High flexibility epoxy resin composition

An epoxy resin and flexibility technology, applied in epoxy resin coatings, coatings, powder coatings, etc., can solve the problem of inability to encapsulate electronic components with thermal shock resistance, insufficient epoxy resin toughness, and easy cracks. problem, to achieve the effect of improving thermal shock resistance, strong environmental protection, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

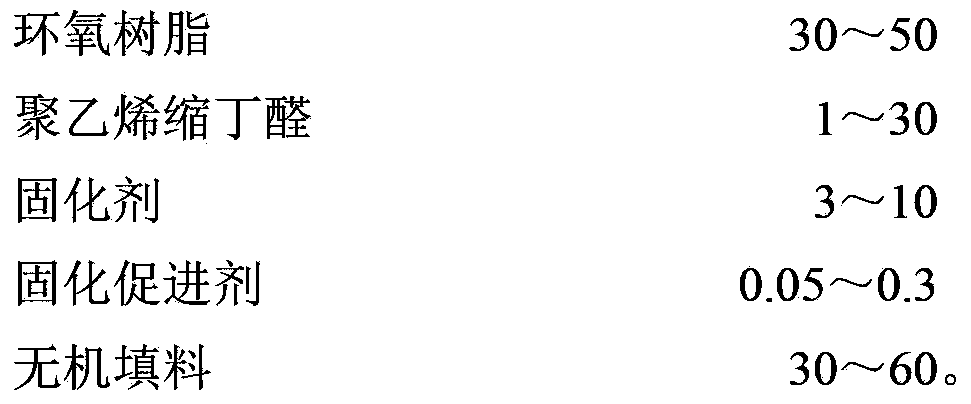

Method used

Image

Examples

Embodiment 1

[0027] A kind of epoxy resin composition with high flexibility, the specific components and consumption are shown in Table 1, and the preparation method is as follows:

[0028] Mix epoxy resin (E-12), polyvinyl butyral PVB (I), curing agent, curing accelerator and inorganic filler according to the ratio of parts by mass. The mixing time is 5-20 minutes, and the speed is 500- 1000r / min; then melt and knead and extrude (extrusion temperature 70-150°C, extruder speed 1500-3000r / min, feeding speed 900-2400r / min), and then crush and sieve to obtain the epoxy resin composition.

[0029] Among them, the specific parameters of polyvinyl butyral PVB (I) are: polyvinyl alcohol hydroxyl content of 21wt%, polyvinyl butyral content range of 78wt%, vinyl acetate content range of 1wt%, glass transition temperature Tg The range is 63°C.

Embodiment 2

[0031] A kind of epoxy resin composition with high flexibility, the specific components and consumption are shown in Table 1, and the preparation method is as follows:

[0032] Mix epoxy resin (E-12), polyvinyl butyral PVB (II), curing agent, curing accelerator and inorganic filler according to the ratio of parts by mass. The mixing time is 5-20 minutes, and the speed is 500- 1000r / min; then melt and knead and extrude (extrusion temperature 70-150°C, extruder speed 1500-3000r / min, feeding speed 900-2400r / min), and then crush and sieve to obtain the epoxy resin composition.

[0033] Among them, the specific parameters of polyvinyl butyral PVB (II) are: polyvinyl alcohol hydroxyl content of 25wt%, polyvinyl butyral content range of 74wt%, vinyl acetate content range of 1wt%, glass transition temperature Tg The range is 61°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com