Method and process for high strength curing of drilling waste

A drilling waste solidification treatment technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the application of high transportation costs, high energy consumption, and no effective solidification of salty drilling waste Technical and other issues, to achieve the effect of simple curing process, strong compressive strength, and easy operation of curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

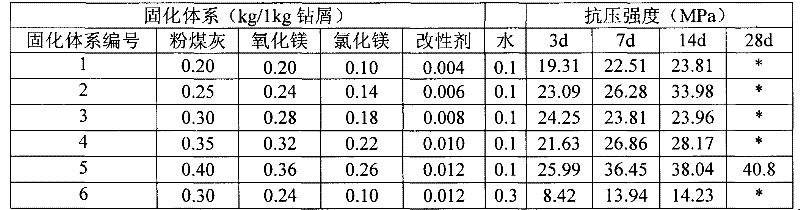

[0022] Take 1kg of solid waste discharged from the solid control system during the drilling process of an oilfield, mix it with curing agents of different compositions, compact and form, demould after consolidation, and naturally cure at ambient temperature, respectively measure the 3d, 7d, 14d, 28d resistance The compressive strength, the results are shown in Table 1.

[0023] Table 1 Composition and compressive strength of curing agent for high-strength curing treatment of drilling waste

[0024]

[0025] Note: "*" means "untested"

Embodiment 2

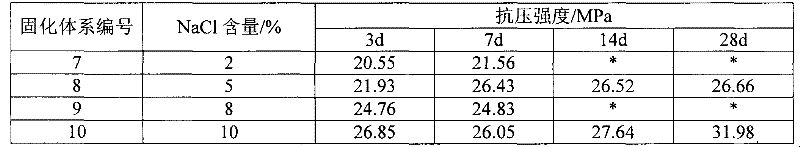

[0027] Take the drilling waste in Example 1 and add sodium chloride respectively to make 1 kg of simulated saline drilling waste with different sodium chloride content, and perform curing treatment according to the composition of No. 5 curing agent in Table 1. The compressive strength results are shown in Table 2.

[0028] Table 2 High-strength solidification and compressive strength of saline drilling waste

[0029]

[0030] Note: "*" means "untested"

Embodiment 3

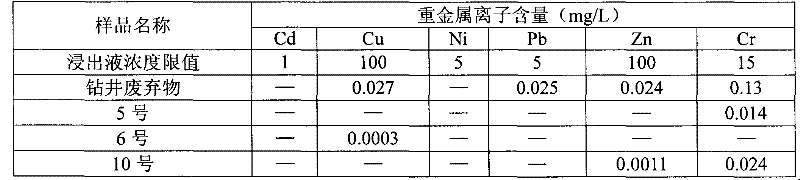

[0032] Take the above-mentioned drilling waste, No. 5, No. 6, and No. 10 solidified drilling waste samples, grind them to a particle size of less than 9.5 mm, and adjust the pH of laboratory pure water to 3.25 with sulfuric acid-nitric acid (mass ratio 2:1). Weigh the solid sample and extractant according to the ratio of 1:10, shake horizontally for 8 hours (frequency 110±2 times / min), stand still for 16 hours, filter with 0.45 cellulose acetate filter membrane, test the composition of heavy metal ions in the leachate, the results are shown in the table 3.

[0033] Table 3 Composition of heavy metal ions in leachate of solidified drilling waste

[0034]

[0035] Note: "-" indicates "not detected"

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com