin, and hardening function.

Owner:SOUTH CHINA UNIV OF TECH

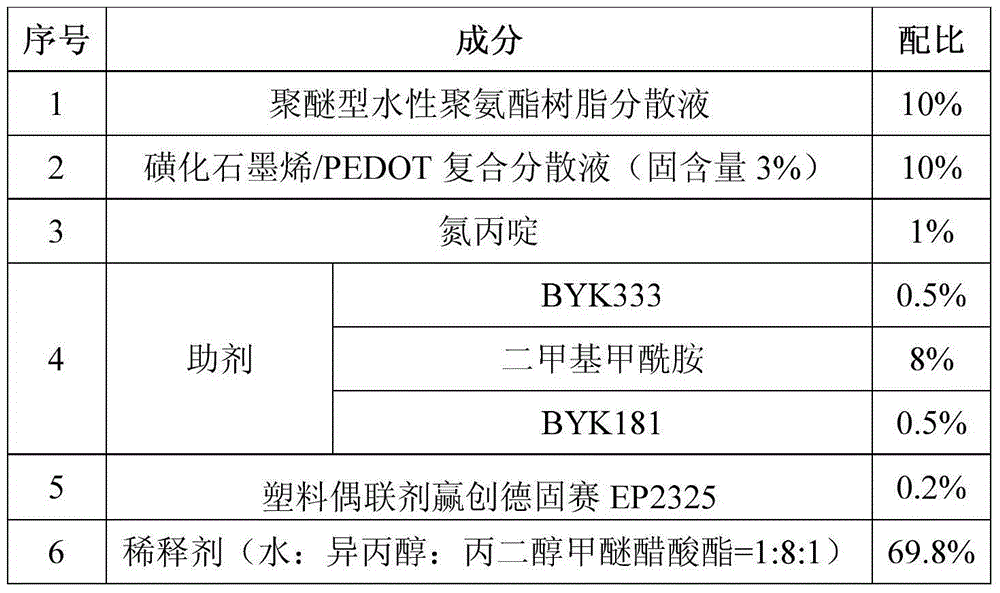

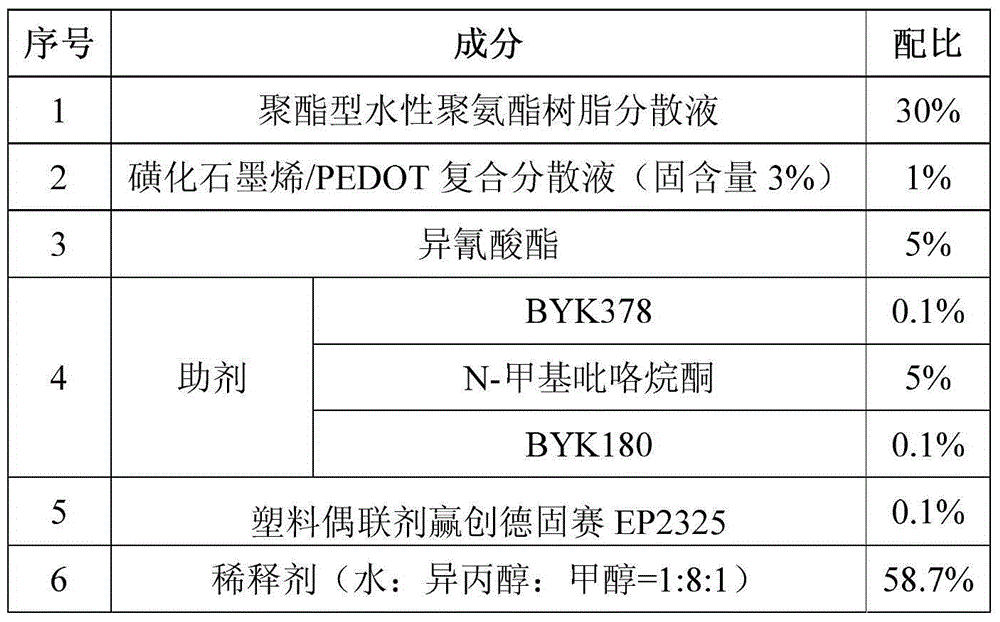

Waterborne antistatic coating as well as preparation method and application thereof

ActiveCN104893538AGood water solubilityImprove conductivityPolyurea/polyurethane coatingsElectrically-conductive paintsTransmittanceSolvent

The invention discloses a waterborne antistatic coating. The waterborne antistatic coating comprises the following components in percent by weight: 1-30% of waterborne polyurethane, 1-30% of sulphonated graphene / PEDOT hybrid dispersion liquid, 0.1-5% of a crosslinking agent, 0.1-0.5% of a coupling agent and 25-80% of a thinning agent, wherein the sulphonated graphene / PEDOT hybrid dispersion liquid contains 1-5wt% of sulphonated graphene / PEDOT compound, the sulphonated graphene / PEDOT compound is mainly composed of sulphonated graphene the surface of which is polymerized with PEDOT in situ, and the mass ratio of sulphonated graphene to PEDOT is 1:(0.2-5). The invention also discloses a method for preparing the waterborne antistatic coating. The waterborne antistatic coating has the excellent characteristics of high light transmittance, high conductivity, good stability, good solvent resistance and high elongation, can be widely applied to antistatic coating of various plastic substrates, can be successively subjected to plastic moulding and still maintains good antistatic characteristics, can be used as an electronic package material, an electronic tray, a support and the like, and has an important commercial application prospect.

Owner:SUZHOU NANOPLASTIC NEW MATERIAL CO LTD

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

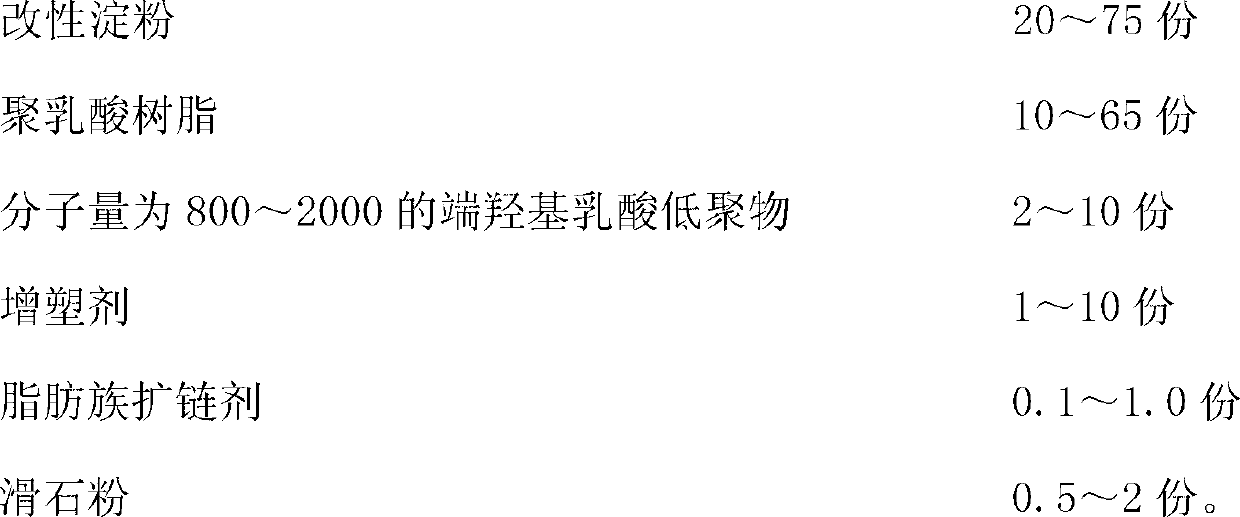

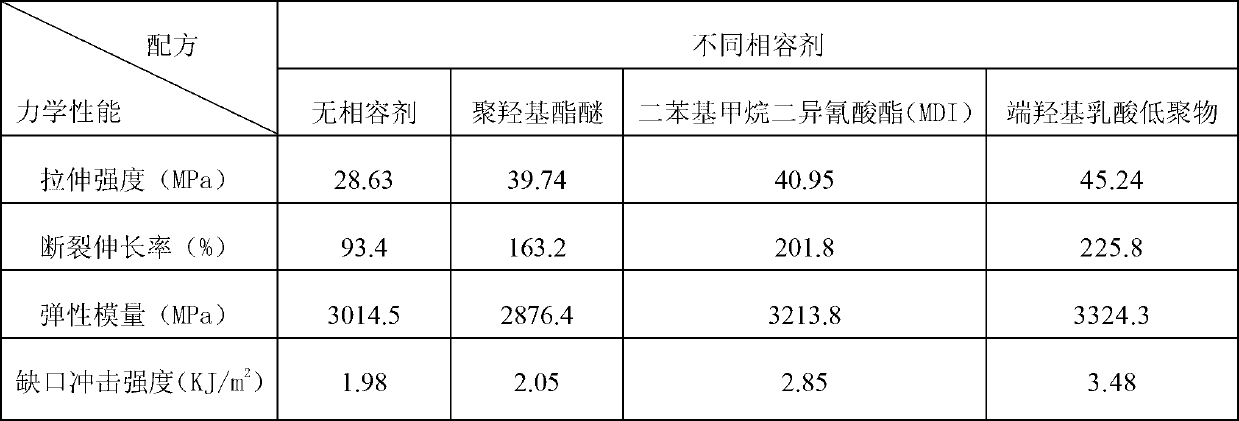

Starch and polylactic acid composite material and preparation method thereof

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

High-performance polyglycolic acid-based composite material and preparation method thereof

InactiveCN113088055AImprove interface interaction forceImprove heat resistancePolyesterPolymer science

The invention discloses a high-performance polyglycolic acid-based composite material and a preparation method thereof, and belongs to the technical field of polymer processing. A compatilizer is added, so that the interfacial interaction force between a polyglycolic acid matrix and degradable polyester B is remarkably improved, and the toughening effect of the degradable polyester B is further remarkably improved in cooperation with a specific blending process; in addition, an added functional filler is subjected to an in-situ reaction with a polyglycolic acid matrix, so that dispersion is promoted, a crystallization effect is favorably provided, and the heat resistance of the composite material is better improved. The polyglycolic acid composite material disclosed by the invention is high in material toughness, strength and heat resistance, and can be applied to the field of equipment manufacturing and packaging of high-performance degradable materials.

Owner:JIANGNAN UNIV

High-toughness high-modulus polypropylene composite material and preparation method thereof

The invention discloses a high-toughness high-modulus polypropylene composite material and a preparation method thereof. The high-toughness high-modulus polypropylene composite material consists of 50-62.5 parts of a polypropylene base body, 10-12 parts of high-density polyethylene, 12-15 parts of a polyolefin elastomer, 6-9 parts of modified wollastonite, 0.5-2 parts of nano modified particles, 1-2 parts of modified boron nitride, 5-6 parts of a compatibilizer, 1-1.5 parts of an antioxidant and 2-2.5 parts of a lubricating agent, wherein the nano modified particles are obtained by mixing a silane coupling agent and nano titanium dioxide in a weight ratio of 1 to 100. The preparation process is simple and convenient, the adopted materials are cheap, the comprehensive cost is lower than that of conventional toughness-modified polypropylene, and the produced high-toughness high-strength high-modulus polypropylene is excellent in performance. A composite system disclosed by the invention forms a polymer / flexible interface layer / inorganic particle three-phase composite system.

Owner:HENAN UNIV OF SCI & TECH

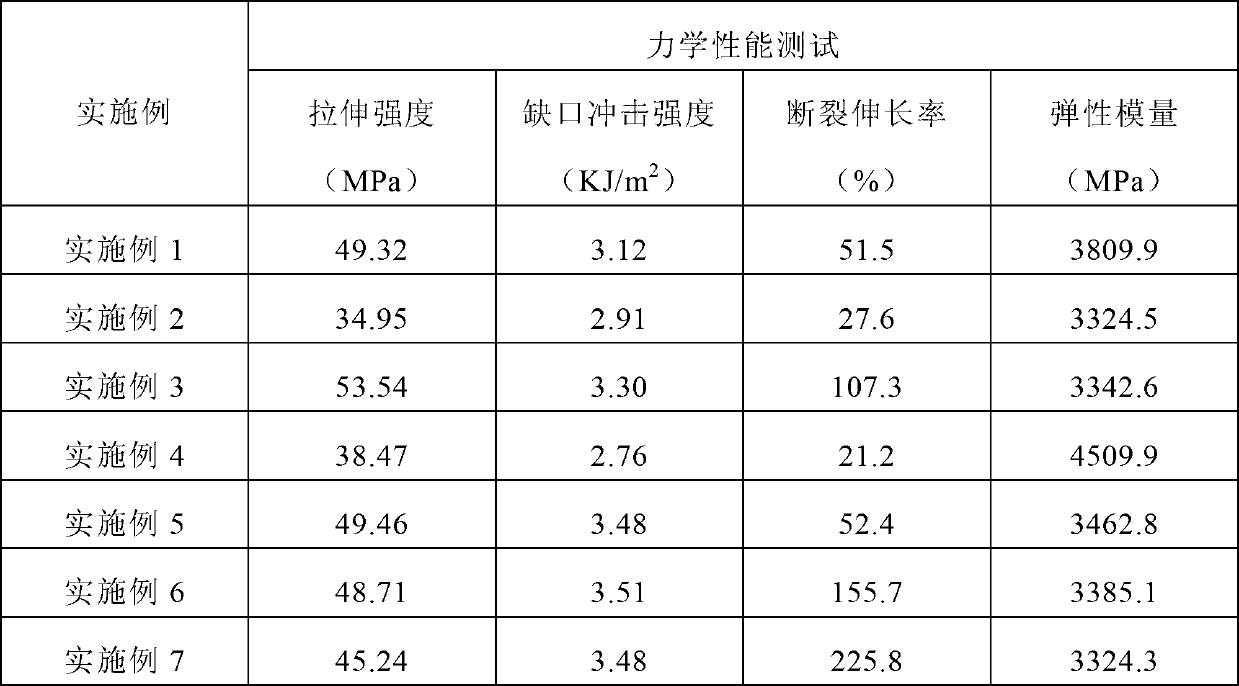

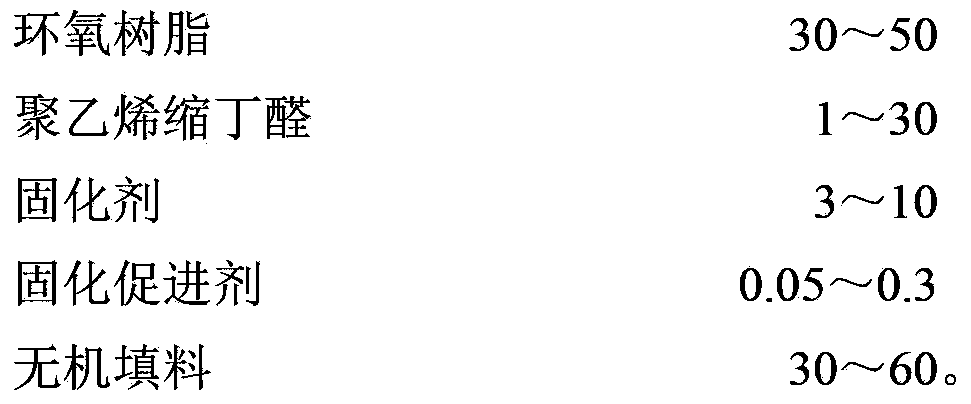

High flexibility epoxy resin composition

ActiveCN103467912AGood flexibilityImprove thermal shock resistancePowdery paintsEpoxy resin coatingsEpoxyNetwork structure

The present invention provides a high flexibility epoxy resin composition, which can be used in the fields of electronic packaging materials and powder coating materials, and comprises, by mass, 30-50 parts of an epoxy resin, 1-30 parts of polyvinyl butyral (PVB), 3-10 parts of a curing agent, 0.05-0.3 part of a curing accelerator, and 30-60 parts of an inorganic filler. The epoxy resin has characteristics of excellent interpenetrating network structure and excellent flexibility, and can be used in the fields of electronic packaging materials and powder coating materials.

Owner:天津凯华绝缘材料股份有限公司

Chitin whisker/magnesium oxide whisker/biodegradable polyester composite material as well as preparation method and application thereof

ActiveCN105504715AImprove performanceGood toughening effectMagnesiaBiocompatibility TestingSynthetic Polymeric Macromolecules

The invention belongs to the field of composite materials and discloses a chitin whisker / magnesium oxide whisker / biodegradable polyester composite material as well as a preparation method and an application thereof. The composite material comprises the following components in percentage by weight: 0.1-20% of chitin whisker, 0.1%-20% of magnesium oxide whisker and 60-99.8% of biodegradable polyester, wherein the chitin whisker is a natural high polymer polysaccharide whisker, the magnesium oxide whisker is an inorganic whisker, and biodegradable polyester is a class of synthetic high polymers. The ternary composite material is skillfully integrated with the advantages of a natural high polymer material, a synthetic high polymer material and an inorganic material; by adjusting the mass ratio of the chitin whisker to the magnesium oxide whisker, the reinforcing and toughening effects which are superior to the reinforcing and toughening effects of single chitin whisker or magnesium oxide whisker to a biodegradable polyester matrix can be obtained; and furthermore, a poly-dopamine layer modified on the surface of the whisker has excellent biocompatibility and osteogenic activity and can endow the composite material with relatively ideal bone tissue healing promoting capacity.

Owner:JINAN UNIVERSITY

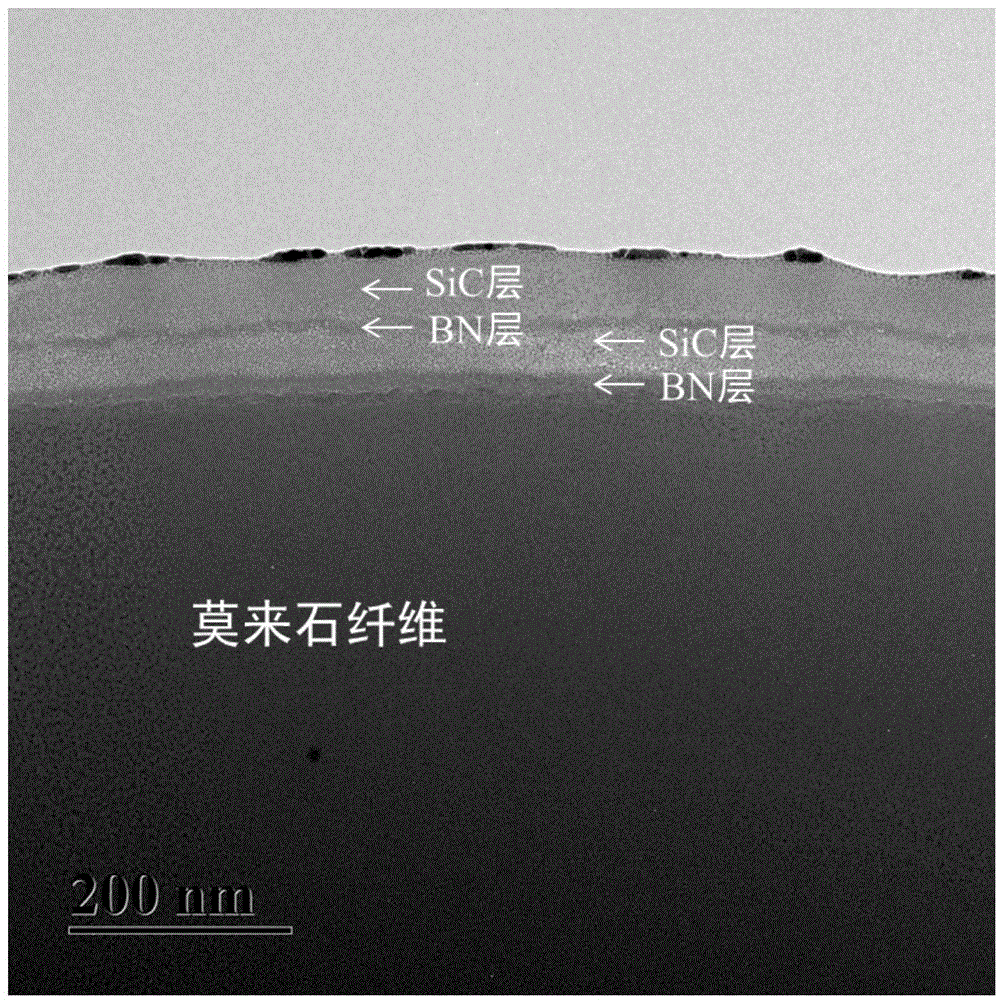

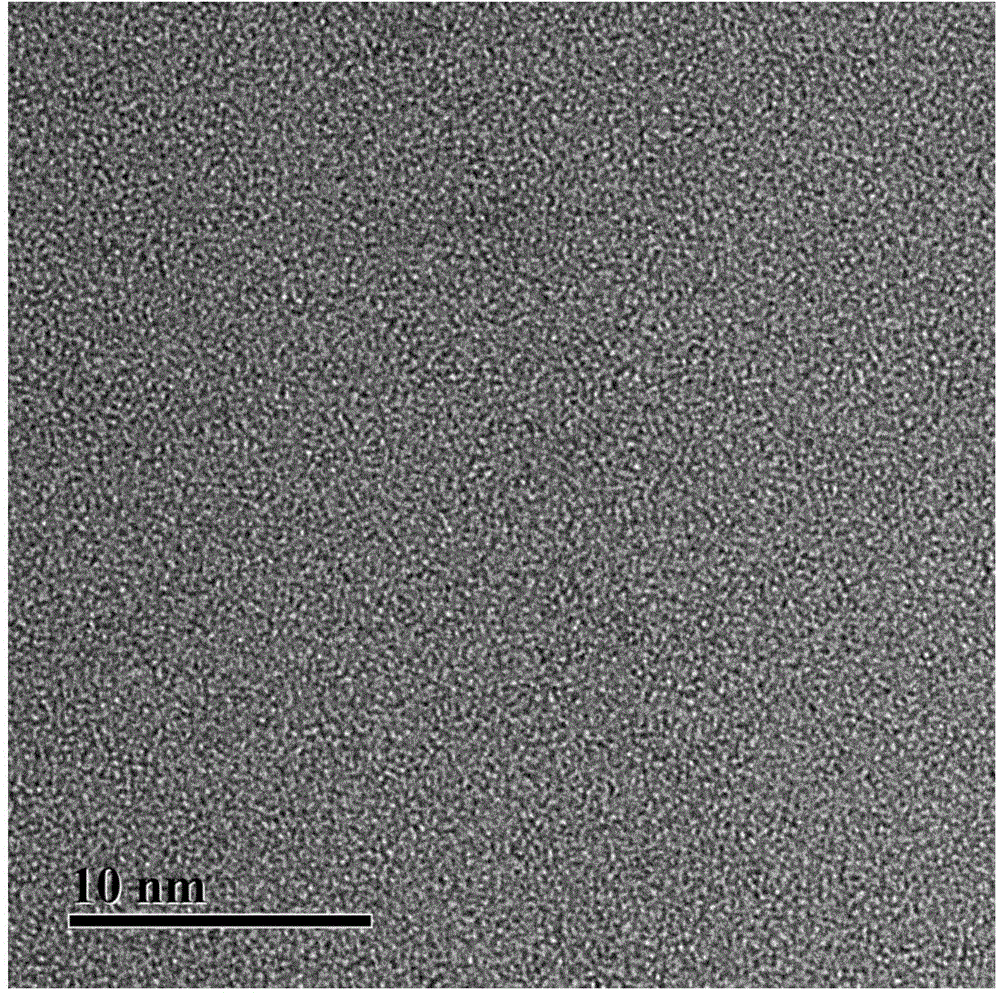

(BN/SiC)n composite interface-phase coating, coating fiber and preparation method

The invention discloses a (BN / SiC)n composite interface-phase coating. The (BN / SiC)n composite interface-phase coating has a periodic laminated structure, wherein BN layers and SiC layers are alternatively and periodically overlapped; the thickness of the BN layers is not greater than that of the SiC layer. A coating fiber comprises a fiber substrate and the (BN / SiC)n composite interface-phase coating; the innermost layer closest to the fiber substrate is the NB layer and the outermost layer further away from the fiber substrate is the SiC layer. A preparation method for the coating fiber comprises the steps: cleaning the fiber substrate; putting into a deposition hearth, vacuumizing and filling with inert gases to exchange with air; realizing a preset vacuum degree and a preset temperature; bringing precursors into the reaction by carrier gas in a bubbling manner, maintaining a specified pressure of a reaction system, and alternatively depositing the BN layers and the SiC layers on the fiber substrate through changing a precursor gas source. The product has the advantages of good compatibility, high-temperature resistance, anti-oxidation and good toughening effect.

Owner:NAT UNIV OF DEFENSE TECH

Composite toughening modifier for plastics and preparation method thereof

ActiveCN102464839AGood toughening effectReduce energy consumptionPigment treatment with macromolecular organic compoundsElastomerMethacrylate

The invention provides a composite toughening modifier for plastics and a preparation method thereof. The composite toughening modifier for plastics comprises nanometer calcium carbonate and polyacrylate elastomer coated on the nanometer calcium carbonate, wherein, the polyacrylate elastomer is formed by using a soft monomer and a hard monomer through polymerization, the soft monomer comprises one or more of acrylic acid butyl ester, isobutyl acrylate, octyl acylate, or octyl methacrylate, and the hard monomer comprises one or more of methyl methacrylate, styrene or vinyl acetate. The composite toughening modifier can be used as a filling material of a rubber and plastic material, can be used for toughening toughening cooperating with CPE to increase the impact strength of the material by more than 5 times, and the impact strength of the toughened material is increased by over more than 10 times more than that of untoughened PVC, the application range of nanometer calcium carbonate is greatly enlarged, and the cost of rubber and plastic products can be greatly reduced.

Owner:SHANGHAI HUAMING HI TECH GRP

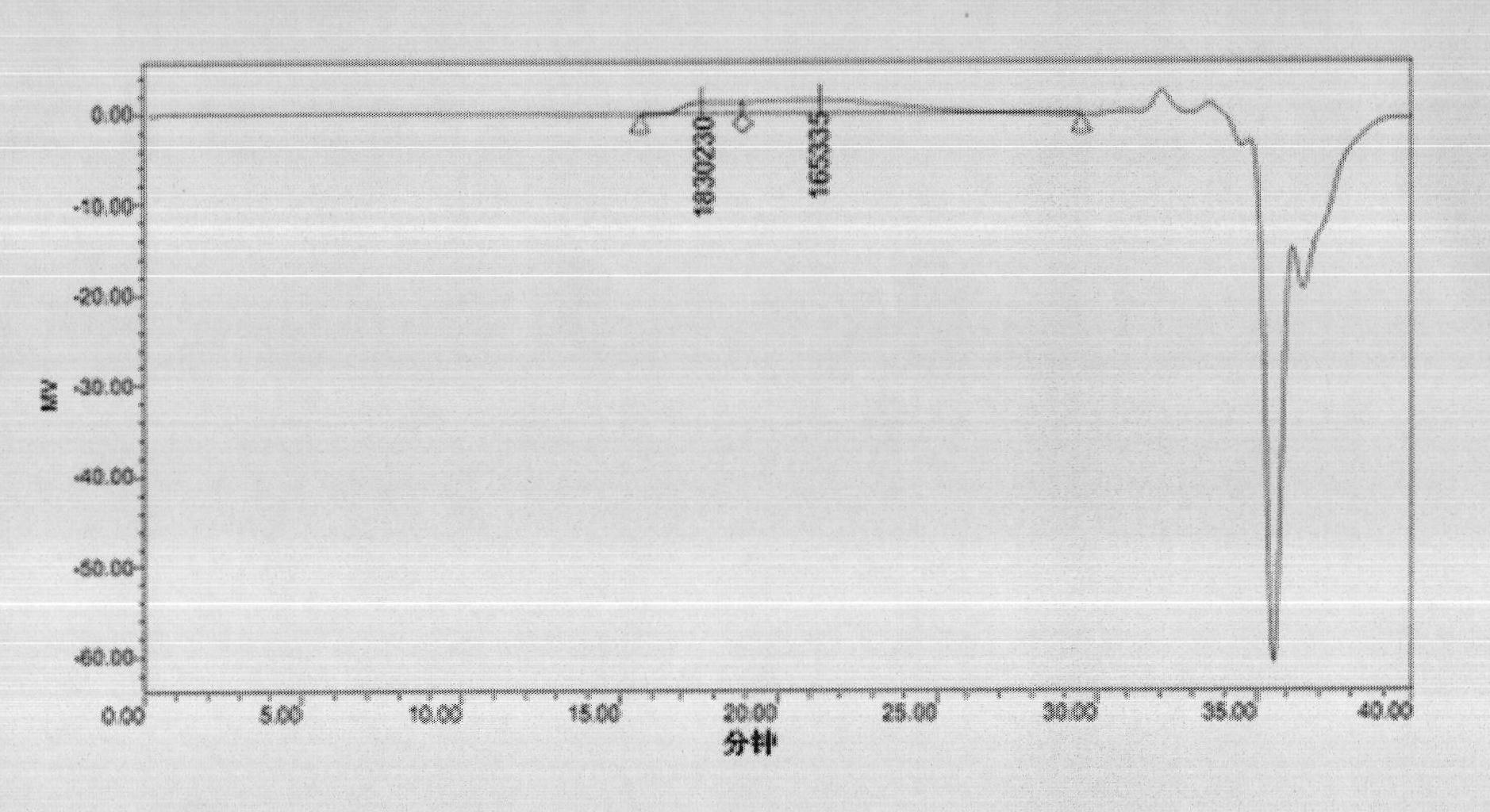

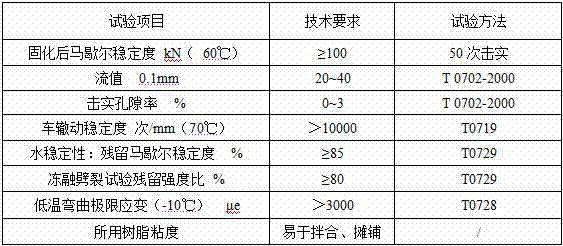

Steel bridge deck pavement cold mixing maintenance material and manufacturing method thereof

ActiveCN103114526AImprove bonding effectImprove interlayer bond strengthIn situ pavingsBridge structural detailsStructural engineeringResin bonding

The invention discloses a steel bridge deck pavement cold mixing maintenance material and a manufacturing method thereof. The maintenance material comprises a resin detritus waterproof layer, a resin bonding layer and a resin concrete pavement layer. The resin detritus waterproof layer is coated on a steel bridge panel required maintenance and is formed by solidifying resin and detritus spread on the surface of the resin. The resin bonding layer is coated on the resin detritus waterproof layer. The resin concrete pavement layer is coated on the resin bonding layer and is formed by solidifying the resin and aggregate in a mixed mode. According to the maintenance material, construction is convenient, influence on construction conditions by temperature is small, performance is excellent, maintenance time is short, production is convenient and rapid, construction period is short and influence on traffic is small.

Owner:江苏苏科建设项目管理有限公司

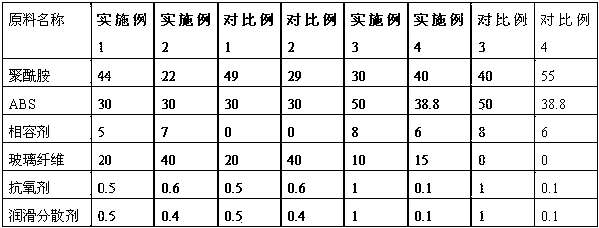

High-strength high-toughness glass-fiber-reinforced PA/ABS (polyamide/acrylonitrile-butadiene-styrene) composite material and preparation method thereof

The invention discloses a high-strength high-toughness glass-fiber-reinforced PA / ABS (polyamide / acrylonitrile-butadiene-styrene) composite material which is prepared from the following raw materials in percentage by weight: 10-65% of polyamide, 10-50% of ABS, 5-15% of compatilizer, 10-40% of glass fiber, 0.1-1% of antioxidant and 0.1-1% of lubricating and dispersing agent. The invention also discloses a preparation method of the high-strength high-toughness glass-fiber-reinforced PA / ABS composite material. The glass-fiber-reinforced PA / ABS composite material disclosed by the invention has the advantages of high strength, high toughness, stable quality and excellent comprehensive mechanical properties, and can be widely used in products in the fields of automobile interior and exterior components, electronic and electric appliances and the like.

Owner:SHANGHAI SUNNY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com